Patents

Literature

2251 results about "Gold plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold plating is a method of depositing a thin layer of gold onto the surface of another metal, most often copper or silver (to make silver-gilt), by chemical or electrochemical plating. This article covers plating methods used in the modern electronics industry; for more traditional methods, often used for much larger objects, see gilding.

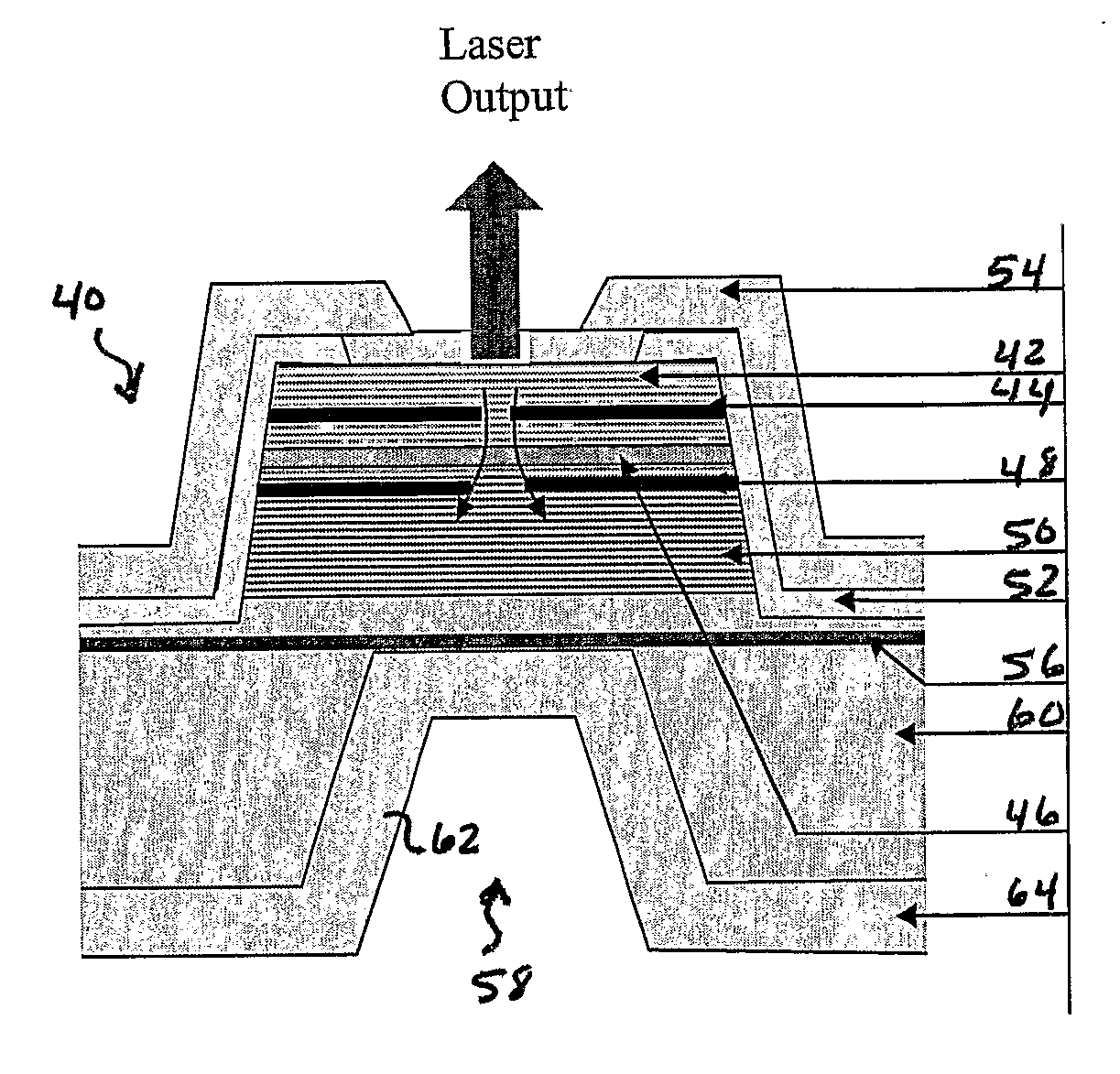

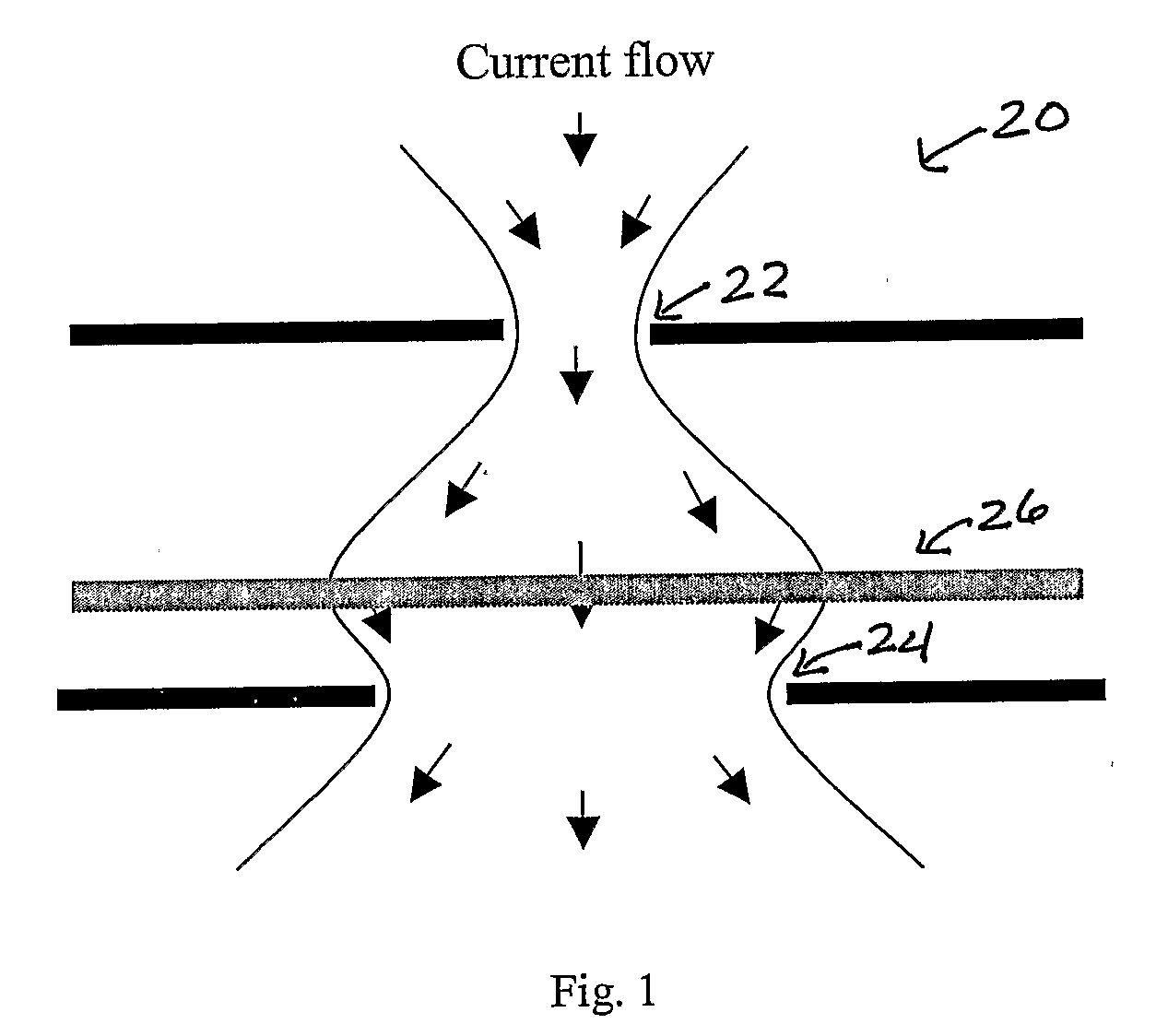

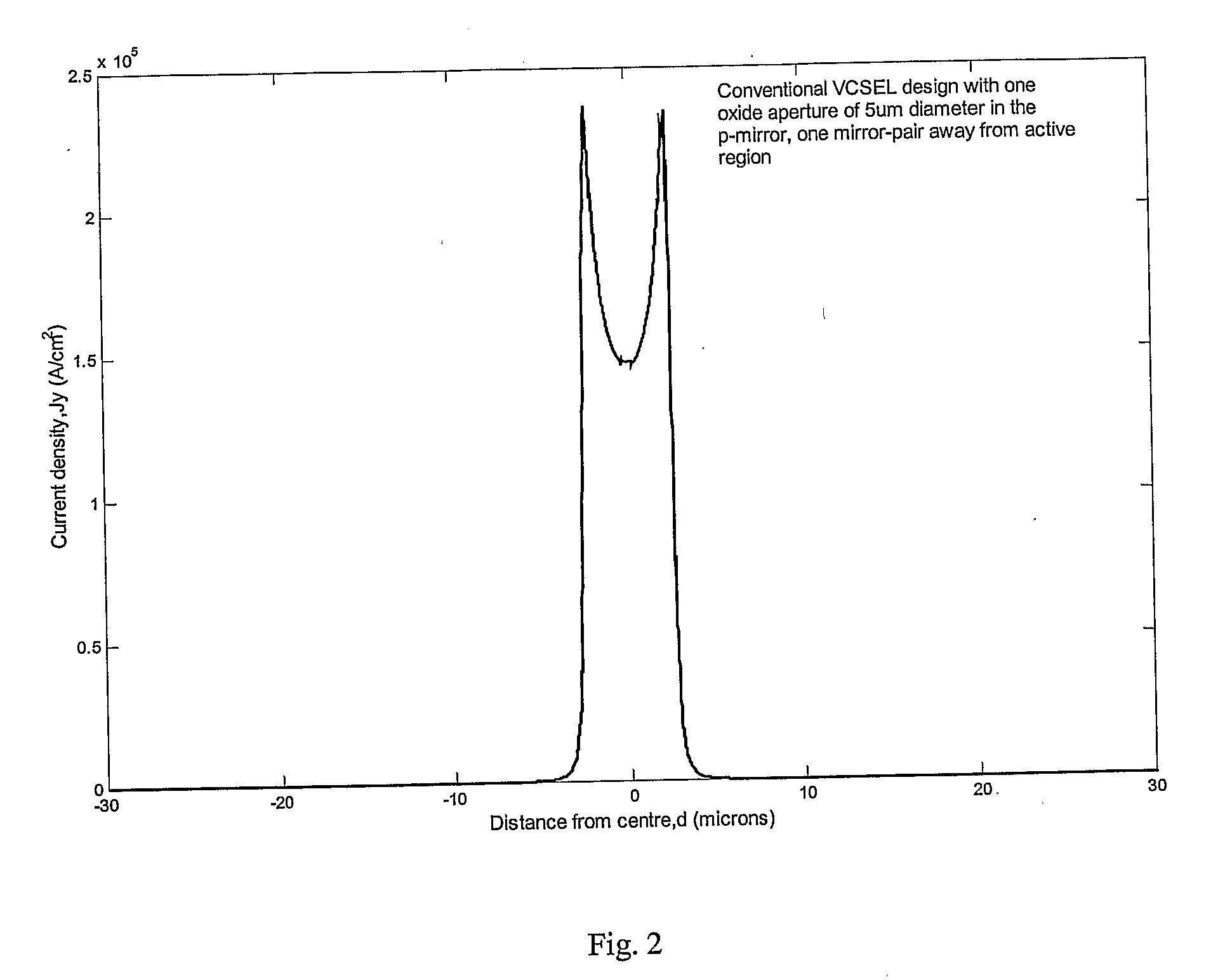

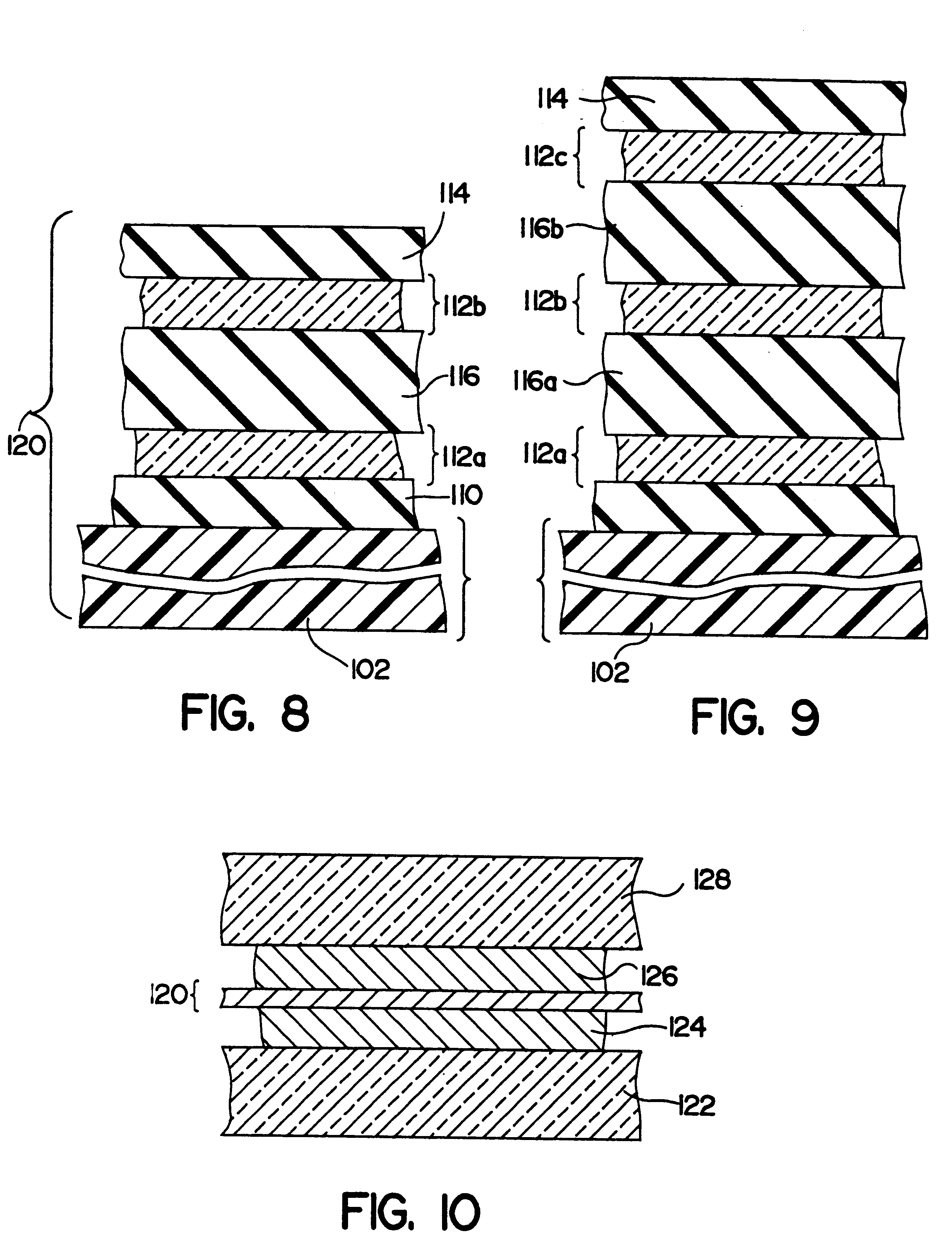

High Power Vcsels With Transverse Mode Control

InactiveUS20070242716A1High yieldSimple designLaser detailsSemiconductor lasersHigh power lasersMode control

A single mode high power laser device such as a VCSEL is formed with two oxide apertures, one on each side of the active region or cavity. The sizes of the apertures and the distances from the apertures to the cavity center are chosen or optimum, near-Gaussian current density distribution. The high power of a VCSEL thus formed is improved still more by good heat removal by either formation of a via through the substrate and gold plating on top and bottom of the VCSEL (including the via) or by lifting the VCSEL structure from the substrate and locating it on a heat sink.

Owner:ARIZONA STATE UNIVERSITY

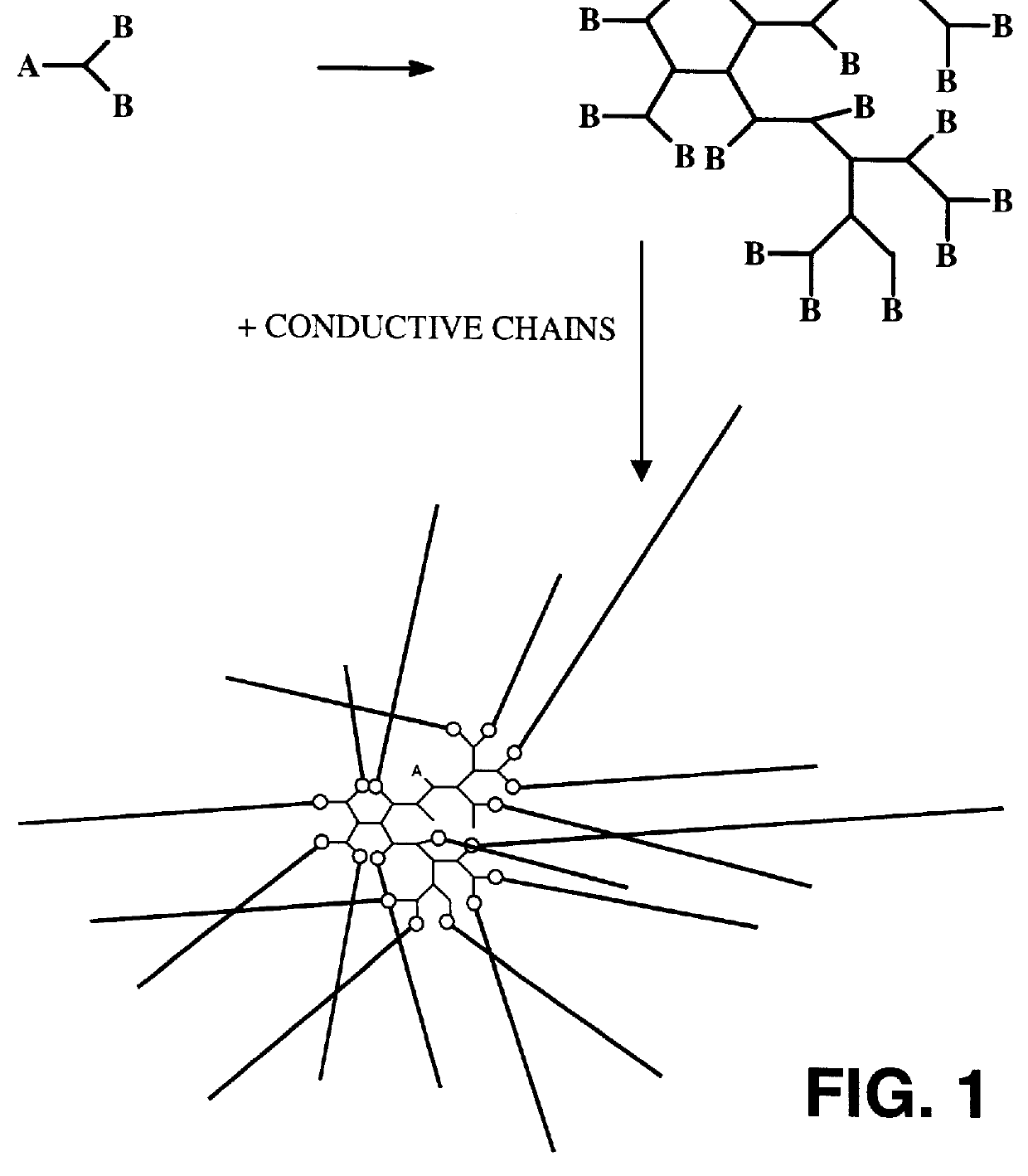

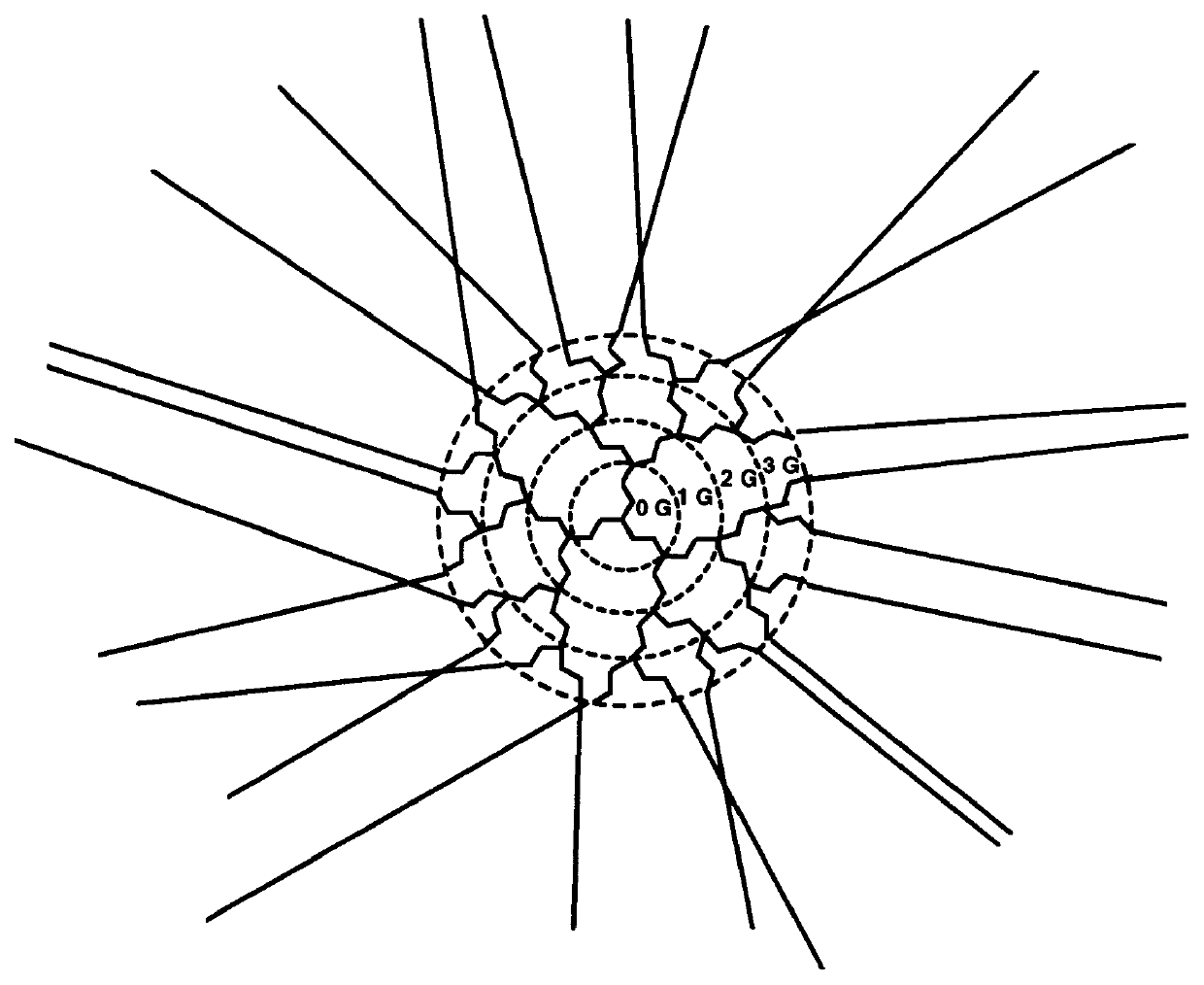

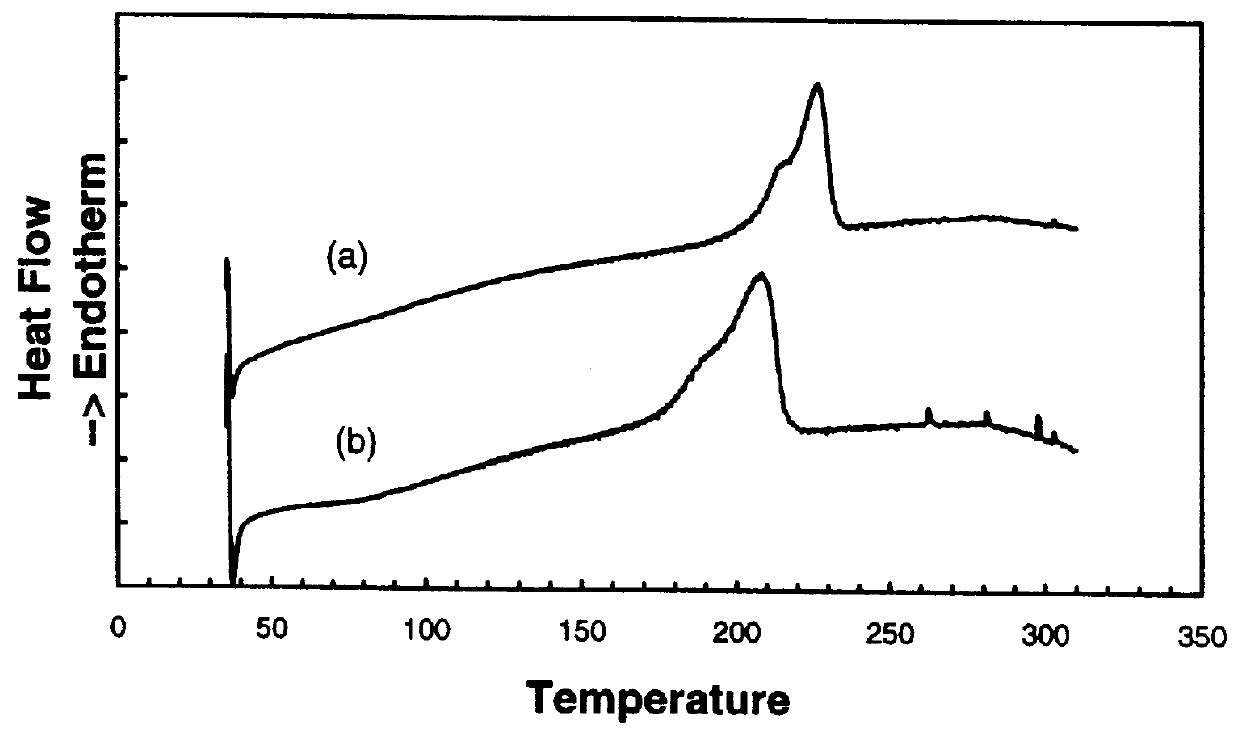

Reflective and conductive star polymers

Conductive polymers having a star structure comprising a central core with multiple attachment sites and conjugated charge transporting arms radiating therefrom. The cores are derived from hyperbranched polymers, dendrimers, or other molecules with a multiplicity of attachment sites. The arms are derived from conjugated oligomers and polymers such as polythiophene, polyaniline or polyphenylene. The subject polymers allow assembly of the macromolecules in all three dimensions in the solid state. A ramification of the compact assembly is the realization of highly reflective, smooth coatings simply applied from solution. A preferred embodiment having a 1,3,5 hyperbranched polyphenylene core and poly (3-hexylthiophene) arms provides lustrous reflective gold coatings.

