Patents

Literature

773 results about "Sodium cyanide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium cyanide is an inorganic compound with the formula NaCN. It is a white, water-soluble solid. Cyanide has a high affinity for metals, which leads to the high toxicity of this salt. Its main application, in gold mining, also exploits its high reactivity toward metals. It is a moderately strong base.

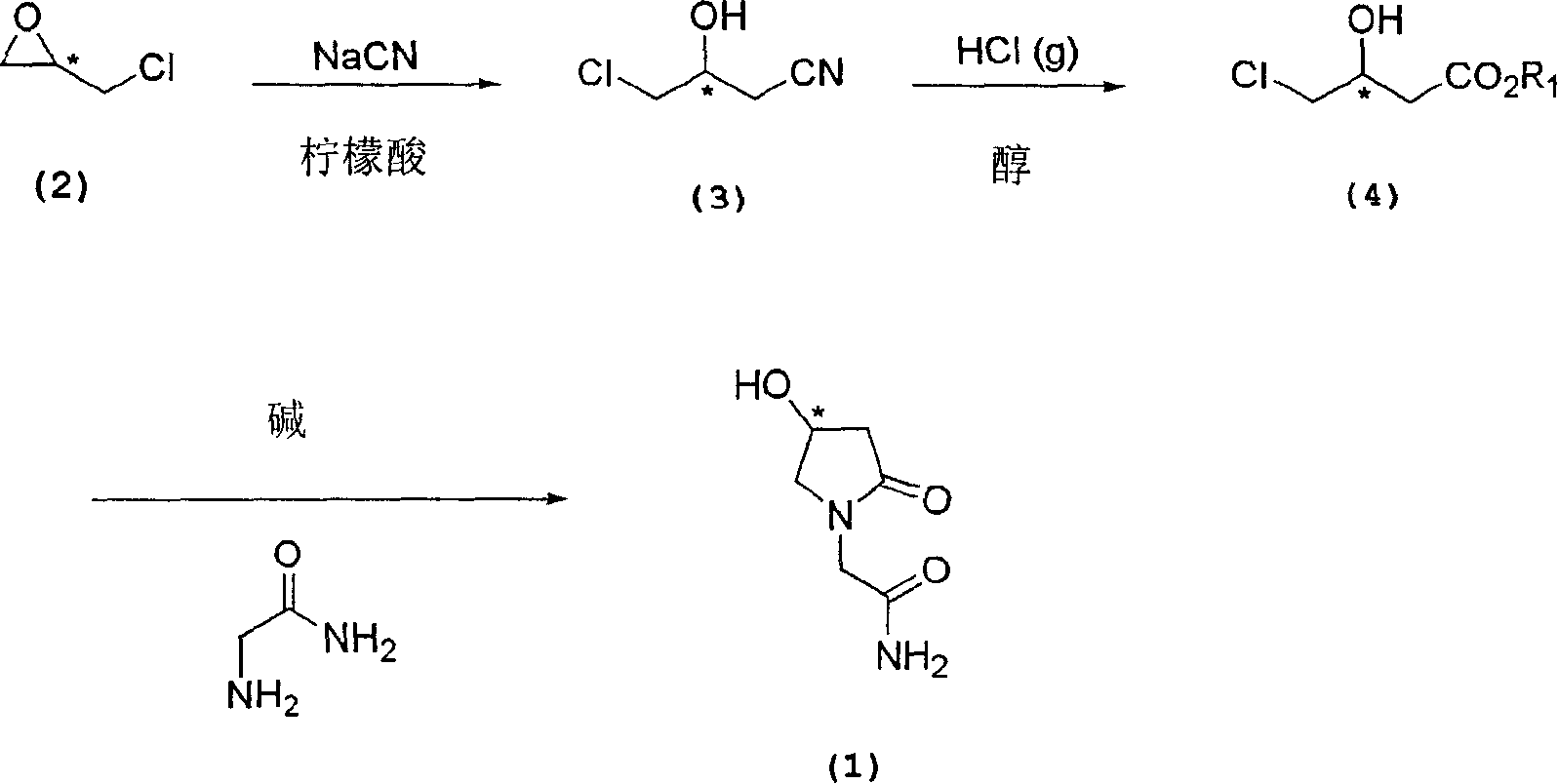

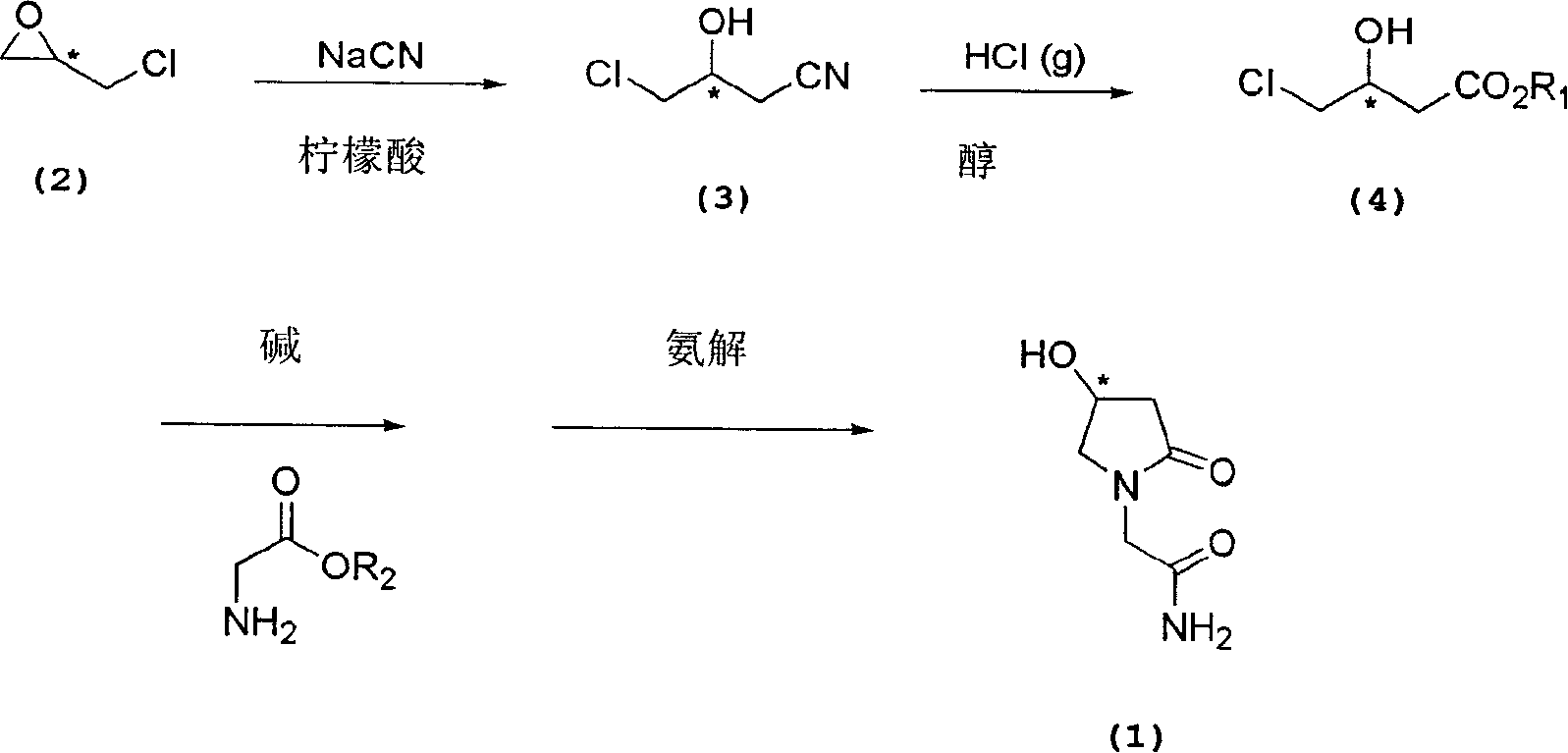

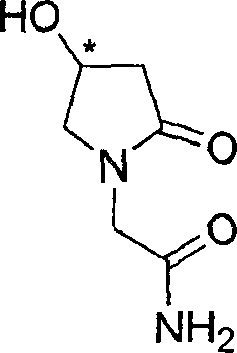

Process for the preparation of optically pure 4-hydroxy-2-oxo-1-pyrrolidine acetamide

The present invention relates to a process for the preparation of chiral 4-hydroxy-2-oxo-1-pyrrolidine acetamide. The process comprises adding sodium cyanide together with citric acid to a solution of chiral epichlorohydrin to obtain chiral 3-chloro-2-hydroxypropionitrile by ring opening reaction of the chiral epichlorohydrin, reacting the obtained product with an alcohol containing hydrochloride gas to obtain chiral 4-chloro-3-hydroxybutyric acid ester, and reacting the obtained product in a presence of a base with glycinamide or with glycine ester accompanied by ammonolysis with ammonia to produce the targeted chiral 4-hydroxy-2-oxo-1-pyrrolidine acetamide. The process according to the present invention provides optically pure 4-hydroxy-2-oxo-1-pyrrolidine acetamide in high yield and in high purity, which is suitable for industrial mass-production.

Owner:AHN GOOK PHARMA CO LTD +1

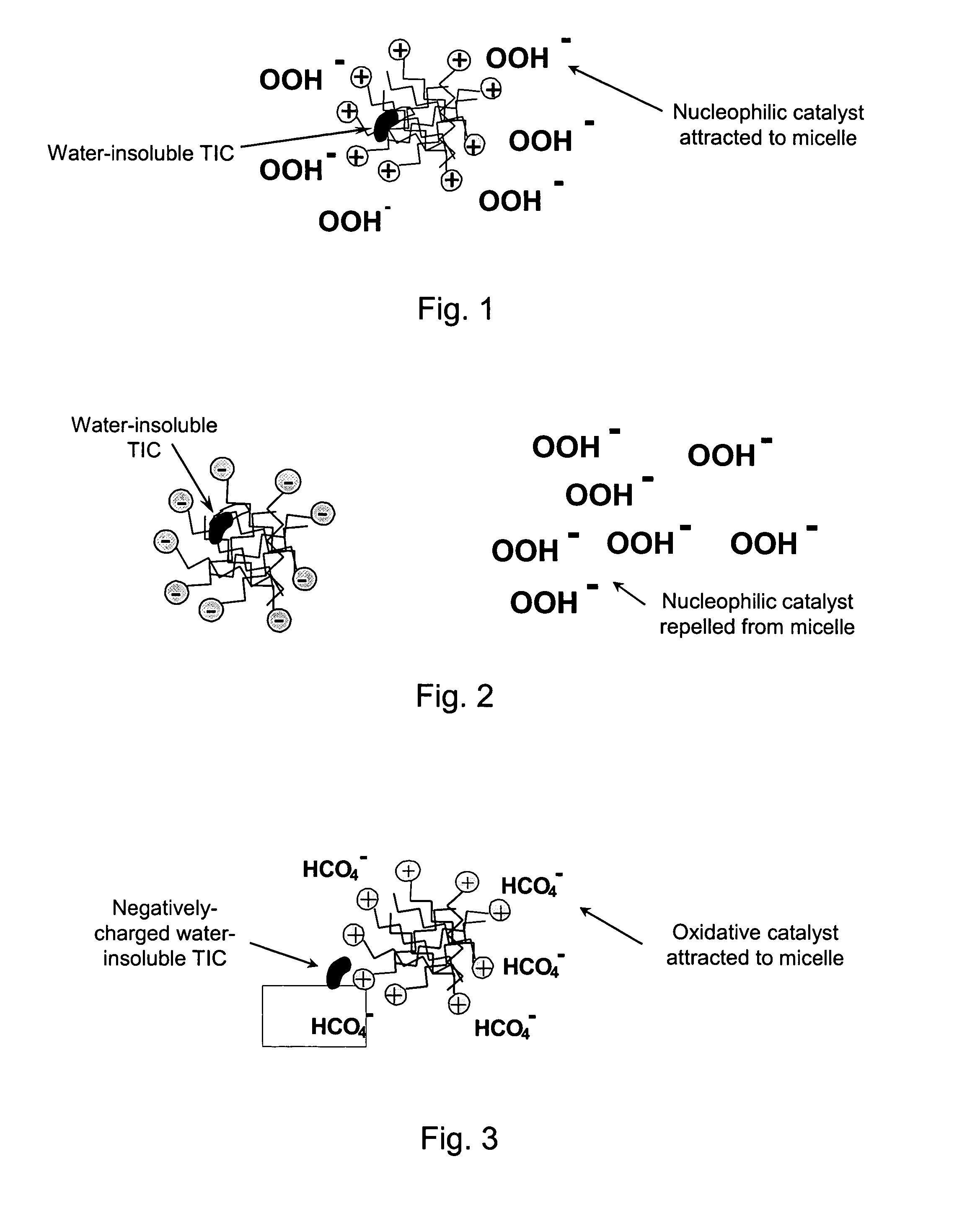

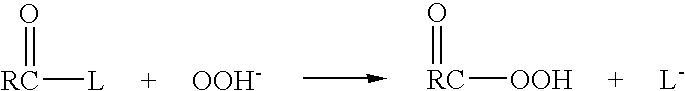

Reactive formulations for a neutralization of toxic industrial chemicals

InactiveUS7125497B1Efficiently neutralizedHydrogen peroxideLiquid degasificationBoron trichlorideMalathion

Decontamination formulations for neutralization of toxic industrial chemicals, and methods of making and using same. The formulations are effective for neutralizing malathion, hydrogen cyanide, sodium cyanide, butyl isocyanate, carbon disulfide, phosgene gas, capsaicin in commercial pepper spray, chlorine gas, anhydrous ammonia gas; and may be effective at neutralizing hydrogen sulfide, sulfur dioxide, formaldehyde, ethylene oxide, methyl bromide, boron trichloride, fluorine, tetraethyl pyrophosphate, phosphorous trichloride, arsine, and tungsten hexafluoride.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

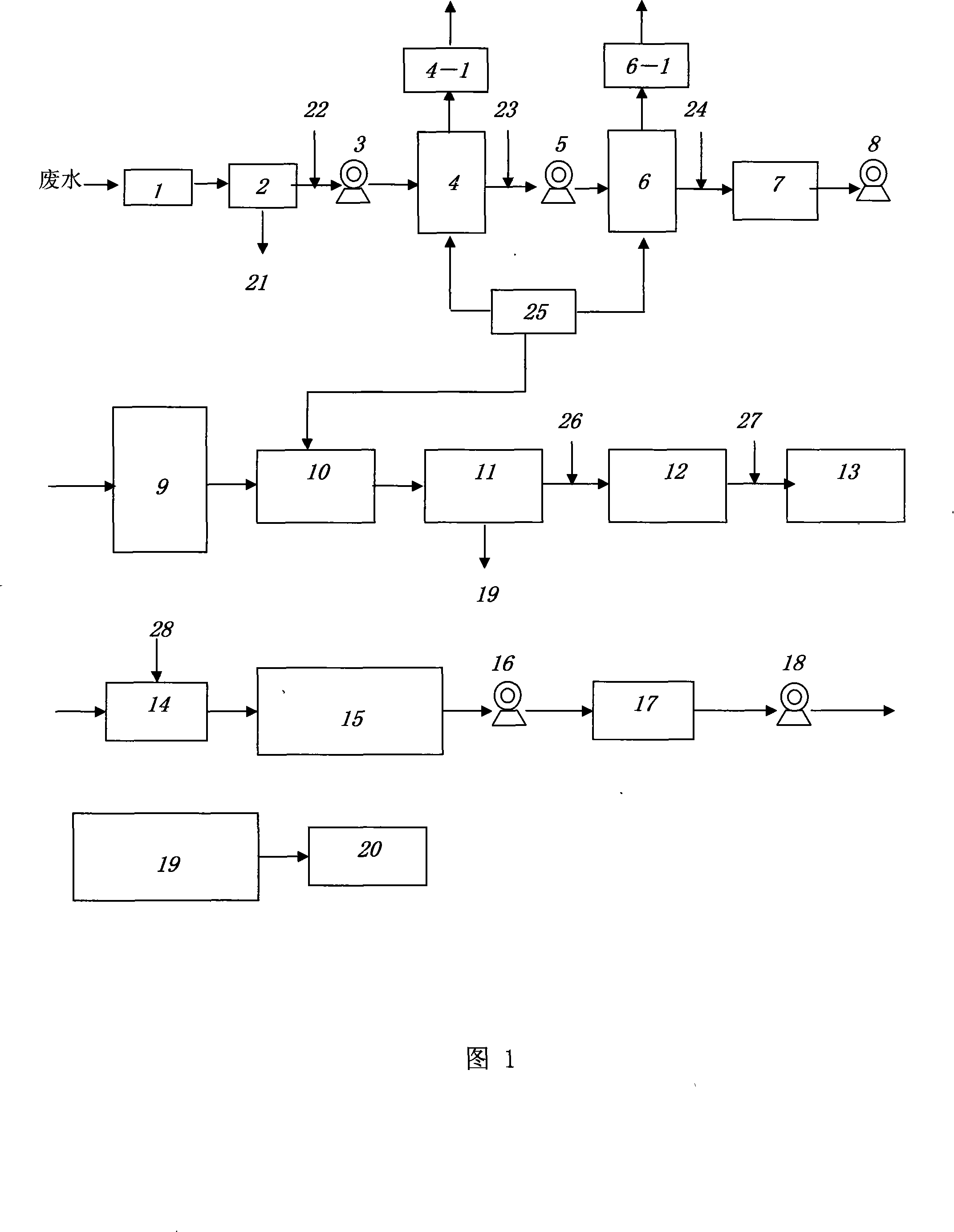

Combination technique for processing and recycling high-cyanogen high-ammonia high-salt organic waste water

InactiveCN101172743AProcess Combination ScienceReasonable process combinationWater contaminantsWater/sewage treatment bu osmosis/dialysisIndustrial waste waterCombined technique

The invention relates to a combined technique of treating and reusing the organic sewage which is rich in cyanogen, ammonia and salt, and adopts the combined techniques of acidified decyanation (with the sodium cyanide recollected), basified ammonia blowing (with ammonium salt recollected), oxidation by adding chlorine, biological treatment, precipitation and clarification, deep oxidation, biological active carbon filtering, one-time brine refining, microstraining film, and other combined techniques, and then the chlorine alkali is produced after the secondary brine refining in the chlorine alkali industry and the entrance into the ionic membrane electrobath. The combined technique can be used for treating the industrial sewage in the tricyanogen chloride, chlorine alkali, gold mine, galvanization and other industries and conduct recovery of the resources, thereby overcoming the disadvantages that the prior art has narrow applicability and treatment function and disappointing treatment result, cannot recollect the resources, and has high treatment cost and unobvious economical benefit. The combination of the technique is scientific and reasonable, the technique is novel, unique and mature, the treatment is good, and the combined technique has a plurality of functions, strong applicability, wide use range and remarkable environmental and economical benefit.

