Patents

Literature

928 results about "Triallyl isocyanurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

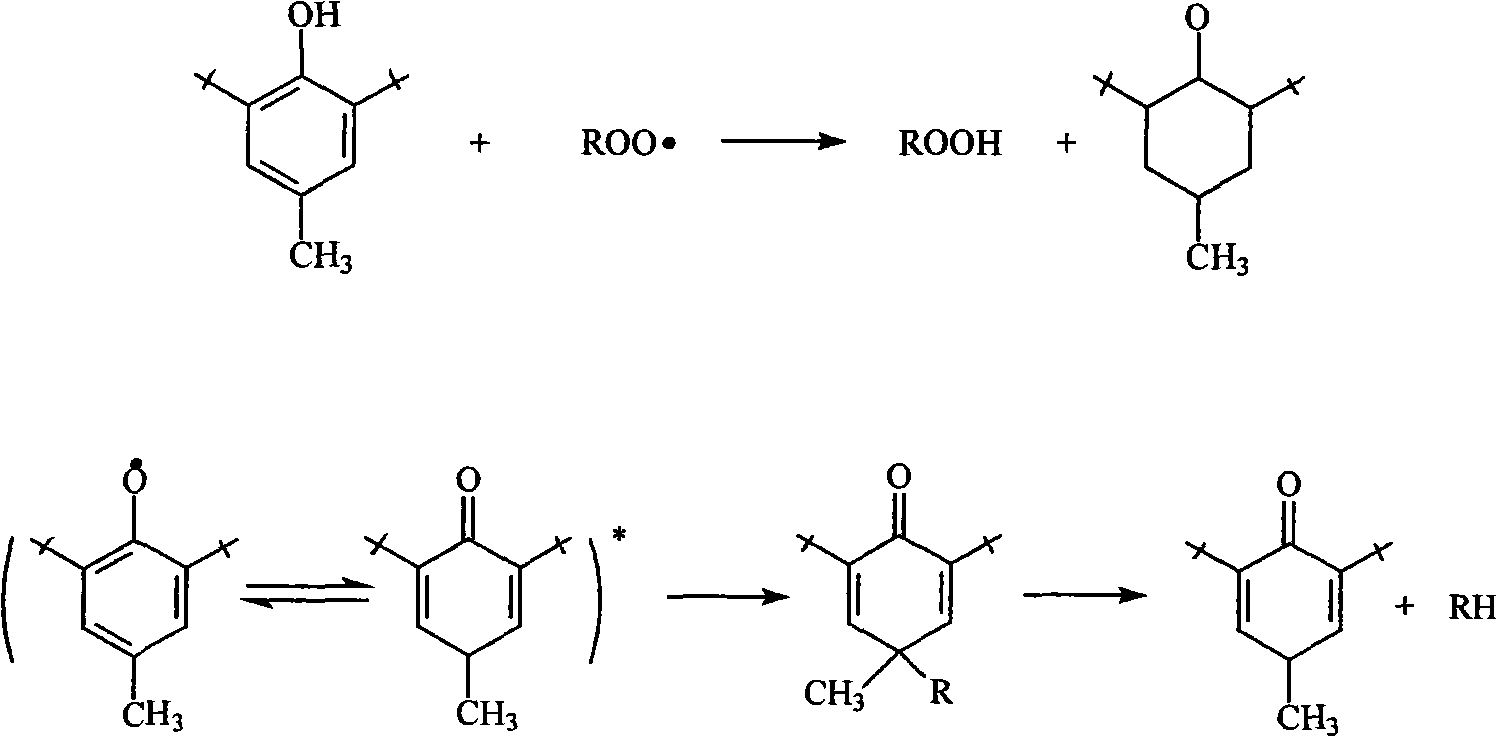

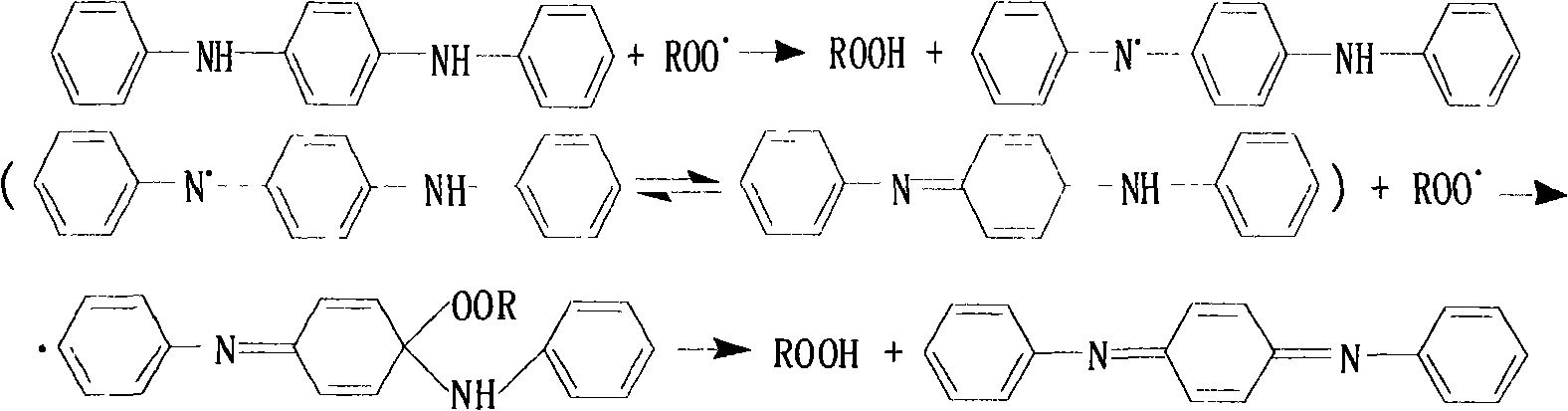

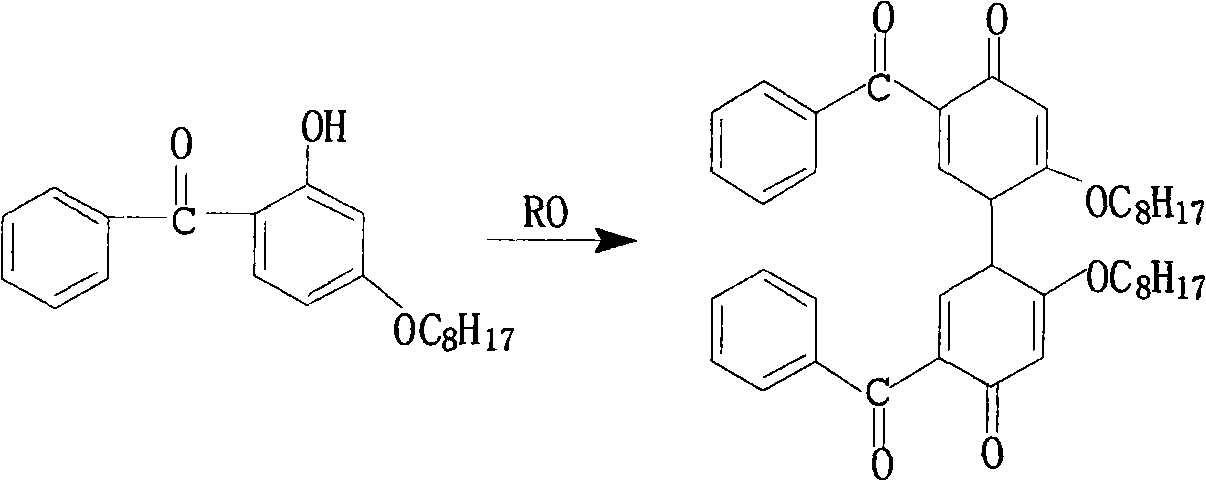

Isocyanates and thioisocyanates, such as TRIALLYL ISOCYANURATE, are incompatible with many classes of compounds, reacting exothermically to release toxic gases. Reactions with amines, aldehydes, alcohols, alkali metals, ketones, mercaptans, strong oxidizers, hydrides, phenols, and peroxides can cause vigorous releases of heat.