Owner:EIC LAB

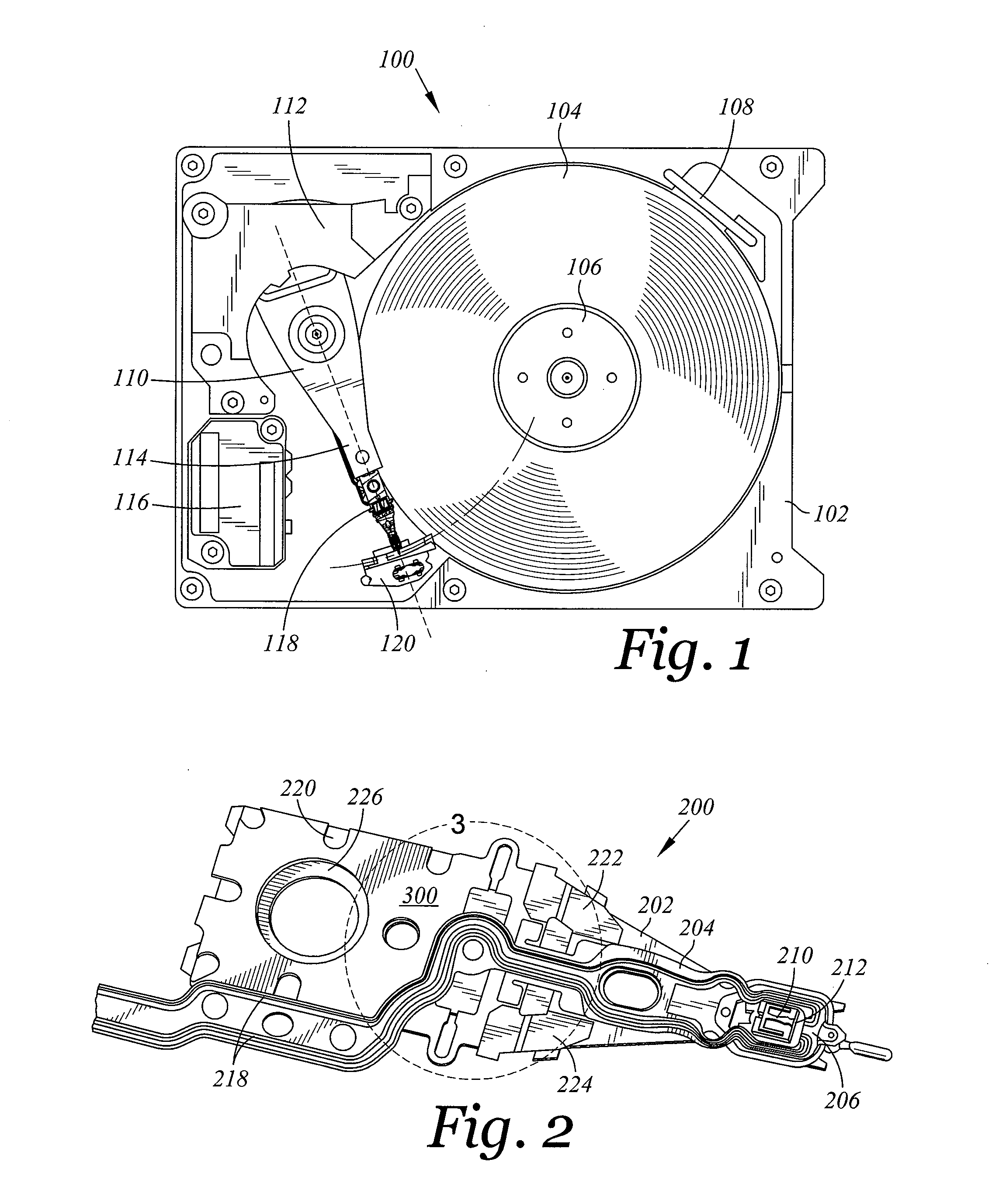

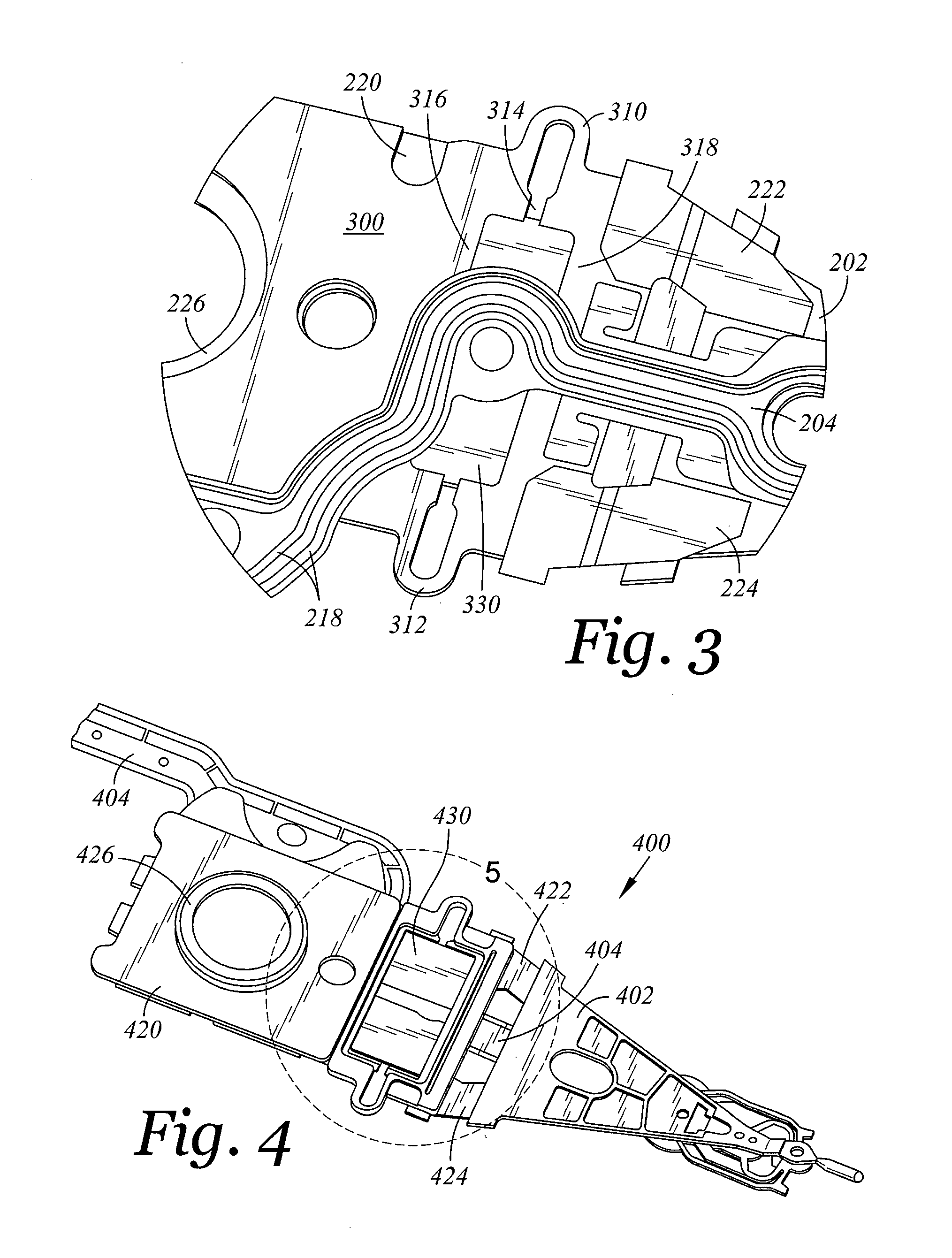

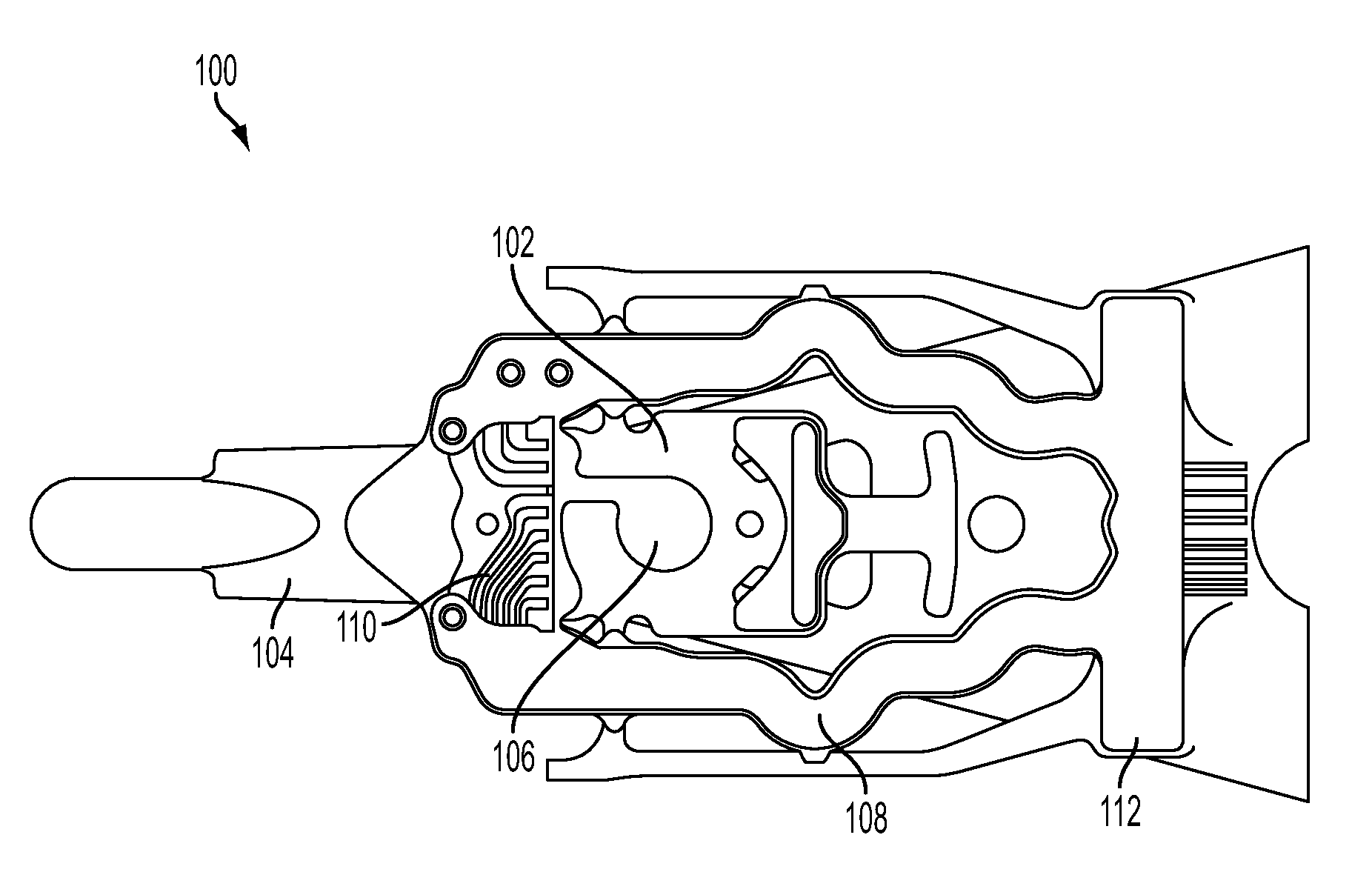

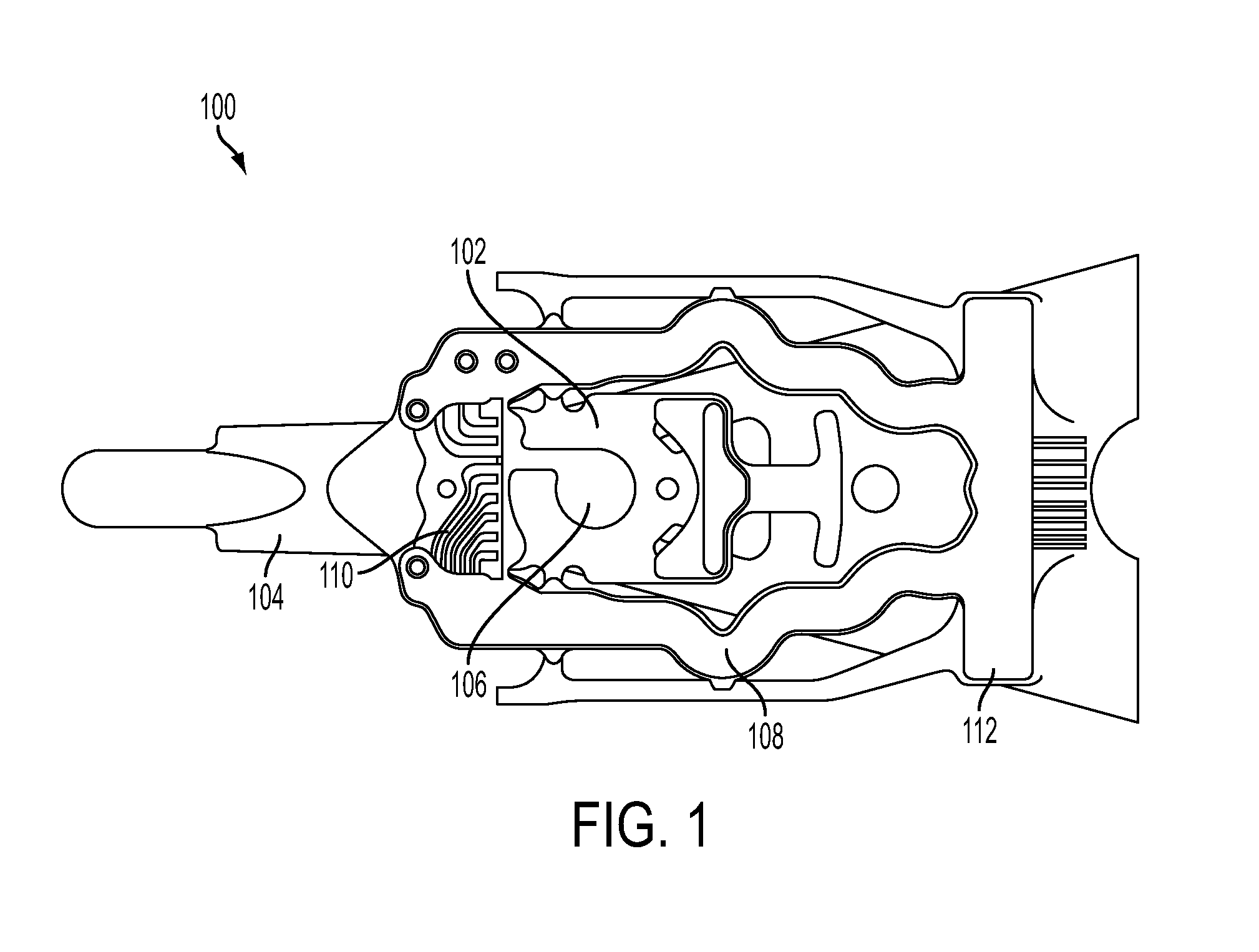

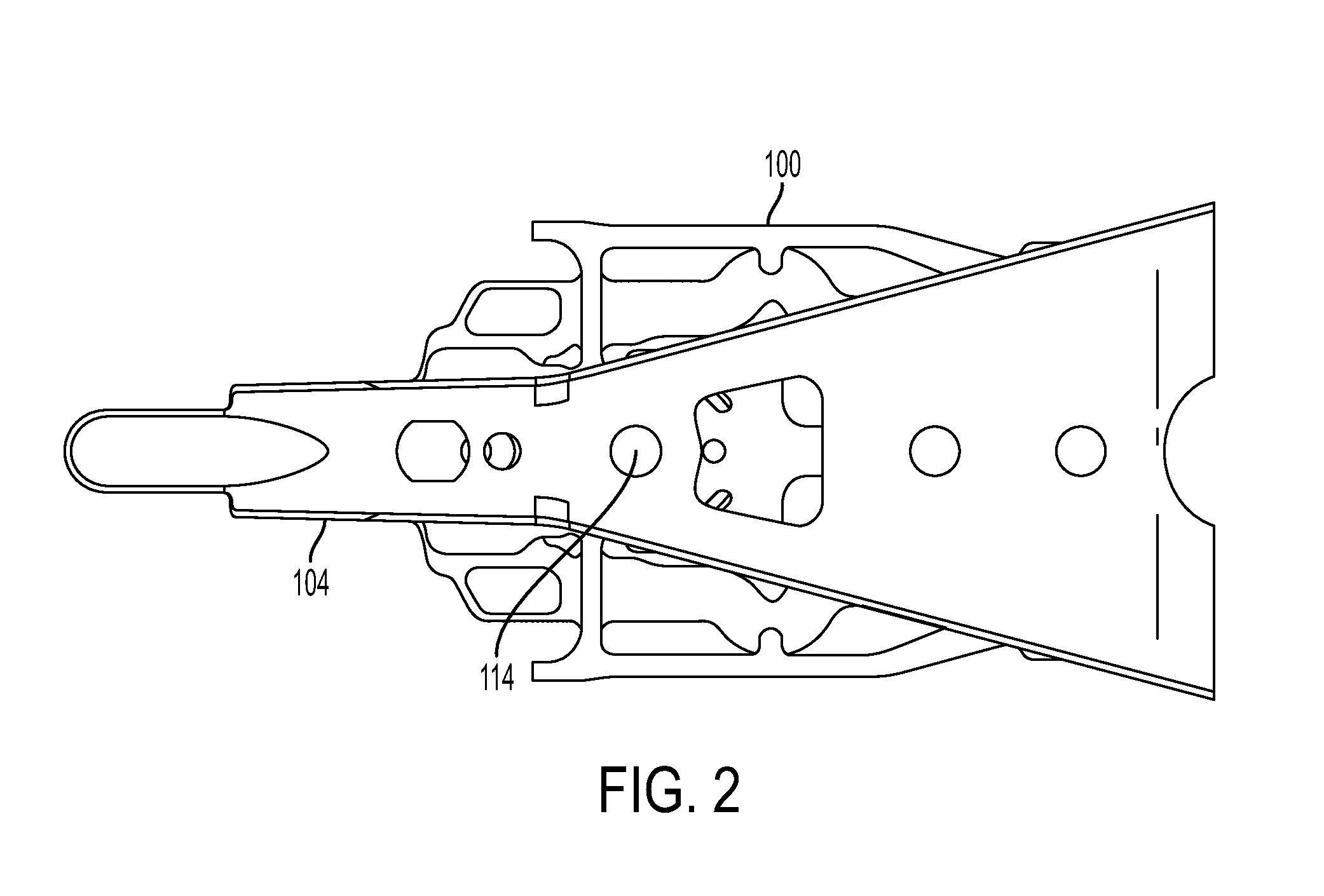

Suspension assembly having a microactuator electrically connected to a gold coating on a stainless steel surface

ActiveUS8542465B2Electrical connection between head and armArm with actuatorsPiezoelectric microactuatorEngineering

