Patents

Literature

483results about How to "No short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery diaphragm and its preparation method and lithium ion secondary battery containing the diaphragm

InactiveCN101000951AGood chemical stabilityNo ruptureSecondary cellsCell component detailsLithiumPower battery

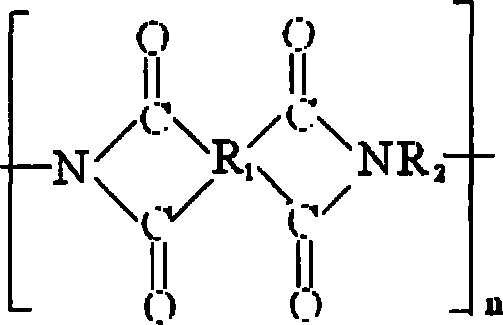

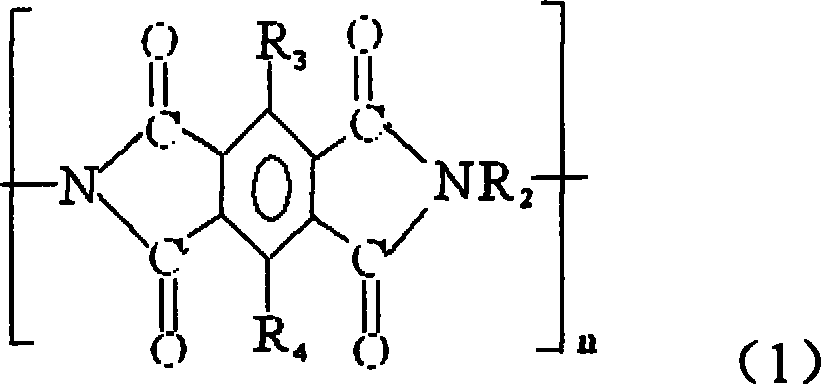

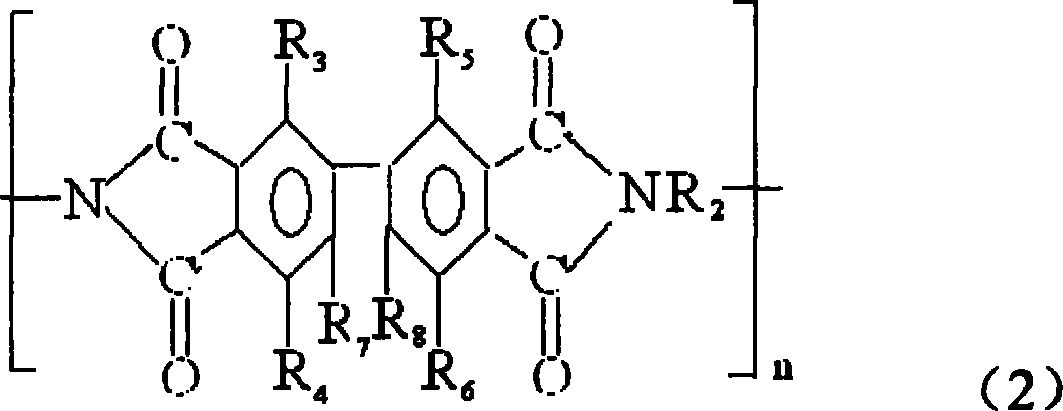

A battery separator includes the substrate and holes distributed on it, in which, the substrate contains polyimide. The battery separator of this invention uses polyimide which is a new material bearing high temperature as substrate, so that it has excellent chemical stability, high temperature, good permeability and high mechanical strength. The lithium-ion rechargeable batteries using this invention don't appear short circuit even in 150 deg. C, thus this battery separator can be used for high-capacity and power batteries.

Owner:BYD CO LTD

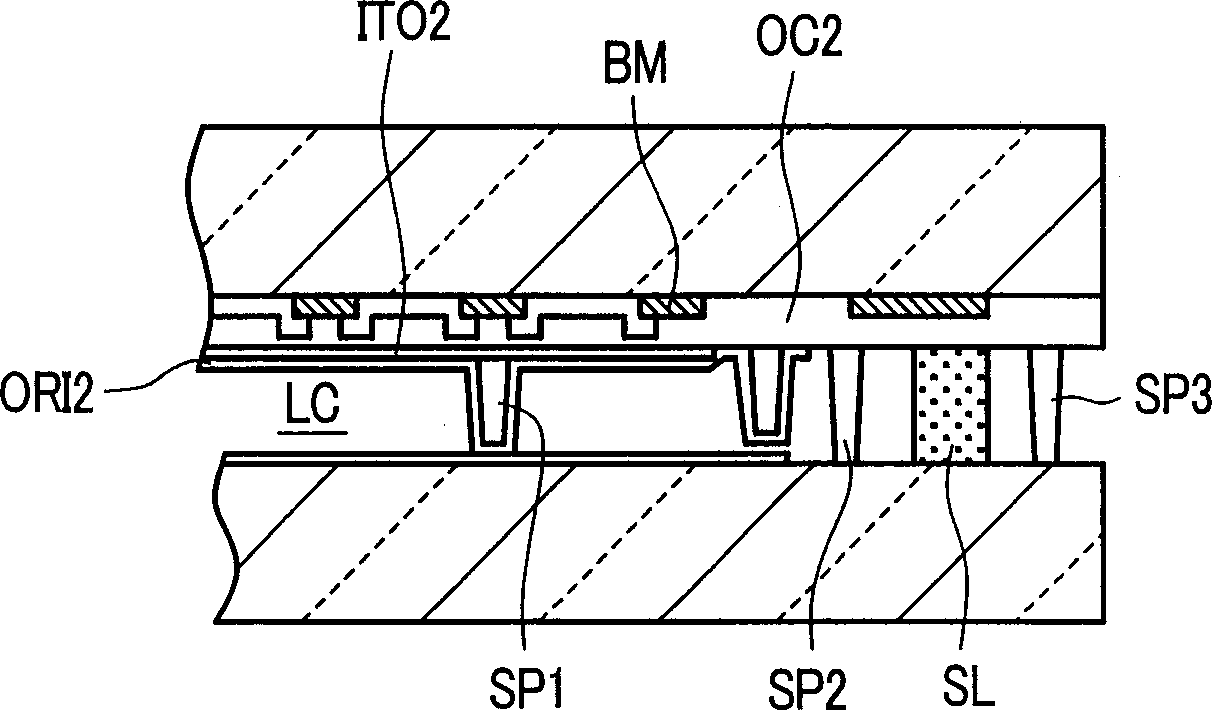

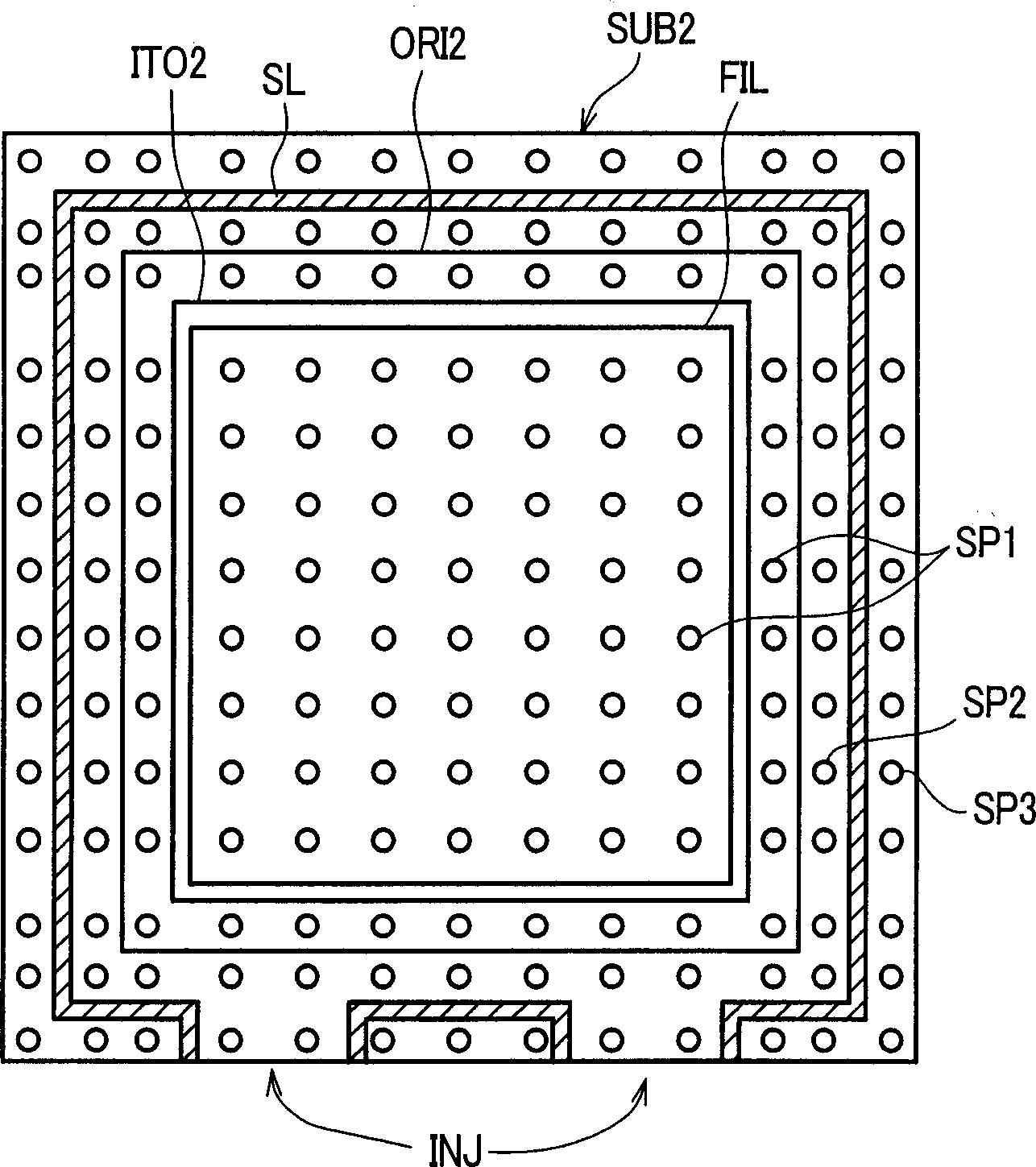

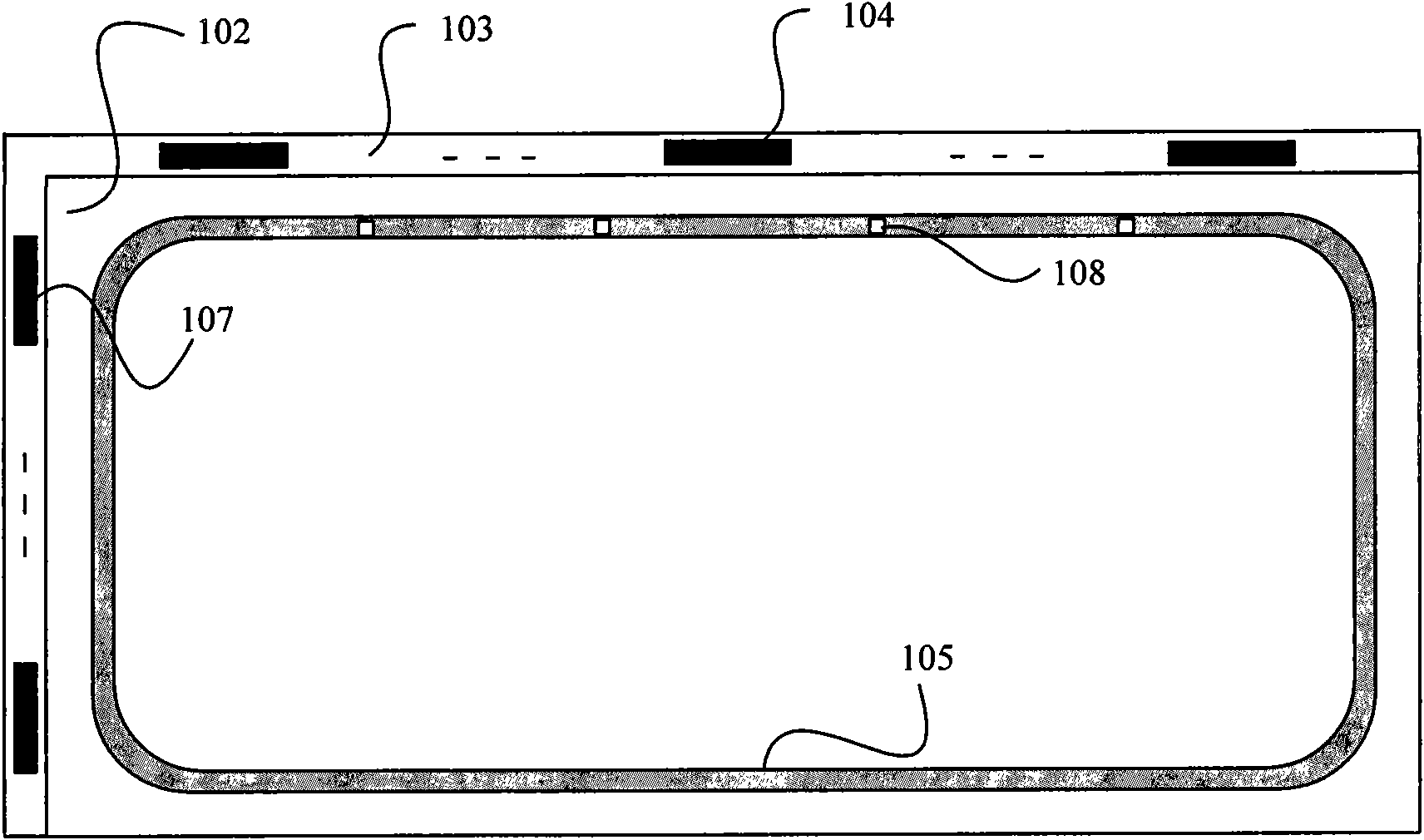

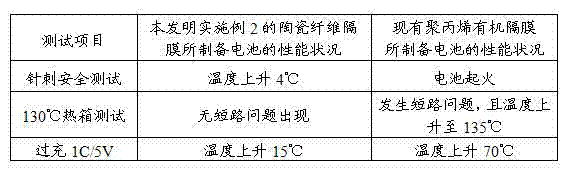

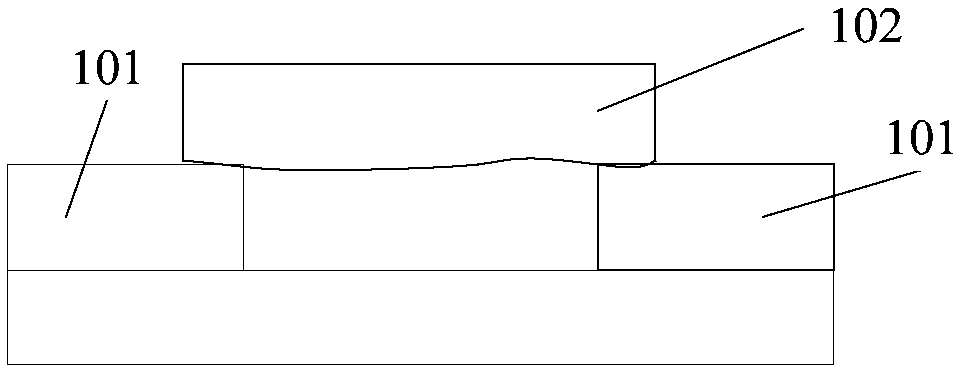

Liquid crystal display device

InactiveCN1400500AShort circuit between electrodes and wiringNo short circuit between electrodes and wiringNon-linear opticsColor gelEngineering

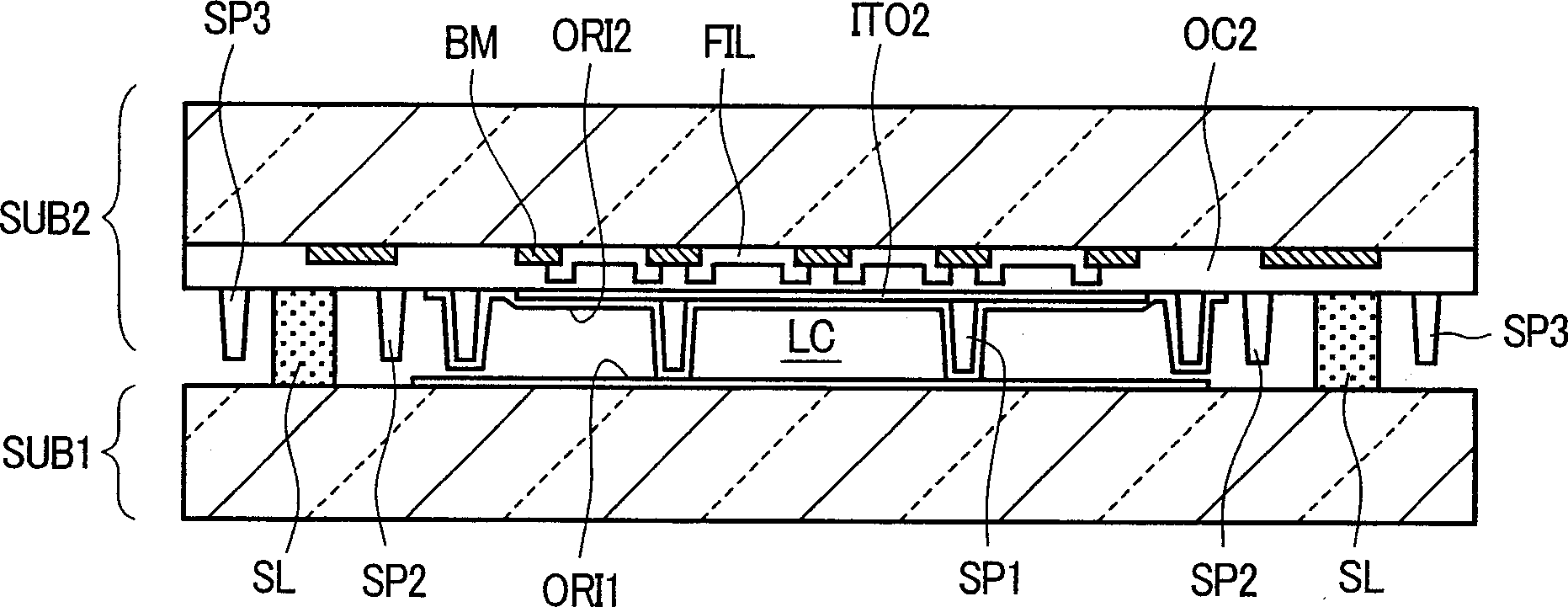

The present invention provides a liquid crystal display unit to prevent a shortcircuit between a common electrode on the side of a color filter substrate and a wiring and an electrode on the side of a thin film transistor and to set a precise cell gap in the entire area including the sealing area of two substrates. In which, columnar spacers SP1 are fixed in prescribed positions by forming the columnar spacers on the common electrode ITO2 and on a transparent protective film OC2 where the common electrode does not exist at the color filter substrate SUB2 and coating the columnar spacers on the common electrode with an alignment layer. Columnar spacers SP2 and SP3 are provided in the vicinity of the inner and the outer parts of a sealing area SL to secure the prescribed cell gap in the entire area of the two substrates and the sagging and to secure the height of the applied sealing material.

Owner:JAPAN DISPLAY INC

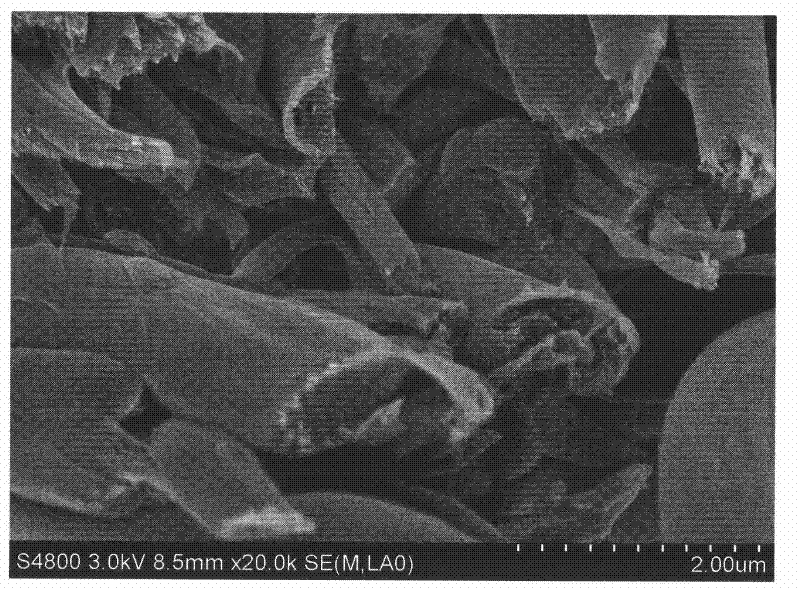

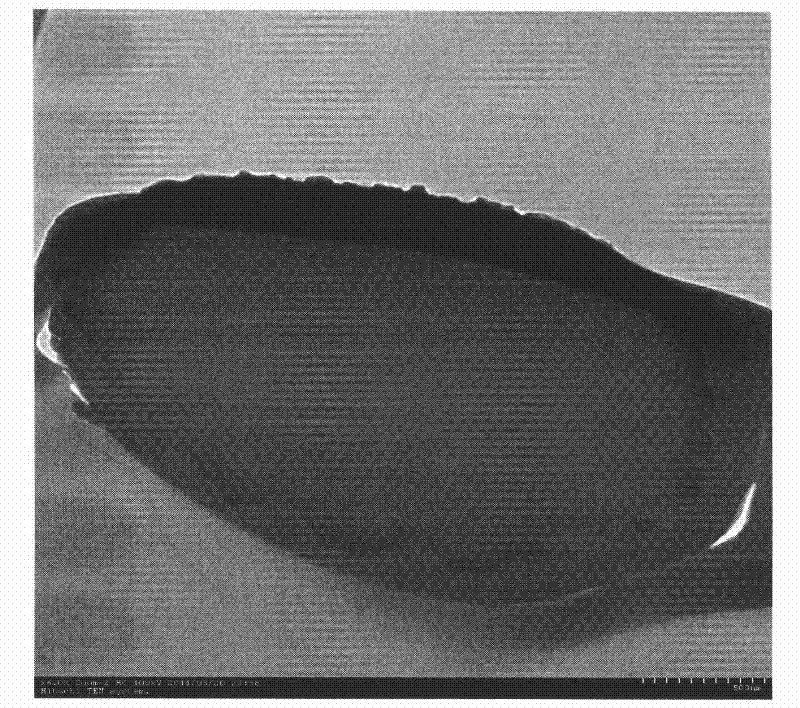

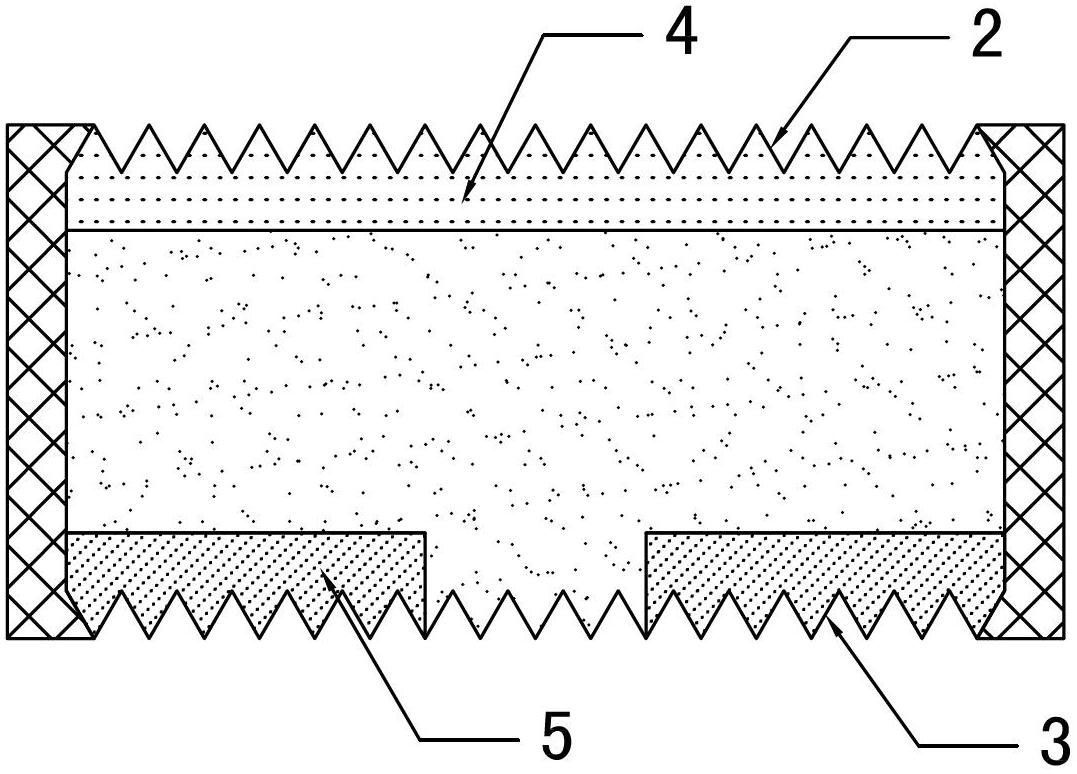

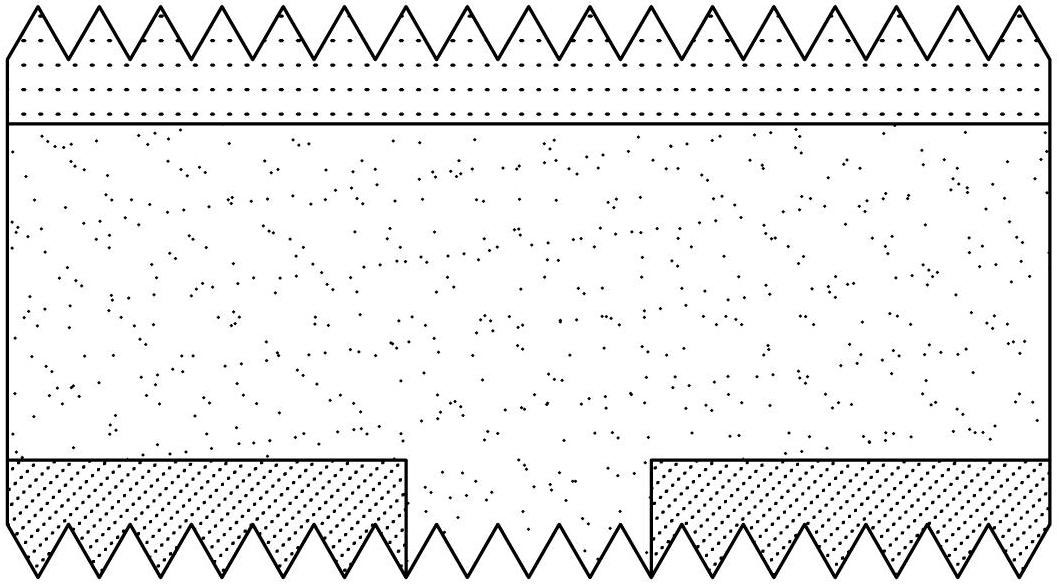

Coaxial compound nanometre fibre film as well as preparation method and application thereof

ActiveCN102230257AImprove permeabilityHigh tensile strengthFilament/thread formingCell component detailsFiberPolymer science

The invention discloses a coaxial compound nanometre fibre film composed of compound nanometre fibres of a fluorine-containing polymer skin layer and a polyimide core layer, wherein the upper and the lower surfaces and inner holes of the film are distributed symmetrically. The coaxial compound nanometre fibre film is prepared from a fluorine-containing polymer solution and a polyamic acid solution through coaxial static spinning compounding, mechanical roller pressing and thermal imidization; the nanometre fibre film provided by the invention integrates the advantages of fluorine-containing polymer and polyimide; the fluorine-containing polymer has excellent electrolyte wetting property, liquid maintaining property and ion conductivity; and the polyimide has high mechanical strength and high heat resistance. The compound nanometre film provided by the invention is fit for high-energy lithium ion energy storage batteries and high-power electrokinetic cells.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

