Patents

Literature

331 results about "Hydroxyethyl methyl cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

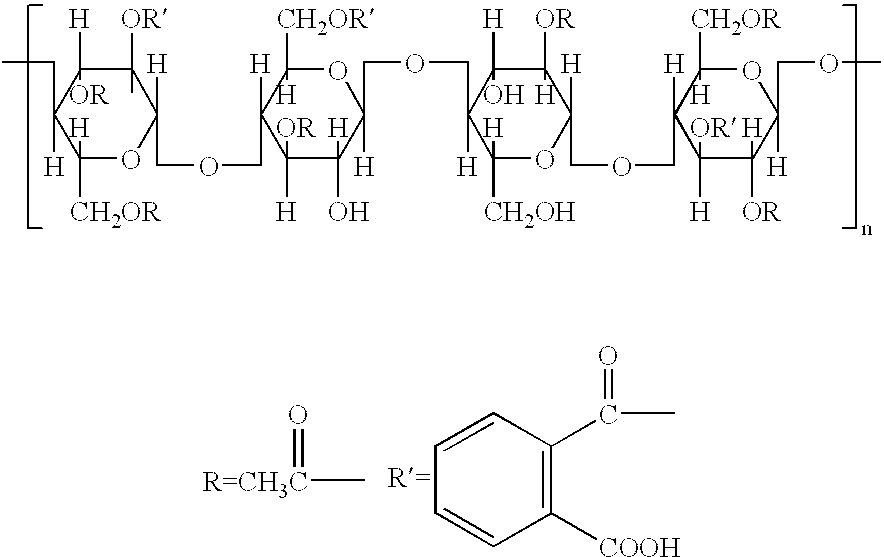

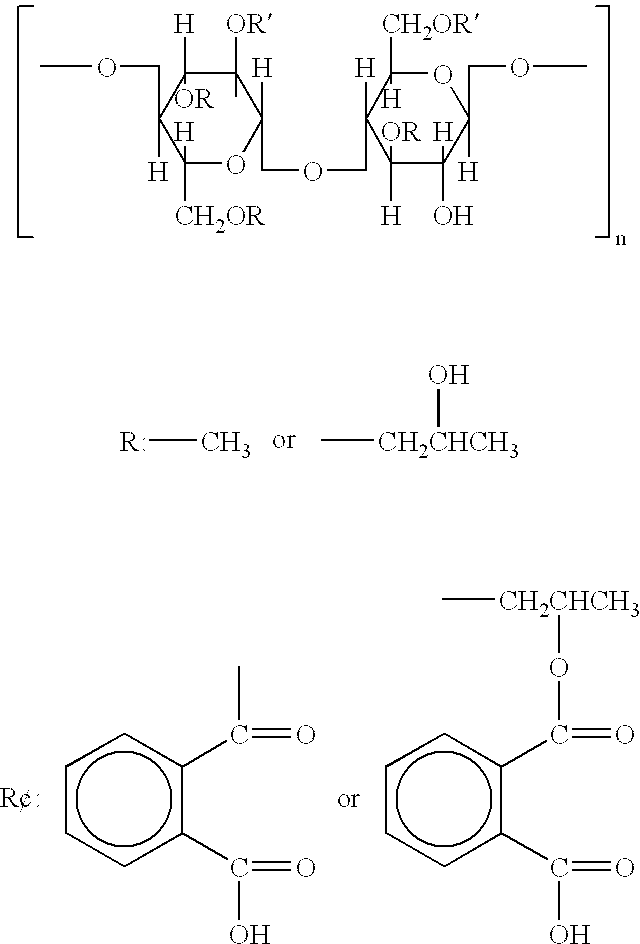

Hydroxyethyl methyl cellulose is a gelling and thickening agent derived from cellulose.

