Patents

Literature

97results about How to "Reduce equipment investment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

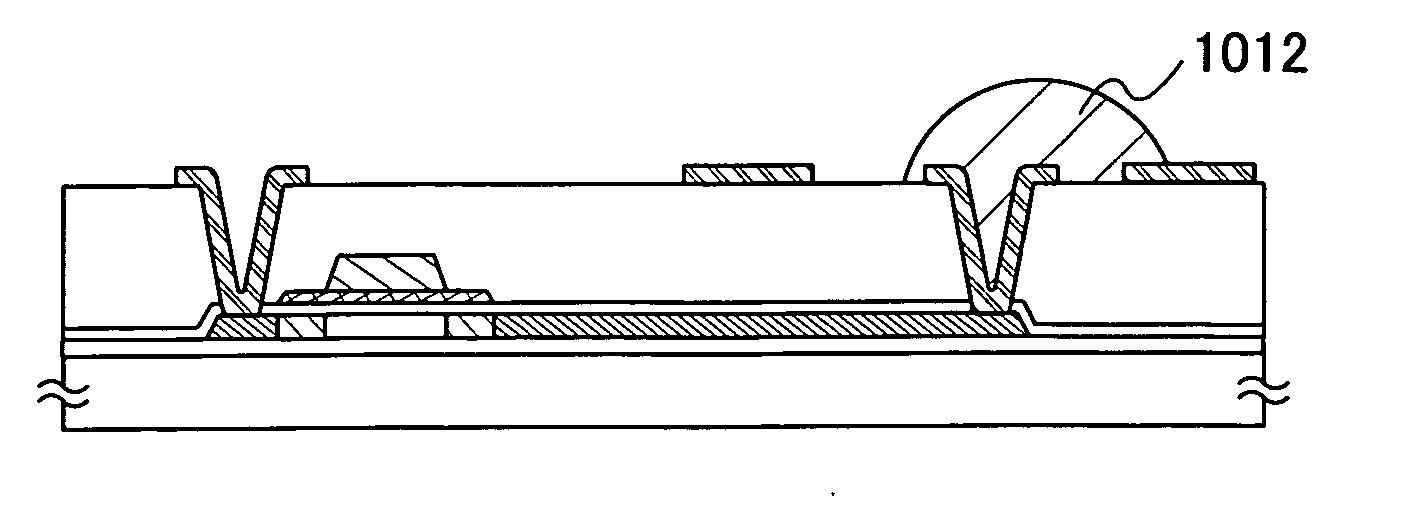

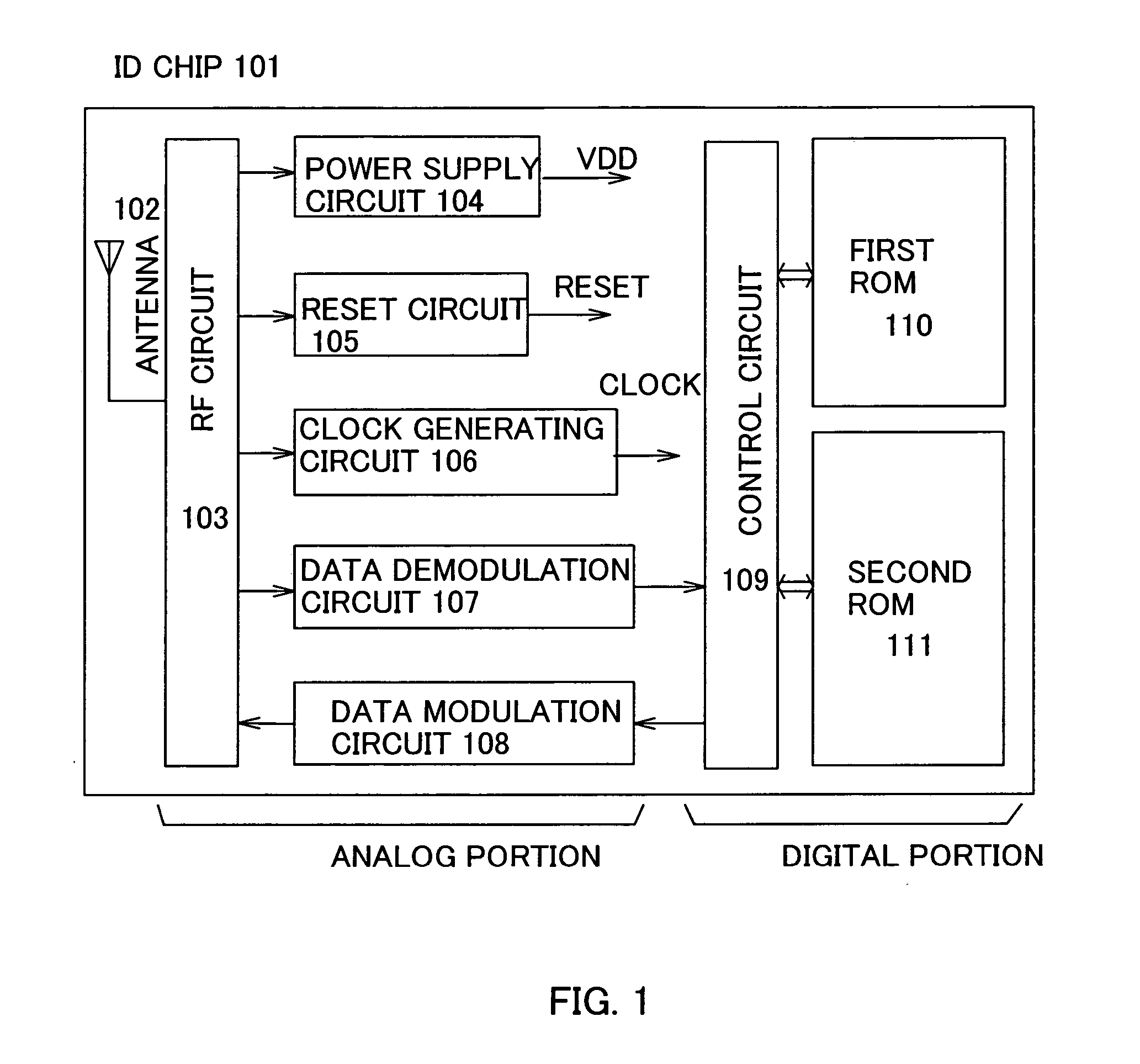

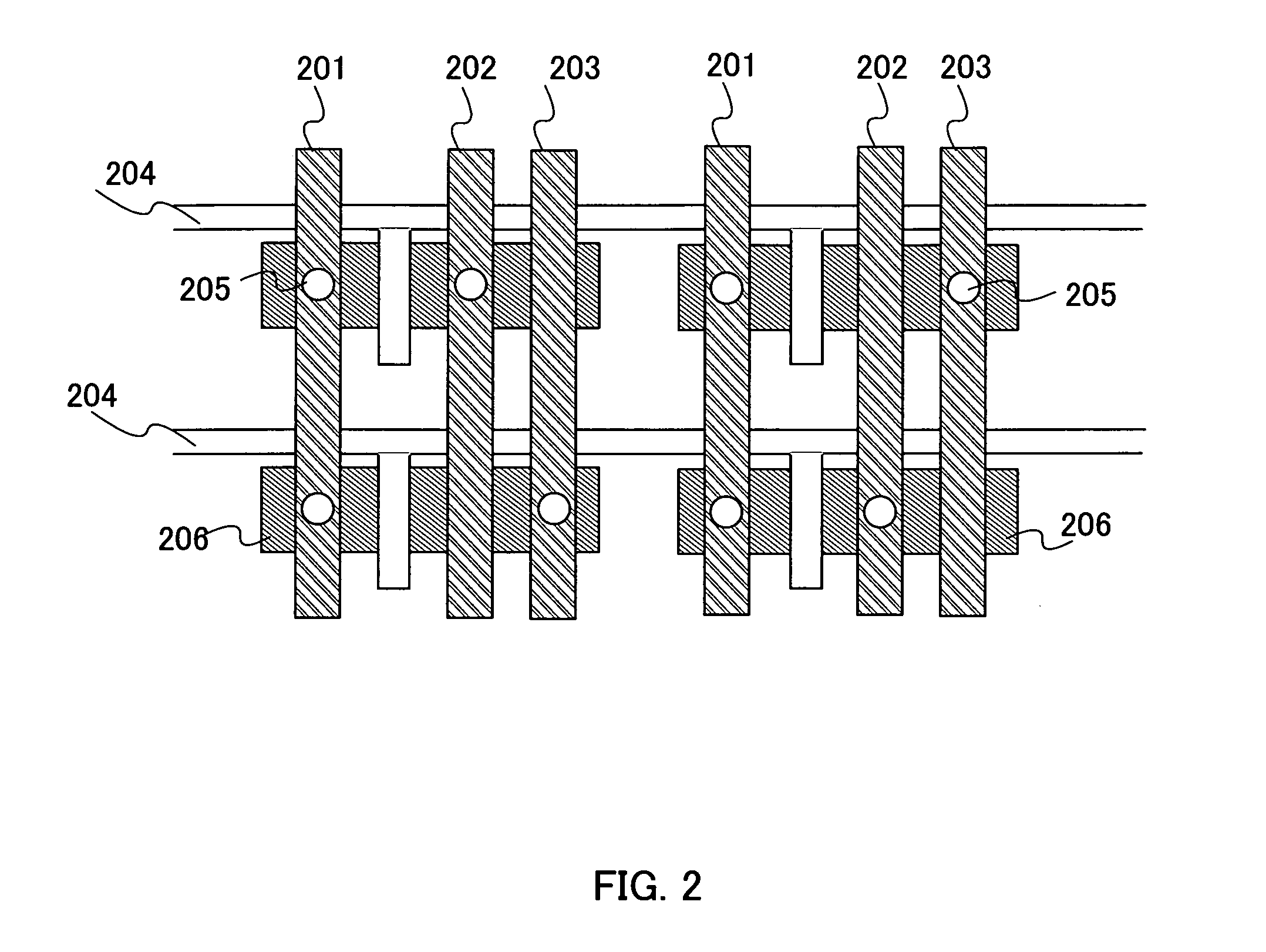

Semiconductor integrated circuit, semiconductor device, and manufacturing method of the semiconductor integrated circuit

InactiveUS20050133790A1Improve efficiencySmall amount of wasteTransistorSolid-state devicesDevice materialLaser cutting

A chip with increased impact resistance, attractive design and reduced cost, and a manufacturing method thereof are provided. A semiconductor integrated circuit is formed on a large glass substrate, and a part of data of a ROM included therein is determined by an ink jet method or a laser cutting method. Accordingly, the cost can be reduced without requiring a photomask, resulting in an inexpensive ID chip. Further, depending on the application, the semiconductor integrated circuit is transposed to a flexible substrate, thereby an ID chip with improved impact resistance and more attractive design can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

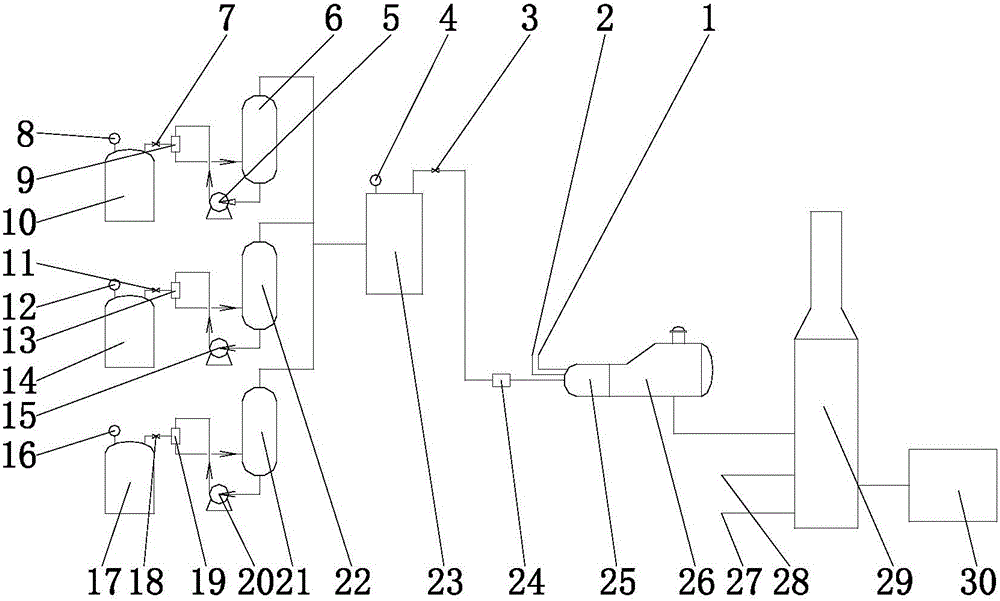

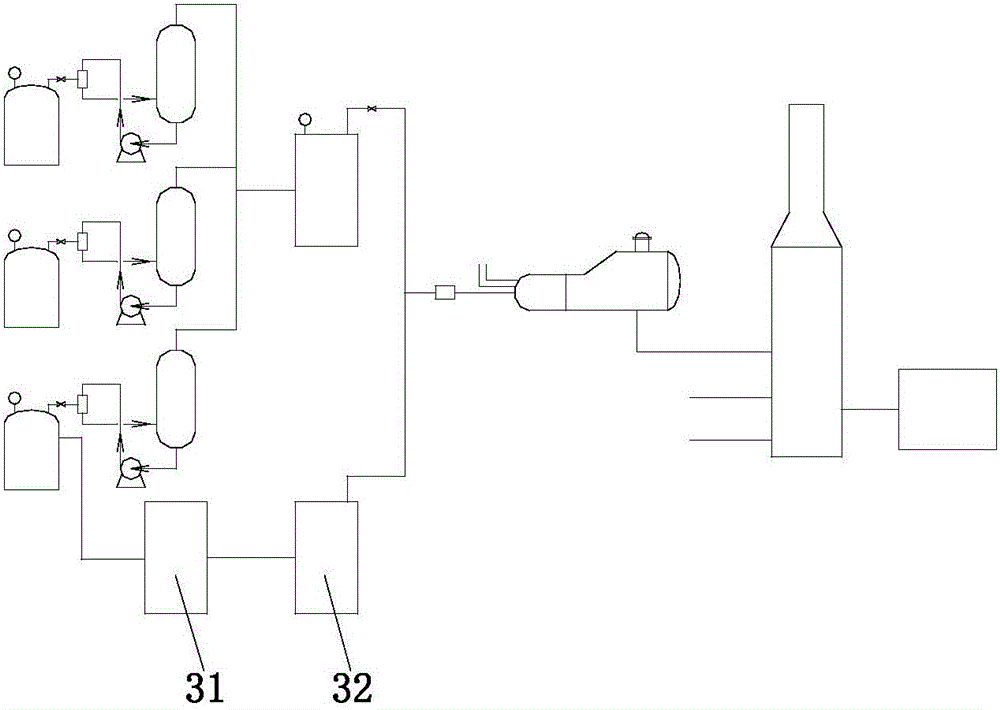

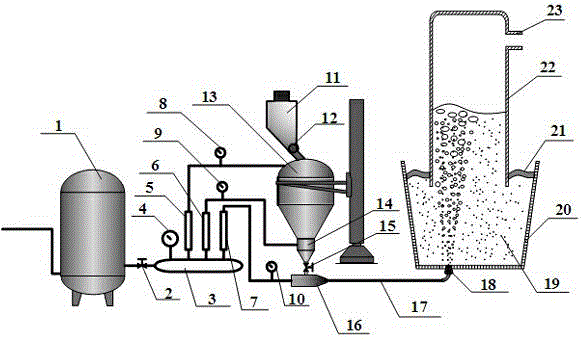

Integrated treatment method for malodorous VOCs gas of refining devices

InactiveCN105841168AReduce dosageSimple processDispersed particle separationIncinerator apparatusLiquid jetBurn units

The invention discloses an integrated treatment method for unorganized emission of malodorous VOCs gas from refining and chemical equipment, which collects VOCs gas emitted from refining and chemical storage tanks including residual oil tanks, intermediate product tanks, and acid water tanks. The VOCs gas outlet of the tank is connected to the injection fluid inlet of the liquid jet vacuum pump; the working fluid inlet of the liquid jet vacuum pump is connected to the outlet of the circulation pump, and the mixed fluid outlet is connected to the gas-liquid separation tank; the inlet of the circulation pump is connected to the The liquid outlet of the gas-liquid separation device is connected; the gas outlet of the gas-liquid separation device is connected with the buffer tank; the inlet of the incineration unit is also fed with combustion-supporting gas and air in addition to the VOCs gas in the gas storage buffer tank. , VOCs gas and malodorous gas are incinerated in the incineration unit, and the incineration temperature is 800-1000°C.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

