Patents

Literature

186 results about "Gold ball" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold ball having a foamed layer created by infrared radiation

InactiveUS20070155542A1Avoid excessive densityDomestic articlesSolid ballsGold ballCompound (substance)

This invention is directed to a golf ball having a foamed layer and the method for creating the foamed layer by the heating of blowing agents with infrared radiation. Either physical blowing agents can be de-volatized, or chemical blowing agents (both organic and inorganic) may be decomposed wherein the blowing agents are generated within the layer. The resultant layer is less dense than the core layer beneath it.

Owner:ACUSHNET CO

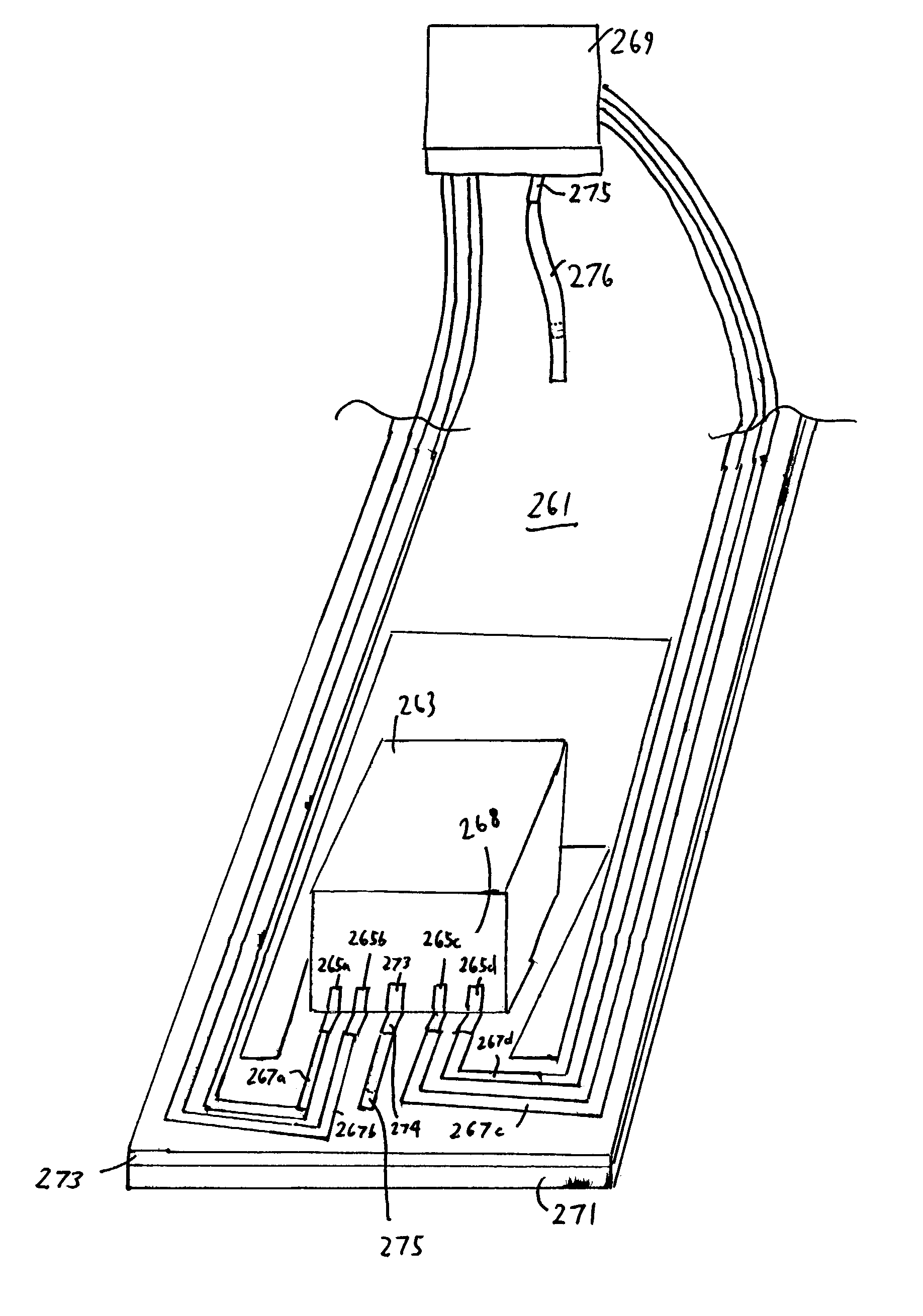

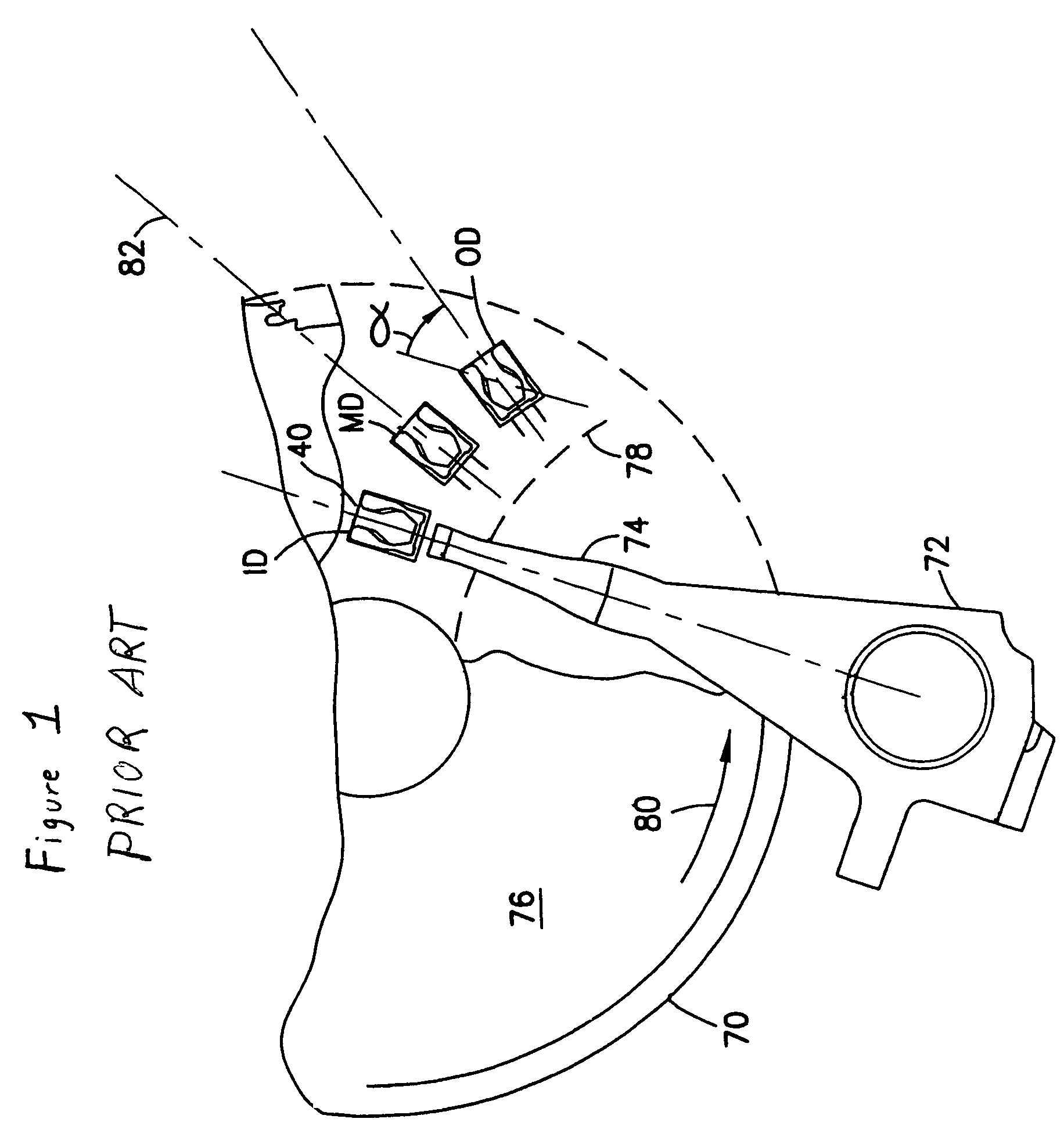

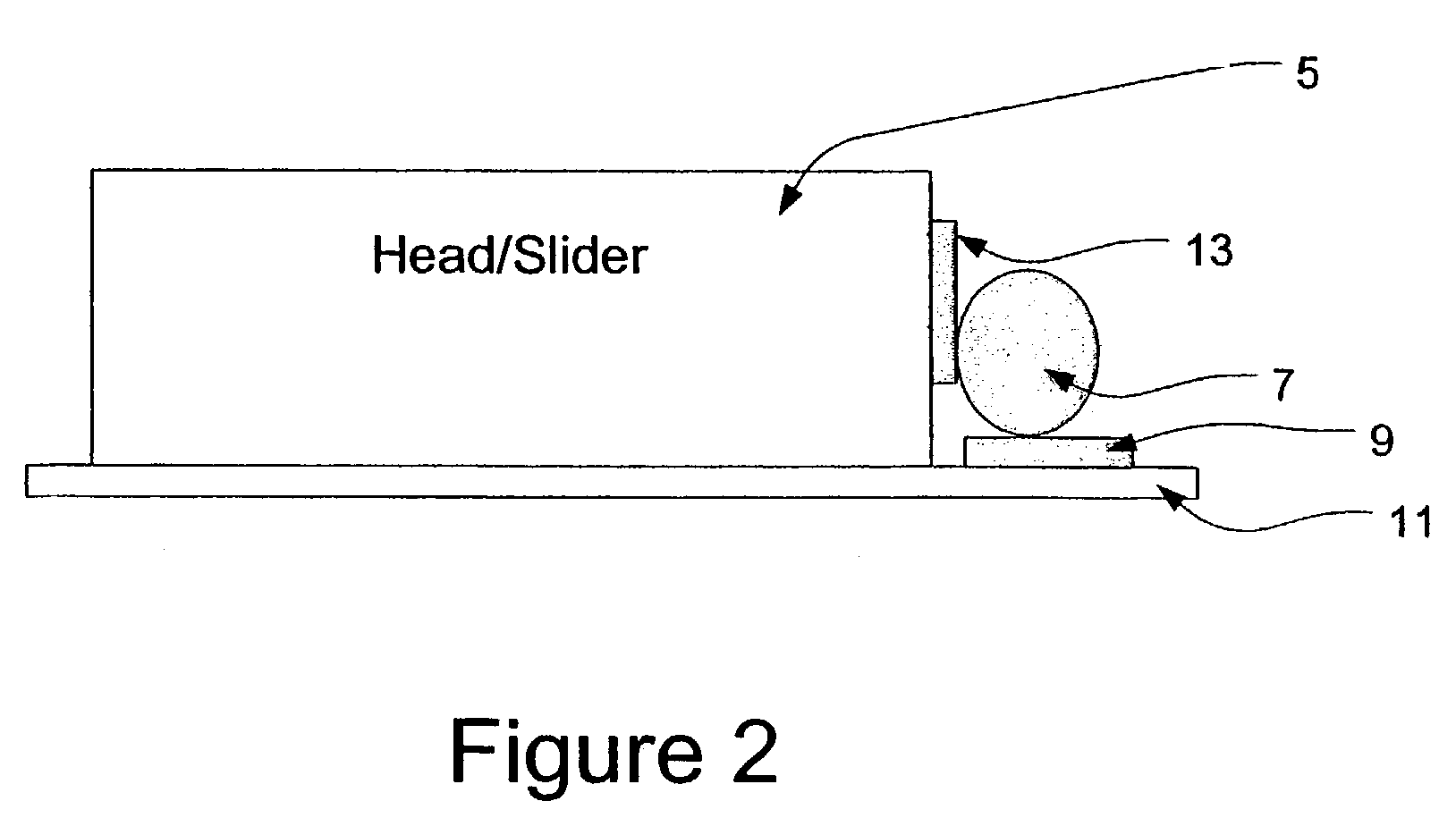

Method and apparatus for providing an additional ground pad and electrical connection for grounding a magnetic recording head

InactiveUS7064928B2Electrical connection between head and armPrinted circuit groundingElectricityElectrical conductor

Method and apparatus are presented for electrically coupling a slider to ground. In one embodiment, a bonding pad is provided on a side of the slider body separate from the bonding pad(s) used for read / write signals. This separate bonding pad is electrically coupled within the slider body to components that are to be coupled to ground. A separate conductor provided on the suspension (e.g., a trace, a flex circuit, etc.) may be electrically coupled to the separate bonding pad via gold ball bonding. The conductor is also coupled to ground in the hard-disk drive device (e.g., via the preamplifier). The use of the separated bonding pad and trace may negate the need to use a conductive adhesive to electrically ground the slider via its attachment to the tongue of a slider.