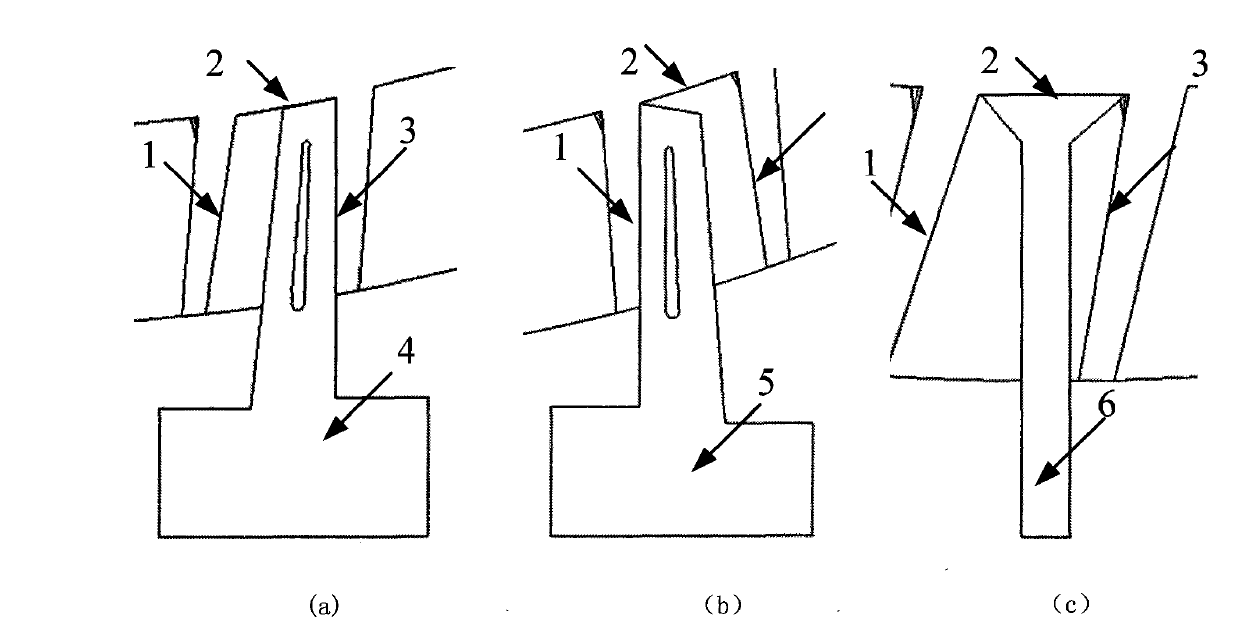

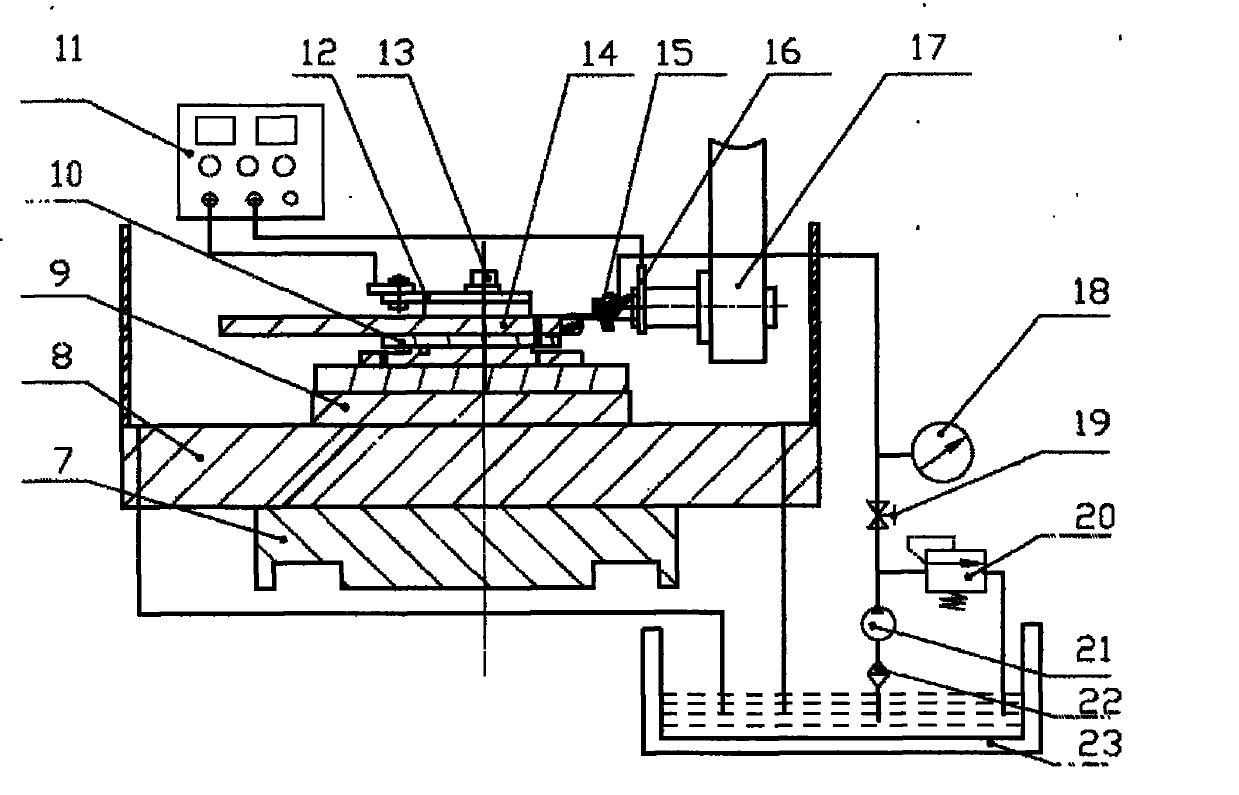

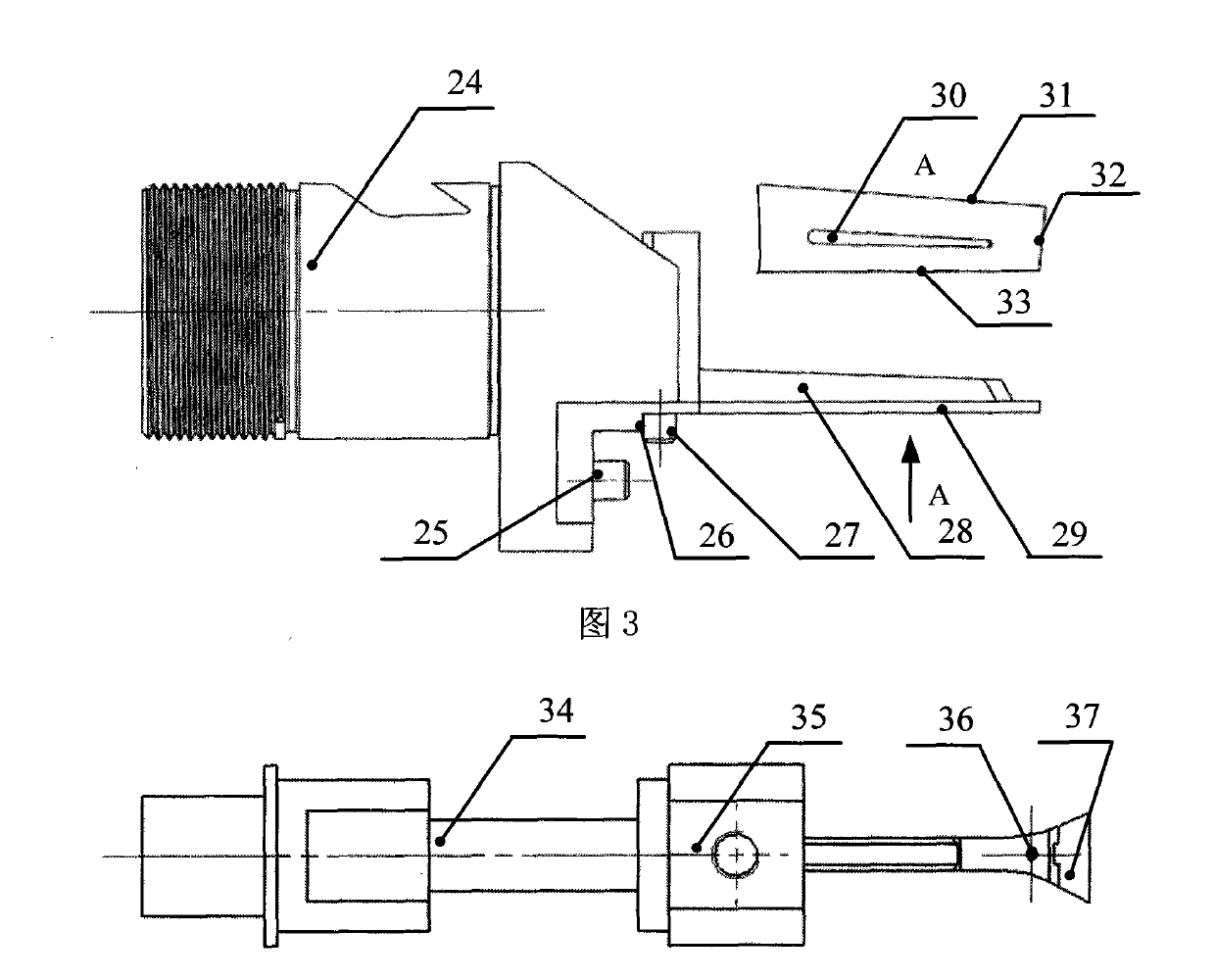

Step and zone type integral impeller electrolytic processing process and device

InactiveCN101767233AGuaranteed machining accuracyImprove machining accuracyElectrochemical machining apparatusImpellerElectrolysis

The invention discloses step and zone type integral impeller electrolytic processing process and device, which belong to the field of impeller electrolytic processing. The integral impeller electrolytic processing has three processing procedures of impeller disc, impeller back and impeller root. The impeller back is firstly processed, then the impeller disc is processed, and the impeller root is processed. The impeller disc, the impeller back and impeller root can be respectively processed along the respective profile by a sweeping forming method. The device comprises an X-axis slide unit, a Y-axis slide unit, a Cw-axis rotary table, an index plate, a processing power supply, an anode conductive plate, a center shaft, a cathode, a cathode conductive plate, a pressure gauge, a ball valve, a water pump, a filter and an electrolytic tank. The invention effectively solves the problem of blade processing of the integral impeller, and is suitable for processing the integral impellers of aerospace engines and advanced power units.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

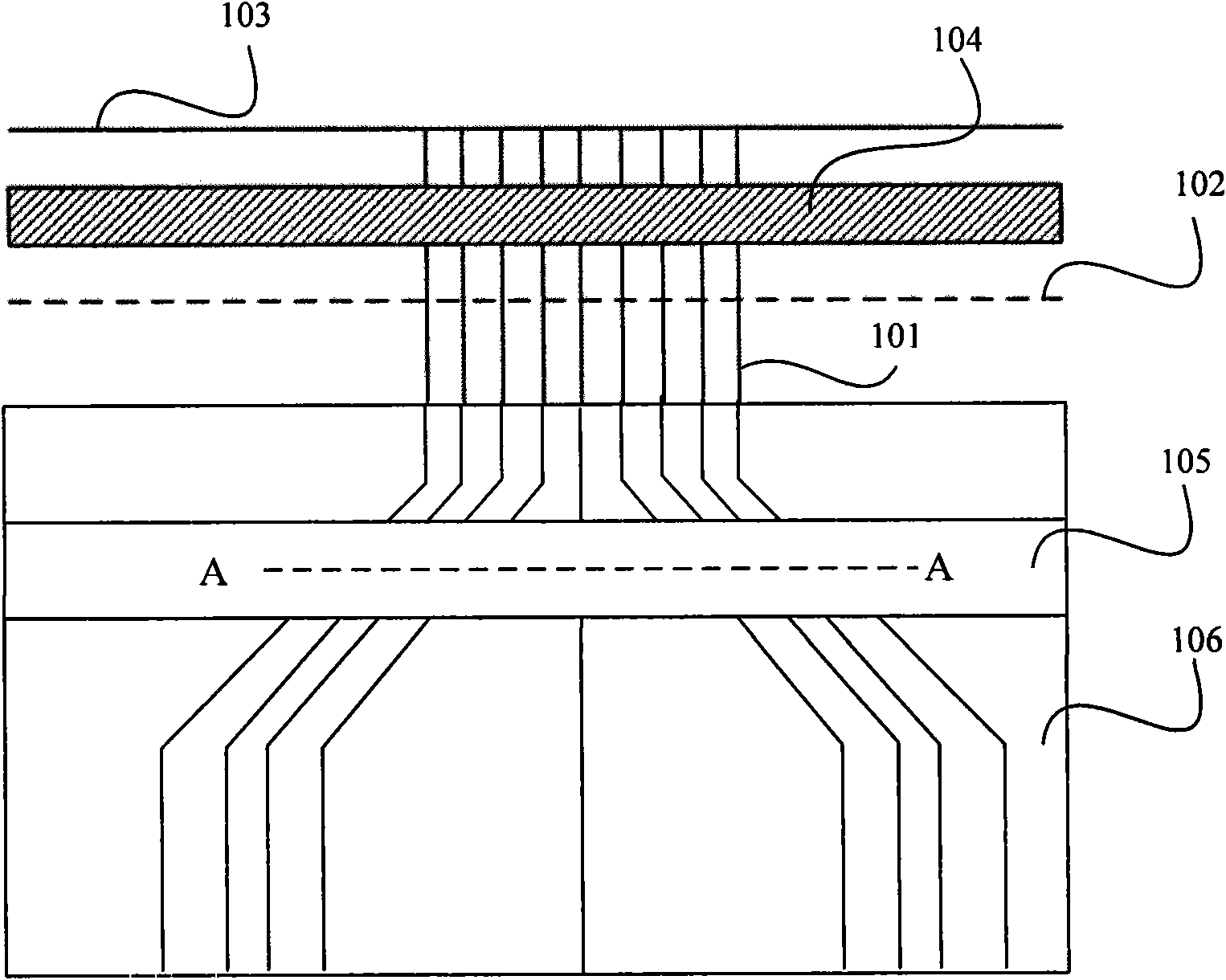

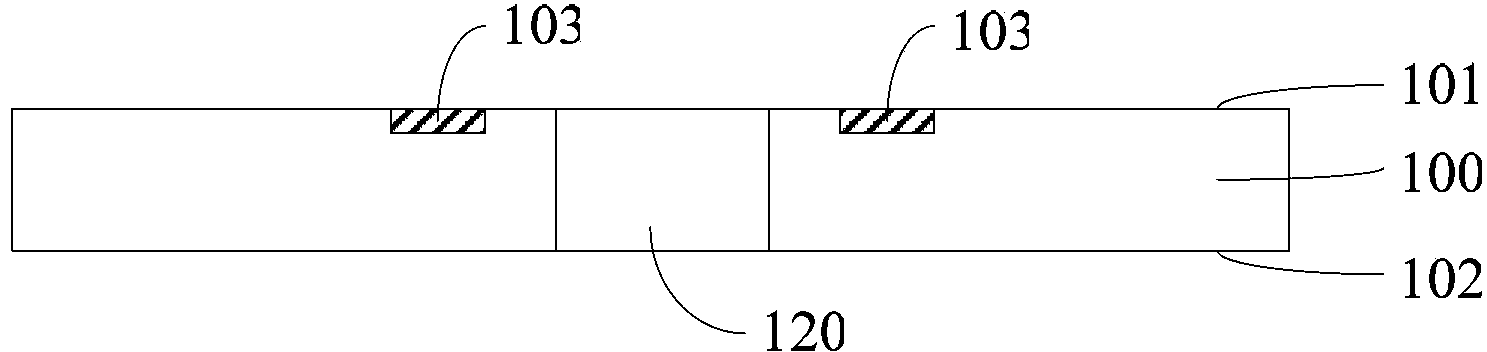

Panel and manufacturing method thereof

The invention relates to a panel and a manufacturing method thereof, wherein, the manufacturing method of the panel comprises the following steps: finishing the manufacturing of film transistor arraysand peripheral graphs on a substrate to form an array substrate; coating main frame sealing glue in which no golden ball is doped at the periphery of the array substrate; coating secondary frame sealing glue in which golden balls are doped outside of the main frame sealing glue, wherein the secondary frame sealing glue is partly overlapped with or completely separated from the main frame sealingglue, and is positioned in the connecting electrode area of the array substrate but keeps away from the lead wire area of data lines; and aligning the array substrate and a color-film substrate to form the panel. To the panel and the manufacturing method thereof, due to the absence of golden balls in the lead wire area of the date lines, ESD can not occur, simultaneously golden balls are only doped in the secondary frame sealing glue, the usage amount of golden balls is greatly reduced, thereby lowering the cost of the panel.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