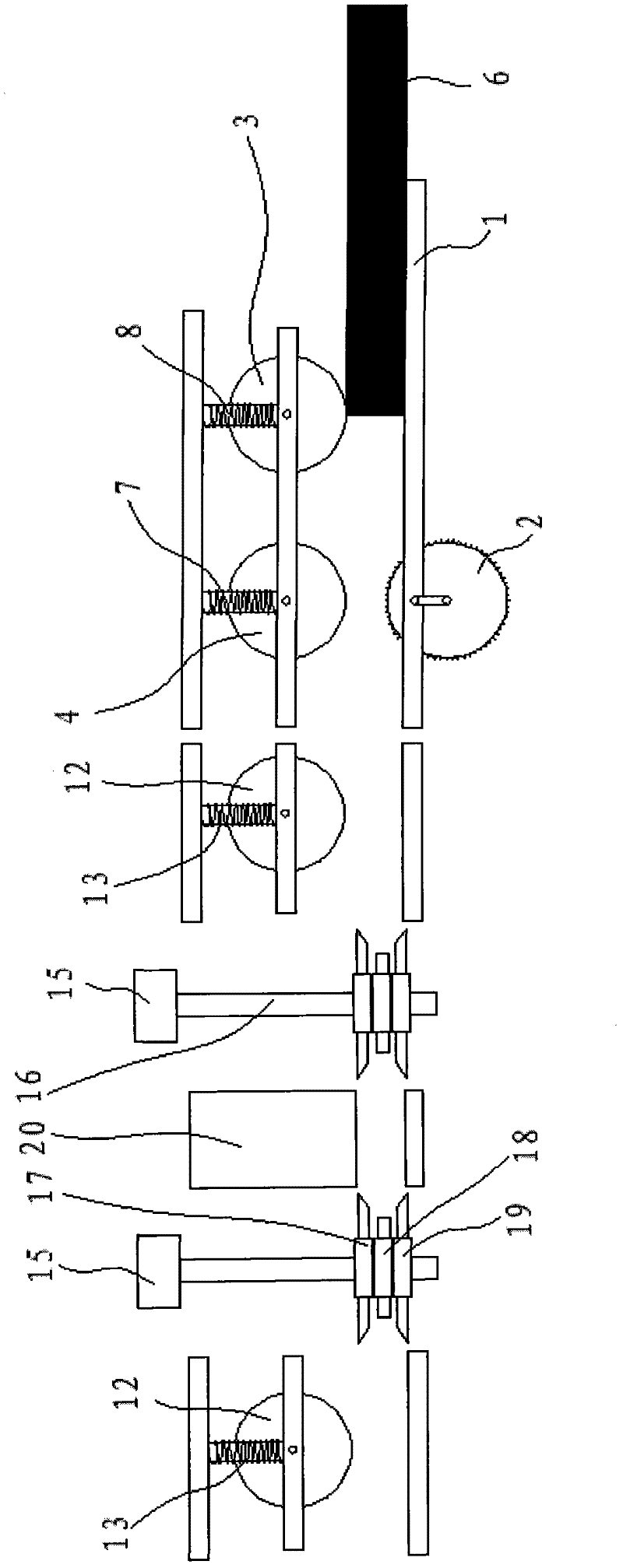

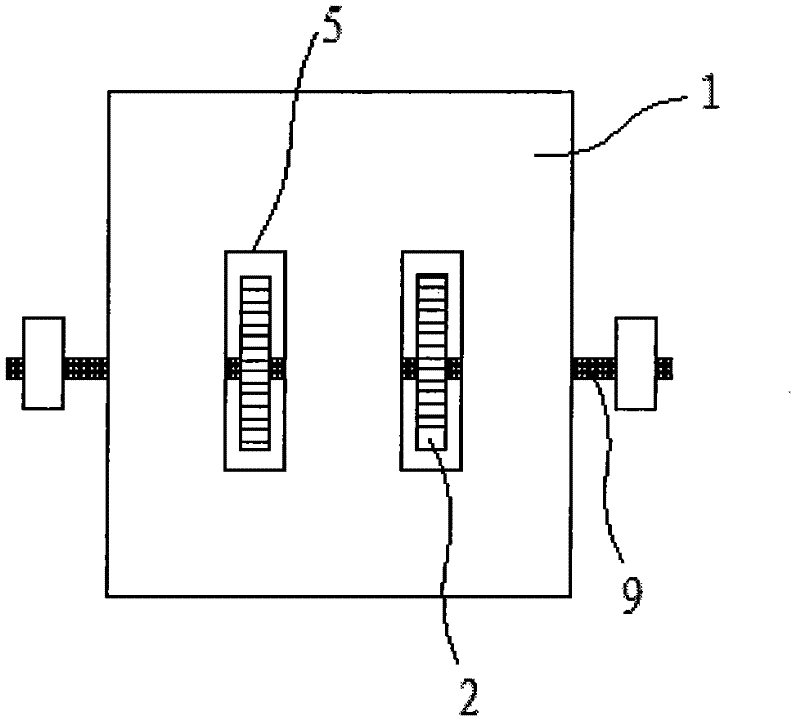

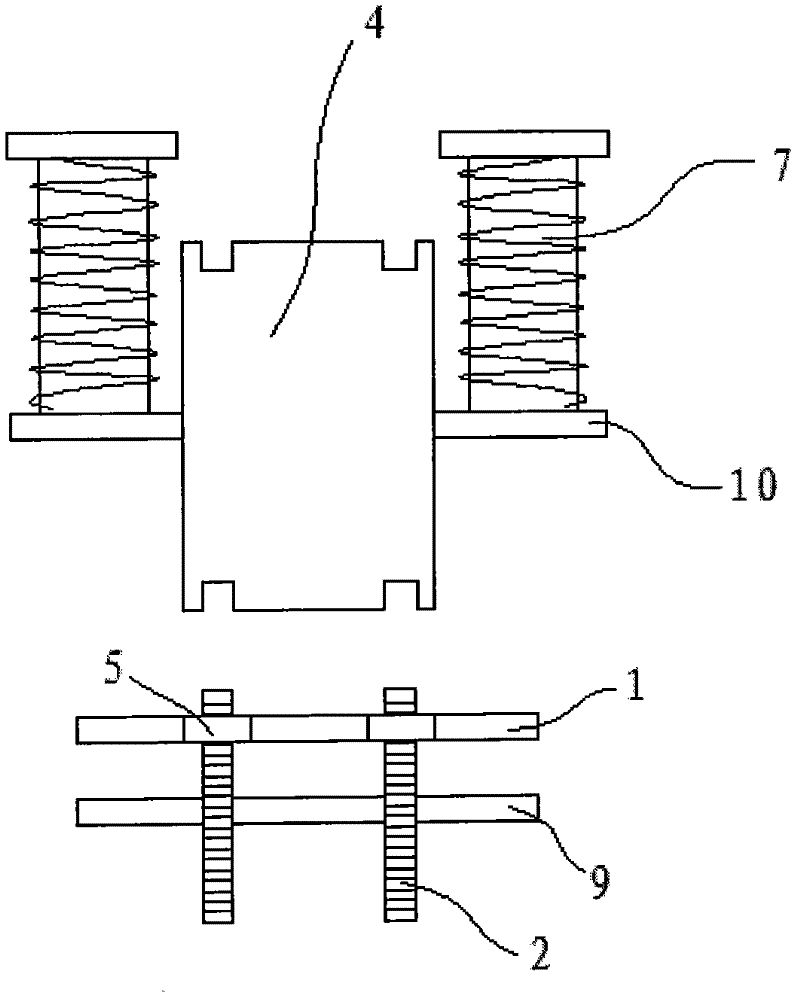

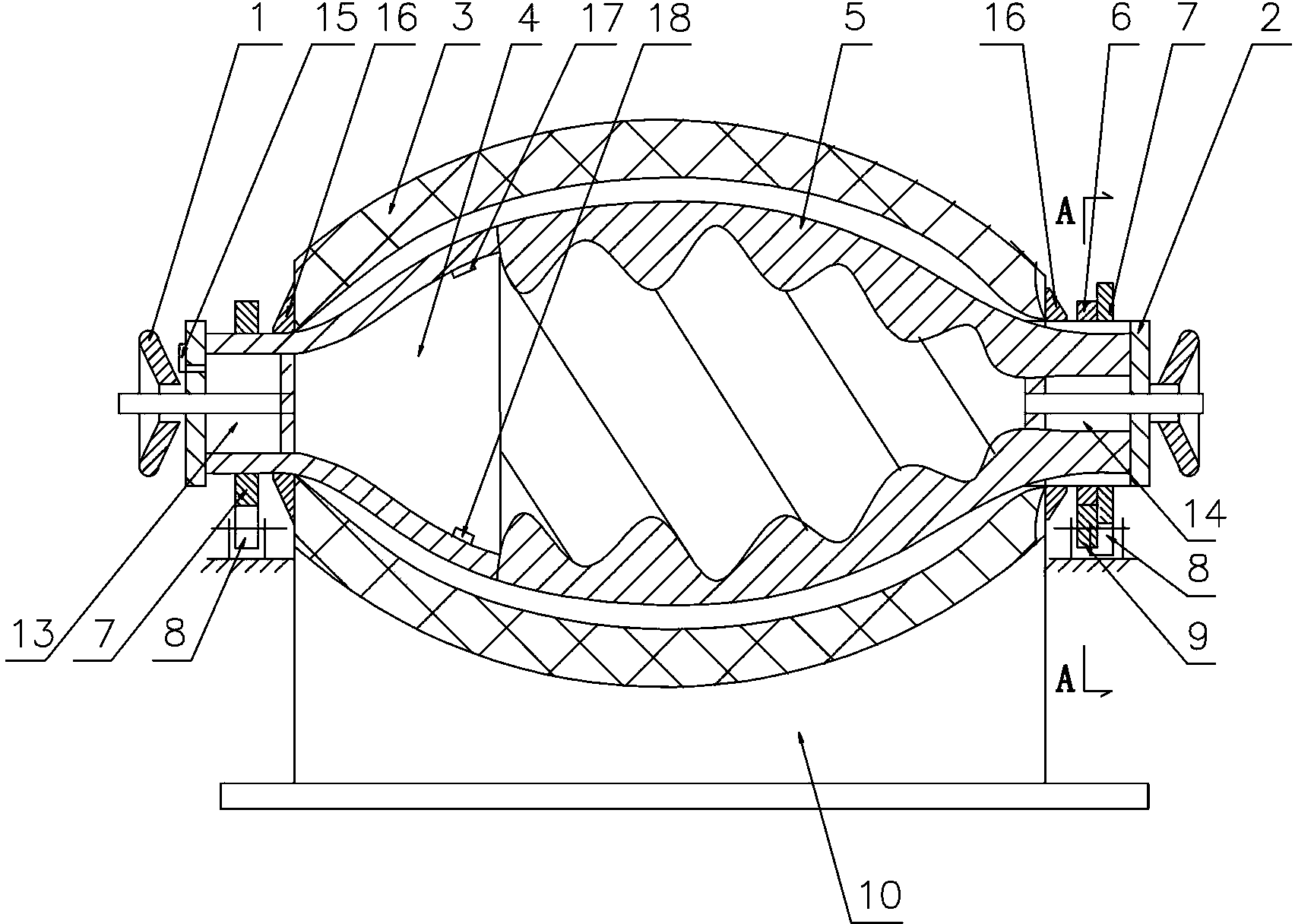

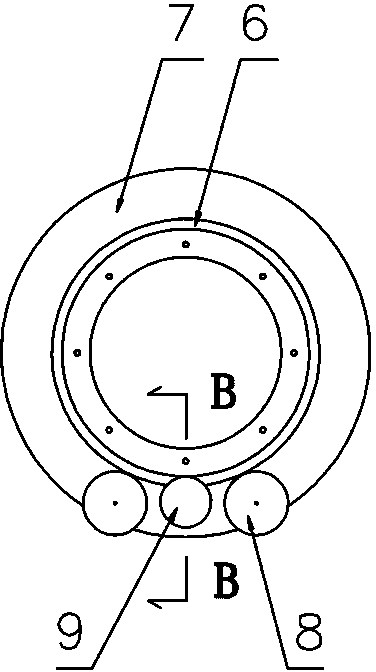

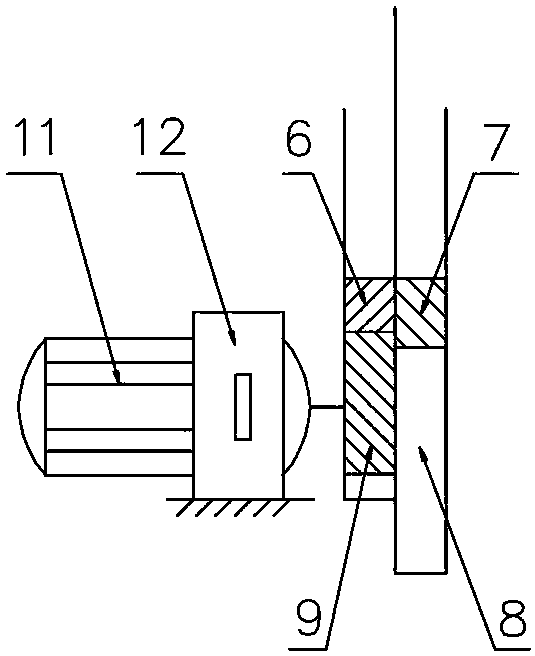

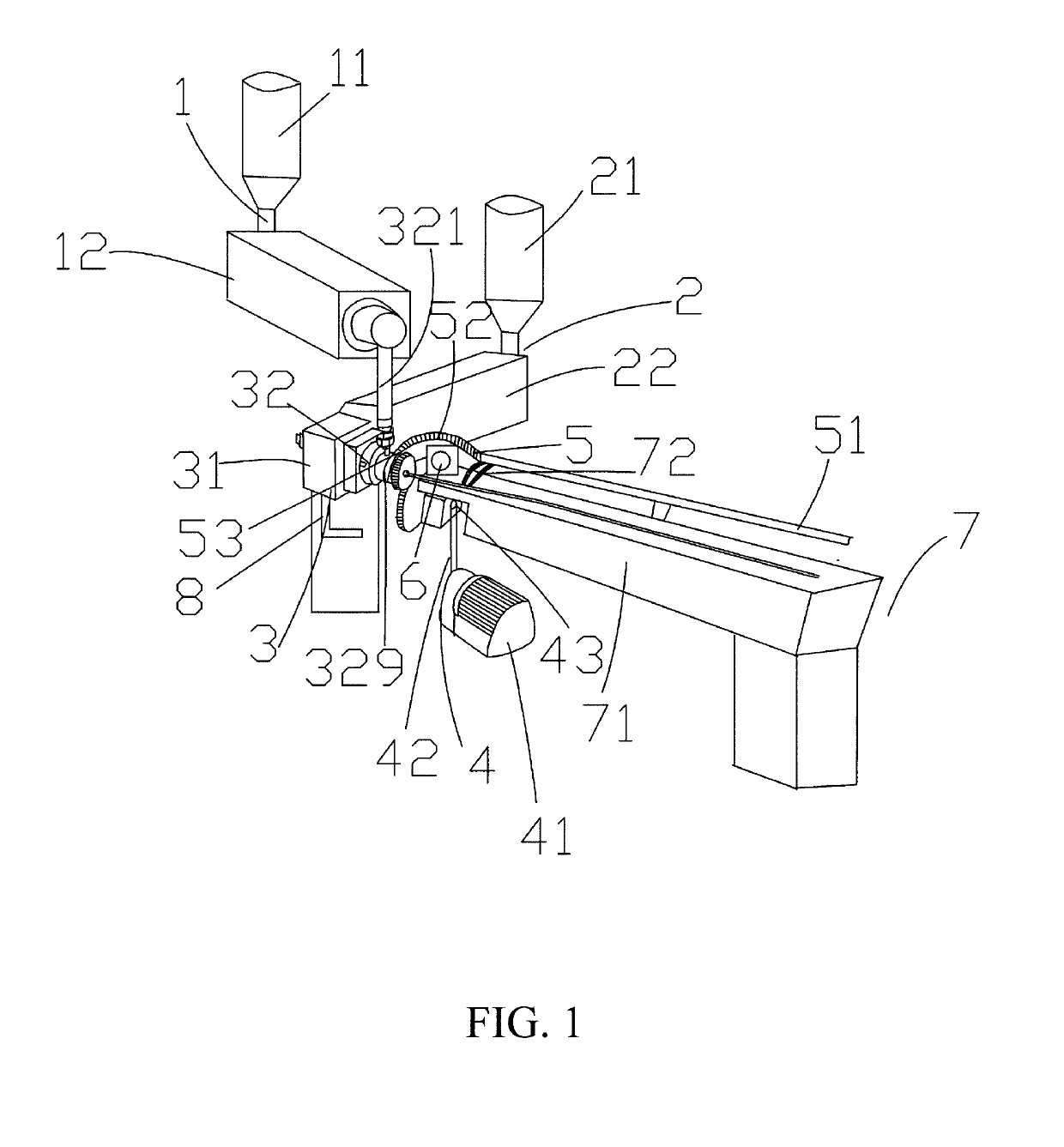

Four-side planer for wood workpiece

InactiveCN102248558AReduce equipment investment costsEquipment maintenance is simpleFlat surfacing machinesSmooth surfaceEngineering

The invention relates to a wood processing device, in particular to a four-side planer aiming at wood workpiece processing. The four-side planer for a wood workpiece is characterized by comprising a cutting device, two polishing devices, two edge planers and an upender, wherein the cutting device comprises a rectangular working table; a rectangular through hole is arranged in the working table; an electric saw shaft is arranged at the lower part of the working table; width directions of the electric saw shaft and the working table are same; an electric saw blade is arranged on the electric saw shaft; and the upper part of the electric saw blade penetrates through the rectangular through hole of the working table. According to the four-side planer for the wood workpiece, provided by the invention, a blank wood workpiece can be rapidly processed into the wood workpiece with a smooth surface and an octagonal section; and the four-side planer has the advantages of lower investment cost, simpleness in maintenance and benefit of rapid development of small and medium sized enterprises.

Owner:ANHUI HANWEN SPORTING GOODS

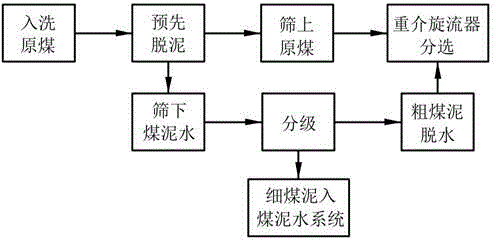

Process of coarse coal slime back washing in pre-desliming dense medium cyclone sorting

InactiveCN104525358ASimple processReduce equipment investment costsWet separationProcess engineeringCoal

The invention discloses a process of coarse coal slime back washing in pre-desliming dense medium cyclone sorting. Pre-desliming is carried out on raw coal fed to be washed to obtain plus sieve raw coal and minus sieve coal slime water, and the plus sieve raw coal enters a dense medium cyclone directly to be sorted; hydraulic cyclone grading is carried out on the minus sieve coal slime water to obtain coarse coal slime and fine coal slime; the coarse coal slime is dehydrated and then fed into the dense medium cyclone again to be sorted; the fine coal slime enters a coal slime water system of the next procedure to be recovered and floated. By the utilization of the advantage that the sorting minimum of the dense medium cyclone is smaller than 0.25 mm, the coarse coal slime obtained after desliming is fed into the dense medium cyclone again to be sorted, so that the flow path is simplified, a set of conventional sorting equipment is omitted, a high-level and high-benefit production system with the non-pressure feeding three-product dense medium cyclone as the main washing equipment is formed, and equipment investment is lowered. Particularly, if the raw coal fed to be washed contains batt, coal slime is seriously slimed, conventional coarse coal slime sorting equipment is low in sorting index, and the process is high in sorting index and can meet process requirements.

Owner:纪玉华

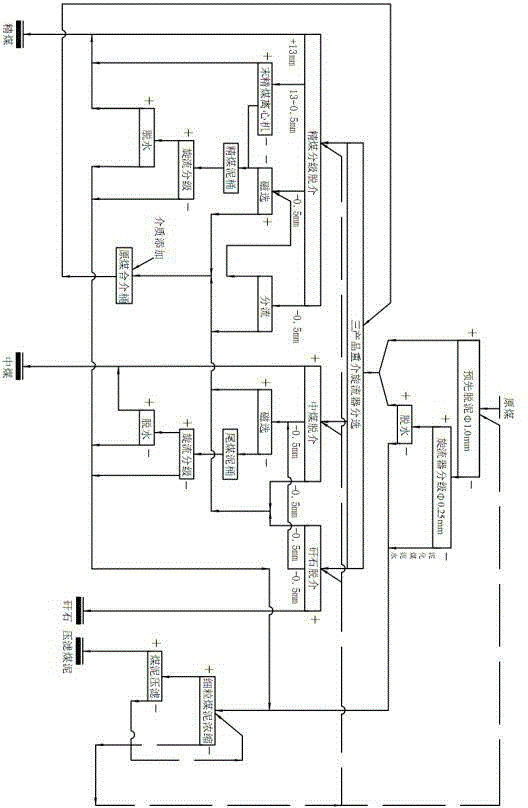

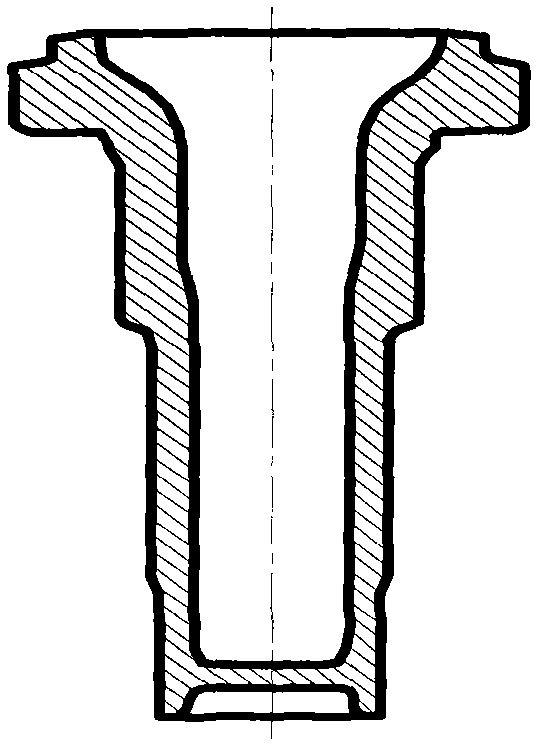

Technical method for forming semi-axle housing tube for large-diameter flange

ActiveCN102513791AReduce equipment investment costsReduce process difficultyForming forceEngineering

The invention discloses a technical method for forming a semi-axle housing tube for a large-diameter flange. The technical method comprises the following steps of: sawing hot-rolled round steel serving as a blank, heating, and upsetting by using an extruding machine; performing rotary forging for forming by using a rotary forging press; and performing forward extrusion once and backward extrusion to form a forged piece of the semi-axle housing tube. According to technical method, in the maximum process step of forming force required by the semi-axle housing tube, the flange is formed by the rotary forging press; and only an outer step axle and an inner step hole are formed when the head flange is formed by the rotary forging and is extruded. The technical method has the advantages that: the full filling of flange corners is ensured effectively, the investment cost of equipment is reduced effectively, the process difficulty of the subsequent extrusion process step is reduced, the coaxiality of finished products is easy to ensure, and the production cost of the forged piece is reduced while the yield of the products is improved.

Owner:SHIYAN YUANJUN IND & TRADE

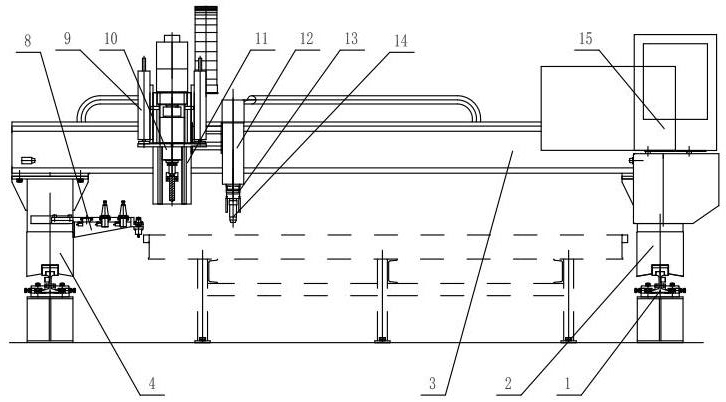

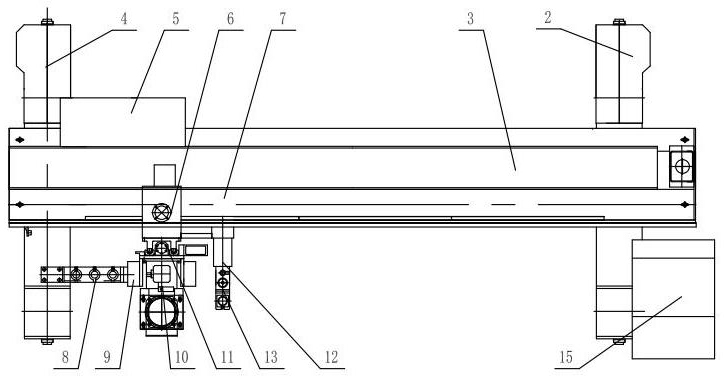

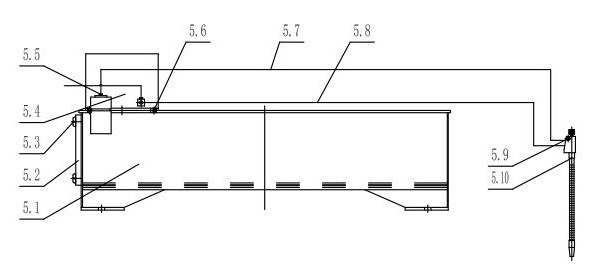

Numerical control drilling and cutting combination machine

ActiveCN102601618ASmall footprintReduce manufacturing costOther manufacturing equipments/toolsPositioning apparatusControl systemCompression device

The invention discloses a numerical control drilling and cutting combination machine. Tool change and length measurement of the drilling spindle structure on a drilling tool magazine mechanism are realized by means of controlling a main frame component, an auxiliary frame component, a driving slide carriage, a servo motor on a drilling lifting mechanism, a spindle motor on a drilling spindle structure and a tool impacting cylinder by a numerical control system, a steel plate is drilled under auxiliary effects of an iron plate compression device and a drilling aerial fog cooling system, and the steel plate is cut and discharged through a cutting torch by means of controlling the main frame component, the auxiliary frame component, a servo motor on the driving slide cartridge, a motor on a cutting torch lifting device and an inductive switch on an initial positioning device. The aid of the numerical control drilling and cutting combination machine has the advantages that two machining tool are combined, occupied area, production cost and investment cost of the equipment are greatly reduced, accordingly, requirements on capabilities of drilling, tapping and cutting steel plates on the same equipment can be met, and the economic benefit is remarkable.

Owner:WUXI HUALIAN SCI & TECH GROUP

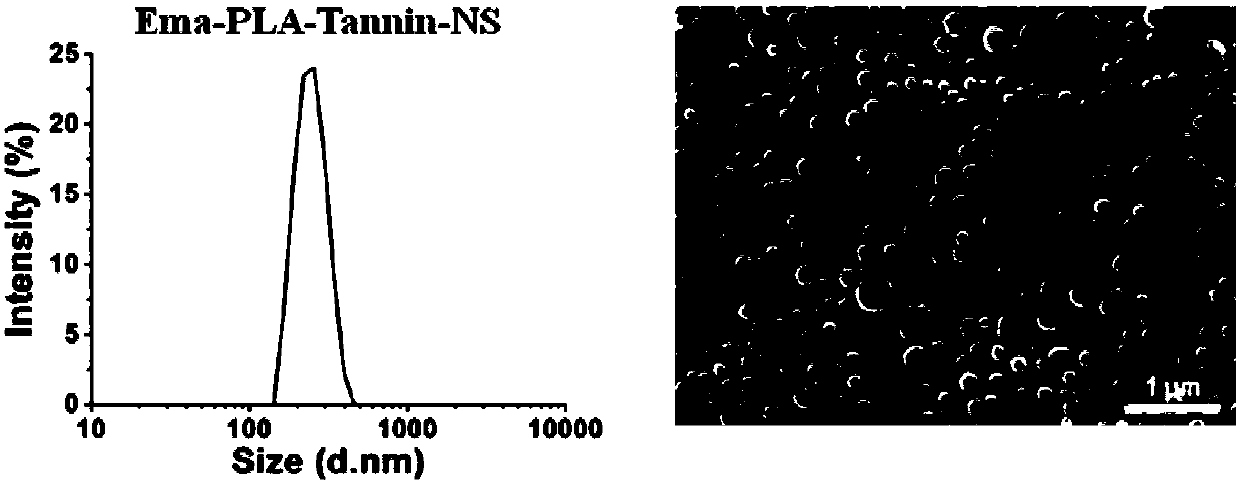

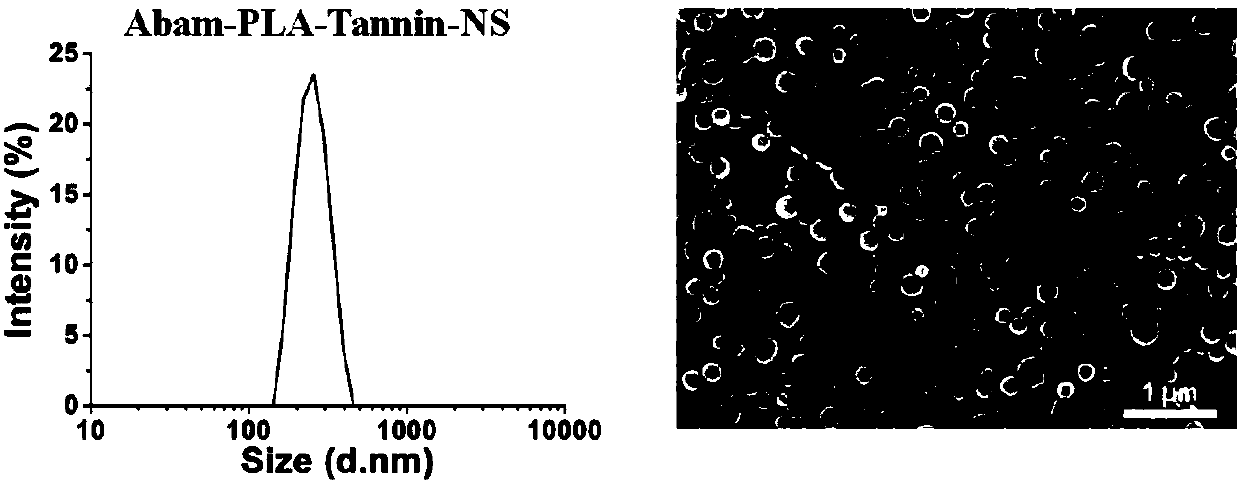

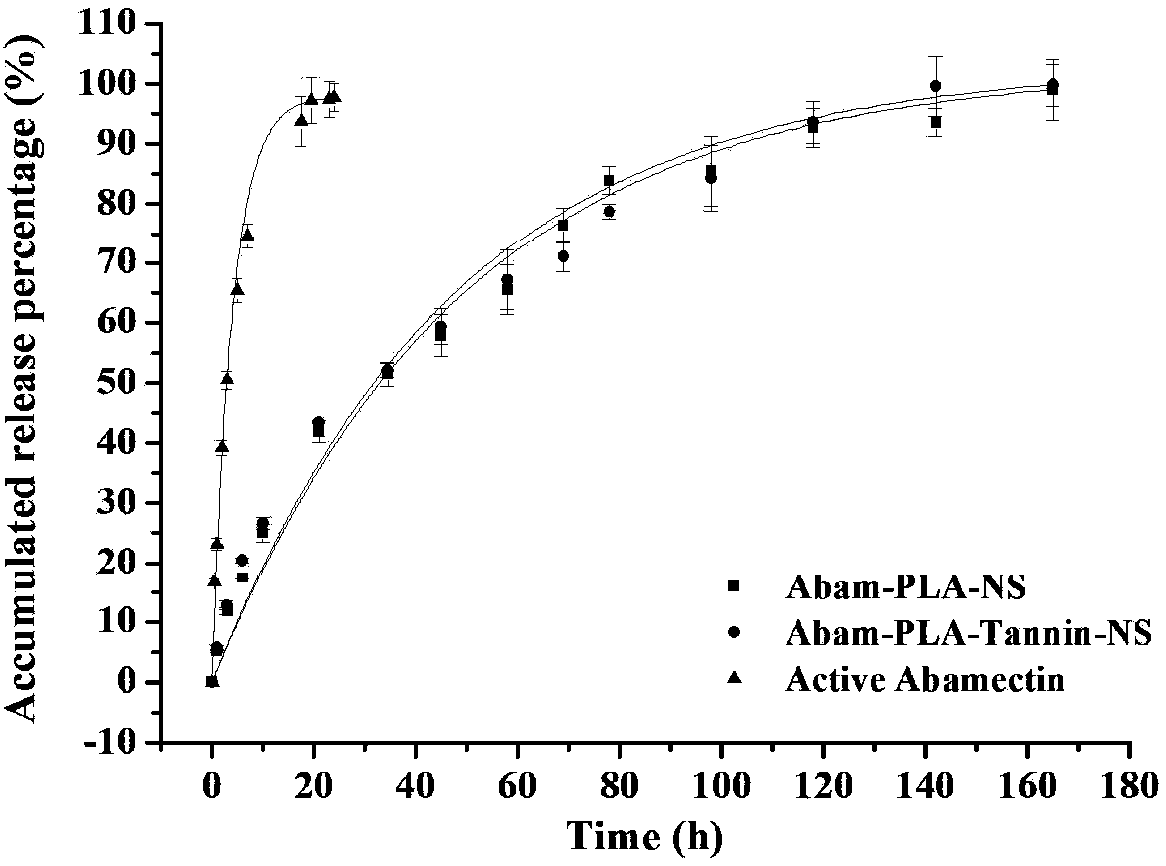

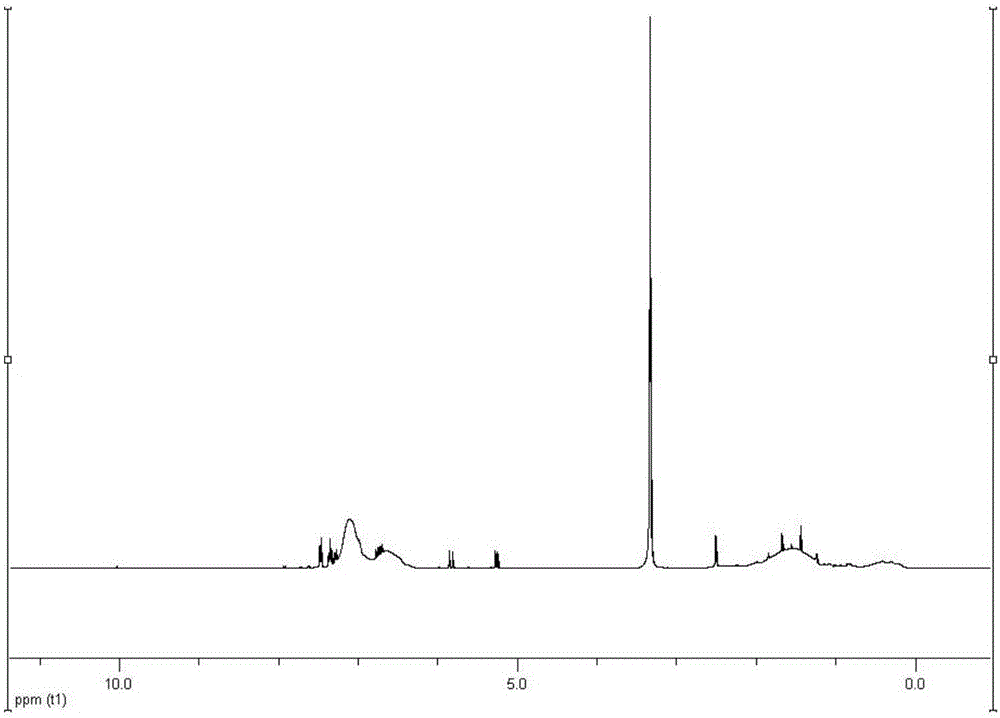

Preparation method of nano drug-loading system of leaf surface affiliated pesticide

