Patents

Literature

224 results about "Gold content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On Earth, gold is found in ores in rock formed from the Precambrian time onward. It most often occurs as a native metal, typically in a metal solid solution with silver (i.e. as a gold silver alloy). Such alloys usually have a silver content of 8–10%. Electrum is elemental gold with more than 20% silver.

Gold complex catalyst for hydrochlorinating acetylene

ActiveCN102631947AImprove stabilityHigh activityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsGold contentPotassium

The invention discloses a gold complex catalyst, and particularly relates to a non-mercury catalyst which is applicable to synthesizing vinyl chloride by acetylene hydrochlorination, and a preparation method of the non-mercury catalyst. The non-mercury catalyst comprises potassium aurate tetra-thiocyanate taken as a main active component, one or a combination of more than two of potassium chloride, copper chloride, cobalt chloride and zinc chloride taken as auxiliary active components, and carrier activated carbon, wherein gold complex accounts for 0.1-2.5% of the weight of the catalyst, and the auxiliary active components account for 0.05-15% of the total weight of the catalyst. According to the gold complex catalyst prepared by the invention, the gold content is lower, so that the cost of noble metal catalyst can be remarkably reduced; and the novel non-mercury catalyst is good in activity, high in stability and strong in selectivity. The gold complex catalyst has the advantages of being simple in production technology, short in production cycle and environment-friendly.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

Method for comprehensively recovering gold, iron and sulphur resource from gold-containing sulfurous iron ore

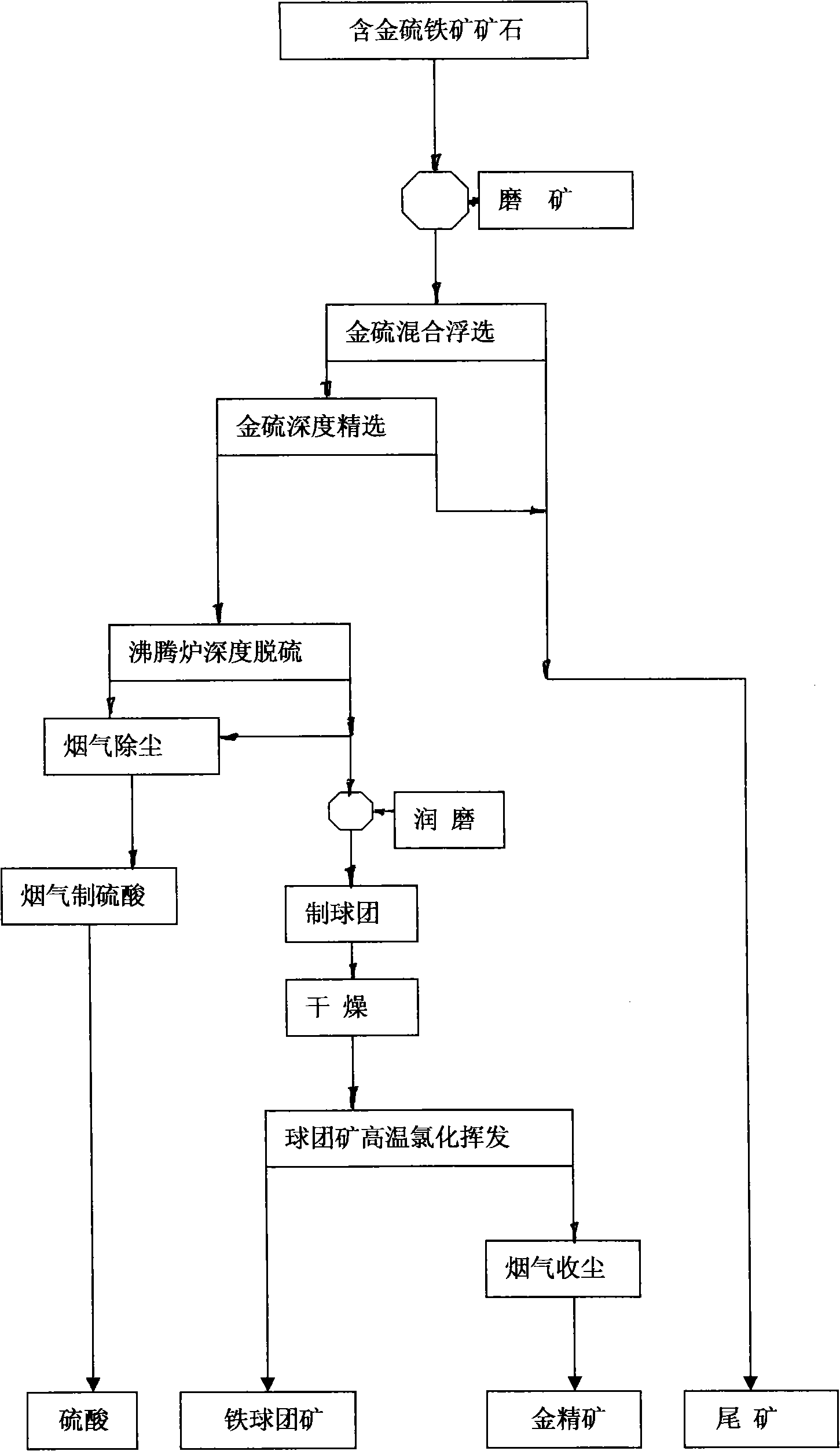

The invention discloses a method for comprehensively recovering gold sulfurous iron resources from gold-bearing sulfurous iron ore, comprising the following steps: middle and low-grade sulfurous iron ore containing micro-gold and enclosed gold is grinded, and gold-bearing high-grade sulfur ore concentrate is obtained after sulfate dipping, mixture, floatation and concentration for a plurality of times; the ore concentrate undergoes high-temperature overoxidation roasting in a fluid-bed furnace to prepare sulfuric acid after flue gas undergoes dust removal and purification, and cinder becomes high-iron low-sulfur gold-bearing slag; the cinder is added with a pellet adhesive and a chlorating agent for grinding, and a pellet is prepared; the pellet is dried and then undergoes high-temperature chlorination-evaporation roasting; the flue gas is roasted and gold concentrate is obtained after dust collection; and the roasted pellet ore is a high-quality iron-making raw material the iron content of which is more than 60 percent and the gold content of which is less than 0.2 grams per ton. The technology highly efficiently recovers a large amount of gold resources which is lost in the sulfurous iron ore due to difficult cyanidation and leaching caused by containing the micro-gold and the enclosed gold through mixture and floatation of gold and sulfur, concentrate for a plurality of times, high-temperature overoxidation roasting deep desulfurization and high-temperature chlorination roasting degolding, obtains high-quality iron pellet ore while obtaining the sulfuric acid, and highly efficiently utilizes iron resources.

Owner:KUNMING UNIV OF SCI & TECH

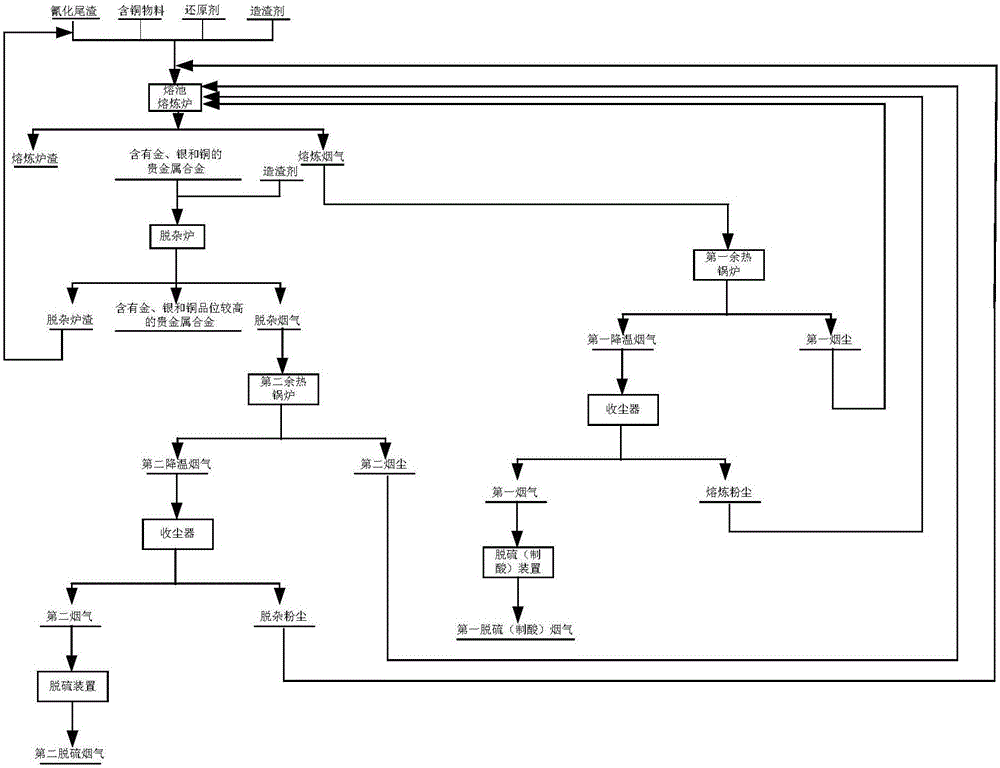

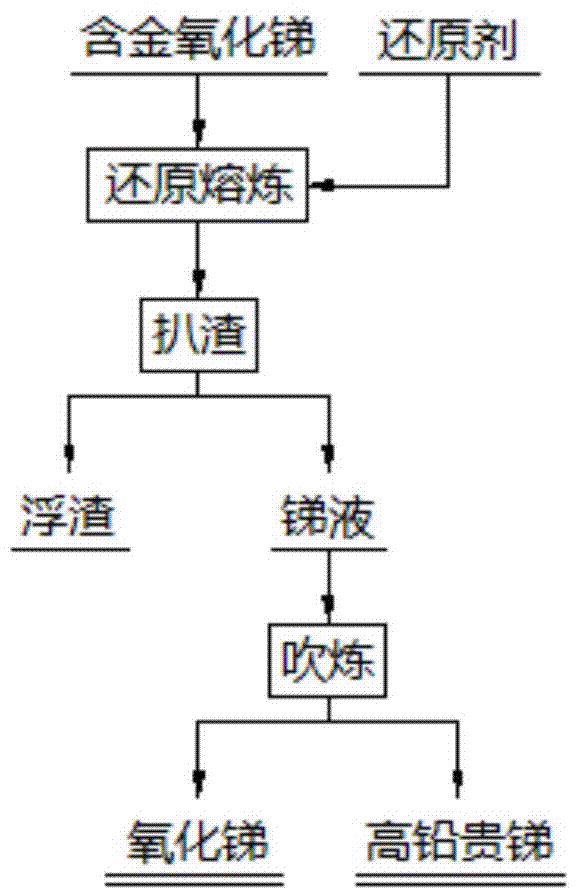

Method for comprehensively efficiently processing lead anode slime by using top-blown converter

ActiveCN103397191AAdaptableImprove reducibilityProcess efficiency improvementEnvironmental resistanceMelting tank

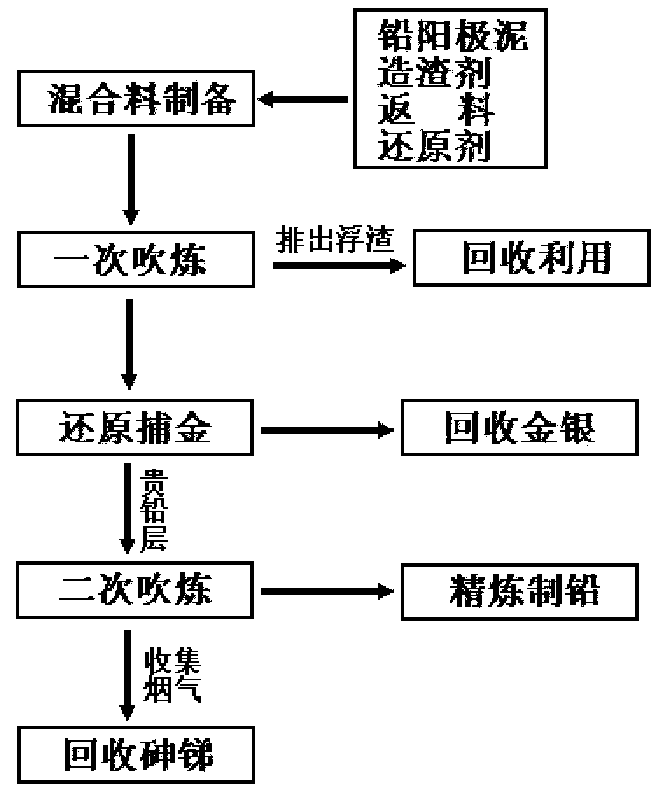

The invention discloses a method for comprehensively efficiently processing lead anode slime by using a top-blown converter. The method comprises processes of preparation of a mixed material, first reduction smelting, reduction for gold catching, secondary converting, and recovering of arsenic and antimony. The method specifically comprises: uniformly mixing lead anode slime according to dry weight, a slagging flux, a recycled material and a reducing agent to form the mixed material; spraying a fuel accounting for 1-10% by weight of the material into the molten pool of the top-blown converter, controlling melting temperature of the top-blown converter at 900 DEG C-1200 DEG C, after a complete reaction, discharging a slag layer formed by floating upward through a discharge outlet for recovery processing, wherein lead reduced by the reducing agent catches gold and silver and forms an expensive lead layer; performing further strengthening converting on the expensive lead layer, discharging through the discharge outlet for continuous refining; and cooling and dedusting the high-temperature flue dust via a waste-heat reclamation device to obtain an arsenic antimony flue dust. The method of the invention has the advantages of a show flow, low gold content and silver content in the slag, a long service life of the converter, substantial economical benefit, large processing amount, strong raw-material adaptability, high automation level, environmental protection, safe and the like.