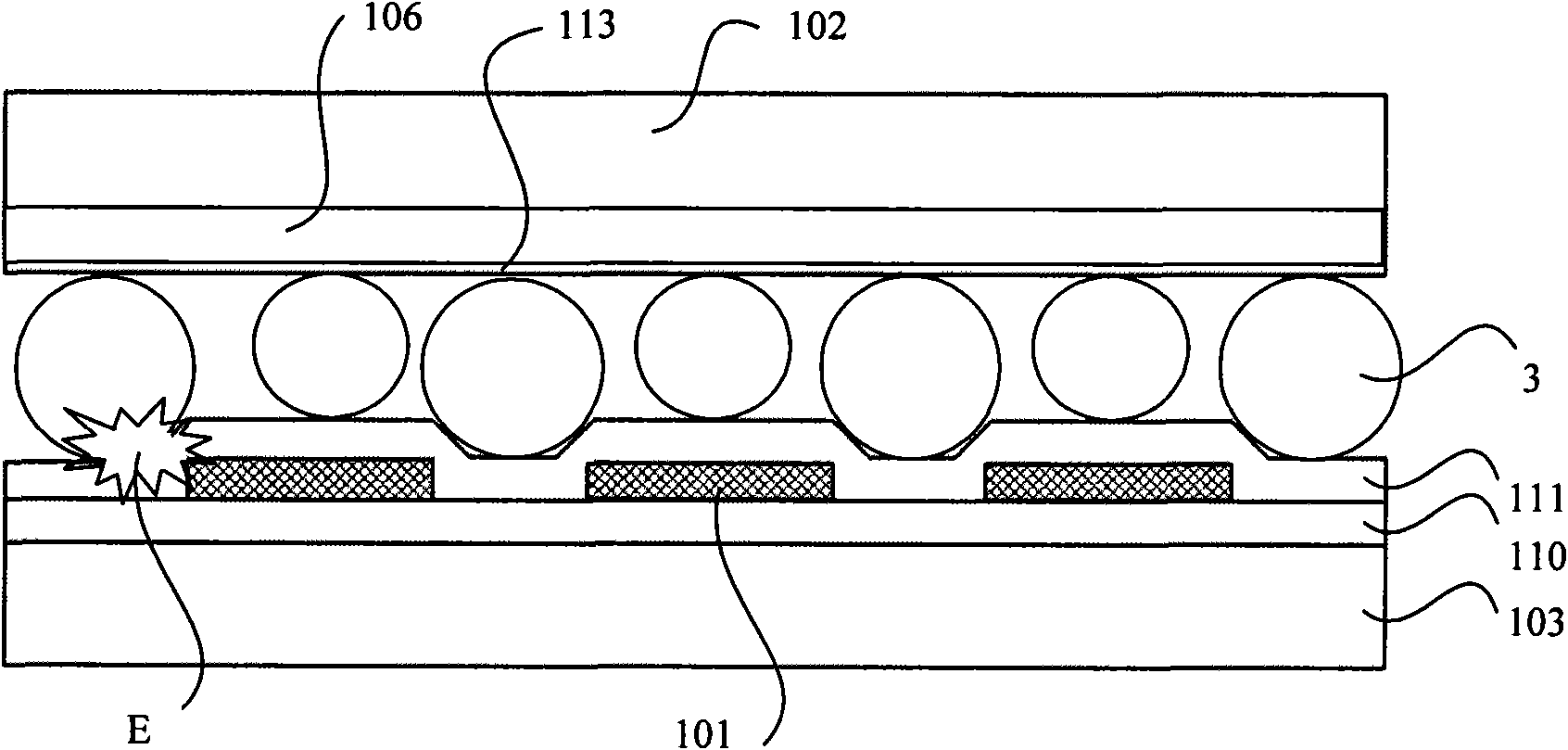

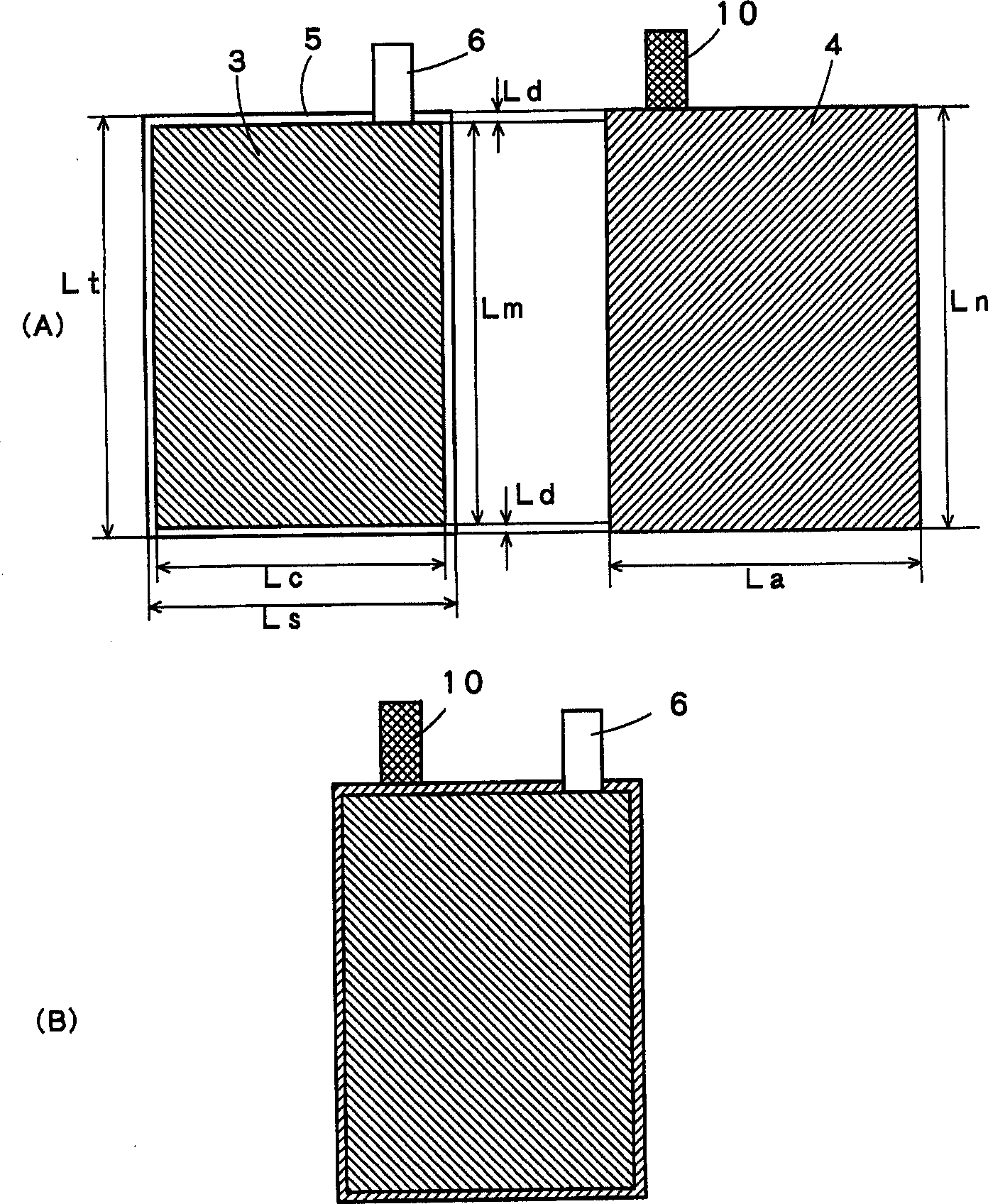

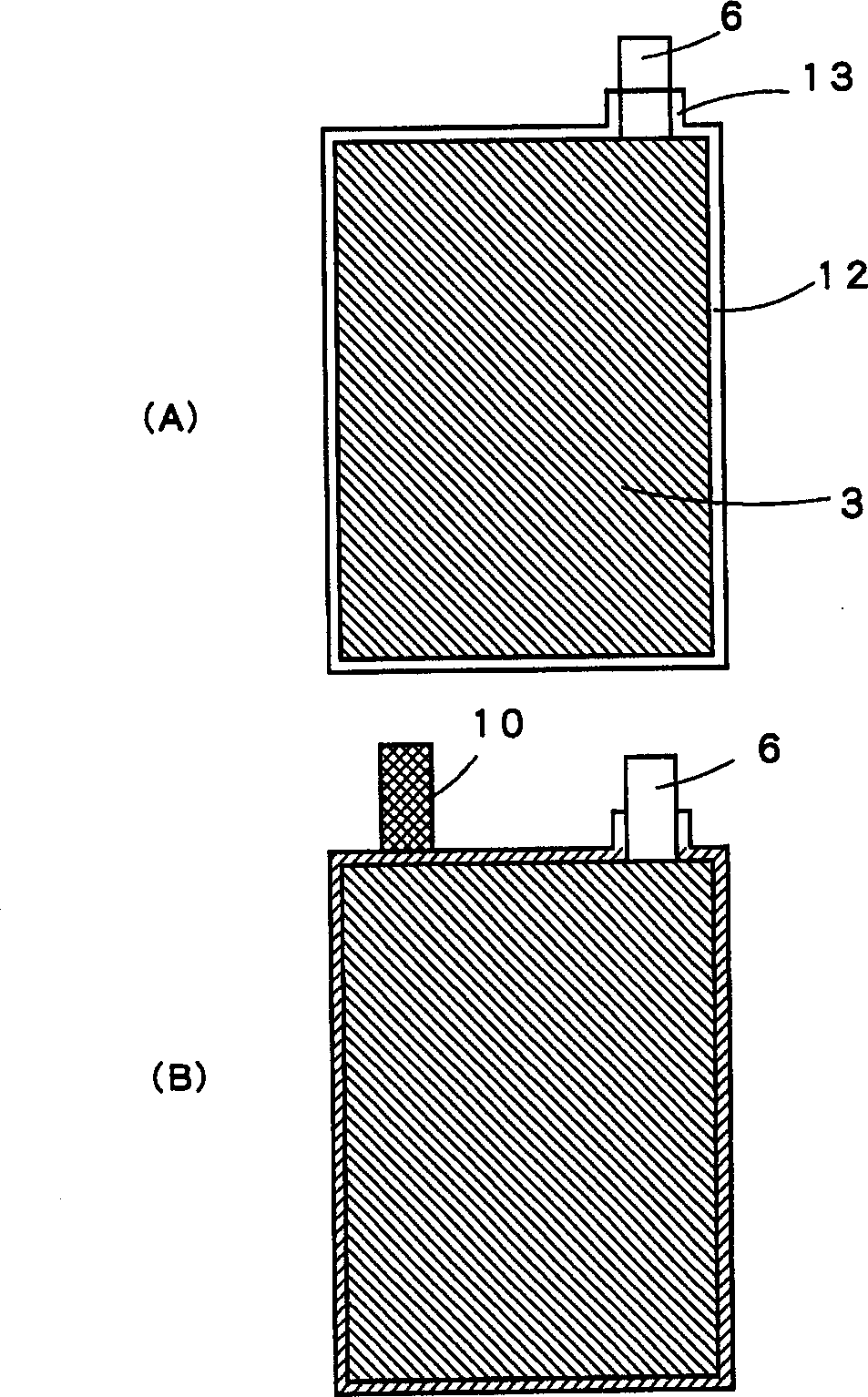

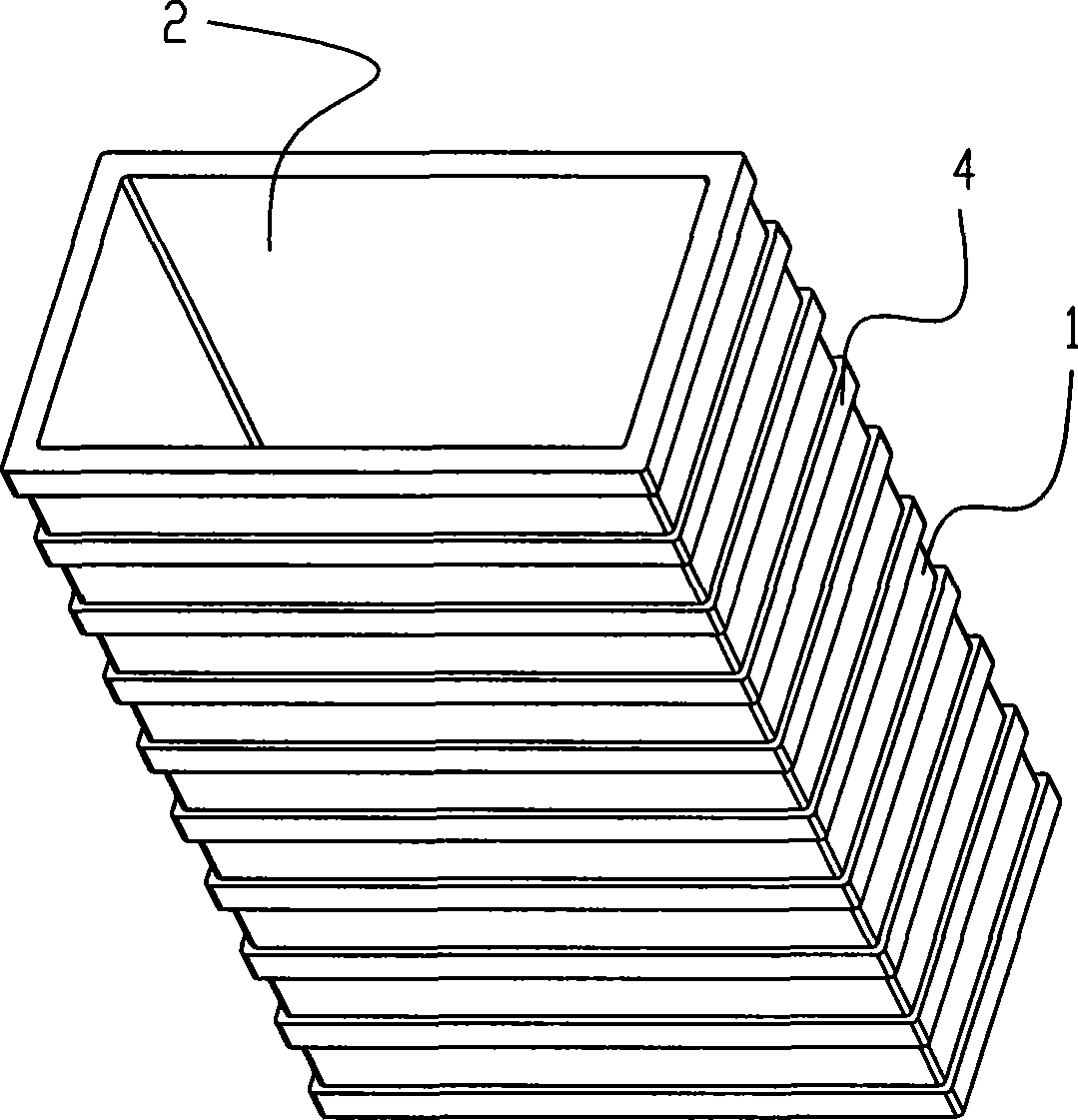

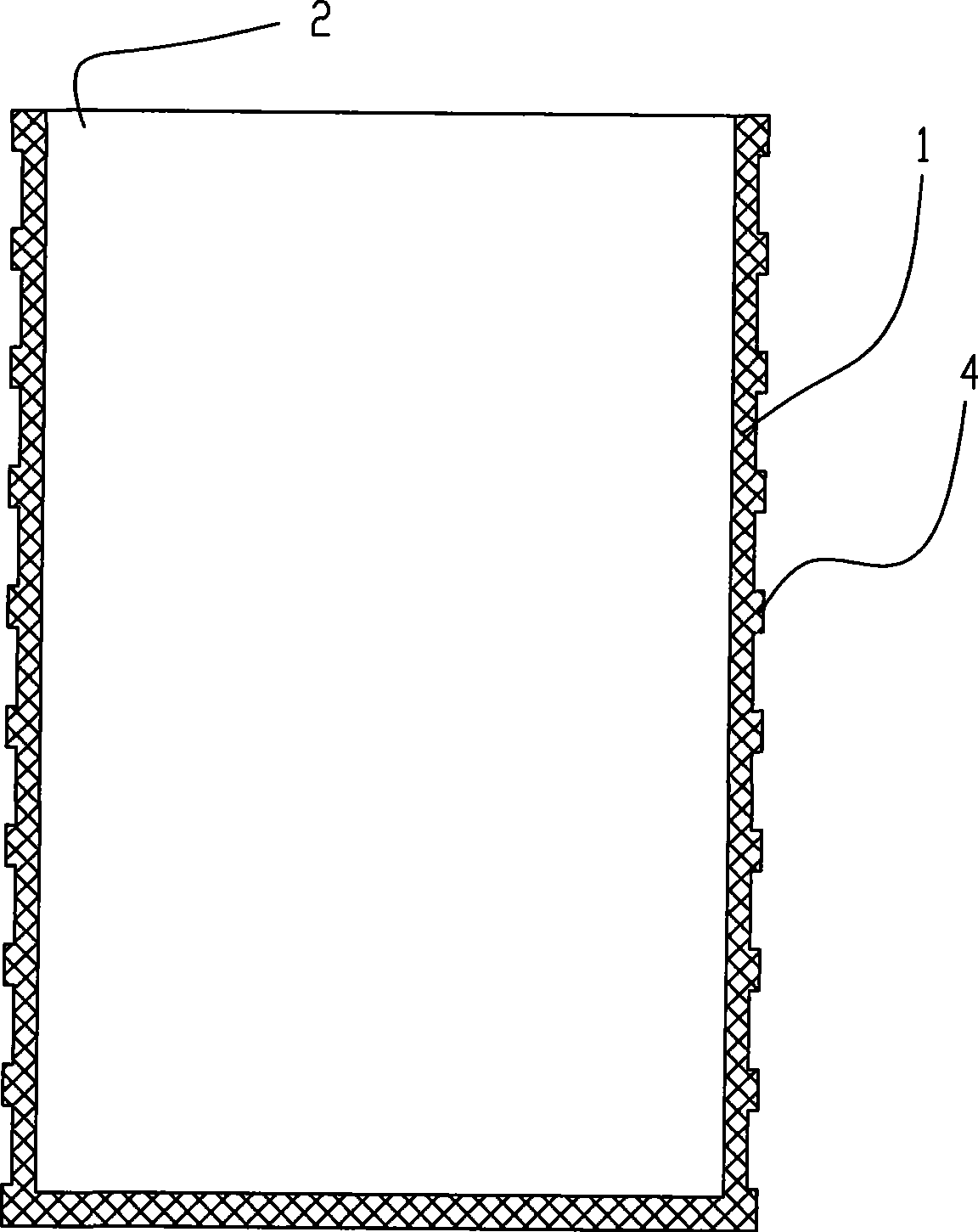

Laminated secondary cell

InactiveCN1372345ANo short circuitImprove featuresCell electrodesFinal product manufactureEngineeringElectrode

Owner:ENVISION AESC ENERGY DEVICES LTD +1

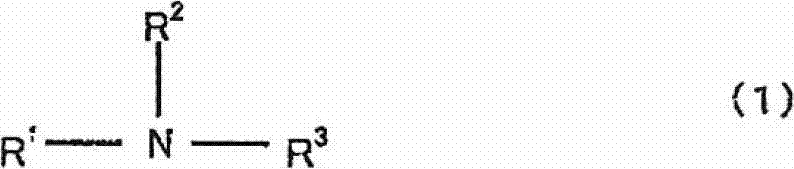

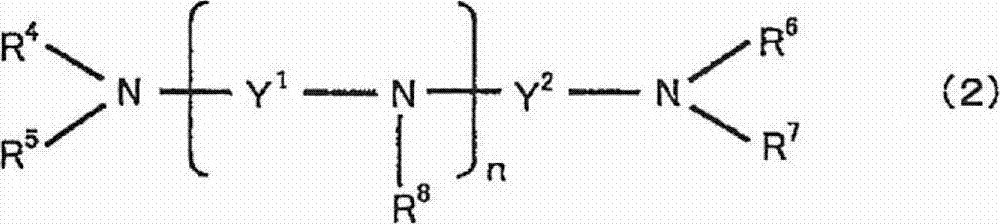

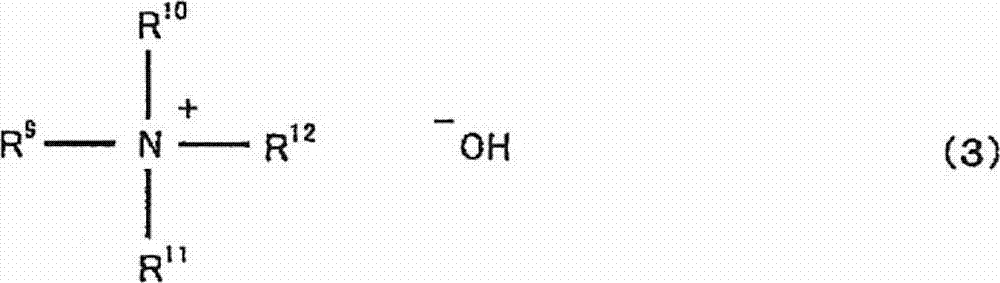

Cleaning agent for semiconductor provided with metal wiring

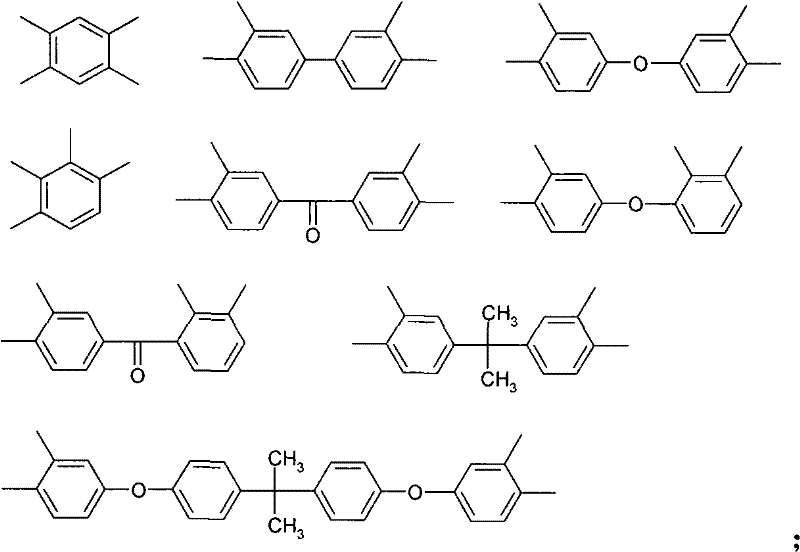

ActiveCN102770524AImprove corrosion resistanceIncrease contact resistanceOrganic detergent compounding agentsOther chemical processesCopperCleansing Agents

A cleaning agent for a microelectronic device provided with metal wiring, which has an excellent ability to remove polishing particle residues derived from a polishing agent and an excellent ability to remove metallic residues on an insulating film, and has excellent anticorrosiveness to the metal wiring. The cleaning agent is used at a step subsequent to chemical mechanical polishing in a manufacturing process of a microelectronic device in which a metal wiring, e.g., copper or tungsten, is formed.

Owner:ENTEGRIS INC

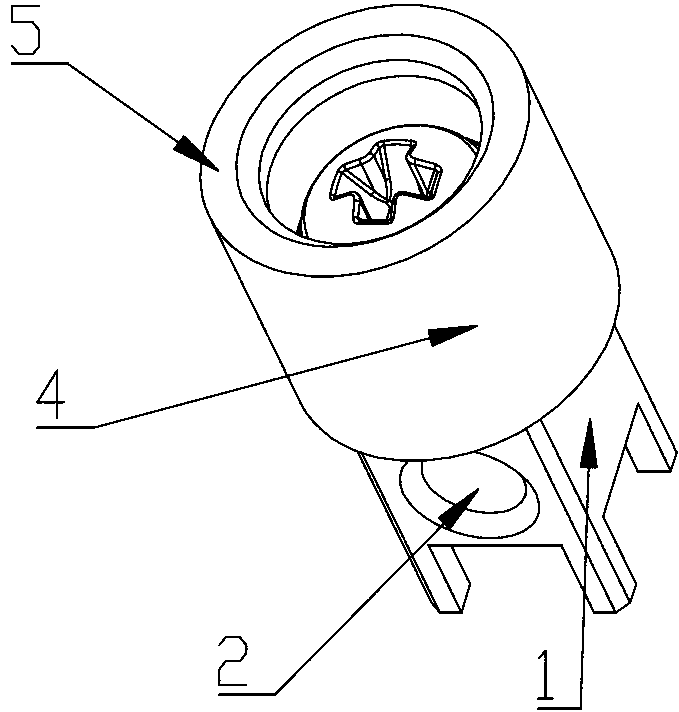

Wiring post

InactiveCN102983426AWon't fall offNot easy to loseClamped/spring connectionsMulticonductor cable end piecesReciprocating motionEngineering

The invention provides a wiring post which comprises a wire holder and a wire pressing screw. A wiring hole is opened on one side face of the wire holder, a threaded hole is opened at the top of the wire holder, the threaded hole is communicated with the wiring hole, and the wire pressing screw is connected with the wire holder through the screw hole. The wiring post further comprises a cap sleeve with inner threads, outer threads are opened at the upper end of the wiring post, and the cap sleeve is in threaded connection with the wiring post. A cap is arranged at the top of the cap sleeve, a hole for a screw driver to penetrate through is opened on the cap, and the diameter of the hole is smaller than that of a screw cap of the wire pressing screw. By means of the wiring post with the structure, the wire pressing screw only reciprocates in the cap sleeve and cannot fall off the wire holder, and the wire pressing screw cannot be lost easily, so that the short-circuit phenomenon caused by the loss of the wire pressing screw in products can be avoided.

Owner:APPLIED OPTOELECTRONICS INC

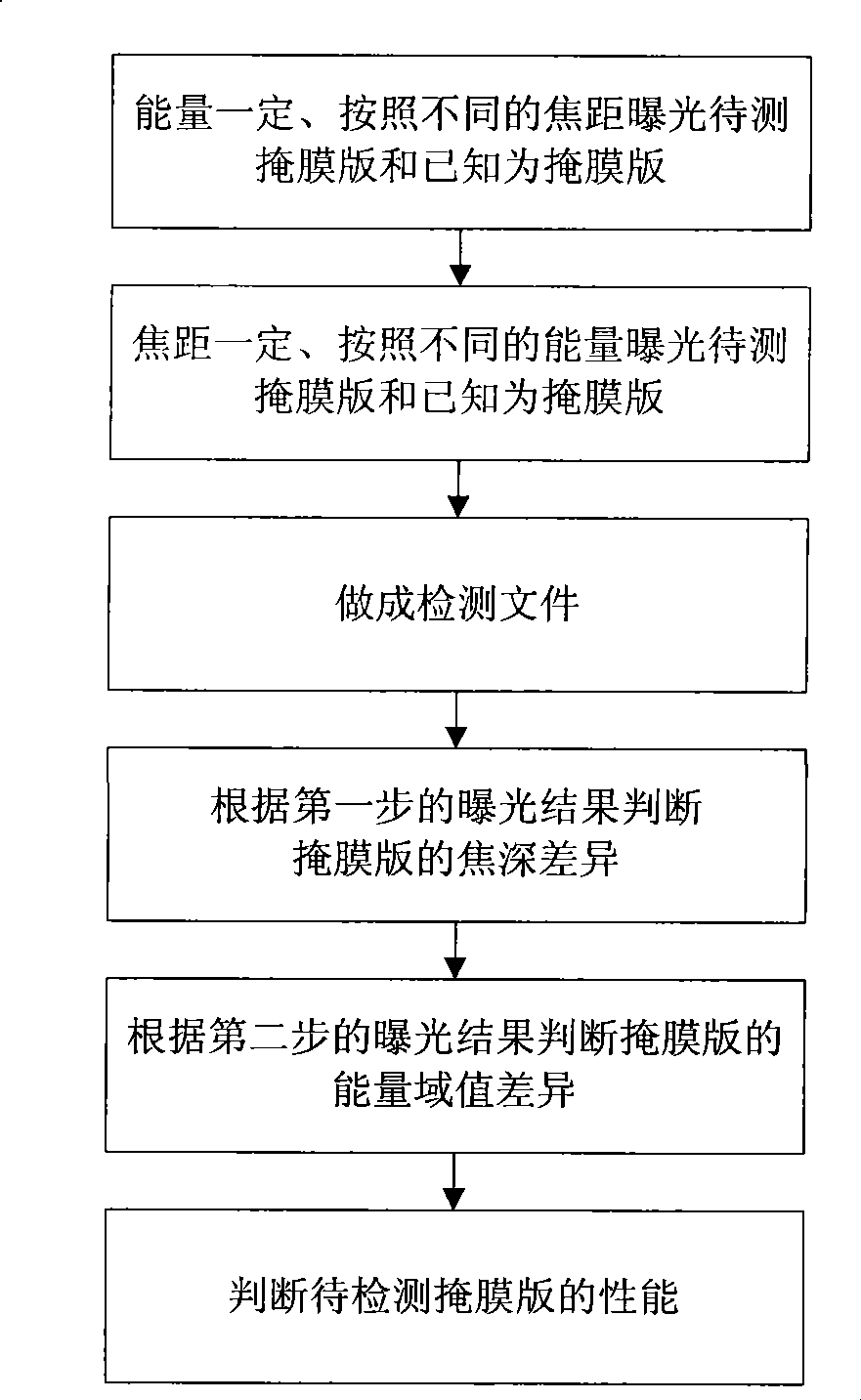

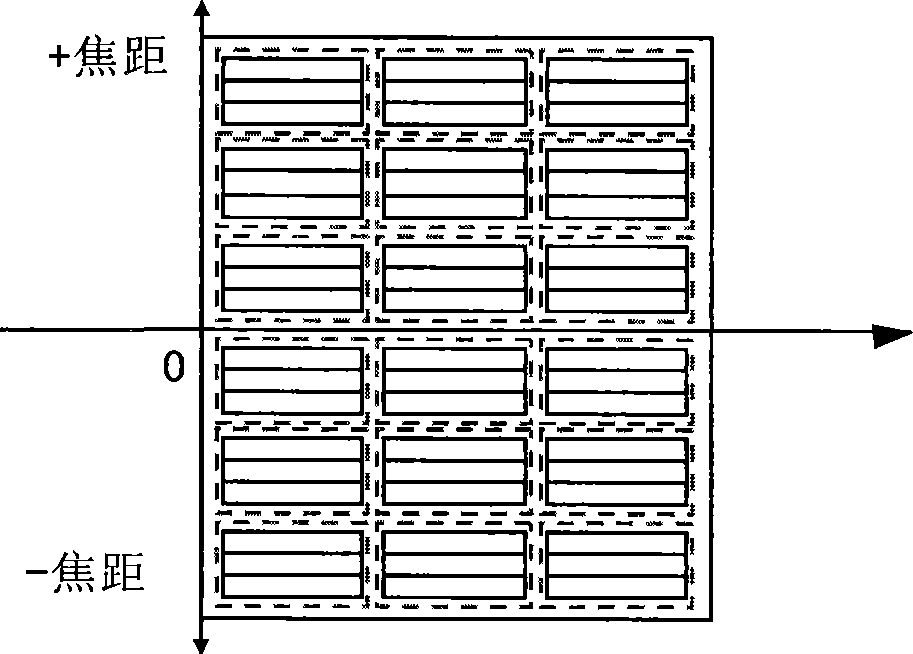

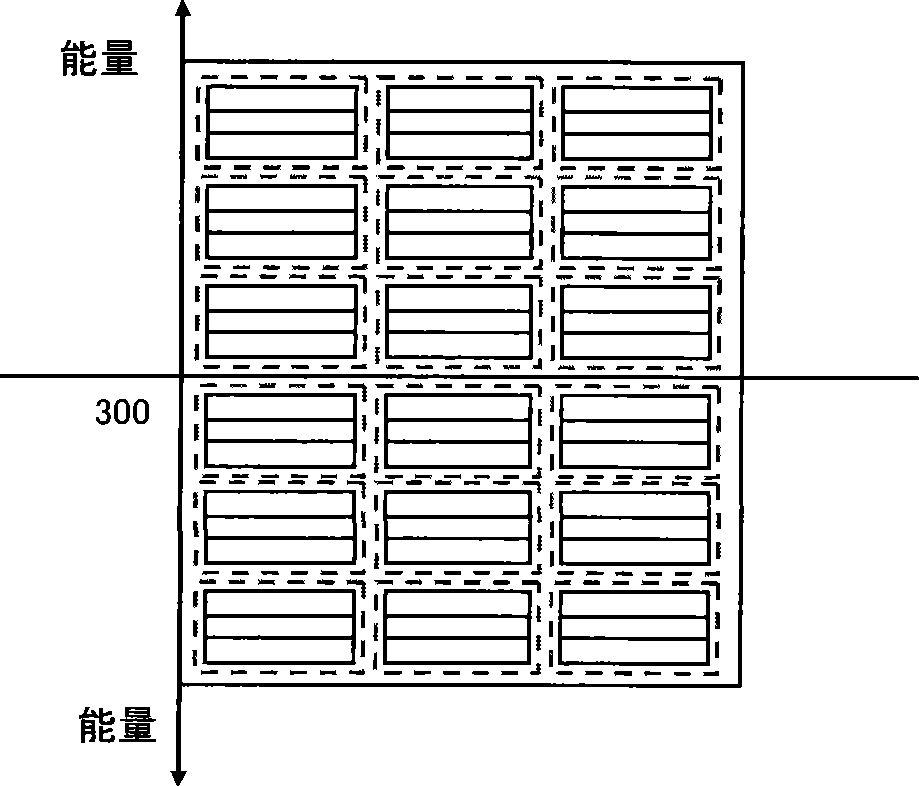

Method for detecting mask printing plate

ActiveCN101452201ANo open circuitNo short circuitSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingWorkloadPhysics

The invention discloses a method for detecting a masking plate. The method comprises the following steps: 1, under the condition of unchanged energy, carrying out simultaneous exposure of patterns of a masking plate to be detected and a masking plate known as a non-defective product on an optical piece according to different focal lengths; 2, under the condition of unchanged focal length, carrying out the simultaneous exposure of the patterns of the masking plate to be detected and the masking plate known as the non-defective product on the optical piece according to different energy; 3, making a detection file; 4, according to exposure results of the step 1, judging focal depth difference between the masking plate to be detected and the masking plate known as the non-defective product and the patterns and condition of particles of the two masking plates; 5, according to exposure results of the step 2, judging energy domain value difference between the masking plate to be detected and the masking plate known as the non-defective product and the patterns and the condition of the particles of the two masking plates; and 6, according to results of the step 4 and step 5, judging the performance of the masking plate to be detected. The method can reduce the workload and improve the working efficiency.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

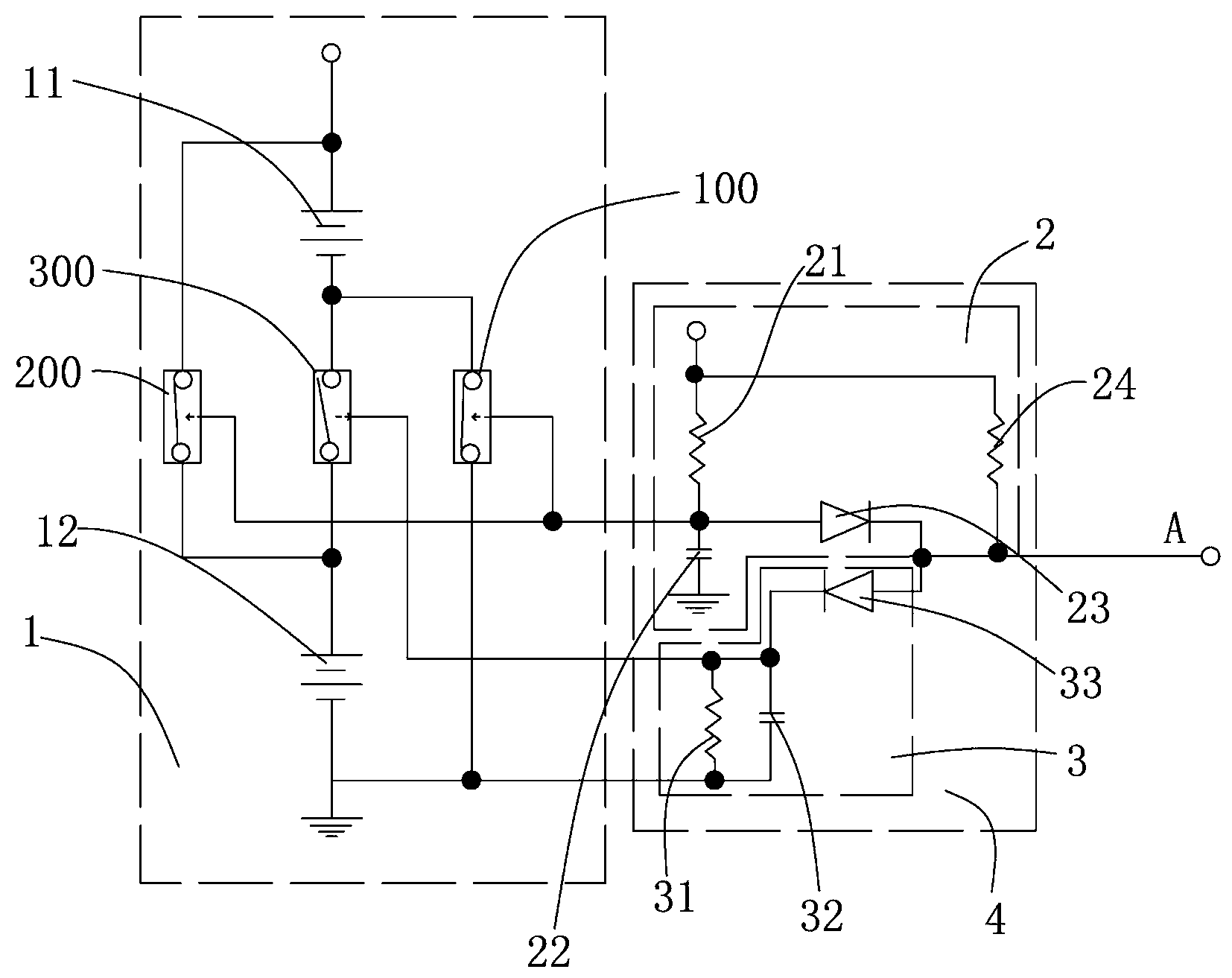

Logic timing control circuit and parallel charging and serial discharging control circuit

InactiveCN103236832ANo short circuitExtended service lifeBatteries circuit arrangementsElectronic switchingTime delaysControl signal

The invention discloses a logic timing control circuit. The logic timing control circuit comprises a first logic timing control circuit and a second logic timing control circuit, wherein the first logic timing control circuit comprises a first unidirectional connection element which contains at least a PN junction and a first time delay circuit which is electrically connected with the positive pole of the first unidirectional connection element which at least contains the PN junction; the second logic timing control circuit comprises a second unidirectional connection element which at least contains the PN junction and a second time delay circuit which is electrically connected with the negative pole of the second unidirectional connection element which contains at least the PN junction; and the common connection point of the negative pole of the first unidirectional connection element which contains at least the PN junction and the positive pole of the second unidirectional connection element which contains at least the PN junction is provided with a control signal input end. The logic timing control circuit is adopted so as to mutually switch the parallel charging with the serial discharging of a plurality of battery packs; and the logic timing control circuit has the advantages that the logic timing control circuit is simple in structure and convenient to use, the battery packs cannot be caused to shortcircuit in a mutual switching process, and the service lives of the battery packs are prolonged.