Owner:SAE MAGNETICS (HK) LTD

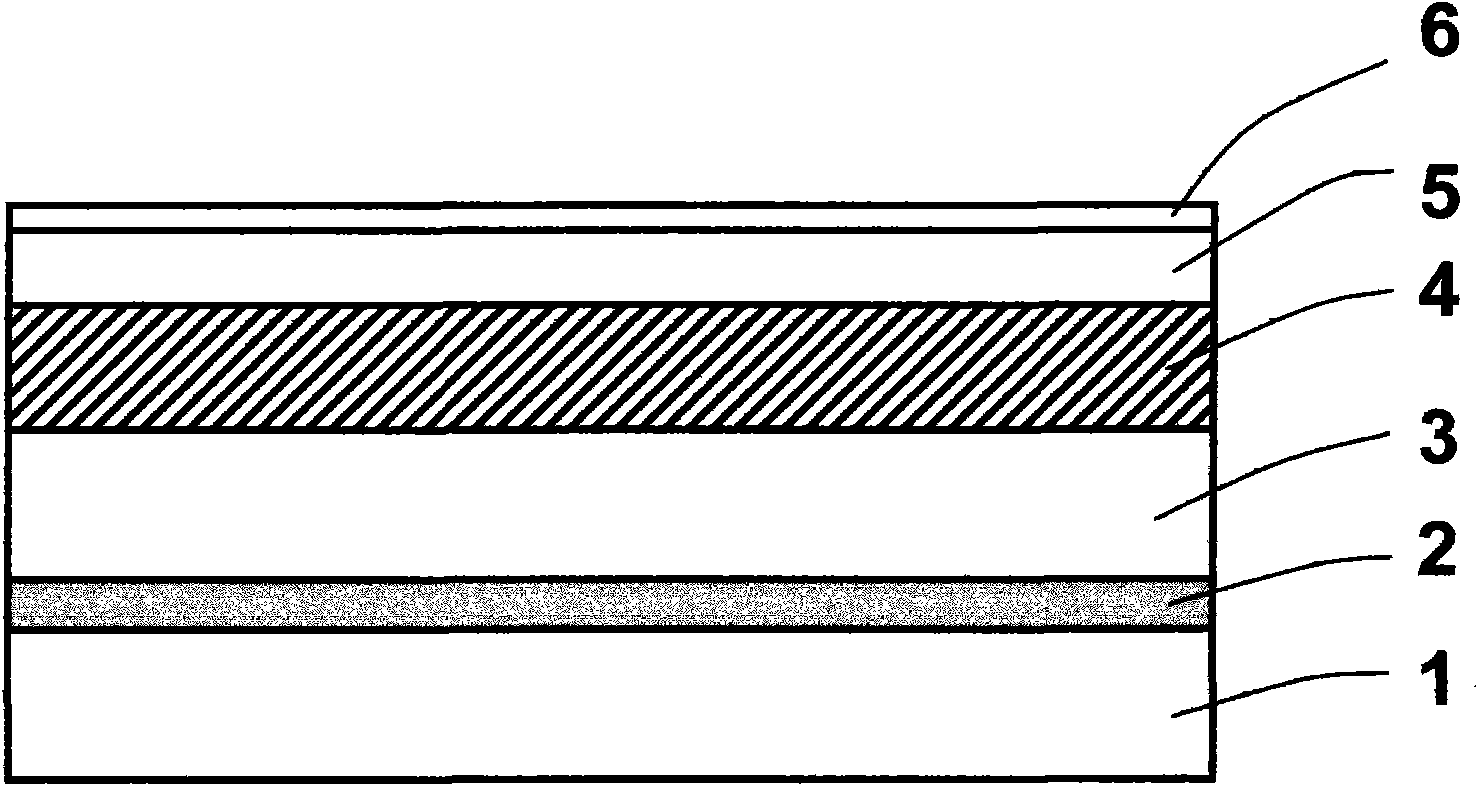

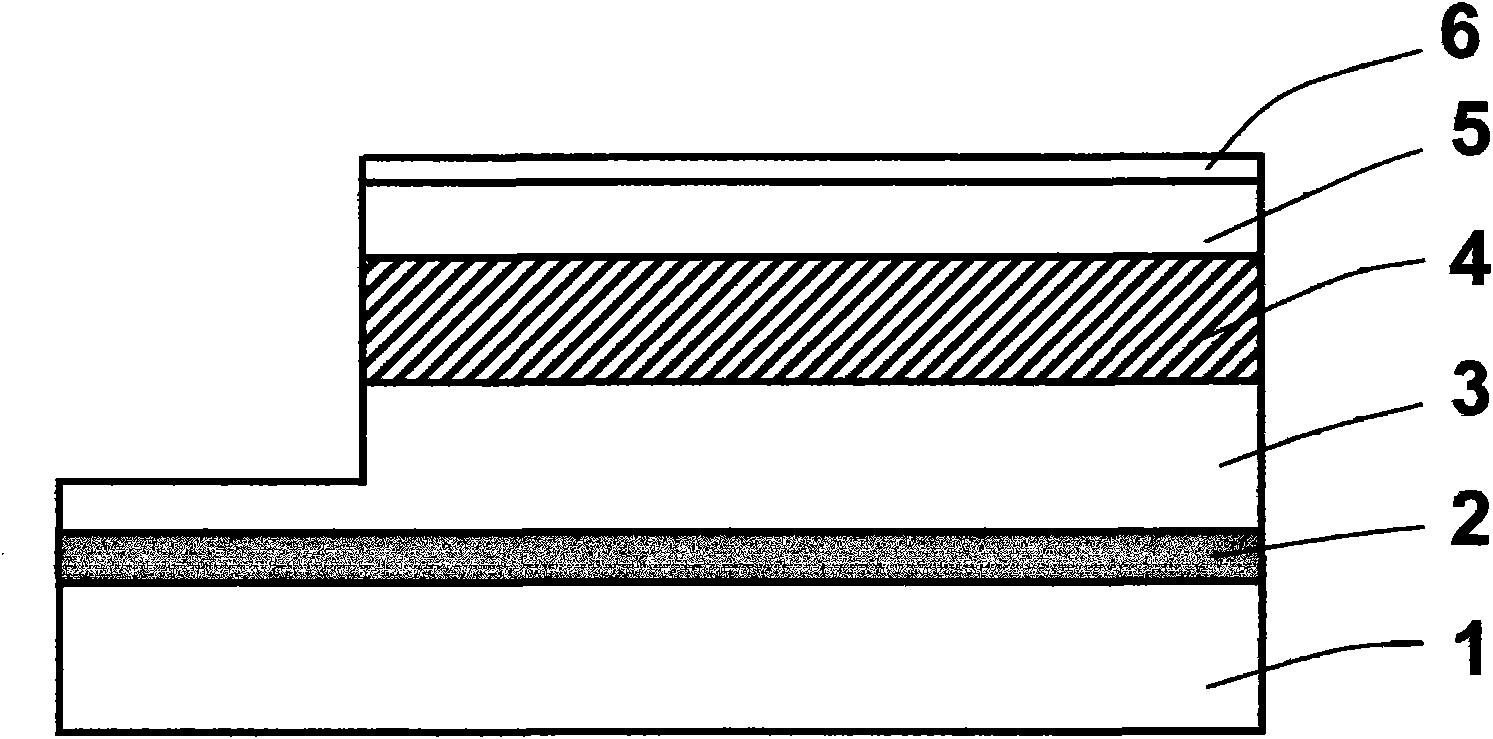

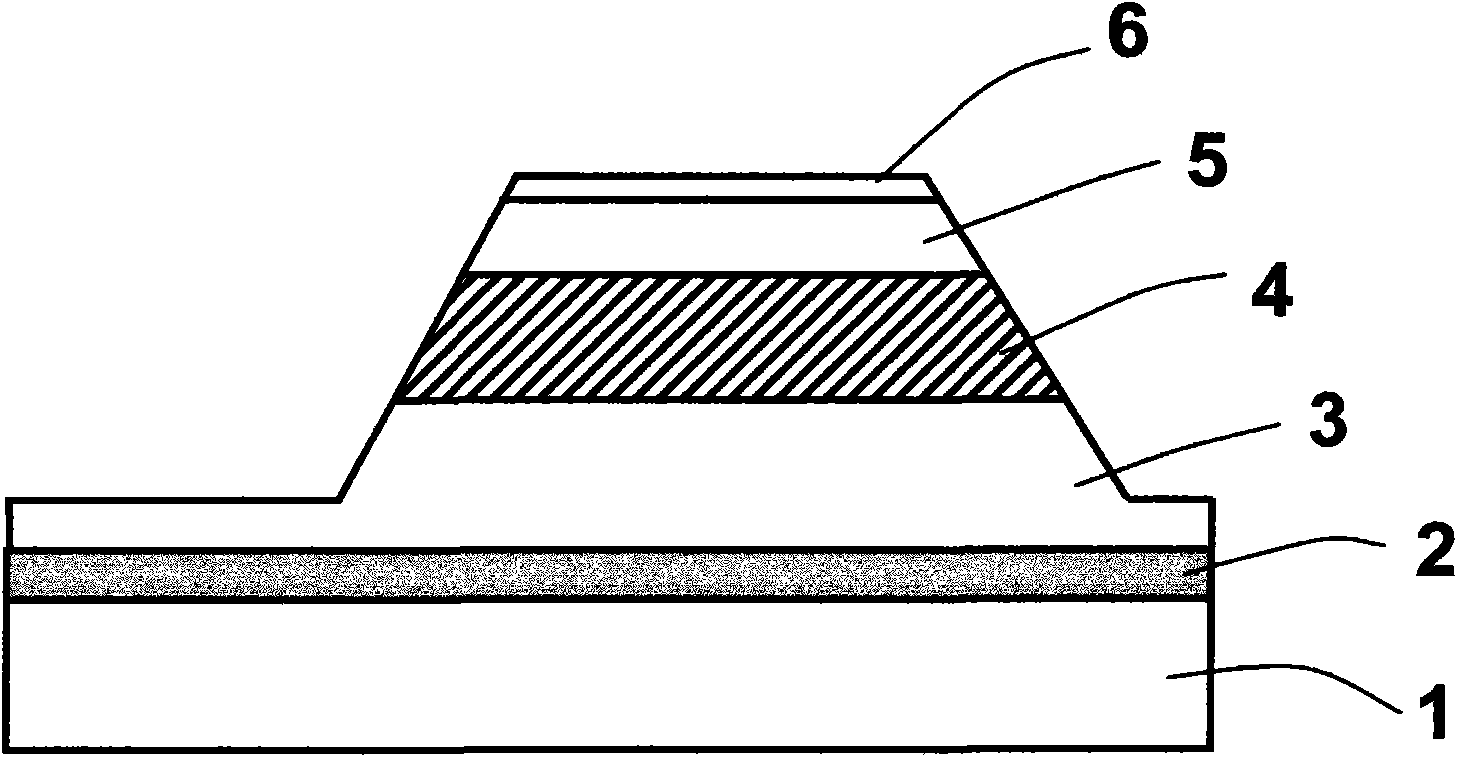

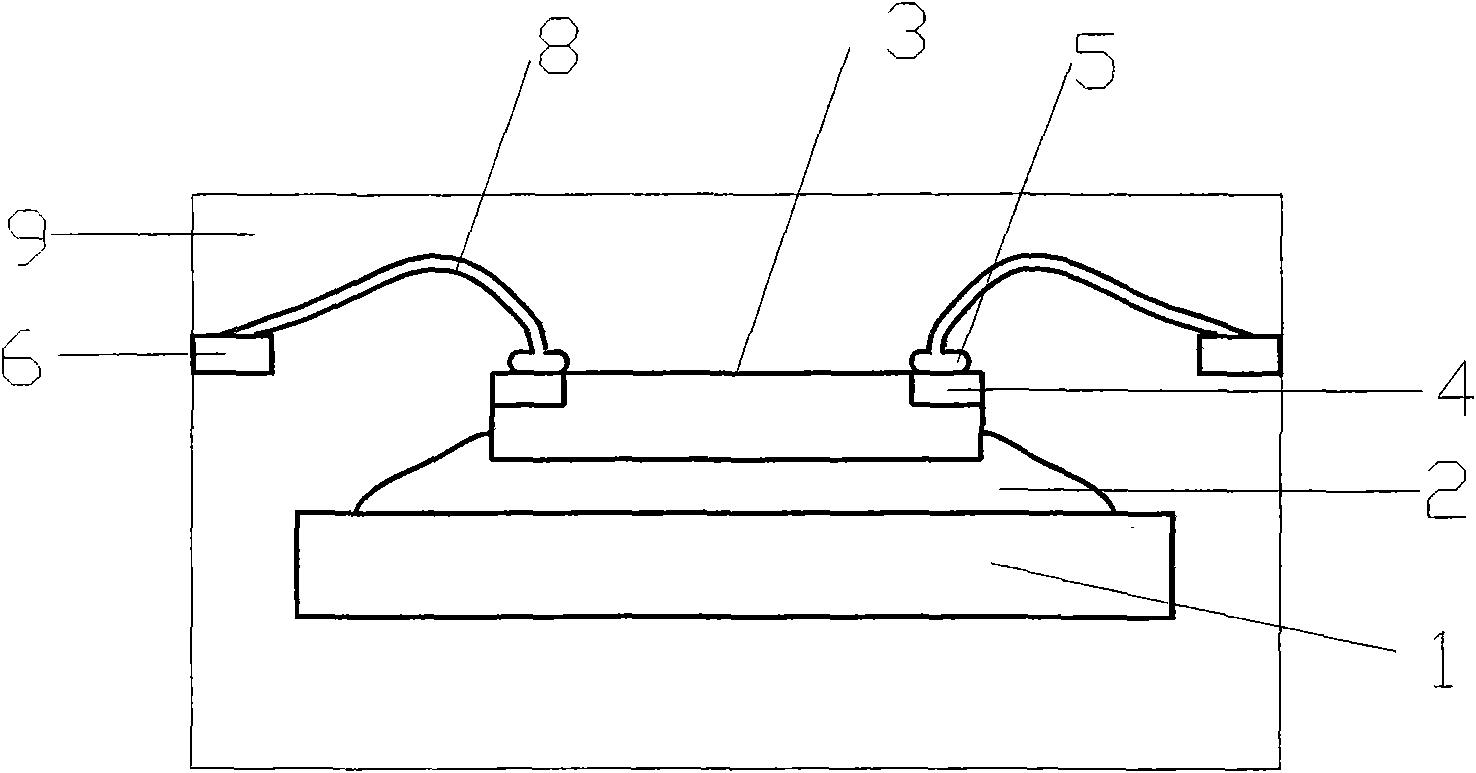

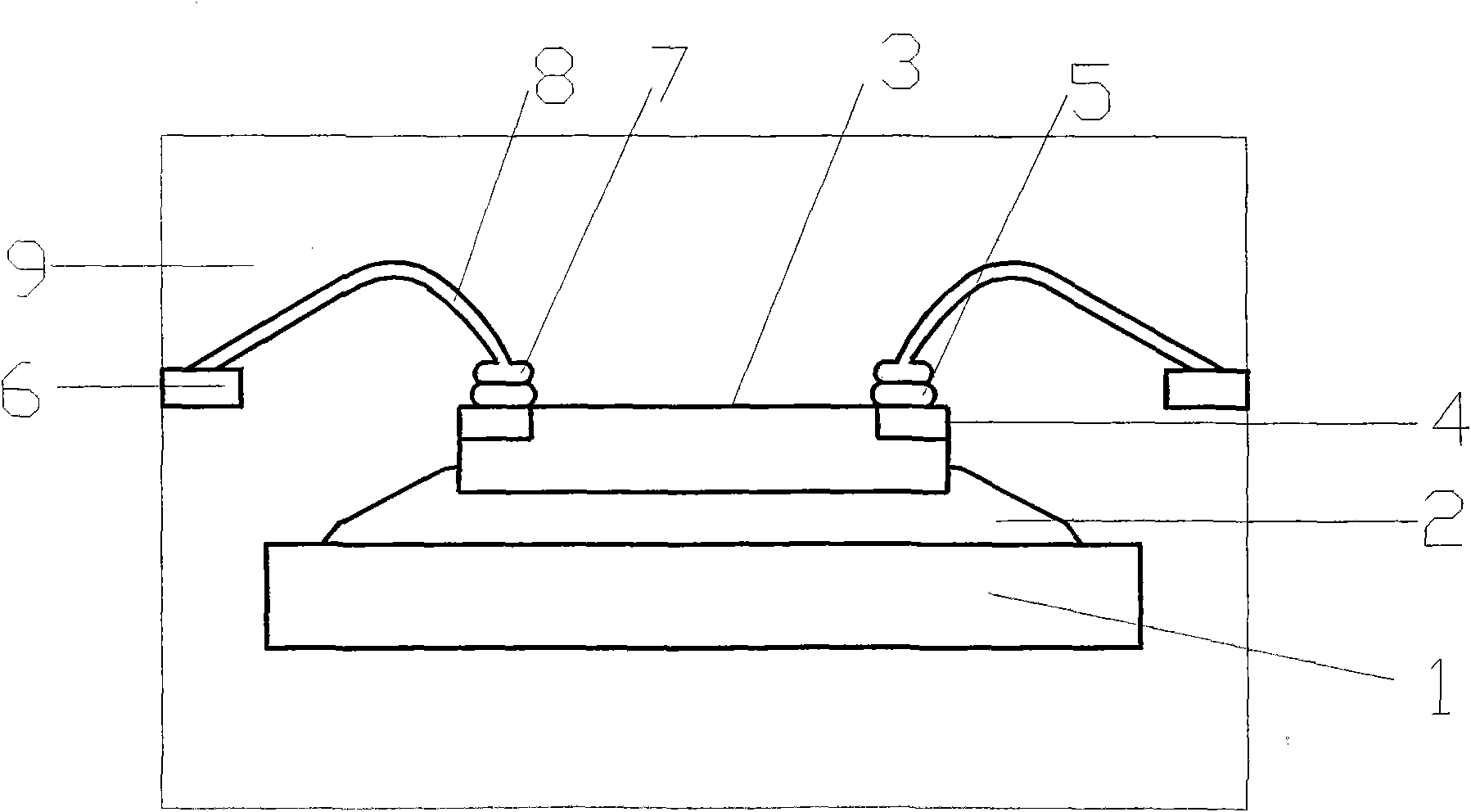

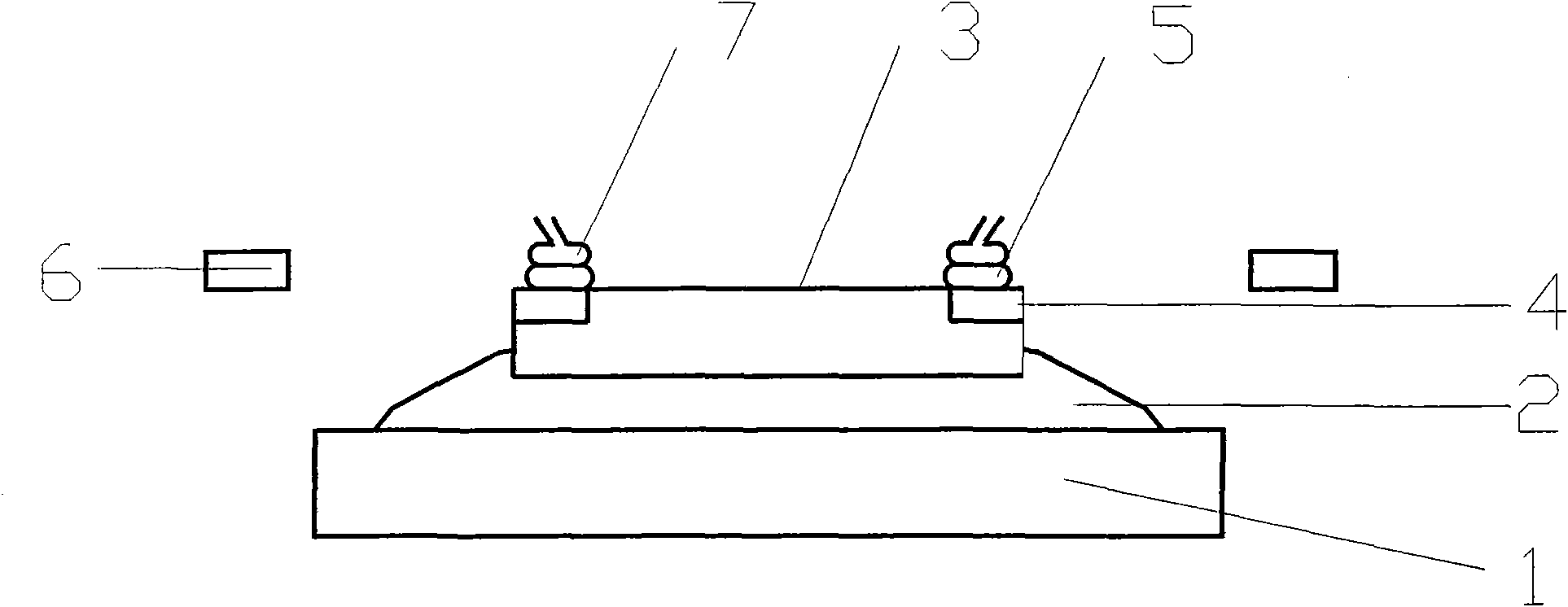

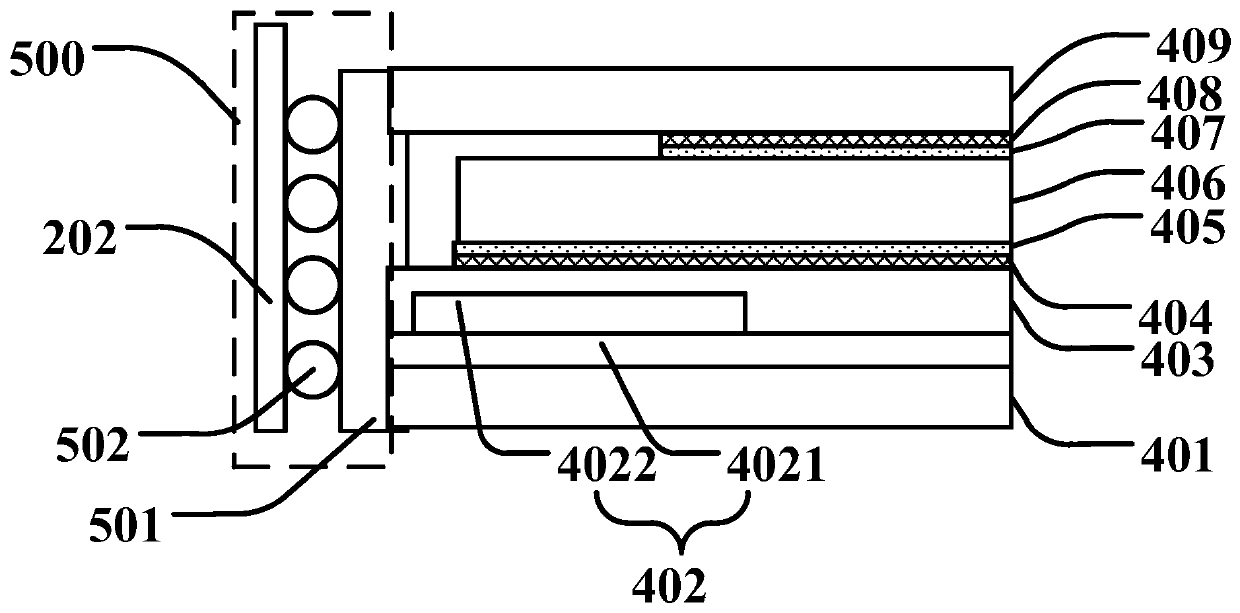

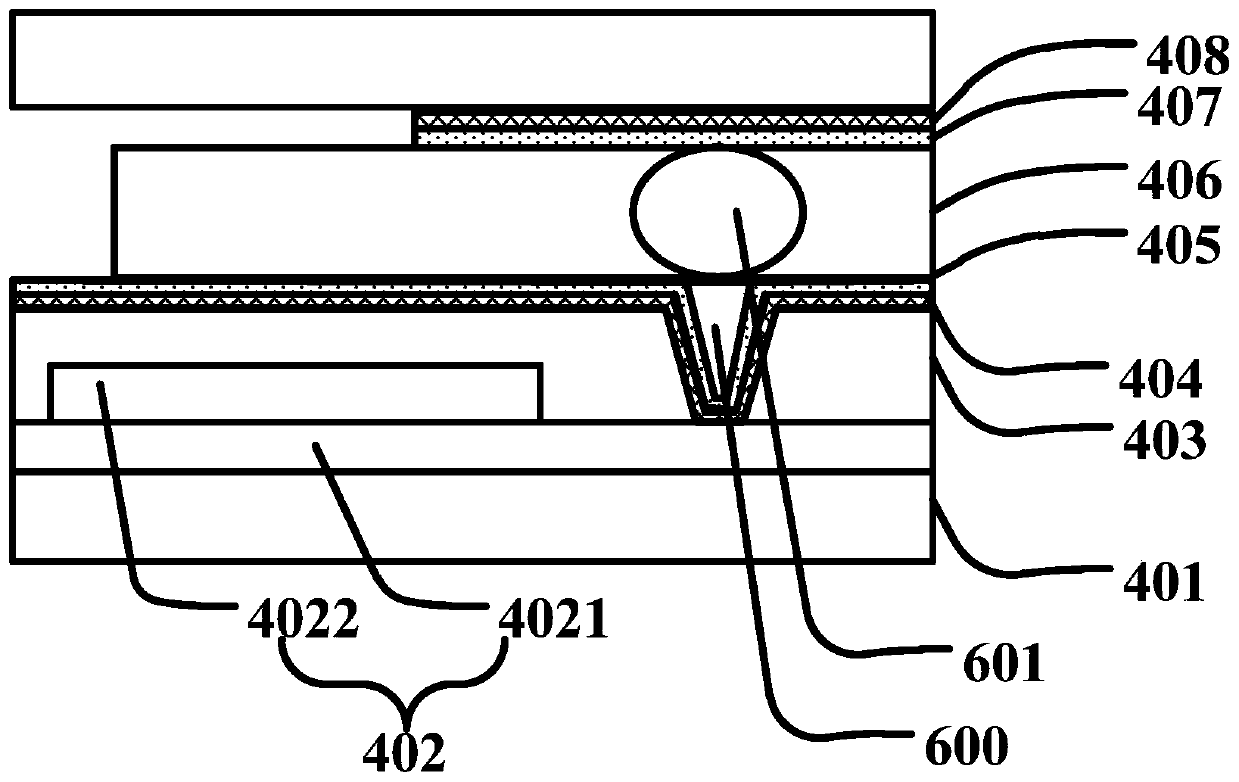

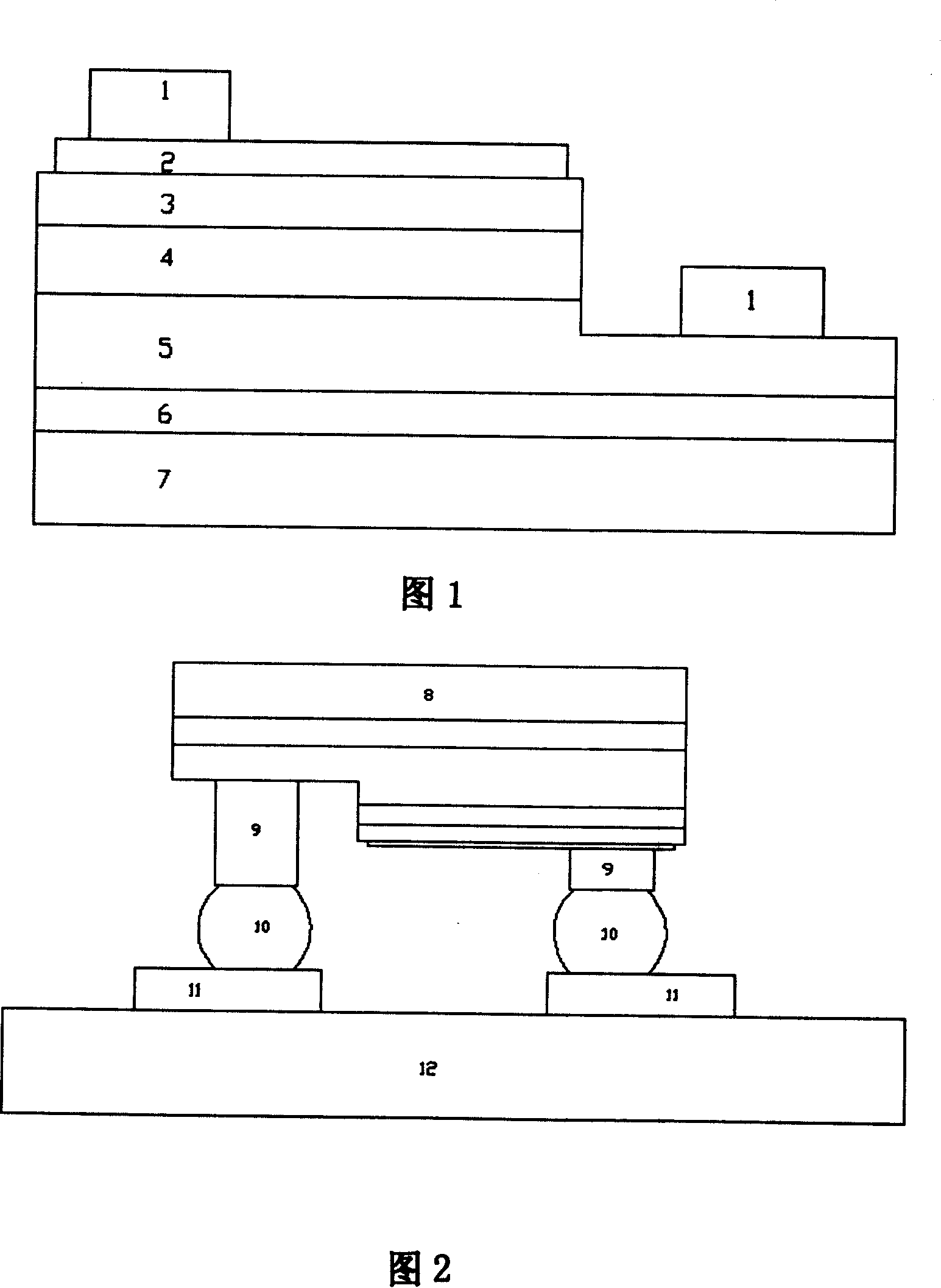

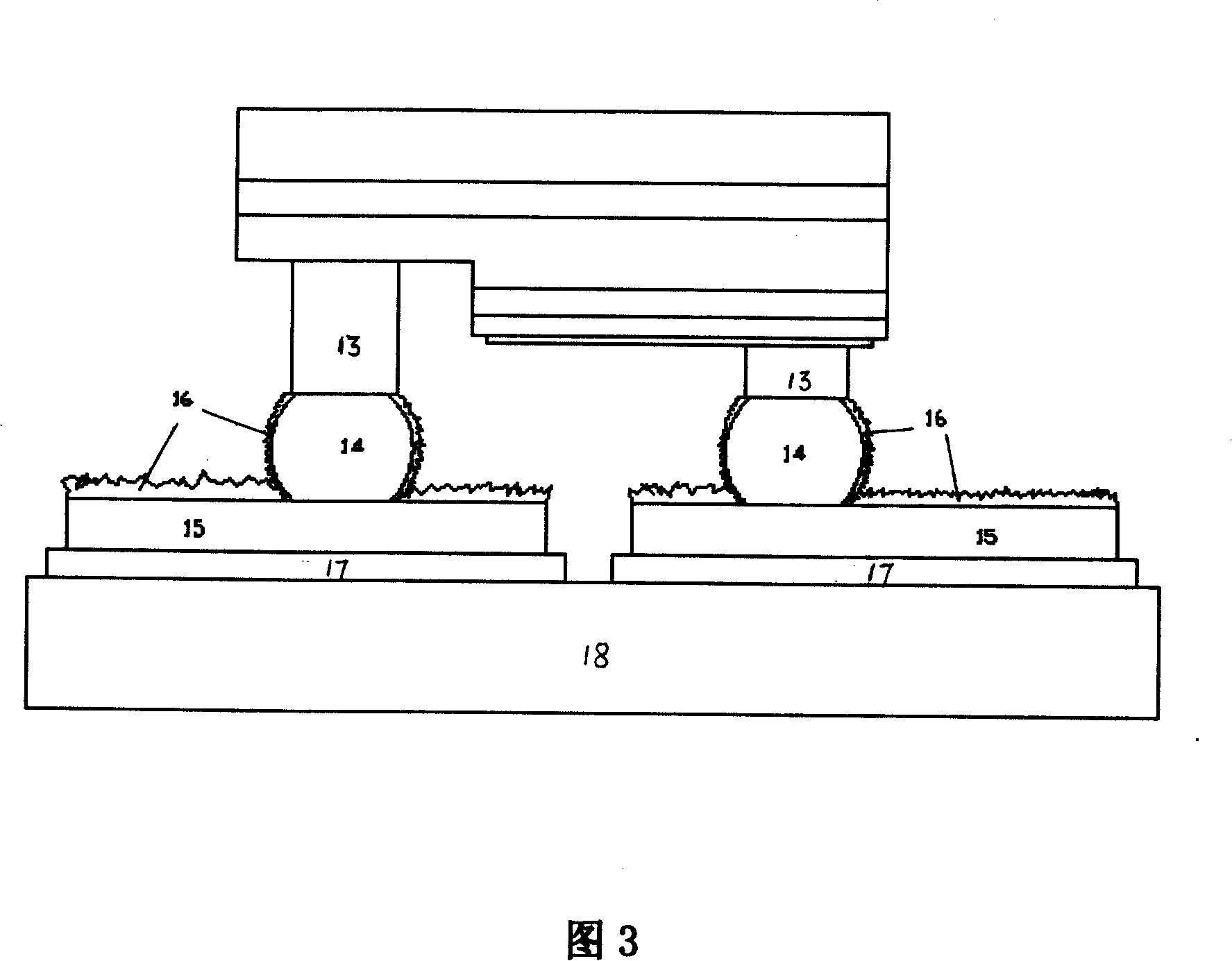

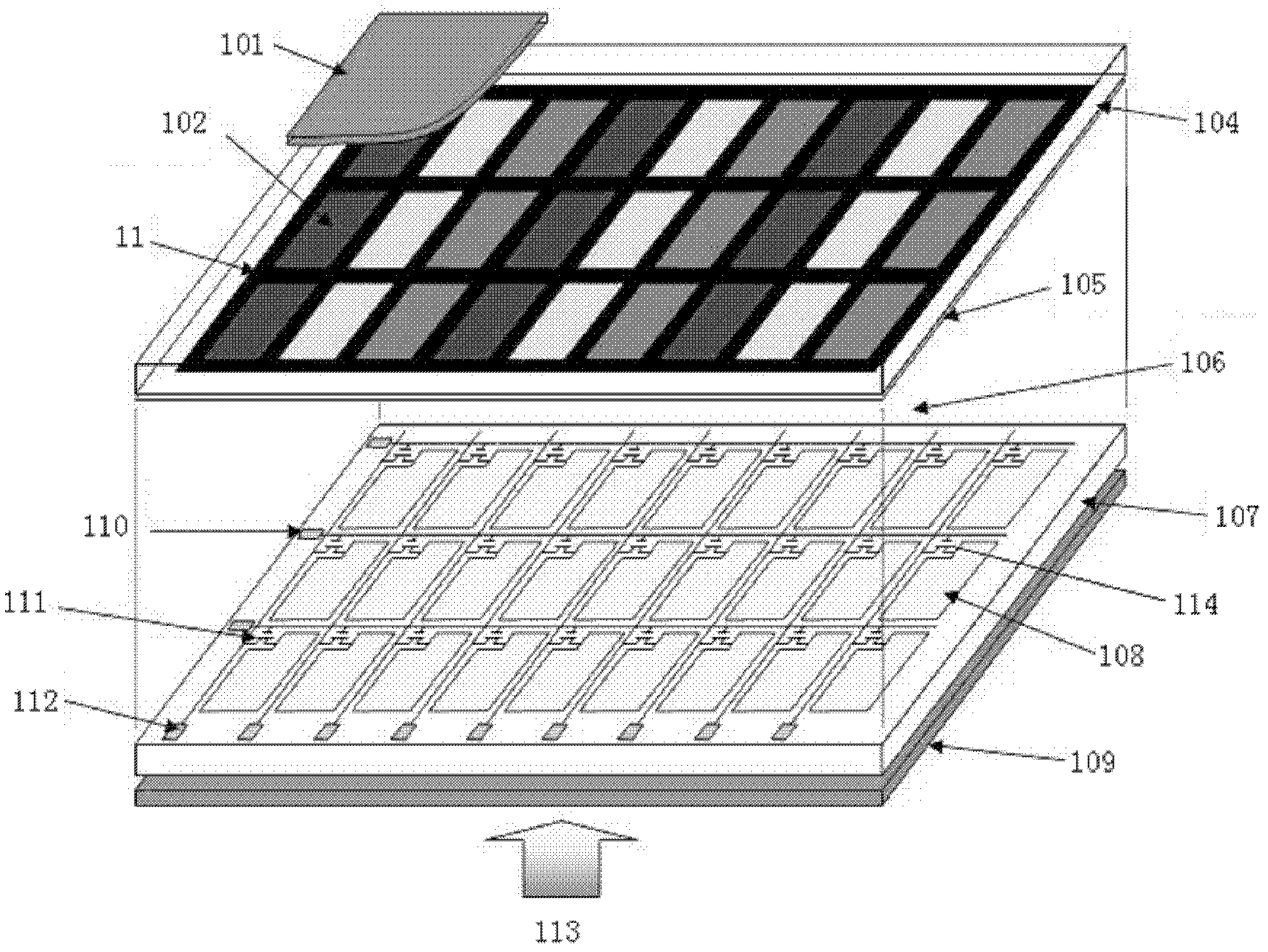

Gallium nitride-based inverted light-emitting diode (LED) with two reflecting layers on lateral surfaces and preparation method thereof

InactiveCN101872824AImprove reflective effectImprove light extraction efficiencySemiconductor devicesGold ballOhmic contact

The invention discloses a dual-reflecting layer gallium nitride-based inverted light-emitting diode (LED) with a distributed Bragg reflecting layer and a metal reflecting layer on lateral surfaces and a preparation method thereof. The preparation method comprises the following steps of: sequentially laminating and forming a buffer layer, a N-GaN layer, a multiple-quantum well layer and a P-GaN layer on a sapphire substrate; forming a transparent conducting layer on the P-GaN layer; covering the distributed Bragg reflecting layer on the lateral surfaces of an epitaxial layer and the transparent conducting layer; forming the metal reflecting layer on the distributed Bragg reflecting layer; forming a P electrode ohmic contact metal layer on an alloy metal reflecting layer; forming a N electrode ohmic contact metal layer on the exposed N-GaN layer; and bonding the P electrode ohmic contact metal layer and the N electrode ohmic contact metal layer with a heat radiating substrate through an alloy metal conducting layer and gold ball bonding points. A dual-reflection structure combining the distributed Bragg reflecting layer and the metal reflecting layer is arranged on the oblique lateral surface of an LED chip, thereby the excellent reflectivity of the reflecting layers is fully performed and the light-emitting efficiency of the LED is improved.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

