Light scattering microsphere containing benzoate polysilsesquioxane, and preparation method and application thereof

A technology of siloxane light and ester trialkoxysilane, which is applied in the field of light-scattering functional masterbatches, can solve problems such as difficulty in uniform dispersion, poor matrix compatibility, and poor heat resistance stability, and achieve good compatibility, The effect of good heat resistance stability, good mechanical properties and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

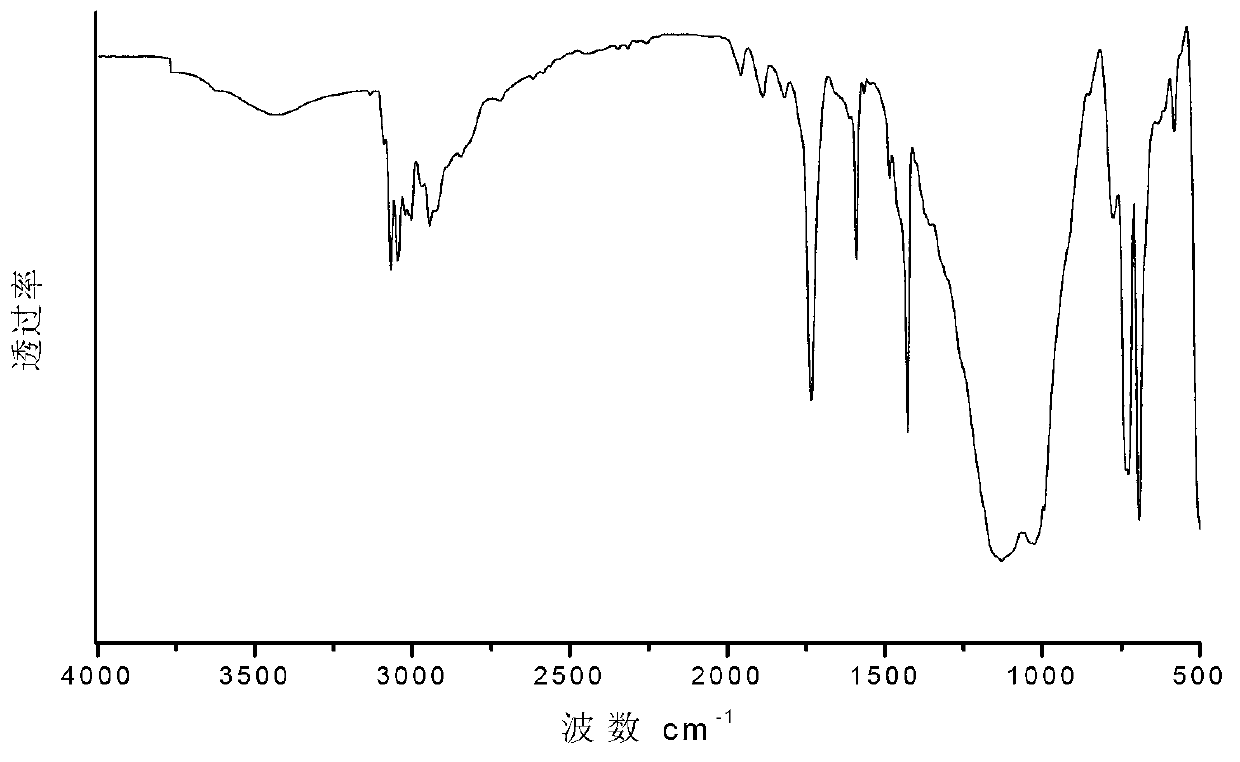

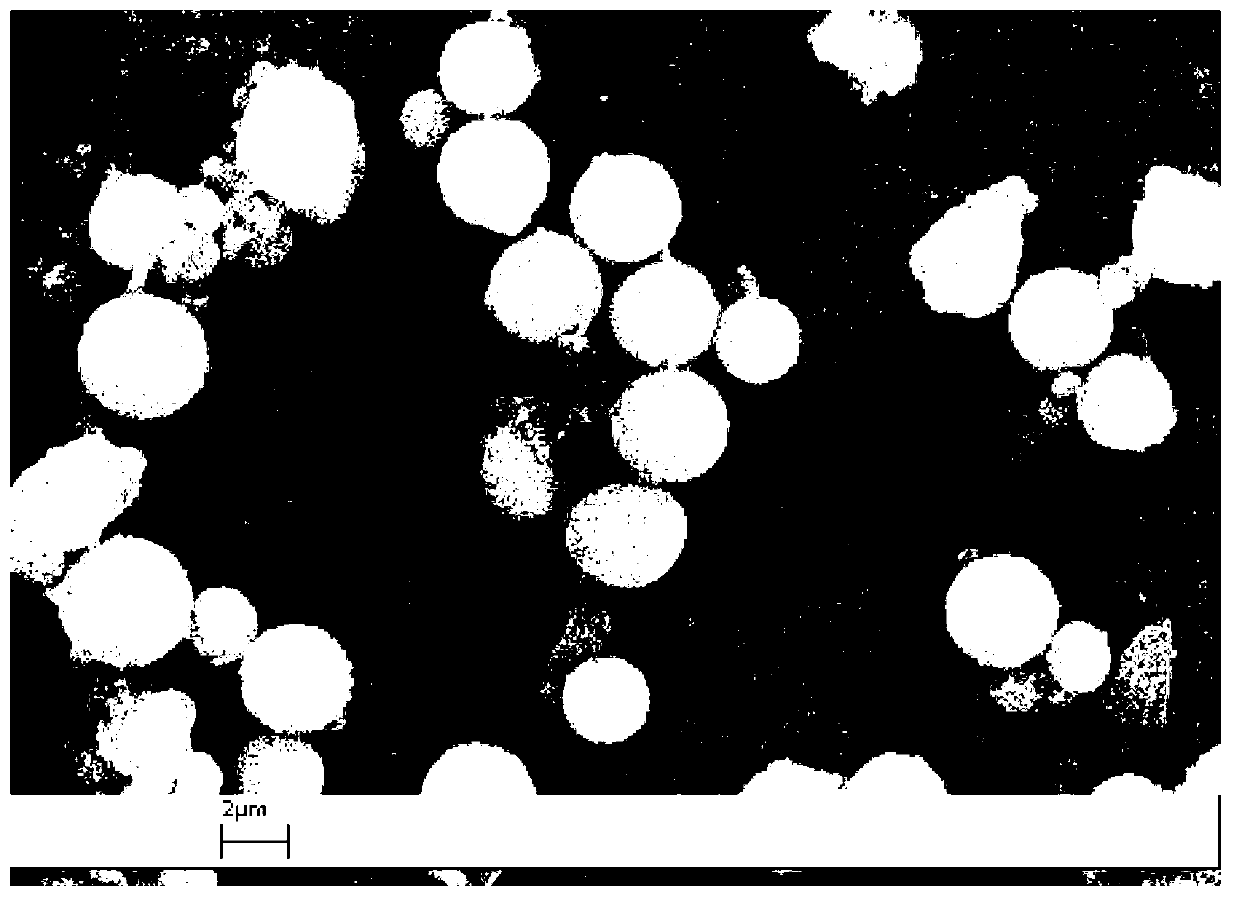

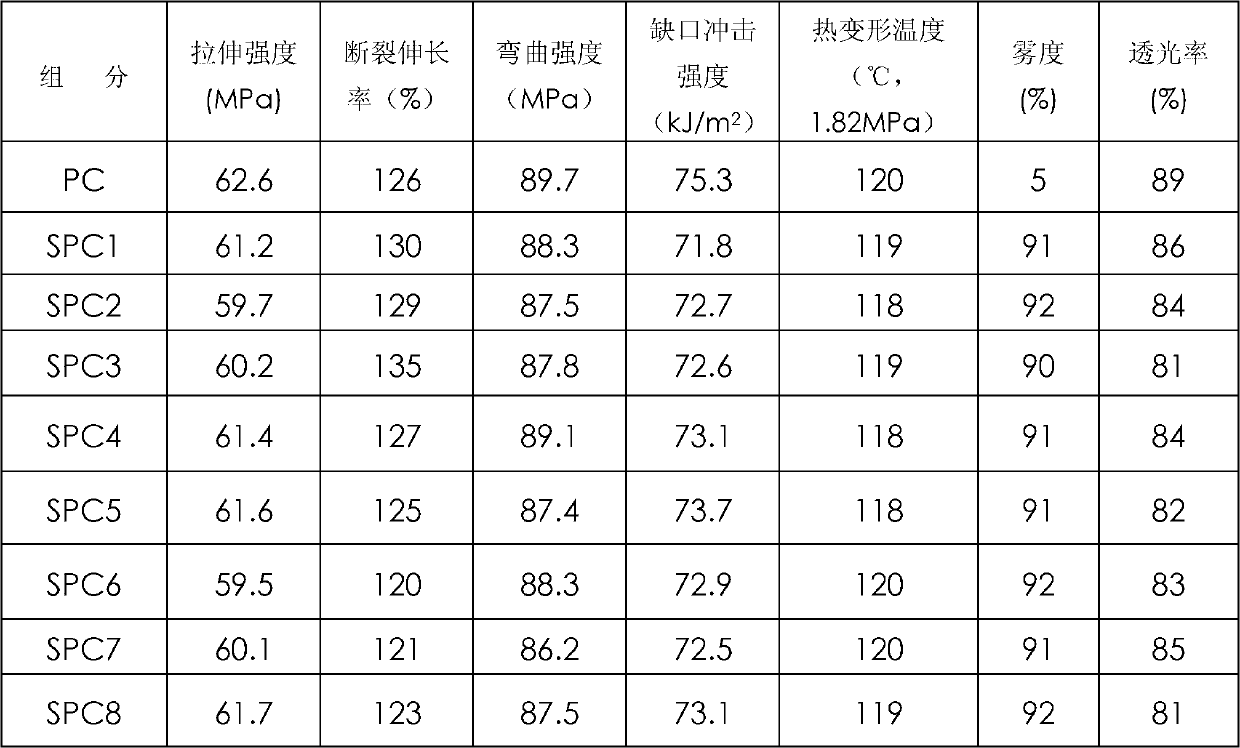

Method used

Image

Examples

Embodiment 1

[0031] Step (1), add 0.30mol Y-chloropropyltriethoxysilane, 0.33mol sodium n-propyl hydroxybenzoate and 518g ethanol in the 1000ml three-neck flask that mechanical stirrer, thermometer are housed, stir and mix, at 80 React at ℃ for 4 hours, cool to room temperature, filter, distill off the ethanol in the filtrate under reduced pressure, and obtain triethoxysilane containing n-propyl benzoate after drying;

