Patents

Literature

1124results about How to "Strong water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

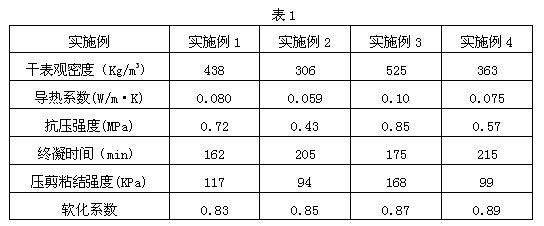

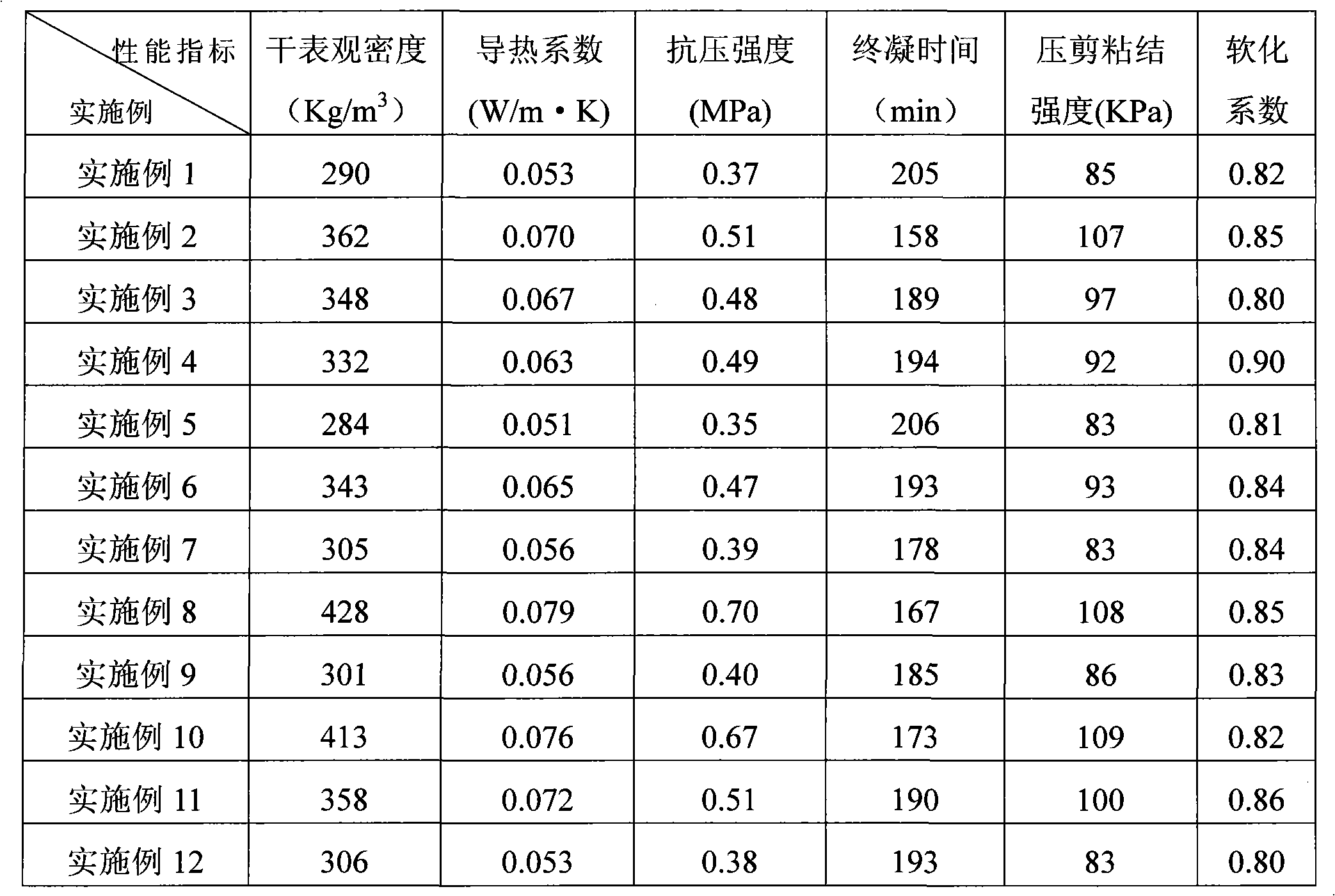

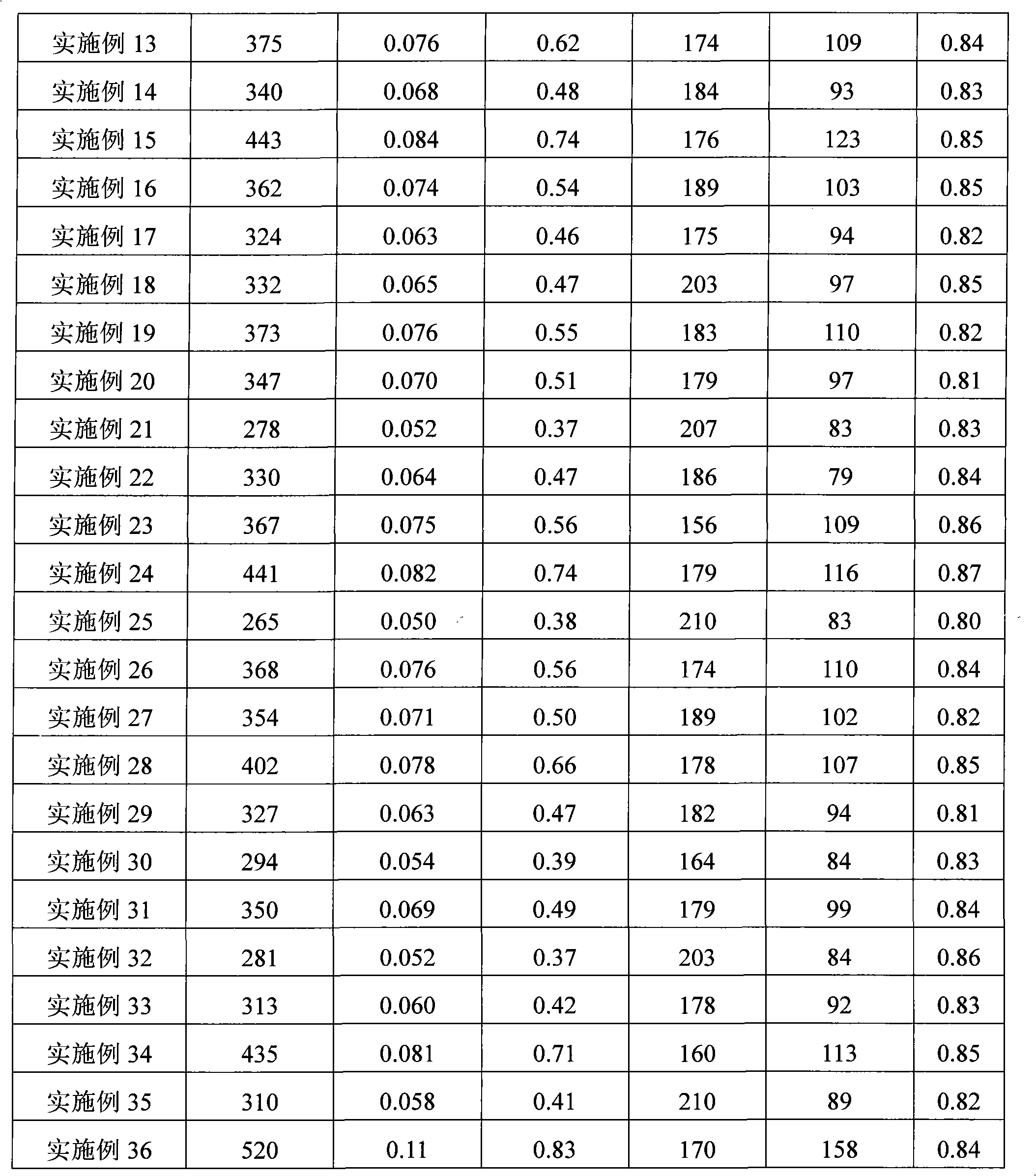

Super-light foam cement concrete and preparation method thereof

The invention discloses a super-light foam cement concrete and a preparation method thereof. The super-light foam cement concrete comprises the following raw materials by weight parts: 9-36 parts of dead burnt magnesium oxides, 9-32 parts of dihydric phosphates, 0.5-7 parts of adjustable solidification agents, 6-25 parts of light burnt magnesium oxides, 0.5-7 parts of sulfur-containing components, 1-25 parts of industrial slag powder, 1-20 parts of kieselguhrs, 0.3-3.9 parts of waterproof agents, 0.2-1.7 parts of foam stabilizing agents, 1.0-8.9 parts of foaming agents and 25-90 parts of water. The preparation method of the high-performance super-light foam cement concrete comprises the following steps of: metering raw materials; preparing the slurry containing the foam stabilizing agents; uniformly mixing the foaming agents; pouring and standing by; foaming and expanding; coagulating and curing; and naturally maintaining. The super-light foam cement concrete has the advantages of light weight, high strength, heat preservation and insulation, stable volume, low production cost, energy-saving property, no environmental pollution, and the like. The super-light foam cement concrete is simple in production process and is especially suitable for the heat-insulating material of external building wall, roof and floor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

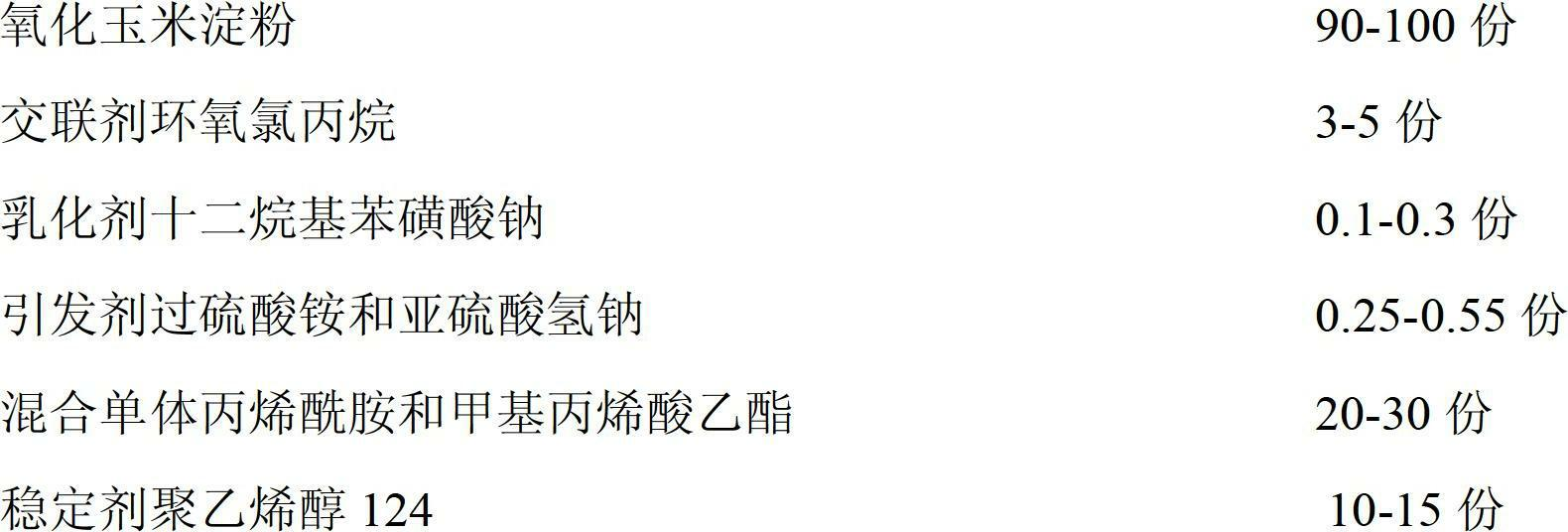

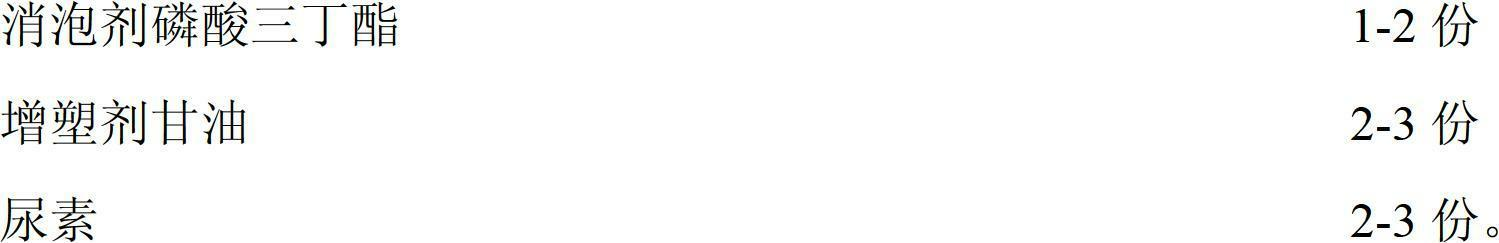

Modified-starch-based wood adhesive and preparation method thereof

InactiveCN102676098AReduce dependenceStrong water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseCross-link

The invention discloses a modified-starch-based wood adhesive and a preparation method thereof. The preparation method comprises the steps that oxidized corn starch is used as a main raw material, a cross-linking agent is added into the oxidized corn starch to conduct crosslinking modification, and then an initiating agent and a high molecular monomer are added to the oxidized corn starch to conduct graft modification, so as to obtain a modified starch emulsion in a complex net structure; and after the modified starch emulsion is warmed up and pasted, modifying agents comprising a stabilizing agent, a defoaming agent, a plasticizing agent and the like are added into the modified starch emulsion, and the high-performance green environment-friendly adhesive is manufactured. Each performance of the adhesive disclosed by the invention can reach or exceed requirements of a GB / T9846-2004 standard, the adhesive has the characteristics of high bonding strength, good water resistance, long storage time, high solid content, low cost, greenness, environment friendliness and wide use range, and can be widely applied to the bonding and the use of wood materials such as artificial boards, plywood and cellulose boards.