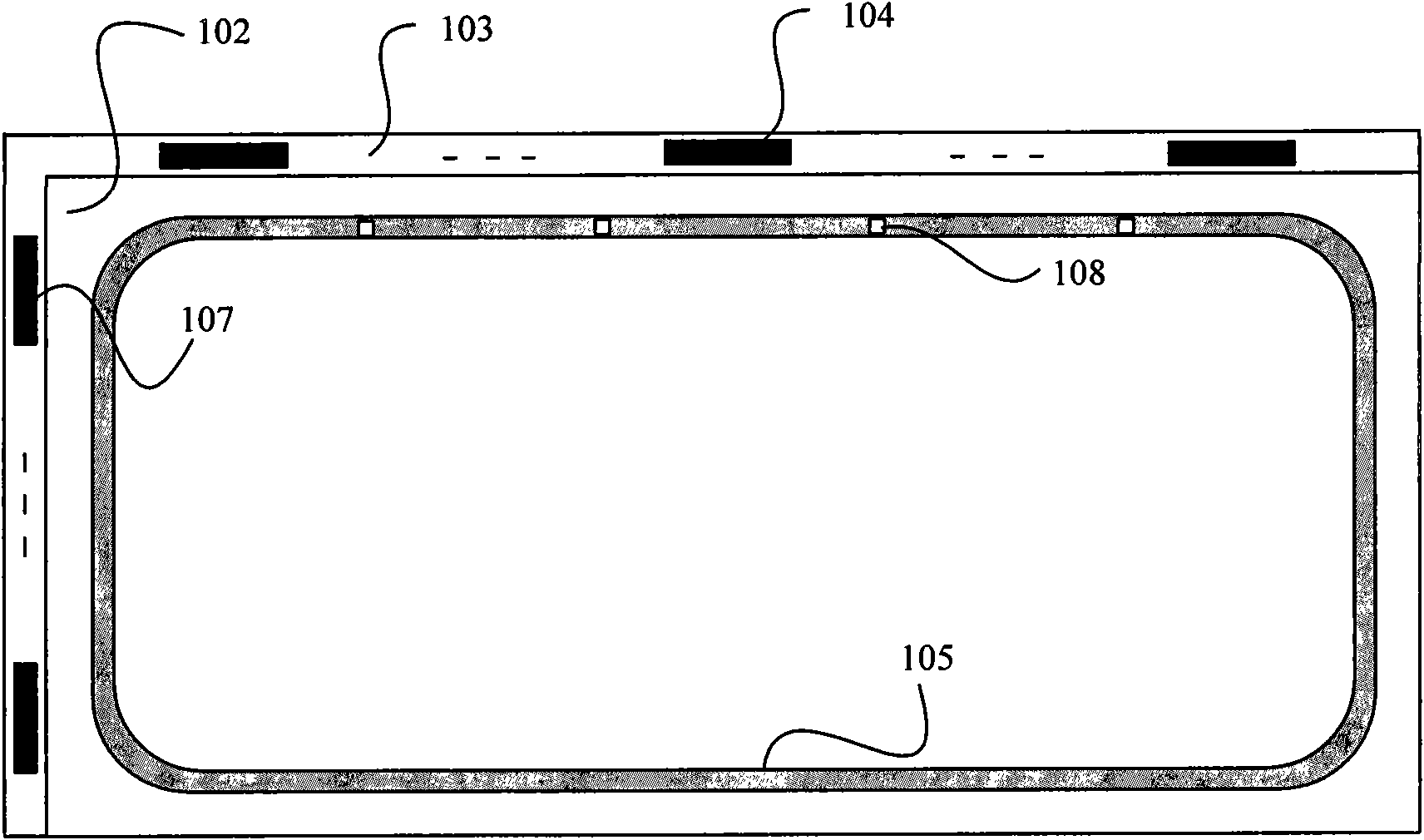

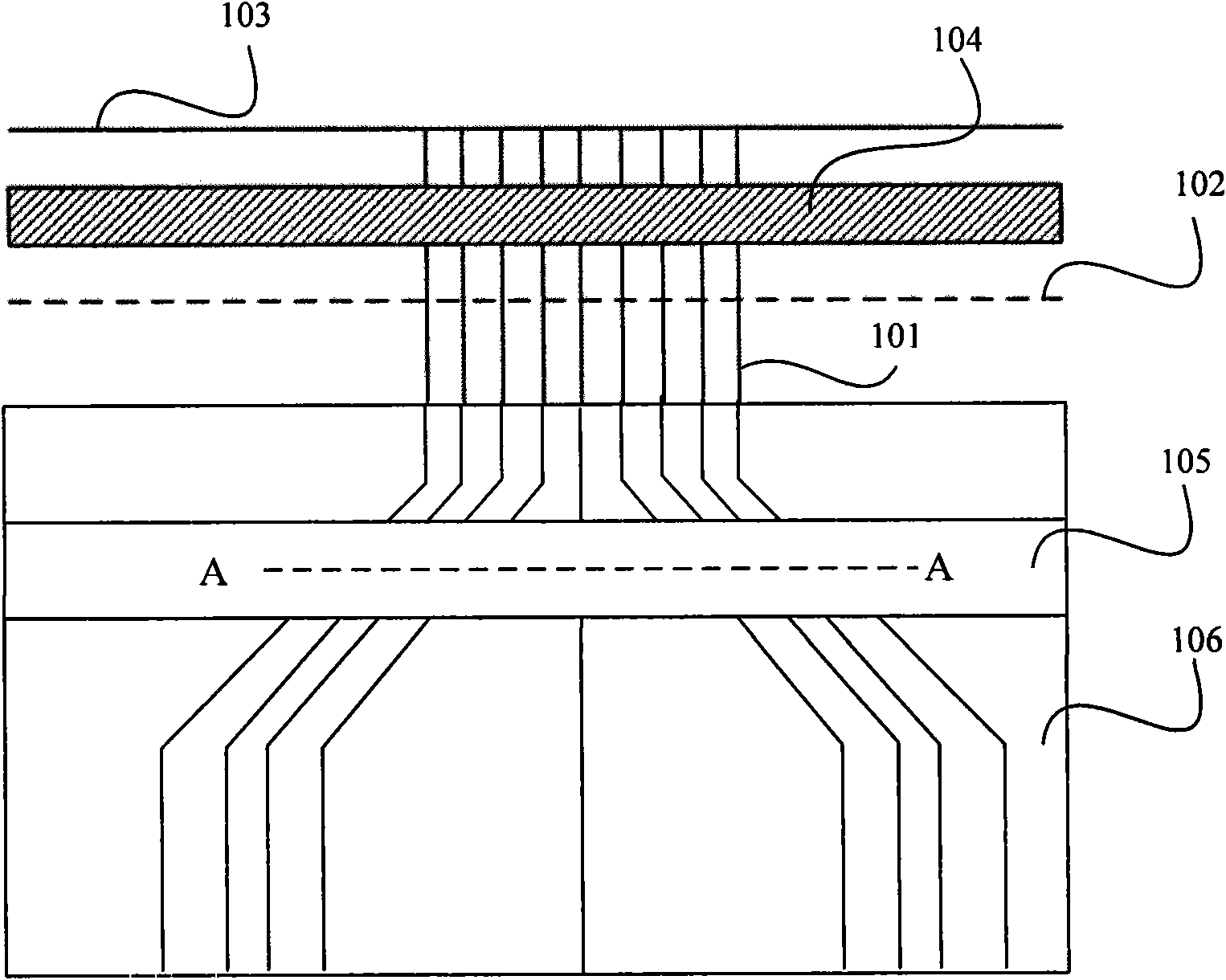

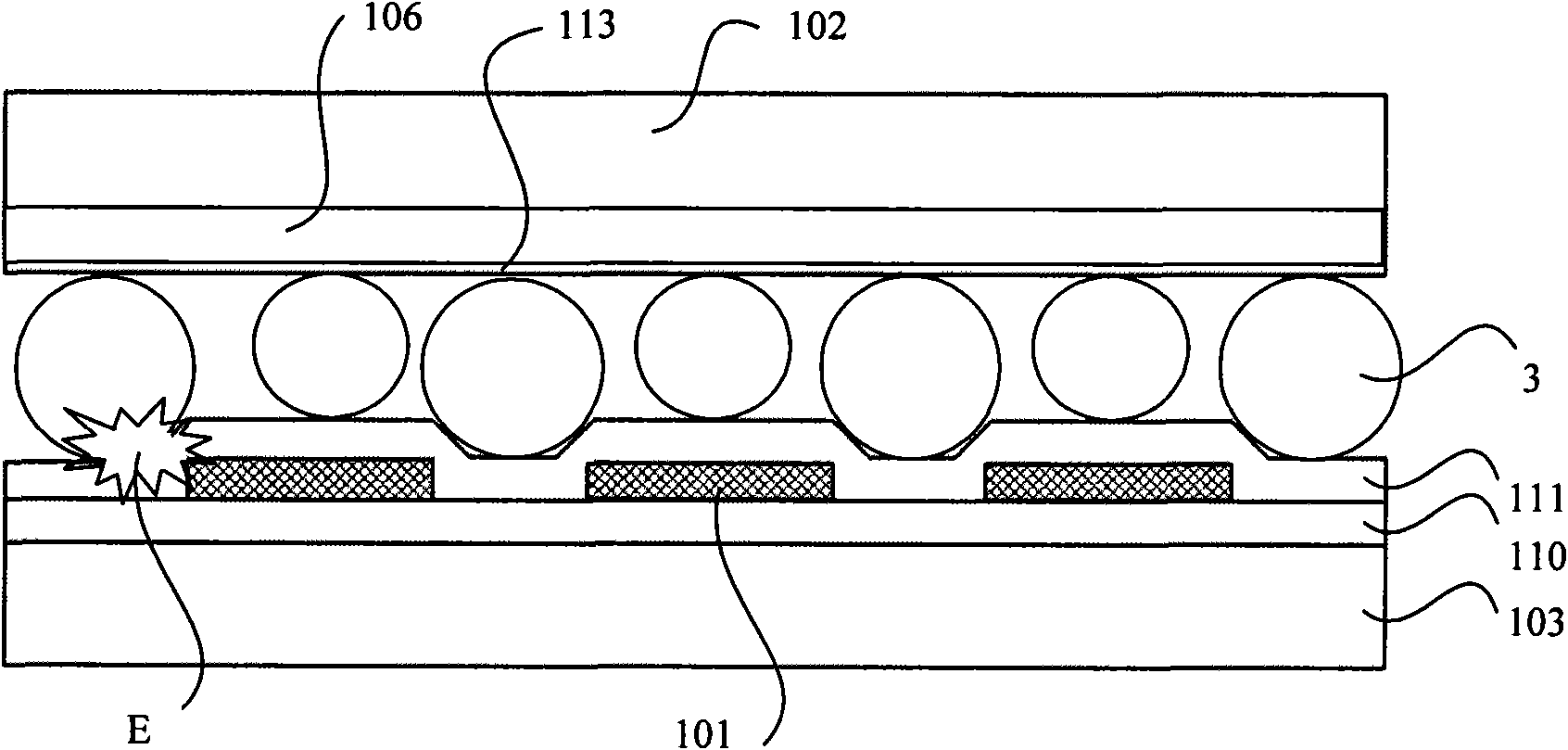

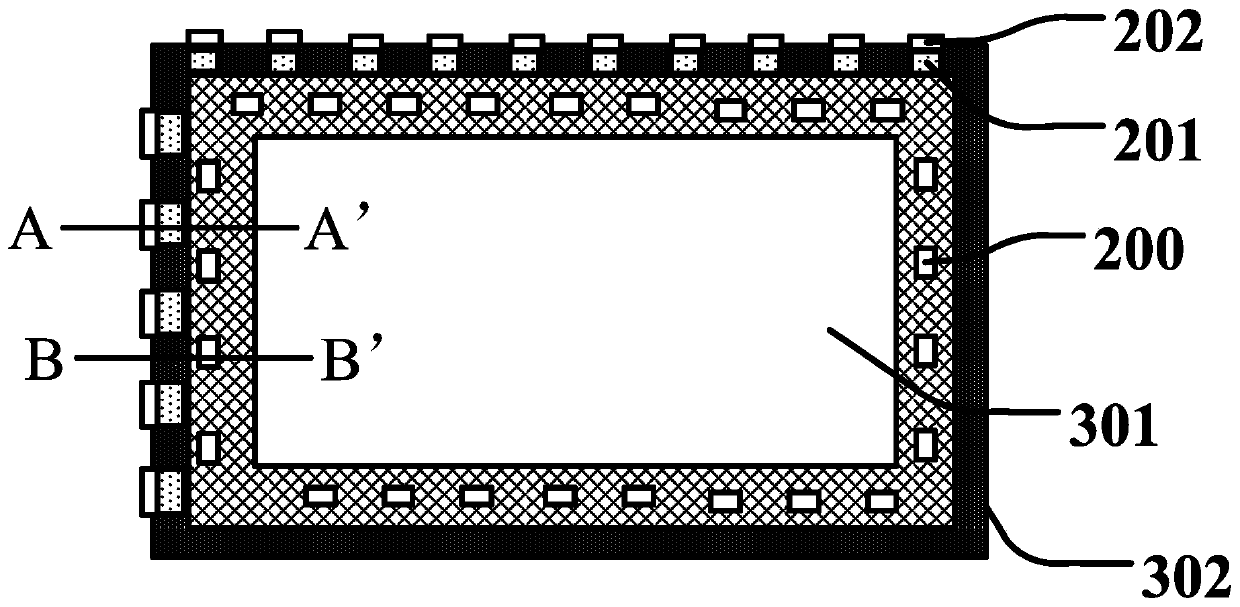

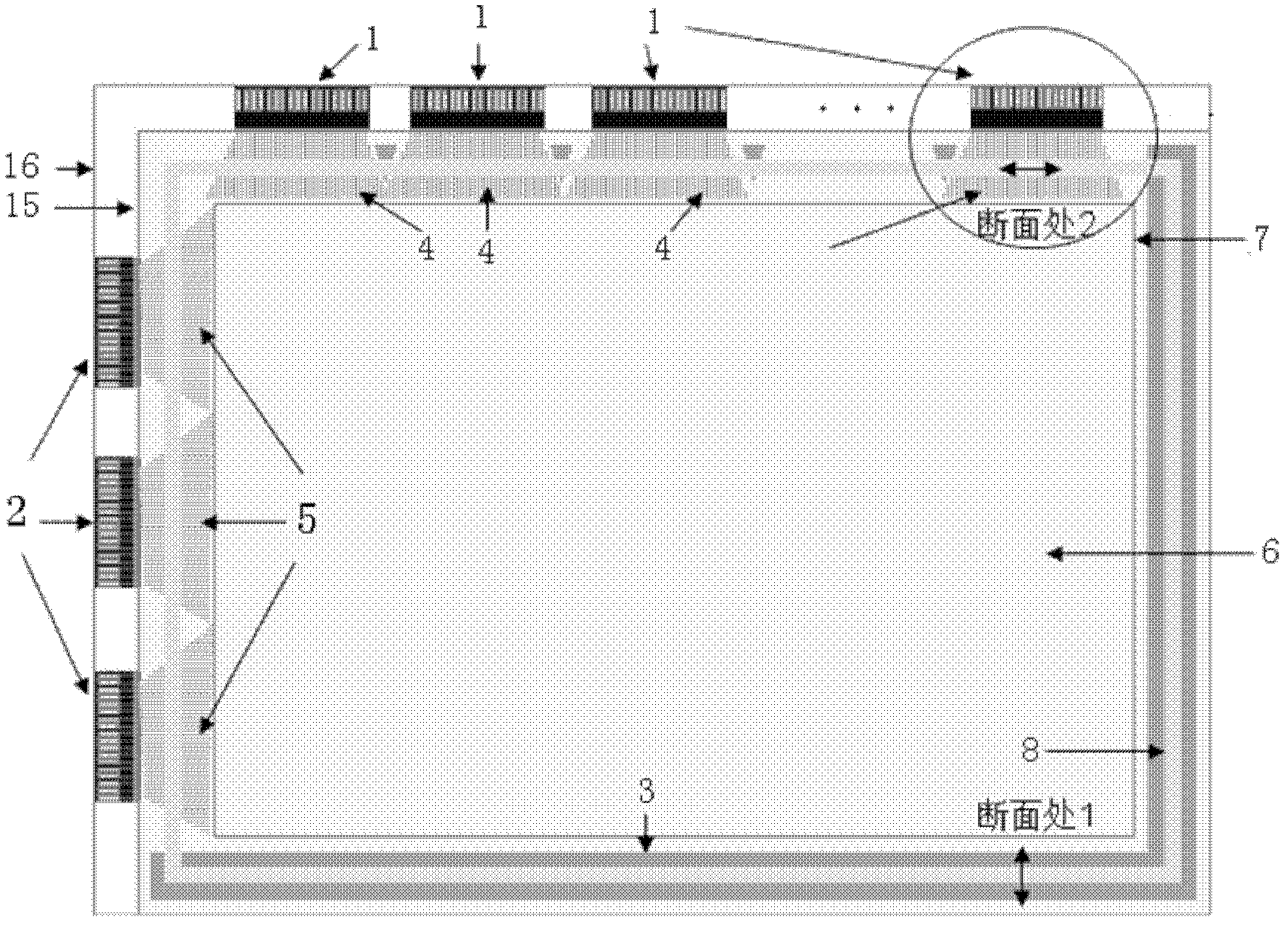

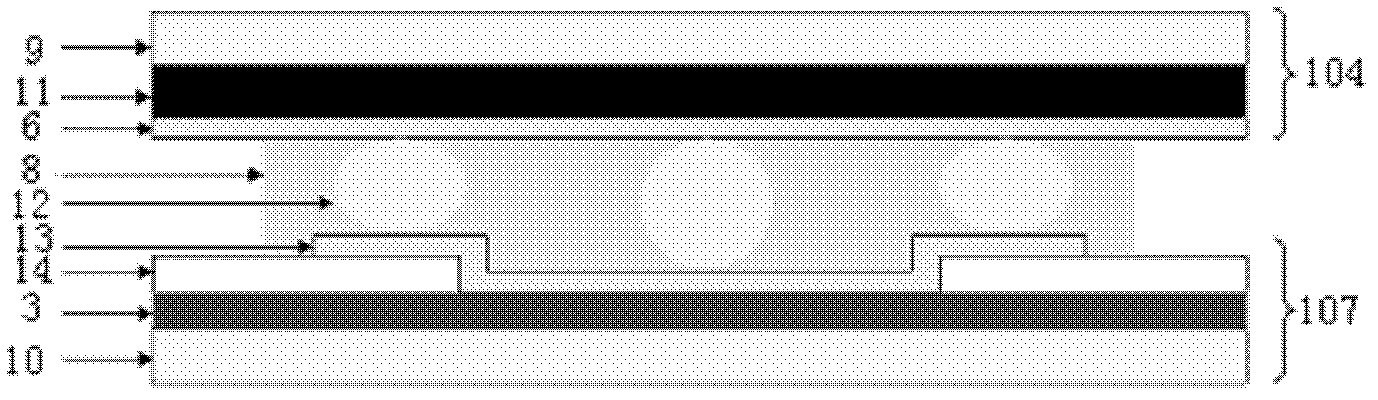

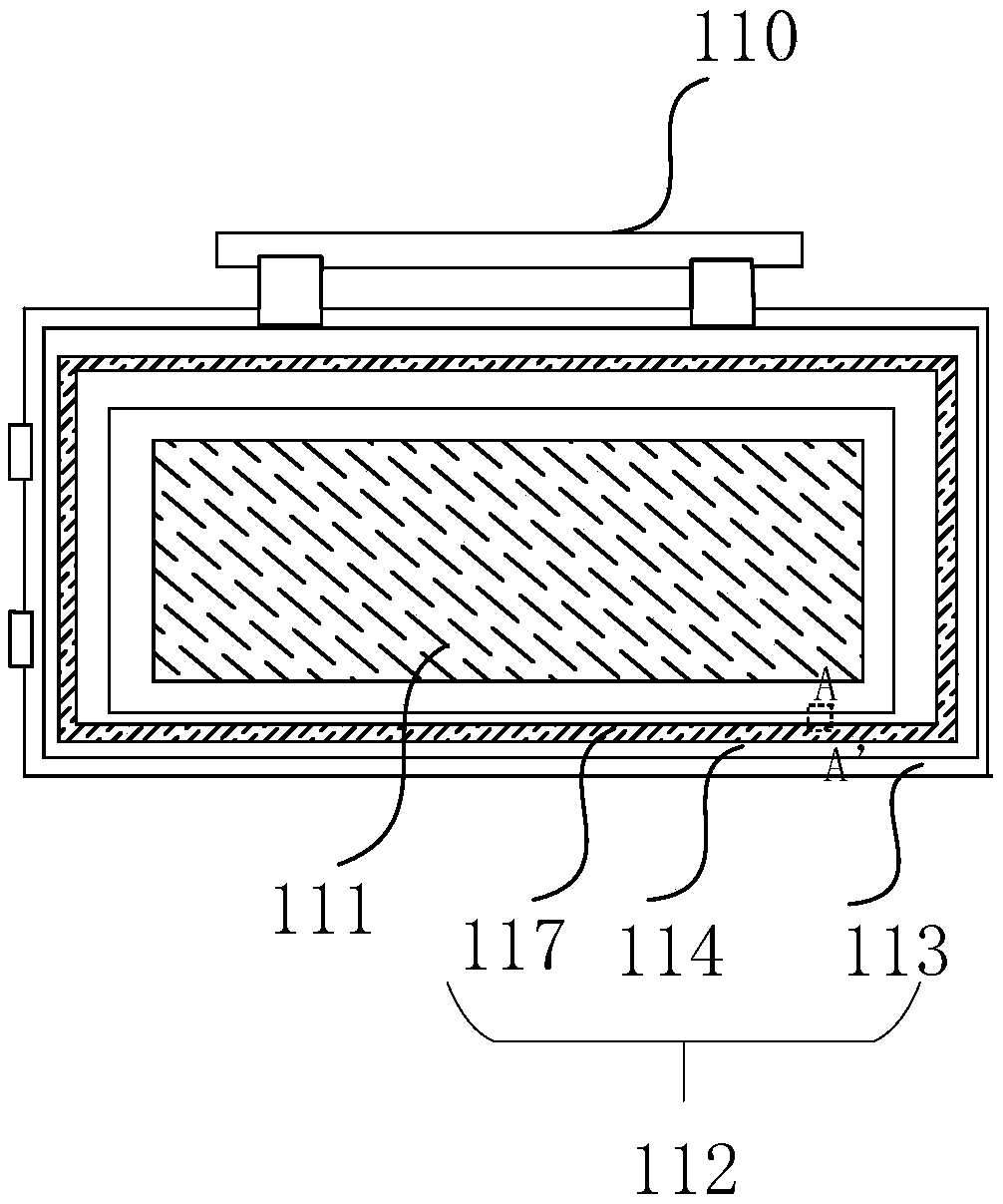

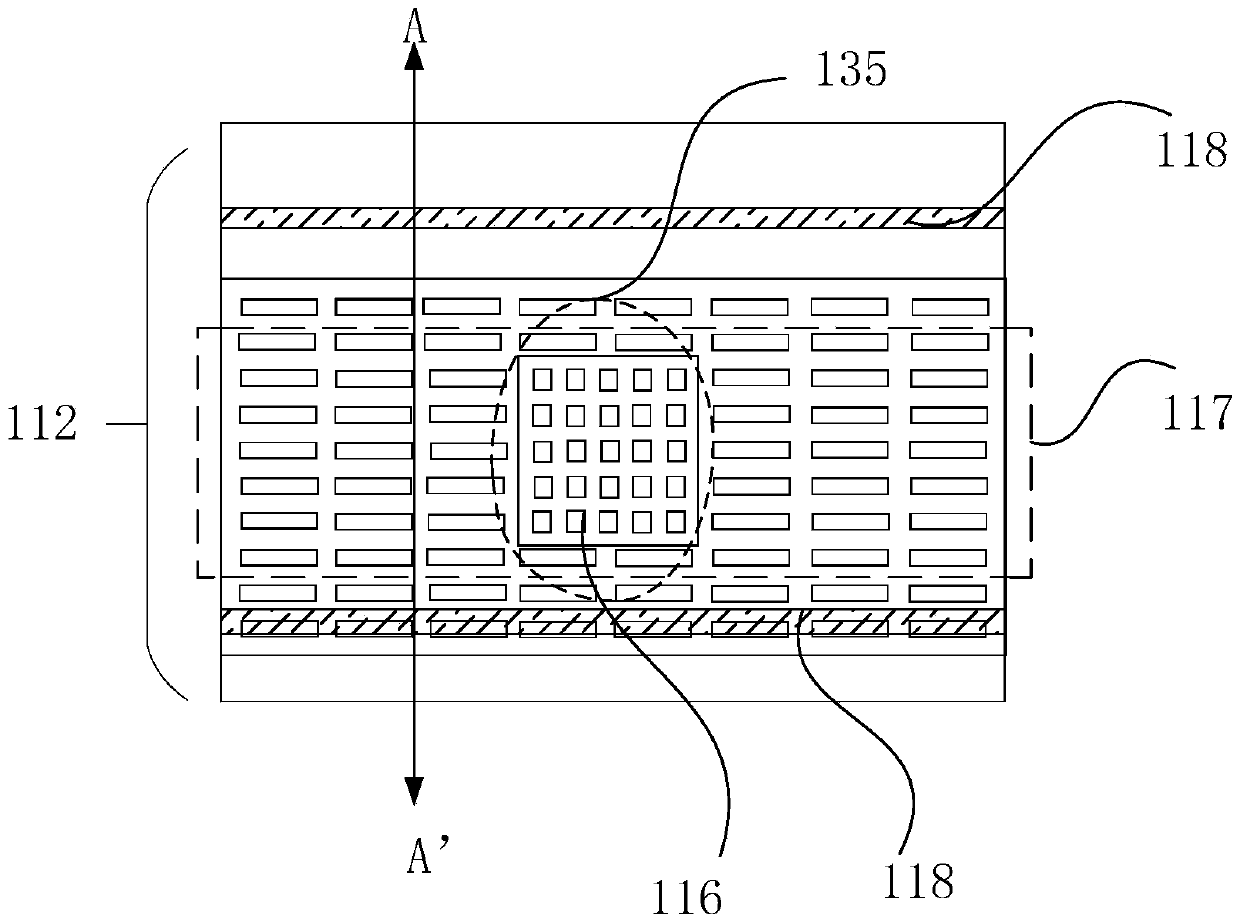

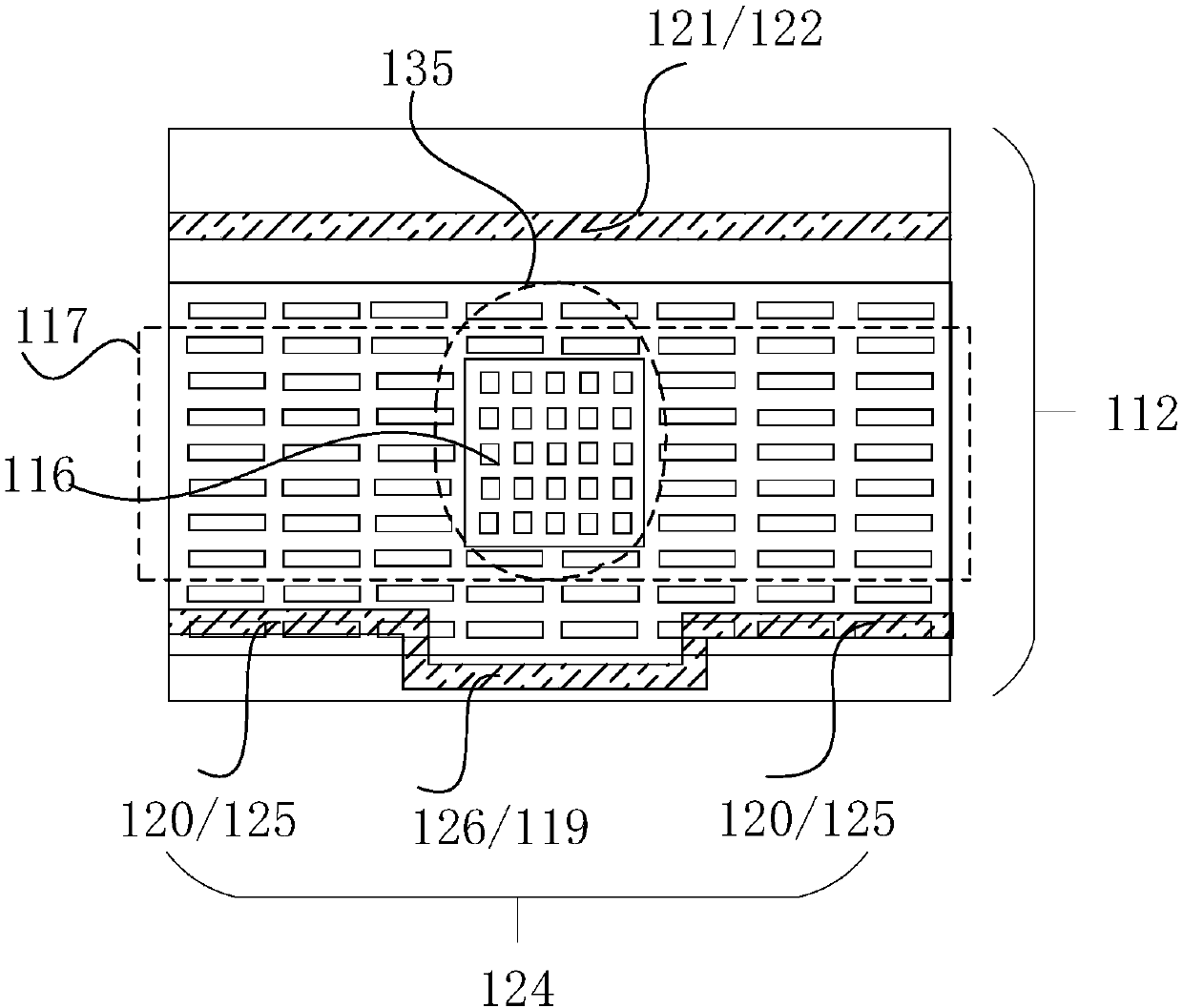

Panel and manufacturing method thereof

The invention relates to a panel and a manufacturing method thereof, wherein, the manufacturing method of the panel comprises the following steps: finishing the manufacturing of film transistor arraysand peripheral graphs on a substrate to form an array substrate; coating main frame sealing glue in which no golden ball is doped at the periphery of the array substrate; coating secondary frame sealing glue in which golden balls are doped outside of the main frame sealing glue, wherein the secondary frame sealing glue is partly overlapped with or completely separated from the main frame sealingglue, and is positioned in the connecting electrode area of the array substrate but keeps away from the lead wire area of data lines; and aligning the array substrate and a color-film substrate to form the panel. To the panel and the manufacturing method thereof, due to the absence of golden balls in the lead wire area of the date lines, ESD can not occur, simultaneously golden balls are only doped in the secondary frame sealing glue, the usage amount of golden balls is greatly reduced, thereby lowering the cost of the panel.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

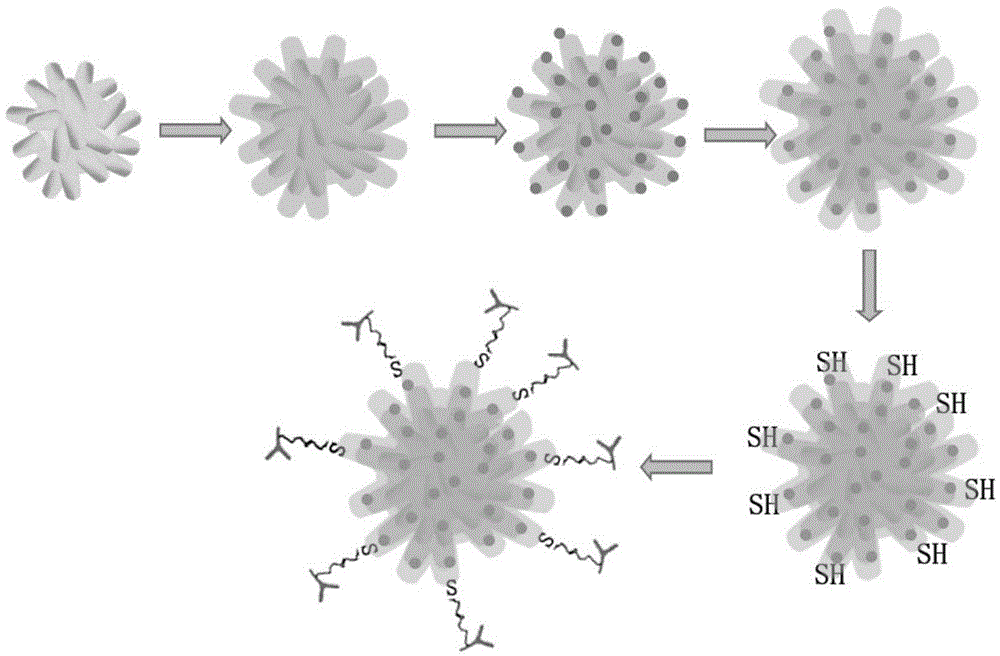

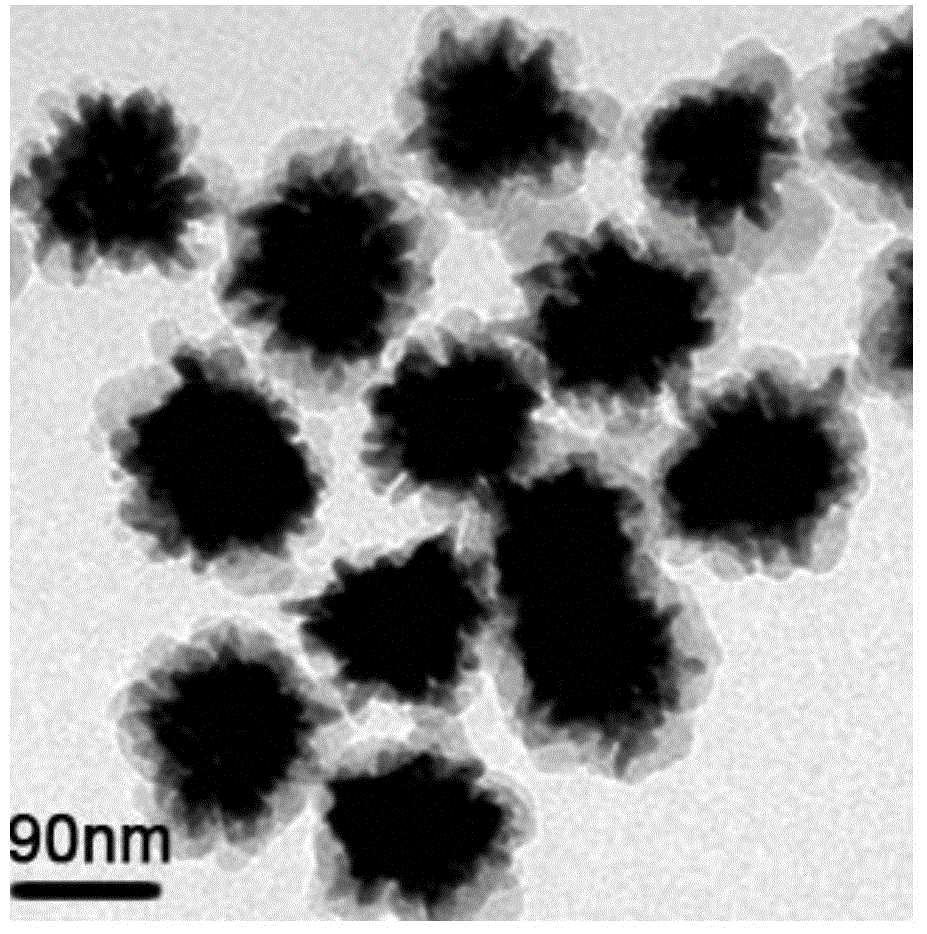

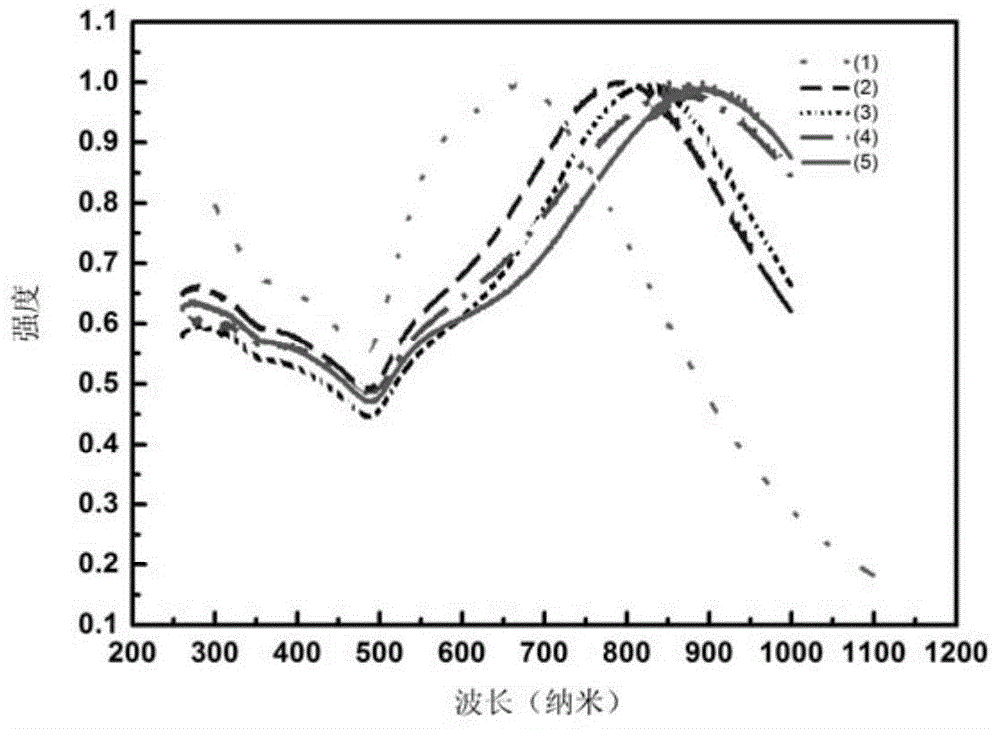

Gold nanoparticle flower or quantum dot composite probe for living cell immunofluorescent labeling and photothermal treatment

InactiveCN104416152AImprove stabilityEffective orientationMaterial nanotechnologyPowder deliveryHigh concentrationGold ball

The present invention provides are a gold nanoflower structure and a preparation method therefor. The gold nanoflower structure is a gold nanoflower particle, with round-head columns being uniformly distributed at the periphery thereof, obtained by using gold octahedrons, gold balls or gold tetrahedrons as seed crystals and reducing chloroauric acid by using weak reductant in an environment of high-concentration polyvinylpyrrolidone. In addition, also provided in the present invention are a gold nanoflower / quantum dot composite probe for living cell immunofluorescent labeling and photothermal therapy, a preparation method therefor and a use thereof. In comparison with traditional probes, the probe, incorporates the features of photothermal therapy and fluorescent labeling, and is capable of killing cancer cells in an effective and directional way. Two light sources are adopted to bring a tremendous photothermal conversion efficiency and a greater enhancement on fluorescence intensity of quantum dots respectively, thus mutual interference of two effects are avoided tactfully. The coating of silicon dioxide averts the biotoxicity of the gold nanoflower and the quantum dot effectually, enabling the surface of the composite probe to be easily functionalized and also imparting an extraordinarily excellent biocompatibility to the composite probe.