[0032] Step (2), add 0.78g tetramethylammonium hydroxide, 195g Virahol and 58.5g water in the 500ml there-necked flask that mechanical stirrer, thermometer are housed, with 0.05mol containing n-propyl benzoate group triethoxy Silane was mixed with 0.1mol phenyltrimethoxysilane and the two silane monomers were added to the reaction flask, stirred and reacted at 25°C for 8 hours, and after standing for 4 hours, a white precipitate precipitated, vacuum filtered, and the mass ratio was After cleaning with a 4:1 mixture of ethanol and water, put it in a vacuum oven and dry at 50...

Embodiment 2

[0036] Step (1), add 0.40mol Y-chloropropyl triethoxysilane, 0.42mol sodium ethyl hydroxybenzoate and 580g ethanol in a 1000ml three-necked flask equipped with a mechanical stirrer and a thermometer, stir and mix, and heat the mixture at 80°C React at room temperature for 2 hours, cool to room temperature, filter, and distill off the ethanol in the filtrate under reduced pressure, and obtain ethyl benzoate-containing triethoxysilane after drying;

[0037] Step (2), add 1.57g potassium hydroxide, 94.2g methyl alcohol and 47.1g water in the 250ml there-necked flask that mechanical stirrer, thermometer are housed, with 0.02mol containing ethyl benzoate group triethoxysilane and 0.1mol Phenyltriethoxysilane and two silane monomers were mixed and added to the reaction flask, stirred and reacted at 50°C for 8 hours, after standing for 5 hours, a white precipitate precipitated, vacuum filtered, and the mass ratio was 4:1 After cleaning with a mixture of ethanol and water, put it into...

Embodiment 3

[0039] Step (1), add 0.50mol Y-chloropropyl triethoxysilane, 0.50mol sodium methyl hydroxybenzoate and 482g ethanol in a 1000ml three-necked flask equipped with a mechanical stirrer and a thermometer, stir and mix, and heat at 50°C React at room temperature for 6 hours, cool to room temperature, filter, distill off the ethanol in the filtrate under reduced pressure, and obtain triethoxysilane containing methyl benzoate after drying;

[0040] Step (2), add 0.3g sodium hydroxide, 238.4g ethanol and 47.7g water in the 500ml there-necked flask that mechanical stirrer, thermometer are housed, with 0.1mol containing methyl benzoate group triethoxysilane and 0.1mol Phenyltriethoxysilane and two silane monomers were mixed and added to the reaction flask, stirred and reacted at 25°C for 12 hours, after standing for 3 hours, a white precipitate precipitated, vacuum filtered, with a mass ratio of 4:1 After cleaning with a mixture of ethanol and water, put it into a vacuum oven, and dry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com