The invention discloses a preparation method of a nano drug-loading system of leaf surface affiliated pesticide. The method comprises the following steps: preparing a polylactic acid carrier, primaryemulsion and the nano drug-loading system, carrying out affiliated modification on the nano drug-loading system and the like. According to the nano drug-loading system of the leaf surface affiliated pesticide, disclosed by the invention, the average grain diameter range is 300nm to 800nm, the drug loading amount can reach 15 percent or more and the encapsulation rate reaches 75 percent or more; compared with an abamectin crude drug, traditional Chinese medicine components in the nano drug-loading system have remarkably improved the light stability, and the nano drug-loading system has a remarkable slow release effect. The preparation technology of the nano drug-loading system of the leaf surface affiliated pesticide is simple; the preparation cost and the equipment investment cost are low,pollutants are not generated and the quality of a product is stable and reliable; the leaf surface retention behavior of pesticide liquid drops can be remarkably improved. Therefore, the production method of the nano drug-loading system of the leaf surface affiliated pesticide has a very wide application prospect.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

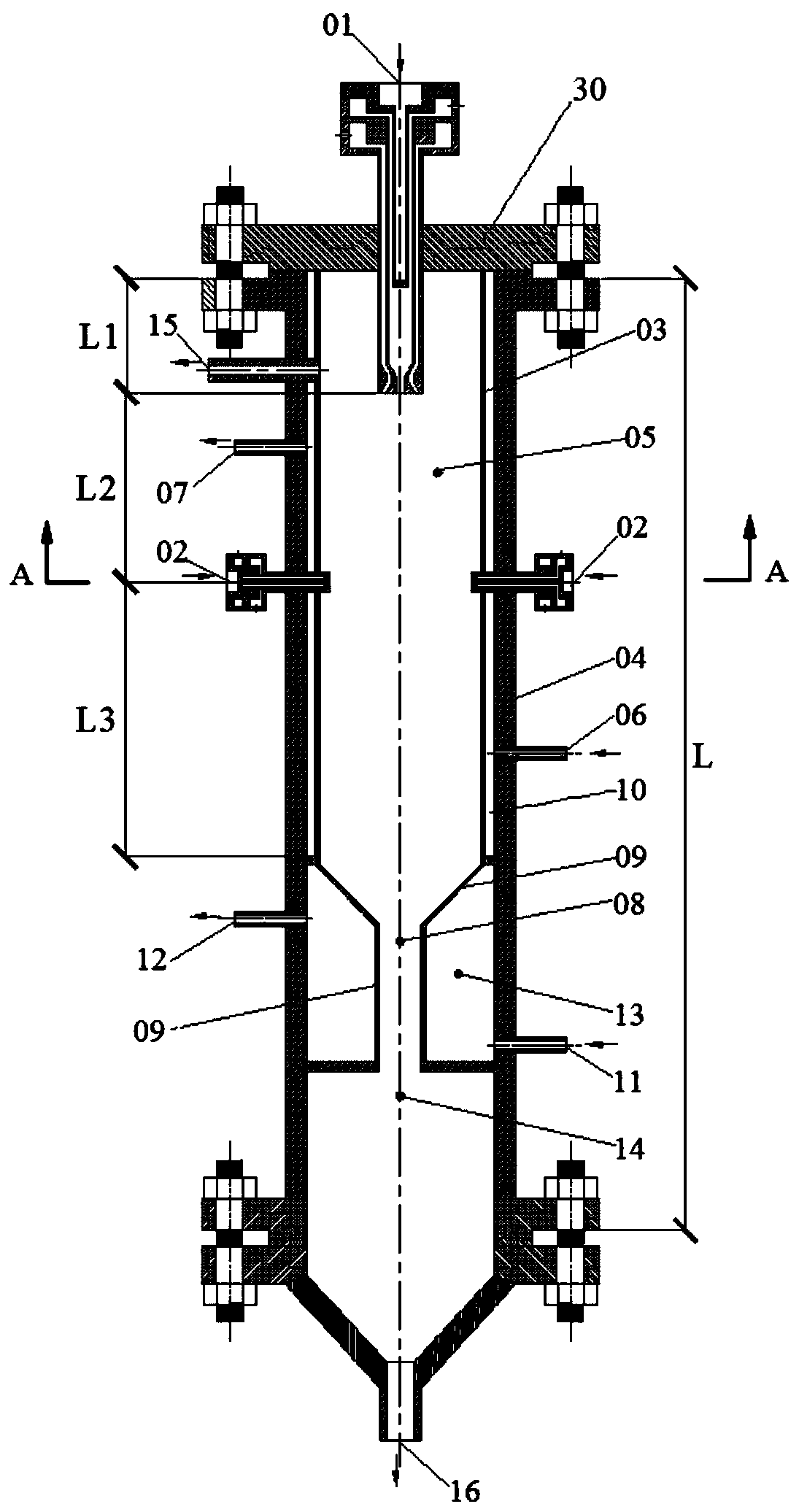

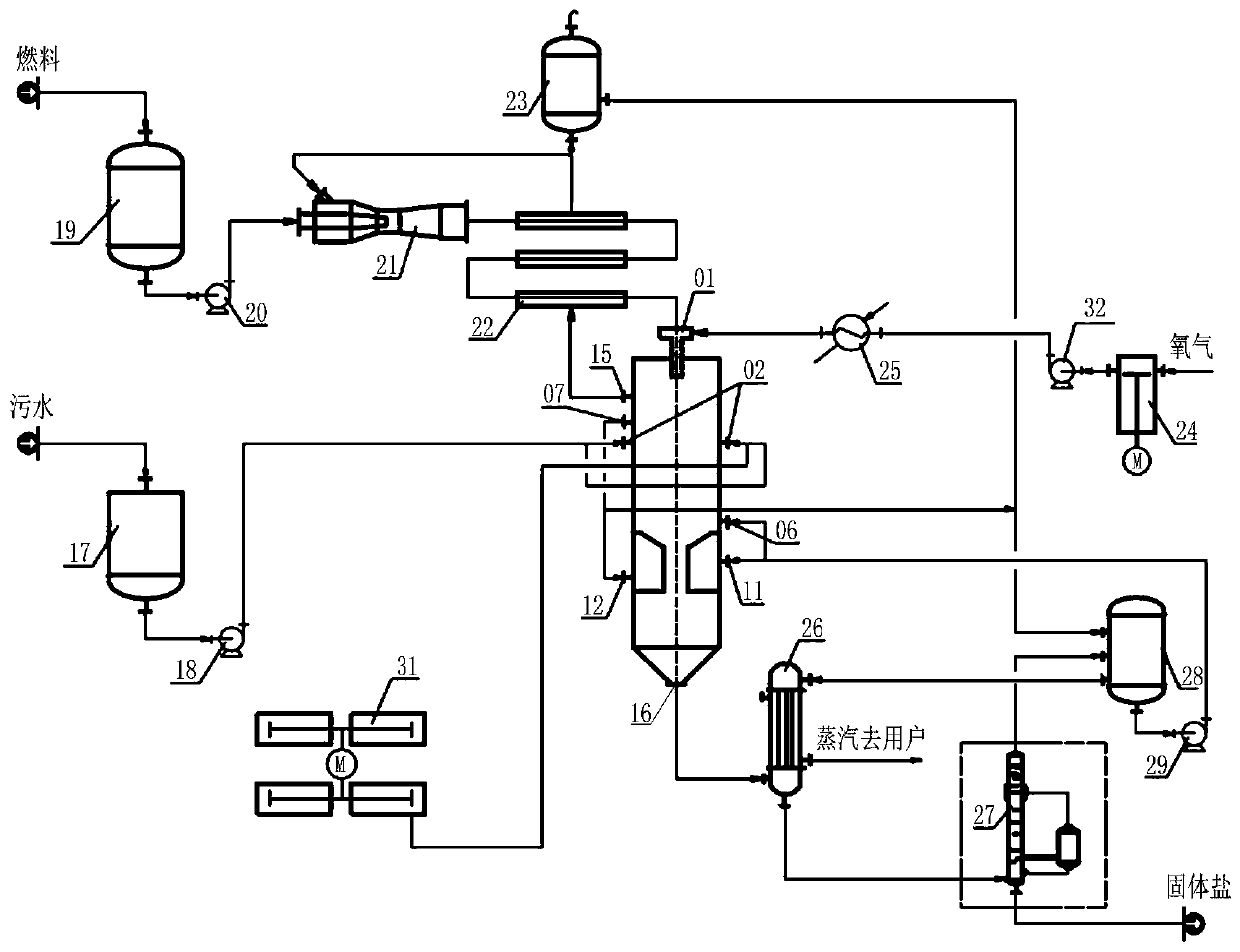

Supercritical hydrothermal combustion reactor for recovering salt from organic wastewater and application thereof

PendingCN111470559ASolve corrosiveSolving Salt Deposition ProblemsWater contaminantsMultistage water/sewage treatmentSaline waterSalt water

Owner:成都九翼环保科技有限公司

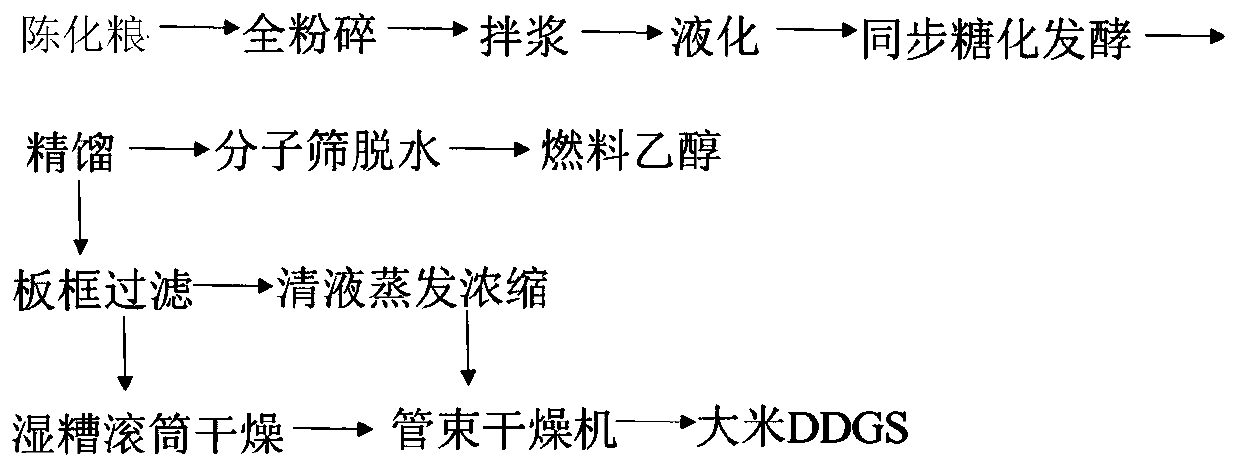

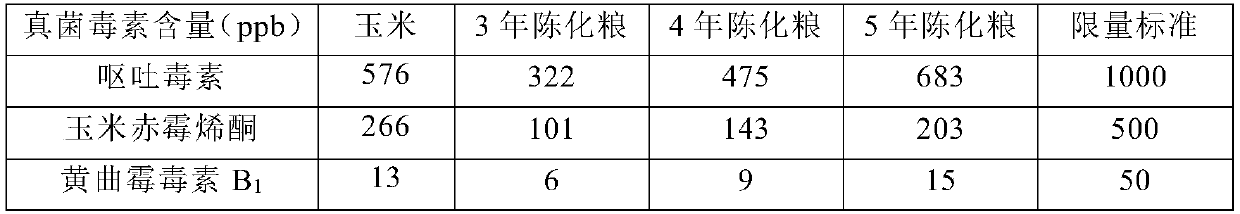

Method for producing fuel ethanol and by-product rice DDGS by rice processing

The invention relates to a method for producing fuel ethanol and by-product rice DDGS by using rice as a raw material. The method comprises the following steps: (1) rice smashing preprocessing; (2) preparing liquefied mash; (3) preparing wine mash; (4) preparing fermented mature mash; (5) preparing fuel ethanol; (6) preparing rice DDGS. The product fuel ethanol obtained from the method has high volume fraction of ethanol, and the quality conforms to the national standard GB 18350-2013 Denatured Fuel Ethanol. In addition, a detection result of mycotoxin in the by-product rice DDGS is lower thanthe limit standard, and the protein content is high. Therefore, the industrial production of the rice processed fuel ethanol and the by-product rice DDGS is achieved, the risk that the harmful mycotoxin enters a food chain system is avoided and causes the mycotoxin exceeding the standard in the DDGS is avoided, the protein content in the DDGS is increased, and the comprehensive utilization valueof the rice is greatly improved.

Owner:JILIN COFCO BIOCHEM +3

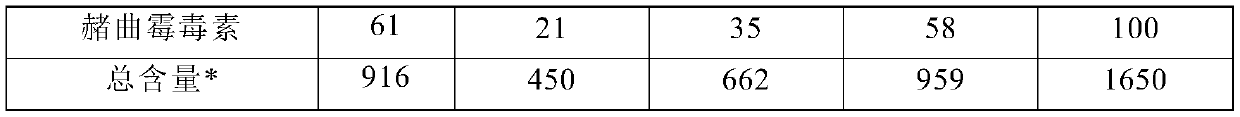

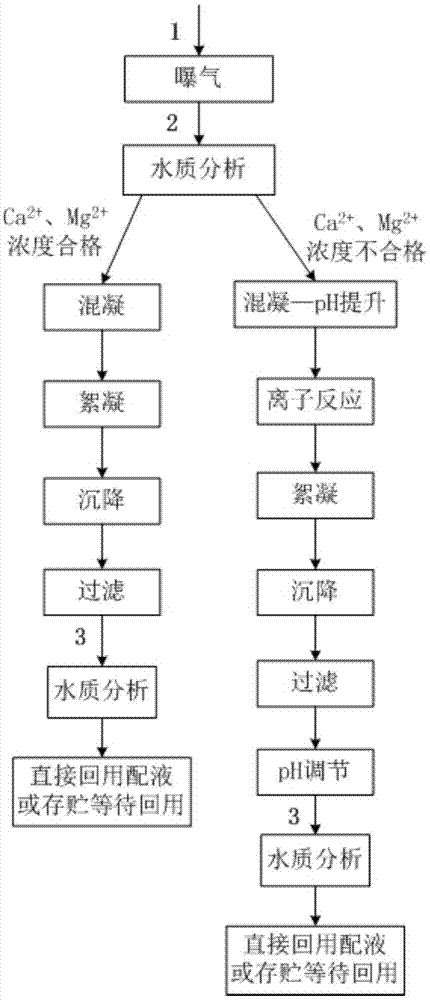

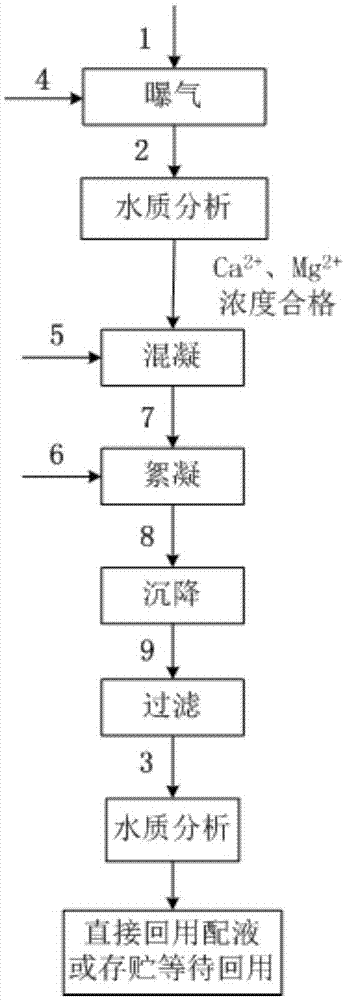

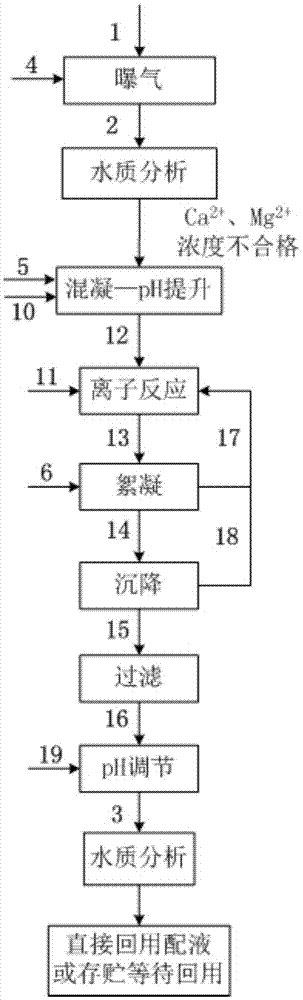

Method for treating and reusing fracturing backflow fluid of shale gas

ActiveCN106892513AImprove adaptabilityReduce equipment investment costsWaste water treatment from quariesMultistage water/sewage treatmentShale gasWater quality

The invention discloses a method for treating and reusing fracturing backflow fluid of shale gas. The method comprises the following steps: (a) oxidizing Fe<2+> in original fracturing backflow fluid into Fe(OH)3, so as to obtain oxidized fracturing backflow fluid; (b) carrying out water quality analysis on the oxidized fracturing backflow fluid; (c) making comparison on the water quality of the oxidized fracturing backflow fluid and a reuse liquid preparation water quality requirement, and judging whether the concentrations of Ca<2+> and Mg<2+> in the oxidized fracturing backflow fluid of the shale gas are qualified; (d) if yes, sequentially carrying out coagulation, flocculation, sedimentation and filtration on the oxidized fracturing backflow fluid, and if no, sequentially carrying out coagulation-pH increase, ionic reaction, flocculation, sedimentation, filtration and pH value adjustment on the oxidized fracturing backflow fluid, so as to obtain treated fracturing backflow fluid; and (e) directly reusing the treated fracturing backflow fluid for liquid preparation or directly storing the treated fracturing backflow fluid. The method can adapt to the characteristics that the change of the water quality of the fracturing backflow fluid of the shale gas is large and reuse fracturing construction liquid preparation standards are different, and the instant continuous treatment can be realized.

Owner:PETROCHINA CO LTD

Method and device for producing alpha-type gypsum in large scale with low cost

InactiveCN104230192ARealize industrialized mass productionReduce manufacturing costWater vaporWater of crystallization

The invention discloses method and device for producing alpha-type gypsum in a large scale with a low cost. The method comprises the following steps: spraying a proper amount of water into gypsum powder which comprises 10-15% of attached water and 15-20% of crystal water and has the grade of calcium sulphate dehydrate being 90-95% and preparing into dihydrate gypsum pellets; then, putting the dihydrate gypsum pellets in a rotary kiln body of a special rotary calcining kiln for alpha-type gypsum and sealing; heating the rotary kiln body by using a heating electric furnace body to evaporate the attached water and crystal water out of the dihydrate gypsum pellets in the rotary kiln body so as to form water vapor with pressure of 0.5-0.8MPa and temperature of 150-180 DEG C inside the sealed rotary kiln body; holding the temperature and pressure for 10-20 minutes under the condition so as to convert the dihydrate gypsum pellets in the rotary kiln body into alpha hemihydrate gypsum; then, switching on a decompression valve to relieve pressure and switching off the switch of the heating electric furnace body; and drying the residual water in alpha hemihydrate gypsum by using waste heat of the kiln body, and discharging and refining into 100-150 meshes powder to obtain a finished product alpha-type gypsum. The method provided by the invention is simple in process, convenient and efficient to operate, small in equipment investment and low in production cost, can be used for producing alpha-type gypsum in large scale, and is worthy widely popularizing.