Owner:THE FIRST AFFILIATED HOSPITAL OF ANHUI MEDICAL UNIV

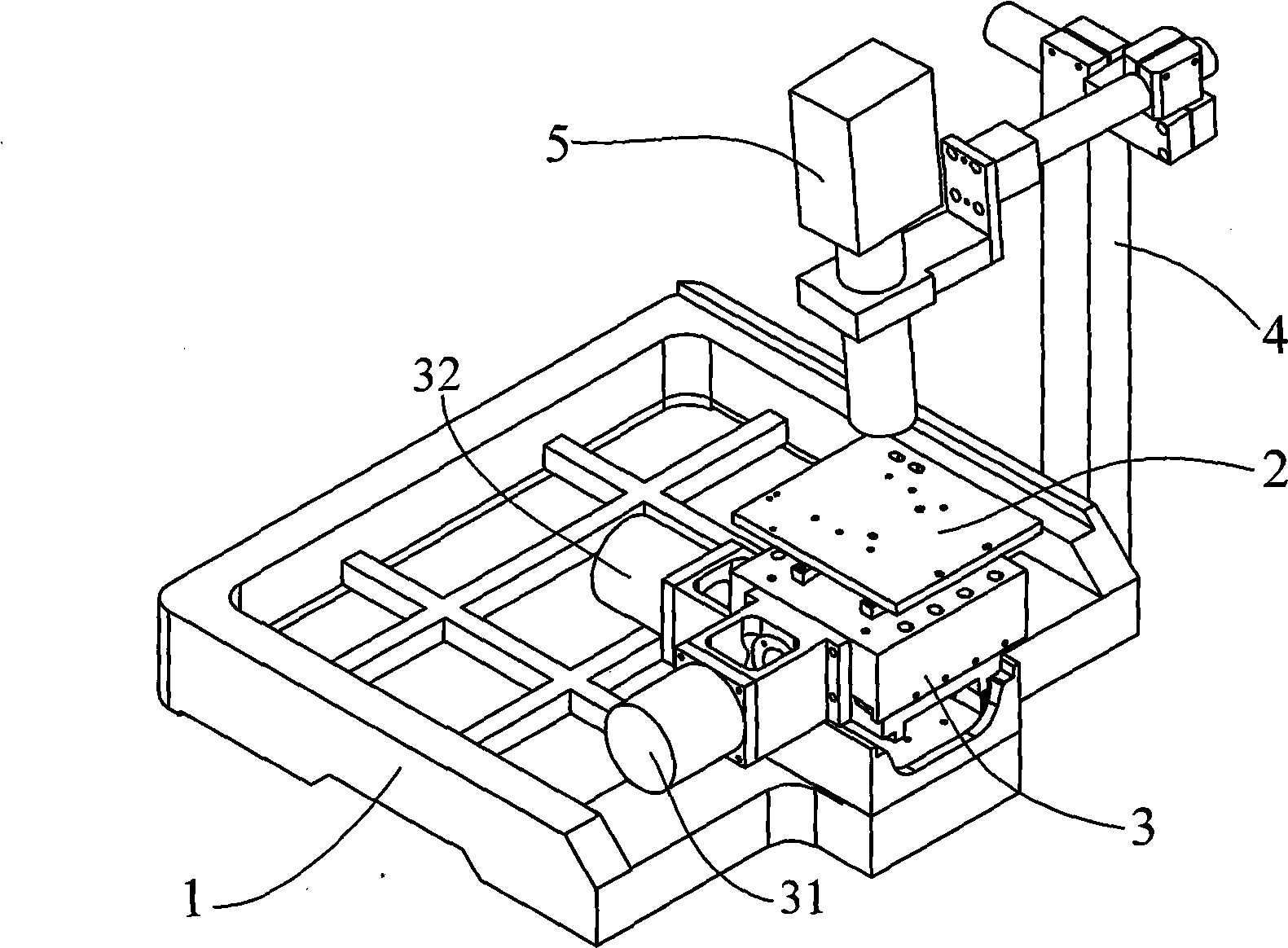

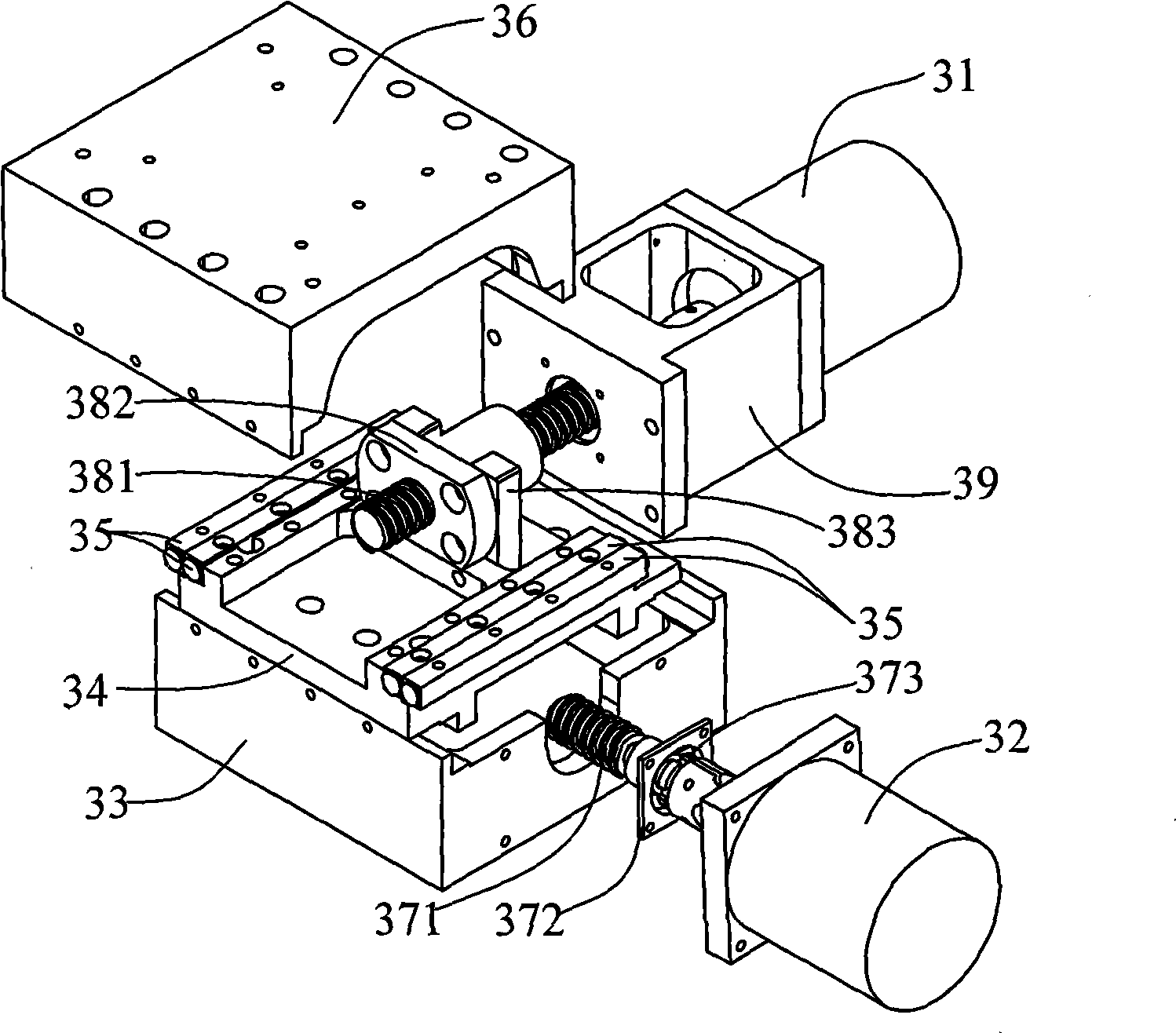

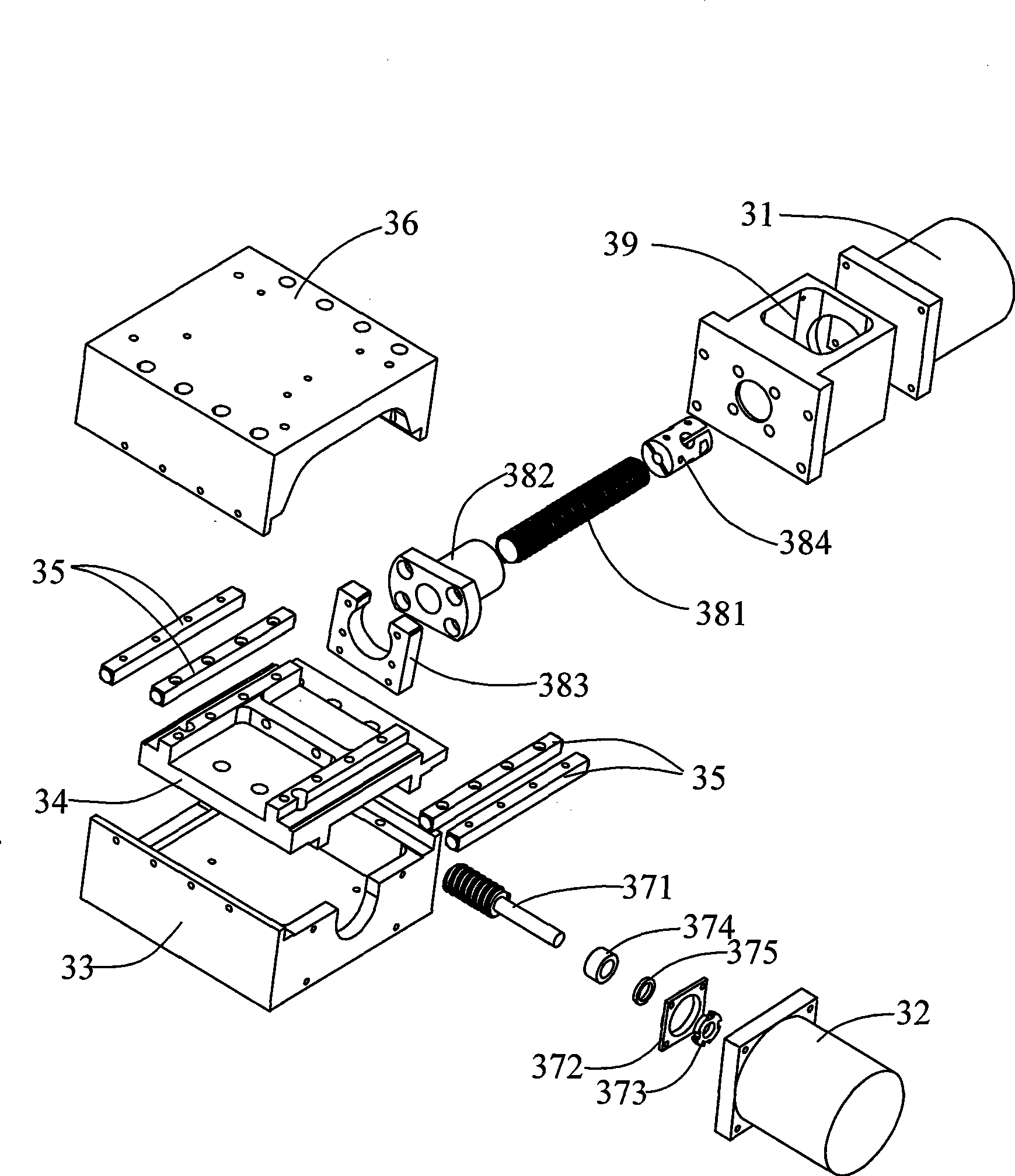

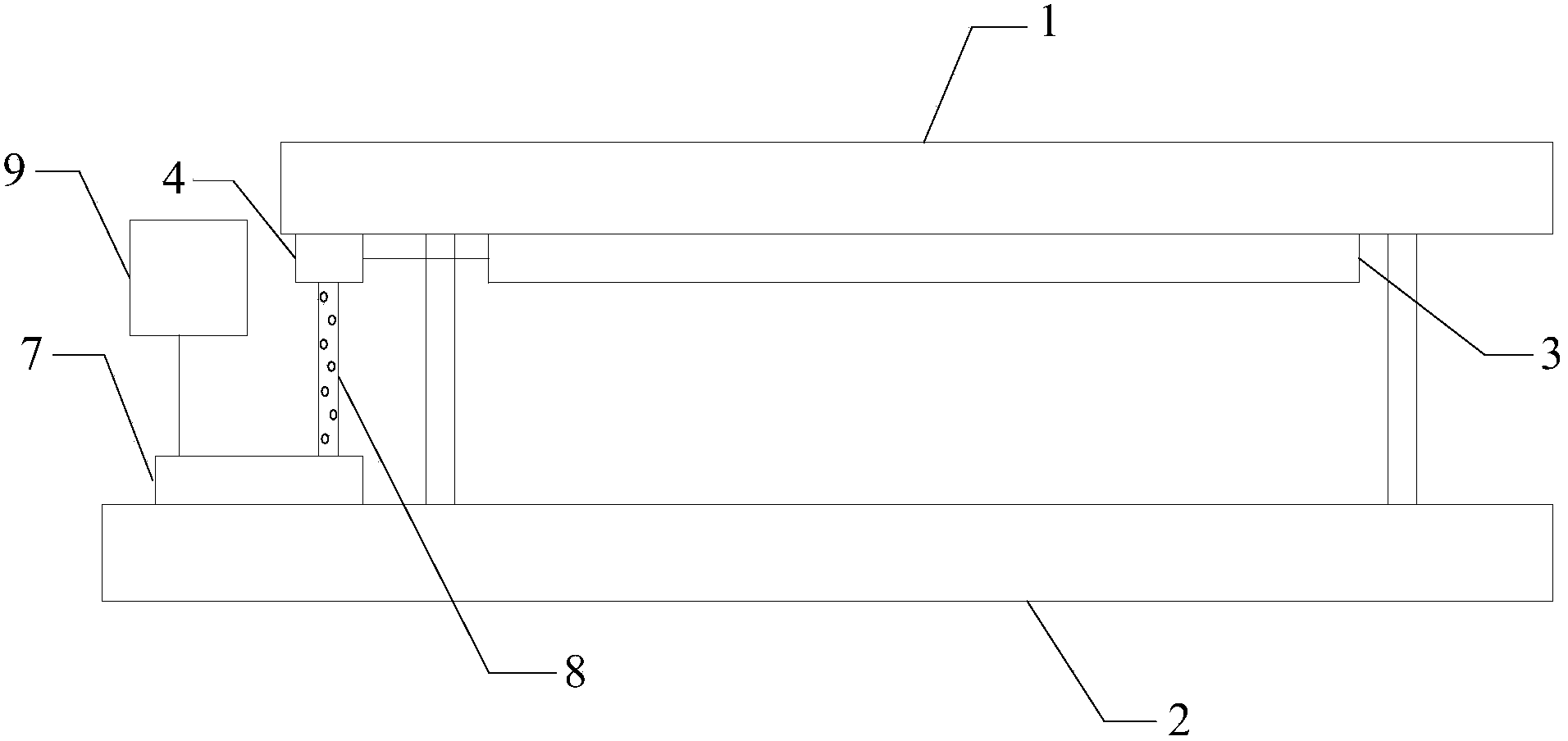

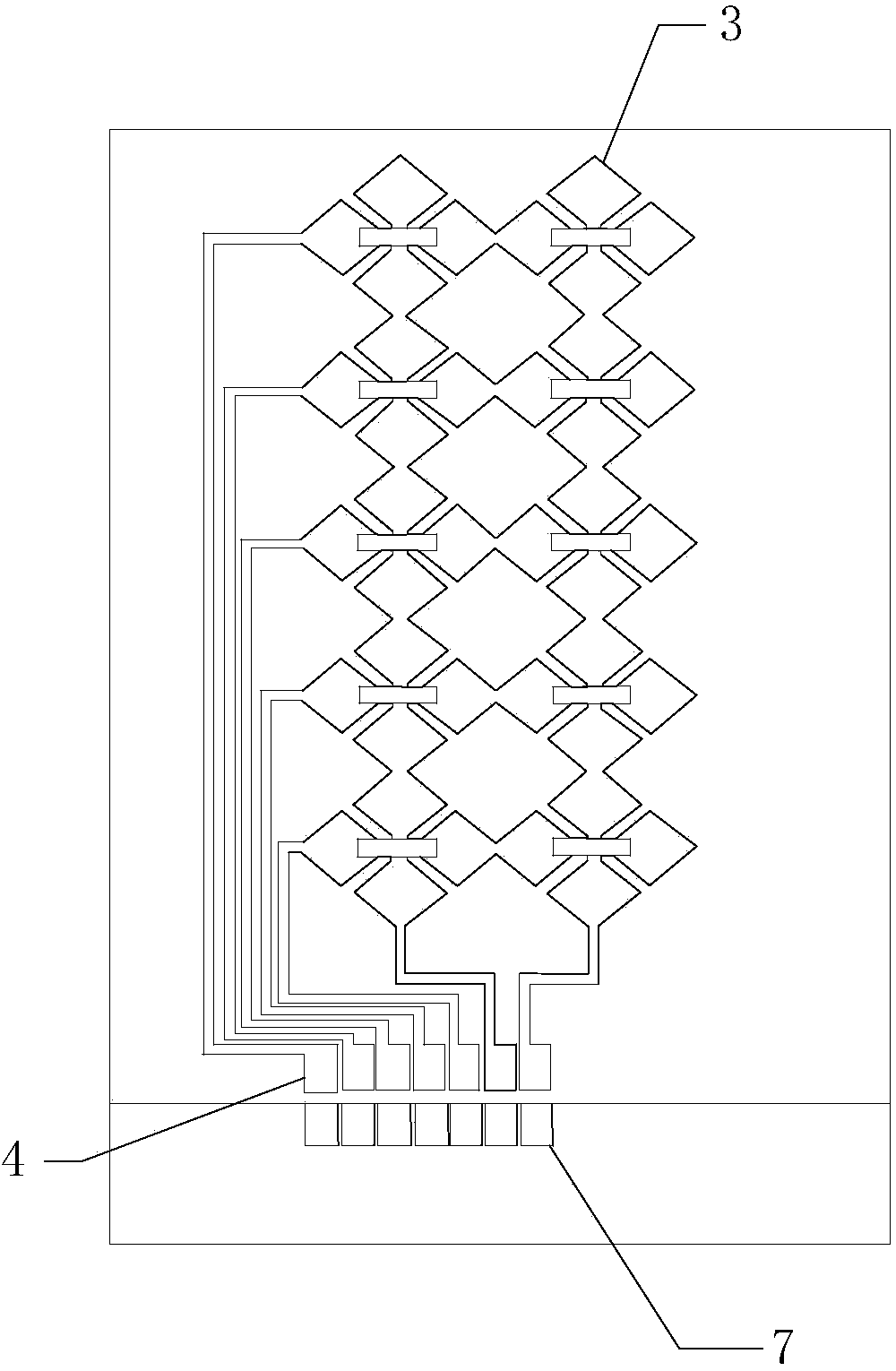

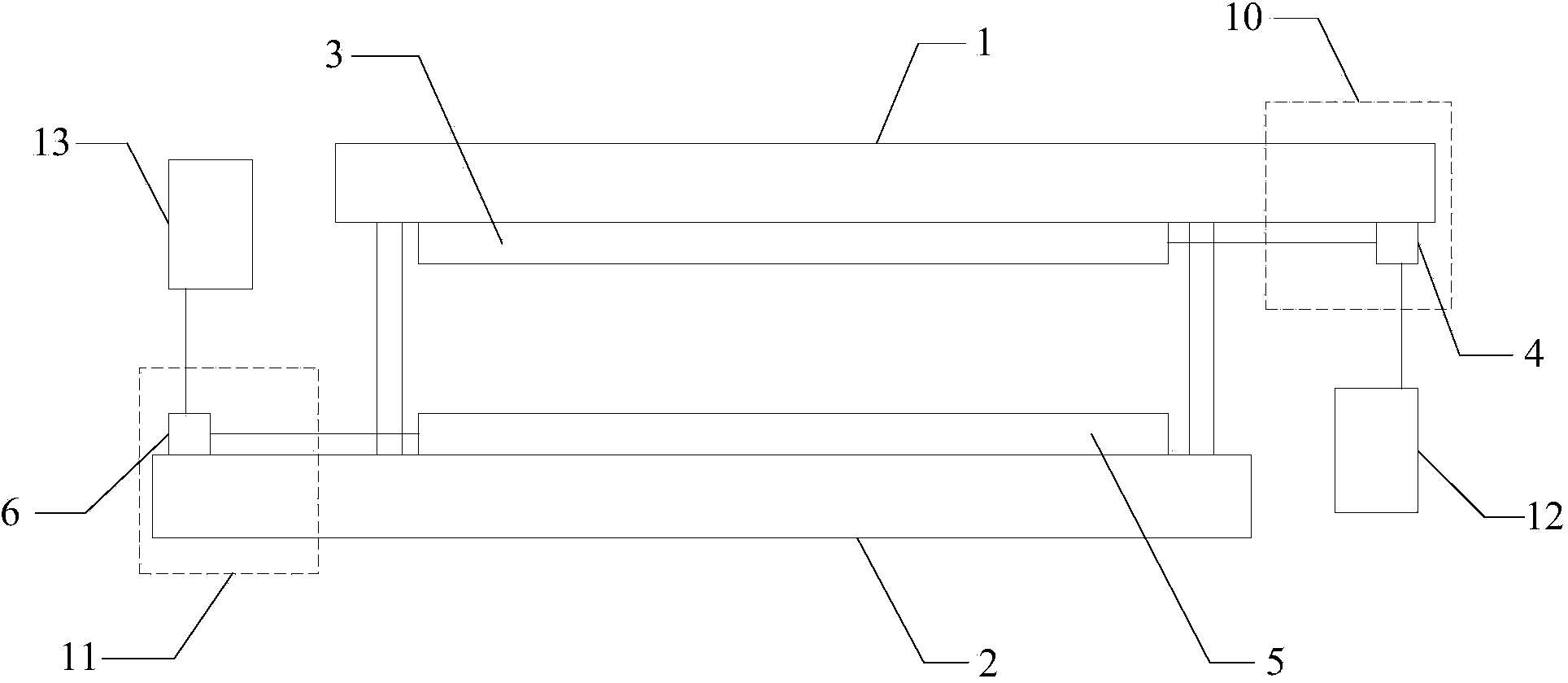

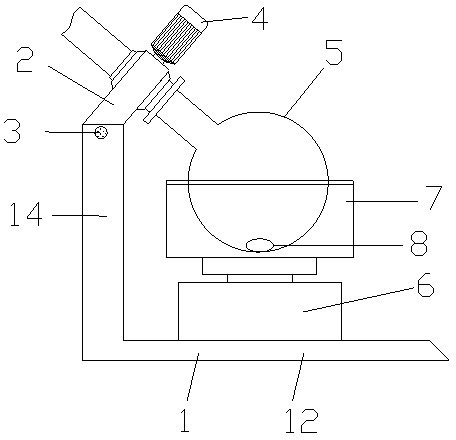

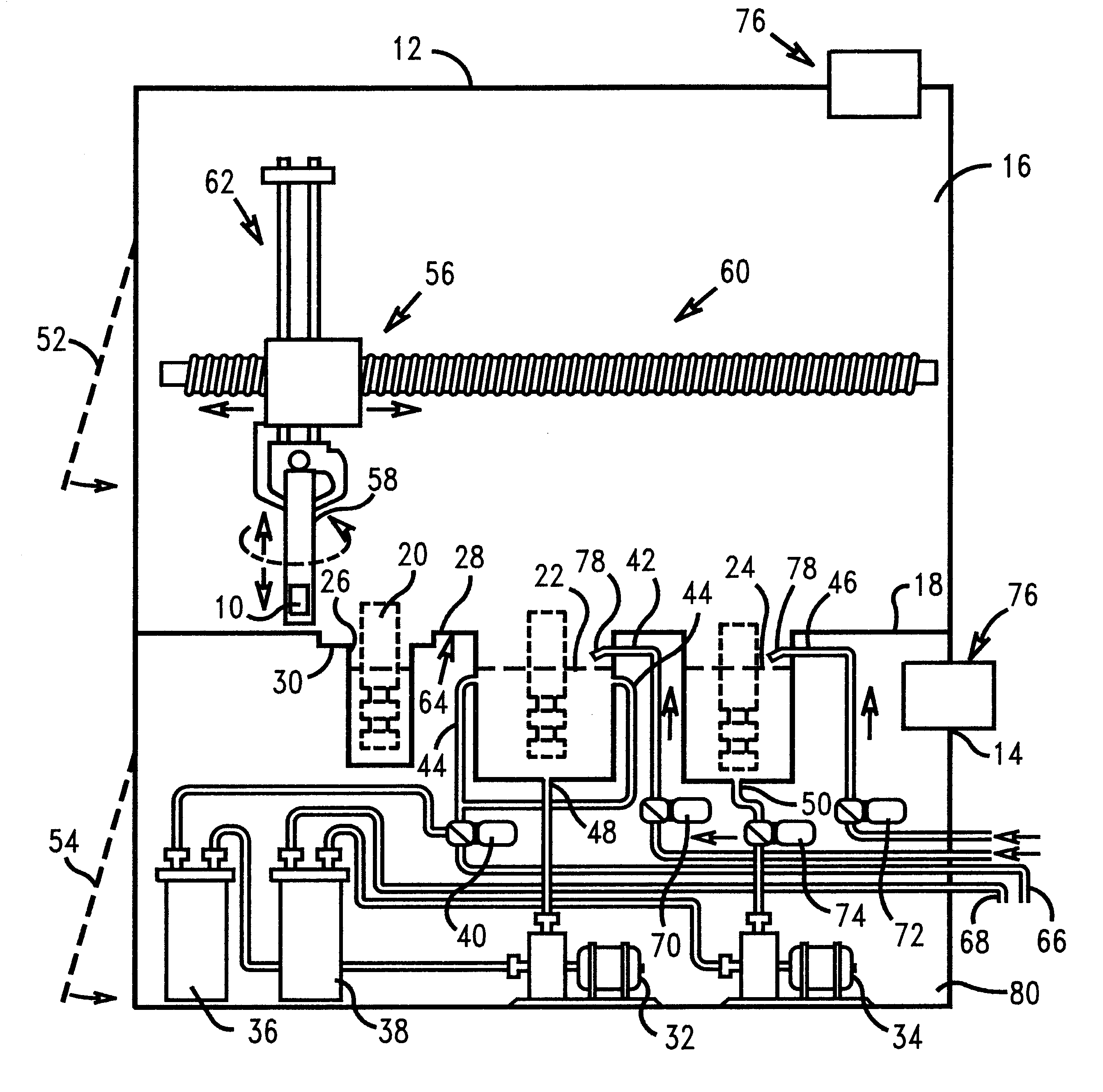

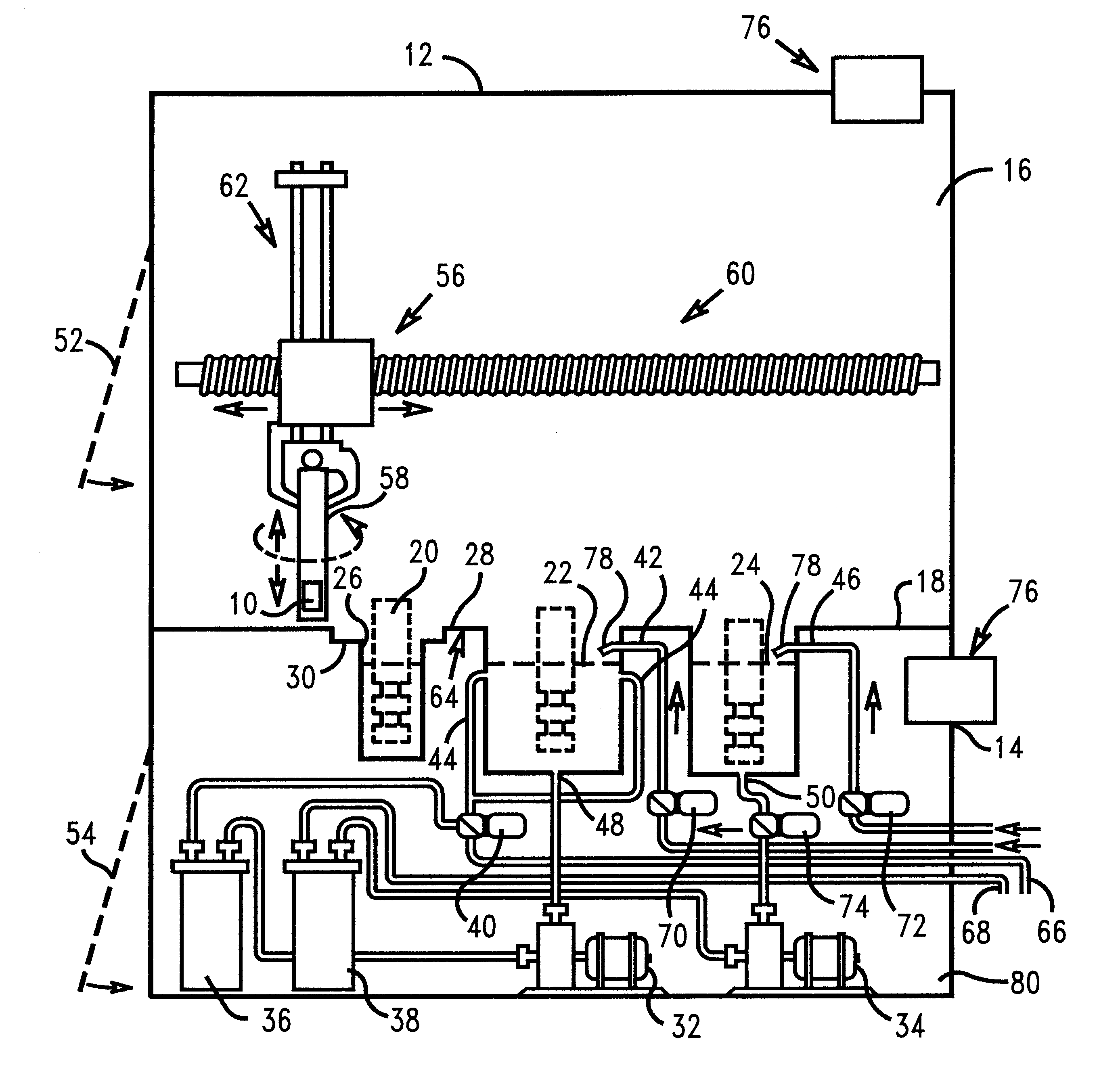

Spun gold ball welding machine, and device and method for adjusting welding spot position thereof

InactiveCN101474736AProtect healthEnsure consistencyWelding/cutting auxillary devicesAuxillary welding devicesGold ballEngineering

The invention relates to a welding point position adjustment device, a method thereof and a gold ball welding apparatus. The gold ball welding apparatus comprises a base, a workbench and the welding point position adjustment device arranged between the base and the workbench. The welding point position adjustment device comprises a digital vedio recording device, a bracket, a positioning adjustment platform, a driver and a computer, wherein the digital vedio recording device is supported by the bracket and is connected with the computer, the position adjustment platform is used for supporting the workbench and adjusting the position thereof, and the computer is connected with the position adjustment platform by the driver. The method for adjusting the welding point position includes the steps: firstly, pictures of a work piece to weld are taken and transferred to the computer; secondly, after processing the pictures, the computer calculates the position deviation of the welding point; and thirdly, the position adjustment platform is driven to eliminate the position deviation. As an operator is no longer needed to adjust the position of the welding point with a microscope, the training cost is greatly saved, the health of the operator is ensured, and the consistency of the welding quality is improved on the basis of reduced labor intensity and increased production efficiency.

Owner:深圳市因沃客科技有限公司

Production method of encapsulated component of copper wire bonding IC chip

InactiveCN101626008ASolving the crater puzzleSaving wire costSemiconductor/solid-state device detailsSolid-state devicesGold ballPlastic packaging

The invention relates to a production method of an encapsulated component of a copper wire bonding IC chip. A welding plate of the IC chip is provided with a golden ball on which copper bonding balls are stacked, an arch wire is provided with a copper welding point on an inner pin of a lead frame, and a welding plate of the IC chip is connected with the pin of the lead frame. A plastic packaging body is covered on the IC chip, the copper balls stacked on the packed golden ball, the copper welding point of the arch wire on the inner pin of the lead frame and partial inner pins of the lead frame to form a whole circuit. The production method comprises wafer grinding, wafer scribing, core installing, press welding, plastic package, post curing, printing, punching separation, inspection, packaging and warehousing. The invention has simple and reasonable structure, easy use and high qualified rate in encapsulation and testing as well as high reliability, avoids craters, the intensity of the welding point is improved, the pull force of copper welding wires and the shearing strength of the welding point through the production method are greater than that in a copper (golden) bonding production method through direct wire threading, and unsoldering can not happen to the inner welding point.

Owner:TIANSHUI HUATIAN TECH

Liquid crystal display capable of preventing short circuit of electric gold ball, and preparation method

The invention discloses a LCD for preventing the short circuit of conductive metal balls, and the making method thereof. A liquid crystal empty box is made by aligning and binding transferring points made on upper and lower ITO glass substrates with sealing glue frame after sprayed with liners, then heat-pressing and curing, where the transferring points are arranged in a small frame range needing to lead out row electrodes and made of transferring sealing glue scattered with conductive metal balls by silk-screen. The invention can obviously raise finished product yield.