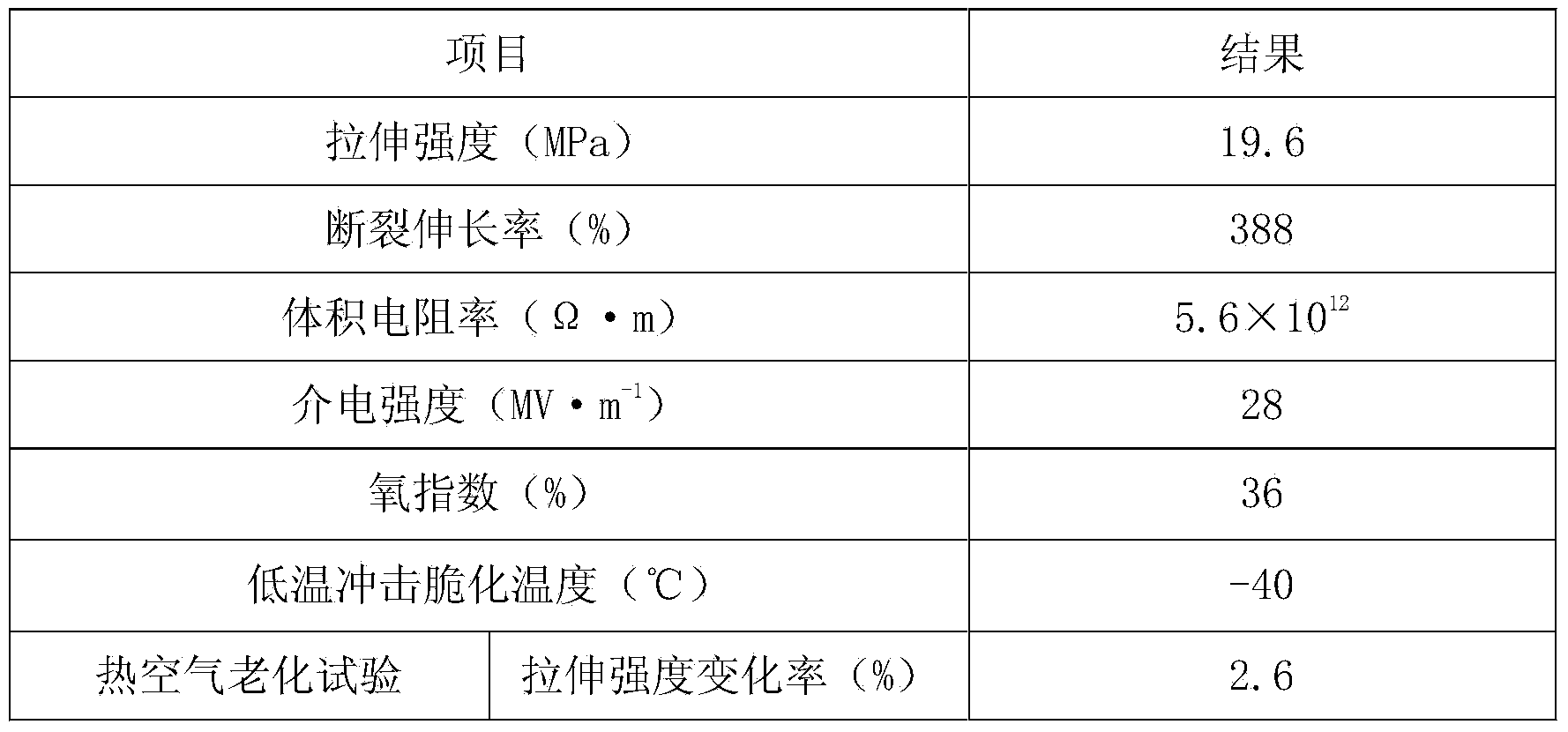

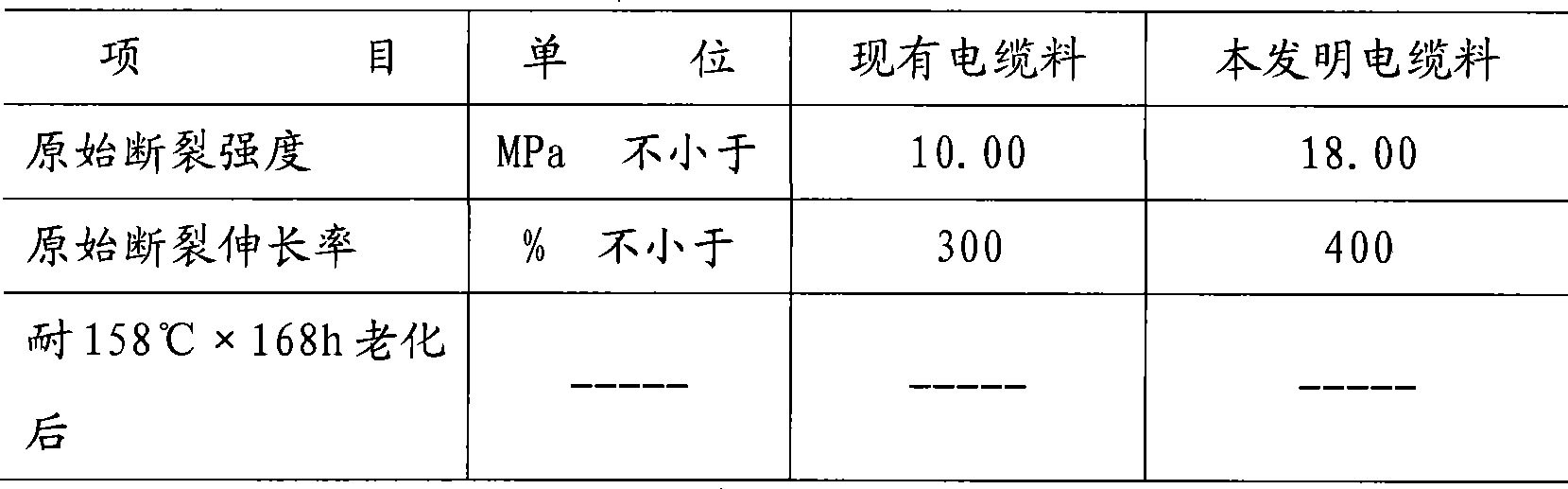

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

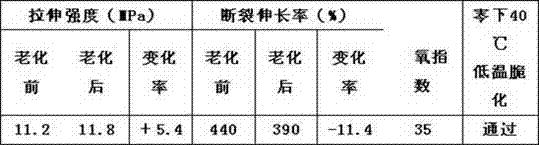

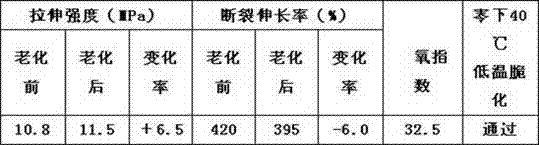

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

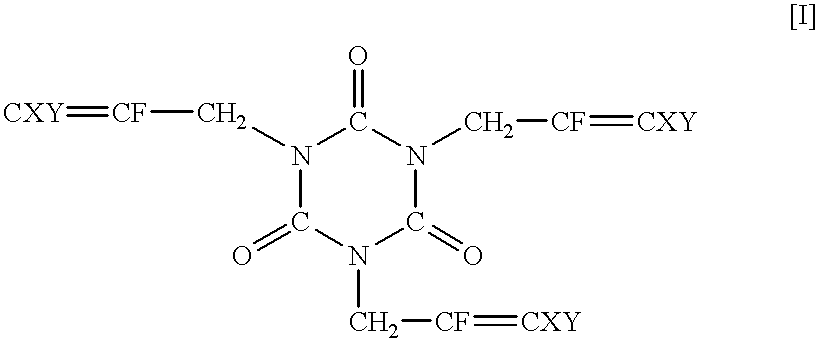

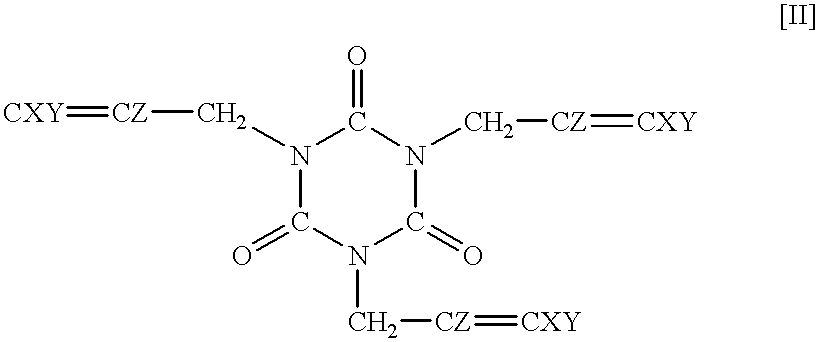

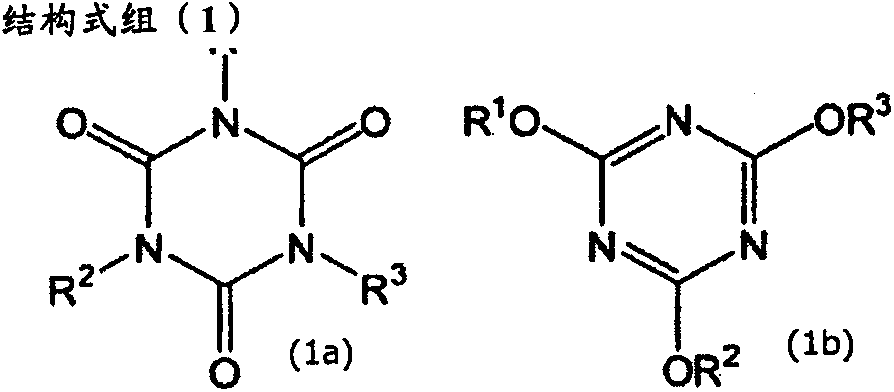

Fluorinated triallyl isocyanurates, vulcanizable elastomer compositions containing the same, and method for vulcanization

InactiveUS6191233B1Improve curing effectMaintain good propertiesOrganic chemistryElastomerHydrogen atom

A fluorine-containing triallyl isocyanurate of the formula [I]:wherein at least one of X and Y is a fluorine atom, and the other is a hydrogen atom or a fluorine atom, exhibits good curing properties even when it is used as a crosslinking aid for elastomers which are required to have good heat resistance, such as in particular, fluororubbers, and provides cured materials having good mechanical properties and heat resistance.

Owner:DAIKIN IND LTD

Solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging

InactiveCN101626039AIncrease crosslink densityModerate reaction temperatureElectrical equipmentGlass/slag layered productsAntioxidantPhosphate

The invention relates to a solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging, which comprises the following materials by weight portions: 100 portions of copolymer of ethylene vinyl acetate, 0.8-1.4 portions of crosslink curing agent, 0.05-0.15 portion of crosslink curing accelerator, 0.2-0.6 portion of tackifier, 0.1-0.5 portion of antioxidant, 0.05-0.25 portion of ultraviolet light stabilizer and 0.1-0.3 portion of ultraviolet light absorbent, wherein the crosslink curing agent is tert butyl peroxy 2-ethyl hexyl carbonate; the crosslink curing accelerator is triallyl isocyanurate; the tackifier is r-glycidyl ether oxy-propylltrimethoxysilane; the antioxidant is one or two selected from the group consisting of bis(2,4-dicumylphenyl)pentaerythritol diphosphite, distearyl pentaerythritol diphosphite, tris(nonyl phenyl)phosphate and tris(2,4-butylphenyl)phosphate; and ultraviolet light absorbent is gas phase silicon dioxide. The solar cell packaging EVA adhesive film can resist high temperature of 85 DEG C, humidity of 85 percent, ultraviolet light and thermal oxidative aging.

Owner:苏州爱康商务咨询服务有限公司

Ethylene propylene rubber cable insulating material for ship and ocean use and manufacturing method thereof

ActiveCN102344612ASmall outer diameterReduce weightPlastic/resin/waxes insulatorsMicrocrystalline waxPolymer science