Owner:艾何示

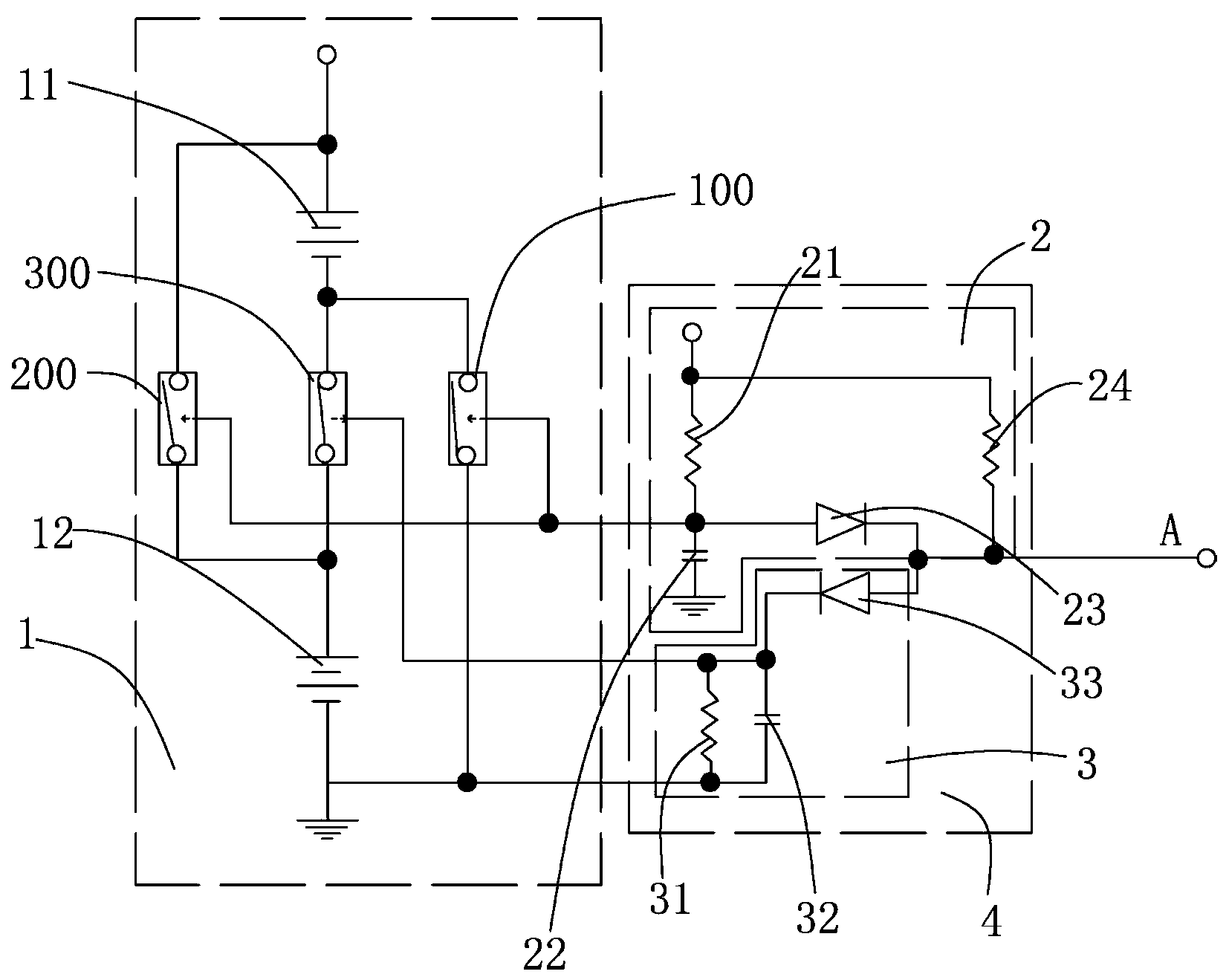

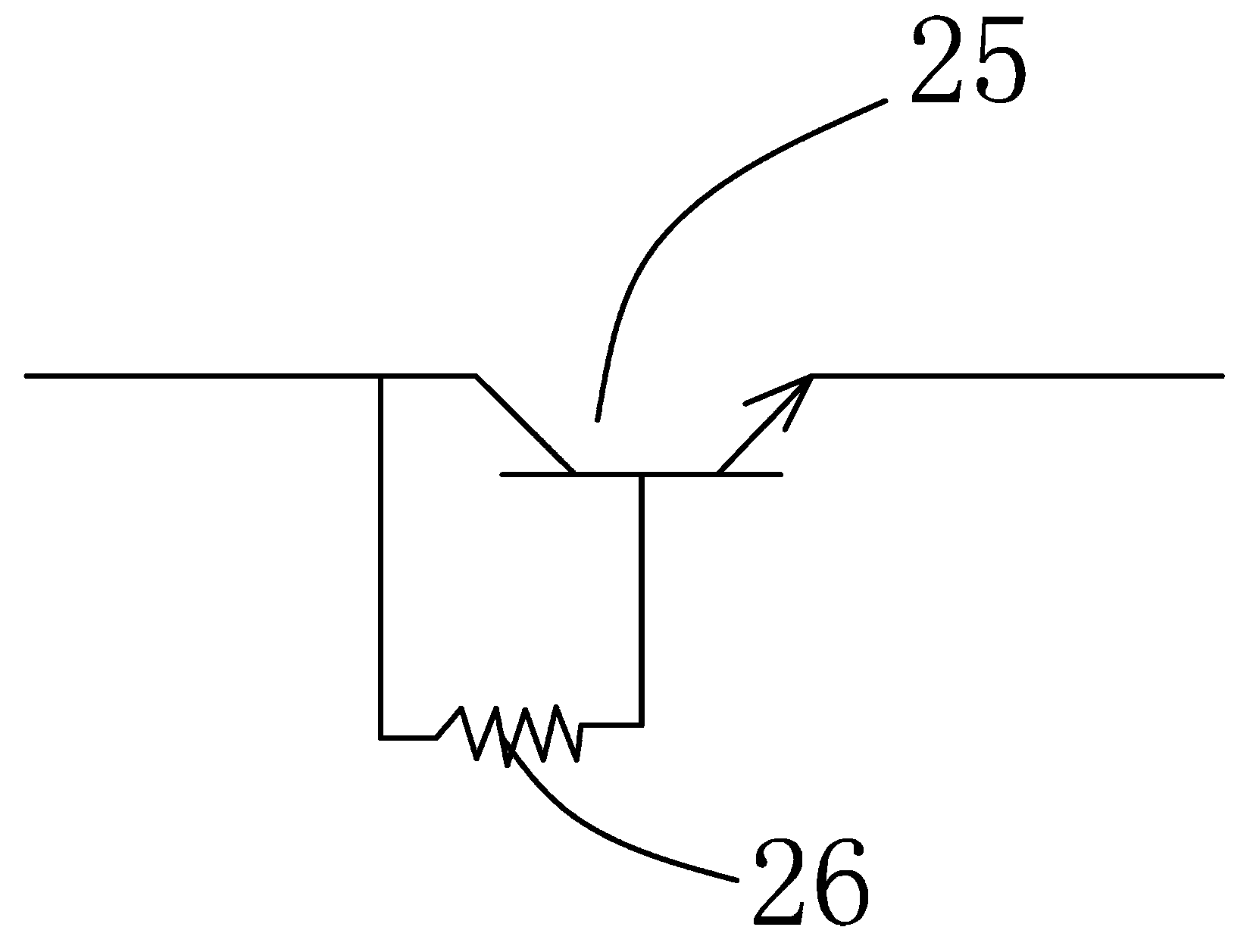

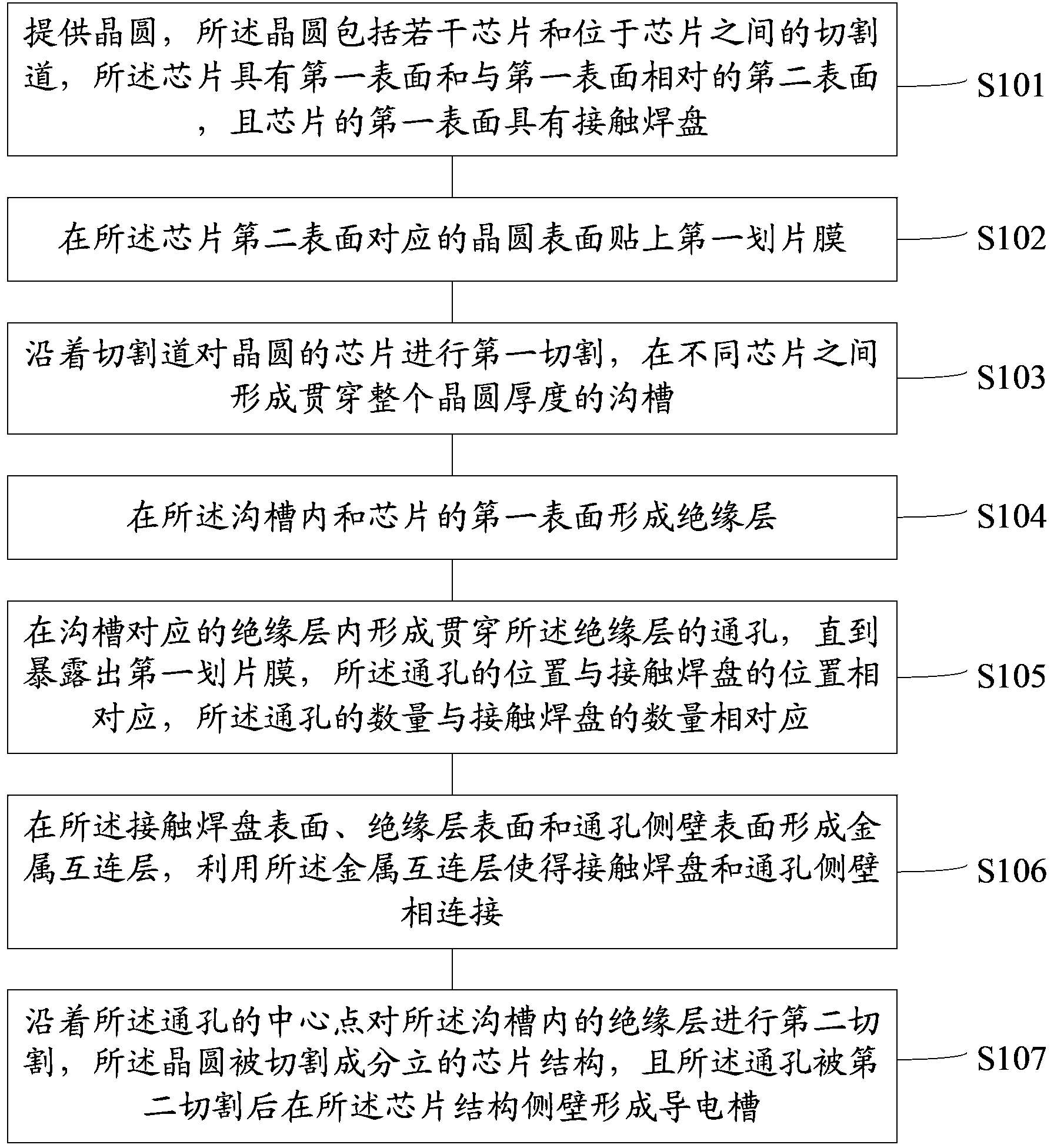

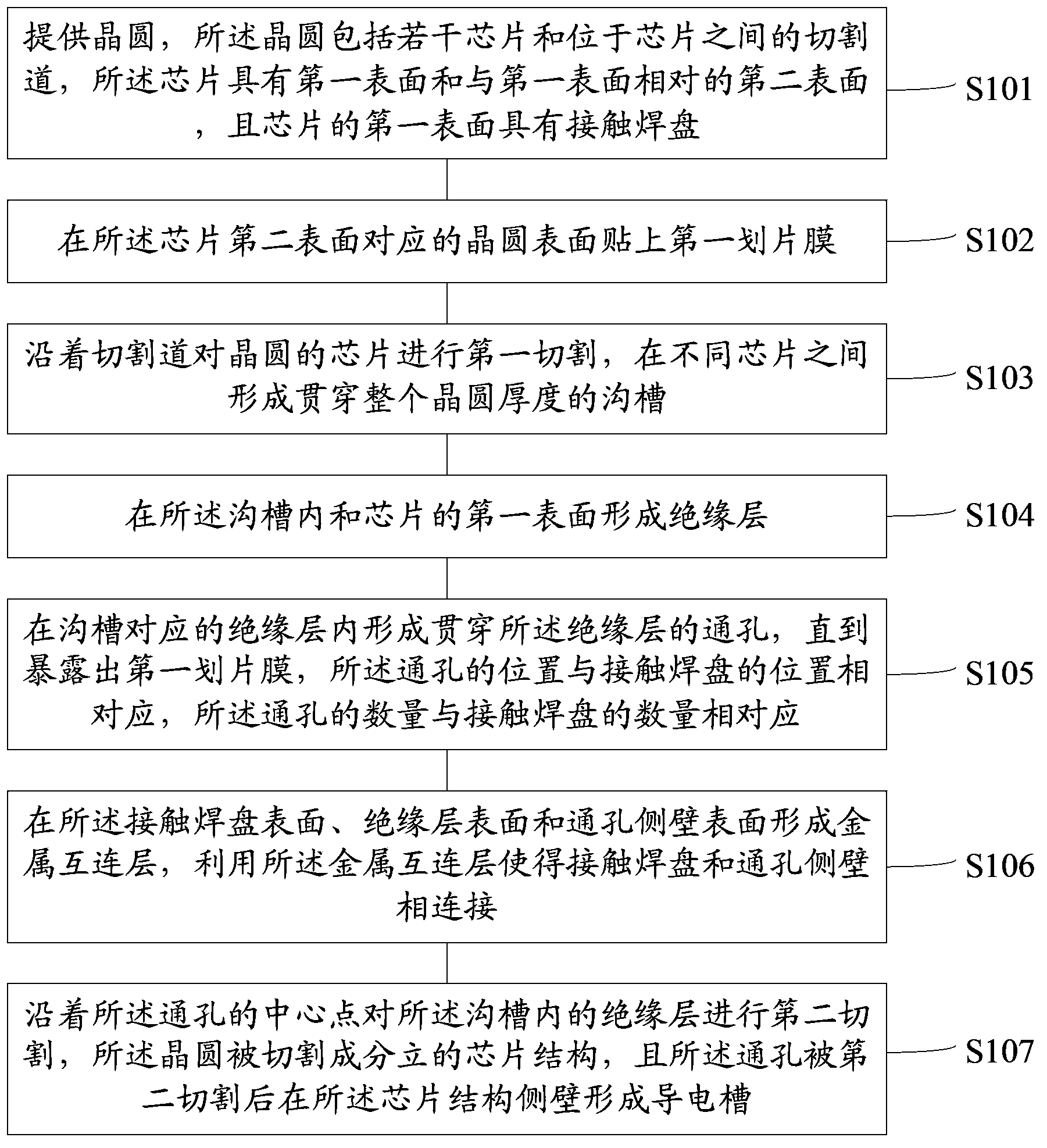

Chip cutting method and chip packaging method

ActiveCN103413785AReduce areaNo short circuitSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveInterconnection

Provided are a chip cutting method and a chip packaging method. The chip packaging method includes the steps that at least two chip structures are provided, wherein each chip structure comprises a chip and an insulating layer at least located on the side wall of the chip, the side wall of the insulating layer of each chip structure is provided with a conductive groove, the chip structures are stacked, and the conductive grooves of the different chip structures correspond to each other in position; the insides of the conductive grooves are filled with conductive adhesives, wherein circuits in the different chip structures are electrically connected through the conductive adhesives. Due to the fact that the conductive grooves are formed in the side walls of the insulating layers, the conductive adhesives formed in the conductive grooves cannot be in direct contact with the chips, and short-circuit phenomena cannot occur; due to the fact that the conductive grooves and contact welding plates are connected through metal interconnection layers on the surfaces of the insulating layers, the insulating layers cannot influence layout design of other metal interconnection structures in the chips, the chip area occupied by the metal interconnection structures can be saved, and the component integration degree of the chips can be beneficially improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

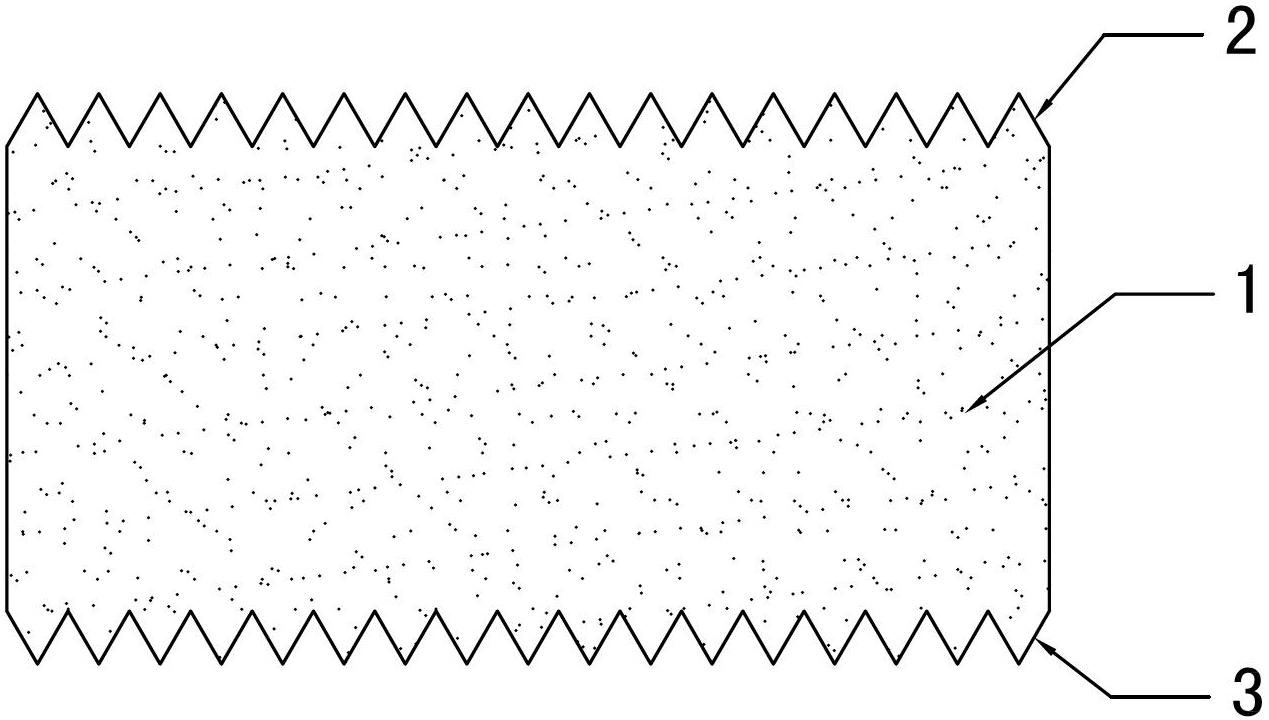

Preparation method of N-type crystalline silicon double-sided back contact solar cell

InactiveCN102683493AExcellent electrical performanceSimple preparation processFinal product manufactureSemiconductor devicesElectricityPhosphorus doped

The invention discloses a preparation method of an N-type crystalline silicon double-sided back contact solar cell, which comprises the following steps of: (1) cleaning and velvet-making; (2) carrying out local phosphorus doping on the back surface of a silicon chip; (3) carrying out boron diffusion on the front surface of the silicon chip; (4) etching a peripheral junction; (5) passivating the front surface and the back surface of the silicon chip or the front surface of the silicon chip; (6) arranging antireflective films on the front surface and the back surface of the silicon chip; (7) forming a hole on the silicon chip; (8) arranging a hole metal electrode in the hole; and printing metal electrodes on the double sides and sintering to obtain the N-type crystalline silicon double-sided back contact solar cell. The preparation method has the advantages that the local phosphorus doping is carried out on the back surface of the silicon chip, a non-phosphorus doping area on the back surface of the silicon chip is a peripheral area of a hole to be formed on the silicon chip, and the problems of short circuit and electricity leakage at the diffused junction are avoided in the solar cell obtained by the preparation method, so that the remarkable effect is obtained.

Owner:CSI CELLS CO LTD +1

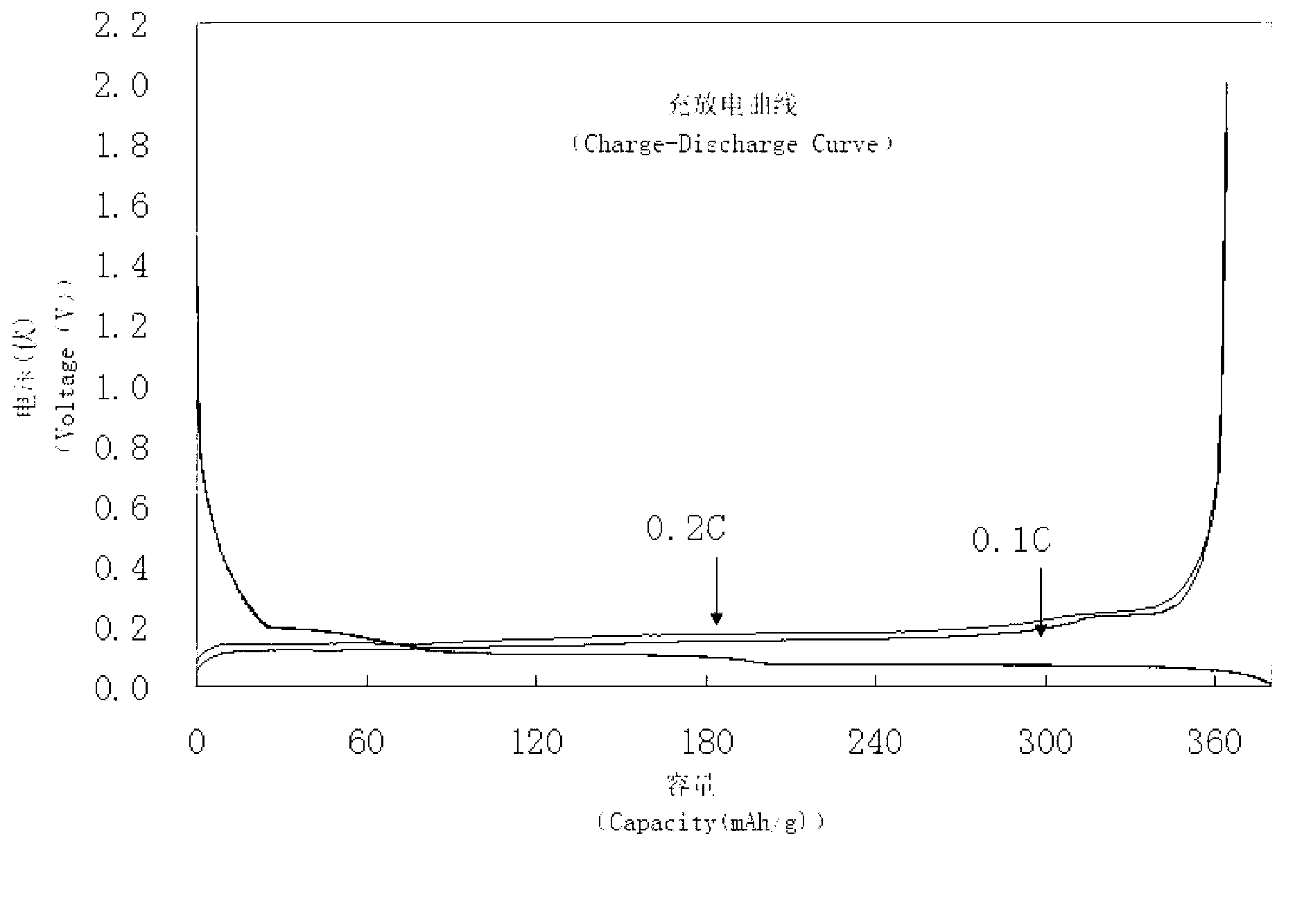

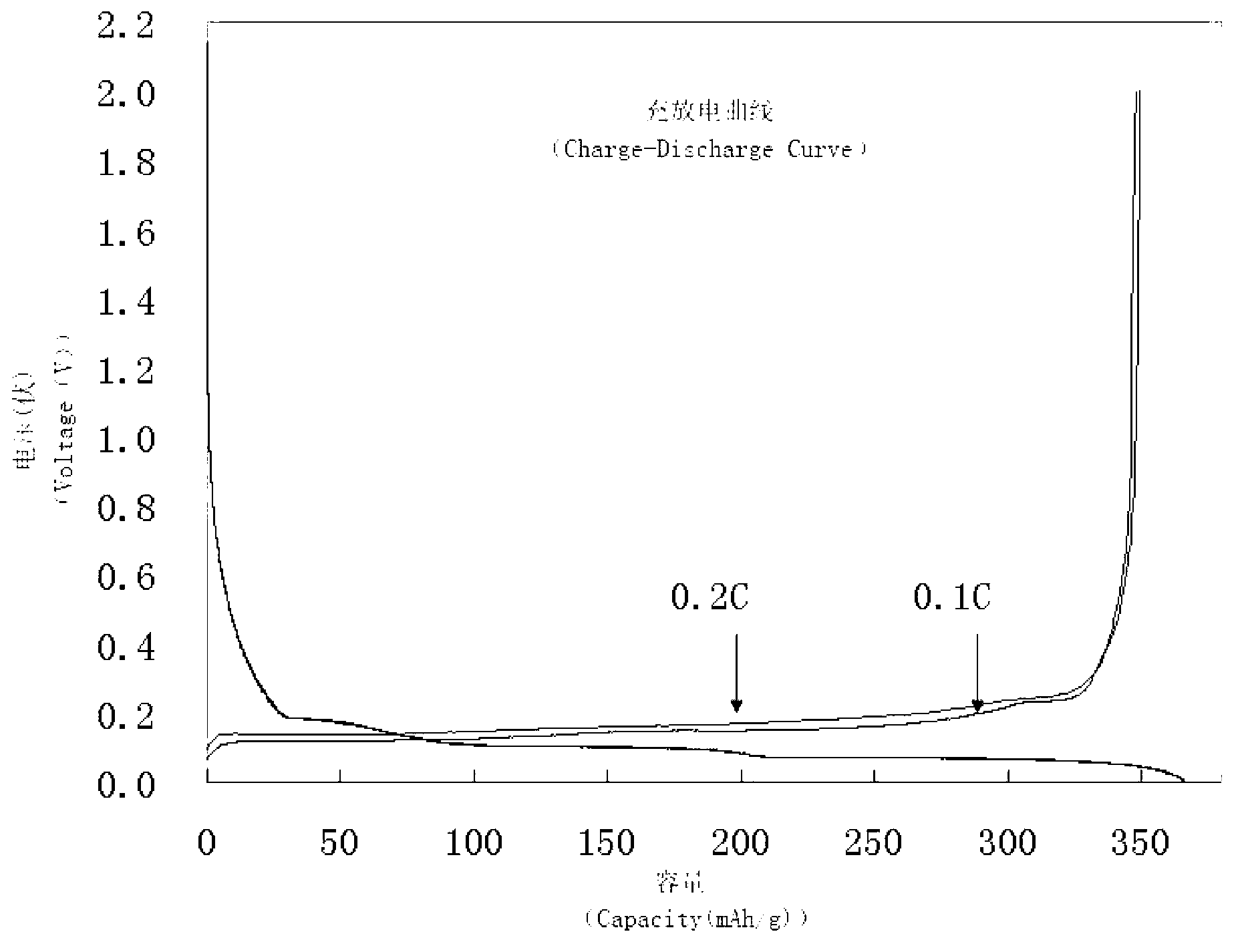

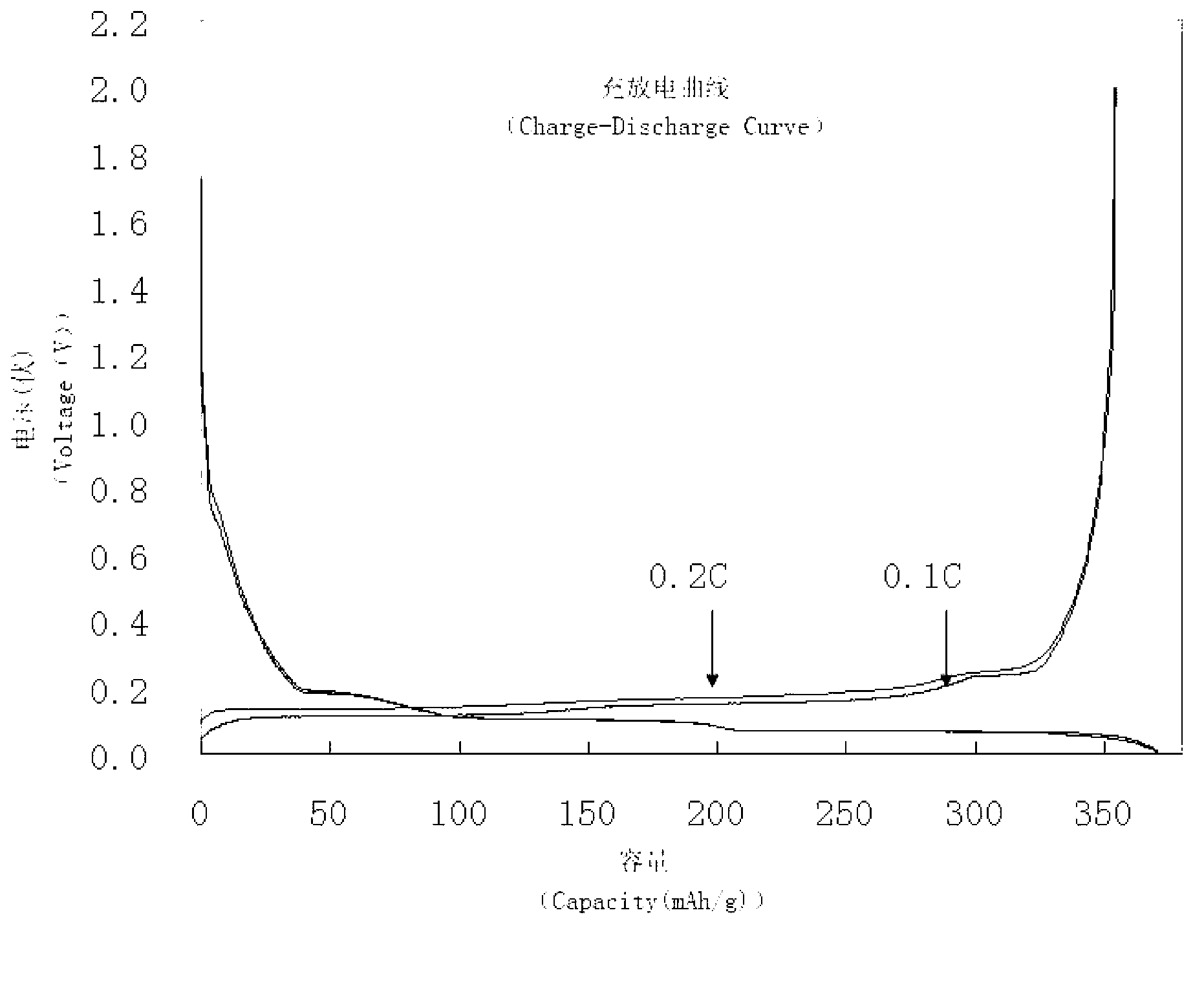

Quick test technique for electrochemical performances of carbon anode materials

ActiveCN103018301AEffective contactElectrochemical performance testing process is simpleMaterial electrochemical variablesElectrical batteryCopper foil

A quick test technique for electrochemical performances of carbon anode materials comprises the following steps: a, the carbon anode materials to be tested and electrode plate dressing are evenly coated on copper foils by the areal density of 0.6-1.0 g / dm<2>, and are dried to form electrode plates, wherein the electrode plate dressing is prepared by conductive agent, binding agent and thickening agent; b, the electrode plates are rolled by the compacting density of 1.1-1.5 g / cm<3> and are cut to electrode plates which are needed by half cells; c, half cell modules are assembled by the sequence of anode casings, electrode plates, diaphragms, lithium plates, washers and cathode covers, and are sealed under the pressure of 70-85 MPa to form the half cells; and d, the half cells are divided into a normal group and an experimental group for testing through a test cabinet, the test is implemented for one time or is circulated for a plurality of times, and judging whether the first charge-discharge gram specific capacity and the first charge-discharge efficiency of the carbon anode materials meet the requirements or not according to test results is carried out. The technique can easily, quickly and accurately test the electrochemical performances of the carbon anode materials, and can effectively reduce the test cost of the electrochemical performances of the carbon anode materials.