Owner:深圳市合力泰光电有限公司

Narrow-frame display panel and display device

InactiveCN111427202AIncrease contact areaSolve the problem of insufficient power supplyNon-linear opticsGold ballColor film

The invention provides a narrow-frame display panel and a display device. The narrow-frame display panel comprises a display area and a non-display area surrounding the display area. The narrow-framedisplay panel further comprises a color film substrate, an array substrate, a frame glue, a first conducting layer and a power supply circuit. In the invention, two metal wires are additionally arranged on a side of the color film substrate, on one hand, signals of a common electrode are connected into the color film substrate from a COF so that peripheral wires of the common electrode on the sideof the array substrate, needed when an existing array substrate is powered on, and conversion terminals and gold balls needed for conducting an upper substrate and a lower substrate, are removed; andon the other hand, the two metal wires are arranged in the non-display area and are connected with ITO wires so that a contact area of the metal wires and the ITO wires is increased, and purposes ofeffectively reducing a contact impedance and reducing signal voltage drop are achieved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

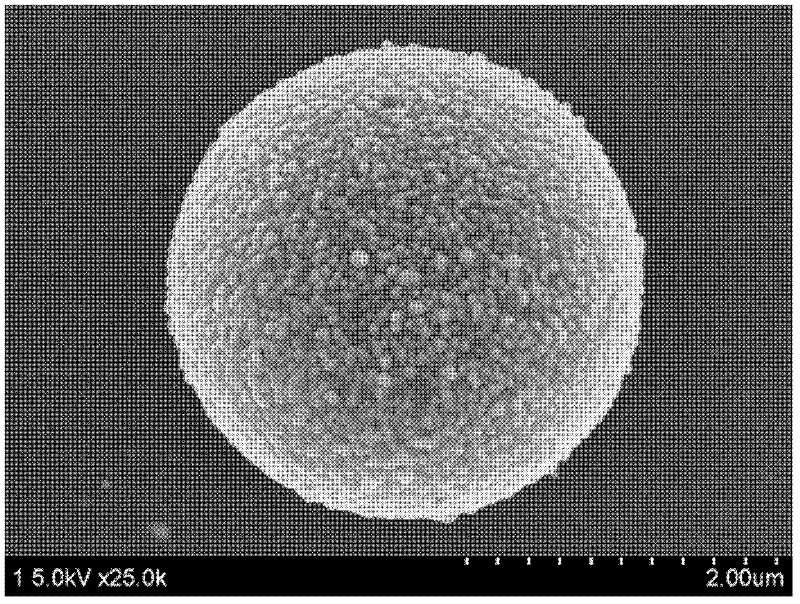

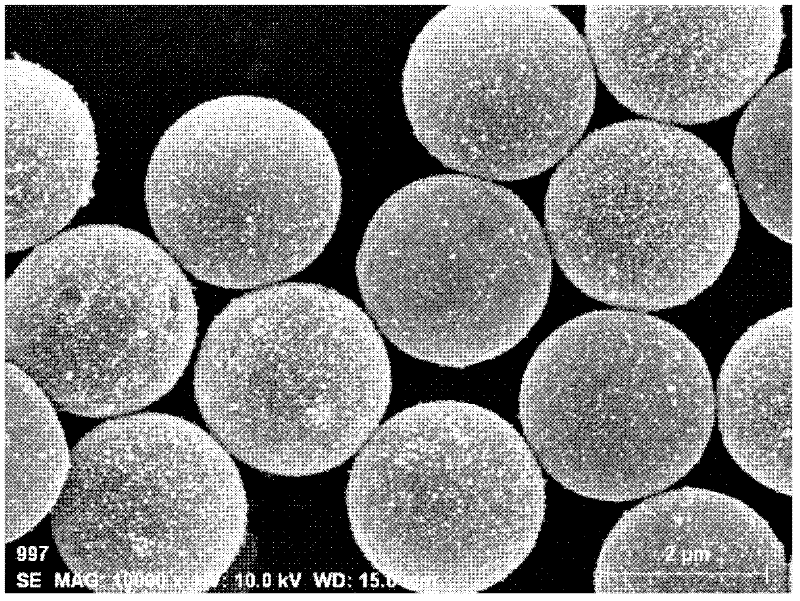

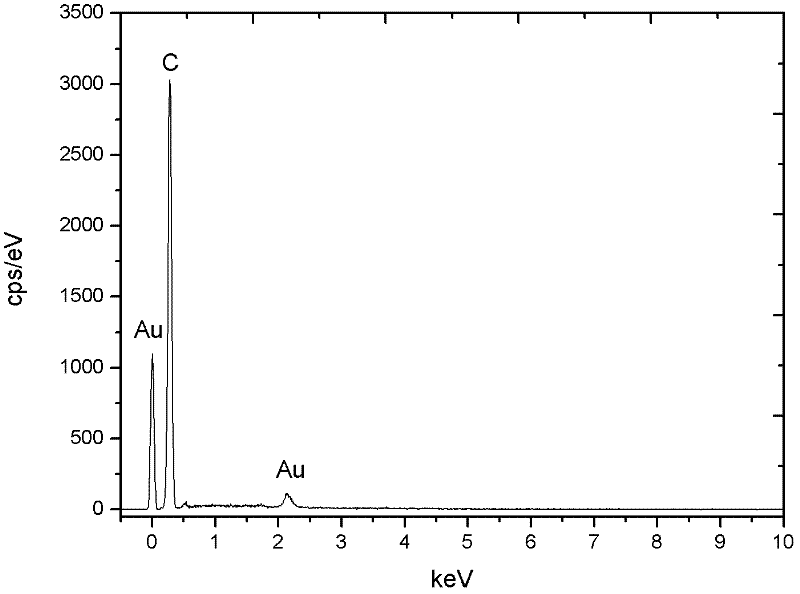

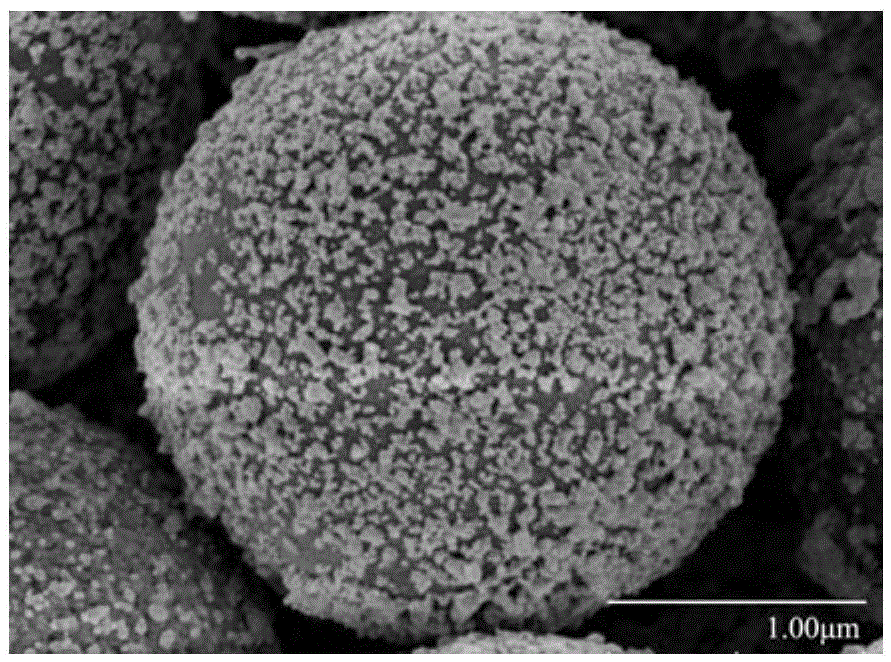

Preparation method of high performance conductive gold balls with monodispersity

InactiveCN102352495AEasy to prepareFew stepsLiquid/solution decomposition chemical coatingGold ballMicrosphere

The invention relates to a preparation method of high performance conductive gold balls with monodispersity. The method comprises the steps of: (1) adding a monomer, a dispersant, an initiator and a solvent into a reaction container for a reaction of 12-24h so as to obtain polymer microspheres; (2) dispersing the polymer microspheres into a strong acid for treatment, then adding them into a polyelectrolyte aqueous solution with positive electricity; (3) dispersing the microspheres treated in step (2) into a precious metal sol, the surface of which has negative electricity; (4) conducting ultrasonic dispersing to the microspheres treated in step (3) to disperse the microspheres in an electroless gold plating bath, after the reaction, carrying out centrifugation, washing and drying, thus obtaining the high performance conductive gold balls. The method of the invention provides a solution to the problems of tin ion interference, activation under an acidic condition, complex operations and toxicity of electroless gold plating bath etc. in traditional electroless plating activation technologies. With simple preparation process, the method provided in the invention can be used for batchproduction and has good application prospects.

Owner:DONGHUA UNIV

Preparation method of micron polymer-based composite conductive gold balls

ActiveCN105478752AGood lookingAvoid multi-step preprocessingTransportation and packagingMetal-working apparatusGold ballChemical plating

The present invention relates to a preparation method of micron polymer-based composite conductive gold balls. The method comprises: dispersing polymer microparticles in water; then adding stabilizing agent; stirring to obtain polymer microparticle dispersion liquid; then adding an amino-modified reagent; mechanically stirring and reacting to obtain amino-modified polymer microparticles; ultrasonically dispersing in water; adding carboxylic acid-modified gold sol; magnetically stirring, washing, centrifuging and drying to obtain polymer microparticles overlapped with nanoparticles on the surface; ultrasonically dispersing in a cyanide-free gold growth solution; under a condition of 40-80 DEG C, ultrasonically or mechanically stirring and reacting, washing, centrifuging and drying to obtain the product. The preparation method in the present invention is environmentally friendly and is simple and convenient to operate, avoids the heavy and complicated pre-treatment process in the traditional chemical plating and solves the problems of interference of impurity ions such as tin and palladium and toxicity of chemical plating solution such as cyanide.

Owner:DONGHUA UNIV

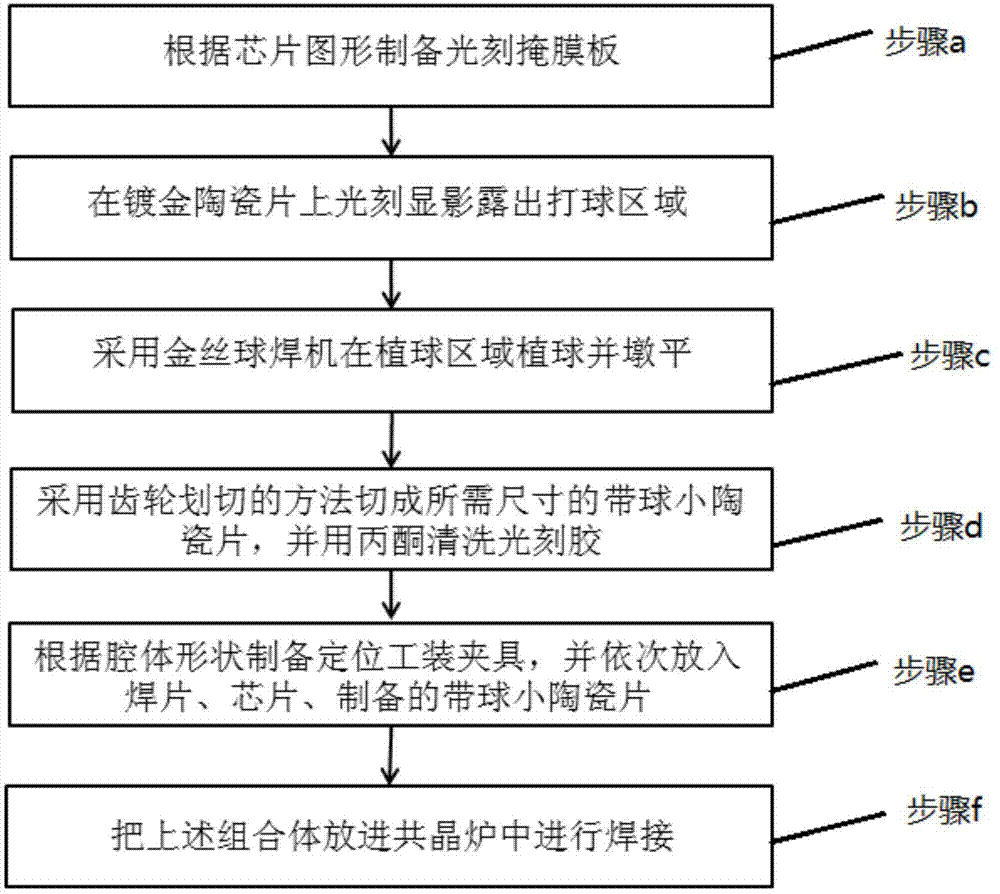

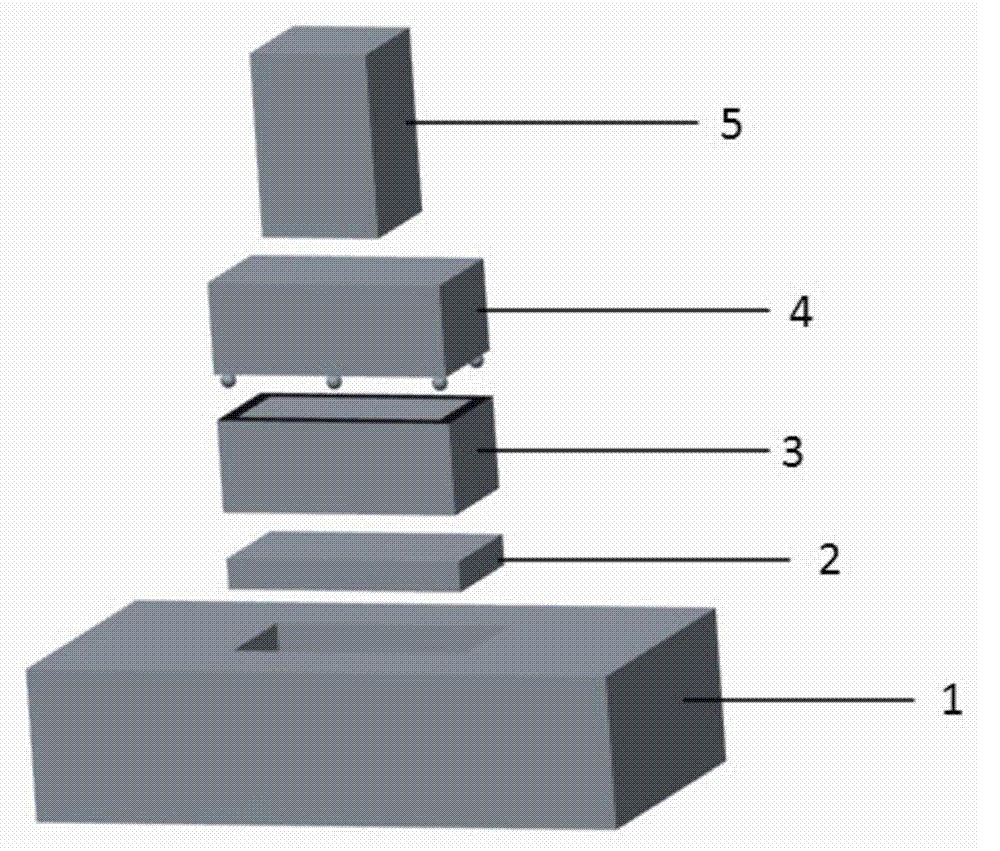

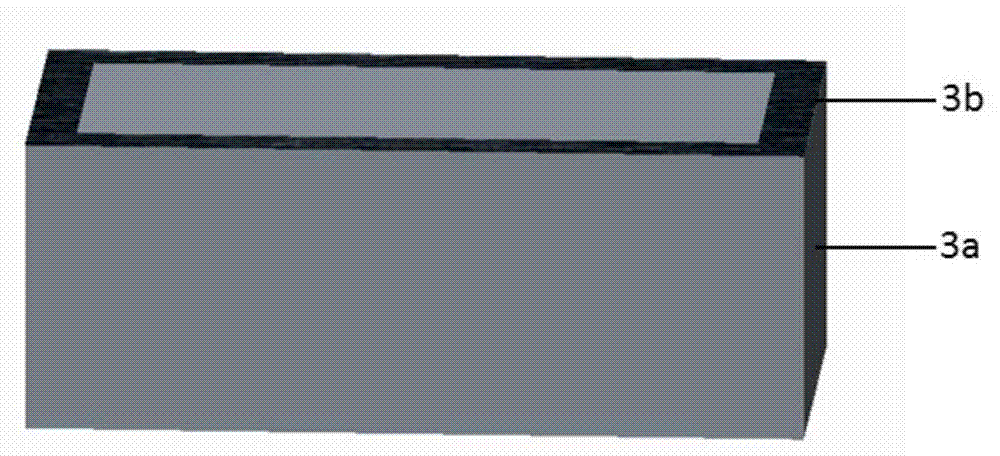

Method for achieving eutectic soldering of chips

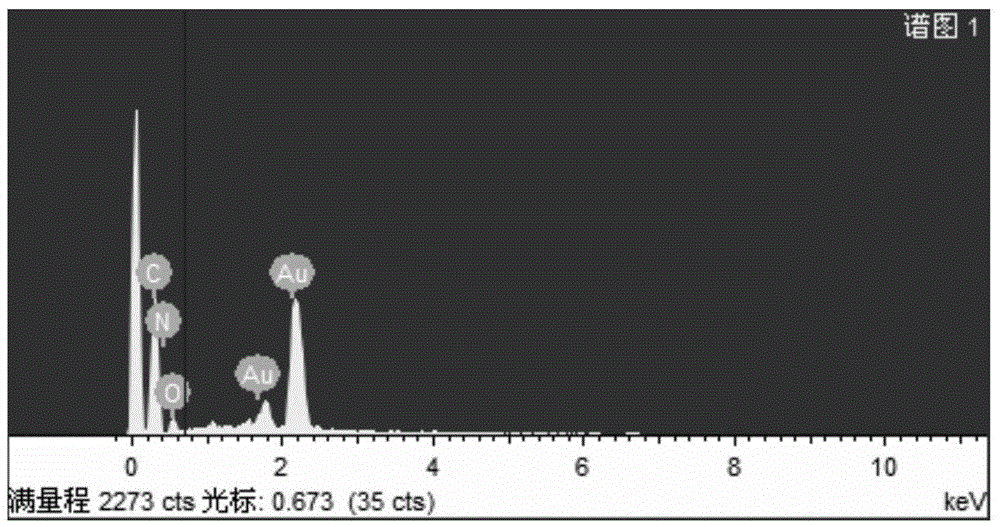

ActiveCN103617957ASolve stressSolve the positioning problemSolid-state devicesSemiconductor/solid-state device manufacturingGold ballAdhesive

The invention provides a method for achieving eutectic soldering of chips. The method comprises the steps of a, compressible areas in the chips are determined, and a photoetching mask panel is manufactured; b, conducting adhesives in the compressible areas of the chips are removed through a photoetching develop method on a gilded ceramic wafer; c, ball points, used as protruding points, are planted at the position, where the adhesives are removed, on the ceramic wafer through a gold ball bonding method; d, the ceramic wafer is cut into small ceramic wafers consistent with the chips in size through a gear cutting method; e, a tool locating clamp is manufactured according to the shapes of cavities to be welded, and a small ceramic wafer pressing block clamp with gold protruding points makes contact with non-circuit areas of the chips through the protruding points; f, a pressing block is arranged on the small ceramic wafer pressing block clamp, and vacuum compressible soldering of the chips is indirectly achieved. The gilded ceramic wafer is used as the base material, the mature photoetching technology and the ball-bonding ball planting technology are used for manufacturing the protruding points to provide effective mechanical support for soldering, and the method is wide in application range.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

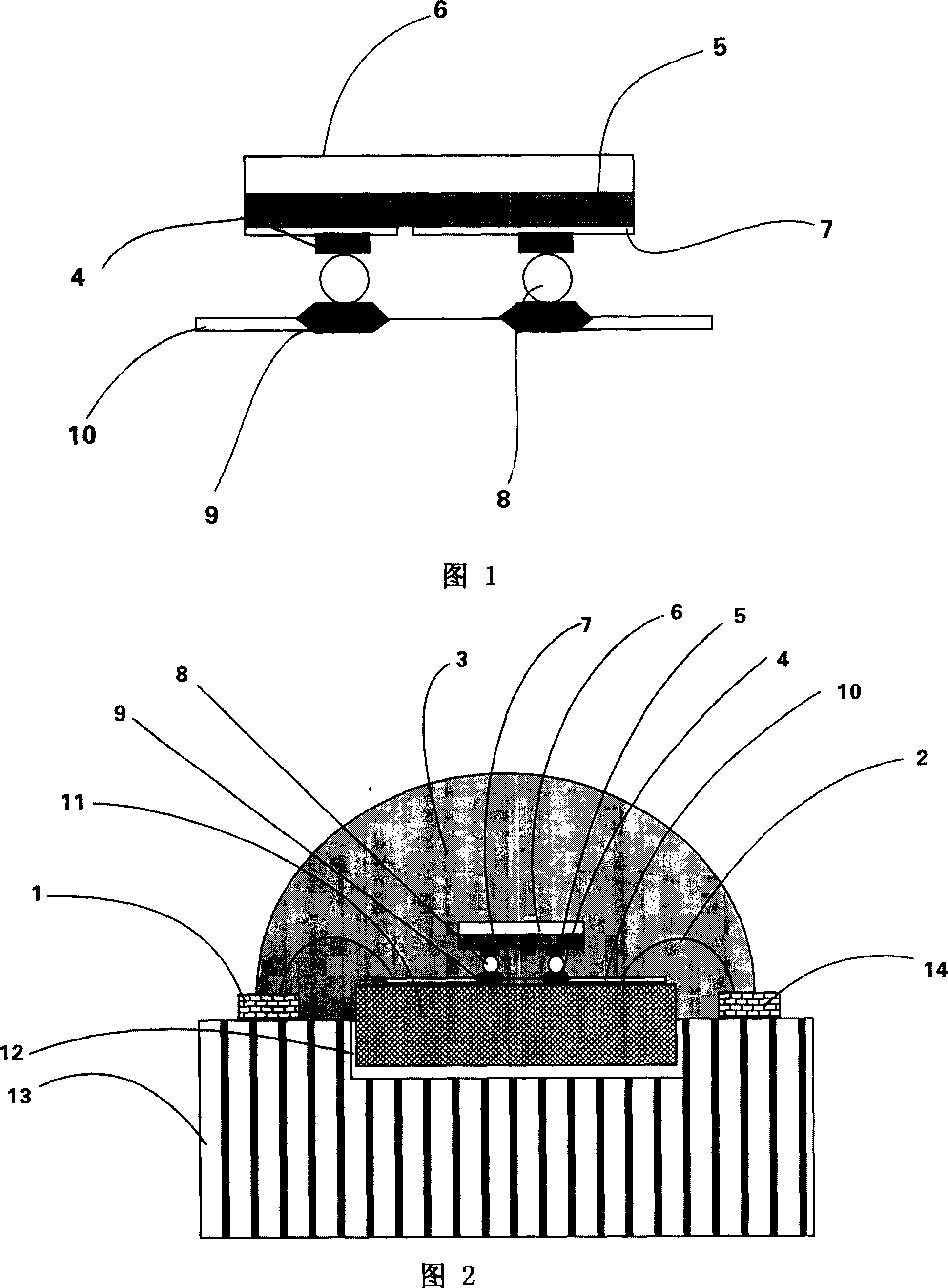

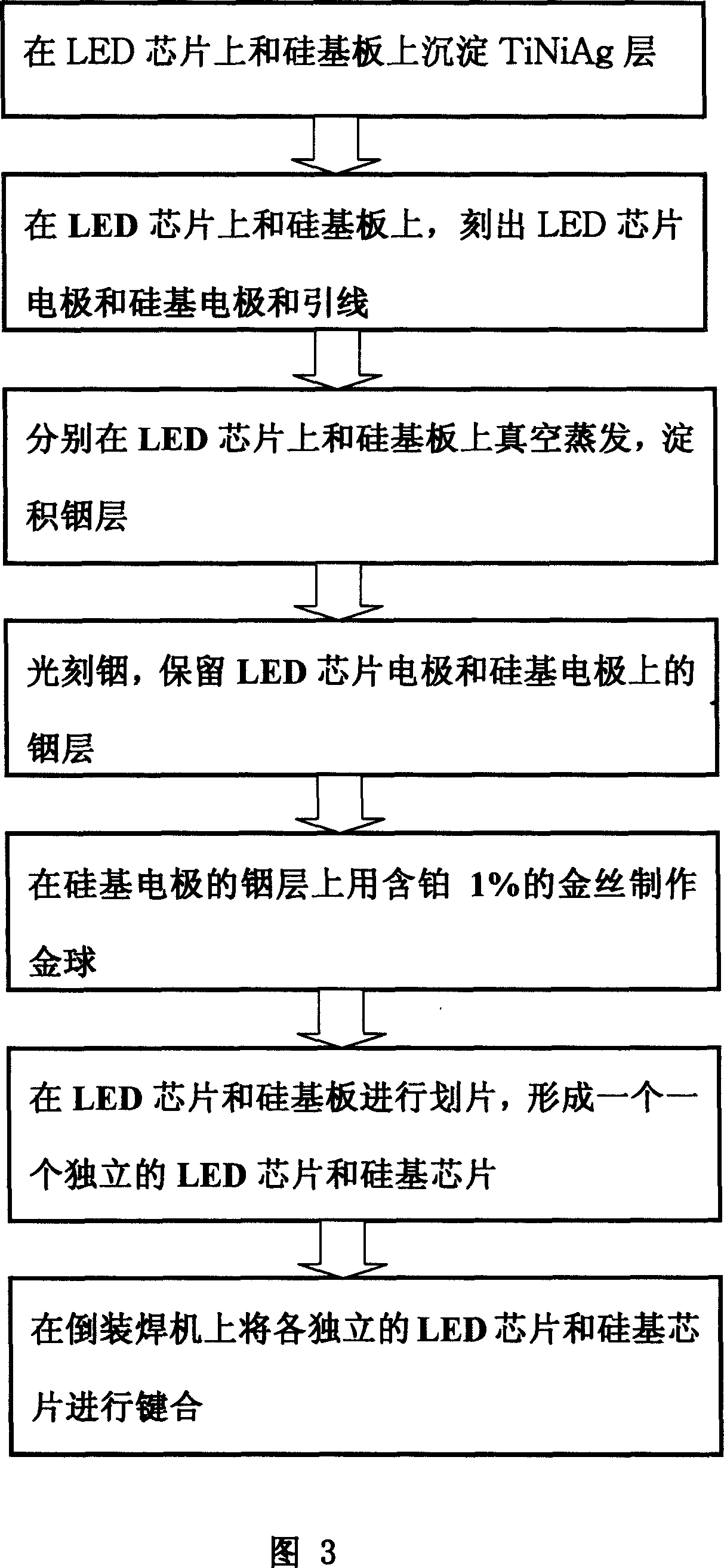

Converse welding method of high power LED chip

InactiveCN1971952AWell matched thermal expansionImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingIndiumGold ball

This invention relates to one large power LED chip inverse weld method in micro electron technique, which comprises the following steps: depositing Tania layer on LED chip and metal indium on LED chip electrode; depositing Tania layer on silicon baseboard and indium on silicon base circuit board on LED chip electrode position to process gold ball; then welding the LED chip and silicon baseboard together to form indium to gold to cadmium structure with cadmium as expansion buffer.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Dense-pitch small-pad copper-wire bonded single intelligent card (IC) chip packing piece and preparation method thereof

ActiveCN102437141AAvoiding Solder Joint Shorting ProblemsSolve the previous thread that is easy to bruiseSemiconductor/solid-state device detailsSolid-state devicesGold ballPunching

The invention relates to a dense-pitch small-pad copper-wire bonded single intelligent card 9IC) chip packing piece, which is characterized in that: a lead framework carrier and framework lead inner pins are arranged inside a plastic-sealed body, the lead framework carrier is fixedly connected with an IC chip, the IC chip is provided with a plurality of welding pads corresponding to the framework lead inner pins one by one, each welding pad iis connected with the corresponding framework lead inner pin through a bonding line, a bold ball is respectively welded on a welding pad or on a spaced welding pad in each welding pad group, each gold ball is connected with a first copper bonding ball in a welding way, a crescent copper welding point is punched on the corresponding inner pin to form a first copper bonding line; and the welding pad which is not connected with the gold ball is connected with a second copper bonding ball in a welding way, a crescent copper welding point is also punched on the corresponding inner pin to form a second copper bonding line, and the gold balls in two rows of welding pad groups are alaternatively arranged. Due to the adoption of the packing piece and the preparation method, the open-circuit potential danger of a plastic-sealed punching line caused by a crater on the welding pad, short circuit of two adjacent welding points and a previous line is easy to damage can be avoided.