Owner:HAINAN CHENGTAI ENVIRONMENT ENG

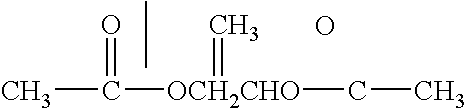

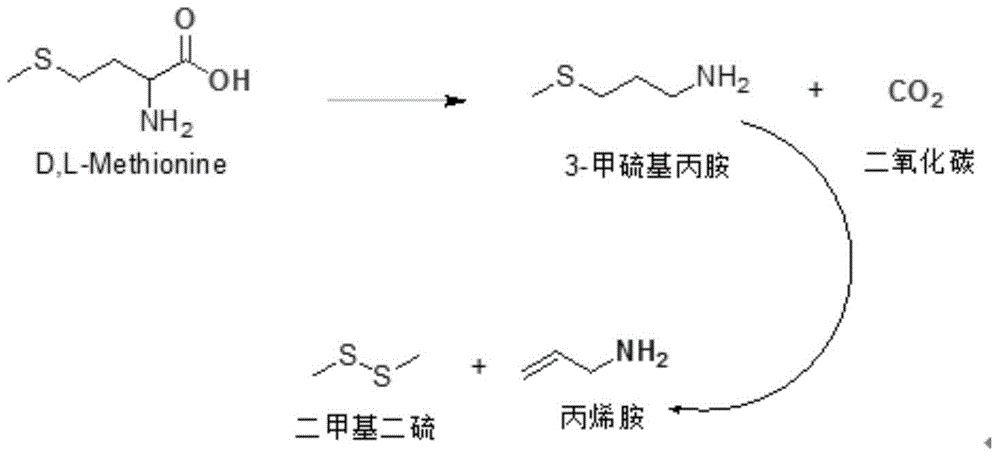

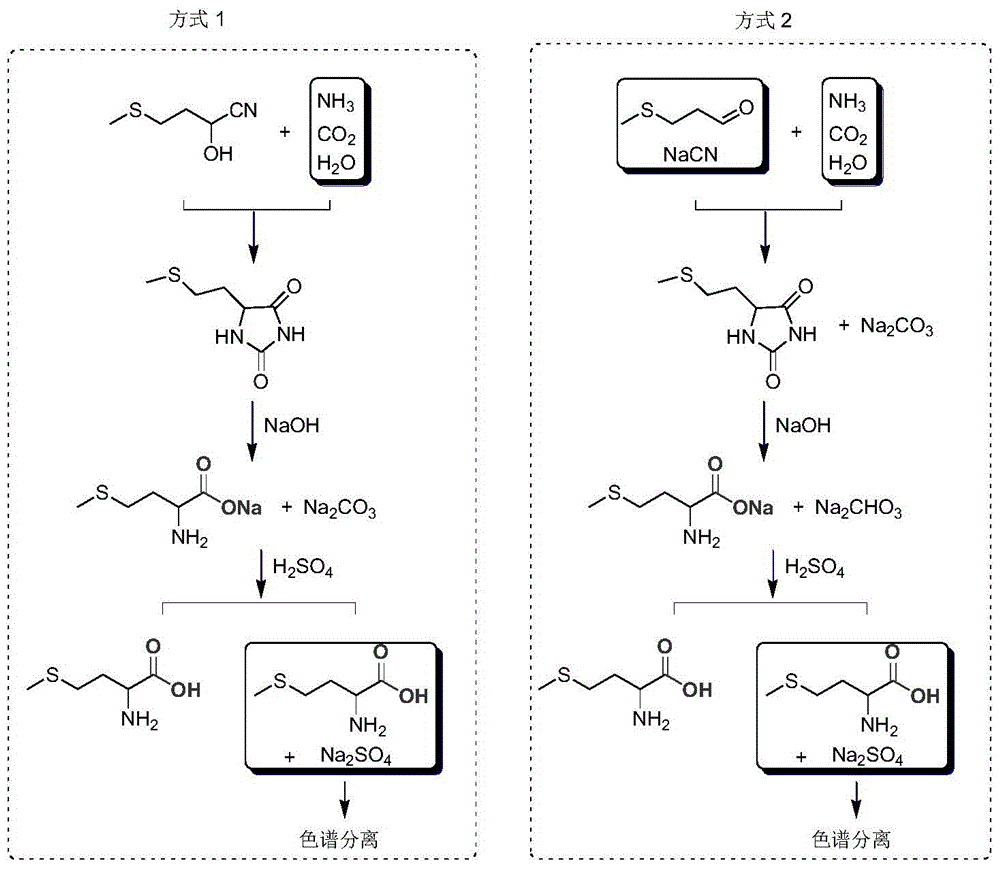

Method for preparing methionine

The invention discloses a method for preparing methionine. The method for preparing the methionine concretely comprises the steps that cyanohydrins, carbon dioxide and ammonia or sodium cyanide, 3-(Methylthio)propionaldehyde, carbon dioxide and ammonia serve as raw materials to prepare hydantoin; alkaline hydrolysis is conducted on the hydantoin and then the hydantoin is acidized to pH 3.0-6.0 to obtain a compound of the methionine and salts; crystallization is conducted under the condition of temperature ranges from 8 DEG C to 45 DEG C, then the compound is separated to obtain a methionine crystal and salt mother liquor, the methionine crystal is washed by water and dried, and washing liquor is standby; finally, the salt mother liquor is concentrated under the condition of temperature which is lower than 60 DEG C, and then the salt mother liquor passes through a chromatographic column to obtain an inorganic salt and the methionine; the preparation method can efficiently separate the methionine and the salts, the recovery rate of the methionine can reach 99%, and the method is green and protects the environment, no methionine is resolved, no large number of acid and stink wastewater is discharged, and the purity of the inorganic salt is high and can be sold as a commodity.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

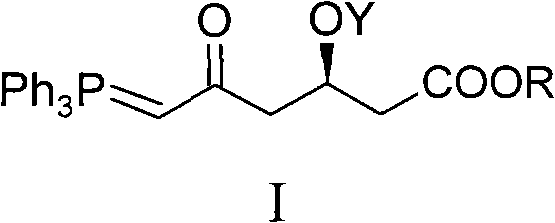

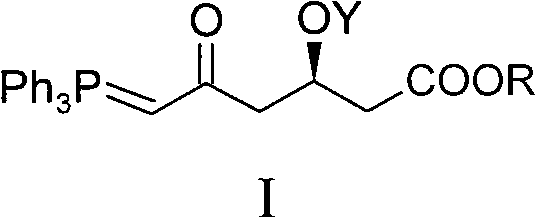

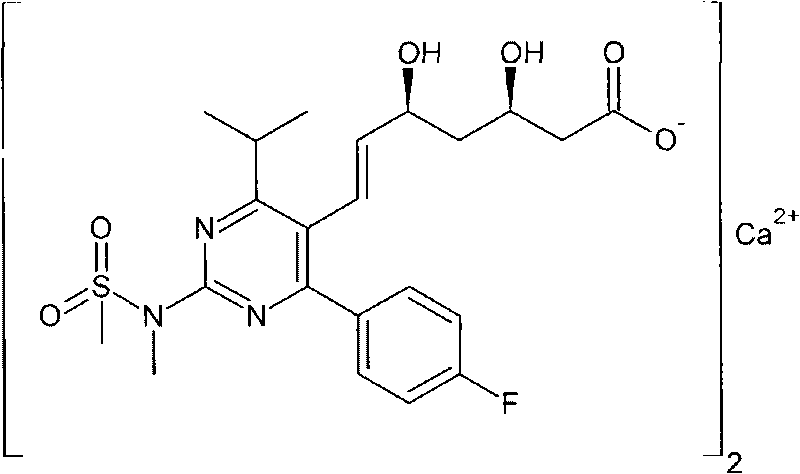

Method for preparing rosuvastatin calcium midbody

ActiveCN101735272AHigh yieldReduce pollutionGroup 5/15 element organic compoundsBulk chemical productionWittig reactionGrignard reaction

The invention discloses a method for preparing a rosuvastatin calcium midbody, namely a compound (R is C1-C10 alkyl, and Y is a hydroxyl protecting group) shown as the general formula I. Chloroethylene and R-epoxy chloropropane as initial raw materials are carried out seven steps of reaction, such as Grignard reaction, sodium cyanide nucleophilic substitution reaction, alcoholysis reaction, hydroxyl protection, oxidizing reaction, methylchloroformate acylation reaction and Wittig reaction to prepare the compound shown as the general formula I. The method has mild condition, simple and convenient operation, stable process, low cost and easy acquisition of raw materials, high product yield, easy disposal of the three wastes, less environmental pollution, low preparation cost and suitability for industrialized large-scale production.

Owner:JIANGXI DONGBANG PHARMA

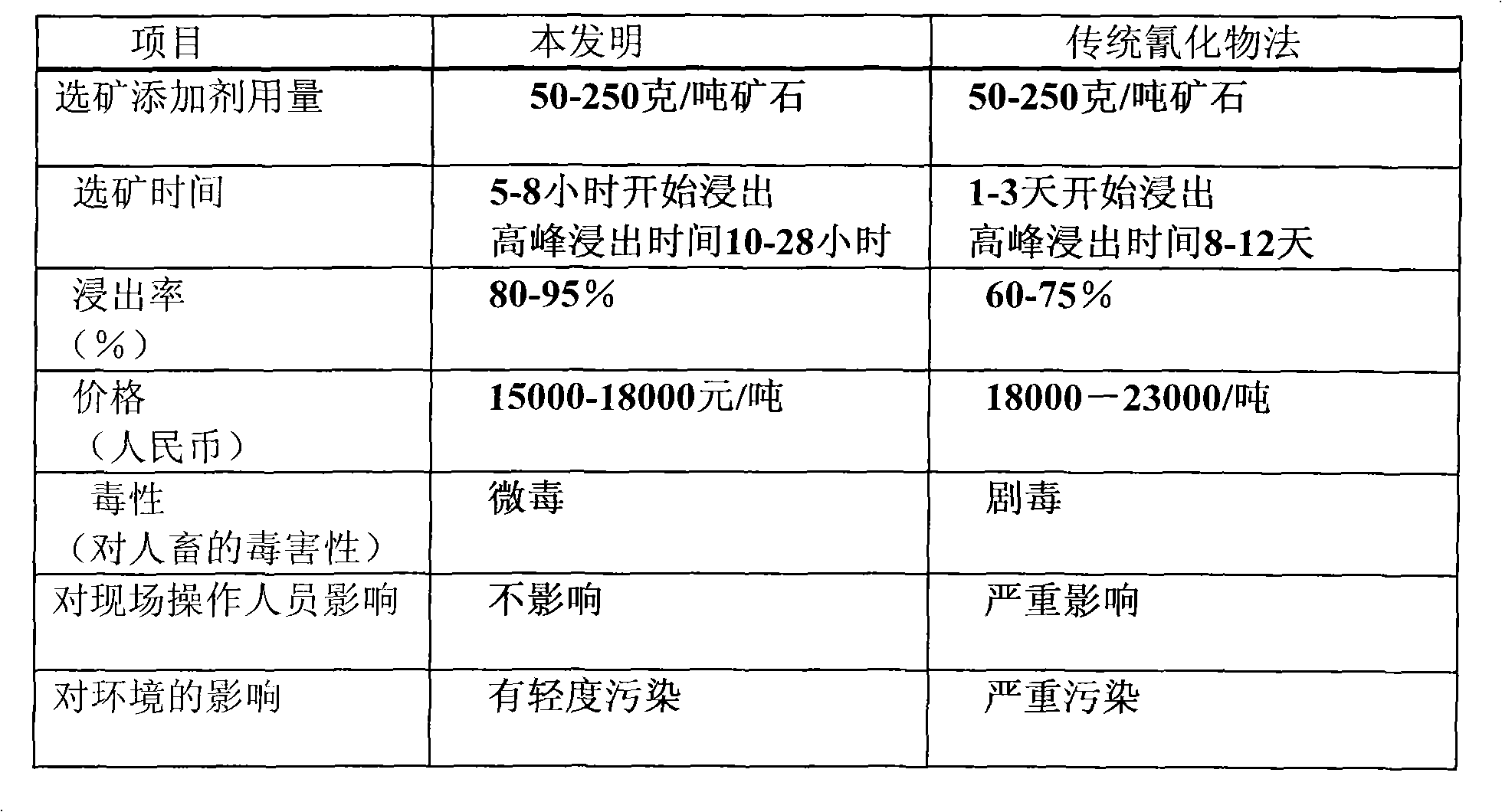

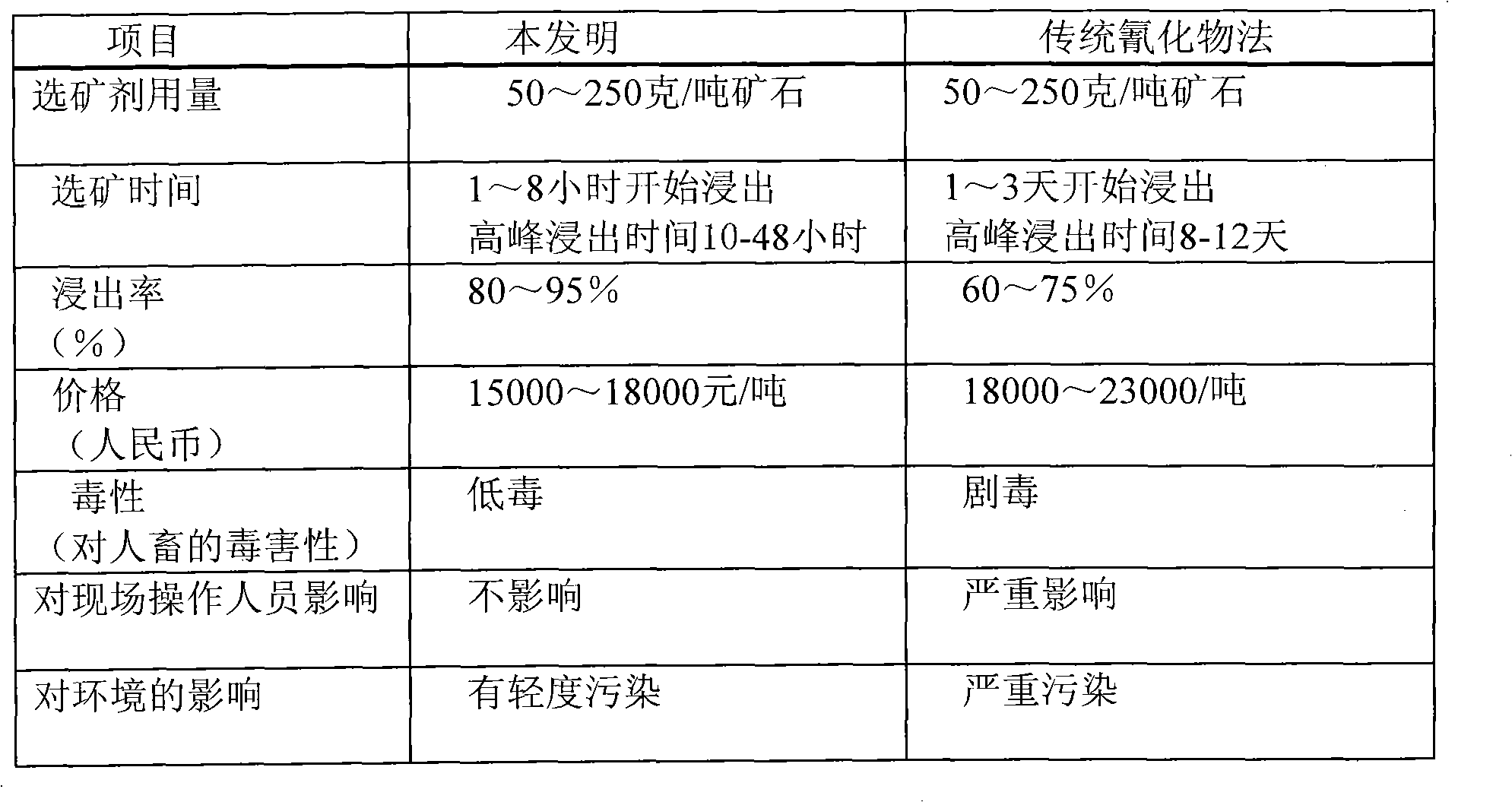

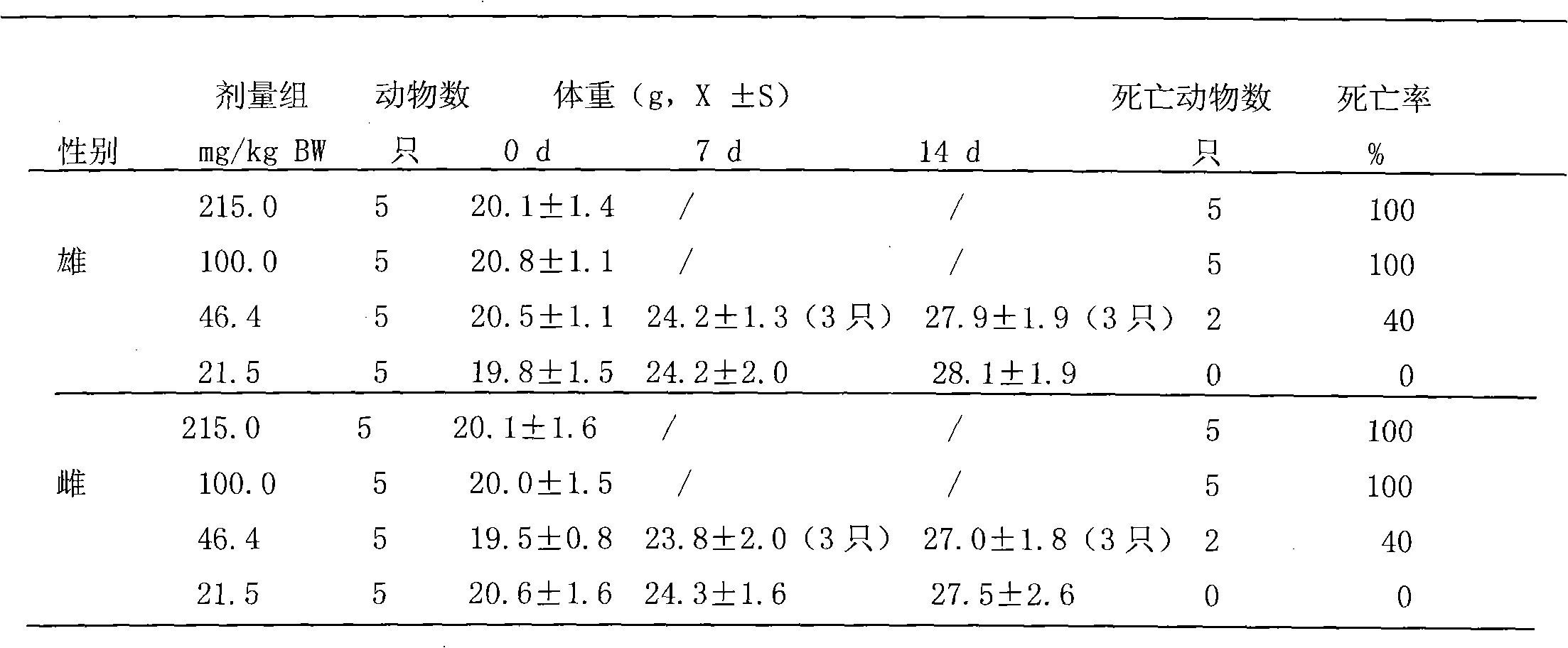

Nuisanceless oredressing additive as well as preparation method and application thereof

ActiveCN102121067ADrug stabilityLow costRotary drum furnacesCrucible furnacesSodium bicarbonateMolten state

The invention relates to a low-toxicity and environmentally friendly gold and silver oredressing additive as well as a preparation method and application thereof. The main raw materials of the additive comprise sodium hydroxide, sodium carbonate, urea and potassium ferrocyanide. The preparation method comprises the following steps of: heating the sodium hydroxide, the sodium carbonate, the urea and the potassium ferrocyanide to 600-1,000 DEG C, and after the materials reach a molten state, continuing to preserve heat for 1-2 hours; directly cooling to normal temperature; and demoulding to obtain a nubby gold and silver oredressing additive. The product of the invention can be widely applied to producing noble metal mines, such as soaking, core spraying, and the like of gold oxide mines, silver oxide mines, copper oxide mines, and also can be used for industrial production industries of electroplating, and the like for replacing highly toxic sodium cyanide chemicals. Compared with other non-toxic sodium cyanide drugs, the additive provided by the invention has the advantages of good effect, stable drug properties, environmental friendliness, lower cost, and the like.