Owner:HUANGSHI YANRAN IMPORT & EXPORT

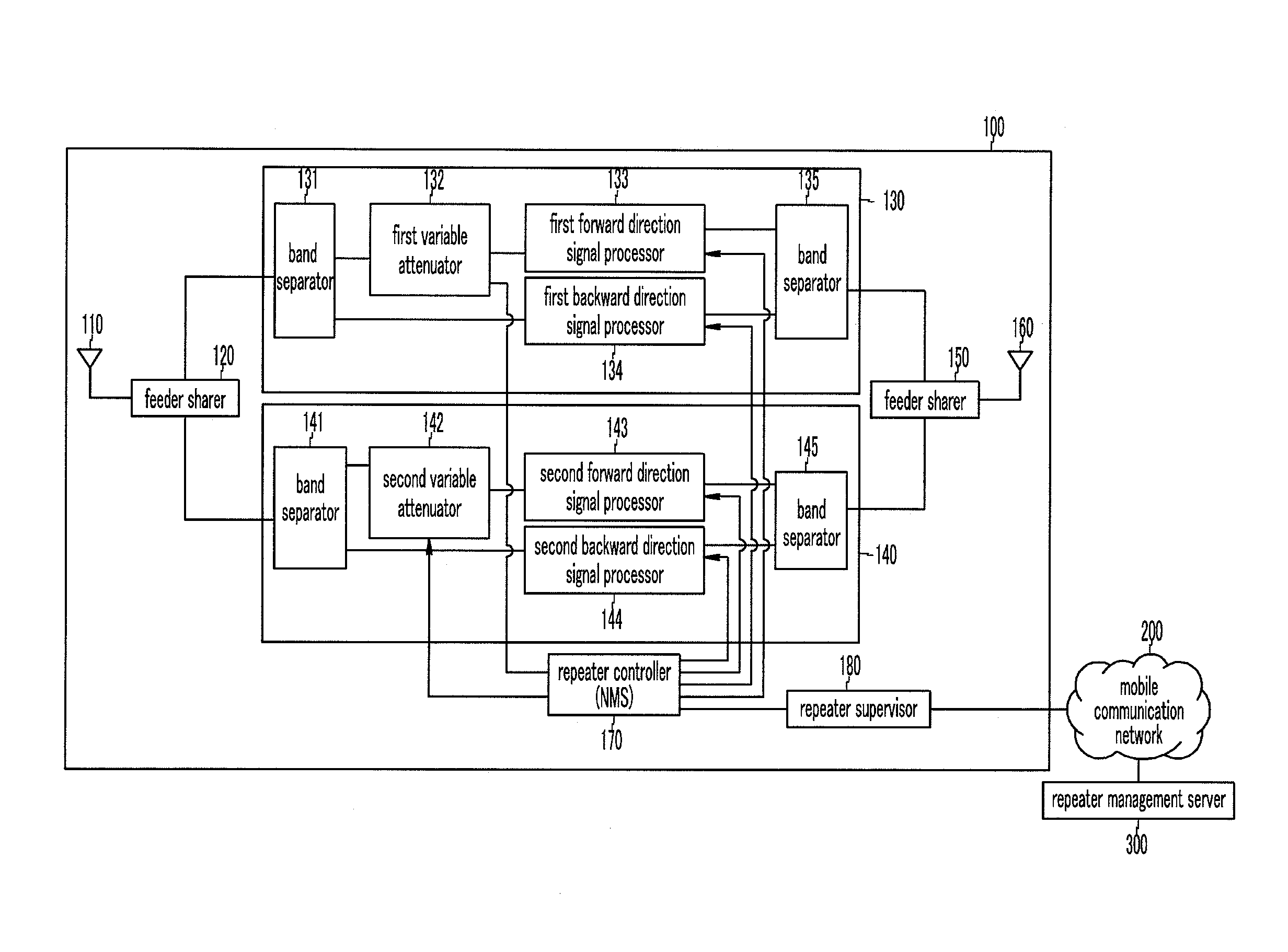

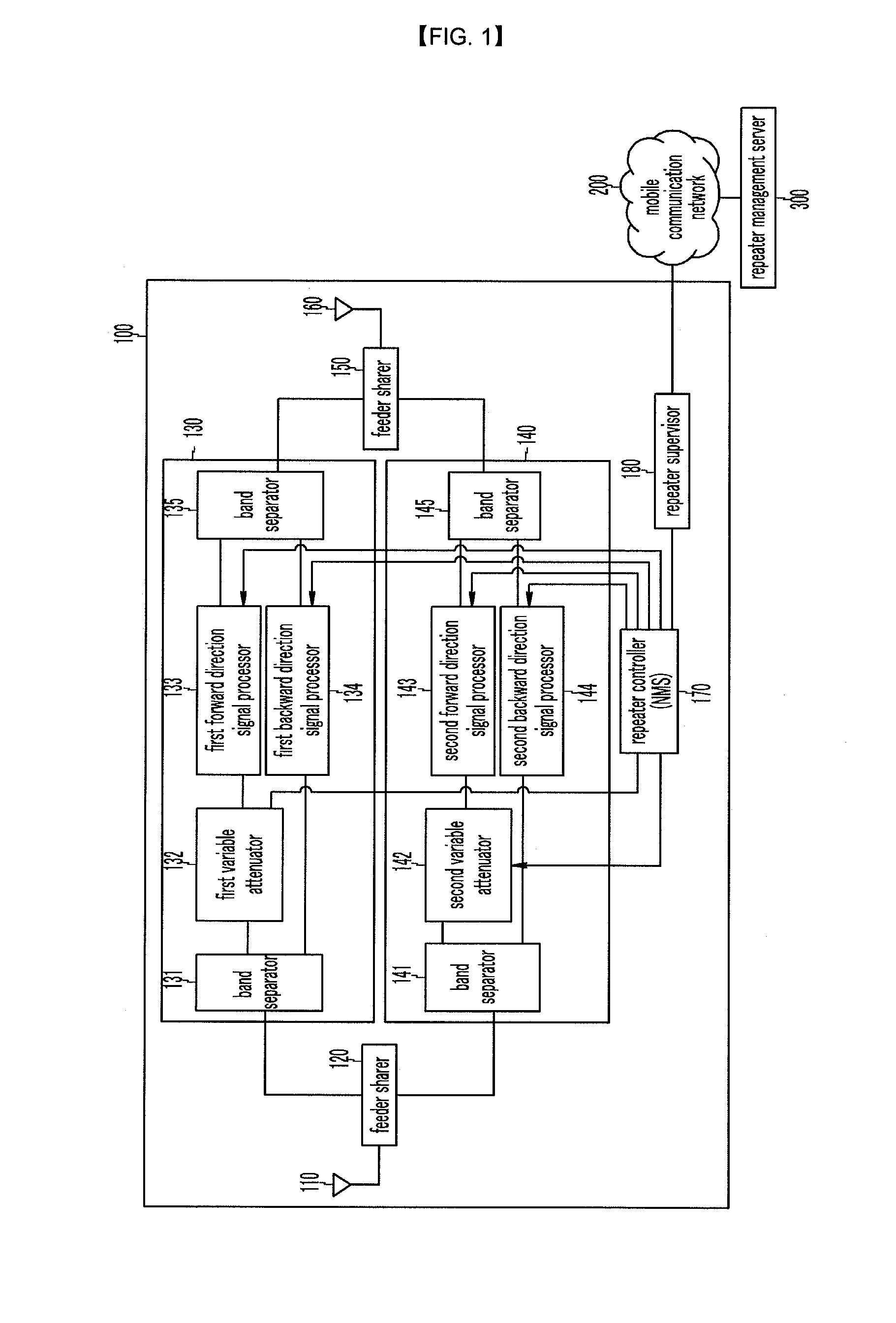

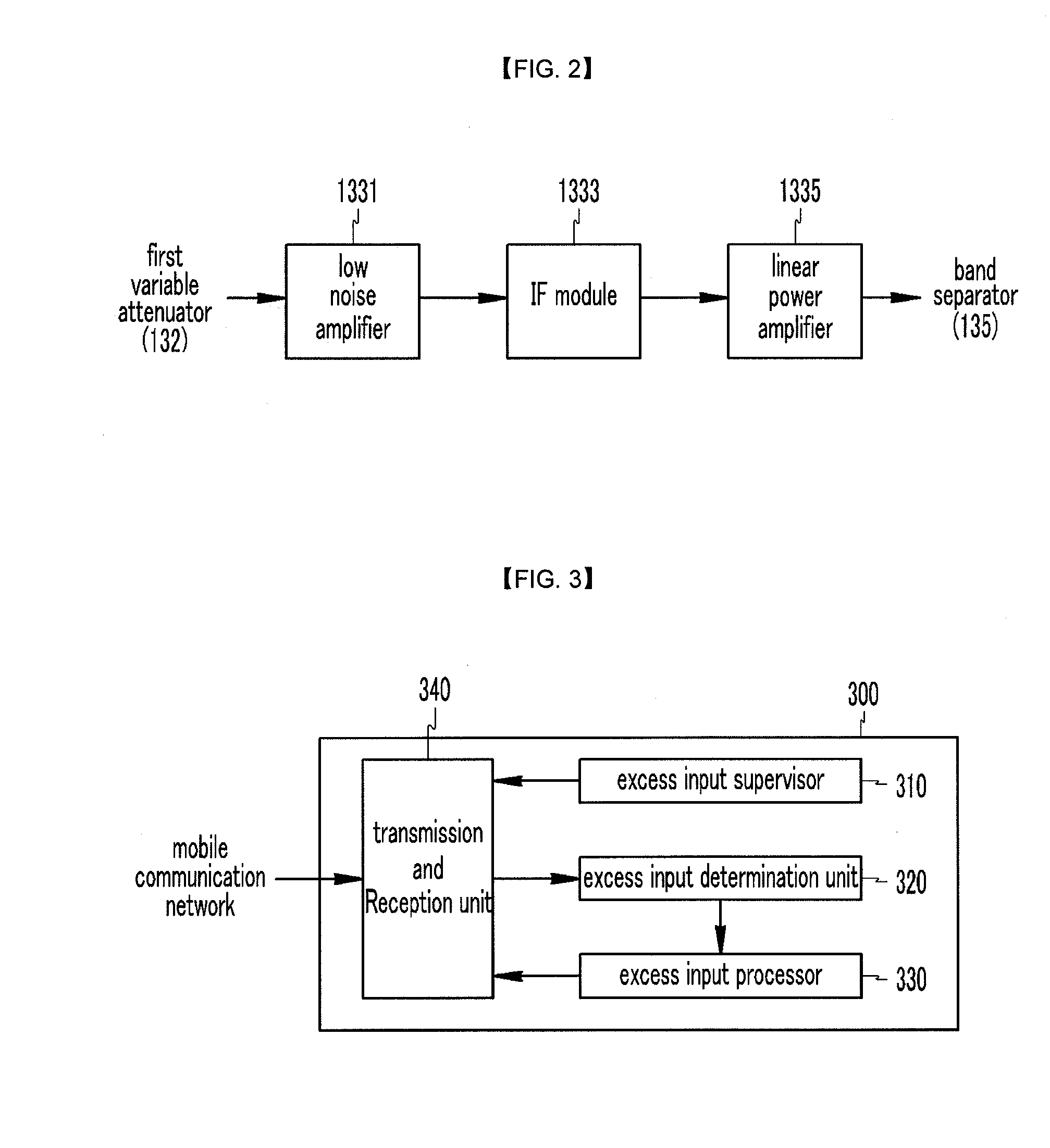

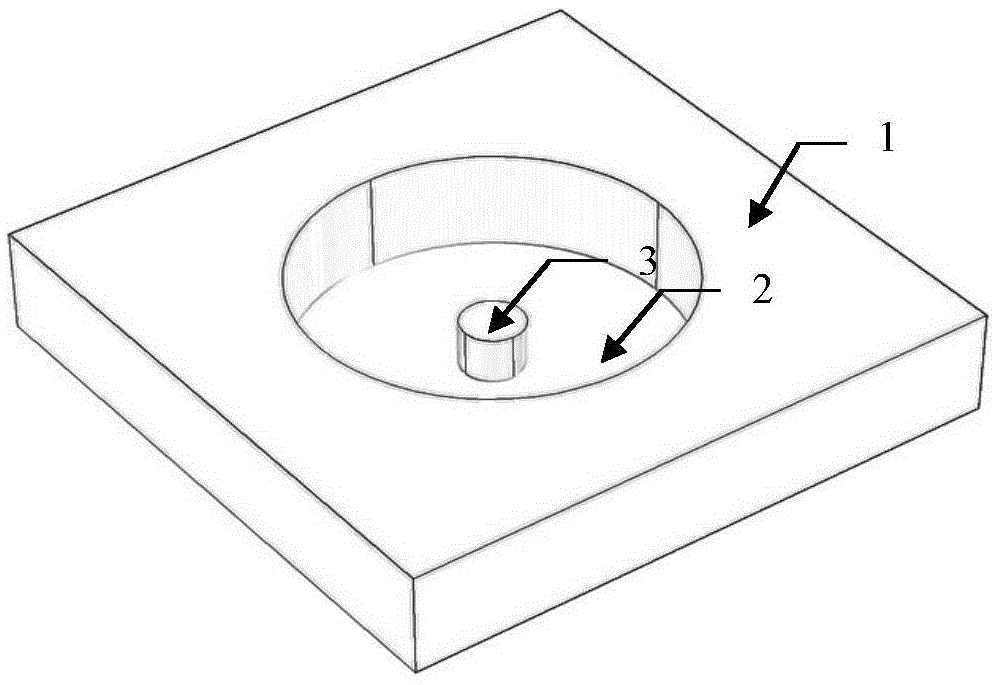

Repeater equipped with attenuator and variable attenuation method in the repeater and system for remotely managing the same

InactiveUS20100120356A1Reduce equipment investment costsReduce time and costFrequency-division multiplex detailsRepeater/relay circuitsUltrasound attenuationMobile communication network

A repeater relays at least one frequency band signal between a base station and a service side, includes at least one variable attenuator for variably attenuating each of at least one frequency band signal, variably attenuates an input signal that is received from the base station through the variable attenuator, and transfers the input signal to the service side. Further, a remote management system of the repeater communicates through the repeater and a mobile communication network and includes a repeater management server for requesting to change an attenuation value of the variable attenuator to the repeater when the input signal is an excess input signal. When an excess input signal is received in the repeater using the repeater and a remote management system of the repeater, an input signal level of the repeater can be remotely adjusted and an input signal level of the repeater can be managed without directly going out to the location, so that a maintenance cost of the repeater can be reduced.

Owner:KT CORP

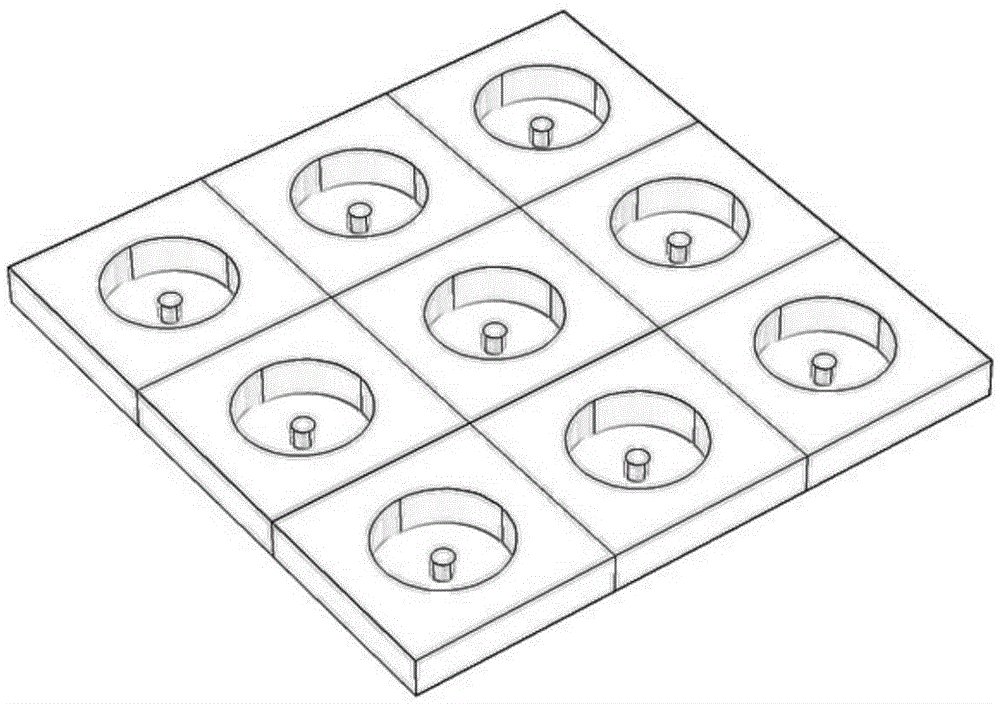

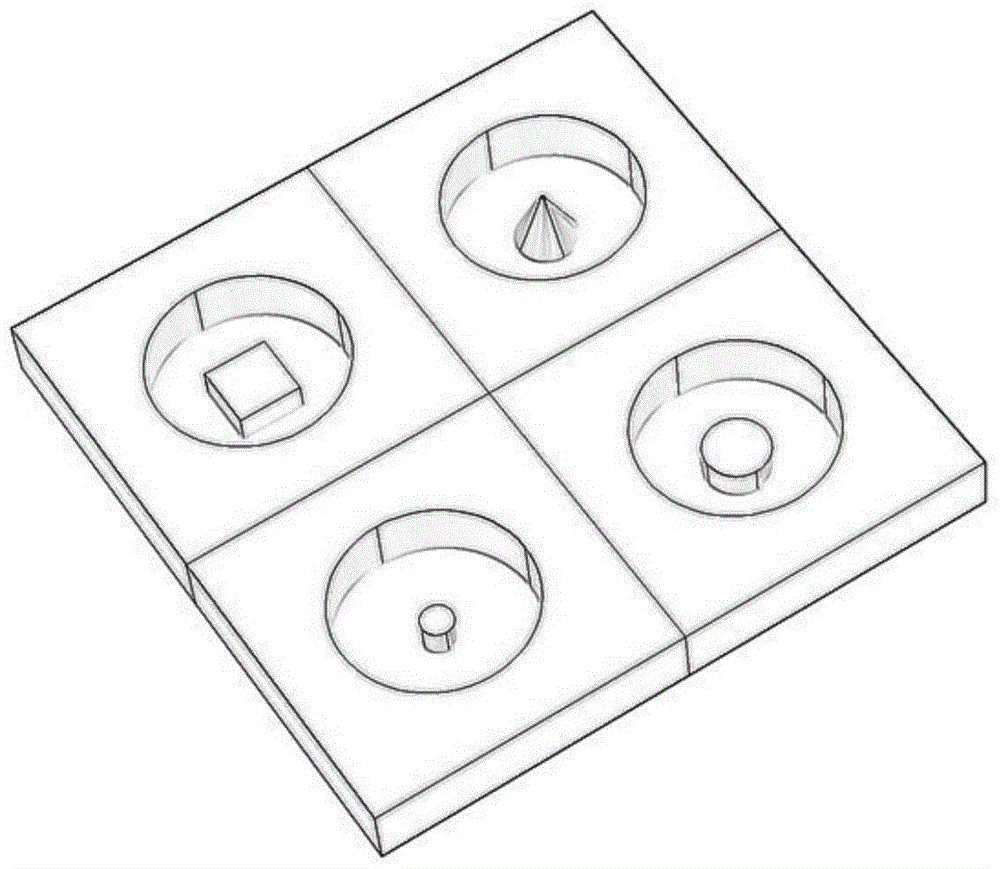

Low and medium frequency sound insulation meta-material structure prepared by 3D printing

InactiveCN104837098AReduce equipment investment costsSimple processPiezoelectric/electrostrictive transducersEngineeringMedium frequency

The invention discloses a low and medium frequency sound insulation meta-material structure prepared by 3D printing, comprising a unit body, formed by integrating a frame, a connecting body, and a center body. The unit body is composed of single materials. The center body is disposed at the center of the frame, and the connecting body is connected to the frame and the center body, and the thickness of the frame is five times or over five times of that of the connecting body. The low and medium frequency sound insulation meta-material structure prepared by 3D printing is advantageous in that with no counterweight block and no hard base body, the integral density of the meta-material will no exceed 1300kg / m3; use is rapid and convenient, device investment cost is low, process is simple, energy is saved and environment is protected, time consumed is short, and sound isolation of low and medium frequency can be realized.

Owner:SHANGHAI JIAO TONG UNIV

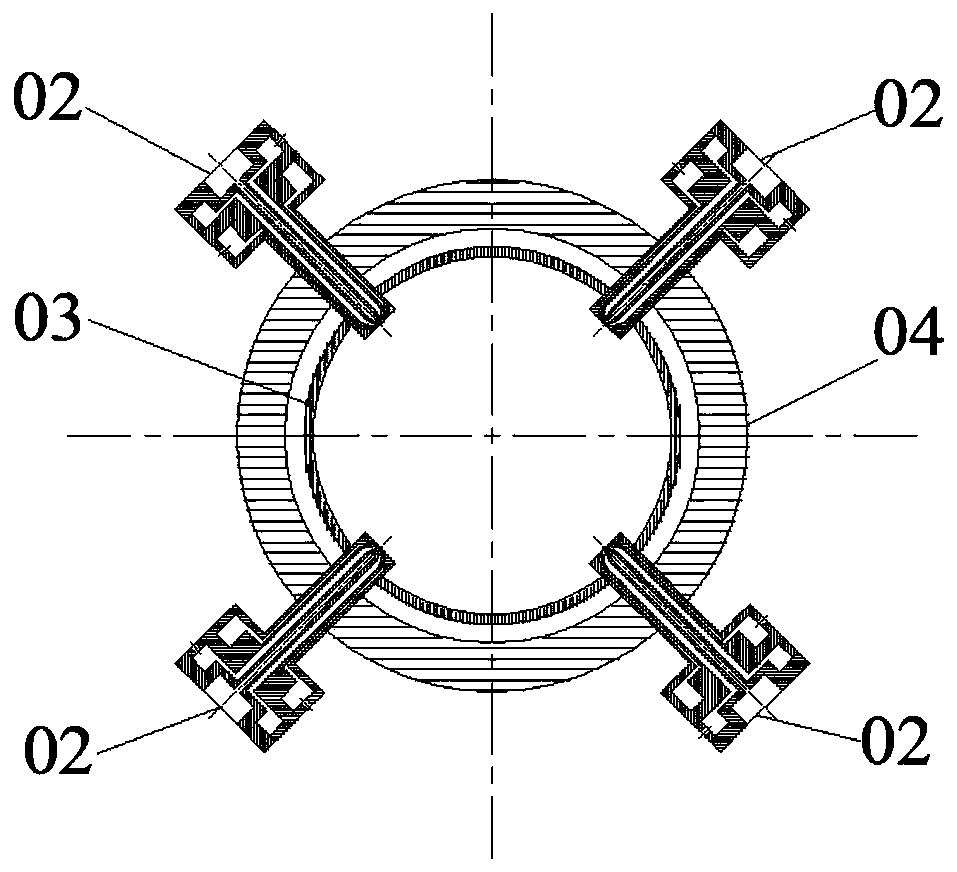

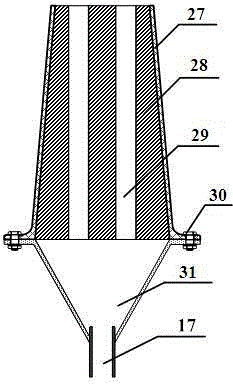

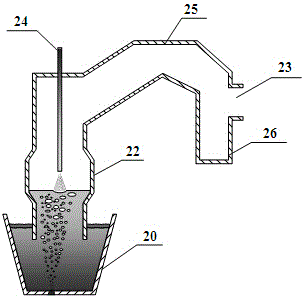

Device and method for single snorkel vacuum degassing refining of molten steel by employing bottom injection

The invention belongs to the technical field of steel refining, and particularly relates to a device and a method for single snorkel vacuum degassing refining of molten steel by employing bottom injection. The device disclosed by the invention comprise an air supply system, a powder spray system, a single snorkel vacuum degassing refining furnace, wherein an airflow distributor on the air supply system is branched into three gas circuits which are connected with the powder spray system; a powder airflow delivery pipe in the powder spray system is connected with a bottom powder injection element; the bottom powder injection element is built at the bottom of a ladle furnace of the single snorkel vacuum degassing refining furnace; and an opening is formed in the lower end of a vacuum chamber of the single snorkel refining furnace and is inserted into a steel ladle molten pool. The method for single snorkel vacuum degassing refining of molten steel by employing bottom injection comprises the following steps: firstly, blowing a gas and stirring molten steel; blowing powder into the steel ladle through the bottom powder injection element under the transportation of a carrier gas flow; and after the blowing time is ended, entering the next work circle. The device and the method are easy to achieve, short in production cycle, and high in production capacity; equipment investment and operation costs on an overhead bunker and a wire feeding mechanism are reduced; the technological operation is simple; and energy conservation and emission reduction are facilitated.

