Pesticide nano-microsphere and production method thereof

A production method and technology of nano-microspheres, which are applied in the fields of botanical equipment and methods, biocides, plant growth regulators, etc., can solve the problems of easy decomposition, reduction of effective utilization rate, loss of activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

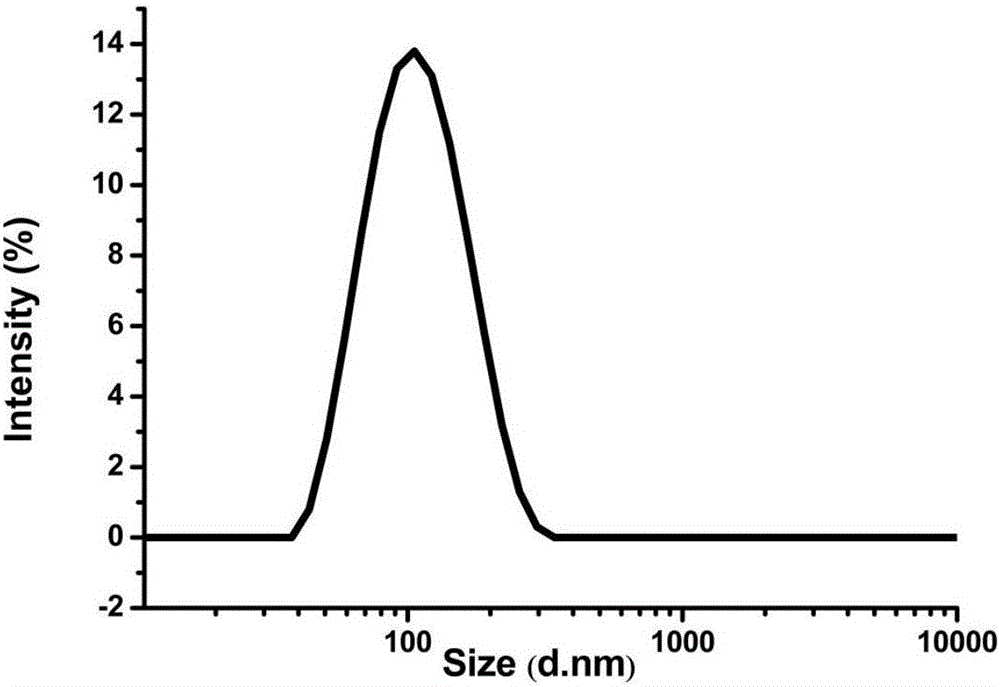

[0108] Embodiment 1: Production of pesticide nano microspheres

[0109] The implementation steps of this embodiment are as follows:

