Gold potassium citrate for gold plating and preparation method thereof

A technology of gold potassium citrate and lemon, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as too wide coverage, achieve convenient safety management, improve stability, and improve gold plating quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

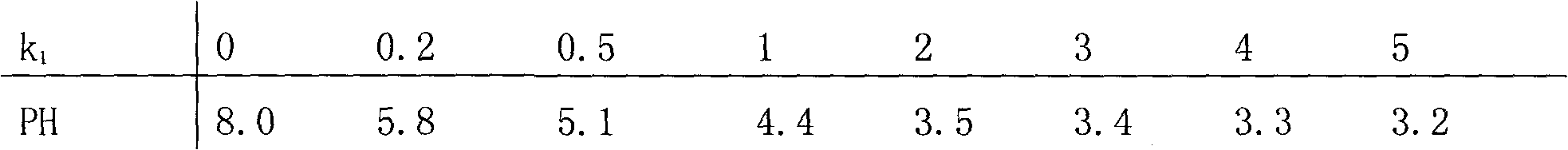

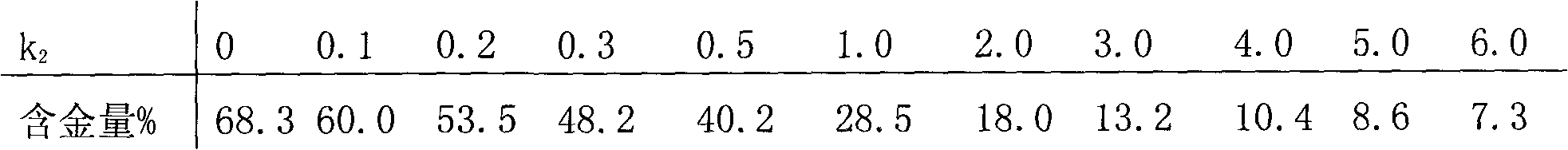

[0035] Embodiment 1, electroplating thick gold

[0036] main salt type

[0037] It can be seen from the comparison that using gold potassium citrate as the main salt makes it easy to start and refill the tank. During the gold plating process, the composition of the plating solution is stable and the gold plating effect is good.

Embodiment approach 2

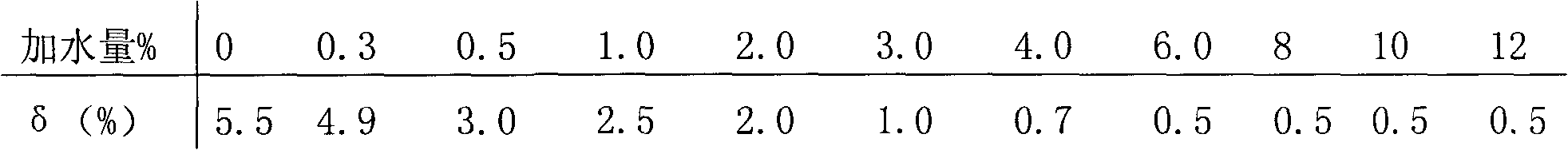

[0038] Embodiment 2 Thin gold plating

[0039] main salt type

Potassium aurous cyanide

(68.3% gold content)

Potassium Gold Citrate

(20% gold, PH=5.1)

open cylinder

(per liter)

Potassium aurous cyanide 6g

Diammonium hydrogen citrate 120g

Antimony Potassium Tartrate 0.1g

PH 5.0-5.6

Potassium Gold Citrate 20.5g

* Diammonium hydrogen citrate 109g

Antimony Potassium Tartrate 0.1g

PH 5.0-5.6

Cylinder replenishment

1. Add cyanide for every gram of gold consumed

Potassium aureus 1.46 g (every 30 minutes

make up once)

2. Test citric acid every hour

root and add

3. Adjust the PH value every hour

1. For every gram of gold consumed, add gold citrate

Potassium 5.0 grams (replenish every 30 minutes)

2. Check citric acid every 4 hours

root and add

3. Adjust the PH value every 4 hours

[0040] *The main salt is gold potassium citrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com