Patents

Literature

486results about How to "Improve flotation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS6896815B2Small sizeChemical cost reductionSolid sorbent liquid separationGold compoundsWater useSludge

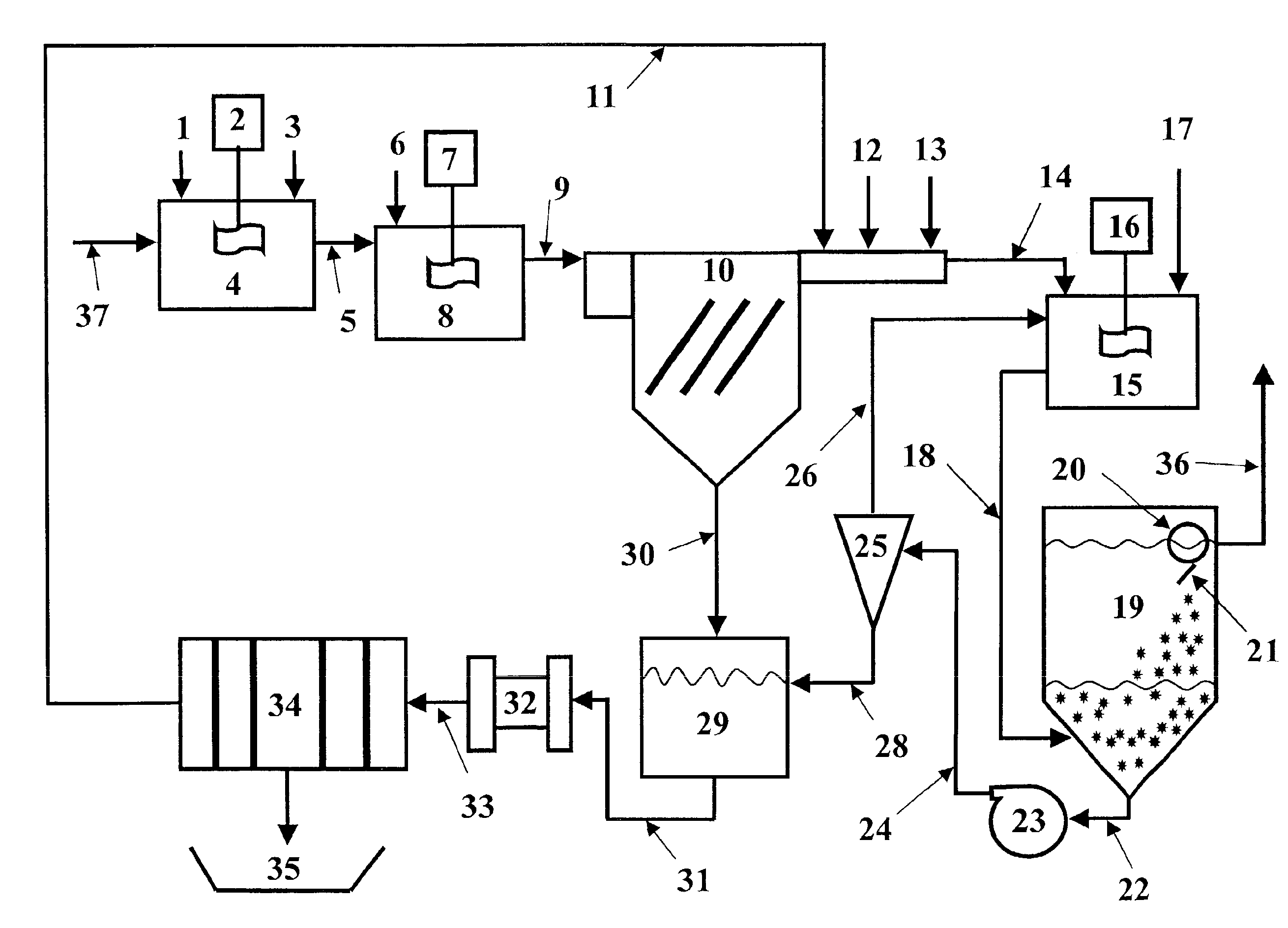

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation” technology such as magnetic separation, dissolved air flotation, vortex separation or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment.