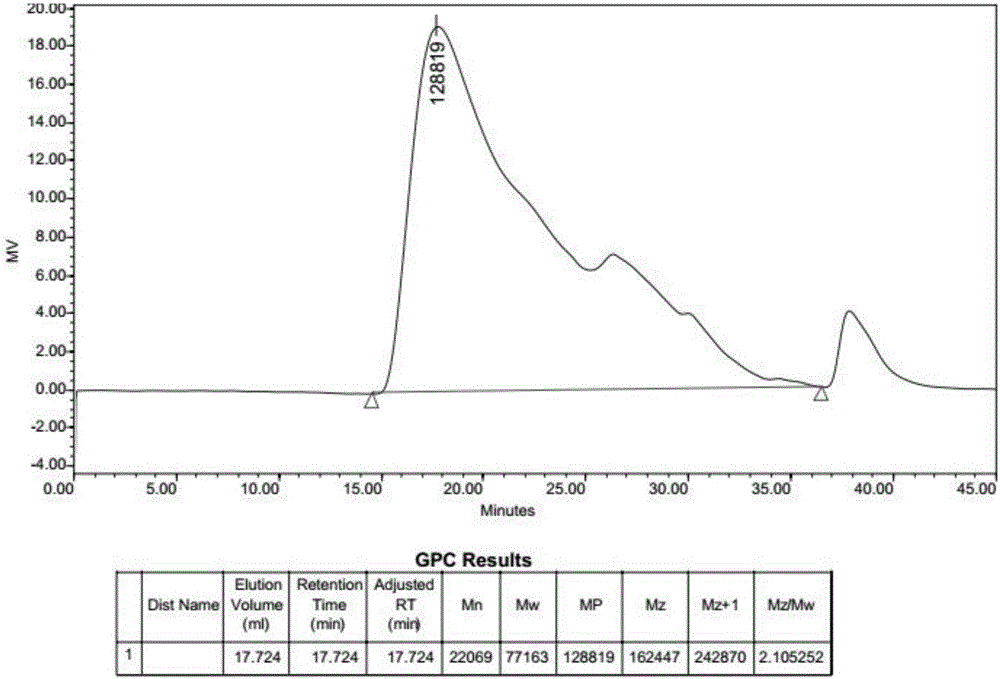

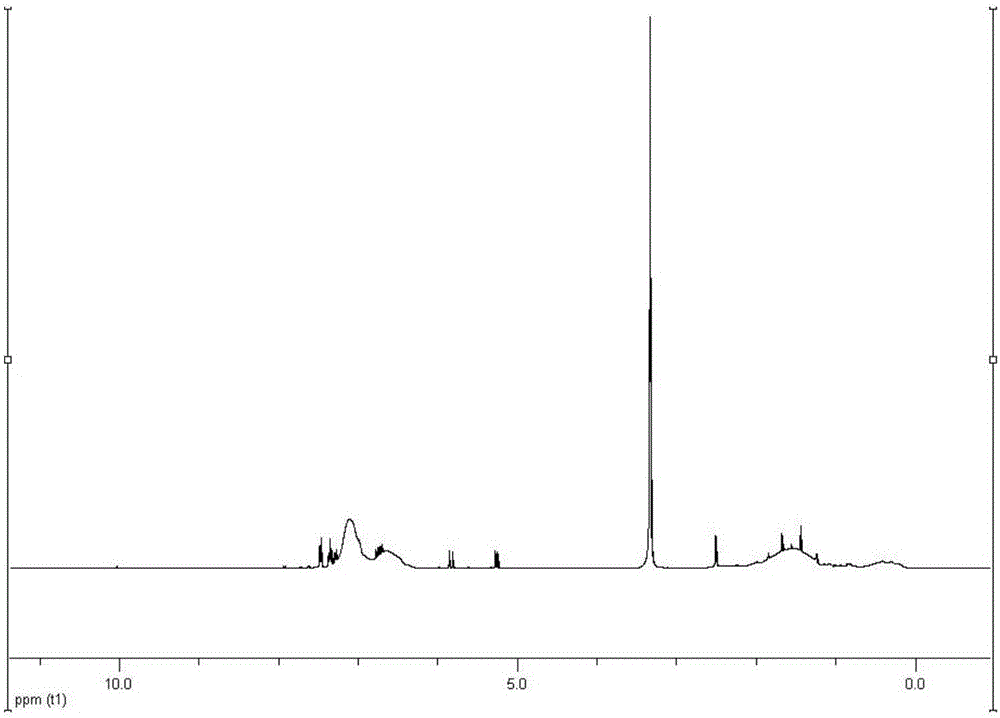

[0110] A. Preparation of styrene-methacrylic acid polymer

[0111] According to the weight ratio of styrene, methacrylic acid and chloroform 1:0.1:5, styrene and methacrylic acid are dissolved in chloroform solvent to obtain a kind of chloroform solution, then according to the ratio of styrene and azobisisobutyronitrile initiator Weight ratio 1:0.02, add azobisisobutyronitrile initiator to the chloroform solution, mix well, then carry out polymerization reaction at 68°C for 12 hours, cool the polymerization reaction solution to room temperature, and remove it by solvent evaporation method Chloroform solvent, obtains styrene-methacrylic acid polymer;

[0112] B. Preparation of primary emulsion

[0113] Sodium dodecylbenzenesulfonate is dissolved in water to obtain a concentration of 0.3% sodium dodecylbenzenesulfonate aqueous solution by weigh...

Embodiment 2

[0119] Embodiment 2: Production of pesticide nano microspheres

[0120] The implementation steps of this embodiment are as follows:

[0121] A. According to the weight ratio of styrene, methacrylic acid and chloroform 1:0.1:15, dissolve styrene and methacrylic acid in chloroform solvent to obtain a chloroform solution, and then trigger the reaction according to styrene and azobisisobutyronitrile The weight ratio of the agent is 1:0.02, add the azobisisobutyronitrile initiator to the chloroform solution, mix well, then carry out the polymerization reaction at a temperature of 68 ° C for 12 hours, cool the polymerization reaction solution to room temperature, and use solvent volatilization The chloroform solvent was removed by method to obtain styrene-methacrylic acid polymer;

[0122] B. Preparation of primary emulsion

[0123] Sodium dodecylbenzenesulfonate is dissolved in water to obtain a concentration of 0.3% sodium dodecylbenzenesulfonate aqueous solution by weight;

[...

Embodiment 3

[0129] Embodiment 3: Production of pesticide nano microspheres

[0130] The implementation steps of this embodiment are as follows:

[0131] A. Preparation of styrene-methacrylic acid polymer

[0132] According to the weight ratio of styrene, methacrylic acid and chloroform 1:0.2:10, styrene and methacrylic acid are dissolved in chloroform solvent to obtain a kind of chloroform solution, then according to the ratio of styrene and azobisisobutyronitrile initiator The weight ratio is 1:0.03, add azobisisobutyronitrile initiator to the chloroform solution, mix well, then carry out polymerization reaction at a temperature of 70°C for 10h, cool to room temperature, and remove the chloroform solvent by solvent volatilization method to obtain Styrene-methacrylic acid polymer;

[0133] B. Preparation of primary emulsion

[0134] Sodium dodecylbenzenesulfonate is dissolved in water to obtain a concentration of 0.4% sodium dodecylbenzenesulfonate aqueous solution by weight;

[0135]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com