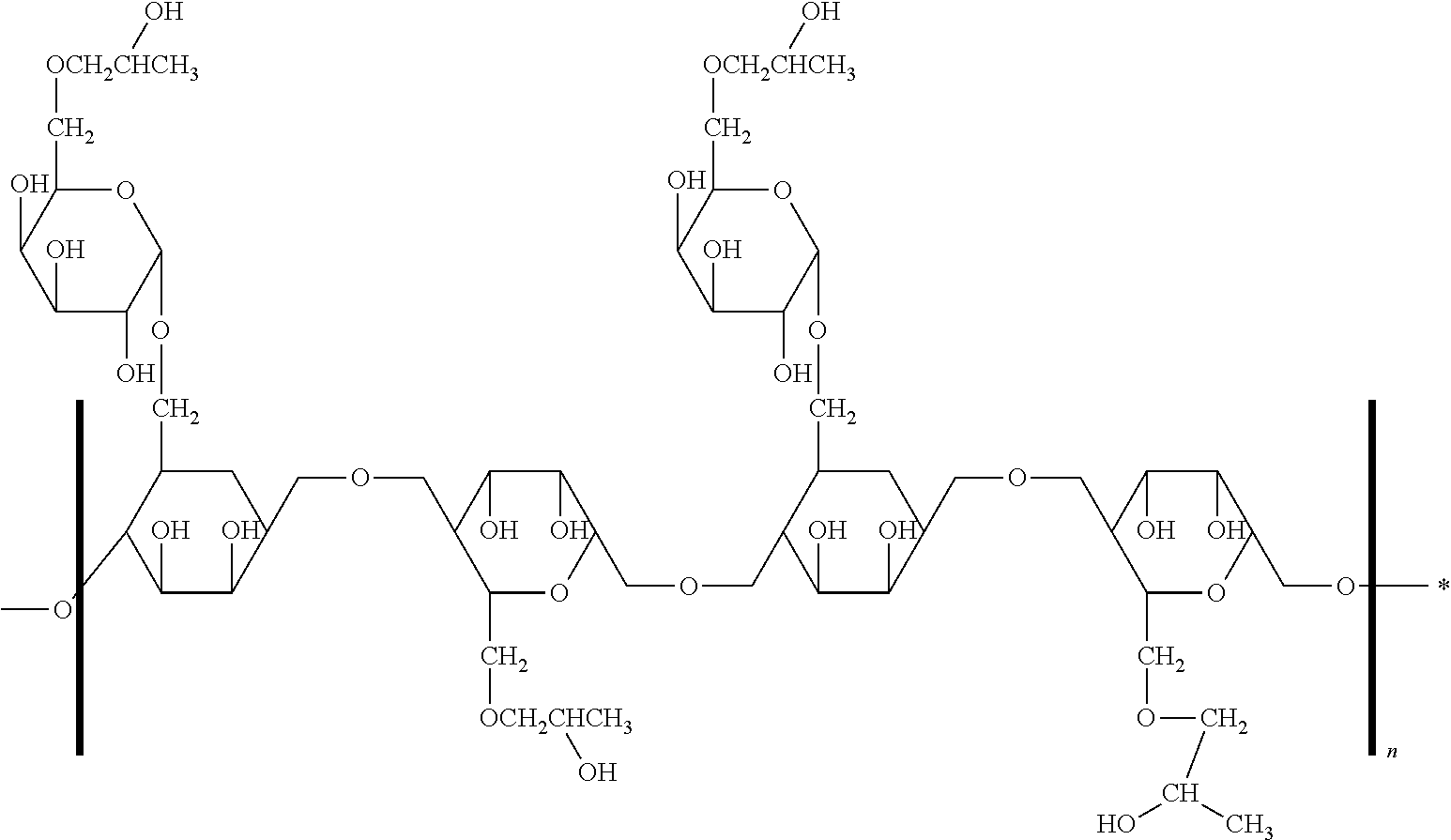

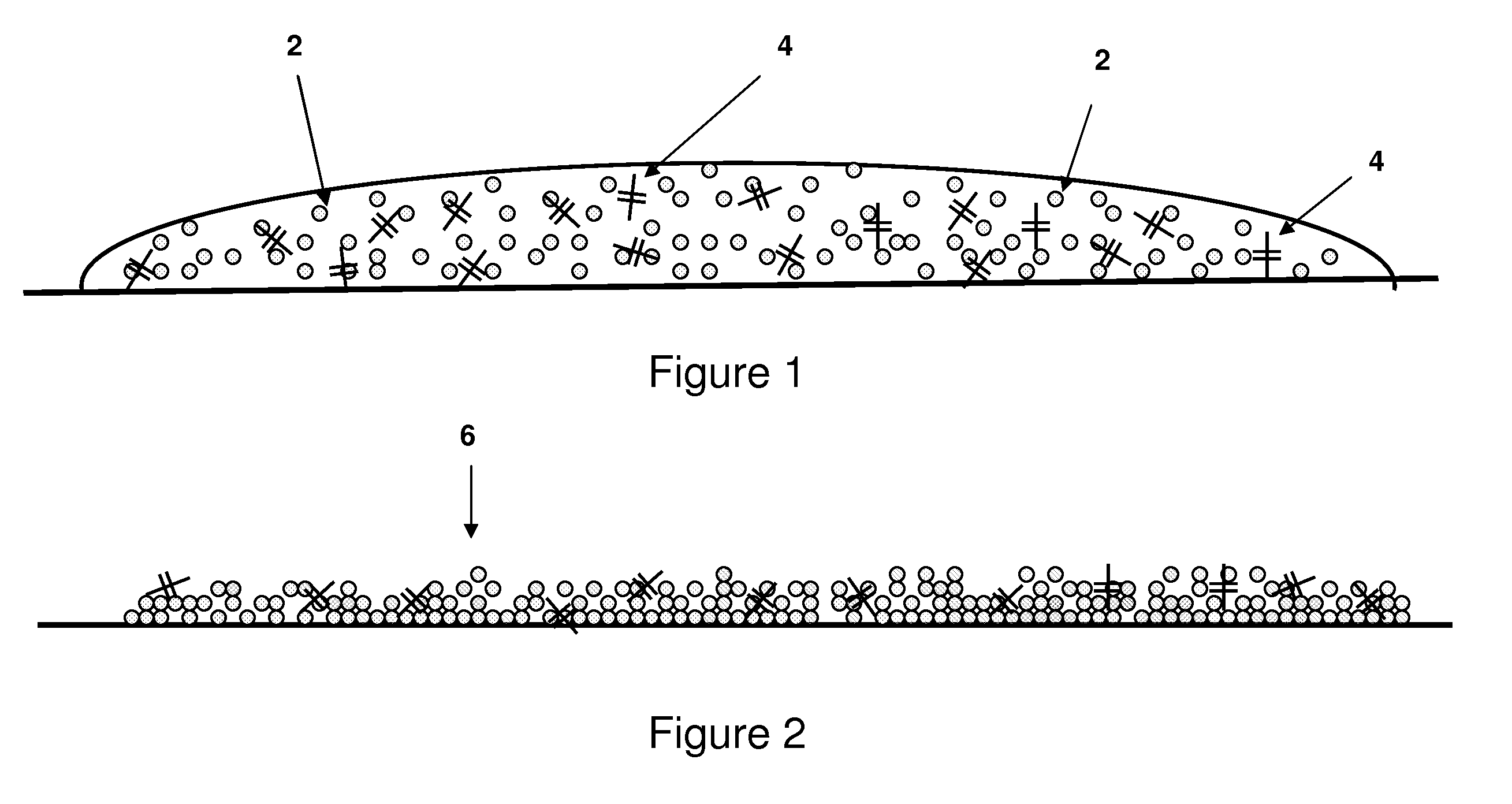

Benefit agent delivery particles comprising non-ionic polysaccharides

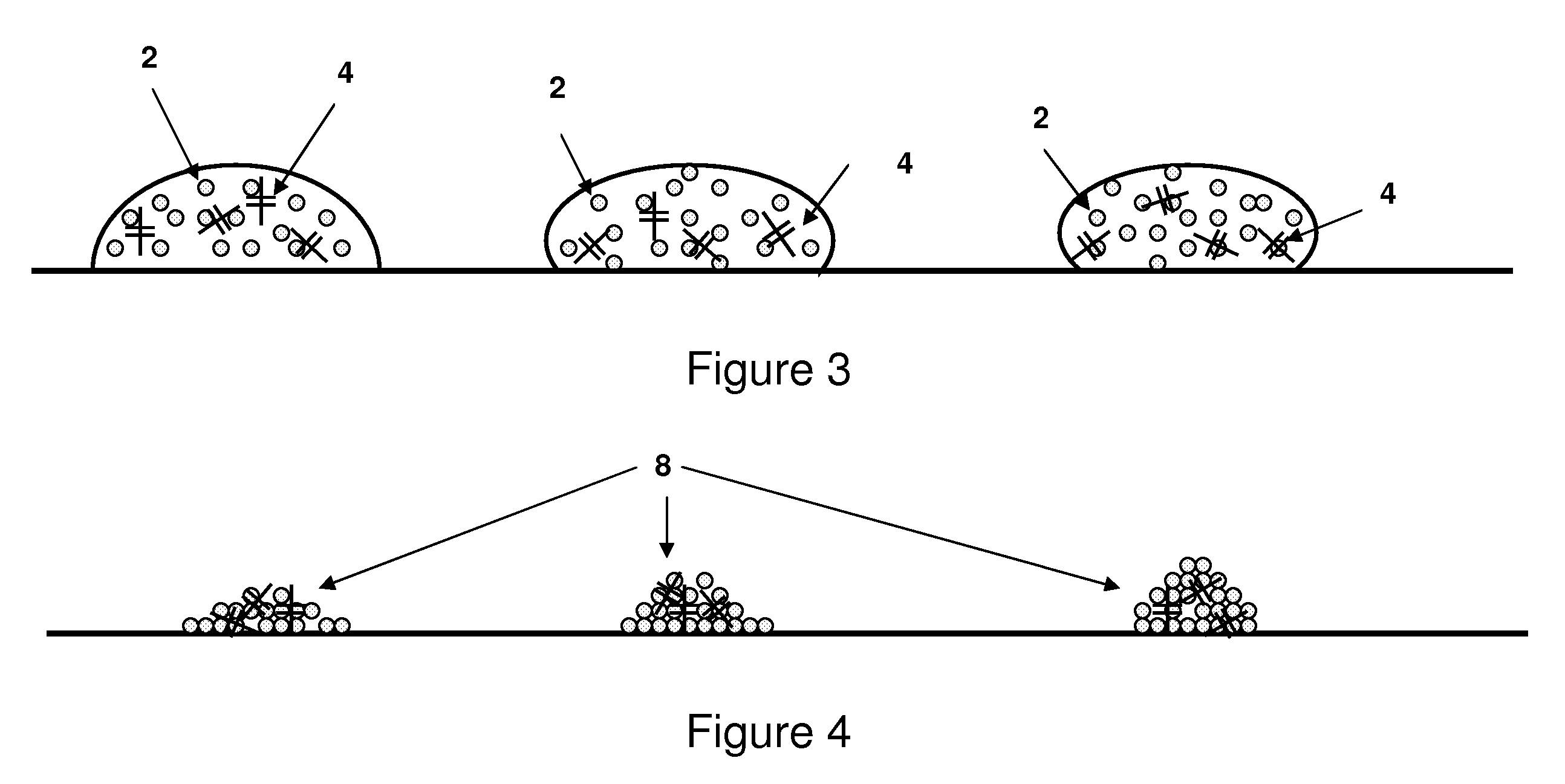

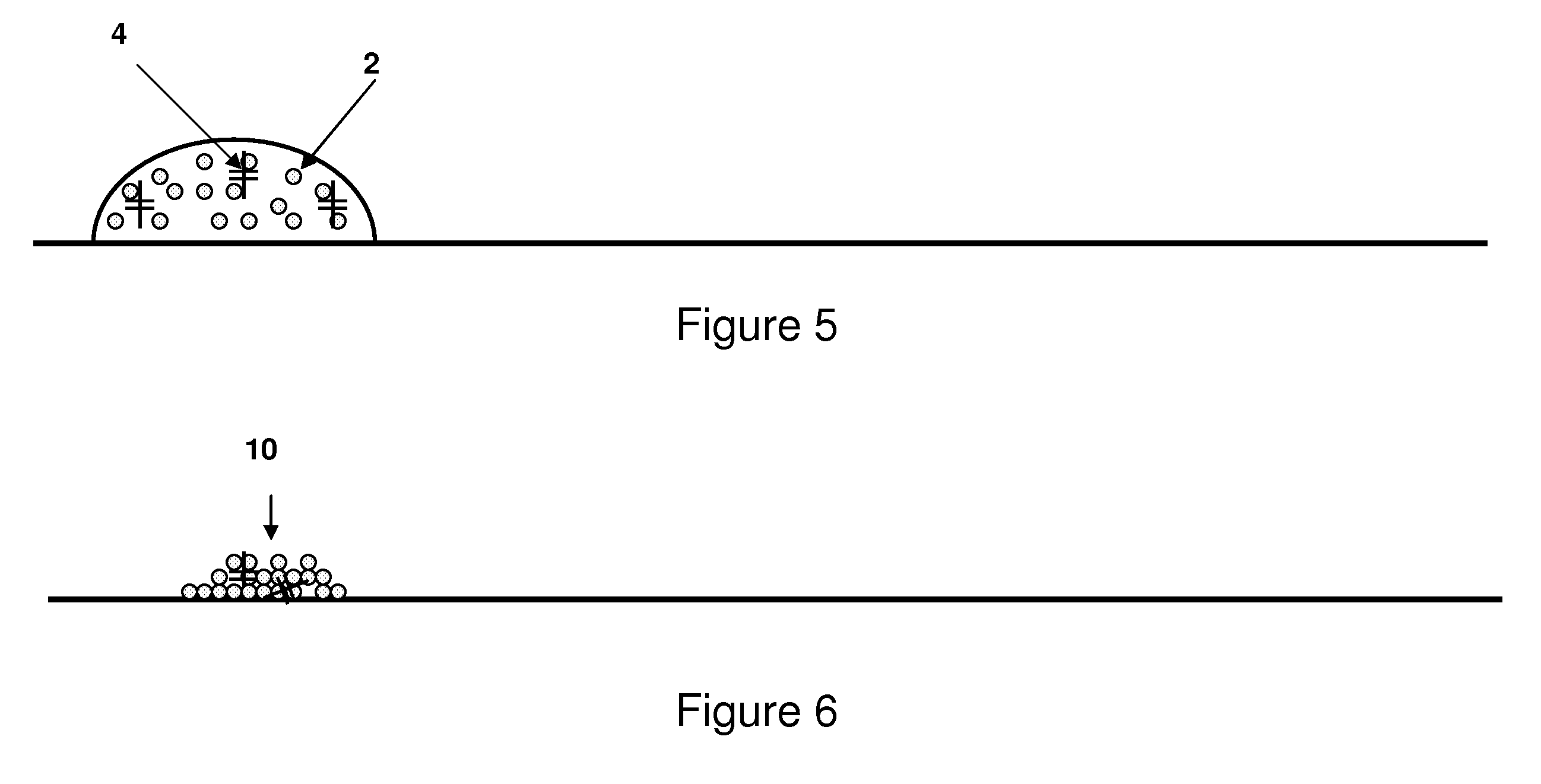

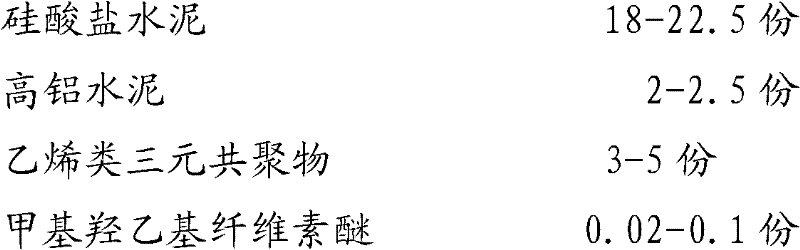

InactiveUS20140206587A1High affinityCosmetic preparationsHair cosmeticsHydroxyethyl ethylcelluloseEmulsion polymerization

The invention provides a composition comprising a benefit agent delivery particle comprising at least one of hydroxylpropyl methyl cellulose, hydroxylethyl methyl cellulose, hydroxylpropyl guar, hydroxylethyl ethyl cellulose or methyl cellulose. The benefit agent delivery particle may further comprise a non-polysaccharide polymer, preferably an aminoplast polymer. The benefit agent delivery particle may comprise a perfume. The invention also provides a process for the manufacture of the particles in which perfume oil is encapsulated using emulsion polymerization to form core-shell particles, (in the alternative the perfume may be adsorbed later) and, a further polymer layer is formed on the outer surface of the core shell-particles in the presence of the delivery aid.

Owner:CONOPCO INC D B A UNILEVER

Modified membrane fabric, preparation method and application thereof

ActiveCN103976886AStrong residentReduce evaporationCosmetic preparationsAntipyreticPullulanCarrageenan

The invention provides a modified membrane fabric and a preparation method and application of the modified membrane fabric. The surface of the modified membrane fabric is coated with a polymer or polymer dispersion, and the polymer in the polymer or polymer dispersion may be polysaccharide, polypeptide and protein, may be an artificial polymerized polymer or may be a modified natural high polymer material or a mixture thereof, including but not limited to one or more selected from the group consisting of gelatins (such as gelatin and gelatin hydrolysate), cellulose ethers (e.g., carboxymethyl cellulose and hydroxyethyl methyl cellulose), modified starches (e.g., pullulan and hydroxypropyl starch), PVP, PVA, hyaluronic acids, albumin, chitosan, dextran, Arabic gum, xanthan gum, carrageenan, pectin, konjac gum, agar, Carbomer, carrageenin, polyvinylpyrrolidone, polyacrylamide, polyacrylate and polyacrylic acid and its derivatives. When the modified membrane fabric comes across water in use, the polymer on the surface of the modified membrane fabric can bond with water molecules to form a water retention system which has better retention performance compared with pure water and enables an evaporation speed to be slower and retention performance on the skin to be better.

Owner:李和伟

High-strength micro-expansive grouting material and its preparation method

The invention provides a high-strength micro-expansive grouting material and its preparation method. Raw materials of the high-strength micro-expansive grouting material comprise Portland cement having a compressive strength of above 42.5MPa, sulphoaluminate cement or aluminous cement having a compressive strength of above 42.5MPa, a calcium sulphoaluminate expanding agent, quartz sand or corundum or iron tailings, an organic silicon antifoaming agent, a polycarboxylate superplasticizer, calcium formate or lithium carbonate, sodium gluconate, and methyl cellulose ether or hydroxypropyl methyl cellulose ether or hydroxyethyl methyl cellulose ether. Compared with present cement-based grouting materials treating the sulphoaluminate cement and the aluminous cement as main cementing materials, the high-strength micro-expansive grouting material, which is obtained through treating the Portland cement as a main cementing material component, carrying out ultrafine crushing of the cementing material component via an ultrafine crushing technology, and processing, has the characteristics of high early-stage strength, excellent fluidity, increased long-term strength, and good durability; and compared with traditional epoxy mortars, the high-strength micro-expansive grouting material has the characteristics of micro-expansion, simple and fast construction, non-toxicity, and harmlessness.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