Owner:TIANSHUI HUATIAN TECH +1

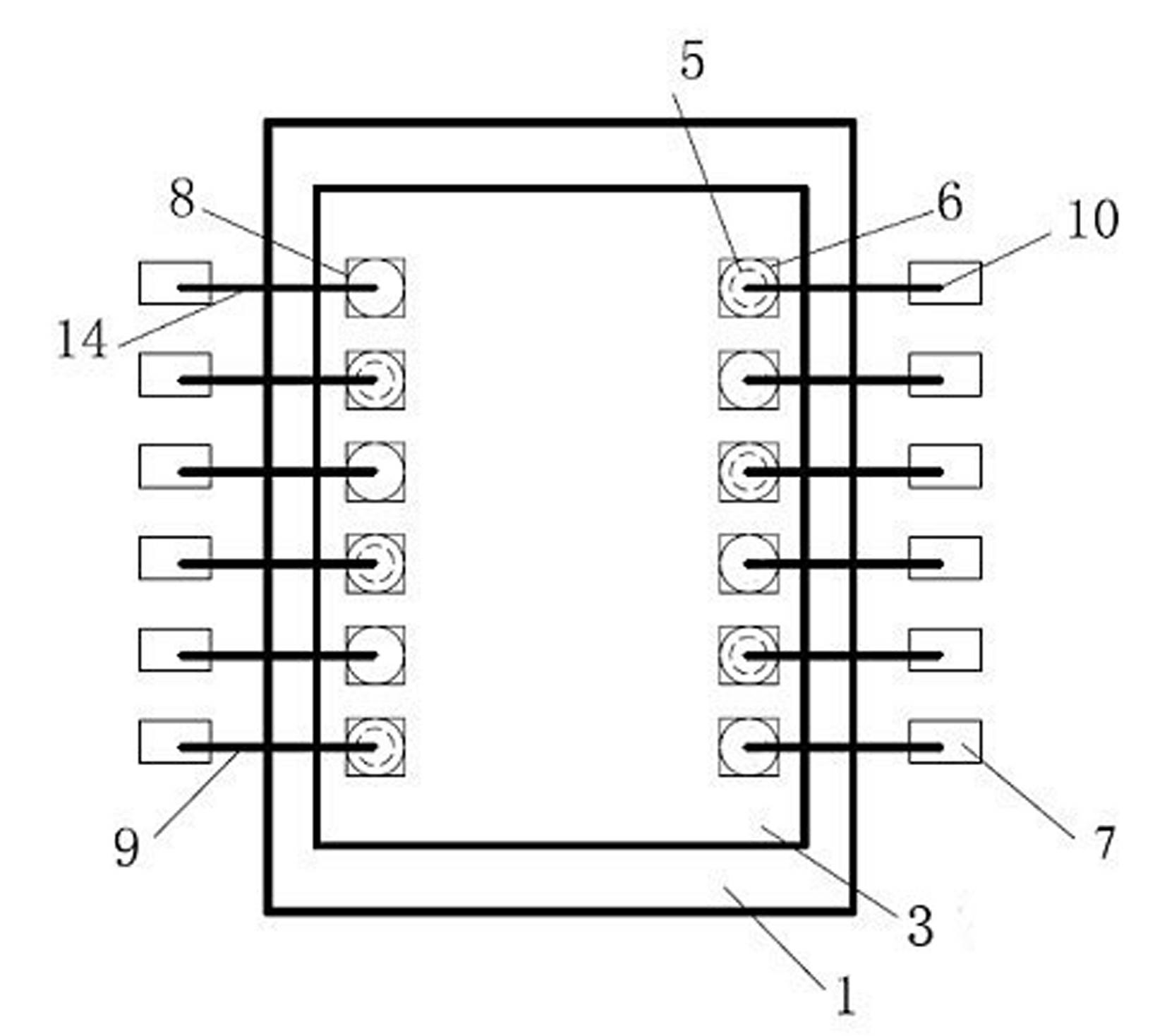

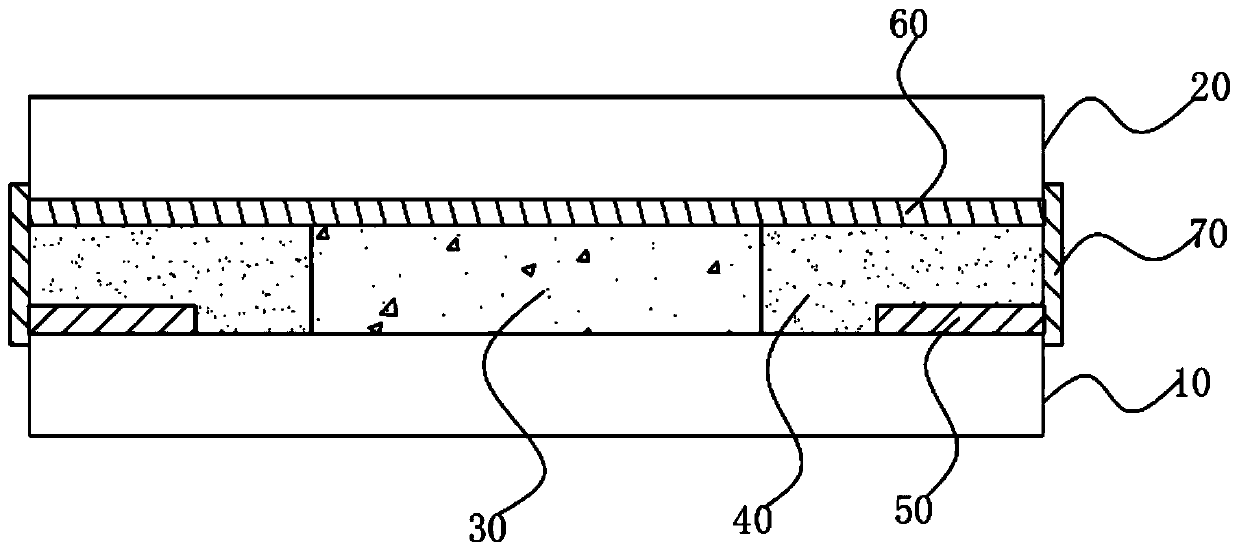

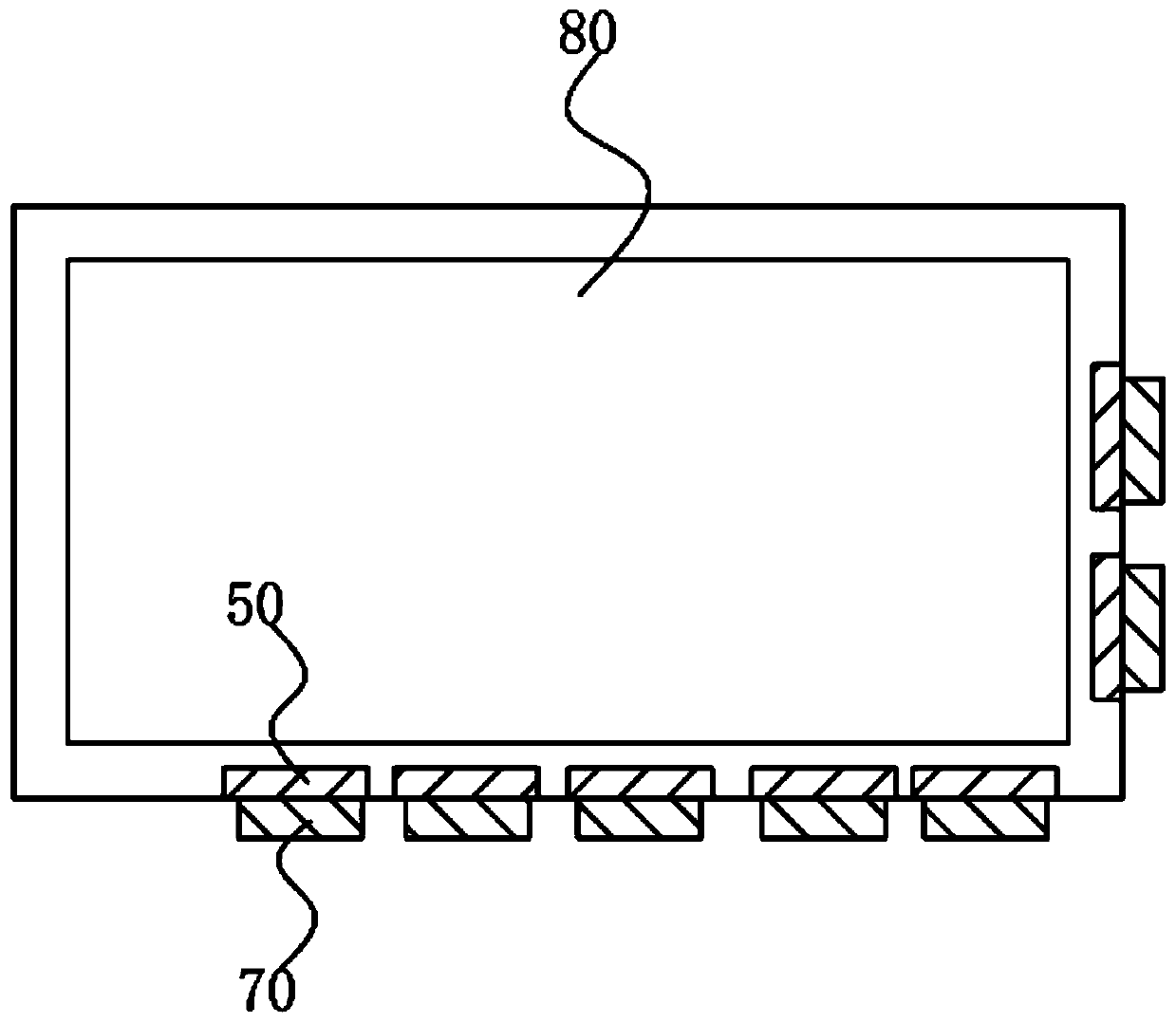

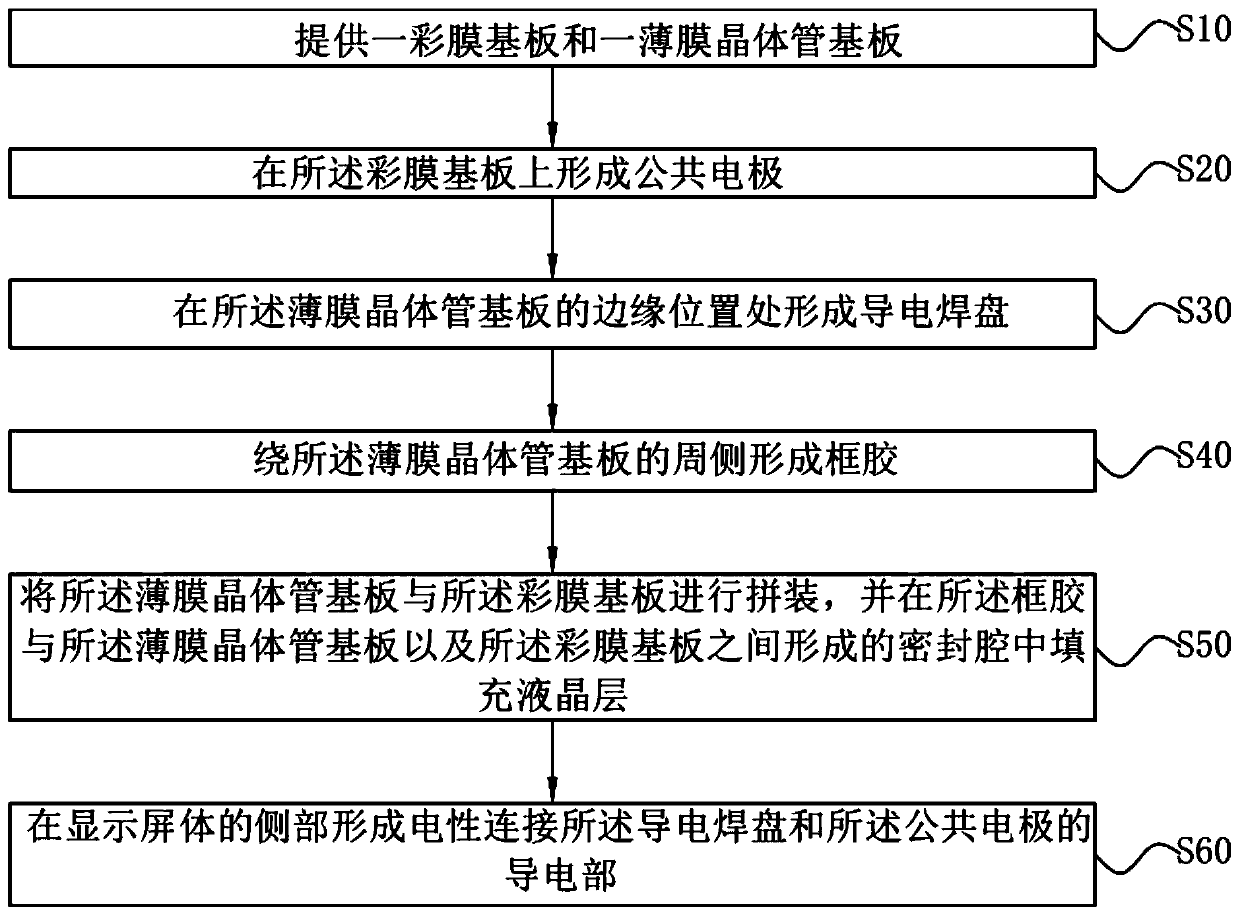

Liquid crystal display panel and preparation method thereof

The invention provides a liquid crystal display panel which comprises a display screen body. The display screen body comprises a thin film transistor substrate, a color film substrate, a liquid crystal layer and frame glue, wherein the liquid crystal layer and the frame glue are arranged between the thin film transistor substrate and the color film substrate. A conductive pad is arranged on the thin film transistor substrate, a common electrode is arranged on the color film substrate, and a conductive part which is electrically connected with the conductive pad and the common electrode is arranged on the side part of the display screen body. The common electrode is electrically connected with the conductive bonding pad on the outer side of the display screen body through the conductive part; therefore, a signal on the thin film transistor substrate does not need to be conducted to the color film substrate by a gold ball via the conductive bonding pad, the gold ball does not need to becoated, the technological process is simplified, the space occupied by the gold ball is saved, the frame glue is prevented from overflowing to the cutting line or the display area when the frame glueis formed, and a narrower bezel of the liquid crystal display panel can be achieved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

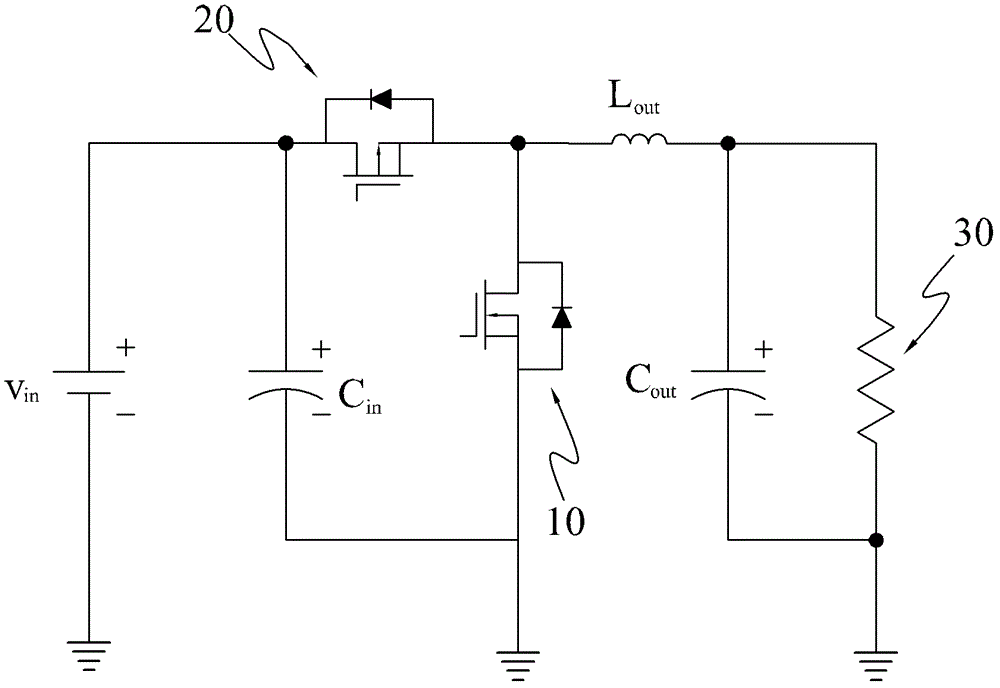

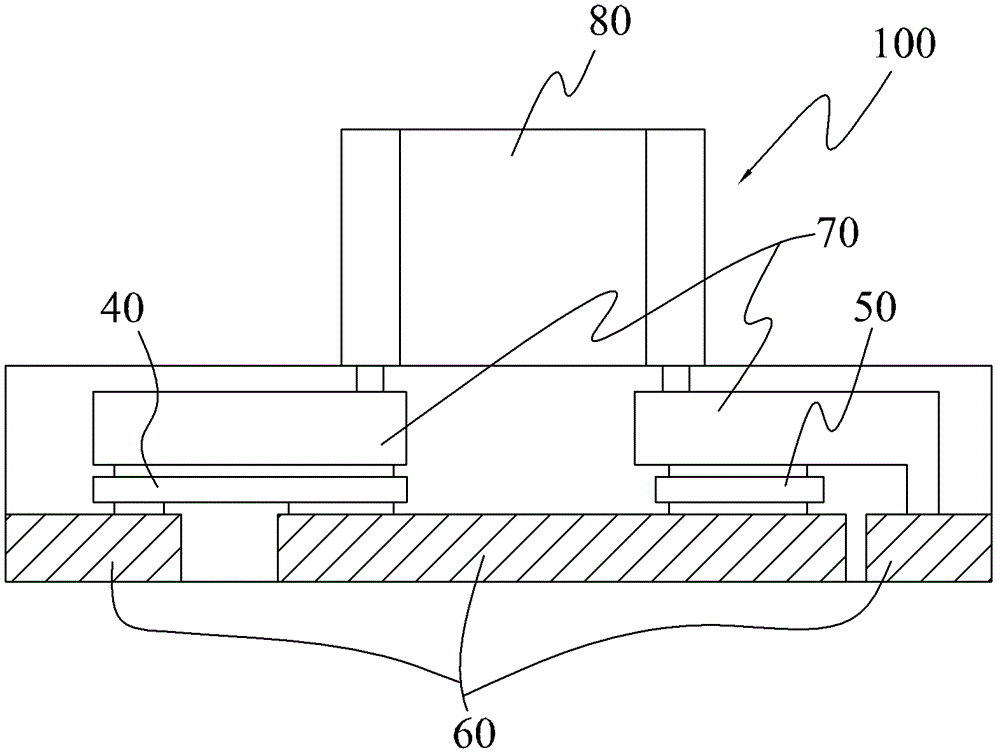

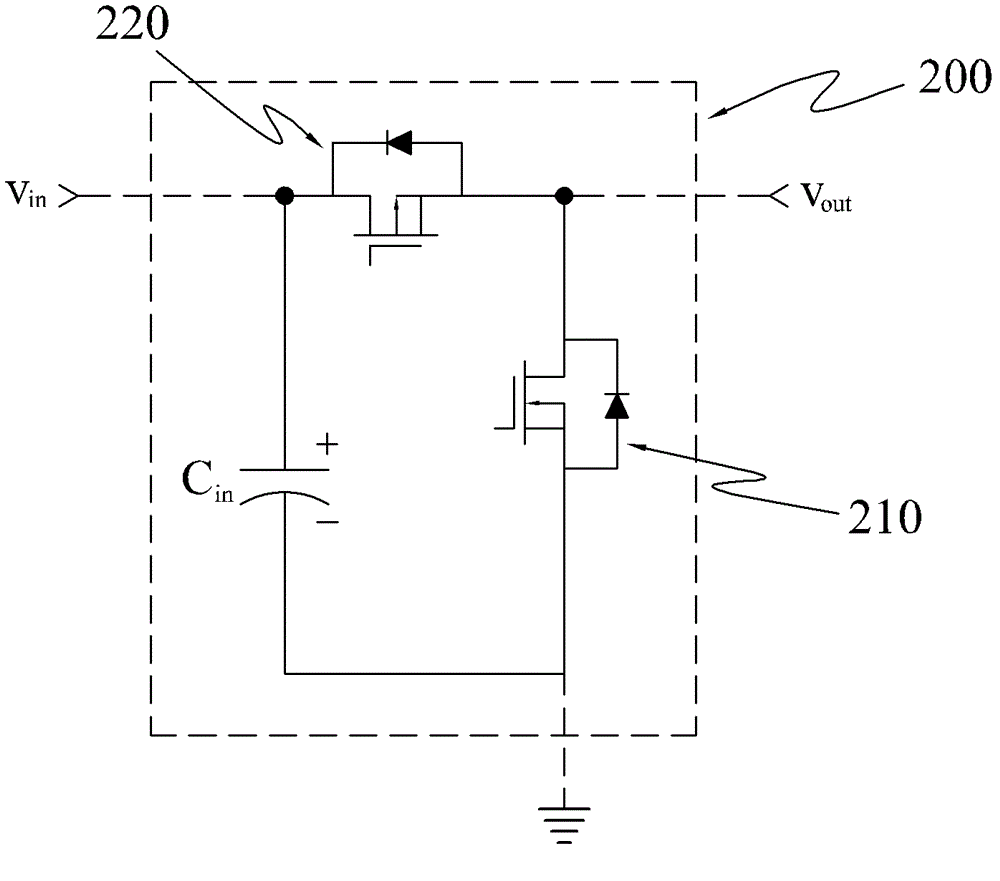

MOSFET pair with stack capacitor and manufacturing method thereof

ActiveCN102751268AAvoid parasitic inductanceOptimizing the EMI loopSemiconductor/solid-state device detailsSolid-state devicesThermal energyMOSFET

A MOSFET pair with a stack capacitor is disclosed herein. It can regulate the input voltage and optimize a short EMI loop. It has a bottom lead frame and an up lead frame, which can simultaneously dissipate the heat generated by two MOSFETs to achieve excellent thermal-dissipation. It can adopt solder, Ag epoxy, or gold balls to implement the electrical bonding of two MOSFETs with the bottom lead frame and the up lead frame to achieve excellent structural flexibility. A device, such as an IGBT, a diode, an inductor, a choke, and a heat sink, can be stacked above the up lead frame to form a powerful SiP module. A corresponding method of manufacturing the MOSFET pair with a stack capacitor is also disclosed herein, which is simple, time-saving, flexible, cost-effective, and facile.

Owner:CYNTEC

Method for cultivating tree-shaped gold-ball elms

The invention relates to a method for cultivating tree-shaped gold-ball elms. The method aims to create a 'gold-ball ulmus pumila' which is an exotic landscape elm and is a novel type of garden tree, and two colors and two shapes grow on the elm. The method is characterized in that thin and tall elm seedlings are cultivated by a seeding close planting process in April, bare roots are transplanted in the second year, trunks are set when the heights of the tree trunks reach 130cm, and fertilizer and water management and conservation management are intensified, so that growth of the elm seedlings can be promoted; rootstocks and scions with identical thicknesses are selected by a multi-bud long tube sleeving process in July and August, the ulmus pumila scions with the lengths of about 5cm are wrung and sleeved on elm branches (the rootstocks) of which barks with the lengths of 5cm are peeled, scion sleeving tubes are sleeved to the bottoms of the elm branches of which the barks with the lengths of 5cm are peeled, and each scion sleeving tube and the corresponding elm branch are matched with each other without binding or bagging; scion grafting for ulmus pumila cv. Jinye is carried out in the same manner; a top grafting and breed changing procedure is completed; drooping and flat branches of ulmus pumila naturally grow after the ulmus pumila survives, the ulmus pumila cv. Jinye continuously grows upwardly, and a hemispherical crown of the ulmus pumila cv. Jinye can be formed only by means of repeatedly cutting back the ulmus pumila cv. Jinye.

Owner:BEIJING FORESTRY UNIVERSITY

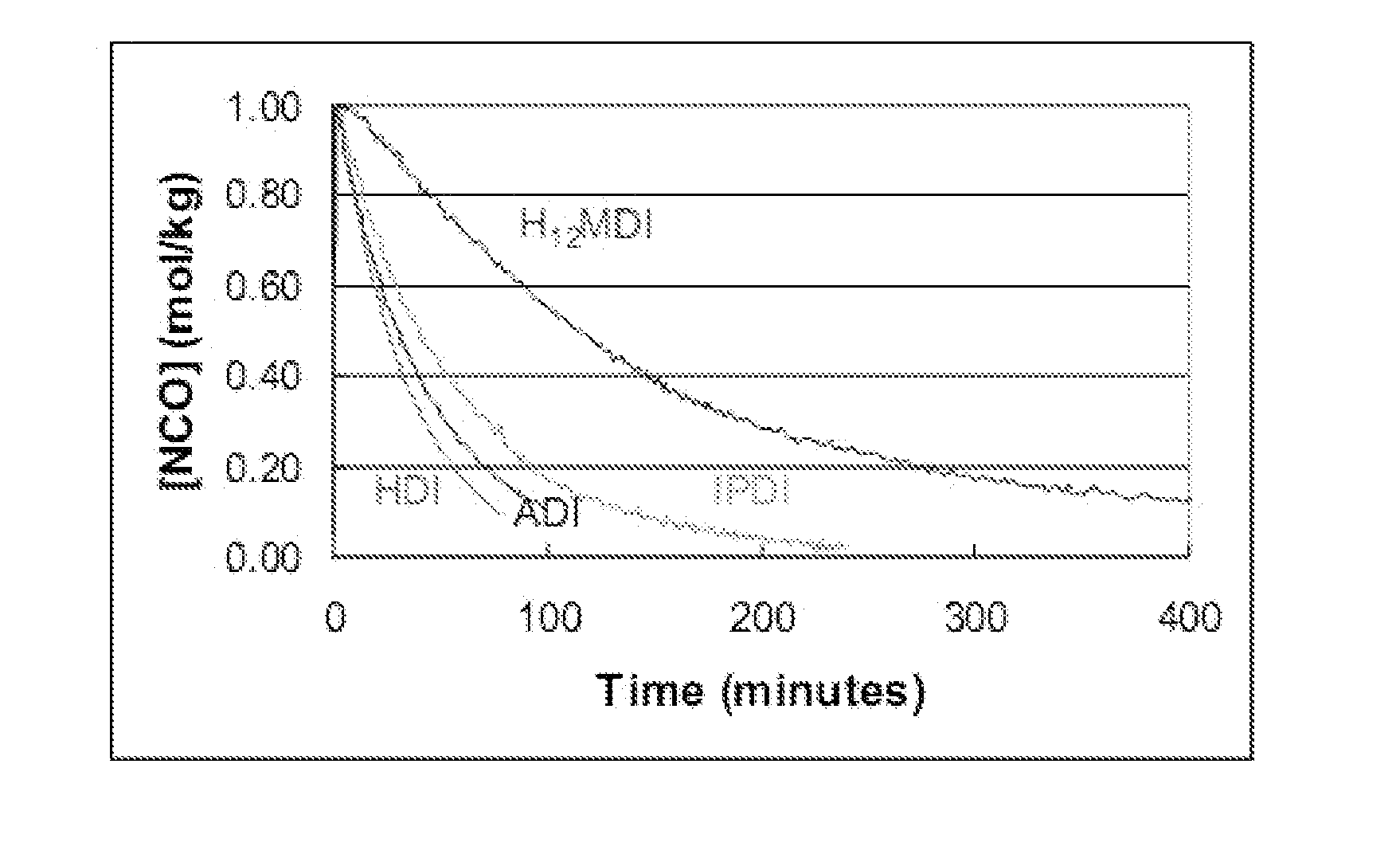

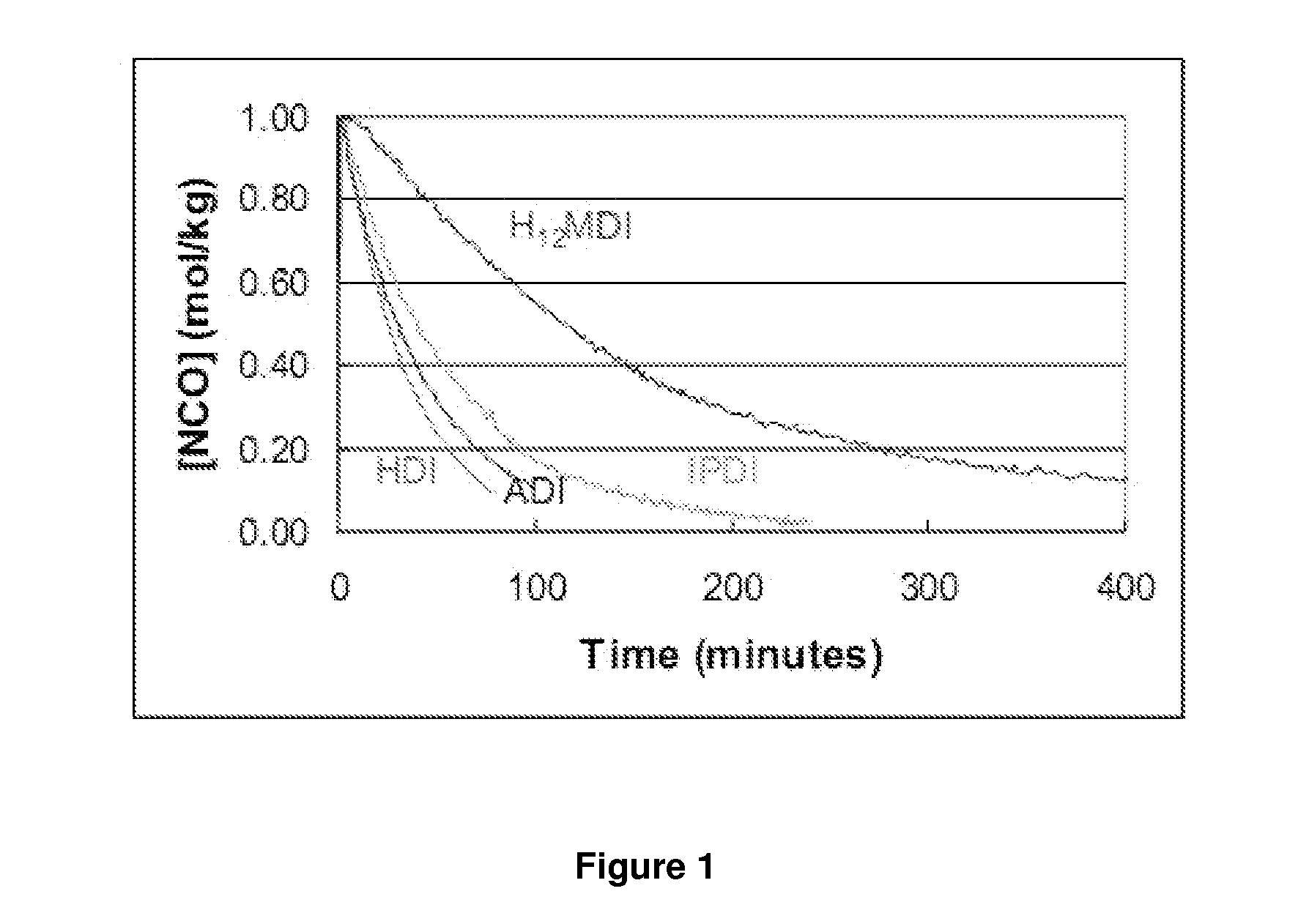

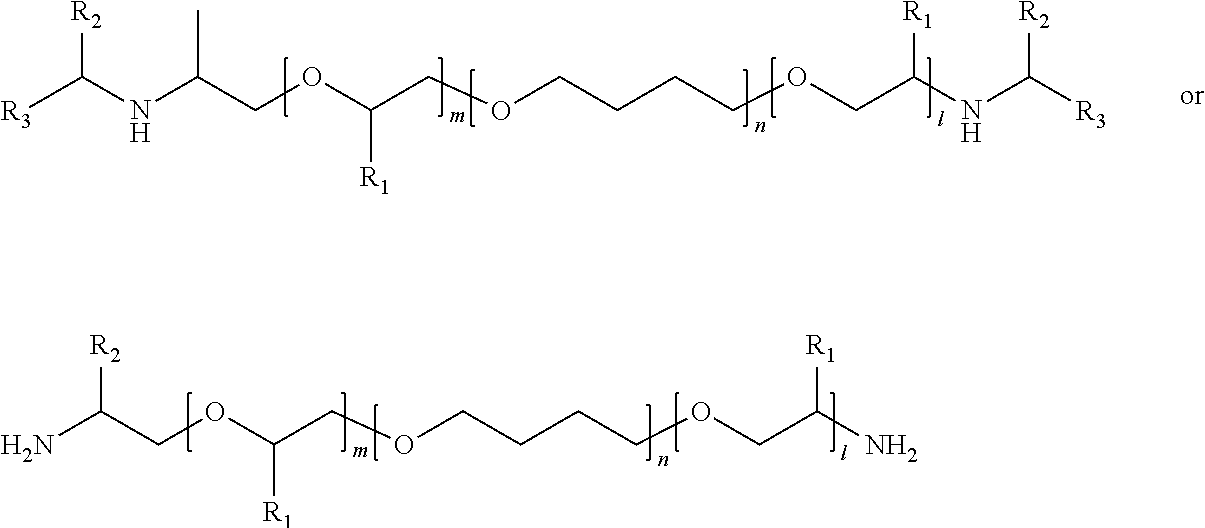

Castable polyurea compositions for golf ball covers

InactiveUS20120035001A1Improve heat stabilityIncrease elasticityGolf ballsSolid ballsPolyesterGold ball

Disclosed herein is a golf ball having improved cut and shear resistance. Such gold balls comprise a core, an inner cover layer, and an outer cover layer, the outer cover layer being formed from a polyurea or poly(urea-co-urethane) comprising: 1) a polyurea prepolymer comprising: the reaction product of at least one first polyisocyanate, wherein the polyisocyanate has a reactivity greater than that of 4,4′-methylene bis(cyclohexyl) isocyanate and a functionality of 1.7 to 2.3, and at least one amine-terminated compound, wherein the amine-terminated compound is selected from the group consisting of amine-terminated hydrocarbons, amine-terminated polyethers, amine-terminated polyesters, amine-terminated polycaprolactones, amine-terminated polycarbonates, amine-terminated polyamides, and mixtures thereof; and at least one second polyisocyanate with a vapor pressure lower than 0.01 mm Hg at 20° C.; and 2) at least one curing agent comprising amine or hydroxyl functional curatives.

Owner:DOW GLOBAL TECH LLC

Touch screen, manufacturing method thereof and display device

InactiveCN103558937AIncrease profitAvoid occupyingInput/output processes for data processingGold ballAdhesive

The invention discloses a touch screen, a manufacturing method thereof and a display device. Due to the fact that an opposite substrate and an array substrate are arranged in a staggered mode, the opposite substrate and the array substrate are overlapped and staggered, the overlapped region of the opposite substrate and the array substrate is provided with a touch electrode, and the staggered region of the opposite substrate and the array substrate is provided with a first wiring terminal which is connected with the touch electrode. Therefore, the first wiring terminal on one side of the opposite substrate does not need electrically connecting to the array substrate so as to omit the usage of high-cost gold-ball-contained conductive adhesive, so that the manufacturing costs can be reduced; besides, the region of the opposite substrate, which needs cutting off in the prior art, is provided with the first wiring terminal connected with the touch electrode, so that the utilization rate of the opposite substrate is improved and meanwhile the space of the array substrate can avoid being occupied.

Owner:BOE TECH GRP CO LTD +1

Method for enhancing upside-down mounting welding core plate brightness

InactiveCN101140963AReduce absorptionReduce the use temperatureSolid-state devicesSemiconductor/solid-state device manufacturingGold ballSurface oxidation

The invention relates to a method for lighting up the backbonded chip, which is characterized in plating the metal of high reflectivity onto the original metal circuit and the light absorbed golden ball. The method is: first, oxidizing the silicon substrate with heat reacting furnace to generate a silicon dioxide layer, photoetching the pattern by photo exposure machine and etching the needless silicon dioxide with hydrofluoric acid buffer solution of 1% to 3%, vapor depositing a layer of high reflectivity metal onto the silicon dioxide layer by thermal coater and etching two adjacent positive and negative electrodes which covers 40% to 95% surface areas of the silicon substrate ferric nitrate mixed solution; second, balling the golden balls on the surface of both positive and negative electrodes by balling machine, plating a layer of high reflectivity metal respectively on two positive and negative electrodes and the golden balls by thermal coater, etching the high reflectivity metal layer with hydrofluoric acid buffer solution and the left metal layer is adhered to two positive and negative electrodes and the golden balls; finally, converting the chip by wire bonder to make its electrodes aligned with the golden balls, and compaginating the electrodes with golden balls by heating and ultra audible sound. The invention has the advantage of increasing the optical efficiency of 40% more than that of traditional backbonded chip.