Owner:CORT STEVEN L

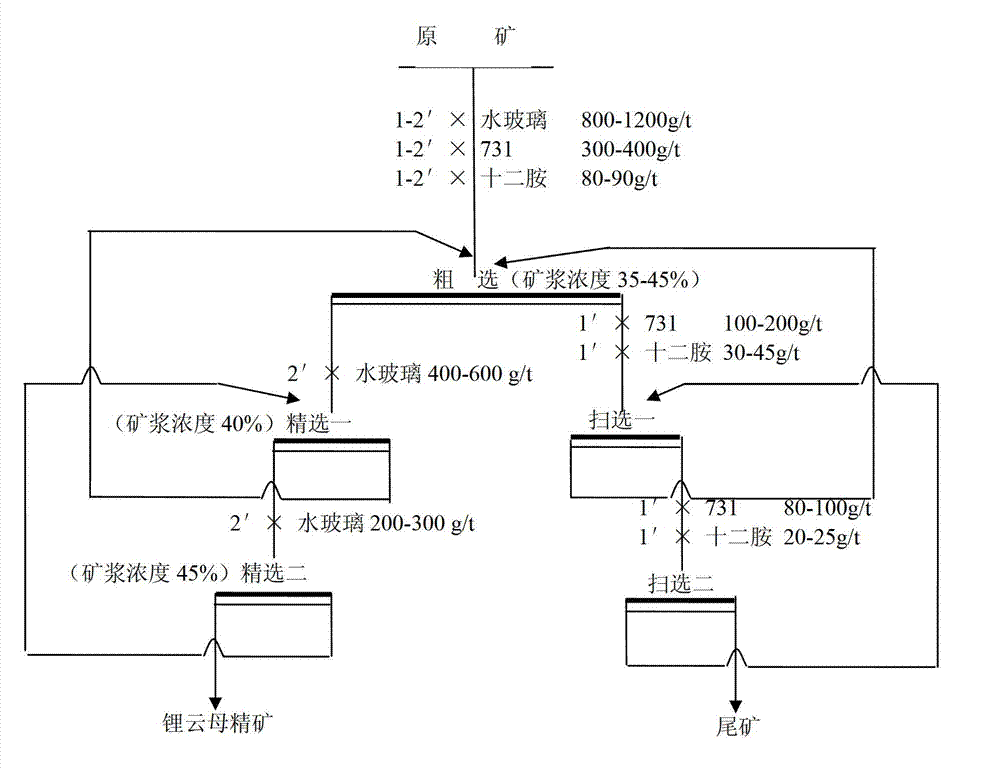

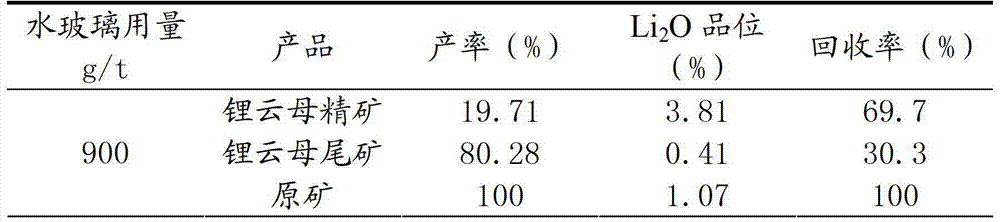

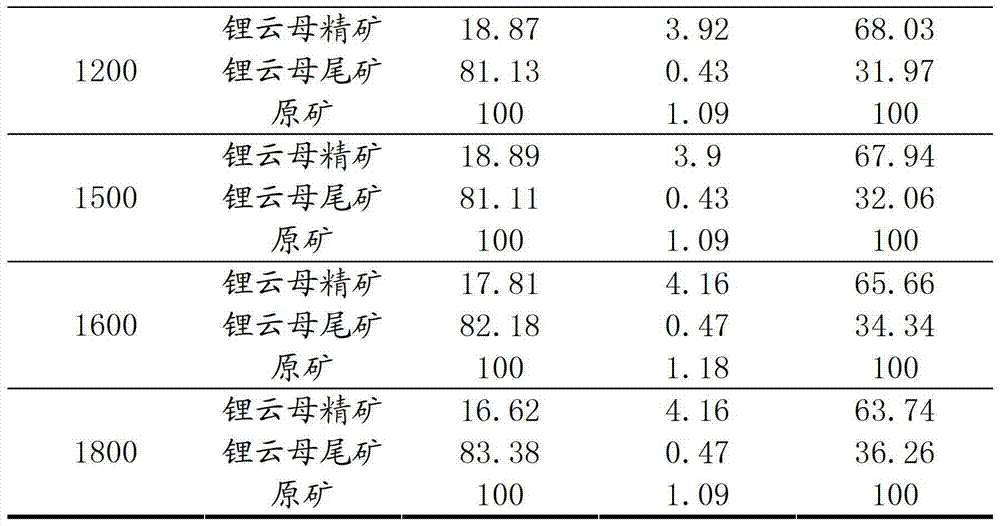

Novel lepidolite flotation method

InactiveCN103240185AEfficient separationLarge adsorption capacityFlotationCoconut oilCharge compensation

The invention discloses a novel lepidolite flotation method including primary rough selection, secondary fine selection and secondary scavenging. During the flotation, sodium silicate is added as an inhibitor with the amount ranging from 1400g / t to 1900g / t; an anionic collector is sodium oleate or oxyparaffin soap 731 with the amount ranging from 480g / t to 700g / t; and a cationic collector is dodecylamine or coconut oil amine with the amount ranging from 130g / t to 160g / t. The adding sequence of collectors is the anionic collector first and the cationic collector second, or the anionic collector and the cationic collector are added together. By the method, the lepidolite is selected through the combination of the anionic and the cationic, good flotation effect can be realized, flotation efficiency is high, and meanwhile, the synergistic effect is generated between the anionic collector and the cationic collector, and results from joint action of three mechanisms of coadsorption, charge compensation and function complementation.