Owner:GUANGXI SENHE HIGH TECH CO LTD

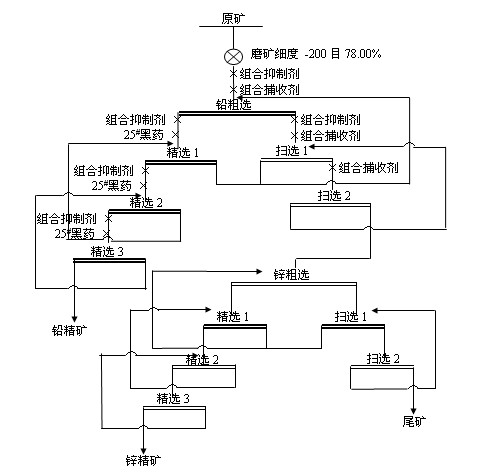

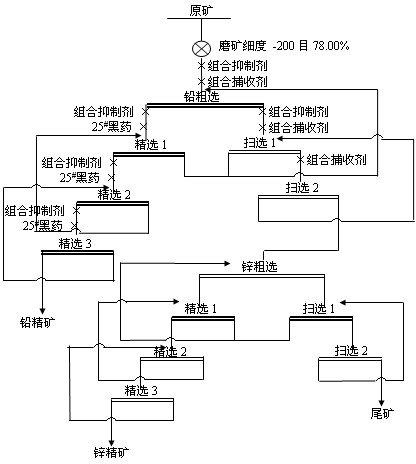

Beneficiation method for replacing sodium cyanide floating lead zinc to difficultly select ore

The invention relates to a beneficiation method for difficultly selecting lead-zinc ore, in particular to a beneficiation method for replacing sodium cyanide floating lead zinc to difficultly select ore. The beneficiation method comprises the steps of: (1) ore grinding: grinding raw ore into the ore with the material particle size being smaller than 0.074mm and being 72%-84% of the whole raw ore;(2) differential flotation of lead; and (3) differential flotation of zinc in float lead tailings. Particularly, the method adds a combined inhibitor and a combined collector in the beneficiation process to replace highly-toxic sodium cyanide selecting lead-zinc ore, so that the environmental pollution is reduced. In addition, the method is used for increasing the recovery ratio of lead-zinc concentrate, increasing the recovery ratio of precious metals including gold and silver, and increasing the economic benefit of enterprises.

Owner:HUNAN RES INST FOR NONFERROUS METALS

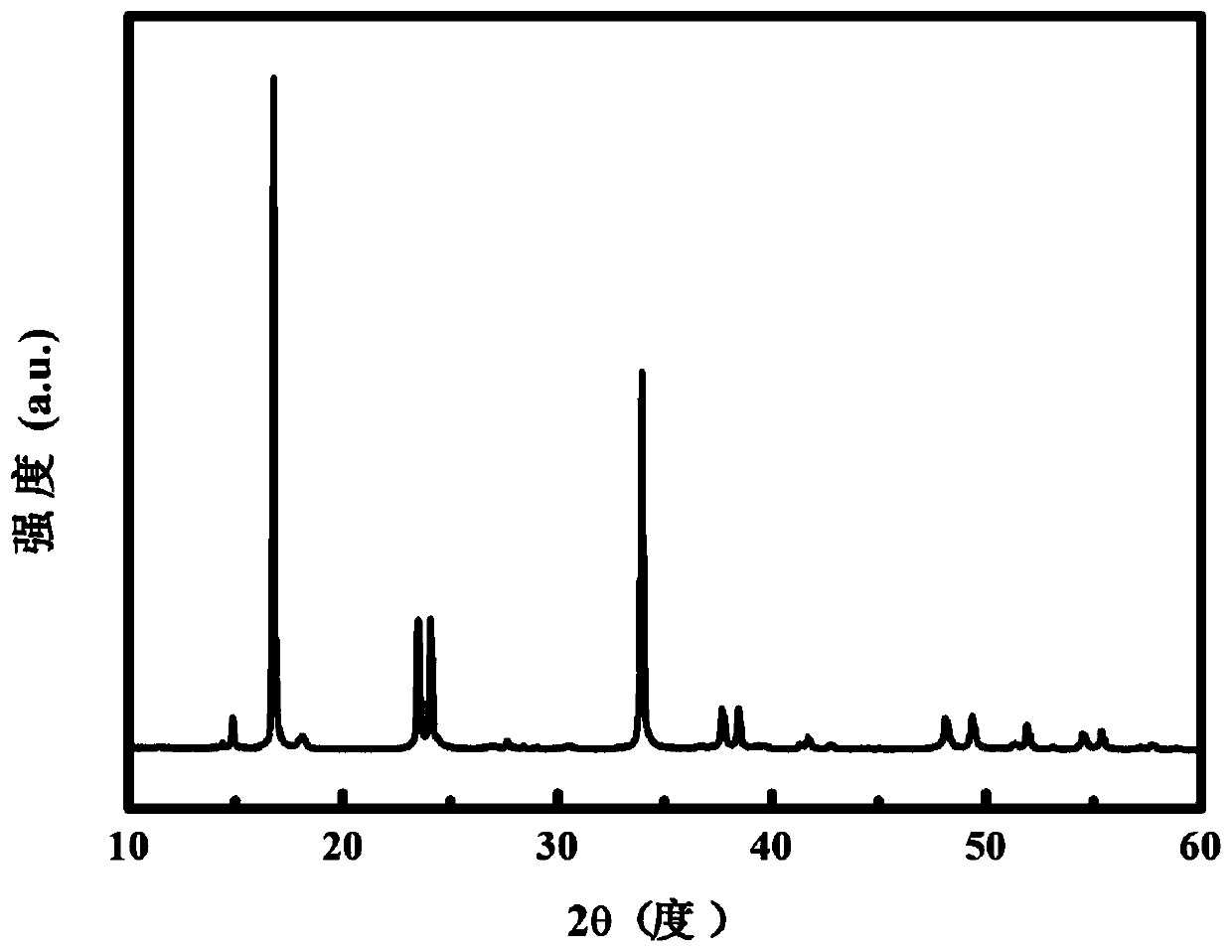

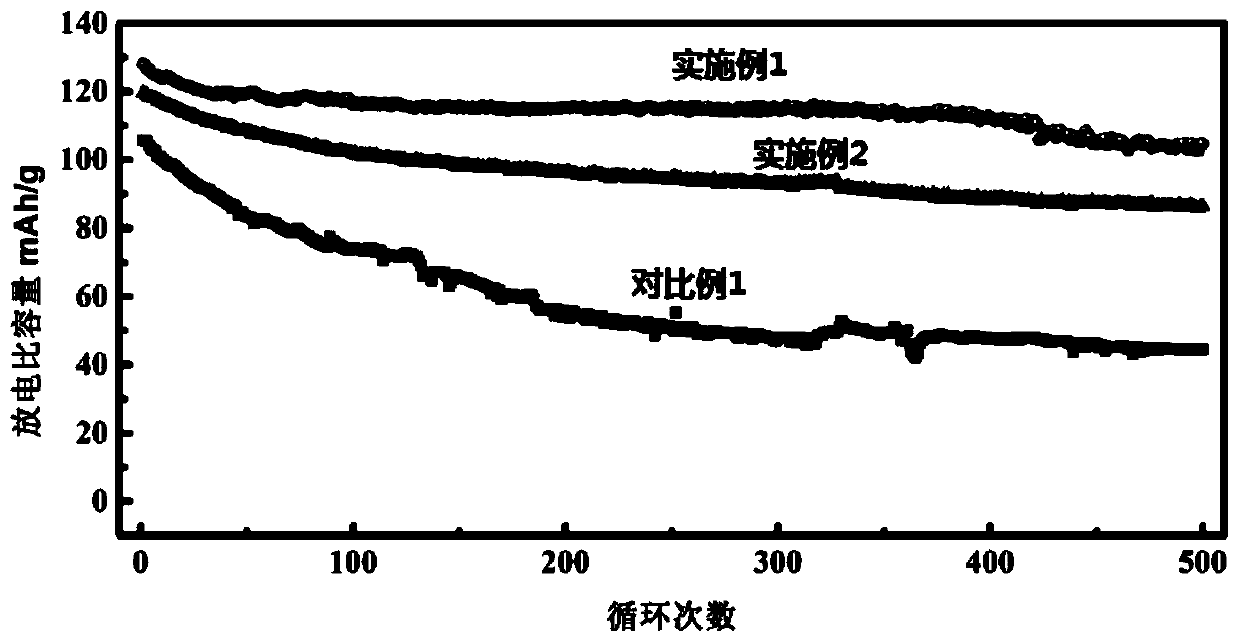

Modified prussian blue material, sodium ion battery positive electrode plate and preparation method

InactiveCN106960956ALow crystal water contentReduce defectsCell electrodesSecondary cellsWater contentPyrrole

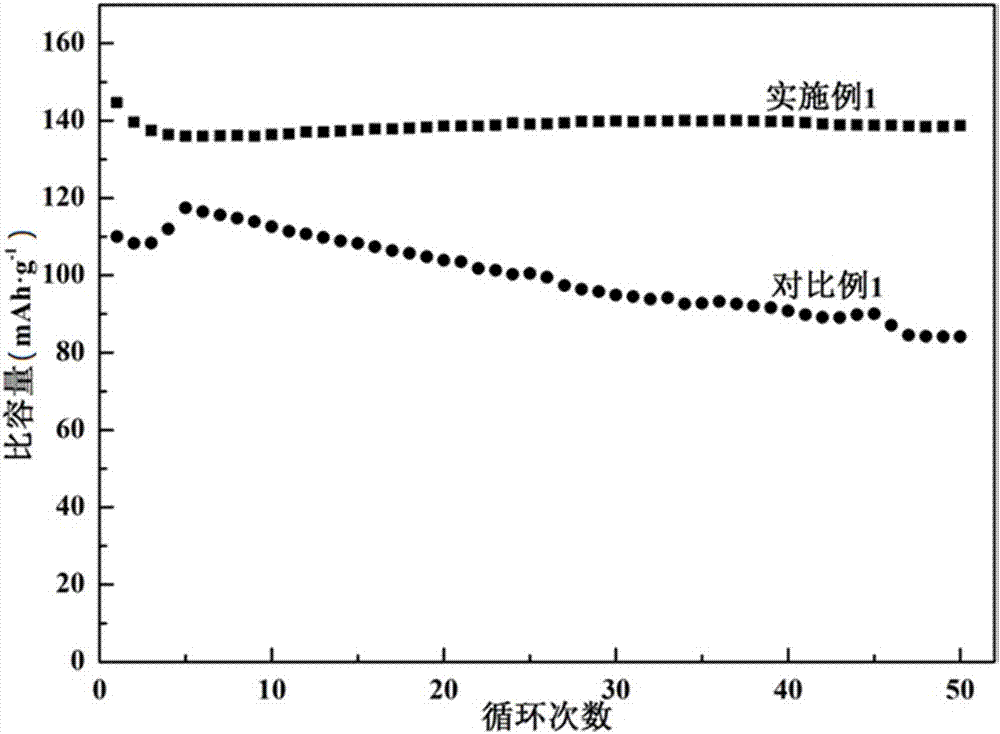

The invention discloses a modified prussian blue material, a sodium ion battery positive electrode plate and a preparation method. The preparation method for the modified prussian blue material at least comprises the steps of performing a reaction on methyl orange, ferric chloride and pyrrole based on a certain proportion to obtain a solution, then performing a reaction on the obtained solution with a mixed solution of sodium ferrocyanide and inorganic acid, and next, performing processing of centrifuging, washing, drying and the like to obtain the modified prussian blue material. Compared with the conventional synthesis method, the prepared modified prussian blue material is lower in crystal water content, less in defects, high in tubular polypyrrole conductivity and relatively high in environment stability, so that an electrolyte can permeate rapidly, and rapid diffusion of Na+ can be promoted to form a three-dimensional conductive network with prussian blue nanoparticles; therefore, the material conductivity is improved, and the material is novel and unique; in addition, the cycling performance and the rate capability of the material are greatly improved; and the modified prussian blue material is more suitable for application of an energy storage material, such as the positive electrode material of the sodium ion battery.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

Production and using method of environmentally-friendly noble metal mineral processing reagent

ActiveCN102321807AEasy to produceAccurate ingredientsProcess efficiency improvementMolten stateCopper oxide

The invention discloses the production method of an environmentally-friendly noble metal mineral processing reagent. The method comprises the following steps: putting potassium ferrocyanide and urea after being mixed into a reactor; adding a pH regulator during the slow temperature rise process; heating to the molten state; taking a small amount of molten material detection samples, cooling and dissolving into water; measuring the pH value, enabling the molten material pH value to be 8-14; keeping the molten temperature for 5-60 minutes; and cooling to the normal temperature, thus the environmentally-friendly noble metal mineral processing reagent is obtained. The product obtained from the invention can be widely applied to the production of noble metal mine, such as the soaking, core spray of gold oxide ores, silver oxide ores and copper oxide ores, also can be used in industrial production industries such as electroplating, and used as medicaments for replacing toxic Cymag; and compared with all the other non-toxic or low-toxicity mineral processing reagents, the noble metal mineral processing reagent has the advantages of good effect, stable drug property, environmentally-friendly product, simple production method, low cost and the like.

