Patents

Literature

785 results about "Benzioc acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

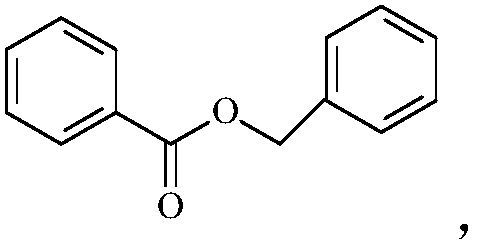

Among the derivatives of benzoic acid are sodium benzoate, a salt used as a food preservative; benzyl benzoate, an ester used as a miticide; and benzoyl peroxide, used in bleaching flour and in initiating chemical reactions for preparing certain plastics. carboxylic acid: Aromatic acids.

Fragranced Therapeutic Delivery System

The present invention relates to multi-functional topical delivery systems for providing long-lasting delivery of fragrance as. well as skin-supporting and / or pharmaceutically active ingredients comprising (i) an oil phase; (ii) an aqueous phase; (iii) phenoxyethanol at a concentration of from about 2.0% to about 2.7% based on the total weight of the composition; (iv) an effective exfoliating amount of a hydrophobic hydroxycarboxylic acid selected from the group consisting of orthohydroxybenzoic acid, hydroxycarboxylic acids containing a C12-C24 fatty acid esterified to the alpha carbon hydroxyl group, hydroxycarboxylic acids containing a C12-C24 fatty alcohol esterified to a carboxyl group; (v) a non-ionic emulsifier having an HLB of from about 7 to about 10; (vi) a fragrance composition; and (vii) at least one skin-supporting or dermatopharmaceutically active agent.

Owner:TREMO TEC GMBH

Environmental-friendly white emulsion

InactiveCN103725229AOptimal temperature timeImprove adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesDioxyethylene EtherBenzioc acid

The invention discloses an environmental-friendly white emulsion. The environmental-friendly white emulsion is prepared from the components in percentage by weight: 1.8-2.5 percent of polyvinyl alcohol PVA, 23-27 percent of vinyl acetate VAC, 0.3-0.8 percent of acrylic acid AA, 0.8-1.5 percent of acryl amide AM, 0.1-0.15 percent of ammonium persulfate, an anionic emulsifier A-102, alkyl polyoxyethylene ether LCN-287, a nonionic emulsifier, 5-7 percent of corn starch, a transparent powder, a plasticizer, 2.5-4 percent of diethylene glycol dibenzoate, 0.2-0.3 percent of preservative KSG-201, 0.1-0.2 percent of sodium hydroxide NaOH, 0.3-0.5 percent of methanol, 3-6 percent of functional filler, 0.15-0.3 percent of compound emulsifier and 56-58 percent of water. The environmental-friendly white emulsion is strong in the adhesive force and the adhesive strength, is low in the production cost and is good in the environmental protection performance.

Owner:GUANGZHOU YIJIANG CHEM CO LTD

Liquid benzoate ester compositions and aqueous polymer compositions containing same as plasticizers

Owner:EASTMAN SPECIALITIES HLDG CORP

Stainless steel degreasing agent

InactiveCN101979711AImprove solubilityImproves the properties of uniform corrosionActive agentBrominated hydrocarbon

The invention provides a stainless steel degreasing agent, which comprises the following components in percentage by weight: 5 to 25 percent of organic solvent, 2 to 5 percent of corrosion inhibitor, 10 to 25 percent of surfactant, 5 to 10 percent of inorganic salt, 1 to 3 percent of defoaming agent and the balance of deionized water, wherein the organic solvent is bromohydrocarbon; the corrosion inhibitor is sodium benzoate, ammonium benzoate, triethanolamine, ethanolamine or benzotriazole; the surfactant is one or more of alkylphenol polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the inorganic salt is alkaline salt; and the defoaming agent is tributyl phosphate, organic silicon, oleic acid or sodium oleate. The stainless steel degreasing agent can replace the currently used ODS cleaning agents, can achieve the cleaning effect of the ODS cleaning agents, does not damage the surface of the stainless steel, has obvious cleaning effect, can clean a large number of products, and does not harm a human body; and the preparation method is simple, safe, and environment-friendly.

Owner:JIANGSU TIANHENG NANO SCI & TECH

Liquid benzoate ester compositions and aqueous polymer compositions containing same as plasticizers

InactiveUS20030050372A1Antifouling/underwater paintsOther chemical processesPolymer scienceDiethylene glycol

The addition of at least about 30 weight percent of diethylene glycol (DEG) monobenzoate or dipropylene glycol (DPG) monobenzoate to diethylene glycol (DEG) dibenzoate, which is a solid at 28° C., results in a mixture that is unexpectedly a liquid at this temperature. The resultant mixtures are effective plasticizers for aqueous polymer compositions, including adhesives and caulks.

Owner:EASTMAN SPECIALITIES HLDG CORP

Products comprising an isothiocyanate preservative system and methods of their use

The present disclosure relates to products, including preservative systems and compositions (e.g., foods, beverages, health care products, personal care products, herbicidal products, and containment devices). The products comprise a constituent comprising an isothiocyanate compound. The products may further comprise a preservative selected from sorbate preservatives, benzoate preservatives, and mixtures thereof. The present disclosure further relates to methods of preserving products comprising incorporating the foregoing preservative systems into such products.

Owner:ALBION LAB

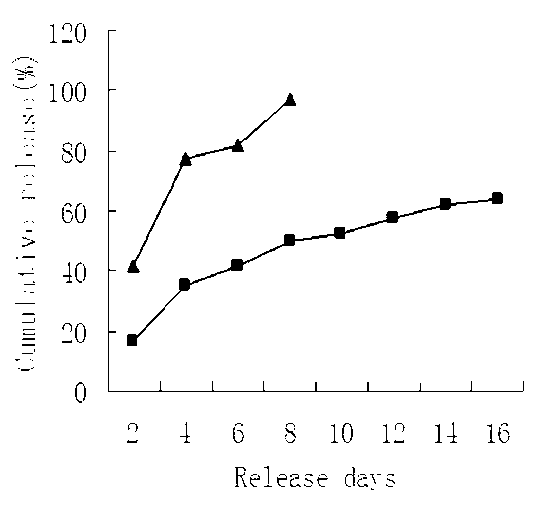

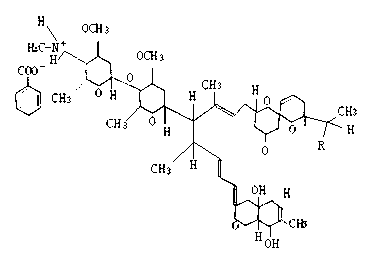

Emamectin benzoate polylactic acid microsphere suspension and preparation method thereof

The invention discloses an emamectin benzoate polylactic acid microsphere suspension and a preparation method thereof, and belongs to the field of pesticide preparation. The emamectin benzoate polylactic acid microsphere suspension comprises the following raw materials in mass percentage: 3.0% of emamectin benzoate polylactic acid microspheres, 5.0-7.0% of wetting and dispersing agent, 2.0-3.0% of thickener, 2.5-3.5% of anti-freezing agent, 0.1% of preservative, and water for supplementing to 100%. The preparation method comprises the following steps: weighing emamectin benzoate polylactic acid microspheres, the wetting and dispersing agent, the thickener, the anti-freezing agent, the preservative and water according to the mass percentages of the raw materials; and oscillating and dissolving the raw materials to obtain the emamectin benzoate polylactic acid microsphere suspension with the mass percentage of 3.0%. The emamectin benzoate polylactic acid microsphere suspension is unique in formulation, simple in preparation method, significant in effect and has significant economic and social benefits.

Owner:FUJIAN AGRI & FORESTRY UNIV

Forage for artificial breeding of Monochamus alternatus Hope and method for preparing the same

InactiveCN101983580AWide variety of sourcesEasy to manufactureAnimal feeding stuffAccessory food factorsSucroseArtificial rearing

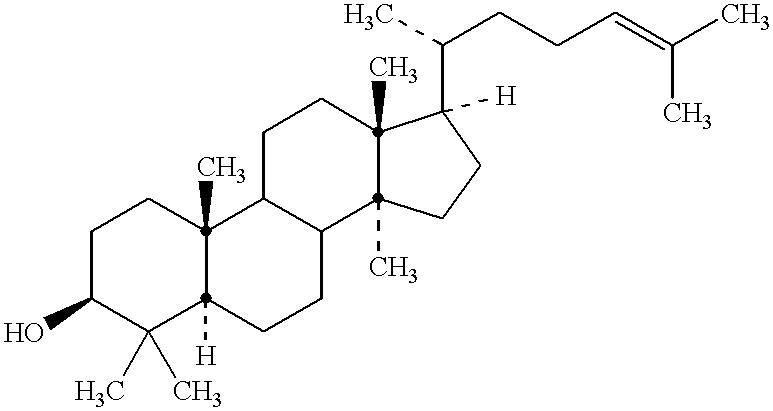

The invention discloses the forage for artificial breeding of Monochamus alternatus Hope and method for preparing the same. The forage comprises 90-110 g of pine wood chip, 18-22 g of cane sugar, 10-15 g of yeast powder, 35-45 g of agar, 1.8-2.1 g of sodium benzoate, 0.9-1.2 g of mythyl p-hydroxybenzoate, 10 mL of H2SO4 (0.5 mol / L), 15-25 g of wheat germ powder, 1.2-1.5 g of cholesterol, 3-4.5 g of ascorbic acid, 18-21 g of casein, 0.7-1.1 g of choline and 750-850 mL of water. The forage provided by the invention has the advantages of abundance in resources, convenient manufacture and low cost, and the method for preparing the same is simple and workable. The development time of larvae fed with the above forage is significantly shortened, compared with that of larvae under natural circumstance in the forest. The development period of larvae that develop from egg development to adult emergence lasts for about 100 days. The forage is applicable to the large-scale breeding of Monochamus alternatus Hope larvae. Reproduction and breeding of Monochamus alternatus Hope at controlled temperatures can be realized to ensure the supplies of experimental populations of different stages, different instars and stable activities.

