Numerical control drilling and cutting combination machine

A combined machine and component technology, applied in the field of cutting equipment and drilling, can solve problems such as single processing of steel plates, and achieve the effect of reducing floor space and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

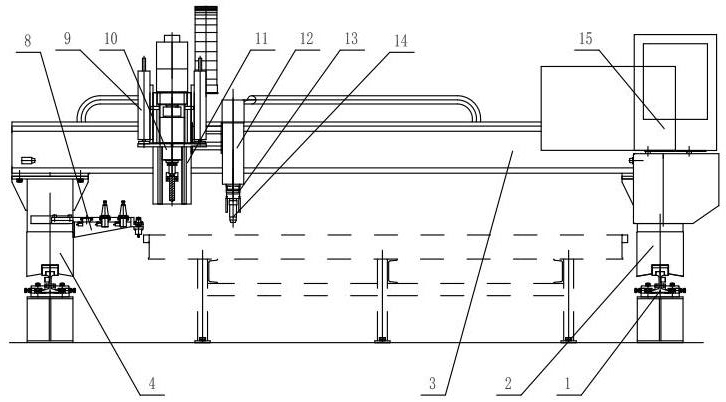

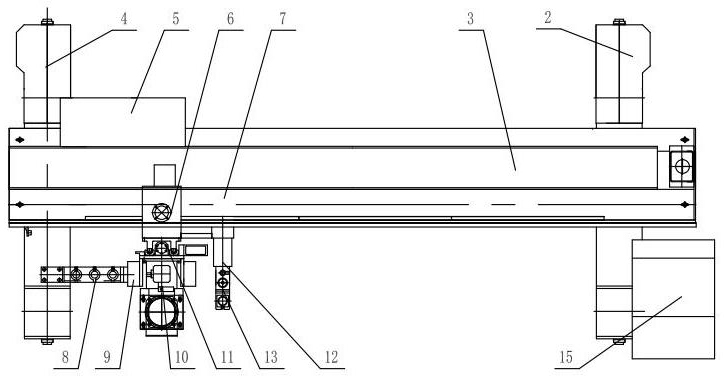

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

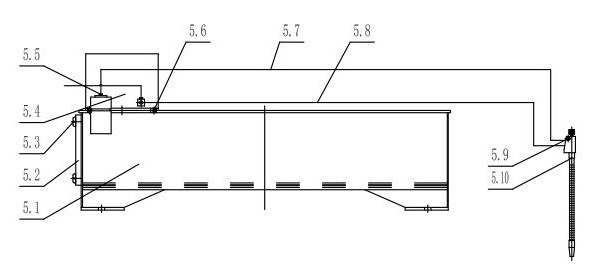

[0023] Such as Figure 1 to Figure 2 As shown, the guide rail assembly 1 of the CNC drilling and cutting combined machine described in the present invention is installed on the basic H-shaped steel, and maintains a certain degree of parallelism and levelness. The gears on the top mesh with the racks on the guide rail assembly 1, the two ends of the crossbeam part 3 are installed on the main frame part 2 and the subframe part 4 by bolts, and the drilling air mist cooling system 5 is installed on the crossbeam part 3 with screws Above, the driving slide 6 and the driven slide 7 are respectively installed on the linear guide rail slider in front of the beam part 3, and the driving slide 6 is engaged with the gear on the servo motor and the rack on the beam part 3 to drive the slide 6 Connect with the driven slide plate 7 with a transition pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com