Owner:四川金汇能新材料股份有限公司 +2

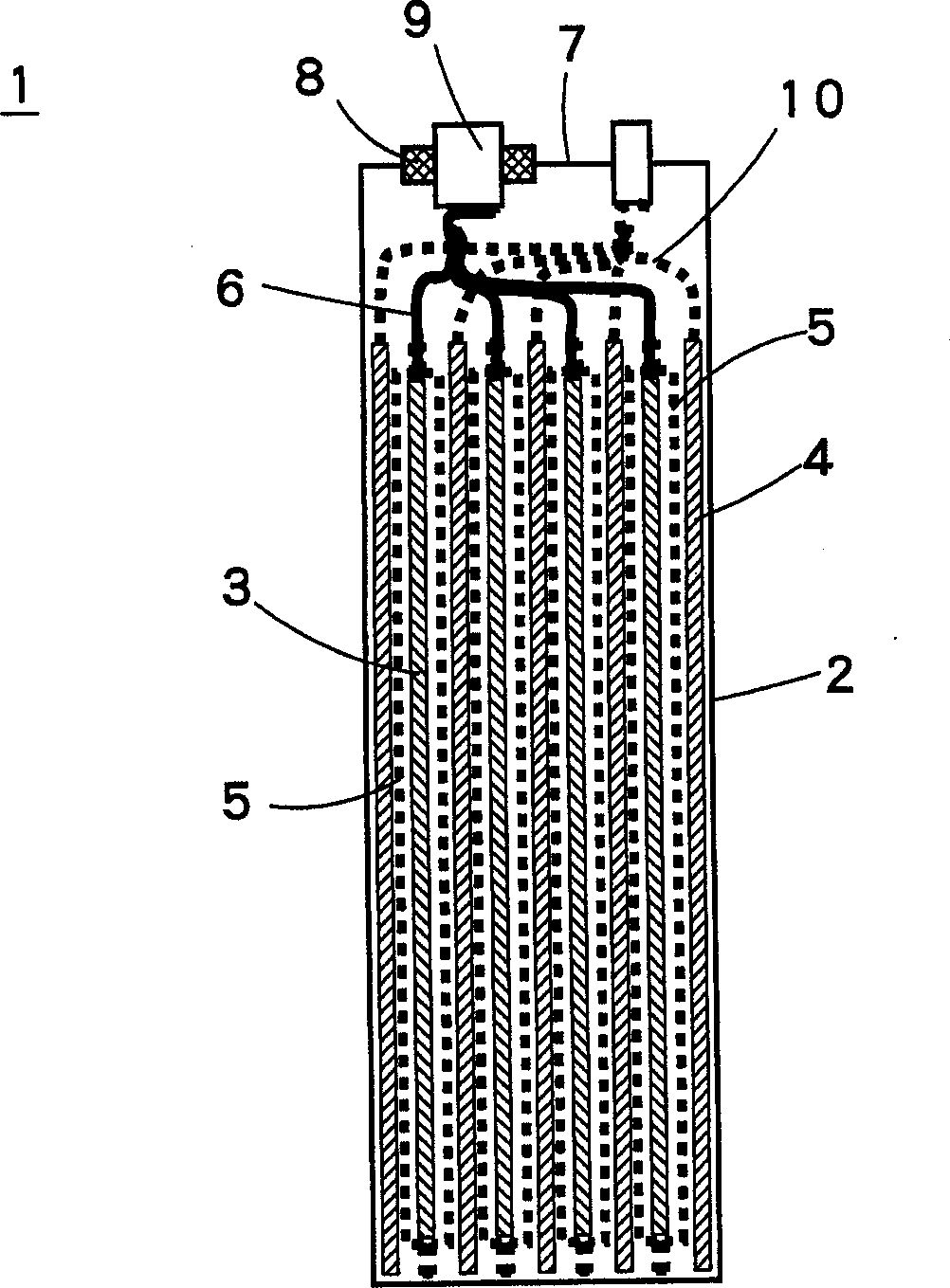

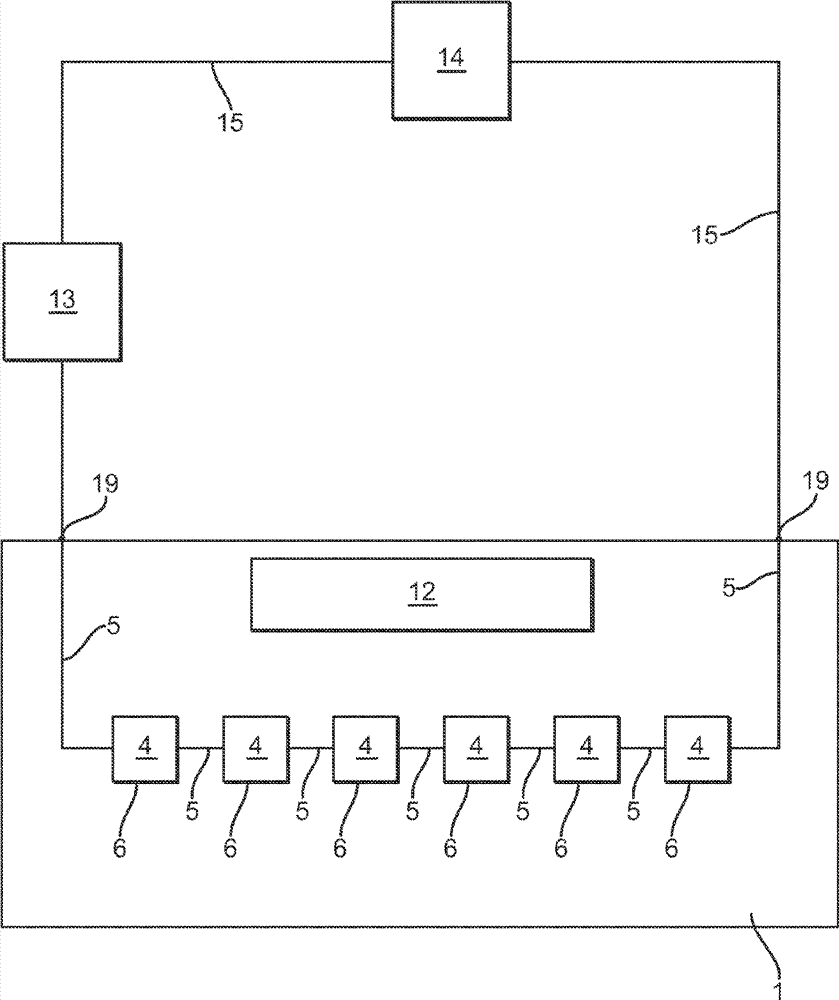

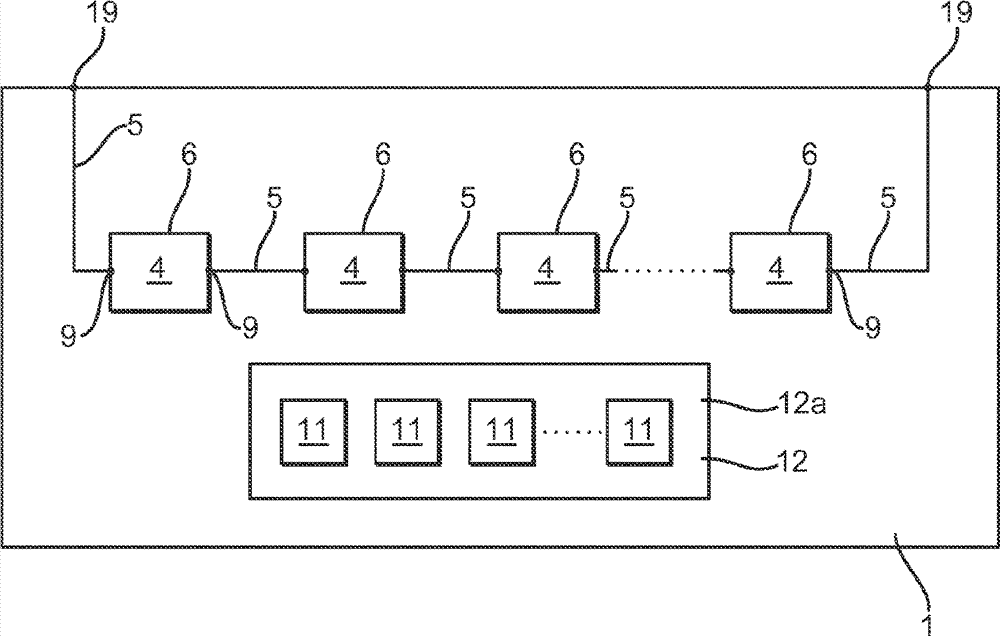

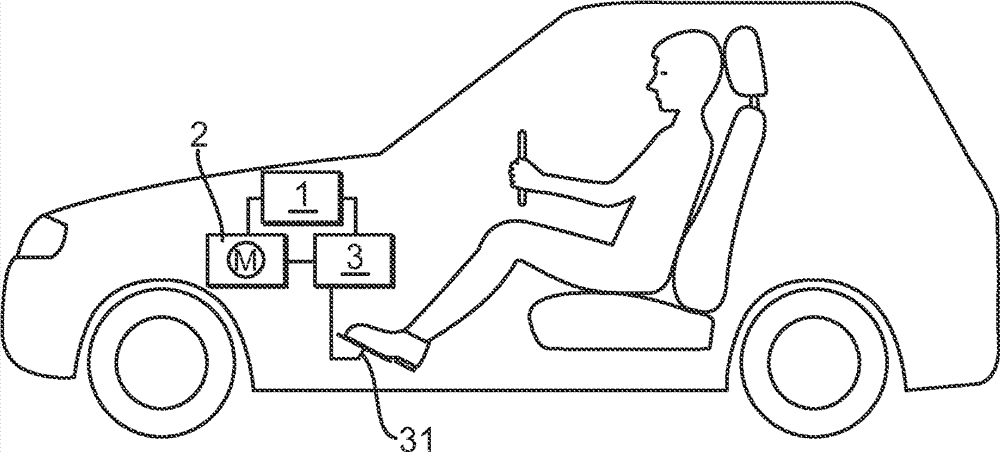

High-current battery system and method for controlling a high-current battery system

InactiveCN102742066AAvoid short circuitNo short circuitCircuit monitoring/indicationIndicating/monitoring circuitsElectricityComputer module

The present invention relates to a high-current battery system (1) in which a high operating current flows, in particular for vehicle drives. The high-current battery system (1) has a battery system monitoring electronics unit (12) and a plurality of battery modules (4), each module including at least one rechargeable battery cell (10) and being electrically connected in series by means of an operating current line (5) such that an operating current flows through the operating current line (5) during operation. At least one of the battery modules (4) is designed as a bypass battery module (6) which comprises a bypass switch (7) and a bypass line (8), which are designed and disposed such that the battery module (6) is electrically bridged by the bypass line (8) after the bypass switch (7) is switched from a normal operating position into a bypass position, so that the operating current flows through the bypass line (8). For each bypass battery module (6), the battery system monitoring electronics unit (12) incorporates a module monitoring unit (11) which monitors the associated battery module (6) and detects a fault state of the module (6). Upon detection of a fault state of a battery module (6) by one of the module monitoring units (11), the battery system monitoring electronics unit (12) measures the current flow in the operating current line (5) and switches the bypass switch (7) of the battery module (6) in question from the normal operating position into the bypass position at a time at which the current flow in the operating current line (5) is less than a predetermined limit value.

Owner:INNOLITH ASSESTS AG

Chip structure and chip packaging structure

ActiveCN103413798AReduce areaNo short circuitSemiconductor/solid-state device detailsSolid-state devicesAdhesiveInterconnection

Provided are a chip structure and a chip packaging structure. The chip packaging structure comprises at least two chip structures and conductive adhesives located in conductive grooves, wherein the side walls of the chip structures are provided with the conductive grooves, the chip structures are stacked, the conductive grooves of the stacked chip structures correspond in position, and circuits in the stacked chip structures are electrically connected through the conductive adhesives. Due to the fact that the conductive grooves are formed in the side walls of insulating layers, the conductive adhesives formed in the conductive grooves later cannot be in direct contact with chips, and short-circuit phenomena cannot occur; due to the fact that the conductive grooves and contact welding plates are connected through metal interconnection layers on the surfaces of the insulating layers, the insulating layers cannot influence layout design of other metal interconnection structures in the chips, the practice that extra metal interconnection structures are designed due to positions of the contact welding plates is needless, the chip area occupied by the metal interconnection structures can be saved, and the component integration degree of the chips can be beneficially improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

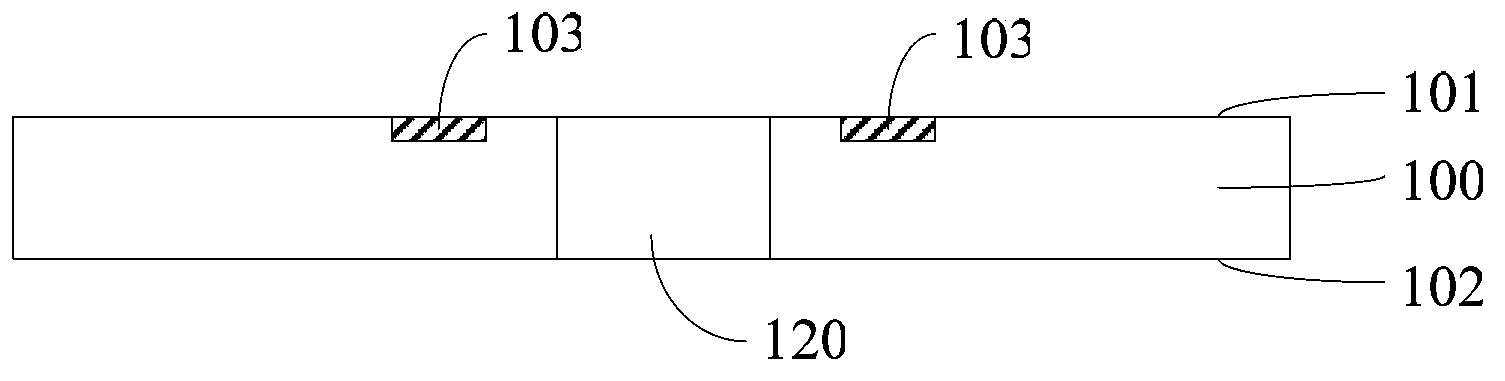

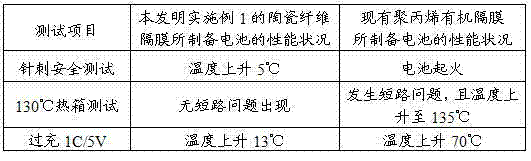

Diaphragm for lithium ion battery and lithium ion battery applying diaphragm

ActiveCN102832368AReliable performanceTroubleshooting Shorted Battery ProblemsSecondary cellsCell component detailsElectrical batteryLithium electrode

The invention discloses a diaphragm for a lithium ion battery and the lithium ion battery applying the diaphragm. The diaphragm is a ceramic fiber diaphragm and comprises ceramic fiber, inorganic fillers and inorganic adhesive and / or organic adhesive. The diaphragm for the lithium ion battery has the advantages that the performance is stable and reliable, the short-circuited problem of the battery due to melting of the diaphragm of an electrode can be solved, the safety accidents can be avoided, the safety performance is good, the long-time normal use of the lithium ion battery is guaranteed, and the service life of the lithium ion battery is prolonged, so that the diaphragm is wide in market application prospect and great in production and practice significance.

Owner:山东泰一新能源股份有限公司

Display panel, production method thereof and display device

PendingCN107784952ANo short circuitImprove yieldSolid-state devicesIdentification meansForeign matterDisplay device

The invention provides a display panel, a production method thereof and a display device. The display panel has the advantages that an insulating layer is arranged on a first conductive electrode in adisplay panel binding area to allow the insulating layer to cover the first conductive electrode, and the insulating layer can be punctured by ACF particles; when the display panel is bound with an FPC through ACF, a second conductive electrode on the FPC can be communicated with the first conductive electrode on the display panel through the ACF particles, and accordingly binding connection of the display panel and the FPC is achieved; even if conductive foreign matter falls into the area where the first conductive electrode is located, short circuit can be avoided, and accordingly product yield is increased.

Owner:BOE TECH GRP CO LTD +1

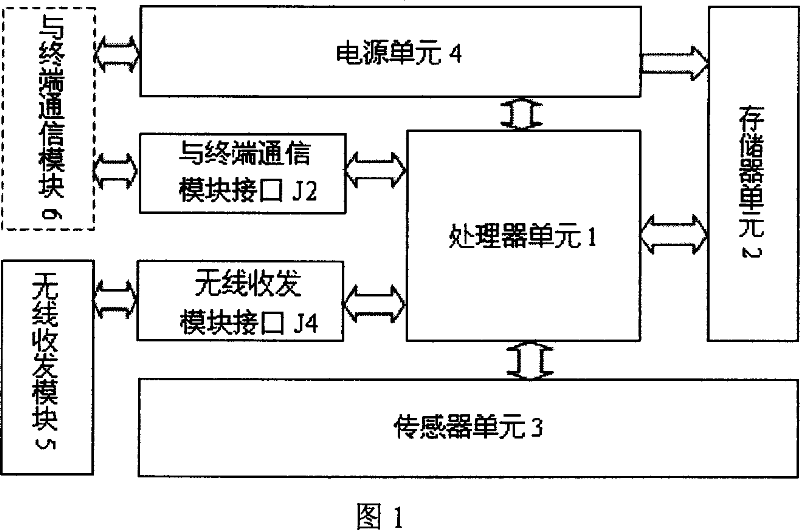

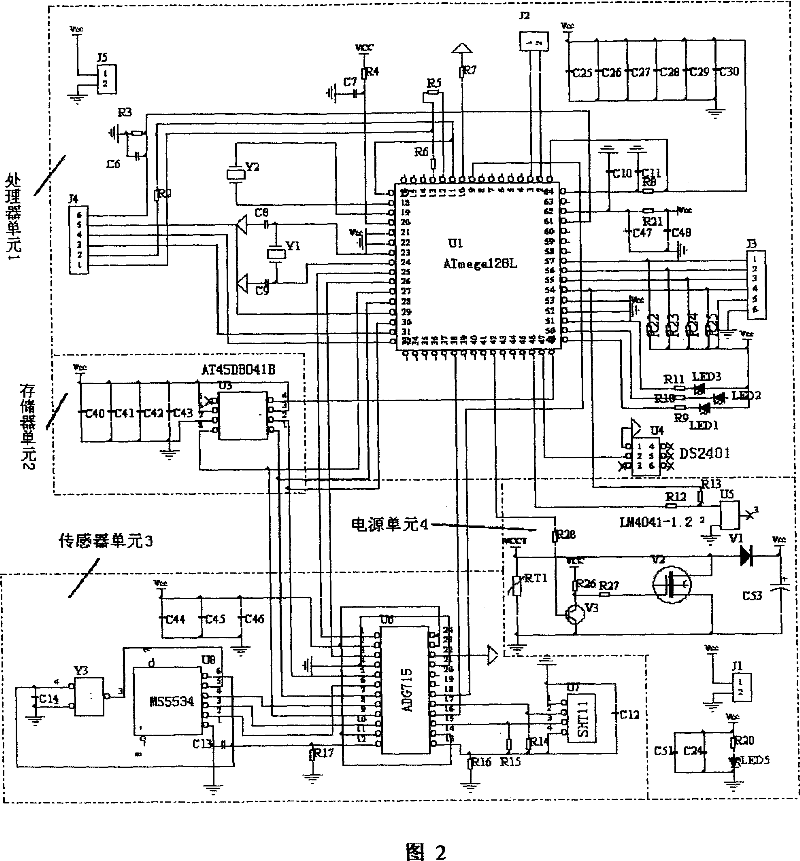

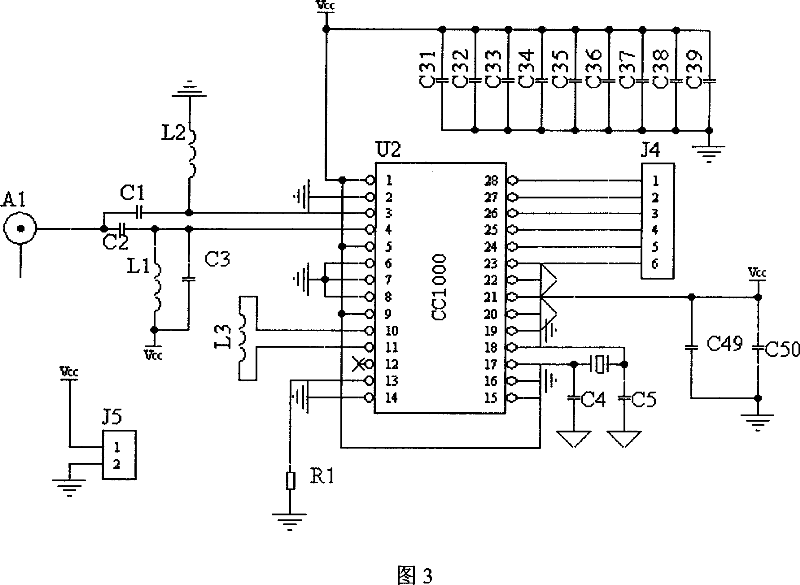

Wireless sensor network node device used for environmental monitoring

InactiveCN101042584AReasonable structureReduce power consumptionTotal factory controlProgramme total factory controlWorking environmentFunctional module

This invention relates to one wireless sensor network point device for animal and plant grow and cultivation indoor chamber, nuclear pollution area, atmosphere and industry spot environment monitor for environment temperature and humidity and atmosphere monitor; in the network, the point work environment is of complex one and independent unit with proper structure and special energy consumption, reliability and life cycle.

Owner:SOUTHEAST UNIV

Improved battery

ActiveCN101465412AImprove cooling effectDo not change shapeSmall-sized cells cases/jacketsManufacturing technologyEngineering

The invention belongs to the technical field of battery manufacturing of electric motor cars and in particular relates to an improved battery; the battery comprises a shell, an upper cover, a pole rod, a lithium battery and an electric conducting bar; the shell is a cuboid shape, and the opening of the shell is sealed by the upper cover, and a strengthening rib is formed by the outer wall of the shell forms, and the lithium battery is arranged in the shell; the pole rod is embedded on the upper cover, and the outer end of the pole rod is connected with the electric conducting bar; the strengthening rib is transversely and uniformly distributed by the way that the strengthening rib is parallel to the edge of the opening of the shell. The improved battery has the advantages of high-strength shell, good heat radiating performance, simple structure, high using safety, high sealing property, long service life and the like.

Owner:ZHEJIANG GBS ENERGY

Single-component room temperature vulcanization type ceramic fireproof silicon rubber coating material as well as preparation method and application thereof

The invention discloses a single-component room temperature vulcanization type ceramic fireproof silicon rubber coating material as well as a preparation method and an application thereof. The coating material comprises the following components in parts by weight: 100 parts of alpha, omega-dihydroxy polydimethylsiloxane, 10-20 parts of fumed silica, 5-10 parts of aluminum oxide, 0.5-2 parts of a sintering additive, 5-15 parts of a cross-linking agent, 0.1-0.5 part of a catalyst, 20-60 parts of a plasticizer, 0.5-1.5 parts of a tackifier and 0.1-0.5 part of a surface treating agent. The coating material does not need to be extruded at high temperature, can be vulcanized at room temperature after being applied, has the characteristics of a dense ceramic body, a stable structure, stable fireproof performance, good insulation performance and the like, and is applied to electric wires and cables; the thickness of a conventional silicon rubber fireproof layer is greatly reduced.

Owner:WUXI JIANGNAN CABLE

Road traffic dustproof device

ActiveCN110005021AReduce wasteReduce the number of spraysGeneral water supply conservationRoad cleaningRate limitingWater storage

The invention discloses a road traffic dustproof device, including a guardrail arranged on a road. The road is provided with a compressed air cavity. A specialized air inlet is arranged on the compressed air cavity. A pressing plate is slidably connected in the compressed air cavity in a sealed mode. The upper end of the pressing plate is fixedly connected with a rate-limitingbelt through a supporting rod. According to the road traffic dustproof device, the waste of water resources is reduced through use of rain collected by a water-collecting bucket; and water in the water storage cavity is sprayed out after a vehicle drowns out the rate-limiting belt for multiple times, the number of spraying water can be self-adjusted according to traffic flow amount.The larger the traffic flow amount,the more times of spraying water while the smaller the traffic flow amount, the less times of spraying water.A pure mechanical structure is adoptedand hence, compared with the prior art, the product is more safe and stable, and safety hazards such as short circuit, circuit breakand the like do not happen, and hence a service lifeis long.