Owner:广西地生金矿业科技有限公司 +2

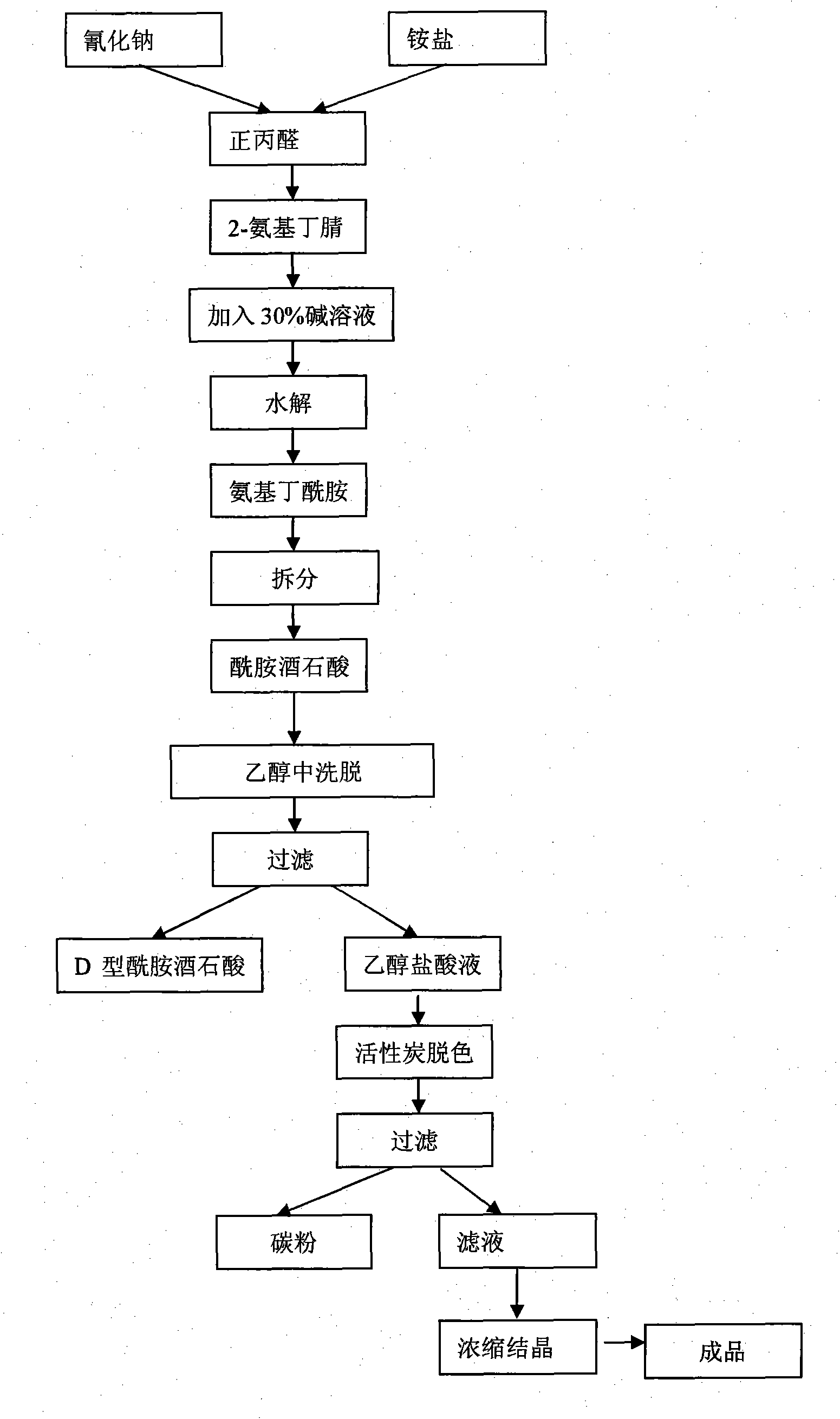

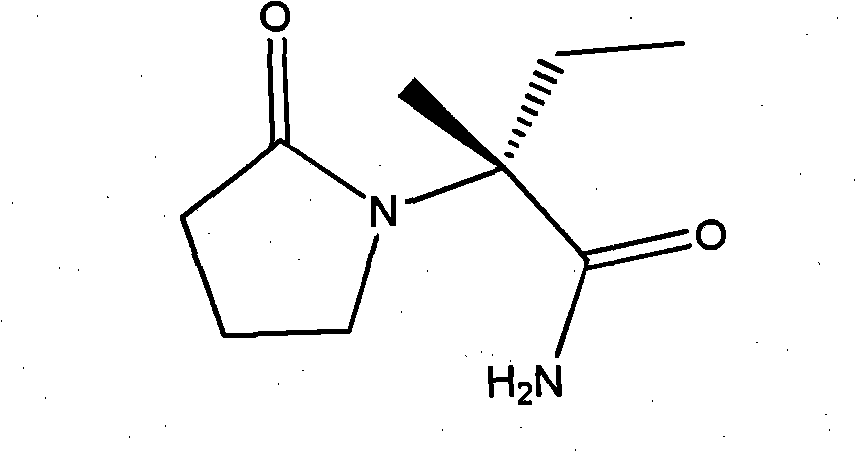

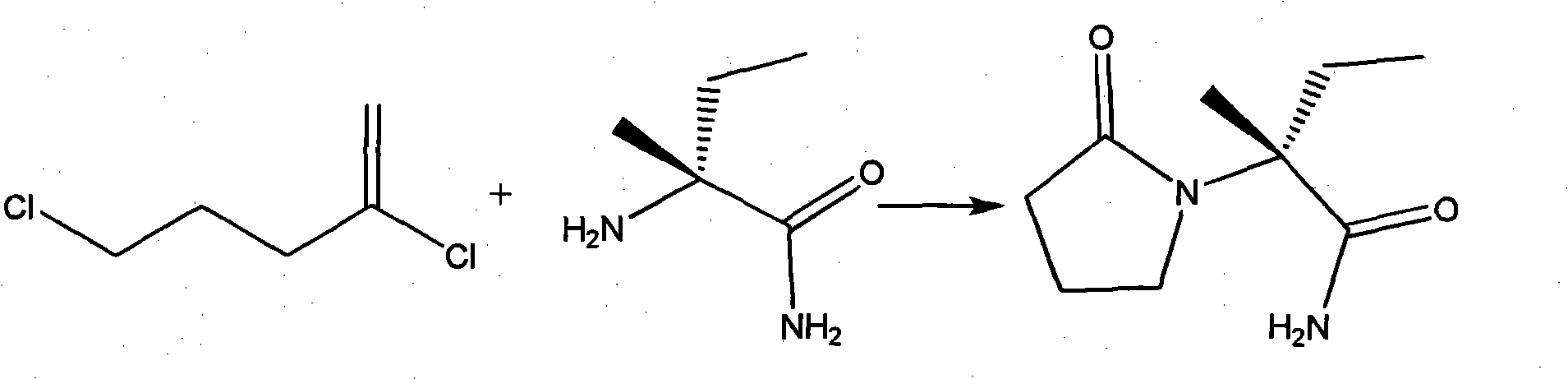

Process method for producing L-2-aminobutanamide hydrochloride serving as intermediate of levetiracetam

InactiveCN101928229ALow costShort synthesis cycleOrganic compound preparationCarboxylic acid amides preparationSodium cyanideHydrolysis

The invention discloses a process method for producing L-2-aminobutanamide hydrochloride serving as an intermediate of levetiracetam, which solves the problem that the conventional produced product has excessively high impurity content or production cost is too high for an enterprise to bear and the like. The method is characterized by comprising the following steps of: reacting propionaldehyde with ammonia water, ammonium chloride and sodium cyanide to obtain 2-amino butyronitrile; hydrolyzing the 2-amino butyronitrile under an alkali condition to obtain 2-aminobutanamide; and splitting the 2-aminobutanamide with L-tartaric acid to obtain the L-2-aminobutanamide hydrochloride. An L-2-amino amides product of which the content is over 99.5 percent is obtained by removing a byproduct, namely, sodium chloride by recrystallization so as to meet the use requirement of foreign customers. The process has the advantages of high yield, high safety and low cost and can be widely suitable for industrialized production of medium-sized and small enterprises.

Owner:HUANGGANG HUAYANG PHARMA

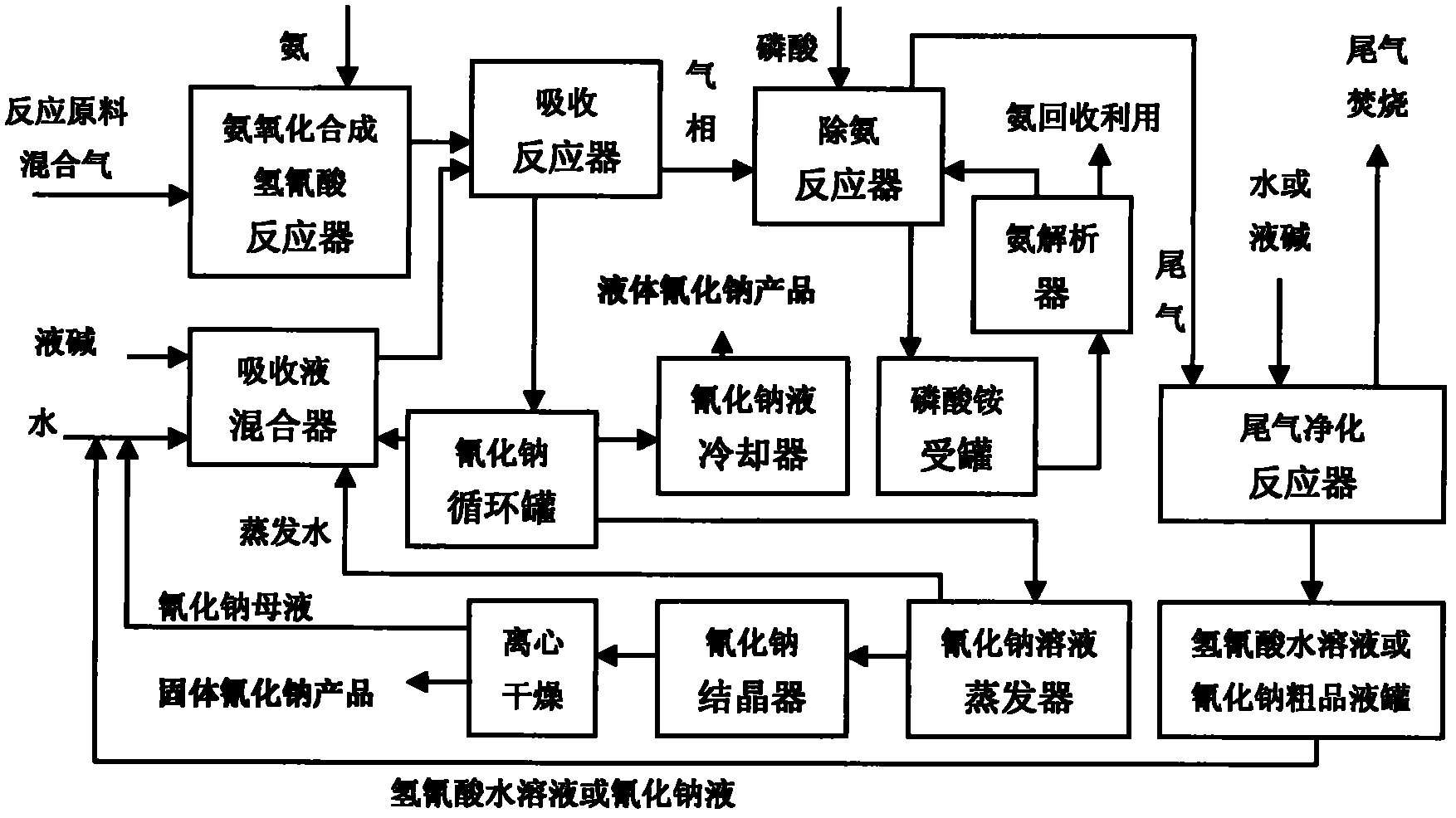

Environment-friendly clean production method for high purity sodium cyanide

InactiveCN103073027ARealize recyclingAchieving a circular economy modelAlkali metal cyanidesPhosphoric acidSodium cyanide

The invention provides an environment-friendly clean production method for high purity sodium cyanide. The production method comprises the following steps that: without removal of ammonia, hydrocyanic acid synthetic gas synthesized through ammoxidation is directly absorbed by and reacts with an aqueous sodium hydroxide solution to obtain a high purity aqueous sodium cyanide solution, and free ammonia remains in tail gas; the aqueous sodium cyanide solution is cooled and blended to obtain a high purity liquid sodium cyanide product, the high purity liquid sodium cyanide product undergoes condensation, crystallization and centrifugation to obtain a high purity solid sodium cyanide product, and mother liquor is indiscriminately used in liquid alkali absorption liquor; phosphoric acid or ammonium biphosphate is employed as a carrier for repeated cyclic indiscriminate application of ammonia so as to recover ammonia in the tail gas; and after recovery of ammonia, the tail gas is purified and absorbed with water or the aqueous sodium hydroxide solution, a small amount of the aqueous hydrocyanic acid solution or a crude aqueous sodium cyanide solution product is obtained while the tail gas is purified, the purified tail gas is burned with a tail gas boiler, and the aqueous hydrocyanic acid solution or the crude aqueous sodium cyanide solution product is indiscriminately used in the liquid alkali absorption liquor.

Owner:龙智

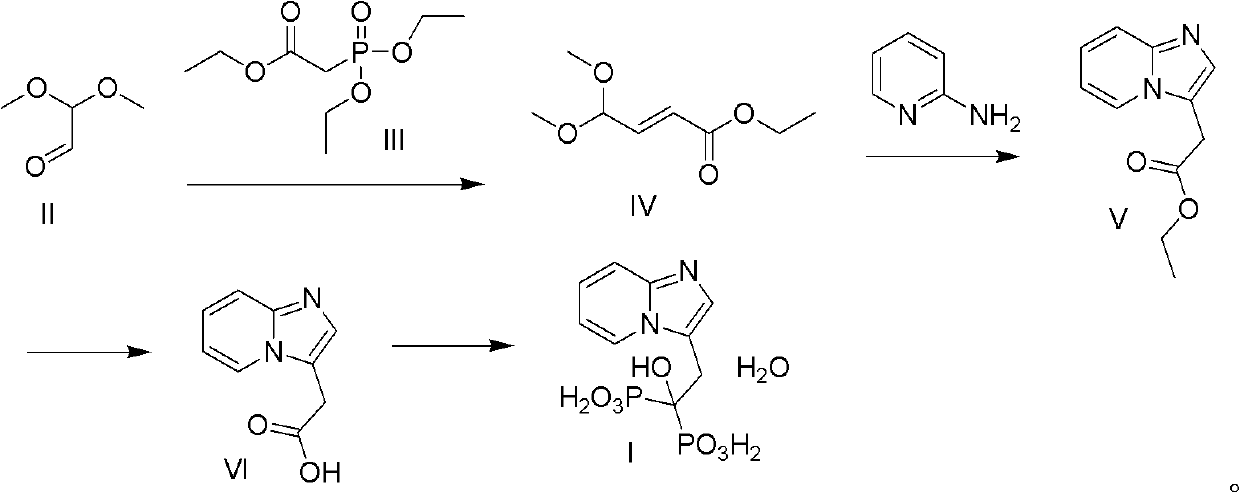

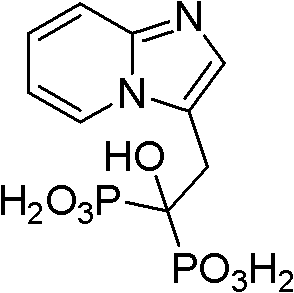

Method for preparing minodronate

ActiveCN102020676AThe reaction conditions are mild and controllableShort reaction stepsGroup 5/15 element organic compoundsBromineSodium cyanide

The invention discloses a method for preparing minodronate, which comprises the following steps of: condensing a compound II and a compound III to form a compound IV, closing rings of the compound IV and 2-aminopyridine to obtain a compound V, hydrolyzing the compound V into a compound VI, and finally performing phosphonation to form a compound I. The method avoids using virulent chemical reagents such as sodium cyanide or bromine and the like, has mild and controllable reaction condition, short reaction step, high yield and low cost, and is suitable for industrialized production.

Owner:JIANGSU LEEWAY BIOLOGICAL TECH

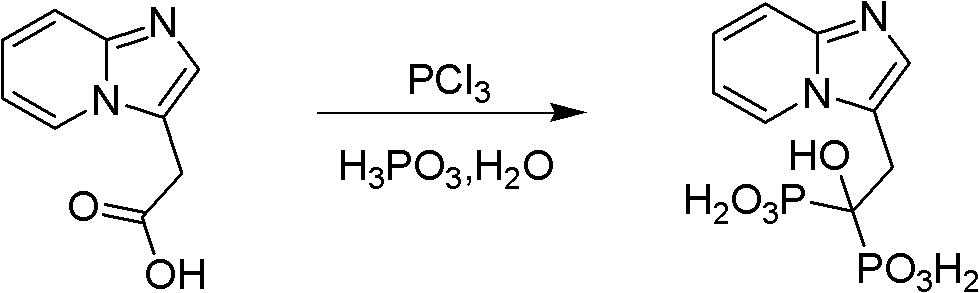

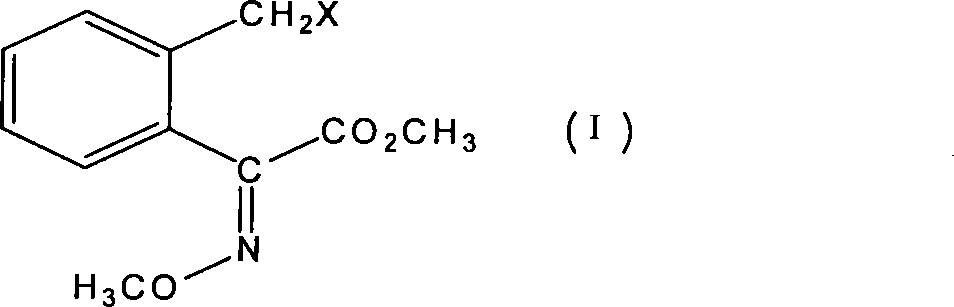

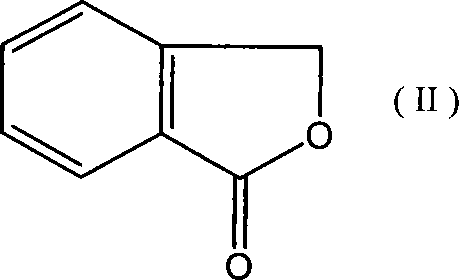

Method for preparing bactericidal agent intermediate (E)-2-(2'-chloromethyl)phenyl-2-methoxy imino methyl acetate

ActiveCN101139308AReduce energy consumptionReduce riskBiocideFungicidesPotassium cyanideProduction risk

The preparation method of the fungicide intermediate (E)-2-(2'-chloromethyl)-2-methicillin imino acetic methyl ester is: 1) the phenyl phthalate and the thionyl dihalide react with the influence of a catalyst; the catalyst is the Louis acid and phosphonic derivative; 2) the product of the first step and the alkali metal cyanide react with the influence of the organic solvent and phase transfer catalyst; the organic solvent is selected from the non-polar aromatic solvent or the halogen hydrocarbon; the phase transfer catalyst is selected from the halide of the four-level nitride or the ammonium salt; the alkali metal cyanide is selected from the sodium cyanide and potassium cyanide; 3) the products of the second step and the methanol react under the condition with the organic solvent and the chlorinated hydrogen; 4) the products of the third step and the methicillin amine hydrochloride under the condition with the organic solvent; thus, the target product can be got. The energy consumption and production risk of the present invention are obviously lowered; the relative collection rate is high; the safety in the production process is improved; and the present invention has no drawbacks such as the obstruction.

Owner:JIANGSU GENGYUN CHEM CO LTD

Preparation method of environment-friendly type precious metal beneficiation agent

ActiveCN103937986AAvoid pollutionEfficient leachingProcess efficiency improvementLead saltSodium cyanide

The invention relates to a preparation method of a low-toxic environment-friendly type novel precious metal beneficiation agent. Raw materials of the low-toxic environment-friendly type novel precious metal beneficiation agent comprise a cyanate, sodium hydroxide, sodium sulfate, sodium ferrocyanide, a bromide, and a lead salt. The preparation method comprises following steps: sodium cyanate, sodium hydroxide, sodium sulfate, and sodium ferrocyanide are mixed at a certain ratio; an obtained mixture is delivered into a smelting pot which is heated to be slightly red, and is heated to 650 to 750 DEG C so as to obtain a fused material, temperature is maintained to be 750 DEG C for 30 to 50min of reaction, and then an obtained product is collected and cooled; the obtained product is smashed, the bromide and the lead salt are added for stirring, and the environment-friendly type precious metal beneficiation agent is obtained via combination. The environment-friendly type precious metal beneficiation agent can be widely used for precious metal beneficiation metallurgy of nonferrous metals ores, contains no hypertoxic compounds, is safe for human and animal, and is friendly to the environment. Compared with other metal beneficiation agents, the environment-friendly type precious metal beneficiation agent is excellent in effects, stable in performance, and low in production cost; the preparation method is simple; and environmental protection can be realized.