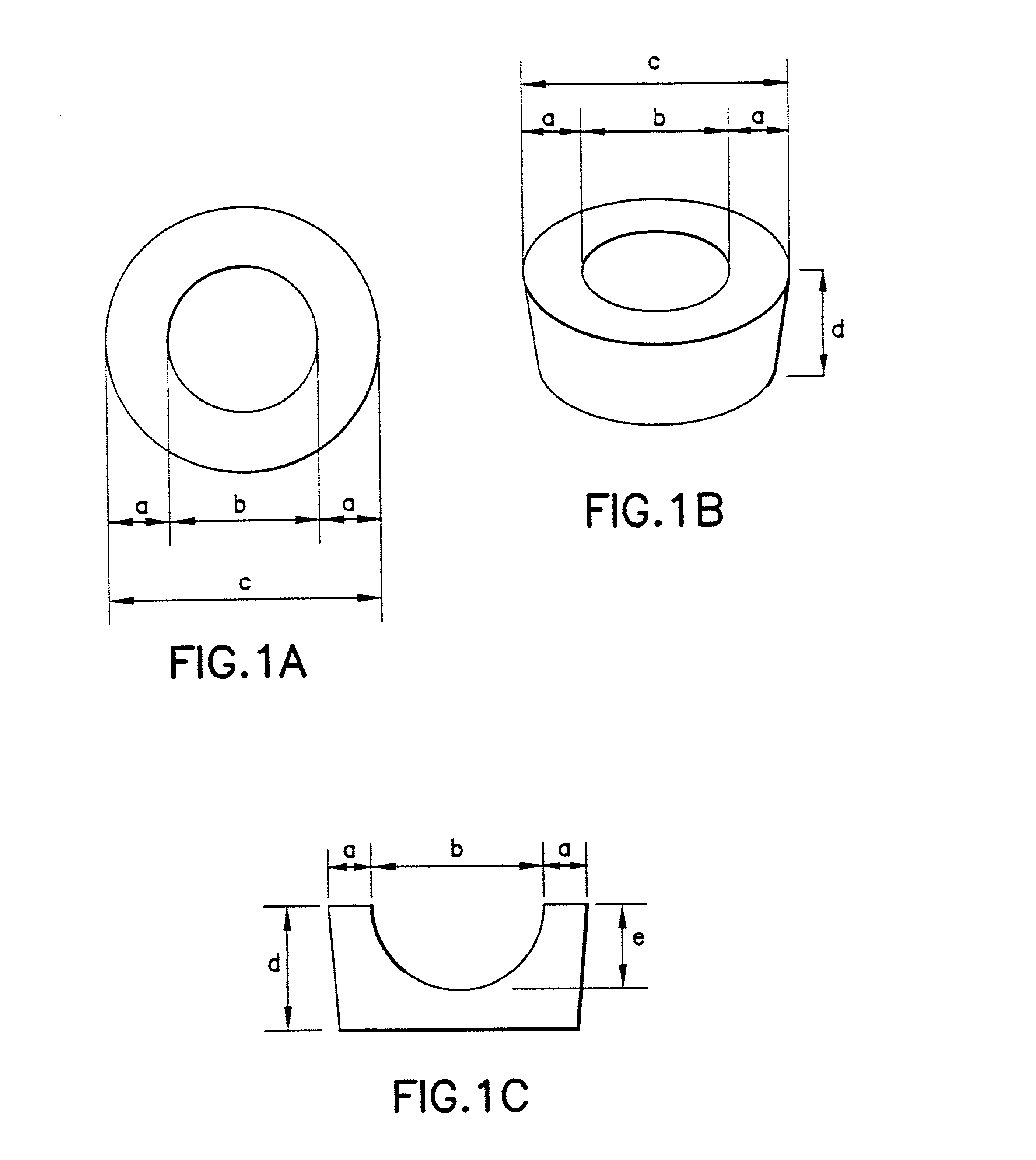

Controlled release composition

InactiveUS20080254124A1Easy for to follow prescribed regimenConstant of releasePowder deliverySolution deliveryEthyl(hydroxyethyl)celluloseCellulose acetate

A composition for controlled delivery of at least one active substance into an aqueous medium by erosion at a preprogrammed rate of at least one surface of the composition, comprising a matrix comprising the active substance, the matrix being erodible in the aqueous medium in which the composition is to be used, and a coating having at least one opening exposing at least one surface of said matrix, the coating comprising a first cellulose derivative which has thermoplastic properties and which is substantially insoluble in the aqueous medium in which the composition is to be used, and at least one of a second cellulose derivative which is soluble or dispersible in water, a plasticizer, and a filler. The coating is a coating which crumbles and / or erodes upon exposure to the aqueous medium such as a body fluid. The first cellulose derivative may be, e.g., ethylcellulose, cellulose acetate, cellulose propionate or cellulose nitrate, and the second cellulose derivative may be, e.g. methylcellulose, carboxymethylcellulose or salts thereof, cellulose acetate phthalate, microcrystalline cellulose, ethylhydroxyethylcellulose, ethylmethylcellulose, hydroxyethylcellulose, hydroxyethylmethylcellulose, hydroxypropylcellulose, hydroxypropylmethylcellulose, hydroxymethylcellulose or hydroxymethylpropylcellulose.

Owner:EGALET LTD

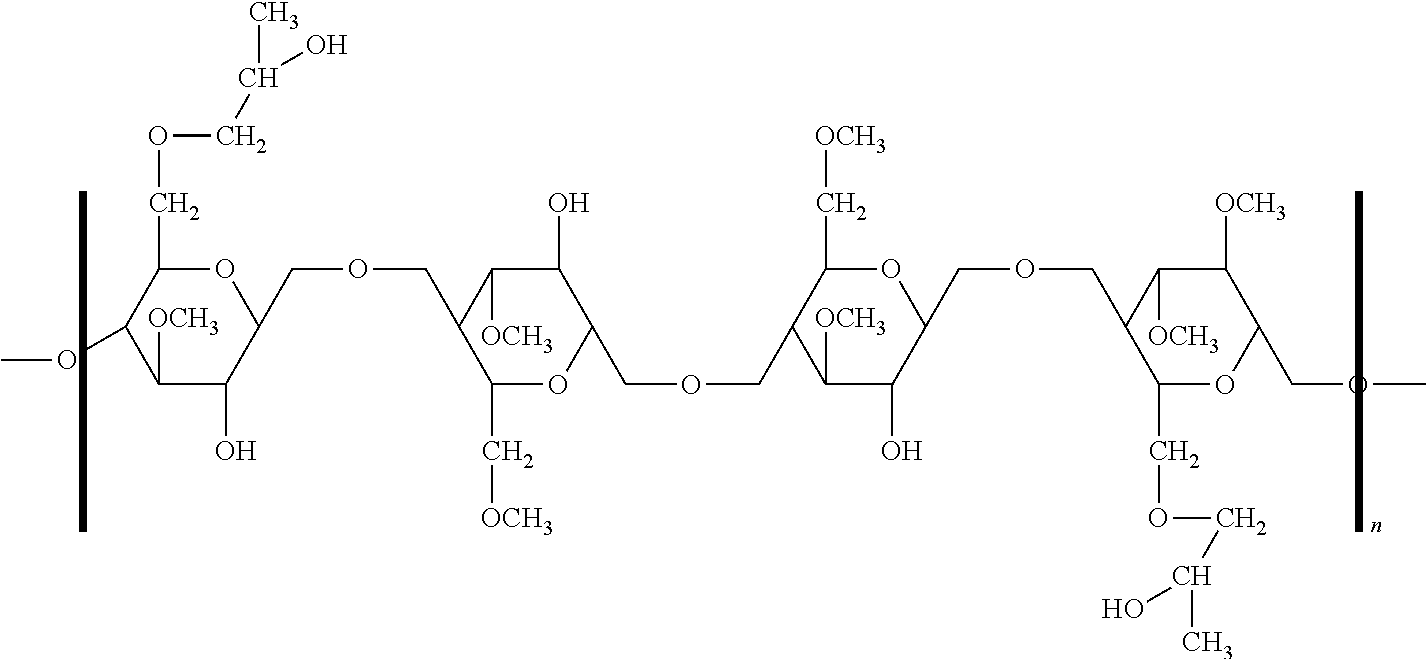

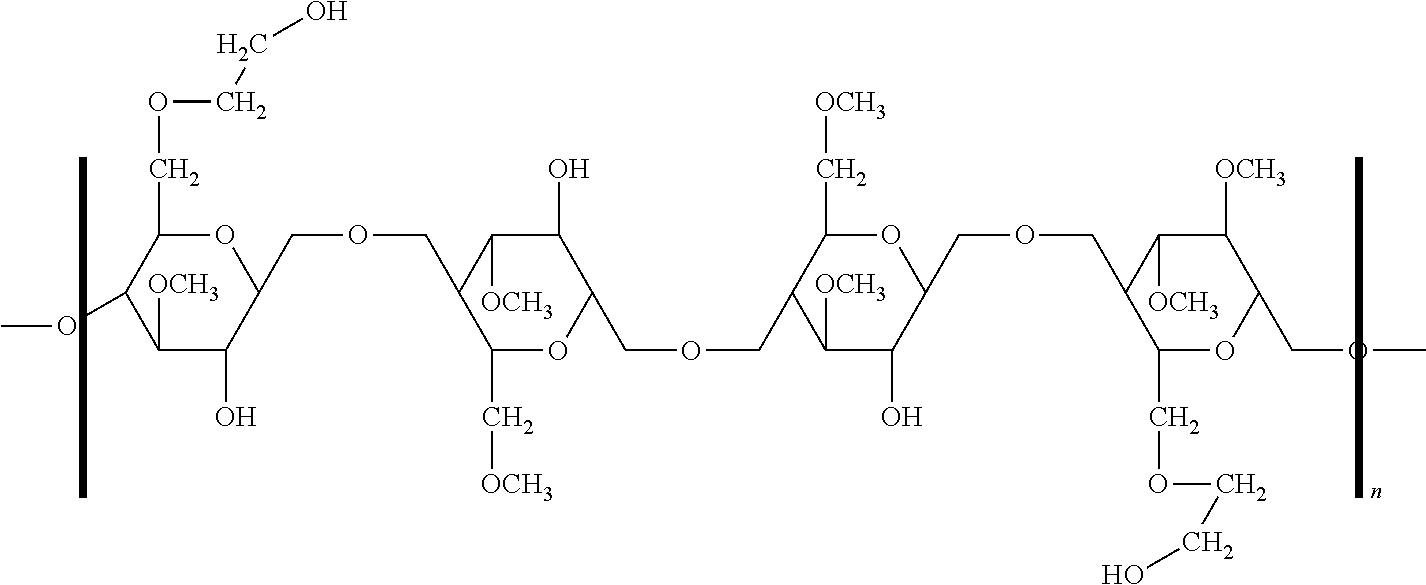

Modified cellulose products

A modified cellulose product comprising cellulose ether, such as carboxymethyl cellulose, hydroxyethyl cellullose, carboxymethyl hydroxyethyl cellulose, methyl cellulose, hydroxyethyl methyl cellulose or ethyl hydroxyethyl cellulose, or xanthan gum product, characterized in that it further comprises salts of aluminium-, ferro-, ferri-, zinc-, nickel-, tin(2)- or tin(4)-cations, and nitrilo-tri-acetic acid, 1,2-cyclo-hexan-di-amin-N,N,N',N'-tetra-acetic acid, di-ethylen-tri-amine-penta-acetic acid, ethylen-di-oxy-bis(ethylen-nitrilo)-tetra-acetic acid, (N-(2-hydroxy-ethyl)-ethylen-diamin-N, N',N',tri-acetic acid, tri-ethylen-tetra-amine-hexa-acetic acid or N-(hydroxyethyl) ethylene-di-amine-tri-acetic acid as a ligand. The product can be used especially as a drilling mud additive.