Owner:KUNMING METALLURGY INST

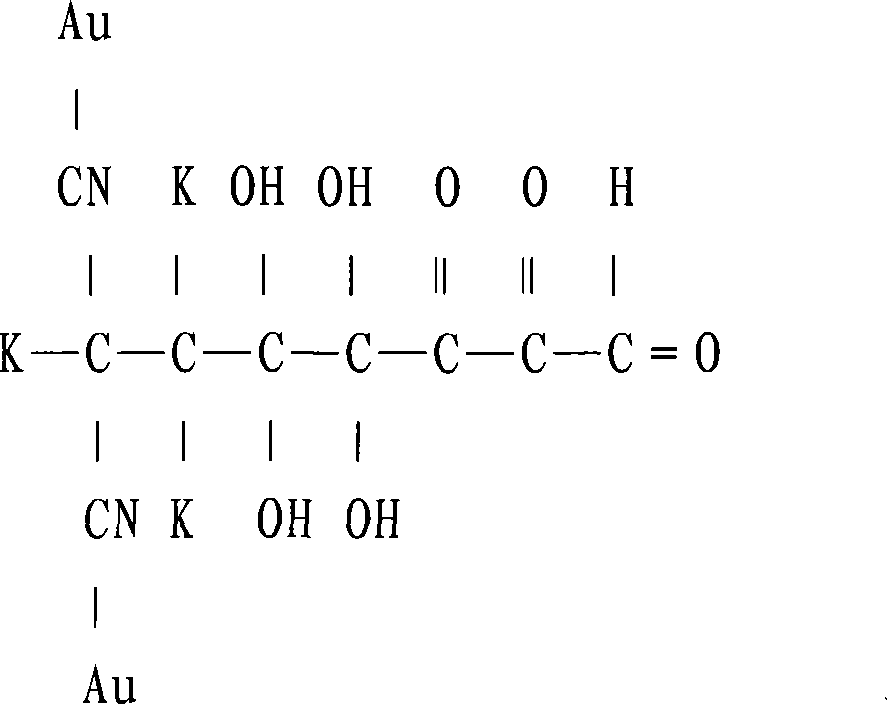

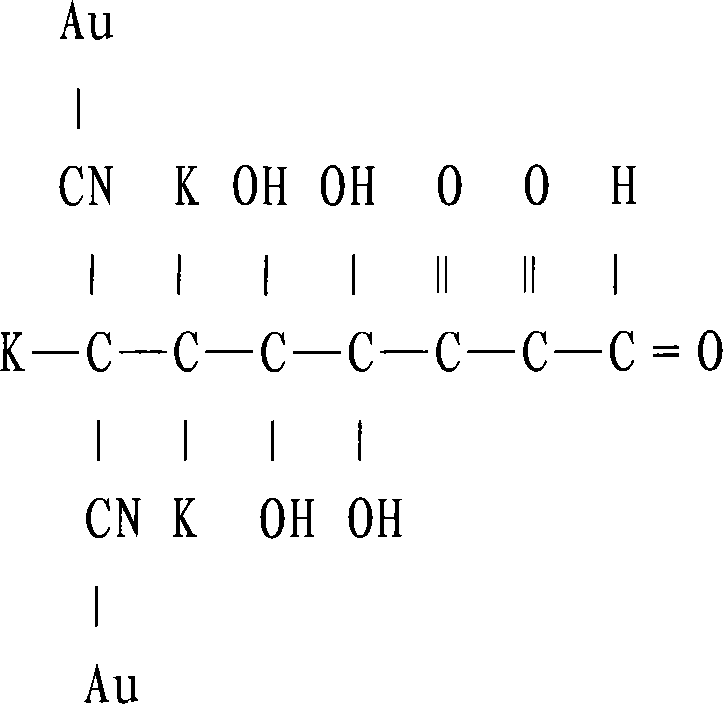

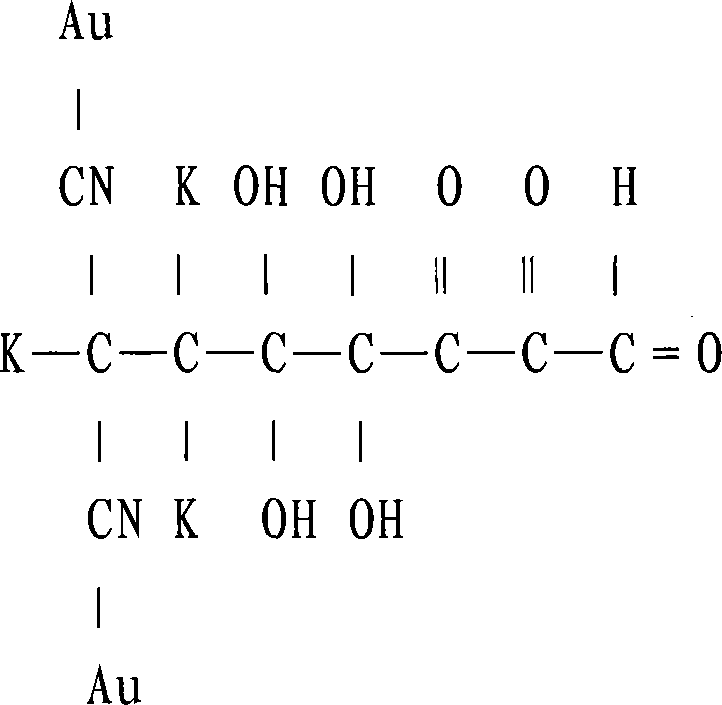

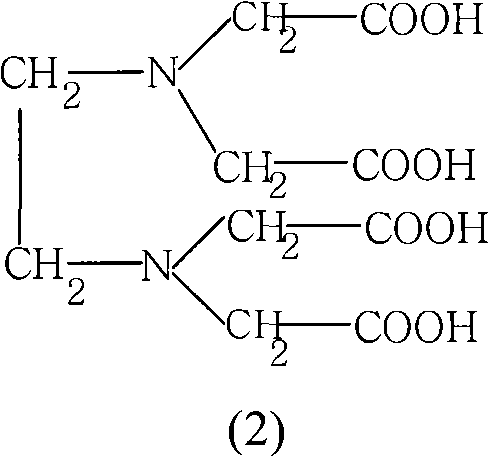

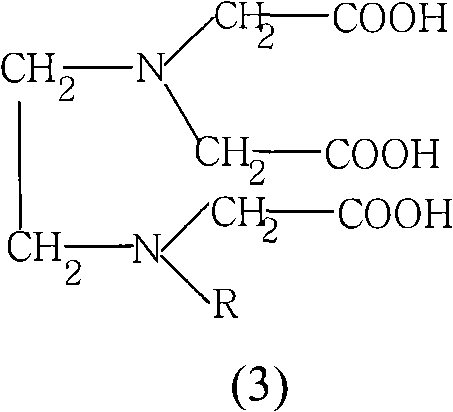

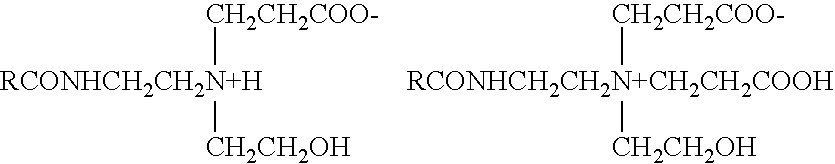

Gold potassium lemon acid for gold plating and method for producing the same

ActiveCN101172946BReduce processing costsReduce pollutionCarboxylic acid salt preparationGold contentPotassium

The invention discloses citric acid gold potassium used for gold plating and the preparation method thereof. The molecular formular of the citric acid gold potassium is K3Au2C9H5O7N2. The method comprises the steps as follows: gold trichloride is dissolved in water of certain temperature, is concentrated and diluted under the temperature for multiple times, and is reacted with potassium citrate, ethylene diamine tetraacetic acid and malononitrile in a reactor under the certain temperature and the certain time to produce the organic gold salt which has low toxicity and contains no free cyanogen. When the product has the same gold content with the potassium gold cyanide, the total CN- is 5 to 6 percent, being 50 percent lower than that of the CN- in the potassium gold cyanide. The waste liquid after gold plating contains free the CN- in small amount. The invention reduces the cost of waste water treatment for the electroplating plants.

