Preparation method for energy-storing and temperature-adjusting phase-change material and fibres thereof

A phase-change material and phase-change fiber technology, which is applied in the chemical characteristics of fibers, materials for heat exchange, chemical instruments and methods, etc., can solve the problem of not having high temperature stability, and achieve strong energy storage and temperature control ability and preparation cost. Low, agglomeration-preventing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

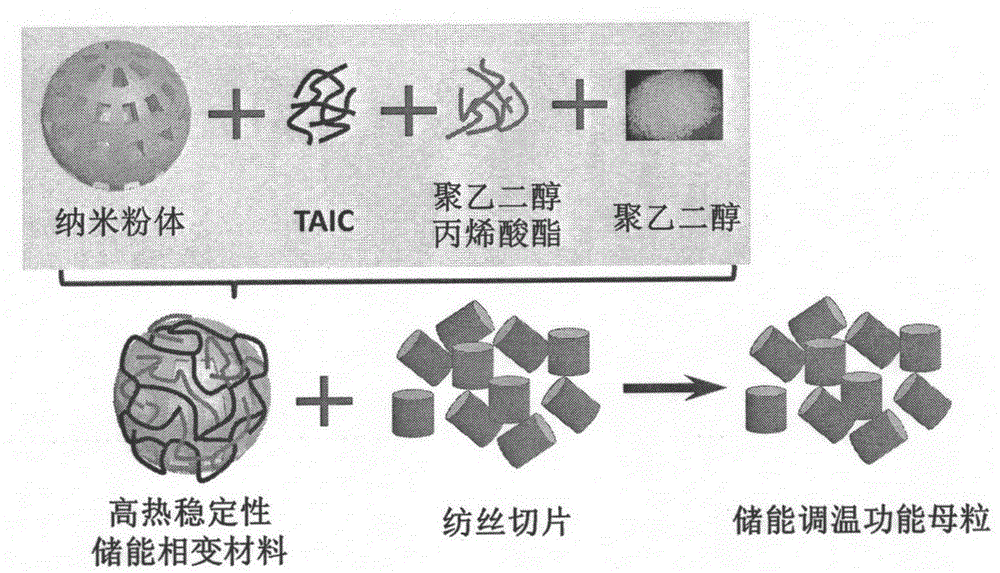

[0021] A method for preparing an energy-storage temperature-regulating phase-change fiber, specifically:

[0022] First, 30g of halloysite nanotubes (about 200nm in length and 10-50nm in diameter), 10g of triallyl isocyanurate, 10g of polyethylene glycol diacrylate, and 1g of initiator Add ammonium sulfate and 49g of polyethylene glycol (the number average molecular weight is about 1000) into 200ml of deionized water, adopt the method of decompression ultrasonic dispersion, under the conditions of pressure 200Pa ~ 500Pa, ultrasonic frequency 20 ~ 40KHz, the temperature is raised to 70 °C for 5 hours. After centrifugation and dehydration, a phase change material with high thermal stability and energy storage and temperature adjustment was obtained, and dried at 80°C for 12 hours for use.

[0023] 30g of phase-change materials dried and 70g of polyethylene terephthalate chips were blended and granulated by a twin-screw extruder at 260°C, and melt-spun by a melt-spinning machine...

Embodiment 2

[0025] A method for preparing an energy-storage temperature-regulating phase-change fiber, specifically:

[0026] First, 60g of carbon nanotubes (about 600nm in length and 2 to 200nm in diameter), 5g of triallyl isocyanurate, 5g of polyethylene glycol diacrylate, and 0.1g of initiator persulfuric acid Add ammonium and 29.9g of polyethylene glycol (the number average molecular weight is about 6000) into 200ml of deionized water, adopt the method of decompression ultrasonic dispersion, under the conditions of pressure 200Pa ~ 500Pa, ultrasonic frequency 20 ~ 40KHz, the temperature is raised to 70 °C for 2 hours. After centrifugation and dehydration, a phase change material with high thermal stability and energy storage and temperature adjustment was obtained, and dried at 80°C for 12 hours for use.

[0027] The dry-processed 5g phase change material and 95g polytrimethylene terephthalate chips were granulated through a twin-screw extruder at 270°C, and melt spun through a melt ...

Embodiment 3

[0029] A method for preparing an energy-storage temperature-regulating phase-change fiber, specifically:

[0030] First, 40g of porous nano-silica (particle size is about 50nm), 5g of triallyl isocyanurate, 5g of polyethylene glycol diacrylate, 0.1g of initiator ammonium persulfate, 49.9 Add 2 g of polyethylene glycol (the number average molecular weight is about 2000) into 200ml of deionized water, adopt the method of decompression ultrasonic dispersion, under the conditions of pressure 200Pa ~ 500Pa, ultrasonic frequency 20 ~ 40KHz, heat up to 70 ° C to react 4 Hour. After centrifugation and dehydration, the energy-storage temperature-regulating phase-change material was obtained, and dried at 80°C for 12 hours for use.

[0031] The dried 10g of phase change material and 90g of polyethylene naphthalate chips were granulated through a twin-screw extruder at 305°C, and melt spun through a melt spinning machine to obtain energy storage and temperature-regulated polyparaphenyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com