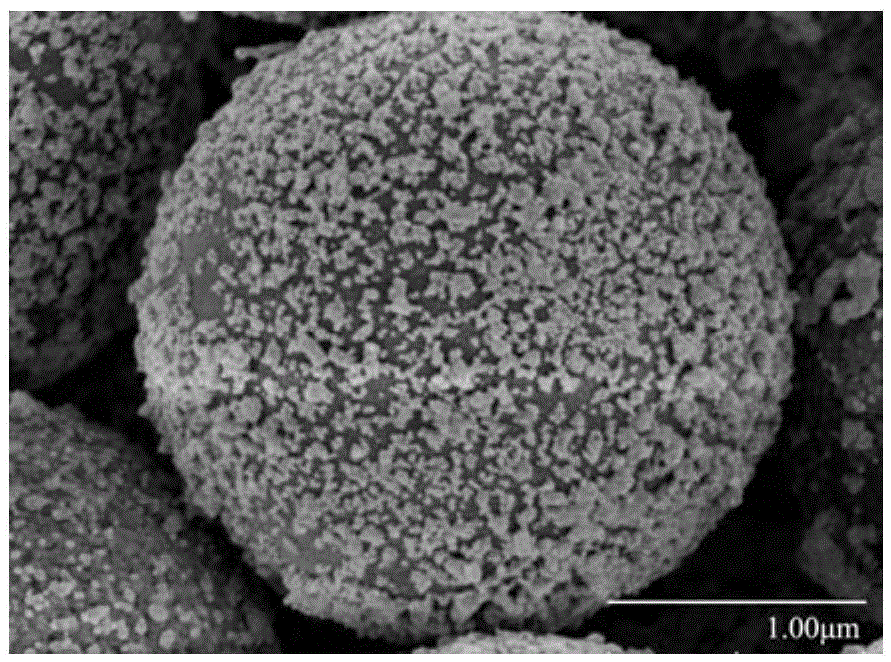

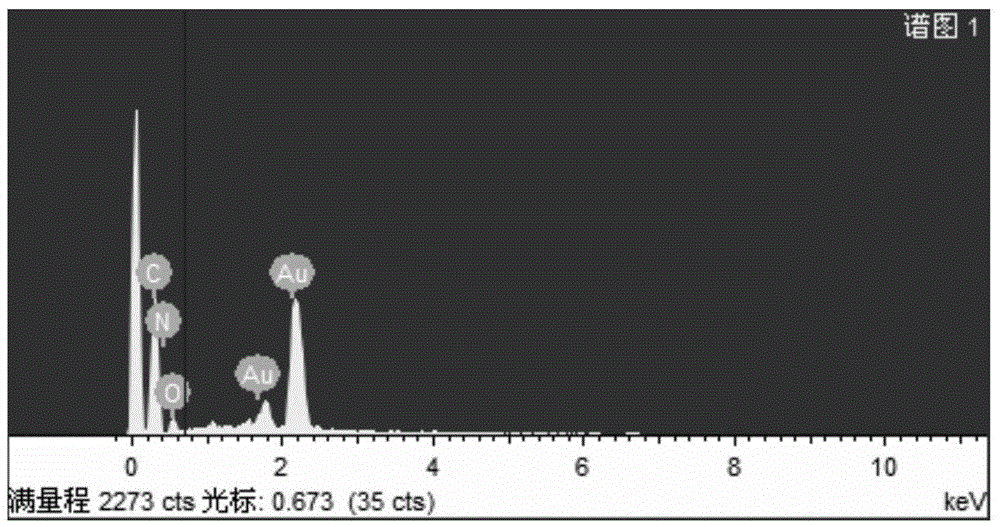

Preparation method of micron polymer-based composite conductive gold balls

A composite conductive and polymer technology, used in metal processing equipment, transportation and packaging, can solve the problems of poor bonding fastness between the gold layer and the polymer matrix, endangering the life safety of operators, and uneven adsorption. Large-scale production, low production cost, and the effect of enhancing bond fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Dissolve 1 g of the dispersant polyvinylpyrrolidone (PVP) in 22 g of ethanol solvent, then add 10 g of styrene monomer with 0.11 g of azobisisobutyronitrile into the ethanol solution, and stir evenly , added to a four-necked flask with nitrogen, the reaction temperature was 75 ° C, mechanically stirred for 20 h, and then centrifuged and washed to obtain monodisperse polystyrene microspheres.

[0035] (2) Disperse the polystyrene microspheres synthesized above in an appropriate amount of water, add polyvinyl alcohol, and stir thoroughly to obtain evenly and stably dispersed microspheres.

[0036] (3) Disperse 1 g of the above-prepared polystyrene microspheres in a mixed solution of water and ethanol, add 0.1 g of 2-aminopyrrole after stirring evenly, add 0.05 g of ammonium persulfate and place on ice React in a water bath for 12 hours, wash by centrifugation, and vacuum-dry at 60°C to obtain aminated polystyrene microspheres.

[0037] (4) Add mercaptobutyric acid to...

Embodiment 2

[0040] (1) dispersant polyvinyl alcohol 1g, dissolve in the methanol solvent of 22g, add 0.75g polyacrylic acid, then add the methyl methacrylate monomer 10g that is dissolved in the benzoyl peroxide of 0.11g to methanol solution After stirring evenly, it was added into a four-necked flask with nitrogen gas, the reaction temperature was 75°C, mechanically stirred for 20 hours, and then washed by centrifugation.

[0041] (2) Disperse the polymer microspheres synthesized above in an appropriate amount of water, add polyvinylpyrrolidone, and stir thoroughly to obtain evenly and stably dispersed microspheres.

[0042] (3) Disperse 1 g of the polymer microspheres prepared above in a mixed solution of water and ethanol, stir well and add 0.1 g of diphenylamine, mix well, add 0.05 g of ferric chloride, and place in an ice-water bath React for 12 hours, wash by centrifugation, and dry under vacuum at 60°C.

[0043] (4) Add thioglycolic acid to the gold sol reduced with dimethylborane...

Embodiment 3

[0046] (1) Dissolve 1 g of polyvinyl alcohol as a dispersant in 22 g of ethanol solvent, then add 10 g of methyl methacrylate monomer 0.11 g of azobisisobutyronitrile into the ethanol solution, and stir evenly , was added to a four-neck flask with nitrogen gas, the reaction temperature was 75°C, mechanically stirred for 20 hours, and then washed by centrifugation.

[0047] (2) Disperse the polymer microspheres synthesized above in an appropriate amount of water, add polyvinylpyrrolidone, and stir thoroughly to obtain evenly and stably dispersed microspheres.

[0048] (3) Disperse 1 g of the polymer microspheres prepared above in a mixed solution of water and ethanol, stir evenly, add 0.1 g of 4-(2-aminoethyl)-1,2-benzenediol, mix well Finally, 0.05 g of ammonium persulfate was added, reacted for 12 hours, washed by centrifugation, and dried in vacuum at 60°C.

[0049] (4) Add thioglycolic acid to the gold sol reduced with sodium borohydride to obtain a carboxylic acid-modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com