Owner:NANJING FORESTRY UNIV

Antiperspirant formulations

InactiveUS20020034481A1Ameliorating and avoiding undesirable attributeImprove bindingCosmetic preparationsToilet preparationsWaxParticulates

Anhydrous antiperspirant formulations in which a particulate antiperspirant active is suspended in a carrier fluid can result in significant visible deposits when applied to skin or when transferred onto clothing. Anhydrous antiperspirant suspension sticks which exhibit very low visible deposits are obtainable by employing a carrier fluid in which at least 45% and preferably at least 60% of its weight comprises a mixture of a hydrocarbon oil with an oxygen-containing emollient oil, the mixture having a refractive index of at least 1.46, in conjunction with structurant comprises a wax or a non-polymeric fiber-forming gellant. Preferred oxygen-containing emollient oils include alkyl benzoates. The waxes can even comprise fatty alcohols.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Preparation method of acrylic modified alkyd resin

The invention provides a preparation method of acrylic modified alkyd resin. The acrylic modified alkyd resin is prepared from a 1 component and a 2 component according to parts by weight, wherein the 1 component comprises 15.0 to 25.0 parts of methyl methacrylate, 15.0 to 25.0 parts of styrene, 3.0 to 5.0 parts of butyl acrylate, 2.0 to 4.0 parts of acrylic acid, 1.5 to 2.5 parts of benzoyl peroxide and 36.5 to 61.5 parts of xylene, and the 2 component comprises 20.0 to 25.0 parts of sunflower oil, 9.0 to 10.0 parts of phthalic anhydride, 7.0 to 9.0 parts of pentaerythritol with 96 percent, 15.0 to 20.0 parts of acrylic prepolymer, 0.01 to 0.02 part of lithium hydroxide, 2.0 to 4.0 parts of benzoic acid and 41.5 to 52.0 parts of mixed solvent of a 200# solvent and xylene. The preparation method of the acrylic modified alkyd resin comprises the following steps of: preparing; adding the xylene into a four-mouth flask, heating up to 130 to 140 DEG C and refluxing; adding monomers sequentially, wherein the benzoyl peroxide is firstly added by 90 percent of the total quantity; after refluxing the xylene for 10 to 30min, starting the operation of dripping, controlling the finish of the operation of dripping within 3 to 5h, afterwards carrying out heat preservation for 0.5 to 1.0h, then adding the balance of 10 percent of benzoyl peroxide, cooling after carrying out heat preservation for 0.5 to 1h, and discharging so as to obtain the acrylic prepolymer; and adding the 2 component after firstly mixing the 200# solvent and the xylene according to the proportion of 7:3 evenly so as to obtain the acrylic modified alkyd resin by preparation.

Owner:XINJIANG HONGSHAN PAINT

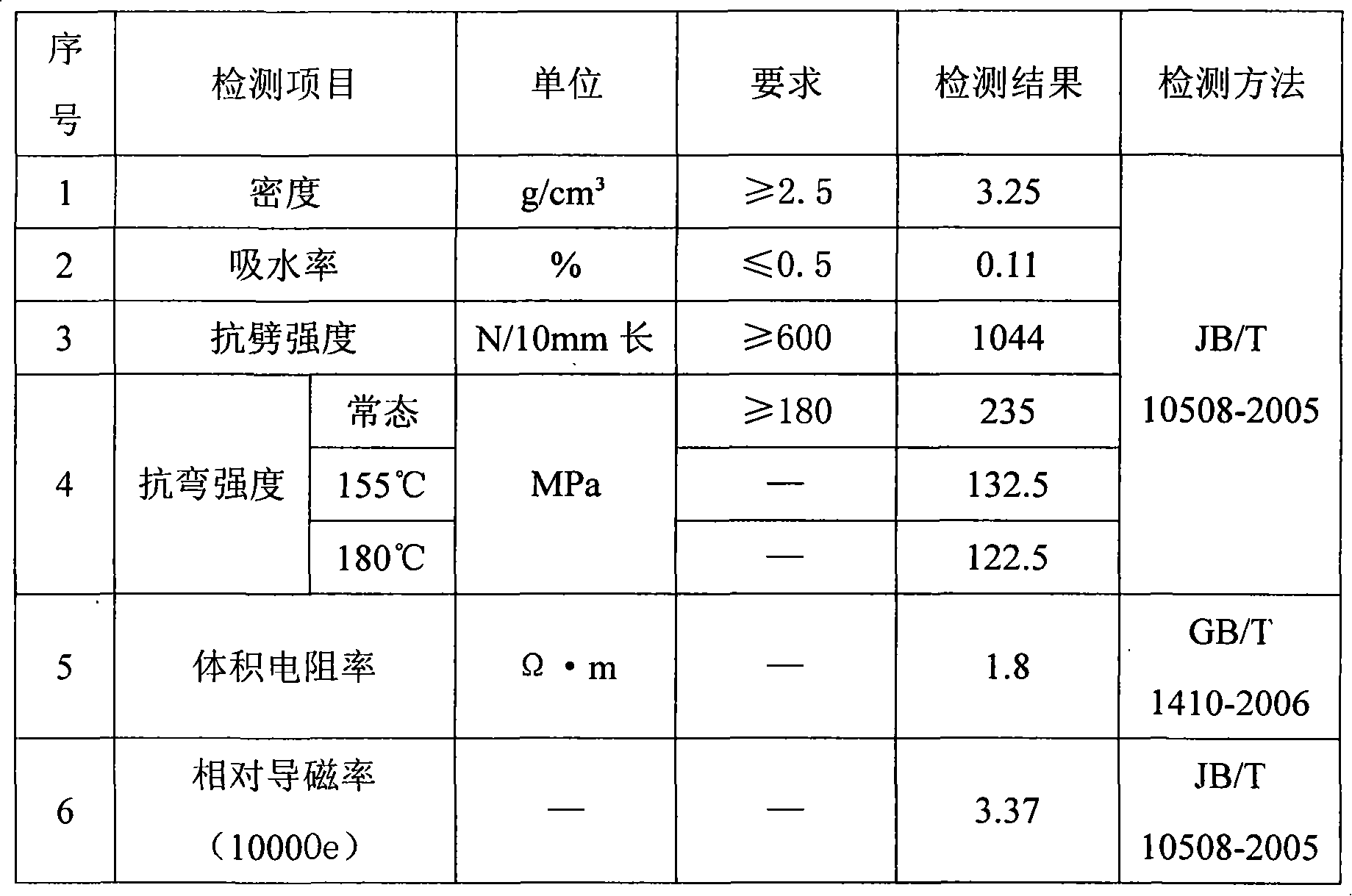

Magnetic wedge and production method thereof

ActiveCN101295894AHigh strengthReduce iron consumptionWindingsManufacturing dynamo-electric machinesGlass fiberAdhesive cement

The invention discloses a magnetic slot wedge and a production method thereof. The magnetic slot wedge comprises 18 percent to 20 percent of 943 unsaturated polyester resins, 0.5 percent to 1 percent of an internal releasing agent, 0.2 percent to 0.5 percent of tert-butyl peroxy benzoate, 0.1 percent to 0.3 percent of benzoyl peroxide, 54 percent to 57 percent of magneto-increasing material and 24 percent to 25 percent of alkali free glass fiber. The production method comprises the steps that: 1. the unsaturated polyester resins, the internal releasing agent and a peroxide evocating agent are prepared into an adhesive according to proportion; 2. a mould is heated to be 150 DEGC -200 DEG C and extraction speed is 0.8-1.40r / min; 3. the alkali free glass fiber soaking the adhesive is treated with pultrusion by the mould; 4. cooling and cutting are carried out; 5. the cut slot wedge is treated with head grinding; 6. the surface of the slot wedge is treated with paint treatment to become bright and clean with no burr; and 7. airing, detecting and packaging are carried out. The magnetic slot wedge has high magnetoconductivity, high cleavage strength, great bending strength and simple production method.