Owner:HENGSHENG TECH R&D CO LTD

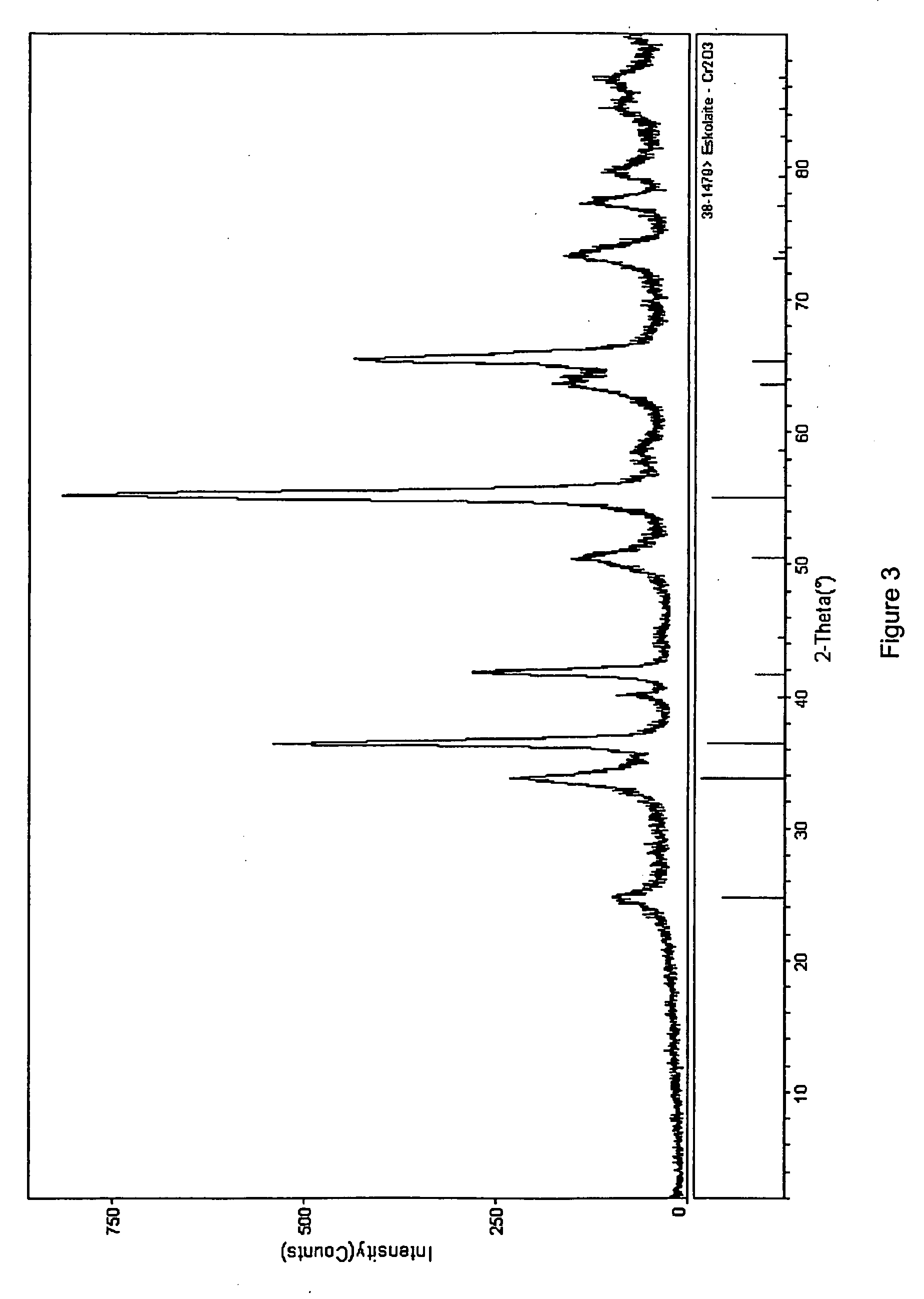

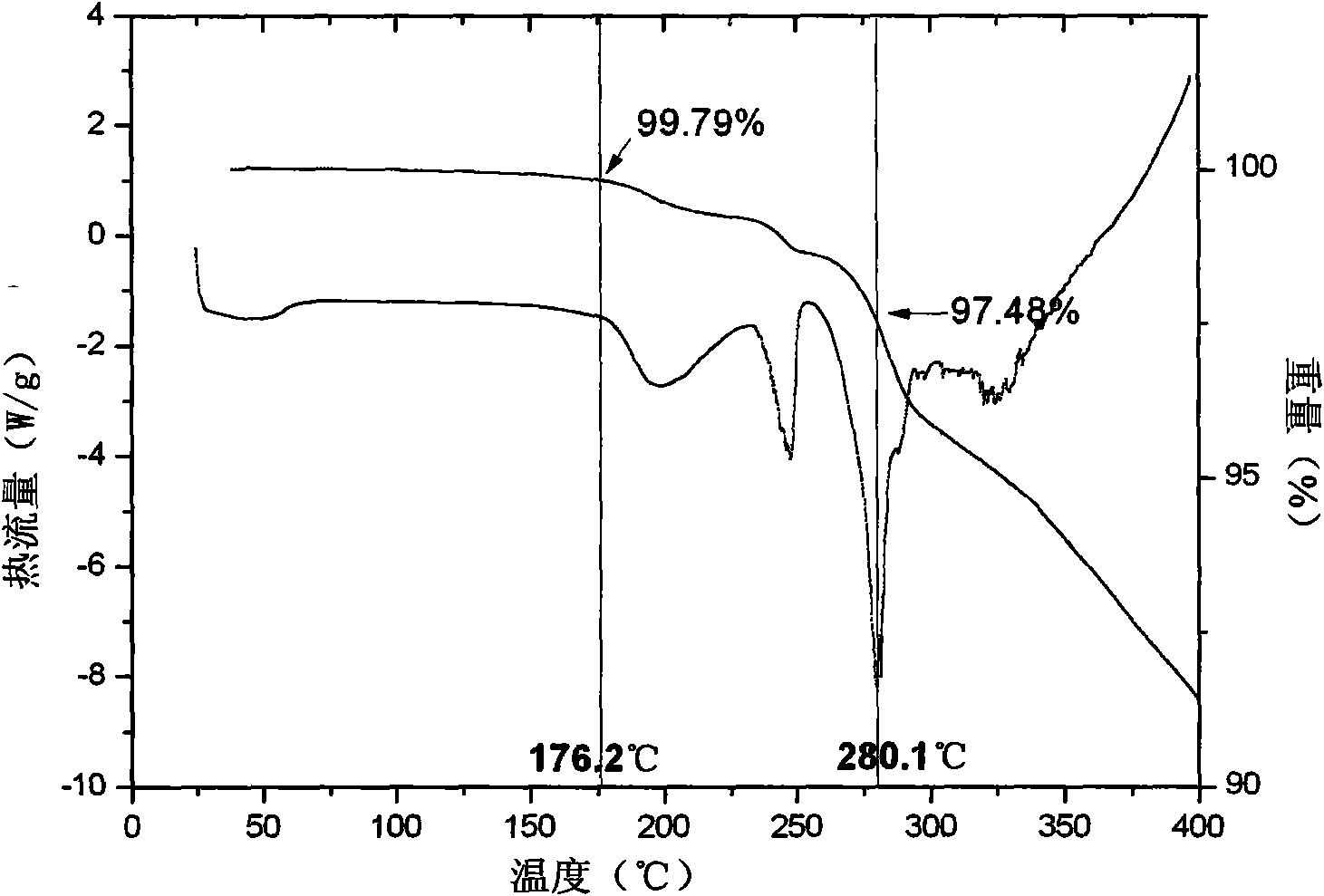

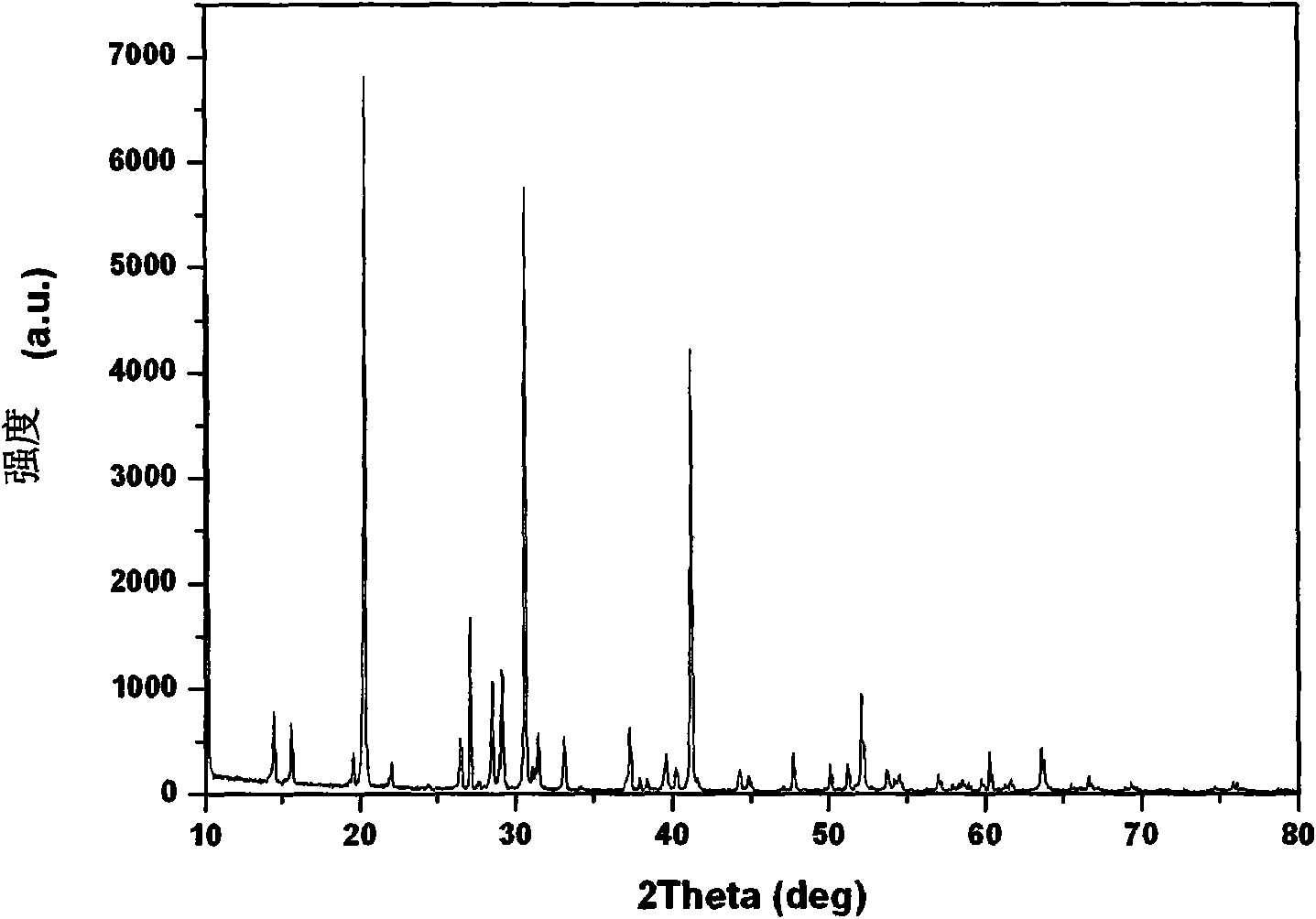

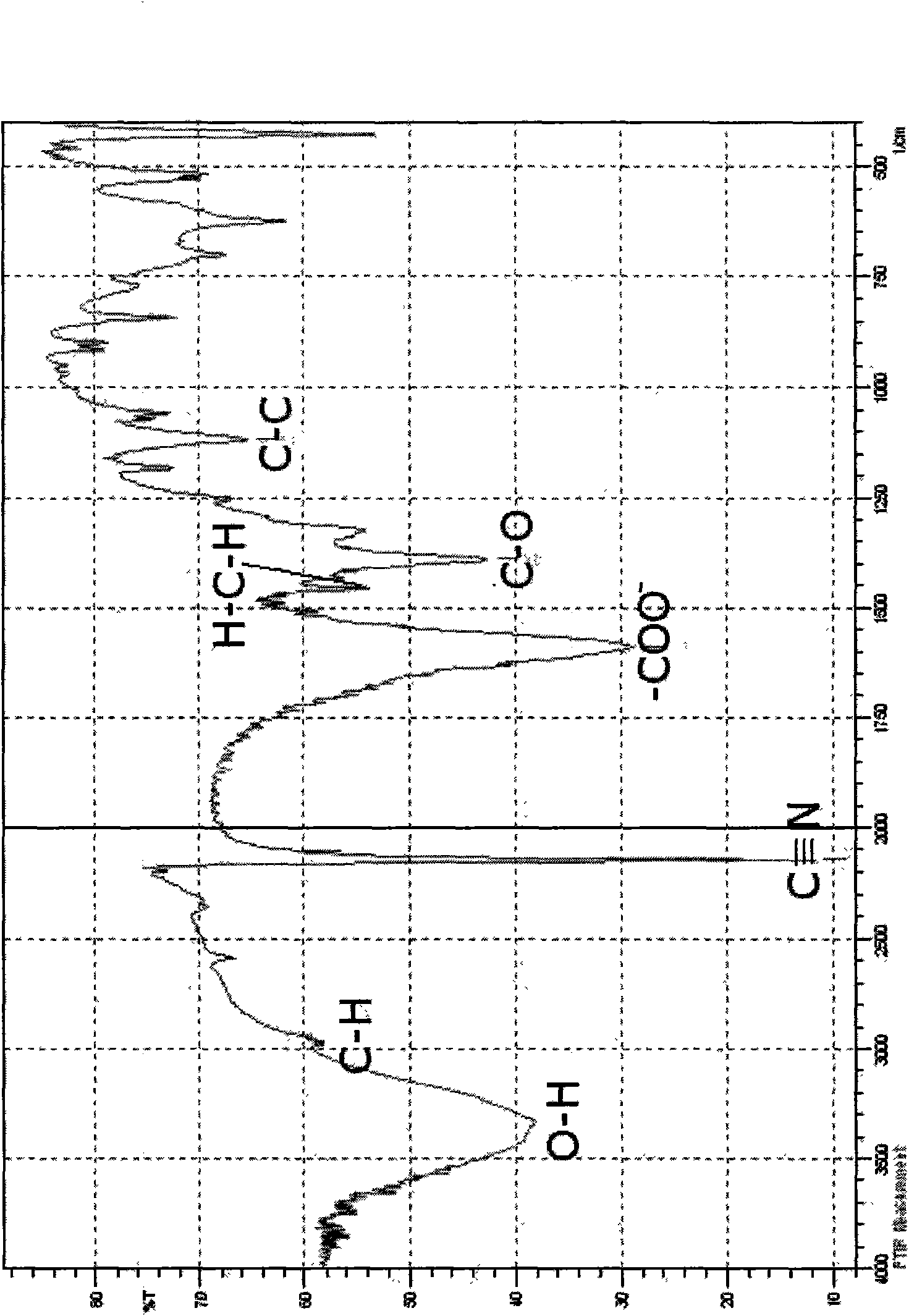

Compositions containing chromium, oxygen and gold, their preparation, and their use as catalysts and catalyst precursors

InactiveUS20080207964A1Preparation by dehalogenationPreparation by hydrogen halide split-offGold contentOxygen