Owner:METSA SPECIALTY CHEM

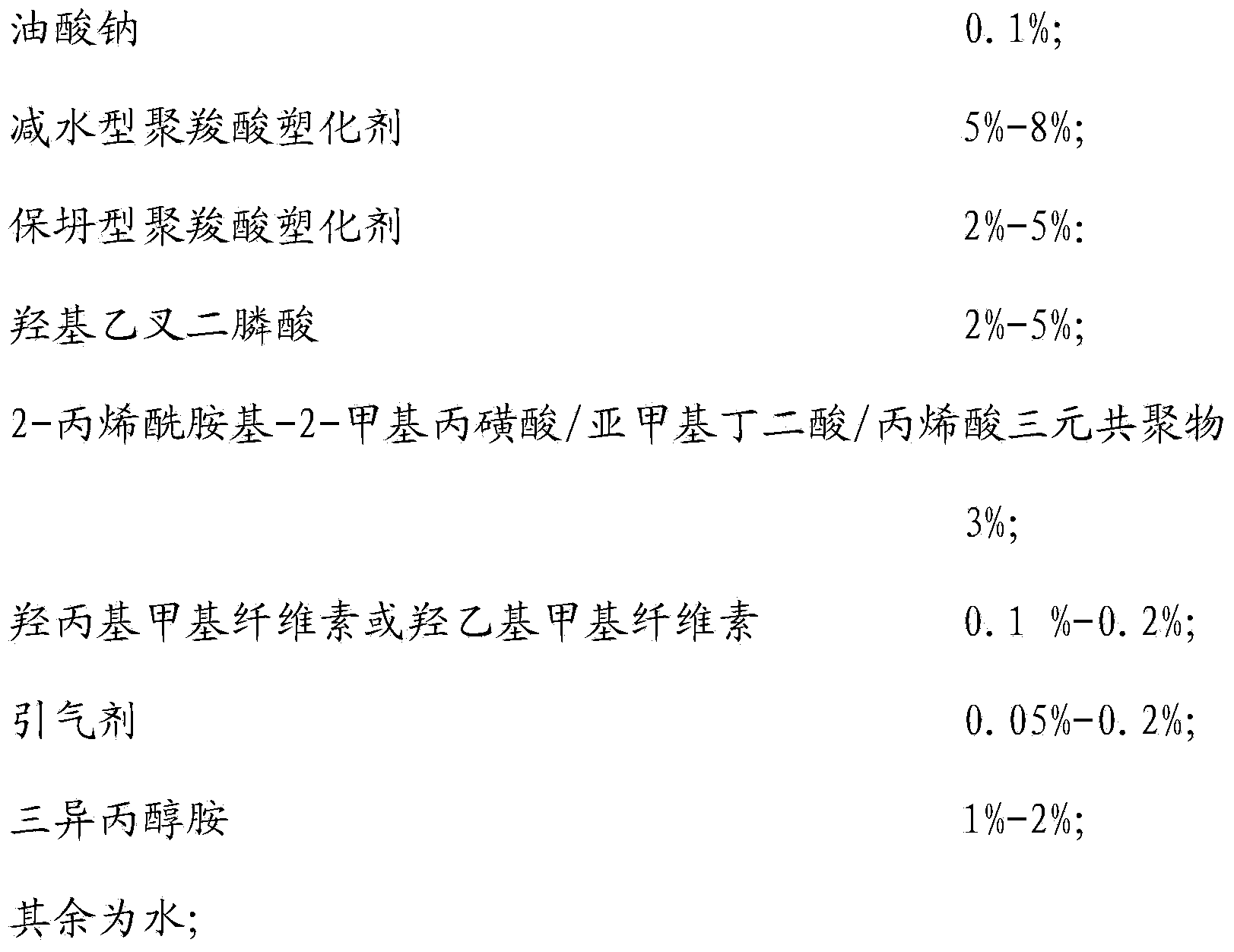

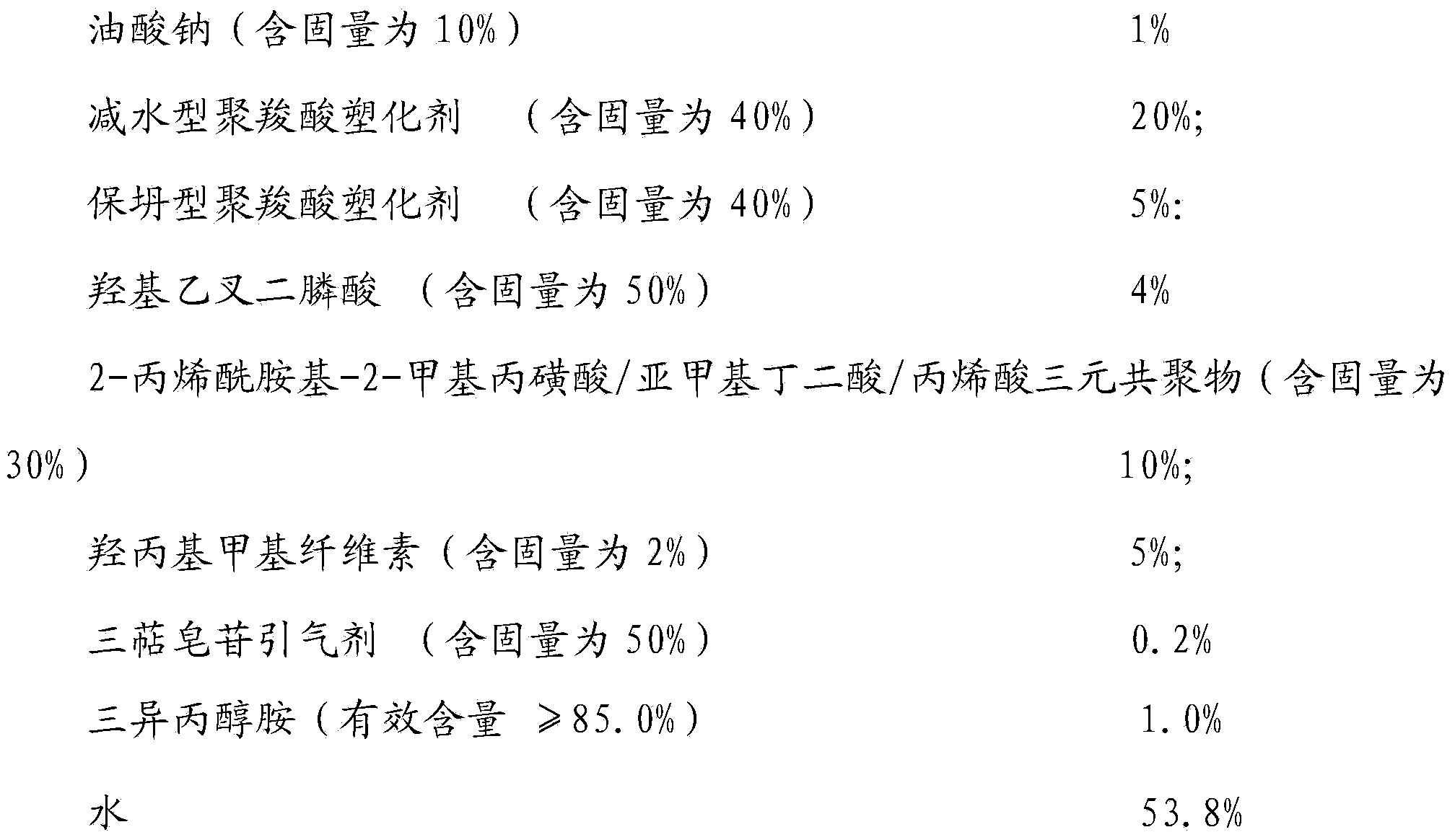

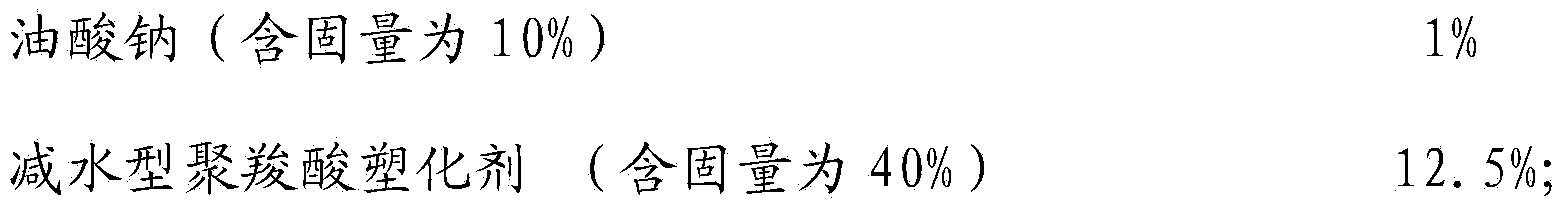

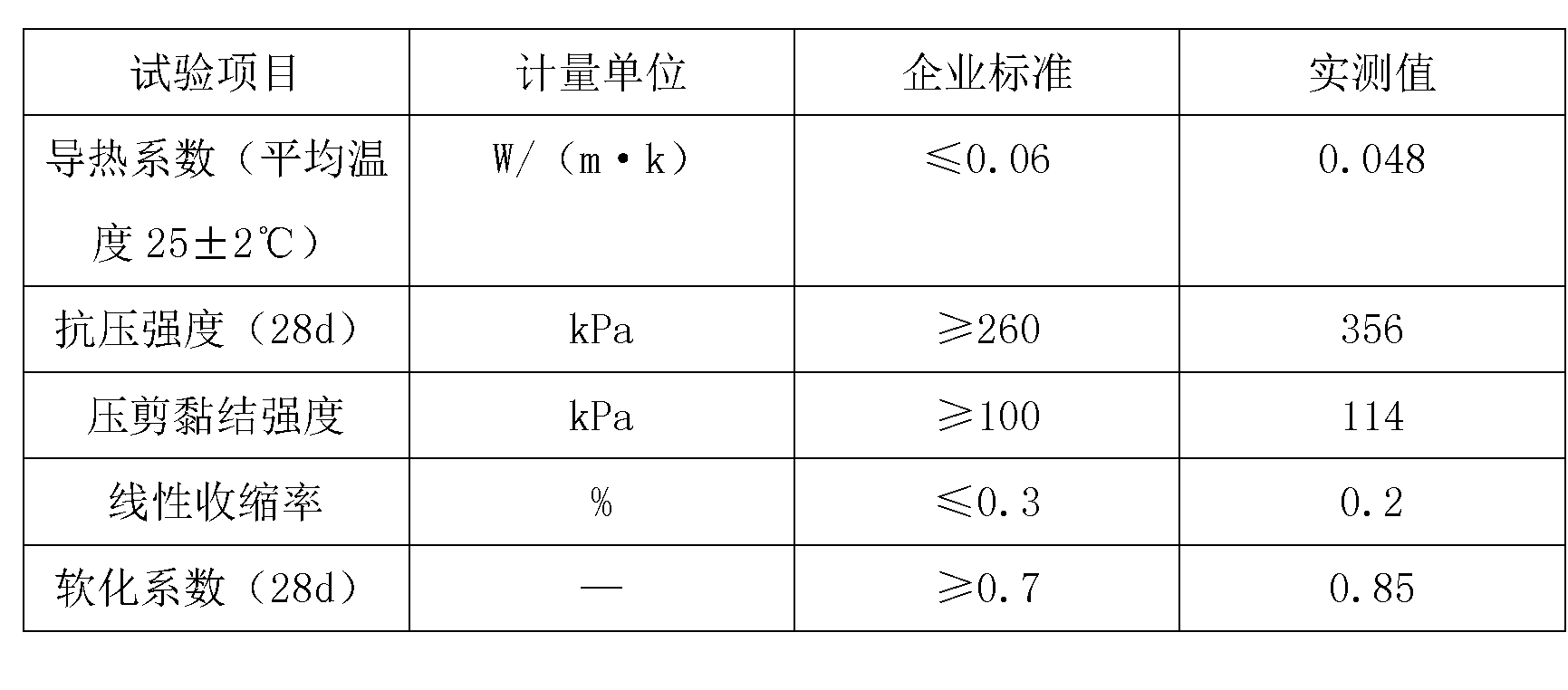

Super slump type polycarboxylate water reducing agent for bored pile concrete and preparation method thereof

ActiveCN103408242AGood slump performanceReduce bleedingWater reducerHydroxyethylidene Diphosphonic Acid

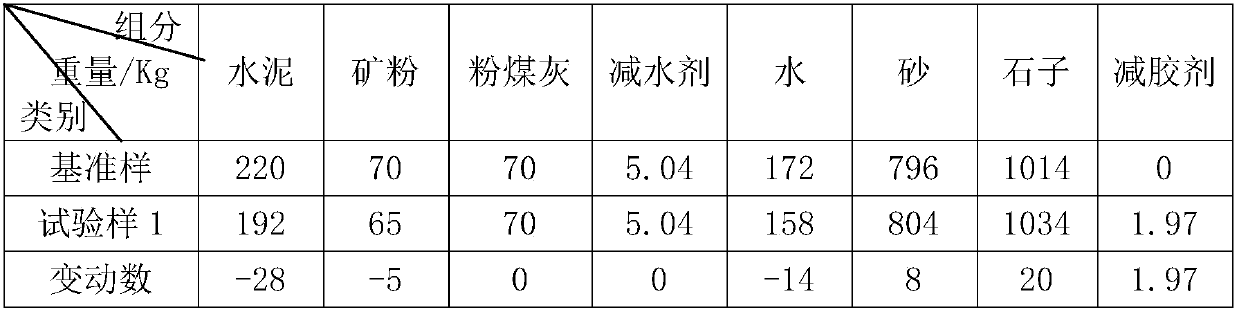

The invention provides a super slump type polycarboxylate water reducing agent for bored pile concrete. The water reducing agent is in a liquid state and comprises the following ingredients: sodium oleate, water reducing type polycarboxylate plasticizer, slump type polycarboxylate plasticizer, hydroxyethylidene diphosphonic acid, 2-acrylamide-2-methylpropanesulfonic acid / itaconic acid / acrylic acid terpolymer, hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose, air entraining agent and triisopropanolamine. The super slump type polycarboxylate water reducing agent for bored pile concrete provided by the invention has the following beneficial effects that by using the super slump type polycarboxylate water reducing agent, the bored pile concrete is good in homogeneity, the static bleeding rate of the bored pile concrete can be generally less than 1%, stable working performance can be maintained within a long time span, meeting the working property of concrete after 0.5-5.0h can be met by adjusting the formulation and dosage and improving the compressive strength ratio of the concrete, and the 28 d strength can be more than 130% of that of benchmark concrete. The invention further provides a preparation method of the super slump type polycarboxylate water reducing agent for bored pile concrete.