Owner:浙江博菲电气股份有限公司

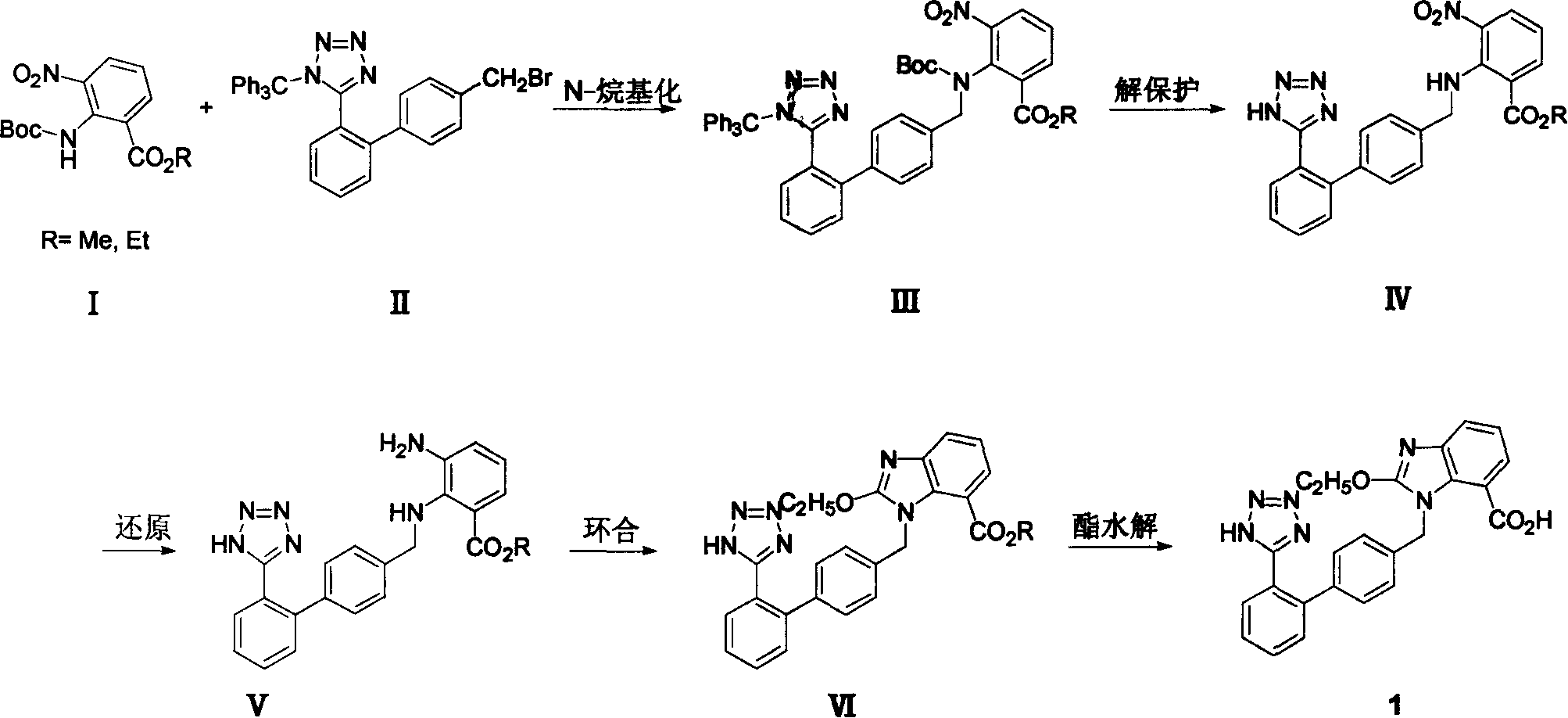

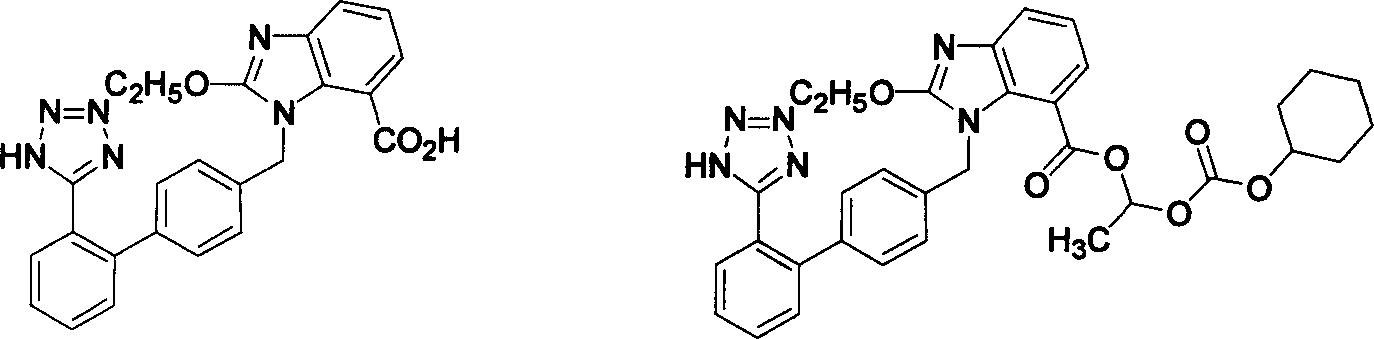

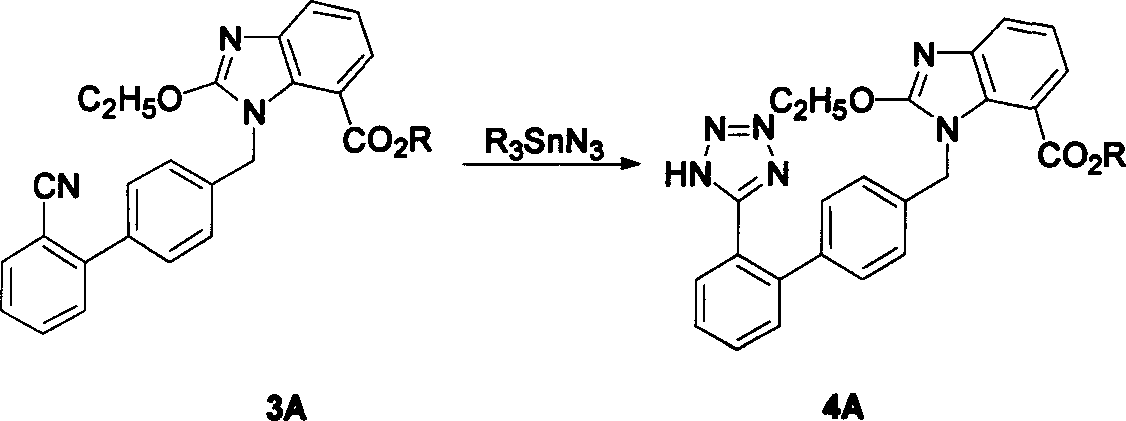

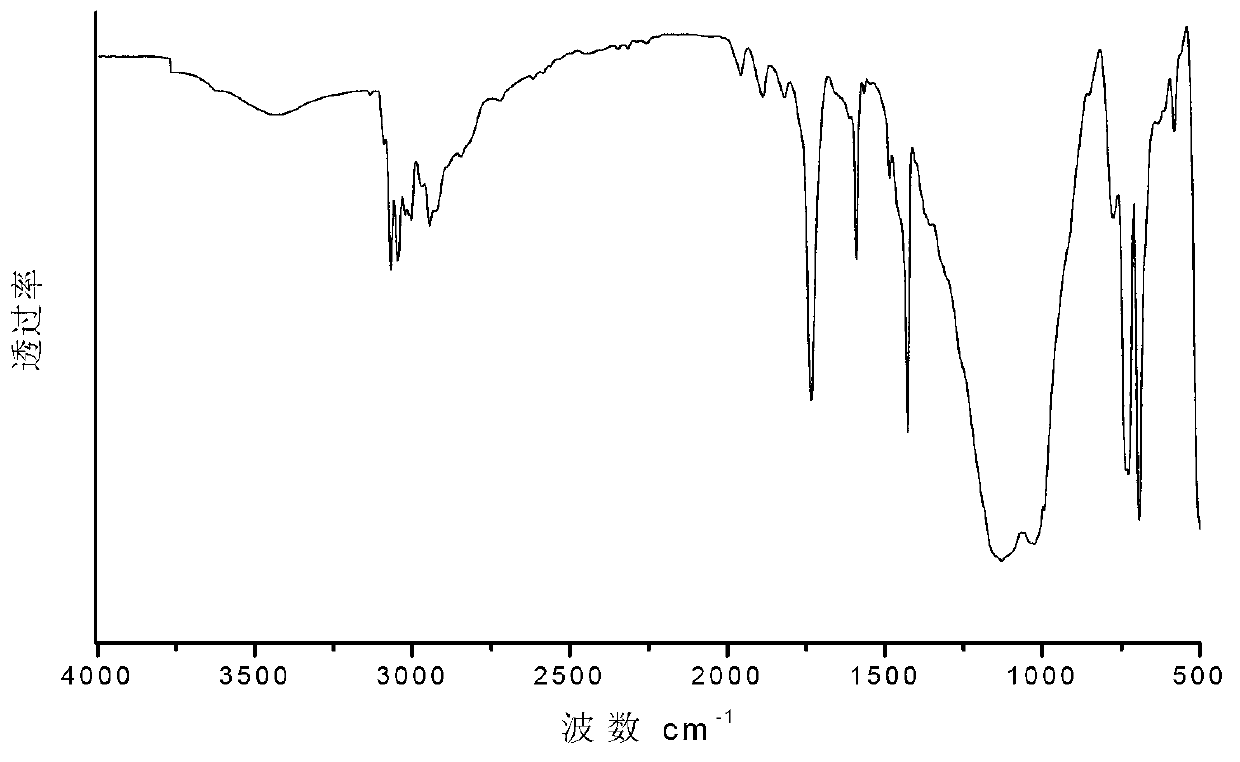

Method for preparing candestartan

ActiveCN1800179ARaw materials are easy to getSimple operation processOrganic chemistryTert-Butyloxycarbonyl protecting groupOxygen

The invention relates to a method for synthesizing ridge sha tan, which uses the 2-tert-butyl ketonic oxygen amido-3-nitro benzoate (I) and N-(trityl )-5-(4'-morphine methylbiphenyll-2-group) tetrazolium (II) as raw material to do N-alkanisation reaction, protecting-released reaction, reduction reaction, ring-closed reaction and ester hydrolytic reaction. <0The protecting-released reaction can slough trityl and tert-butyl ketonic oxygen protect group in the lower aliphatic alcohol organic mixing solution.

Owner:LINHAI TIANYU PHARMA

Long carbon chain dicarboxylic acid total synthesis cutting fluid and preparation method thereof

InactiveCN102766520ASolve the shortcomings of poor anti-rust performance and large amount of additionSolve the case of clumpingLubricant compositionHexamethylenetetramineEngineering

The invention relates to a metal processing cutting fluid and specifically relates to a long carbon chain dicarboxylic acid total synthesis cutting fluid and a preparation method thereof. Long carbon chain dicarboxylic acid, borate and triazole are selected to be coordinated with an antirusting agent for using, and water, lubricating agents, organic amine, boric acid, the long carbon chain dicarboxylic acid, antiseptics, the triazole, softening agents and defoaming agents are used as main ingredients so that defects of poor antirust performances and large additive amounts, which are caused by independently using the borate, benzoate, sebacic acid and urotropine, are overcome. The cutting fluid is stable, good in the antirust performances, excellent in performances of lubrication, rust protection and corrosion prevention and capable of meeting requirements of short-term rust protection among processes; simultaneously, problems of caking of sodium nitrite on metal surfaces during the using of the sodium nitrite are solved, and the long carbon chain dicarboxylic acid is biodegradable and is a green and environment-friendly antirusting agent; and the long carbon chain dicarboxylic acid total synthesis cutting fluid is biodegradable, green and environment-friendly and suitable for various mechanical processing and particularly for various grinding machine processing technologies.