Owner:WESTERN DIGITAL TECH INC

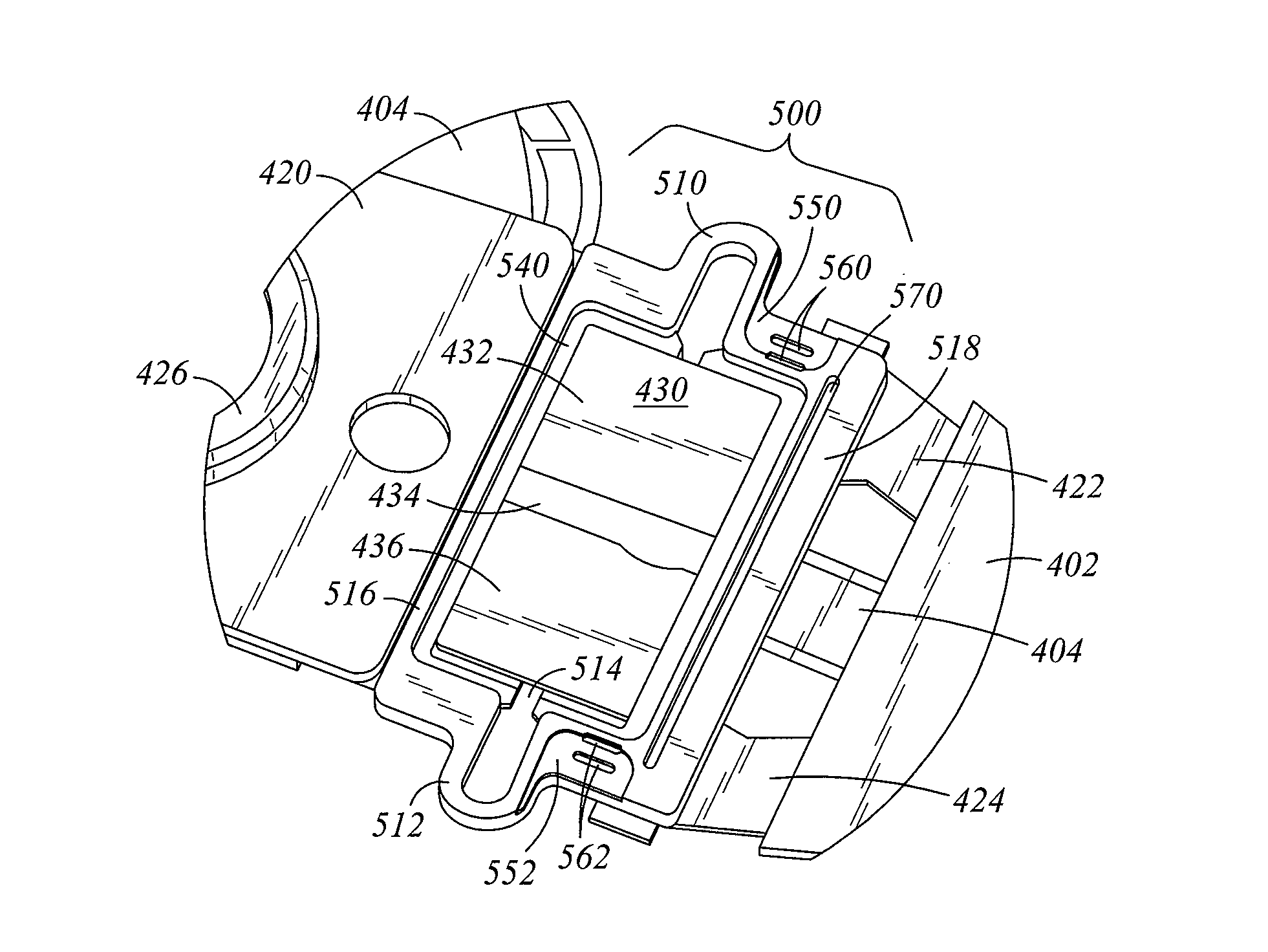

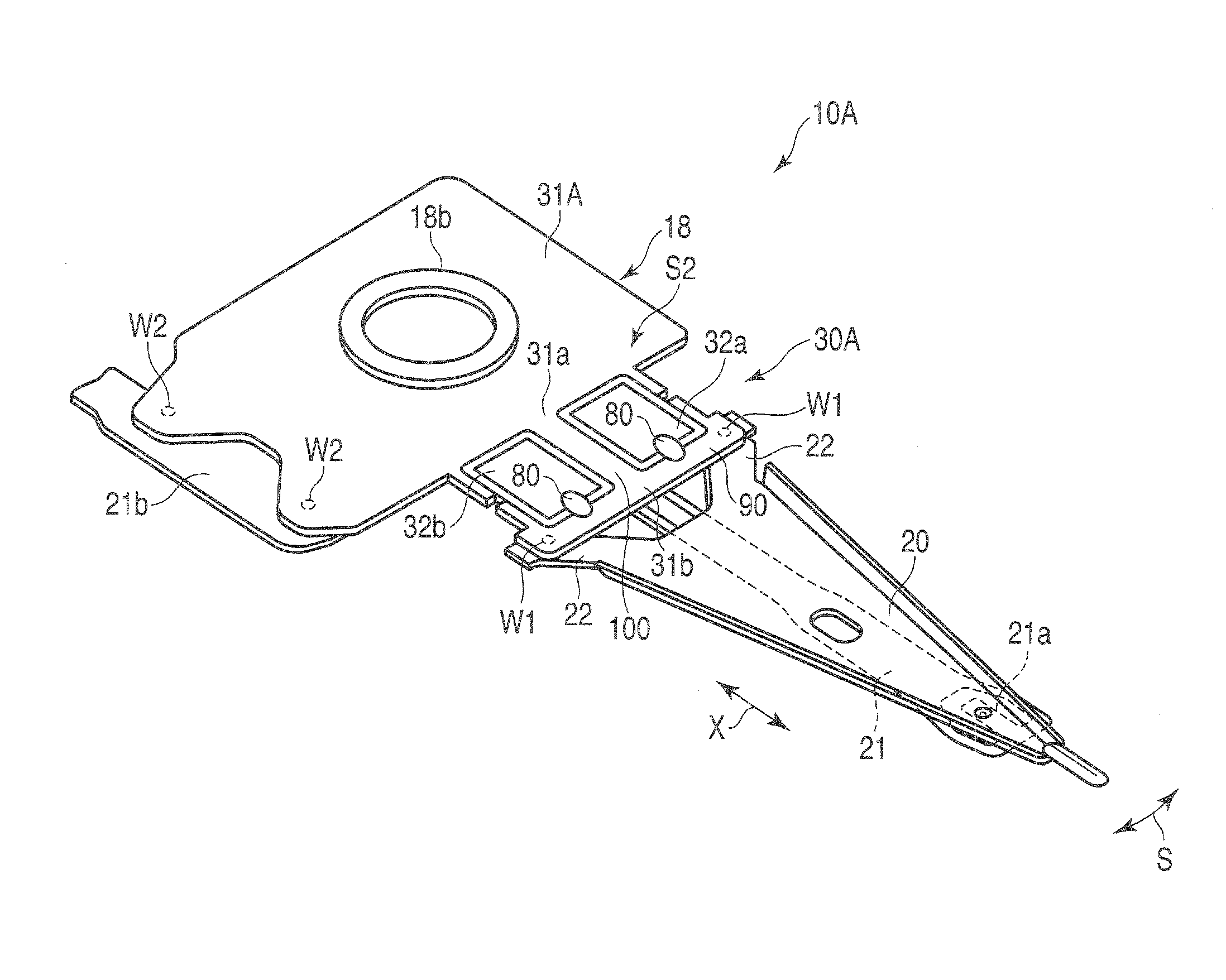

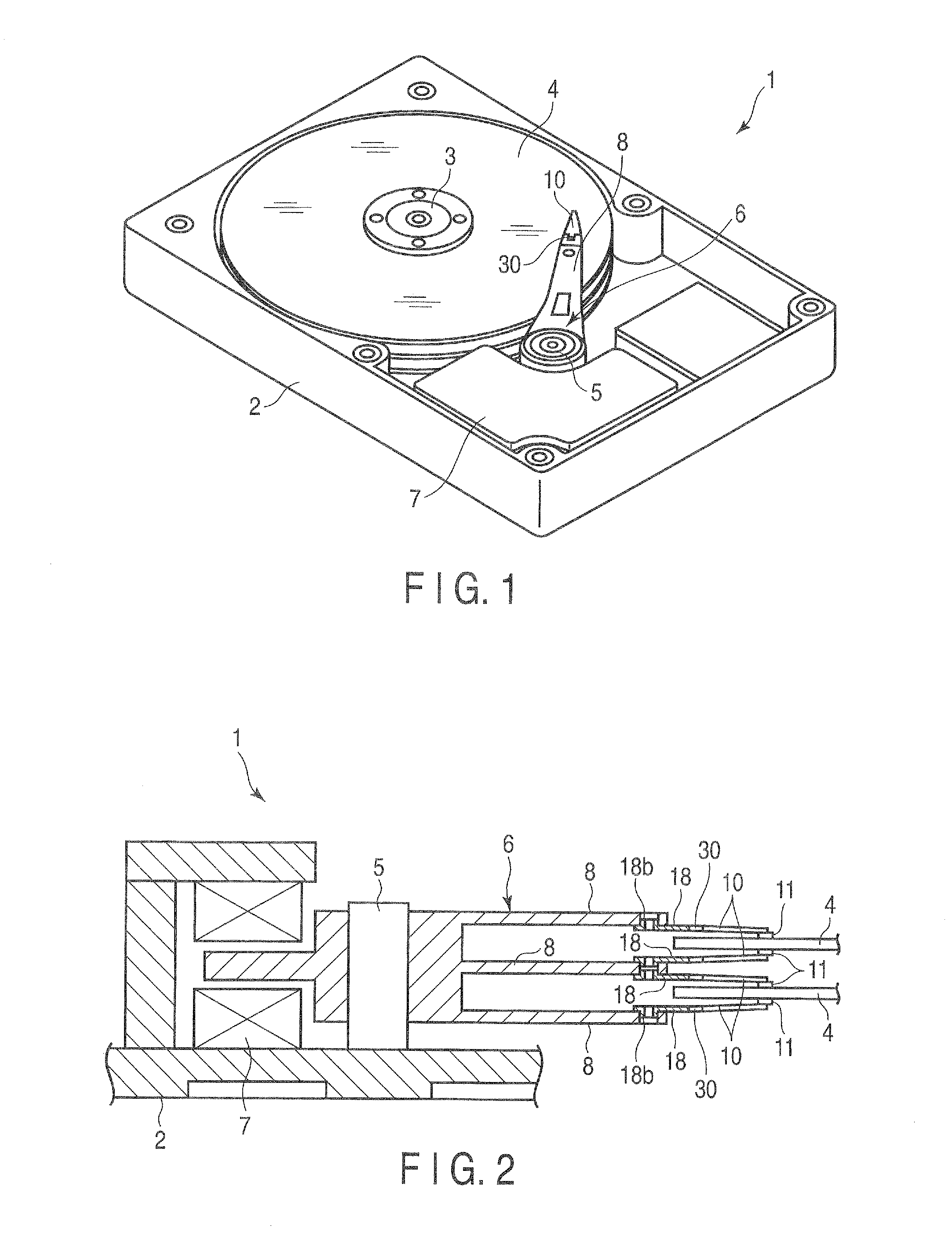

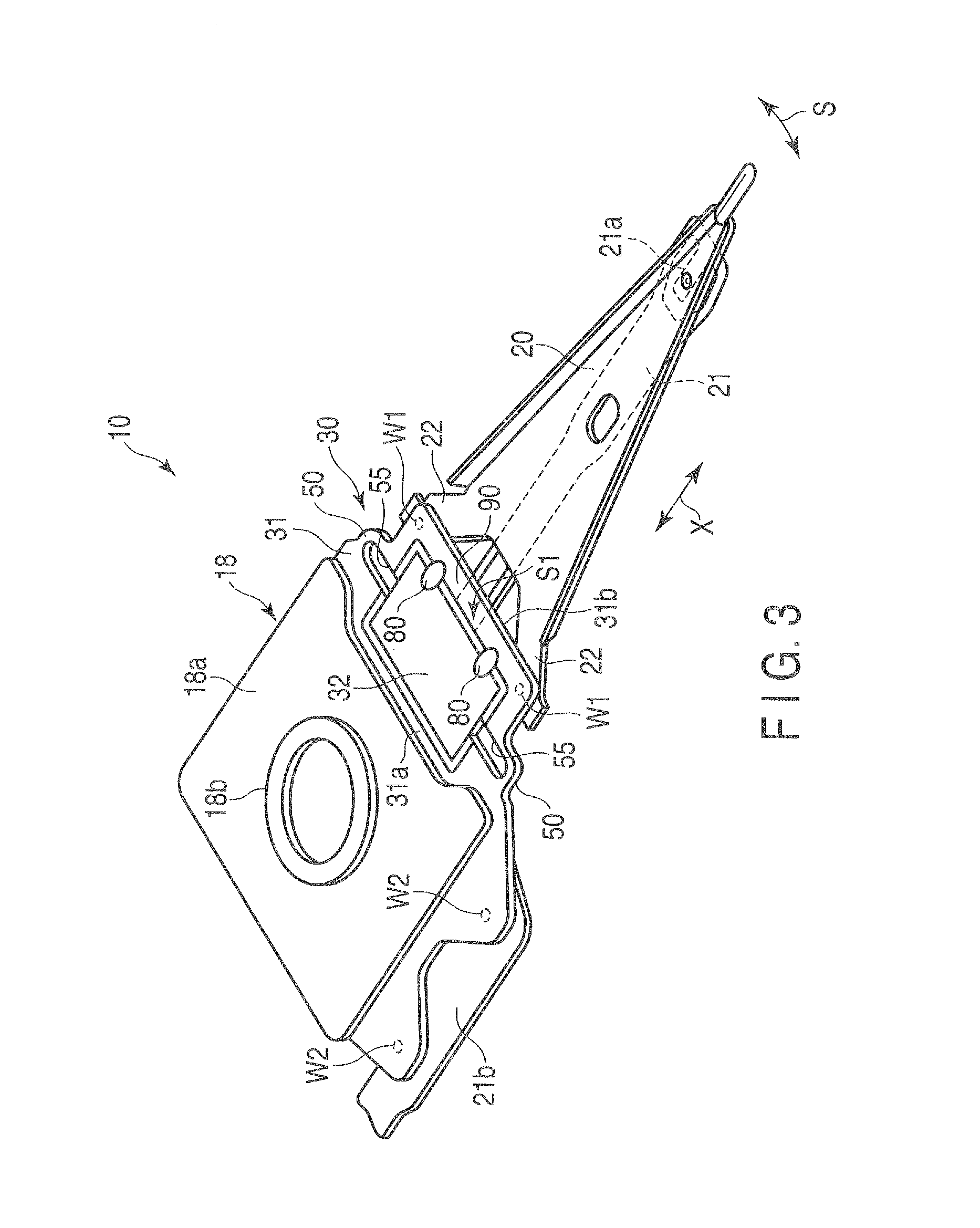

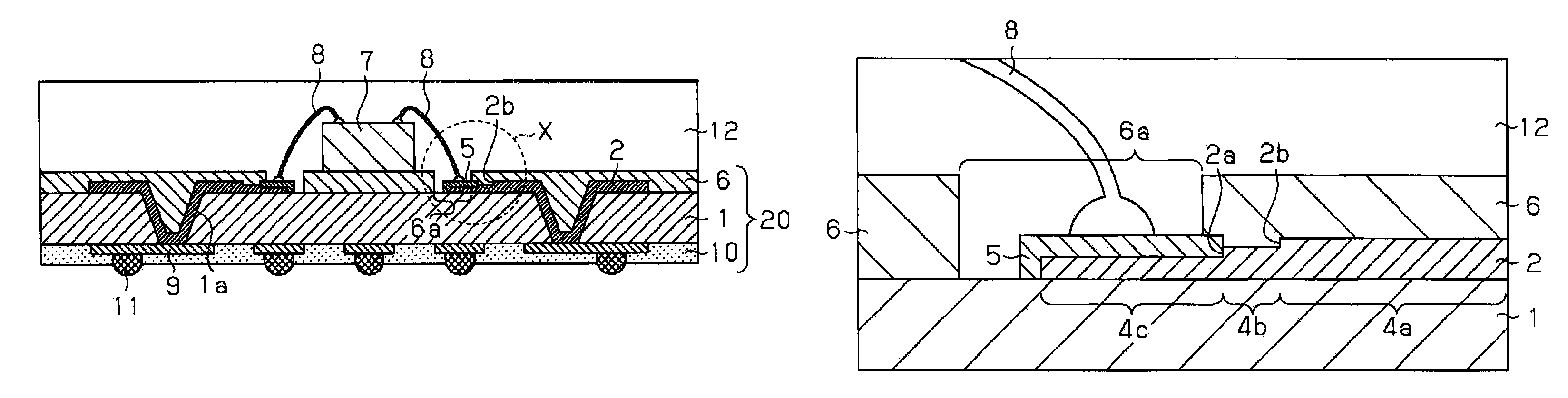

Electronic apparatus and disk drive suspension

ActiveUS20110242708A1Conductive and reliableReliable conductionArm with actuatorsRecord information storageGold particlesMicroactuator

A microactuator element as an example of an electrical component is disposed on a metallic, electrically conductive plate member. A conductive resin member is disposed on a current-carrying part of the conductive plate member and a conduction part of the microactuator element. A thin porous plating layer of thickness 100 nm or less includes a large number of gold particles is formed in a region of a surface of the conductive plate member which covers the current-carrying part. The conductive resin member is secured to the conductive plate member through the thin porous gold plating layer and electrically connected to the conductive plate member.

Owner:NHK SPRING CO LTD

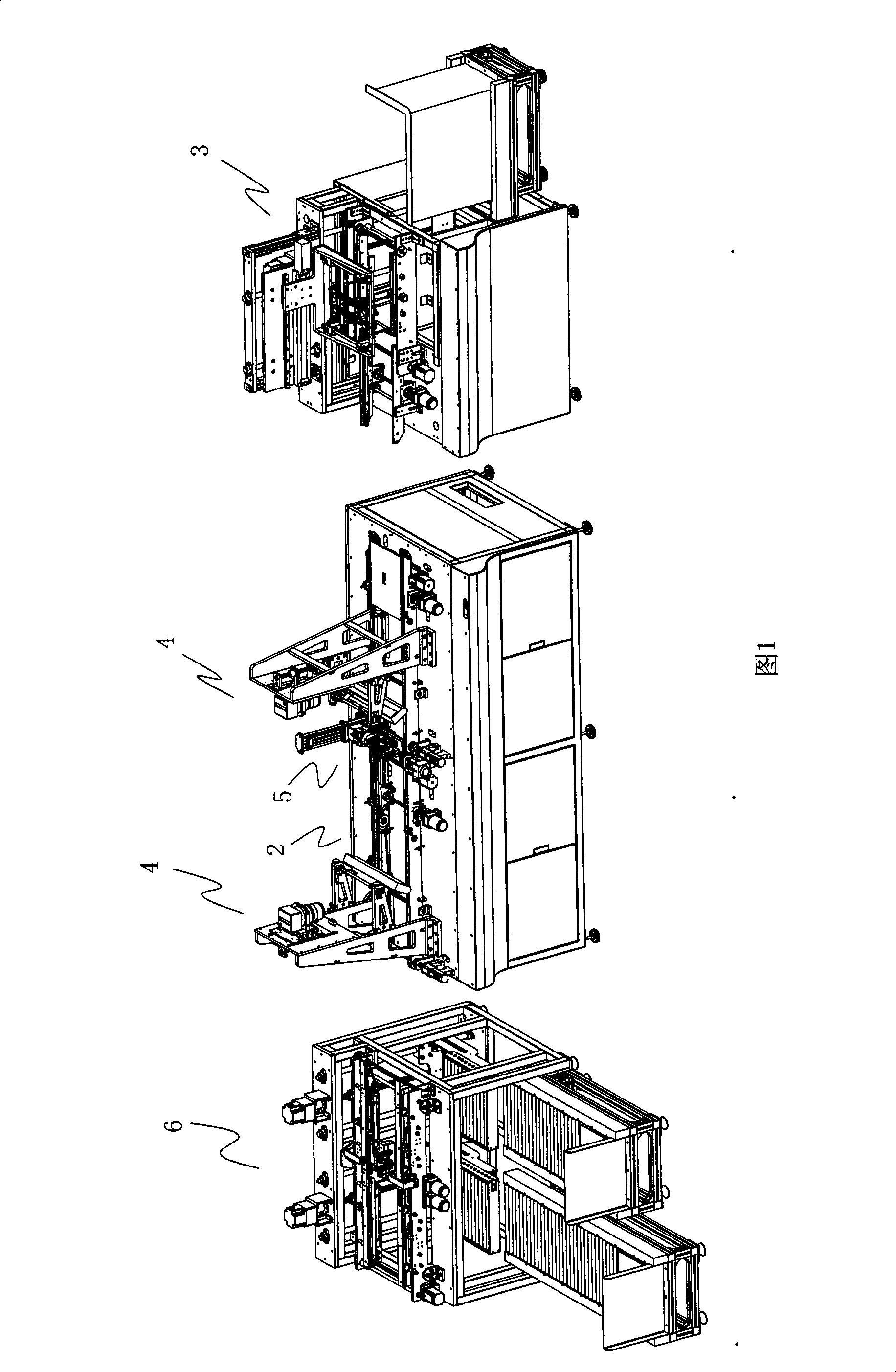

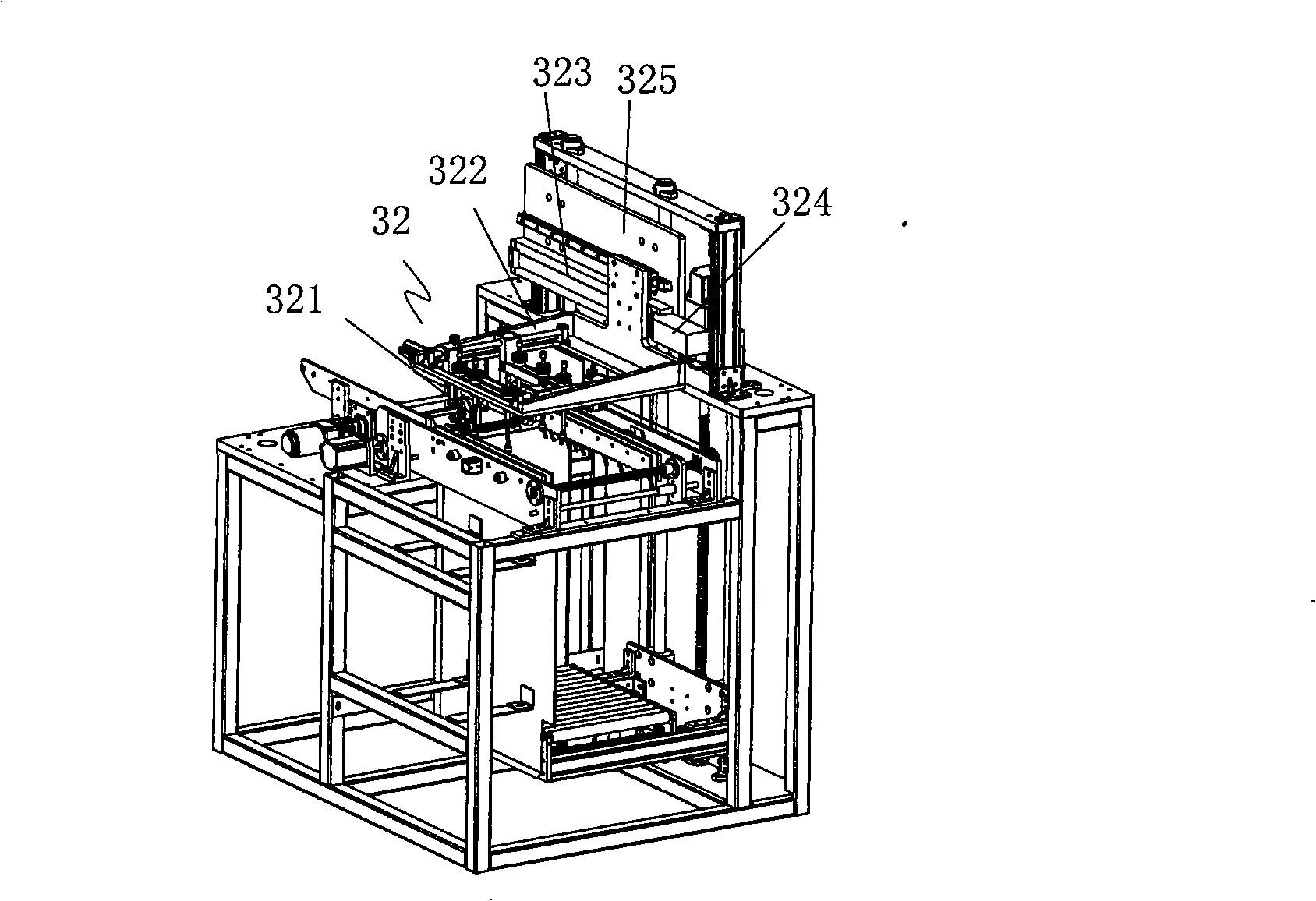

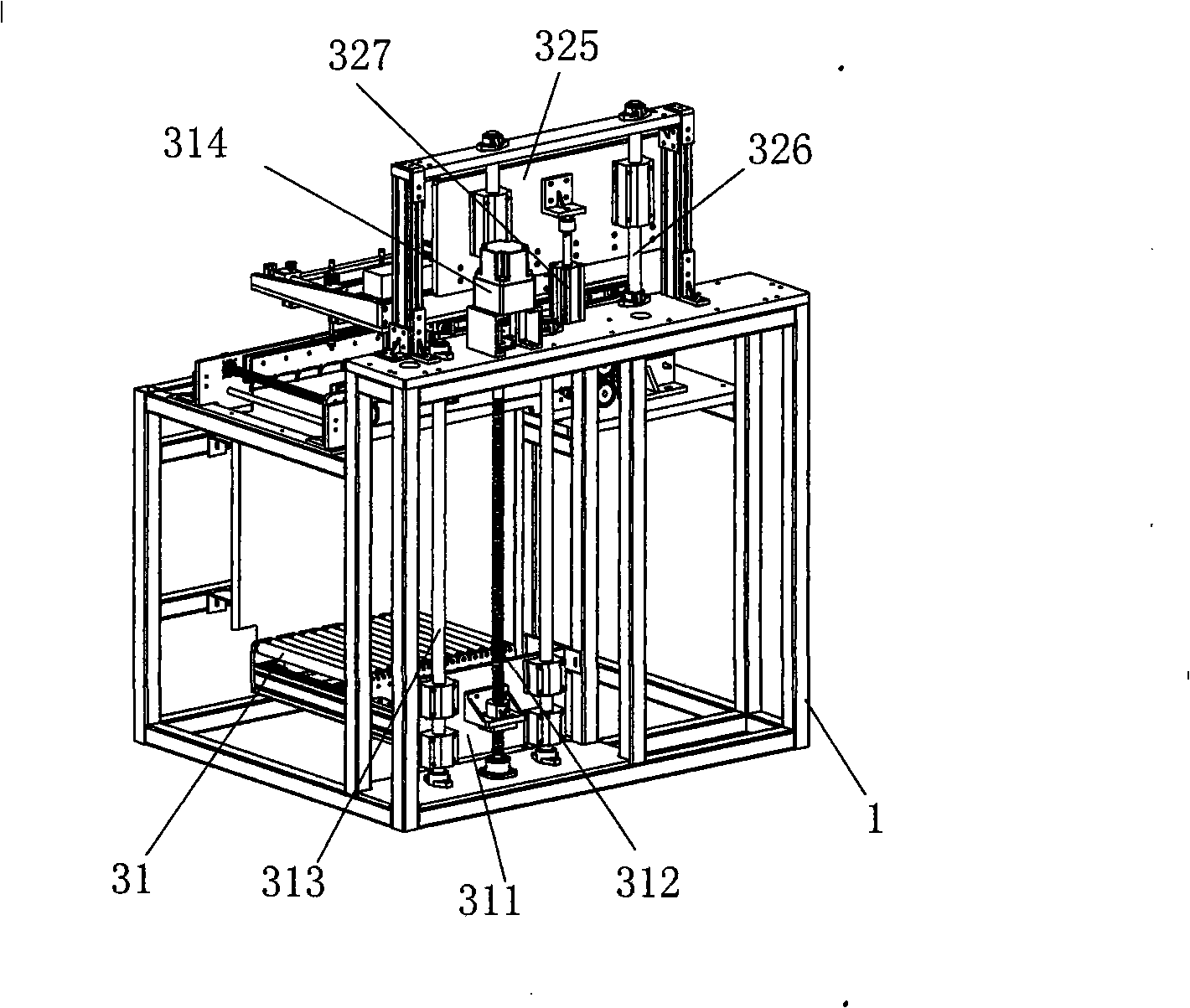

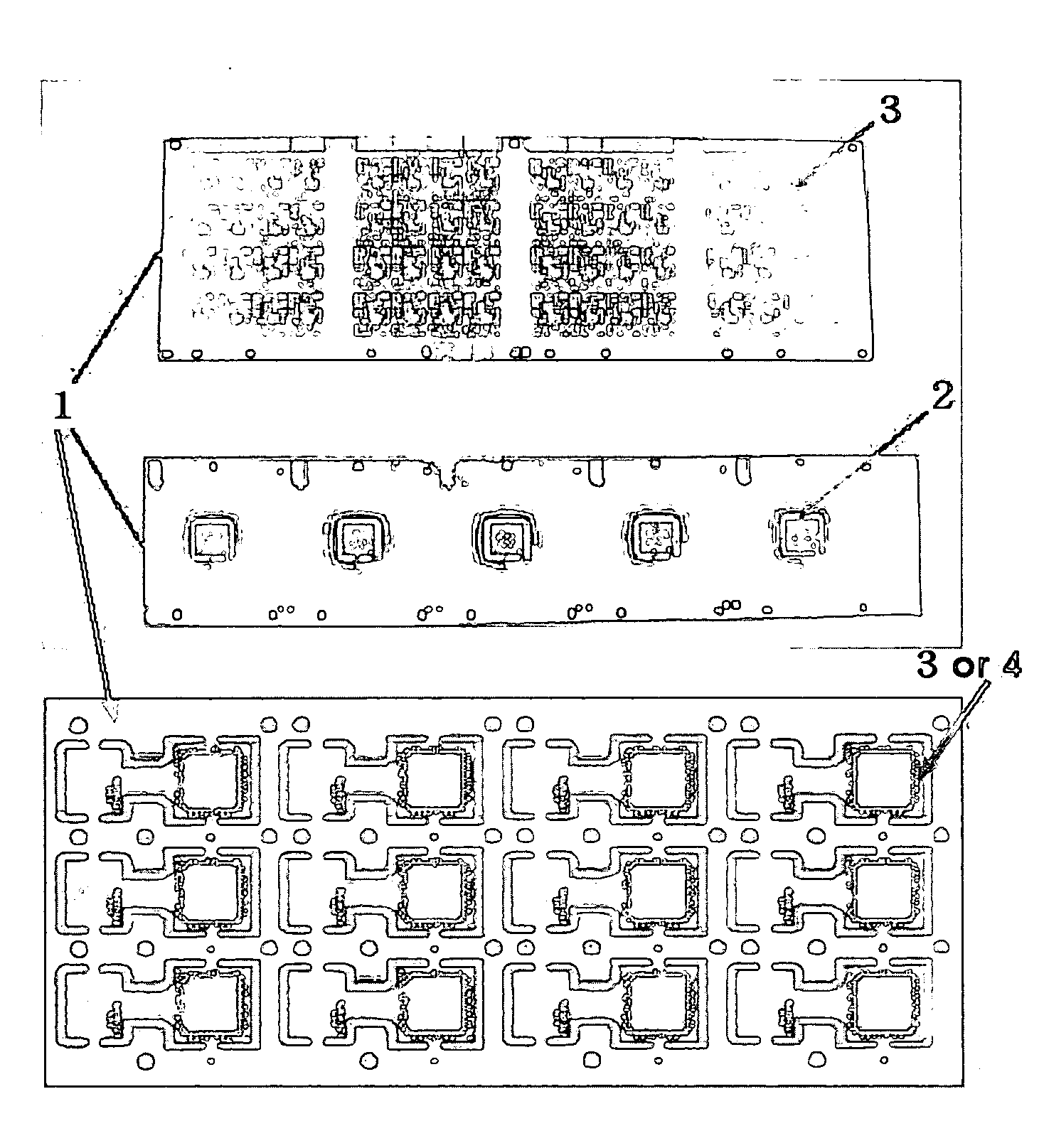

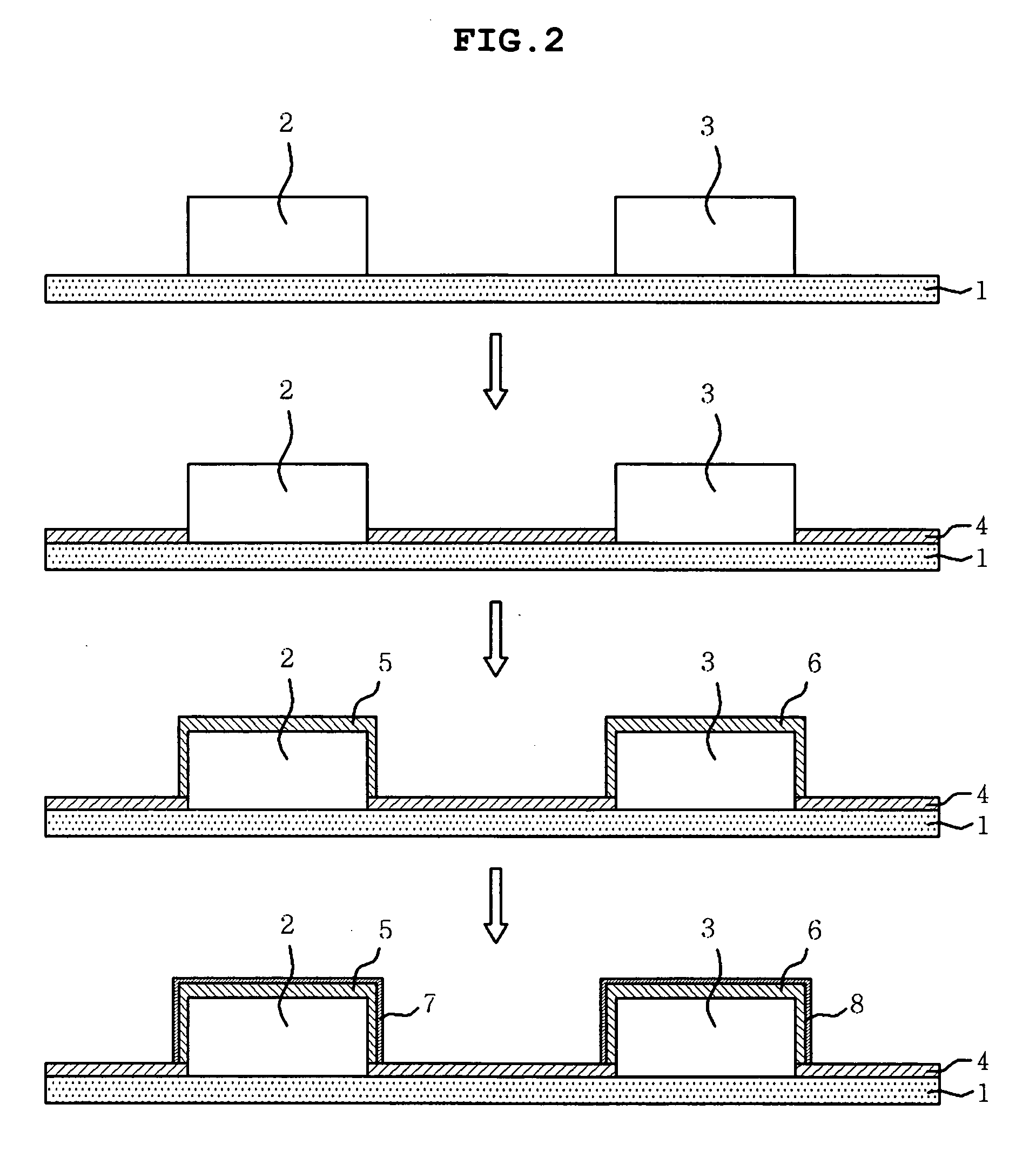

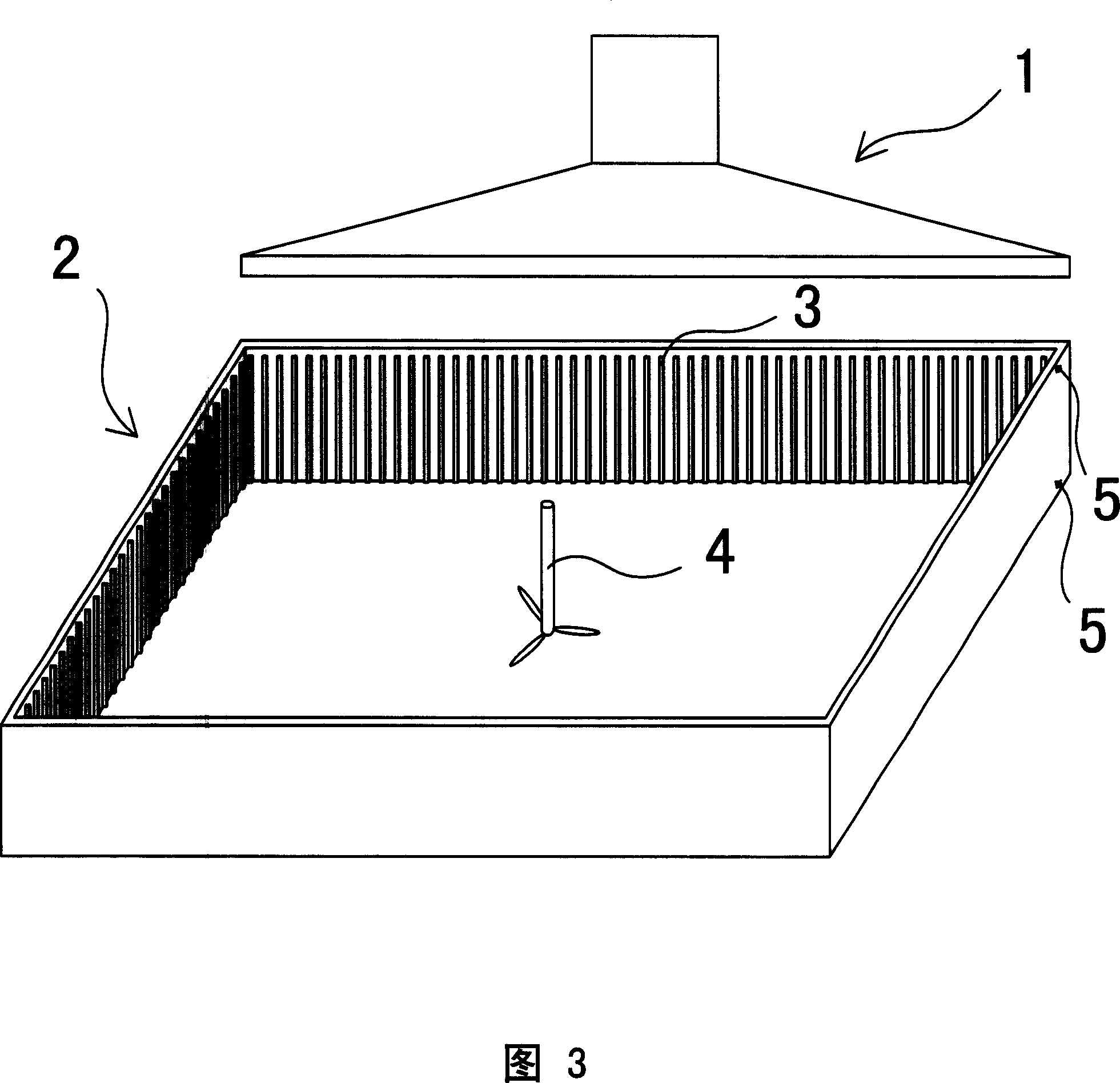

Appearance inspection machine for printed circuit board

InactiveCN101403709AThe detection process is fastImprove detection efficiencyMaterial analysis by optical meansSortingForeign matterEngineering