Owner:赣州金路交通设施有限公司

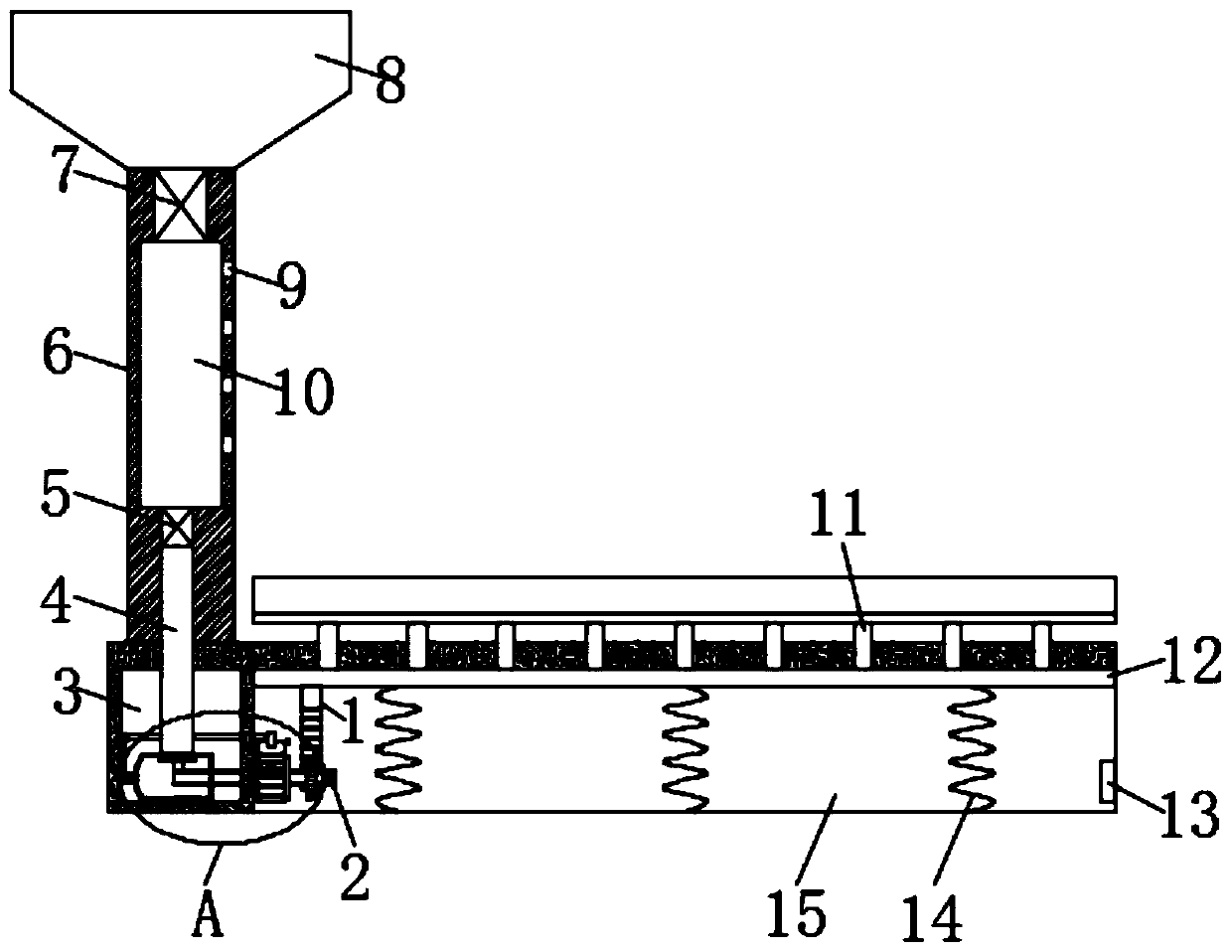

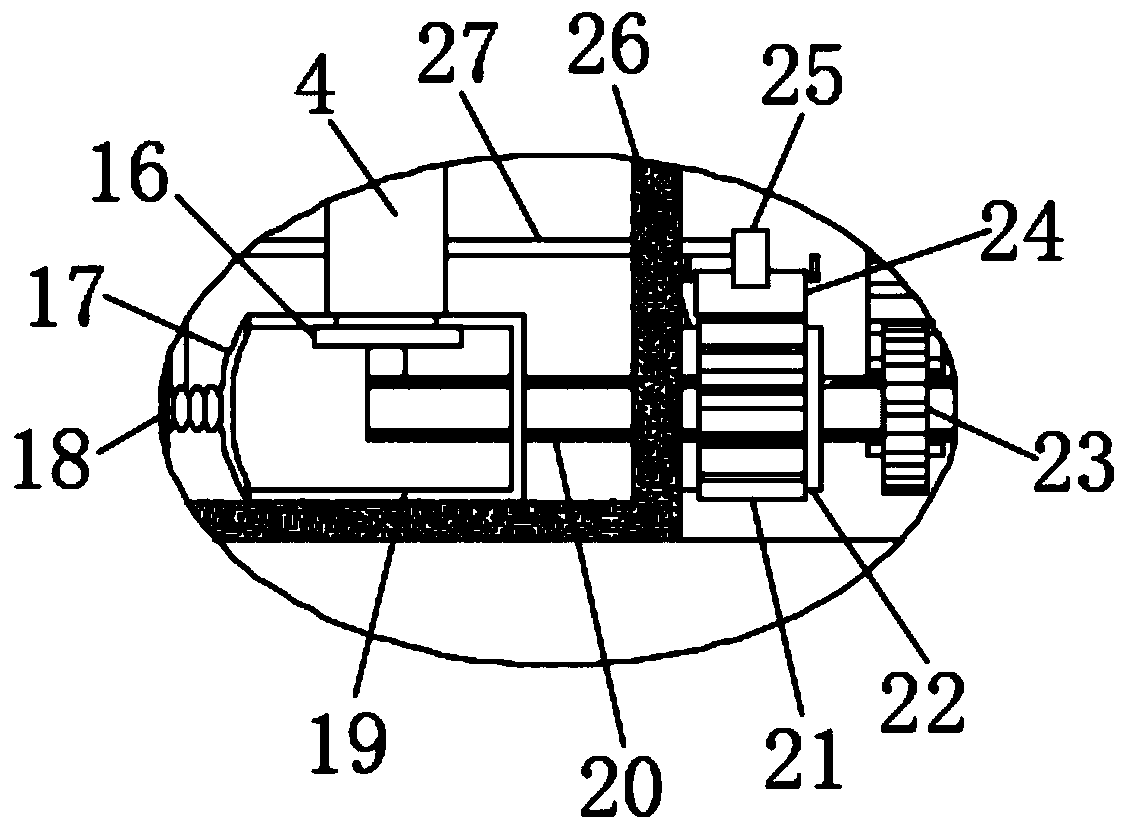

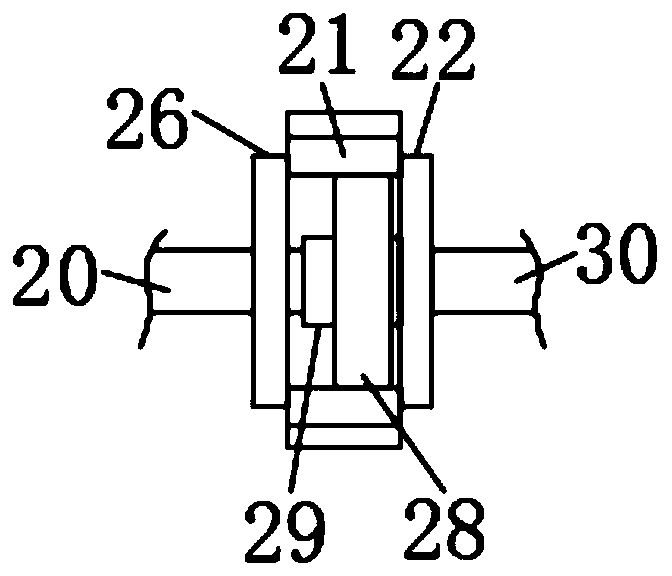

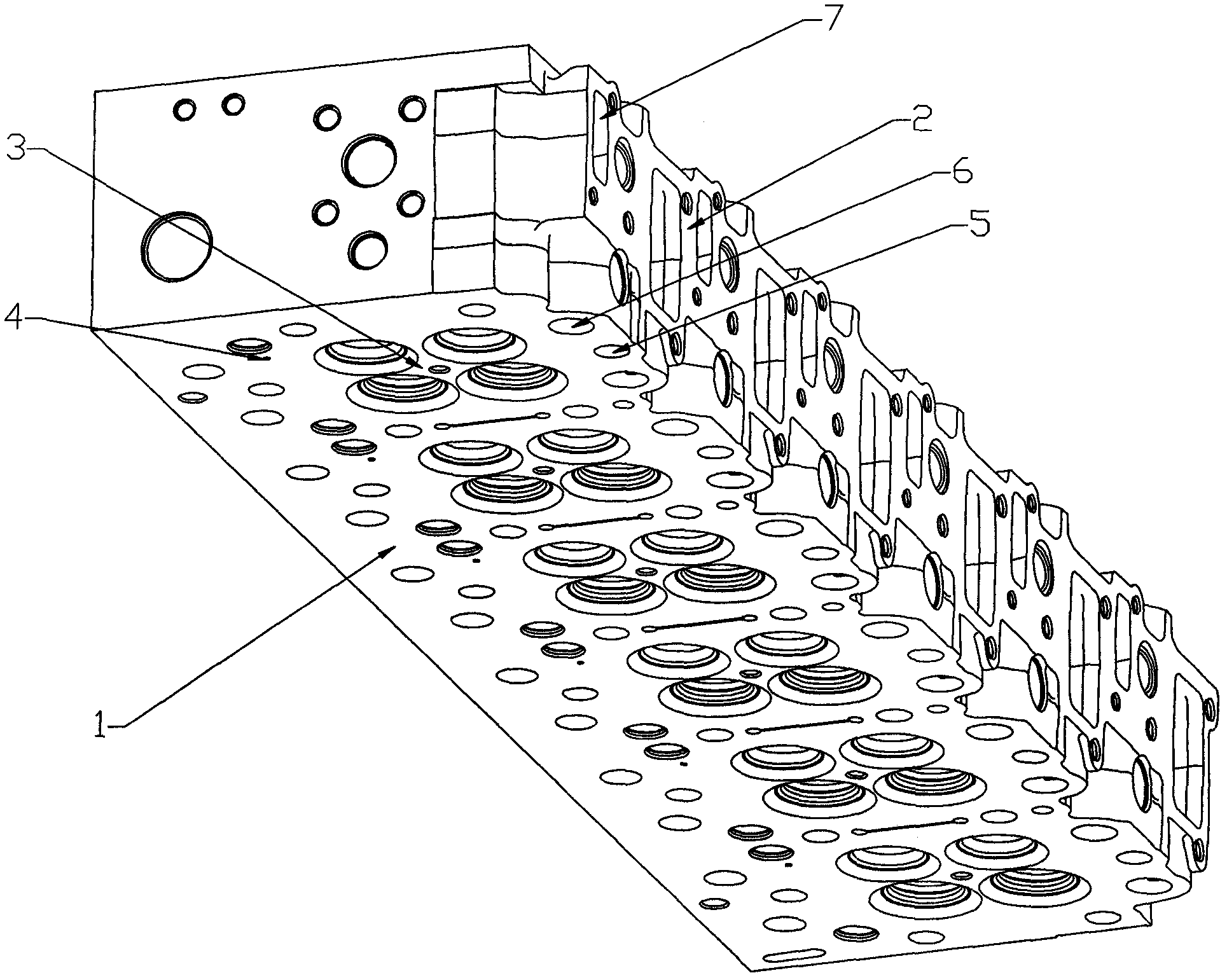

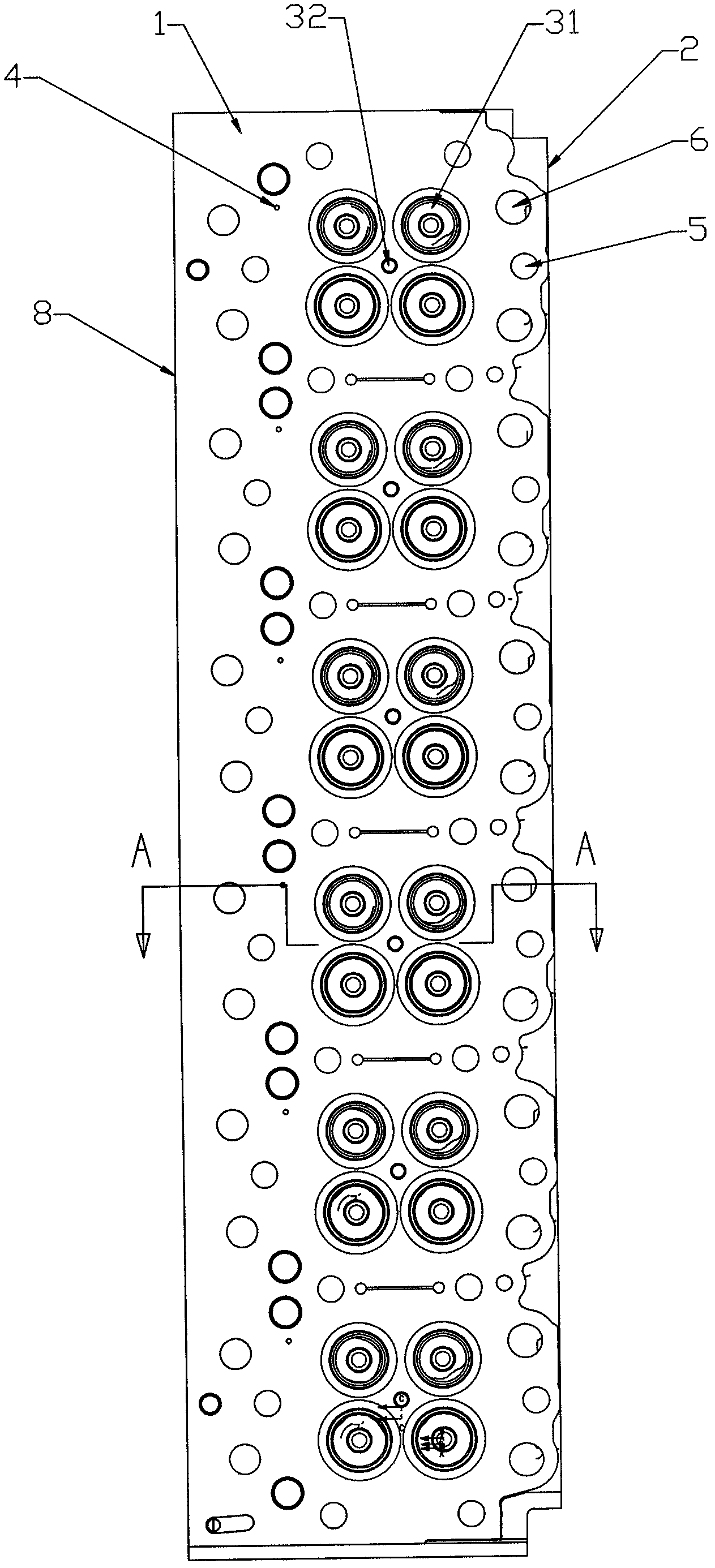

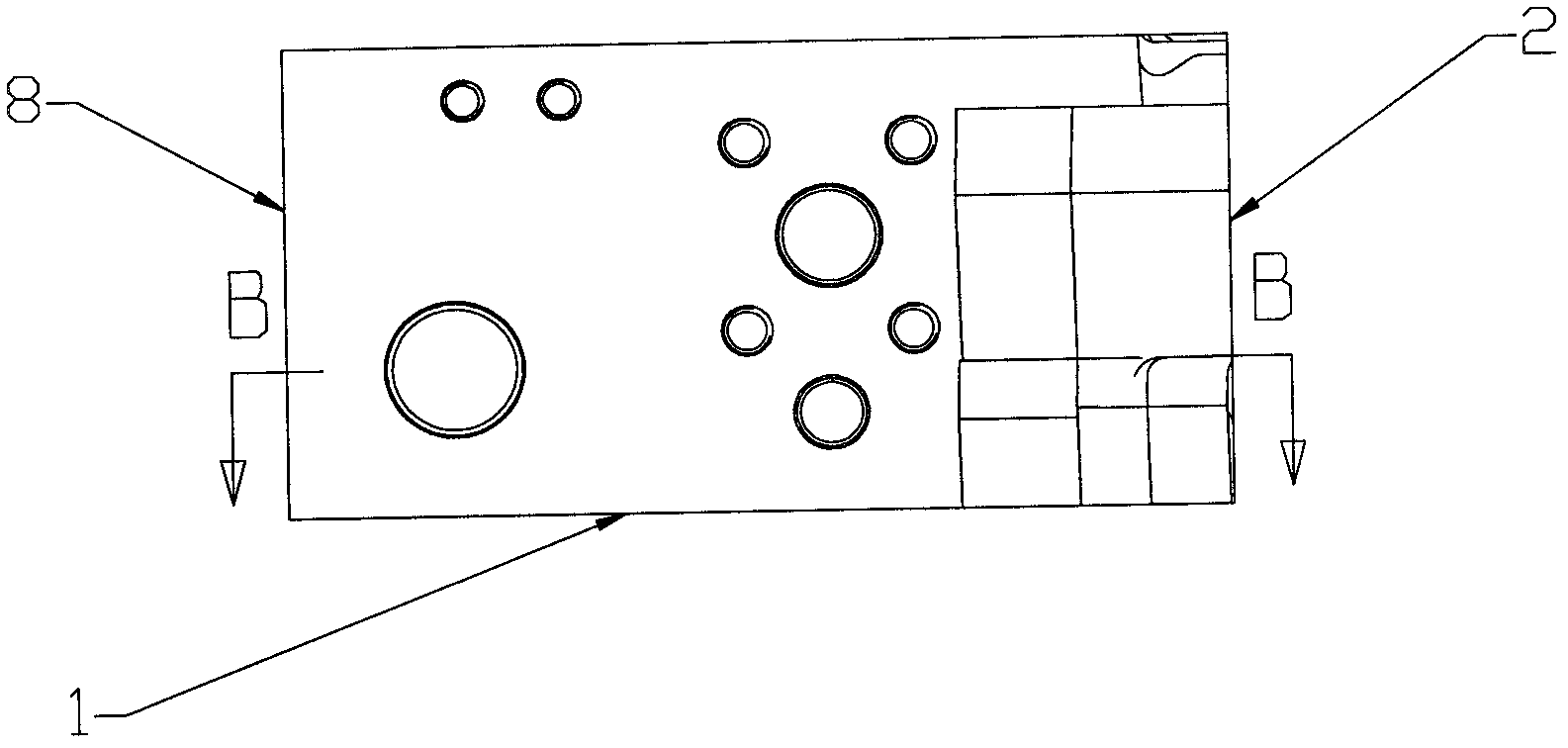

Integral cylinder cover of water-cooled four-valve diesel engine and corresponding diesel engine water cooling method

InactiveCN102758701ANo short circuitImprove cooling effectLiquid coolingCylinder headsCooling effectWater cooling

The invention discloses an integral cylinder cover of a water-cooled four-valve diesel engine and a corresponding diesel engine water cooling method based on the cylinder cover. According to the cylinder cover, a partition plate for partitioning a water cooling cavity into an upper cavity and a lower cavity is arranged in the water cooling cavity, wherein a water feeding passage for communicating the upper cavity and the lower cavity is formed on one side of the partition plate; a bottom plate is provided with an exhaust duct side exhaust hole corresponding to the water feeding passage; and a water inlet hole and an intake duct side exhaust hole which are communicated with the lower cavity are formed on the other side of the bottom plate. The diesel engine water cooling method comprises the following steps of: circulating water cooling outside a diesel engine cylinder from one side to the other side through a circulating water pump; and flowing the cooling water into the lower cavity from the water inlet hole on the bottom plate of the cylinder cover, then flowing to the upper cavity through the water feeding passage from the lower cavity and flowing out from the water outlet. By arranging the partition plate in the cylinder cover, forced cooling water passes through a nose bridge region so as to guarantee a cooling effect of the noise bridge region and the bottom plate of the cylinder cover; and bubbles produced on the outer wall of the cylinder can be quickly washed away and vapor can be discharged, so that cooling water of high water temperature does not easily occur in the diesel engine.

Owner:GUANGXI YUCHAI MASCH CO LTD

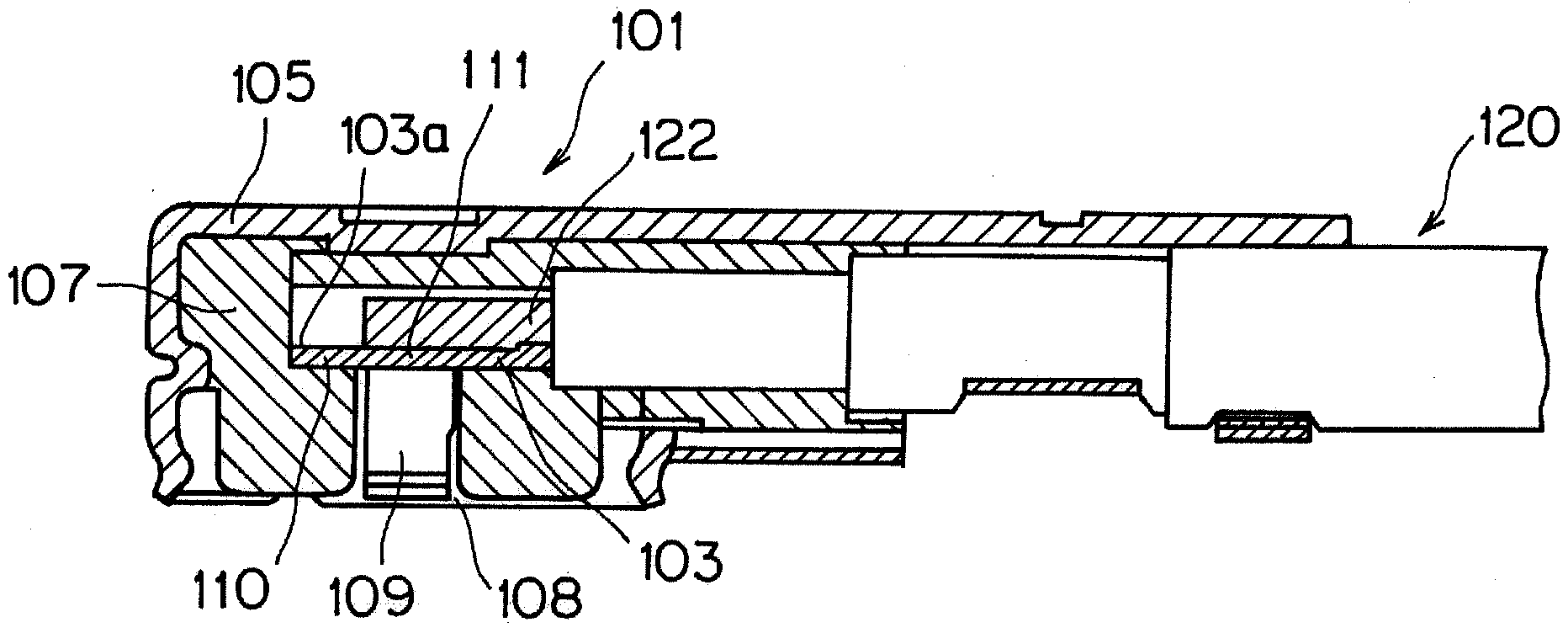

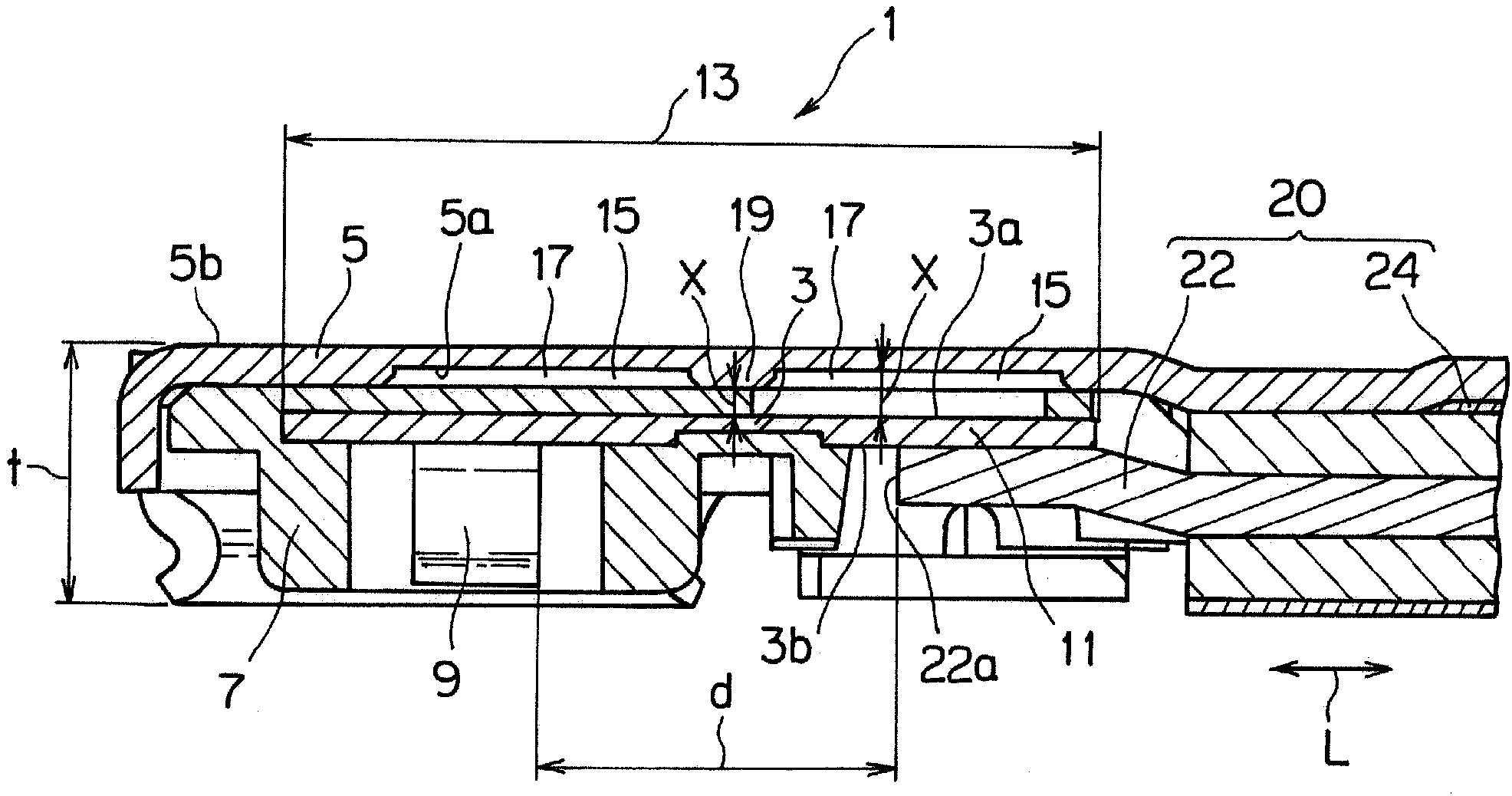

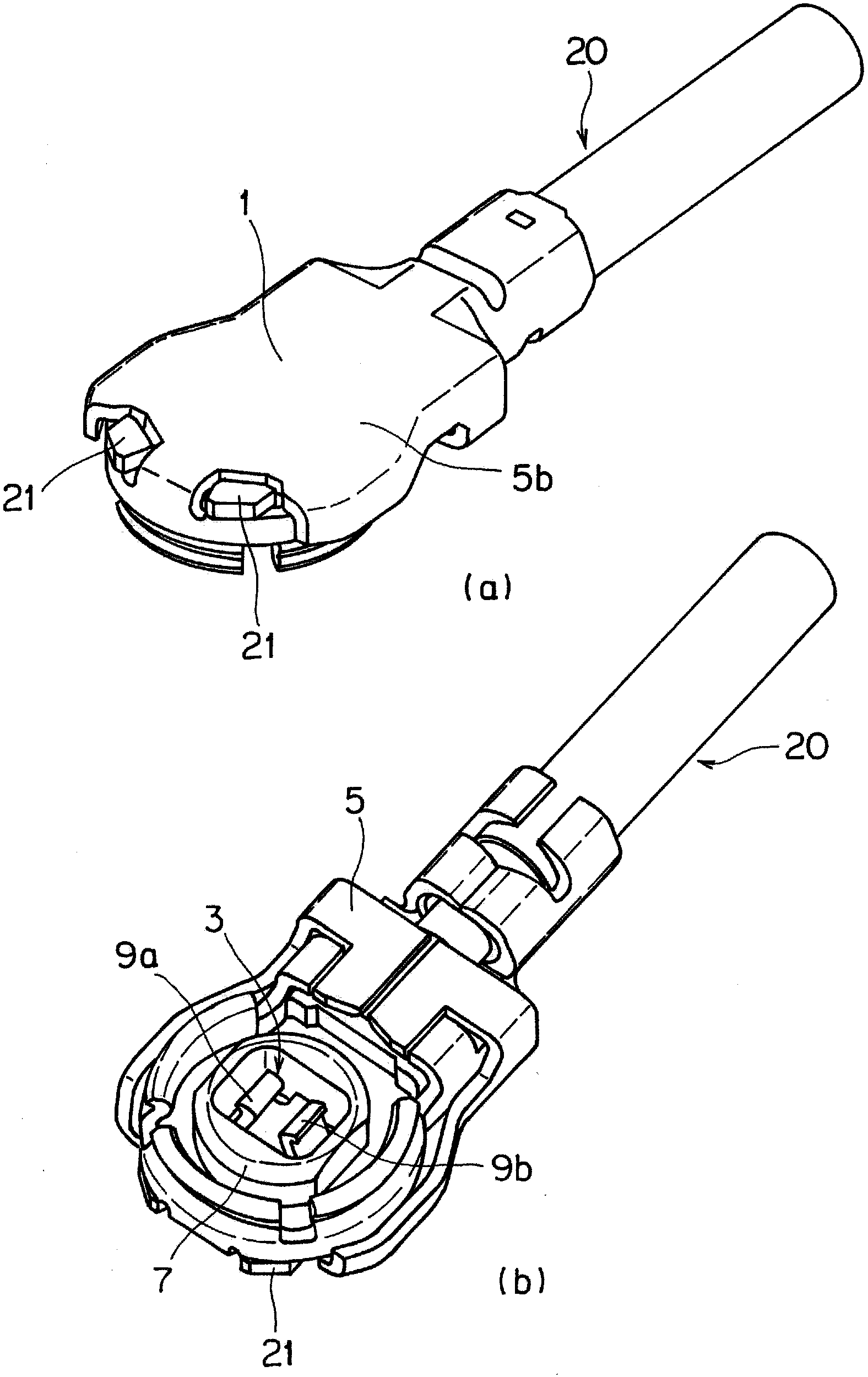

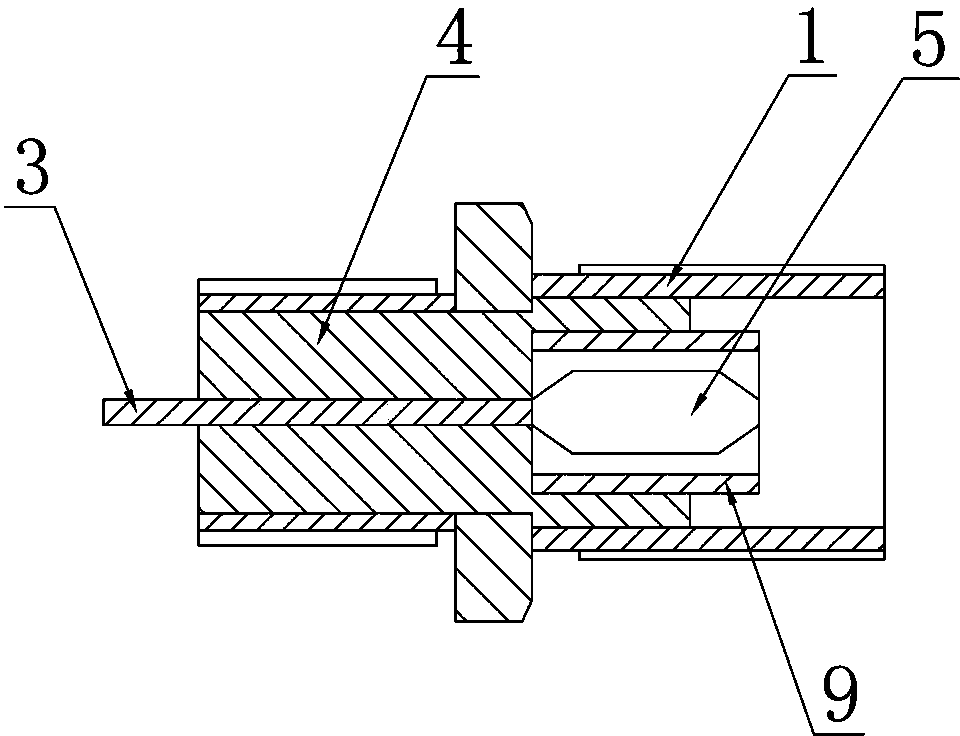

Plug connector, receptacle connector, and coaxial connector configured from these connectors