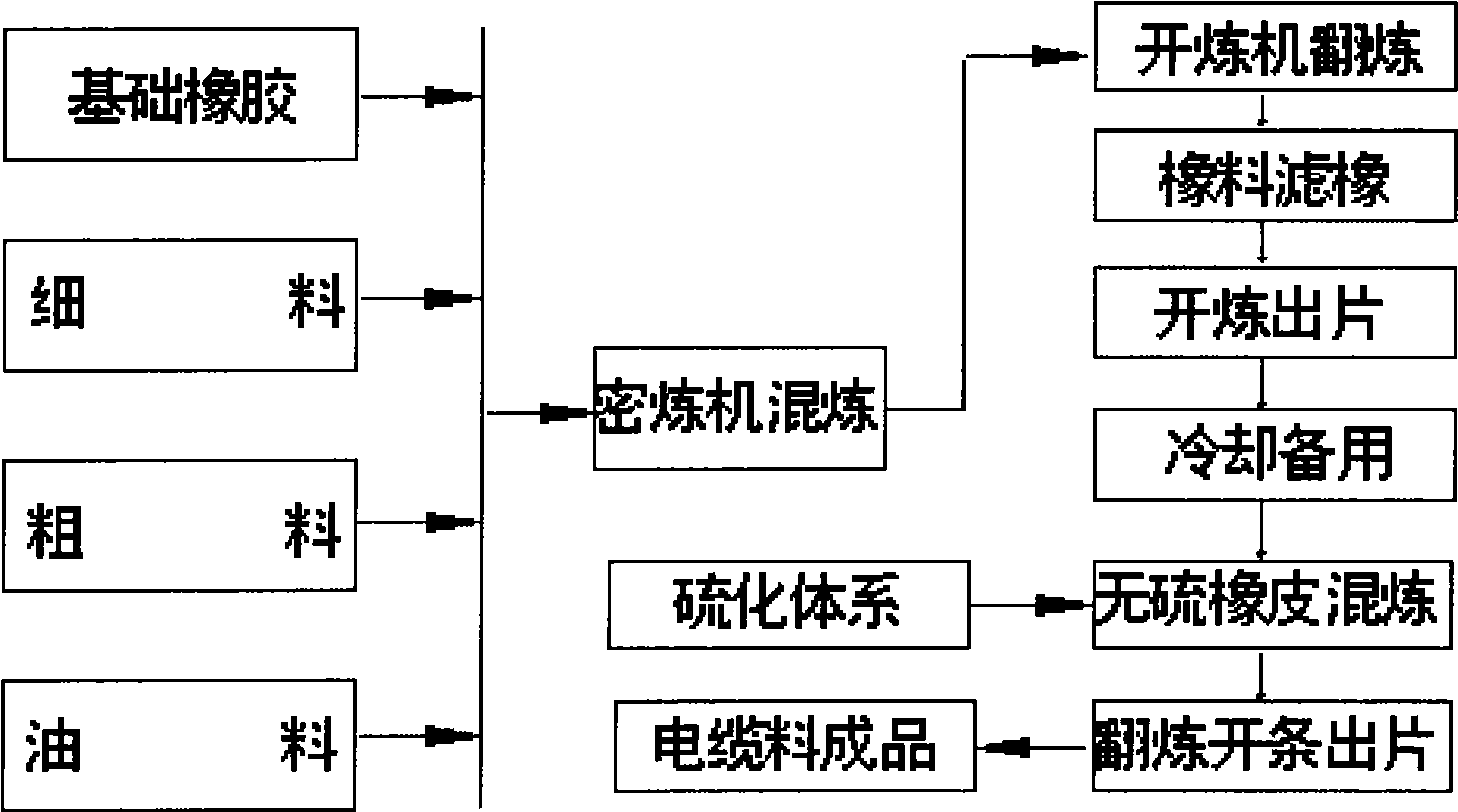

The invention discloses an ethylene propylene rubber cable insulating material for ship and ocean use and a manufacturing method thereof. The insulating material comprises by weight: 11 parts of ethylene propylene rubber 2470; 9 parts of ethylene propylene rubber 4044; 1.0-1.5 parts of high pressure polyethylene; 0.5-1.0 part of dicumyl peroxide; 0.3-0.4 part of triallyl isocyanurate; 0.5-0.8 part of 2-mercaptobenzimidazole; 1-1.5 parts of titanium dioxide; 1.0-1.5 parts of paraffin oil; 1.0-1.5 parts of zinc oxide; 0.6-1.0 part of microcrystalline wax; 0.2-0.5 part of stearic acid; 1-2 partsof white carbon black; 10-15 parts of superfine talc powder; and 12-16 parts of modified calcined argil. The method consists of the steps of: conducting uniform banbury mixing to ethylene propylene rubber and high pressure polyethylene; then adding titanium dioxide and the like in order for uniform mixing; carrying out triangle bag packaging with an open mill for 7 times, then filtering rubber, and putting the filtered rubber in a banbury mixer and adding an antioxidant for mixing well; finally conducting triangle bag packaging in an open mill for 5 times and extruding rubber sheets. The insulating material has the advantages of low smoke, free of halogen, flame retardation, high mechanical strength and high insulation resistance.

Owner:嘉兴顾翔制冷设备有限公司

Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

InactiveCN103509274AImprove mechanical propertiesImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsDiethylene glycol monobutyl etherPolymer science

A disclosed oil-resistant cold-resistant ultraviolet-proofpolyvinyl chloride / nitrile rubber composite cable material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type polyethylene, 20-30 parts of POE, 30-50 parts of nitrile rubber, 15-20 parts of fluorubber, 10-15 parts of dioctyl phthalate, 5-10 parts of di(butylcarbitol)adipate, 0.5-1 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of titanium dioxide, 5-10 parts of paraffin oil, 2-3 parts of zinc oxide, 4-8 parts of microcrystalline paraffin and the like. The cable materials of the invention ahs excellent thermoset rubber apparence and thermoplastic elastomer characteristics, and good mechanical properties and low-temperature flexibility; the long-term suitable operation temperature is -40 DEG C to 105 DEG C; the cable material is capable of retarding flame, resisting oil, resisting acid and base, resisting wear, resisting weather, resisting ozone, resisting thermal aging and resisting ultraviolet ray, and is applicable as high-oil-resistance weatherable cable sheath materials.

Owner:安徽天民电气科技有限公司

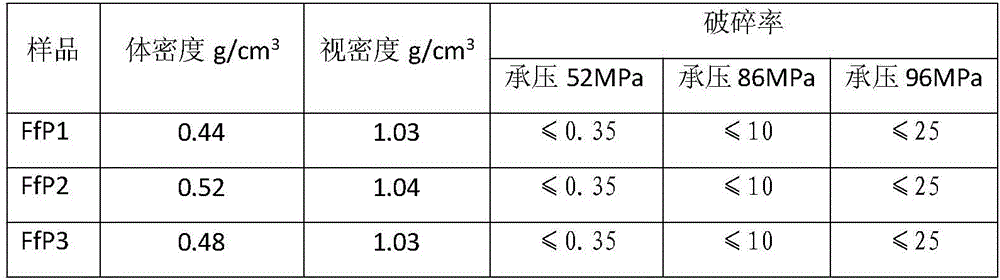

Phase change fracturing fluid system for phase change fracturing

ActiveCN106190086AReduce frictionLower requirementFluid removalDrilling compositionFracturing fluidAcrylonitrile

The invention discloses a phase change fracturing fluid system for phase change fracturing. The phase change fracturing fluid system is prepared from, by weight, 10%-40% of supramolecular building structure, 0-40% of supramolecular function unit, 0.5%-2% of surfactant, 0-5% of inorganic salt, 0.5%-2% of oxidizing agent, 0-2% of cosolvent and the balance solvent, wherein the supramolecular building structure is melamine or triallyl isocyanurate or a mixture of melamine and triallyl isocyanurate, the supramolecular function unit is vinyl acetate or acrylonitrile or a mixture of vinyl acetate and acrylonitrile, and the solvent is methylbenzene or ethylbenzene or o-xylene or m-xylene or p-xylene. In the fracturing construction process, a conventional fracturing fluid is used for fracturing a stratum, the phase change fracturing fluid is injected into the stratum, or the phase change fracturing fluid and other fluids which cannot be subjected to phase change are injected into the stratum together, a supramolecular material in the phase change fracturing fluid is subjected to self-assembly to form a solid phase material with a certain strength, support to cracks is achieved, and construction operation is easy, convenient, safe and efficient.

Owner:PETROCHINA CO LTD +1

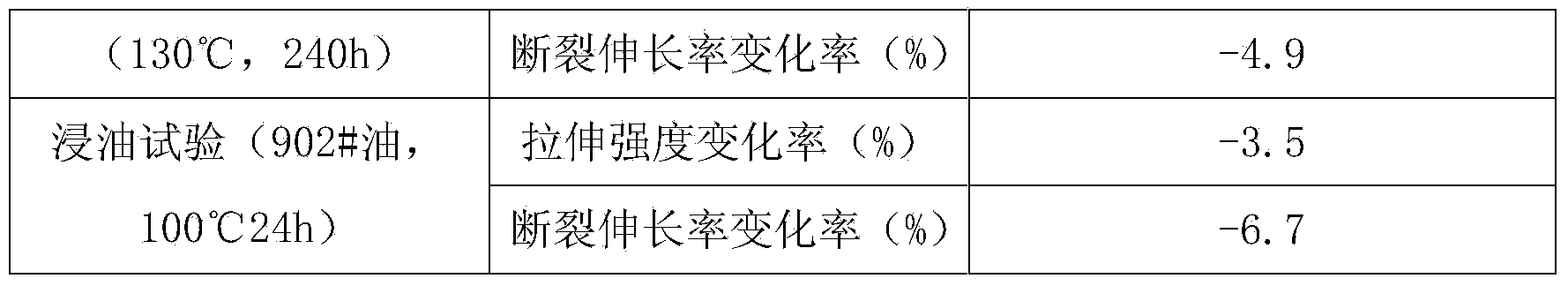

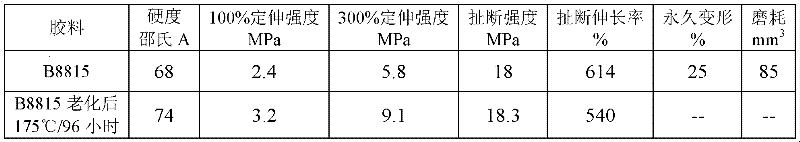

Low rigidity, low compression permanent deformation cold tolerant butadiene nitrile rubber compositions

