Battery diaphragm and its preparation method and lithium ion secondary battery containing the diaphragm

A battery separator and separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of poor heat resistance and poor mechanical strength of porous membranes, and achieve high mechanical strength, good permeability, and excellent air permeability. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

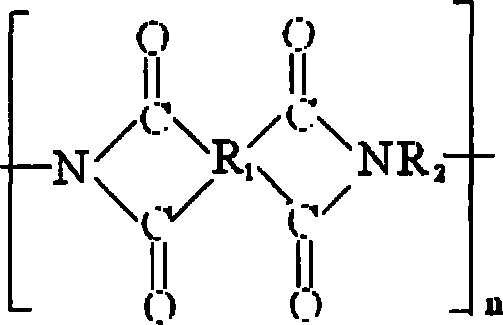

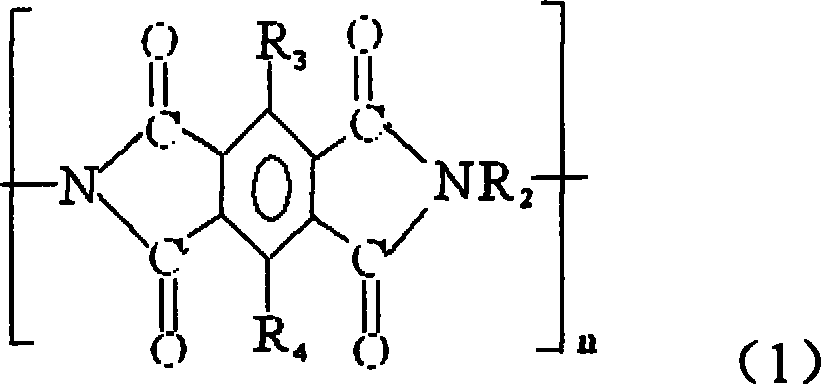

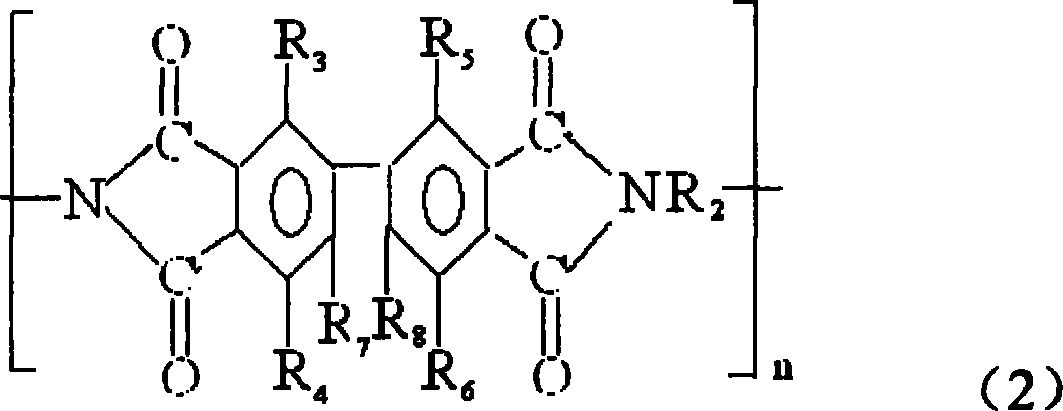

[0032] The preparation method of the battery separator provided by the present invention includes forming a film from a solution containing a substrate, a pore-forming substance and a solvent, and removing the pore-forming substance at a temperature lower than the glass transition temperature of the substrate, wherein the substrate contains polyimide amine.

[0033] Preferably, the polyimide is polypyromellitic imide, polybiphenyl tetracarboxylic imide, polybenzophenone tetramethylimide having the structure described in the above structural formula (1), (2) or (3). One or more of imides. Since general polyimide is an insoluble substance, in order to use polyimide to obtain a battery separator with uniform quality, it is necessary to mix polyimide and pore-forming substances uniformly, so polyimide is used as a raw material to prepare When the battery separator, the present invention preferably said polypyromellitic imide is selected from polyN-alkylphenylpyromellitic imide, p...

Embodiment 1

[0055] This example is used to illustrate the battery separator provided by the present invention and its preparation method.

[0056] 5.214 grams of pyromellitic dianhydride, 4.786 grams of diaminodiphenyl ether, 10.015 grams of polystyrene containing amino groups at one end of the polymer chain (the weight-average molecular weight is 15000, purchased from Aldrich Company) and 100 grams of N-2-methyl Pyrrolidone (NMP) was stirred and mixed uniformly at room temperature to obtain a uniform solution, and then coated with an I-shaped film applicator to obtain a film with a thickness of 0.5 mm. The film was heated at 120°C for 2 hours to remove the solvent, then the temperature was programmed to 300°C at 5°C / min for imidization for 3 hours, and then the temperature was raised to 350°C for 1.5 hours, and finally cooled to 120°C while performing biaxial For stretching treatment, the stretching speed is 10 mm / min, and the stretching ratio is 2 times in the longitudinal direction (MD...

Embodiment 2

[0058] This example is used to illustrate the battery separator provided by the present invention and its preparation method.

[0059] 8.864 gram of biphenyltetracarboxylic dianhydride, 3.224 gram of p-phenylenediamine, 8.032 gram of polypropylene oxide (weight average molecular weight is 18000, purchased from Aldrich Company) and 150 gram of DMSO are stirred and mixed at room temperature Uniform, after obtaining a uniform solution, use an I-shaped film coating applicator to coat a film to obtain a film with a thickness of 0.4 mm. The film was heated at 160°C for 2 hours to remove the solvent, then programmed at 4°C / min to 270°C for imidization for 5 hours, then raised to 350°C for 1.5 hours, and finally cooled to 120°C for biaxial stretching Stretching treatment, the stretching speed is 10 mm / min, the stretching ratio is 2 times in the longitudinal direction (MD), and 2 times in the transverse direction (TD), thus obtaining the battery separator of the present invention. Amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com