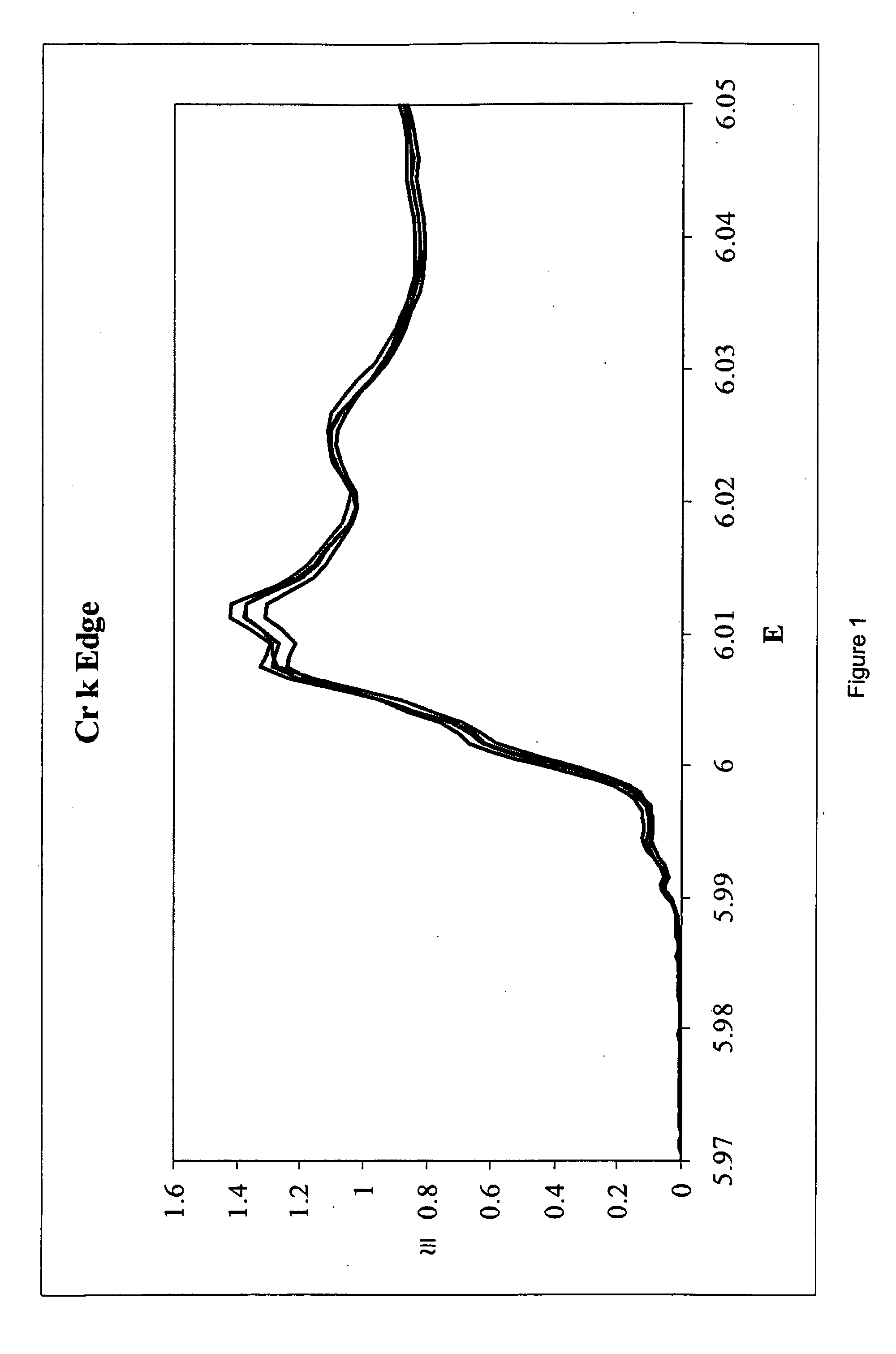

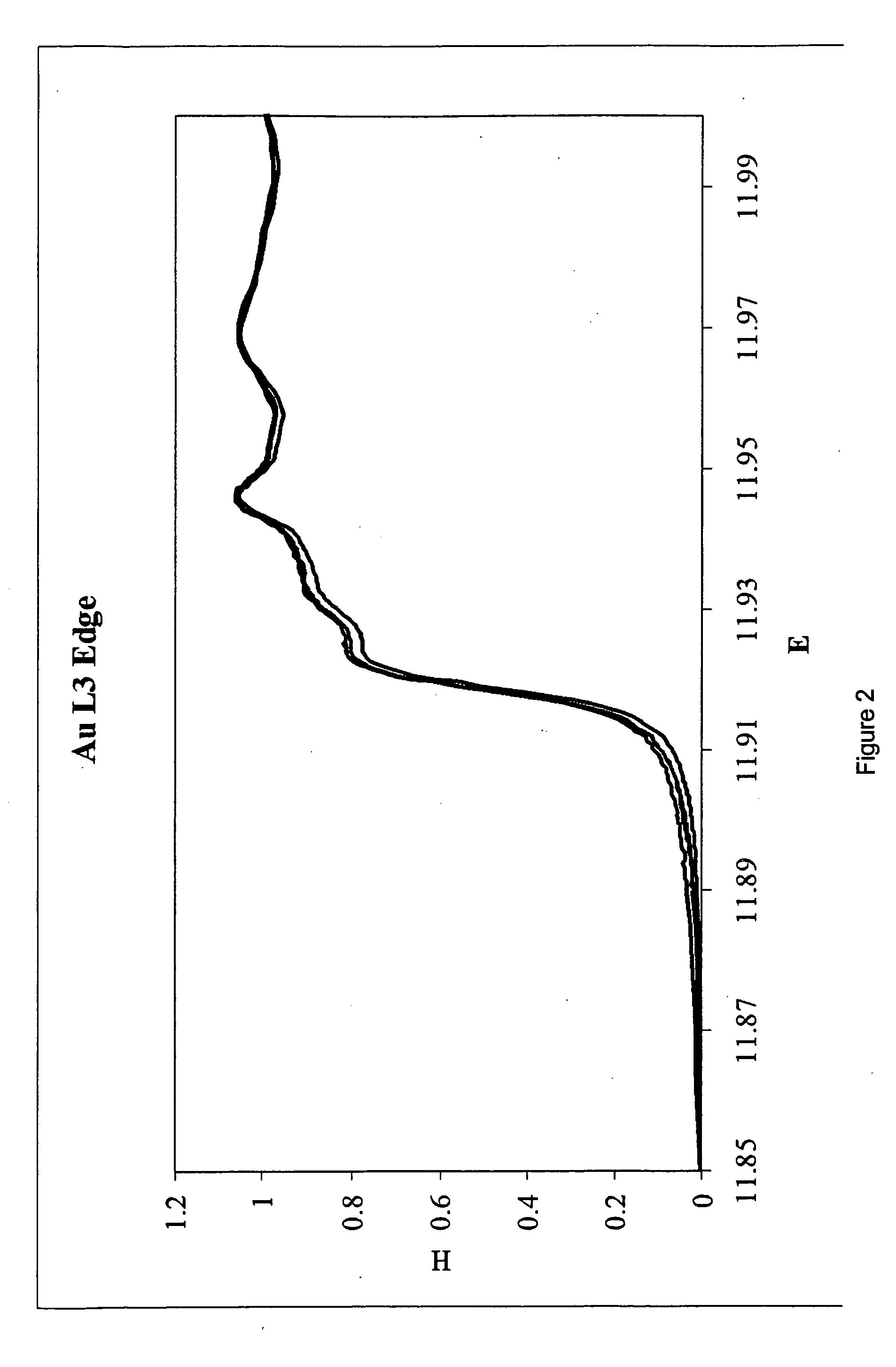

A catalyst composition is disclosed that includes chromium, oxygen, and gold as essential constituent elements. The amount of gold in the composition is from about 0.05 atom % to about 10 atom % based on the total amount of chromium and gold. Also disclosed is a process for changing the fluorine distribution (i.e., content and / or arrangement) in a hydrocarbon or halogenated hydrocarbon in the presence of the catalyst composition; and methods for preparing said catalyst composition. One preparation method involves; (a) co-precipitating a solid by adding ammonium hydroxide (aqueous ammonia) to an aqueous solution of a soluble gold salt and a soluble chromium salt that contains at least three moles of nitrate per mole of chromium in the solution and has a gold content of from about 0.05 atom % to about 10 atom % of the total content of gold and chromium in the solution to form an aqueous mixture containing co-precipitated solid; (b) drying the co-precipitated solid formed in (a); and (c) calcining the dried solid formed in (b) in an atmosphere containing at least 10% oxygen by volume. Another preparation method involves (a) impregnating solid chromium oxide with a solution of a soluble gold salt, (b) drying the impregnated chromium oxide prepared in (a); and optionally, (c) calcining the dried solid. A third preparation method involves (a) evaporating an aqueous solution of chromium(VI) oxide and a soluble gold salt to form a solid; (b) drying the solid formed in (a); and (c) calcining the dried solid formed in (b) in an atmosphere containing at least 10% oxygen by volume.

Owner:EI DU PONT DE NEMOURS & CO

Citric acid gold potassium for gilding and preparation method thereof

The invention relates to citric acid gold potassium for gilding and a preparation method thereof. The molecular formula of the citric acid gold potassium is KAu2N4C12H11O8. The citric acid gold potassium is prepared by dissolving auric chloride in water, concentrating and diluting for several times, and reacting the obtained liquid with sodium potassium, edetic acid and malononitrile in a reactor.The citric acid gold potassium has the advantages of low toxicity and no free cyanogens in the product. Compared with gold potassium cyanide, the total CN<-> content of the citric acid gold potassiumis 5-6 percent in case of the same gold content, and is above 50 percent lower than that in the gold potassium cyanide. The waste liquid after gilding only contains the micro-free CN<->, thereby thewaste water processing cost in electroplating enterprises is reduced.

Owner:HENGSHENG TECH R&D CO LTD

Method for treating cyanide tailings

InactiveCN106676269AReduce gold contentEfficient recyclingProcess efficiency improvementMelting tankCyanide

The invention discloses a method for treating cyanide tailings. The method comprises the following steps that the cyanide tailings, copper-containing materials, a reducing agent and a slagging agent are mixed and then supplied to a molten pool smelting furnace for smelting treatment, and therefore smelting slag, smelting flue gas and precious metal alloys containing gold, silver and copper are obtained. According to the method, the cyanide tailings are treated through the molten pool smelting furnace, the cyanide tailings can be treated harmlessly, meanwhile the valuable metals such as gold and silver in the cyanide tailings can be recovered effectively, the gold content in the molten pool smelting furnace can be lowered to 0.3 g / t, and the silver content can be lowered to 3-5 g / t.

Owner:CHINA ENFI ENGINEERING CORPORATION

Gold potassium lemon acid for gold plating and method for producing the same

ActiveCN101172946AReduce processing costsReduce pollutionCarboxylic acid salt preparationGold contentPotassium

The invention discloses citric acid gold potassium used for gold plating and the preparation method thereof. The molecular formular of the citric acid gold potassium is K3Au2C9H5O7N2. The method comprises the steps as follows: gold trichloride is dissolved in water of certain temperature, is concentrated and diluted under the temperature for multiple times, and is reacted with potassium citrate, ethylene diamine tetraacetic acid and malononitrile in a reactor under the certain temperature and the certain time to produce the organic gold salt which has low toxicity and contains no free cyanogen. When the product has the same gold content with the potassium gold cyanide, the total CN- is 5 to 6 percent, being 50 percent lower than that of the CN- in the potassium gold cyanide. The waste liquid after gold plating contains free the CN- in small amount. The invention reduces the cost of waste water treatment for the electroplating plants.

Owner:HENGSHENG TECH R&D CO LTD

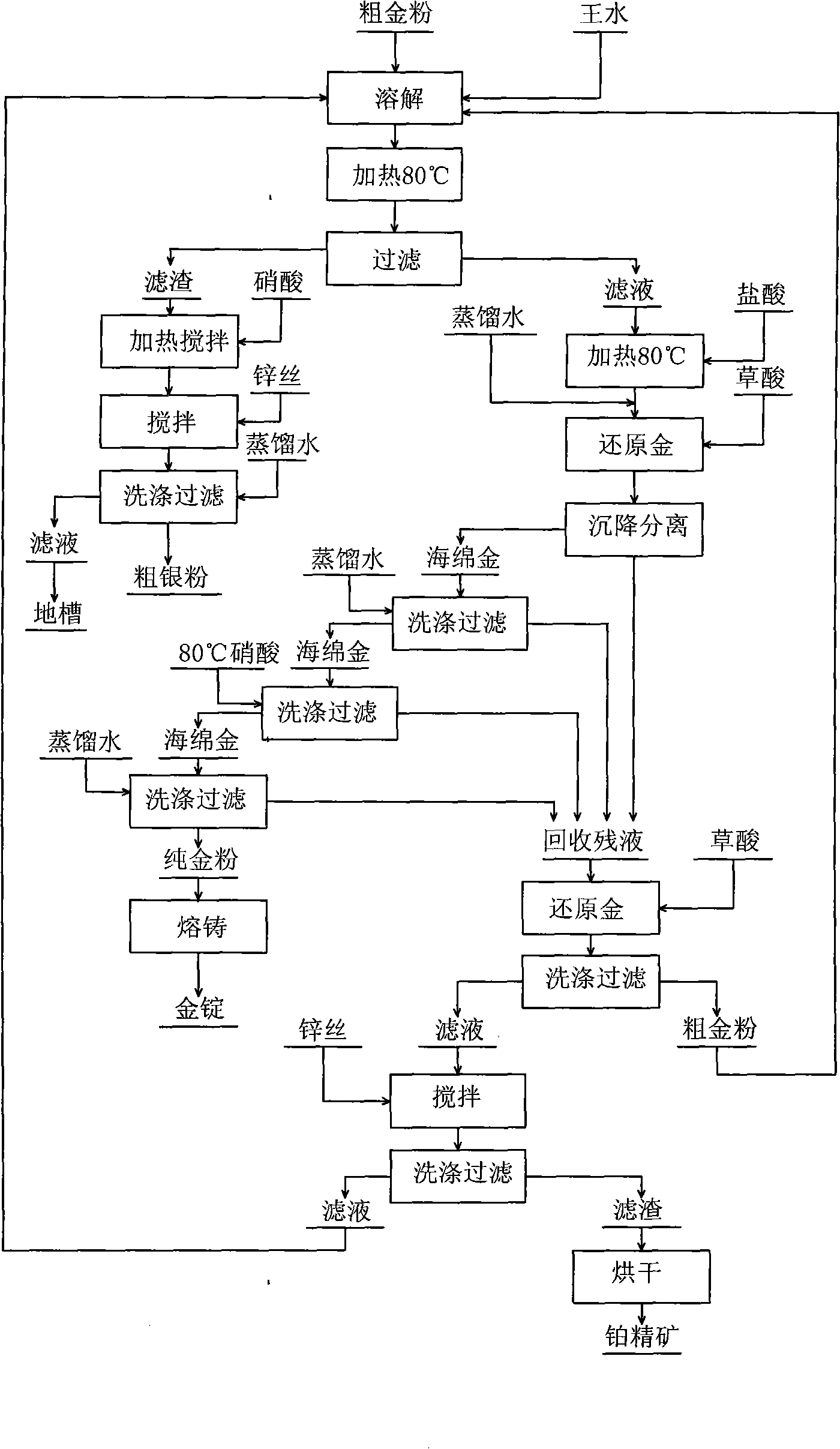

Gold wet purification process

The invention relates to a process for purifying gold by the wet method. Firstly, aqua fortis is used to remove silver; secondly, nitric acid is used to remove impurities such as bismuth and copper, etc.; the separation is performed by filtering; in the richly contained gold solution, the gold is reduced to gold powder deposited by an oxalic acid reducing agent with strong reducibility, and the impurities such as platinum, the bismuth and the copper, which are reduced simultaneously, are redissolved by nitric acid added later and enter the solution, and the solution is subjected to the filtering separation to obtain pure gold powder; and the pure gold powder is made to be ingot-shaped by fushion casting, and the finished gold ingots with a gold content of 99.99 percent are obtained. In the invention, the reduction reaction is made by oxalic acid at a low temperature, so that the process of the invention has the advantages of not causing environmental pollution, favorability for the heath of operators, lowering cost, shortening the period and obvious economic and social benefits.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

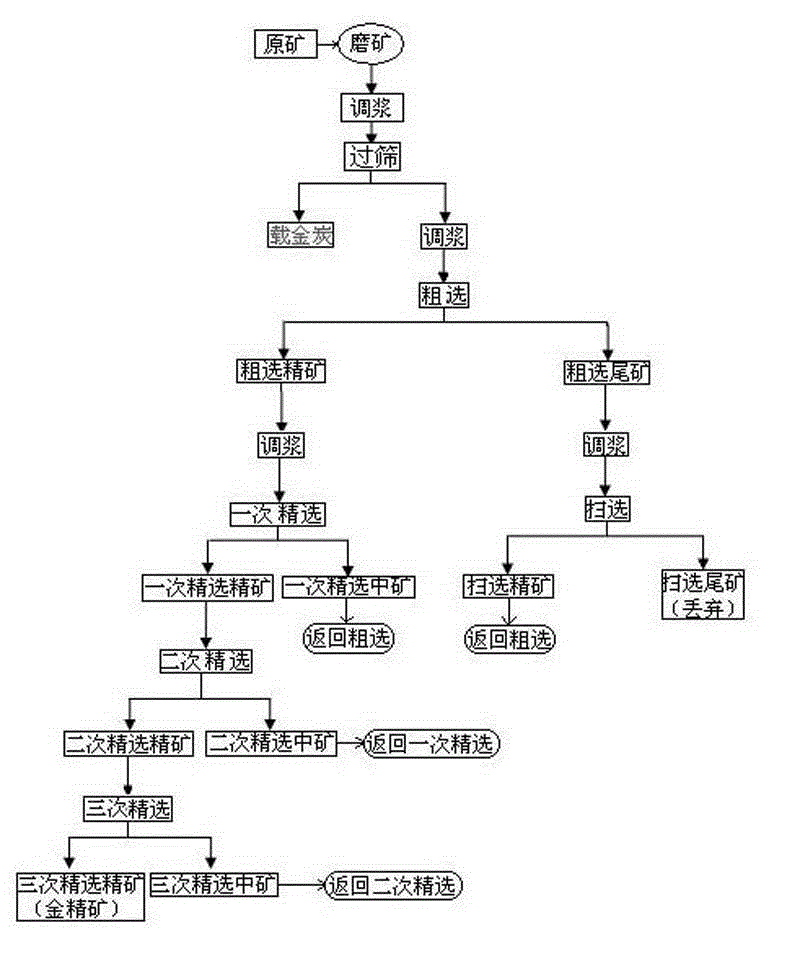

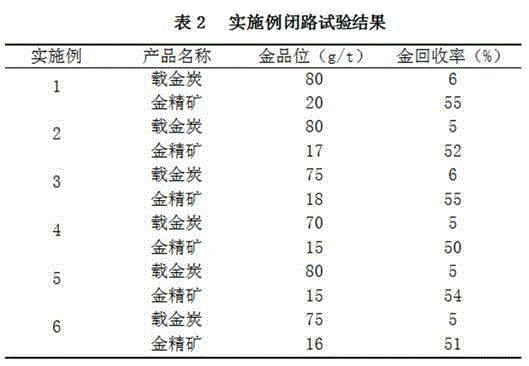

Method for selecting gold from gold ore leaching residue

ActiveCN103977881AAchieve recyclingProcess results are simpleFlotationWet separationDibutyl dithiophosphateFoaming agent