Owner:广西河池鑫银环保科技有限公司

Selective heap leaching gold extraction process for gold mine containing copper

ActiveCN101818247AReduce consumptionImprove leaching rateProcess efficiency improvementSelective leachingHydrometallurgy

The invention discloses a selective heap leaching gold extraction process for gold mine containing copper, belonging to the field of hydrometallurgy. The process comprises the steps of: smashing and heaping gold mine containing copper; carrying out alkali treatment on the mine; then adding ammonium salt and sodium cyanide according to a certain proportion to realize the selective leaching of the gold and the restriction to the leaching of the copper; and finally absorbing and extracting the gold from leaching solution by conventional active carbon. The invention has the advantages of simple process method, short procedure, simple equipment, easy implementation, high gold leaching efficiency, low consumption of sodium cyanide, low energy consumption, little investment and low cost, and is the gold extraction method with easy realization of industrialized production and favorable economical benefit.

Owner:ZIJIN MINING GROUP

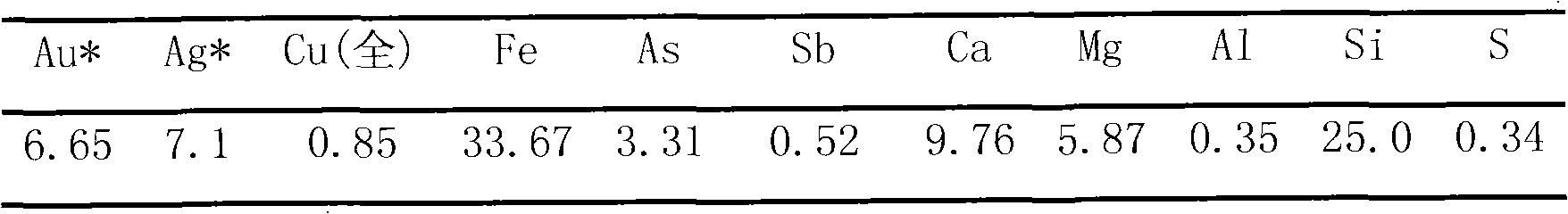

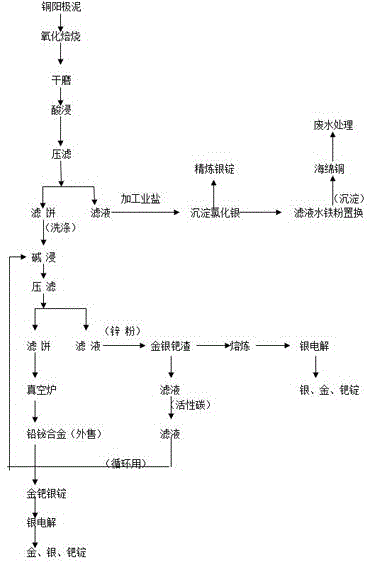

Method for separating and recovering valuable metals from copper anode slime

ActiveCN105543485ALess investmentShorten the timeProcess efficiency improvementElemental selenium/telluriumPregnant leach solutionLead bismuth

The invention discloses a method for separating and recovering valuable metals from copper anode slime. The method comprises the following steps: (1) the copper anode slime is subjected to oxidizing roasting, and primary dust and a roasting product are obtained; selenium is recovered from the primary dust, and secondary dust and crude selenium powder are obtained; (2) the roasting product is broken and added to a reactor, acid is added for acid leaching, an oxidizing agent is added continuously in an acid leaching process, acid leached residues and an acid leached liquid are obtained, and silver and copper are recovered from the acid leached liquid; (3) alkali is added to the acid leached residues for alkaline leaching, sodium cyanide and an ore selecting agent are added simultaneously, alkaline leached residues and an alkaline leached liquid are obtained, the valuable metals are recovered from the alkaline leached liquid, and a lead bismuth alloy and heavy metals are recovered from the alkaline leached residues. The method has the advantages of short process flow, low investment, short time, fast effect taking, high comprehensive recovery rate, high technical-economic indicators and high metal recovery rate.

Owner:郴州百一环保高新材料有限公司

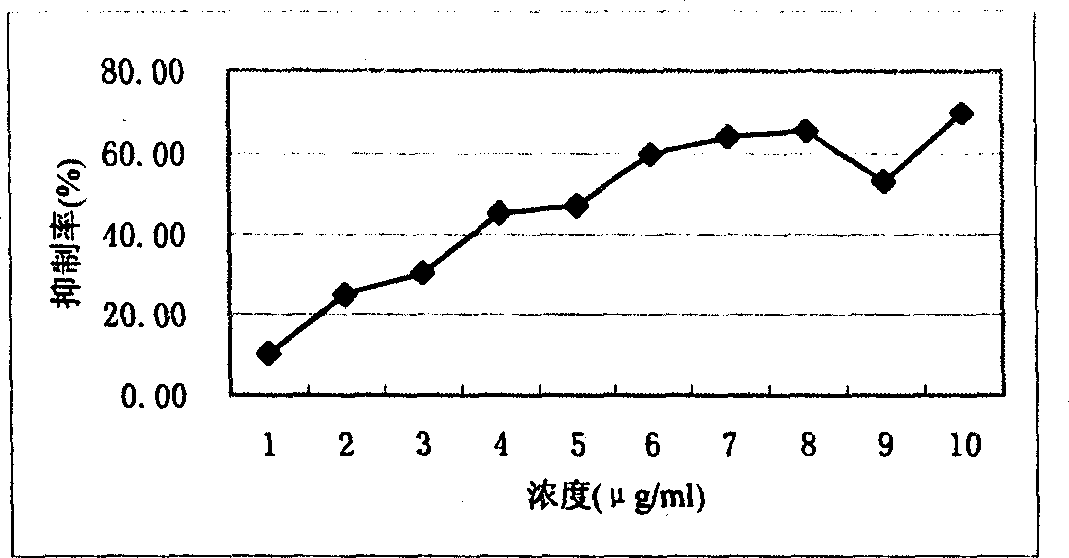

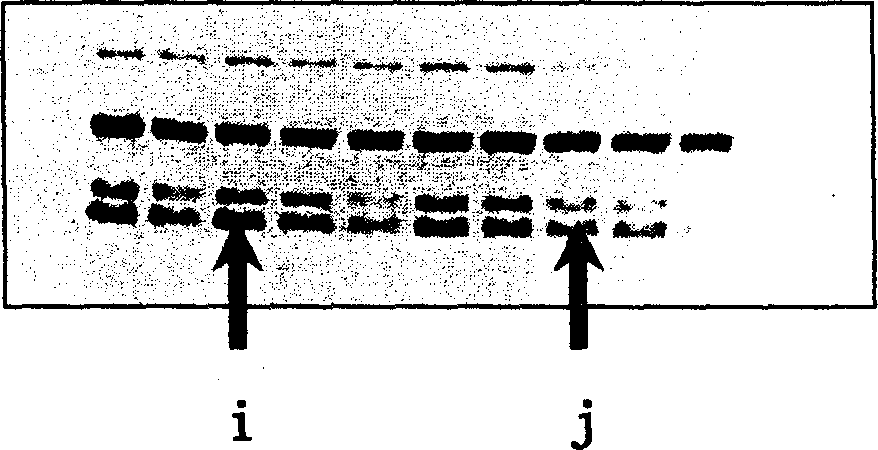

Cyanoacrylate derivatives and their preparation method and biological activity

This invention discloses a medicine of anti-tumor and anti-plant virus effect---- cyanoacrylate category derivative and its preparing method and biological activity. The following general formula denotes the compound and its preparing method. The definition of R1, R2, R3 in the formula is in instruction book. Materials are carbon bisulfide, cyan acetic ester, dimethyl sulfate, aromatic amine, and sodium cyanide is catalyst, cyanoacrylate category derivative is synthesized by three steps. There is proliferation inhibitory effect of compound b, k to PC3 prostate cancer cell gene stock, and proliferation inhibitory effect of compound i, j to NIN3T3 cell ERK albumen phosphorylation, and good anti-cancer activity is revealed. There is inhibitory activity of compound b, n to tobacco mosaic, and certain anti-plant virus activity is revealed.

Owner:GUIZHOU UNIV

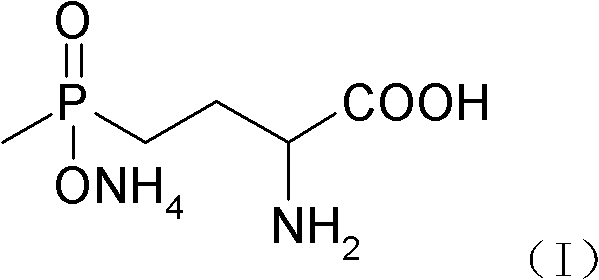

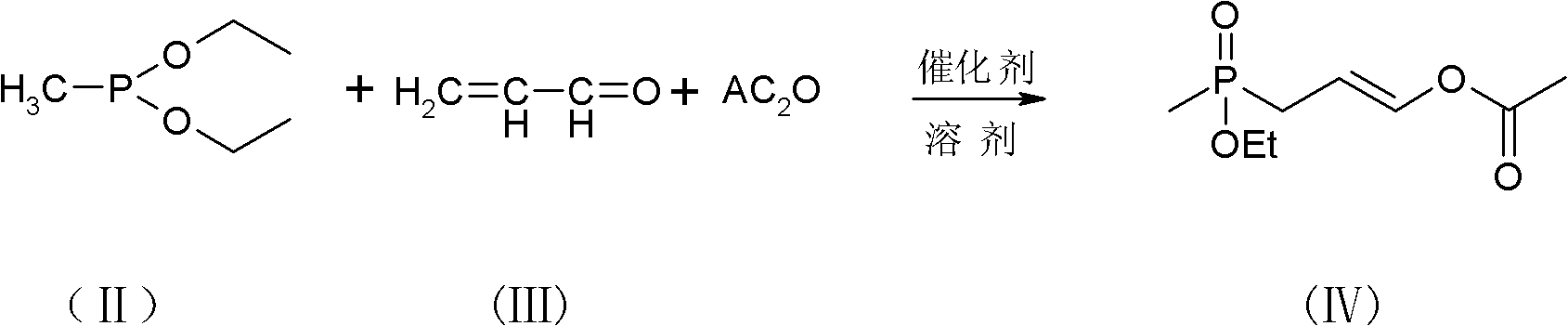

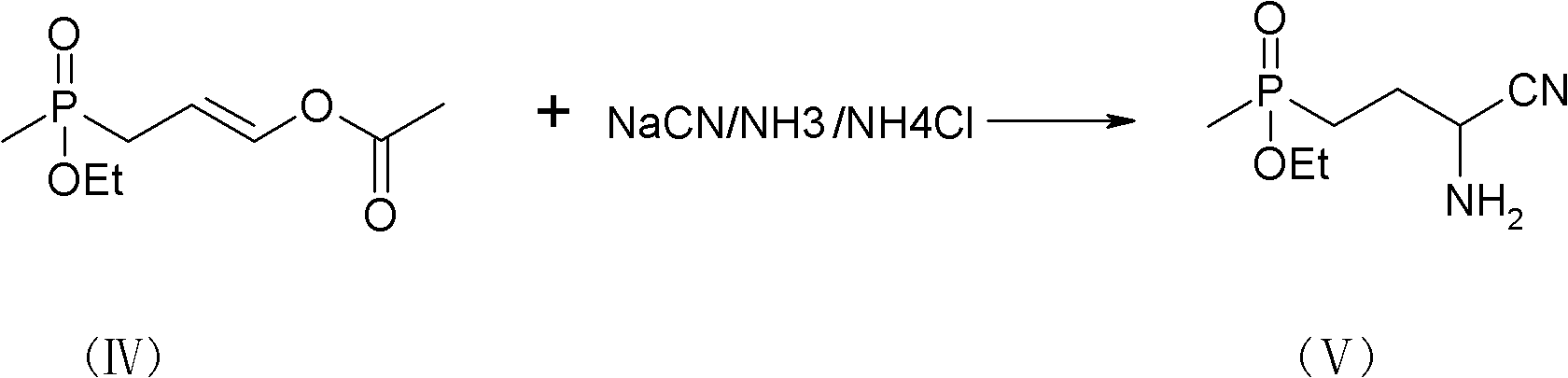

Glufosinate-ammonium preparation method

ActiveCN103183707AHigh selectivityHigh yieldGroup 5/15 element organic compoundsGlufosinate-ammoniumAcetic anhydride

The invention discloses a Glufosinate-ammonium and its derivative improved preparation method, the method comprises the following steps: diethyl methyl-phoshphonite, acraldehyde and acetic anhydride are subjected to an addition reaction, a reactant, sodium cyanide (editpotassium cyanide for replacing) and an ammonia water solution of ammonium chloride are subjected to an improved STRECKER reaction without separation, the product is subjected to hydrolysis and ammonification for forming salt to obtain Glufosinate-ammonium. The preparation method has the characteristics of high selectivity and high yield.

Owner:SINOCHEM LANTIAN +1

Method for integrated treatment of electroplating wasterwater

ActiveUS20200048125A1Efficient removalSolve problemsTreatment using aerobic processesGeneral water supply conservationCarboxyl radicalThio-

A method for integrated treatment of electroplating wastewater includes steps of: adjusting and maintaining pH of wastewater at 10.5-12; oxidizing pollutants such as sodium cyanide and hydroxyl-containing organic amine complexants with sodium hypochlorite; precipitating carboxyl-containing organic acid complexants with synergistic effect of ferrous and calcium ions; reducing hexavalent chromium to trivalent chromium and forming chromium hydroxide precipitate; removing precipitate by filtering; adjusting wastewater to pH of 4.5-5.5; precipitating heavy metal ions with sodium dimethyldithiocarbamate or sodium diethyldithiocarbamate; adsorbing precipitate and heavy metal capturing agents with activated carbon; filtering to remove precipitate; adjusting wastewater to pH of 6-8; and destroying aliphatic polyamine complexants and reducing COD using an available biological degradation technique. This method can effectively and economically remove the pollutants such as heavy metals in the electroplating wastewater for a good market prospective.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

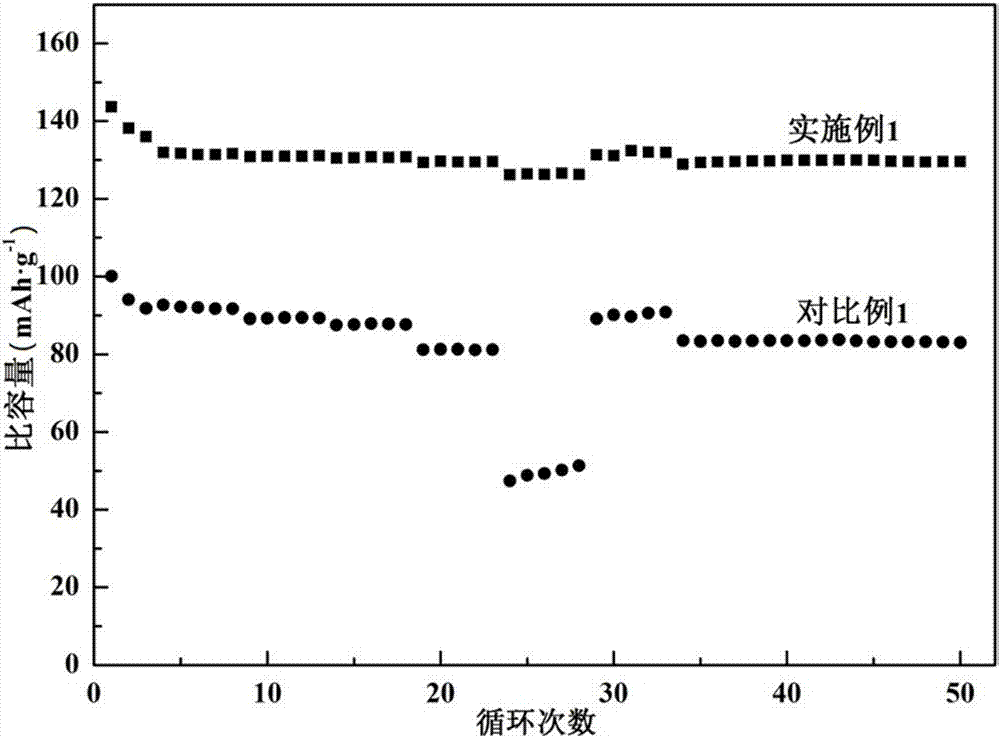

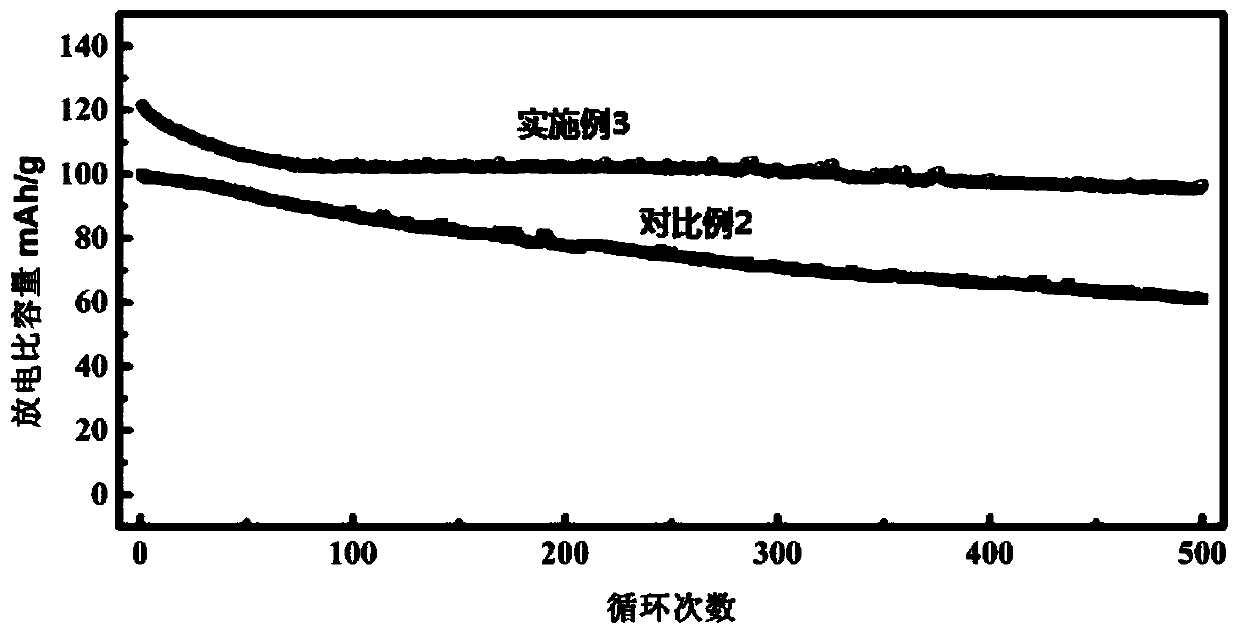

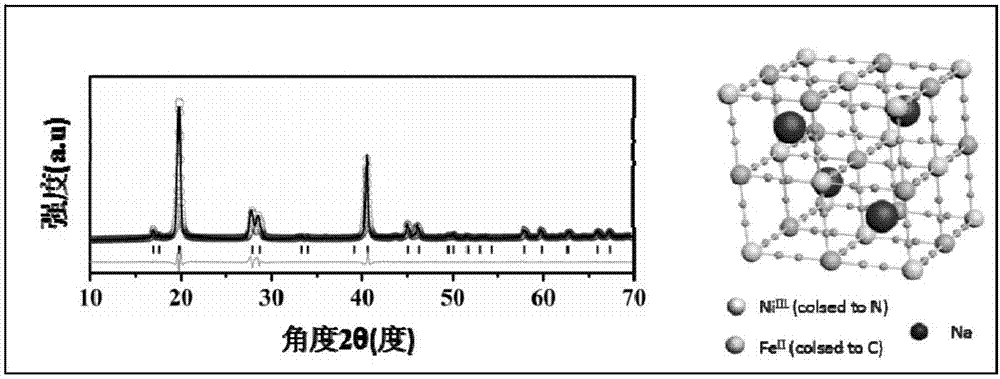

Prussian blue positive electrode material, sodium ion battery and preparation method and application thereof