The invention provides a testing machine used for testing the appearance of a printing circuit board, comprising a frame which is provided with a transmission mechanism; the front end of the transmission mechanism is provided with an upper plate mechanism; the transmission mechanism is internally provided with two scanning mechanisms; a panel turnover mechanism is arranged between the two scanning mechanisms; the tail part of the transmission mechanism is butt-jointed with a sorting mechanism; and all mechanisms are controlled by control host machines cooperatively. The testing machine adopts a whole-line digital camera photographing technique to detect the defects on the printing circuit such as foreign matter, exposed copper, supplemented oil, scraping, poor gold-plating, character error, non-uniform green oil, non-uniform welding disc, non-uniform depth of channel, residual copper, omitted printing, developing and the like, automatically feeds and sorts the nondefective and waster, improves the simpleness and reliability of the operation, can observe the defects of the board in real-time by adopting a powerful image processing and analysis software system to provide a plurality of image processing and analysis systems, has quick detection speed, high detection efficiency, safe and reliable equipment, simple operation, is convenient and easy to be learned and meets the man-machine interaction.

Superficial treatment method of printed wiring board

ActiveCN101525744APrevent oxidationGuaranteed reliabilityLiquid/solution decomposition chemical coatingCompound (substance)Palladium

The invention discloses a superficial treatment method of printed wiring board, which is dedicated to solving the technical problem of preventing black pad in the process of plating ENIG by chemical means, ensuring reliability of welding and routing process. The method comprises the following steps: chemical Immersion of nickel, chemical immersion of palladium and chemical gilding. Compared with the prior art, chemical immersion of nickel, chemical immersion of palladium and chemical gilding are carried out on the printed wiring board to obtain Ni / Pd gold plating, thus effectively preventing long-term oxidization of palladium surface in the air and ensuring reliability of welding combination and routing combination.

Owner:SHENZHEN CHENGGONG CHEM

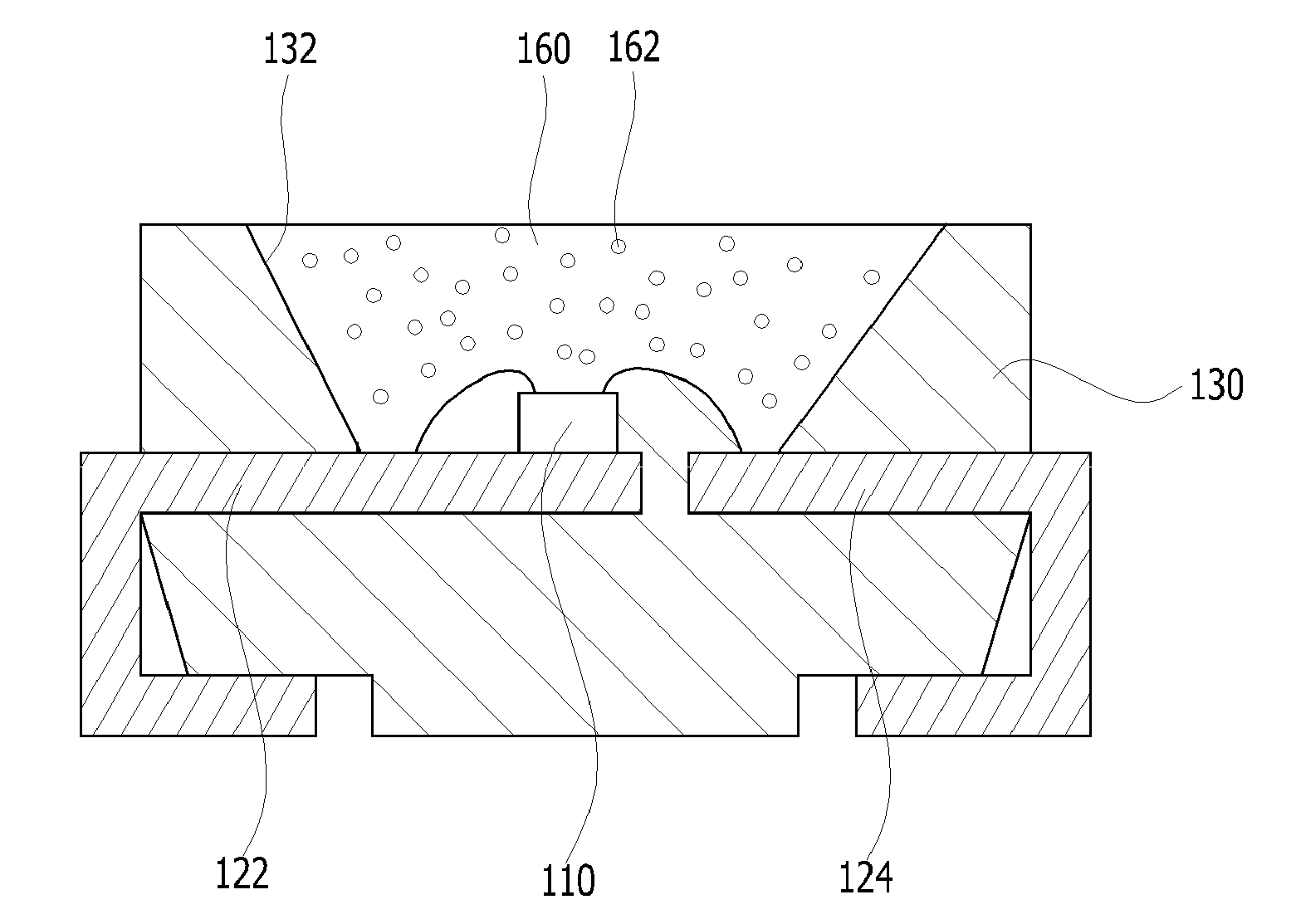

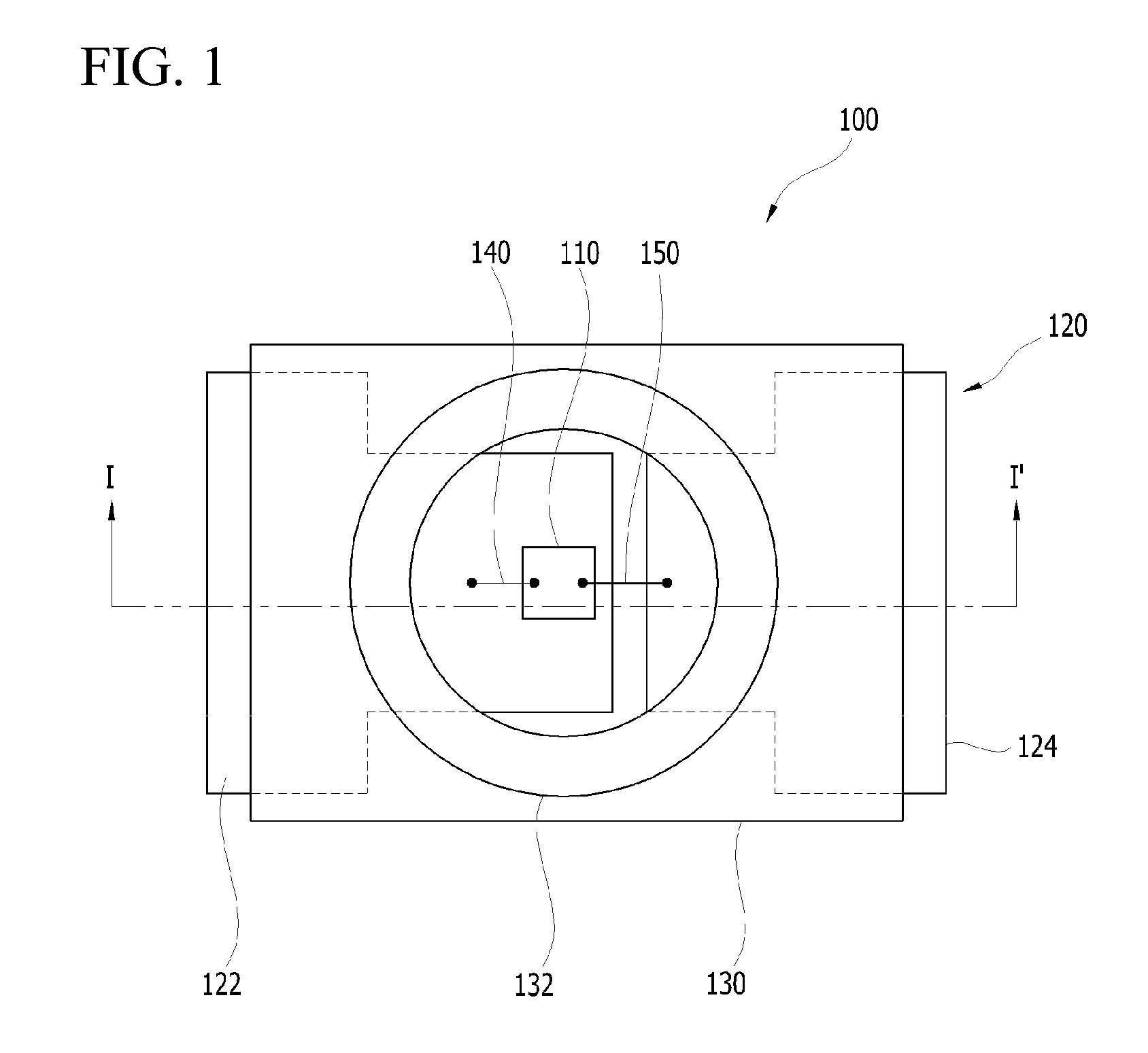

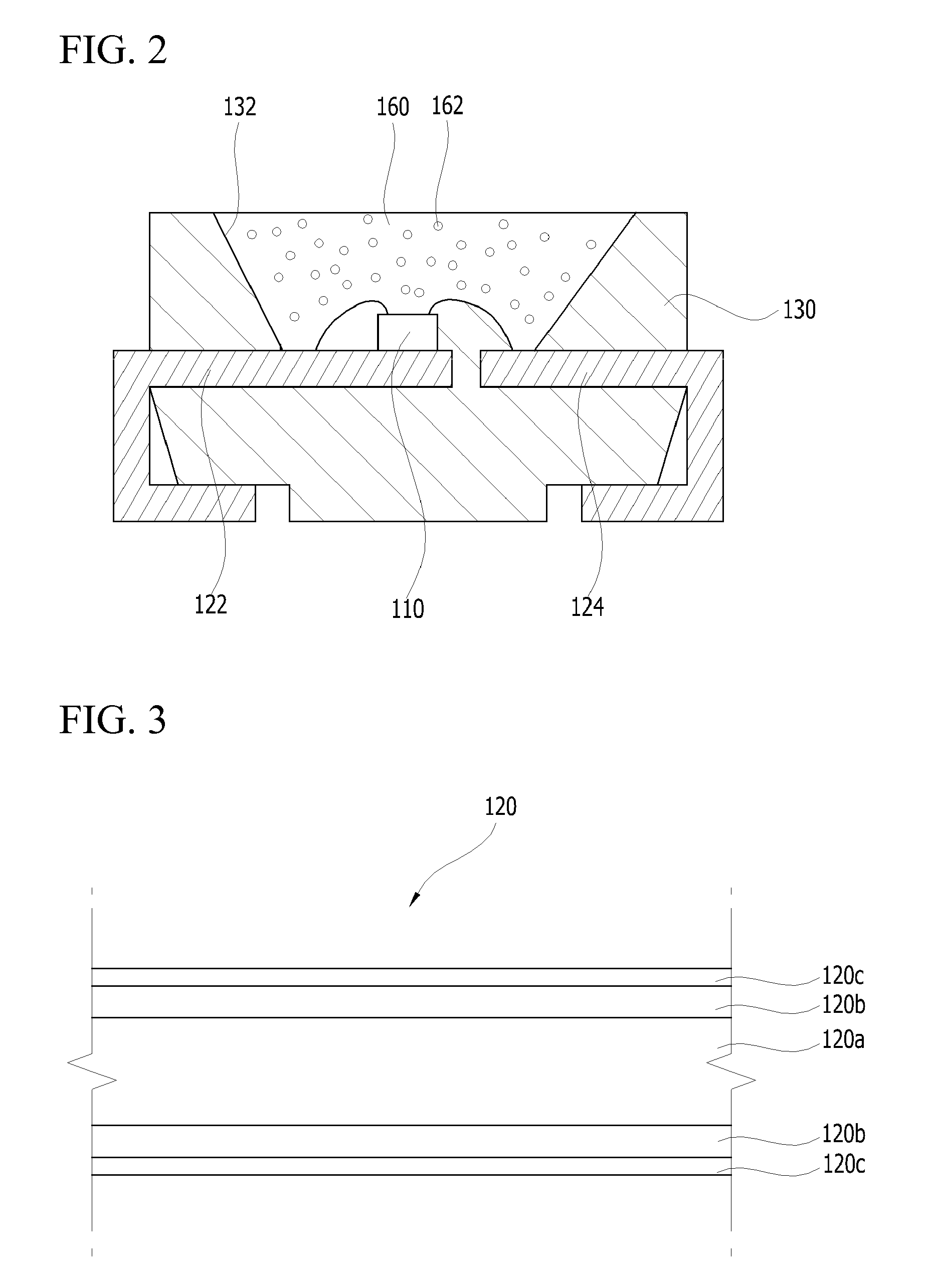

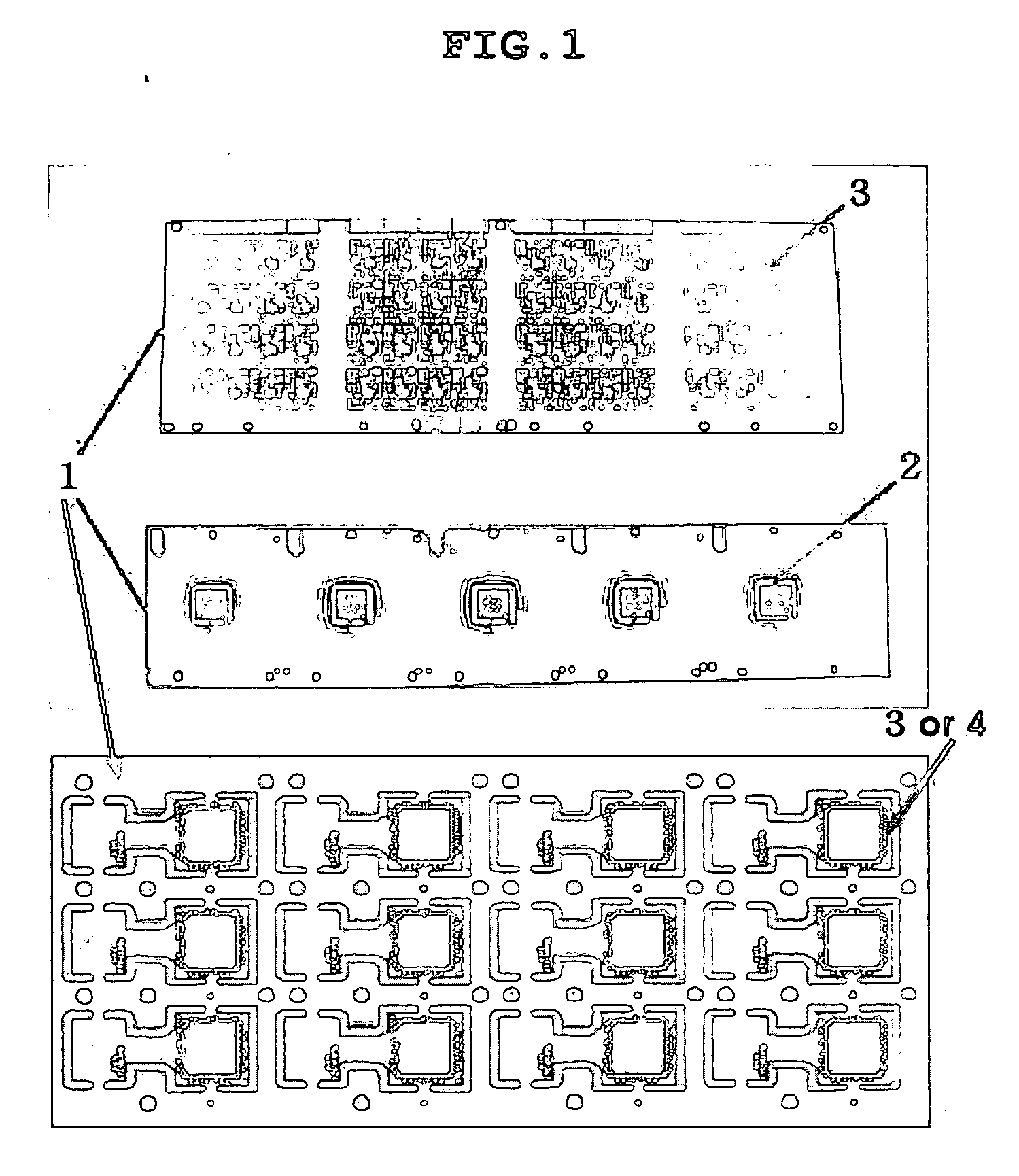

Light emitting device and lead frame for the same

InactiveUS20100078669A1Reduce corrosionReduce reflectivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

An LED according to the present invention includes a light-emitting chip emitting light, a chip-mounting portion on which the light-emitting chip is mounted, a light-reflecting layer formed on at least a portion of the chip-mounting portion and a gold plating layer formed on at least a portion of the light-reflecting layer, the gold plating layer having a thickness such that the gold plating layer has a different color from a color of gold. The chip-mounting portion may have various shapes and materials. For example, the chip-mounting portion may be a lead terminal, a slug, a printed circuit board, a ceramic substrate, a CNT substrate, etc.

Owner:SEOUL SEMICONDUCTOR

Non-electrolytic gold plating liquid and non-electrolytic gold plating method using same

InactiveUS6287371B1Improve adhesionInhibits excess local etching or corrosionAnti-corrosive paintsLiquid/solution decomposition chemical coatingEtchingCobalt

The present invention provides an excellent non-electrolytic gold plating liquid which produces a gold plating layer firmly adhered to a surface selected from the group consisting of nickel, cobalt, palladium or a metal alloy containing nickel, cobalt or palladium, as well as a method for performing a non-electrolytic gold plating method using the non-electrolytic gold plating liquid. The non-electrolytic gold plating liquid comprises:(1) a water-soluble gold compound;(2) a complexation agent which stabilizes a gold ion in the plating liquid, but does not substantially dissolve nickel, cobalt or palladium; and(3) an anti-gold deposit agent which inhibits excess local etching or corrosion by substitution reaction between the metal surface and gold during the gold plating.

Owner:LEARONAL JAPAN

Gimbal assembly with a gold tongue/dimple interface and methods of making the same

ActiveUS20130265674A1Electrical connection between head and armRecord information storageDual stageWear particle

A gimbal assembly of a single or dual stage actuator is provided with gold at a tongue / dimple interface where a dimple of a supporting loadbeam contacts a tongue on the gimbal assembly. Using gold at the tongue / dimple interface greatly reduces the amount of wear particles formed during assembly and operation of the microactuator. The tongue may include a gold coating on the tongue at the tongue / dimple interface, or the tongue may have a hole etched in a stainless steel layer at the tongue / dimple interface to expose a gold layer disposed below the stainless steel layer. The tongue portion of the tongue / dimple interface may also be formed from a gold-coated copper pad with a polymer coating over the gold.

Owner:NHK SPRING CO LTD

Method for plating printed circuit board and printed circuit board manufactured therefrom

InactiveUS20070104929A1Reduce thicknessDecreasing solderabilitySemiconductor/solid-state device detailsSolid-state devicesElectroless nickelCrazing

Disclosed herein are a method for plating a printed circuit board and the printed circuit board manufactured therefrom. In the method, a bare soldering or wire bonding portion of a copper (Cu)- or copper alloy layer, is plated with palladium (Pd) or a palladium alloy, and then gold (Au) or a gold alloy is deposited over the palladium or palladium alloy plated layer by an electroless substitution plating process based on ionization tendency. Having superior hardness, ductility and corrosion resistance, palladium is suitable for use between a connector and a substrate and meets requirements for the printed circuit board even when applied to a low thickness, greatly reducing the process time. Accordingly, the problem of black pad, which frequently occur on electroless nickel and electroless gold finish upon surface mount technology, can be perfectly solved. Particularly, fatal bending cracks can be prevented from occurring in the rigid-flexible or flexible printed circuit boards.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

Gold-coated nanoparticles for use in biotechnology applications

InactiveUS20050025969A1Enough timePowder deliveryMaterial nanotechnologyMagnetite NanoparticlesMaterials science

A process of preparing gold-coated magnetic nanoparticles is disclosed and includes forming a suspension of magnetic nanoparticles within a suitable liquid, adding an amount of a reducible gold compound and a reducing agent to the suspension, and, maintaining the suspension for time sufficient to form gold-coated magnetic nanoparticles.

Owner:LOS ALAMOS NATIONAL SECURITY

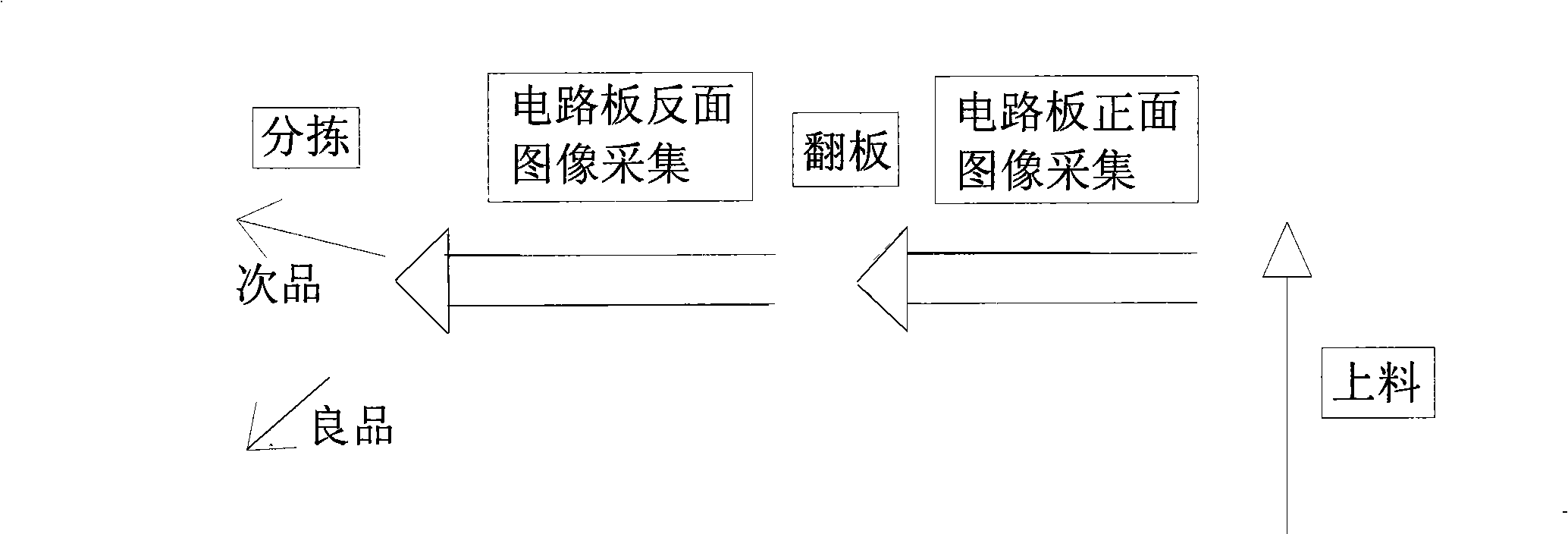

External appearance defect examination method for circuit board

InactiveCN101403708AFacilitate inspection of appearance defectsFast appearance defect inspectionMaterial analysis by optical meansSortingForeign matterAutomatic control

The invention provides a method used for testing the appearance defects of a circuit board, comprising the steps as follows: loading, collecting frontal images of the circuit board, collecting the reverse images of the circuit board, analyzing and sorting the images. The method can complete the appearance defect check on two surfaces of the circuit board extremely conveniently and quickly, can adopt a computer for automatic control, has quick check speed and high check efficiency, and can check the defects on the circuit board such as foreign matter, exposed copper, supplemented oil, scraping, poor gold-plating, character error, non-uniform green oil, non-uniform welding disc, non-uniform depth of channel, residual copper, omitted printing, developing and the like.

