Low-temperature sulphur-resisting denitration catalyst and preparation method thereof

A denitrification catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of reduced catalyst activity, weak resistance to sulfur poisoning, nitrogen oxide pollution, etc., and achieve low temperature denitrification Improved performance, remarkable sulfur resistance, and strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

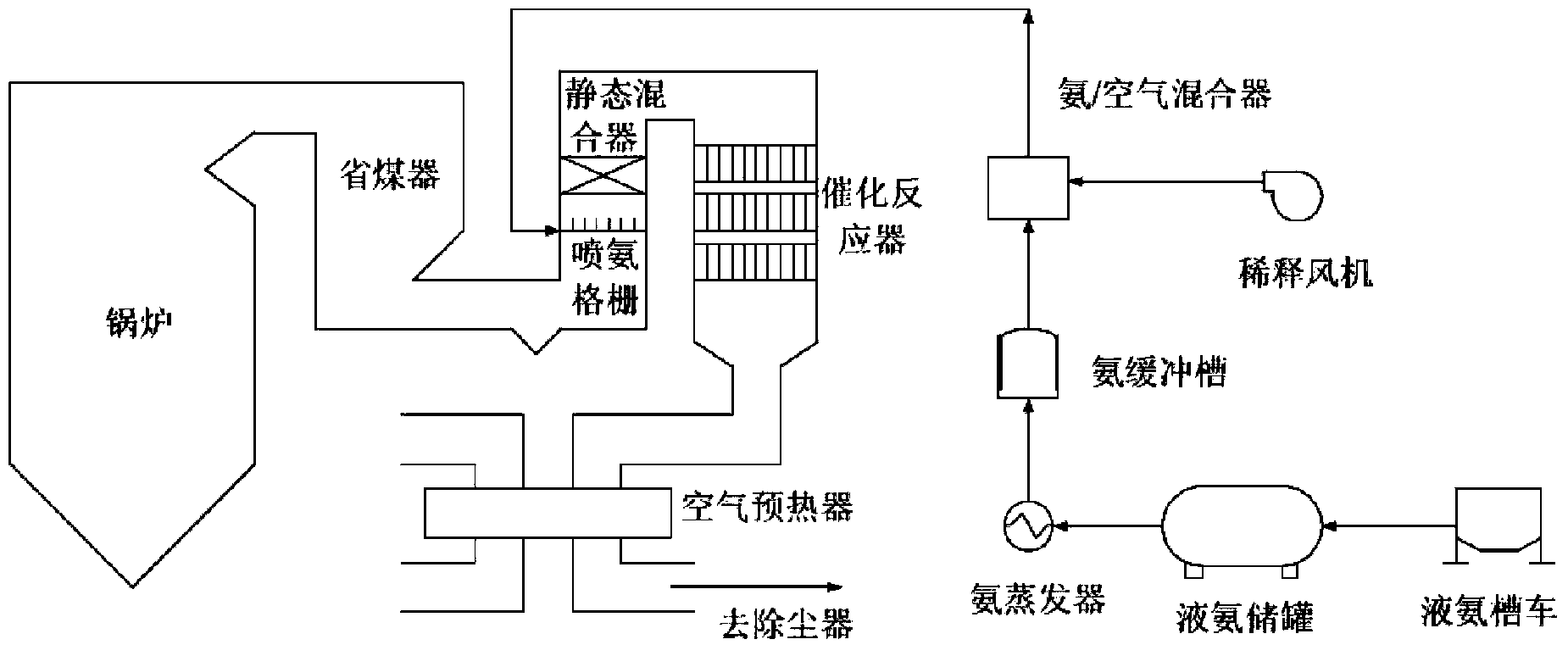

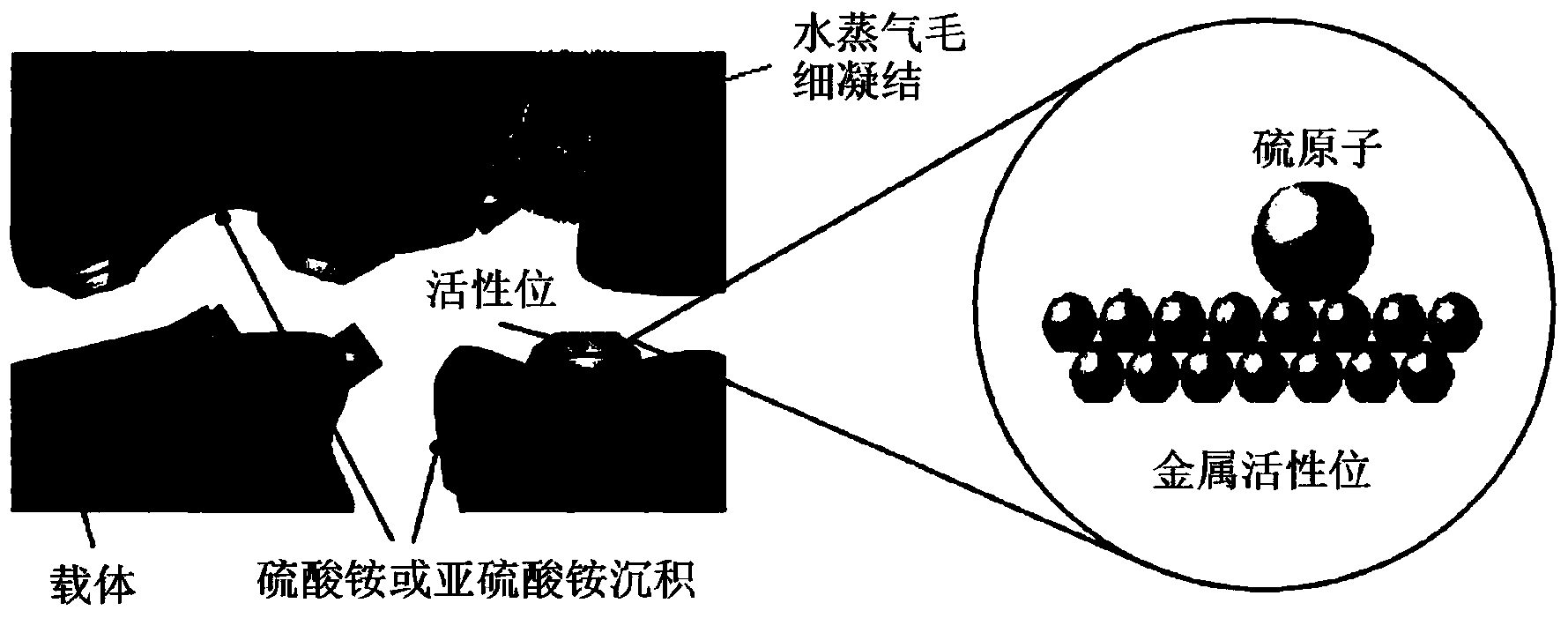

Method used

Image

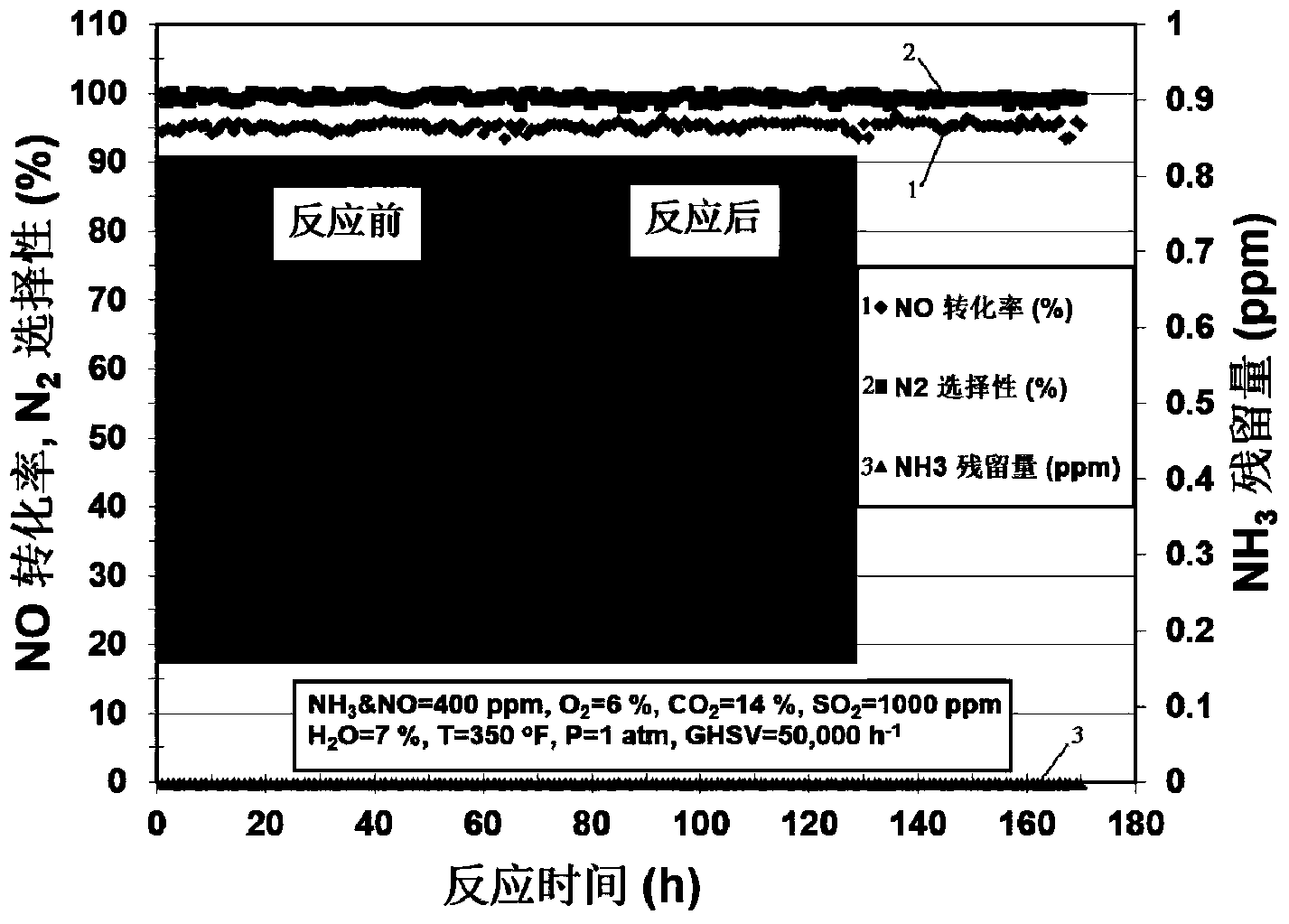

Examples

Embodiment 1

[0048] 1%V-10%Sn / AC (Note: The percentage signs in the following catalyst compositions are all mass percentages)

[0049] Its preparation process is as follows:

[0050] 1) Weigh a certain amount of activated carbon columnar particles at 30% H 2 / N 2 Continuous activation at 800°C for 1 hour under an atmosphere. After this step of hydrogenation treatment, the pore structure of activated carbon will be more developed, so as to facilitate the loading of denitrification active sites in the later stage;

[0051] 2) The above-mentioned activated carbon was placed in 1N hydrochloric acid and nitric acid aqueous solution and continued to soak for 8 hours. Wherein, the mol ratio of hydrochloric acid and nitric acid is 1:1;

[0052] 3) The activated carbon after the acidification treatment is repeatedly rinsed with deionized water at room temperature and under the condition of vacuum filtration until the filtrate becomes neutral;

[0053] 4) Place the cleaned activated carbon in...

Embodiment 2

[0066] 5%K-1%Ag-1%V-10%Sn / AC

[0067] Its preparation process is as follows:

[0068] 1) Weigh a certain amount of activated carbon columnar particles at 30% H 2 / N 2 Continuous activation at 800°C for 2 hours under an atmosphere. After this step of hydrogenation treatment, the pore structure of activated carbon will be more developed, so as to facilitate the loading of denitrification active sites in the later stage;

[0069] 2) The above-mentioned activated carbon was placed in 1N hydrochloric acid and nitric acid aqueous solution and continued to soak for 8 hours. Wherein, the mol ratio of hydrochloric acid and nitric acid is 1:1;

[0070] 3) The activated carbon after the acidification treatment is repeatedly rinsed with deionized water at room temperature and under the condition of vacuum filtration until the filtrate becomes neutral;

[0071] 4) Place the cleaned activated carbon in an oven and dry at 105°C for 8 hours;

[0072] 5) Weigh a certain amount of potas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com