Water-resistant interior and exterior wall putty capable of absorbing and burying carbon dioxide in air

A carbon dioxide and interior wall putty technology, applied in the direction of filling slurry, etc., can solve the problems of environmental protection not up to the standard, inability to absorb and bury, no curing, etc., to achieve a wide range of extended use, improved air permeability, and water retention strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

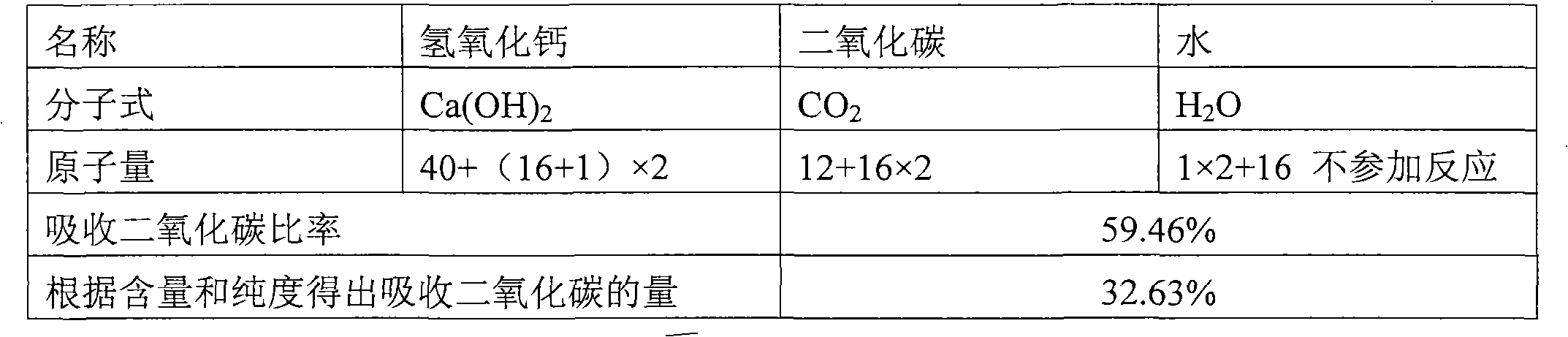

Method used

Image

Examples

Embodiment 1

[0038] Weigh the following raw materials in parts by weight: 60 parts of calcium hydroxide, whose mesh number is 400-600 mesh; 30 parts of heavy calcium carbonate, whose mesh number is 320-500 mesh; 30 parts of diatomite, whose mesh number is 320-500 mesh; 1 part of pharmaceutical grade hydroxyethyl methyl cellulose; 0.5 part of catalyst powder, put into a horizontal mixer in order to mix until uniform, and then the interior wall putty powder of the present invention can be prepared.

[0039] Wherein, the catalyst is a mixture of sodium aluminate and polyacrylamide, and the weight ratio of sodium aluminate and polyacrylamide is 7:1.

Embodiment 2

[0041]Weigh the following raw materials in parts by weight: 56 parts of calcium hydroxide, whose mesh number is 400-600 mesh; 21.75 parts of heavy calcium carbonate, whose mesh number is 320-500 mesh; 21.75 parts of diatomite, whose mesh number is 320-500 mesh; 0.3 parts of pharmaceutical grade hydroxyethyl methyl cellulose; 0.2 parts of catalyst powder, put them into a horizontal mixer in order to mix until uniform, and then the interior wall putty powder of the present invention can be prepared.

[0042] Wherein, the catalyst is a mixture of sodium aluminate and polyacrylamide, and the weight ratio of sodium aluminate and polyacrylamide is 5:1.

Embodiment 3

[0044] Weigh the following raw materials in parts by weight: 24 parts of calcium hydroxide, whose mesh number is 400-600 mesh; 20 parts of heavy calcium carbonate, whose mesh number is 320-500 mesh; 20 parts of diatomite, whose mesh number is 320-500 mesh; 0.1 part of pharmaceutical grade hydroxyethyl methyl cellulose; 0.05 part of catalyst powder; 40 parts of 42.5# white cement and 5 parts of ELOTEX redispersible rubber powder FL1212, put into the horizontal mixer in order and mix until Evenly, the exterior wall putty powder of the present invention can be made.

[0045] Wherein, the catalyst is a mixture of sodium aluminate and polyacrylamide, and the weight ratio of sodium aluminate and polyacrylamide is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com