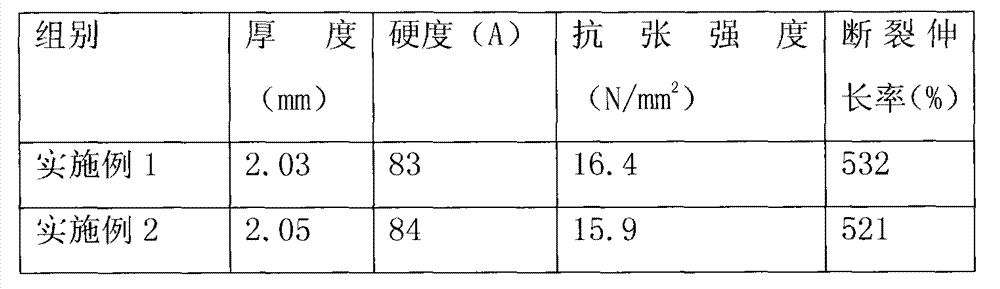

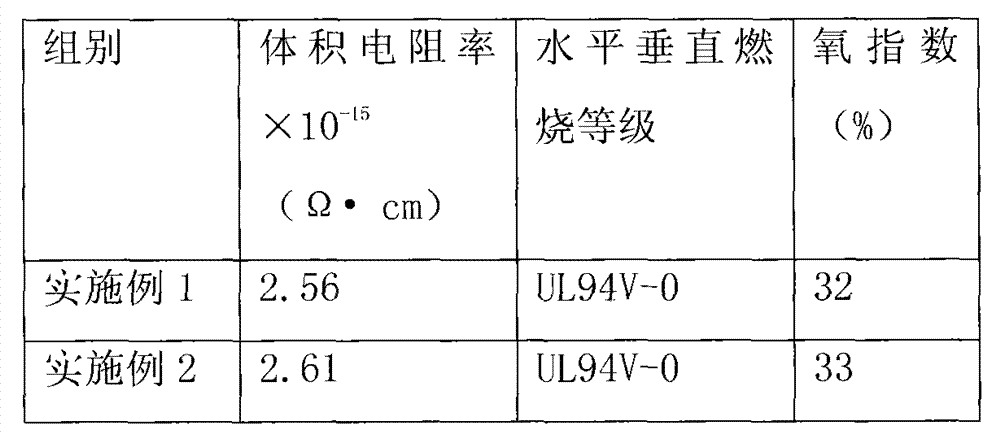

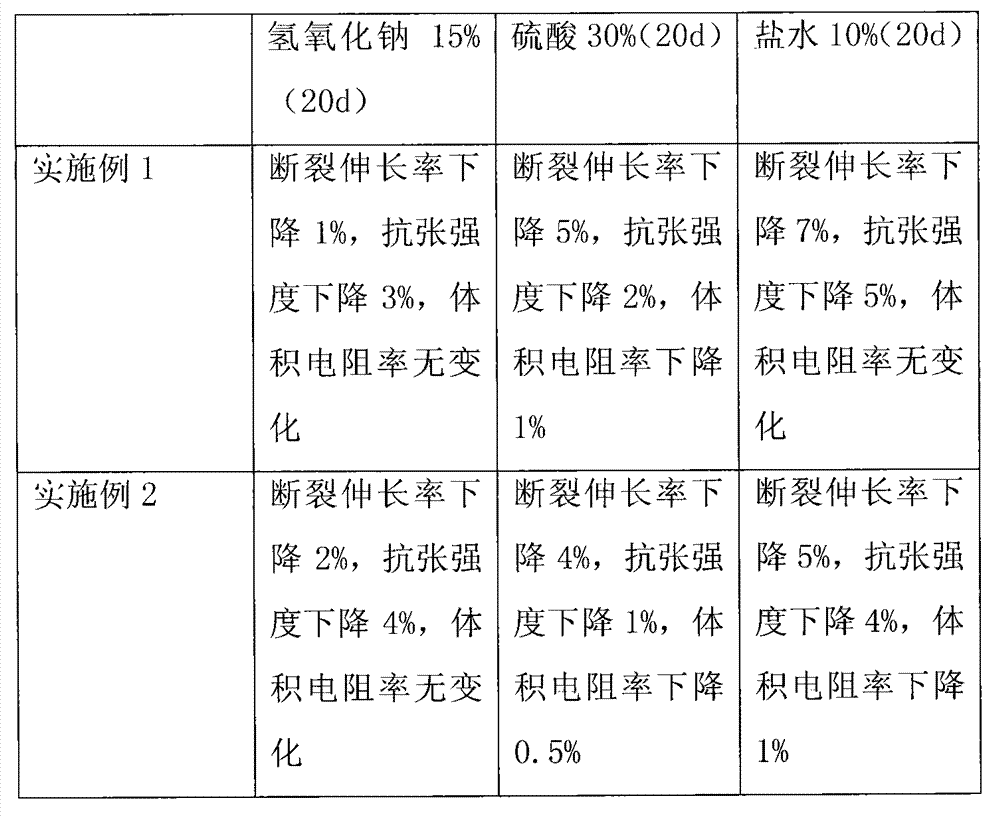

The invention provides a permanent deformation cold resistance nitrile-butadiene rubber composition with low hardness and low compression, which contains nitrile-butadiene rubber, peroxides and auxiliary crosslinking agents; wherein, the auxiliary crosslinking agents are selected from one or a plurality of 1, 3-(citraconic maleimide methyl) benzene, meta phenylene bis maleimide, triallyl cyanurate and triallyl isocyanurate. The nitrile-butadiene rubber which is prepared by the nitrile-butadiene rubber composition has the advantages that peroxide curing system containing the auxiliary crosslinking agents of the invention can improve the cold resistance and has small compression permanent deformation; at the same time, the tensile strength and the elongation at break are large, and the fatigability is good. The advantages are not possessed by the curing systems that singly use peroxides and the combination of the peroxide sulphur and other auxiliary crosslinking agents.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

Halogen-free environmentally-friendly power cable material for wind power generation, and its preparation method

The invention discloses a halogen-free environmentally-friendly power cable material for wind power generation, and its preparation method. The cable material comprises the following raw materials, by weight, 90-110 parts of a polyolefin elastomer (POE) 8450 / American DuPont, 50-60 parts of PVC resin powder, 40-60 parts of wollastonite powder, 60-80 parts of nanometer attapulgite, 50-80 parts of ethylene-propylene-diene terpolymer rubber, 40-50 parts of nitrile butadiene rubber, 20-30 parts of nanometer pottery clay, 30-40 parts of aluminum hydroxide, 1-4 parts of precipitated white carbon black, 60-80 parts of light calcium carbonate, 3-5 parts of insoluble sulfur, 1-4 parts of triallyl isocyanurate, 3-5 parts of an antiager TPPD, 4-6 parts of dicumyl peroxide (DCP), 3-8 parts of dibasic lead phosphite, 5-7 parts of an antioxidant 1010, 2-5 parts of monoglycerin stearate and 50-70 parts of antimony trioxide. The cable material has the advantages of simple preparation method, excellent electrical property, good heat, ageing and wear resistances, small swelling deformation at a high temperature, secondary vulcanizing processing benefiting, low smoke and fire resistance, and environmental protection and safety.

Owner:苏州益普敦新材料科技有限公司

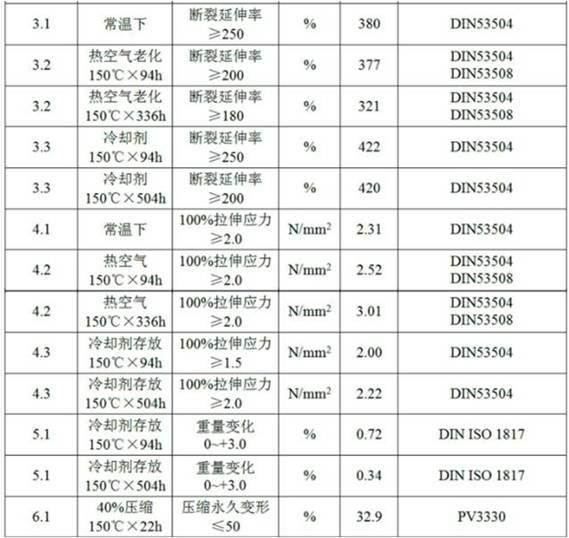

Ethylene propylene diene monomer rubber material for automobile cooling system sealing elements and preparation method thereof

The invention discloses an ethylene propylene diene monomer rubber material for automobile cooling system sealing elements and a preparation method thereof, belonging to the field of rubber materials and preparation methods thereof. The ethylene propylene diene monomer rubber material disclosed by the invention is prepared from the following components in percentage by mass: 53-58% of ethylene propylene diene monomer unvulcanized rubber, 20-25% of high-wear-resistance carbon black, 5-10% of semi-reinforcing carbon black, 3-5% of zinc oxide, 0.5-1.0% of stearic acid, 1.0-1.5% of 4,4'-di(phenylisopropyl)diphenylamine, 0.5-1.0% of 2-thiol tolimidazole zinc salt, 2.0-2.5% of alpha,alpha'-bis(tert-butylperoxy)diisopropylbenzene and 1.5-2.0% of triallyl isocyanurate. The preparation method comprises the following steps: mixing master batch; carrying out two-section sulfurization on the master batch; and vulcanizing. The ethylene propylene diene copolymer rubber sealing element material disclosed by the invention has the advantages of high temperature resistance, overheated coolant immersion resistance and excellent low compression permanent set, improves the elasticity and compression permanent set of the rubber, and ensures the high strength of the rubber, thereby satisfying the service performance of the material.

Owner:南京金三力高分子科技有限公司

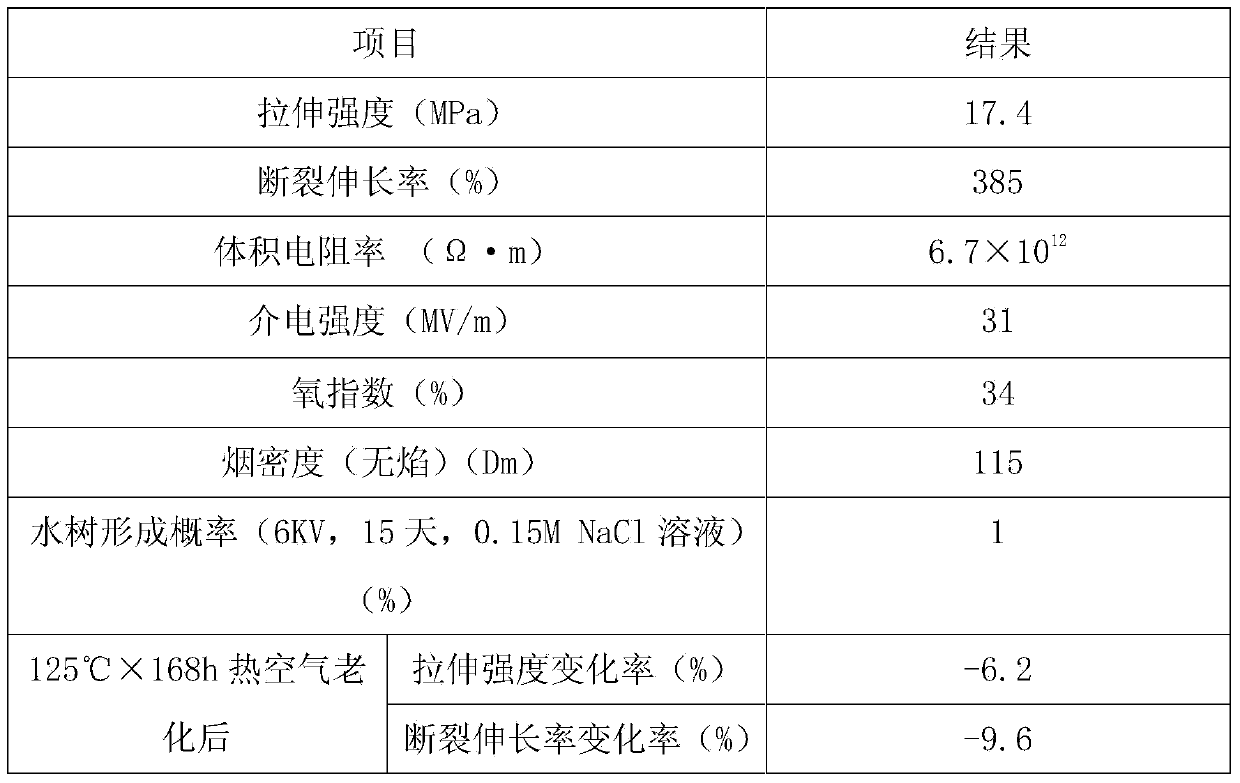

Water tree-resistant polyethylene insulated cable material and preparation method thereof

InactiveCN103467818ASimple structureImprove anti-water tree agingPlastic/resin/waxes insulatorsLow-density polyethyleneElastomer

The invention discloses a water tree-resistant polyethylene insulated cable material and a preparation method thereof. The cable material is prepared by the following raw materials in parts by weight: 70-80 parts of low-density polyethylene, 10-15 parts of maleic anhydride grafted EVA (ethylene vinyl acetute), 5-10 parts of maleic anhydride grafted POE (polyolefin elastomer), 0.5-1.5 parts of sorbitol, 2-3 parts of polyethylene glycol, 2-3 parts of dicumyl peroxide, 0.4-0.6 parts of antioxidant DLTP (dilauryl thiodipropionate), 3-4 parts of triallyl isocyanurate, 2-3 parts of polydimethylsiloxane and the like. According to the cable material and the method, maleic anhydride grafted EVA and maleic anhydride grafted POE with good compatibility with low-density polyethylene are added to improve a polyethene structure, and sorbitol, polyethylene glycol, polydimethylsiloxane and the like are added to inhibit water tree formation, so that the water tree aging resistance and physical and mechanical properties of the polyethylene cable material are improved obviously; a technical bottle neck of water tree growth of the cable insulation layer is solved; the service life of a cable is prolonged; and the cable safety during use is improved.