Owner:GUANGDONG ZHENGYE TECH

Flux for soldering and circuit board

InactiveUS20060147683A1High bonding strengthSuppress DiffuseBlast furnace componentsBlast furnace detailsSolventCopper complex

A flux contains resin having film forming ability, activator, solvent, and at least one complex selected from silver complex and copper complex. The flux is used when soldering is performed onto a circuit having electroless nickel plating or further having gold plating on the electroless nickel plating. Allowing a barrier layer of silver or copper to deposit on the surfaces of lands suppresses the diffusion of nickel into the melted solder alloy during soldering, and also prevents phosphorous concentration. This improves the bonding strength of soldering and suppresses the reduction deposition of silver and / or copper to portions other than circuit patterns.

Owner:HARIMA CHEM INC

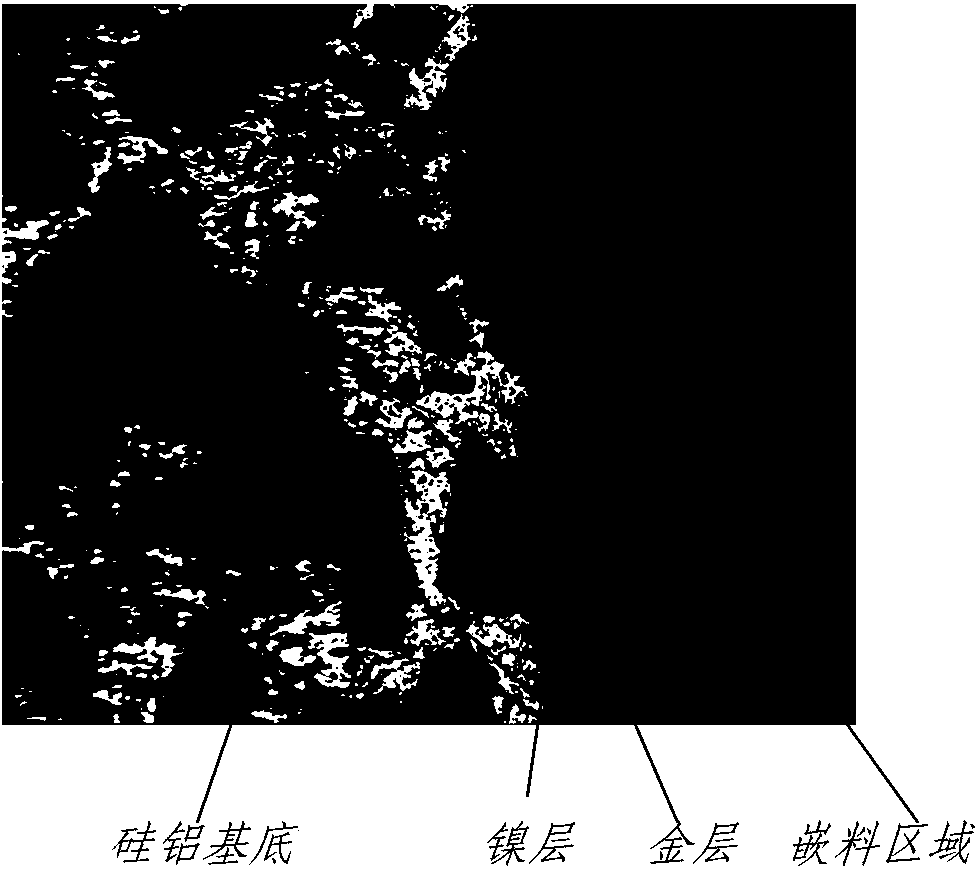

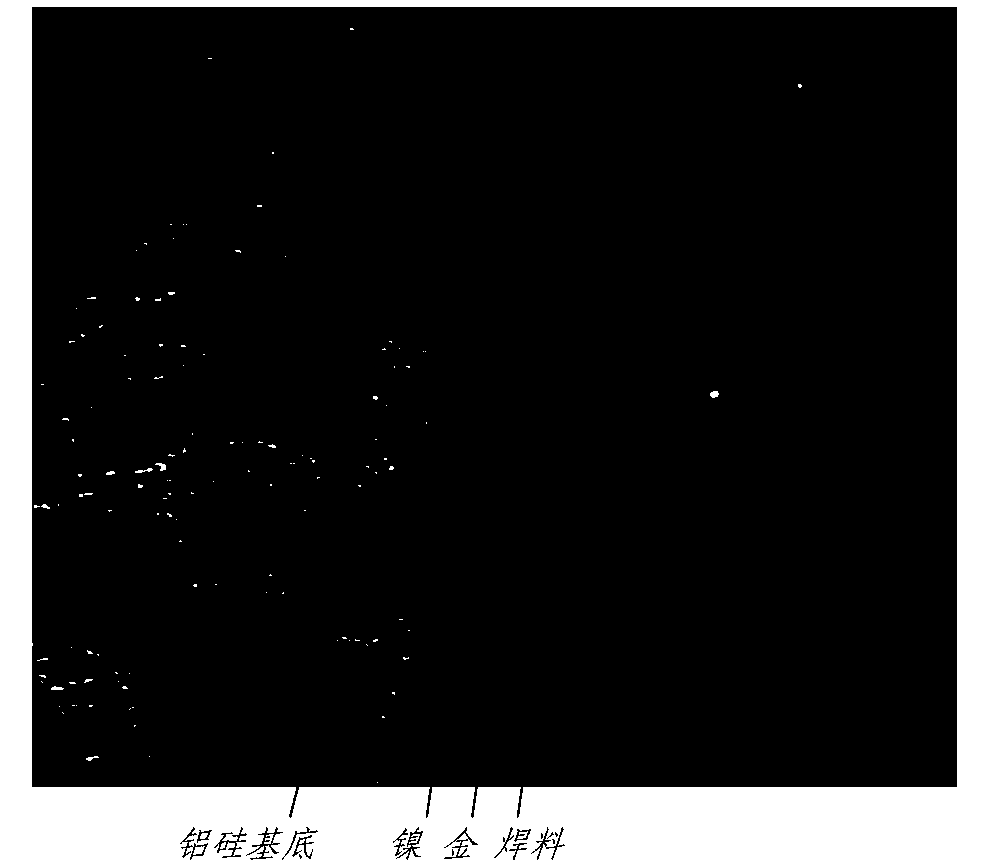

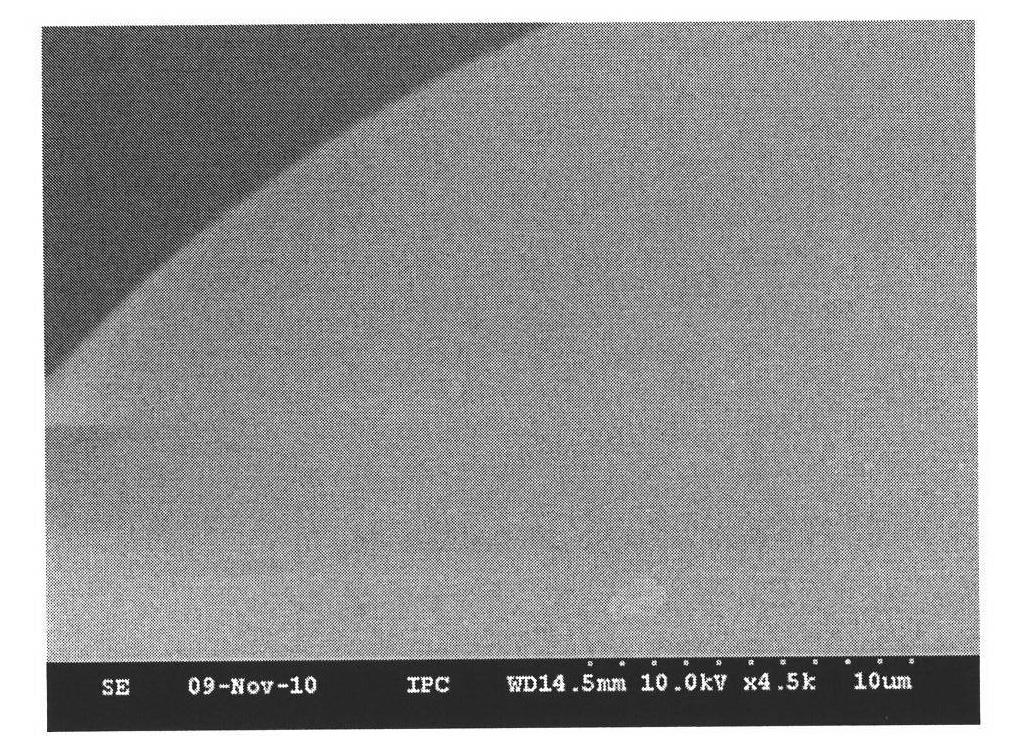

Gold-plating method of high silicon-aluminum composite material

ActiveCN103540935AImprove bindingNo foamingSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBinding forceAlkaline etching

The invention relates to a gold-plating method of a high silicon-aluminum composite material. According to a second zinc immersion treatment method of conventional aluminum alloy electroplating, pre-treatment of the method comprises the following six steps: cleaning and oil removing; alkaline etching; bright dipping; primary zinc immersion; zinc annealing; secondary zinc immersion. The gold-plating method subsequently comprises the following steps: I, preplating chemical nickel in a chemical nickel-plating liquid; II, plating nickel for the first time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; III, performing aging treatment; IV, performing activating treatment; V, plating nickel for the second time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; VI, taking a pure gold plate or a platinum titanium mesh as an anode and the high silicon-aluminum composite material as a cathode according to a conventional pure gold-plating method, wherein the gold layer is 2-3 microns thick; VII, detecting the binding force of the plating layer. The plating layer observed under tenfold amplifying glass is free from peeling and bubbling phenomena and good in binding force. The binding force of the gold-plating plating layer and a high silicon-aluminum base material adopted by the method provided by the invention is firm and reaches the standard of appendix A of GJB1420 General Specification of Semiconductor Integrated Circuit Shell.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Preparation method of ceramic circuit board

ActiveCN102695370AGood choiceImprove bindingInsulating substrate metal adhesion improvementLiquid/solution decomposition chemical coatingChemical platingHemt circuits

The invention relates to a ceramic surface modifying technology, particularly relates to a method for metalizing the surface of a ceramic profiled bar, and specifically provides a preparation method of a ceramic circuit board... The preparation method of the ceramic circuit board comprises the preparation steps of: (1) preparing a ceramic substrate; (2) engraving a required circuit pattern with laser on the surface of the ceramic substrate; (3) in chemical plating, and chemically plating copper on the ceramic substrate obtained in the step (2) to realize bottoming; and (4) chemically plating nickel or chemically plating gold or silver on the surface of a plated layer, so as to prevent copper from being oxidized. According to the preparation method of the ceramic circuit board provided by the invention, a laser engraving technology is combined with chemical copper plating, so that the ceramic board is selectively coated with copper, and the good selectivity is achieved. By using the laser engraving technology, the binding force of a conductive layer with a ceramic base body is good; production equipment is cheap and easy to obtain. Furthermore, the three-dimensional ceramic circuit board can be easily produced; the circuit pattern design is very simple; and the circuit precision is high. Moreover, compared with the other technologies, the preparation method provided by the invention has the advantage that the 'three wastes' emission in a production process is reduced.

Owner:黄石星河电路有限公司

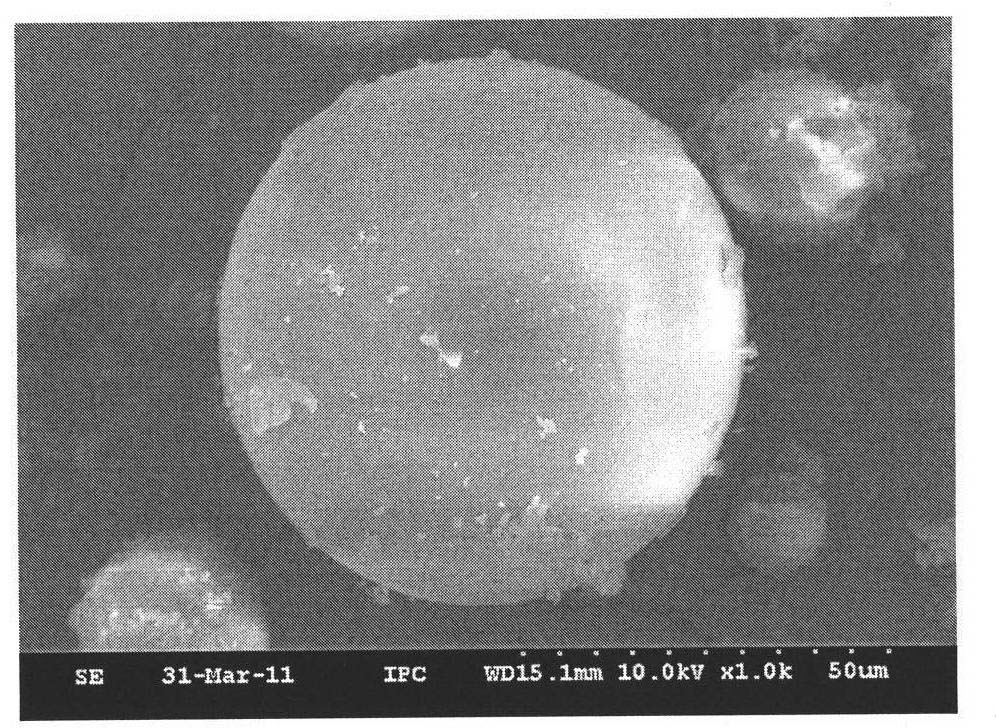

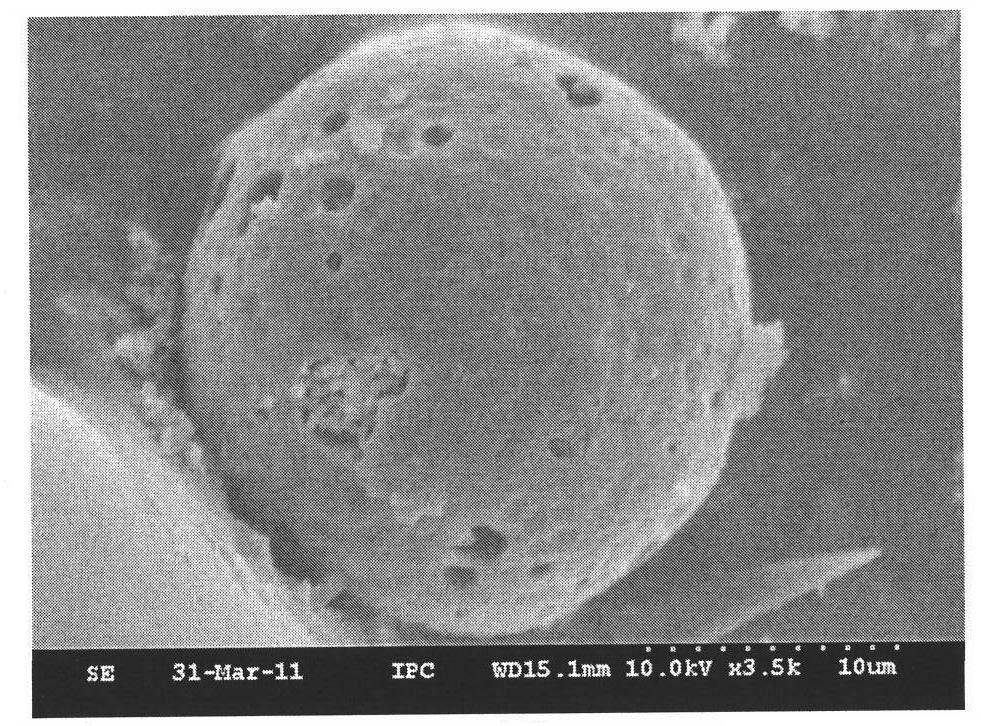

Surface chemical plating treatment process for hollow glass microsphere, plated metal hollow glass microsphere and application thereof

The invention relates to the technical field of a composite material with a core shell structure and provides a surface chemical plating treatment process for hollow glass microspheres. The surface chemical plating treatment process comprises the following steps: carrying out alkaline wash and hydrogen peroxide wash before plating to coarsen and hydroxylate the surface of the hollow glass microsphere; and carrying out chemical plating on the processed hollow glass microsphere to obtain a metal-plated hollow glass microsphere. In the method, complex preprocessing technology, such as sensitization, activation and the like in the existing method, can be simplified, and the use of expensive stannous chloride and palladium chloride which are not environmentally-friendly is avoided. Compared with the existing hot alkaline liquor processing method, the process provided by the invention has the advantages that possible microsphere fracture caused by the long-time soaking in the alkaline liquor can be avoided, and the surface hydroxylation efficiency of the hollow glass microsphere can be greatly increased by using hydrogen peroxide. The hollow glass microsphere processed with the method is easy to plate. The obtained metal-plated hollow glass microsphere has the advantages of a complete metal layer, light weight, good electrical conductivity and the like. When the obtained metal-plated hollow glass is used as a filler, material density can be lowered, cost is lowered, mechanical property is enhanced, and the plated metal hollow glass microsphere is applied to the aspects of staticelectricity coating, electromagnetic wave interference coating, wave adsorption coating and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