ActiveCN104126255ACharacteristic Impedance RetentionThe characteristic impedance value is maintainedElectrically conductive connectionsCoupling contact membersElectrical conductorCoaxial cable

The present invention provides a coaxial connector and the like which can be adjusted such that the VSWR is improved and the characteristic impedance of a coaxial cable is maintained, and effectively achieves a great reduction in height. This coaxial connector (1) is characterized by being provided with a signal conductor (3), a ground conductor (5), and an insulator (7), and in that in a both-conductor-opposed region (13) in which the ground conductor (5) and the signal conductor (3) are disposed opposing each other, a distance enlargement part (15) in which the vertical distance (X) between the inner surface (5a) of the ground conductor (5) and the back surface (3a) of the signal conductor (3), which is the surface facing the inner surface (5a), becomes larger without increasing the thickness dimension (t) of the coaxial connector (1) is formed.

Owner:DDK LTD

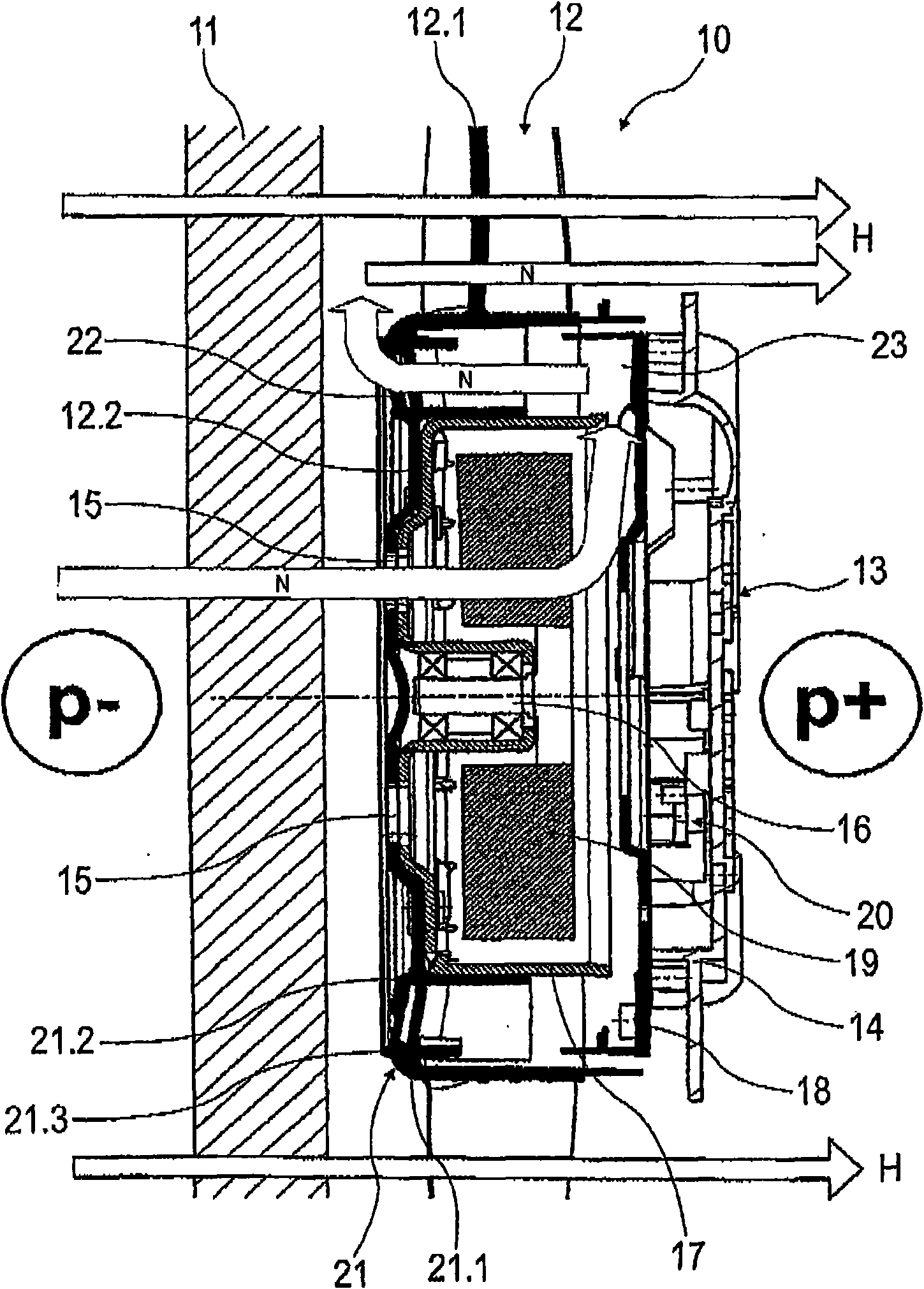

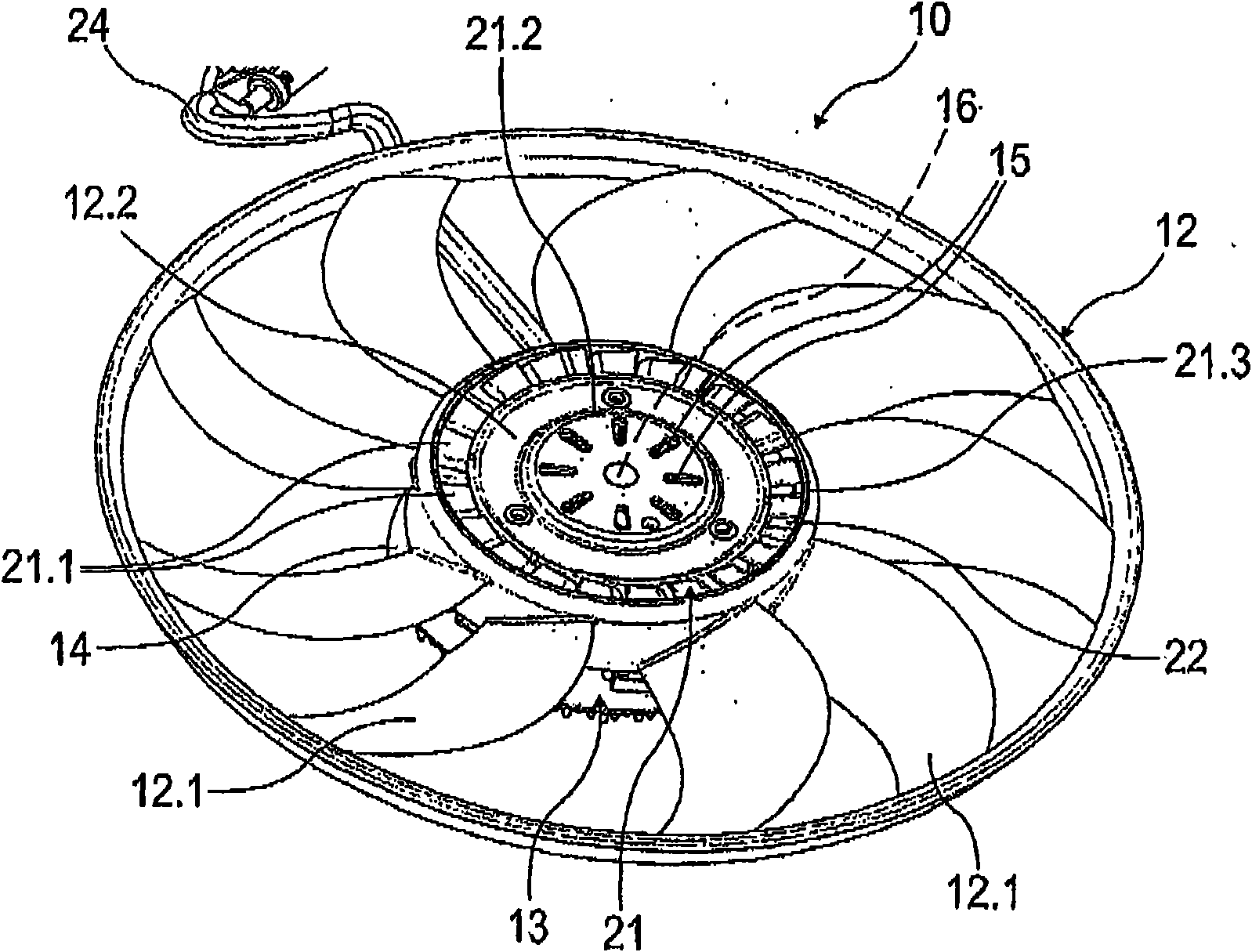

Axial fan for a vehicle radiator

ActiveCN101617126AImprove cooling effectLow efficiencyPump componentsPump installationsBusiness efficiencyHeat spreader

Owner:博泽汽车部件有限公司及两合公司,乌茨堡

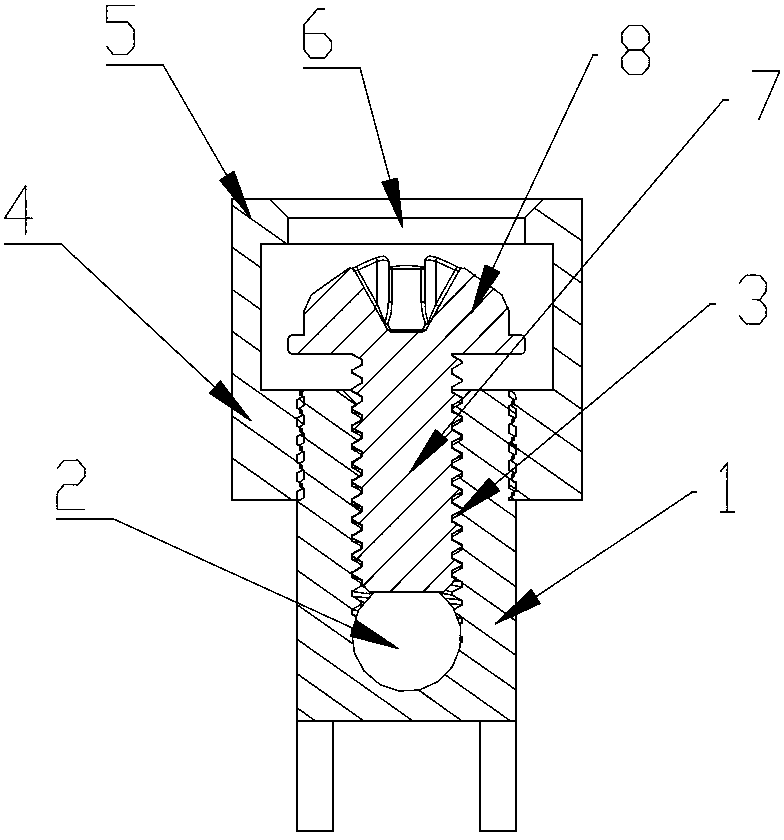

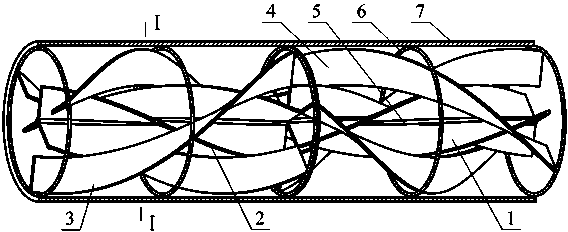

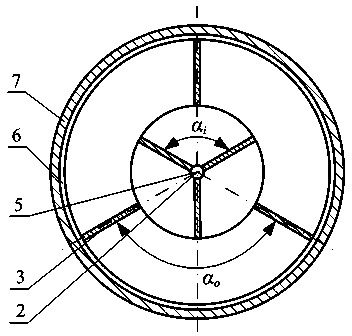

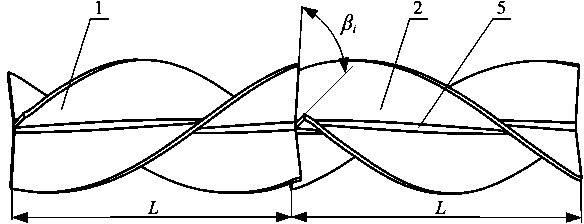

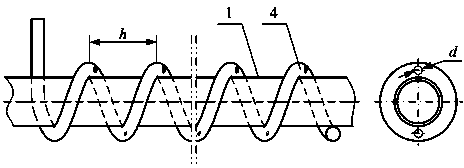

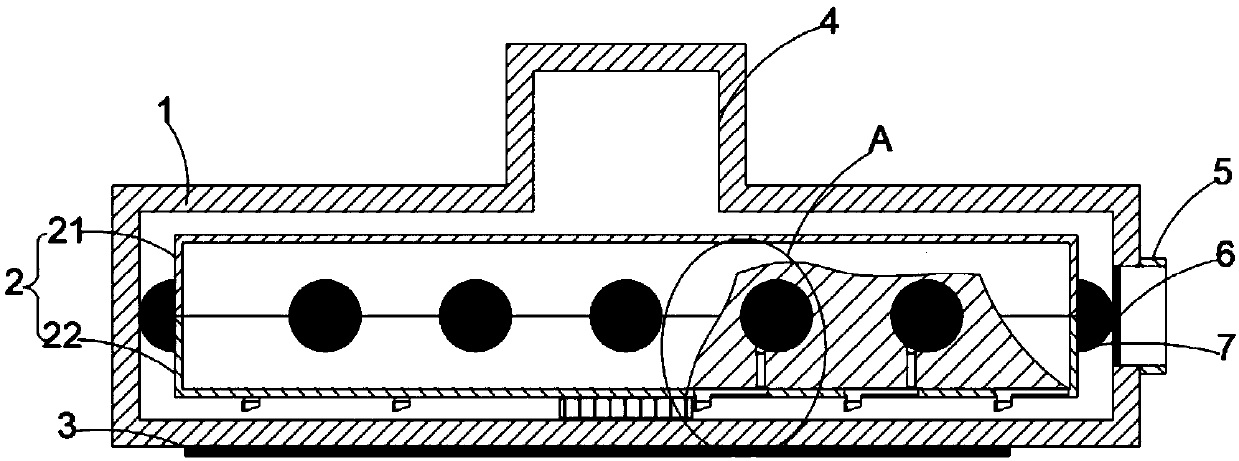

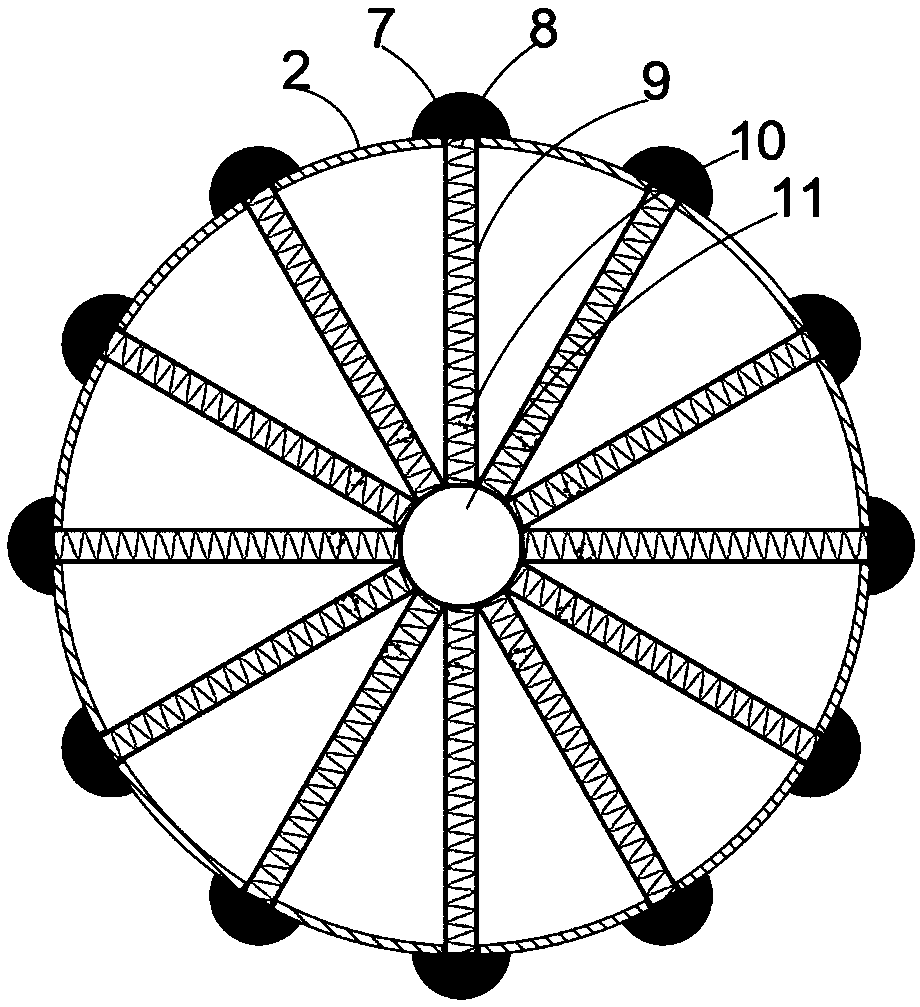

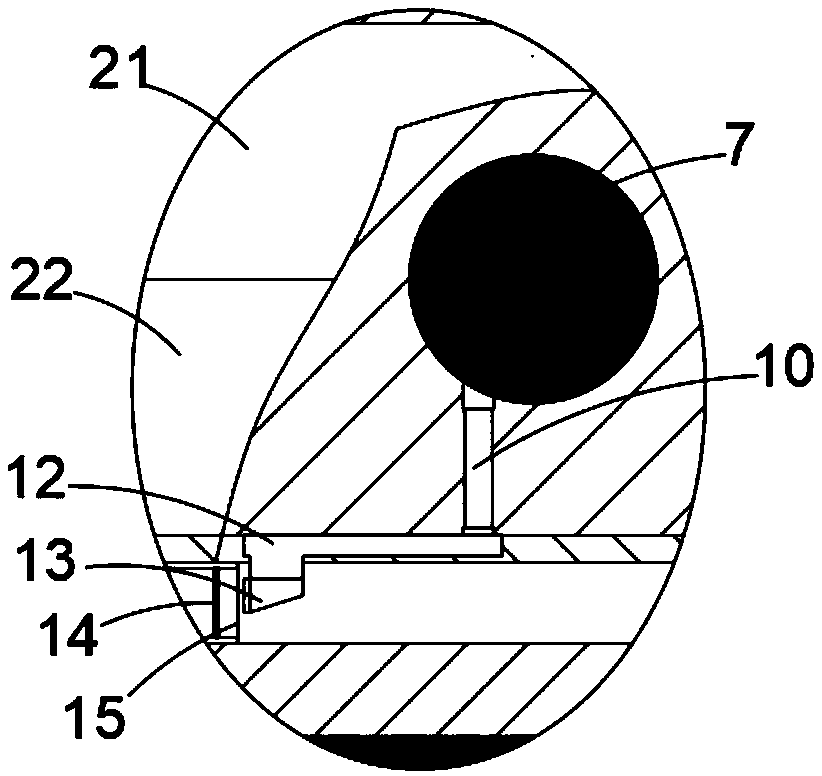

In-tube concentric double helix static mixer

The invention relates to an in-tube concentric double helix static mixer, and relates to a fluid mixer. In-twisted blades with the same helical direction are uniformly distributed on an outer wall of a positioning round bar (6) along a circumference direction, to form an inner helical element. Out-twisted blades with the same helical direction are uniformly distributed on an inner wall of a tubular body (7) along a circumference direction, to form an outer helical element. Radial adjacent inner (outer) helical elements have opposite helical directions. Heads and tails of the helical elements are successively connected and staggered a certain angle in a circumferential direction. Lengths of inner and outer helical elements are identical and helical directions of the inner and outer helical elements at corresponding radial positions are opposite. The fluid can form two inner and outer concentric helix flows with the opposite helical directions under the effect of inner and outer helical elements; fluid in each helical flow can be cut, rotated and merged; and radial mixture of the fluid can be reinforced. The invention is suitable for mixture or reaction of various fluids, and is particularly suitable for operation conditions with large processing capacity, relatively small requirements for flow pressure drop but not relatively long mixer length.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

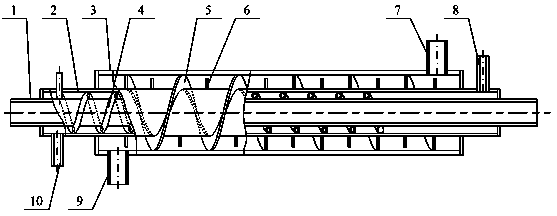

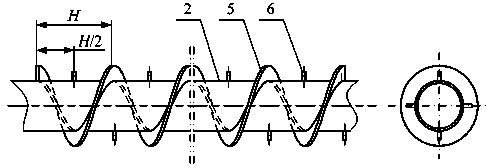

Double-side cooling concentric tube-in-tube type sulfonating reactor

ActiveCN104226207AAchieve spiral flowIncrease heat transfer areaChemical/physical processesEngineeringSulfur trioxide

The invention relates to a double-side cooling concentric tube-in-tube type sulfonating reactor. The double-side cooling concentric sleeve type sulfonating reactor comprises a cooling inner tube (1), a reaction sleeve (2), a cooling sleeve (3), a spiral jet pipe, a spiral flow deflector, spoiler columns (6), a cooling sleeve outlet pipe (7), a reaction sleeve outlet pipe (8), a cooling sleeve inlet pipe (9), a reaction sleeve inlet pipe (10), and the like, wherein the cooling inner tube, the reaction sleeve and the cooling sleeve are arranged in a concentric way, so that a reaction cavity and two heat exchange cavities are formed; furthermore, the spiral jet pipe and the spiral flow deflector are respectively arranged in the reaction cavities, so that the reaction material and a coolant can flow in a spiral way, and mass transfer and heat transfer are synchronously enhanced. The double-side cooling concentric tube-in-tube type sulfonating reactor is rapid in heat exchange speed and safe and reliable in reaction, thus being especially suitable for a continuous sulfonation reaction technology taking liquid-phase sulfur trioxide as a sulfonating agent.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

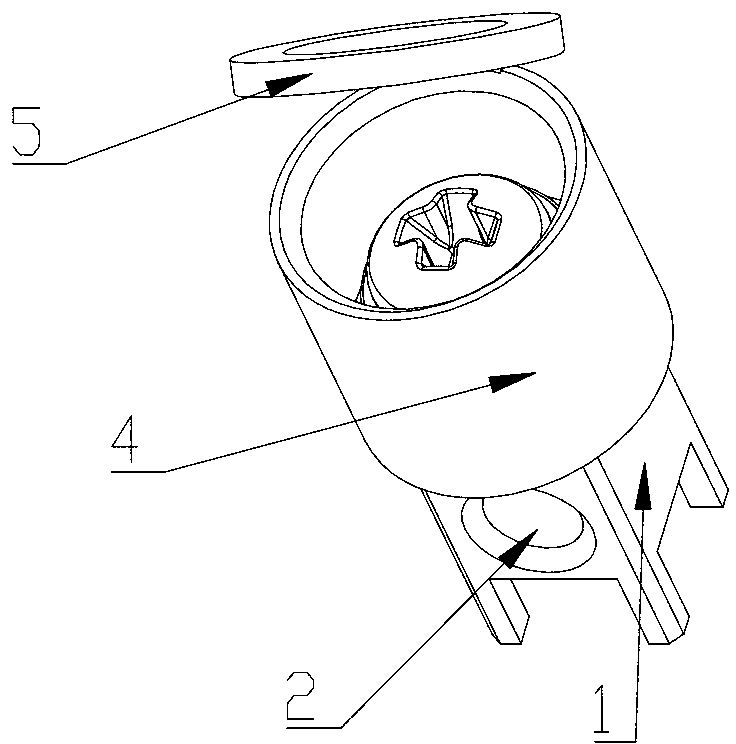

Fuse capable of being automatically recovered

ActiveCN109672138ATimely replacementNo short circuitEmergency protective arrangements for automatic disconnectionEmergency protective devicesElectrical and Electronics engineering

The invention discloses a fuse capable of being automatically recovered, which comprises a shell. A first wiring port and a second wiring port are formed in the upper end and the side wall of one sideof the shell correspondingly. A mounting opening is formed in the bottom end of the shell. The mounting opening is in threaded connection with a bottom plate. A bearing is arranged on the side wall of the center of the bottom plate. A rotating rod which is vertically arranged is fixedly inserted into the inner ring of the bearing. A rotating block is arranged at the end, away from the bottom plate, of the rotating rod. The rotating block is of a hollow structure. A fixing rod is arranged on the inner wall of the bottom end of the rotating block. A plurality of sleeves are arranged on the sidewall of the outer side of the fixing rod in a surrounding and arrayed mode. Fuse wires are arranged in the sleeves. A plurality of metal contacts are arranged on the side wall of the outer side of the rotating block in a surrounding and arrayed mode. The fuse wires in the sleeves are electrically connected with the metal contacts. According to the invention, the fuse can automatically recover theconduction of a circuit after the breaking of an overload circuit. The frequent replacement of the fuse or fuse wires is avoided, thereby bringing great convenience to users.

