Panel and manufacturing method thereof

A manufacturing method and panel technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

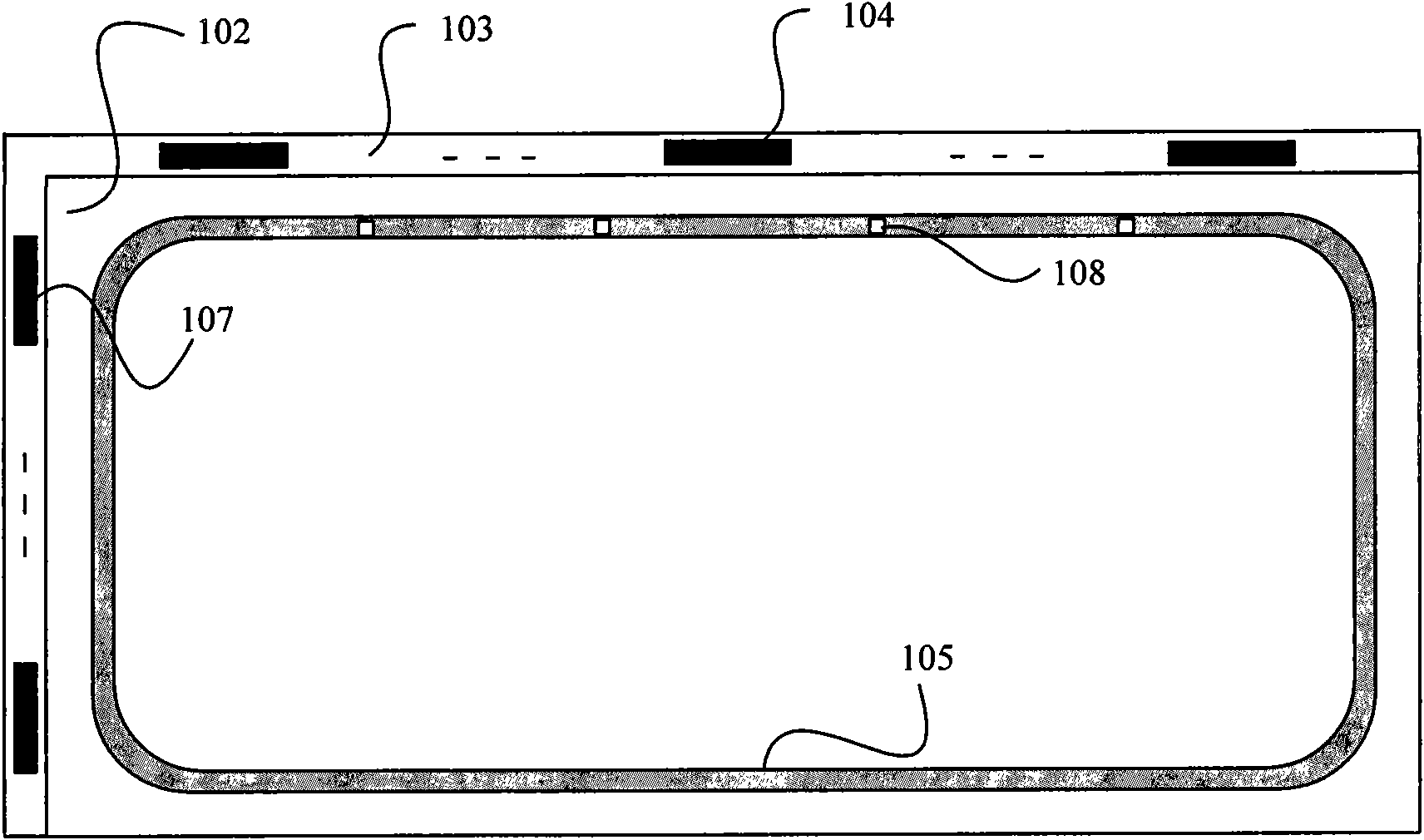

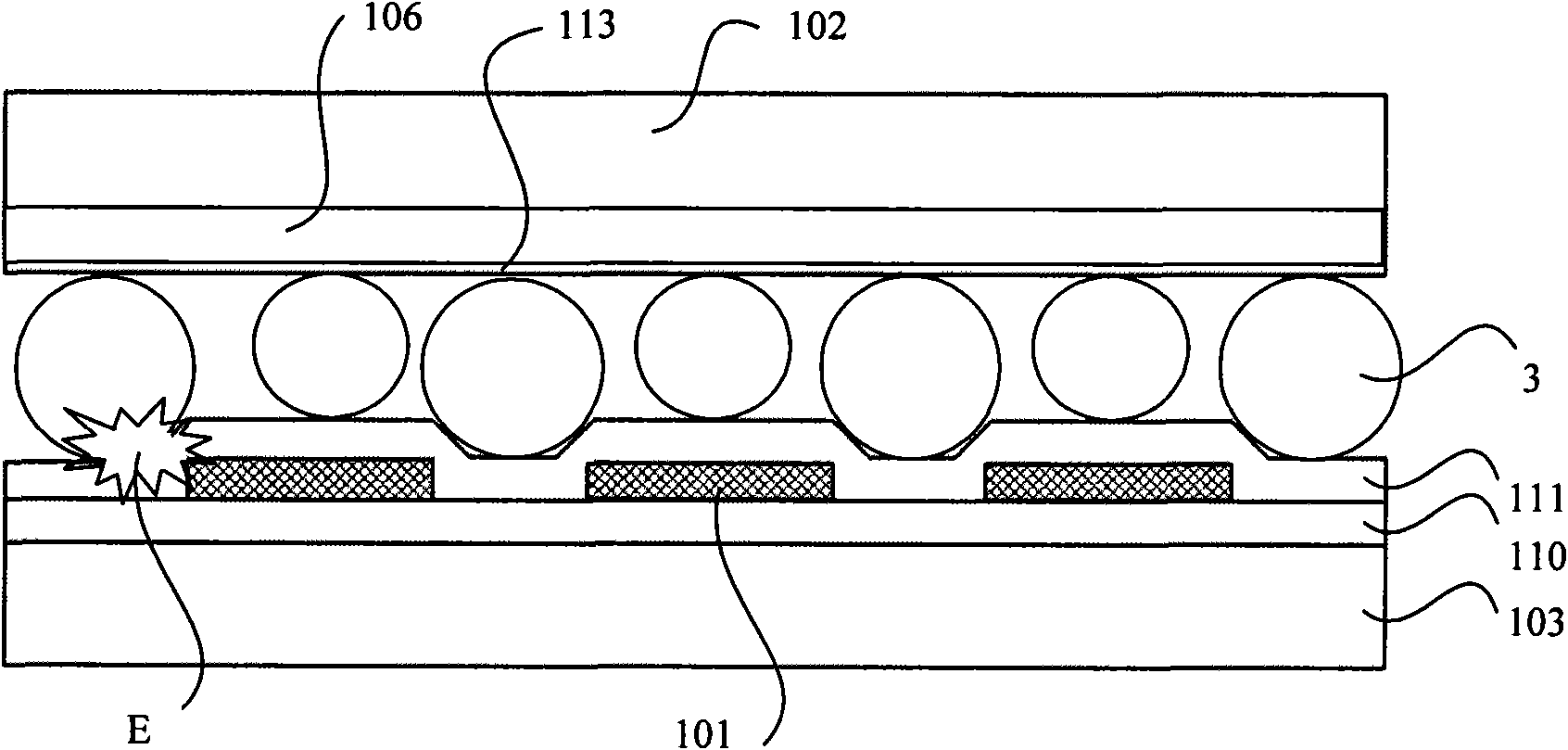

[0029] Such as Figure 4 As shown, it is a structural schematic diagram of an embodiment of the sealing glue of the present invention. The secondary sealing glue 2 is doped with a certain density of gold balls, as long as it is selectively coated in a dot shape, and its coating position is generally the main sealing frame. The outer side of the adhesive 1, and can be selected on the four peripheries of the array substrate 103, such as the side with the data line pad 104, the side with the gate line pad 107, the side opposite the data line pad 104, and the gate line pad. On the opposite side of the disk 107, it is usually selected in the middle of the data line pad on the side with the data line pad 104, as shown in the figure; in order to better avoid the occurrence of ESD, the secondary sealing glue 2 needs to be Avoid the data line lead area, preferably also avoid the gate line lead area.

[0030] Such as Figure 5 Shown is a flowchart of an embodiment of the panel manufac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com