Method for detecting mask printing plate

A mask and mask technology, applied in the field of mask detection, can solve problems such as long time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

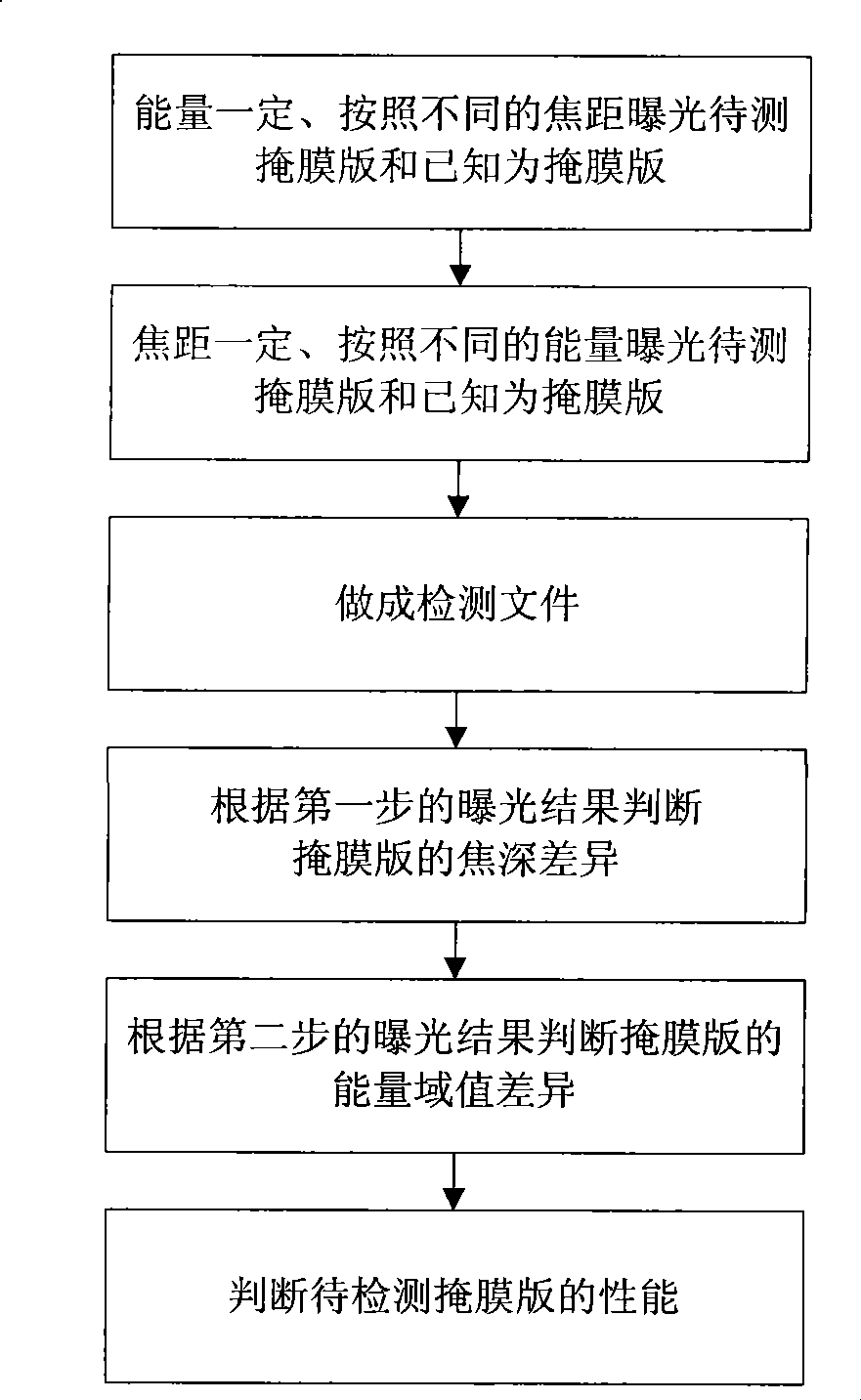

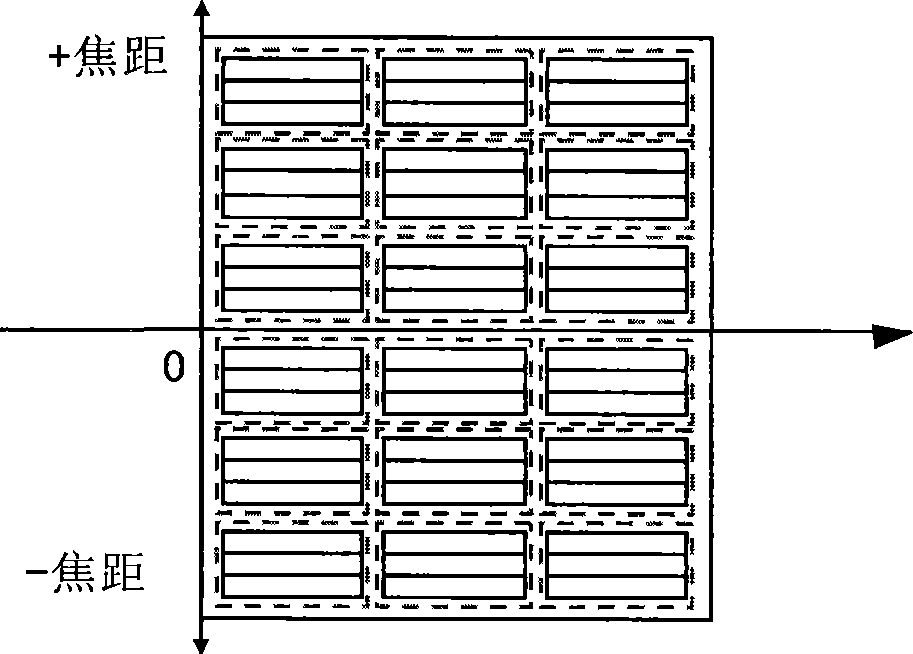

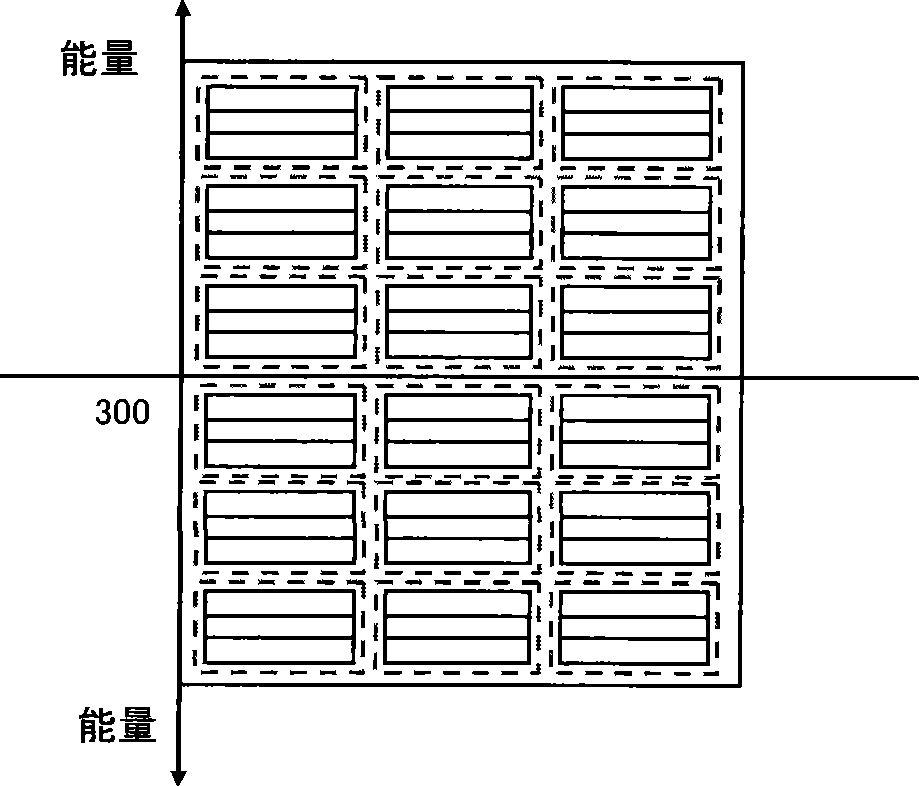

[0014] like figure 1 As shown, the steps included in the detection of the mask in the present invention are: 1, the energy is constant, and the mask to be detected and the pattern known as the good mask are exposed on the light sheet at the same time according to different focal lengths; 2, the focal length is fixed, Simultaneously expose the pattern of the mask to be detected and the known good mask on the light sheet according to different energies; 3, judge the difference between the mask to be detected and the mask known to be good according to the exposure result of the first step Depth of focus difference, and the pattern and particle status of the mask; 4. According to the exposure results of the second step, judge the energy threshold difference between the mask to be detected and the mask known to be a good product, and the mask 5. Combine the results of the third step and the fourth step to judge the performance of the mask to be tested.

[0015] like Figure 2 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com