Owner:ANHUI KANGYU HYDROPOWER MACHINERY COMPLETE EQUIP CO LTD

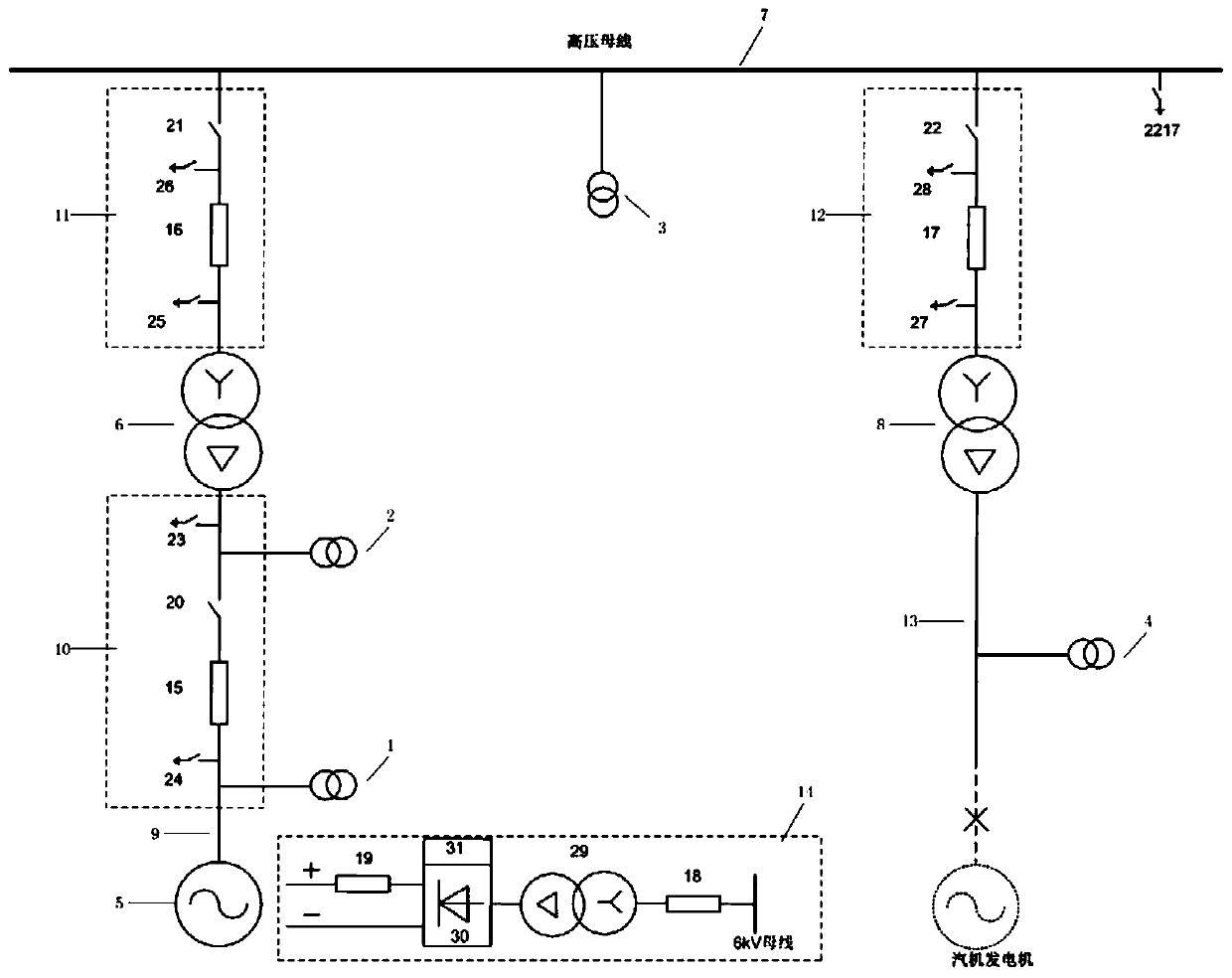

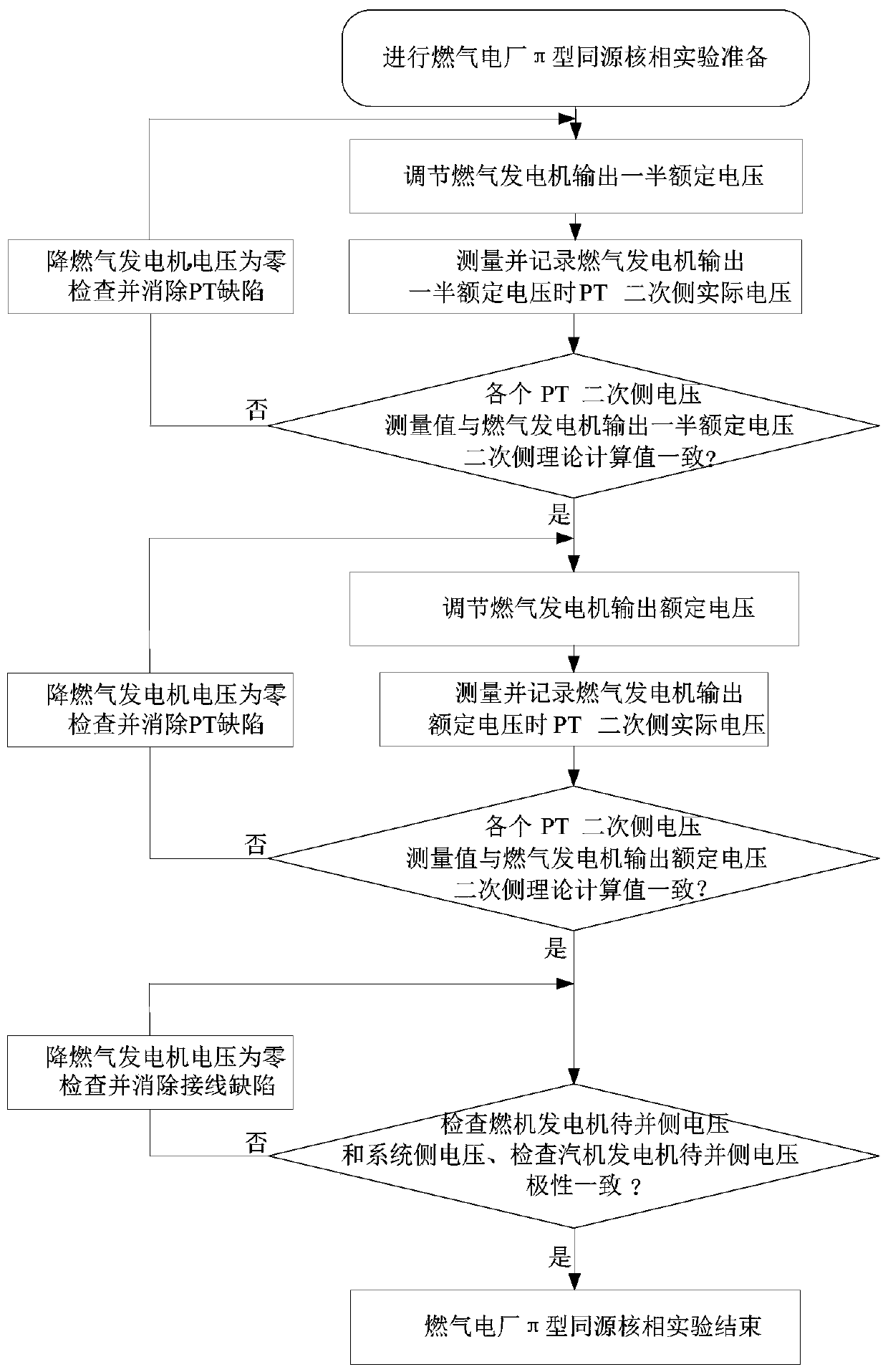

Pi-type homologous nuclear phase system and method for gas power plant

ActiveCN110504712AStart test went wellAvoid damageSingle network parallel feeding arrangementsPhase sequence/synchronism indicationLow voltageTransformer

The invention discloses a pi-type homologous nuclear phase system and method for a gas power plant. An excitation unit of a gas turbine generator is connected with a rotor of the gas turbine generator; the output end of the gas turbine generator is connected with the low-voltage side of a gas turbine main transformer through an outlet enclosed bus of the gas turbine generator and one synchronization point unit of the gas turbine generator sequentially; the high-voltage side of the gas turbine main transformer is connected with a high-voltage bus through two synchronization point units of the gas turbine generator; the high-voltage side of a steam turbine main transformer is connected with the high-voltage bus through a synchronization point unit of the steam turbine generator; and the low-pressure side of a steam turbine main transformer is connected with the output end of the steam turbine generator through an outlet enclosed bus of the steam turbine generator. According to the systemand the method, homologous nuclear phases of the plurality of synchronization points can be completed once; it is not required to change a running mode and operate a knife switch frequently; dangerous sources are relatively few; experiment time and fuel are saved; the experiment efficiency is relatively high; and asynchronous accidents caused by wiring errors can be effectively reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

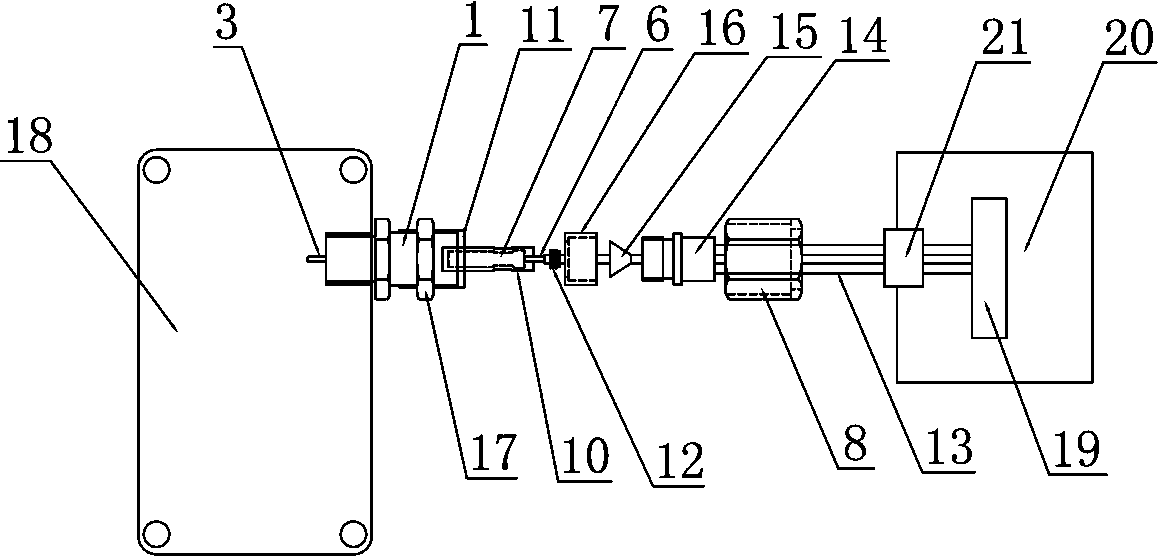

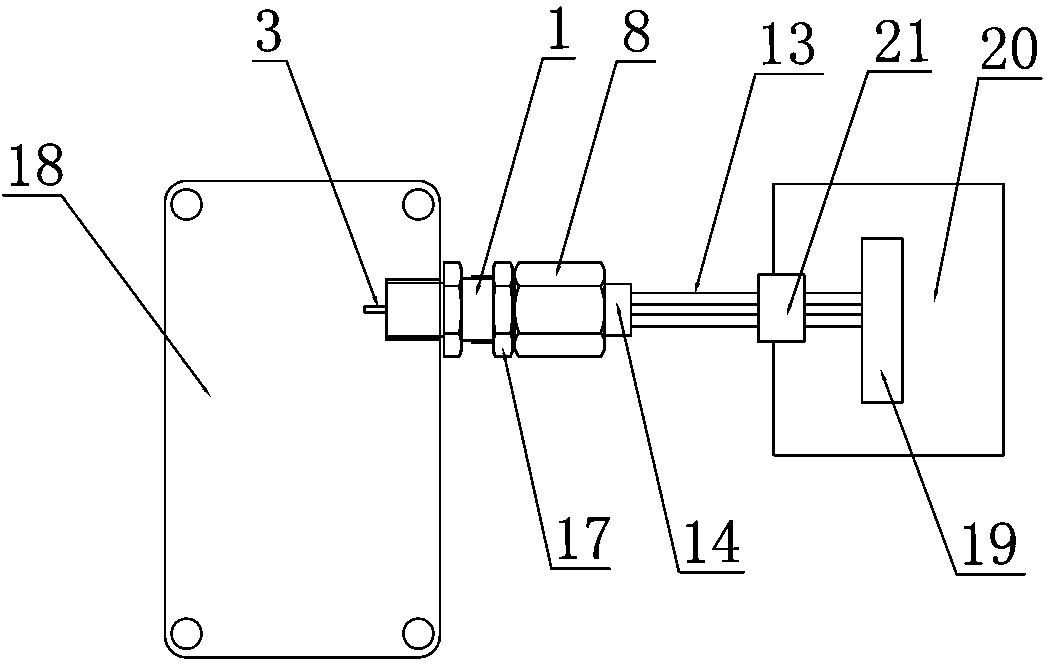

Connecting joint device of LNG (Liquefied Natural Gas) liquid level sensor output cable and transmitter

ActiveCN103682794ADifficult to enterNo short circuitCouplings bases/casesEngineeringLiquid level sensor

The invention discloses a connecting joint device of an LNG (Liquefied Natural Gas) liquid level sensor output cable and a transmitter. The connecting joint device includes a connecting seat fixed and sealed on the transmitter; the connecting seat is filled with an insulating sealing element; a joint wire is sealed in and penetrates through the insulating sealing element; one end of the joint wire is fixed with a connector male head; a connecting end of an insulating wire is provided with a connector female head which is electrically connected with a wire of the insulating wire and can be matched with the connector male head for connecting; a connector fastening sleeve can connect a tubular fastening joint and a connecting seat together; a first insulating sleeve pipe for surrounding the connector male head is sealed on the insulating sealing element; a second insulating sleeve pipe is sealed and sleeved outside the connector female head; when the connector female head and the connector male head are connected, the first insulating sleeve pipe and the second insulating sleeve pipe are mutually sealed and connected; and the connector male head and the connector female head are enabled to be sealed with and insulated from the connecting seat and the tubular fastening joint. The invention has the advantages of the good insulating and sealing performance.

Owner:苏州赛智达智能科技有限公司

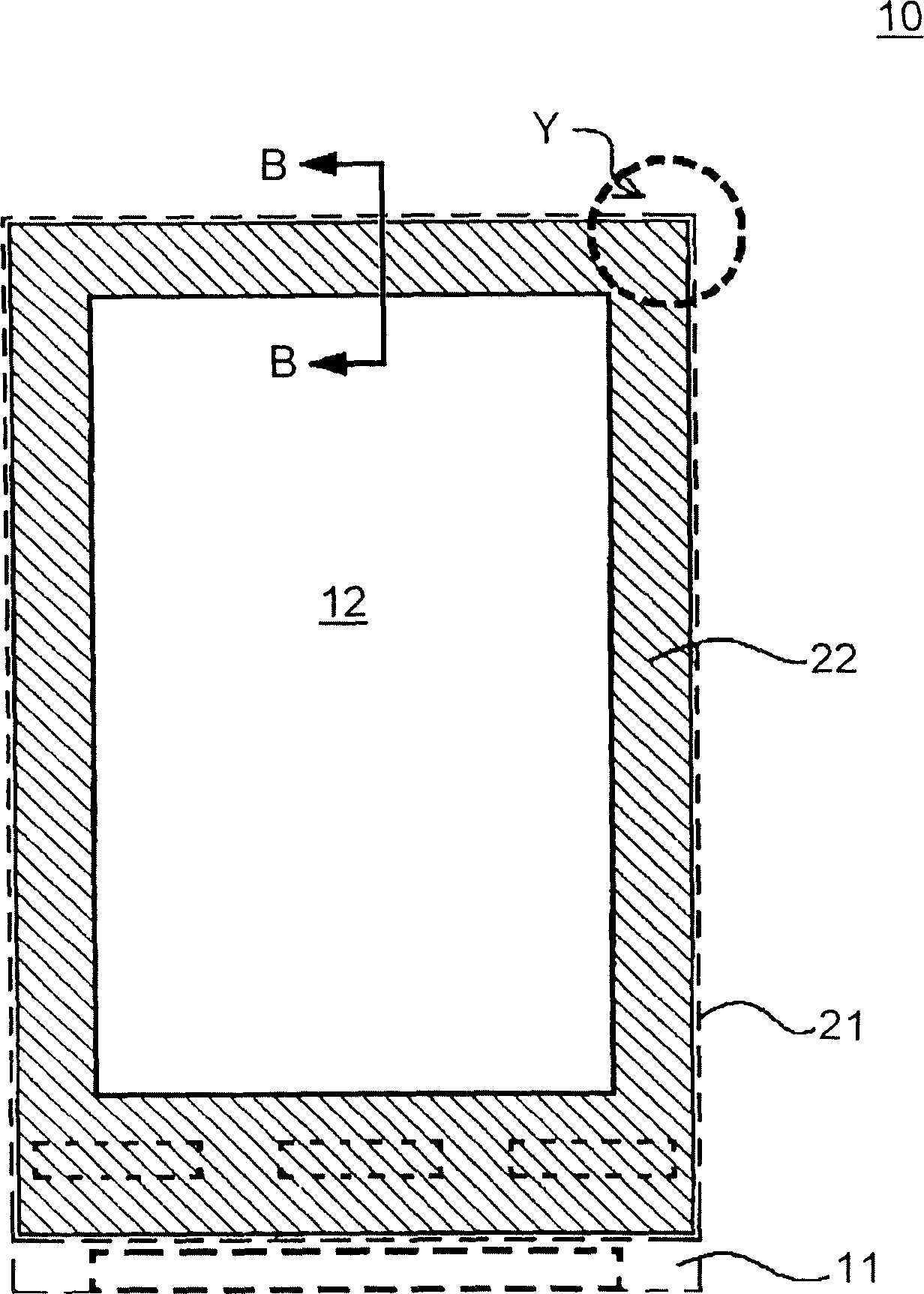

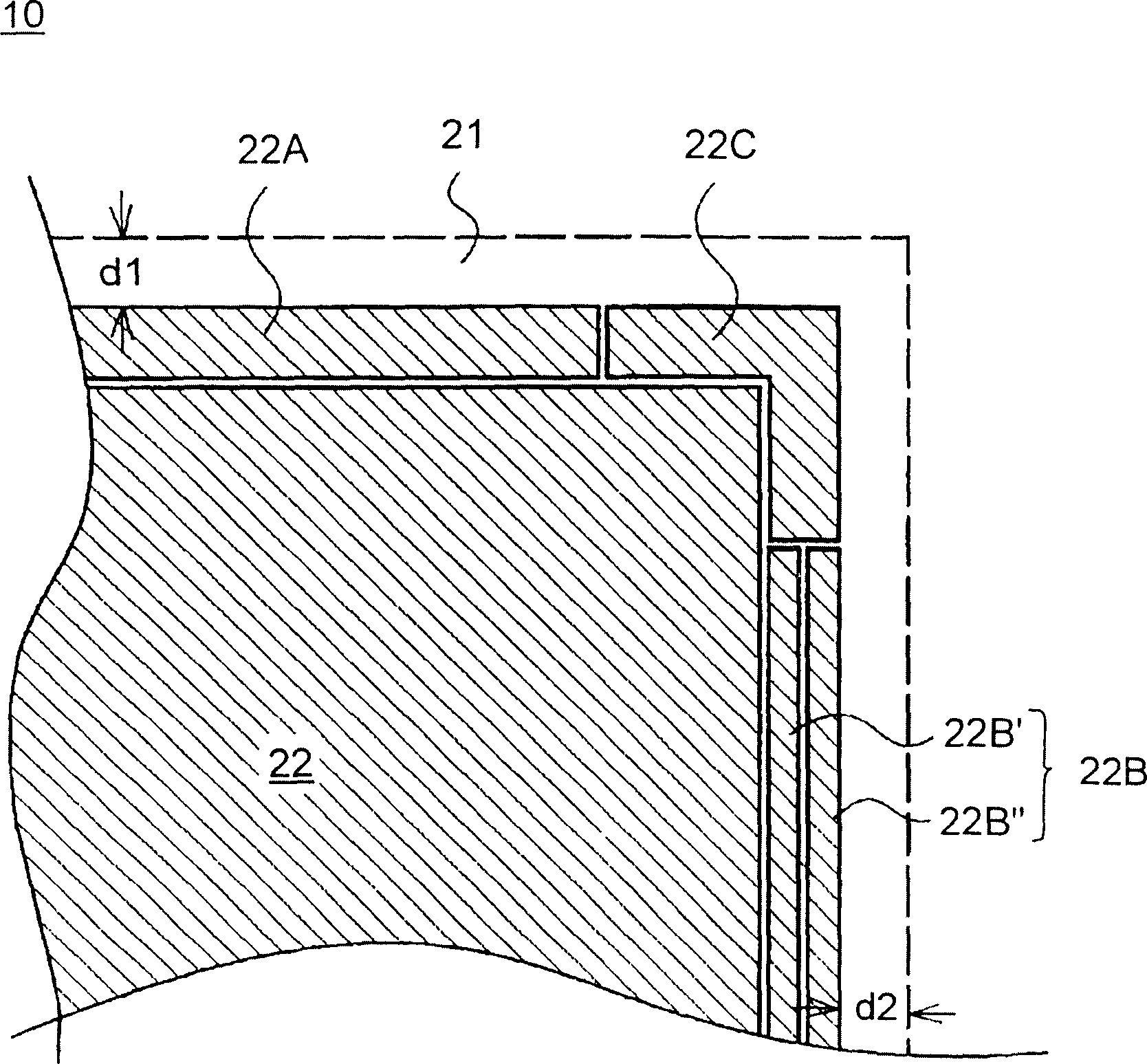

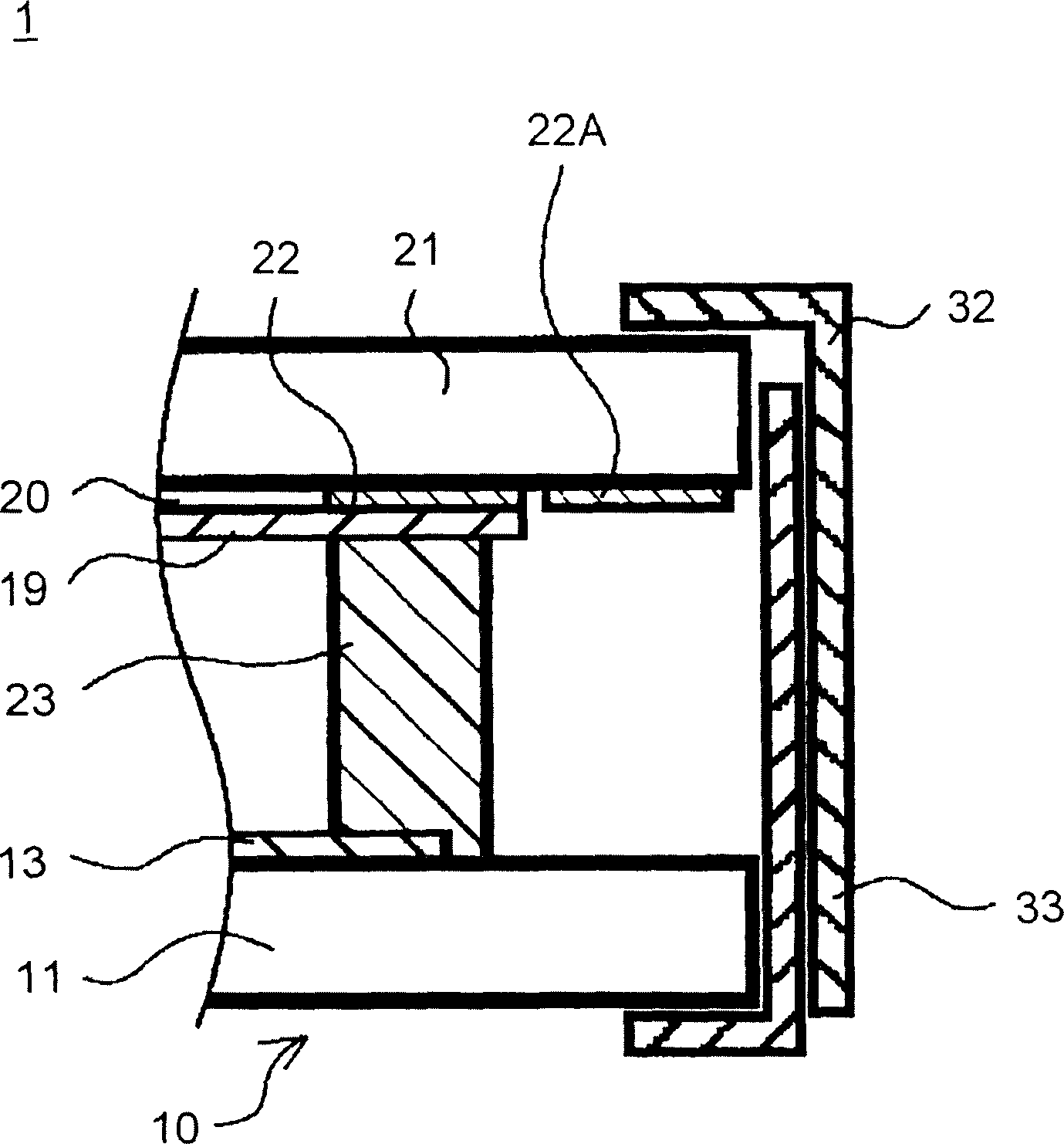

Liquid crystal display device

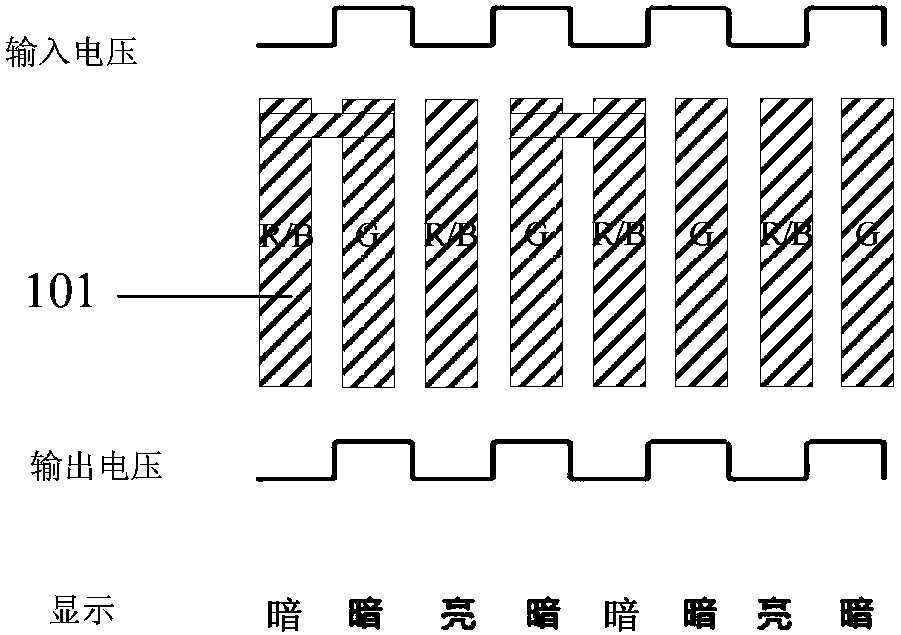

ActiveCN1755749AQuality improvementNo short circuitNon-linear opticsIdentification meansLiquid-crystal displayEngineering

In a liquid crystal display apparatus having a backlight disposed behind a liquid crystal display panel 10 , the liquid crystal display panel 10 has first and second substrates 11 and 21 disposed to face each other. The second substrate 21 has a common electrode 20 laid in a display area 12 thereon. The second substrate 21 further has a light-shielding inner black matrix 22 laid around the display area 12 and a light-shielding electrically insulated black matrix 22 A, 22 B, and 22 C laid outside the inner black matrix 22 and electrically separated from the inner black matrix 22 and the common electrode 19 . The liquid crystal display panel 10 is held, at the periphery thereof, by metal support frames 32 and 33.

Owner:JAPAN DISPLAY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com