Method for separating copper-lead sulfurized minerals

A separation method and mineral technology, applied in the direction of solid separation, flotation, etc., can solve the problems of strong harm to the human body, easy to cause death, inconvenient use, etc., achieve the effects of less environmental pollution, improve the working environment, and add convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

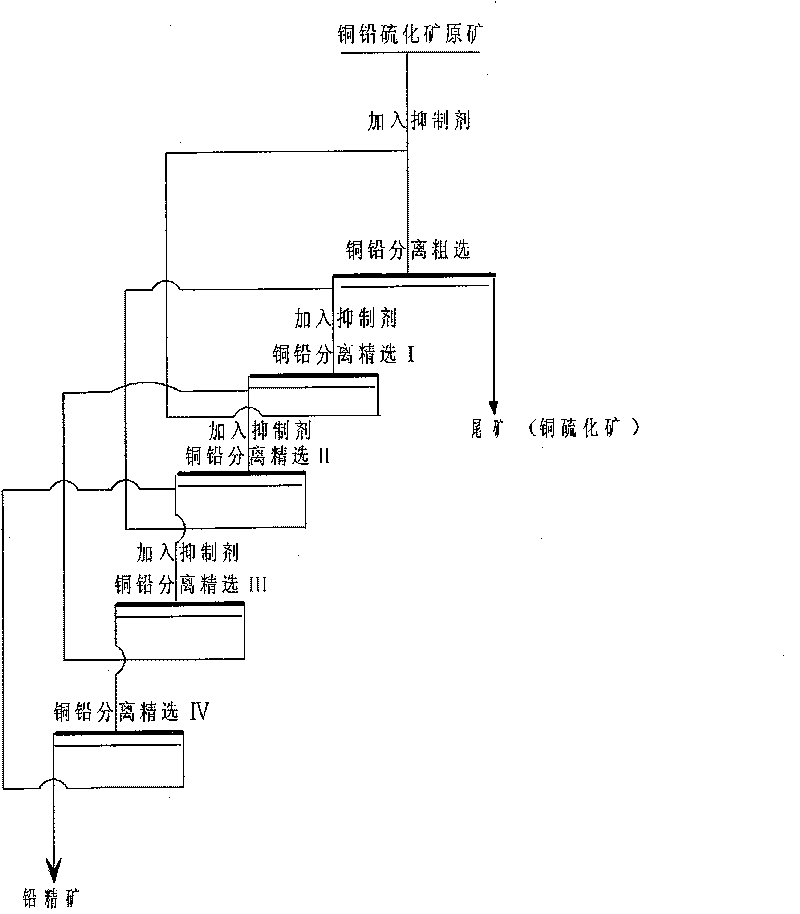

[0017] This embodiment 1 provides a method for separating copper-lead sulfide minerals, which uses the raw ore of copper-lead sulfide minerals as raw material, and performs preferential flotation separation on the raw ore of copper-lead sulfide minerals to obtain lead concentrate minerals. The method includes :

[0018] Using the raw ore of copper-lead sulfide minerals as raw material, the raw ore of copper-lead sulfide minerals is separated and roughed to obtain lead coarse concentrate minerals; during the process of separating and roughing the raw ore of copper-lead sulfide minerals, water-soluble thioglycolate or mercapto Acetic acid as an inhibitor of copper sulfide minerals in the separated ore;

[0019] Afterwards, the obtained lead coarse concentrate minerals are refined and separated to obtain lead concentrate minerals. In the process of refining lead concentrate minerals, water-soluble thioglycolate or thioglycolic acid is also added as Inhibitors of copper sulfide m...

Embodiment 2

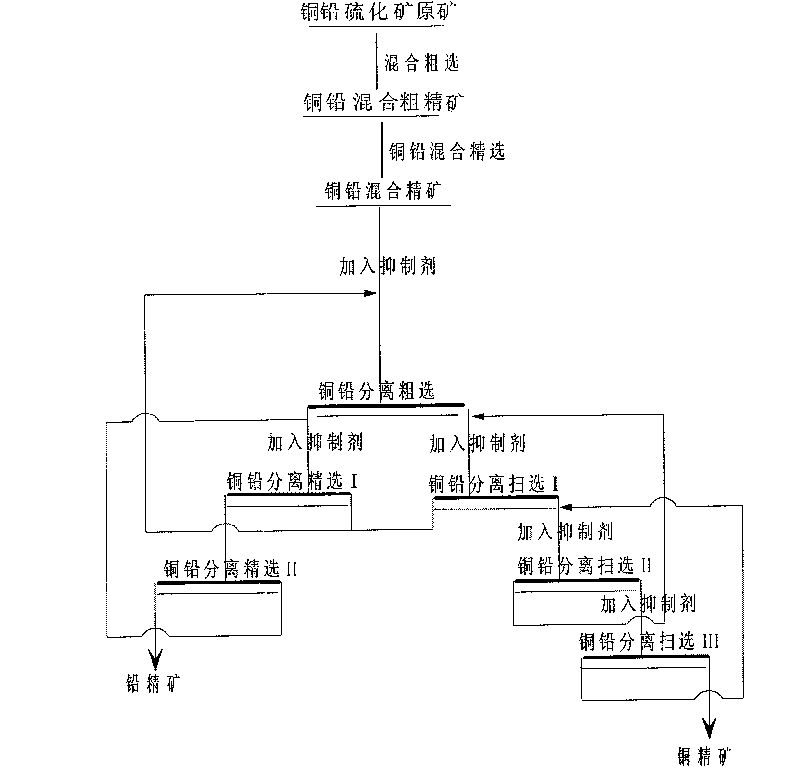

[0028] This embodiment 2 provides a method for separating copper-lead sulfide minerals, which uses the raw ore of copper-lead sulfide minerals as raw material, and performs preferential flotation separation on the raw ore of copper-lead sulfide minerals to obtain lead concentrate minerals. The separation method that embodiment 1 provides is basically the same, and the difference is that in the flotation separation process to minerals, potassium thioglycolate is used as the inhibitor to copper sulfide minerals in the separated minerals, and the specific steps are as follows:

[0029] The raw ore grade of copper-lead ore is Cu 0.61%, Pb 11.23%. The raw ore is added to the flotation tank for copper-lead separation and roughing operation. During the separation and roughing process, potassium thioglycolate is added as the copper sulfide mineral in the separated minerals. Inhibitor, the amount of inhibitor added is 1000g / t, that is, 1000g inhibitor is added for each ton of separated ...

Embodiment 3

[0033] This embodiment 3 provides a method for separating copper-lead sulfide minerals, which uses the raw ore of copper-lead sulfide minerals as raw material, and performs preferential flotation separation on the raw ore of copper-lead sulfide minerals to obtain lead concentrate minerals. The separation method that embodiment 1 provides is basically the same, and the difference is that in the flotation separation process to minerals, ammonium thioglycolate is used as the inhibitor to copper sulfide minerals in the separated minerals, and the specific steps are as follows:

[0034]The copper-lead ore raw ore grade is Cu 0.55%, Pb 4.98%. The raw ore is added to the flotation tank for copper-lead separation and roughing operation. During the separation and roughing process, ammonium thioglycolate is added as the copper sulfide mineral in the separated minerals. Inhibitor, the amount of inhibitor added is 260g / t, that is, 260g of inhibitor is added for each ton of separated minera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com