Owner:NORTHEASTERN UNIV

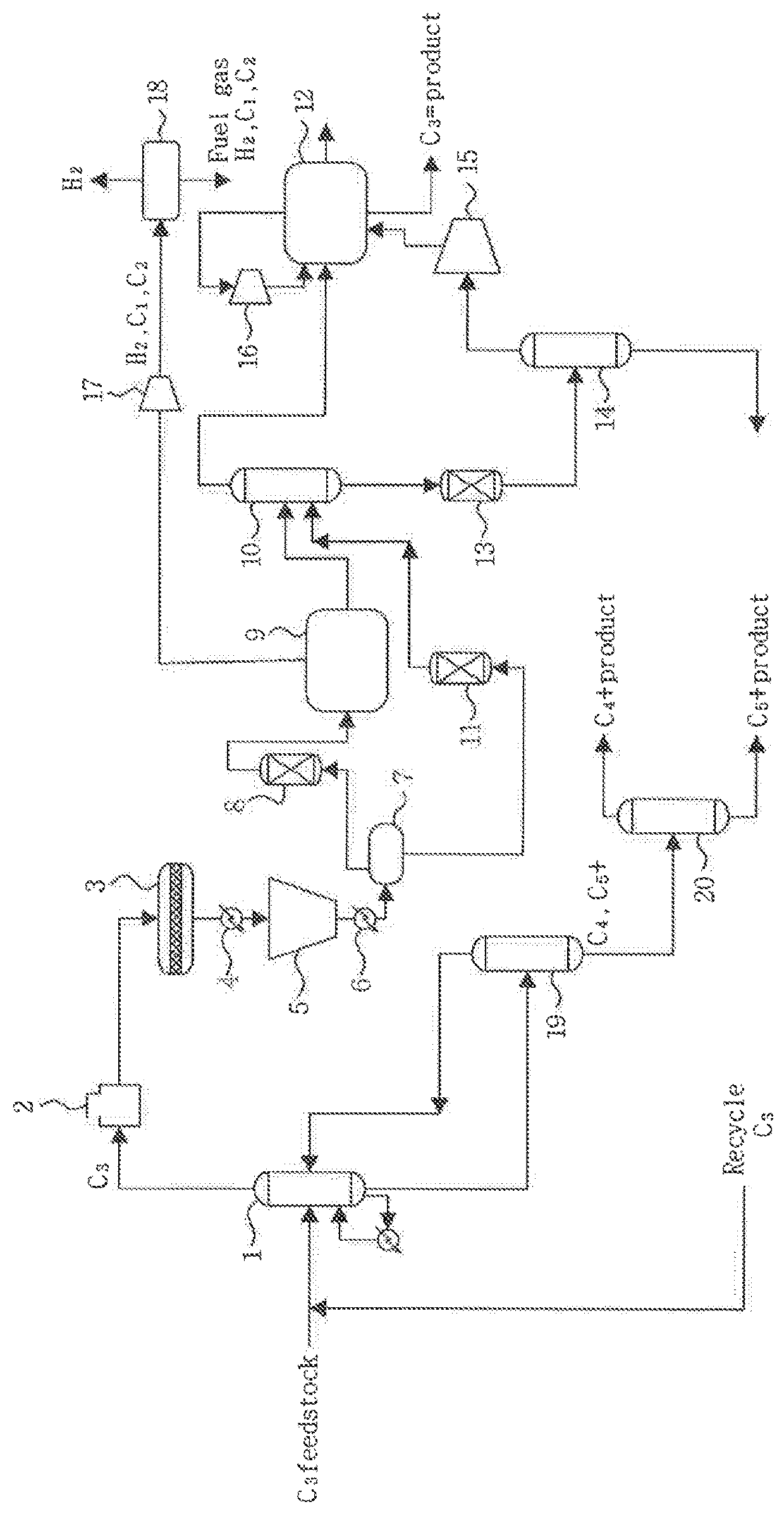

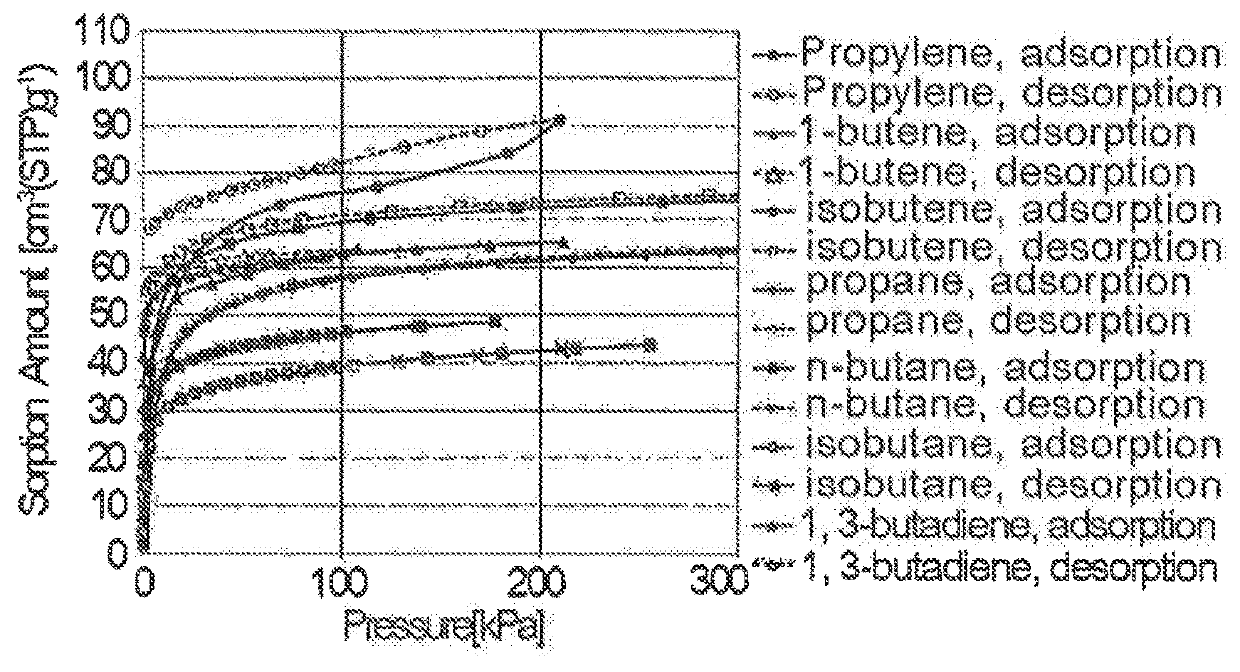

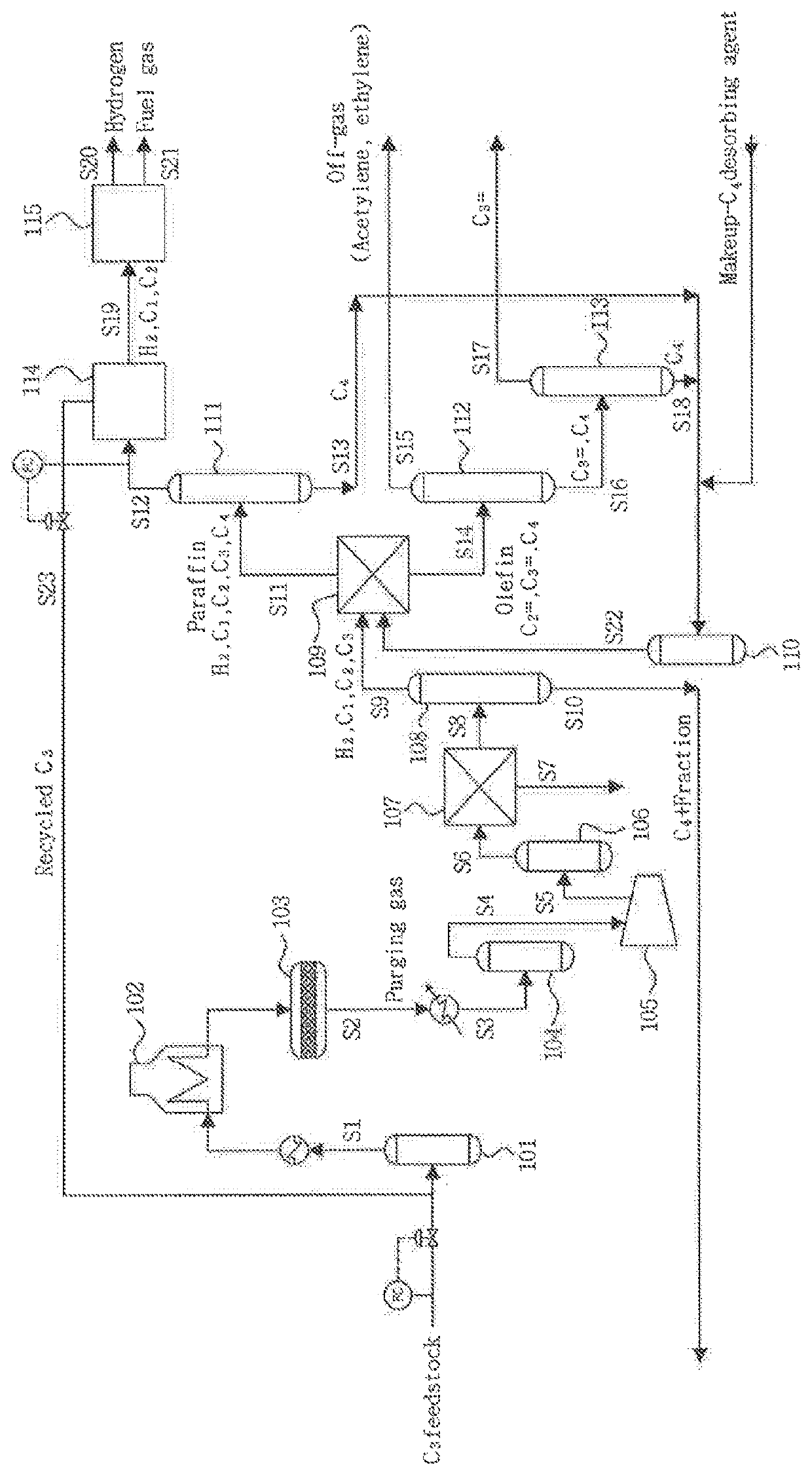

Method for separating propylene from dehydrogenation reaction products of propane-containing feedstock

ActiveUS20180265430A1Reduce investment costIncrease energy efficiencyGas treatmentDispersed particle separationChemistrySeparation process

An embodiment of this invention provides a method of effectively producing propylene by separating reaction products obtained by dehydrogenating propane-containing feedstock, using an adsorption process in lieu of conventional low-temperature separation processes.

Owner:GAS CO

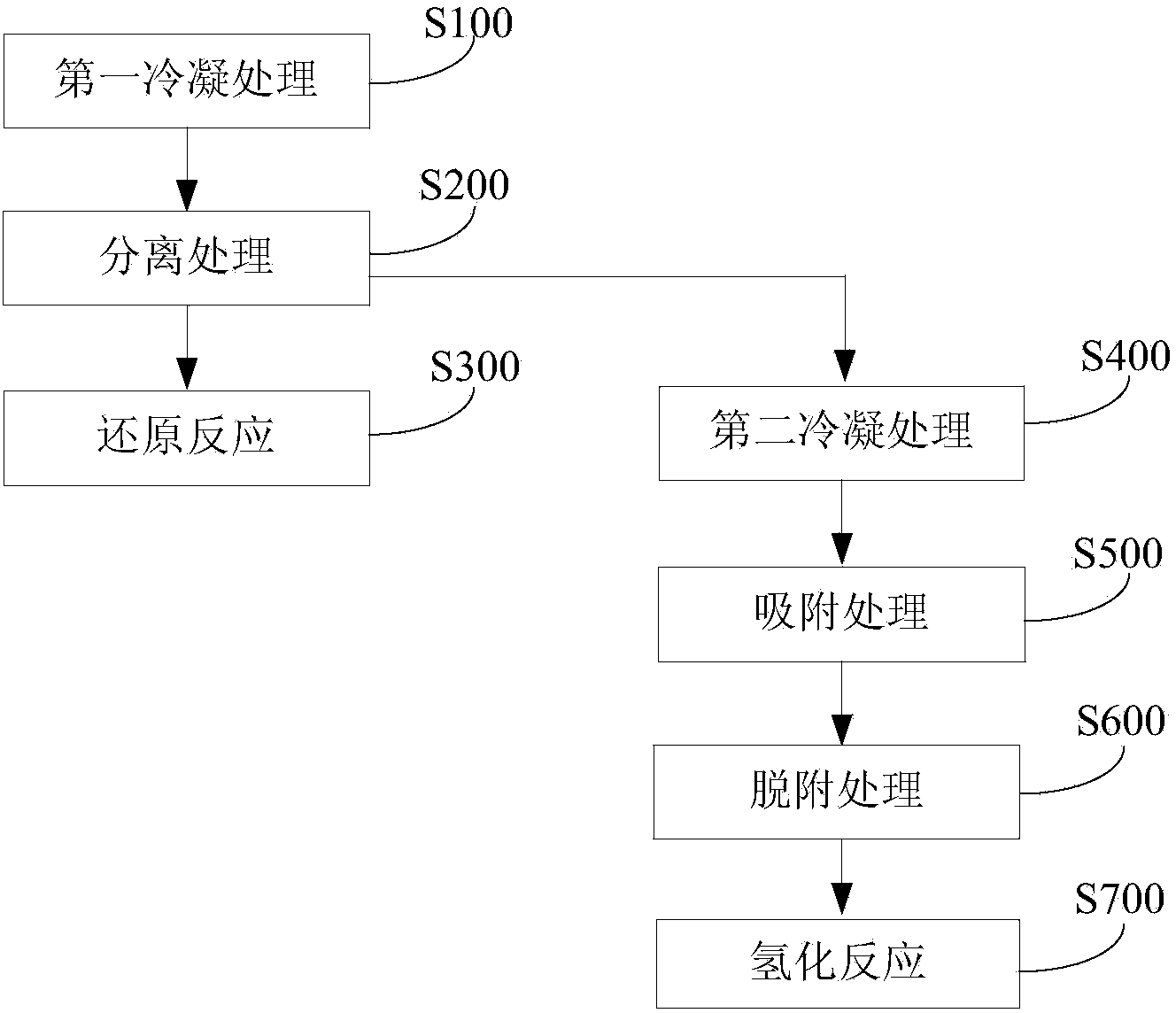

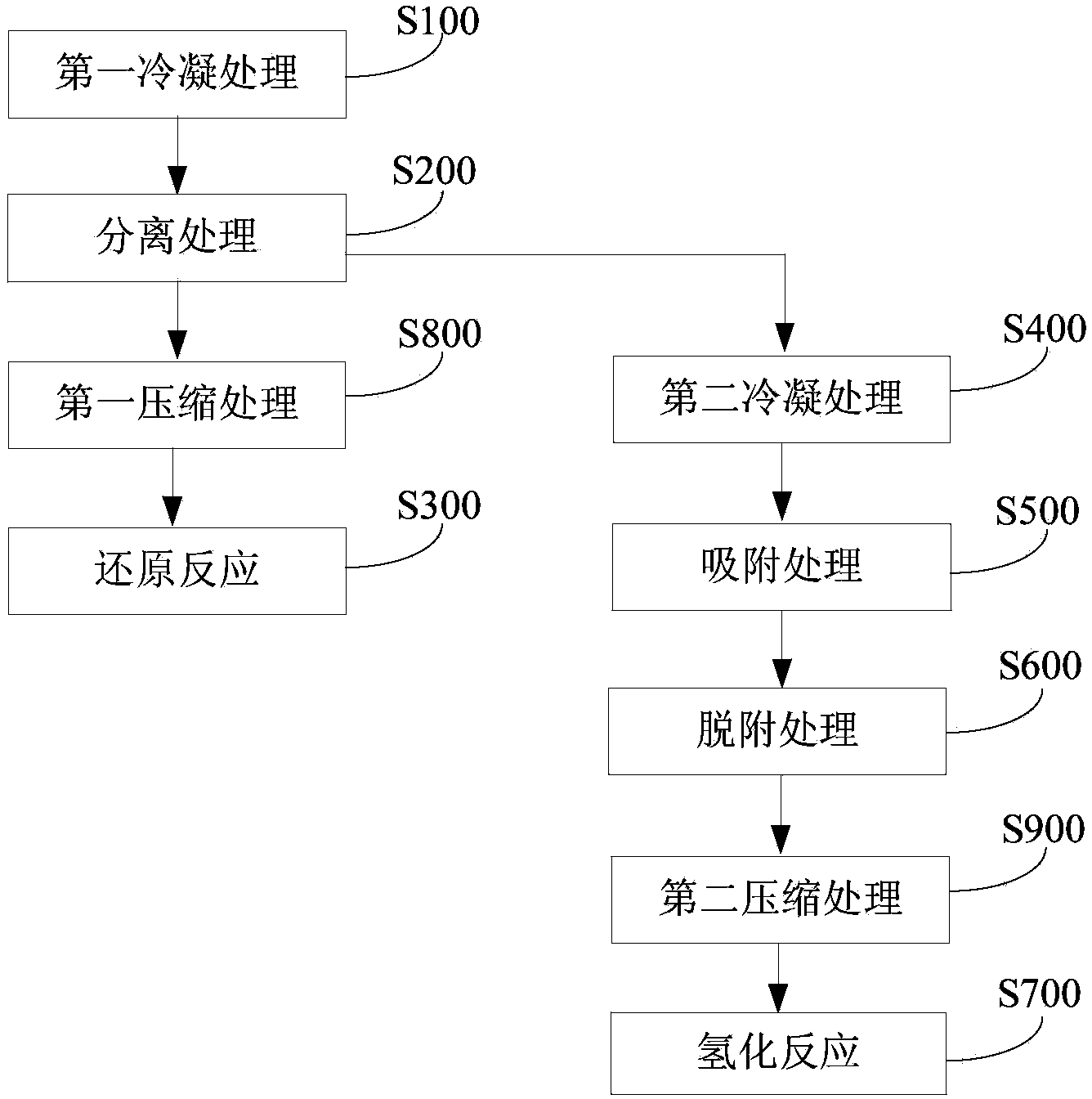

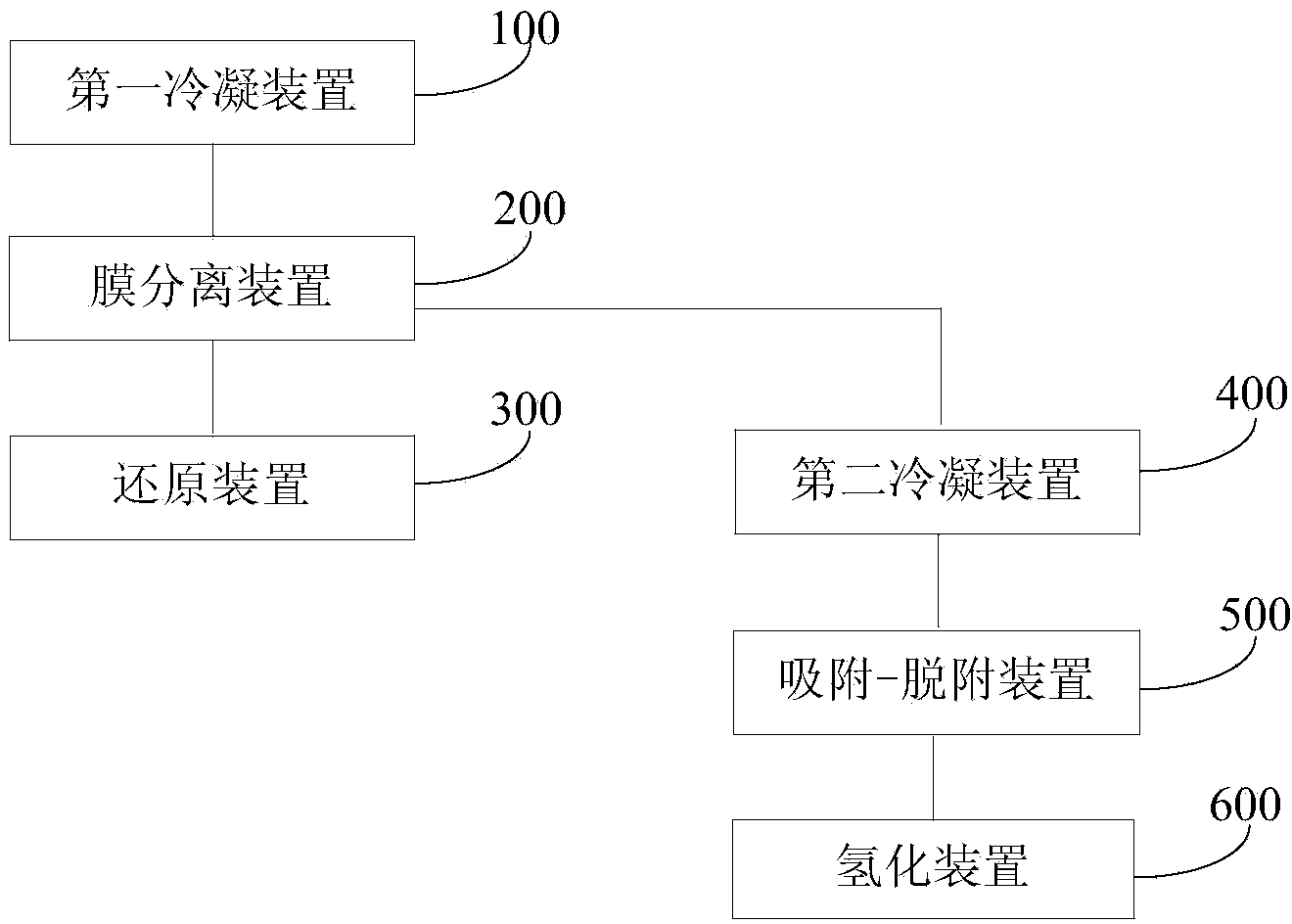

Method for treating polycrystalline silicon reduction tail gas

ActiveCN104140106AHandle large scaleAchieve recyclingHalogenated silanesDesorptionHydrogenation reaction

The invention discloses a method for treating polycrystalline silicon reduction tail gas. The method comprises the steps that (1), primary condensing is carried out on the polycrystalline silicon reduction tail gas, (2), a membrane separator is adopted for separating the polycrystalline silicon reduction tail gas treated through primary condensing, so that hydrogen and mixed gas are respectively obtained; (3), the hydrogen is supplied to a reducing furnace to be subjected to reduction reaction with trichlorosilane; (4), secondary condensing is carried out on the mixed gas to obtain chlorosilane condensate and non-condensable gas; (5), adsorbing is carried out on the non-condensable gas to obtain the hydrogen and adsorbing agents for adsorbing chlorosilane and hydrogen chloride, and a part of the hydrogen is supplied to the reducing furnace; (6), the other part of the hydrogen in the step (5) is adopted for carrying out desorption on the adsorbing agents for adsorbing the chlorosilane and the hydrogen chloride to obtain a mixture containing the chlorosilane and the hydrogen chloride; (7), the mixture and silicon tetrachloride are subjected to hydrogenation reaction. The method can remarkably reduce energy consumption and the equipment investment cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

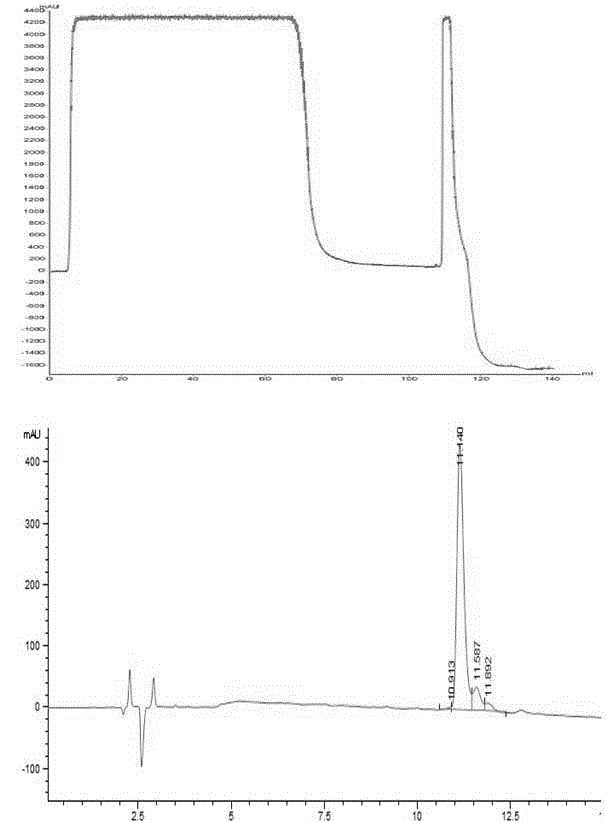

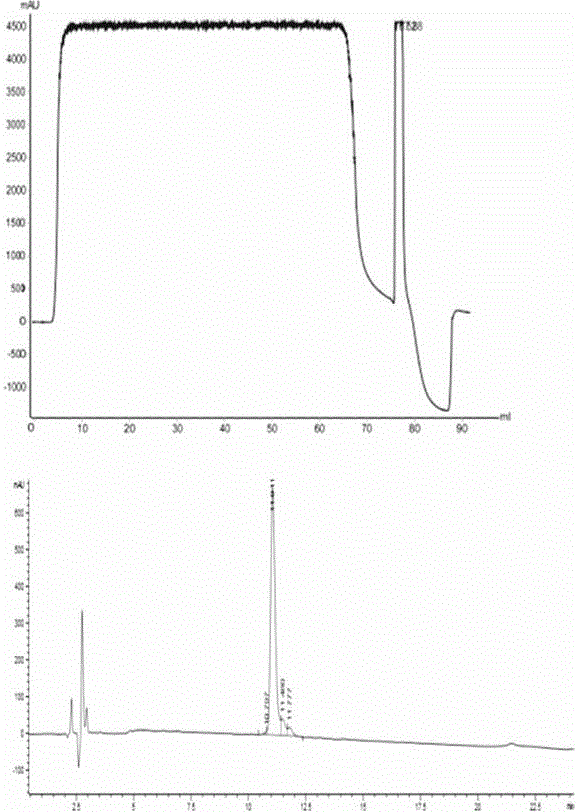

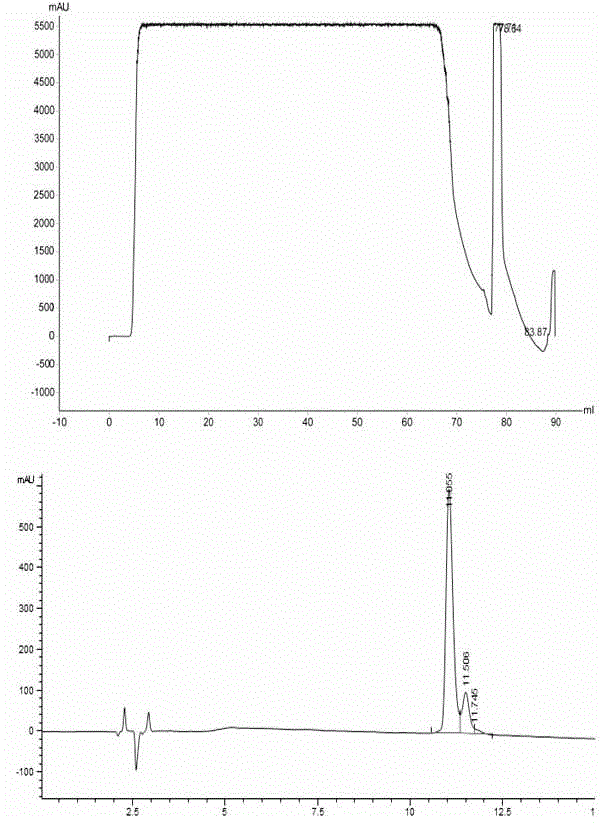

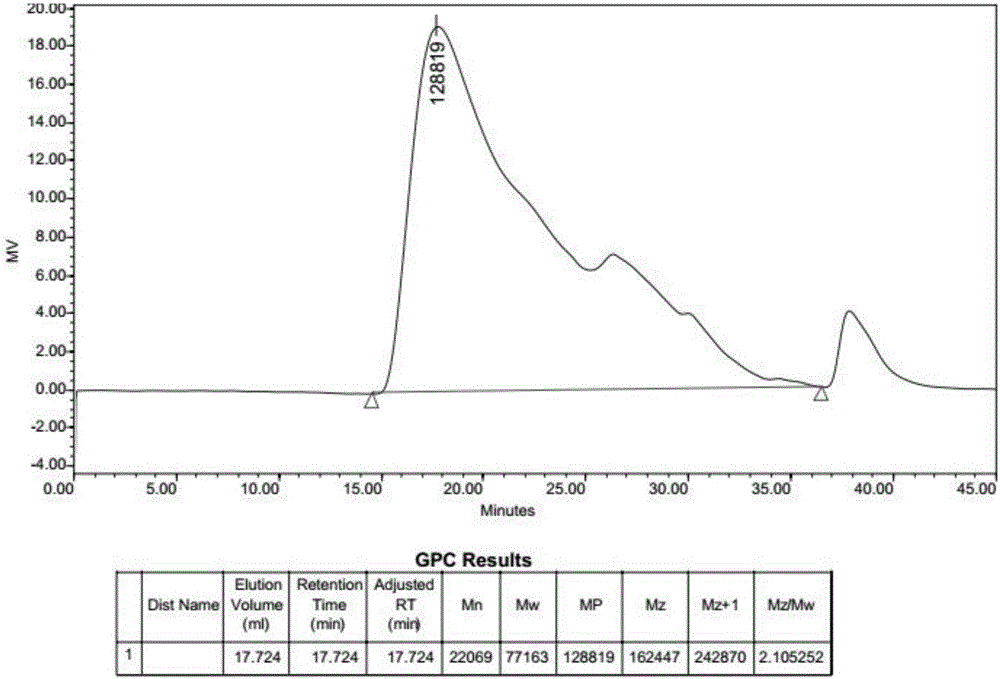

Recombinant insulin and insulin analogue precursor purification method

InactiveCN105153294AGood technical effectAvoid time costPeptide preparation methodsInsulinsPurification methodsCentrifugation

The invention relates to the field of insulin production methods and discloses a recombinant insulin and insulin analogue precursor purification method. The invention solves the problems that conventional chromatographic packing cannot tolerate high-salinity sample loading, the amount of used organic reagent is great, the cost is high and the product purity is not high in the purification process of recombinant expressed insulin precursors and insulin analogue precursors. The invention adopts the technical scheme that the method comprises the steps of performing pH regulation and centrifugation to centrifuged fermentation supernatant, then directly loading a sample and performing adsorption, separation, purification and elution through a chromatographic column prepared by using any packing of Capto S, Capto MMC, Uni PMM S and Uni MSP to finally obtain high-purity recombinant insulin and insulin analogue precursors. Compared with the existing purification method, the recombinant insulin and insulin analogue precursor purification method has the advantages that the operation is simple, the yield is high, the spent time is short, the environmental influence is small, and the product production cost of the existing insulin and insulin analogues can be greatly reduced.