Owner:JING FENG GRP

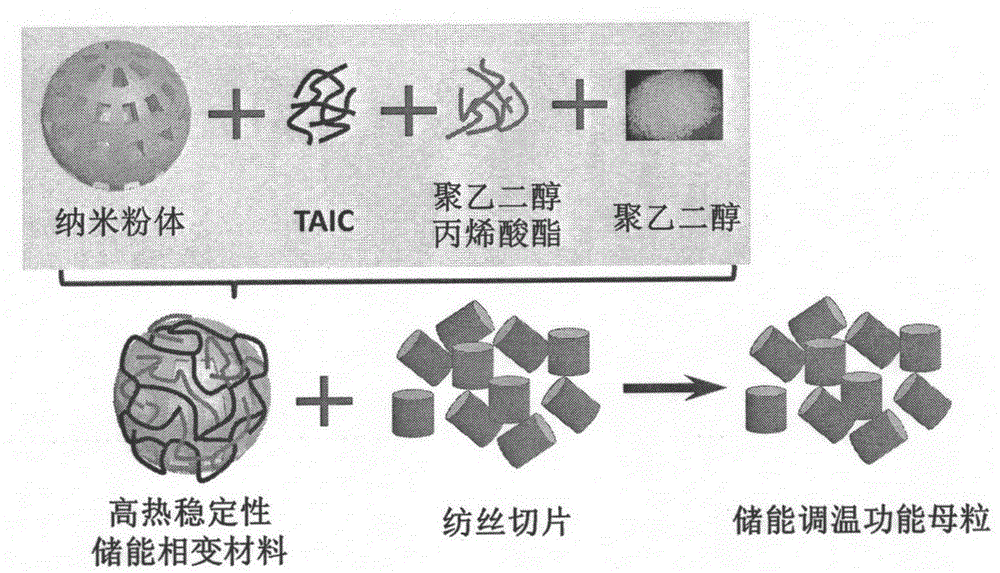

Preparation method for energy-storing and temperature-adjusting phase-change material and fibres thereof

ActiveCN104910334AStrong energy storage and temperature control abilityReduce manufacturing costHeat-exchange elementsArtifical filament manufacturePolymer scienceHigh energy

The invention provides a preparation method for an energy-storing and temperature-adjusting phase-change material and fibres thereof. The preparation method for the energy-storing and temperature-adjusting phase-change material is characterized by comprising the following specific steps: placing porous nano-powder, triallyl isocyanurate, polyethylene glycol acrylate, polyethylene glycol and an initiator in solvent water, reacting for 2-5 hours at 65-75 DEG C by means of reduced pressure ultrasonic dispersion, and finally centrifugally dewatering to obtain the energy-storing and temperature-adjusting phase-change material. The energy-storing and temperature-adjusting phase-change material is subjected to drying treatment, then sliced with polymers and blended and granulated through a double-screw extruder, and then subjected to melt-spinning to obtain the energy-storing and temperature-adjusting fibres. The phase-change energy-storing material prepared by the preparation method provided by the invention has the characteristic of high energy-storing and temperature-controlling capacity, and has the advantages of low preparation cost, good heat-resistant stability and simple operation.

Owner:DONGHUA UNIV

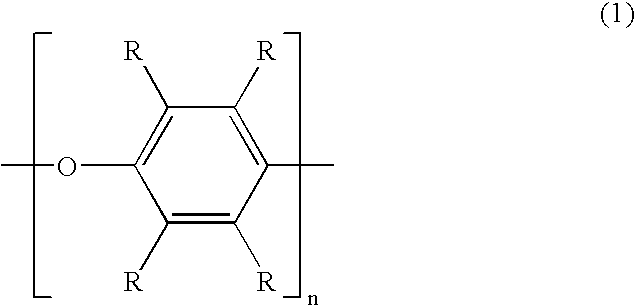

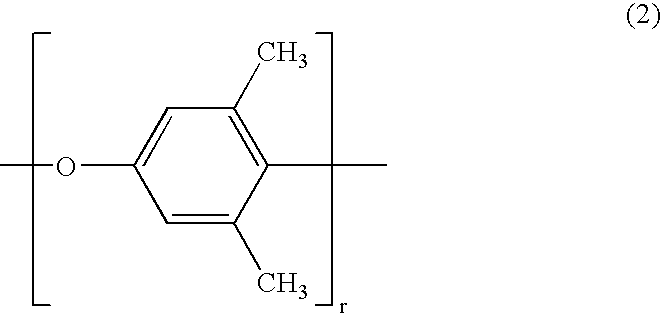

Poly(phenylene oxide) resin composition, prepreg, laminates sheet, printed wiring board, and multilayer printed wiring board

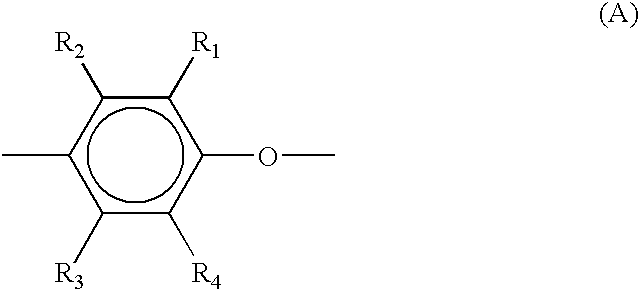

InactiveUS7288587B2Improve electrical performanceHigh glass transition temperatureSynthetic resin layered productsThin material handlingHeat resistanceTriallyl isocyanurate

The poly(phenylene oxide) resin composition of the invention is a poly(phenylene oxide) resin composition containing poly(phenylene oxide) and triallyl isocyanurate, wherein the poly(phenylene oxide) has a number average molecular weight in a range from 2,000 to 12,000 and the IPN structure can be formed in a cured product of the poly(phenylene oxide) and triallyl isocyanurate to provide a high heat resistance, and at the same time by using a poly(phenylene oxide) with a relatively low molecular weight, the fluidity of the melt resin can be made desirable at the time of molding to result in high molding properties.

Owner:MATSUSHITA ELECTRIC WORKS LTD

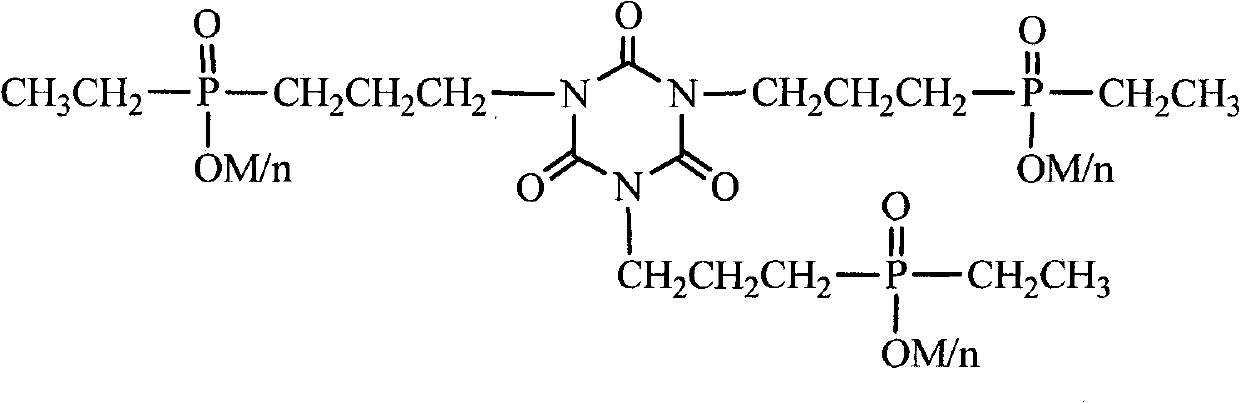

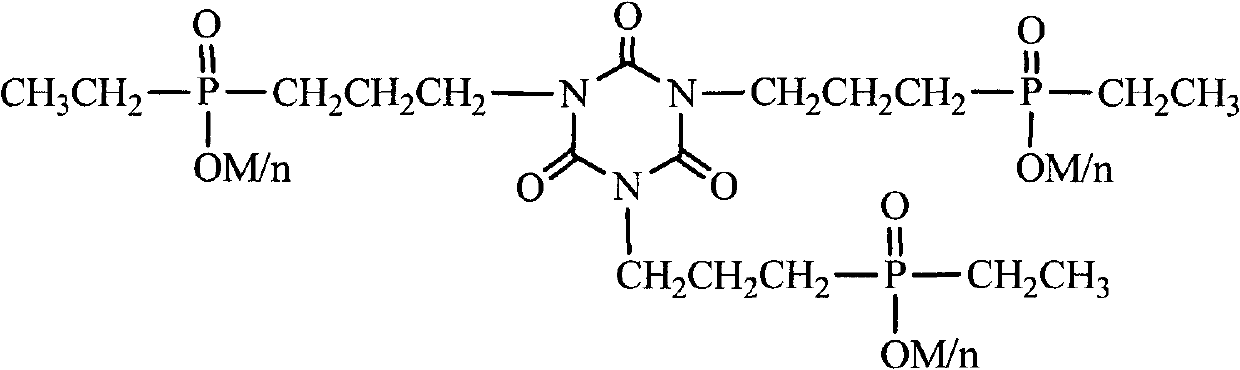

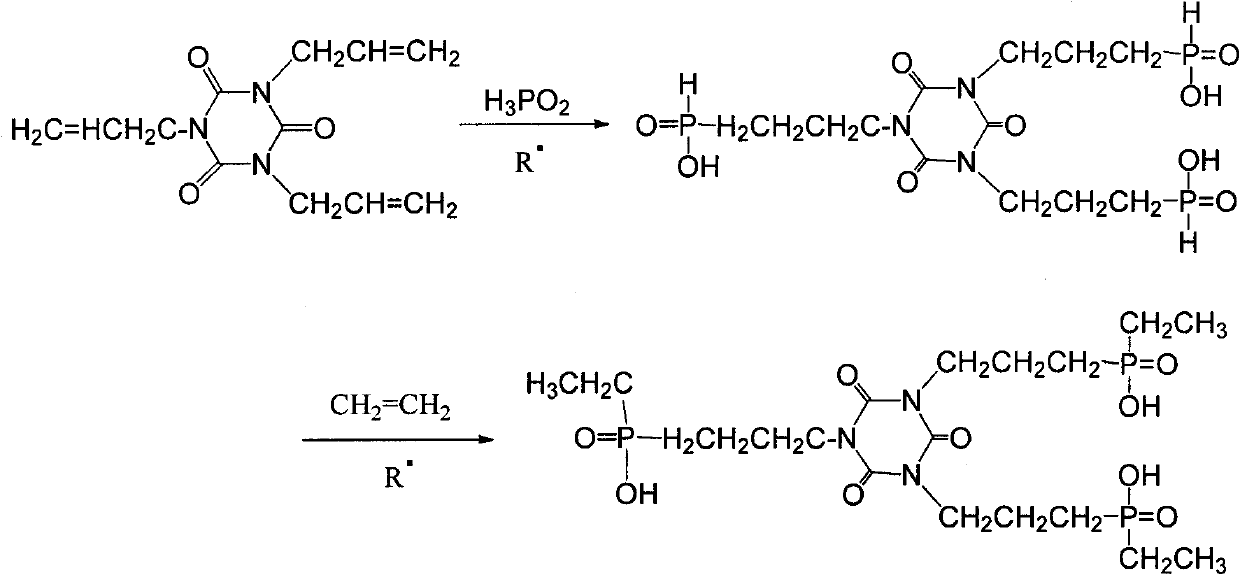

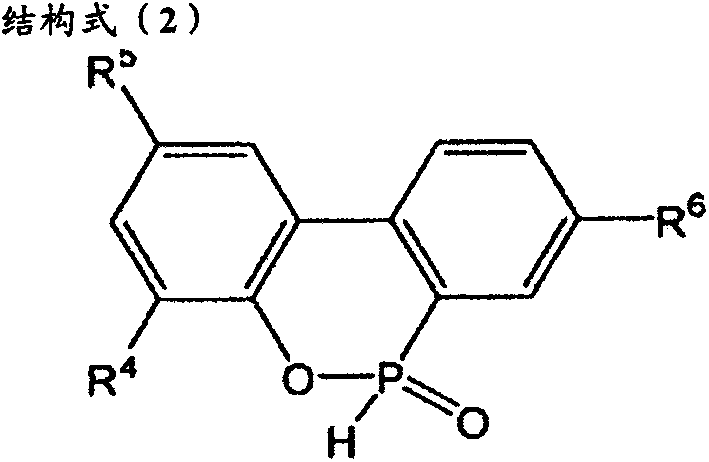

Organic phosphinic acid metal salt containing triazine ring and preparation method thereof