Owner:北京金隅节能科技有限公司

Controlled release composition

InactiveUS20050019405A1Easy for to follow prescribed regimenConstant of releasePharmaceutical non-active ingredientsCoatingsEthyl(hydroxyethyl)celluloseCellulose acetate

A composition for controlled delivery of at least one active substance into an aqueous medium by erosion at a preprogrammed rate of at least one surface of the composition, comprising a matrix comprising the active substance, the matrix being erodible in the aqueous medium in which the composition is to be used, and a coating having at least one opening exposing at least one surface of said matrix, the coating comprising a first cellulose derivative which has thermoplastic properties and which is substantially insoluble in the aqueous medium in which the composition is to be used, and at least one of a second cellulose derivative which is soluble or dispersible in water, a plasticizer, and a filler. The coating is a coating which crumbles and / or erodes upon exposure to the aqueous medium such as a body fluid. The first cellulose derivative may be, e.g., ethylcellulose, cellulose acetate, cellulose propionate or cellulose nitrate, and the second cellulose derivative may be, e.g., methylcellulose, carboxymethylcellulose or salts thereof, cellulose acetate phthalate, microcrystalline cellulose, ethylhydroxyethylcellulose, ethylmethylcellulose, hydroxyethylcellulose, hydroxyethylmethylcellulose, hydroxypropylcellulose, hydroxypropylmethylcellulose, hydroxymethylcellulose or hydroxymethylpropylcellulose.

Owner:EGALET LTD

Modified nano-kieselguhr inorganic thermal-insulation mortar coated with plant ash and preparation method thereof

InactiveCN103011721AHigh cylinder compressive strengthLow water absorptionEnvironmental resistanceMicrosphere

The invention discloses a modified nano-kieselguhr inorganic thermal-insulation mortar coated with plant ash. The thermal-insulation mortar comprises the following raw materials in parts by weight: 50-60 parts of 42.5-level ordinary Portland cement, 20-30 parts of coal slack powder, 10-20 parts of plant straw powder, 10-20 parts of nano-kieselguhr, 40-50 parts of plant ash, 10-15 parts of starch emulsion, 2-3 parts of tetraisopropyl di(dioctylphosphate) titanate, 10-15 parts of modified vitrified microspheres, 2-4 parts of redispersible latex powder, 0.5-1.5 parts of methyl cellulose ether, 0.5-1 part of wood fiber, and 1-2 parts of polypropylene fiber. According to the invention, the produced thermal-insulation mortar is excellent in thermal insulation property and construction performance, high in intensity, good in weatherability, green and environment-friendly, and has extremely great market space and development prospect in the field of the building energy-saving application in China.

Owner:合肥神舟建筑集团有限公司

Wet-mixed mortar modifier

The invention provides a wet-mixed mortar modifier. Every 1,000 parts of the wet-mixed mortar modifier comprises 15-20 parts of sodium tripolyphosphate, 1-2 parts of sodium hexametaphosphate, 4-5 parts of phosphonobutane tricarboxylic acid, 32-44 parts of glucose, 24-33 parts of citric acid, 50-80 parts of zeolite powder, 80-100 parts of silica fume, 200 parts of heavy calcium carbonate, 10-15 parts of starch ether, 20-40 parts of hydroxyethyl methyl cellulose ether, 1-2 parts of sodium dodecyl sulfate, 28-50 parts of a polycarboxylate superplasticizer, 20-25 parts of a polycarboxylate slump retaining agent, 40-80 parts of a naphthalene-based superplasticizer, 20-25 parts of redispersible latex powder, 8-10 parts of beta-cyclodextrin and the balance of fly ash. The plasticity-maintaining time of the wet-mixed mortar modifier is prolonged to 36 h, the later strength and bondability of the wet-mixed mortar are improved simultaneously, the mortar durability is improved, the problems of high probability of hollowing, cracking, leaking and the like of plastering mortar are solved, and the wet-mixed mortar modifier has low energy consumption and is free of chemical and radioactive contamination.

Owner:ZHEJIANG JIANKE NEW MATERIAL DEV

Early strength asater resistant dispersion and anti-dissolving shielding tunnel back lining filling material and its preparation method

ActiveCN1868956AHigh viscosityImprove the coagulation effectSolid waste managementSlagFilling materials

An early-strengthening grouting material for the back liner of tunnel to resist against dispersing in water and denudation is proportionally prepared from powdered coal ash, slag, steel dregs, meta-kaolin, sodium fluorosilicate, stellite, hydroxyethyl methylcellulose, sand, water, and water glass solution. Its preparing process is also disclosed.

Owner:武汉市城市建设投资开发集团有限公司 +3

Self-heat insulation aerated concrete building block and mortar for construction of building blocks

InactiveCN105924113AHigh mechanical strengthLow thermal conductivitySolid waste managementCalcium in biologyFiber

The invention provides a self-heat insulation aerated concrete building block and mortar for construction of building blocks, and relates to the field of building walls. The building block is prepared by the following components in parts by weight: 60-110 parts of a siliceous material and 25-65 parts of a calcareous material which are used as main materials, 2-6 parts of vitreous beads, 5-30 parts of an additive, 0.07-0.2 parts of a foaming agent, 1-10 parts of a foaming conditioning agent, 0.08-0.2 parts of a foam stabilizer, and water. The building block has the advantages of fire prevention, flame retardation, good mechanical strength, low heat conduction coefficient, and good thermal insulation performance. The mortar is mixed from the following components in percentages by weight: 15-45% of Portland cement, 10-30% of coarse sand, 30-50% of fine sand, 0.05-0.15% of PP fiber, 0.02-0.07% of methyl 2-hydroxyethyl cellulose, 3-5% of heavy calcium powder, 3-8% of coal ash, 0.5-1.5% of rubber powder, and water. The mortar has a high hardening volume density, so that generation of wall cracks and mortar joints is prevented, and thermal insulation performance of the wall is guaranteed.

Owner:YANCHENG INST OF TECH

Oral medicinal formulation of moxifloxacin and its preparation method

ActiveCN1762357APromote dissolutionDissolution unchangedAntibacterial agentsOrganic active ingredientsCarboxymethyl cellulosePolyethylene glycol

The invention relates to an oral medicinal formulation of moxifloxacin and its preparation method, which comprises Moxifloxacin or its salt and / or its hydrate, and at least one film forming material for preparing intermediate particles of the preparation selected from hydroxy propyl methyl cellulose, hydroxy ethyl methyl cellulose, cellulose methyl, hydroxy propyl cellulose, hydroxy ethyl cellulose, sodium carboxymethyl cellulose, polyacrylic resins, polyethylene glycol, polyvinyl pyrrolidon-vinyl acetate copolymer, polyvinyl alcohol-polyethylene glycol grafted copolymer, carbopol, gelatine, poloxamer and polyvinyl pyrrolidon. The invention also discloses the process for preparing the pharmaceutical preparation.

Owner:JIANGSU TIANYISHI PHARMA

Ultra-light-weight foam concrete and manufacturing method of same

InactiveCN102863193AReduce dry densityLow thermal conductivityCeramicwareFoam concreteThermal insulation

The invention relates to an ultra-light-weight foam concrete and a manufacturing method of the same. The manufacturing method comprises the following steps of: slowing stirring water, a cementing material, a water reducer and basalt fiber at a speed of 120rpm for 2 minutes after being mixed uniformly, quickly stirring the water, the cementing material, the water reducer and the basalt fiber at a speed of 240rpm for 2 minutes, mixing foam and cement paste, adding hydroxyethyl methyl cellulose into the mixture, stirring the mixture at a speed of 120rpm for 2 minutes to obtain paste, pouring the paste into a mould, putting the paste into a curing chamber for standard curing after being demoulded, and standing the paste for 28 days to obtain the ultra-light-weight foam concrete. Compared with the prior art, the ultra-light-weight foam concrete provided by the invention has the advantages of small dry density, low thermal conductivity and high compressive strength, can be made into a sheet material with a fire rating A and applied in an external thermal insulation system, and has the advantages of short curing time and no easy for surface pulverization.

Owner:WUHAN UNIV OF TECH

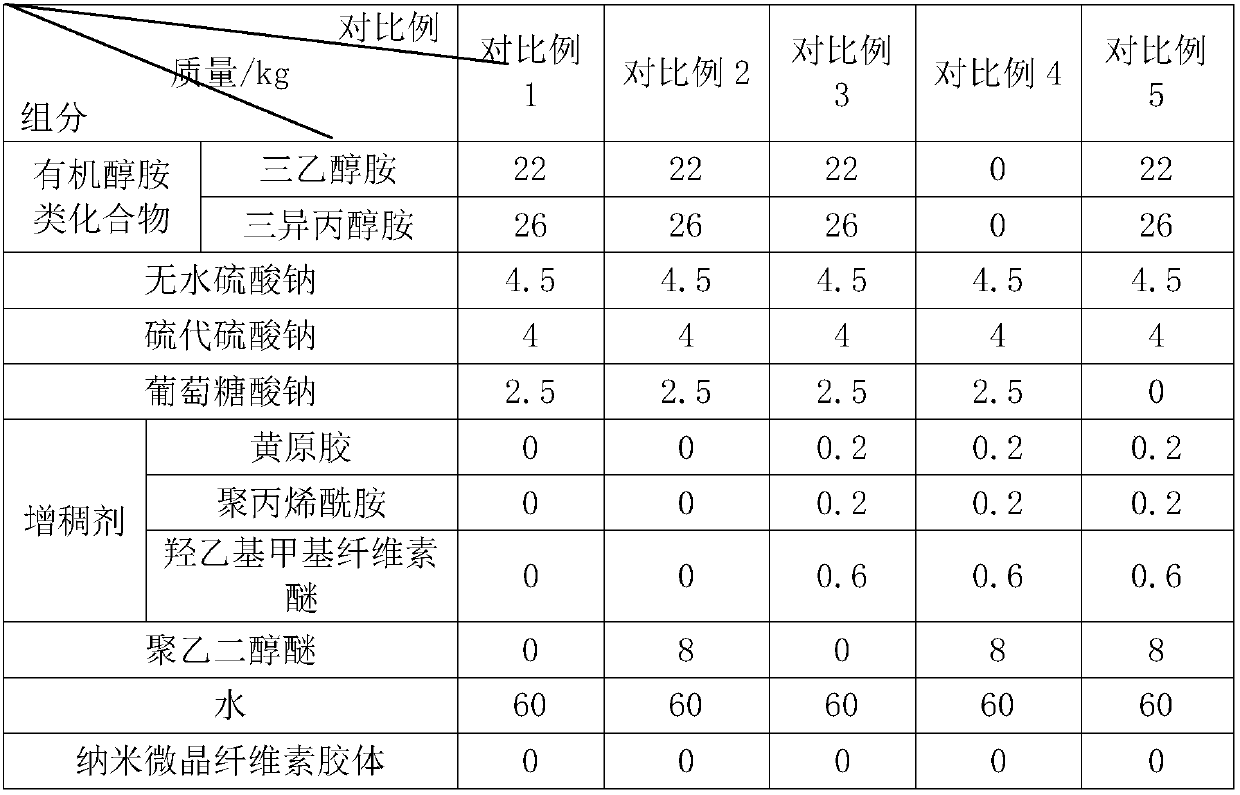

Concrete glue reducing agent and preparation process and application method thereof

ActiveCN109574538AAdjust and control viscosityImprove liquidityPolyethylene glycolMethyl palmoxirate

The invention discloses a concrete glue reducing agent and a preparation process and application method thereof. The concrete glue reducing agent comprises the following components in parts by weight:35-50 parts of an organic alkylol amines compound, 1-5 parts of anhydrous sodium sulfate, 2-10 parts of sodium thiosulfate, 0.1-3 parts of sodium gluconate, 1-5 parts of a thickening agent, 3-10 parts of polyglycol ether and 55-70 parts of water. The organic alkylol amines compound comprises at least one of triethanolamine and triisopropanolamine; and the thickening agent comprises at least one of xanthan gum, polyacrylamide and hydroxyethyl methyl cellulose. The concrete glue reducing agent can be used for a concrete blending process, does not have irritating odor, has the advantage of environmental protection, and has effects of reducing the using amount of cement and improving the strength of the concrete when added in the concrete.