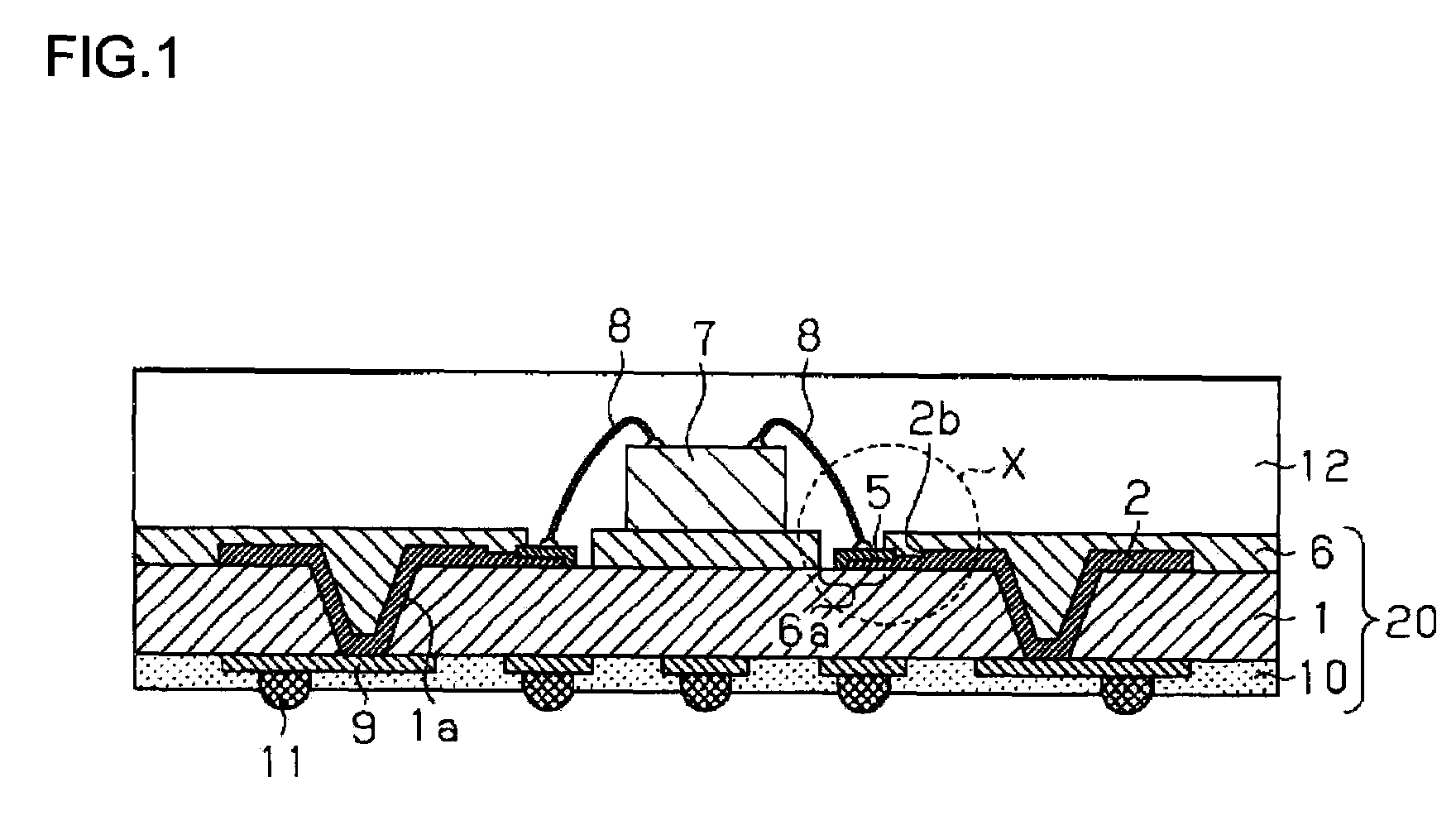

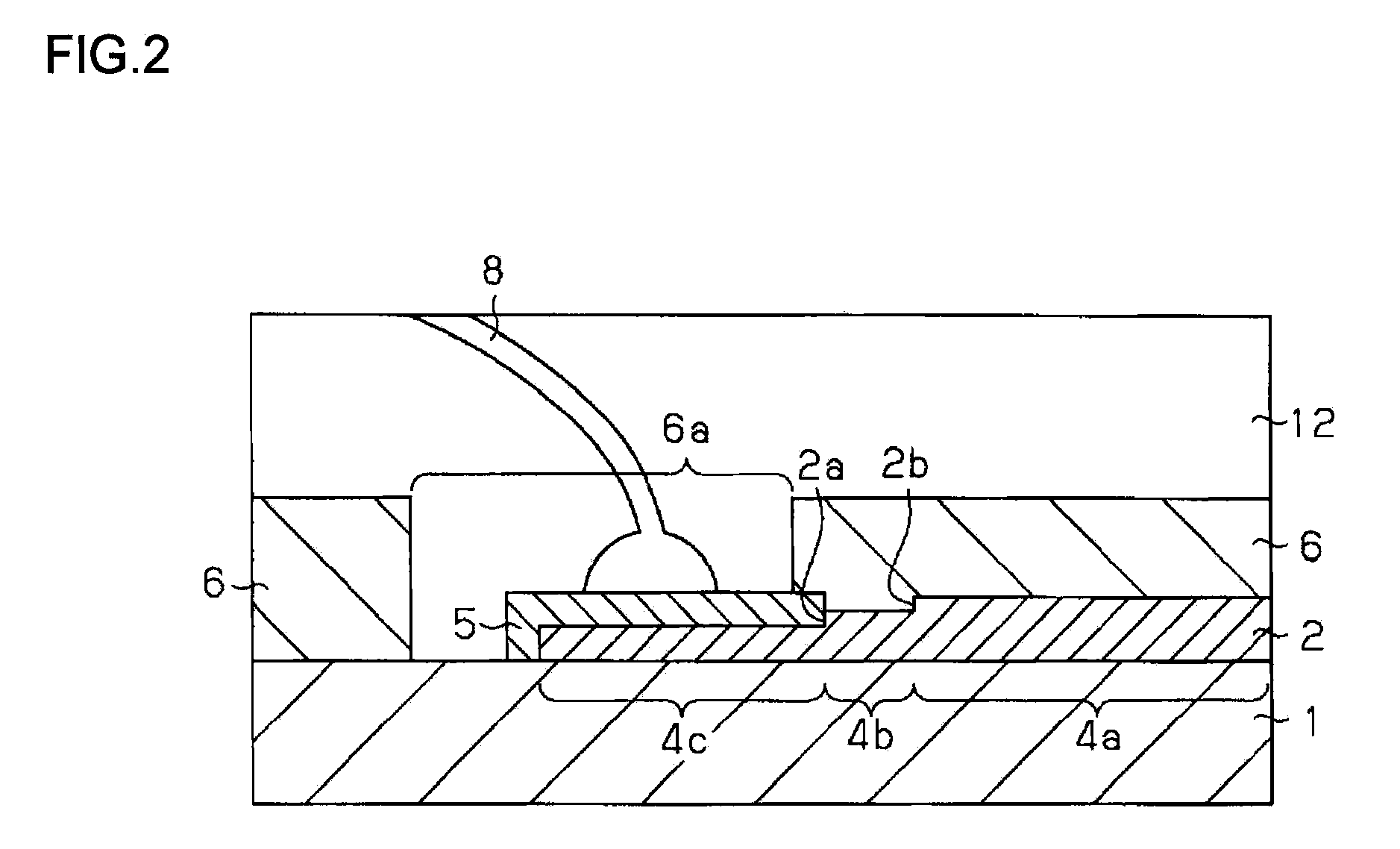

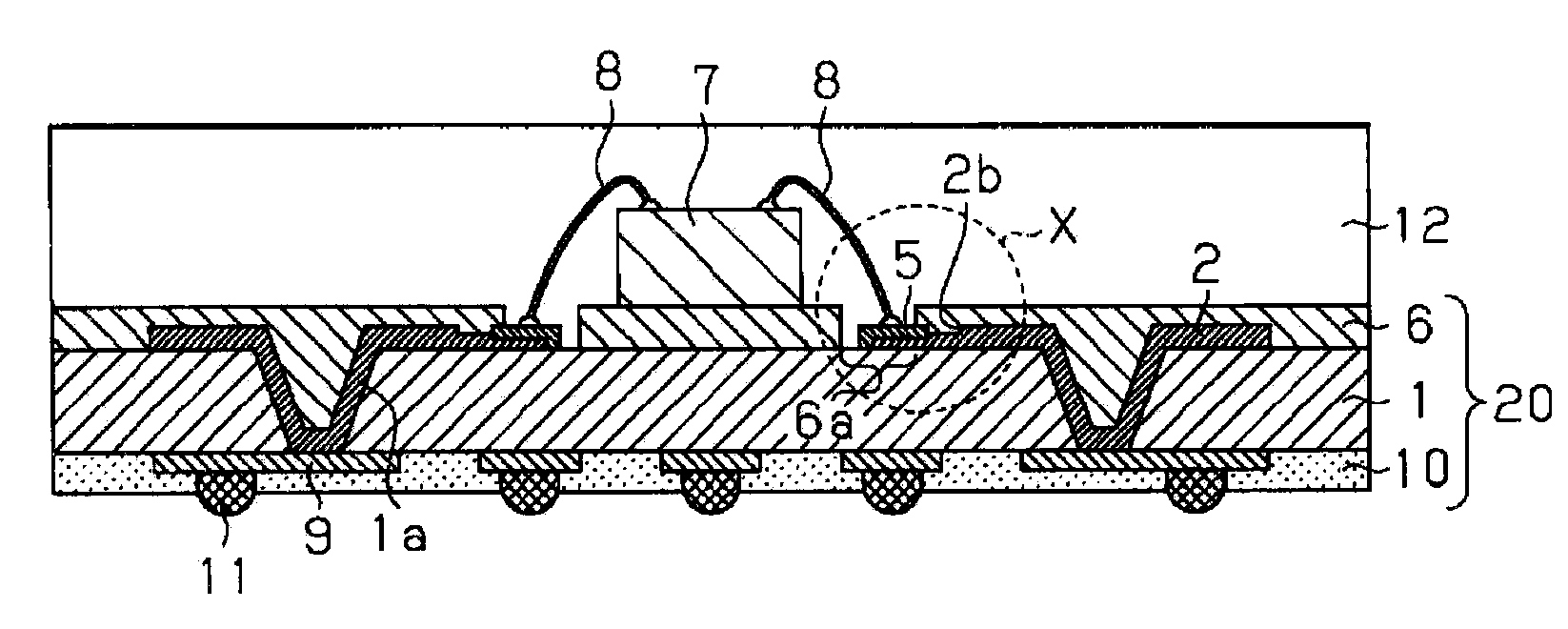

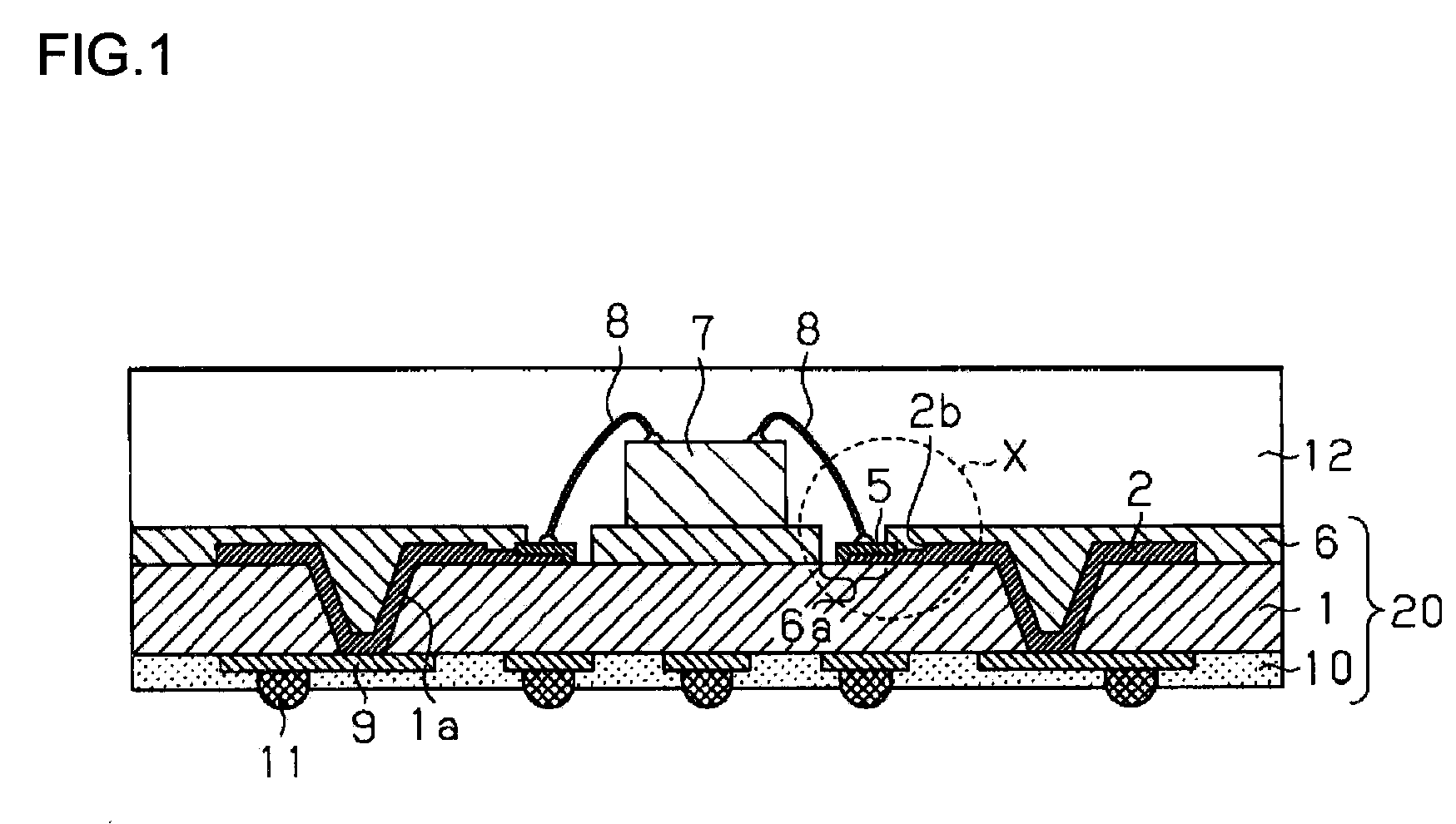

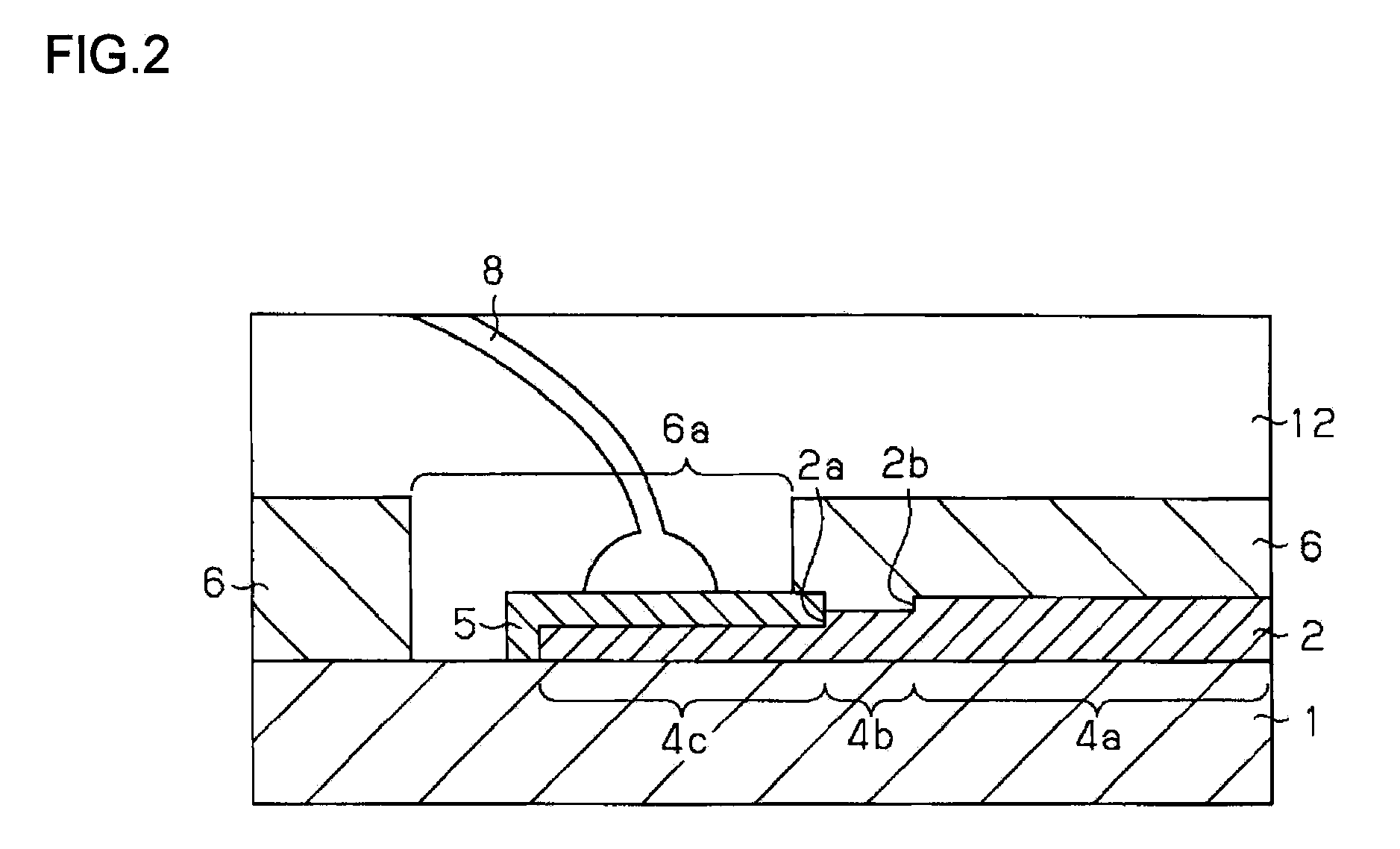

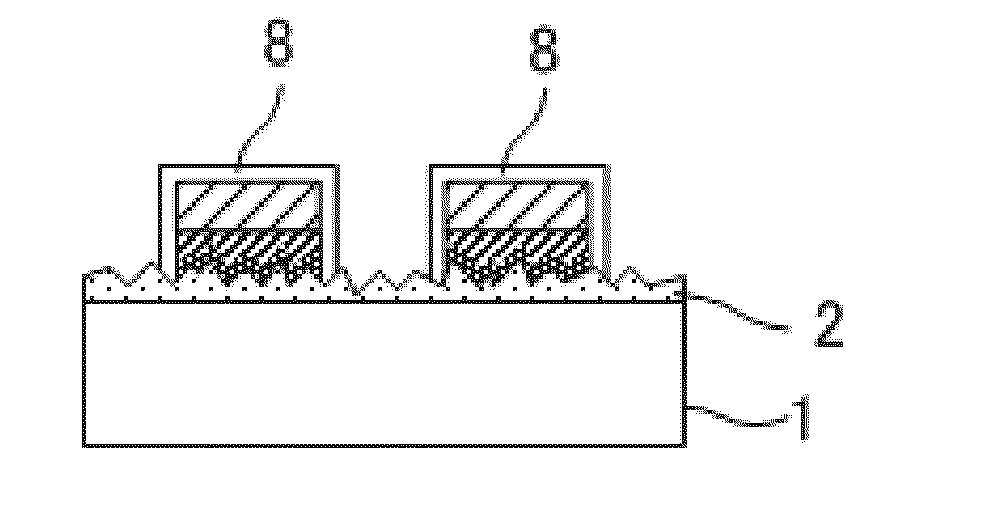

Packaging board and manufacturing method therefor, semiconductor module and mobile apparatus

ActiveUS7595553B2Improve package reliabilityLong distance of spreadingFinal product manufactureSemiconductor/solid-state device detailsResistComputer module

An advantage of the present invention is to suppress moisture infiltrating from a pad electrode portion from spreading over the surface of a wiring pattern and improve the reliability of a packaging board. The wiring pattern of the packaging board is formed on an insulating substrate and includes a wiring region, an electrode region (pad electrode) connected with a semiconductor device, and a boundary region provided between the wiring region and the electrode region. A gold plating layer is provided on the surface of the electrode region of the wiring pattern. The top surface of the boundary region of the wiring pattern is so formed as to be dented from the top surface of the wiring region of the wiring pattern, and there is provided a stepped portion in the boundary region. A solder resist is formed in such a manner as to cover part of the gold plating layer and the wiring pattern corresponding to the boundary region and the wiring region, and the solder resist has a predetermined opening through which to connect to the semiconductor device. A conductive member is connected to the gold plating layer in the electrode region, and a molded resin layer seals the entire semiconductor module.

Owner:III HLDG 12 LLC

Metallic separtor for fuel cell and production method for the same

ActiveUS20040197661A1Contact resistanceDifficult to separateAnodisationFinal product manufactureFuel cellsContact resistance

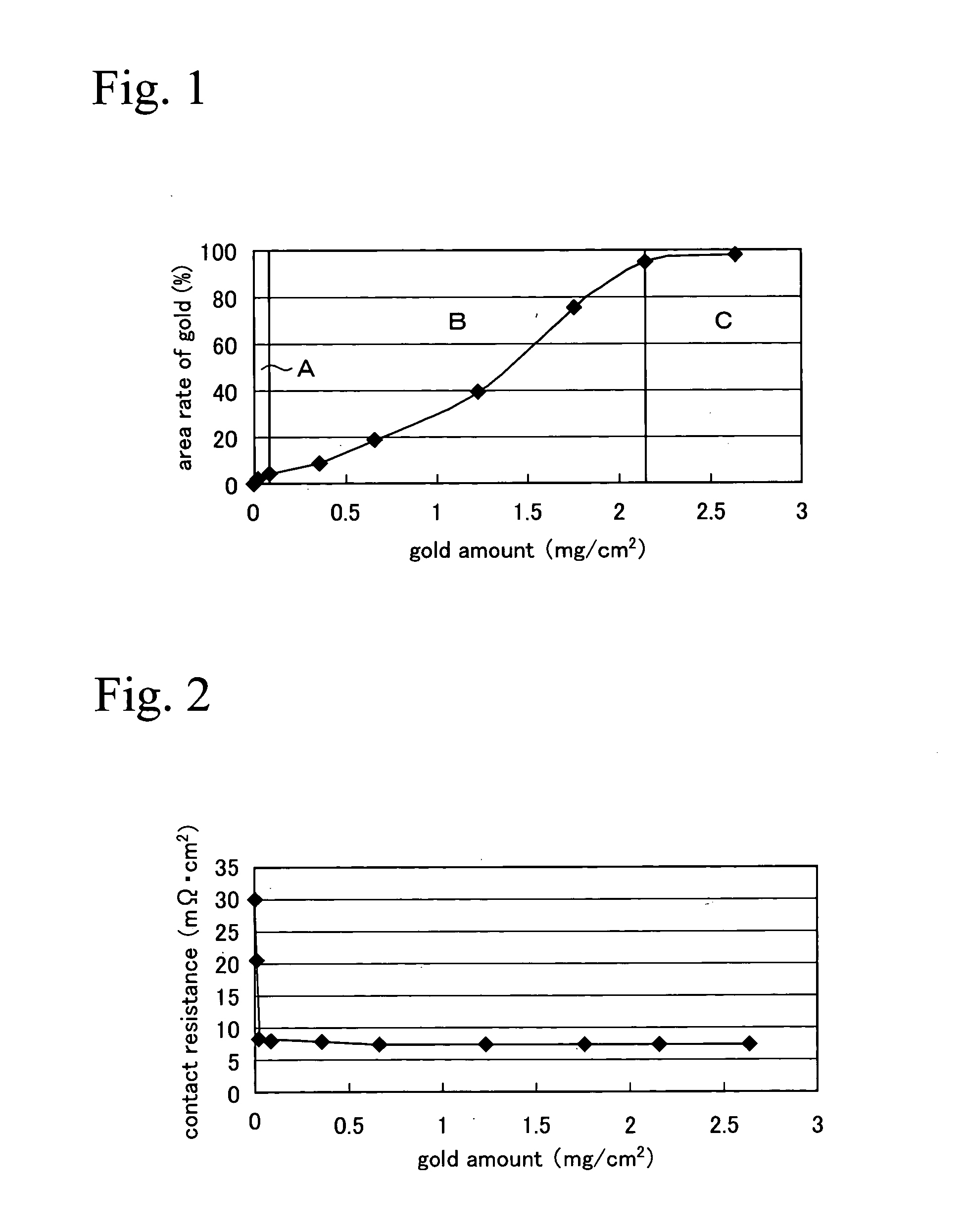

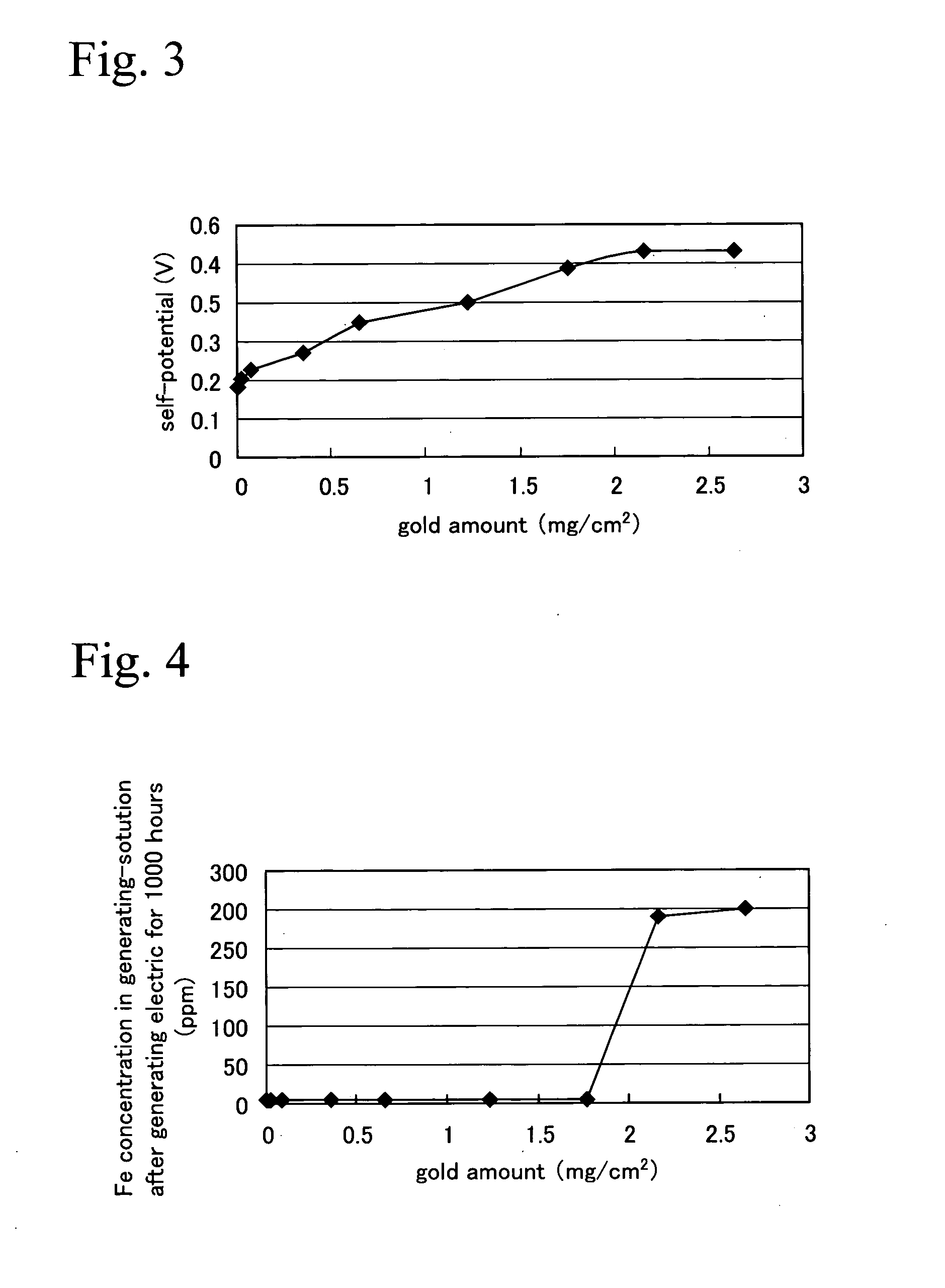

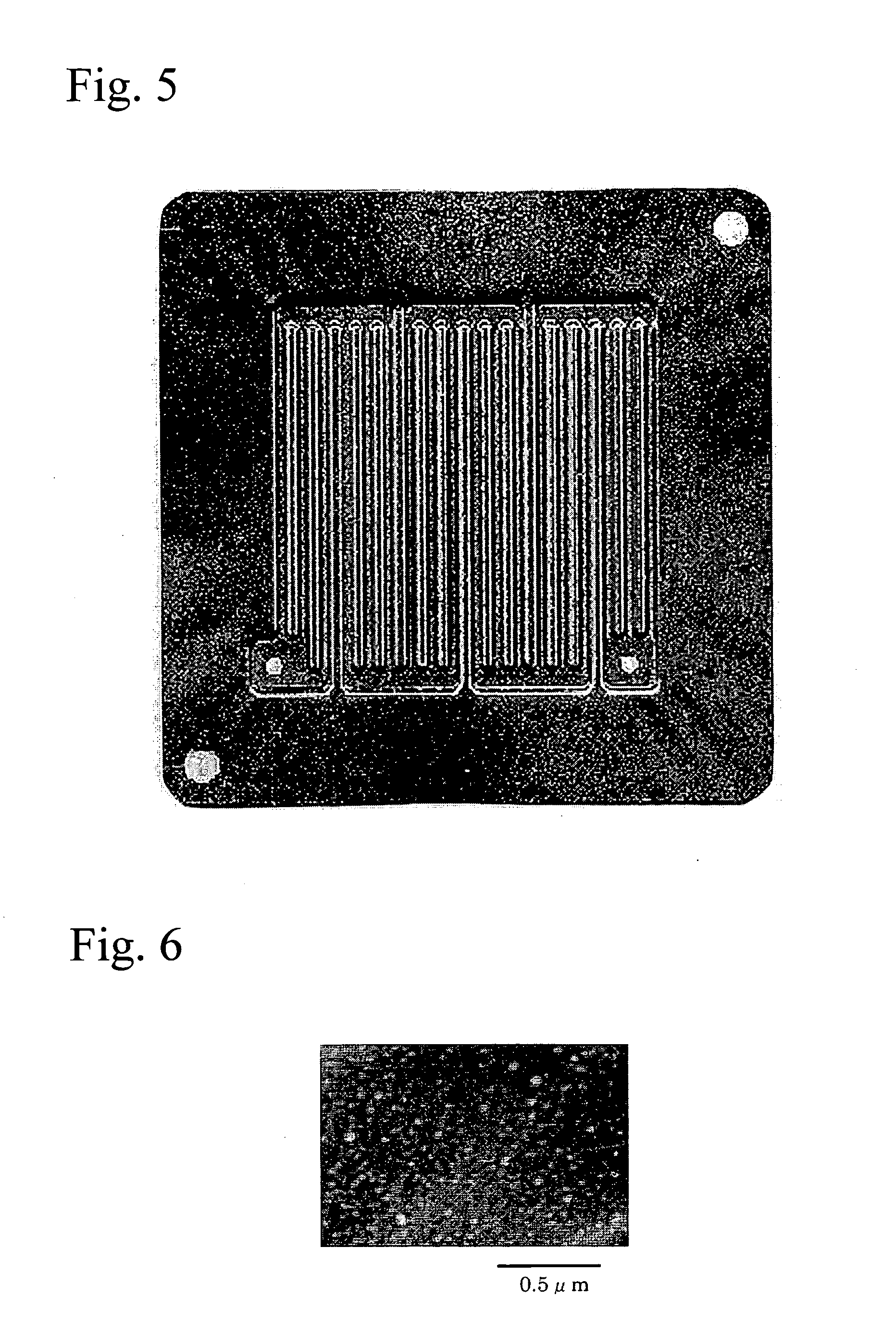

A metallic separator for a fuel cell has excellent corrosion resistance and contact resistance, even when a gold coating is applied directly without a surface treatment by a nickel coating. The metallic separator for a fuel cell, comprising stainless steel having a surface, can be obtained by coating at 2.3 to 94 % of area rate on the surface without a surface treatment.

Owner:HONDA MOTOR CO LTD

Gold potassium citrate for gold plating and preparation method thereof

InactiveCN101781784ALow toxicityPH value is stableLiquid/solution decomposition chemical coatingChemical compositionCITRATE ESTER

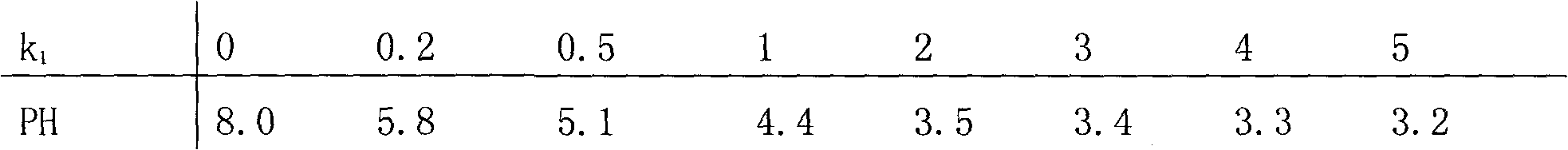

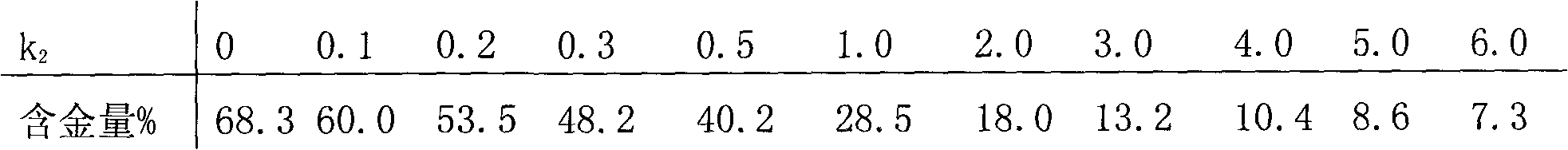

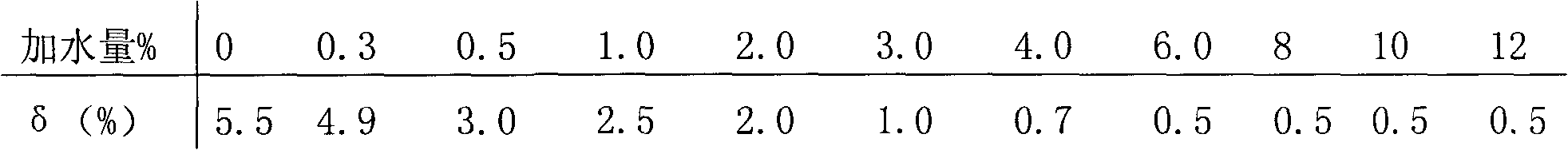

The invention relates to gold potassium citrate for gold plating and a preparation method thereof. The gold potassium citrate is used to substitute for gold potassium cyanide in acidic and neutral gold plating technology. The problem that the product coverage area is too wide when gold citrate is used in the gold plating technology is solved. The technical scheme is that the gold potassium citrate is the mixed crystal of gold potassium cyanide and citric acid potassium salt and the chemical composition of the gold potassium citrate is KAu (CN)2 (K3C6H5O7. k1C6H8O7) k2, wherein KAu (CN)2 is gold potassium cyanide, K3C6H5O7.k1C6H8O7 is citric acid potassium salt which is mixed by potassium citrate K3C6H5O7 and citric acid C6H8O7, k1 is the molar ratio of potassium citrate to citric acid, is more than or equal to zero and is less than or equal to three, and k2 is the molar ratio of citric acid potassium salt to gold potassium cyanide, is more than or equal to one point three and is less than five. The method is mainly suitable for the acidic and neutral gold plating technology.