Owner:HEFEI UNIV OF TECH

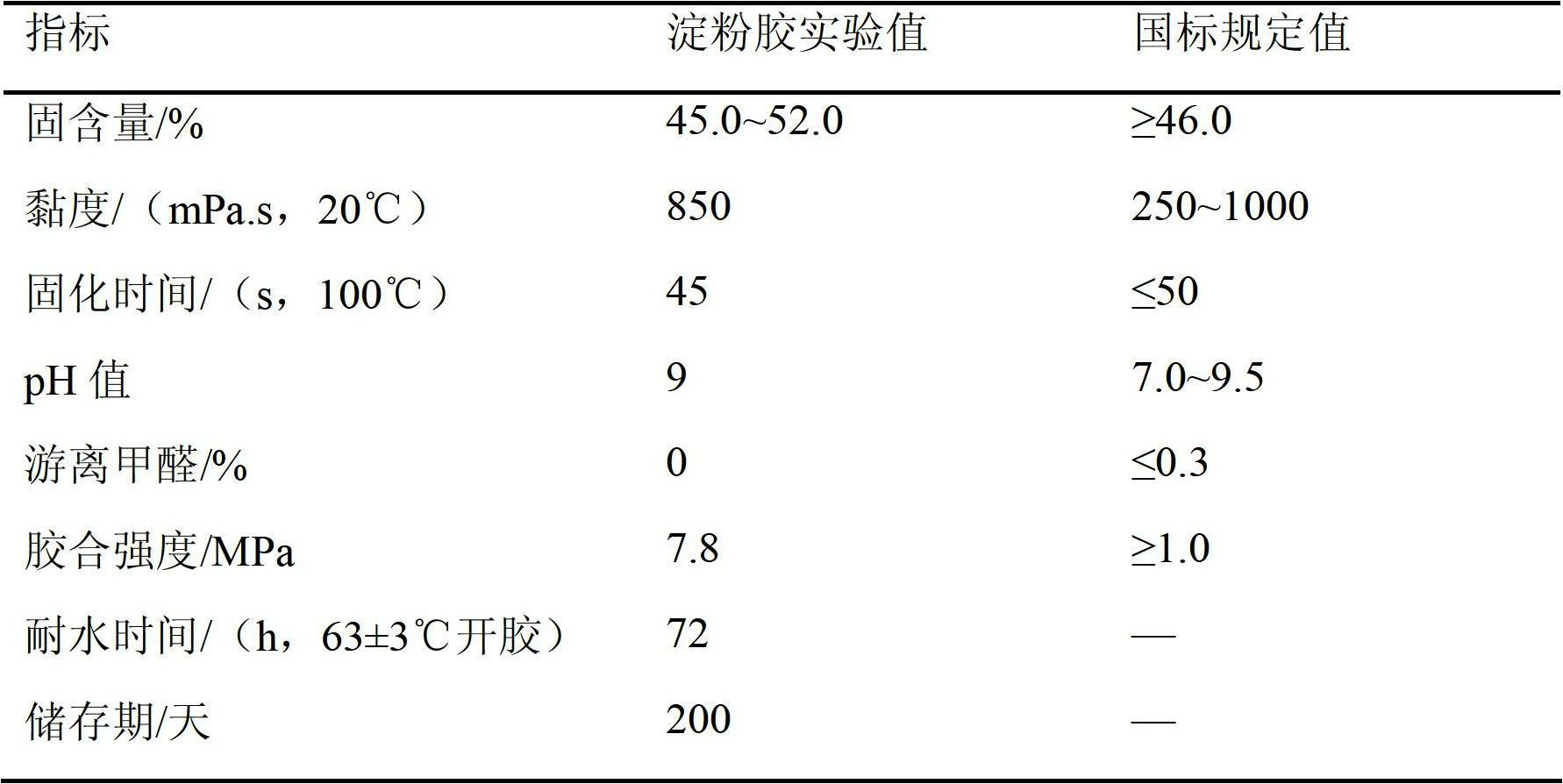

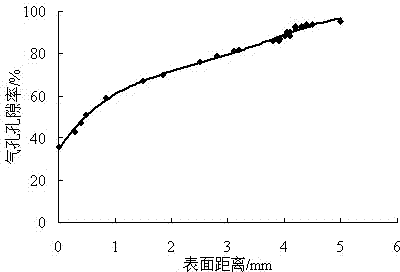

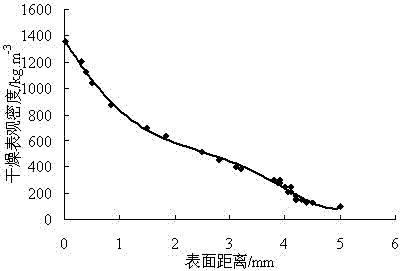

Functionally-graded cellular-concrete thermal-insulating material and preparation method thereof

ActiveCN102561532AOvercoming the Interface Breaking DilemmaImprove bending strengthHeat proofingCeramicwareFoam concreteThermal insulation

The invention relates to a functionally-graded cellular-concrete thermal-insulating material and a preparation method thereof. The functionally-graded cellular-concrete thermal-insulating material comprises a cellular-concrete thermal-insulating core, a plurality of air holes are uniformly distributed in the thermal-insulating material, and the surface of the cellular-concrete thermal-insulating core is wrapped with a functionally-graded layer; in the air holes of the functionally-graded cellular-concrete thermal-insulating material, the air hole in the cellular-concrete thermal-insulating core has a maximum diameter, then, the diameters and porosities of the air holes from the cellular-concrete thermal-insulating core to the outside are in a continuous graded change in a descending order, the thickness of the functionally-graded layer is 0.1-20 mm, the porosities of the air holes are in a continuous graded change in a range of 1- 95%, and the diameters of the air holes are in a continuous graded change in a range of 0.1-8 mm. According to the invention, the interior of the material is porous and thermal-insulating, and the surface of the material is high in density and strength, the mechanical strength of the material is gradually improved from the inside to the outside, and the thermal conductivity factor of the material is gradually reduced front the outside to the inside, thereby achieving an effect of integrating light weight, high strength, thermal insulation and fire prevention.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

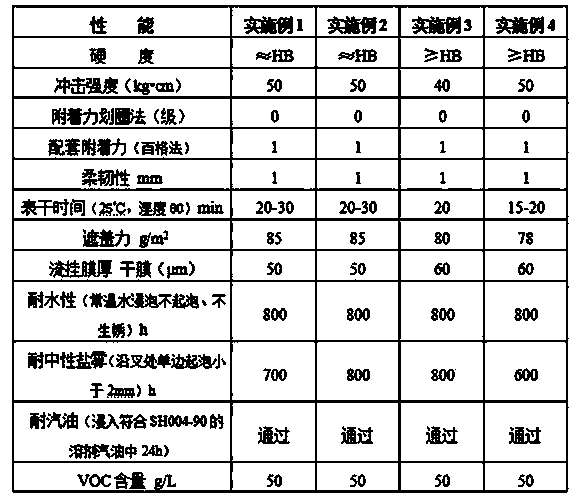

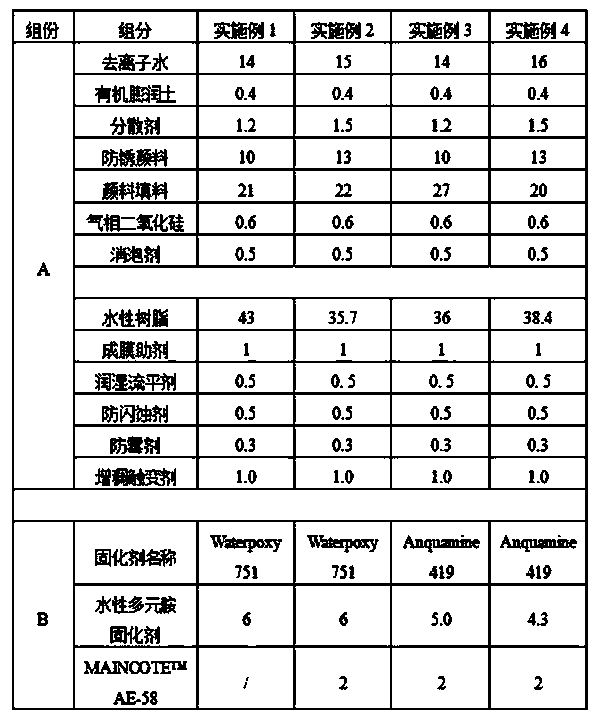

Room-temperature-curable aqueous anticorrosion primer used for coating external surface of construction crane and preparation method of primer

ActiveCN103436136AIntensity rises fastShort construction intervalAnti-corrosive paintsPolyurea/polyurethane coatingsAntifoam agentCorrosion resistant

The invention discloses a room-temperature-curable aqueous anticorrosion primer used for coating the external surface of a construction crane. The primer comprises the following components by weight: 35-45% of an aqueous resin, 5-8% of a curing agent, 1-3% of a dispersant, 5-12% of an antirust pigment, 20-35% of a pigment filling material, 1-2% of an anti-settling agent, 0.5-1% of a wetting agent, 0.5-1% of a thixotropic agent, 0.5-1% of an antifoaming agent, 0.1-0.8% of a flash etching inhibitor, 0.1-0.8% of a mildew inhibitor, 1-3% of a film-forming auxiliary agent and 10-20% of deionized water. The invention also discloses a preparation method of the aqueous anticorrosion primer. The aqueous anticorrosion primer has a room-temperature-curable paint film, is energy-saving and environment friendly, and can satisfy safe production requirements of enterprises; the primer is high in solidity, low in viscosity, convenient for construction; and the coating of the primer has good corrosion resistance and water proofness, and the comprehensive properties of the coating reach performance indexes of same-type oiliness products.

Owner:GUANGZHOU KINTE IND +1

Thermal insulation mortar

InactiveCN102010174AGood volume stabilityStrong water resistanceSolid waste managementPolystyreneTime control

The invention discloses thermal insulation mortar which comprises the following components in percentage by weight: 20 to 60 percent of caustic calcined magnesia, 1 to 25 percent of fly ash, 5 to 35 percent of thickening time control agent, 0 to 40 percent of enhanced thickener, 1 to 20 percent of kieselguhr, 5 to 35 percent of expanded aggregate, 0 to 5 percent of polystyrene foam particles, 0 to 0.2 percent of polypropylene fiber, 0.5 to 8 percent of water-resisting admixture, and 0 to 2 percent of water reducing agent. The thermal insulation mortar has the characteristics of capability of coagulating and hardening quickly and having strong binding capacity with base materials, good volume stability, capability of producing volume micro-expansion in the process of coagulating and hardening, no crack, no splitting, strong water resistance, ageing resistance, long service life, light weight, and good heat preservation and heat insulation performance, wherein the coefficient of thermal conductivity is 0.05 to 0.30 W / m.k. The thermal insulation mortar has the advantages of no toxicity, odourlessness, zero radioactivity, no harm to human bodies, no pollution to environments, energy conservation, environmental friendliness and low production cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

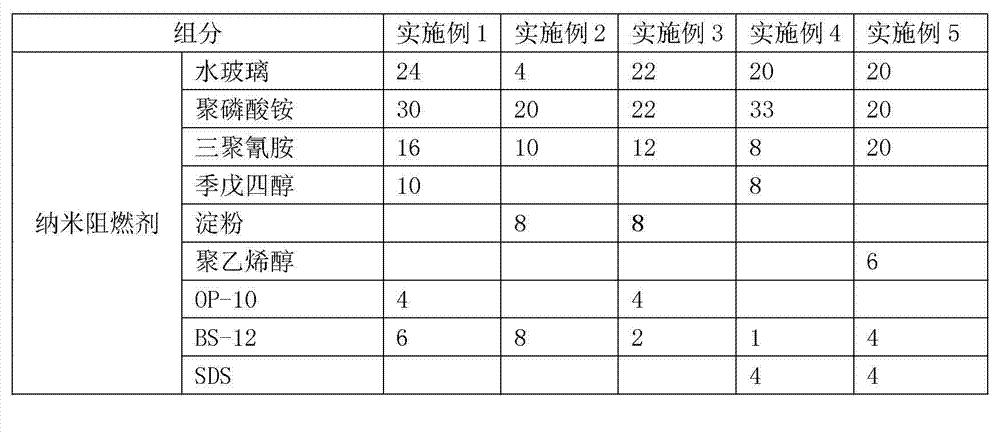

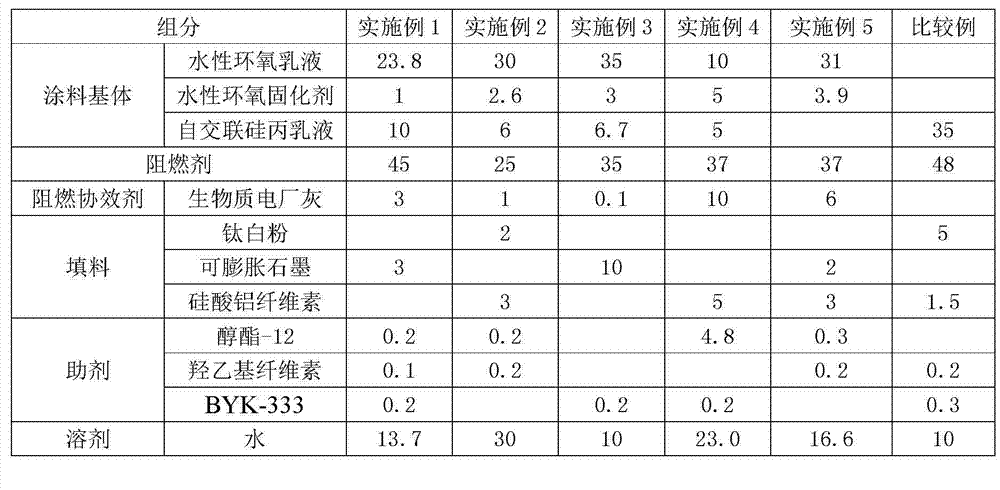

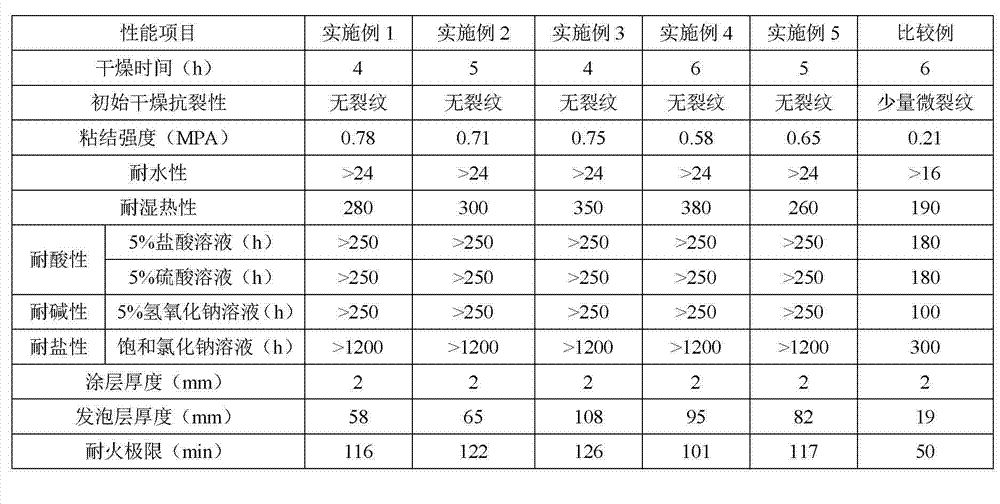

Water-based expandable fireproof steel structure coating and preparation method

ActiveCN103045037AStrong weather resistanceImprove dispersion performanceFireproof paintsAcid polymer adhesivesEmulsionBiomass

