Biodegradation sustained-release fertilizer coating material containing soybean oil polyhydric alcohol and preparation process thereof

A technology of soybean oil polyol and coating material, applied in the field of controlled release fertilizer, can solve the problems of unreachable, poor strength and stability of starch coating material, poor controlled release performance, etc. The effect of better thermal decomposition and thermal oxidation performance and lower swelling property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

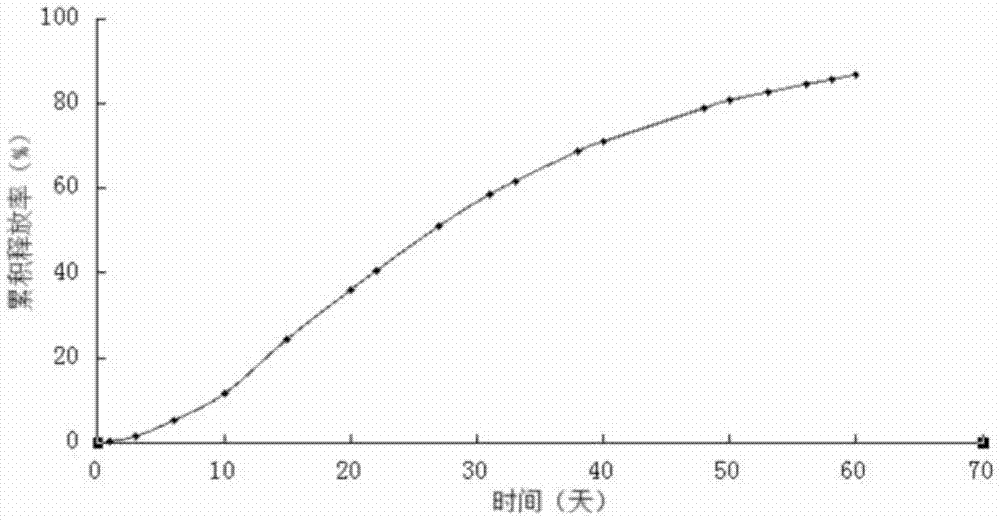

Image

Examples

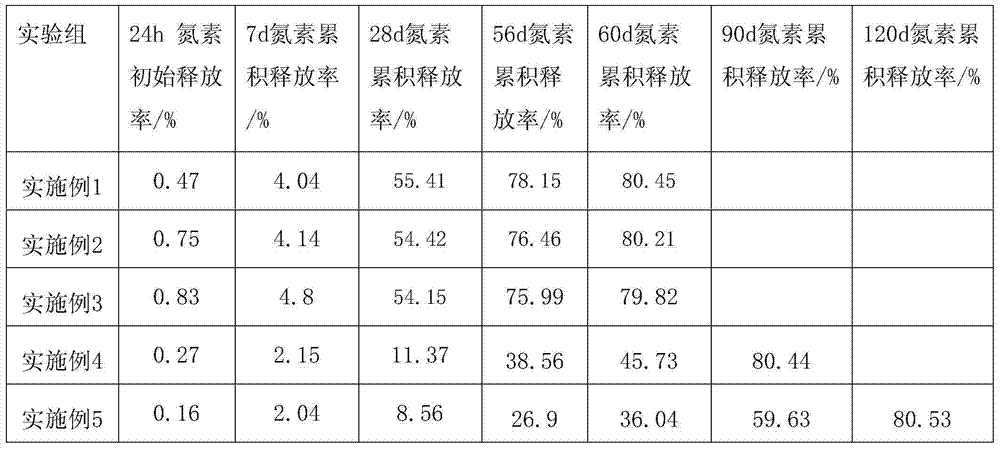

Embodiment 1

[0034] (1) Preparation of biodegradable controlled-release fertilizer coating material

[0035] Add 24kg of soybean oil polyol and 11kg of isocyanate (the amount of coating material corresponding to 1 ton of urea) into the reaction kettle, stir at 68°C for 8s, and mix well to prepare a biodegradable slow-controlled release product containing soybean oil polyol. Fertilizer coating material.

[0036] (2) Preparation of coated slow-release fertilizer

[0037] Add granular urea with a particle size of 2-4.7mm into the high-efficiency coating machine and heat it to about 65°C, and pump the prepared slow-release fertilizer coating material containing soybean oil polyol biodegradation into the constantly moving fertilizer in batches On the surface, the coating material is quickly and evenly distributed to the surface of each fertilizer, and the input amount of the coating material is 1wt% of the total weight of the granular fertilizer, and it is repeatedly coated until the coating m...

Embodiment 2

[0044] (1) Preparation of biodegradable controlled-release fertilizer coating material

[0045] Add 18.5 kg of soybean oil polyol and 5.5 kg of castor oil into the reactor, mix and stir for 6 minutes, then add 11 kg of isocyanate, and stir for 10 seconds at 70°C to prepare a biodegradable slow-release fertilizer bag containing soybean oil polyol clothing material.

[0046] (2) Preparation of coated slow-release fertilizer

[0047] Add granular urea with a particle size of 2-4.7mm into the high-efficiency coating machine and heat it to about 68°C, and pump the prepared slow-release fertilizer coating material containing soybean oil polyol biodegradation into the constantly moving fertilizer in batches On the surface, the coating material is quickly and evenly distributed to the surface of each fertilizer. The input amount of the coating material is 1wt% of the total weight of the granular fertilizer, and it is repeatedly coated until the coating material accounts for 4% of the...

Embodiment 3

[0053] (1) Preparation of biodegradable controlled-release fertilizer coating material

[0054] Add 15kg of soybean oil polyol, 3.5kg of castor oil, and 5.5kg of polyether polyol into the reaction kettle, mix and stir for 8 minutes, then add 11kg of isocyanate, and stir for 10s at 72°C to obtain a biodegradable polyol containing soybean oil slow-release fertilizer coating material.

[0055] (2) Preparation of coated slow-release fertilizer

[0056] Add granular urea with a particle size of 2-4.7mm into the high-efficiency coating machine and heat it to about 70°C, and pump the prepared slow-release fertilizer coating material containing soybean oil polyol biodegradation into the constantly moving fertilizer in batches On the surface, the coating material is quickly and evenly distributed to the surface of each fertilizer, and the input amount of the coating material is 2wt% of the total weight of the granular fertilizer, and it is repeatedly coated until the coating material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com