Owner:张东山

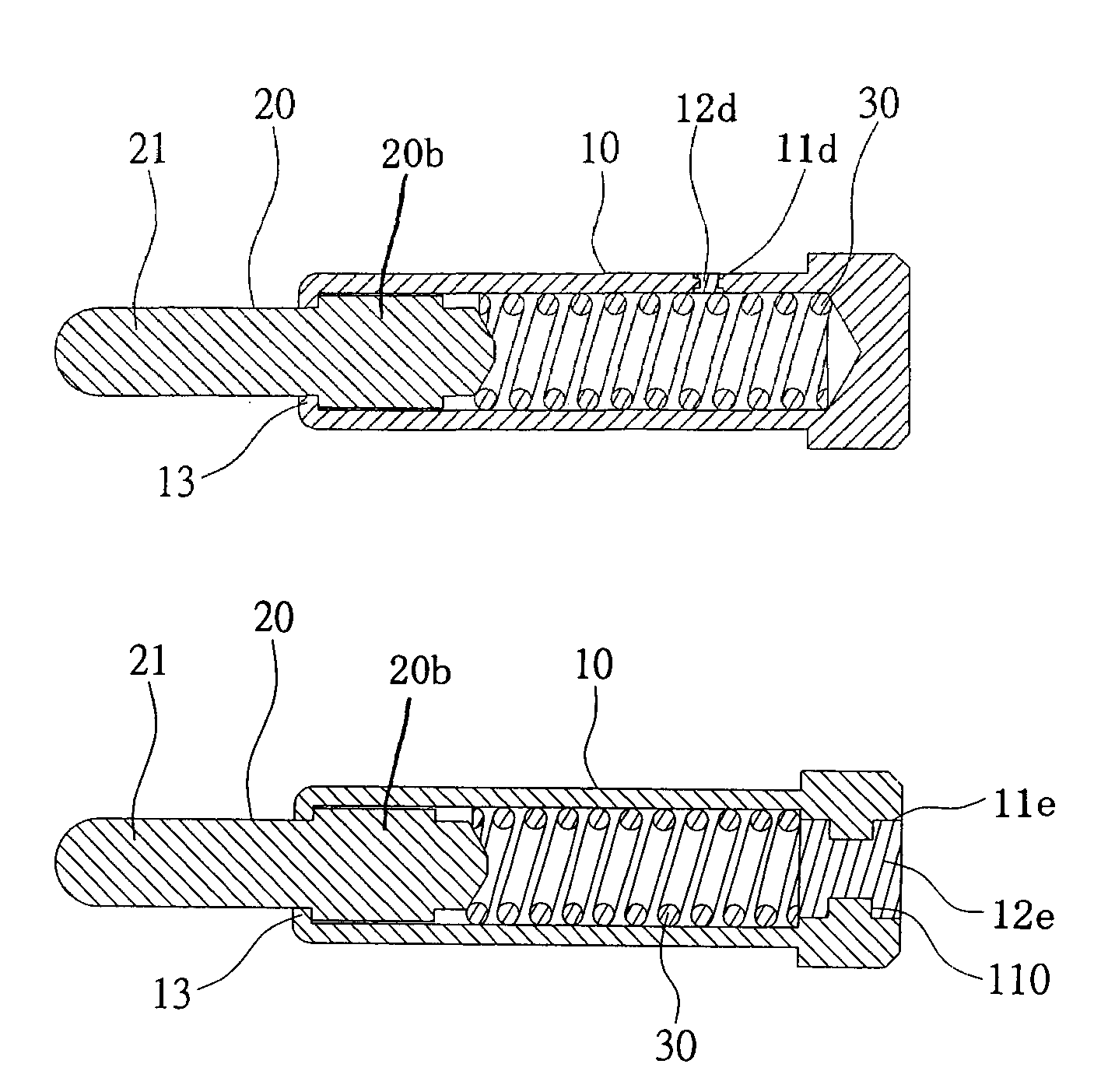

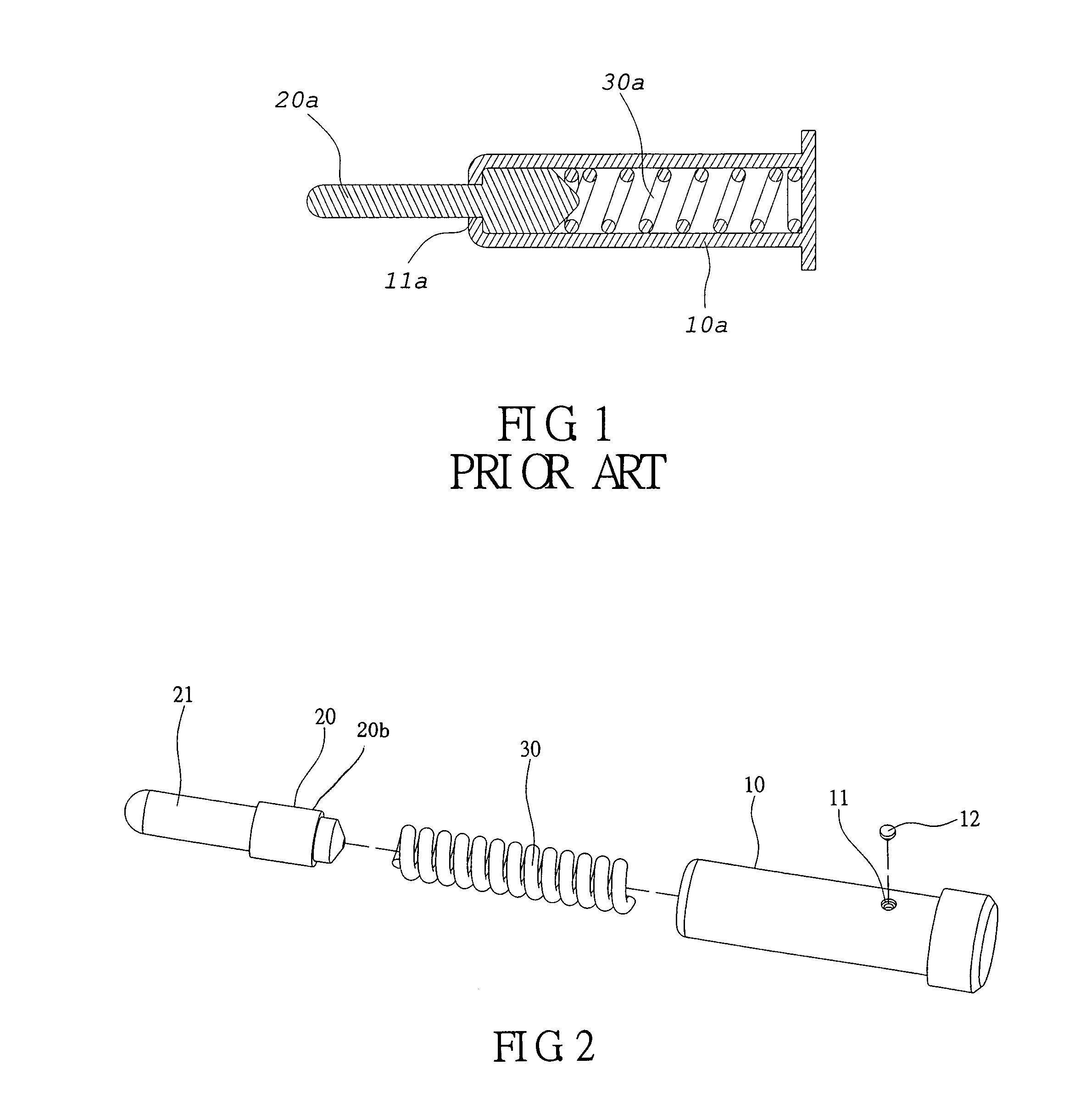

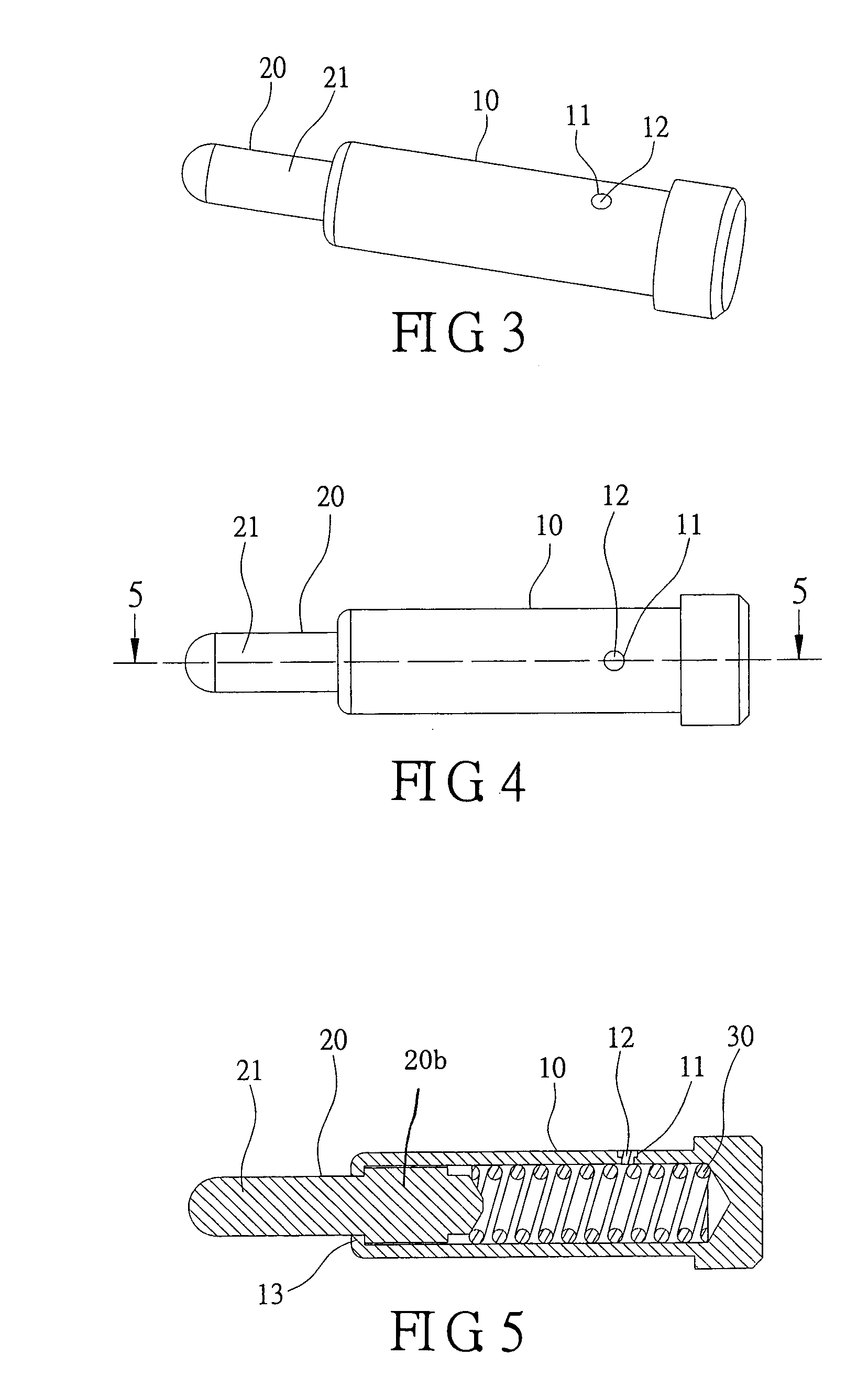

Compressible pin assembly

ActiveUS6957986B2Reduce the amount requiredImprove conductivityCoupling contact membersTesting/measuring connectorsEngineeringContact element

A compressible pin assembly includes a barrel, a contact pin and an elastic element. The contact pin is arranged within the barrel. The contact pin has a contact element. The elastic element is arranged within the barrel to bias the contact pin, so that the contact element is flexibly extended out the front end of the barrel. The barrel has aperture formed therein, which allows superfluous gold plating liquid within the barrel to be eliminated smoothly, after the gold plating process. Thus, the barrel will obtain a more uniform and complete electroplated layer with the use of less gold plating liquid. A stopper will then be inserted into the aperture to prevent impurities from entering the hollow chamber of the barrel. This invention will provide a less expensive compressible pin assembly having greater conductivity.

Owner:MOLEX INC

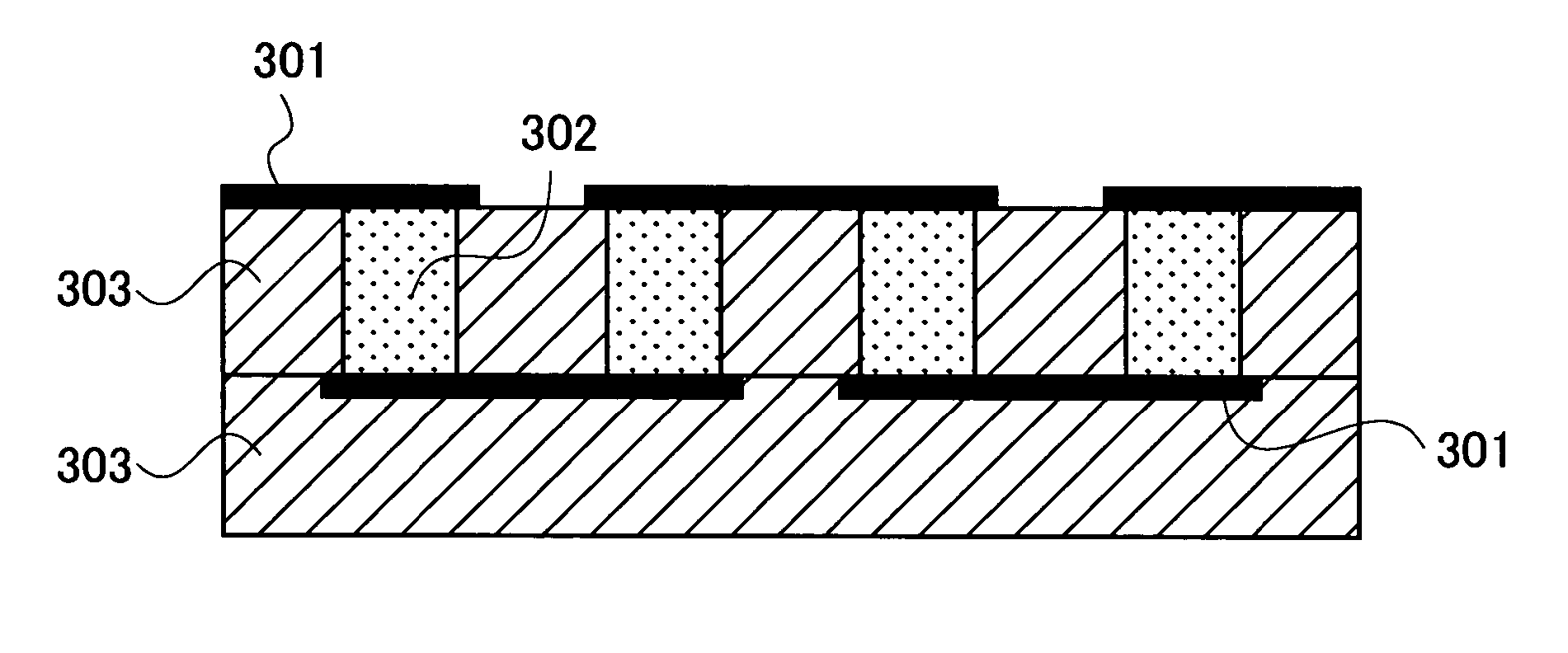

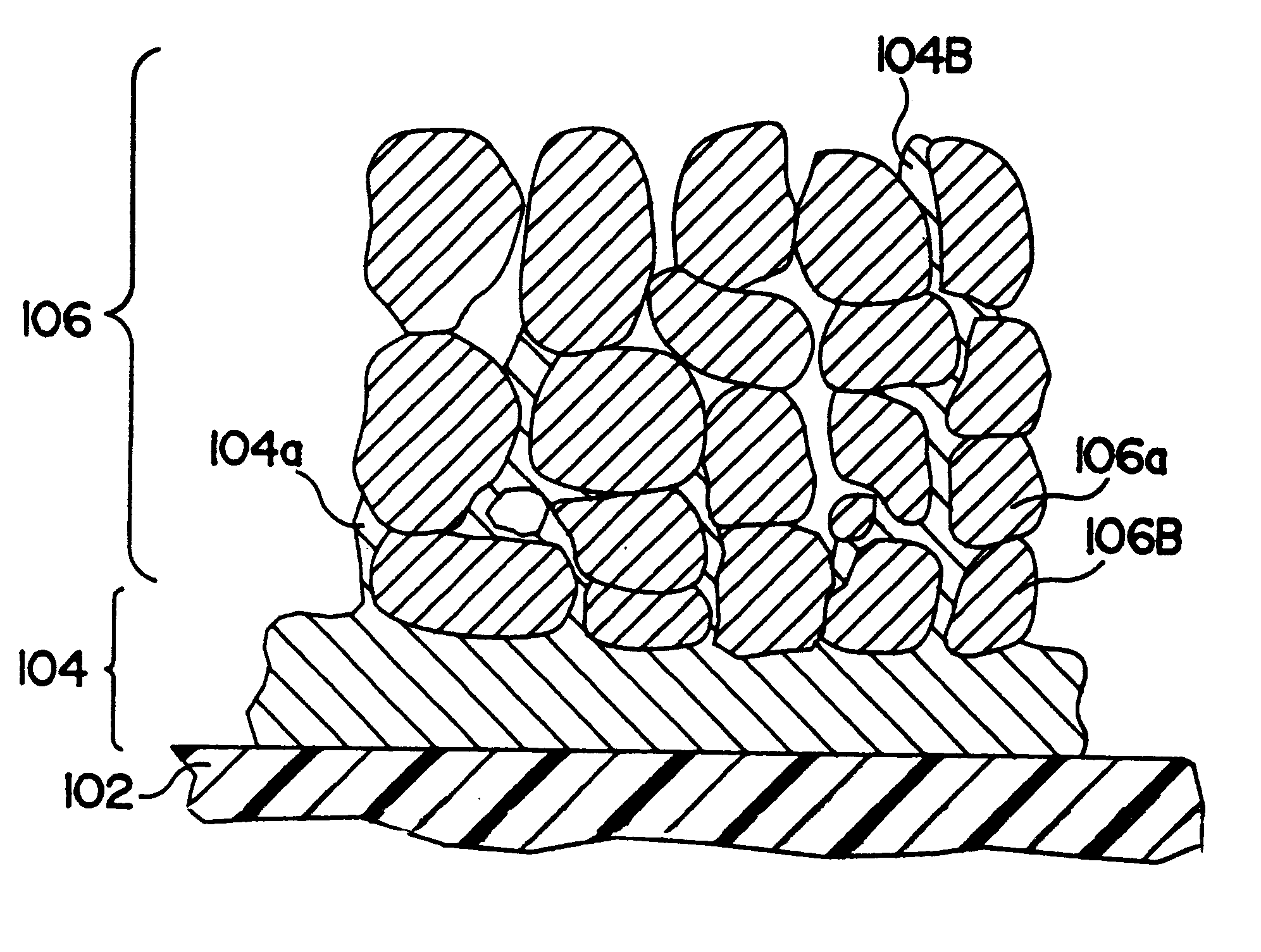

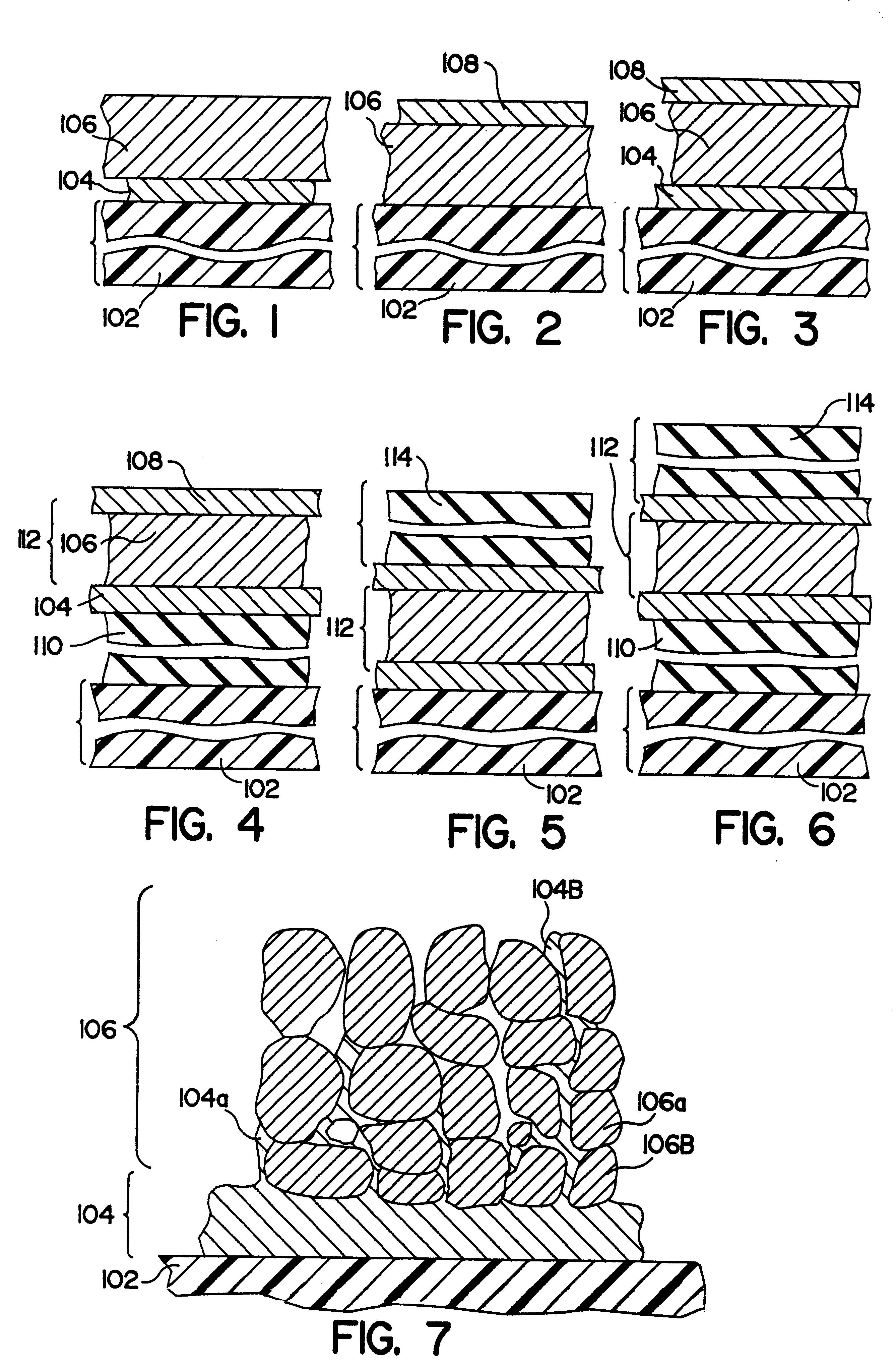

Formation method of metal layer on resin layer, printed wiring board, and production method thereof

InactiveUS20050106370A1Improve electrical performanceDispersion suppressionSurface layering apparatusThin material handlingElectrical conductorSurface roughness

A printed wiring board having a conductor circuit comprising a copper layer adjacent to an insulating layer and an electroless gold plating, wherein the insulating layer has ten-point mean surface roughness (Rz) of 2.0 μm or less is provided. According to the present invention, there is no such a defect that gold plating is deposited on a resin, and fine wiring formation with accuracy is realized.

Owner:HITACHI CHEM CO LTD

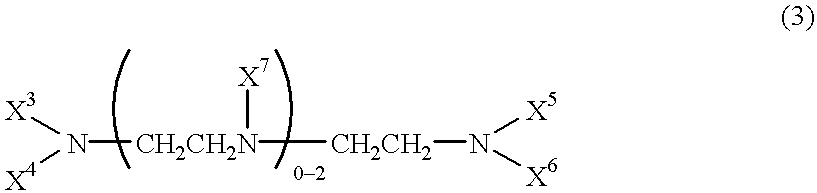

Cyanide-free gold plating solution

The invention discloses a cyanide-free gold plating solution. The cyanide-free gold plating solution comprises sulphurous acid gold salt, a main complexing agent, an auxiliary complexing agent, conducting salt, a stabilizing agent and a pH buffering agent. Under the synthetic action of the sulphurous acid gold salt, the stabilizing agent and the other components, stable composite complex ions are formed through the cyanide-free gold plating solution, the plating solution is more stable, the storage period of the plating solution is long, and the sealed storage period at the normal temperature can reach over 6 months.

Owner:SHENZHEN RUN SUN CHEM TECH

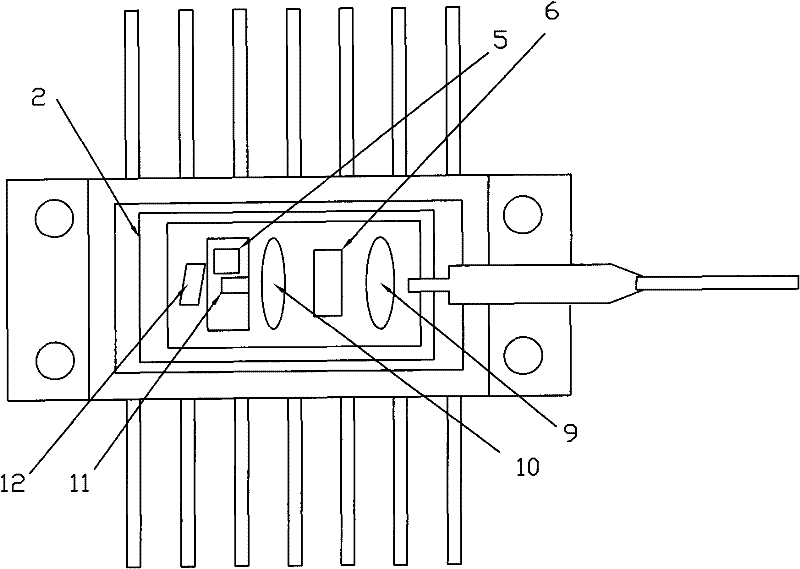

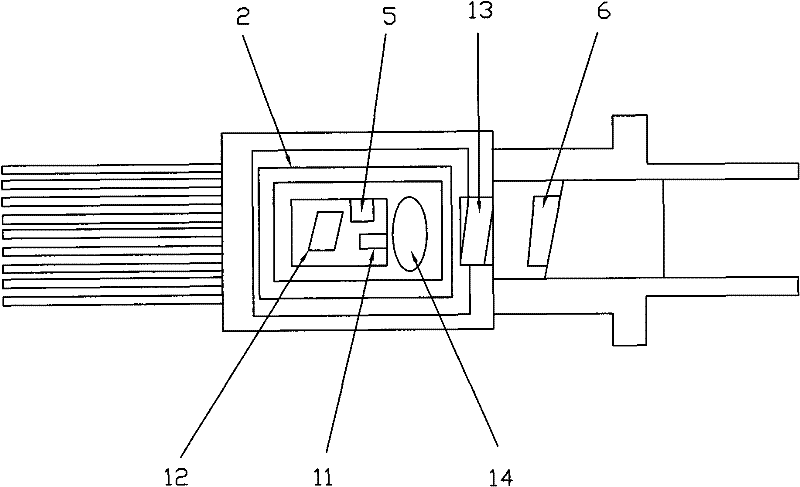

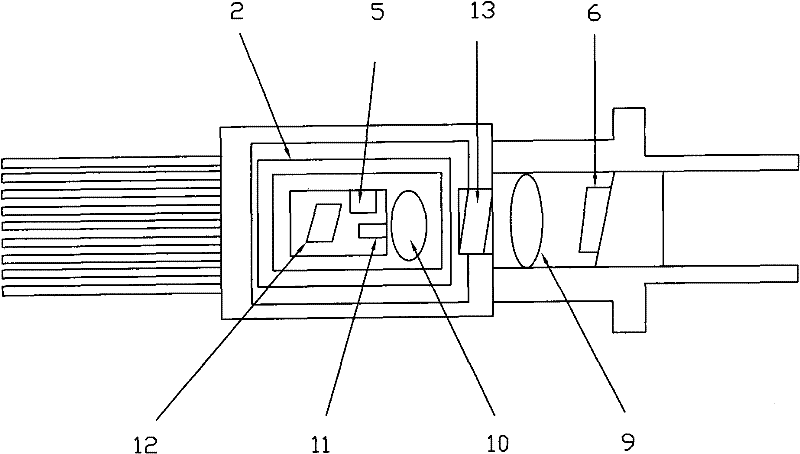

High-speed butterfly-shaped encapsulating tube shell with coupling lens, light emitter assembly and manufacture process

ActiveCN102129101ARealize the coupling functionEnsuring Optical IsolationCoupling light guidesFiberThermistor

The invention relates to the technical field of fiber-optic communication, in particular to a high-speed butterfly-shaped encapsulating tube shell with a coupling lens, a light emitter assembly and a manufacture process of the assembly. The assembly mainly comprises a butterfly-shaped metal ceramic tube shell, a semiconductor refrigerator, a heat sink, a transition block, a collimating lens, an optical isolator, a thermistor, an emitter chip, a backlight detector, a focusing lens, a metal sleeve, a welding workpiece and a ceramic fiber-optic pin, wherein the tail of the butterfly-sahped metal ceramic tube shell is provided with an opening, and a gold-plating layer is arranged at the inner side of the opening; the semiconductor refrigerator is fixed inside the tube shell; the heat sink is fixed on the semiconductor refrigerator; the transition block, the collimating lens and the optical isolator are all fixed on the heat sink; the thermistor, the emitter chip and the backlight detector are fixed on the transition block; the focusing lens is integrally formed by pressing the metal sleeve and lens glass with a metal die; a gold-plating layer is also arranged at the outer side of the metal sleeve, the focusing lens is welded and fixed at the opening of the butterfly-shaped metal ceramic tube shell through AuSn solder; and the welding workpiece and the ceramic fiber-optic pin are welded and fixed on the tube shell. In the invention, the focusing lens is directly welded on the tube shell without assistance of a special optical calibration platform, the process is simple and the production cost is greatly decreased.