Owner:温州宝罗润滑材料有限公司

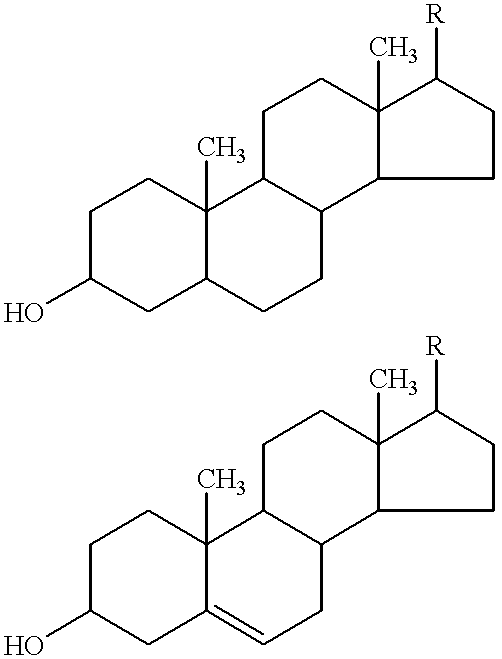

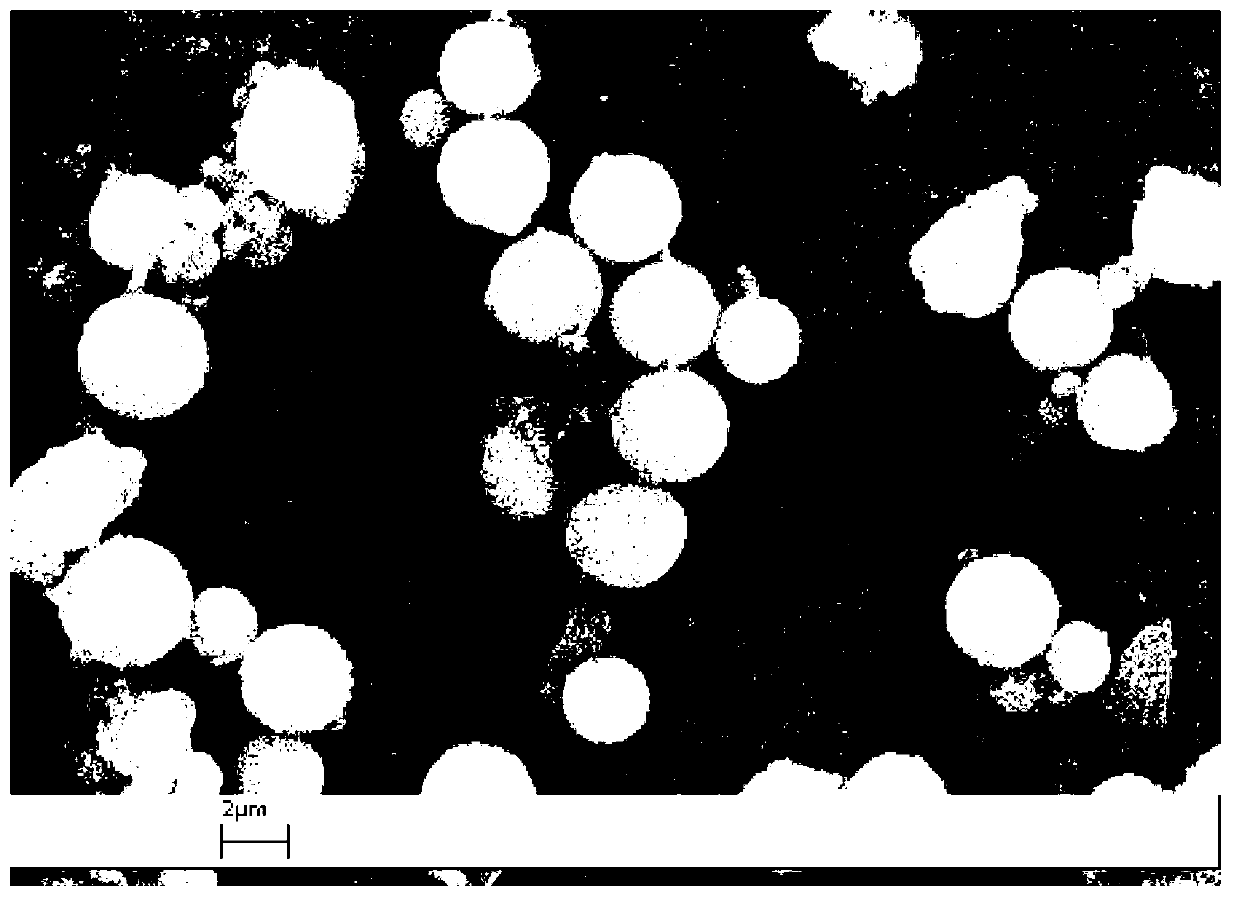

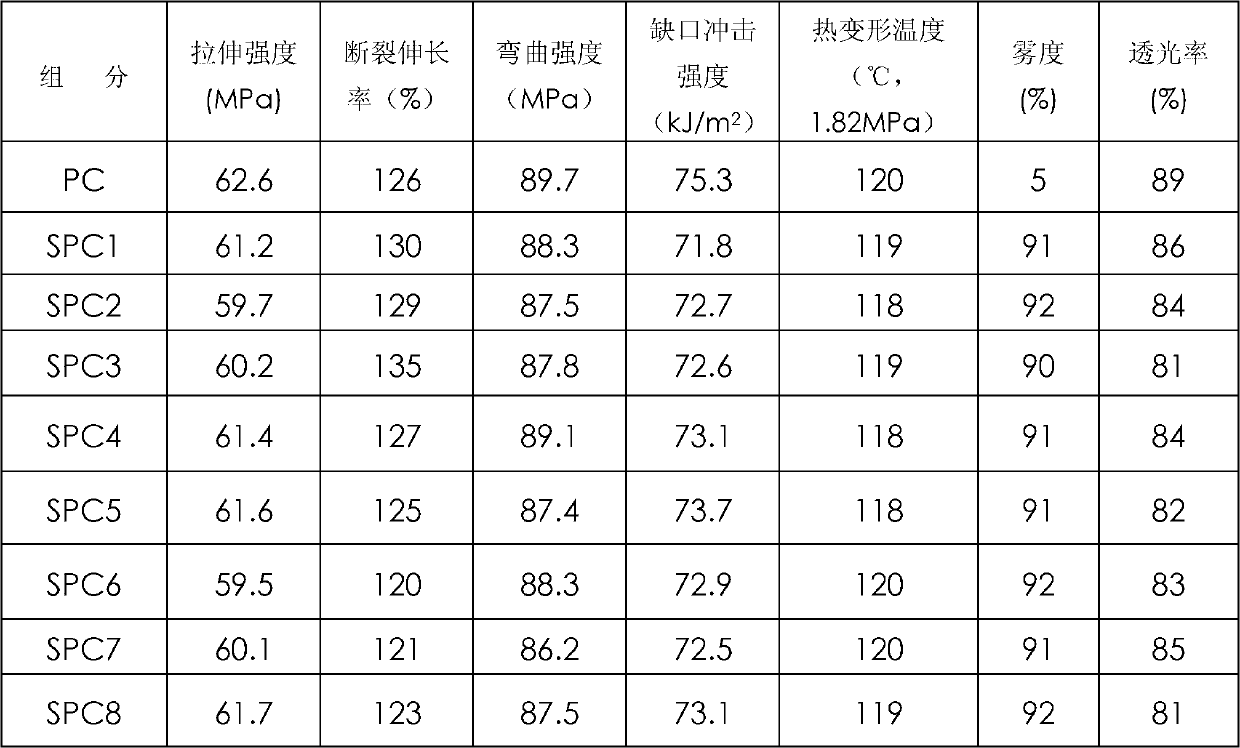

Light scattering microsphere containing benzoate polysilsesquioxane, and preparation method and application thereof

InactiveCN102786690AImprove heat stabilityGood compatibilityPoint-like light sourceGlobesMicrosphereOrganic group

The invention discloses a light scattering microsphere containing benzoate polysilsesquioxane, and a preparation method and application thereof. The light scattering microsphere has a following structural general formula shown in the description; and R represents methyl, ethyl, n-propyl, isopropyl, isobutyl or n-butyl. The molecular structure also comprises a polysilsesquioxane microsphere, which contains benzoate and phenyl organic group, has high thermal stability, good compatibility with matrix and light scattering function. A light scattering functional master batch containing the light scattering microsphere can be used for modification of polycarbonate, has good processing performance and significant effects of opalization and atomization, increases haze of polycarbonate to higher than 90%, and maintains transmittance higher than 80%; besides, the master batch has good light scattering and light permeability, and basically keeps the original good mechanical and thermal properties.