ActiveCN111377462AControllable crystallization rateReduce crystal defectsIron cyanidesSecondary cellsSodium cyanideEthylenediaminetetraacetic acid

The invention discloses a prussian blue positive electrode material, a sodium ion battery, and a preparation method and application thereof. The molecular formula of the prussian blue positive electrode material is NaxM [Fe (CN) 6] y.nH2O, wherein M is transition metal, x is less than or equal to 2 and greater than or equal to 1.8; y is less than or equal to 1 and greater than or equal to 0.95; and n is less than or equal to 2 and greater than or equal to 0. The prussian blue positive electrode material has low lattice defect and stable performance; and the sodium ion battery prepared from thematerial is high in capacity and good in cycle performance. The preparation method comprises the following steps of: S1, adding an aqueous solution of weak acid into an aqueous solution of sodium ferrocyanide and transition metal ethylenediamine tetraacetic acid sodium salt to obtain a precipitate; and S2, drying the precipitate. The preparation method can be adopted to control the crystallization speed, and has advantages of simple process, low production cost, non-toxicity, harmlessness and short production period.

Owner:浙江钠创新能源有限公司

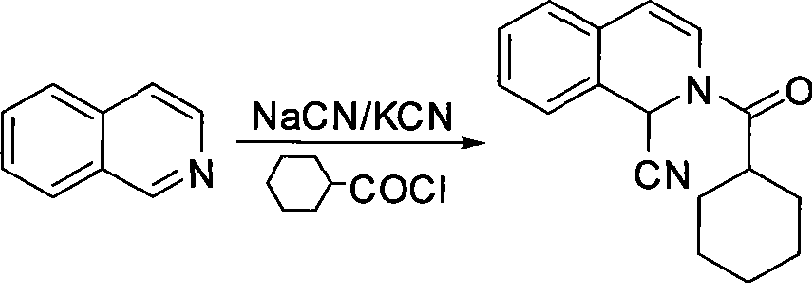

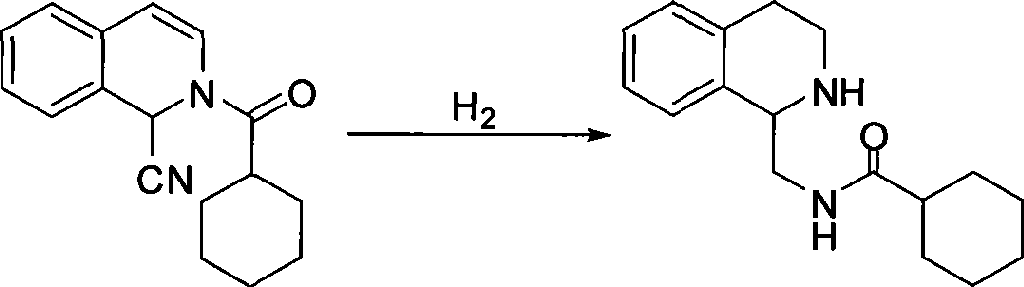

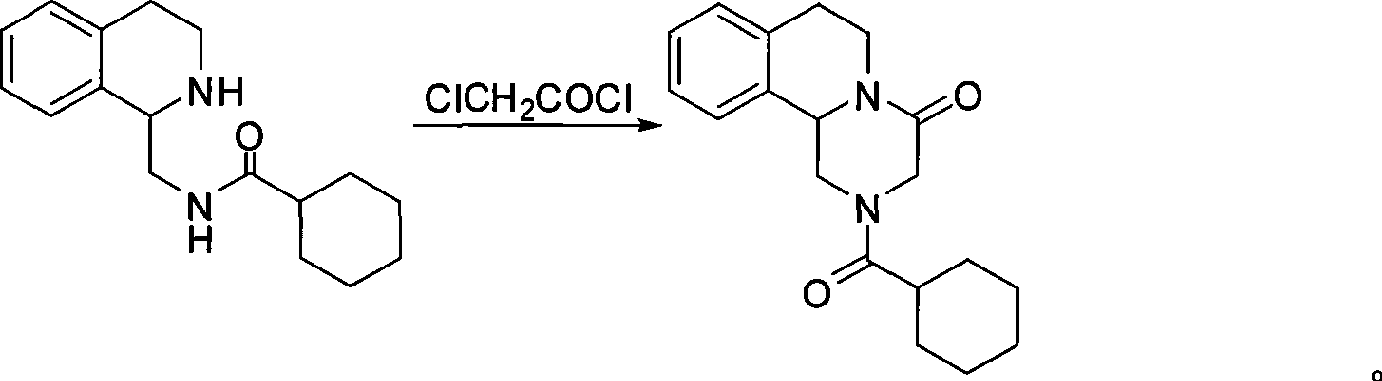

Method for preparing praziquantel

InactiveCN101445507AShort synthetic stepsMild reaction conditionsOrganic chemistryHigh pressureSodium cyanide

The invention relates to a method for preparing praziquantel, which is characterized by comprising the steps: (1) isoquinolin, sodium cyanide or potassuim cyanide and triethylamine or pyridine are added into a reactor to react, and yellow solid which is a first step product is obtained; (2) the first step product is added into a high-pressure hydrogenation kettle and filled with hydrogen to react under the action of catalyst, so that a second step product is obtained; (3) after being stirred and dissolved, the second step product and ethyl acetate is added with anhydrous potassium carbonate or anhydrous sodium carbonate, and then is stirred at the room temperature and dripped with chloracetyl chloride to be stirred at the room temperature to react, so that the solid obtained in the reaction is crude product of the praziquantel, and fine product is obtained by recrystallization of absolute methanol. Compared with the prior art, the method has the advantages of shortening the reaction process, reducing the energy consumption, improving the overall yield, etc.

Owner:SHANGHAI WANXIANG INDAL

Electroless copper plating solution and electroless copper plating method

InactiveUS20070071904A1Improve responseEfficient productionLiquid surface applicatorsSemiconductor/solid-state device manufacturingCopper platingThiourea

Owner:JX NIPPON MINING & METALS CO LTD

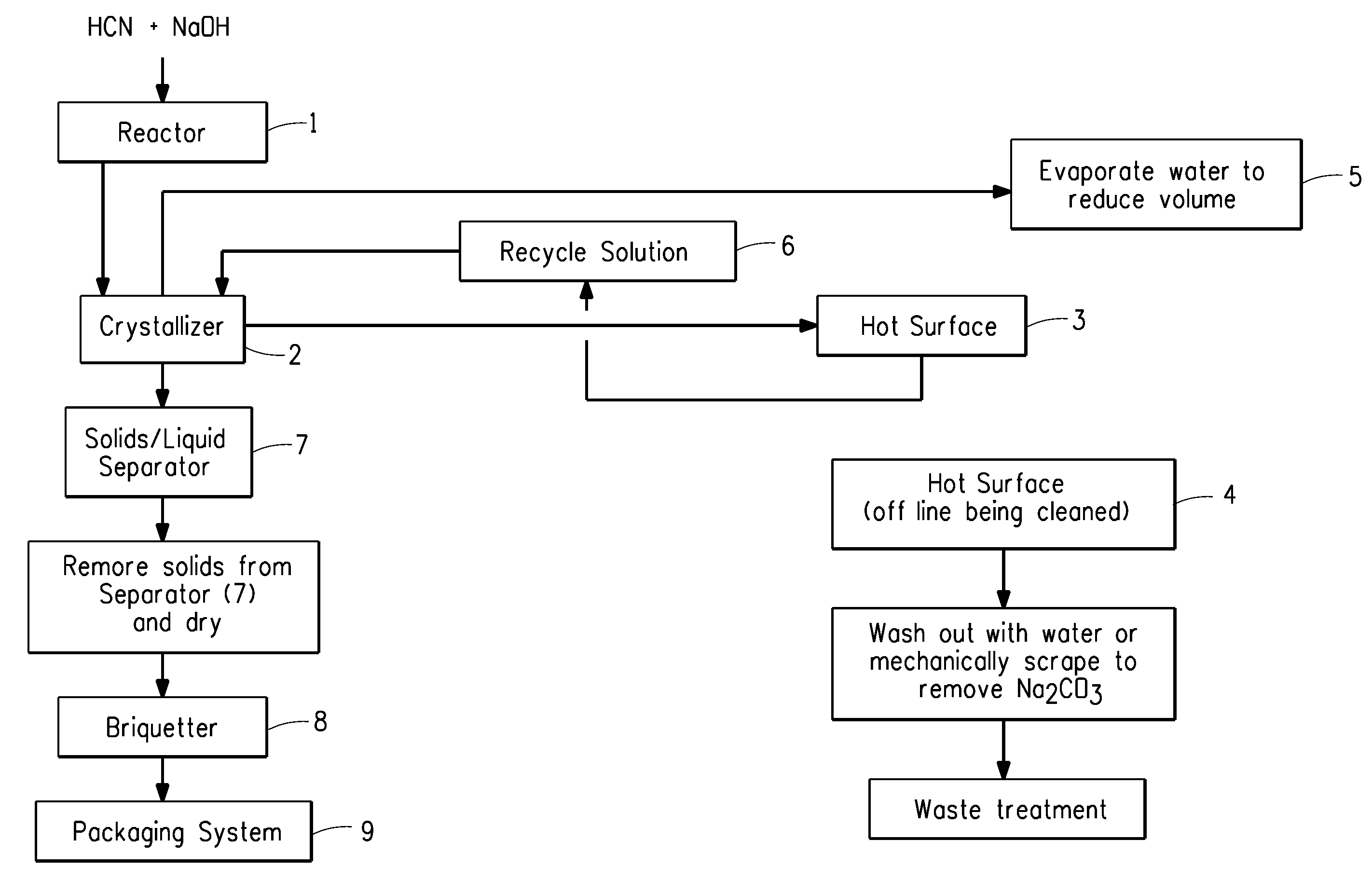

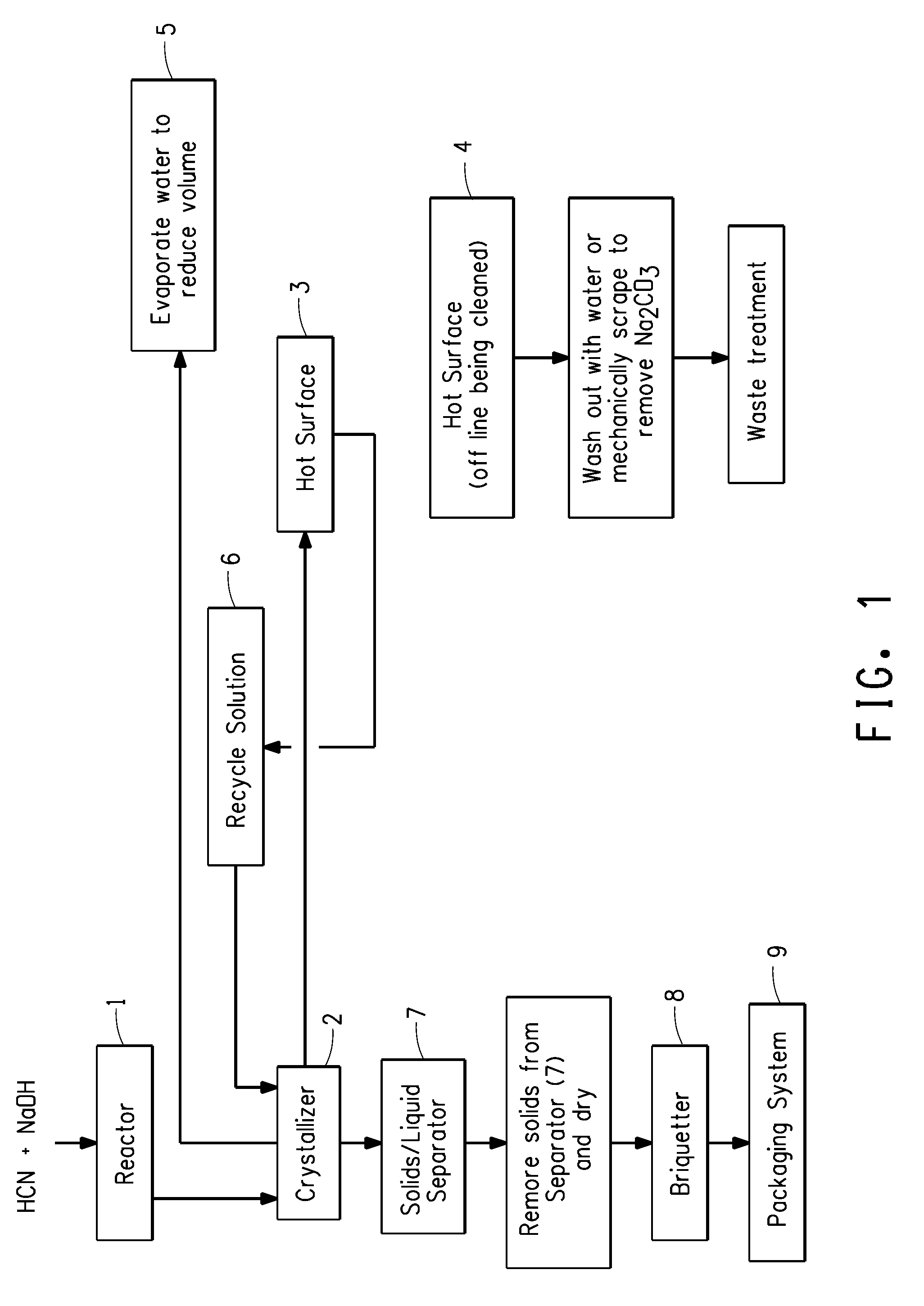

Sodium cyanide process

A process for the production of sodium cyanide crystals comprising;(a) contacting impure hydrogen cyanide and sodium hydroxide in a reactor with mixing for a maximum contact time of about 5 seconds;(b) feeding the resulting mixture to a continuous evaporative crystallizer to produce a slurry of sodium cyanide crystals;(c) passing the slurry of sodium cyanide crystals from the crystallizer over a hot surface to precipitate onto the surface and remove sodium carbonate, and passing said slurry back to the crystallizer; and(d) separating the sodium cyanide crystals from the slurry.