ActiveCN102229622AImprove mechanical propertiesHigh molecular weightGroup 5/15 element organic compoundsCoatingsEpoxyPolyester

The invention relates to organic phosphinic acid metal salt containing a triazine ring and a preparation method thereof. The structure of the compound is represented as follows: FORMULA, wherein M is a metal ion of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Ce, Sn, Fe, Mn, Li, Na or K; and n is a valence of the M. The preparation method comprises the following steps of: reacting the phosphinic acid or alkali metal salt of the phosphinic acid with triallyl isocyanurate and ethylene in the presence of a radical initiator so as to obtain organic phosphinic acid or alkali metal salt of the organic phosphinic acid containing the triazine ring; and then, reacting with a metal compound of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Ce, Sn, Fe and Mn so as to obtain the relative organic phosphinic acid salt containing the triazine ring. The compound can be used as a fire retardant of nylon, polyester, polyurethane, epoxy resin, glass fibre reinforced resin, coat and the like. The preparation method is simple in process and easy to perform industrial production.

Owner:昆山卡帝德塑料制品有限公司

High-temperature-resistant vapour-resistant sheath material for nuclear power station cables and preparation method thereof

ActiveCN103509350AImprove high temperature resistanceExcellent water vapor resistanceRubber insulatorsInsulated cablesAntimony trioxidePetroleum

The invention discloses a high-temperature-resistant vapour-resistant sheath material for nuclear power station cables and a preparation method thereof. The sheath material is prepared from the following raw materials in parts by weight: 50-70 parts of methyl vinyl phenyl polysiloxane rubber, 20-30 parts of ethylene-propylene-diene monomer, 15-25 parts of poly(thiophenylene), 10-15 parts of C5 petroleum resin, 20-30 parts of acetylene black, 1-2 parts of zinc oxide, 2-3 parts of stearic acid, 3-5 parts of triallyl isocyanurate, 15-20 parts of magnesium hydroxide, 10-15 parts of antimony trioxide, 5-10 parts of zinc stannate, 1-2 parts of zine stearate, 1-2 parts of barium stearate, 1.5-2.5 parts of gamma-methacryloxy propyl trimethoxyl silane, 10-15 parts of dimethyl phthalate and the like. The cable material of the invention has excellent performances comprising high temperature resistance, vapour resistance, radiation resistance, corrosion resistance, aging resistance and the like, good flame retardant efficiency, does not spread flame and is automatically extinguished after on fire, has low smoke, no halogens, no toxicities and no corrosive gases, and is capable of satisfying special environmental requirements of special nuclear power stations.

Owner:安徽天民电气科技有限公司

Lead-free environmental-friendly circuit board conductive silver paste and preparation method thereof

InactiveCN104036842AReduce dosageImprove printing effectMetal/alloy conductorsCable/conductor manufactureEnvironmental resistanceMicrosphere

The invention provides a kind of lead-free environmental-friendly circuit board conductive silver paste, which is prepared by the following raw material by weights: 60 to 70 of silver powder of 20 to 30mum, 5 to 8 of copper powder of 1 to 10nm, 8 to 10 of glass powder, 5 to 7 of SnO2 powder, 5 to 8 of silver powder of 40 to 60nm, 2 to 4 of pentaerythritol tristearate, 4 to 6 of isophorone, 3 to 5 of saturated polyester resin EK410, 4 to 7 of bisphenol F epoxy resin, 1 to 2 of salicylic acid, 3 to 5 of polyurethane resin, 1 to 2 of triallyl isocyanurate, 1 to 2 of microsphere starch, 1 to 2 of fumed silica, 4 to 6 of isobutyl ketone, 6 to 8 of ethanol , 2 to 4 of butanol, and 6 to 8 of butyl acetate. The lead-free environmental-friendly circuit board conductive silver paste and the preparation method thereof are characterized in that the use amount of the silver powder is small, the printing performance is good, the yield of the circuit board is high, the conductive performance is good, lead-free environmental-friendly performance is provided, the technology is simple, the operation is convenient and easy, and the product performance is convenient to control.

Owner:铜陵市超远精密电子科技有限公司

Curable sheet for circuit transfer

InactiveUS6455784B1Simplification of multiplayer laminationSimple processPrinted circuit aspectsElectrical connection printed elementsEtherTriallyl isocyanurate

Provided is a curable sheet for the formation of a wiring circuit layer by circuit transfer from a transfer base material, wherein the curable sheet comprises (A) a reaction product between a polyphenylene ether resin and an unsaturated carboxylic acid or acid anhydride, (B) triallyl isocyanurate and / or triallyl cyanurate, (C) a hydrogenated block copolymer obtained by hydrogenation of a block copolymer comprising at least one polymer block A mainly comprising an aromatic vinyl compound and at least one polymer block B mainly comprising a conjugated diene compound, and (D) an inorganic filler; said Component (A), Component (B) and Component (C) being contained in amounts of 45 to 55 parts by weight, 55 to 45 parts by weight, and 25 to 35 parts by weight, respectively, each based on 100 parts by weight of total of Components (A) and (B), and said Component (C) being contained in an amount of 20 to 80 vol. %.

Owner:ASAHI KASEI E-MATERIALS CORPORATION +1

High-temperature-resistant cable sheath material and preparation method thereof

ActiveCN103524844AExtended service lifeImprove high temperature resistanceInsulated cablesInsulatorsPolymer sciencePhosphate

The invention discloses a high-temperature-resistant cable sheath material and a preparation method thereof. The sheath material comprises the following raw materials in parts by weight: 70-80 of high density polyethylene, 20-30 of ethylene-propylene-diene monomer, 10-15 of maleic anhydride grafted polyethylene, 5-10 of bisphenol A novolac epoxy resin, 8-12 of diphenyl tolyl phosphate, 4-8 of dioctyl maleate, 0.5-1 of di(tert-butylperoxyisopropyl)benzene, 2-3 of p-benzoquinone dioxime, 1-2 of triallyl isocyanurate, 3-5 of paraffin oil, 2-3 of active zinc oxide, 10-15 of magnesium hydroxide, 5-10 of aluminum hydroxide, 4-6 of talcum powder, 8-12 of fly ash, 5-10 of nano bauxite, 2-3 of dibutyltin dilaurate, 1-2 of an anti-aging agent MB, 1-2 of an anti-aging agent TPPD, and 4-6 of a composite filler. The sheath material prepared by the invention not only has good high temperature resistance and can be used in a 125 DEG C working environment for a long time, but also has good flame retardant effect, has the oxygen index of more than 35%, has non halogen and low smoke, and solves the problem of poor heat resistance of a high-flame-retardant sheath material.

Owner:滁州三界外信息科技有限公司

Corrosion-resistant electric material and application thereof

InactiveCN104086888AImprove defectsImprove corrosion resistancePlastic/resin/waxes insulatorsEpoxyTriallyl isocyanurate

The invention discloses a corrosion-resistant electric material which is prepared from the following raw materials: graphite, borax, kieselguhr, kaolin, polypropylene resin, bisphenol F-type epoxy resin, polysiloxane, dicyclopentadiene, dimethylamino ethoxyethanol and triallyl isocyanurate. The invention further discloses an application of the electric material. The corrosion-resistant electric material disclosed by the invention is applicable to multiple different severe environments, and potential safety hazard of an ordinary electric material is avoided.