Owner:上海蓝宝光电材料有限公司

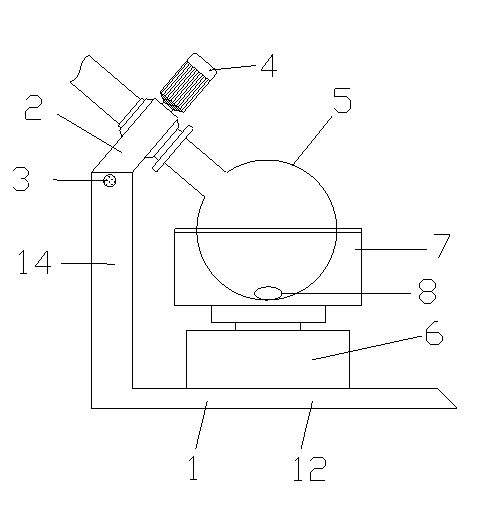

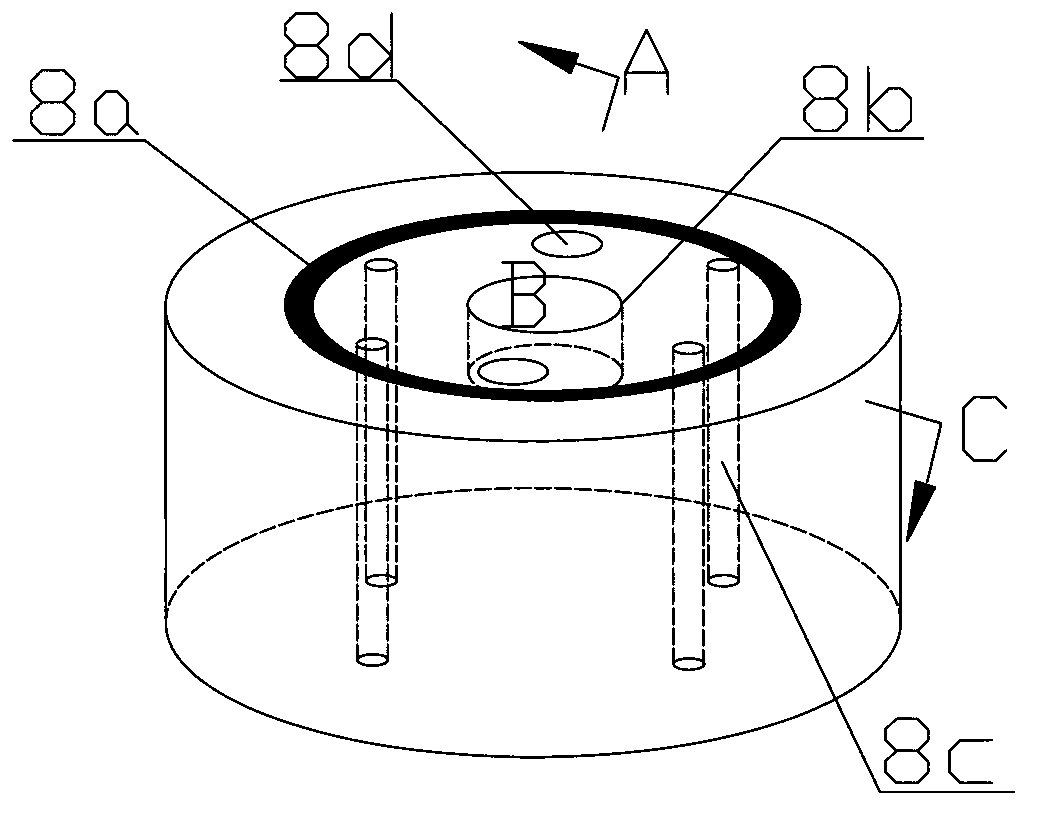

Rotating and revolving magnetic stirrer for production of conductive gold balls

ActiveCN102641686AStir fully and evenlyGood surface treatmentRotating receptacle mixersTransportation and packagingGold ballElectric machine

A rotating and revolving magnetic stirrer for the production of conductive gold balls comprises a mounting rod, a rotary motor, a flask, a magnetic stirrer and a magnetic rotor; the rotary motor is mounted on the mounting rod; the flask is rotatably mounted on the mounting rod; the rotary motor provides rotating power, so that the flask can rotate; the magnetic rotor is placed in the flask; and the magnetic rotor is rotated under the effect of the magnetic force of the magnetic stirrer. According to the rotating and revolving magnetic stirrer, the solvent in the flask not only can revolve as the flask rotates, but also can rotate as the magnetic rotor rotates, carrying out revolution and rotation at the same time, consequently, mixing is more uniform and sufficient, and an excellent mixing effect can be achieved.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Liquid crystal display device

ActiveCN102253536AImprove insulationAvoid short circuitNon-linear opticsLiquid-crystal displayLiquid crystal

The invention discloses a liquid crystal display device, which comprises a color film substrate, an array substrate arranged opposite to the color film substrate, a conducting layer arranged on the color film substrate, an insulation layer arranged on the array substrate, a data line layer arranged in the insulation layer, a section difference layer arranged on the array substrate of a non-date line region, and a frame sealing rubber layer arranged between the array substrate and the color film substrate, wherein a space between the array substrate and the color film substrate is called as the thickness of a liquid crystal box; the region having the data line layer is defined as a data line region; the region without the data line layer is defined as the non-date line region; and a plurality of gold balls are arranged in the frame sealing rubber layer. The liquid crystal display device effectively prevents short circuit of the data line at the frame sealing rubber coating part on the array substrate and a common electrode on the color film substrate caused by the gold balls in the frame sealing rubber, and reduces the occurrence of displaying bad phenomena so as to improve yield and dependency for long-term use of products.

Owner:NANJING CEC PANDA LCD TECH

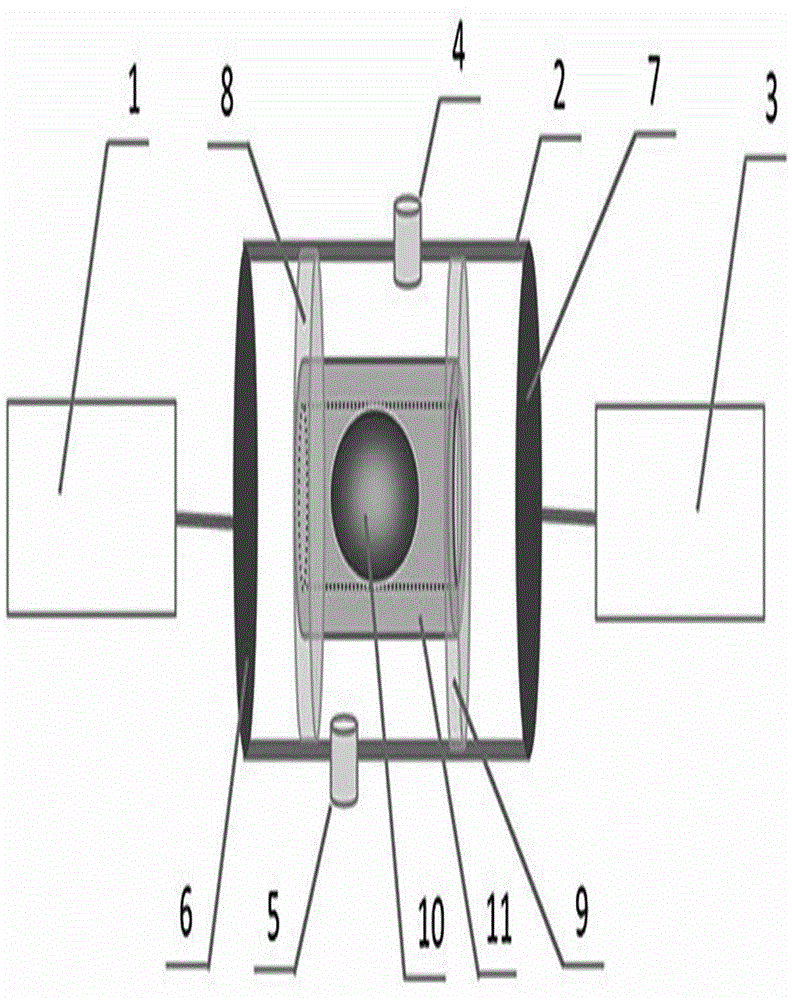

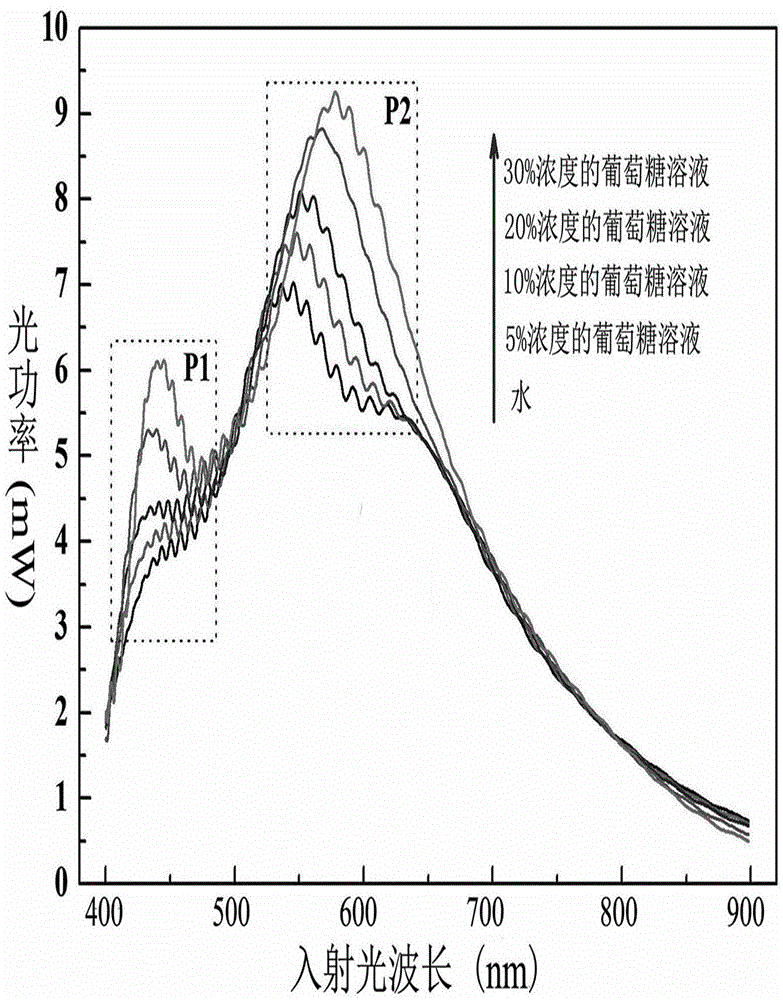

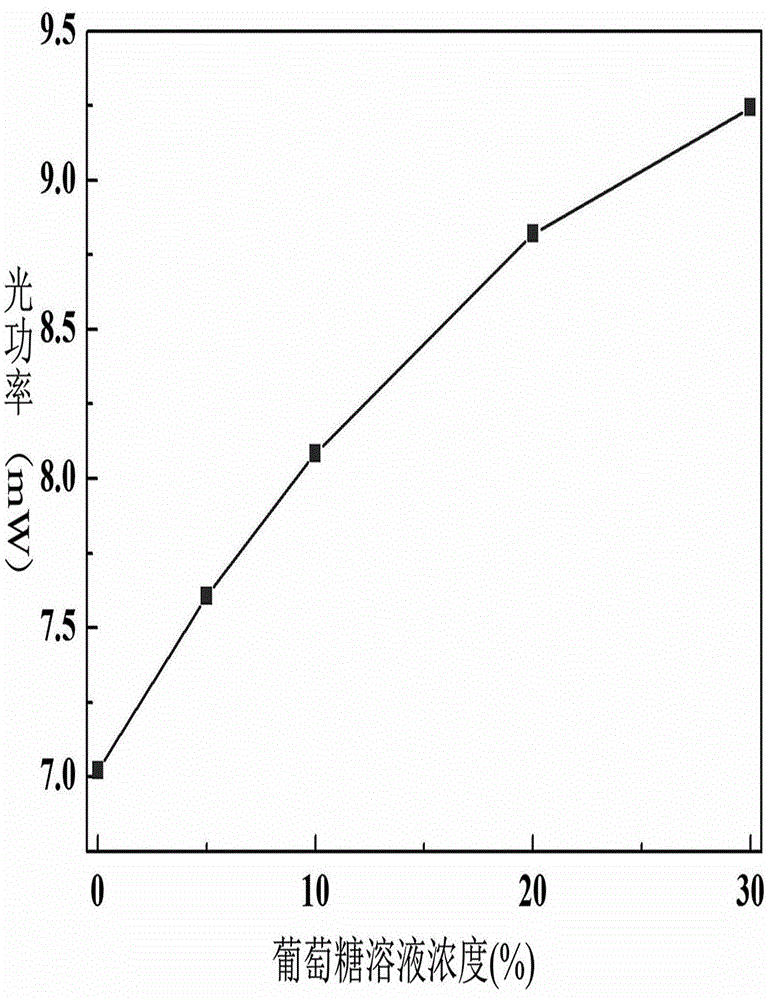

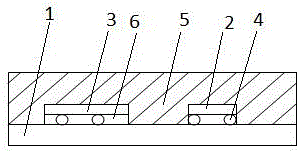

Miniature quartz hollow pipe composite optical fiber structure for detecting glucose concentration

ActiveCN104833635ARealize detectionHigh sensitivityMaterial analysis by optical meansContinuous measurementGold ball

The invention discloses a miniature quartz hollow pipe composite optical fiber structure for detecting a glucose concentration. The miniature quartz hollow pipe composite optical fiber structure comprises a visible light source 1, a sealing chamber 2, a detector 3, a liquid inlet pipe opening 4, a liquid outlet pipe opening 5, a coupling lens 6, an output lens 7, a first isolation casing pipe 8, a second isolation casing pipe 9, micrometer gold balls 10 and micrometer quartz hollow pipes 11. Through evanescent field effects produced by lights illuminating quartz hollow optical fibers and surface plasma resonance effects produced by lights illuminating micrometer gold ball surfaces, sensor sensitivity is improved. An experiment result shows that the structure can continuously measure change of a glucose concentration, has good linear characteristics, has concentration detection sensitivity of 5.6 micromoles per liter and realizes detection of glucose concentrations of body fluid and blood. The miniature quartz hollow pipe composite optical fiber structure can be integrated to a miniature chip and reduces an equipment installation space.

Owner:NORTHEASTERN UNIV

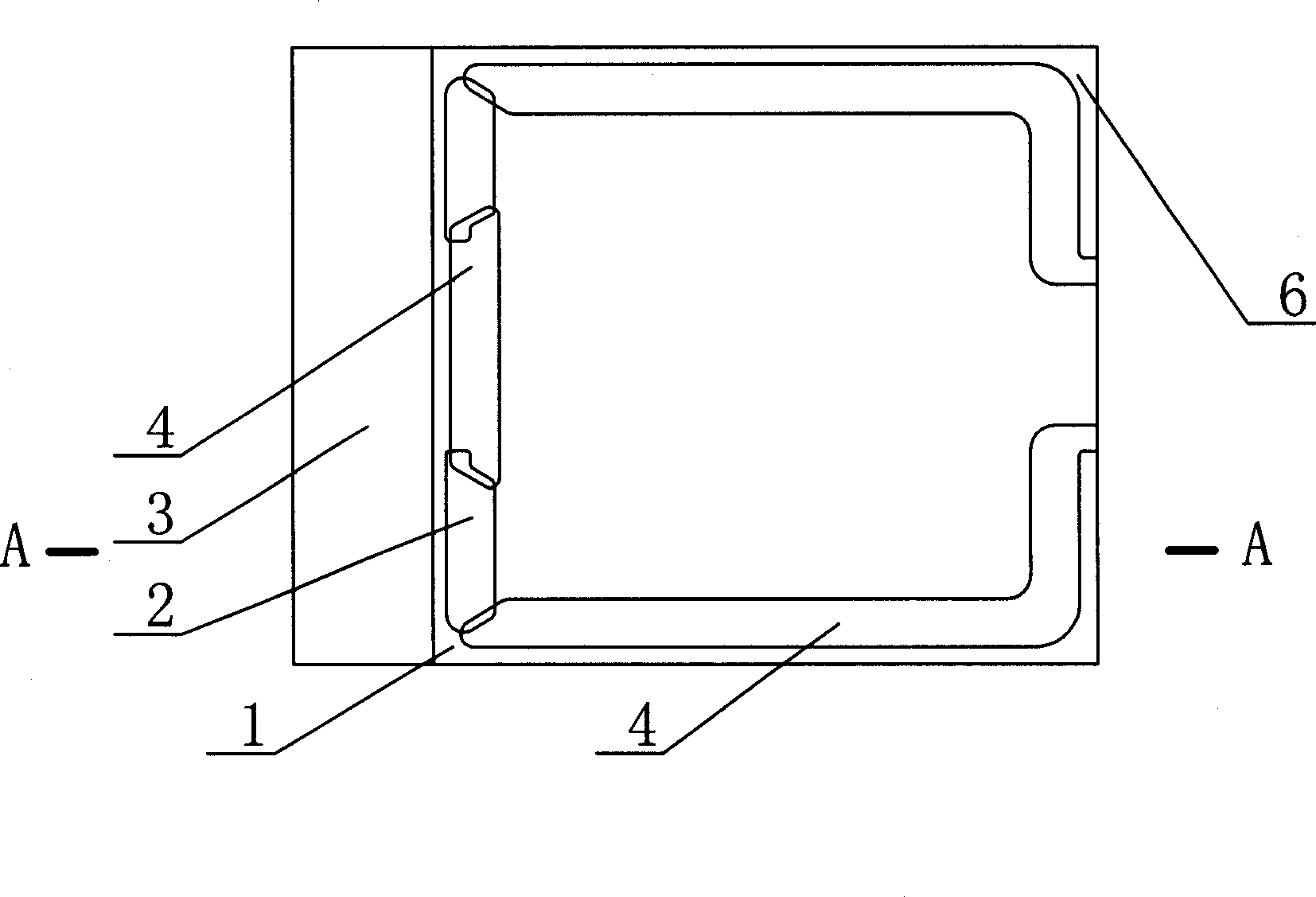

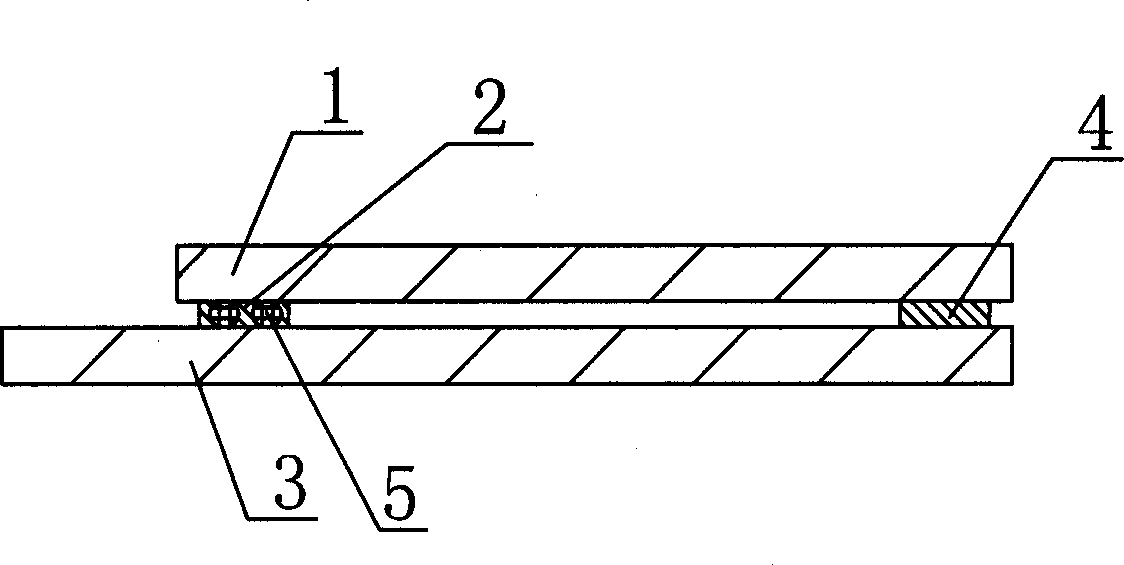

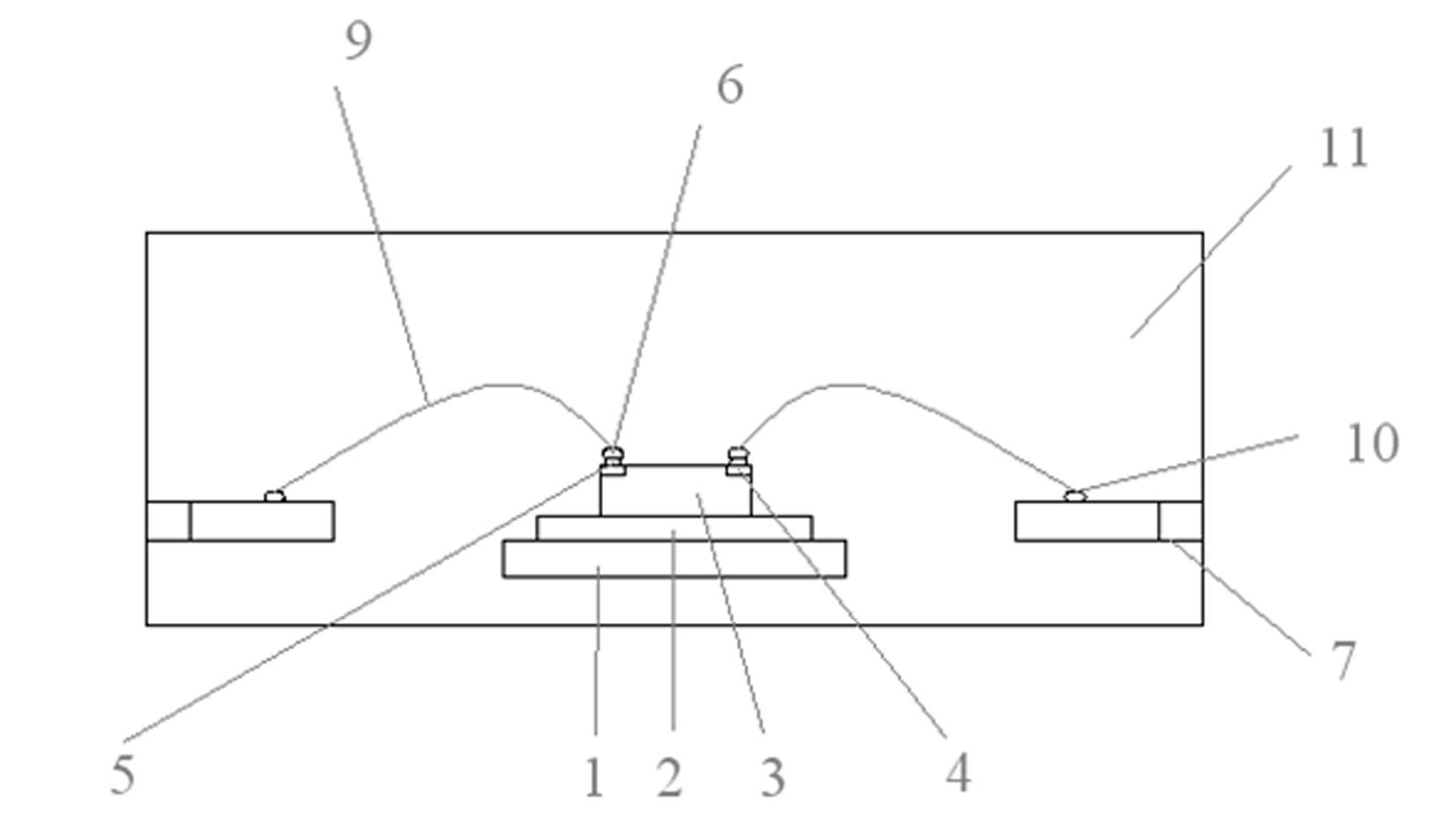

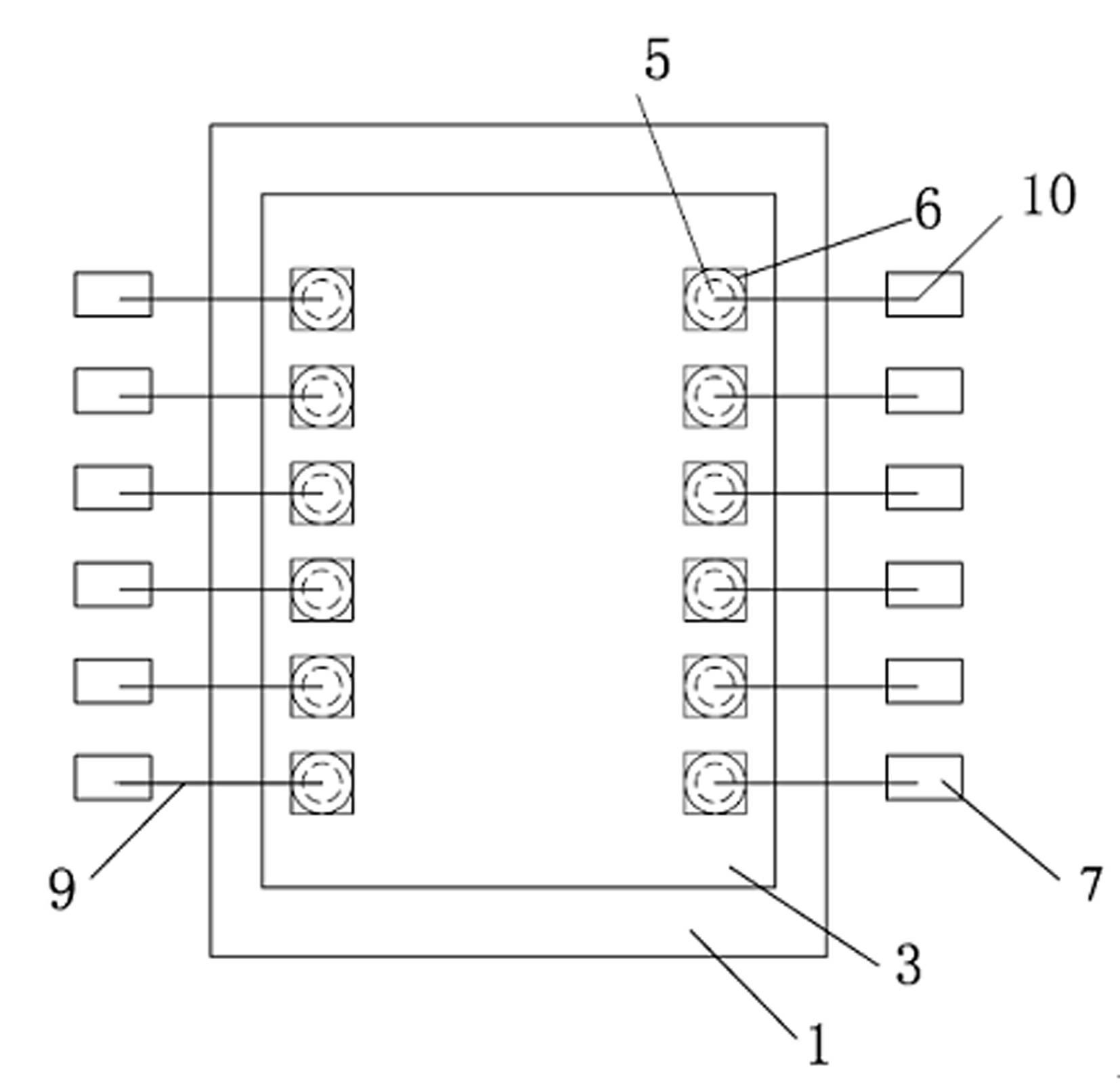

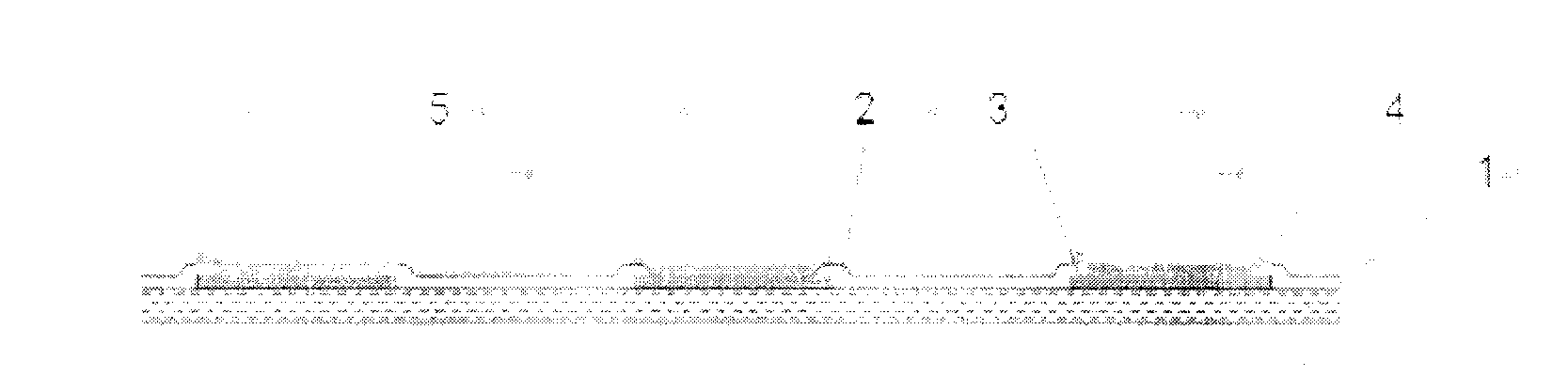

Packaging structure and packaging method of module comprising bare chips of thin-film bulk acoustic wave device

InactiveCN106783814AReduce volumeImprove packaging efficiencySemiconductor/solid-state device detailsSolid-state devicesGold ballAcoustic wave

The invention discloses a packaging structure and packaging method of a module comprising bare chips of a thin-film bulk acoustic wave device. The packaging structure of the multi-chip module comprises a substrate and bare chips, wherein the bare chips include the bare chips of the thin-film bulk acoustic wave device and other functional bare chips; electrodes of all bare chips are correspondingly connected with electrodes of the substrate through golden balls in a flip-chip manner; a film is bonded and fixed on the surface of the substrate; the film is clung to the surface of the substrate and coats all bare chips; and vacuum chambers are formed between all bare chips and the substrate. The electrodes of the bare chips on the to-be-packaged multi-chip module are welded on the corresponding electrodes in corresponding packaging areas on the substrate through a flip-chip technology during packaging; the protective film is laminated on the substrate through a vacuum laminating technology and coats all chips; and heating and solidifying are carried out and the substrate is finally cut according to the packaging areas. According to the packaging structure and the packaging method, the bare chips are directly adopted for packaging, so that the volume is greatly reduced in comparison with that of original secondary packaging, and meanwhile, the packaging efficiency is improved.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

Manufacturing method for flip chip gold bumps

InactiveCN103151275AGuaranteed uniformityEnsure consistencySolid-state devicesSemiconductor/solid-state device manufacturingScreen printingElectricity

The invention belongs to the field of semiconductor package and discloses a manufacturing method for flip chip gold bumps. The method includes the following steps: by utilization of screen printing method, scaling powder with high viscosity is printed on an electrode under bump metal (UBM) plating layer; by utilization of a ball placing device, a matched template is chosen, gold balls are placed on a weld plating layer and the situation that the gold balls are adhered to the chip electrode UBM plating layer is ensured; and by utilization of lasers, the gold balls are re-melted, appropriate irradiation time and power are chosen, and the gold bumps are obtained and meet the shape requirement and requirements of electricity and mechanical performance. By utilization of laser braze, the manufacturing method for the flip chip gold bumps has the unique advantages of being capable of heating locally and quickly, cooling quickly and the like. The laser input power and the laser irradiation time are controlled, the gold bumps with optimal bump shapes, the mechanical performance and the electricity performance are obtained.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