The method discloses a method for selecting gold from gold ore leaching residue. The method comprises the following steps: ore grinding, grid screening, roughing, scavenging, first selection, second selection and third selection. Active carbon is added during ore grinding, gold loaded carbon with higher gold content is firstly screened by adopting a 40-mesh grid screen at a ball-milling ore discharge port, then an inhibitor, a collecting agent and a foaming agent are added during the floatation process, and finally size mixing and stirring are carried out for roughing floatation work. The inhibitor is sodium fluosilicate, the collecting agent is Ammonium dibutyl dithiophosphate, and the foaming agent is terpenic oil. According to the method, through reasonable allocation of ore grinding and grid screening, the gold grade of the gold loaded carbon reaches to 70-80 g / T, the gold grade of floatation gold concentrate reaches to 15-20 g / T, the recovery rate of the gold loaded carbon reaches to 5-6%, the recovery rate of floatation gold reaches to 50-55%, and the total recovery rate of gold reaches to 55-61%. The ore dressing method is simple in technology and easy to operate on site.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

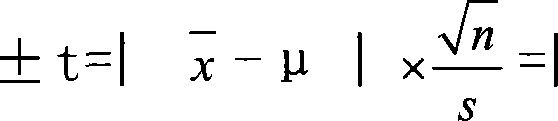

Iodometry process of measuring gold content in high accuracy and precision

ActiveCN101046453AImprove accuracyGood reproducibilityMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationWater bathsGold content

The present invention relates to gold content measuring method, and is especially iodometry process of measuring gold content in high accuracy. The iodometry process include the following steps: 1. preparing standard gold solution through weighing gold in 0.1000g, setting in a 50 ml beaker, adding aqua regia in 10 ml, heating to dissolve, adding 5 drops of 200g / l concentration potassium chloride solution, evaporating to dry in a water bath, adding 2 ml of hydrochloric acid, evaporating to dry, repeating for three times, adding 10 ml hydrochloric acid and 3-5 drops of hydrogen peroxide to dissolve, and adding water to 100 ml to form solution of gold content of 1 mg / ml; and 2. preparing standard work solution of gold content 0.1 mg / ml with the standard gold solution. The present invention is suitable for gold content detection of different kinds of gold content material.

Owner:青海西部矿业科技有限公司 +1

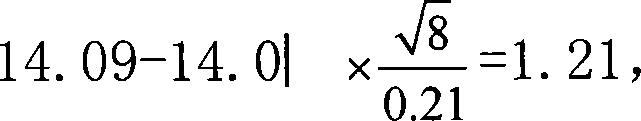

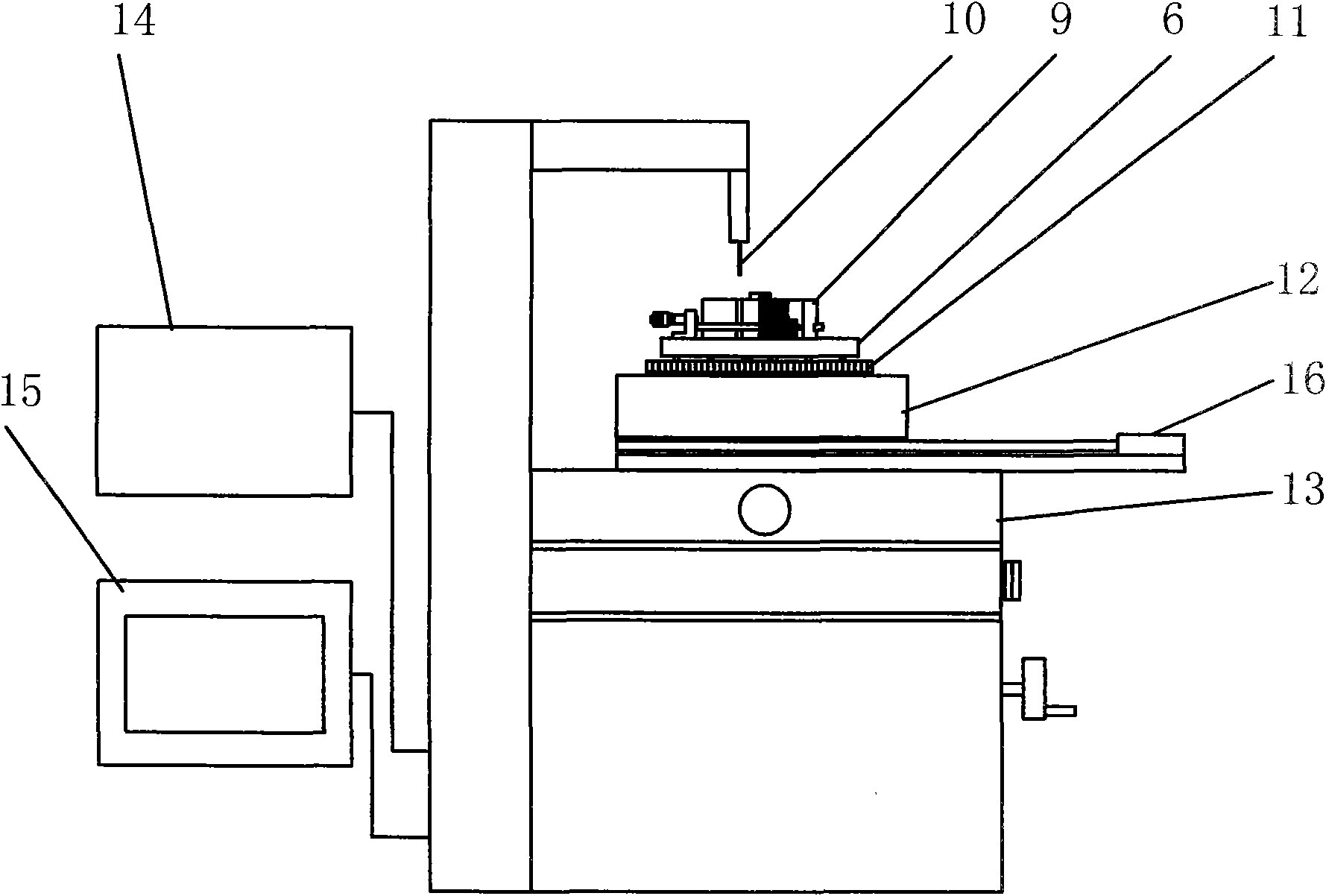

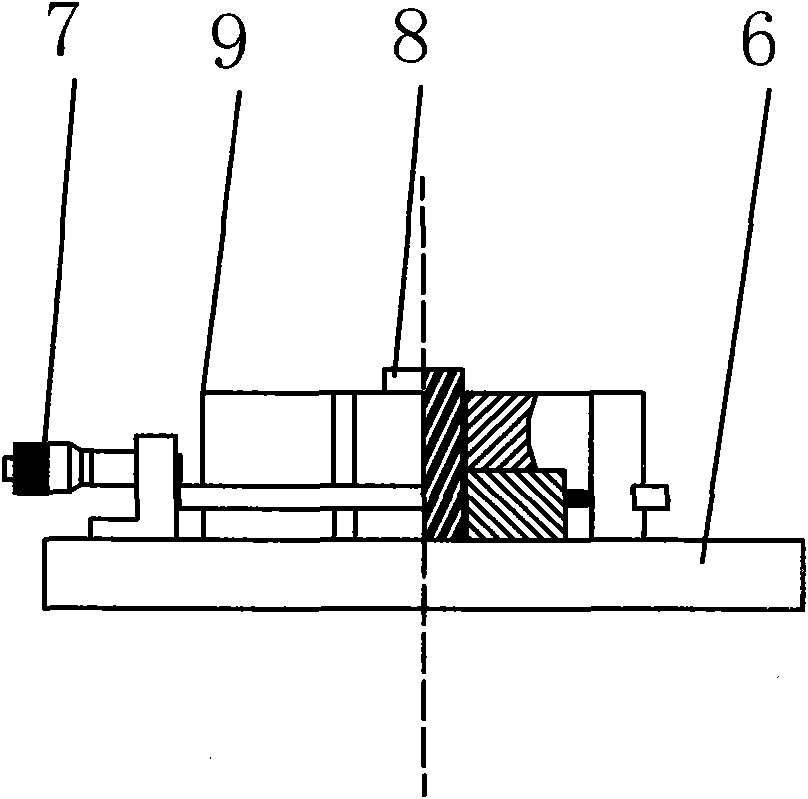

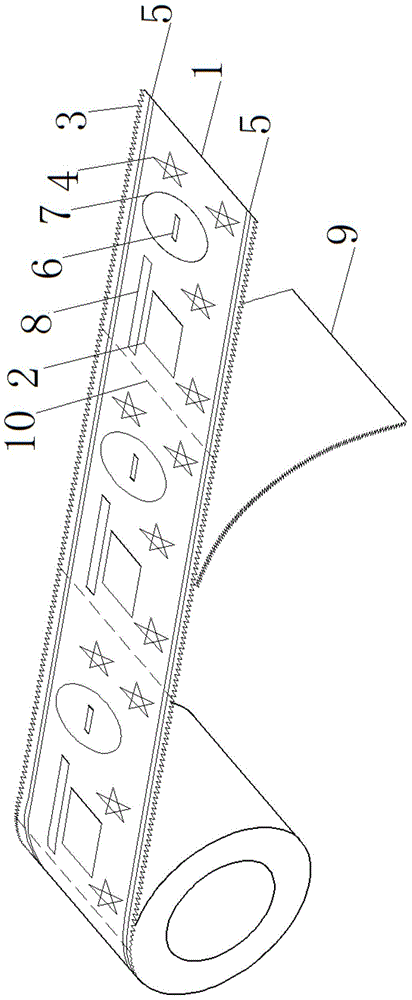

Solderless automatic welding machine of golden bracelets and welding method

ActiveCN101987392AReduce lossIt is not easy for the gold content to meet the requirements of the national standardWelding/cutting auxillary devicesAuxillary welding devicesMotor driveGold content

The invention provides a solderless automatic welding machine of golden bracelets and a welding method. The solderless automatic welding machine of the golden bracelets is characterized by comprising a movable clipping suite, a motor-driven platform controlling machine (15), and a welding machine, wherein the movable clipping suite is used for clipping the golden bracelet workpieces to be processed; the motor-driven platform controlling machine (15) is used for controlling and driving the movable clipping suite to conduct two-dimensional or three-dimensional motion; the welding machine is used for outputting and controlling high pulse of spot welding; the movable clipping suite comprises a motor-driven translation platform (13), a motor-driven rotating platform (12), a rotary tray (6) and a fixture (9); a welding head (10) is arranged above the fixture (9) by a cantilever; and the output end of a welding machine controller (14) is connected with the welding head (10). The automatic welding machine of the invention has the advantages of high automaticity, low energy consumption, high processing efficiency, firm welding, less material losses and the like, has small possibility of deformation, and meets the requirement that gold content in gold manufacturing industry reaches national standards.