Owner:JINAN KANGHE MEDICAL TECH

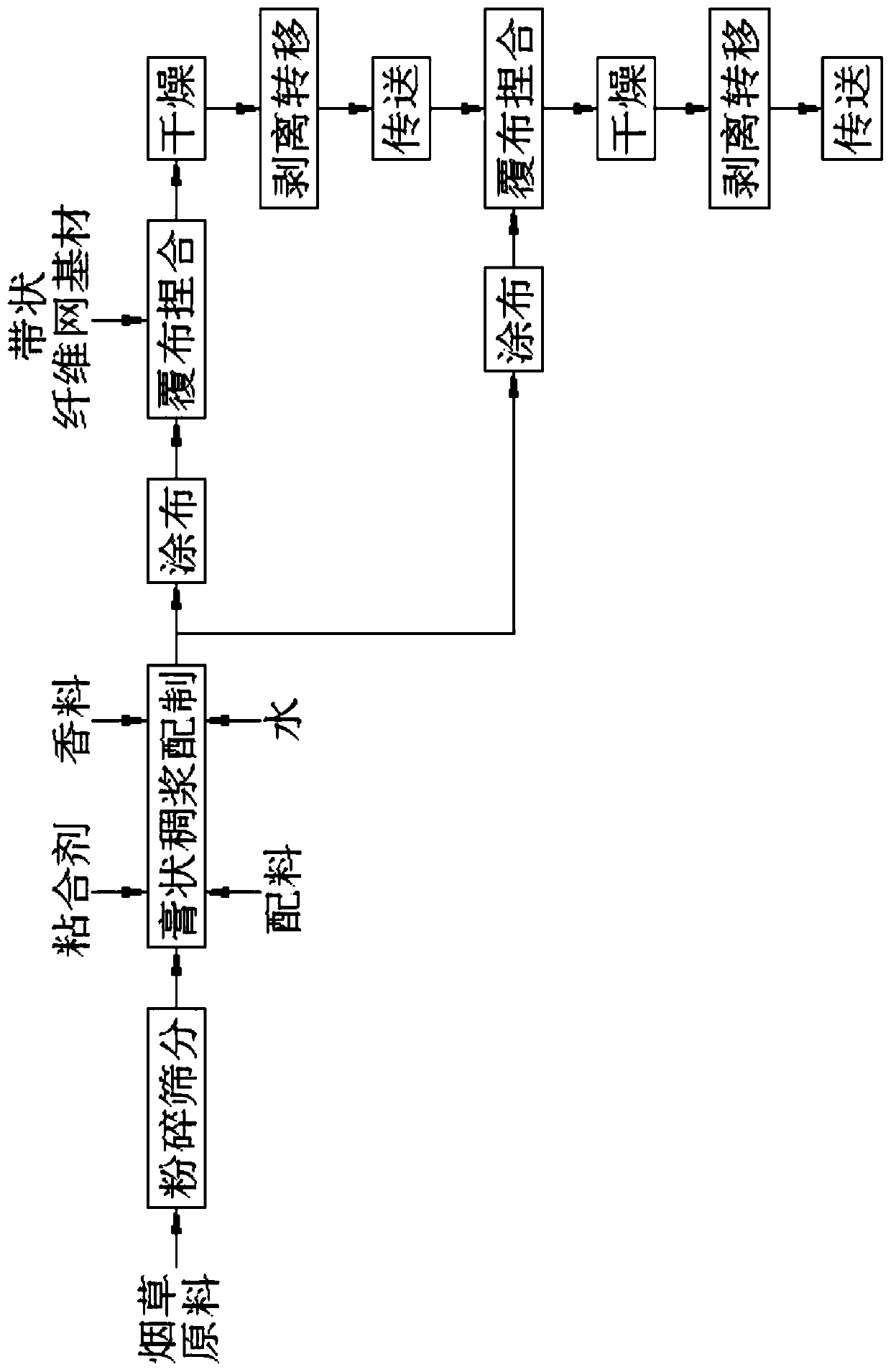

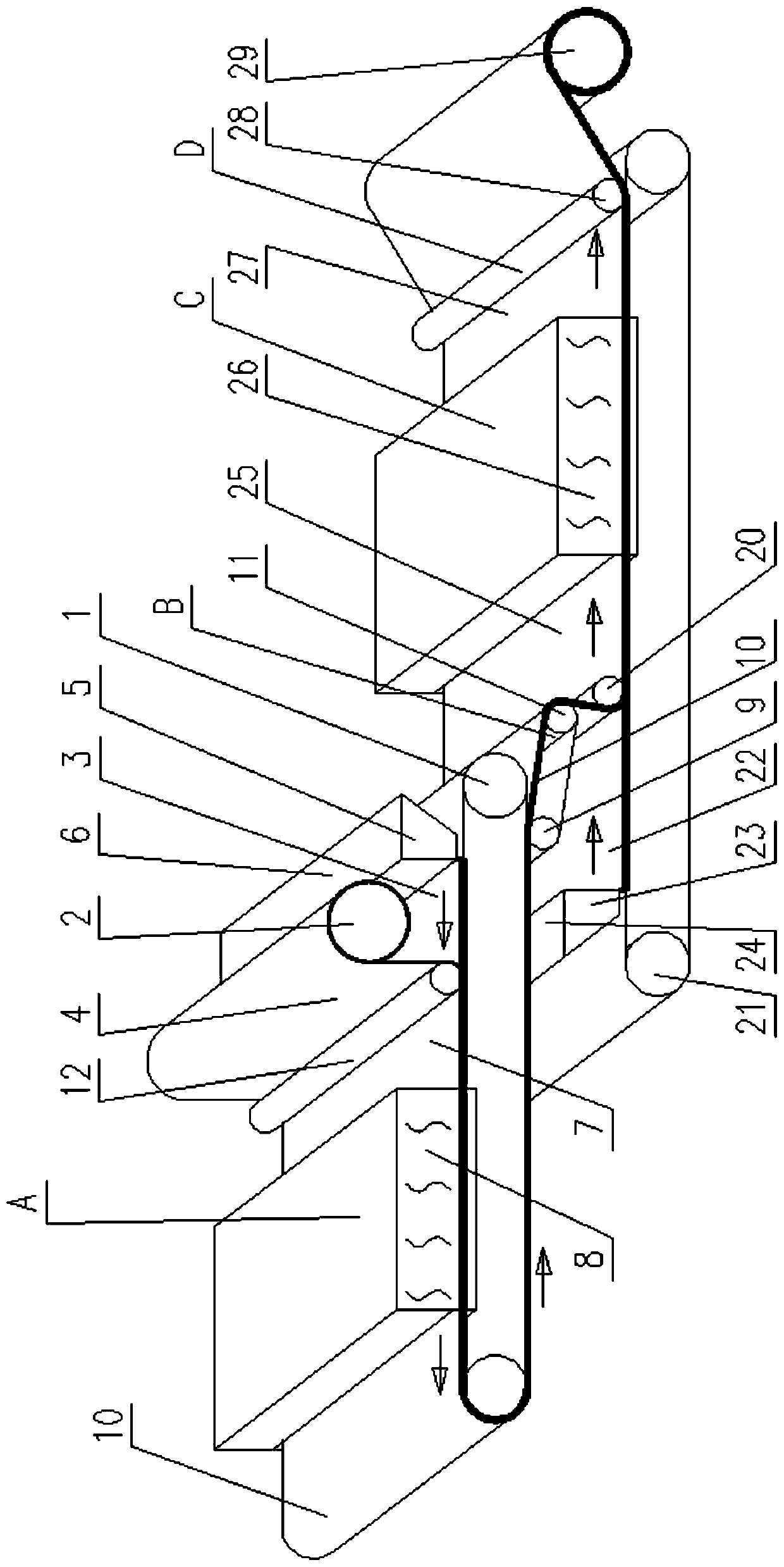

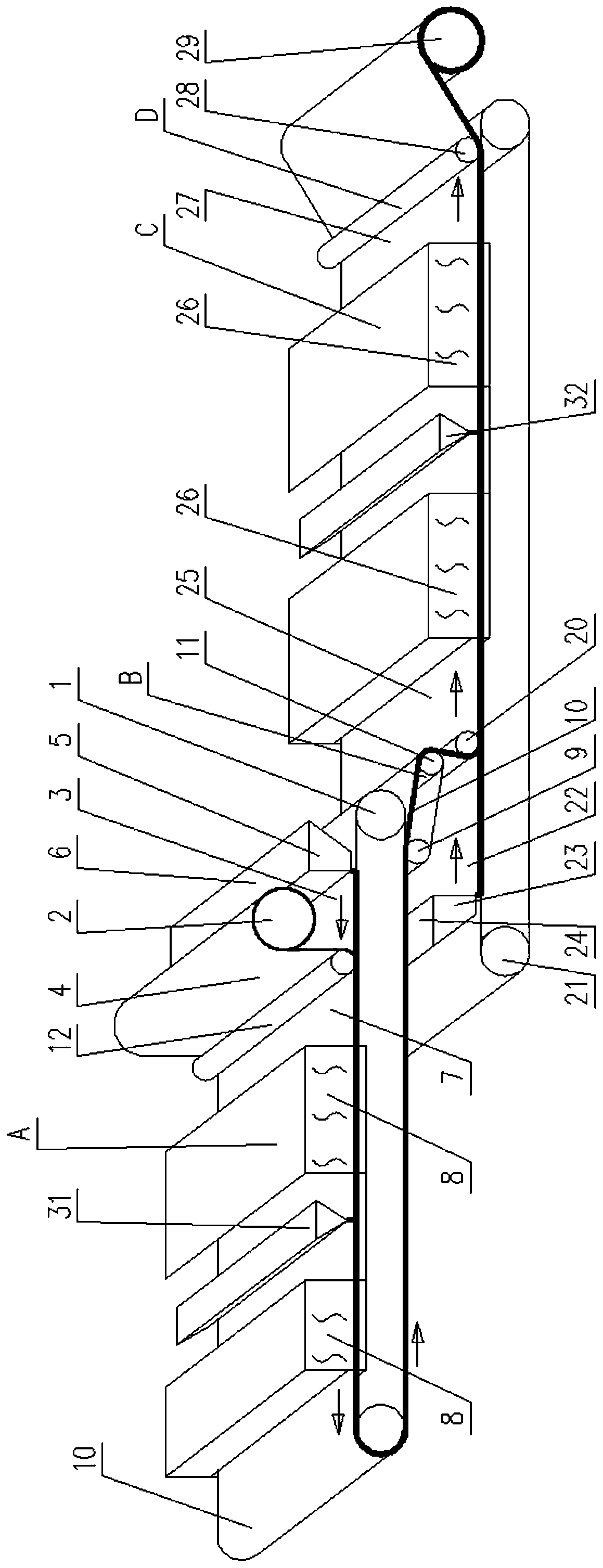

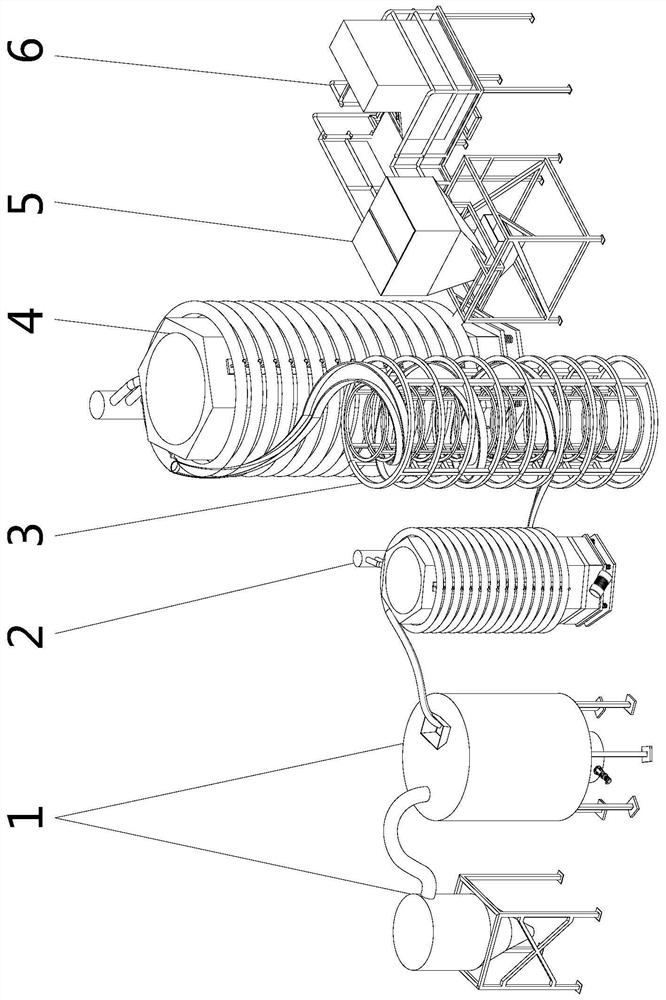

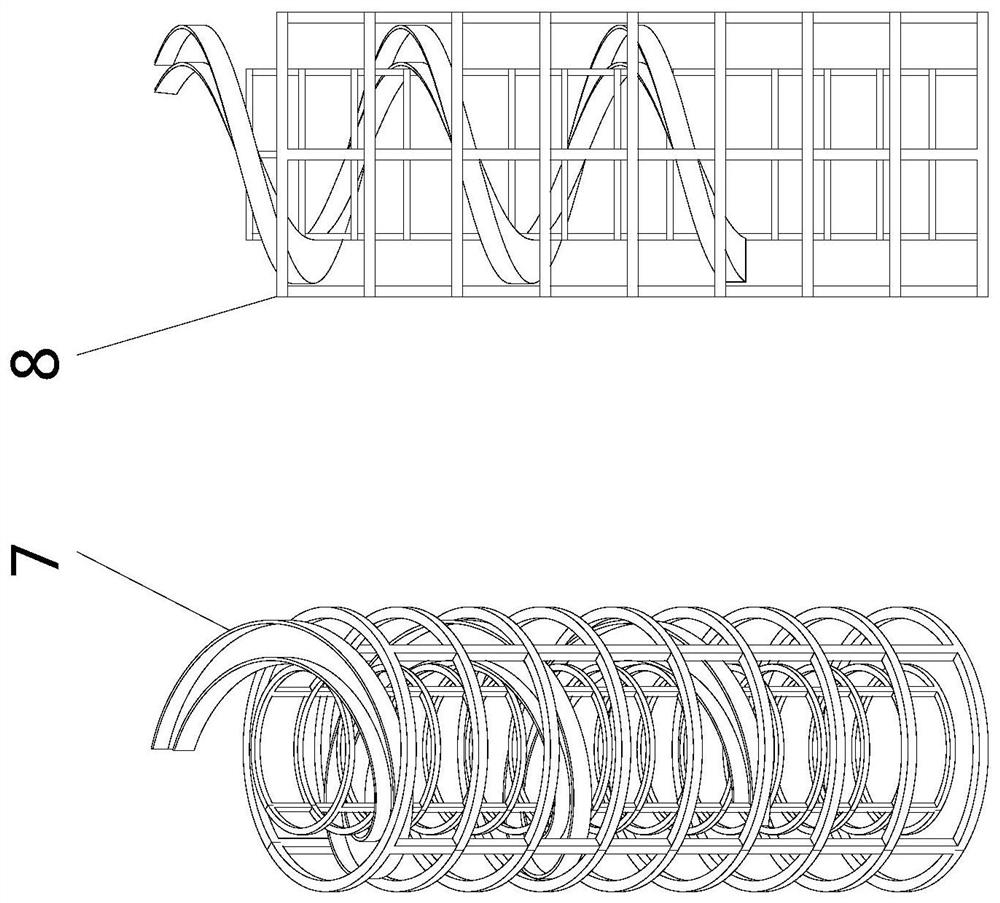

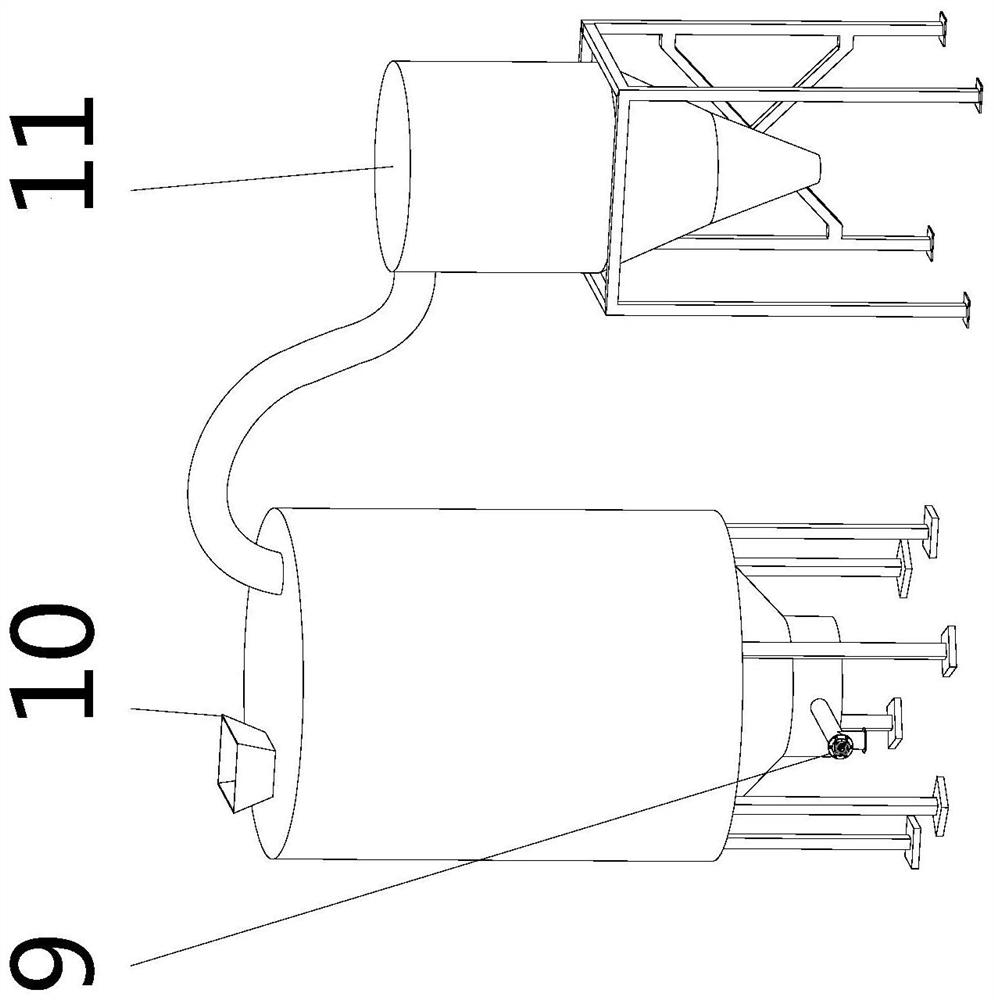

Forming method and forming equipment for ternary composite reconstituted tobacco sheets

PendingCN111134352AReduces the effects of odor inhalationImprove physical strengthTobacco preparationTobacco treatmentFiberPowder mixture

The invention relates to a forming method and forming equipment for ternary composite reconstituted tobacco sheets. The equipment comprises a primary coating composite device, a primary stripping conveying device, a secondary coating composite device and a secondary stripping conveying device. The method comprises the following steps of: coating a tobacco mixture on a first conveying surface in acoating and compounding manner to form a strip-shaped slurry sheet, and coating a fiber net-shaped base material on the surface of the strip-shaped slurry sheet under the condition of smaller tensionto form a strip-shaped binary compound reconstituted tobacco sheet, coating the secondary conveying surface with the tobacco mixture, and coating the surface of the strip-shaped slurry sheet with thestrip-shaped binary composite reconstituted tobacco sheet under the condition of small tension to form the ternary composite reconstituted tobacco sheet. The middle layer of the produced reconstitutedtobacco sheet is a prefabricated strip-shaped fiber net base material, the upper layer and the lower layer are tobacco powder mixtures, the coating rate can be increased, the cigarette smell can be improved, the consistency of finished products can be improved, the tensile strength can be improved, the thickness can be reduced, and the processability can be enhanced.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