Owner:WUHAN TELECOMM DEVICES

Cyanide-free sulfite gold plating solution and application thereof

The invention relates to the field of gold plating, and discloses a cyanide-free sulfite gold plating solution and application thereof. The cyanide-free sulfite gold plating solution is prepared from gold sulfite, alkali metal sulfite, 3-nitrobenzenesulfonate, organic polyamine, organic phosphonate, polyhydric alcohol compounds, a macromolecular polymer containing imine and thiourea compounds. The cyanide-free sulfite gold plating solution contains a current efficiency stabilizer with the excellent property, the current efficiency stabilizer participates in the cathode reduction process in the gold plating process to inhibit side reactions from occurring, therefore, the current efficiency is improved, and the cyanide-free sulfite gold plating solution is obviously beneficial for improving the uniform plating capacity of the plating solution; in addition, a series of the problems that the gold plating amount cannot be accurately estimated, the plating solution dispersing capacity is relatively poor, and the current density is low due to the unstable current efficiency caused by the low current are solved.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV

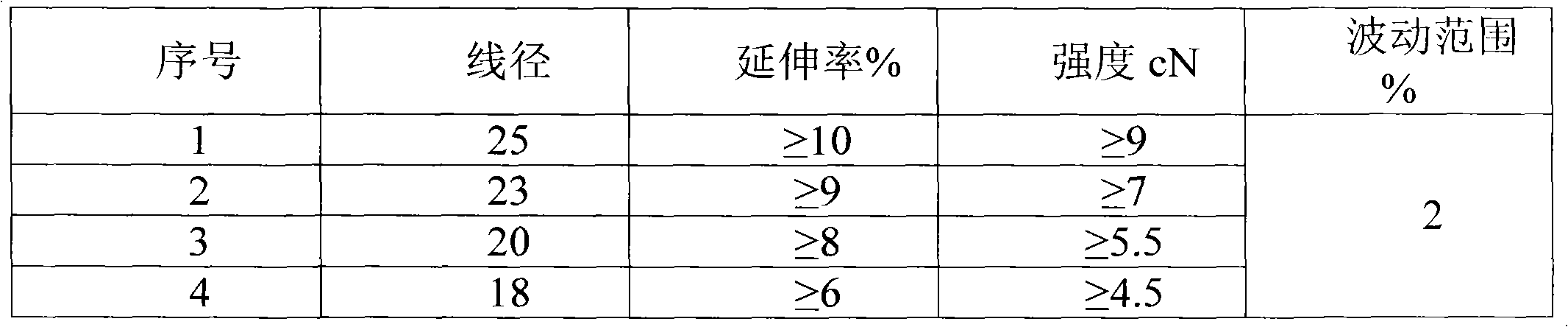

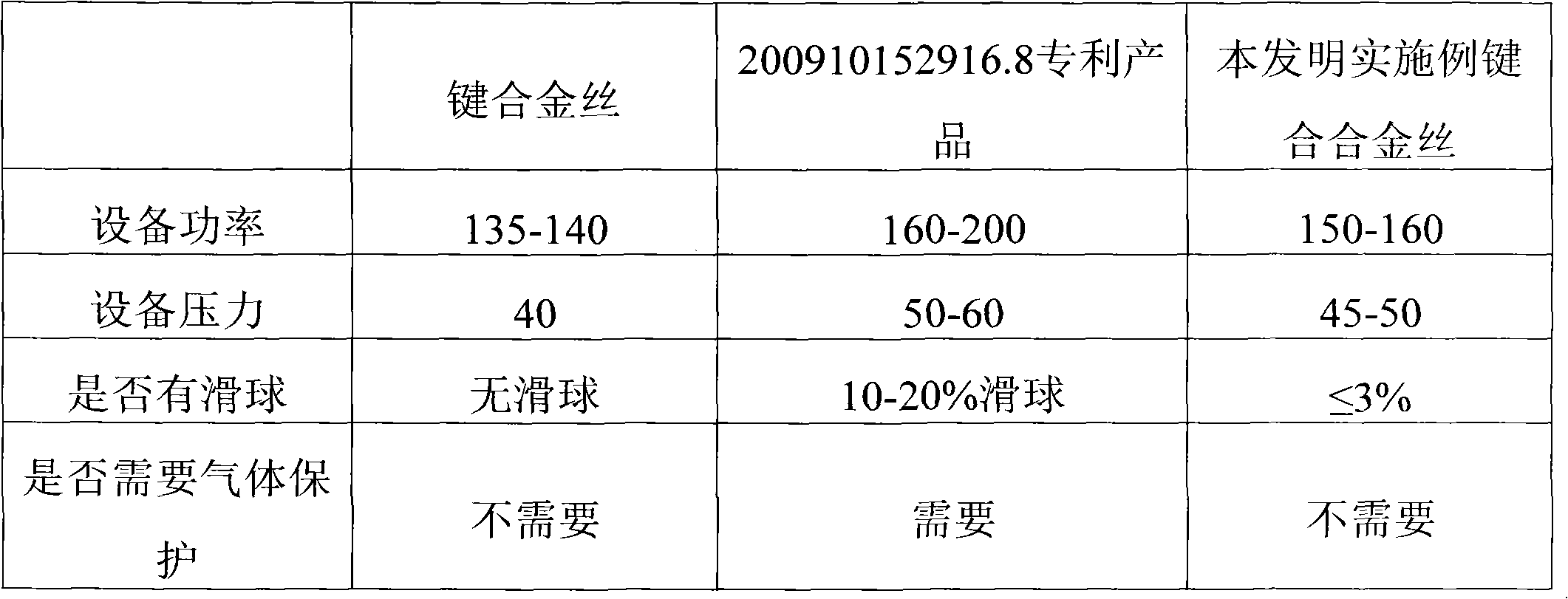

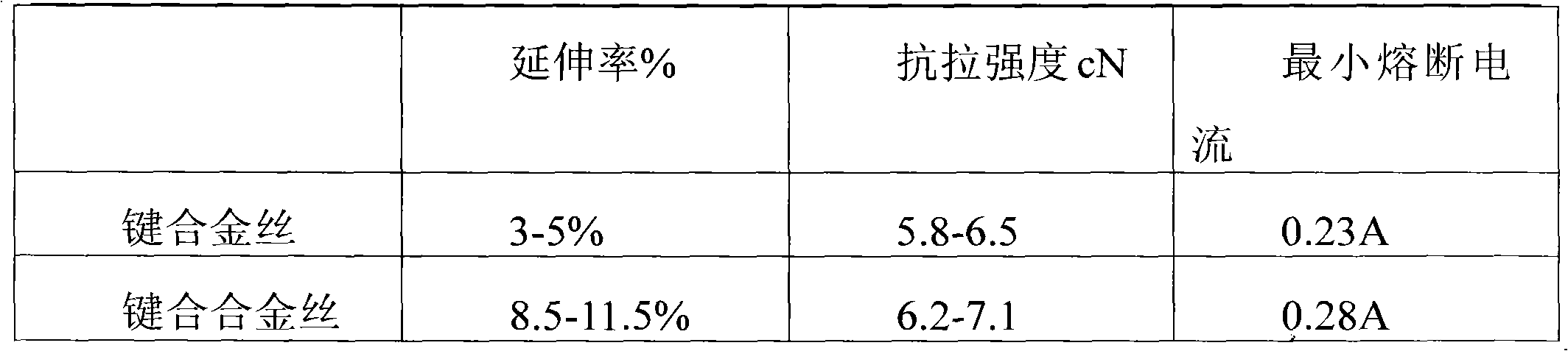

Bonding alloy wire and production technology thereof

ActiveCN102437136AThe production process is convenient and practicalLow costSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationIntegrated circuit

The invention relates to a bonding alloy wire and a production technology thereof. The bonding alloy wire comprises: a base material and a coating plated on a base material surface. The base material is a silver material with a total purity which is greater than or equal to 99.9% and the silver material is added with alloy elements: Ca, Pd and Au. The coating is gold. The production technology ofthe bonding alloy wire comprises the following steps: 1) casting the base material formed by the silver and the alloy elements; 2) performing a large wire drawing to the base material after the fusion casting; 3) plating the gold on the surface of the base material after the large wire drawing; 4) performing wire drawing to the base material whose surface is plated with the gold; 5) performing anannealing process to the gold-plated base material after the wire drawing so as to obtain a needed gold bonding wire. In the invention, the high pure silver material is used as a base, the alloy elements are added and the silver material surface is plated with the gold so that costs can be greatly reduced. An electrical conductivity of the bonding alloy wire whose wire diameter is the same with the wire diameter of the traditional gold bonding wire is higher than the electrical conductivity of the traditional gold bonding wire. The bonding alloy wire of the invention is suitable for an integrated circuit, large-scale integrated circuit miniaturization packaging, a discrete device and LED packaging. The production technology of the bonding alloy wire is convenient and practical.

Owner:浙江佳博科技股份有限公司

Gold-clad-silver-layer-containing films

InactiveUS6255003B1Durability of presentLongevity of presentVacuum evaporation coatingSputtering coatingAlloySolid substrate

Heat wave-reflective or electrically conductive substantially transparent sheets, such as glazing sheets, which include a transparent solid substrate and one or more sequential transparent gold-clad silver layers supported by the substrate are disclosed. These sheets have superior corrosion resistance to equivalent sheets made without the gold cladding or made with gold / silver alloys. Sputter-deposit methods for producing these sheets are also disclosed.

Owner:SOUTHWALL TECH INC

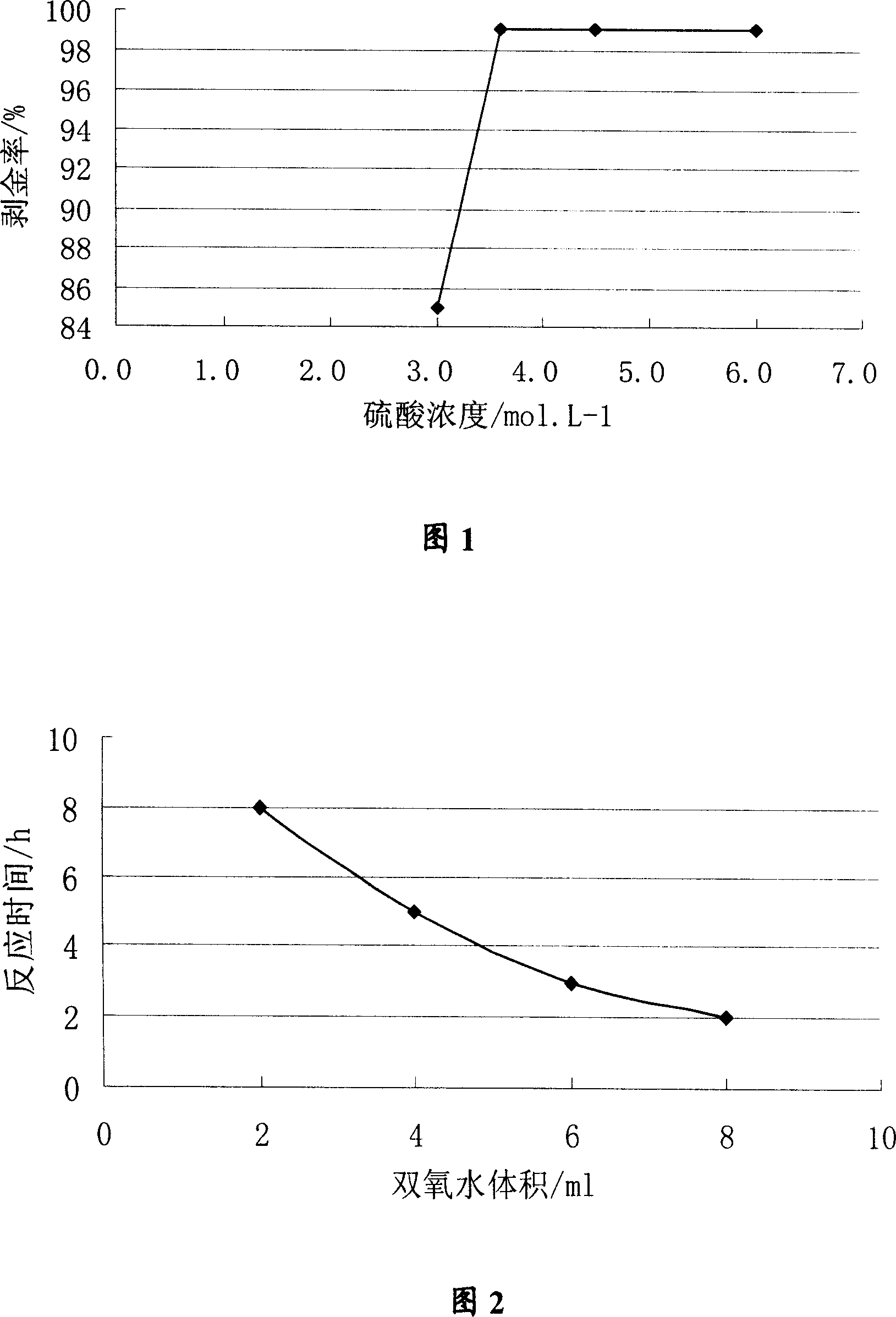

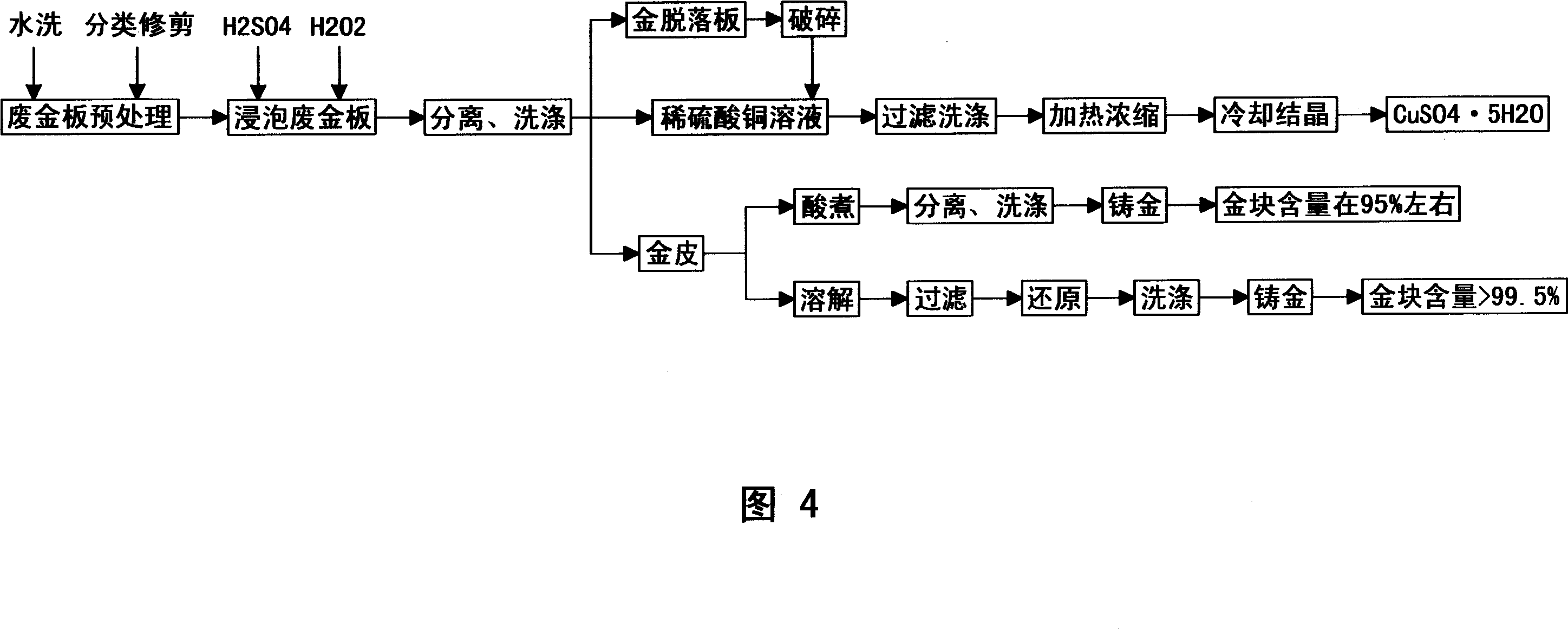

Method for recovering gold and copper from gold-plated printed circuit board waste material

InactiveCN101024864ASuitable for industrial productionGood effectProcess efficiency improvementSocial benefitsTime aspect

The invention is a method for recovering Au and Cu from Au-plated PCB waste, adopting oxydol and vitriol as reacting reagent to recover Au and Cu from the Au-plated PCB waste. And it researches the effect of concentration and utilization of vitriol, oxydol utilization, reacting conditions, and reacting time on the results. And the experimental result indicates that both overhigh and overlow acidity are detrimental to the Au and Cu recovery. Considering from the cost and time aspects, it advances the optimum concentration and utilization of vitriol. And the Au peeling ratio can be 99% and the Cu recovery rate can be 99%; after purified, the obtained Au has purity up to 99%, and the obtained bluestone can crystallize to obtain bluestone products. And the used reagent is nontoxic, cheap and easy to obtain; no harmful matters are generated in the experiment course; and the invention has better economic and social benefits and wide development future.

Owner:苏州天地环境科技有限公司

Packaging board and manufacturing method therefor, semiconductor module and mobile apparatus

ActiveUS20080136033A1Improve package reliabilityLong distance of spreadingFinal product manufactureSemiconductor/solid-state device detailsResistEngineering

An advantage of the present invention is to suppress moisture infiltrating from a pad electrode portion from spreading over the surface of a wiring pattern and improve the reliability of a packaging board. The wiring pattern of the packaging board is formed on an insulating substrate and includes a wiring region, an electrode region (pad electrode) connected with a semiconductor device, and a boundary region provided between the wiring region and the electrode region. A gold plating layer is provided on the surface of the electrode region of the wiring pattern. The top surface of the boundary region of the wiring pattern is so formed as to be dented from the top surface of the wiring region of the wiring pattern, and there is provided a stepped portion in the boundary region. A solder resist is formed in such a manner as to cover part of the gold plating layer and the wiring pattern corresponding to the boundary region and the wiring region, and the solder resist has a predetermined opening through which to connect to the semiconductor device. A conductive member is connected to the gold plating layer in the electrode region, and a molded resin layer seals the entire semiconductor module.

Owner:III HLDG 12 LLC

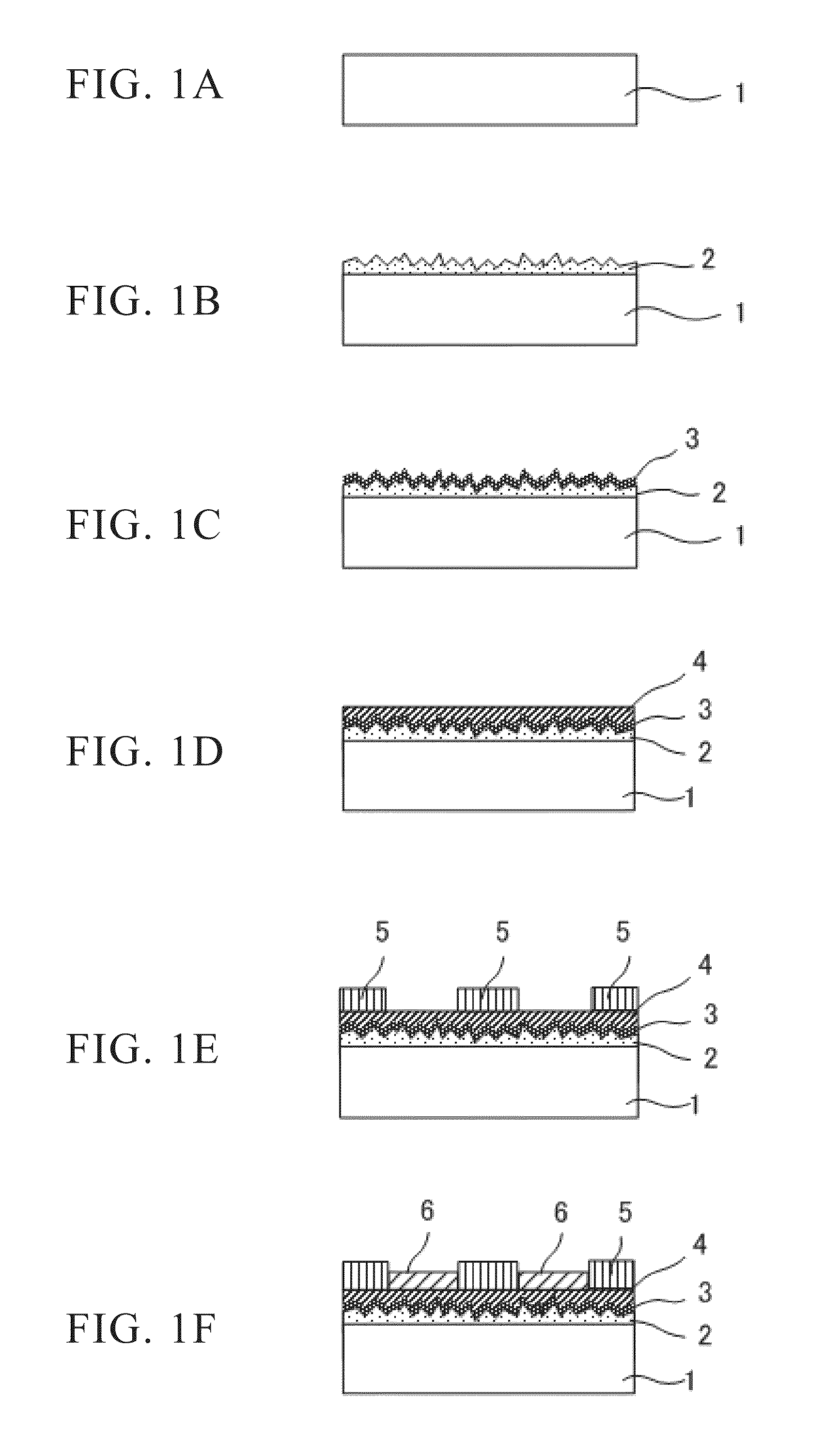

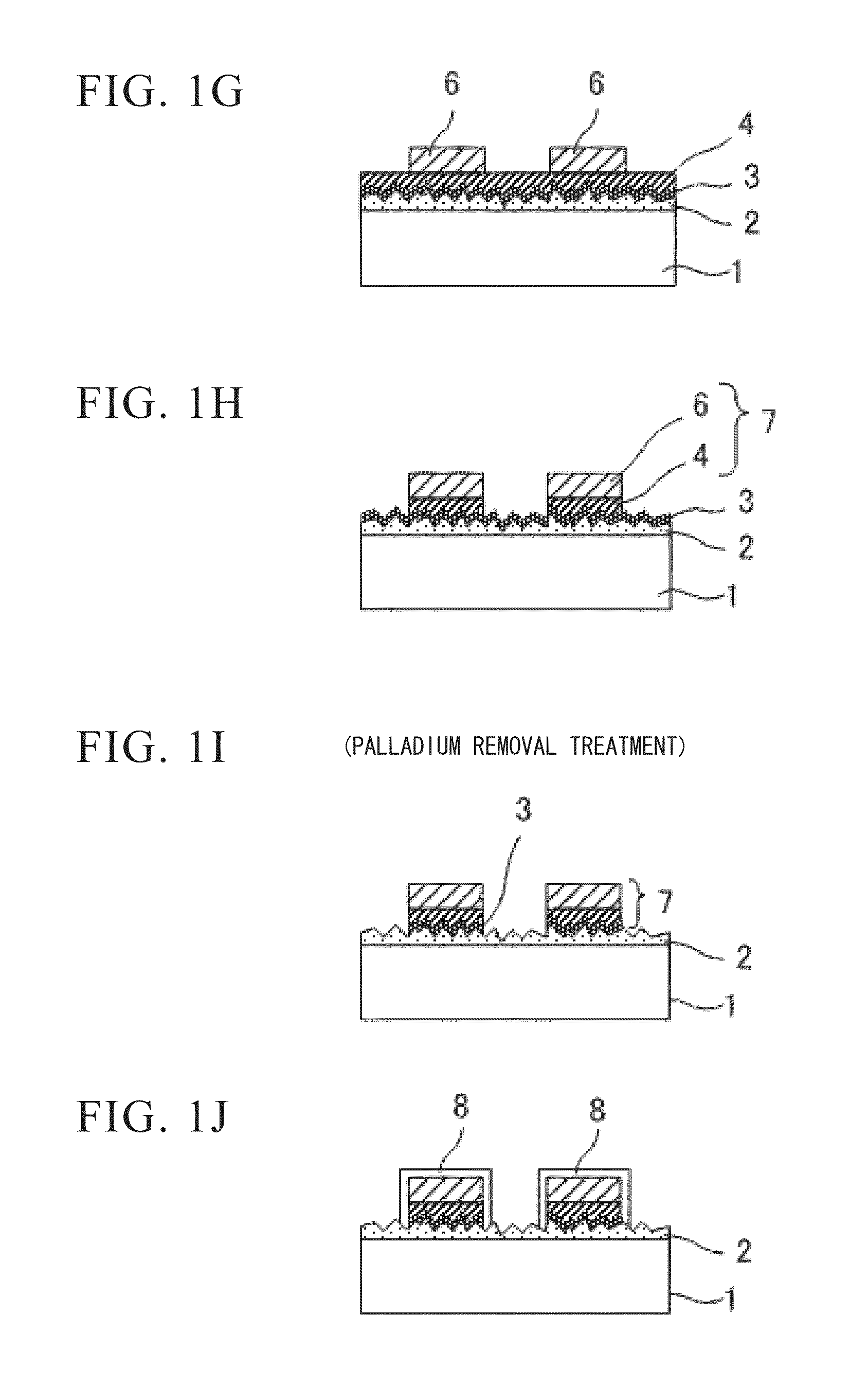

Method for manufacturing base material having gold-plated metal fine pattern, base material having gold-plated metal fine pattern, printed wiring board, interposer, and semiconductor device

InactiveUS20130058062A1Improve adhesionHigh peel strengthSemiconductor/solid-state device detailsPrinted circuit aspectsGilding metalSurface roughness

A method for manufacturing a base material having a gold-plated metal fine pattern is disclosed, comprising the steps of preparing a base material having a supporting surface made of a resin; forming a primer resin layer having surface roughness of 0.5 μm or less on the supporting surface, and forming a metal fine pattern thereon by an SAP process to obtain a base material having a metal fine pattern; and applying a gold-plating treatment to at least one part of a surface of the metal fine pattern; wherein the base material having a metal fine pattern is subjected to a palladium removal treatment in an optional stage before carrying out the gold-plating treatment.

Owner:SUMITOMO BAKELITE CO LTD

Method for chemically plating gold on surface of capacitive touch screen

ActiveCN101845625AEliminate the problemIncrease usageVacuum evaporation coatingSputtering coatingSputteringStrong acids

The invention relates to the technical field of plating gold on the surface of a capacitive touch screen, in particular to a method for chemically plating gold on the surface of the capacitive touch screen. The method has the advantages of enhancing the practical utilization ratio of indium tin oxide (ITO) glass, saving the liquid gold and lowering cost. The method is characterized by comprising the following steps of: sputtering ITO on the surface of a glass substrate of the capacitive touch screen to form double-sided ITO glass; partitioning a visible region and a surrounding region of touch control glass on the double-sided ITO glass according to composition; etching a sensor inductance electrode in the visible region and a trace in the surrounding region of the touch control glass by using a photograph process; printing a gold-plated protective film on the visible region of the touch control glass; and plating gold on the trace of the touch control glass by using a chemical nickel plating process and chemical gold plating process, wherein the gold-plated protective film is a strong acid-resistant and high temperature-resistant protective film to which Ni and Au metal particles cannot be attached.

Owner:HUZHOU SHENGXI ELECTRONICS & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com