Owner:重庆浦盛机电工程有限公司

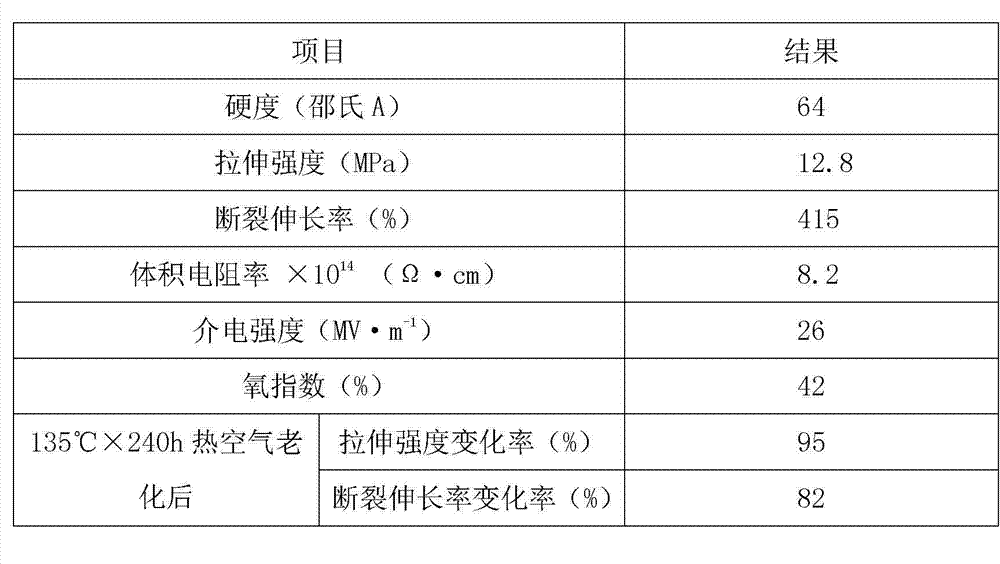

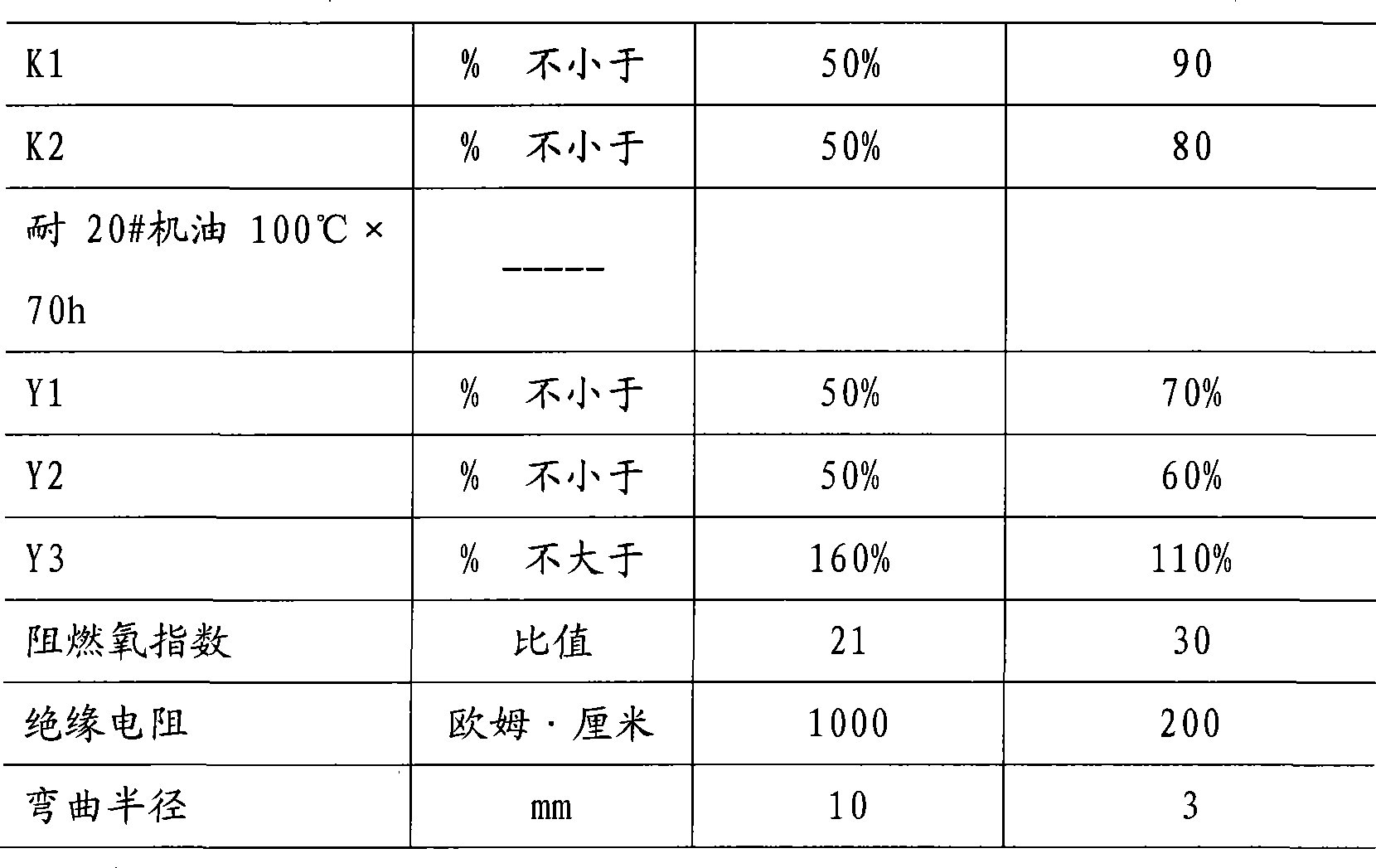

Surface covering glue for high-temperature resistant wire rope core conveyer belt and preparation method of surface covering glue

InactiveCN102504726AExcellent thermal oxygen resistanceGood weather resistanceNon-macromolecular adhesive additivesSheet filmEngineering

The invention relates to a surface covering glue for a high-temperature resistant wire rope core conveyer belt. The surface covering glue can resist a test temperature not higher than 175 DEG C and the highest short-time running temperature at 300 DEG C, and reaches the T4 level of GB / T20021-2005 standard. The surface covering glue for the high-temperature resistant wire rope core conveyer belt is prepared by the steps of mixing ethylene-propylene terpolymer, cumyl peroxide DCP, zinc oxide, Triallyl Isocyanurate TAIC, zinc methacrylic acid ZDMA, stearic acid, anti-aging agent RD, anti-aging agent MB, anti-aging agent 6PPD, N330 carbon black, N550 carbon black, coumarone and paroline, forming glue sheets, molding and finally vulcanizing. The surface covering glue for the high-temperature resistant wire rope core conveyer belt prepared according to the method has excellent heat and oxidization resistance, weather resistance, ozone resistance, acid-base resistance and steam resistance, and can be used for a long term under the use conditions that the temperature is not higher than 175 DEG C and the highest short-time running temperature is at 300 DEG C.

Owner:WUXI BOTON TECH CO LTD

High cold-resistance ethylene propylene diene copolymer insulated cable material and preparation method thereof

ActiveCN102964698AImprove flame retardant performanceImprove cold resistancePlastic/resin/waxes insulatorsPolymer scienceBenzoyl peroxide

The invention discloses a high cold-resistance ethylene propylene diene copolymer insulated cable material and a preparation method thereof. The cable material is made of the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland 9650 ethylene propylene diene copolymer, 20-30 parts of active chlorine type acrylic rubber AR-400, 10-15 parts of duprene rubber CR121, 10-15 parts of di-butyl nylonic acid ester, 5-10 parts of trioctyl trimellitate, 5-10 parts of triethyl phosphate, 1-2 parts of sulphur, 2-4 parts of benzoyl peroxide, 1-2 parts of triallyl isocyanurate and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Buoy communication cable sheath insulating material for ships and preparation method thereof

InactiveCN102993523AMeet the use requirementsImprove compactnessRubber insulatorsPlastic/resin/waxes insulatorsEpoxyMicrocrystalline wax

The invention discloses a buoy communication cable sheath insulating material for ships and a preparation method thereof. The insulating material is prepared from the following raw materials in parts by weight: 95-105 parts of chloroprene rubber S40V, 15-20 parts of thermoplastic polyurethane elastomer (badische aniline soda fabric S90A), 0.7-1 part of di(2-ehtylhexyl) 4, 5-epoxy tetrahydrophthalate, 14-20 parts of sepiolite, 2-3 parts of ferrocene, 1-2 parts of N, N'-m-phenylene dimaleimide, 31-35 parts of blanc fixe, 1-2 parts of anti-aging agent MB, 1.5-2 parts of triallyl isocyanurate, 5-9 parts of microcrystalline wax, 1-2 parts of accelerator DM, 0.8-1 part of ammonium molybdate, 15-23 parts of nano bauxite, 1-3 parts of poly(1,2-propylene glycol adipate), 2-4 parts of zinc borate, 4-6 parts of epoxy fatty acid butyl ester, 0.8-1 part of zinc oxide, 2-3 parts of modified fly ash and 1-2 parts of hexasulfide bis(1-piperidinylthioxomethyl). The produced buoy communication cable sheath insulating material for the ships has excellent physical performance, stable dimensions and low shrinkage factor, and the tensile strength, tear resistance and elastic force performance of a product are all greatly improved.

Owner:安徽文峰电子科技集团有限公司

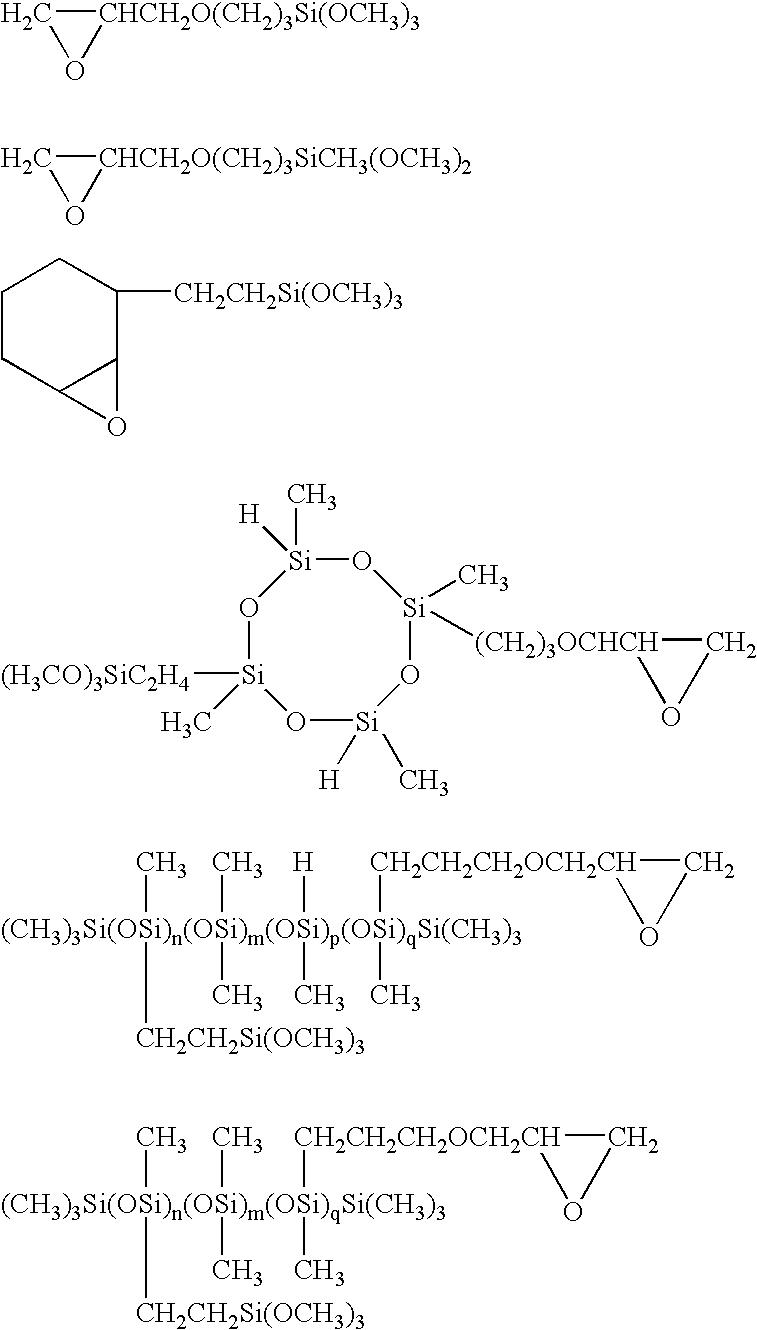

Liquid silicone rubber coating composition, curtain airbag and making method

InactiveUS20070166555A1Improve adhesionLiquid surface applicatorsFibre treatmentPolymer scienceTriallyl isocyanurate

A liquid silicone rubber coating composition comprising (A) an organopolysiloxane containing at least two silicon-bonded alkenyl radicals, (B) an organohydrogenpolysiloxane containing at least two SiH radicals, (C) an addition reaction catalyst, optionally (D) finely divided silica, (E) triallyl isocyanurate, (F) an organosilicon compound containing an epoxy radical and a silicon-bonded alkoxy radical, and (G) a titanium or zirconium compound is coated on a surface of an airbag base fabric and cured to form a rubber coating layer thereon. The composition is suited for curtain airbags.

Owner:SHIN ETSU CHEM IND CO LTD

Insulation cable material and preparation method thereof

InactiveCN104119624AImprove insulation performanceImprove mechanical propertiesEpoxyAluminium hydroxide

The invention belongs to the field of new materials, and discloses an insulation cable material prepared from the following raw materials by weight: 30-40 parts of PVC (polyvinyl chloride), 20-30 parts of polypropylene resin, 16-20 parts of bisphenol F epoxy resin, 12-15 parts of gamma-aminopropyltriethoxysilane, 10-12 parts of phthalic anhydride, 5-6 parts of modified diatomite, 5-6 parts of modified kaolinite, 3-4 parts of dimethyaminoethoxyethanol, 2-3 parts of polyglycolic acid, 1-2 parts of triallyl isocyanurate, 1-2 parts of aluminium hydroxide, 1-2 parts of antimonous oxide and 1-2 parts of titanium carbide. The insulation cable material not only has good insulation properties, but also has the advantages of high mechanical strength, corrosion resistance, good flame retardant performance and low cost , and the like.