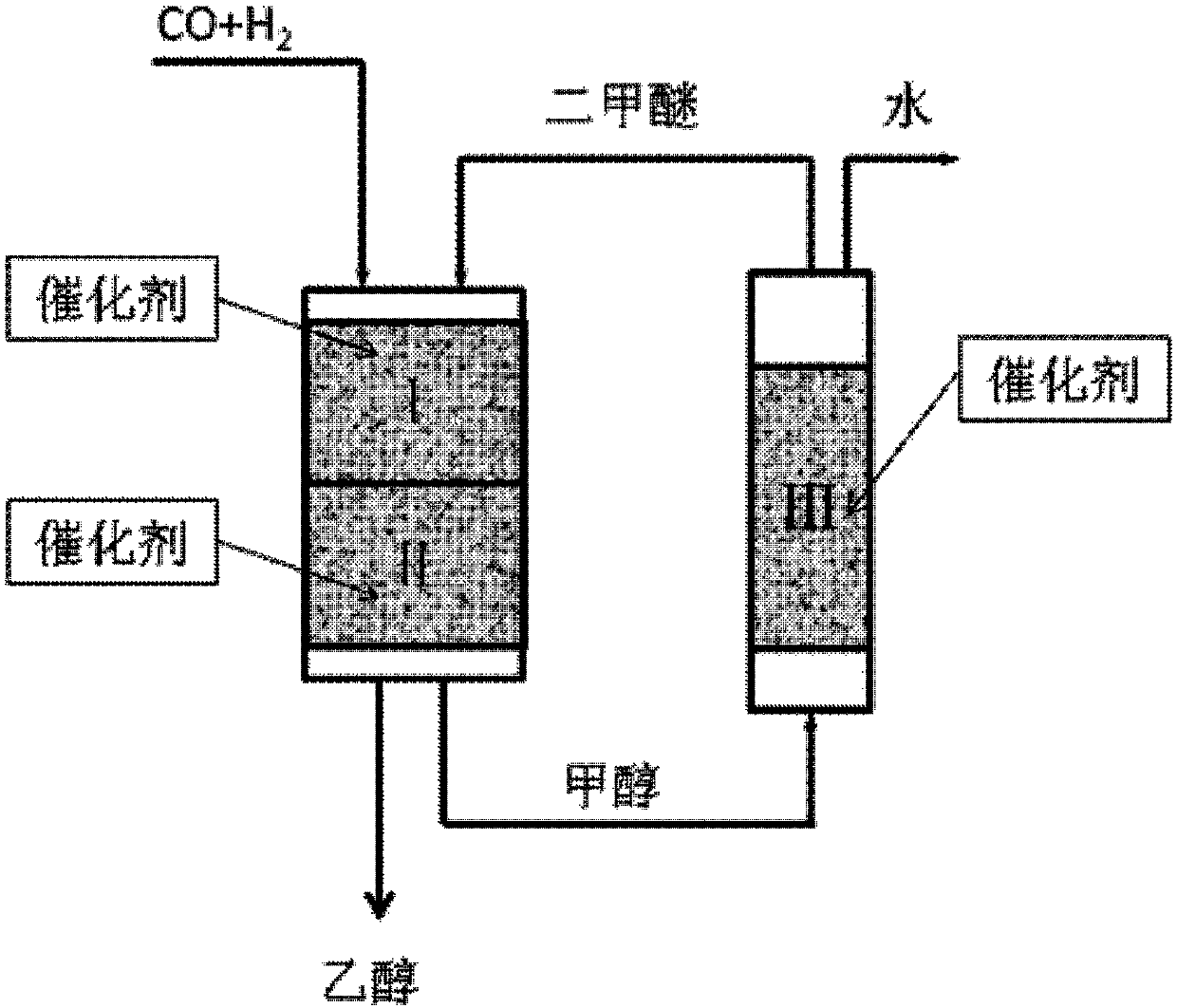

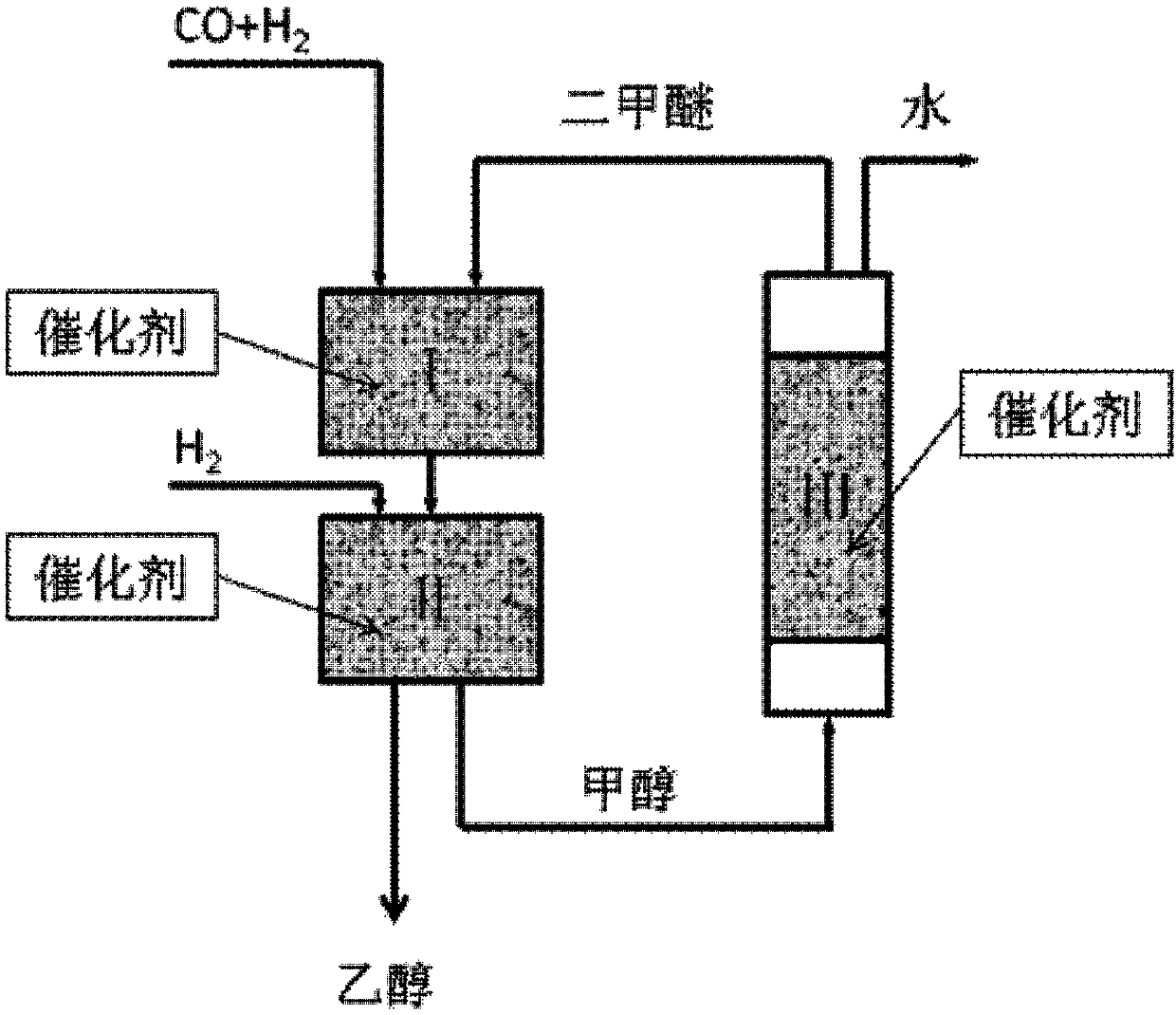

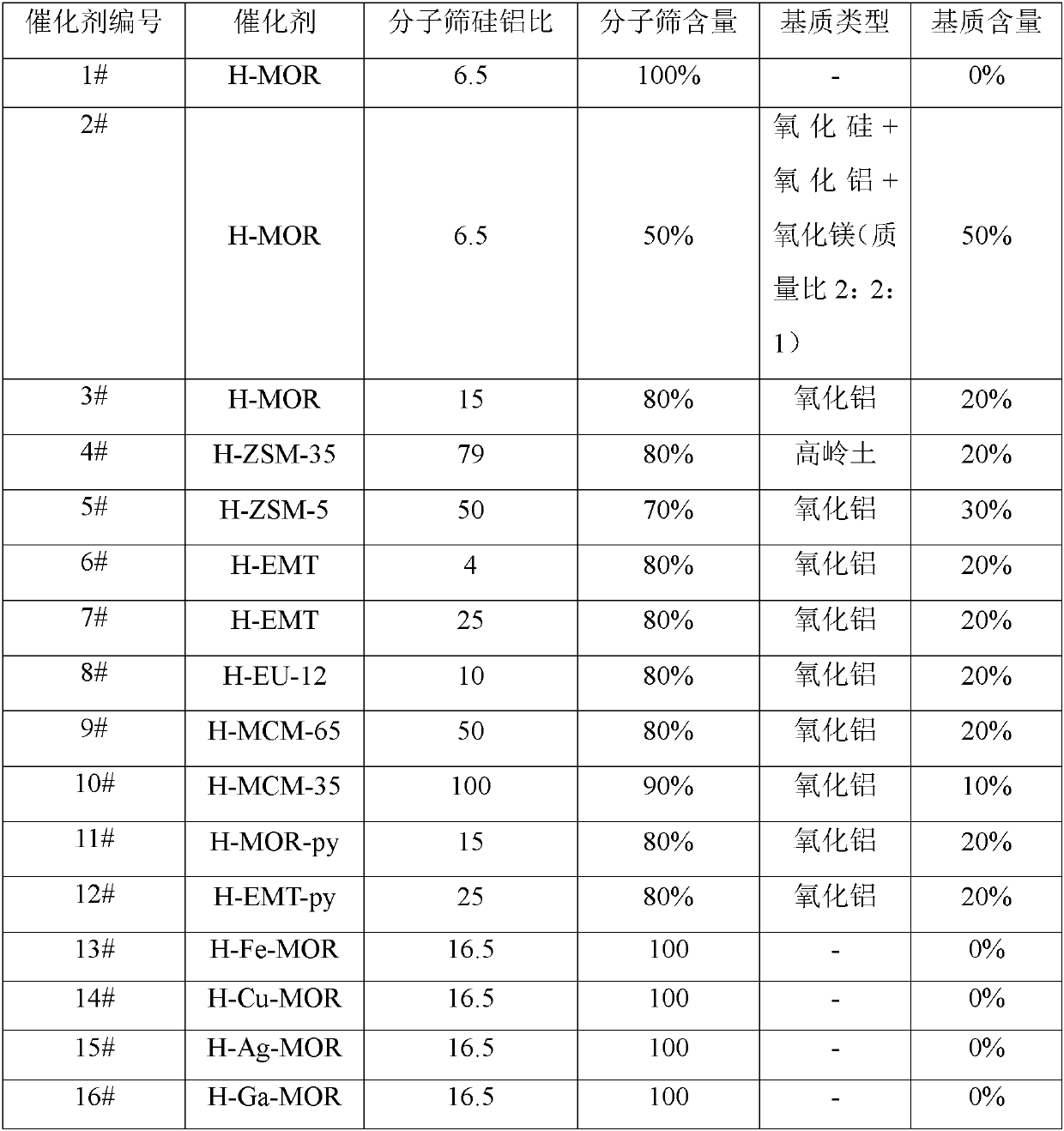

Method for directly producing ethyl alcohol by synthesis gas

PendingCN109574798AReduce equipment investment costsReduce energy consumptionOrganic compound preparationHydroxy compound preparationChemistryDirect production

The invention discloses a method for directly producing ethyl alcohol by synthesis gas. Reaction processes are completed in three reaction areas. The method includes the steps: enabling the synthesisgas and dimethyl ether to enter a first reaction area to perform contact reaction on mixture and solid-acid catalysts; enabling effluents from the first reaction area to enter a second reaction area to perform contact reaction on the effluents and metal catalysts; separating effluents from the second reaction area to obtain product ethyl alcohol by-product methyl alcohol; enabling the by-product methyl alcohol to enter a third reaction area to perform dehydration reaction to obtain dimethyl ether, and enabling the acquired dimethyl ether to enter the first reaction area to perform circular reaction. By the novel method for directly producing the ethyl alcohol by the synthesis gas, an ethyl alcohol product can be directly produced by taking the synthesis gas as a raw material, and the method is simple in process, low in energy consumption and production cost and high in product selectivity and has a great industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

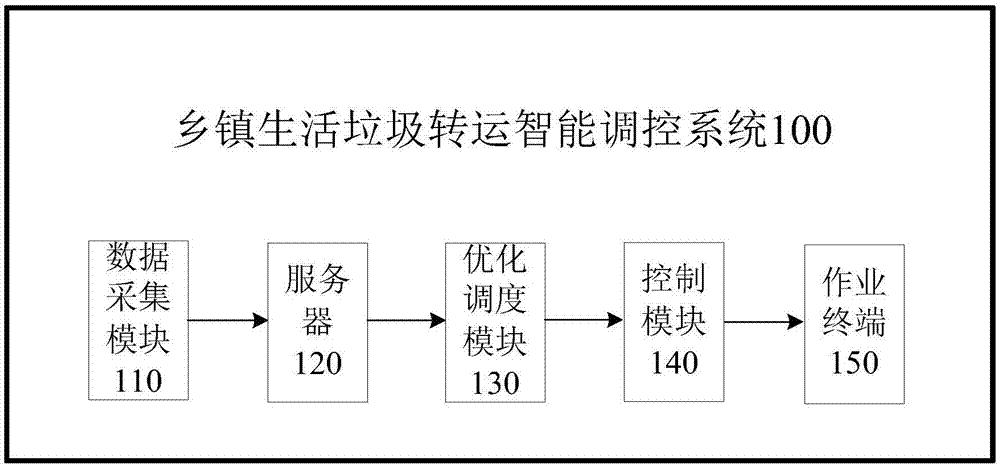

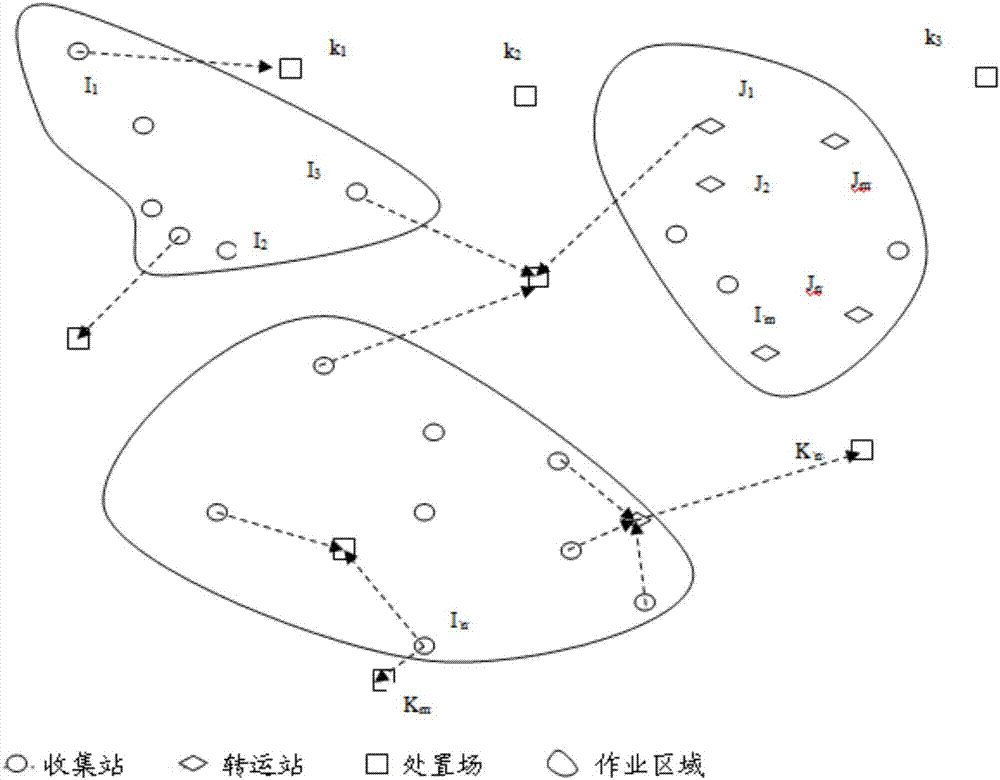

Rural town household refuse transfer intelligent regulation and control system

InactiveCN106875040AImprove transport efficiencyReal-time control of job contentForecastingControl systemGeolocation

The invention provides a rural town household refuse transfer intelligent regulation and control system, including a data collection module, a server, an optimized scheduling module and a control module. The data collection module obtains the operation information of a collection station, the operation information of a transfer station, the operation information and the real-time location information of a transfer vehicle, the geographical location map and the traffic information of an area, the geographical coordinates of the collection station, the transfer station and a disposal site, and the operation information of the disposal site. The server receives the information obtained by the data collection module and transmits the information to the optimized scheduling module. The optimized scheduling module carries out optimized calculation according to the information transmitted by the server, obtains the optimal transfer strategy of the transfer vehicle, and sends the optimal transfer strategy to the control module. The control module generates a corresponding operation instruction hereby and sends the operation instruction to an operation terminal. The system can optimize the refuse transfer and equipment scheduling, take real-time measures according to the operation states of the collection station, the transfer station and the disposal site, reduce the suspension and ineffective operation, and plan the optimal transfer strategy, thereby reducing the burden of labor and the cost and improving the refuse transfer efficiency.

Owner:TSINGHUA UNIV

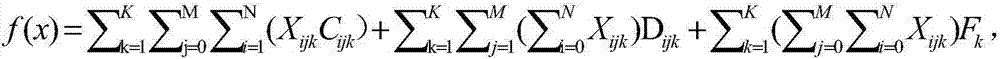

Economical, clean, simple and convenient method for leaching cobalt from high-valence cobalt oxides

ActiveCN103882226ASimplify the leaching processReduce production energy consumptionProcess efficiency improvementSlagLeaching rate

The invention discloses an economical, clean, simple and convenient method for leaching cobalt from high-valence cobalt oxides, and relates to a technology of leaching cobalt from cobalt oxide ores such as asbolite. According to the method disclosed by the invention, a carbon elementary-substance cobalt leaching agent without environmental pollution, which is not used yet at home and abroad, is used by aiming at shortages existing in the prior art, the cobalt leaching agent is low in price, material-saving, ubiquitous, and capable of leaching the high-valence cobalt oxides until the cobalt content of slag is about 0.02% in case of being simply poured in a leaching tank, and the cobalt leaching rate achieves 98%. During the leaching process, gases harmful to environment, such as SO2 and Cl2 are not generated, and the technical process is simplified, so that the method is an economical, clean, simple and convenient method for leaching cobalt from high-valence cobalt oxides.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

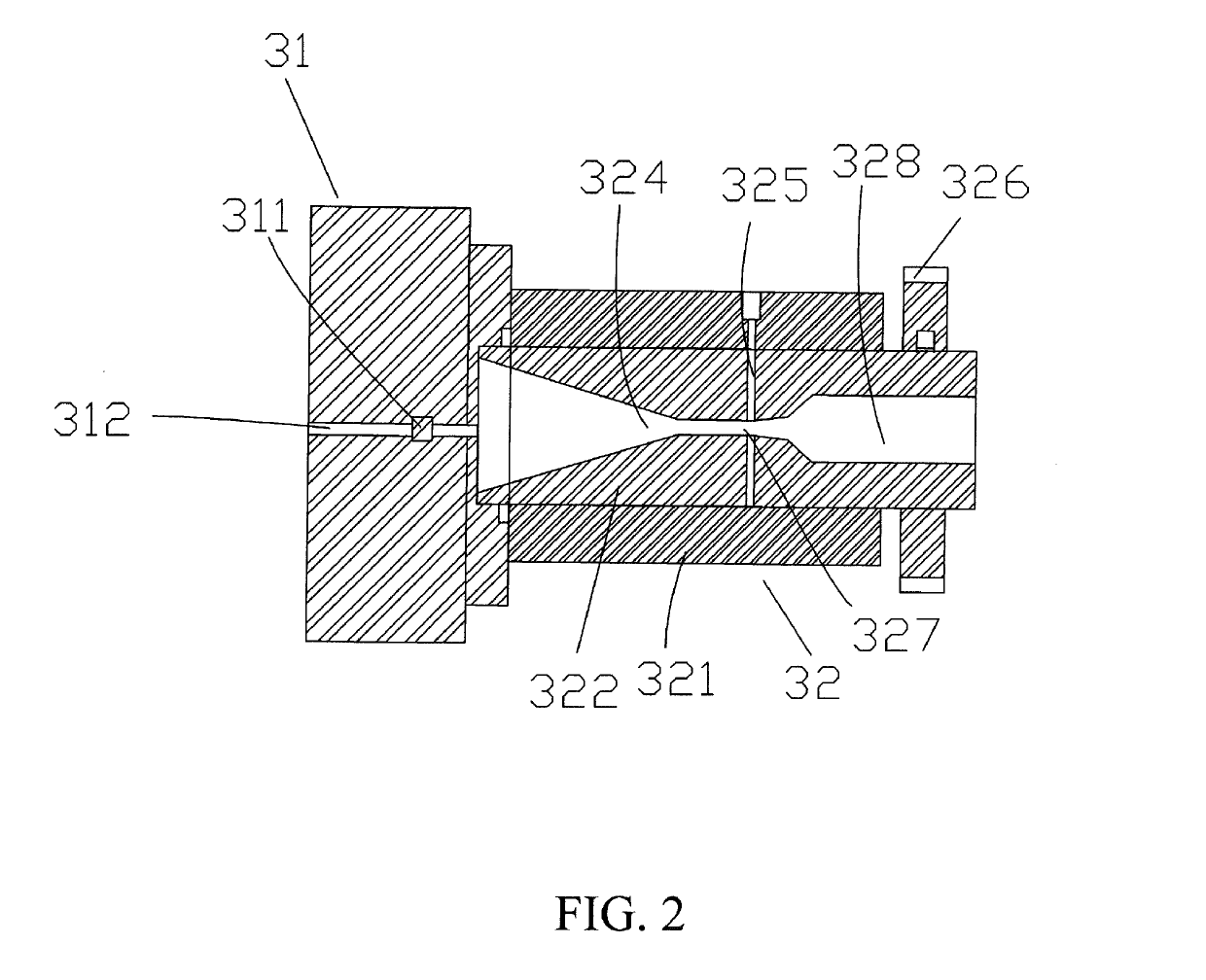

Injection molding machine for manufacturing spiral bicolor LED hose light

ActiveUS20190210258A1Increase productivitySaves equipment investment costElectric lightingDomestic articlesSingle processInjection molding machine

An injection molding machine for manufacturing the spiral bicolor LED hose light just needs a single process and equipment to greatly increase the production efficiency and save the equipment investment costs. The input channel terminal of the second flow channel connected with a first horizontal channel is gradually smaller, and the transportation end terminal of the first horizontal channel connected with a second horizontal channel of larger diameter is gradually larger. The transportation end terminal of the second extruder is connected with the input terminal of the third flow channels. The light strip input channel inputs the LED light strip to pass through the first and second flow channel, which the transparent molten plastic squeezed by the first extruder wraps and covers the LED light strip and the molten plastic with the other color squeezed by the second extruder is spirally wounded on the surface of the transparent molten plastic.

Owner:CAO LIN YU

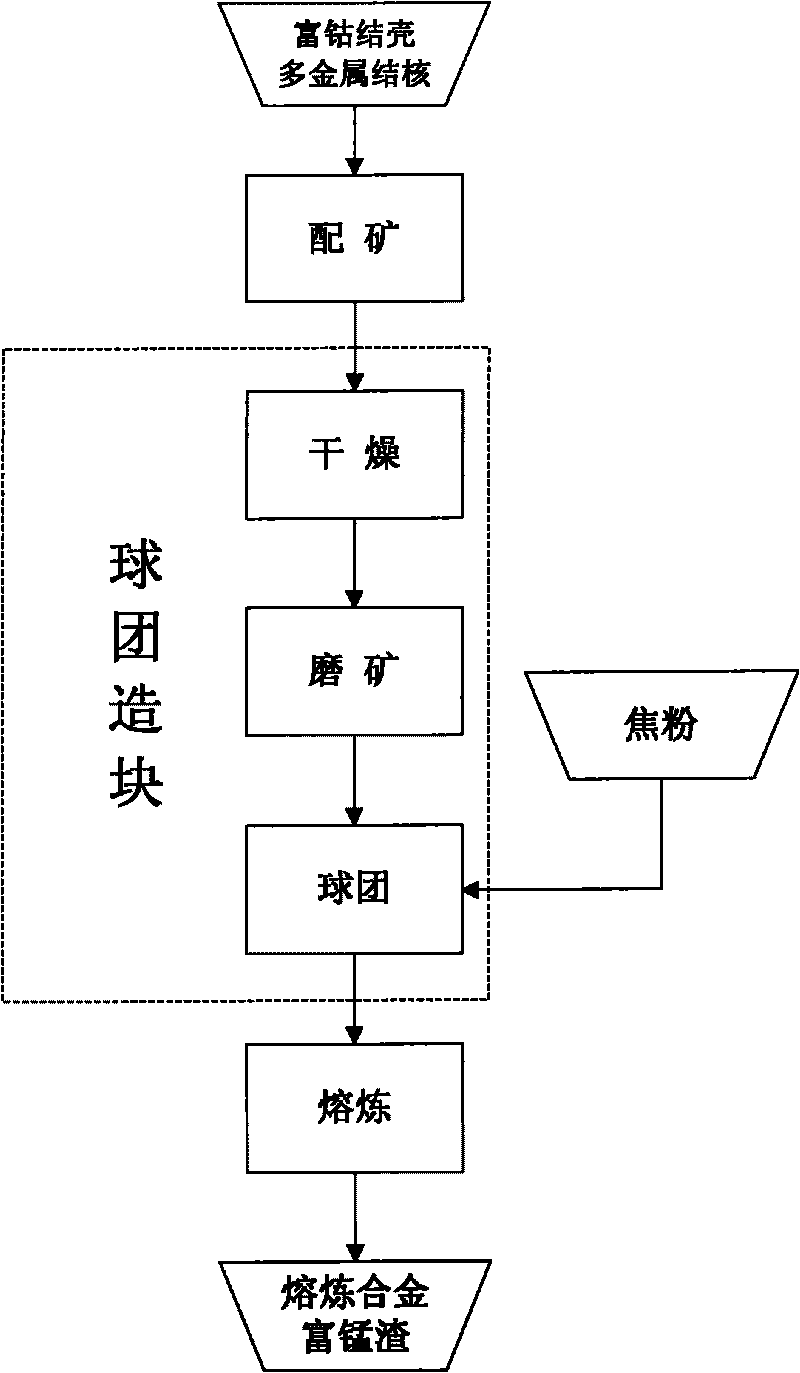

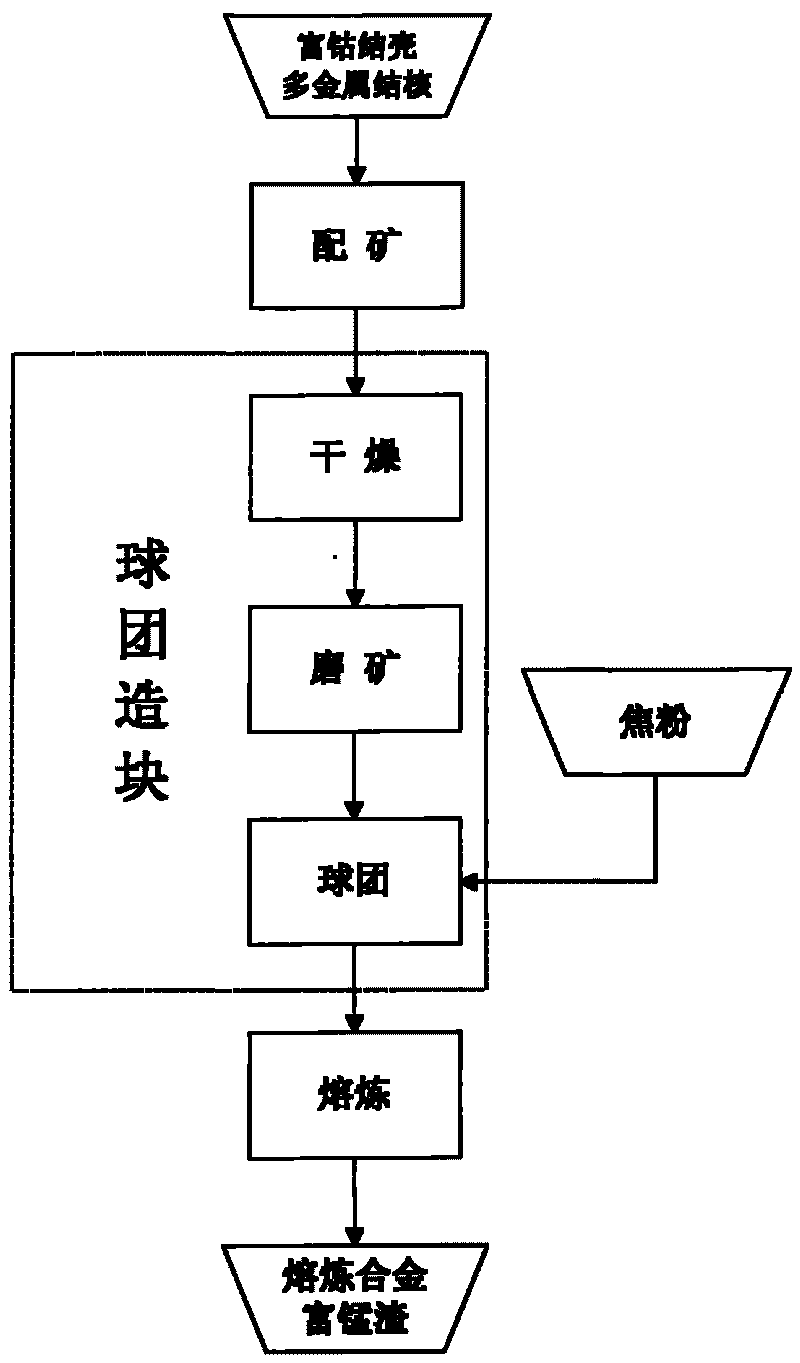

Ore-blending and smelting method of ocean cobalt-rich crusts

The invention discloses an ore-blending and smelting method of ocean cobalt-rich crusts, comprising an ore-blending step and a smelting step. The ore-blending step is as follows: blending ores of more than one ocean cobalt-rich crust and more than one ocean metal nucleus. The ore-blending and smelting method of ocean cobalt-rich crusts has the advantages pf further optimized process, low production cost, little energy consumption and further improved product quality and yield.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