The invention relates to a water-based expandable fireproof steel structure coating and a preparation method thereof. The water-based expandable fireproof steel structure coating comprises the following components in mass percentage: 20-45% of coating matrix, 25-45% of nano-flame retardant, 0.1-10% of flame-retardant synergist, 1-10% of filler, 0.2-5% of auxiliary agent and 5-30% of water. The preparation method of the water-based expandable fireproof steel structure coating comprises the following steps: firstly, preparing the nano-flame retardant; secondly, adding a water-based epoxy emulsion, a water-based epoxy curing agent and a self-crosslinking silicone acrylic emulsion in the coating matrix into a stirring barrel, and stirring uniformly; thirdly, adding the nano-flame retardant, the flame-retardant synergist, the filler, the auxiliary agent and water, stirring for 10-30 minutes, adding a mixture into a ball grinding mil, grinding, checking whether the fineness of the coating meets a requirement, and if so, stopping grinding; fourthly, filtering the mixture with a filter screen, and separating grinding balls from the coating; and finally, filling the coating into a specified jar, discharging and barreling. The water-based expandable fireproof steel structure coating has a high expansion rate, has the fire endurance as long as 120 minutes and the coating thickens of 2 mm; and the water-based expandable fireproof steel structure coating is simple in preparation method, disposes solid wastes in the field of biomass power generation, is low in cost and wide in application and has significant economic and social benefits.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Lightweight insulating brick and production process thereof

The invention relates to the field of building materials, in particular to a lightweight insulating brick. The lightweight insulating brick is prepared by mixing the following raw materials: 8 to 15 percent of gelled material, 30 to 50 percent of aggregate, 25 to 55 percent of lightweight material, 1 to 2 percent of aids and 3 to 4 percent of waterproof powder. Because lightweight materials of industrial and agricultural wastes are added into the lightweight insulating brick, the lightweight insulating brick changes waste into valuable, protects the environment, is energy-saving, insulates sound and heat, has strong insulating property and is warm in winter and cool in summer; and compared with an air-entrained cement building block, the lightweight insulating brick has the advantages of strong water resistance, water leakage resistance, high strength, strong safety, good compactness, slurry drop resistance, low investment and easy popularization.

Owner:连来才

Water super-thin steel structure fire-proof paint and preparation method thereof

InactiveCN101125980AHigh strengthImprove fire performanceFireproof paintsPentaerythritolDiammonium phosphate

The invention relates to a waterborne super thin steel structure fireproof coating and a preparation method Which is evidently different from the solvent-typed expansion foam fireproof coating, the invention solves the problems of environmental pollution, resource waste and high cost in prior solvent-typed super thin steel structure fireproof coating. The invention takes water as solvent and comprises the components with certain weight portions: water of 5-25 weight portions, waterborne resin or mixed waterborne resin of 10-30 weight portions, waterborne expansion additive of 25-50 weight portions, pentaerythritol or dipentaerythritol or starch of 5-15 weight portions, one or two components among urea, melamine and dicyano diammonium with 6-15 weight portions, ammonium dihydrogen phosphate, ammonium polyphoste or diammonium phosphate of 15-30 weight portions, expansion regulator of 3-18 weight portions, titanium dioxide of 3-12 weight portions, dispersion agent of 0.1-1.0 weight portions.

Owner:应急管理部四川消防研究所

Method for producing outer bag paper of apple fruit growing bag by coating method

InactiveCN102277785ASimple production processEasy to adjust process parametersWater-repelling agents additionPaper coatingPesticideCarbon black

The invention discloses a method for producing outer bag paper of apple fruit growing bags by coating method, which comprises pulping, pulping, net part forming, pressing and dehydration, paint preparation, coating, drying, coiling, slitting and rewinding to obtain finished products. The apple fruit bag paper produced by the invention can be divided into base paper and coating. The light-shielding property is completed by the pigment coating containing carbon black. It has the advantages of simple production process, low cost, and less pollution. It also solves the problem of In the layering method, carbon black is used for dyeing in pulp, which causes pollution and low utilization rate. Using carbon black and porcelain clay mixed paint for low-quantity coating can obtain good light-absorbing performance and is not easy to fall off black, maintain high softness and air permeability, high carbon black utilization rate, less usage, and water resistance meet the use requirements. The invention can be used to produce the outer bag paper of the apple fruit-raising bag, can meet the growth requirement of the fruit, prevents the pollution of pesticides and the erosion of wind and rain, and enhances the color and luster of the fruit surface.

Owner:SHAANXI UNIV OF SCI & TECH

Neutral boron silicate glass used for medicinal mold-formed bottle and manufacturing method thereof

InactiveCN101186437AImprove performanceSmall coefficient of thermal expansionElectric furnaceGlass productionSilicate glassHeat stability

Neutral borosilicate glass used for moulding medicinal bottles is provided, which pertains to the technology filed of glass containing aluminum, boron, 40 percent to 90 percent (by weight) of silicon dioxide and provides neutral borosilicate glass meeting the standard of medical packaging container (material) YBB00292002, YBB00322002. The glass contains 8-12 percent of B2O3 with expansion coefficient of 4.0-5.0 multiplied by 10<-6> / K, as well as a series of excellent physical and chemical properties such as good heat stability, strong acid-resistance, alkali-resistance, water-resistance and erosion-resistance. The invention adopts cold furnace top and deep bed, recycles volatiles of boron during the course of melting, thus effectively reducing boron volatilization, preventing unfavorable phenomenon from taking place, for example, the combined material layer from incrustation and reversing, and obtaining comparatively good economic benefit and quality benefit.