Owner:SOUTH CHINA UNIV OF TECH

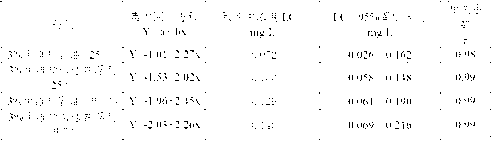

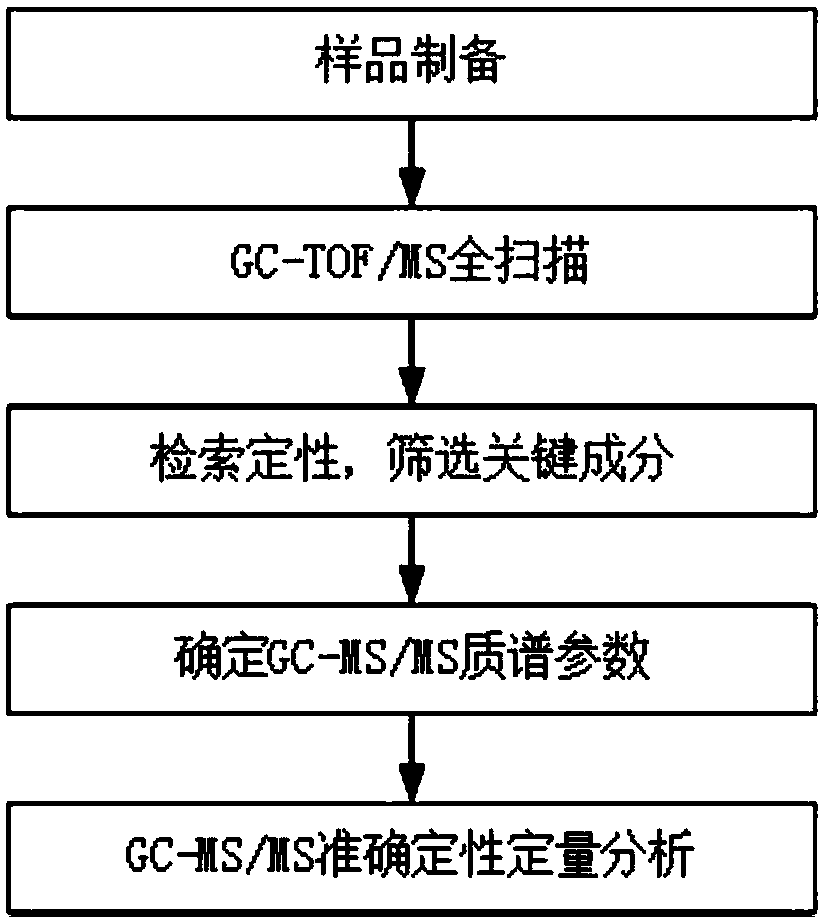

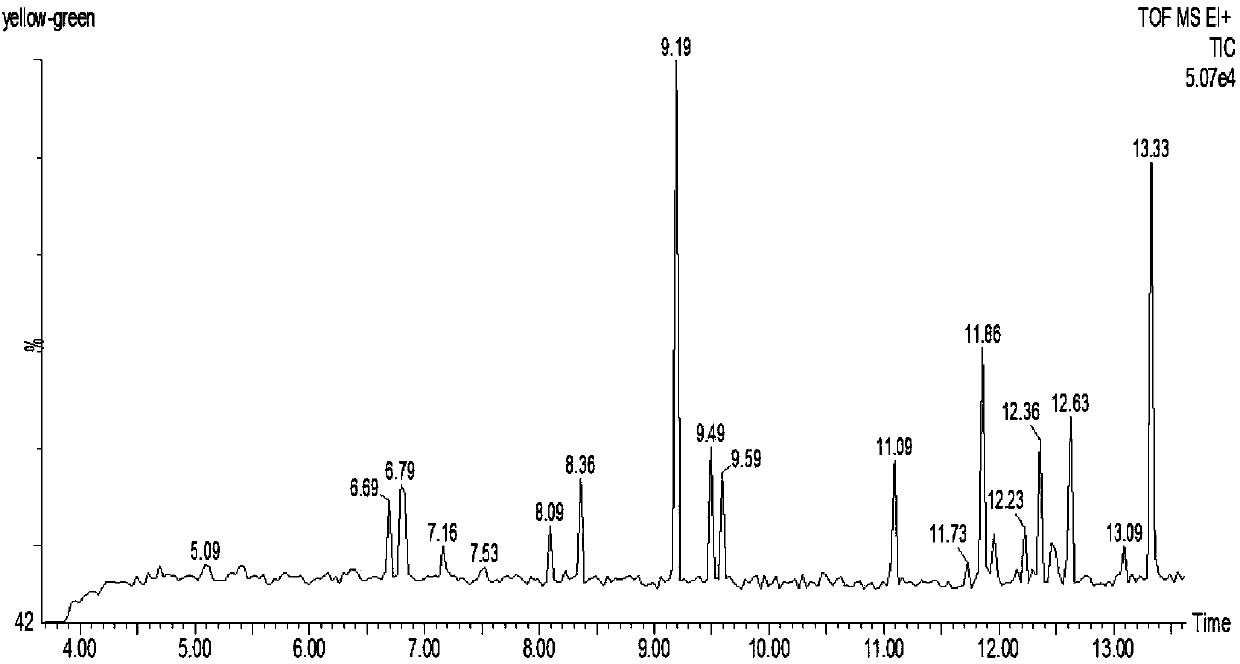

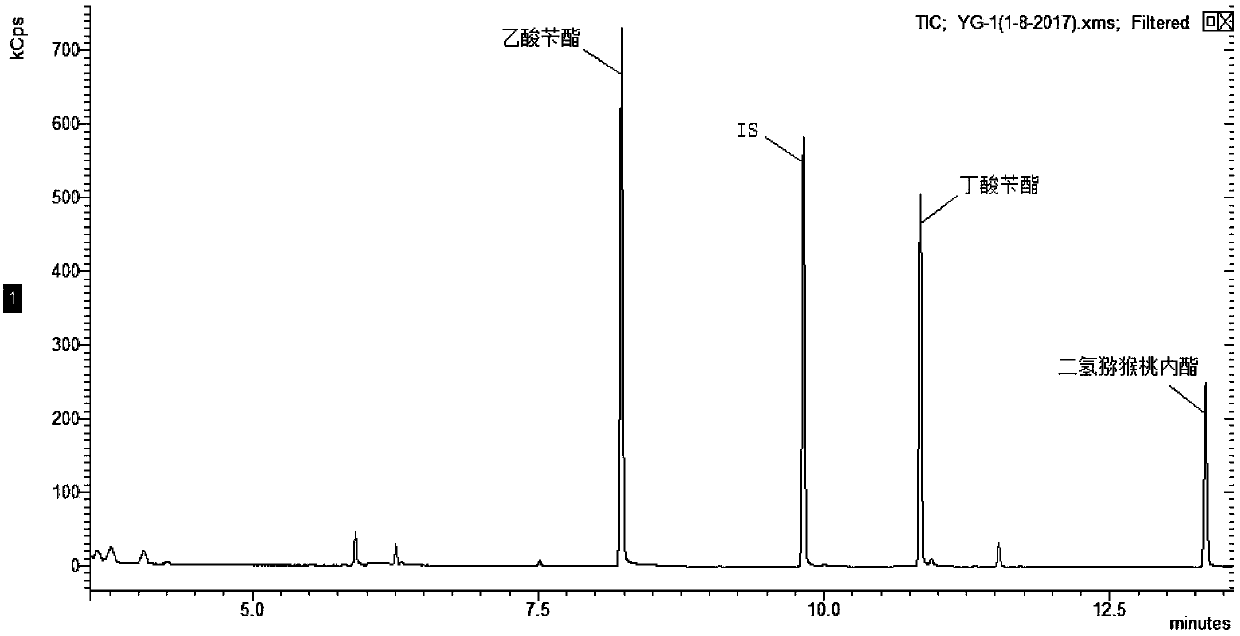

Method for measuring key volatile component in cigarette bead blasting

ActiveCN107764917AHigh speedImprove resolutionComponent separationPropyl benzoateTime-of-flight mass spectrometry

The invention discloses a method for qualitatively and quantitatively analyzing a key volatile component in cigarette bead blasting. The method comprises the following steps: (1) performing full-scanning analysis on a bead blasting isopropanol solution by a gas chromatography high-resolution time of flight mass spectrometry (GC-TOF / MS) to obtain a full-scanning atlas; (2) determining an unknown material and screening the key component by an area normalization method semiquantitative result; (3) determining the mass spectrometric qualitative and quantitative parameters of the key component by taking n-propyl benzoate as an internal standard substance and by combining gas chromatogram secondary mass spectrometry (GC-MS / MS); and (4) drawing a regression curve by a gas chromatogram secondary mass spectrometry combined multi-monitoring scanning mode, and analyzing the content of the key component accurately and quantitatively. The method is simple in operation, high in sensitivity, high inaccuracy degree, short in analysis time and suitable for performing qualitative and quantitative analysis on various volatile and semi-volatile organic compounds in bead blasting simultaneously.

Owner:CHINA TOBACCO YUNNAN IND

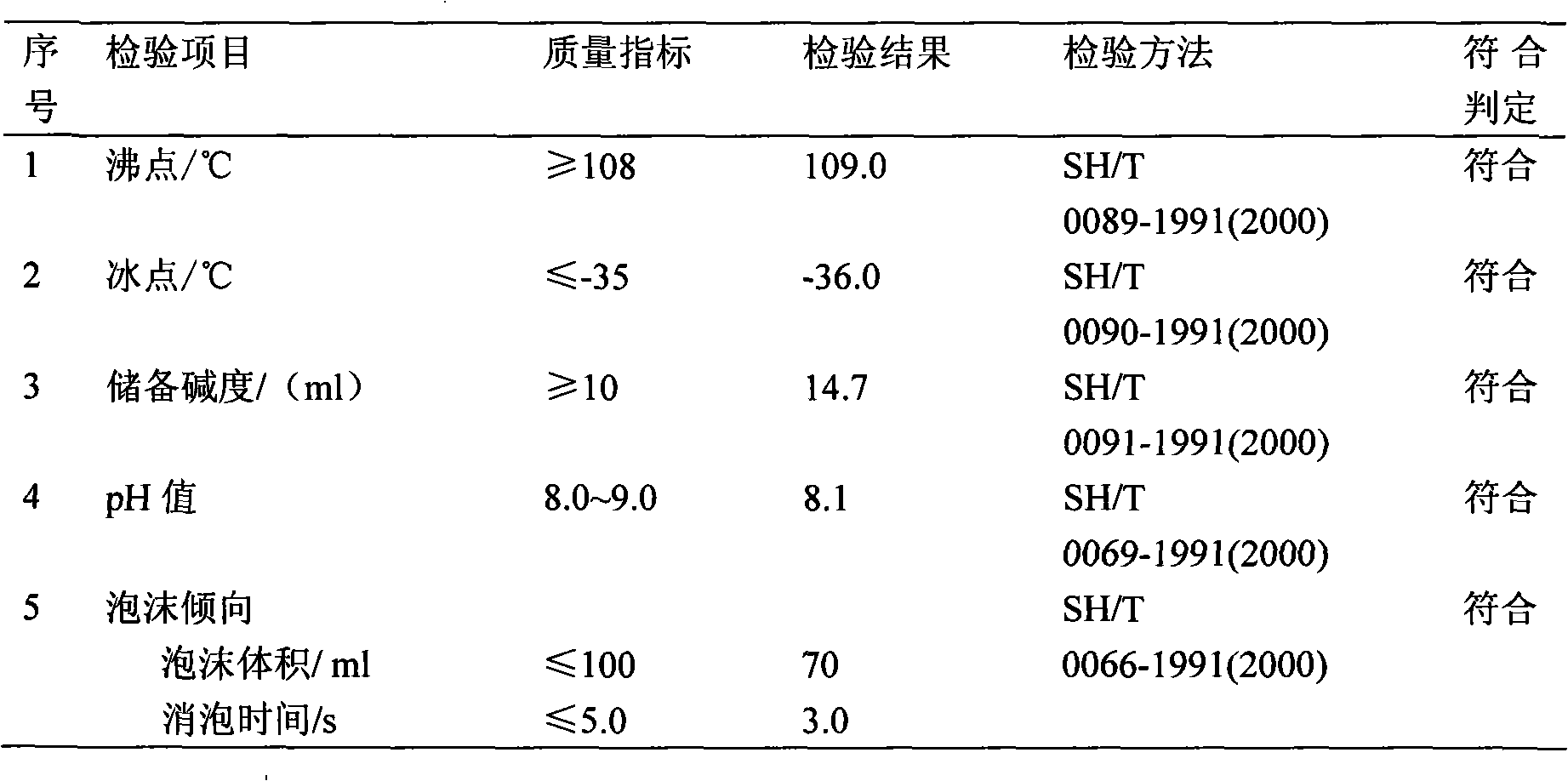

Low silicon content coolant liquid applicable to aluminum radiator of heavy-duty commercial vehicle engine

ActiveCN101602936AImprove heat transfer and cooling performanceMachines/enginesHeat-exchange elementsWater jacketAdipate

The invention relates to low silicon content coolant liquid applicable to an aluminum radiator of a heavy-duty commercial vehicle engine, and belongs to coolant liquid. The coolant liquid comprises the following raw materials in portion by weight: 36 to 52 portions of terylene grade glycol, 1.0 to 1.5 portions of mannite, 0.3 to 0.7 portion of phenylformic acid, 0.7 to 0.9 portion of adipate, 0.1 to 0.2 portion of methylbenzotriazole, 0.05 to 0.1 portion of p-nitrobenzoic acid, 0.001 to 0.004 portion of polyether, 0.3 to 0.7 portion of potassium phosphate, 0.2 to 0.25 portion of sodium nitrite, 0.25 to 0.3 portion of sodium nitrate, 0.5 to 1.0 portion of borax, 0.007 to 0.02 portion of sodium silicate, 0.45 to 0.68 portion of sodium hydroxide, and distilled water for fixing the volume to 100 portions. The coolant liquid contributes to improvement of heat exchange and cooling performance of a water jacket of the engine, is more adapted to an aluminum water tank radiator, is adapted to sedans and light vehicles, and is more adapted to heavy-duty commercial vehicles.