Owner:HANGZHOU LIPING IND & TRADE CO LTD

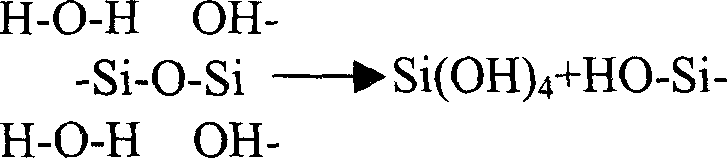

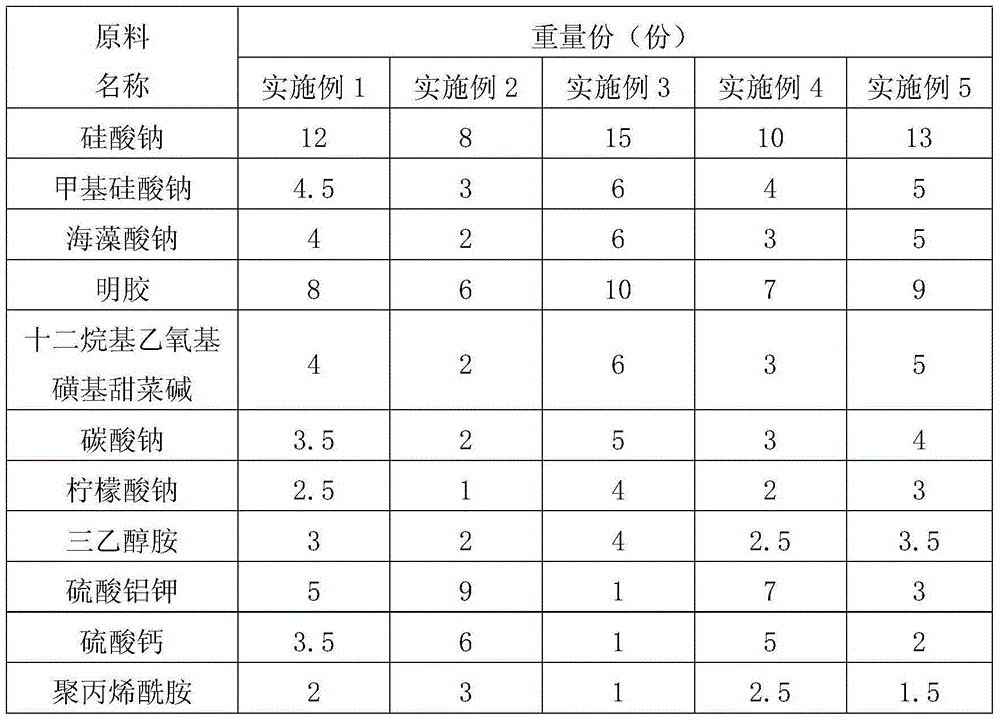

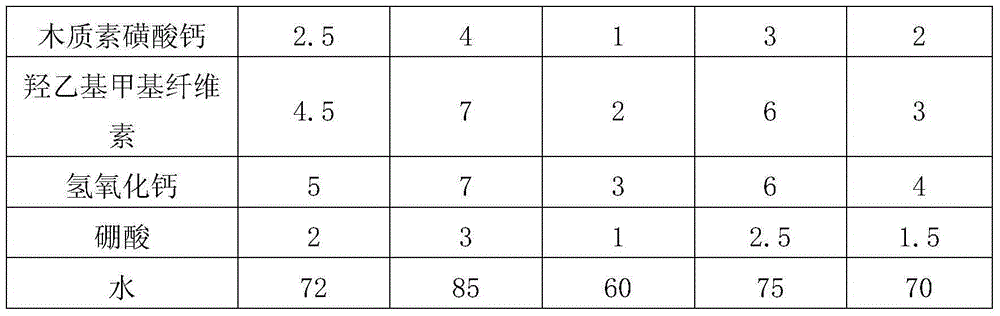

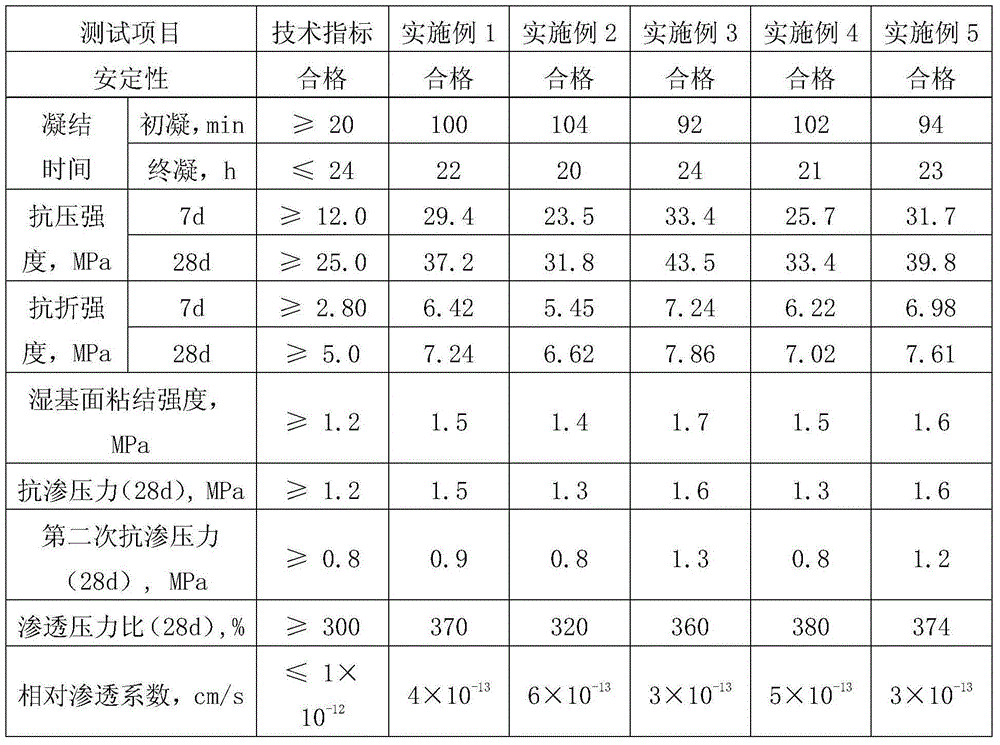

Inorganic-organic composite permeable crystallization type waterproof agent

The invention discloses an inorganic-organic composite permeable crystallization type waterproof agent. The waterproof agent is prepared from, by weight, 8-15 parts of sodium silicate, 3-6 parts of methyl sodium silicate, 2-6 parts of sodium alginate, 6-10 parts of gelatin, 2-6 parts of dodecyl ethoxy sulpho betaine, 2-5 parts of sodium carbonate, 1-4 parts of sodium citrate, 2-4 parts of triethanolamine, 1-9 parts of aluminum potassium sulfate, 1-6 parts of calcium sulfate, 1-3 parts of polyacrylamide, 1-4 parts of calcium lignosulphonate, 2-7 parts of hydroxyethyl methyl cellulose, 3-7 parts of calcium hydroxide, 1-3 parts of boric acid and 60-85 parts of water. The inorganic-organic composite permeable crystallization type waterproof agent has good waterproofness, endurance performance and self-curing performance and is low in cost and capable of being applied to waterproofing of house faces, basements, restrooms and the like.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Environmental-friendly water-soluble flux and preparation method thereof

InactiveCN101850483AImprove the insulation resistance valueReduce corrosionWelding/cutting media/materialsSoldering mediaPolyvinyl alcoholSolvent

The invention relates to an environmental-friendly water-soluble flux which is matched with lead-free solder; the environmental-friendly water-soluble flux comprises anhydrous citric acid, DL-malic acid, triethanolamine, modified polyvinylalcohol, polymethyl acrylate, vinyl acetate-ethylene copolymer powder, hydroxyethyl methyl cellulose ether, surfactant, benzotriazol, phenol and mixed solvent; the anhydrous citric acid, the DL-malic acid, the triethanolamine, the modified polyvinylalcohol, the polymethyl acrylate, the vinyl acetate-ethylene copolymer powder and the hydroxyethyl methyl cellulose ether are prepared into a complex active substance A through microencapsulated coating treatment; and the mixed solvent, the surfactant, the benzotriazol, the phenol, the modified polyvinylalcohol, the polymethyl acrylate and the complex active substance A are uniformly mixed by weight ratio to obtain the environmental-friendly water-soluble flux. The environmental-friendly water-soluble flux can effectively assist lead-free solder, particularly applicable to Sn-Ag-Cu lead-free solder, can enhance the solderability of the lead-free solder, can adapt to the high welding temperature requirement on the lead-free solder, has small action to the corrosion of lead-free solder alloys and little residue after welding, can be cleaned by water, has good welding point quality, clean surface and strong stability, and a dried circuit board has higher insulation resistance value.

Owner:NINGBO YINYANG TIN SOLDER

Ink-jet recording sheet and process for producing the same

InactiveUS6146712AFree from blurringHigh transparencyDuplicating/marking methodsPretreated surfacesImaging qualityMorpholine

The present invention provides an ink-jet recording sheet which is excellent in water resistance, capable of providing excellent ink-drying property and image quality, substantially free from blurring, and suitable for use as OHP sheets of which a high transparency is necessitated. The present process for producing an ink-jet recording sheet comprises applying to a base sheet, an aqueous solution of a water-soluble resin having no radically polymerizable double bond in the molecule and selected from the group consisting of polyvinyl alcohol, polyvinyl pyrrolidone, polyacrylamide, polyacryloyl morpholine, water-soluble polyvinyl acetal, poly-N-vinyl acetamide, hydroxyethyl cellulose, hydroxypropyl cellulose, methyl cellulose, hydroxypropyl methyl cellulose, hydroxyethyl methyl cellulose, gelatin, casein and derivatives of them, irradiating the resultant coating layer with electron beam before the coating layer is dried, to form a hydrogel, and drying the hydrogel. In the present invention, the water-soluble resin is usable in combination with a polyalkylene oxide compatible with the water-soluble resin.

Owner:OJI PAPER CO LTD

Biodegradable microbicidal vaginal barrier device

An intravaginal bio-erodible microbicidal barrier device. The device comprises (a) at least one micronized compound selected from the group consisting of cellulose acetate phthalate and hydroxypropylmethylcellulos- e phthalate, and (b) at least one water soluble or water dispersible cellulose compound selected from the group consisting of hydroxypropylmethylcellulose, methylcellulose, hydroxyethylcellulose, hydroxypropylcellulose, hydroxyethylmethylcellulose, hydroxyethylethylcellulose and hydroxypropylethylcellulose; or a pectin, such as an apple pectin. The device is prepared by a combination of foaming, freezing and freeze-drying processes.

Owner:NEW YORK BLOOD CENT

Volumizing Agents

ActiveUS20070037712A1Improve maximizationImprove brittlenessPowder deliveryBiocideHydroxyethyl methyl celluloseEthyl methyl cellulose

The present composition is capable of forming a particle film and comprises: (a) less than 99.65% by weight of at least one particle; (b) at least one volumizing agent selected from the group consisting of: (i) cellulose selected from the group consisting of ethyl hydroxy ethyl cellulose, hydroxy ethyl cellulose, hydroxy propyl cellulose, hydroxy ethyl methyl cellulose, hydroxy propyl methyl cellulose, methyl cellulose, ethyl cellulose, and ethyl methyl cellulose and present in an amount greater than 0.35% by weight; and (ii) non-cellulosic component or cellulose other than said cellulose (i) present in an amount of at least 0.05% by weight; and optionally (c) at least one spreader. The composition may be used to form agricultural films.