Owner:SHANDONG PHARMA GLASS

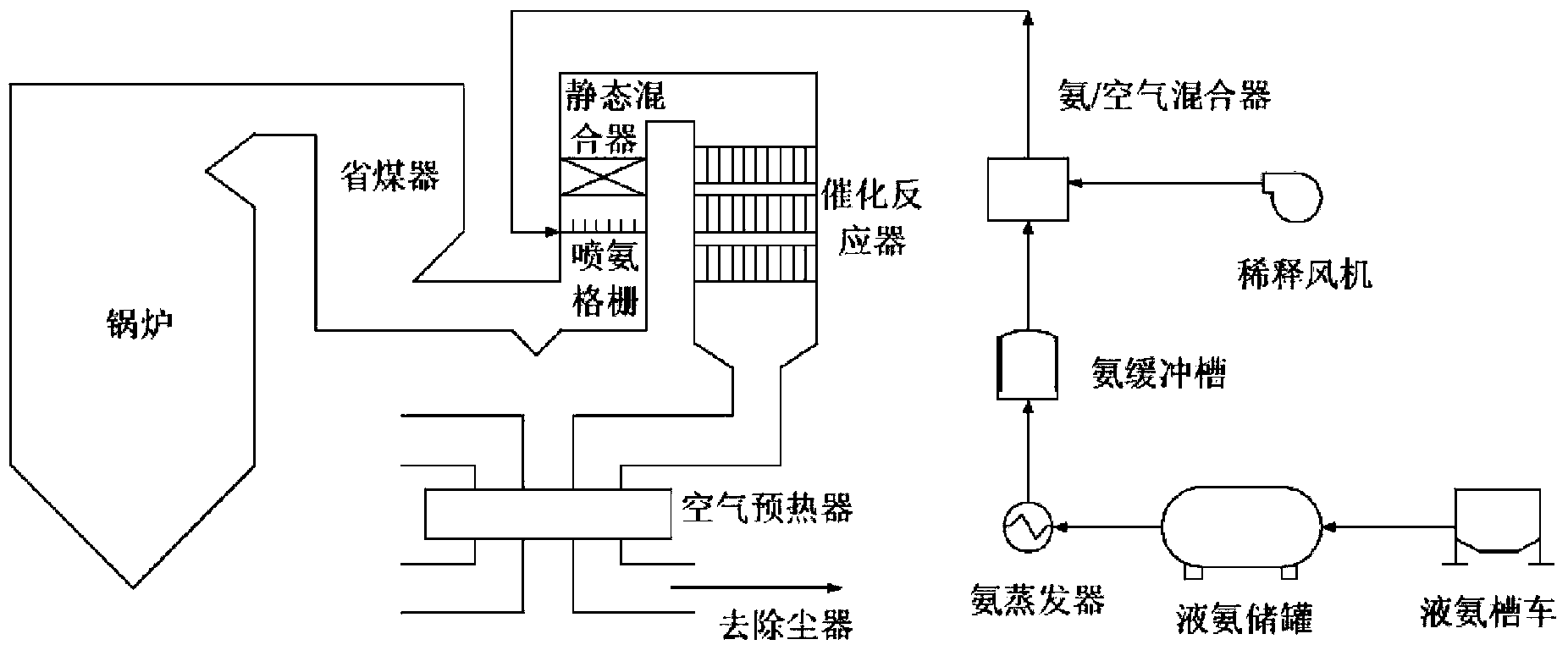

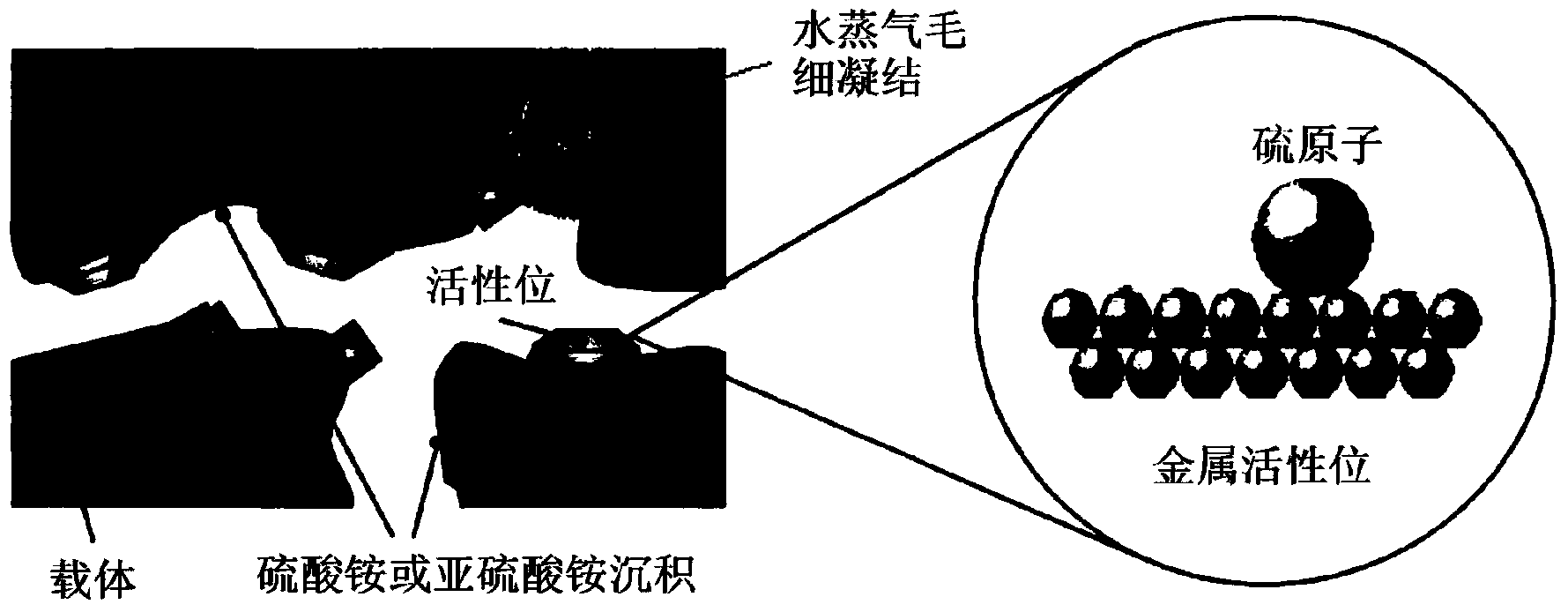

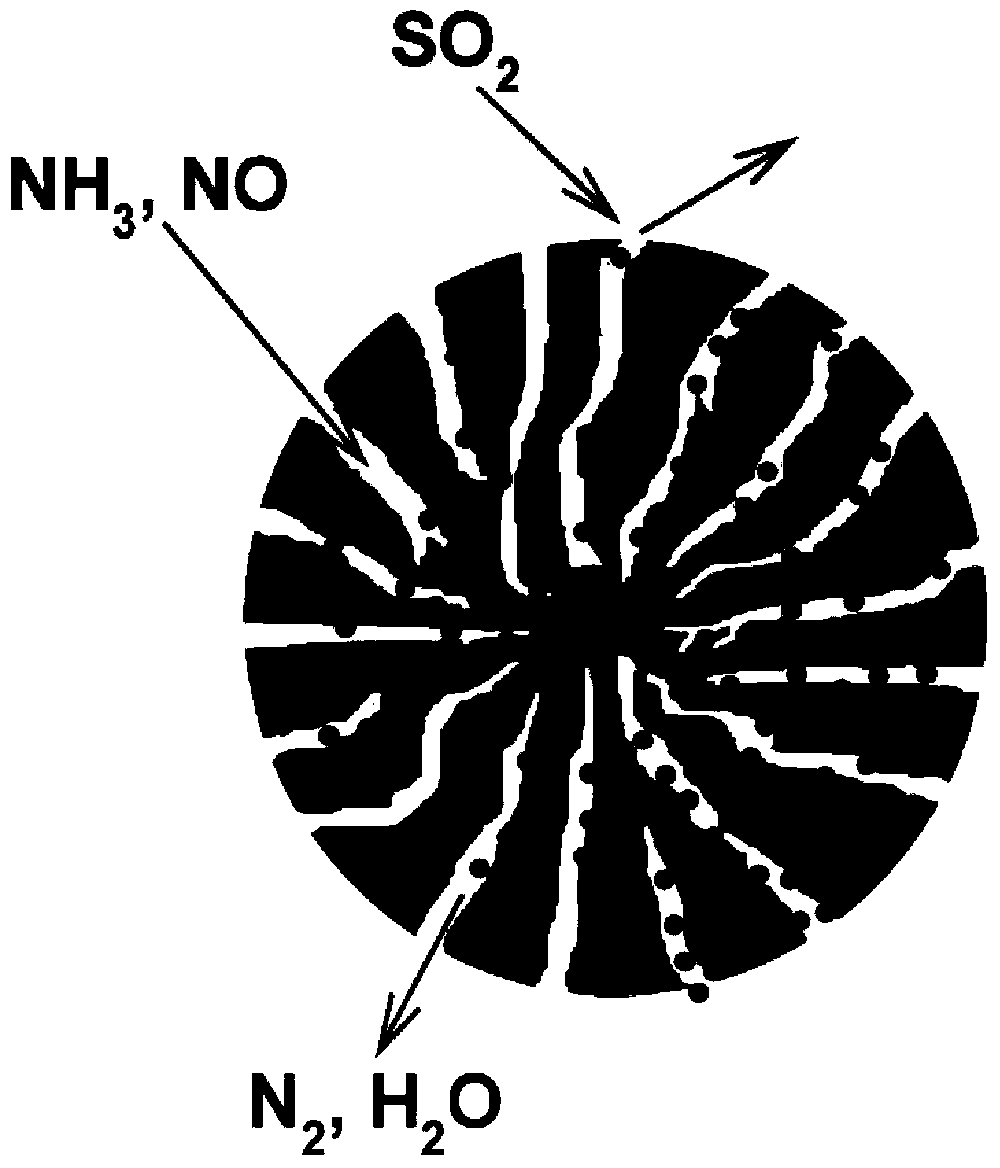

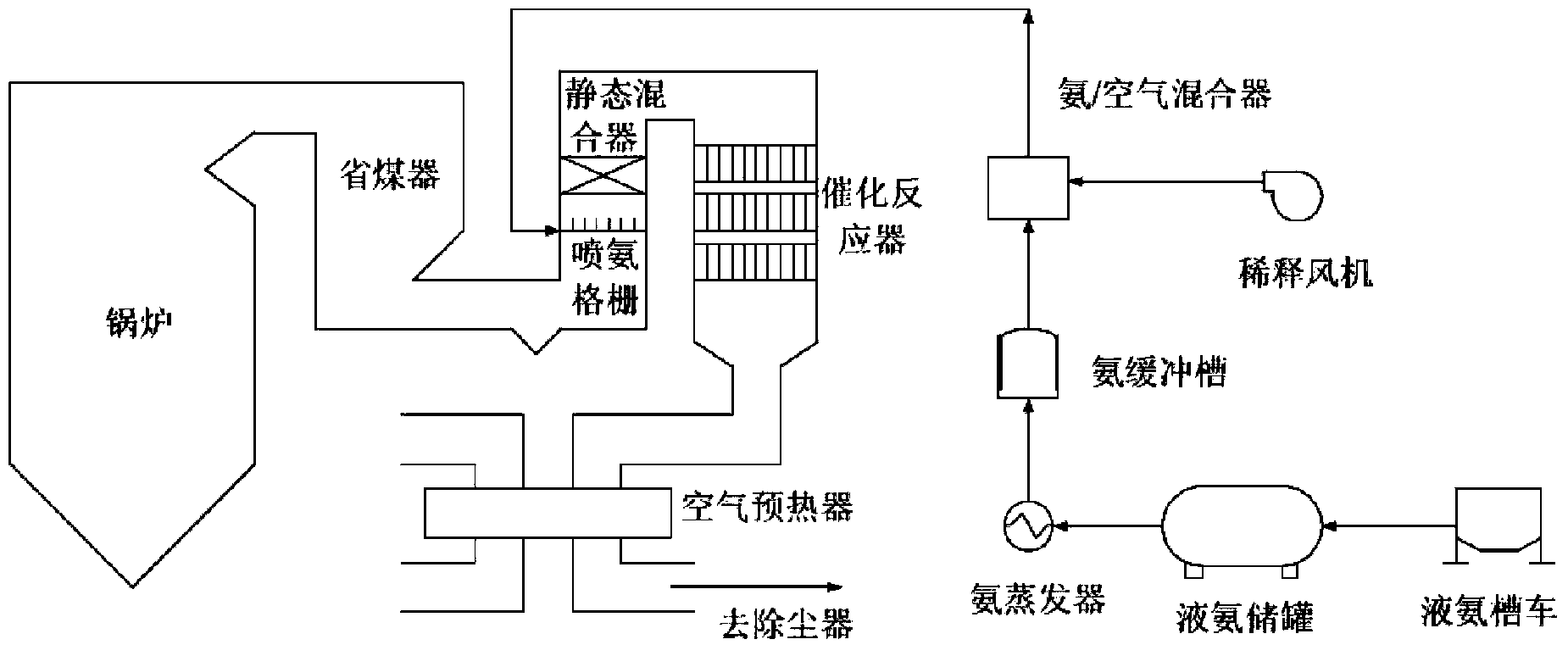

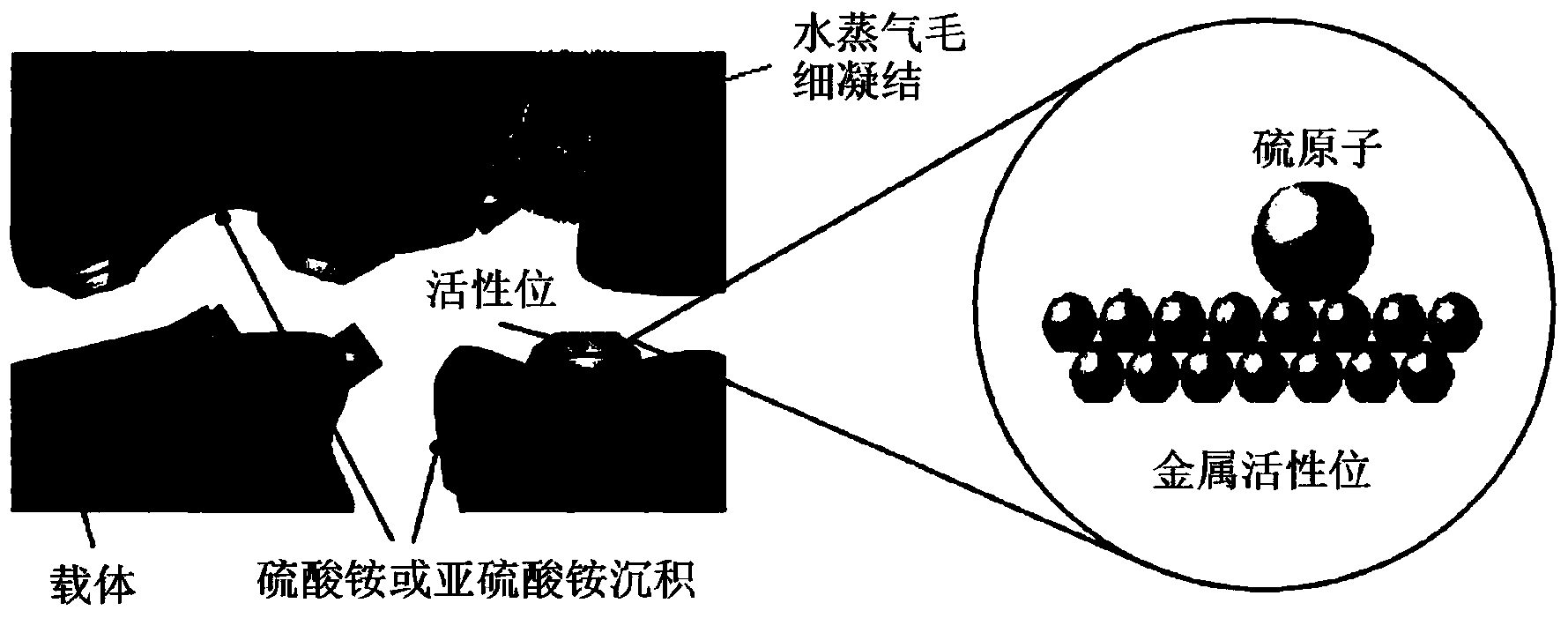

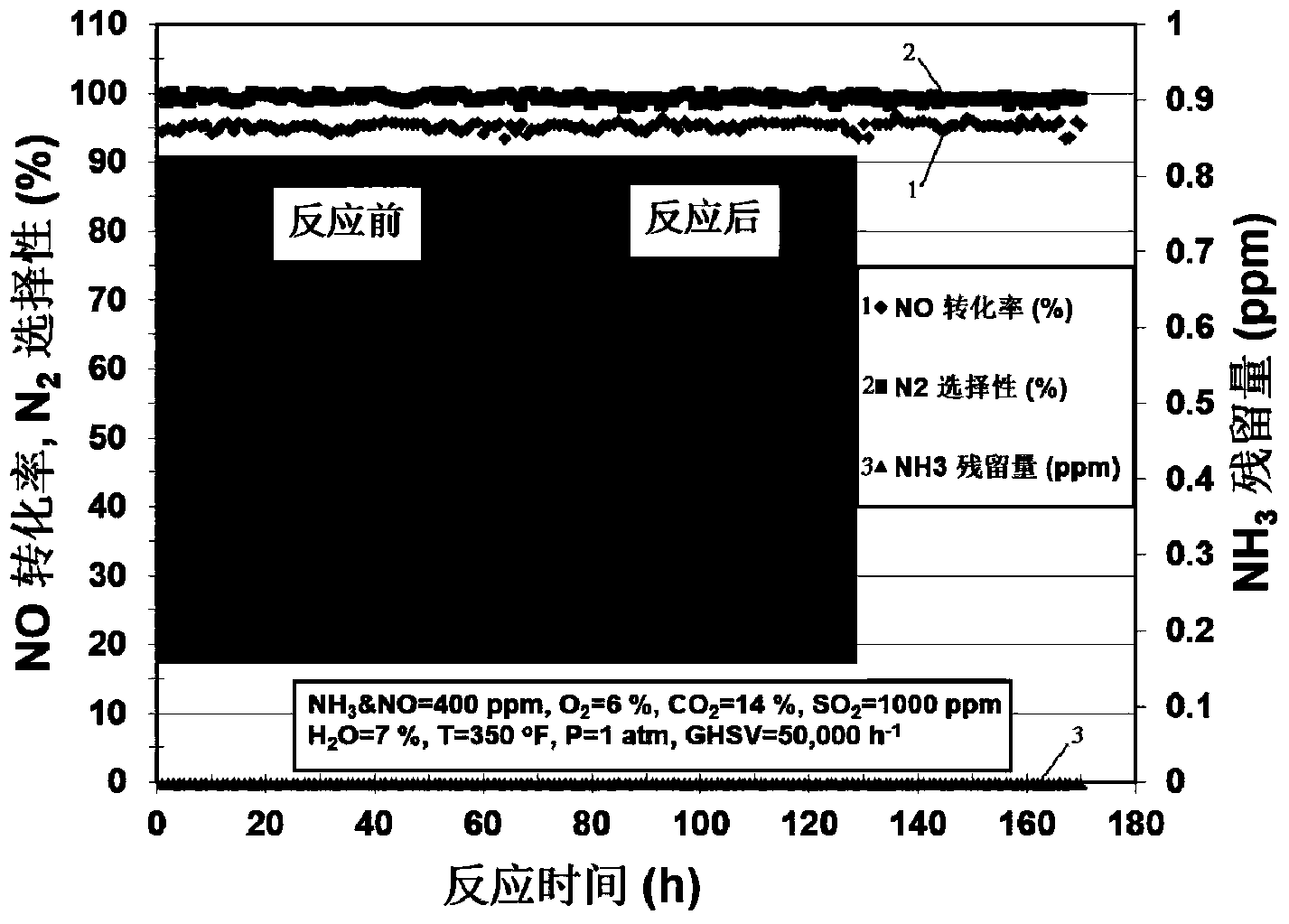

Low-temperature sulfur-resistant denitration catalyst and preparing method thereof

ActiveCN104056658AStrong water resistanceImprove low temperature denitrification performanceMolecular sieve catalystsDispersed particle separationCapillary condensationMolecular sieve

The invention discloses a low-temperature sulfur-resistant denitration catalyst and a preparing method of the low-temperature sulfur-resistant denitration catalyst. The low-temperature sulfur-resistant denitration catalyst is formed by mixing, by weight, 15%-100% of active sites and 0-85% of carbon-based carriers; the active sites are formed by mixing one or two of the first active sites and the second active sites; the first active sites are composed of Mn(0.1-0.8)Ce(0.2-0.9)Ox or Mn(0.1-0.8)Mg(0.2-0.9)Ox dispersed into a 3A molecular sieve, and the value of the x is determined according to the content and the oxidation valence state of metallic elements in the chemical formula; the second active sites are composed of Mn (0.1-0.8)Mg(0.2-0.9) or Mn (0.1-0.8)Ce (0.2-0.9)Ox with the surface coated with a TiO2 or SiO2 protecting layer. According to the method, one or more of the first active sites and the second active site are mixed with carbon-based carriers to obtain the low-temperature sulfur-resistant denitration catalyst. As surface dewatering is performed on the catalyst, water molecules contained in flue gas are attached in an open-framework structure of the catalyst to form capillary condensation very difficultly or form vitriol or sulphurous acid ammonium salt with NH3 and SO2 or SO3 to cause deactivation of the catalyst.