Owner:CHANGCHUN YONGCHANG PETROCHEM

Three-in-one plastic sports ground, and preparation method thereof

InactiveCN105713269ALow costLong lasting bright colorsGround pavingsPolyurea/polyurethane coatingsEpoxyAdhesive

The invention discloses a three-in-one plastic sports ground. The three-in-one plastic sports ground is prepared from, by weight, 1.5 to 2.5 parts of epoxy resin, 70 to 90 parts of regenerated rubber, 10 to 14 parts of an adhesive, 1.5 to 2.5 parts of titanium dioxide, 0.1 to 0.3 part of a reinforcing agent, 1.5 to 2.5 parts of a coloring material containing inorganic pigments, 7 to 9 parts of quartz sand, 2.5 to 3.5 parts of a colorant, and 6 to 8 parts of polyurethane; the coloring material comprises 2 parts of a pigment powder, 0.21 part of titanium dioxide, 0.15 part of antioxidant 1010, 0.18 part of an anti-ultraviolet agent, and 0.15 part of a fortifier; the regenerated rubber is recycled waste rubber; the adhesive contains trimethylolpropane and hexamethylene diisocyanate; the anti-ultraviolet agent is phenyl salicylate; and the reinforcing agent is silicon dioxide. The invention also provides a preparation method of the three-in-one plastic sports ground. The preparation method comprises following steps: smearing of a water-proof layer, laying of an elastic layer, gap filling, and spraying of a wear-resistant layer. The cost of the three-in-one plastic sports ground is lower than that of conventional runways; the three-in-one plastic sports ground possesses permeability; and problems such as bulking, cracking, peeling, and discoloration are not caused.

Owner:梁意昌

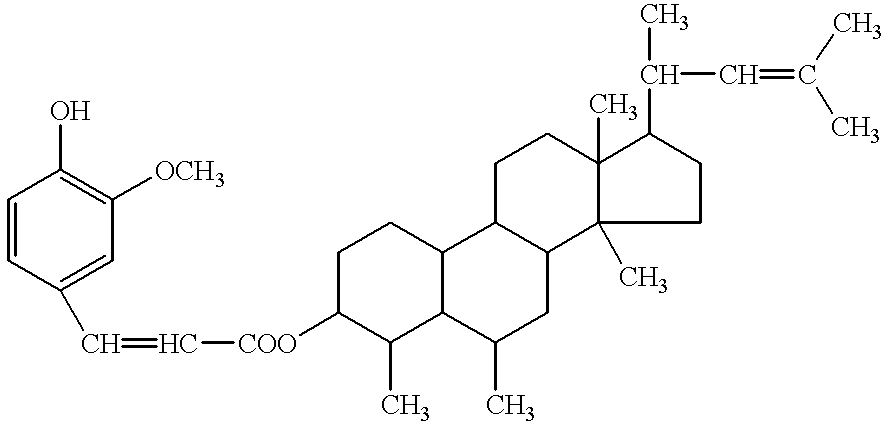

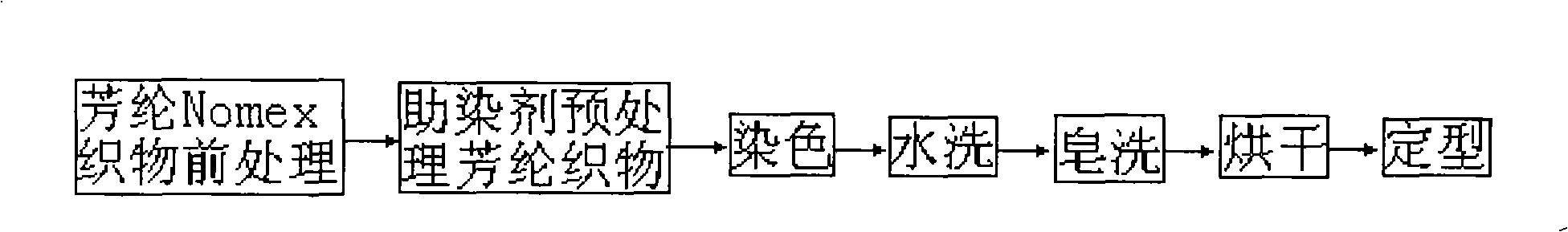

Dyeing-assist agent used for aramid fiber dyeing, preparation method and dyeing method thereof

InactiveCN101319462ALower glass transition temperatureSolve the problem of difficult dyeingFibre typesDyeing processSulfolaneVitrification

The invention discloses a dyeing assistant for aramid dyeing, consisting of the following components in percentage by mass: 8-12 percent of methyl benzoate, 4-6 percent of sulfolane, 1-3 percent of OP-10, 1-3 percent of sodium dodecyl sulfonate and 80-82 percent of water, and the total quantity of the components is 100 percent. A method of putting the raw materials into a high shear mulser for emulsification is adopted to prepare the dyeing assistant. A dyeing method for aramid comprises the following steps that: an aramid fabric is pretreated and then pretreated by using the dyeing assistant; then dyeing, washing, soaping, drying and shaping are carried out to the treated fabric in a conventional method, thus the aramid fabric is dyed. By lowering the vitrification temperature of the aramid, the dyeing method solves the problem that the aramid is difficult to dye and cannot has the dyeing depth reach medium deep color in a dyeing process, is novel in dyeing technique, short in technological process and simple to operate, causes no pollution to environment, and has extensive economic benefit and market benefit.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Color-variable printing ink and preparation method thereof

The invention discloses color-variable printing ink capable of changing colors at different temperatures. The color-variable printing ink comprises cholesteryl nonanoate, C8 aliphatic polyoxyethylene ether, cholesteryl oleylcarbonate, cholesteryl benzoate, acrylate emulsion, 304 silicone emulsion, ethyecellulose, chloroform, isopropanol, gelatin, microcrystalline wax, Arabic gum and polyacrylamide. The printing ink prepared according to the invention can have the following five colors in total within a temperature range of 37 DEG C to 40 DEG C, namely, transparent, reddish orange, green, cyan and purple.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