Owner:STATE GRID CORP OF CHINA +1

Cold-resistant and high-temperature resistant cable material and preparation method thereof

ActiveCN104017333AGood cold and high temperature resistanceLess affected by extreme temperature conditionsEpoxyPolymer science

The invention belongs to the field of a cable, and discloses a cold-resistant and high-temperature resistant cable material. The cold-resistant and high-temperature resistant cable material is prepared from the following raw materials in parts by weight: 20-22 parts of dicyclopentadiene phenol epoxy resin, 15-16 parts of polypropylene resin, 6-8 parts of gamma-aminopropyltriethoxysilane, 5-6 parts of phthalic anhydride, 5-6 parts of alpha-methacrylic acid, 3-4 parts of modified kaolinite, 3-4 parts of modified kieselguhr, 2-3 parts of dimethyaminoethoxyethanol, 2-3 parts of glass fiber, 1-2 parts of polyethylene glycol, 1-2 parts of polyglycolic acid, 1-2 parts of triallyl isocyanurate, 1-2 parts of aluminium hydroxide, 1-2 parts of antimonous oxide and 1-2 parts of titanium carbide. The invention also discloses a preparation method of the cable material. The cable material prepared by the method is good in cold resistance and high-temperature resistance, and wide in application field.

Owner:东莞市台胜五金制品有限公司

125 DEG C resistance low smoke non-halogen rubber-sheathed cable shielding material

InactiveCN101544790AIt has the characteristics of green environmental protectionGood softnessShielded cableActive agent

The present invention discloses a 125 DEG C resistance low smoke non-halogen rubber-sheathed cable shielding material, including 100.00 shares of ethylene / ethylene acetic acid rubber, 60.00 to 100.00 shares of conductive carbon black, 40.00 to 60.00 shares of light calcium carbonate, 10.00 to 15.00 shares of plasticizer, 0.50 to 1.00 shares of active agent, 1.50 to 2.00 shares of anti-aging agent, 0.50 to 1.00 shares of technology operating agent, 1.50 to 2.00 shares of Di(tert-butylperoxyisopropyl)benzene, and 1.00 to 3.00 shares of triallyl isocyanurate. The rubber shielding cable material has characteristics of high temperature resistance, high conductivity, low smoke, non halogen, oil resistance, very plasticity and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

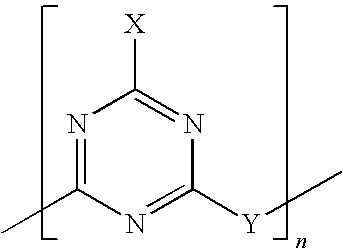

Flame-retardant resin composition

ActiveCN103328583AImprove flame retardant performanceExcellent reflow heat resistanceFireproof paintsHydrogenNitrogen

Contained in a thermoplastic resin (A) are a flame retardant (B) that is composed of the reaction product of a specific nitrogen-containing compound (triallyl isocyanurate and the like) and a specific phosphorus-containing compound (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and the like), is insoluble in toluene and contains the phosphorus atoms in 5.0 to 10.0% by weight; and at least one kind of a component (c) selected from the group consisting of a flame-retardant promoter (Cx), an impact modifier (Cy) and a layer compound (Cz).

Owner:KANEKA CORP

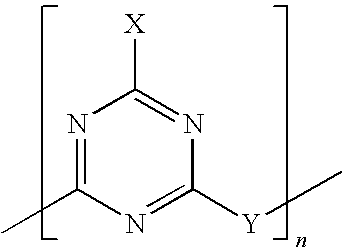

Halogen-free flame-proofing agent

ActiveUS20100298474A1Improve flame retardant performanceLow water solubilityFireproof paintsTriazine derivativeTriallyl isocyanurate

Halogen-free flame retardant for incorporation into a polymer matrix, wherein the flame retardant contains at least ammonium polyphosphate(s) and / or derivatives thereof and an oligomeric or polymeric 1,3,5-triazine derivative or mixtures of several thereof and at least one compound selected from monozinc phosphate, zinc borate, trizinc phosphate, zinc pyrophosphate, zinc polyphosphate, zinc hydroxystannate, zinc stannate, boron phosphate, monoaluminium phosphate, trialuminium phosphate, aluminium metaphosphate and mixtures thereof, precondensed melamine derivatives, melamine salts and adducts, ethylenediamine phosphate, piperazine phosphate, piperazine polyphosphate, 1,3,5-trihydroxyethyl isocyanurate, 1,3,5-triglycidyl isocyanurate and triallyl isocyanurate.

Owner:CHEM FAB BUDENHEIM AG

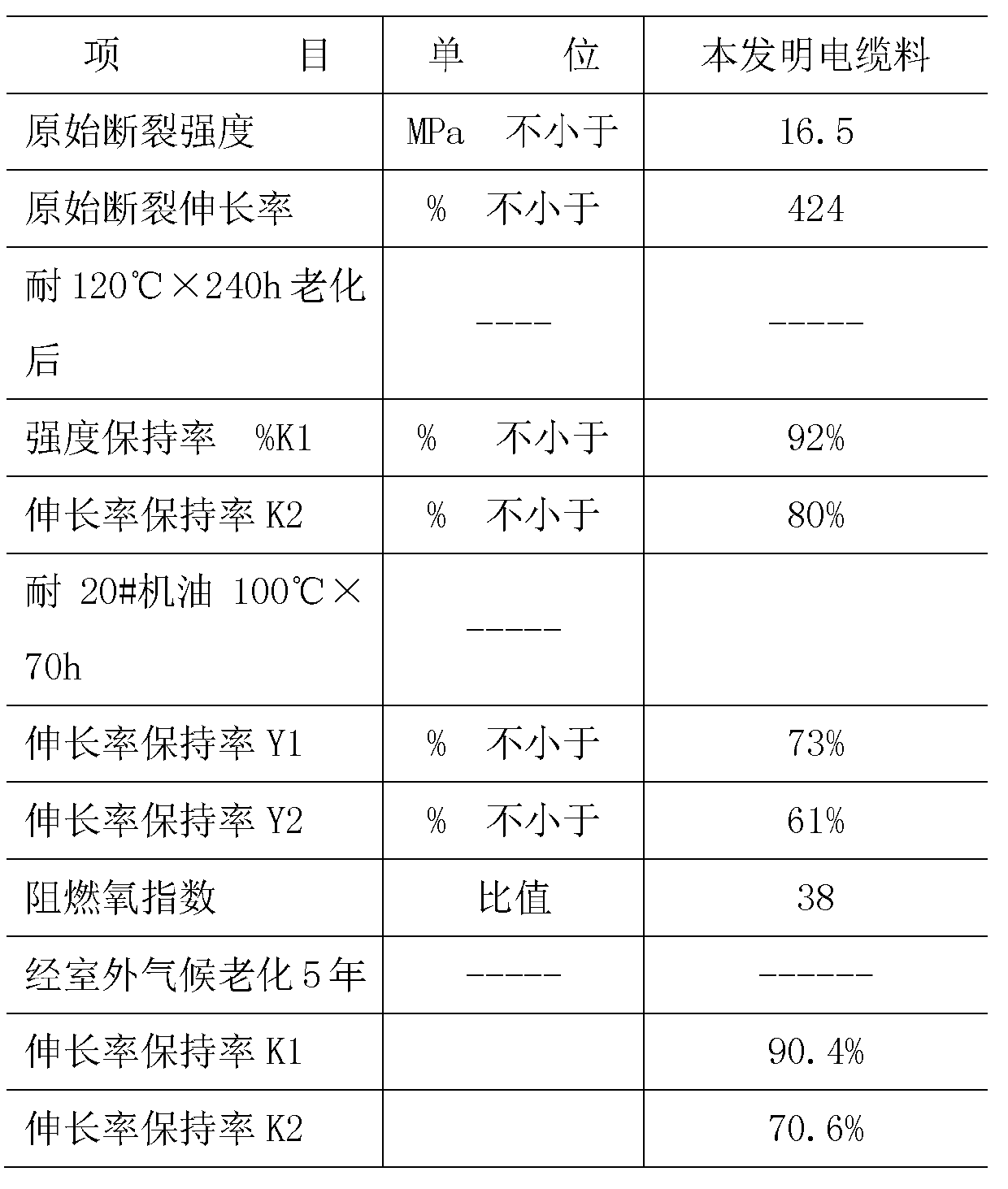

Environment-friendly waterproof and double-shielding control cable material and preparation method thereof

InactiveCN102911504AReasonable formulaEasy to prepareInsulated cablesInsulated conductorsPolymer scienceTriallyl isocyanurate

The invention discloses an environment-friendly waterproof and double-shielding control cable material and a preparation method thereof, materials in terms of parts by weight are: a mixture A: 30-40 parts of methyl vinyl silicone rubber, 10-20 parts of chloroprene rubber, 1-3 parts of semi-reinforcing carbon black, 40-60 parts of modified montmorillonite powder, 1-3 parts of ECHO.A mercapto thiadiazole derivative, 1.5-2.5 parts of triallyl isocyanurate, 1-3 parts of zinc stearate, 3-4 parts of chlorinated paraffin, 10-20 parts of magnesium hydrate and 1-3 parts of octyl ester; a mixture B: 20-30 parts of polypropylene resin, 35-55 parts of chlorinated polyethylene, 25-35 parts of ethylene-vinyl acetate copolymer, 20-30 parts of ethylene vinyl acetate, 0.3-0.5 parts of poly-4-methyl-1-amylene, 2-4 parts of anti-aging agent OD, 2-3 parts of cross-linking agent TAIC (triallyl isocyanurate), 1-3 parts of phenolic resin, 25-35 parts of talcum powder and 1-3 parts of dimethyl dimercapto tin isooctyl. The control cable material has simple preparation method and rational proportion, and drastically improves performance such as tensile strength, elongation at break, tensile strength retention rate and elongation at break retention rate after aging, and impacts brittle temperature performance while obtains excellent performances.

Owner:东莞市富庆电子线材有限公司

Low-temperature-resistant heat-conducting fluororubber material

InactiveCN105086294AImprove high temperature resistanceExcellent high temperature resistance, modified graphene has excellent thermal conductivityPhosphateHeat conducting

The invention discloses a low-temperature-resistant heat-conducting fluororubber material. The fluororubber material comprises, by weight, 90-110 parts of fluororubber, 30-50 parts of ethylene propylene rubber, 30-50 parts of fumed silica, 10-20 parts of nanometer kaolin, 4-7 parts of modified graphene, 10-30 parts of microencapsulated red phosphorus, 5-10 parts of ethyl butyl phosphinate, 5-10 parts of bis(4-hydroxyphenyl) phenyl phosphine oxide, 10-20 parts of acetyl tributyl citrate, 10-15 parts of dioctyl nylon-acdate, 10-20 parts of epoxidized soybean oil, 0.8-1.2 parts of dual-solvent 25, 1-3 parts of triallyl isocyanurate, 0.5-0.9 part of 3# vulcanizing agent, 3-4 parts of Ca / Zn compound stabilizers, 2-4 parts of stearic acid, 1-3 parts of zinc oxide, 1-2 parts of isooctyl phosphate, 1-2 parts of antiager A, 0.5-1.5 parts of antiager 4010 and 3-5 parts of paraffin. The fluororubber material is high in heat conducting performance, low temperature and high temperature resistance and low-temperature elasticity.

Owner:ANHUI JINYANG FLUORINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com