Owner:THE CHEMOURS CO FC LLC

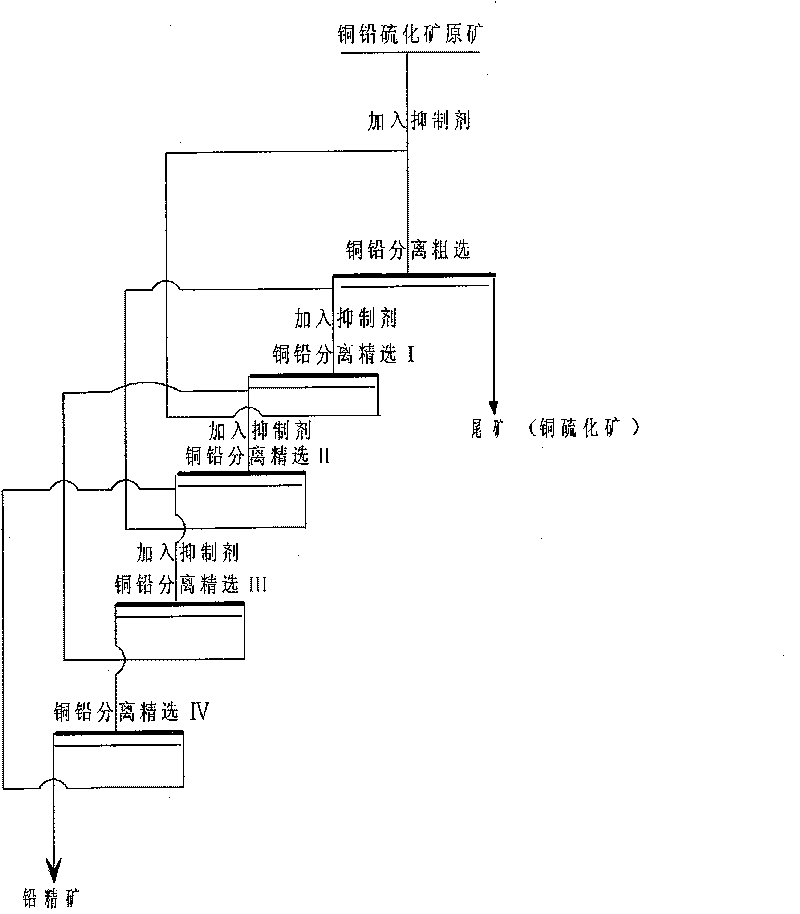

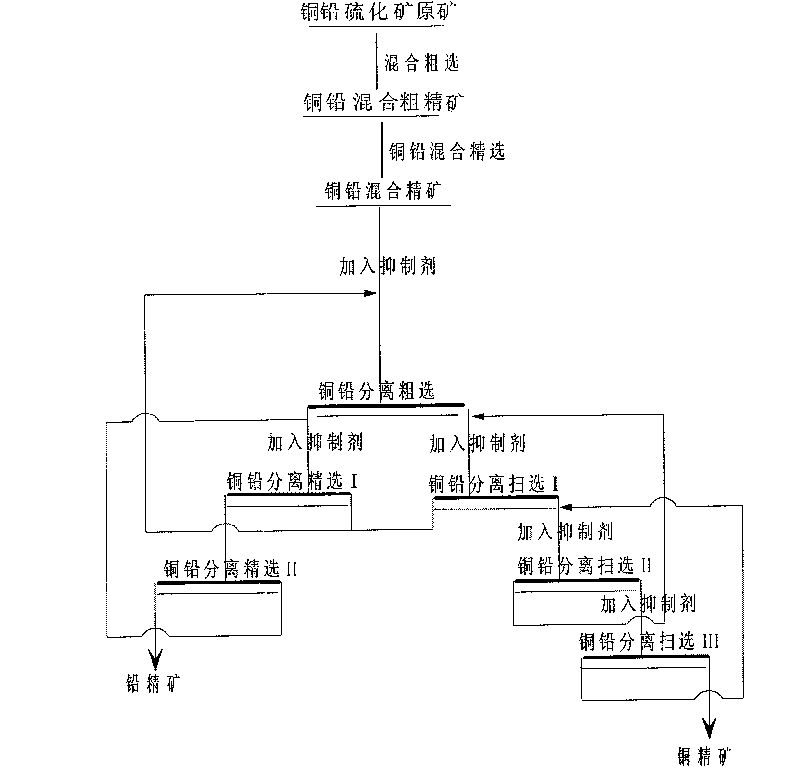

Method for separating copper-lead sulfurized minerals

The invention discloses a method for separating copper-lead sulfurized minerals, and belongs to the technical field of mineral dressing. The method takes raw ores of the copper-lead sulfurized minerals as a raw material, and comprises the following step: performing floatation separation on the raw ores of the copper-lead sulfurized minerals to obtain lead concentrate minerals or obtain the lead concentrate minerals and copper concentrate minerals, wherein water soluble thioglycolate or thioglycollic acid is added to serve as an inhibitor for the sulfur sulfurized minerals in the separated minerals. The water soluble thioglycolate or thioglycollic acid serving as the inhibitor for the copper sulfurized minerals has the advantages of good selectivity, strong inhibition capacity, low consumption, convenient addition and the like, so the water soluble thioglycolate or thioglycollic acid can well inhibit the sulfur sulfurized minerals to achieve better floatation effect; simultaneously, the method effectively overcomes the defects of rank poison, severe operating environment and heavy pollution of commonly used sodium (potassium) cyanide, and also has the characteristics of convenient addition, safe use and the like. The invention provides the method facilitating separating the copper-lead sulfurized minerals.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for preparing gold-nano array electrode

InactiveCN101225515AEnsure sensitizationQuality assurancePolycrystalline material growthFrom normal temperature solutionsChemical platingCombined method

The invention relates to a preparation method of gold nanometer array electrode, which the substrate is polycarbonate filter membrane, after the processes of the pretreatment of chemical plating to the polycarbonate filter membrane, chemical plating, chemical plating after acid leaching, such as cleaning and processing, the former treatment, post acid leaching and rinsing, and assisted by the ultrasonic wave process in the steps of pretreatment, acid leaching and rinsing, using degreasing cotton soaked with dilute sodium cyanide to softly wipe the surface of the filter membrane after chemical plating, then rinsing with methanol, using the combined method of mechanical effect and chemical effect to effectively remove a gold layer on the surface to form the gold nanometer array, then pasting the filter membrane to the collector, assembling into the gold nanometer array electrode. The diameter of a single gold nanometer disk in the array is 10 to 100 nanometers measured by scanning electronic microscope, the component of the array group is pure gold measured with energy dispersive X-ray spectrum. The electrode has the advantages of high mass transfer speed, low double-layer charge current, effectively improving signal-to-noise ratio and the detection limit. The preparation method of gold nanometer array electrode has the advantages of ingenious design, simple operation and good reproduction.

Owner:HARBIN INST OF TECH AT WEIHAI

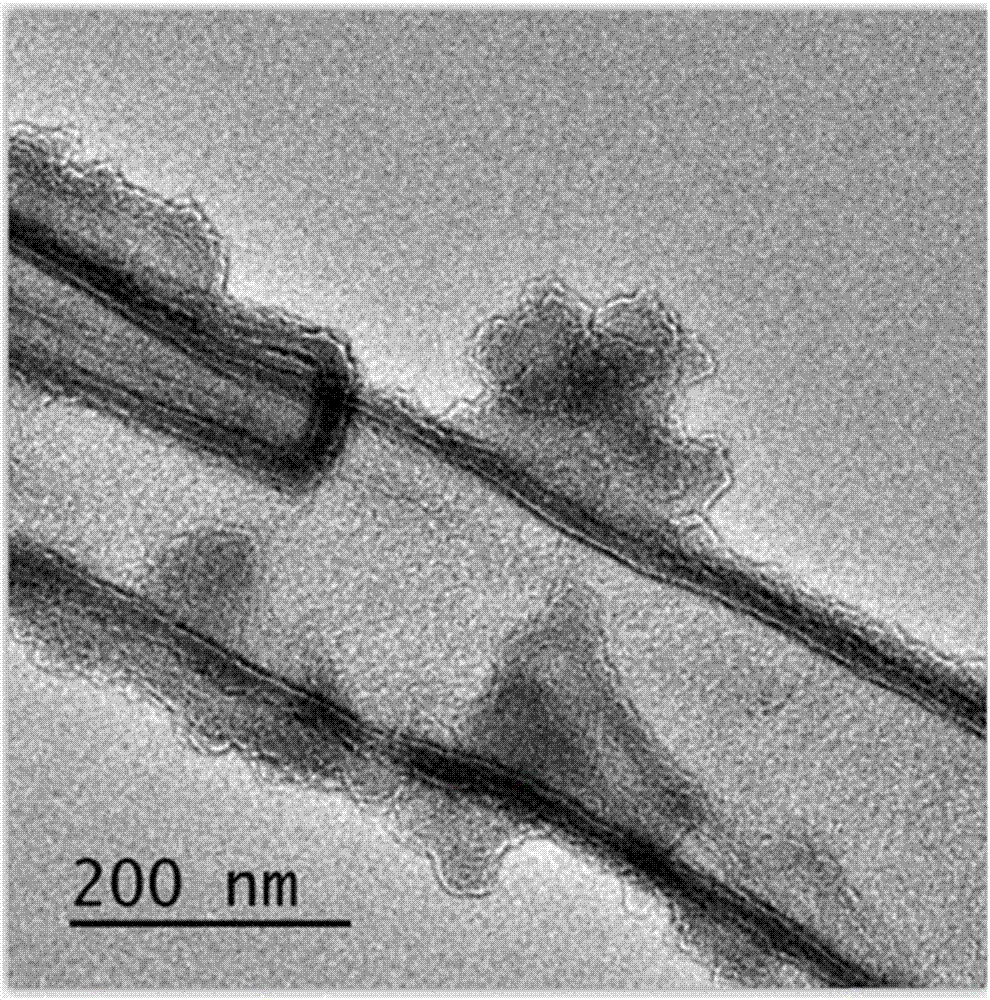

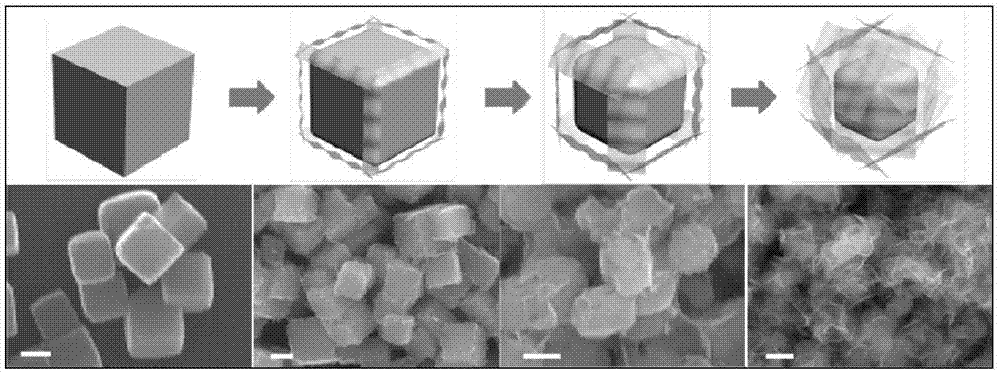

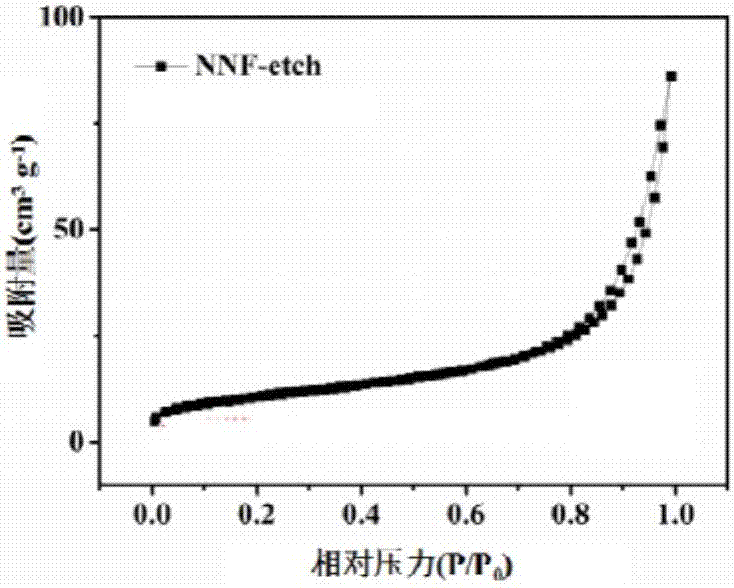

Prussian blue flower-like nano-structure material as well as preparation and application thereof

ActiveCN107082438AAlleviate volume effectImproved magnification performanceIron cyanidesSecondary cellsNano structuringSodium-ion battery

The invention relates to a preparation method of a Prussian blue flower-like nano-structure electrode material. The preparation method comprises the following steps: 1) firstly, dissolving nickel chloride hexahydrate and anhydrous sodium citrate into de-ionized water; 2) dissolving sodium ferrocyanide decahydrate into de-ionized water; 3) pouring a solution of step 2) into a mixed solution obtained by step 1) and uniformly stirring to obtain a mixed solution; 4) standing the mixed solution obtained by step 3); 5) centrifuging and collecting sediment; washing the sediment for several times; drying in vacuum to obtain Prussian blue precursor powder; 6) adding the precursor powder into a sodium hydroxide solution and carrying out ultrasonic treatment; 7) centrifuging and collecting a product and washing; drying in vacuum to obtain light green powder, namely the Prussian blue flower-like nano-structure electrode material. The preparation method provided by the invention has the beneficial effects that the specific surface area is remarkably enlarged so that reaction sites of electrolyte and the electrode material are effectively increased and an ion diffusion distance is reduced; when the Prussian blue flower-like nano-structure electrode material is used as a positive electrode active material of a sodium ion battery, the material has the characteristics of high power and good cycling stability.

Owner:WUHAN UNIV OF TECH

Method for extracting gold and silver

The invention relates to a method for extracting gold and silver, comprising the following steps of: mixing pulp by using barren solution after flotation concentrate, adding sodium cyanide and lime, grinding ores in a ball grinding mill, grading the ores discharged by the ball grinding mill by using a swirler, and returning the ball grinding machine for regrinding the graded ores and settled sand; washing and concentrating the graded overflow by using a thickener, leaching a bottom flow, continuously adding the sodium cyanide and the lime for leaching, and washing cyanogen slag to be sold as sulfur concentrate; forming a precious solution by using overflow water of the thickener, purifying the precious solution, deoxidizing the precious solution, replacing gold and silver by zinc powder to form the barren solution, and making the barren solution return as flotation concentrate pulp-mixing water and washing water. The method for extracting gold and silver is characterized in that in an ore-grinding process, oxygen is introduced to the ball grinding mill, the concentration of the oxygen in the ball grinding mill is improved with the enlargement (destroy of a coated film) of the ore grain grinding degree and the explosion of gold and silver grains, the concentration ratio of a cyanogen radical to the oxygen approaches to the optimum value in a milling-strengthening process, the concentration of the oxygen during grinding and leaching is kept above 5 mg / L, the [CN] is kept at 2,500-3,500 mg / L, and the concentration ratio of the [CN] to the [O] is 500-700. The method realizes oxygen enrichment cyaniding, leaching and ore grinding by filling pure oxygen in the ball grinding mill and improves the leaching rate of gold and silver ore grinding, thereby improving the gold and silver cyaniding recovery rate, reducing the grade of cyanogen slag and obtaining a better economic technical index.