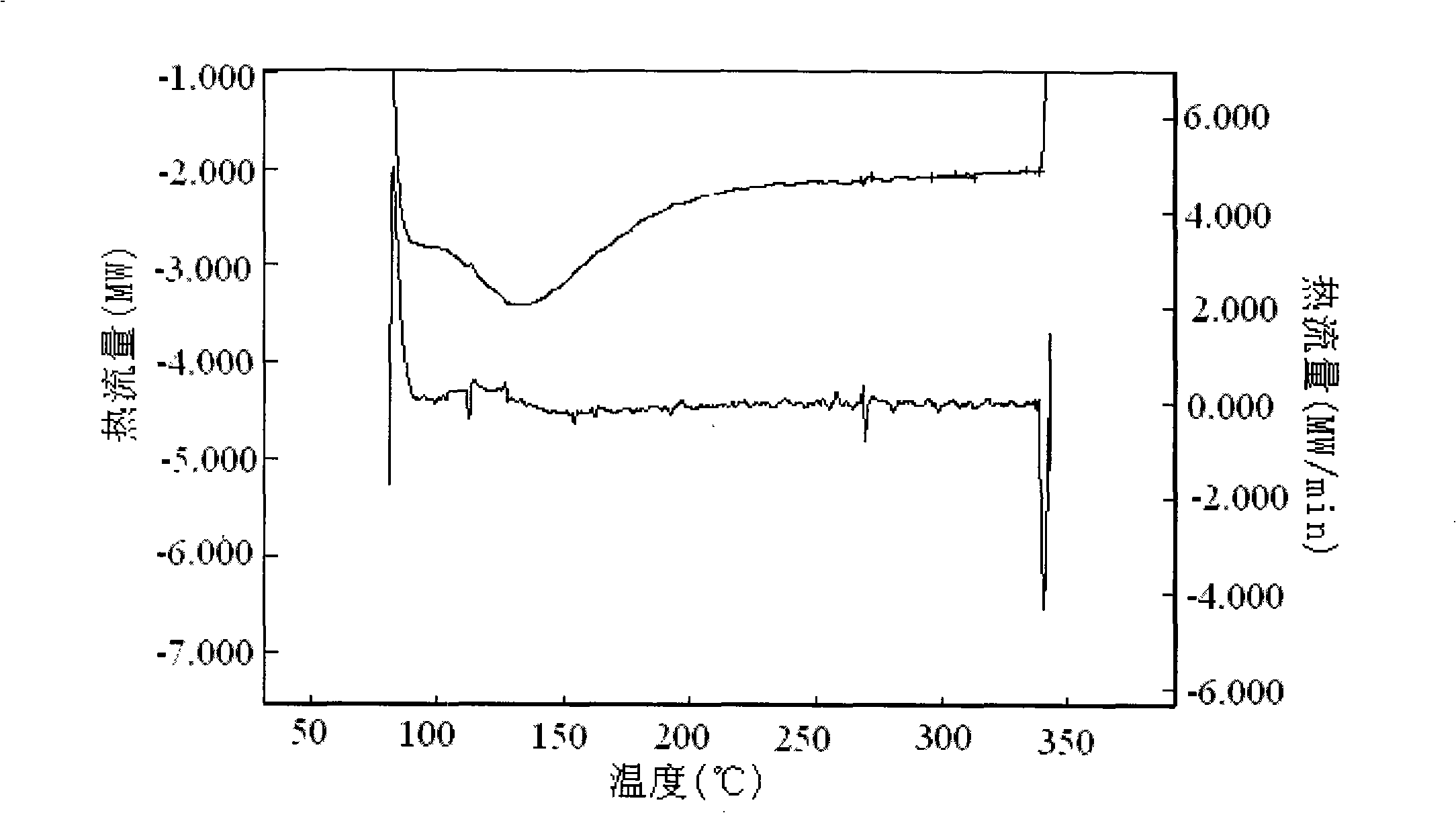

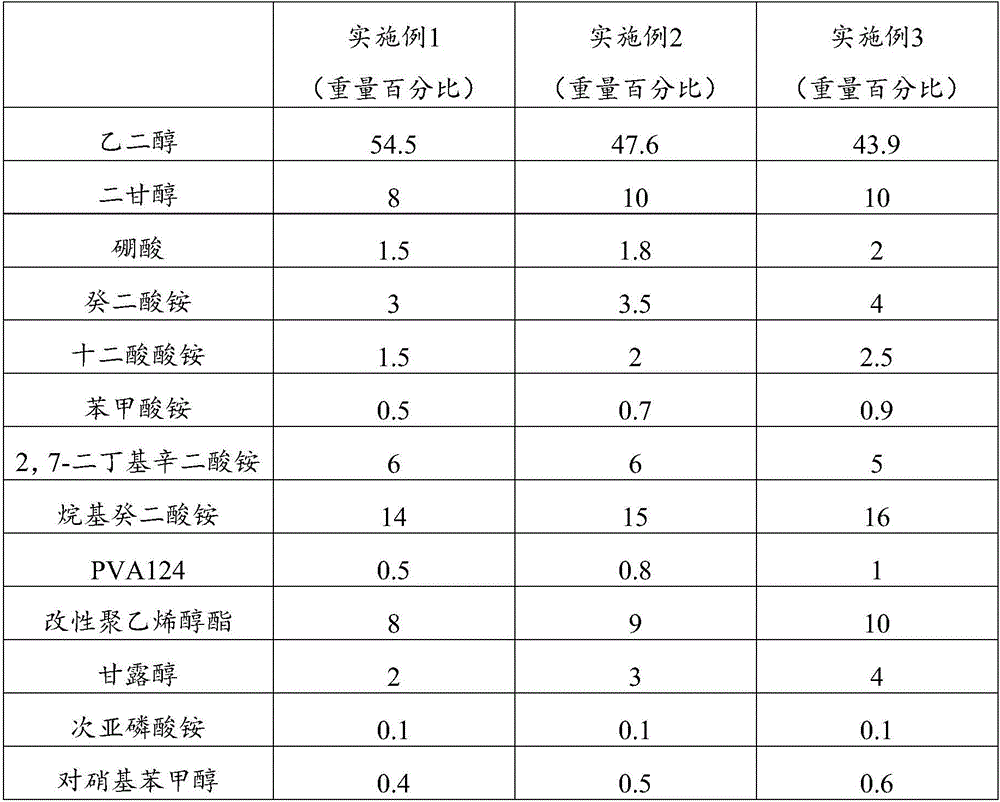

Electrolyte, electrolyte preparation method and aluminum electrolytic capacitor

ActiveCN106098379AImprove temperature resistanceImprove stabilityLiquid electrolytic capacitorsSolventTemperature resistance

The invention discloses an electrolyte, an electrolyte preparation method and an aluminum electrolytic capacitor. The electrolyte comprises, by weight percentage, 50-65w% of solvent, 23-33w% of solute, and 8-19w% of additive. The solute includes boric acid, ammonium benzoate, at least one material selected from ammonium dodecanedioate and 2,7-dibutyl octanedioic acid ammonium, and at least one material selected from ammonium sebate and alkyl ammonium sebate. Through the technical scheme, the temperature resistance performance and stability of the aluminum electrolytic capacitor are improved.

Owner:惠州市智胜新电子技术有限公司

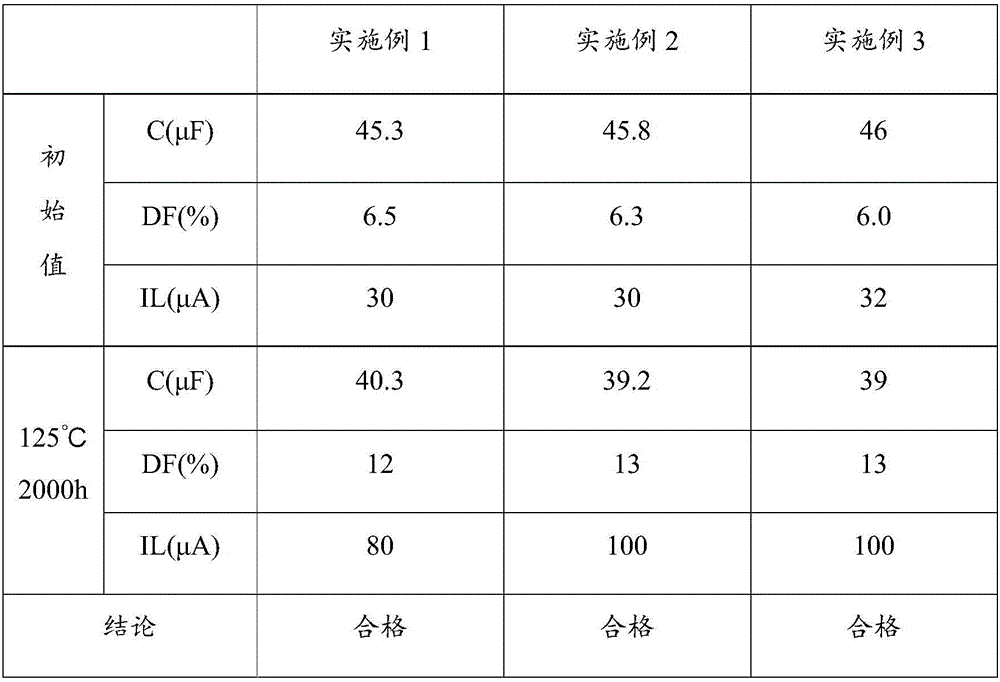

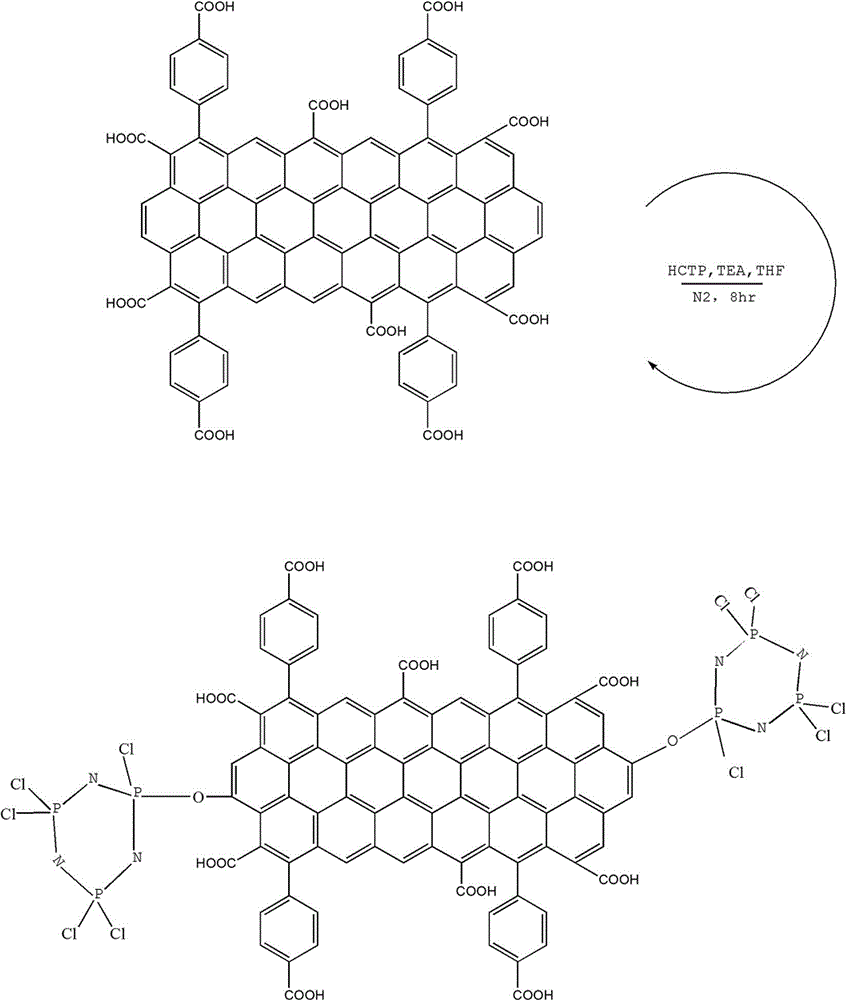

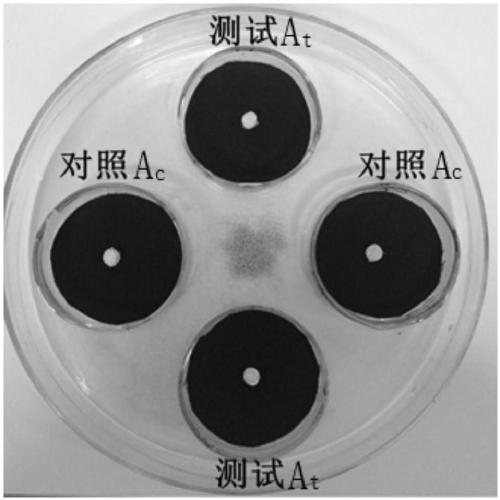

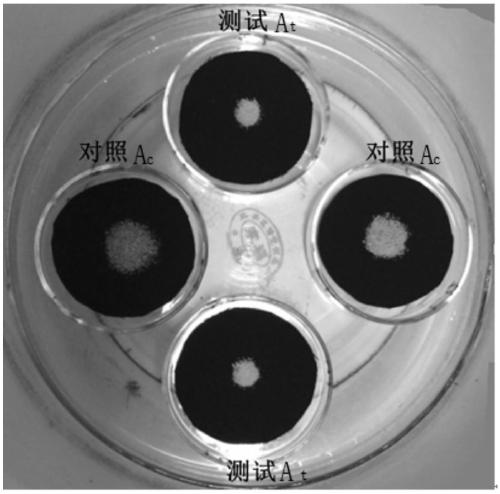

Preparation method of novel nanoscale fire retardant

A preparation method of a novel nanoscale fire retardant comprises the following steps: first, performing reduction on oxidized graphene; then, grafting para aminobenzoic acid on graphene to functionalize reduced graphene oxide; finally, grafting phosphonitrilic chloride trimer to further enhance the stability, and grafting chlorine element and phosphorus element on graphene, that is, combining a graphene flame retardant, a phosphorus flame retardant and a halogen flame retardant to prepare the nanoscale flame retardant. Base materials into which the novel nanoscale flame retardant can be added comprise natural rubber, EPDM (Ethylene Propylene Diene Monomer), butadiene styrene rubber and polypropene plastics. Compared with a traditional intumescent flame retardant and a traditional halogen flame retardant, the novel nanoscale flame retardant prepared by the preparation method can effectively solve the problems that the traditional flame retardant is poor in dispersity in material base bodies, weak in surface migration resisting capability, large in addition amount, poor in compatibility, un-ideal in flame-retardant effect, weak in carbon forming capability and the like, so that the flame retardant property of the composite and the compatibility between the flame retardant and the material base body are greatly improved.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