Owner:US SEC AGRI +1

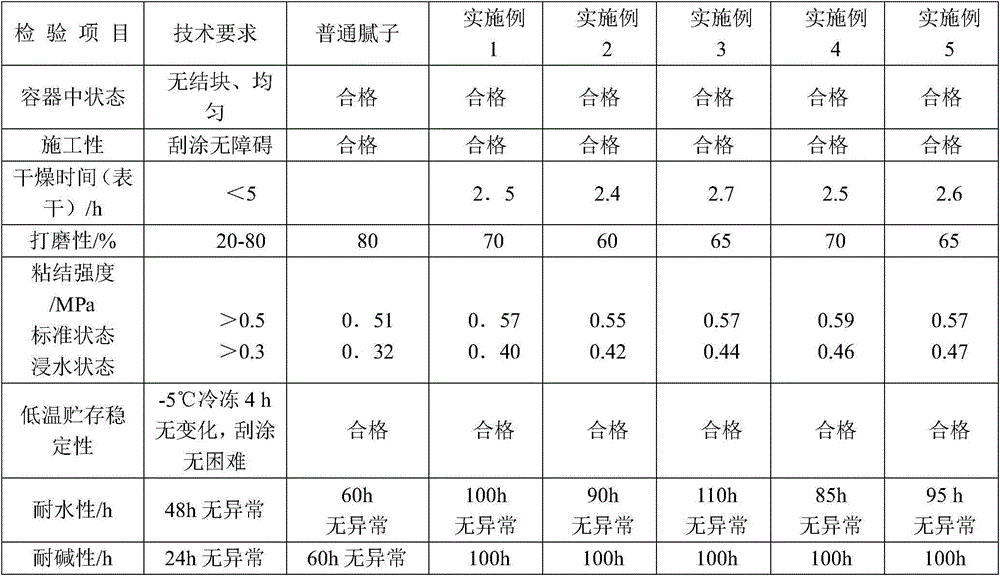

External wall putty

The invention relates to external wall putty, which comprises two components of A and B according to following weight percentage: component A comprises 30-40 percent of heavy calcium carbonate, 5-15 percent of talcum powder, 25-35 percent of quartz sand, 25-30 percent of Portland, 42.5 of cement, 1-3 percent of subdividable latex powder, 0.2-0.5 percent of ethoxyl methyl cellulose ether, and 0.02-0.1 percent of modified starch ether; component B is 5-12 percent of crylic acid latex; assorting ratio of component A and B is 100:5-12. The external wall putty has the advantages that cracks and pores can be padded; after hard drying, the product is characterized by strong adhesion force, good water resistance and corrosion resistance, smooth surface layer, crack control, and good impact resistance; after tested, 0.8 MPa is reached under a standard state in terms of bond strength; after five times of freeze-thaw cycles, bond strength of the putty reaches 1.03 MPa; the putty can be extensively applied to alteration and face lifting of external walls, which provides smooth underside base material for applying dope.

Owner:广福建材(蕉岭)精化有限公司

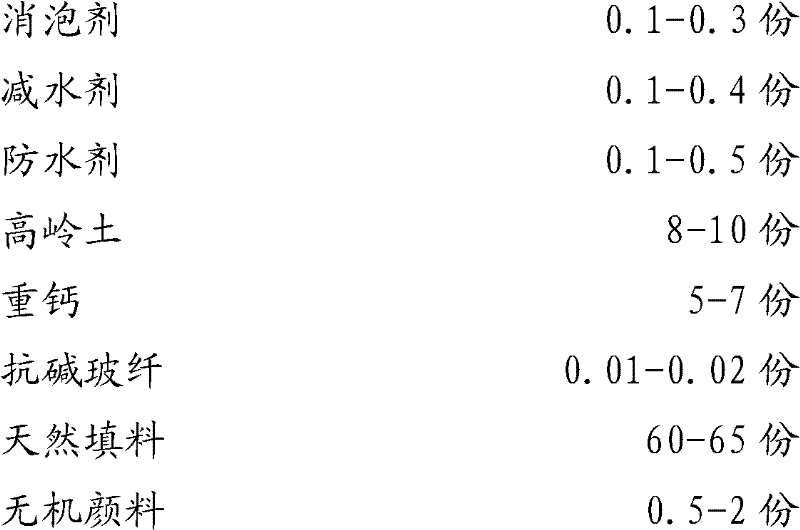

Building external wall powder paint and preparation method thereof

The invention discloses building external wall powder paint, which comprises the following ingredients: silicate cement, high-alumina cement, ethylene terpolymer polymer, hydroxyethyl methyl cellulose, defoaming agents, water reducing agents, waterproof agents, kaolin, coarse whiting, alkali-resistant glass fiber, natural fillings and inorganic pigment. The building external wall powder paint hasthe beneficial effects that the white silicate cement is used as film forming materials, the acetic ether or ethylene terpolymer powder is used for modifying the inorganic silicate cement, the pigment and the natural inorganic decoration fillings are matched, a coating has good attaching force and strong decoration performance through organic silicon functional auxiliary agents, the building external wall powder paint has the characteristics of good ageing resistance and chemical resistance performance of an inorganic coating and also has ventilation, waterproof and strain-proof functions, and the problem of influence on the coating appearance caused by silicate saltpetering is solved. The building external wall powder paint has the advantages that the product preparation and the construction are simple, the water is added for stirring when the paint is used, the paint can be constructed in a way of spray coating, brush coating and scrapping coating, the practicability is high, and the application range is wide.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Admixture for cement mortar having crack resistance and cement mortar including the same

Owner:LOTTE FINE CHEM CO LTD

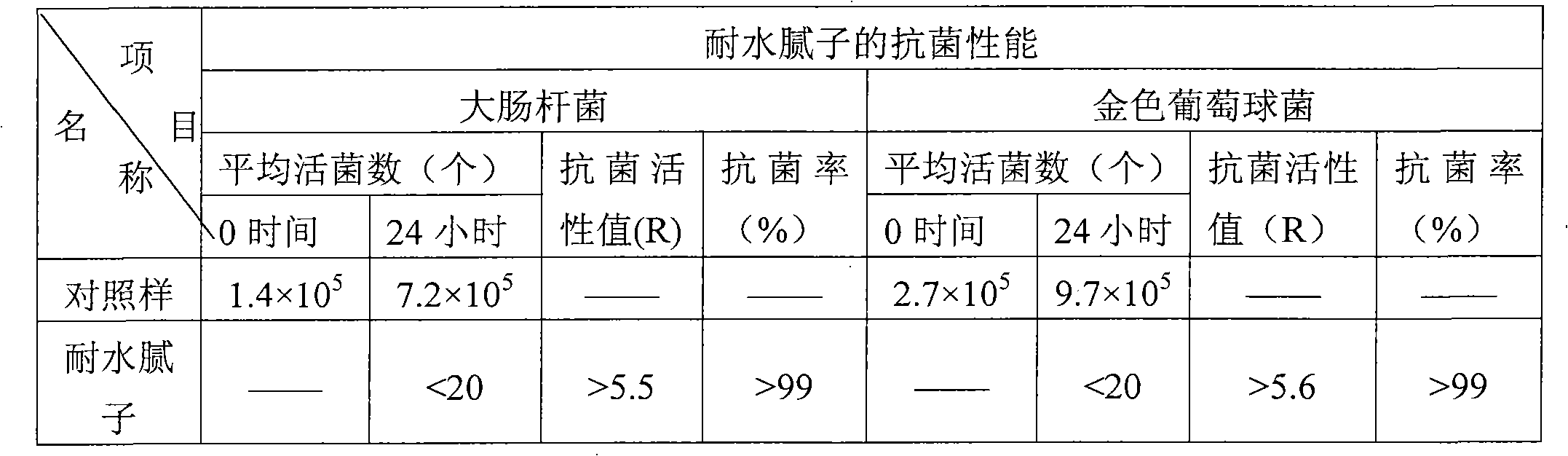

Water-resistant interior and exterior wall putty capable of absorbing and burying carbon dioxide in air

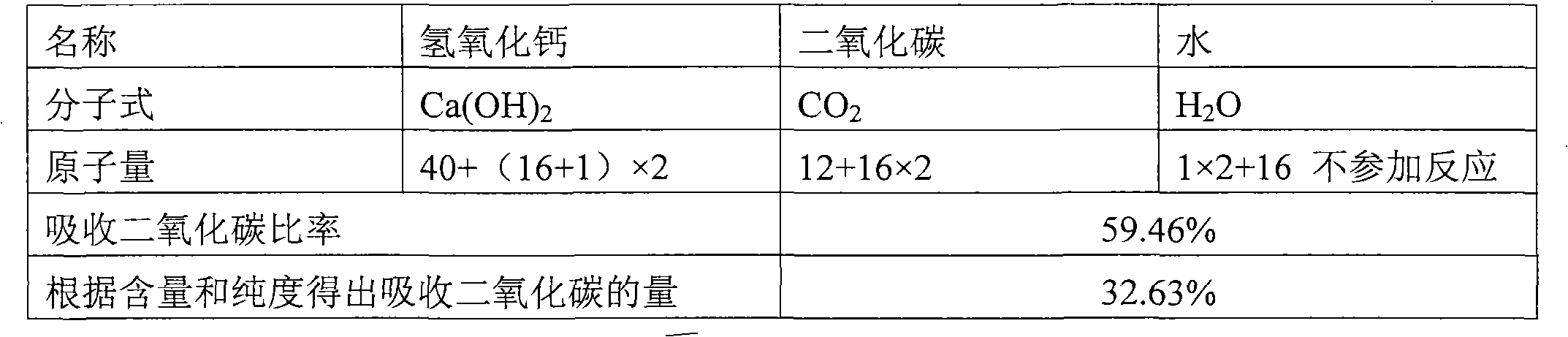

ActiveCN101851442AStrong water resistanceWith spontaneous breathing functionFilling pastesCalcium hydroxideWater resistant

The invention discloses water-resistant interior and exterior wall putty capable of absorbing and burying carbon dioxide in air. When the putty is prepared by the following materials in parts by weight when serving as interior wall putty: 24-60 parts of calcium hydroxide, 20-30 parts of heavy calcium carbonate, 20-30 parts of diatomite, 0.1-1 part of hydroxyethyl methyl cellulose and 0.05-0.5 part of catalyst; and when the putty is served as the exterior wall putty, 20-40 parts of white cement and 1-5 parts of re-dispersible glue powder are further added. The putty of the invention has the advantages of absorption and burial of carbon dioxide in air, sterilization, disinfection and air purification and strong water-resistance after being dried and solidified.

Owner:王贵琦

Anti-dispersion intensifier for underwater cast-in-place pile concrete and using method thereof

ActiveCN101830665AGood flocculation effectExcellent dispersion resistanceSolid waste managementFiberSlag

The invention discloses an anti-dispersion intensifier for underwater cast-in-place pile concrete, which comprises a polycarboxylic acid water reducer, hydroxyethyl methyl cellulose ether, starch ether, polyvinyl alcohol fiber, superfine ground slag, sodium tripolyphosphate, sulphoaluminate cement clinker and desulfurized gypsum. According to the technical scheme, when the product of the invention is added in underwater cast-in-place pile concrete during the preparation of the underwater cast-in-place pile concrete, the flocculability of the concrete is increased, the anti-dispersion performance is improved in a concrete casting process, the increase effect of the post strength of the concrete is obvious, the concrete has certain expansibility, the friction between the pile body and the soil is increased, and the bearing capacity of the pile body is improved.

Owner:珠海市振业混凝土有限公司 +1

Multifunctional antitranspirant and preparation method thereof

InactiveCN101417901AReduce harmEnsure normal breathingBiocideAnimal repellantsDiseaseCompound organic

The invention discloses a multifunctional antitranspirant. The contents and the weight percentage of each content thereof are as follows: hydroxyethyl methyl cellulose: 10 to 60 percent; biochemistry fulvic acid power: 5 to 25 percent; organic rare earths: 1 to 10 percent; sodium hexametahposphate: 0 to 5 percent; dodecyl sodium sulfate 0 to 4 percent; monopotassium phosphate: 3 to 15 percent; organic trace element: 1 to 14 percent; polyacrylate sodium: 0 to 10 percent; uniconazole: 0 to 2 percent; and a- rhodofix: 0 to 2 percent. The organic rare earth is obtained from carrying out chelation reaction to azotic acid rare earth with chelating agent; the organic trace element is a compound organic trace element which obtained from adding deionized water and chelating agent into one or a plurality of combinations of CuSO4, ZnSO4, FeSO4 and MnSO4 to carry out chelation reaction. The invention has the functions of drought control, wind proof, transpiration inhibition, plant growth adjustment and fortification, can raise the survival rate and preservation rate of plants, improve the survival state of plants and furtherly raise the ability to resist degeneration, resist disease, control drought and resist cold, thereby reaching the purpose of water saving, seed preserving and production and income increasing.

Owner:北京华铝爱森化工技术有限公司

Process for preparing color dispersions and the color dispersions made thereof

A process for preparing color dispersions comprising a first step of contacting water, a first colorant, and a gel composition comprising a first gel selected from methylcellulose, hydropropylmethylcellulose, hydroxyethylmethylcellulose, hydroxybutylmethylcellulose, hydroxyethylethylcellulose, and the mixture thereof, and a second gel selected from guar, pectin, carrageenan, gelatin, and the mixture thereof, to form a first colorant dispersion; a second step of contacting the first colorant dispersion with a composition comprising an aqueous dispersion of polymer particles, clay, and a peptizing agent to form a dispersion of protected first colorant particles. A color dispersion comprising the first colorant dispersion and a color coating comprising the color dispersion.