Owner:XIAN SINO GREEN HI TECH CO LTD

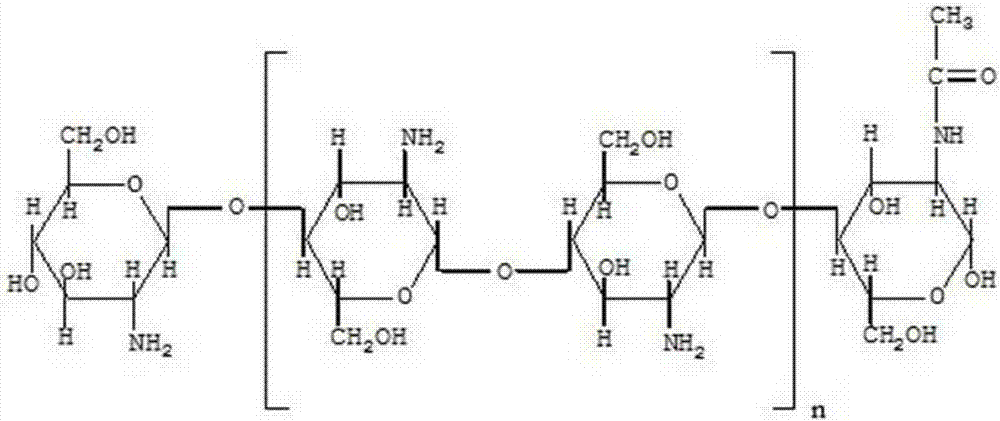

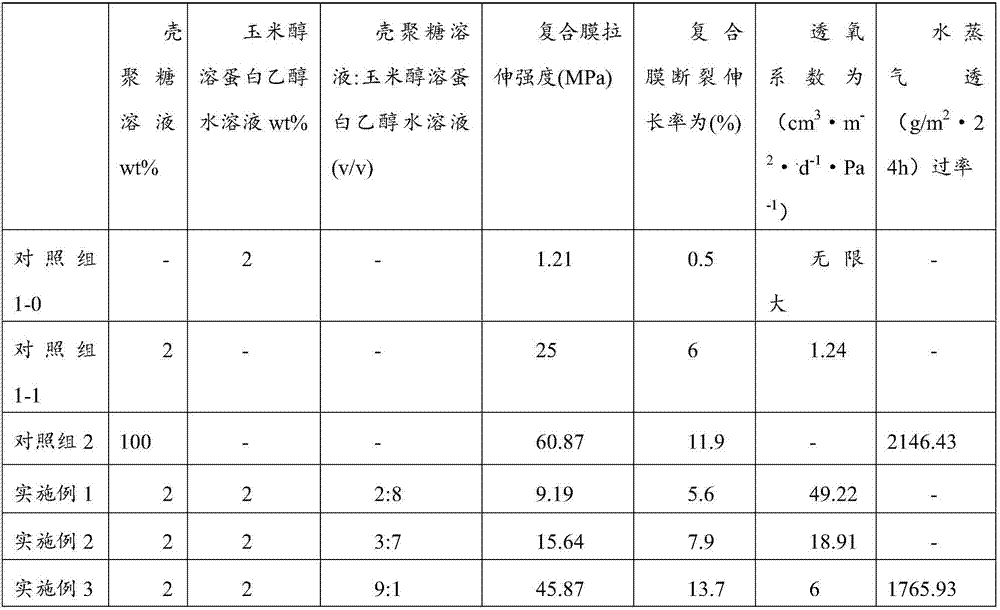

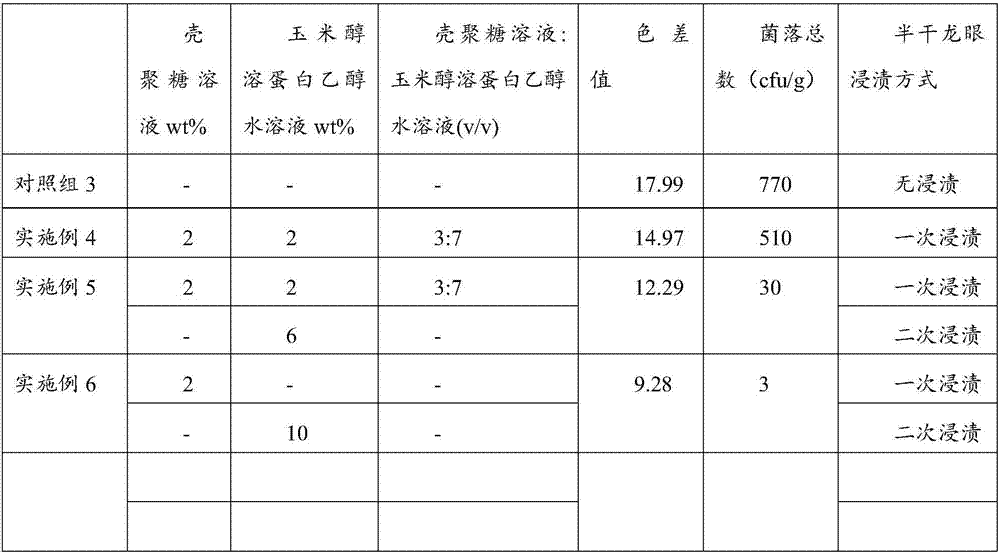

Method of preparing composite preservative film or coating from chitosan and alcohol soluble corn protein

InactiveCN106957458AStrong machineryLow costCoatingsFruits/vegetable preservation by coatingChemistryAqueous solution

The invention relates to a method of preparing a composite preservative film or coating from chitosan and alcohol soluble corn protein. The method mainly comprises the following steps: (1) preparing 2wt% chitosan solution; (2) preparing 1-10wt% ethanol aqueous solution of alcohol soluble corn protein; (3) mixing the solutions prepared in the steps (1) and (2) in a volume ratio of 1:9 to 9:1 (v / v) to obtain a composite film solution; (4) flow casting the composite film solution obtained in step (3) and drying to obtain a film; or sequentially overlaying the solutions prepared in the steps (1) and (2) to obtain a double-layer preservative film. The chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is not only improved in the moisture resistance and ultraviolet resistance of a chitosan film, but also improved in the barrier property, mechanical properties and antibacterial activity of a alcohol soluble corn protein film, and is degradable, edible, etc. When the chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is used to package or wrap foods such as meat, oils and fats, fruits and vegetables, the quality guarantee period thereof can be effectively prolonged. Thus, the method has an extensive application prospect.

Owner:GUANGXI UNIV

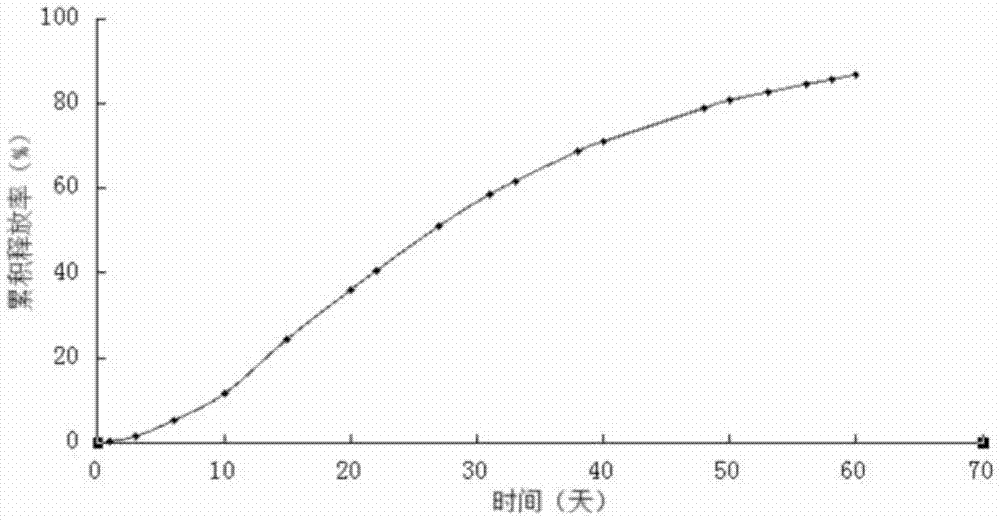

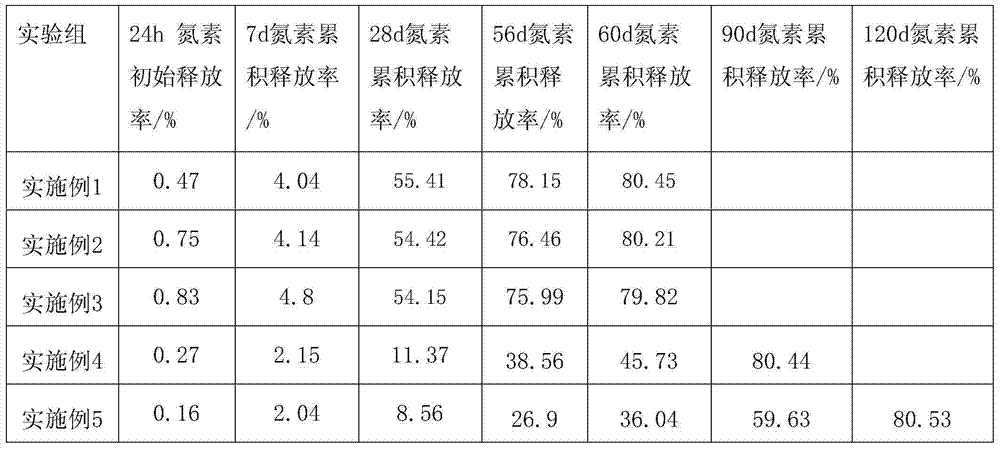

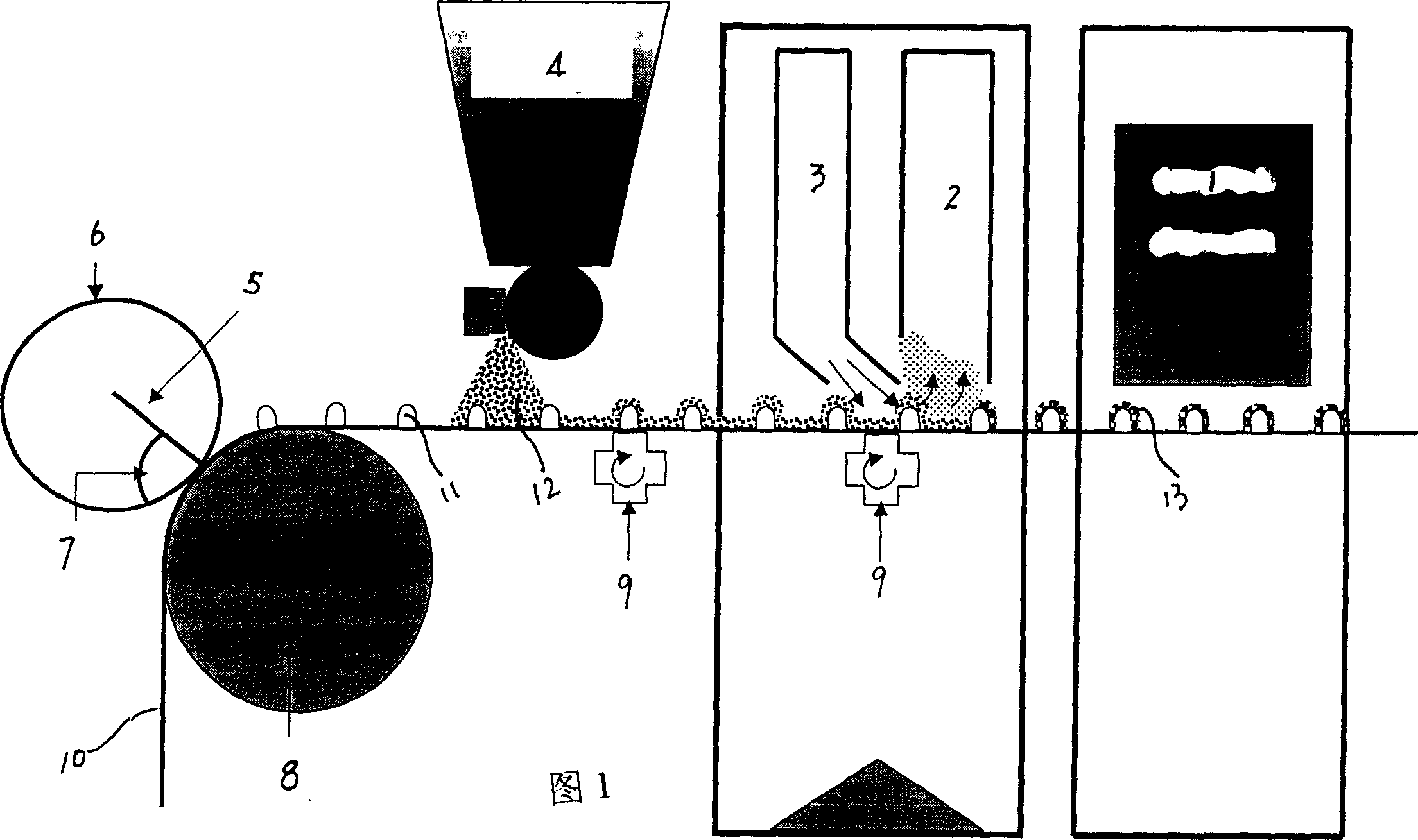

Biodegradation sustained-release fertilizer coating material containing soybean oil polyhydric alcohol and preparation process thereof

ActiveCN103772646AStrong water resistanceImprove biodegradabilityFertilizer mixturesFertilizerSolvent

The invention relates to a biodegradation sustained-release fertilizer coating material containing soybean oil polyhydric alcohol and a preparation process thereof. The coating material is prepared by stirring a material A and a material B for 5s to 15s under the condition of 65 to 75 DEG C, wherein the material A accounts for 50 to 75 percent of the weight of the coating material, and the material B accounts for 25 to 50 percent of the weight of the coating material; the material A is one or combination of soybean oil polyhydric alcohol, polyether polyhydric alcohol and castor oil, and the material B is isocyanate. The soybean polyhydric alcohol prepared from the soybean oil which is low in price and easy to obtain is strong in water resistance, the coating material which is prepared from multiple functional groups and isocyanate is high in strength and biological degradability and environmentally friendly. By adopting the coating technology, no special equipment is needed, so that not only can the equipment investment cost be greatly reduced, but also the waste of solvent in the recycling process can be avoided, and the biodegradation sustained-release fertilizer coating material is free from polluting the soil, plants and the environment after being utilized for a long time.

Owner:MAOSHI AGRI TECH CO LTD

Zincium-calcium dechlorinating agent at normal temperature and its preparing method

ActiveCN101269294AHigh strengthHigh dechlorination precisionDispersed particle separationChlorideBULK ACTIVE INGREDIENT

The invention relates to a normal temperature dechlorinating agent, the dechlorination agent comprises an active ingredient and a carrier, the active ingredient comprises a admixture formed by active ZnO, Ca(OH) 2 or light weight CaCO3; the carrier comprises clay and aluminate cement. The invention also discloses the preparation method of the dechlorination agent, the normal temperature dechlorination agent prepared by the method can realize the dechlorination function of the dechlorination agent in normal temperature with relatively higher chloride content and higher dechlorination accuracy.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Printing adhesive liner cloth and its making process

InactiveCN101008155ARealistic patternStrong three-dimensional senseTransfer printing processTextile decorationSingle pointEngineering

The invention relates to a spinning adhesive liner and relative production, comprising that: preparing needed pattern on the treated base cloth via transfer or screen printing method; secondary treating and feeding it into special coating machine; to coat thermal-sensitive adhesive resin on the base cloth, with slurry point and single point, to obtain the target printed adhesive liner; using thermal rolling method to adhere the printed liner with face fabric to obtain clothes material.