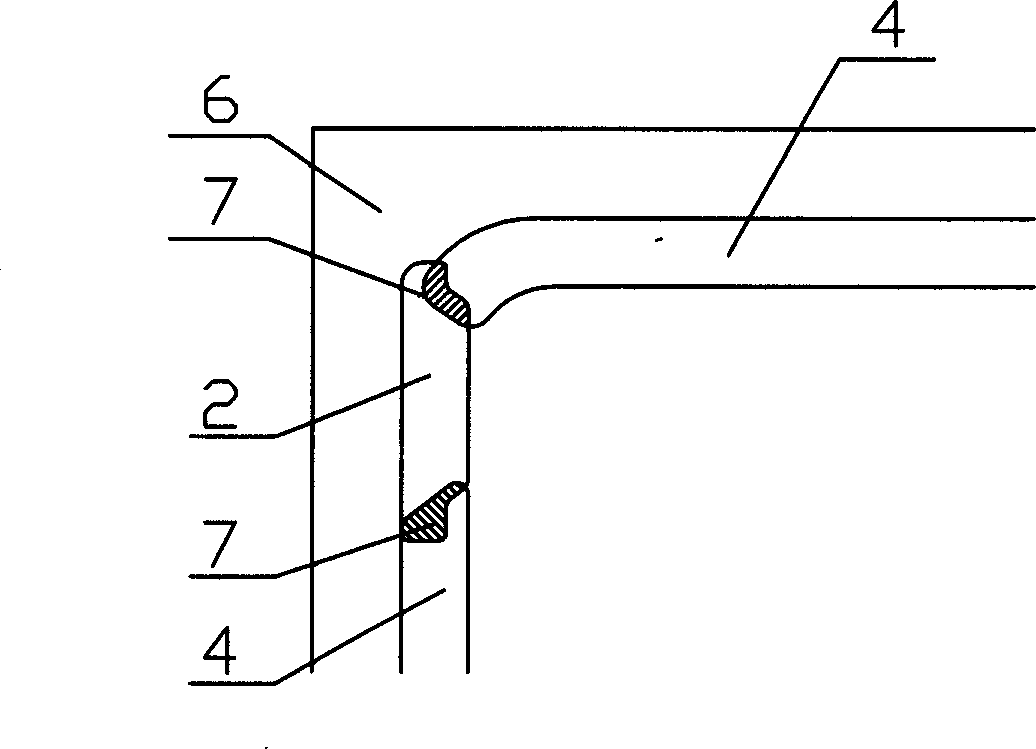

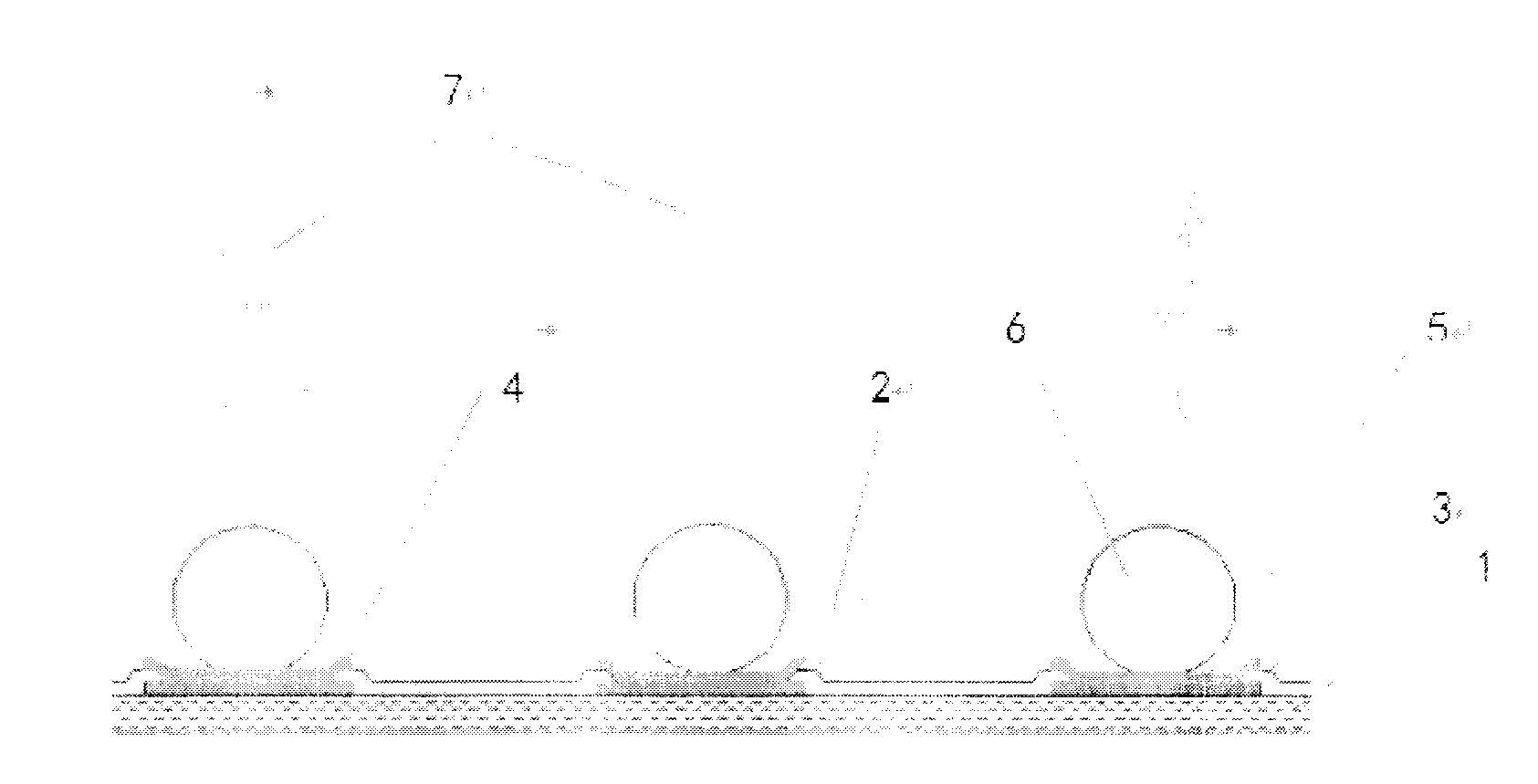

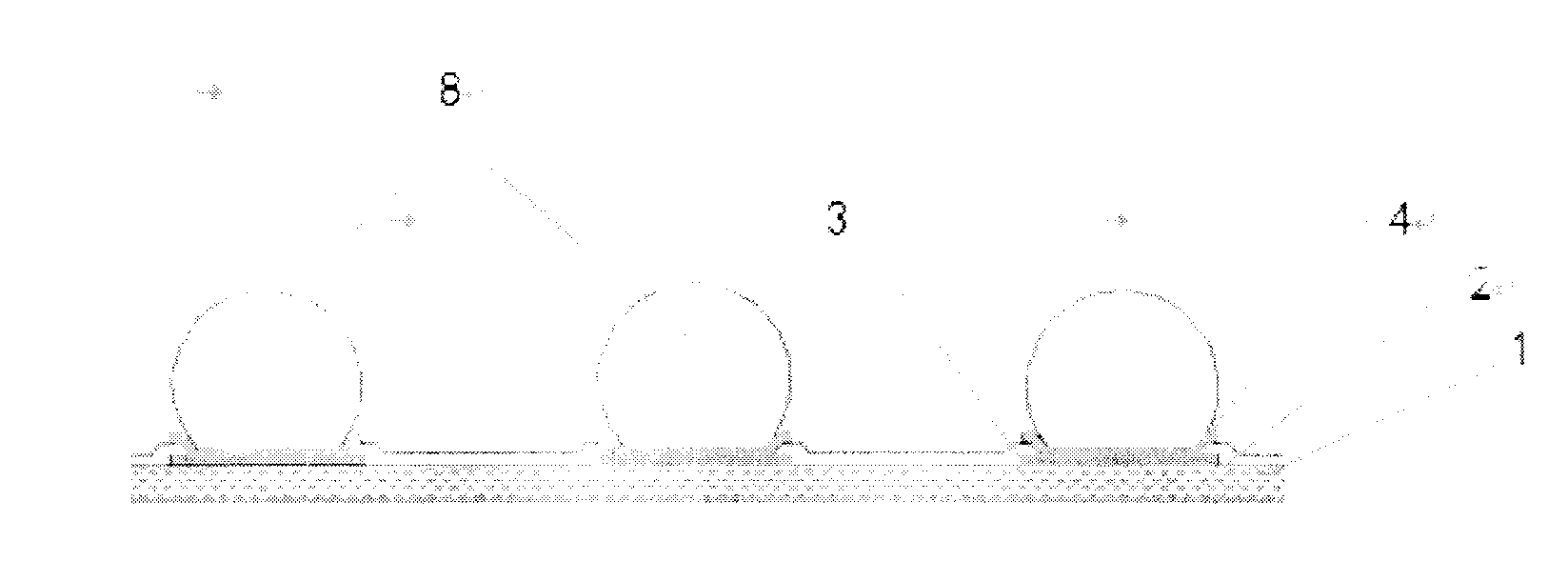

Display panel, manufacturing method and display device

ActiveCN109541856AIncrease the area that the overlay can accommodateBox heightNon-linear opticsGold ballSolder ball

The invention discloses a display panel, a manufacturing method and a display device. The display panel is divided into a display area and a non-display area, and comprises a first substrate, a secondsubstrate, a gold ball, and frame glue. The gold ball communicates with the first substrate and the second substrate, and the area where the gold ball is disposed is a transition area. The frame glueis disposed between the first substrate and the second substrate. The display panel further comprises a retaining wall disposed on the non-display area of the first substrate or the second substrate.The retaining wall is placed on one side of the frame glue to block the frame glue, and comprises a bent portion and a flat portion. The bent portion is connected to the flat portion, corresponds tothe position of the transition area, and protrudes from the flat portion in a direction away from the gold ball. The bent portion in the scheme corresponds to the position of the gold ball, expands outwards in the direction away from the gold ball, enlarges the area in which the frame glue and the gold ball are overlapped, so that the thickness of a box at the edge of the display area can be prevented from being increased, the risk of light leakage is reduced, and the quality of the display panel is improved.

Owner:HKC CORP LTD

Manufacturing method of nail head gold bump

InactiveCN102184875AGood coplanarityAvoid failureSolid-state devicesSemiconductor/solid-state device manufacturingGold ballEngineering

The invention relates to a manufacturing method of a nail head gold bump, comprising the following steps of: establishing an exact energy equation on the relation between a gold wire and a gold ball; vertically moving a riving knife upwards after a first welding point is finished, wherein an opened wire clip makes the gold wire slide in the riving knife and reach the expected height, i.e. the height of a welded gold bump; moving the riving knife at a certain speed rapidly rightwards, and keeping a slight connection between the gold wire and the gold ball; moving the riving knife upwards for a section of distance, and then closing the wire clip; continuously moving the riving knife upwards till the gold wire is pulled apart; and moving the riving knife to a place above a next bonding point to discharge and form a ball, and carrying out a next bonding circulation process. In the manufacturing method of the nail head gold bump disclosed by the invention, the sizes of formed balls are controlled, thus the coplanarity of the bump is improved, the bonding point is prevented from failure, and a high-speed high-precision manufacturing process of the gold bump is obtained.

Owner:SHANDONG UNIV OF TECH

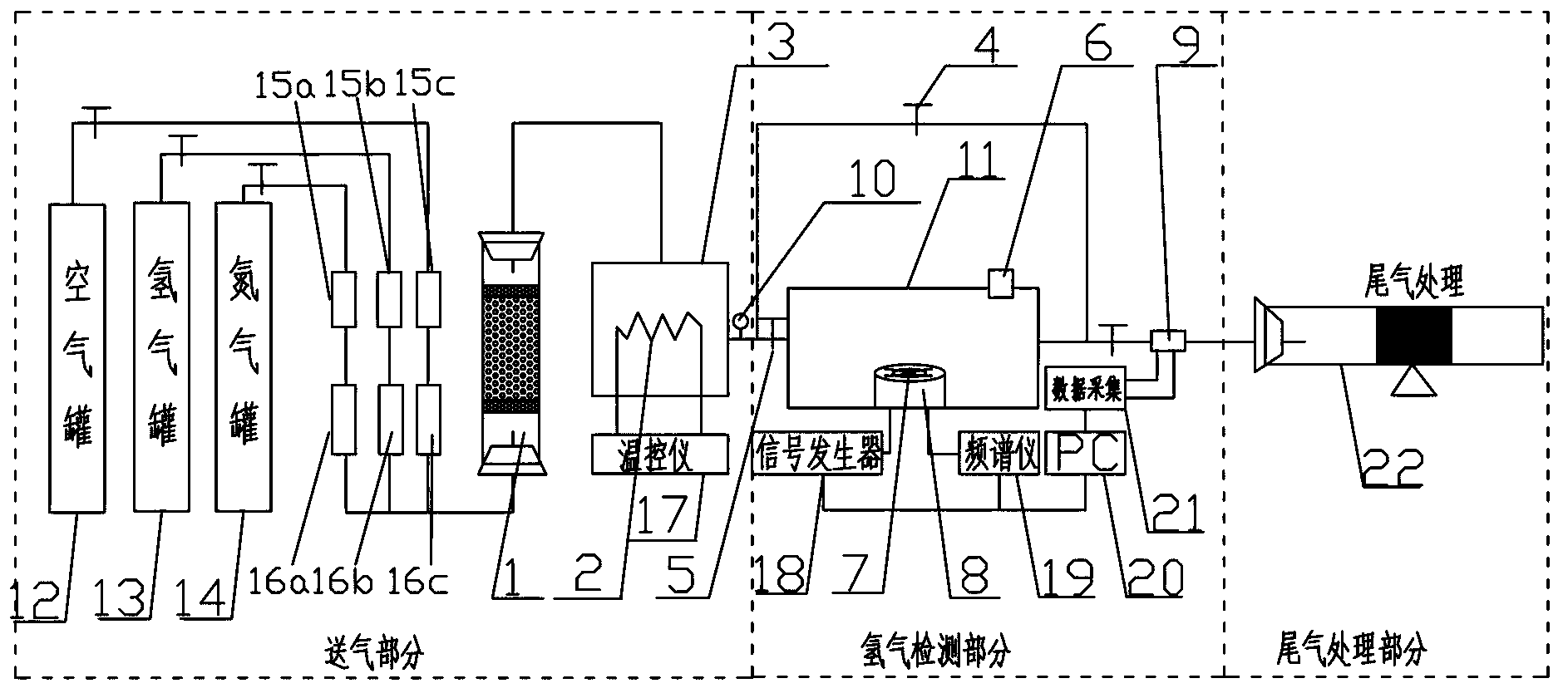

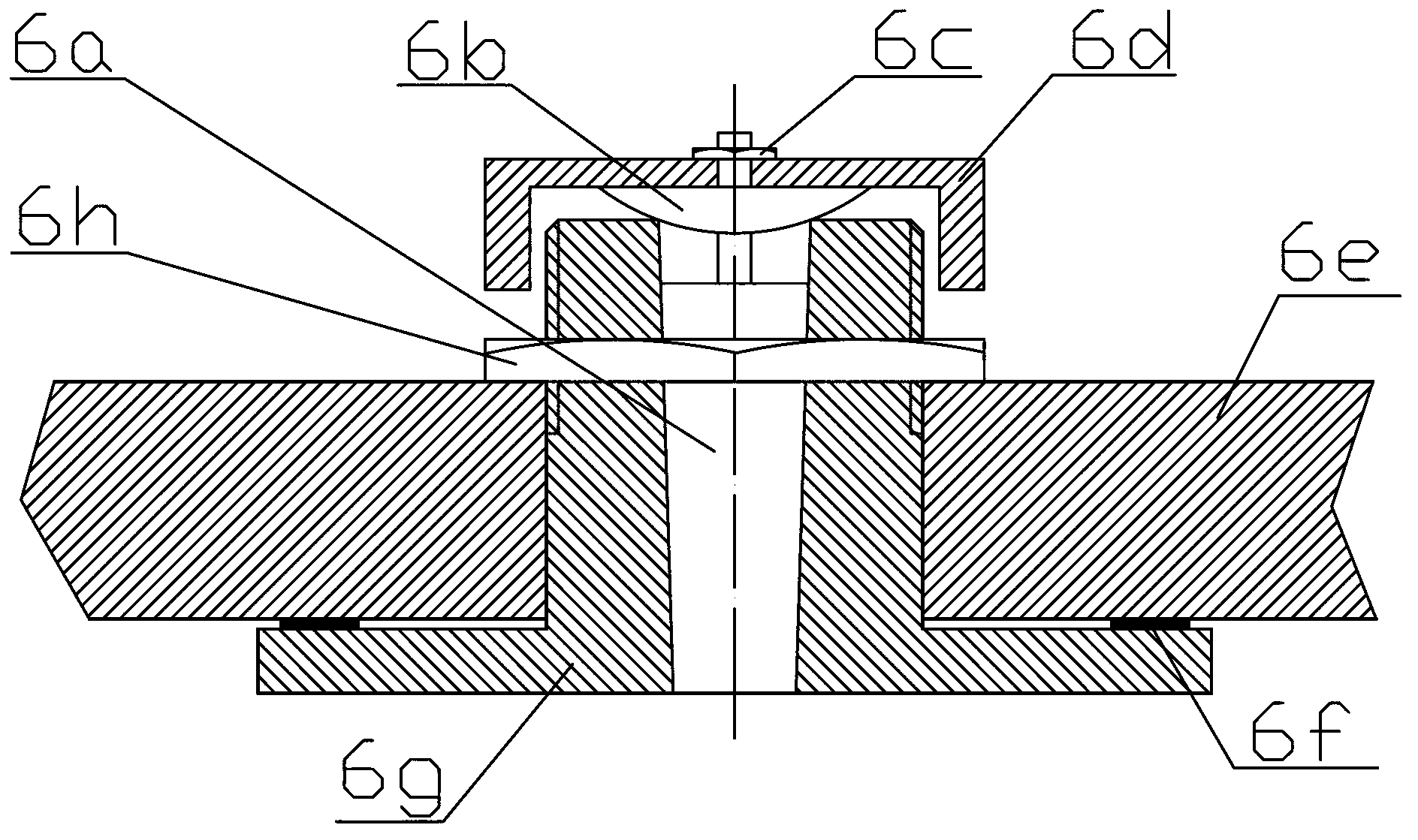

Hydrogen sensor testing system

InactiveCN103323524AWith overpressure protection functionNo pollution in the processAnalysing fluids using sonic/ultrasonic/infrasonic wavesGas analysisGold ball

The invention discloses a hydrogen sensor testing system which comprises a gas supply part and a hydrogen detection part which are connected with each other, wherein the gas supply part comprises a hydrogen tank, a nitrogen tank, an air tank, a dryer and a gas storage chamber; the hydrogen tank, the nitrogen tank and the air tank are communicated to the dryer through pipelines; the dryer is communicated with the gas storage chamber; a heater controlled by a temperature controller is arranged in the gas storage chamber; the hydrogen detection part comprises an airtight chamber communicated with the gas storage chamber, a cylindrical platform in the airtight chamber, a signal generator, a spectrometer, a computer, a data acquisition card, and a tail gas analysis chamber communicated with the airtight chamber; the cylindrical platform is used for accommodating a gold ball bonding rack which is integrally connected with a sensor chip; the signal generator and the spectrometer are electrically, movably and respectively connected with the gold ball bonding rack and are also connected with the computer; a galvanic couple sensor and a gas flow sensor are arranged in the tail gas analysis chamber.

Owner:NANJING UNIV OF TECH

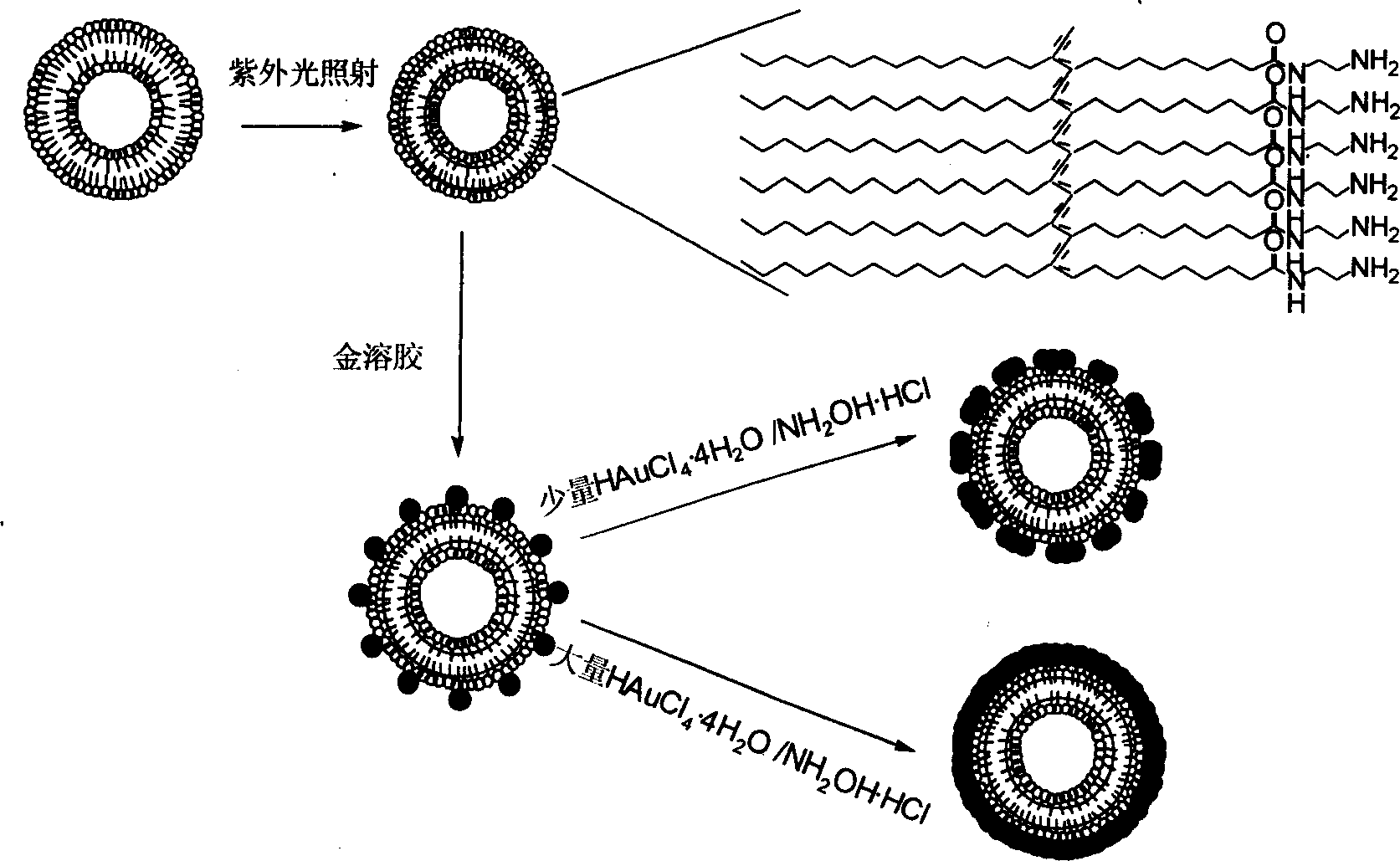

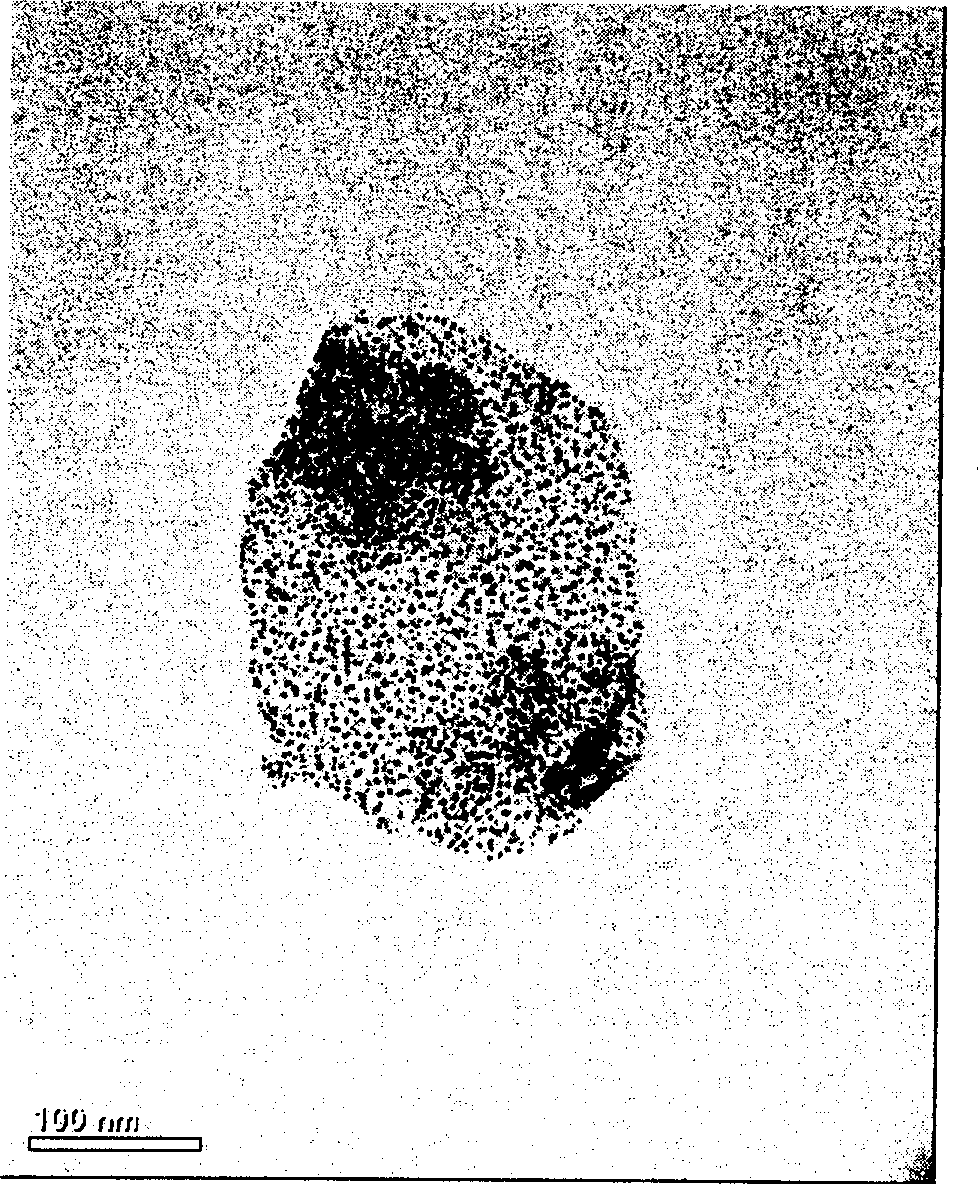

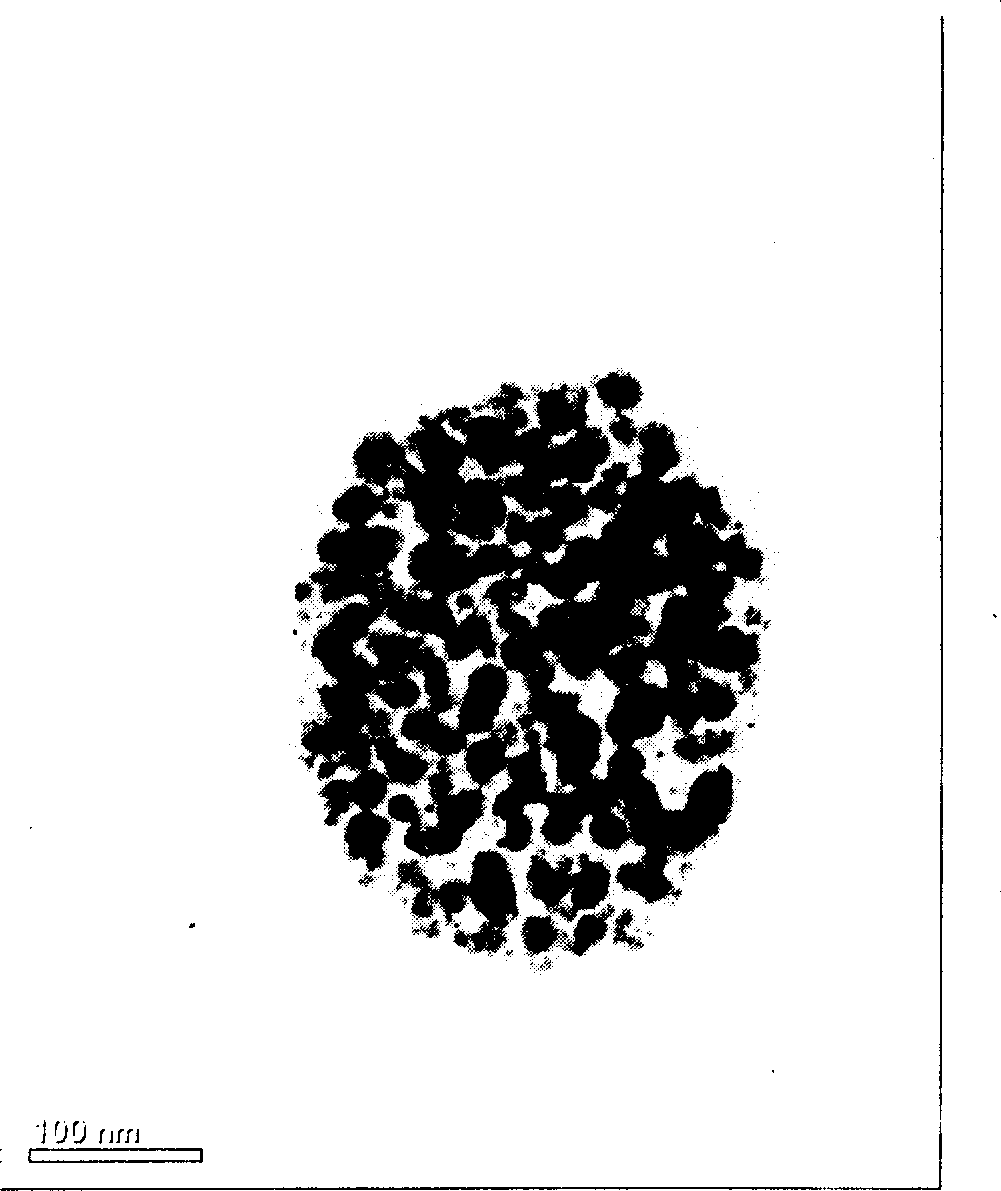

Process for preparing controllable hollow nanometer gold ball based on polymeric vesicle mold plates

InactiveCN1730150AEasy to makeLow costMaterial granulationMicroballoon preparationGold ballControllability

The invention discloses a method of preparing controlled hollow gold nanoball based on synangium mold plates. The invention comprises the following steps: mixing nano-gold solution with acetylene polymer vesicle; shaking, stewing and centrifuging it; removing upper solution; adding deionized water to the bottom; scattering solution at the bottom by supersound and repeating said centrifuging and scattering courses to get hollow gold nanoball. Further more said gold nanoball is added into aqueous solution containing HAuCl4.4H2O and NH2OH.HCl under the condition of stirring and is subject to centrifuging and scattering courses. The invention has the advantages of preparing simplicity, low cost, high stability, good controllability of surface coverage and so on, so can be used in domains such as adsorption and catalysis.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Mercury process gold ballbond removal apparatus

InactiveUS6294028B1Reduce riskManufacture of electrical instrumentsCleaning using toolsGold ballSemiconductor chip

A method and apparatus for reducing the risk of environmental contamination from mercury spillage during carry over between processing tanks during the gold ball bond removal process by providing a self-contained, compact, environmentally safe system for use with toxic chemicals and liquids. The present invention provides a self-contained, integrally molded enclosure upper and lower chambers separated by a partition. The partition has a plurality of stations integrally formed therein, each of which is capable of containing a chemical liquid. The method comprises dipping a slide containing the semiconductor chip first into a toxic liquid, then into a first decontamination station and finally into a second decontamination station.

Owner:GLOBALFOUNDRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com