Owner:JIANGXI UNIV OF SCI & TECH

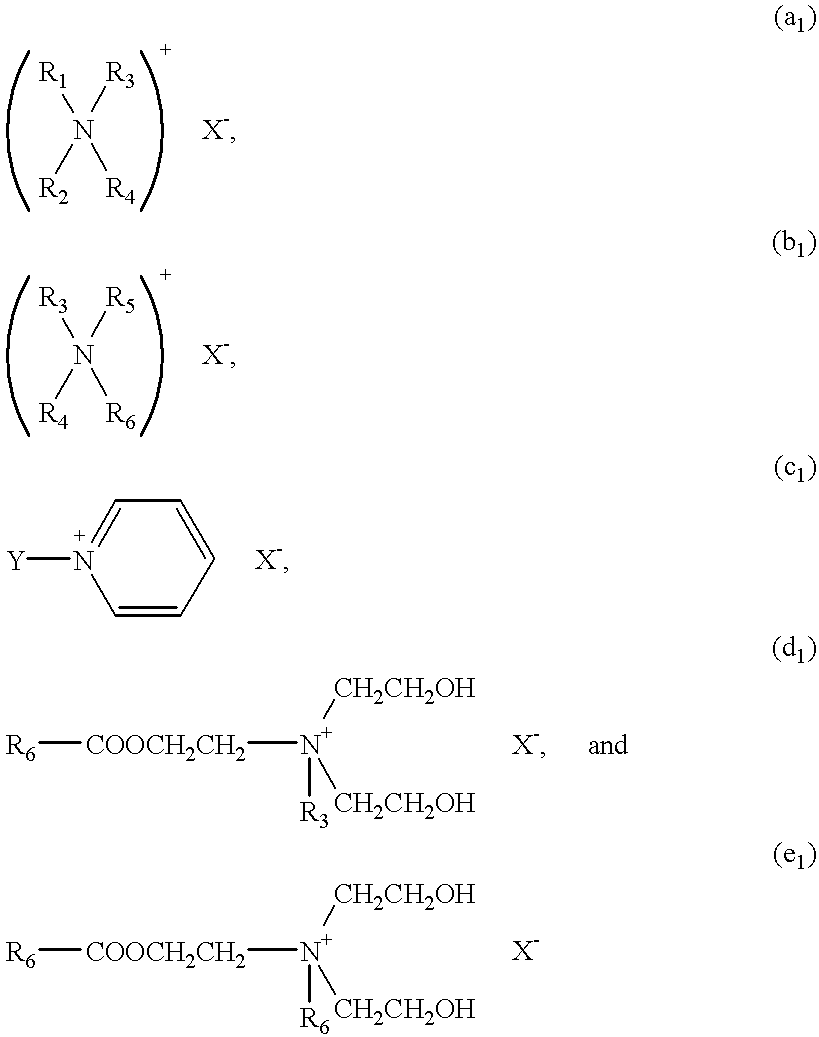

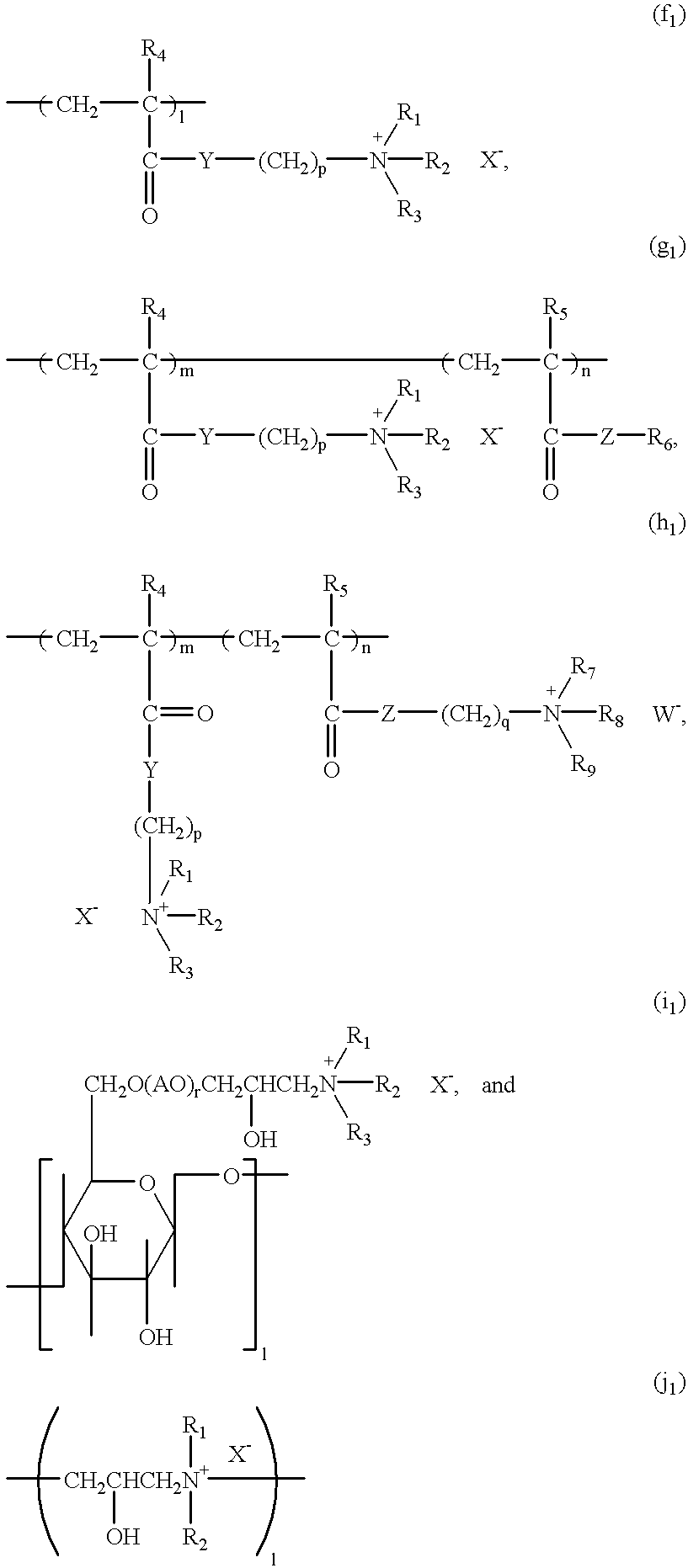

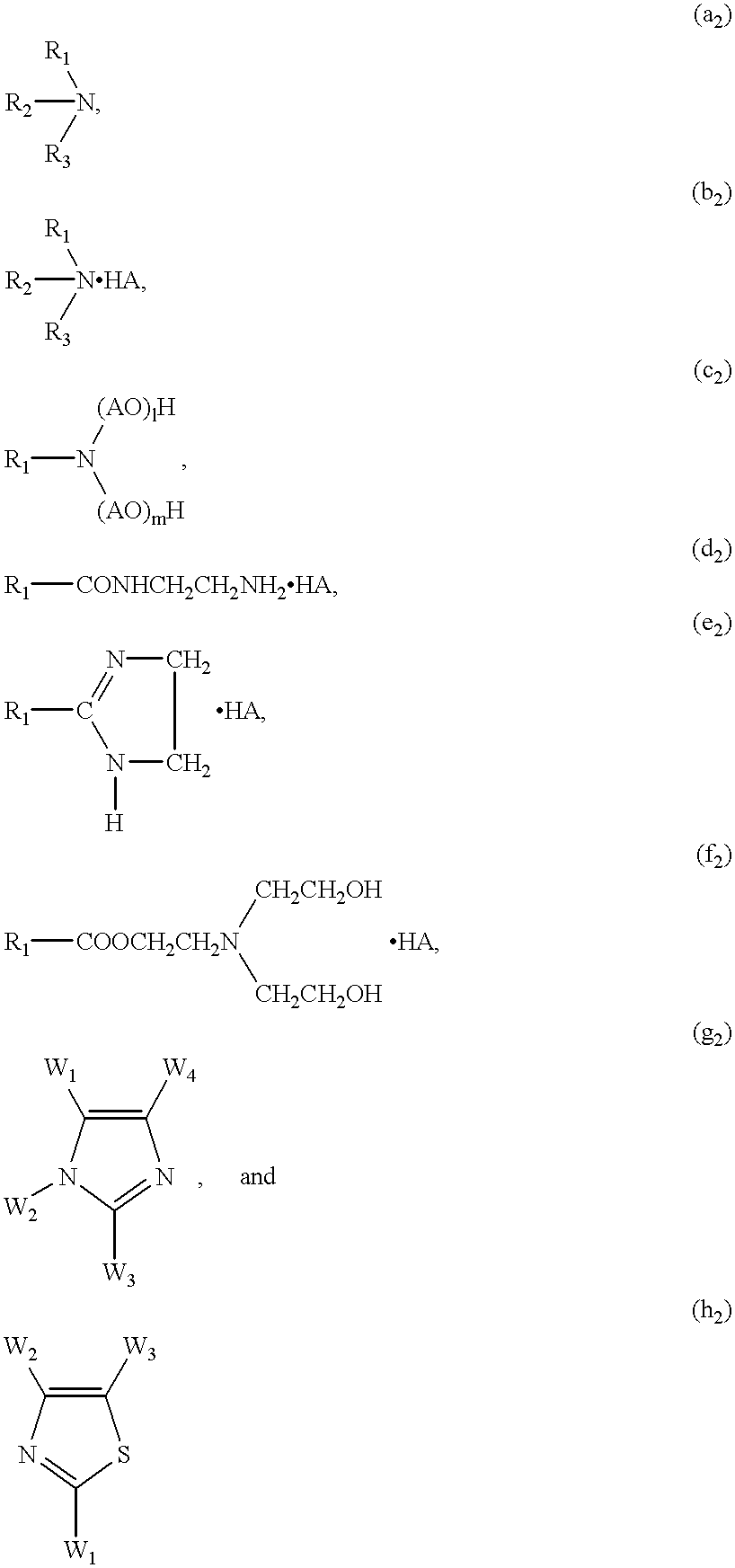

Wastepaper deinking method using amine or acid salt of amine in the flotation stage

InactiveUS6251220B1High whitenessLess residual ink spotPaper recyclingWaste paper working-upFatty acidAdduct

A deinking method comprising the steps of liberating ink from waste paper as a raw material and removing the liberated ink from a flotation system, wherein a nonionic surfactant, e.g., a reaction product obtained by adding an alkylene oxide to a mixture of an oil & fat and an alcohol, an alkylene oxide adduct of a fatty acid, or an alkylene oxide adduct of a higher alcohol, is used for the liberation of ink, and the flotation step is effected in the presence of a cationic compound, an amine, an acid salt of an amine or an amphoteric compound at a pH of from 4 to 9, provides a high quality deinked pulp having a high whiteness and a little residual ink spots.