Owner:武汉新金首饰制造有限公司

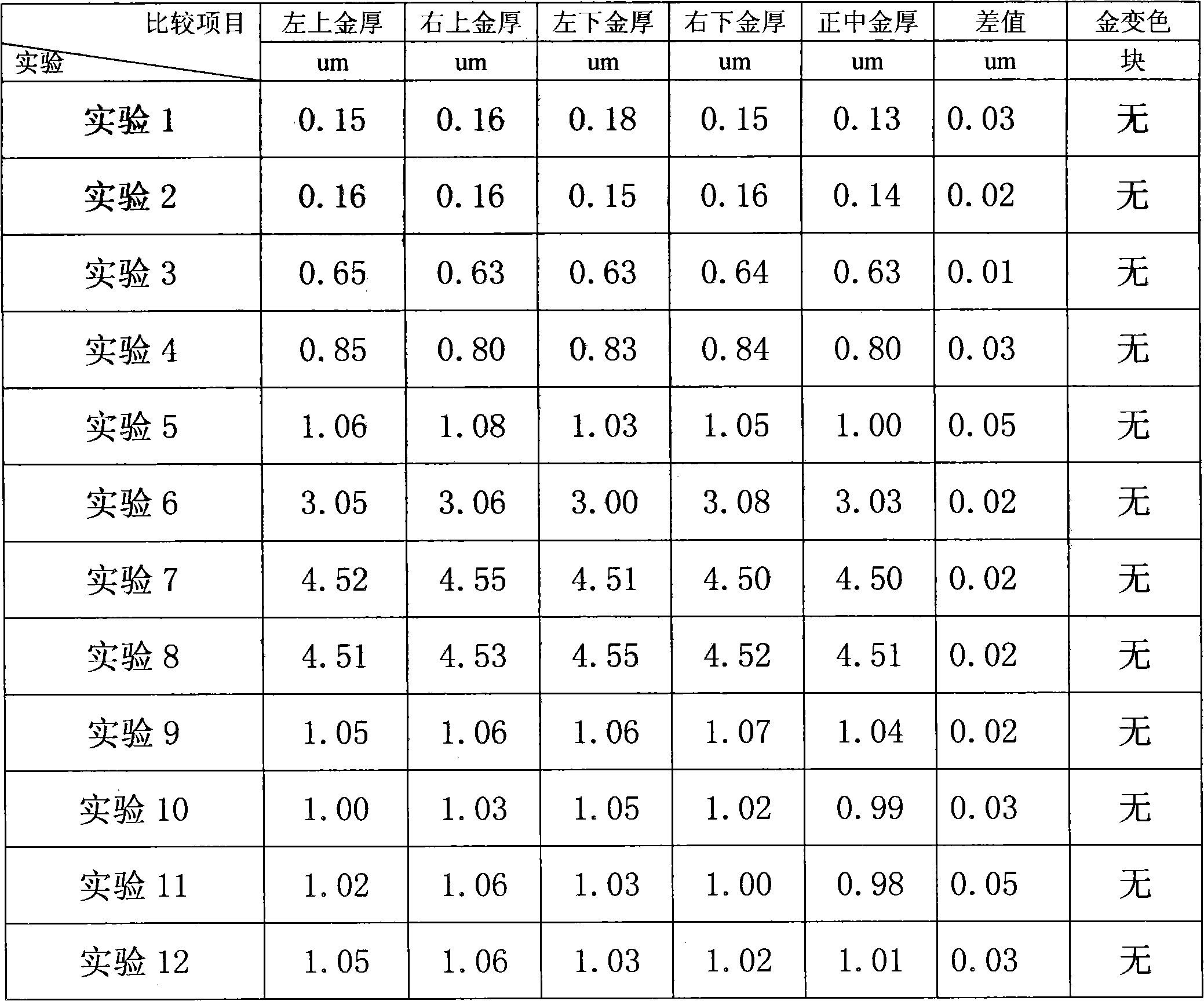

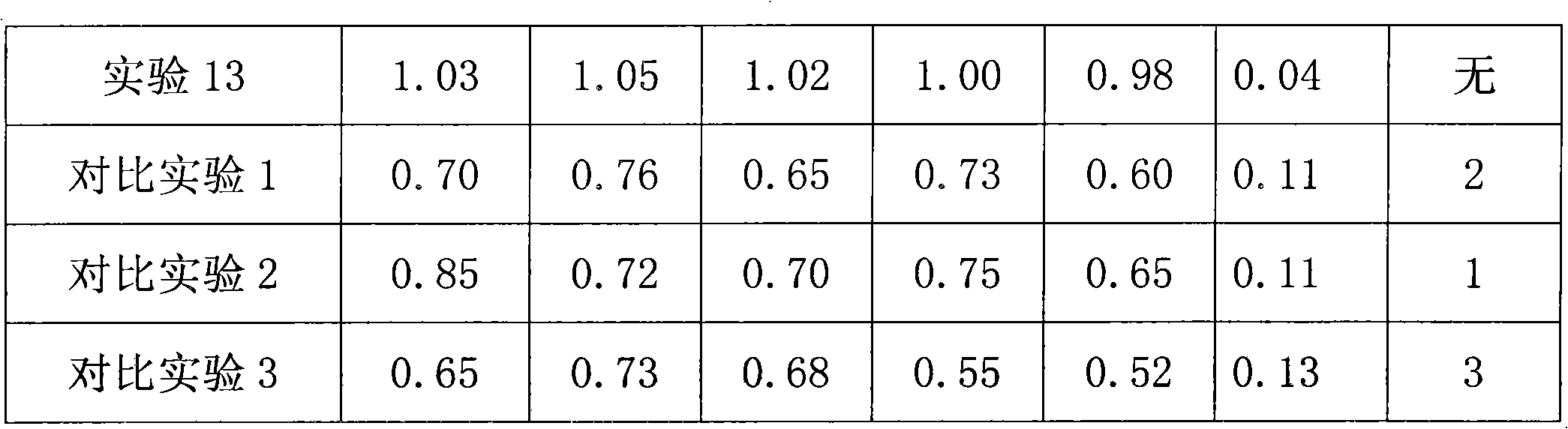

Gold plating solution for plating gold finger on circuit board

The invention discloses a gold plating solution for plating a gold finger on a circuit board, belonging to the filed of plating. The gold plating solution comprises gold salt the gold content of which is 1g / l to 30g / l, conductive salt, buffer solution, compounding agent, metallic brightener, organic brightener and wetting agent. The gold finger plated by the gold plating solution disclosed by the invention has the advantages of even and compact clad layer and gold solution conservation, and the plated gold is not easy to change color.

Owner:秦雅军

Catalyst for synthesizing vinylacetate and preparation method thereof

ActiveCN102218345AHigh reactivityHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGold contentGas phase

The invention relates to a catalyst for synthesizing vinylacetate and a preparation method thereof, and mainly solves the problem that reaction activity and selectivity are reduced because a palladium-gold active ingredient layer in a catalyst is thick to intensify deep oxidation reaction in the prior art. In the catalyst for synthesizing the vinylacetate by ethylene, ethylic acid and oxygen-containing gas through gas-phase reaction, SiO2, Al2O3 or a mixture thereof is taken as a carrier, and active ingredients selected from palladium metal, gold metal and alkali metal acetate are loaded on the carrier, wherein based on the weight of the catalyst, the palladium content is 1-12 grams / liter, the gold content is 0.5-10 grams / liter and the alkali metal acetate content is 10-80 grams / liter; and the Pd and Au alloy layer in the catalyst has the thickness of less than 300 mu m. The invention also provides a preparation method for the catalyst. By the technical scheme, the problem is better solved; and the catalyst can be used in industrial preparation of the vinylacetate by using ethylene, ethylic acid and oxygen-containing gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microalloy strengthened hard pure gold and preparation method thereof

The invention provides a hard pure gold material for pure gold jewelry. The hard pure gold material is prepared from, by mass, 0.1-0.4% of calcium, 0.5-0.8% of titanium, 0.01-0.1% of rare earth elements and the balance gold, wherein the gold content is 99.0% or above. In the preparation process, by introducing the trace element calcium, a dispersed cluster structure is formed in a pure gold matrix, and the structure can effectively promote precipitation of a nano-scale gold titanic compound strengthening phase, so that the hardness and strength of the pure gold are greatly improved. The pure gold in the design is suitable for conventional jewelry processing processes and can be applied to various kinds of pure gold jewelry.

Owner:SHANGHAI QIJIU NEW MATERIAL TECH CO LTD

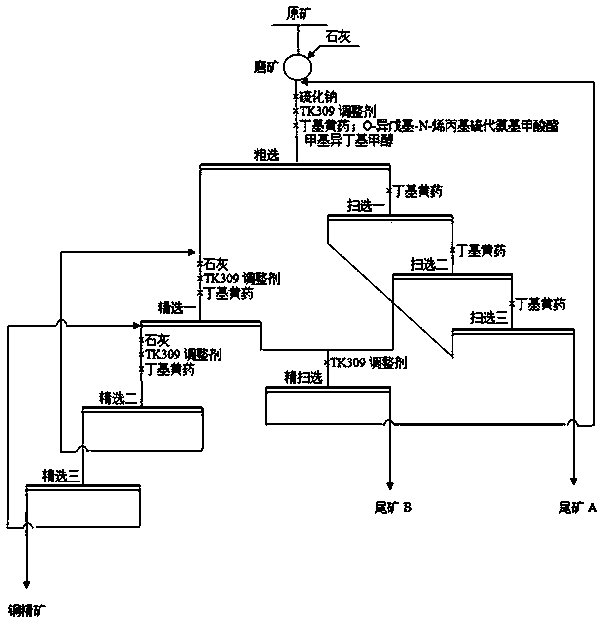

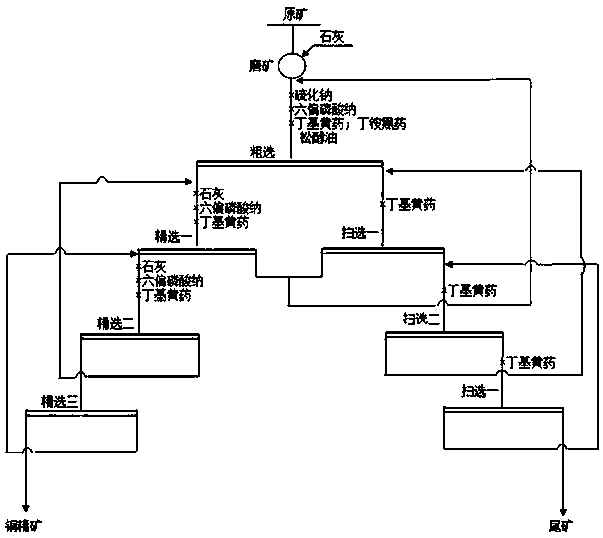

Flotation method for comprehensively recovering copper gold from copper separation tailings

The invention discloses a flotation method for comprehensively recovering copper gold from copper tailings, and belongs to the technical field of flotation. The flotation method comprises the following steps that copper tailings are ground, flotation reagents which comprise lime, sodium sulphide, TK309 regulators, sodium n-butylxanthat, O-isoamyl-N-allyl sulfo-carbamic acid ester, methyl isobutylcarbinol and other flotation reagents are added for slurry mixing, primary rough selection, three-time scavenging, three-time concentration and fine scavenging operation are sequentially carried out,and finally copper ore concentrate is obtained. The copper grade is improved by 3-5% compared with a conventional flotation method, and the copper recovery rate is improved by 4-6%. The associated gold content reaches above the pricing grade (1g / t), and the gold recovery rate is improved by 4-10%. According to the flotation method, the problems that the stockpiling time is long, the components arecomplex, the particle size of the useful mineral embedding cloth is fine, the weathering oxidation of the vulcanized minerals and the mineralization of the gangue minerals are serious, and the coppertailings contain easily-floating iron minerals and calcium-magnesium gangue are solved, the copper concentrate copper, the gold grade and the recovery rate are remarkably improved, and the waste of copper and gold resources is reduced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Graded-hole gold-copper alloy monolithic catalyst and preparation method thereof

InactiveCN102335613AEvenly distributedUniform pore sizeOrganic compound preparationCatalyst activation/preparationGold contentPore diameter

The invention relates to a graded-hole gold-copper alloy monolithic catalyst and a preparation method thereof, belonging to the technical field of chemical catalysts. The graded-hole gold-copper alloy monolithic catalyst consists of a gold-copper alloy core and a graded-hole gold-copper alloy membrane covering the surface of the gold-copper alloy core; the thickness of the graded-hole gold-copperalloy membrane is 0.01-20 microns, the copper content of the graded-hole gold-copper alloy membrane is 10-90 at.%, and the gold content of the graded-hole gold-copper alloy membrane is 90-10 at.%; big holes with the pore diameter of 0.1-10 microns are fully distributed on the graded-hole gold-copper alloy membrane, and the space among the big holes is 0.1-10 microns; and small holes with the porediameter of 1-500 nm are fully distributed on the hole walls of the big holes, and the space among the small holes is 1-500 nm. In the preparation method of the graded-hole gold-copper alloy monolithic catalyst provided by the invention, the gold-copper alloy membrane which has uniform distribution, uniform pore size and a graded-hole structure that the small holes penetrate the hole walls of thebig holes is obtained through a one-step dealloying method; and the prepared graded-hole gold-copper alloy monolithic catalyst macroscopically and independently exists, has good mass-and-heat transfer and conductivity, and is easy to be recycled and reused.

Owner:SHANDONG UNIV

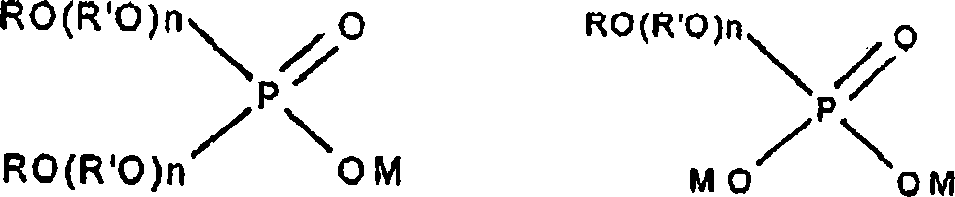

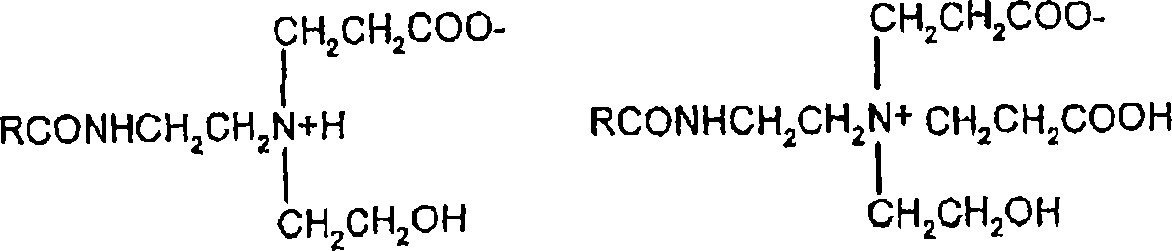

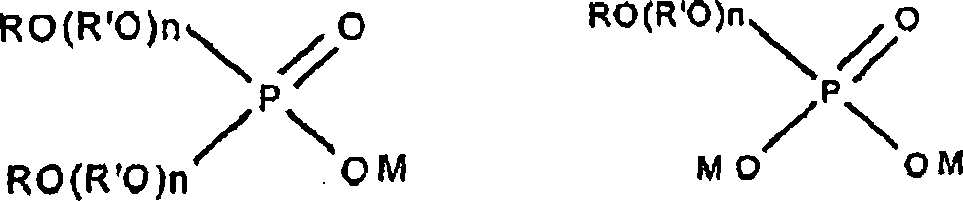

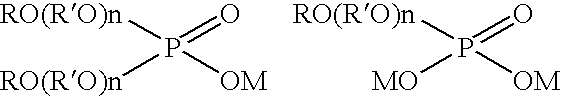

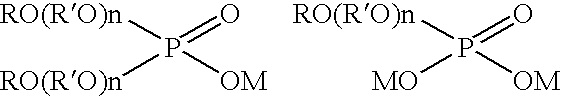

Electroplating solution for gold-tin eutectic alloy

The invention relates to an electrolyte used in connection with the deposition of a gold-tin alloy on an electroplatable substrate. This solution generally includes water; stannous and / or stannic tin ions, a complexing agent to render the stannous and / or stannic tin ions soluble, complexed gold ions, and an alloy stabilizing agent that includes ethoxylated compounds with phosphate ester functional group, brightening additives based on ethoxylated phosphate esters and alkali metal fatty acids dipropionates. The brighteners may be used alone or in conjunction with each other to achieve beneficial synergistic effect. The alloy stabilizing agent is present in an amount sufficient to stabilize the composition of the gold-tin deposit over a usable current density range. The solution has a pH of between 2 and 10 and the gold ions and tin ions are present in relative amounts sufficient to provide a deposit having a gold content less than 90% by weight and a tin content greater than 10% by weight.