Owner:NITTOBO CHINA CO LTD

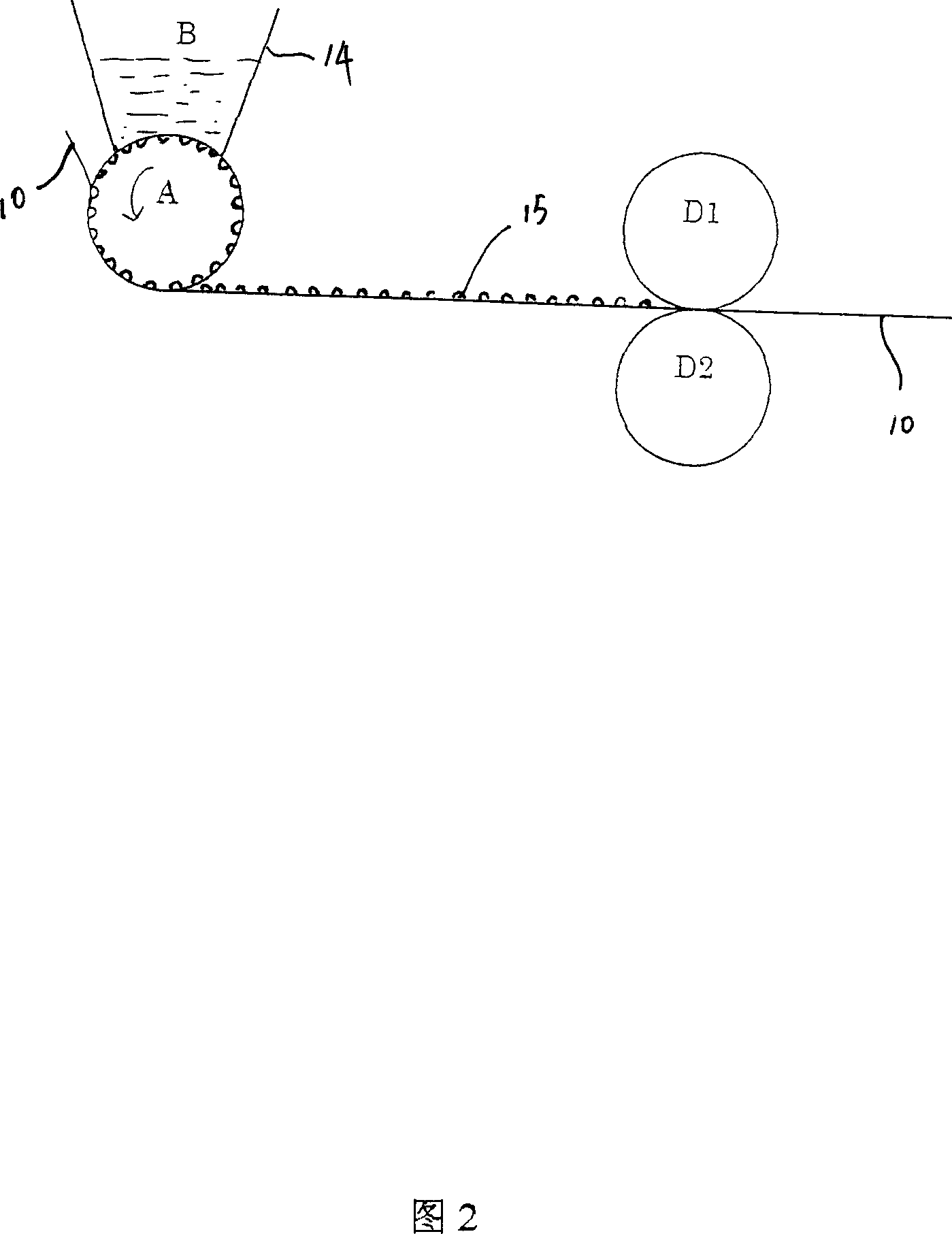

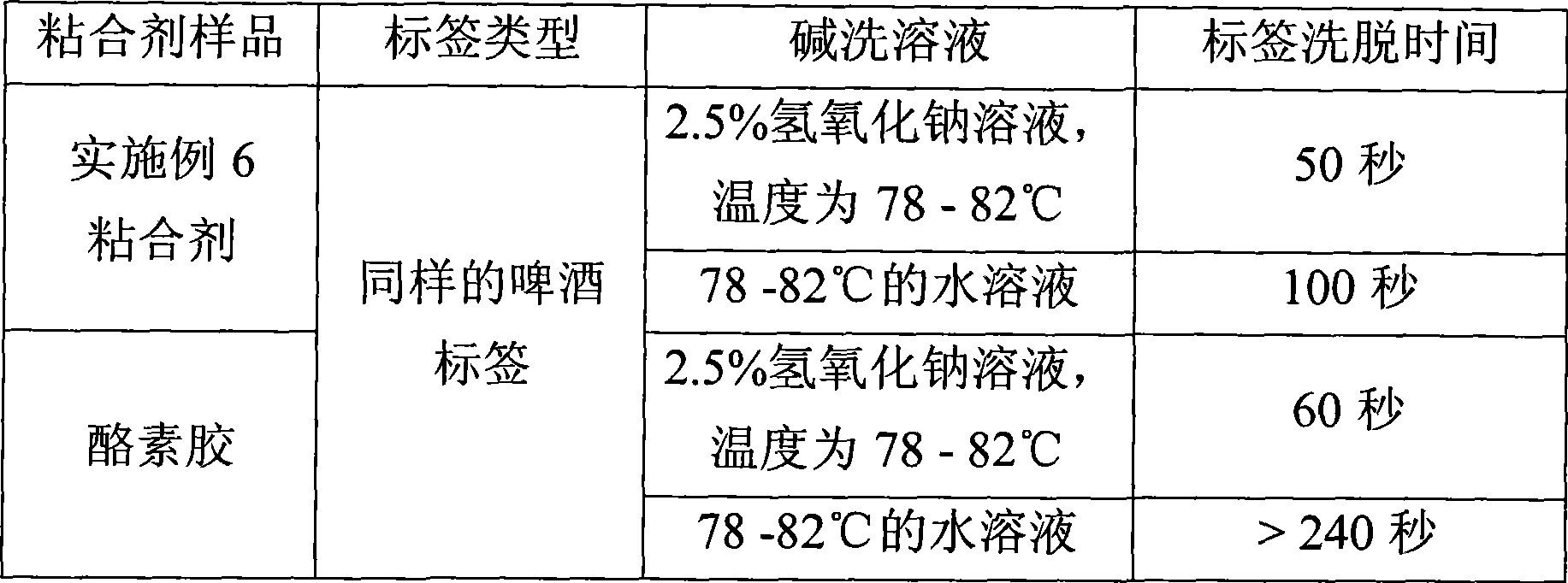

Adhesive, preparation and use thereof

InactiveCN101440269AGood initial adhesionLow freezing pointProtein waste adhesivesStarch adhesivesEnzymatic hydrolysisAdhesive

The invention provides an adhesive for labeling, which comprises 1 to 40 percent of animal glue, 0 to 45 percent of emulsion, 0 to 20 percent of starch, 5 to 40 percent of diluting agent, 0 to 10 percent of cross-linking agent, 0 to 5 percent of thickening agent, 0.001 to 2 percent of additive, and 20 to 50 percent of water. The adhesive has the advantages of good initial adhesion, low solidification point, good water resistance, strong enzyme hydrolysis resistant stability, elution in non-alkaline high temperature water and so on, well meets the requirements of improving production speed, improving the qualification rate of the production and recovering containers at present, and is particularly used for labeling beer bottles.

Owner:HENKEL KGAA

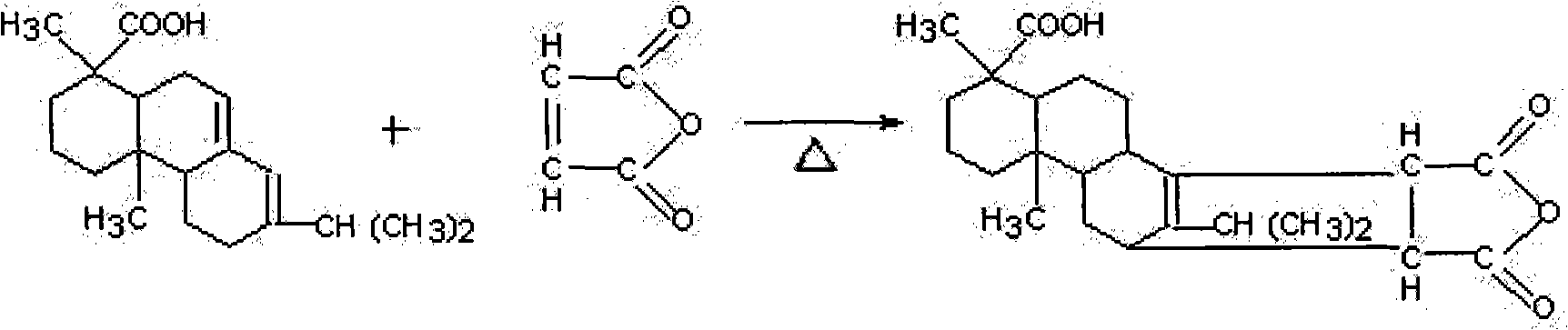

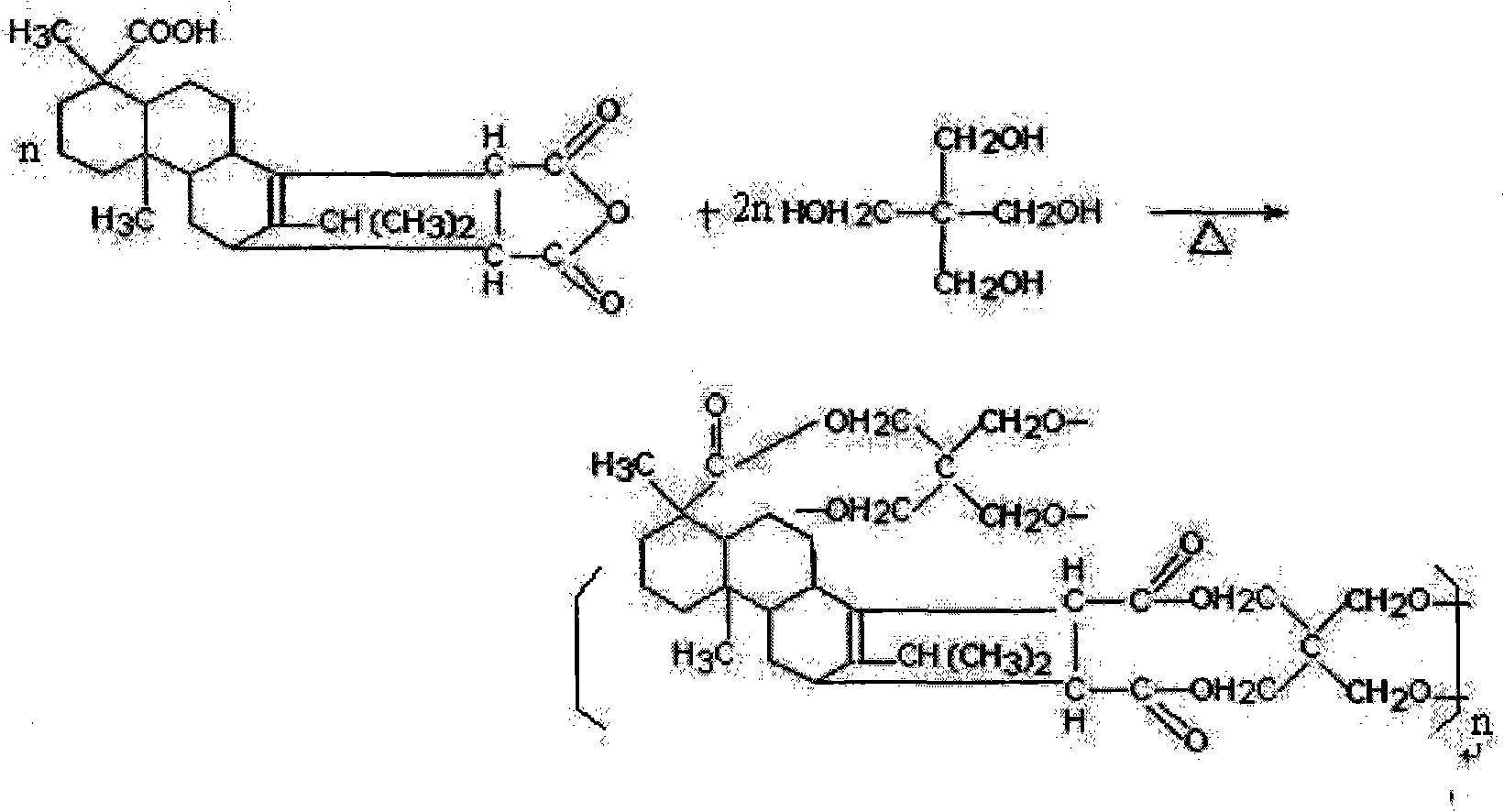

Production method of abietic maleic anhydride resin

InactiveCN102010503AExemption from releaseProtect physical and mental healthInksNatural resin chemical modificationSolubilityReaction temperature

The invention relates to a production method of abietic maleic anhydride resin, comprising the following two reaction steps of: 1, carrying out addition reaction on abietyl and maleic anhydride to generate an abietic maleic anhydride addition product; and 2, carrying out esterification reaction on the abietic maleic anhydride addition product and pentaerythritol to generate the abietic maleic anhydride resin. The production method is easy and convenient to operate, has the advantages of large temperature control range, high operability, small investment and stable product quality and is a method suitable for industrialized production; in the production method, appropriate process conditions including raw material proportion, reaction temperature, reaction time, catalysts, and the like, are adopted, thereby the acid value and the molecular weight range of a resin product can be effectively controlled; in addition, the resin product obtained with the production method has higher acid value of 150-170 mg KOH / g, reasonable softening point at 140-155 DEG C and good water solubility and is suitable for producing water-based ink, and a formed coating film has toughness and better after-tackiness resistance, water resistance and alkali resistance.