Owner:DOW GLOBAL TECH LLC +1

Flame-retardant paste material for coal mine downhole air leakage blocking and preparation method thereof

The invention relates to a flame-retardant paste material for coal mine downhole air leakage blocking and a preparation method thereof, belonging to a coal mine downhole air leakage blocking material and a preparation method thereof. The flame-retardant paste material comprises the following components: 100 parts of water, 0.2-0.4 part of fatty alcohol polyethenoxy ether, 1-1.5 parts of hydroxyethyl methyl cellulose, 1.875-2.5 parts of gypsum, 7.5-10 parts of cement and 30-40 parts of fly ash. The manufacturing process comprises the following steps: 1, adding the fly ash into water, and stirring to obtain a fly ash slurry solution; 2, simultaneously adding the fatty alcohol polyethenoxy ether and the hydroxyethyl methyl cellulose into the fly ash slurry solution, and sufficiently stirring and mixing to form a thickened fly ash slurry solution; and 3, simultaneously adding a mixture of the gypsum and the cement into the thickened fly ash slurry solution, and sufficiently stirring for 5-10 minutes, thus preparing the flame-retardant paste material for coal mine downhole air leakage blocking. The flame-retardant paste material is high in water retaining capacity, favorable in gelling property, obvious in flame-retardant characteristic, remarkable in air leakage blocking effect and low in cost, and has wide applicability in the aspect of coal mine downhole air leakage blocking.

Owner:CHINA UNIV OF MINING & TECH

Environment-friendly flexible interior wall putty and preparation method thereof

ActiveCN103980756AImprove flexibilityImprove waterproof performanceFilling pastesEmulsionCrack resistance

The invention discloses environment-friendly flexible interior wall putty and a preparation method thereof. The environment-friendly flexible interior wall putty comprises the following components by mass percent: 20-26% of water, 20-27% of acrylic emulsion, 5-10% of heavy calcium carbonate powder, 10-15% of light calcium carbonate powder, 12-19% of talcum powder, 5-7% of blanc fixe, 5-8% of bentonite, 2-3.7% of hydroxyethyl methyl cellulose ether, 1-3% of an antifreezing agent, 0.1-0.3% of a defoamer and 0.1-0.3% of a dispersant. The interior wall putty disclosed by the invention has the advantages of good flexibility, strong waterproofness, good crack resistance, fine and smooth surface texture after being scraped and the like, and is environment-friendly and not easy to atomize.

Owner:山东恒远装饰设计工程有限公司

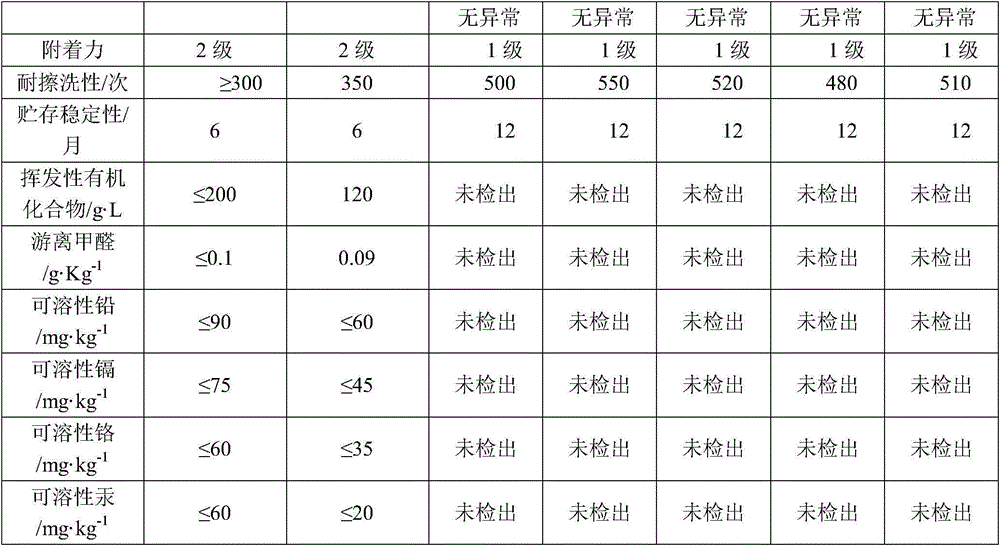

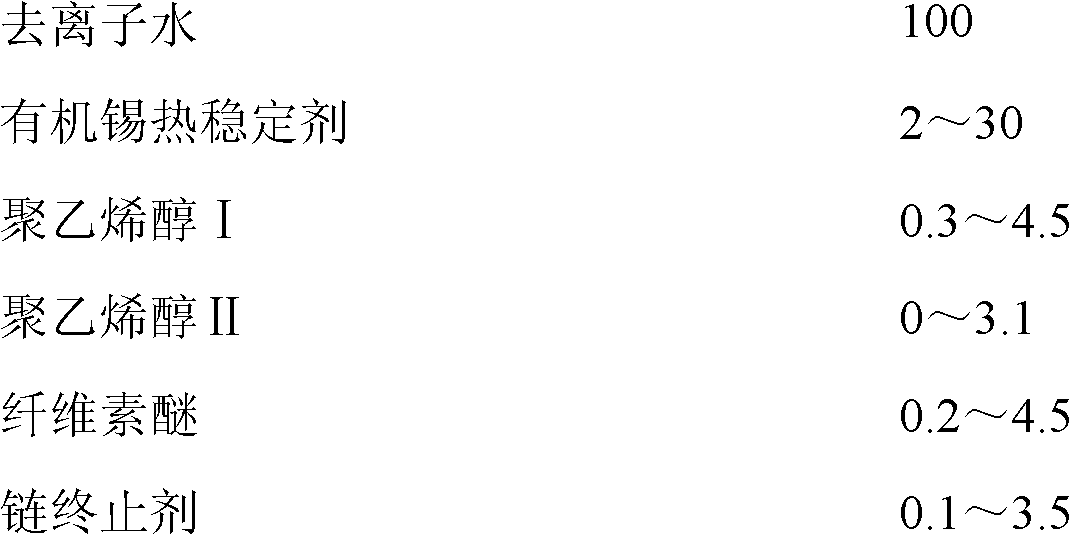

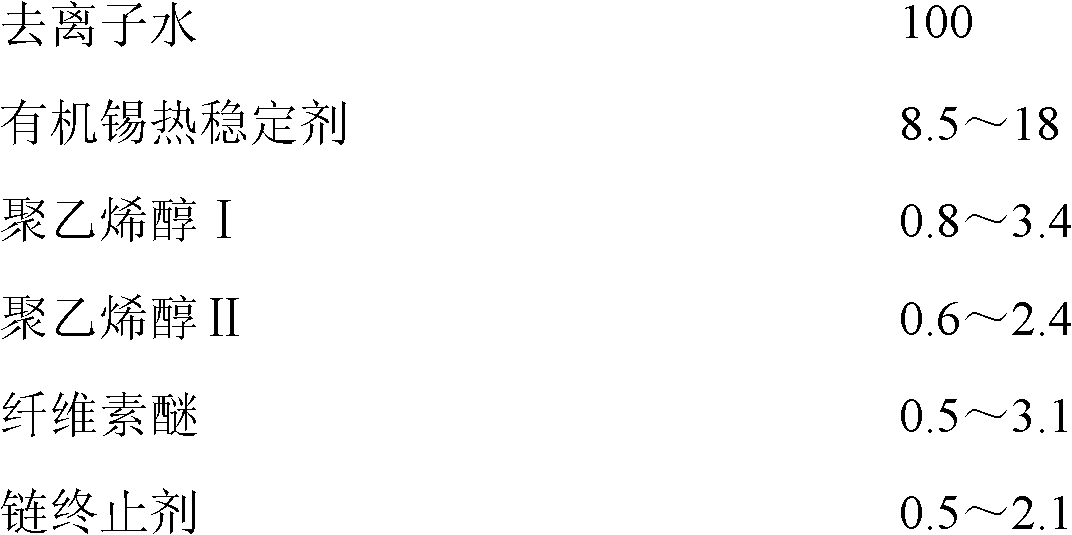

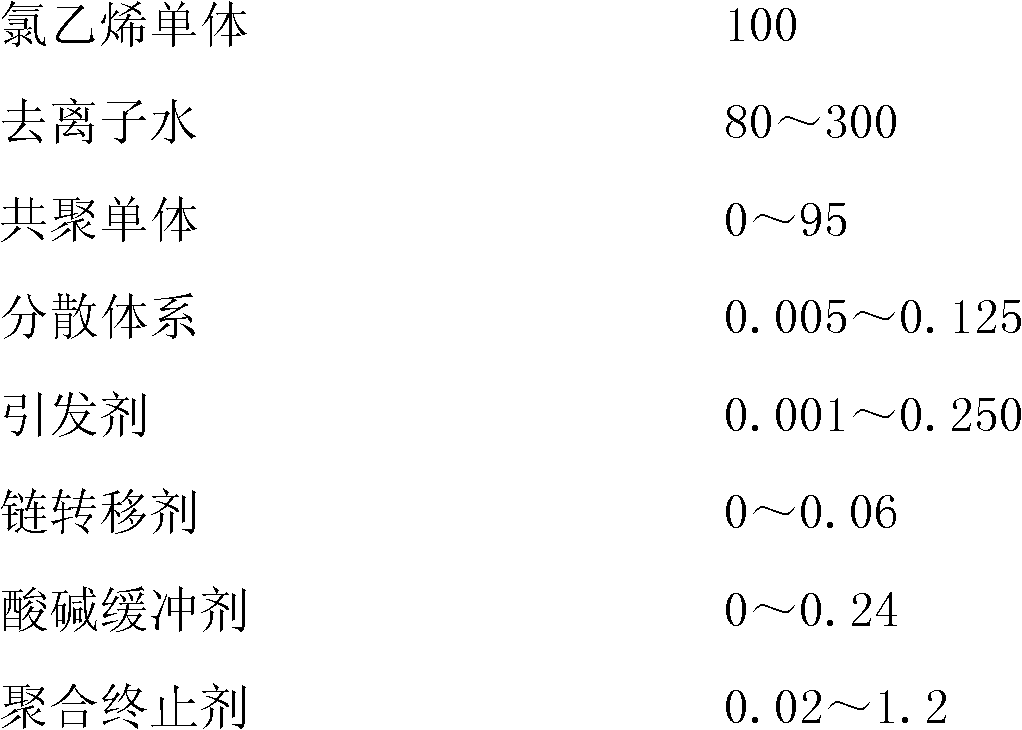

Chloroethylene suspension polymerization terminator and preparation method and use method thereof

The invention discloses a chloroethylene suspension polymerization terminator and a preparation method and a use method thereof, belonging to a terminator used in a chloroethylene polymerization process. The chloroethylene suspension polymerization terminator is characterized by being an aqueous emulsion dispersion liquid and consisting of the following raw materials in parts by weight: 100 parts of deionized water, 2-30 parts of organic tin thermal stabilizer, 0.3-4.5 parts of polyvinyl alcohol I, 0-3.1 parts of polyvinyl alcohol II, 0.2-4.5 parts of cellulose ether and 0.1-3.5 parts of chain terminator, wherein the deionized water is industrial secondary desalted water; the alcoholysis degree of the polyvinyl alcohol I is between 75-85 percent; the alcoholysis degree of the polyvinyl alcohol II is between 50-60 percent; and the cellulose ether is methyl cellulose (MC), hydroxyethylmethylcellulose (HEC) or hydroxypropyl methyl cellulose (HPMC). The invention provides a chloroethylene suspension polymerization terminator which can be used for effectively terminating a chloroethylene polymerization reaction and remarkably improving the aging whiteness and heat resistance of polymerized resin, and the preparation method and the use method thereof.

Owner:CHINA PETROLEUM & CHEM CORP

Putty leveling integrated gypsum mortar

The invention discloses putty leveling integrated gypsum mortar. The mortar is formed by mixing and stirring, by weight, 60-70 parts of desulfurized gypsum, 10-15 parts of 250-mesh heavy calcium carbonate, 6-10 parts of quartz sand of 20-30 meshes, 10-15 parts of 40-mesh quartz sand, 2-5 parts of glass bead heat preservation lightweight aggregate, 1-2 parts of redispersible emulsion powder VAE, 0.2-0.5 part of hydroxyethyl methylcellulose ether and 0.03-0.05 part of modified protein retarder. By means of the putty leveling integrated gypsum mortar, the traditional indoor leveling construction is greatly simplified, multiple construction procedures such as existing adhesion agents, leveling mortar and putty are replaced, forming can be completed at a time, the maintenance period is short, the construction period is greatly shortened, and the construction efficiency is improved.

Owner:上海曹杨建筑粘合剂厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com