Owner:B F TECHNOLOGY INC

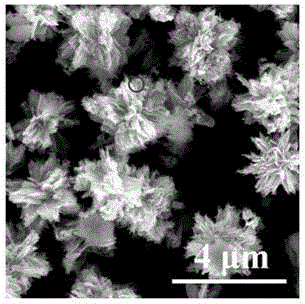

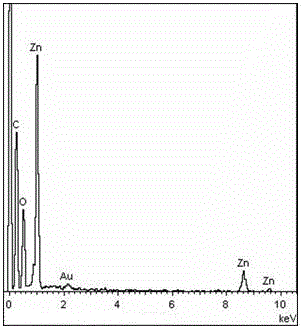

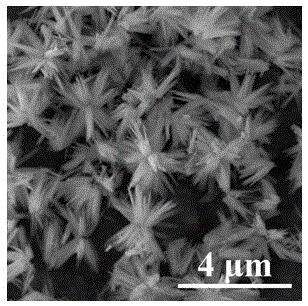

Zinc oxide and gold nanoparticle composite material and preparation method thereof

InactiveCN105215347ASimple and fast operationLow costMaterial nanotechnologyActive agentGold content

The invention discloses a zinc oxide and gold nanoparticle composite material and a preparation method thereof. The preparation method includes the steps that firstly, a zinc source, alkali and a surface active agent are uniformly mixed with deionized water to obtain a mixture; then the mixture is put in a reacting kettle for thermal treatment and then subjected to processes such as centrifugal washing, drying and calcination to obtain zinc oxide; the obtained zinc oxide is uniformly dispersed in the deionized water through magnetic stirring, and then chloroauric acid is added into the system and stirred to obtain the zinc oxide and gold nanoparticle composite material. The zinc oxide and gold nanoparticle composite material with different appearances and gold contents can be obtained through adjustment of reaction temperature, raw material categories and concentrations in the preparation process. The preparation method is simple, low in cost and capable of saving energy; additional reductive agents and additional light sources are not needed during forming of the composite material, and the application prospects are wide in the fields such as mass production of zinc oxide and gold nanoparticle composite materials and photocatalytic degradation organic matters.

Owner:UNIV OF JINAN

Method for improving inclusion gold leaching rate

InactiveCN103122415AImprove leaching rateWide applicabilityProcess efficiency improvementGold contentSodium cyanide

The invention provides a method for improving the inclusion gold leaching rate, which comprises the following steps of: (1) screening and crushing: performing coarse crushing, intermediate crushing and fine crushing of inclusion gold to obtain a crushing qualified product; (2) roasting: performing oxidizing roasting of the crushing qualified product by use of oxygen-rich air; (3) finely grinding; (4) carrying out staged leaching: adding protective alkali calcium oxide and sodium cyanide, and leaching in two stages; and (5) separating and extracting to obtain refined gold. The method for improving the inclusion gold leaching rate provided by the invention has a simple technological process, wide in ore applicability and large in treatment capacity; the conditions of the steps such as roasting, staged leaching and the like are easy to control; and the inclusion gold leaching rate reaches about 83% finally, and the gold content of leaching residue is 0.81g / t.

Owner:SHANDONG QIANSHUN MINING & METALLURGY SCI

Refinement technology of high-purity gold

InactiveCN104789794AImprove recovery rateHigh recovery rateProcess efficiency improvementGold contentIngot

The invention relates to a technology of gold metallurgy, in particular to a refinement technology of high-purity gold, and belongs to the field of gold refinement. The refinement technology of the high-purity gold, which is disclosed by the invention, comprises the following steps: (1) pulverizing gold ingots; (2) performing preimpregnation and impurity removal; (3) performing primary chlorination leaching of gold; (4) performing primary reduction; (5) performing secondary chlorination leaching of gold; (6) performing secondary reduction. The refinement technology of the high-purity gold, which is disclosed by the invention, solves the problems that equipment is seriously corroded and the environment is polluted during the whole production process of an aqueous-solution chlorination method, and realizes the scale production of products of which the gold content is raised from 99.99% to 99.999%.

Owner:SHANDONG ZHAOJIN GOLD & SILVER REFINERY

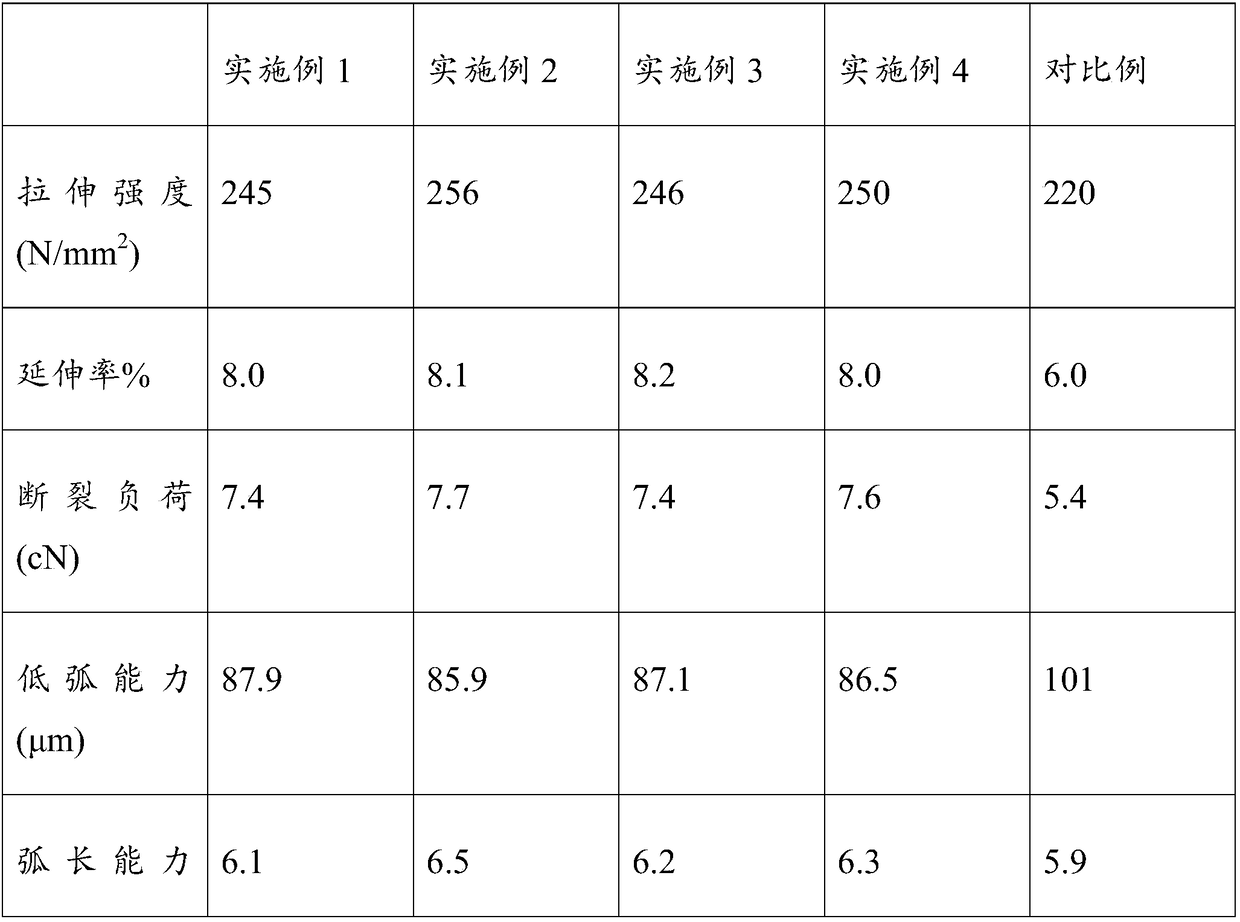

A bond alloy wire and a preparation method thereof

ActiveCN109003903AGuaranteed service lifeFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesCavitationGold content

A bond alloy wire disclosed in the invention includes the following ingredients in percentage by mass, 1, 99 to 99.5 percent of gold, 0.300 to 0.55 percent of cop, 0.190 to 0.44 percent of palladium,0.001 to 0.002 percent of sil, 0.0005 to 0.003 percent of nickel, 0.0005 to 0.0015 percent of bismuth, 0.0005 to 0.001 percent of beryllium, 0.0005 to 0.001 percent of cerium, 0.001 to 0.003 percent of zinc, 0.001 to 0.002 percent of magnesium, 0.0005 to 0.002 percent of calcium, 0.0002 to 0.0008 percent of aluminum and 0.0009 to 0.0035 percent of lead. Due to the action of palladium and copper, the production of gold and aluminum compounds in isolation, the key alloy wire changes the traditional concept of manufacturing the key alloy wire, From the traditional bonding wire with 99.99% gold content to the wire with 99% gold content, the bonding alloy wire not only improves the strength of the wire, but also does not form Kendall cavitation after being used for more than 4000 hours. The connection between the ball welding and the electrode is good, which ensures the service life of the integrated circuit.

Owner:上杭县紫金佳博电子新材料科技有限公司

Pulse plating process for deposition of gold-tin alloy

The invention relates to a solution for use in connection with the deposition of a gold-tin alloy on an electroplatable substrate. This solution generally includes water, stannous tin ions, a complexing agent to render the stannous tin ions soluble, complexed gold ions, and an alloy stabilization agent that includes an imine functional group. The alloy stabilization agent is present in an amount sufficient to stabilize the composition of the gold-tin deposit over a usable current density range. The solution has a pH of between about 2 and about 10 and the deposit having a gold content less than about 90% by weight and a tin content greater than about 10% by weight. An advantageous way for providing the desired deposit is by a pulse plating technique.

Owner:TECHNIC INC

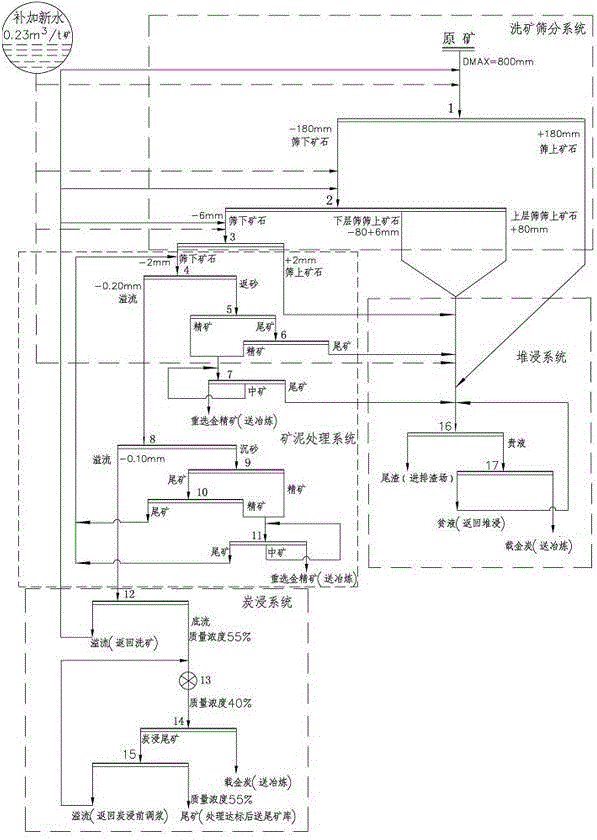

Dressing technology for recycling ultra-low-level gold ore

ActiveCN104307626AGuaranteed leaching rateImprove leaching rateProcess efficiency improvementWet separationMining engineeringGold content

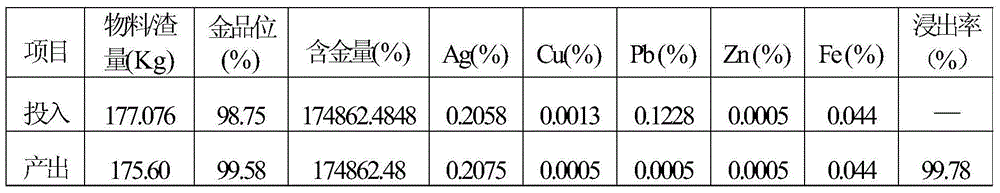

The invention provides a dressing technology for recycling ultra-low-level gold ore. The dressing technology for recycling the ultra-low-level gold ore is composed of an ore washing and screening system, a slime processing system, a carbon leaching system and a dump leaching system, wherein the technological raw ore is directly screened and washed, the ore sand is subjected to dump leaching, the slime is subjected to the stage classification, stage reelecting recycling particle minding and the carbon leaching, gold concentrate, dump leaching gold loaded carbon and carbon leaching gold loaded carbon of a first segment reelecting returning path and a second segment reelecting returning path are obtained, and the reelecting gold concentrate and the gold loaded carbon are sent to a gold melting plant for treatment to obtain gold ingot. According to the dressing technology, the oxidized gold ore with the gold content of the raw ore being under 0.4g / t and the mud content being above 25% is adopted, the gold dressing recycling rate reaches above 75%, the ultra-low-level gold ore resource is fully used, the gold ore resource is enlarged, the water returning use is strengthened in all steps, the corresponding work is returned according to the water returning quality, water is saved, and the ore per unit consumes under 0.23m3 / t of water.

Owner:CHINA NERIN ENG

Two-dimension code saw-tooth-shaped anti-counterfeiting adhesive tape

InactiveCN104910826AEasy to identifyImprove anti-counterfeiting performanceFilm/foil adhesivesRecord carriers used with machinesPackage designGold content

The invention provides a two-dimension code saw-tooth-shaped anti-counterfeiting adhesive tape and relates to the technical field of anti-counterfeiting. The two-dimension code saw-tooth-shaped anti-counterfeiting adhesive tape comprises a sheet-shaped adhesive tape body, wherein a saw-tooth-shaped notch is arranged at the width boundary of the adhesive tape body; a two-dimension code coating is arranged on the adhesive tape body. According to the two-dimension code saw-tooth-shaped anti-counterfeiting adhesive tape, the disadvantages of package designs of products, and the problems of counterfeiting by a counterfeiter in online marketing and physical distribution flowing processes are avoided, and protection and monitoring on the products by producers are enhanced, so that the rights and interests of consumers are not harmed by counterfeited products. Codes in the adhesive tape can be conveniently used for encoding software and then big data collection and analysis can be carried out on sold products by the adhesive tape, and a product marketing plan scheme can be constructed in advance by a user and a living application terminal of the product is traced so that the consumers and the counterfeiters are targeted; by using the adhesive tape, the storage gold content of the product also can be increased.