Owner:KAO CORP

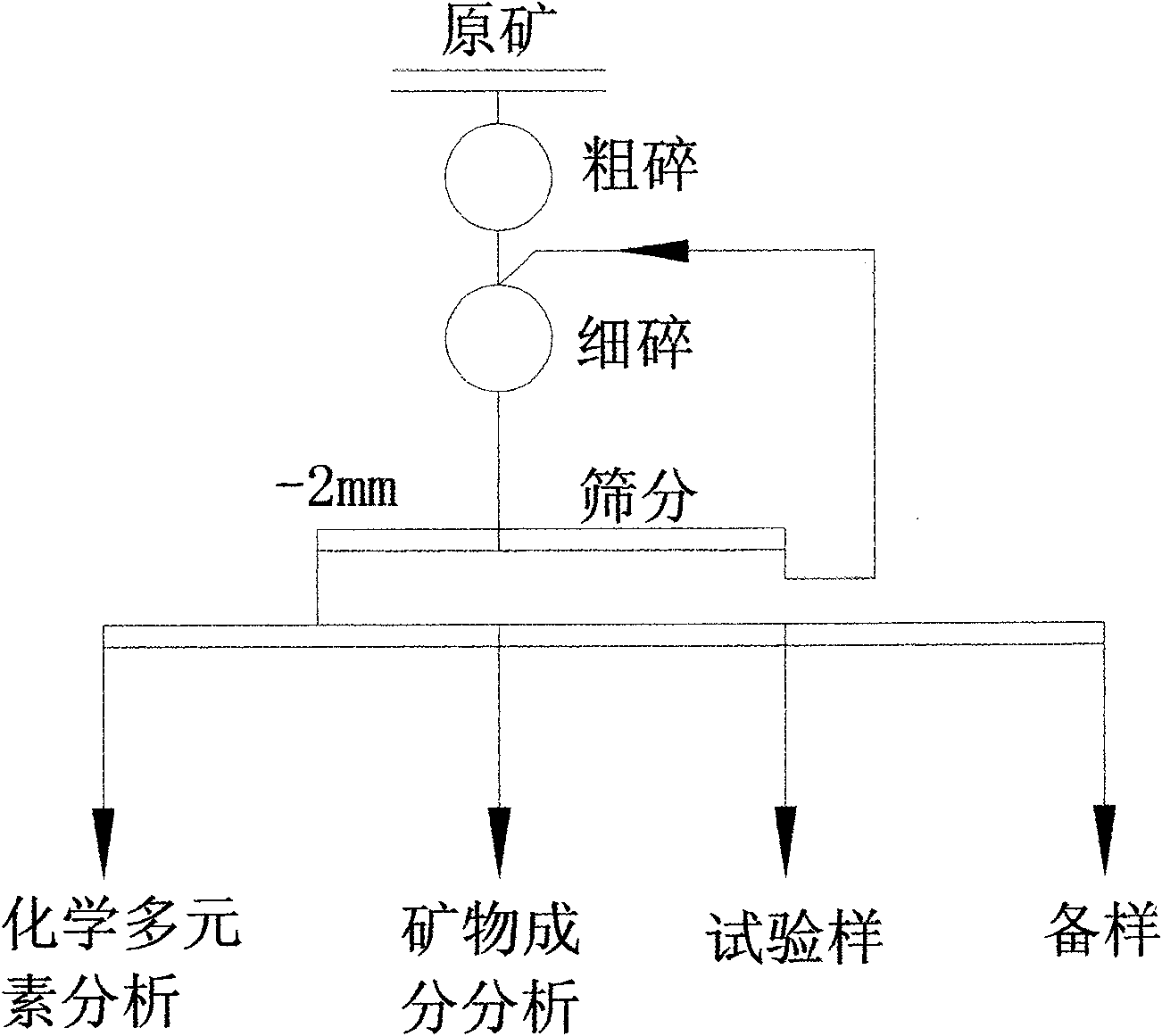

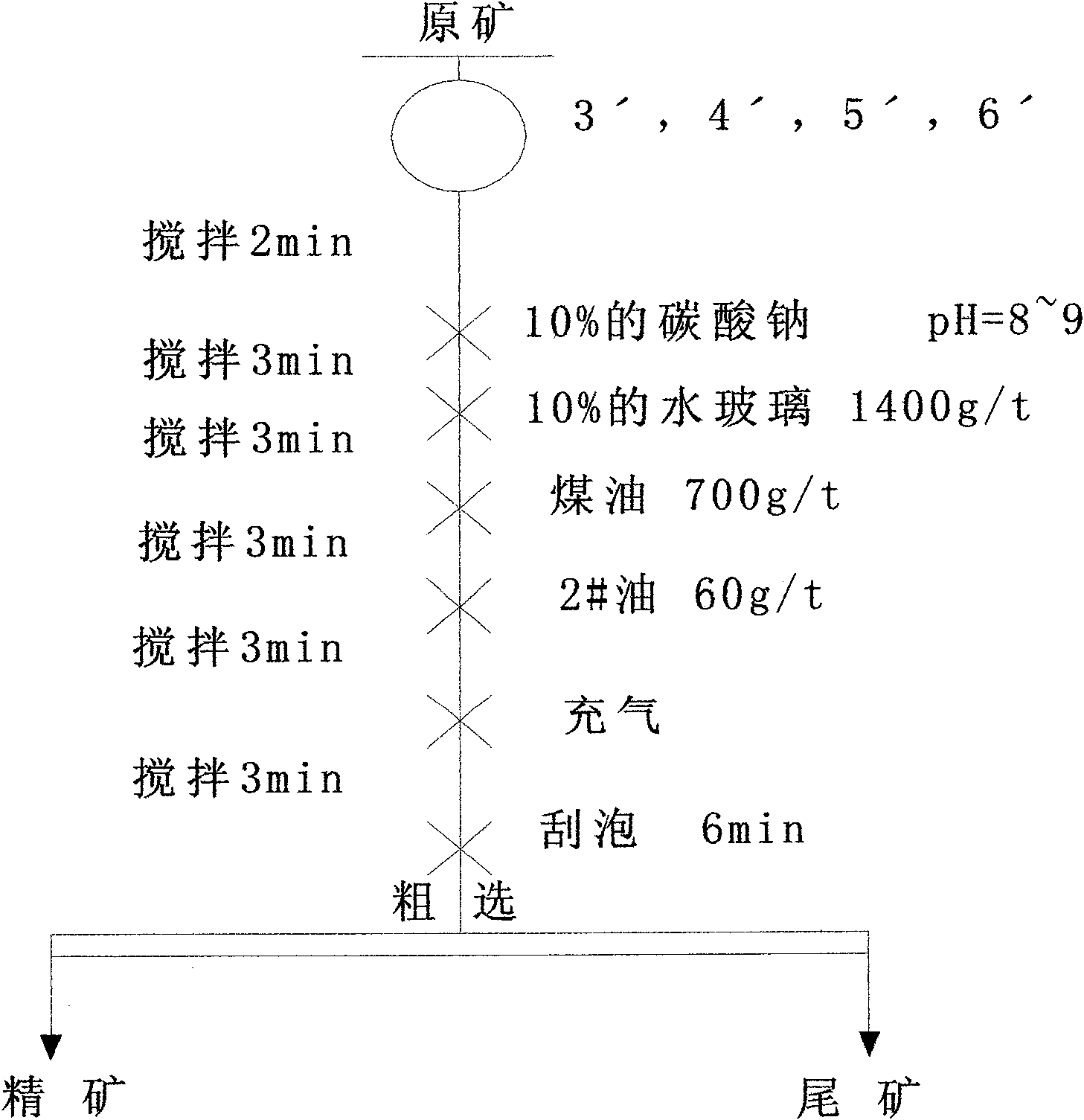

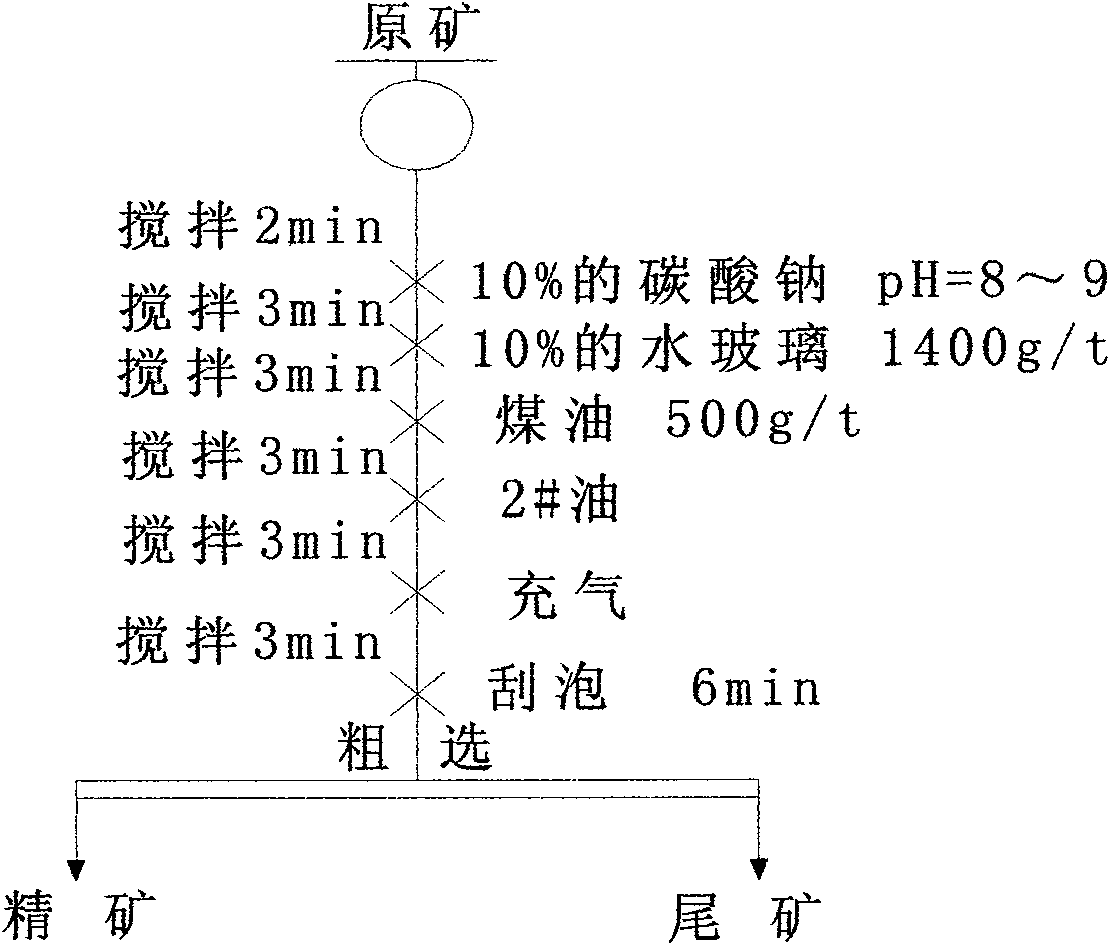

New process for purifying and manufacturing microcrystalline graphite product

The invention discloses a new process for purifying and manufacturing a microcrystalline graphite product, which comprises the following steps: adding calcined lime and water into graphite ore of which the grinding fineness is -200 meshes and the pass rate is above 90 percent after fine grinding, stirring uniformly and making pH of graphite ore slurry containing the calcined lime above 9; adding water glass to stir, adding kerosene to stir, finally adding pine oil to stir, inflating and scraping to perform rough concentration, and collecting roughly concentrated fine ore and tail ore of graphite; adding water glass into the roughly concentrated fine ore to stir, adding kerosene to stir, adding pine oil to stir, inflating and scraping to perform primary fine concentration, and collecting finely concentrated fine ore; adding water glass into the primarily finely concentrated fine ore to stir, adding kerosene to stir, adding pine oil to stir, inflating and scraping to perform secondary fine concentration, and collecting flotation graphite fine ore; adding NaOH solution into the flotation graphite fine ore for mixing, roasting, washing with water to neutral, performing acid leaching with hydrochloric acid, washing with water, dewatering and drying to obtain a high-carbon graphite product with the fixed carbon content in the graphite up to 98.74 percent.