Owner:山东金洲矿业集团有限公司

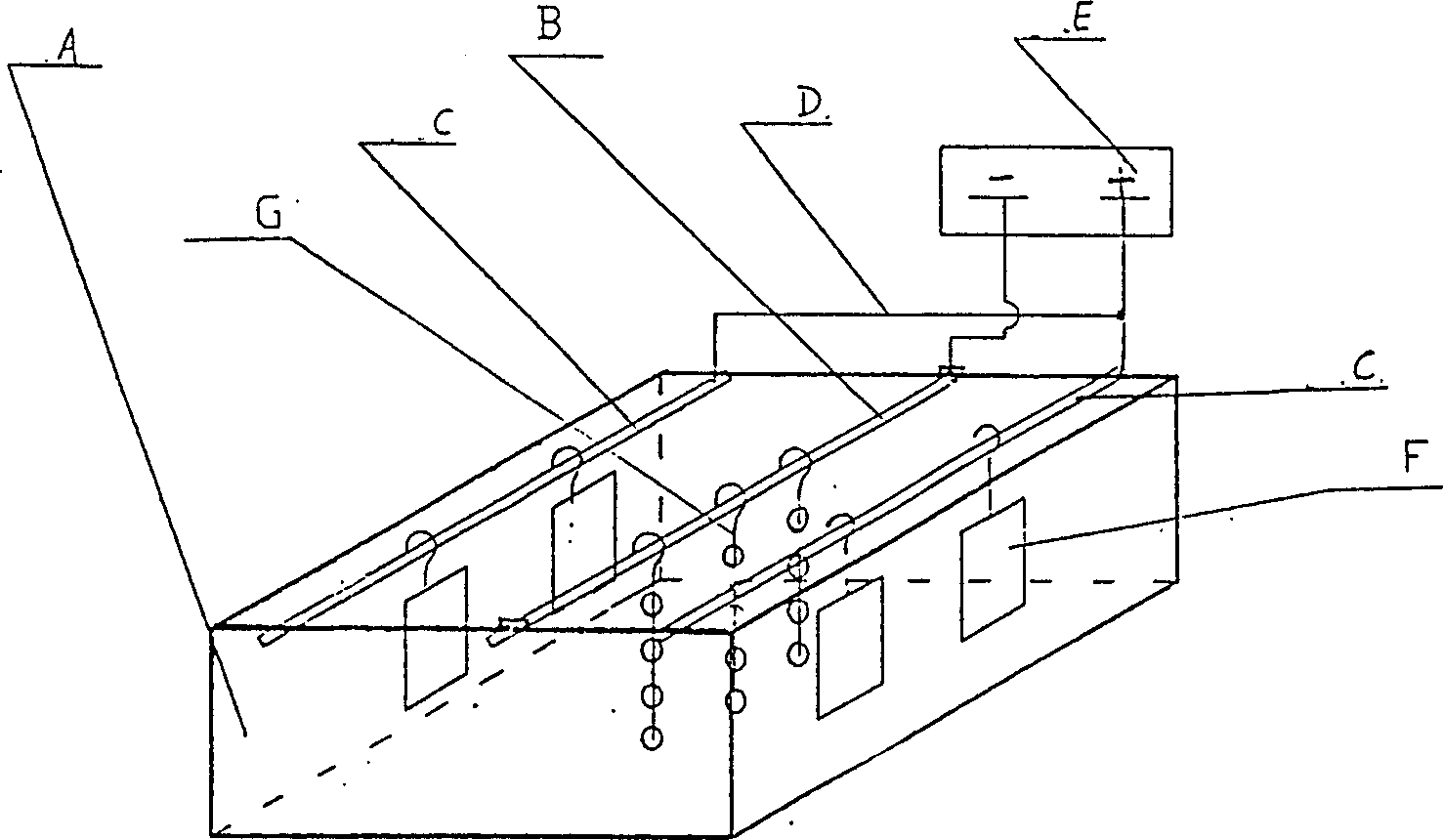

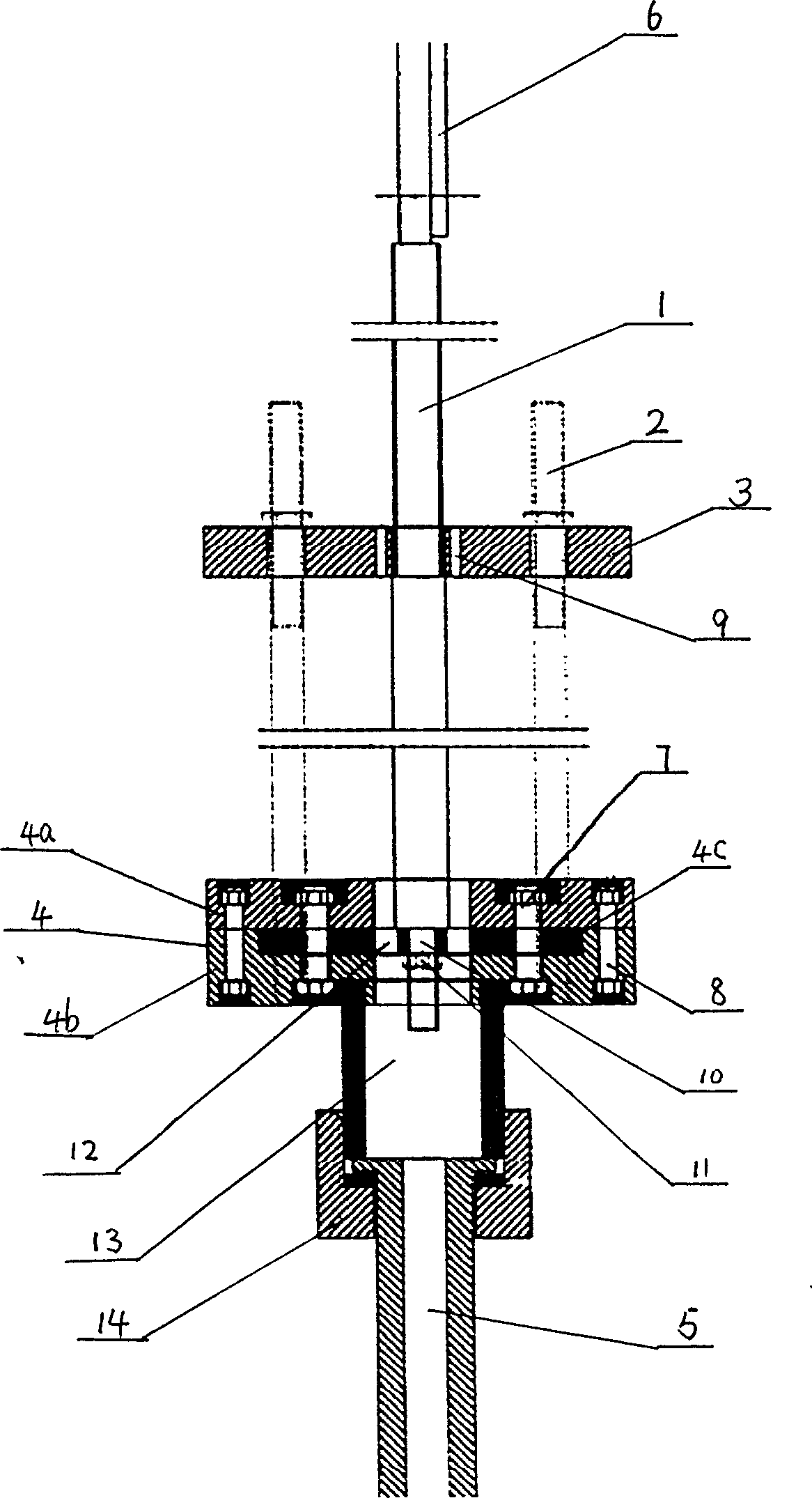

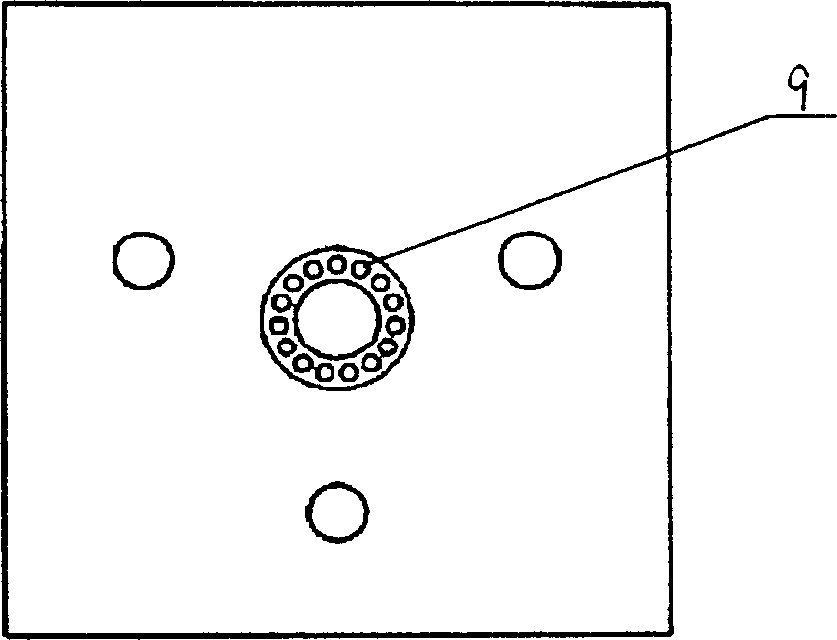

Technique method for electroplating inner surfaces of gear wheel holes and dedicated equipments

A technology and special apparatus for electroplating the inner surface of gear hole is disclosed. The said technology features use of bipolar electroplating method. Its electroplating liquid contains cuprous cyanide, sodium stannate, sodium cyanide and sodium hydroxide. A central anode rod of said special apparatus passes through several gears to hange them in the electroplating liquid for electroplating them after DC is applied across anode and cathode. Its advantages are uniform plated layer and high productivity.

Owner:SHANGHAI UNIV

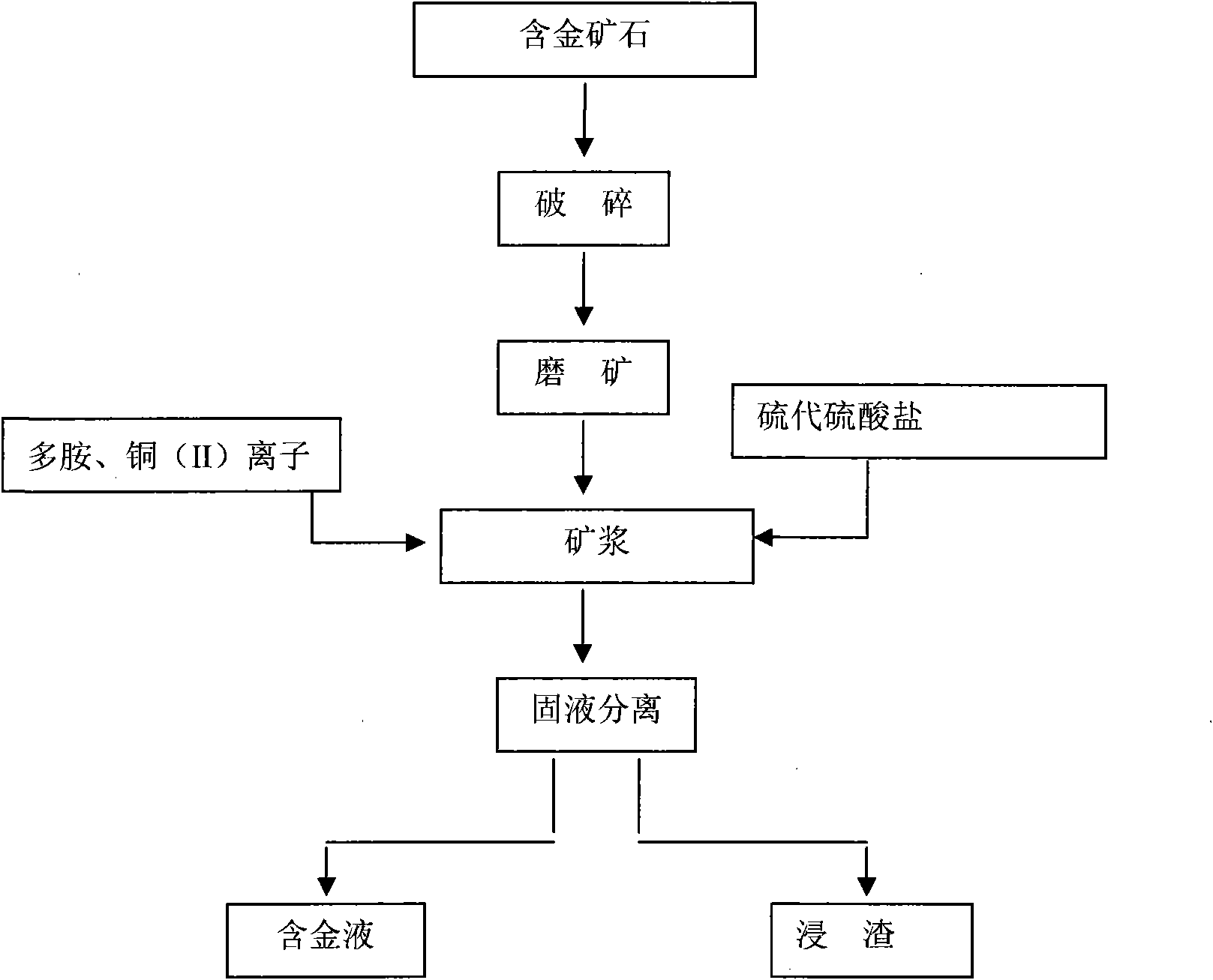

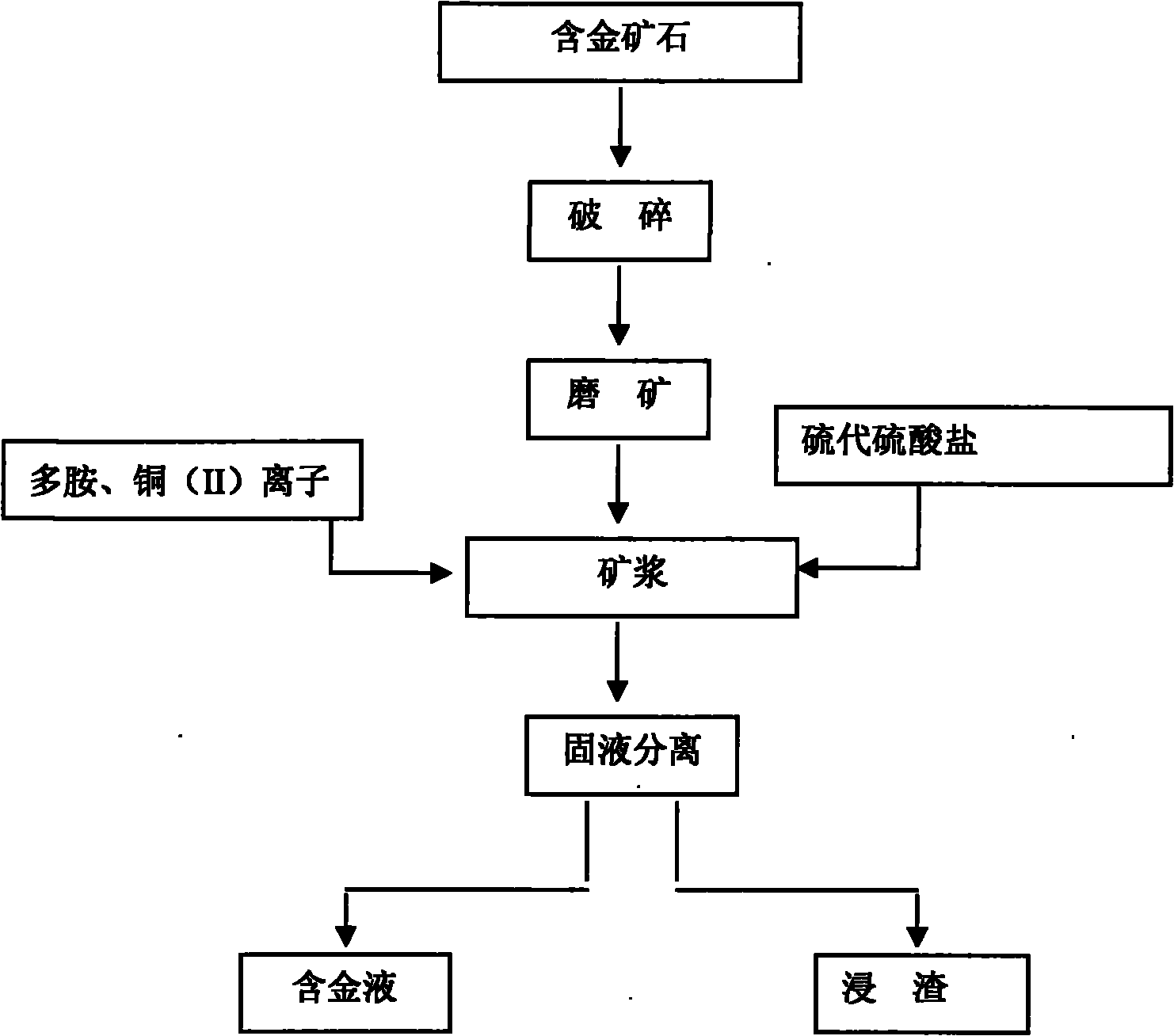

Gold extracting method by thiosulfate using polyamine compoud as additive

InactiveCN101775490AReduce consumptionLittle effect of leachingProcess efficiency improvementToxic materialSodium cyanide

The invention relates to a gold extracting method by thiosulfate using a polyamine compound as an additive, which comprises the steps: after ores are crushed and wet-ground until the fineness is over 90 percent of -200 meshes, 0.03-3mol / dm3 thiosulfate is added to be used as a leaching agent, and then 0.0015-0.09mol / dm3 polyamine compound and 0.0015-0.03mol / dm3 copper (II) ion are added to form a complex ion to be used as an additive to be stirred and leached; and after gold ores are leached, gold from a leaching solution is recovered. The leaching solution is used to extract gold from the ores, so that the gold leaching rate is high, the process operation is simple, the control is easy, the consumption of thiosulfate is extremely low, and the compositions of the gold leaching solution are simple and are favorable for the recovery of the gold; and the application range is wide, the leaching effect is good when the pH value is between 10 and 12, the leaching speed is quick for copper-containing, carbon-containing and other refractory gold ores, quite high gold leaching rate can be maintained, and sodium cyanide and other toxic substances are not used and toxic waste is not discharged in the whole gold extraction process, so the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH

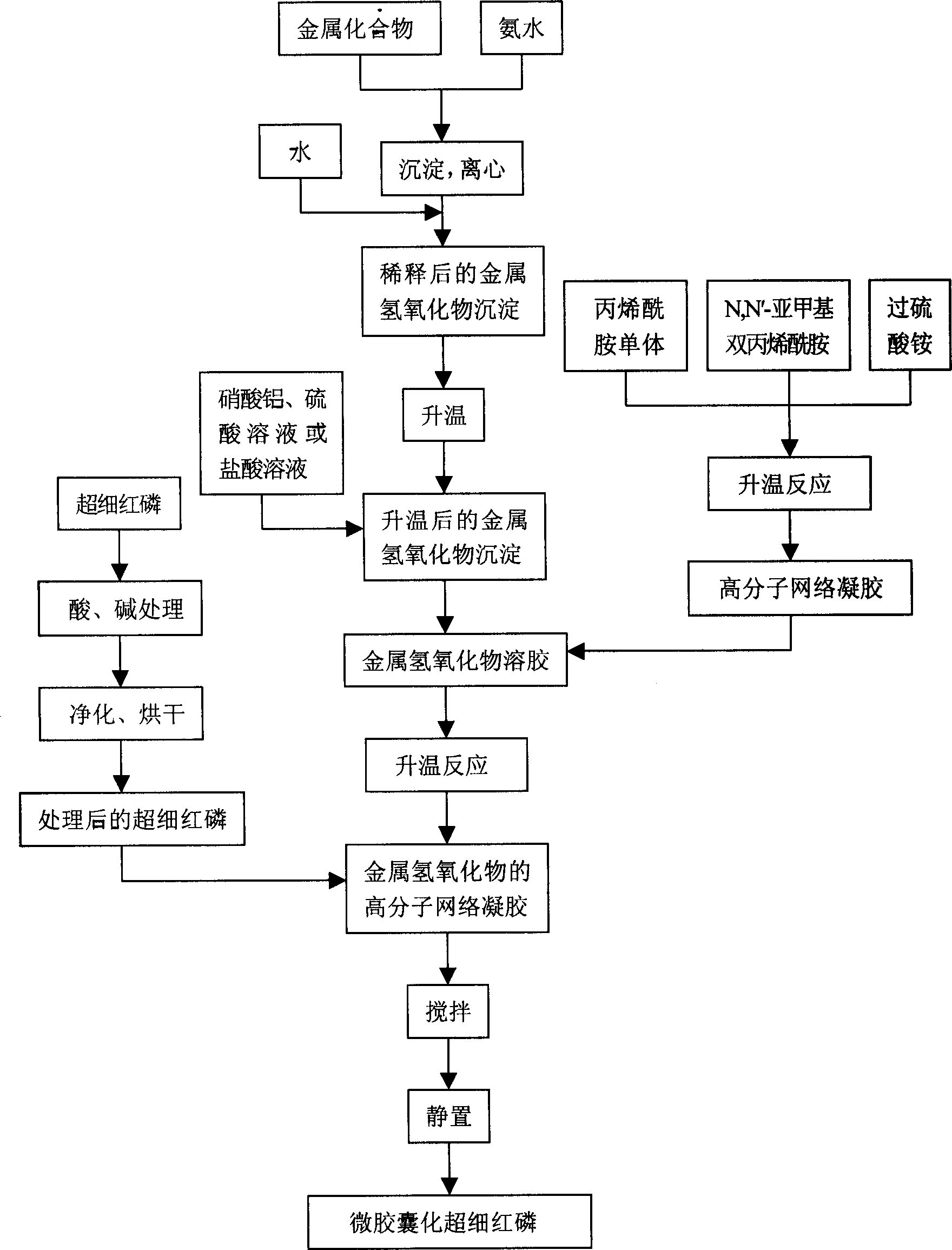

Method for preparing microcapsulated superfine red phosphorus

InactiveCN1775664ASlow water absorptionReduce productionPhosphorus compoundsMolecular networkSodium cyanide

The invention discloses a method for preparing micro-capsulized superfine red phosphorus, boiling the superfine red phosphorus with vitriol, sodium cyanide solution and sodium hydroxide solution, separately, filtering, eliminating impurities, and drying, and storing by sealing; blending and dissolve metal compound, depositing with ammonia, centrifuging and adding water to dilute, raising temperature, dropping in aluminum nitrate, vitriol or HCl and making metal hydroxide sol; mixing propylene acylamide monomers and N, Ní»-methylene dipropylene acylamide with ammonium persulphate, raising temperature and reacting to form high molecular network gel; adding the high molecular network gel into the metal hydroxide sol, raising the temperature and reacting to form high molecular network gel of metal hydroxide, mixing the high molecular network gel of metal hydroxide with the processed superfine red phosphorus, blending and placing still so that the sol takes the red phosphorus as the center to make surface absorption to form gel and coating a layer of colloid membrane on the red phosphorus surface, so as to obtain the micro-capsulized superfine red phosphorus. The advantages of the invention: it improves the stability, invariability and surface activity of the red phosphorus, improving processing property.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com