Water-based paint for pipeline and preparing method of water-based paint

InactiveCN105255332ACorrosionStrong adhesionAntifouling/underwater paintsPaints with biocidesSODIUM METAPHOSPHATEMelamine phosphate

The invention relates to water-based paint for a pipeline. The water-based paint for the pipeline is prepared from modified phenolic resin, pitch, alcohol acid emulsion, chromium oxide green, an anti-rusting agent, low polymer polyhydric alcohols, maleic anhydride, methyl methacrylate, hydroxyl ethyl acrylate, hydroxylated fiber resin, polyether sulfone resin, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy silane modified silicon sol, crosslinked polyethylene, tert-butyl peroxybenzoate, sodium silicate, melamine phosphate, pentaerythritol, aluminum silicate fibers, silicon dioxide, antibacterial preservative, titanium dioxide, Ni, Zn, water and other raw materials. Due to the fact that the ingredients such as Ni and Zn are contained in the water-based paint for the pipeline, the water-based paint for the pipeline has the high-temperature resisting and corrosion resisting performance, is suitable for coating demands of various occasions, does not contain toxic organic solvents, is free of pollution and has the advantages that a paint surface cannot crack, and the paint is resistant to aging, high in adhesive force and the like.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Lip-plumping lipstick and production method thereof

InactiveCN111012690AGood colorImprove cold resistanceCosmetic preparationsAntipyreticSkin barrier functionPolymer science

The invention relates to the technical field of cosmetics, and concretely relates to a lip-plumping lipstick and a production method thereof. The lip-plumping lipstick at least comprises, by weight, 20-35 parts of an emollient, 20-35 parts of an emulsifier, 8-20 parts of a thickener, 15-25 parts of hydrogenated polyisobutene, 3-6 parts of C8-28 alkanol benzoate, 0.8-2 parts of bionic peptide, 1-3.5 parts of filled microspheres, 1.5-3 parts of a film-forming agent and 0.05-0.15 part of a coloring agent. The lip-plumping lipstick can stimulate the synthesis of lip collagen and glycosaminoglycan,keep the elasticity of lip skins, enhance the water absorption and expansion capabilities of the lip, improve the water retention capacity of the lip skins and instantaneously smooth wrinkles, is remarkable in a lip plumping effect, and can moisten the lip skins, so the lip-plumping lipstick has significantly improved color rendering property and durability, has excellent cold-resistant and heat-resistant stability, effectively repairs the lip skin barrier function, well protects the lip skins, and has anti-inflammatory, moisturizing, itching-relieving and anti-aging effects.

Owner:上海瑾亭化妆品有限公司

Method for synthesizing methyl 3-(trifluoromethyl)benzoate

InactiveCN102351704AImprove controllabilityEfficient use ofOrganic compound preparationCarboxylic acid esters preparationSide chainWater chlorination

The invention provides a new method for synthesizing methyl 3-(trifluoromethyl)benzoate, which comprises side-chain chlorination reaction, fluorination reaction and esterification reaction. The method is environment-friendly and high in reaction yield; and the selected raw materials, namely chlorine, m-methylbenzoyl chloride, anhydrous hydrofluoric acid, methanol, light calcium carbonate and the like are cheap and readily available in industry. The related three reactions are high in controllability and easy to operate, and an intermediate product is not required to be purified and can undergo the next reaction. Byproducts generated in the reactions can be effectively utilized, and the industrial feasibility of the method is improved.

Owner:ZHEJIANG WEIHUA CHEMICAL CO LTD

Detergent composition with mite control function

PendingCN109234055AGood anti-mite effectPrevent intrusionInorganic/elemental detergent compounding agentsSoap detergents with organic compounding agentsBenzyl benzoatActive agent

The invention relates to the technical field of daily chemical fabric washing products, in particular to a detergent composition with a mite control function. As benzyl benzoate and methyl dihydrojasmonate with certain content are added in the detergent composition, the detergent has the effect of inhibiting mites from invading washed textile; and moreover, as appropriate amount of surfactant anddetergent assistant are cooperated with benzyl benzoate and methyl dihydrojasmonate, the coordination effect among components is increased, and as a result, the detergent composition has a better mitecontrol effect.

Owner:GUANGZHOU LIBY

Methylamino abamectin benzoate water dispersible granules and method for preparing same

InactiveCN102475084AAddressing Dermal ToxicityReduce pollutionBiocideAnimal repellantsWater dispersibleAbamectin

The invention relates to methylamino abamectin benzoate water dispersible granules and a method for preparing the same. Raw materials include, by weight, 5-50 parts of methylamino abamectin benzoate, 1-15 parts of dispersant, 1-10 parts of wetting agent, 1-10 parts of disintegrant and 2-80 parts of filler. The raw materials are weighed, mixed well and evenly crushed in a jet mill, water is added before mixture is kneaded to lumps extruded for granulation, granules extruded are placed in a drying box to be dried, and finally the finished products are obtained by shaping and screening. Compared with the prior art, the methylamino abamectin benzoate water dispersible granules have the advantages of no dust, high content of active ingredients, proneness to disintegration in water, high dispersibility, high suspendability and the like.

Owner:SHANGHAI NONGLE BIOLOGICAL PROD

High-stability moisture preservation sun-screen cream

InactiveCN107737027AImprove stabilityReasonable formulaCosmetic preparationsToilet preparationsSucroseIrritation

The invention provides high-stability moisture preservation sun-screen cream, which is prepared from cyclopentasiloxane, cyclohexasiloxane, titanium dioxide, caprylic / capric triglyceride, C12-15 alcohol benzoate, CI 77891, PEG-30 dihydroxy stearate, polydimethyl siloxane crosslinked polymers, ethylhexyl methoxycinnamate, disteardimonium hectorite, propylene garbonate, cetyl dimethicone, stearoyl inulin, tocopheryl acetate, bis-PEG / PPG-14 / 14 polydimethylsiloxane, cetyl PEG / PPG-10 / 1 polydimethylsiloxane, cyclopentasiloxane, PEG / PPG-18 / 18 polydimethylsiloxane, sucrose polyoleate, butanediol, propanediol, sodium chloride, 1,2-hexanediol, 1,2-pentanediol, allantoin, EDTA-disodium, butanol polyether-3, azimino-benzene butyl sodium phenolsulfonate, tributyl citrate, lycine, sodium hyaluronate, niacinamide, creatin, methyl hydroxybenzoate, peony root extracts, rice fermentation product filter liquid and phenoxyethanol. The formula design is reasonable; the irritation is small; the stability ishigher than that of a conventional sun-screen cream; the sun-screen and moisture preservation effects are ensured; the formation of free radicals is reduced; the anti-aging function is achieved.

Owner:NOX BELLCOW COSMETICS CO LTD

Nourishing type eye shadow cream

The invention discloses nutrition type eye shadow which is composed of four components of A, B, C and D. According to parts of the weight, the composition of the A, B, C and D is as follows: component A contains 50-60 parts of deionized water, 2-8 parts of propylene glycol, 0.5-2 parts of tiethanolamine, 0.1-0.3 parts of sodiumhydroxide, 1.5-2 parts of colloidality silicic acid magnalium, and 0.1-0.3 parts of methyl hydroxybenzoate; component B contains 3-5 parts of lanolin, 1-3 parts of myristic acid isopropyl ester, 3-8 parts of white oil, 1-2 parts of olive oil, 4-6 parts of stearic acid, and 6-10 parts of bees wax; component C contains 15-20 parts of talcum powder, 2-4 parts of kaolin, 4-6 parts of titanium dioxide, 3-5 parts of magnesium oxide, and 3-7 parts of white mica powder; and component D contains 0.5-1 parts of essence. The invention has the advantages that the usage is convenient, the effect is convenient and the price is low.

Owner:叶芳

Clear isolation cream

InactiveCN103340812AMild in natureKeep it detailed and fullCosmetic preparationsToilet preparationsButanediolBenzioc acid

The invention discloses a clear isolation cream. The clear isolation cream contains propylene glycol, butanediol, glycine betaine, sodium chloride, magnesium sulfate, methyl parahydroxybenzoats, para hydroxybenzene propyl ester, EDTA (Ethylene Diamine Tetraacetic Acid) disodium, cetyl PEG / PPG-10 / 1 polydimethylsiloxane, Dimeticone, caprylic acid, triglyceride fatty acid, shea butter, microcrystalline wax, beeswax, polydimethylsiloxane, grape seed oil, sodium hyaluronate, essence, arbutin, adenosine, allantoin, iron oxide yellow, iron oxide red, black iron oxide and water. The evaluation of users and the result of test on the skin of the users show that the isolation cream has better isolation effect, the cream preparation is light and breathable, and the clear isolation cream can effectively isolate harmful matters in make-up products and the air, block ultraviolet rays, protect the skin from being hurt without blocking pores, and can keep the skin supple and full.

Owner:开平市美康泉生物科技有限公司

Fireproof and high temperature resistant coating

The invention relates to a fireproof and high temperature resistant coating comprising the following components by weight: 20-25 parts of polybutylene, 10-13 parts of decabromodiphenyl ether, 5-8 parts of fireproof short fiber, 4-6 parts of ethyecellulose, 3-5 parts of hexamethylenetetramine, 4-8 parts of titanium dioxide, 5-8 parts of dibutyl benzoate, 2-4 parts of pentaerythritol, 1-5 parts of plaster, 8-11 parts of acrylate resin, 10-15 parts of fire retardant, 2-5 parts of foaming agent, 0.8-2.5 parts of reinforcing agent and 10-20 parts of solvent, wherein the fire retardant is borax or aluminum borate, the foaming agent is ammonium carbonate or melamine, and the reinforcing agent is phenolic fiber or glass fiber. According to the fireproof and high temperature resistant coating provided by the invention, a coating formulation is improved, an environment-friendly flame resistant material is selected, some inorganic materials are added, the high temperature resistant performance of the coating is improved while the coating is fireproof, and the fireproof performance meets the demands of national regulation.

Owner:江苏艾德卡建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com