Owner:FUJIAN FUYOU GRAPHITE TECH

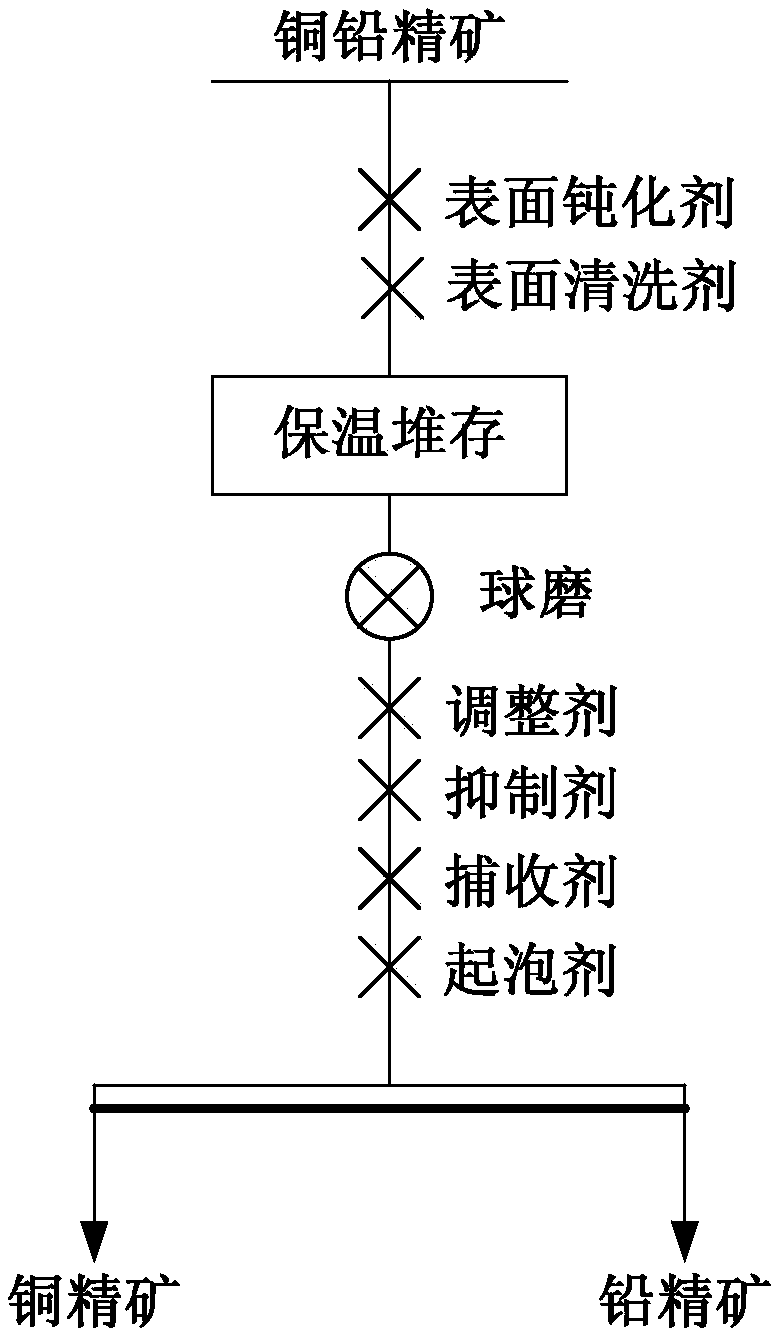

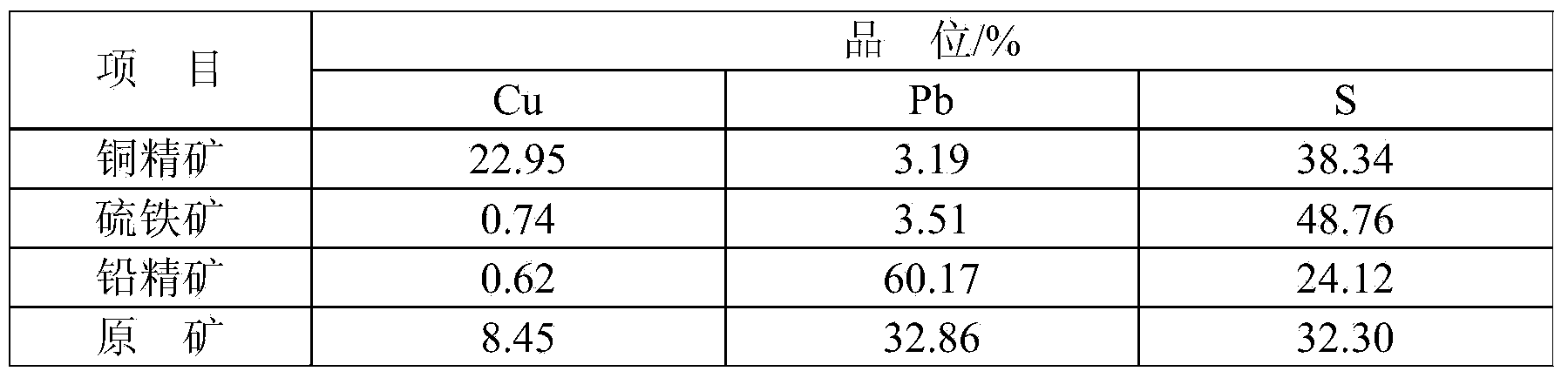

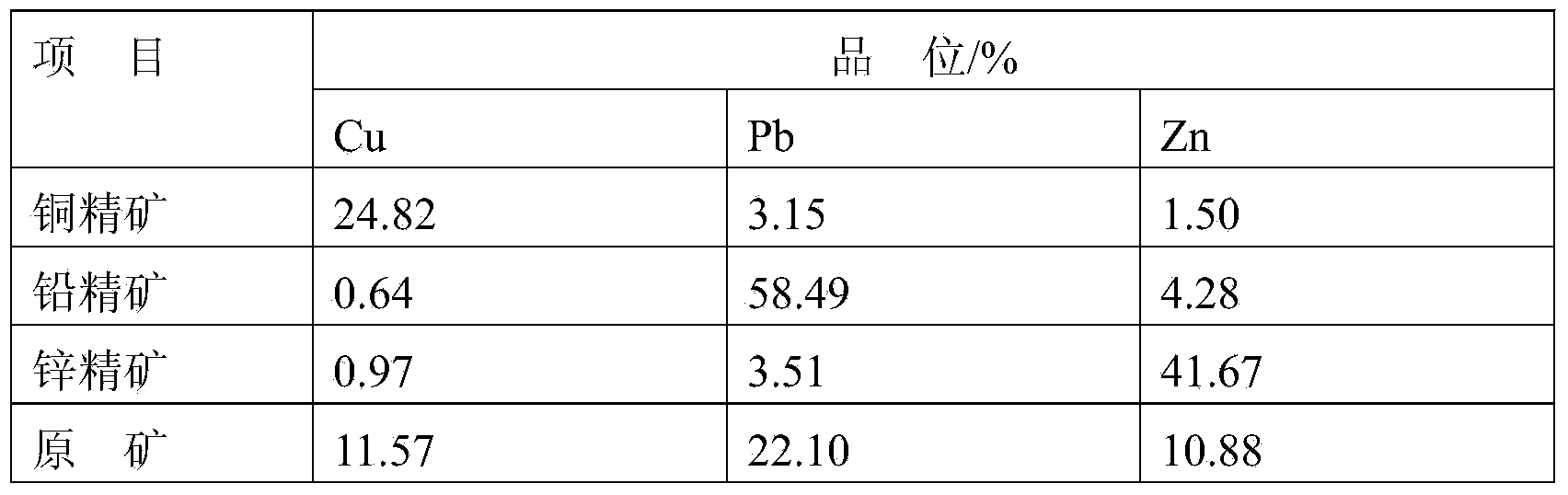

Method for flotation separation of copper sulfide and lead concentrate processed through pre-oxidation

ActiveCN103861740ASlow down the rate of corrosion oxidationImprove flotation effectFlotationSurface cleaningCleansing Agents

The invention discloses a method for flotation separation of copper sulfide and lead concentrate processed through pre-oxidation. A new pretreatment flotation technology comprises the steps that pre-oxidation treatment is carried out on the copper sulfide and lead concentrate by using surface passivator, surface cleaning agents and a certain heat-preservation stockpiling method, wherein the copper sulfide and lead concentrate is obtained through flotation; ball milling is carried out on the preprocessed copper sulfide and lead concentrate; a certain number of floatation reagents including regulators, inhibitors, collecting agents and foaming agents are added, and a foam product, namely copper concentrate and tailings, namely lead concentrate are obtained through flotation separation. According to the new pretreatment flotation technology, the used reagents cannot pollute the environment, and energy consumption of production is reduced; compared with economic value of copper sulfide and lead bulk concentrate, the value of products obtained through separation is greatly improved; the content of heavy metal ions in water is low in the production process, the technology is environmentally friendly, equipment operation and technological process operation are easy, and economy and high efficiency are achieved.