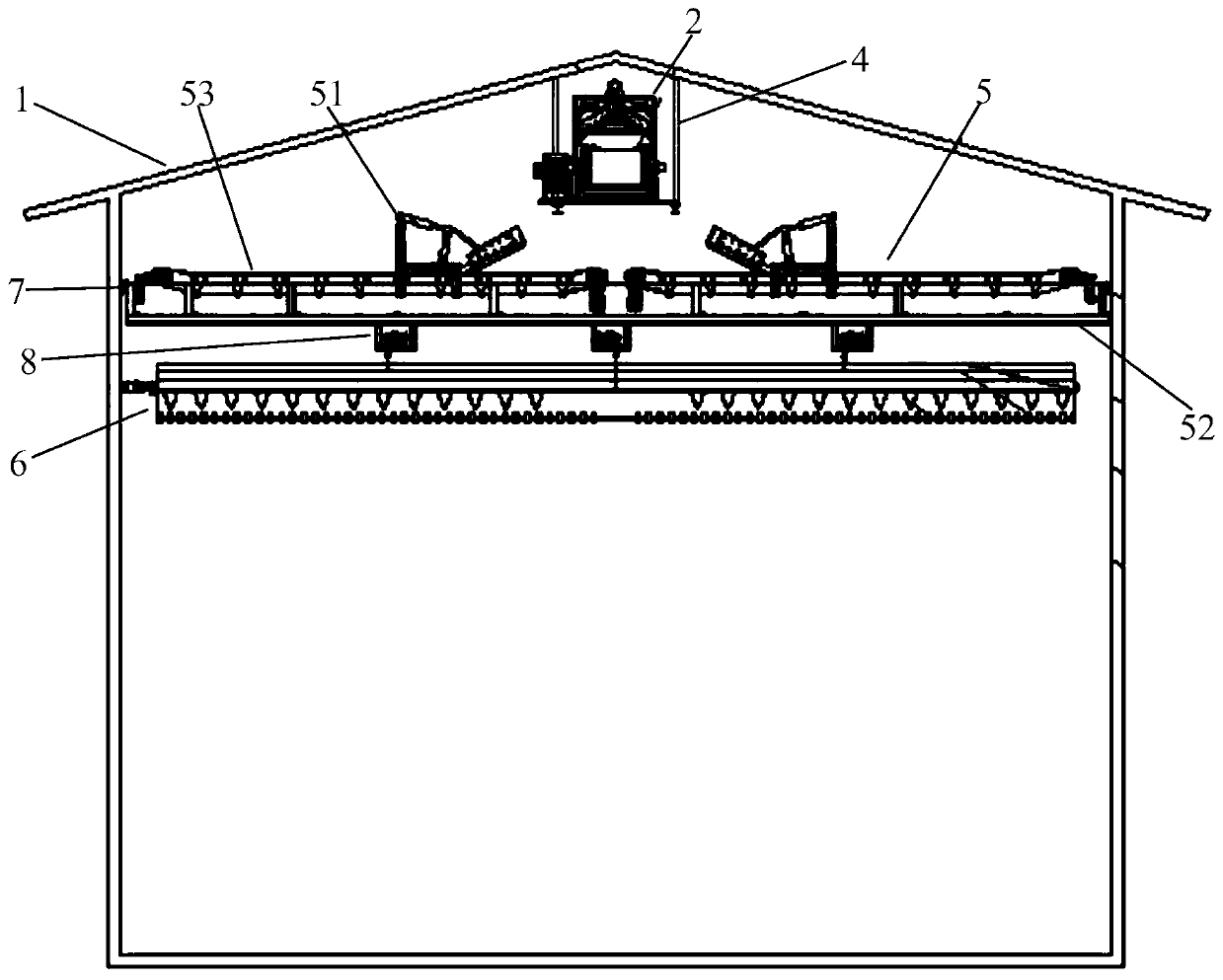

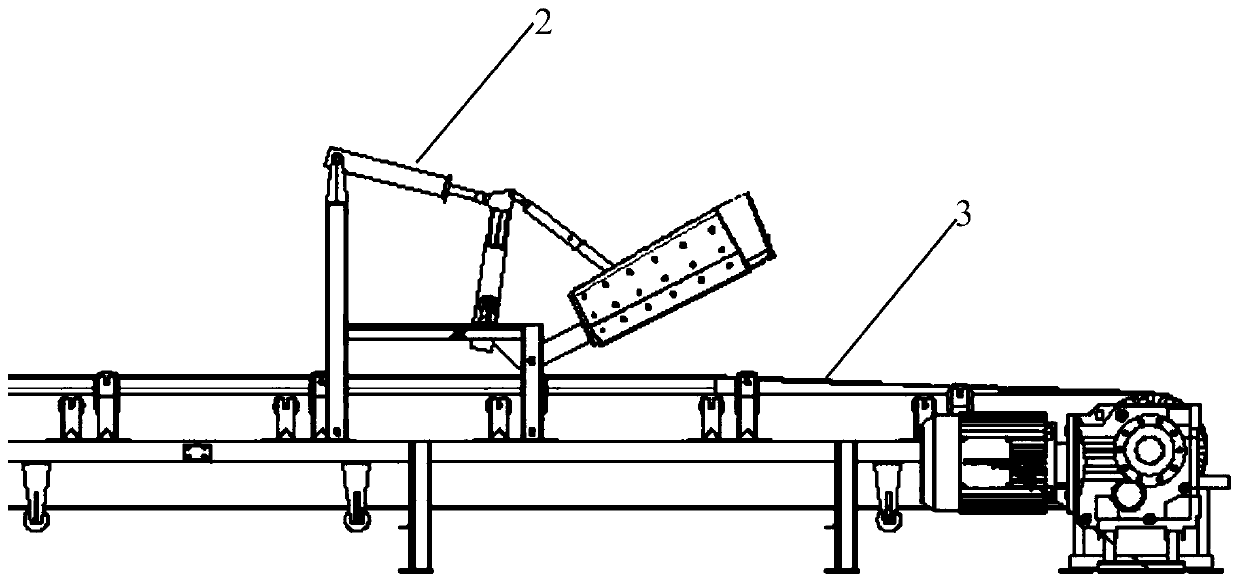

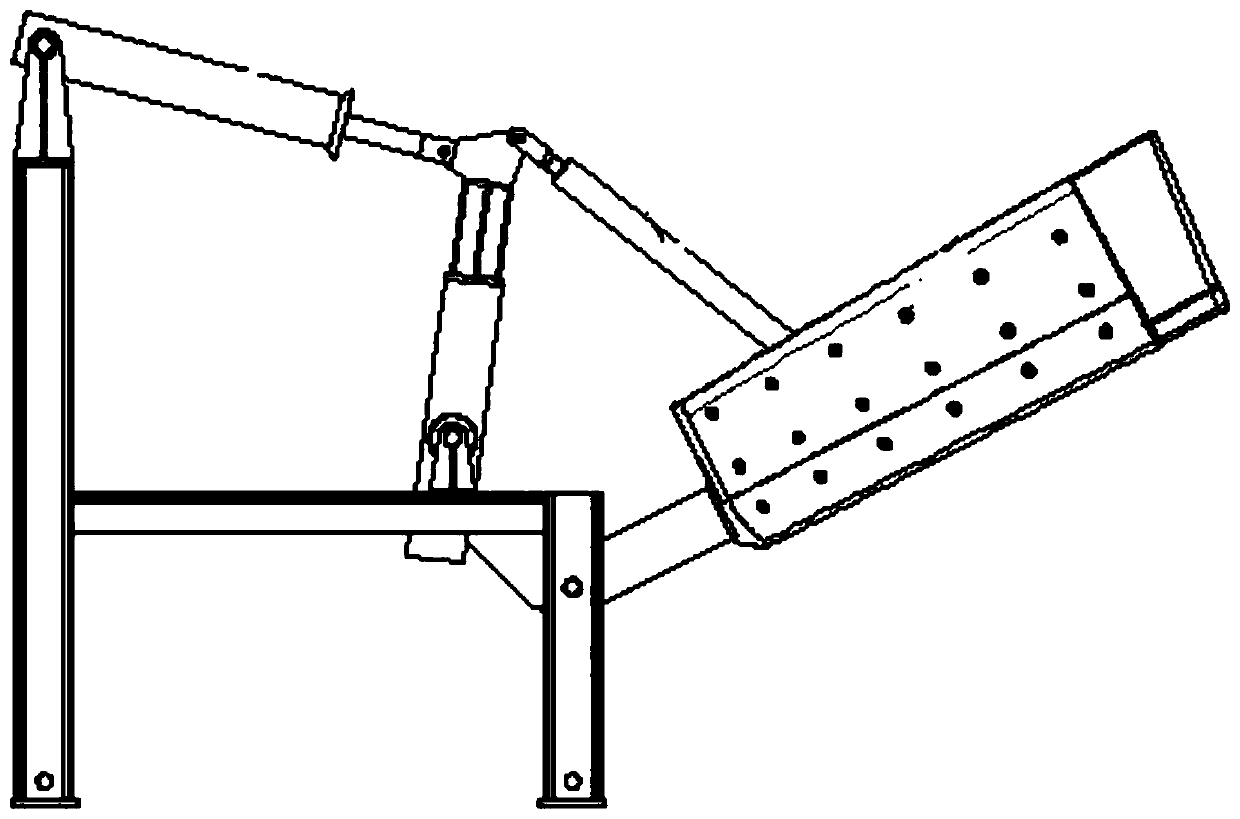

Intelligent granary bulk grain granary entry and grain surface flattening integrated device

PendingCN110255216AReduce labor intensityReasonable structural designConveyorsLoading/unloadingAgricultural engineeringGrain distribution

The invention discloses an intelligent granary bulk grain granary entry and grain surface flattening integrated device. The device comprises a grain distribution trolley, a first belt conveyer, a machine frame, an intelligent traveling device, a grain surface flattening device and second rails. The first belt conveyer is installed on the machine frame. First rails are installed on the two sides of the first belt conveyer. The grain distribution trolley is installed on the first rails. The second rails are installed on the two sides of a granary, and is located below the first belt conveyer. The intelligent traveling device is installed on the second rails and comprises a traveling grain unloading trolley, a traveling machine frame and a second belt conveyer. The traveling machine frame is installed on the second rails. The second belt conveyer is installed on the traveling machine frame. Third rails are installed on the two sides of the second belt conveyer. The traveling grain unloading trolley is installed on the third rails. The grain surface flattening device is installed at the bottom of the traveling machine frame through a lifting device. With the intelligent granary bulk grain granary entry and grain surface flattening integrated device, grain can be evenly distributed at the bottom of the granary without being piled up, the labor intensity of workers can be effectively reduced, and the granary entry efficiency of grain is improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

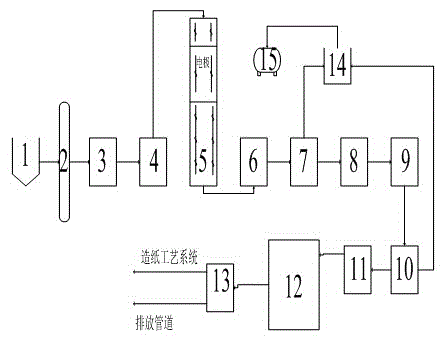

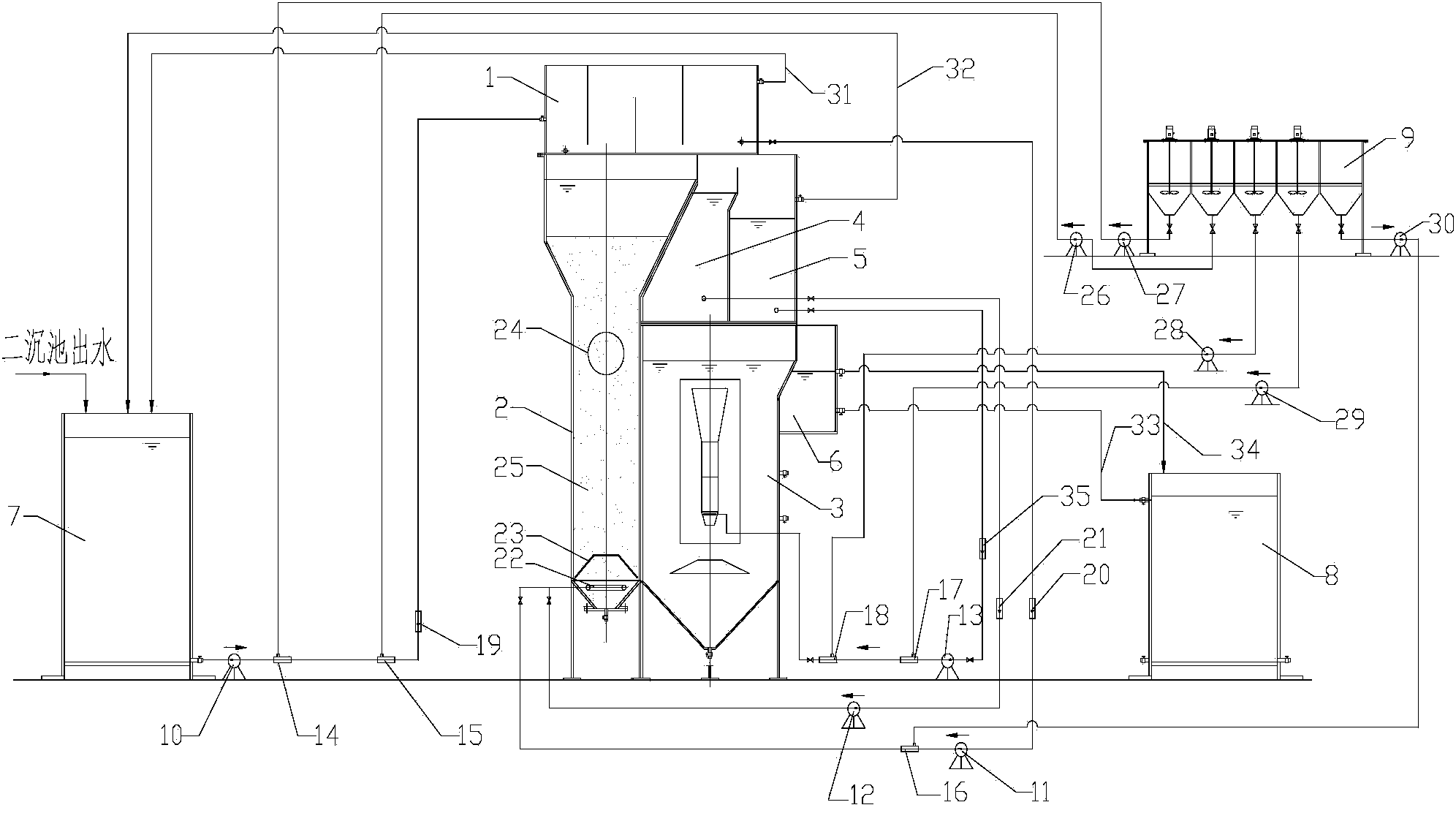

Industrial waste-water treating system for paper making factory

ActiveCN104986924AGood removal effectReduce equipment investment costsMultistage water/sewage treatmentWaste water treatment from plant processingRefluxSedimentation

The invention discloses an industrial waste-water treating system for a paper making factory. The industrial waste-water treating system comprises a pretreatment water collecting tank, a grating, a grit tank, a physical filter tank, an ice grating, an electromagnetic adsorption tank, an air floating tank, an acidification tank, a contact oxidation tank, a secondary sedimentation tank, a reflux treating tank, an artificial wetland treating system, a recirculation storage tank, a sludge storage tank, and a belt pressure filter, wherein the temperature in ice grating equipment is minus 2-10 DEG C. The waste-water treating system adopts environment-friendly ice grating equipment with low energy consumption, and the ice grating equipment is applied for the waste-water treating technology in paper making for the first time; the waste-water treating system has an obvious removing effect on organic matters and small-sized solid suspended matters, which are unique and difficult to remove, in paper-making waste water, and chemical reagents are not added. In the paper-making waste water treated by the waste-water treating system, the removal rate of chemical oxygen demands is 98.1%; the removal rate of total nitrogen is 97.2%; the removal rate of five-day biochemical oxygen demands is 95.1%; the removal rate of suspended matters is 96.1%; the removal rate of chroma is 90.1%; the removal rate of turbidity is 98.8%.

Owner:江苏富星纸业有限公司

Vertical vibration conveying and drying integrated device

PendingCN111912212AReduce consumptionReduce wearDrying gas arrangementsDrying solid materialsVertical vibrationVertical plane

The invention relates to the technical field of material transportation, in particular to a vertical vibration conveying and drying integrated device. The device comprises a feeding structure, a discharging structure, a material conveying structure and a heater. The material conveying structure comprises two or more vertical conveying pipelines and a driver, and every two adjacent vertical conveying pipelines are connected in series in the material conveying direction. The vertical conveying pipelines are driven by the driver to do horizontal plane circular motion and vertical plane up-and-down vertical motion. A feeding hole at the lower part of the material conveying structure is communicated with the feeding structure, and a discharging hole at the upper part of the material conveying structure is communicated with the discharging structure. The heater is used for heating the materials in the vertical conveying pipelines. By means of the structure of the vertical conveying pipelinesand the heater, after-production drying can be achieved while grains are vibrated and vertically conveyed, the labor intensity of workers can be effectively reduced, the grain conveying and drying efficiency is improved, the investment cost of a grain conveying and drying system is reduced, a traditional grain conveying and drying mode is changed, and rapid grain conveying is guaranteed.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

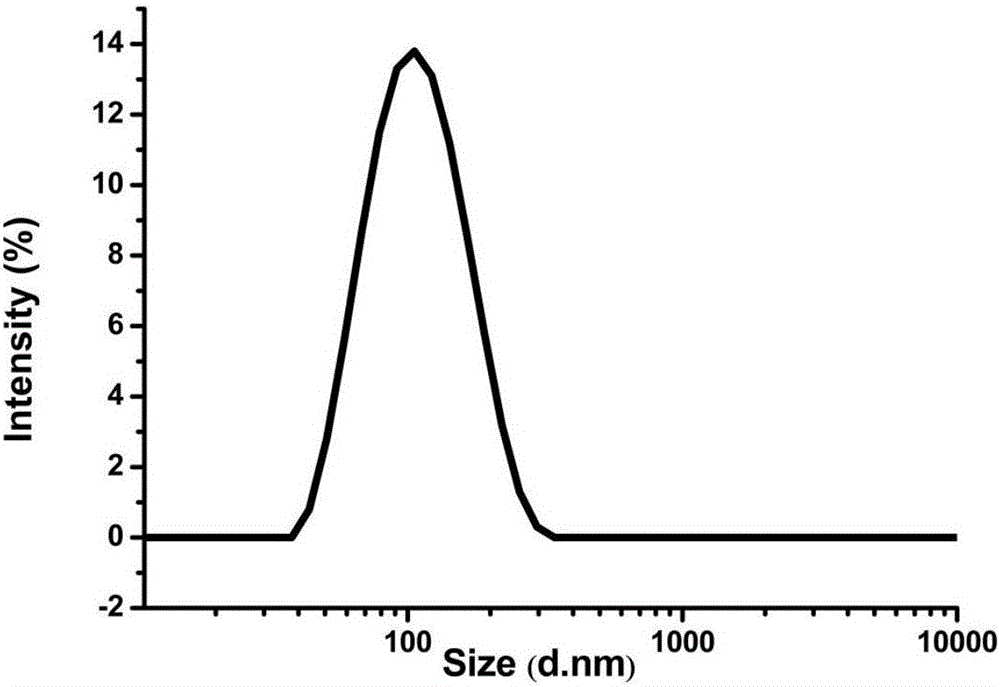

Pesticide nano-microsphere and production method thereof

ActiveCN106614654ASimple production processReduce manufacturing costBiocideDead animal preservationMicrosphereAbamectin

The invention relates to a pesticide nano-microsphere and a production method thereof. The production method includes the steps: preparing phenyl ethylene-methacrylic acid polymers; preparing initial emulsion; preparing the nano-microsphere and the like. The average grain diameter of the pesticide nano-microsphere is about 100nm, the drug-loading rate of the pesticide nano-microsphere reaches 9% or more, and the entrapment rate of the pesticide nano-microsphere reaches 80% or more. Compared with difficultly soluble pesticides without being treated by nano-microsphere, light stability of the pesticide nano-microsphere is obviously improved, release of emamectin benzoate nano-microsphere tends to balance after 200 hours and reaches 94%, and release of emamectin nano-microsphere tends to balance after 100h and reaches 63%. The pesticide nano-microsphere is simple in production process, low in production cost and device investment cost and stable and reliable in product quality, and pollutants are avoided. The production method of the pesticide nano-microsphere has a wide application prospect.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

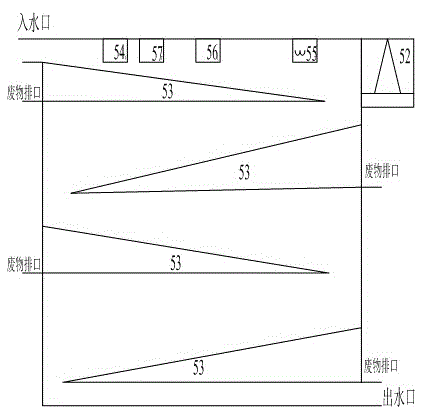

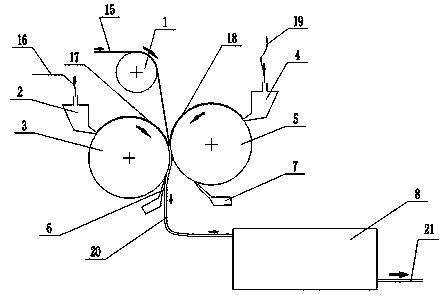

Composite reconstituted tobacco sheet, forming device and forming method thereof

PendingCN109043633AReduce equipment investment costsReduce processing costsTobacco preparationFiberEngineering

The invention relates to a composite reconstituted tobacco sheet, a forming device and a forming method thereof. The forming device comprises a conveying device and a left coating roller and a right coating roller disposed under the conveying device, a first tobacco slurry limiting feeding device is arranged on one side of the left coating roller, a second tobacco slurry limiting feeding device isarranged on one side of the right coating roller, peeling devices are arranged under the left coating roller and the right coating roller, and a fiber web is driven by the conveying device to pass through between the left coating roller and the right coating roller, and is subjected to roll compacting through the left coating roller and the right coating roller to form the ribbon-shaped compositereconstituted tobacco sheet covering the fiber web. The tobacco sheet produced by the method has high physical strength and toughness, uniform thickness and good resistance to processing, is not easily broken, and has good flammability and sufficient smoke flavors.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

Integrated fluidized catalytic oxidation tower and method for deeply treating wastewater by using same

InactiveCN103771624AEasy to handleImprove processing efficiencyMultistage water/sewage treatmentChemical reactionFenton reagent

The invention discloses an integrated fluidized catalytic oxidation tower and a method for deeply treating wastewater by using the same. A balance adjusting unit of the catalytic oxidation tower is connected with a water distribution pipe at the bottom of a catalytic oxidation unit through a pipeline; the outer side of the upper part of the catalytic oxidation unit is provided with a circulating water tank, the outer side of the circulating water tank is provided with an intermediate water tank, and the top of the circulating water tank is connected with the intermediate water tank through an overflow port; the intermediate water tank is connected with a water distribution pipe of a coagulation sedimentation unit through a pipeline, and a water collecting basin is connected with the balance adjusting unit through a pipeline; the balance adjusting unit is connected with the water collecting basin through a first overflow pipe, and the intermediate water tank is connected with the water collecting basin through a second overflow pipe; a water outlet of a water outlet tank is connected with a clean water basin through a water outlet pipe. By using the integrated fluidized catalytic oxidation tower, the mass transfer efficiency and the chemical reaction speed are effectively increased, the oxidative degradation effect for organic pollutants in wastewater is improved, the dosage of a Fenton reagent can be reduced, and the yield of chemical sludge in the later coagulation process can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

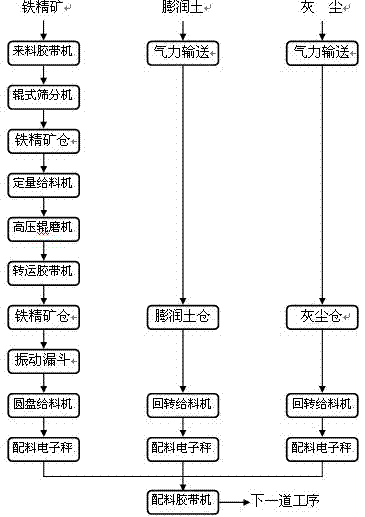

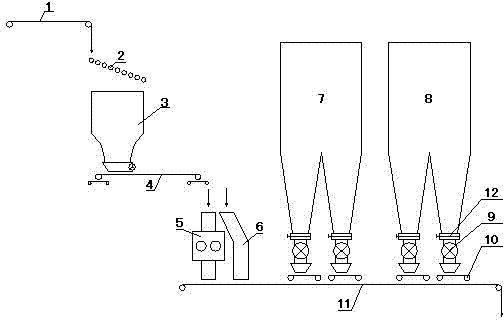

Ferrous metallurgy pellet iron-containing raw material preprocessing and dosing system

The invention discloses a ferrous metallurgy pellet iron-containing raw material preprocessing and dosing system which is characterized by sequentially comprising an incoming material belt conveyer for conveying iron ore concentrate to a high-pressure roller grinding chamber, a roller type sieving machine arranged below the incoming material belt conveyer, an iron ore concentrate buffer cabin arranged below the roller type sieving machine, a movable quantitative feeder arranged below the iron ore concentrate buffer cabin, a high-pressure roller grinder arranged below the head of the movable quantitative feeder, a bypass chute formed in one side of the high-pressure roller grinder, a dosing belt conveyer for conveying materials discharged from the high-pressure roller grinder or the bypass chute to a dosing chamber, and a bentonite and dust storage and feeding system which is arranged in the dosing chamber and is used for conveying bentonite and dust to the dosing belt conveyer and conveying the bentonite and the dust to a next process together with the iron ore concentrate on the dosing belt conveyer. According to the system, the occupied area of the dosing chamber, the basic construction investment, the material transfer and loss and the operating energy consumption are reduced.

Owner:中冶北方(大连)工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com