Owner:重庆千人早科技有限公司

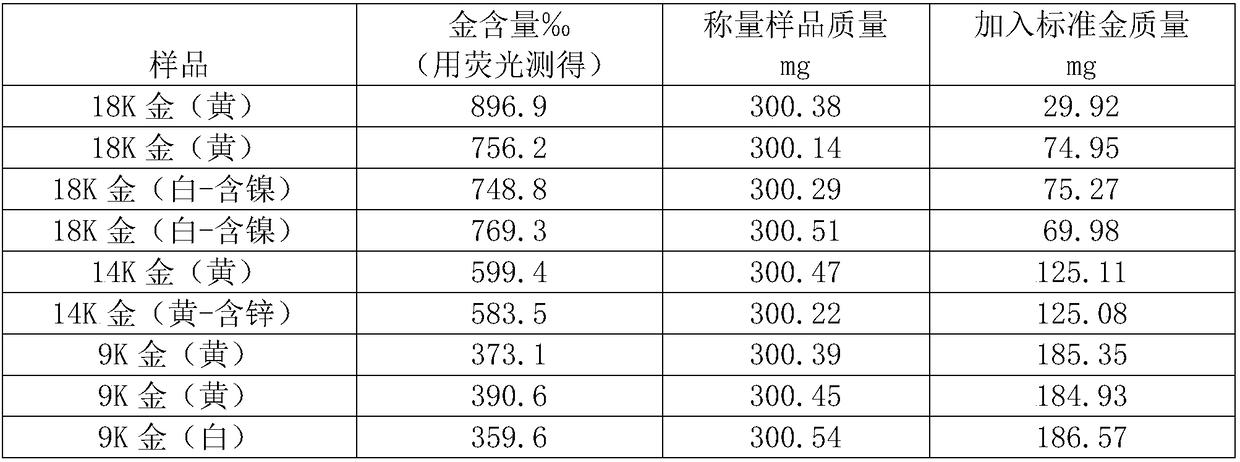

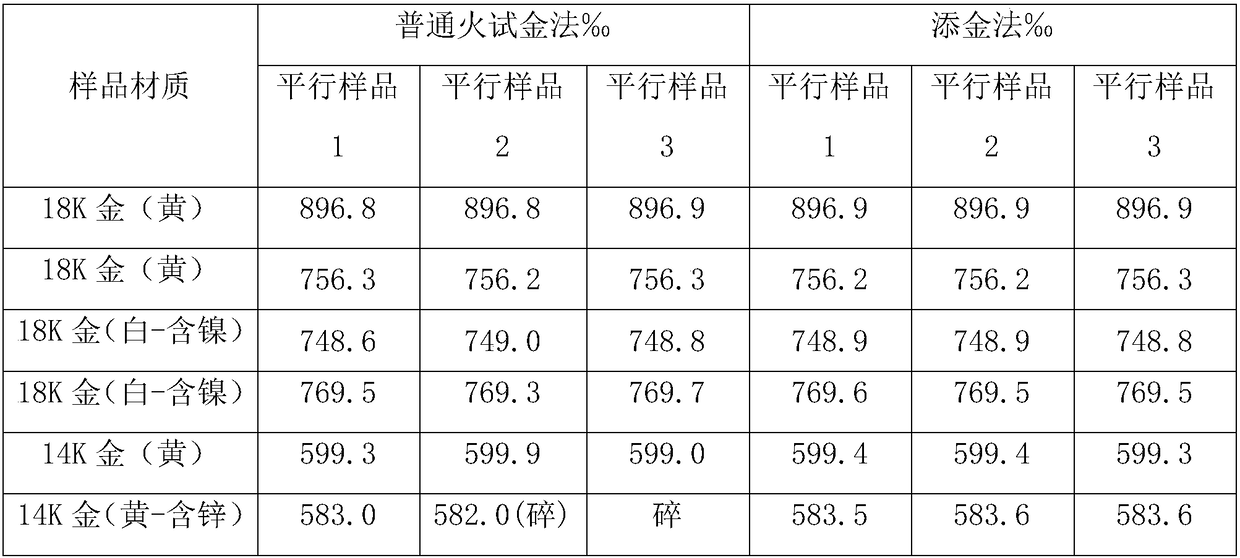

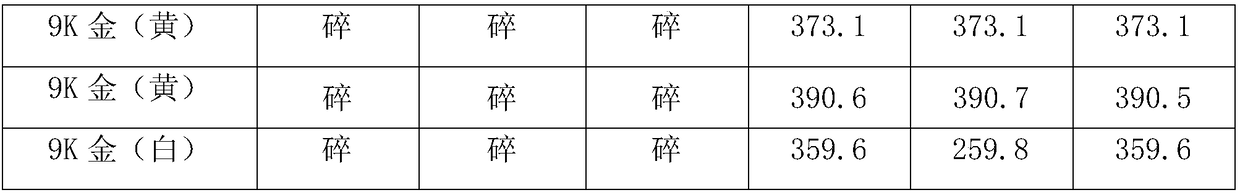

Method for detecting gold content in K gold jewelry by fire assaying gold-adding method

PendingCN108562512AImprove toughnessImprove accuracyMaterial analysis using wave/particle radiationMaterial weighingSuccessful completionGold content

The invention relates to a method for detecting gold content in K gold jewelry by a fire assaying gold adding method. The method comprises the following steps: adding proper amounts of gold and silverto a sample, using lead as a collecting agent, oxidizing and cupelling in a porous cupel, absorbing lead oxide and impurities by the cupel, smelting the retained gold and silver to obtain precious metal balls, rolling into slices and rolling up into small rolls, placing into nitric acid, and gradually dissolving silver to obtain the mass of gold. By the gold-adding method, accuracy of the experiment and parallelism of the data can be greatly enhanced, convenience is brought to daily precious metal jewelry detection work, and smooth and successful completion of the detection work is guaranteed.

Owner:华津国检(深圳)金银珠宝检验中心有限公司 +1

One-step technique for separating antimony from gold and lead in gold-containing antimony oxide smoke dust

ActiveCN104120270AReduce incorporationHigh removal rateProcess efficiency improvementSmelting processGold content

The invention discloses a one-step technique for separating antimony from gold and lead in gold-containing antimony oxide smoke dust, which comprises the following steps: adding a reducer into antimony oxide smoke dust with the gold content of 30g / t, carrying out reduction smelting at 1000-1250 DEG C, removing scum, blowing air or oxygen from the side of a reverberatory furnace at the rate of 50-250 m<3> / minute, converting at the converting temperature of 700-700 DEG C so that the antimony is oxidated and volatilized in the form of antimony oxide and the gold and lead are settled in a concentrated bottom water antimony solution, and obtaining the antimony oxide (in which the gold content is at most 0.5g / t, the lead content is at most 0.5 wt% and the antimony content is at least 73 wt%) and the bottom water antimony solution (in which the gold content is 80-150g / t, the lead content is 8-15 wt% and the antimony content is 84-89 wt%), thereby implementing one-step separation of the antimony from the gold and lead. The technique implements one-step separation of gold and lead in the antimony smelting process, and is suitable for industrial production.

Owner:HUNAN CHENZHOU MINING CO LTD

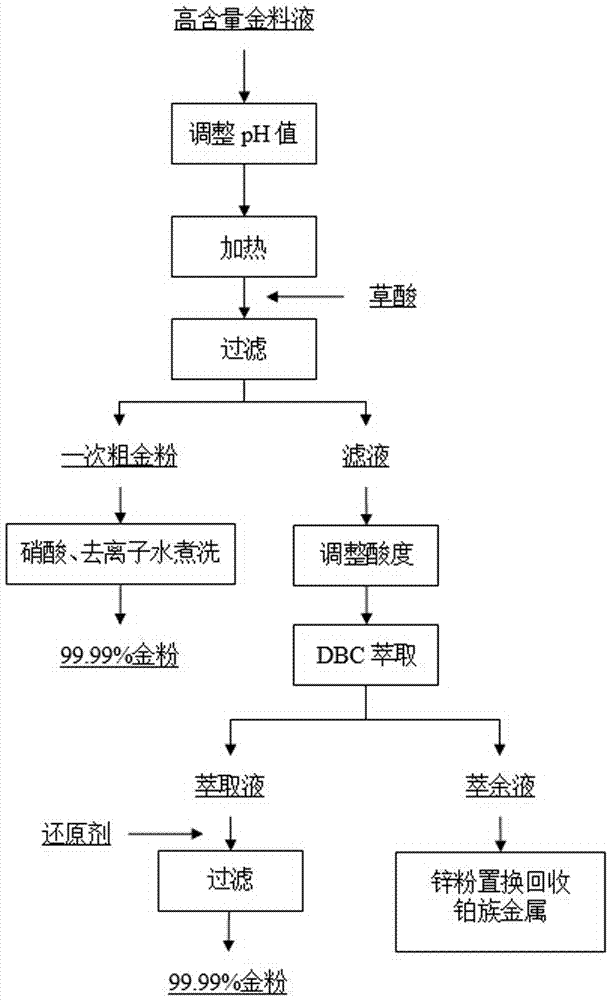

Method for extracting gold from material liquid with high gold content

The invention provides a method for extracting gold from material liquid with the high gold content. The method comprises the following steps that first, the pH value of a solution is regulated; second, the solution is appropriately heated; third, acid is added into the solution for filtering and separating; fourth, primary coarse gold powder purification is conducted; fifth, the remaining solution is subjected to acidity regulating and extraction; sixth, reverse extraction solid-liquid separation is conducted. Furthermore, a reducing agent adopted in the sixth step is oxalic acid; furthermore, the reducing agent adopted in the sixth step is sodium sulfite; furthermore, zinc powder is added into the remaining tail solution in the sixth step, and platinum group metal can be displaced; furthermore, the method is suitable for waste gold electrolyte and gold chloroazotic acid dissolved solutions.

Owner:JINCHUAN GROUP LIMITED

Electroplating solution for gold-tin eutectic alloy

InactiveUS20050252783A1Powerful synergistic brighteningSemiconductor/solid-state device manufacturingBlood vesselsPhosphateGold content

The invention relates to an electrolyte used in connection with the deposition of a gold-tin alloy on an electroplatable substrate. This solution generally includes water; stannous and / or stannic tin ions, a complexing agent to render the stannous and / or stannic tin ions soluble, complexed gold ions, and an alloy stabilizing agent that includes ethoxylated compounds with phosphate ester functional group, brightening additives based on ethoxylated phosphate esters and alkali metal fatty acids dipropionates. The brighteners may be used alone or in conjunction with each other to achieve beneficial synergistic effect. The alloy stabilizing agent is present in an amount sufficient to stabilize the composition of the gold-tin deposit over a usable current density range. The solution has a pH of between 2 and 10 and the gold ions and tin ions are present in relative amounts sufficient to provide a deposit having a gold content less than 90% by weight and a tin content greater than 10% by weight.

Owner:TECHNIC INC

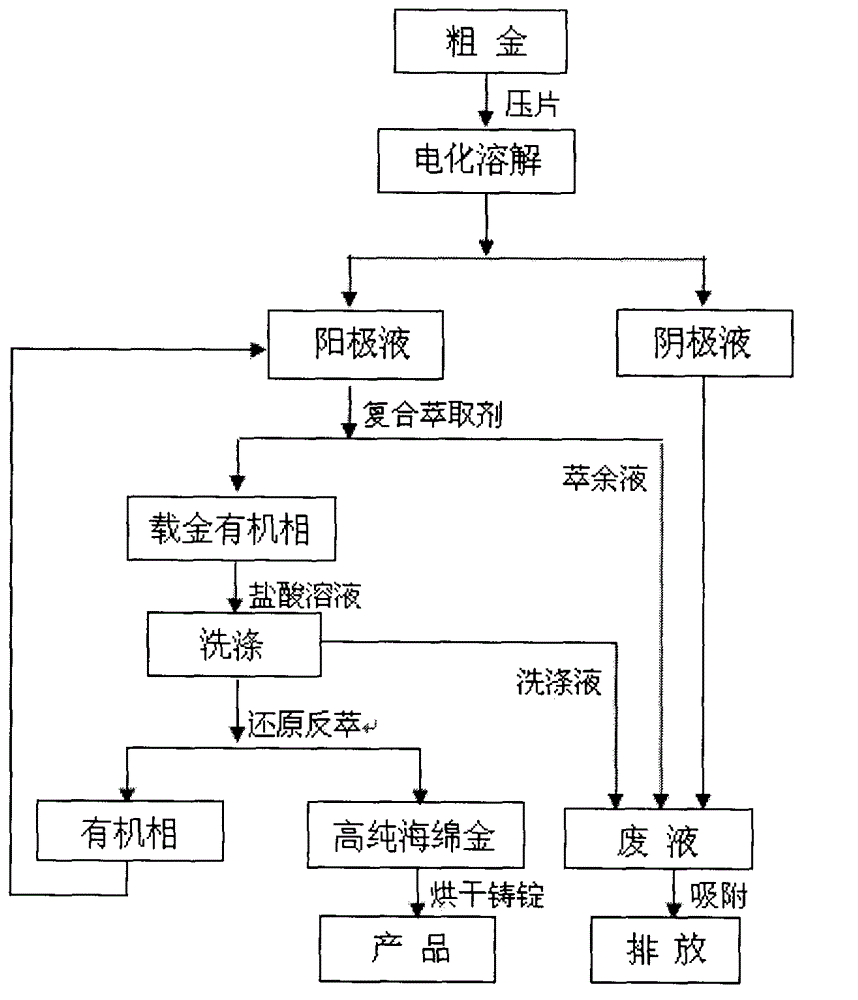

Preparation technology of high purity gold

ActiveCN104404569AAvoid the problem of high energy consumption and low efficiencyAchieve primary purificationPhotography auxillary processesProcess efficiency improvementGold contentPhysical chemistry

The invention discloses a preparation technology of high purity gold. Through a three-grade purifying technology comprising steps of ion membrane electrolyte and liquid-making, extraction, and reduction reverse extraction, high purity gold with a gold content of 99.999% or more can be obtained at one time. At first, coarse gold is dissolved through an ion exchange membrane electrochemical dissolving technology so as to obtain a chloroauric acid solution, a primary purification is achieved and at the same time a solution is prepared. A composite extracting agent is added into the chloroauric acid solution, then a gold-bearing organic phase is separated from the solution and washed, and the secondary purification is achieved. After washing, the gold-bearing organic phase is subjected to chemical reduction and reverse extraction so as to achieve the tertiary purification. The obtained gold powder can be melt and casted into ingots so as to obtain high purity gold with a gold content of 99.999% or more. The provided three-grade purifying technology is simple, is capable of processing different coarse gold materials, and has high production efficiency. Furthermore, the procedure is short. So the energy consumption and waste discharge during the production process are both reduced. Automatic production is easy to achieve, and great economic and social profits are generated by the provided preparation technology.

Owner:CHANGZHOU YIJIN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com