High-temperature-resistant vapour-resistant sheath material for nuclear power station cables and preparation method thereof

A nuclear power plant cable, high temperature resistance technology, applied in the direction of electrical components, insulated cables, cables, etc., can solve the problems affecting the normal operation of nuclear power plants, sheath material failure, etc., to achieve good flame retardant effect, excellent high temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

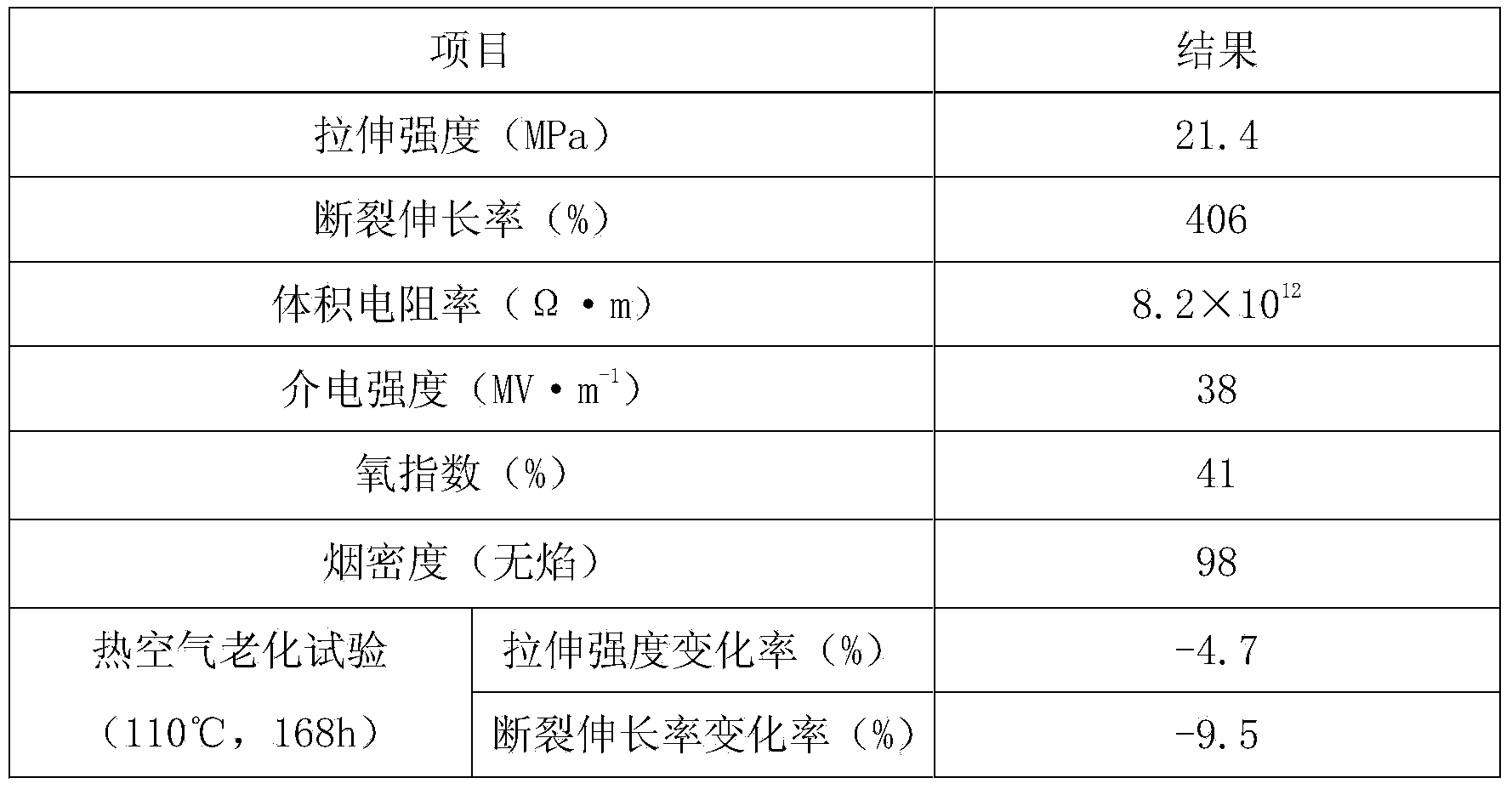

Examples

Embodiment Construction

[0012] A high temperature resistant water vapor sheath material for nuclear power plant cables, made of the following weight (kg) of raw materials: methyl vinyl phenyl silicone rubber 65, EPDM 25, polyphenylene sulfide 15, C5 Petroleum resin 12, acetylene carbon black 25, zinc oxide 2, stearic acid 2, triallyl isocyanurate 4, magnesium hydroxide 20, antimony trioxide 10, zinc stannate 8, zinc stearate 2 , Barium stearate 1, γ-methacryloxypropyl trimethoxysilane 2, dimethyl phthalate 10, diethylene glycol dibenzoate 10, dibenzo disulfide Thiazole 2, trinonylphenyl phosphite 1.5, dicumyl peroxide 3, nano wollastonite powder 10, composite filler 5;

[0013] The method for preparing the composite filler is as follows: a. Take the following weight (kg) of raw materials: attapulgite 7, sepiolite 6, potash feldspar 4, bis(dioctyloxy pyrophosphate) ethylene titanic acid Ester 1, titanium dioxide 4, nano silica 5, nano alumina 3, paraffin oil 5, polyisobutylene 4, ferrocene 2, zinc metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com