Cleaning agent for semiconductor provided with metal wiring

A wiring and chelating agent technology, applied in the field of cleaning agents, can solve the problems that copper wiring is highly corrosive, cleaning agents cannot be applied to new microelectronic devices with fine patterns, etc., and achieve the effect of good contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

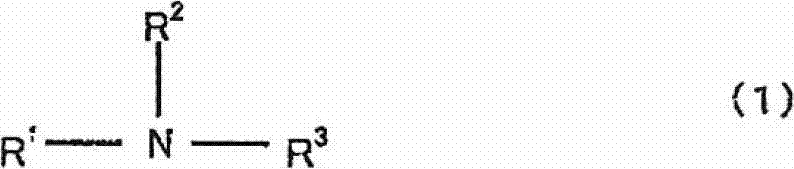

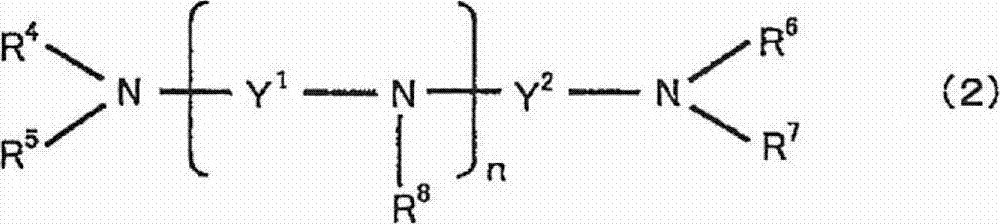

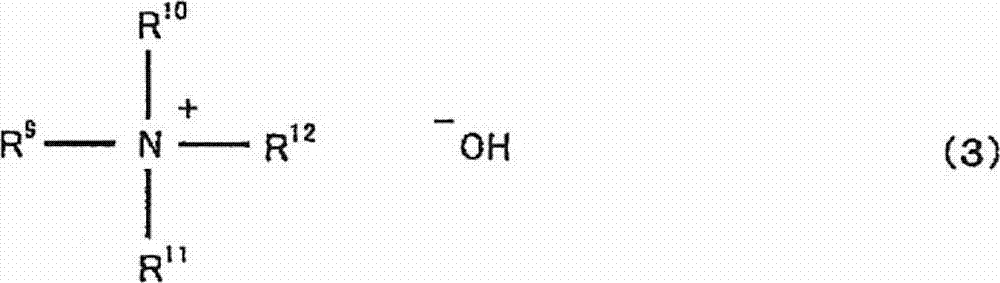

Method used

Image

Examples

Embodiment 1

[0094] 0.14 parts of TEP (A-1) (trade name: AFR-AN6, purity 99.2%, manufactured by Tosoh Corporation), 0.240 parts of 25% TMAH aqueous solution (B-1) (trade name: 25% TMAH solution, having 25% purity , manufactured by Tama Chemicals Co., Ltd.), 0.002 parts of ethylenediaminetetraacetic acid (C-1) (trade name: Chelest 3A, purity 98.0%, manufactured by Chelest Corporation) were added to 300 ml of polyethylene-made in the container. Next, 99.8 parts of water (W) were added so that the total weight was 100 parts. The solution was stirred by a magnetic stirrer to obtain a first composition (D-1) for removing material from a microelectronic device comprising tungsten wiring. The resulting cleaning agent had a pH of 13.2.

Embodiment 2

[0096] The same operation as in Example 1 was carried out, except that 0.14 parts of MEA (A-2) (purity 99%, manufactured by Wako Pure Chemical Industries, Ltd.) was used instead of (A-1) in Example 1, and (B The blending amount of -1) was changed to 0.200 parts, the blending amount of (C-1) was changed to 0.004 parts, and water was added so that the total weight was 100 parts. Thereby a first composition (D-2) for removing material from a microelectronic device comprising tungsten wiring was obtained. The resulting cleaning agent had a pH of 12.5.

Embodiment 3

[0098] The same operation as in Example 1 was carried out, except that 25% TEAH aqueous solution (B-2) (trade name: 25% TEAH solution, aqueous solution with a purity of 25%, manufactured by Wako Pure Chemical Industries, Ltd.) was used instead of Example 1. (B-1). Thereby a first composition (D-3) for removing material from a microelectronic device comprising tungsten wiring was obtained. The resulting cleaning agent had a pH of 12.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com