Owner:上海华谊精细化工有限公司上海南大化工厂

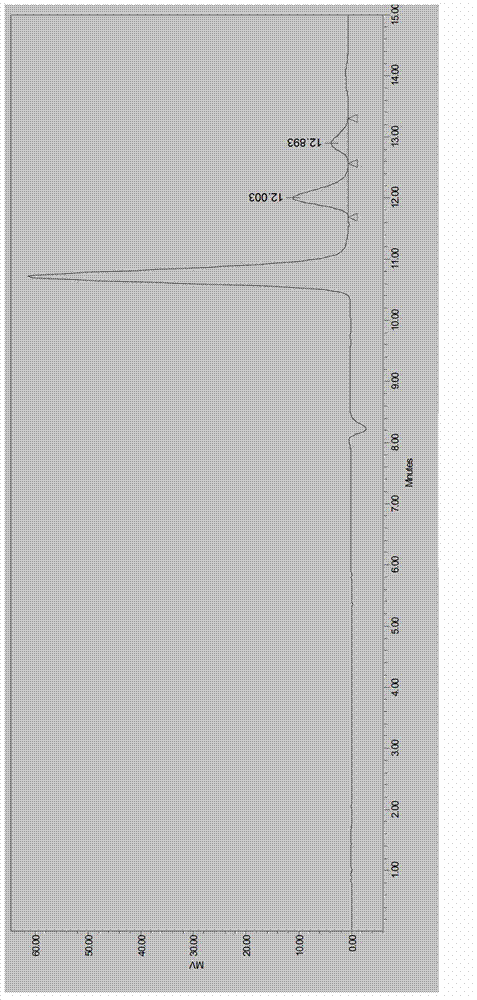

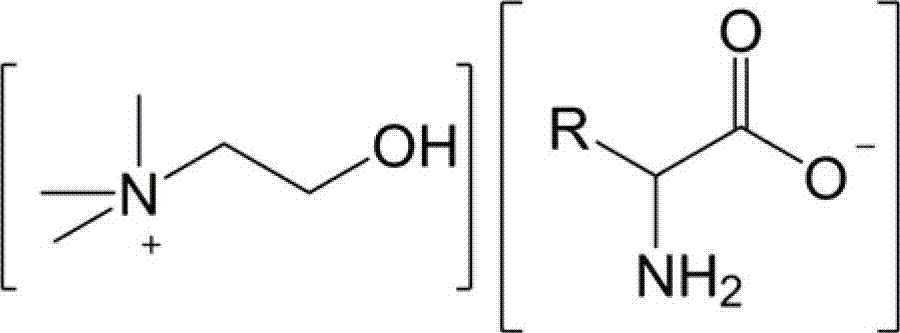

Method for pretreating lignocellulose by using renewable ionic liquid aqueous solution

The invention discloses a method for pretreating lignocellulose by using a renewable ionic liquid aqueous solution, including the steps of: (1) taking a choline and amino acid ionic liquid aqueous solution as a pretreatment solvent, mixing lignocellulose and the pretreatment solvent under the protection of nitrogen, stirring at 50-120 DEG C, cooling to room temperature, filtering, washing residue, and drying to obtain the pretreated lignocellulose; and (2) weighing the pretreated lignocelluloses, adding a citrate buffer, adding cellulase, reacting for 3-12 h with 150-250 r / min at 40-60 DEG C to obtain sugar liquid mainly including glucose and xylose. The pretreatment process not only can effectively enhance the efficiency of enzymatic hydrolysis of lignocelluloses, and improve the yield of fermentable reducing sugar, but also has the advantages of environmental protection, renewability, low viscosity, easy operation, low cost, and low power consumption.

Owner:SOUTH CHINA UNIV OF TECH

Methanol gasoline additive and process for producing methanol gasoline

The invention relates to a preparation method for a methanol oil additive and the methanol oil thereof. The compound additive consists of the components of the following weight percentages; 30 to 50 percent of isopropanol, 10 to 20 percent of tertiary butyl alcohol, 1 to 5 percent of butyl acetate, 1 to 5 percent of methyl ethyl ketone peroxide, 1 to 5 percent of peroxide, 1 to 5 percent of sherwood oil, 5 to 10 percent of dimethylbenzene, 1 to 4 percent of octane enhancing additive, 1 to 5 percent of dimethoxymethane, 0.1 to 0.5 percent of antioxidizing and antigum agent, 0.1 to 0.5 percent of antiseptic, 1 to 8 percent of antiwear agent, 3 to 6 percent of waterproofing agent, 1 to 5 percent of dispersant, 1 to 3 percent of fatty acid amine, 10 to 30 percent of 120# solvent oil as well as 5 to 10 percent of ethanol. The methanol oil consists of the components of the following weight percentages: 10 to 80 percent of methanol, 0 to 85 percent of diesel oil as well as 5 to 20 percent of methanol oil additive. The methanol oil has the advantages of low cost, excellent performance, good environment protection effect, remarkable economic benefit and convenient popularization.

Owner:王宇

Lightly calcined dolomite thermal insulation mortar

InactiveCN102070320ALow costIncrease the use of functionsSolid waste managementCeramicwareThermal insulationPolystyrene

The invention relates to lightly calcined dolomite thermal insulation mortar, which comprises the following components in part by weight: 20 to 60 parts of lightly calcined dolomite, 1 to 60 parts of flyash, 5 to 35 parts of retarding agent, 1 to 40 parts of strengthening and thickening agent, 1 to 20 parts of kieselguhr, 5 to 35 parts of expanded aggregate, 0.5 to 5 parts of polystyrene foam particle, 0.01 to 0.2 part of polypropylene fiber, 0.5 to 8 parts of water resistance additive, and 0.05 to 2 parts of water reducer. The thermal insulation mortar has the advantages of excellent thermal insulation property, good compression strength, freezing resistance and water resistance, good volume stability, low production cost, energy conservation, environmental friendliness and the like. The construction process is simple; and after construction, the lightly calcined dolomite thermal insulation mortar is not hollowed or cracked, and is particularly suitable for a thermal insulation material for building walls.

Owner:内蒙古祥响新型建材开发有限责任公司 +2

Starch adhesive for environment-friendly timbers and preparation method thereof

InactiveCN103788905ALow costLow storage stabilityNon-macromolecular adhesive additivesUnsaturated alcohol polymer adhesivesCross-linkPolymer science

The invention discloses a starch adhesive for environment-friendly timbers and a preparation method thereof. The preparation method comprises the following steps of oxidizing a starch emulsion under the effect of sodium hypochlorite and obtaining oxidized starch through first-step reaction; adding a cross-linking agent into the oxidized starch, enabling the oxidized starch to perform graft copolymerization modification reaction with acrylamide and comonomer of acrylic ester under the effect of the cross-linking agent and obtaining cross-linked oxidized adhesive liquid through second-step reaction; reducing the temperature to be room temperature, then adding a packing and a preservative into the cross-linked oxidized adhesive liquid and finally obtaining the starch adhesive for the environment-friendly timbers. The starch adhesive for the environment-friendly timbers is low in cost and environment-friendly, has the advantages of being good in storage stability and water resisting property, high in bonding strength and the like, can be widely used for timber decoration and bonding of multiple-layer plywoods, shaving boards, artificial boards and other timber adhering products.

Owner:GUIZHOU LANTU NEW MATERIALS

Preparation method of flexible powdery putty for external wall

InactiveCN101381533AImprove flexibilityHigh bonding strengthFilling pastesAntifoam agentMaterials science

The invention provides a method for preparing external-wall flexible powdered putty, which relates to the technical field of building materials. The method comprises the following steps of well mixing cement, dispersible latex powder, inorganic filler and water retaining agent and then adding in and well mixing antifoaming agent and hydrophobic agent. The flexible putty mainly comprises the following materials in weight percentage: 25 to 40 percent of common cement, 2 to 12 percent of dispersible latex powder, 48 to 72 percent of inorganic filler, 0.1 to 0.6 percent of antifoaming agent, 0.03 to 0.15 percent of water retaining agent and 0.05 to 0.3 percent of hydrophobic agent. The putty disclosed by the invention has the advantages of quick drying, easy polishing, construction convenience and the like, has the characteristics of good anti-cracking property, strong water resistance, high flexibility, good bonding strength, heat preservation, alkali return avoidance and other performance, is stable in performance, simple in production process, safe, friendly to environment and free from toxicity. In addition, as the putty is powdered, the putty is convenient to package and transport and simple to use, and can be suitable for manual batch scraping.

Owner:JIANGNAN UNIV

Adhesive and preparation method thereof as well as application of adhesive in vegetable fiberboard or artificial board

ActiveCN104449411ANo pollution in the processGuaranteed environmental performanceNon-macromolecular adhesive additivesInorganic adhesivesAdhesiveVegetable fibers

The invention discloses an adhesive, which is mainly prepared from the following components in parts by weight: 50-60 parts of a sodium silicate solution, 10-20 parts of brine, 20-30 parts of nanosilicon dioxide, 6-8 parts of packing, 0.4-0.6 part of a modifying agent and 0.1-0.3 part of a stabilizer. The preparation method comprises the following steps: firstly mixing and dissolving magnesium chloride and magnesium sulfate at a certain molar ratio, and stirring to obtain brine; adding the sodium silicate solution to the prepared brine and adding the nanosilicon dioxide to the prepared sodium silicate-brine mixture, so as to obtain a mixture; adding the packing to the mixture, and stirring evenly, so as to obtain a semi-finished product; and adding the modifying agent and the stabilizer to the semi-finished product, so as to obtain an adhesive product. The adhesive disclosed by the invention can be applied to the vegetable fiberboard or the artificial board as an inorganic adhesive, does not release pollutants, and is low in cost; and the strength, the fire resistance and the water tolerance of the product can be significantly improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Water resistance putty powder with adsorption function and preparation method thereof

InactiveCN101054486AGood ability to absorb toxic and harmful gasesImprove adhesionFilling pastesCross-linkNanotechnology

The invention discloses a waterproof paint filler powder with absorption function and method for preparing same. Zeolite powder and / or bergmeal are used in the paint filler powder as absorbent, which offers toxic and hazardous gases absorption function for the paint filler powder and improves adhesion of the paint filler powder. When using waterproofing agent especially the cross-linked starch in the paint filler powder, the waterproof function of the paint filler powder is improved apparently.

Owner:翟翠明

Low-temperature sulphur-resisting denitration catalyst and preparation method thereof

ActiveCN104069852AStrong water resistanceImprove low temperature denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCapillary condensationOpen framework

The invention discloses a low-temperature sulphur-resisting denitration catalyst and preparation method thereof. The catalyst is formed by mixing the following components in weight percent: 1-15% of active site and 85-99% of a carbon-base carrier, wherein the active site is formed by mixing one or several of Ag2O, K2O, BaO, SnO2, Bi2O3 or PbO improved vanadium-base alloy oxides. The preparation method comprises the steps of mixing the active site and the carbon-base carrier to prepare the low-temperature sulphur-resisting denitration catalyst. Since the surface hydrophobic treatment is performed on the catalyst prepared by the invention, the situation that water molecules in the flue gas adhere to an open-framework structure of the catalyst to form capillary condensation or form sulfuric acid or ammonium sulfite with adsorbed NH3 and SO2 or SO3 to inactivate the catalyst is avoided.

Owner:XIAN SINO GREEN HI TECH CO LTD

Normal-temperature dechlorinating agent

ActiveCN103127903ARegular crystal formImprove dechlorination effectOther chemical processesDispersed particle separationCopper oxideImpurity

The invention discloses a normal-temperature dechlorinating agent. The normal-temperature dechlorinating agent is mainly prepared from 20-30 parts of ferrous sulfate, 20-40 parts of CaO and 10-25 parts of attapulgite clay in parts by weight and further comprises 15-25 parts of waste catalyst, wherein active components of the waste catalyst include copper oxide and zinc oxide. According to the normal-temperature dechlorinating agent, the ferrous sulfate has weak acidity and can react with calcium carbonate impurity in calcium oxide to enable the crystal form of the calcium oxide to be more regular, and meanwhile, ferrous ions are continuously oxidized into iron oxide to enable the crystal forms of the calcium oxide and the iron oxide to be mutually doped, so that the dechlorinating effect of the dechlorinating agent is improved; and according to a preparation method of dechlorinating agent disclosed by the invention, a roasting process is not needed, the energy consumption is reduced, devices used in the preparation process are decreased, the preparation step is simplified, and the preparation cost is lowered.

Owner:SHENYANG SANJUKAITE CATALYST

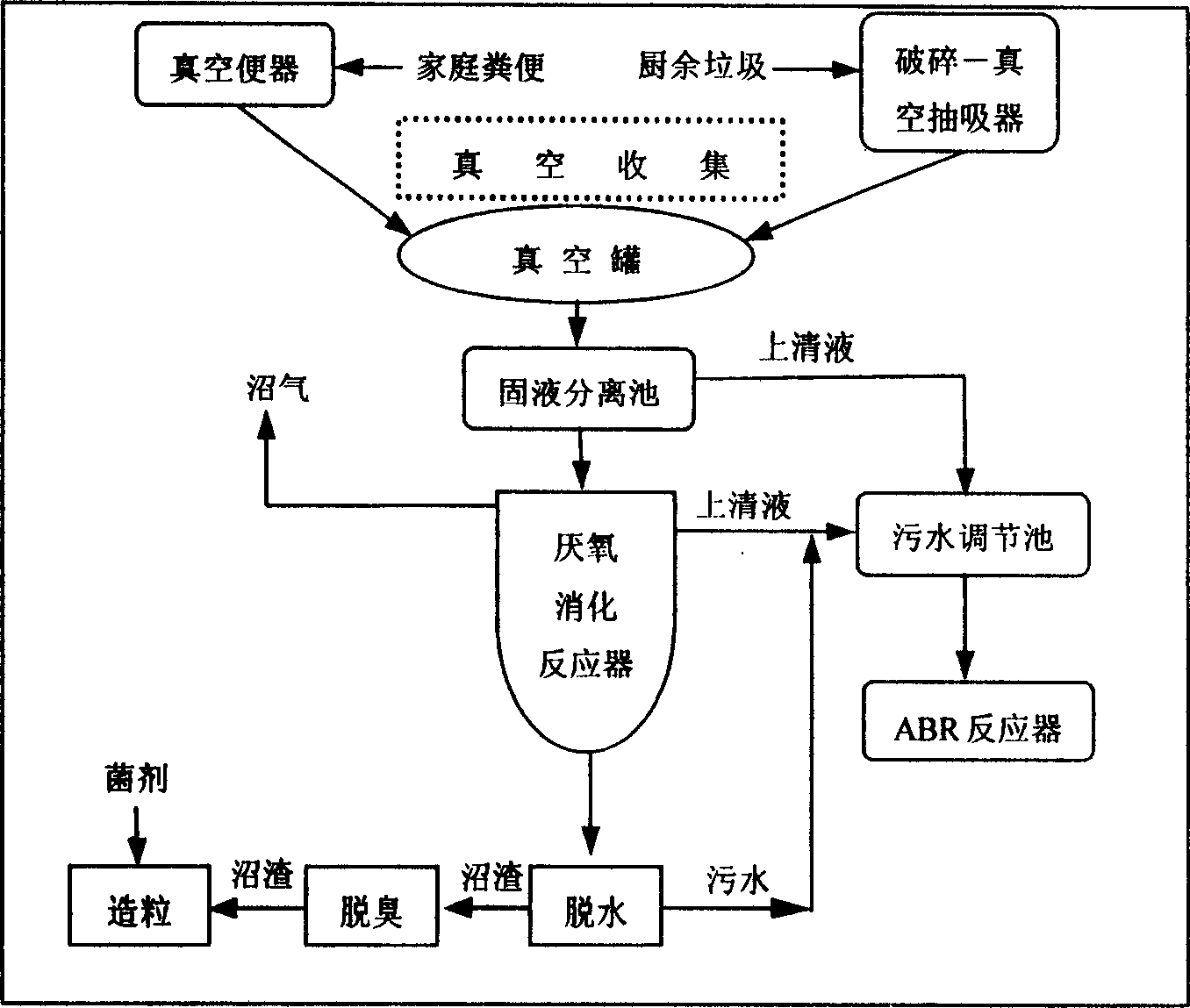

Organic refuse and fecal separating and collecting treatment

InactiveCN1644538AAvoid enteringReduce yieldBio-organic fraction processingSolid waste disposalWater dischargeFeces

A classifying collecting and treating method for organic refuse and excrement includes: 1) sucking the refuse and excrement into vacuum tubing net; 2) mixing them by vacuum pot and discharging into solid-liquid separated pool, and discharging the solid into anaerobic digesting reactor; 3) concentrating and dewatering the marsh slag discharged, adding deodorized bacterial strain, piling up and deodorizing; 4) adding digesting mud into bacterial strain cultured, culturing, drying and obtaining organic composite bacterial manure; 5) discharging the clear liquid and sewage into anaerobic and oxygen sewage treating unit, and the outlet water discharging into sewage tubing net or water body. Its advantages include lower mud output rate and mud account, and higher mud age.

Owner:HUAZHONG UNIV OF SCI & TECH

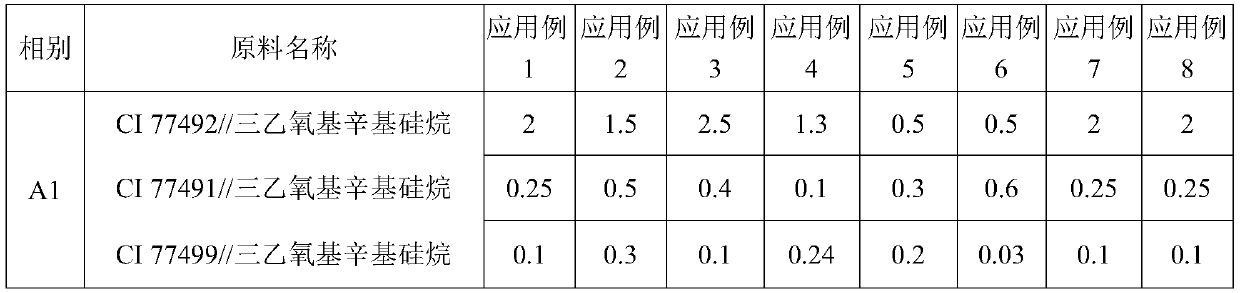

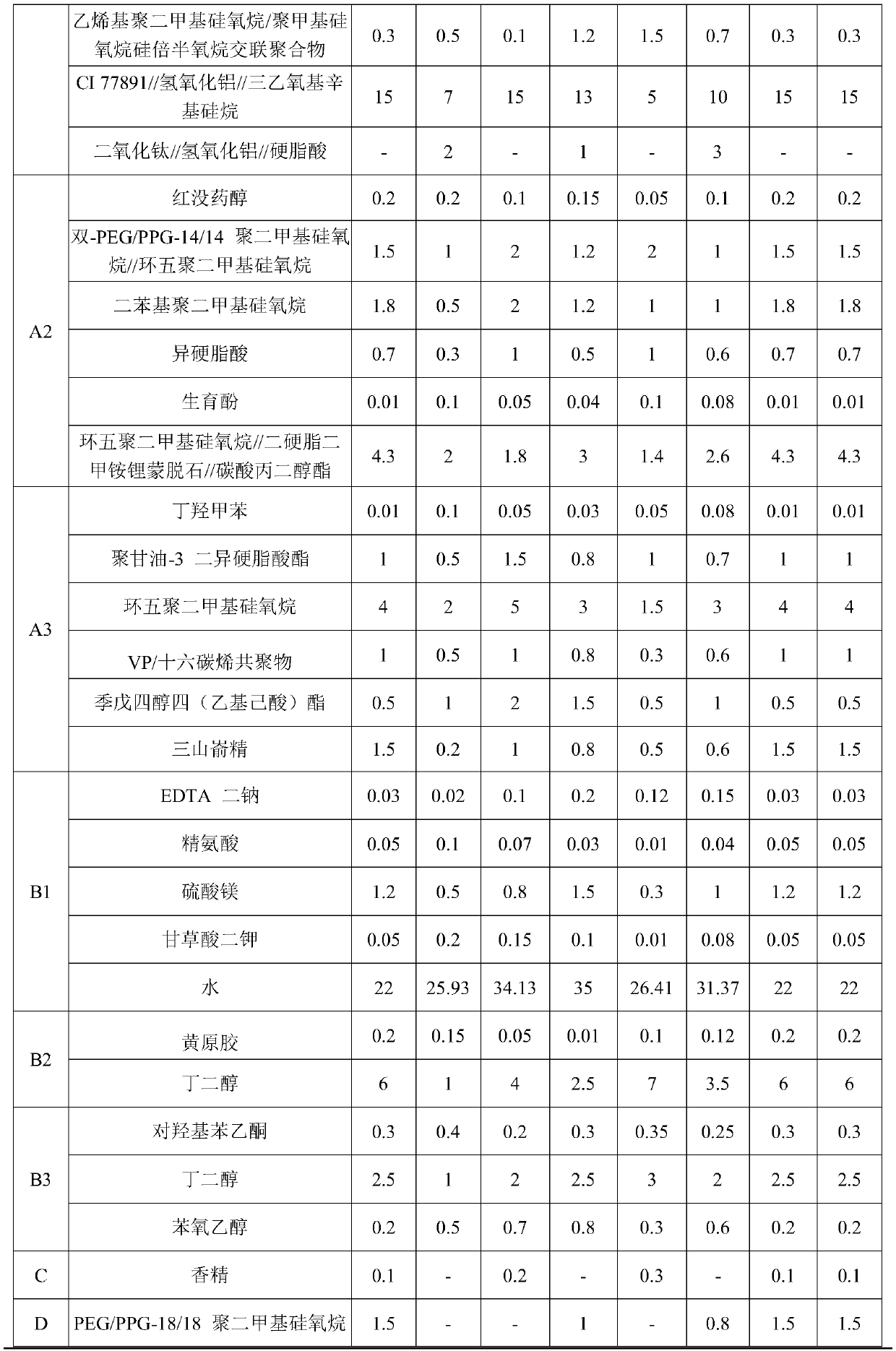

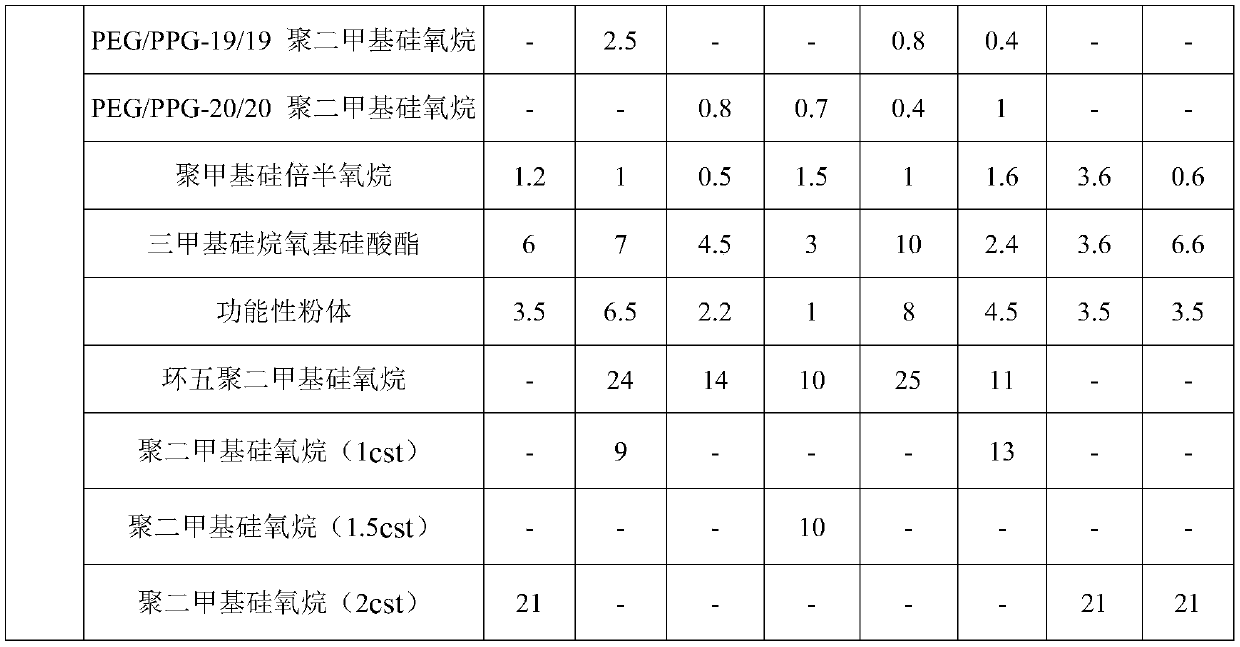

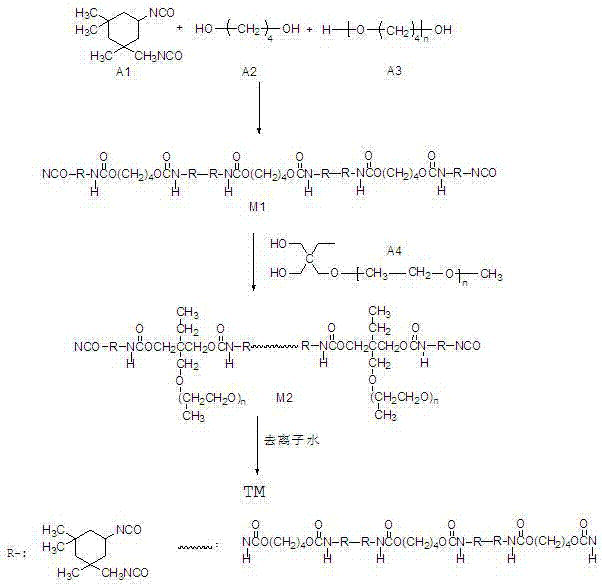

Composition with makeup maintaining and oil controlling effects and cosmetic

The invention discloses a composition with makeup maintaining and oil controlling effects and a cosmetic. The composition can effectively improve the migration resistance of foundation products, directionally absorb, flocculate and solidify sebum, has a good oil controlling effect, can effectively reduce the influence of sebum secreted by skin on makeup, and enables the skin to keep natural and lasting makeup. The composition with the makeup maintaining and oil controlling effects is prepared from, by weight, 0.8-2.5 parts of polydimethylsiloxane and polyol copolymer, 4-11 parts of film forming agent, 1-8 parts of functional powder and 14-33 parts of volatile silicone oil, wherein the functional powder is a mixture of synthetic fluorophlogopite, hydroxyapatite and zinc oxide; and the filmforming agent is a combination of polymethylsilsesquioxane and trimethylsiloxysilicate. The invention belongs to the technical field of cosmetics.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

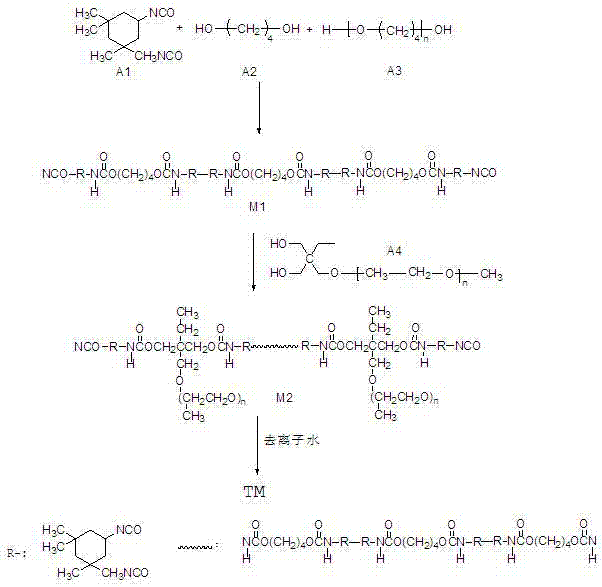

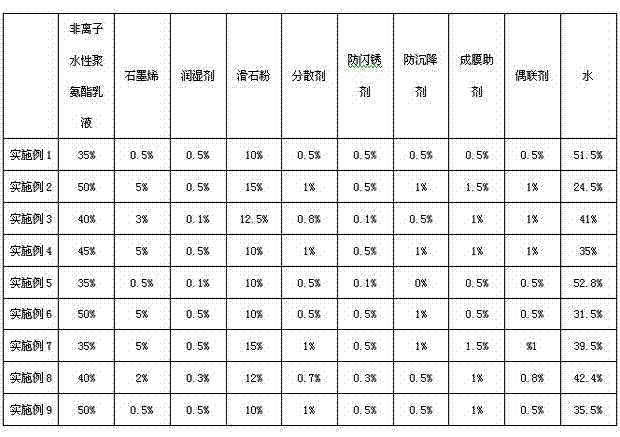

High-performance environment-friendly water-based conductive antistatic coating and preparation method thereof

InactiveCN104497833AImprove adhesionImprove wash resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedEmulsion

The invention relates to a high-performance environment-friendly water-based conductive antistatic coating and a preparation method thereof. The coating comprises the following raw material by weight: 35-50% of a nonionic polyurethane emulsion, 0.5%-5% of graphene, 0.1-0.5% of a wetting agent, 10-15% of talcum powder, 0.5-1% of a dispersing agent, 0.1-0.5% of an anti-rust agent, 0-1% of an anti-settling agent, 5-1.5% of a film forming additive, 0.5-1% of a coupling agent and the balance of the water. The invention has the advantages of reasonable design, environment-friendliness, stable performance and good corrosion resistance; a nonionic waterborne polyurethane emulsion has high adhesion, washing resistance and stable performance; and the graphene has good conductivity and strong anticorrosion performance.

Owner:HANGZHOU LIWEI CHEM INDAL PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com