Owner:CENT SOUTH UNIV

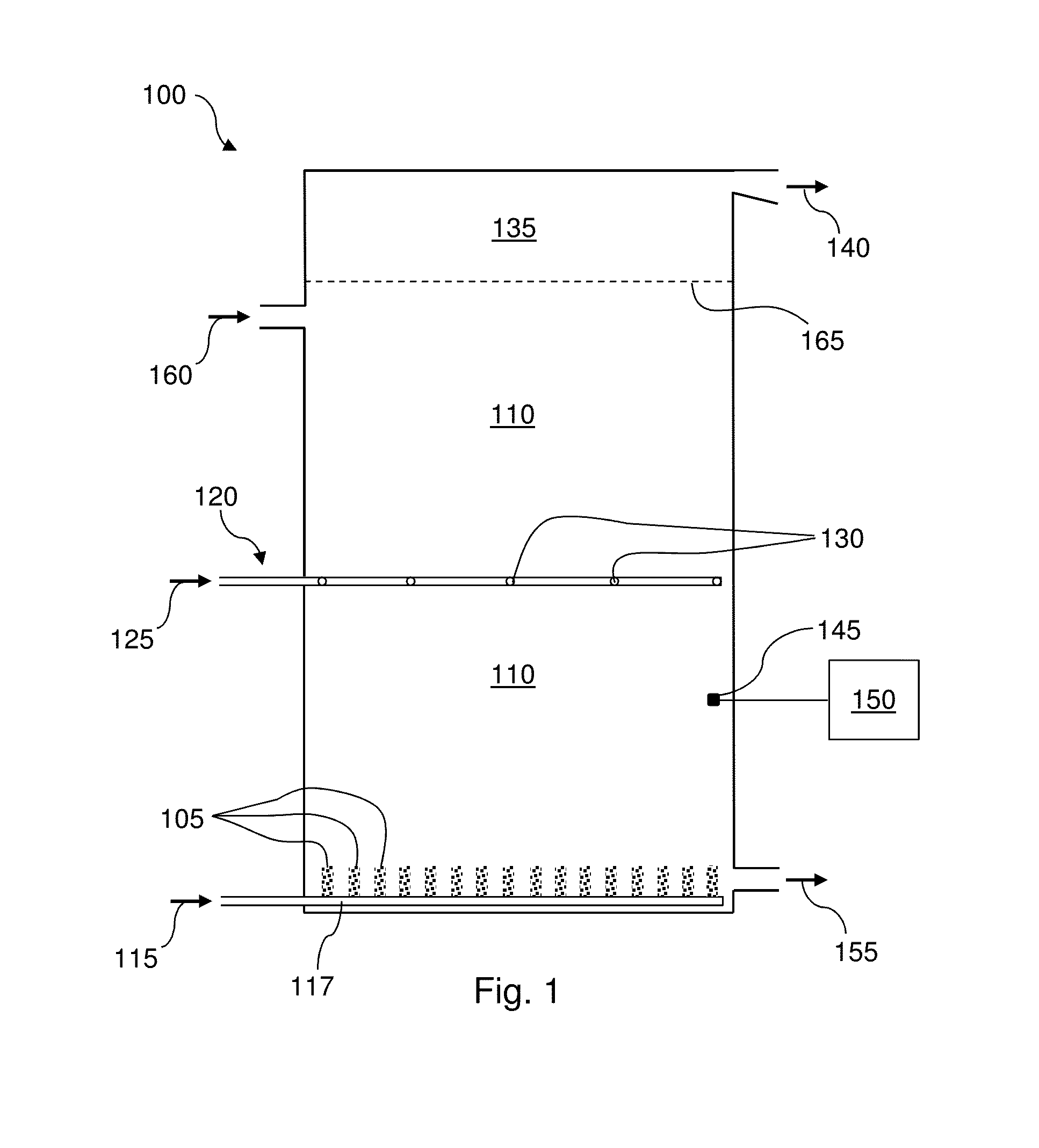

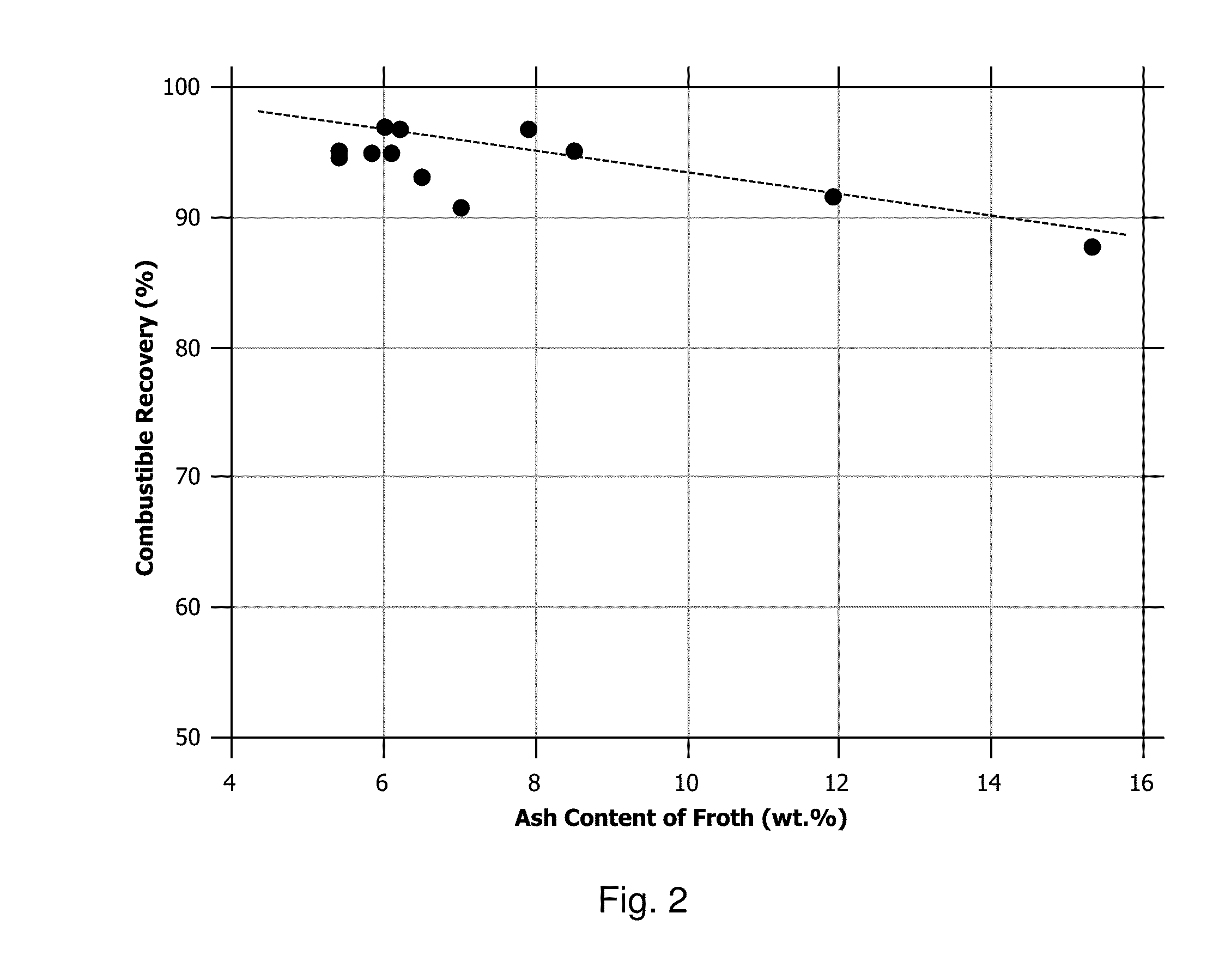

Flotation separation of fine coal particles from ash-forming particles

InactiveUS20160082446A1Provide froth-building capacityEasy to separateSolid fuelsLiquid carbonaceous fuelsPrillSlurry

Coal fines are processed by flotation separation to separate coal particles from ash-forming component particles. Coal fines are mixed water under high shear mixing conditions to form an aqueous slurry of coal fines containing between 15 wt. % and 55 wt. % coal fines. The aqueous slurry is introduced into a coal flotation cell to separate coal particles from ash-forming component particles by flotation separation, wherein the coal fines have a particle size less than 500 μm, and more preferably less than 300 μm. Bubbles are generated in the coal flotation cell having a bubble size and bubble quantity selected to float the coal particles and to form a coal-froth containing at least 15 wt. % solid particles. The solid particles include coal particles and ash-forming component particles. The coal-froth is collected for further processing.

Owner:EARTH TECH USA

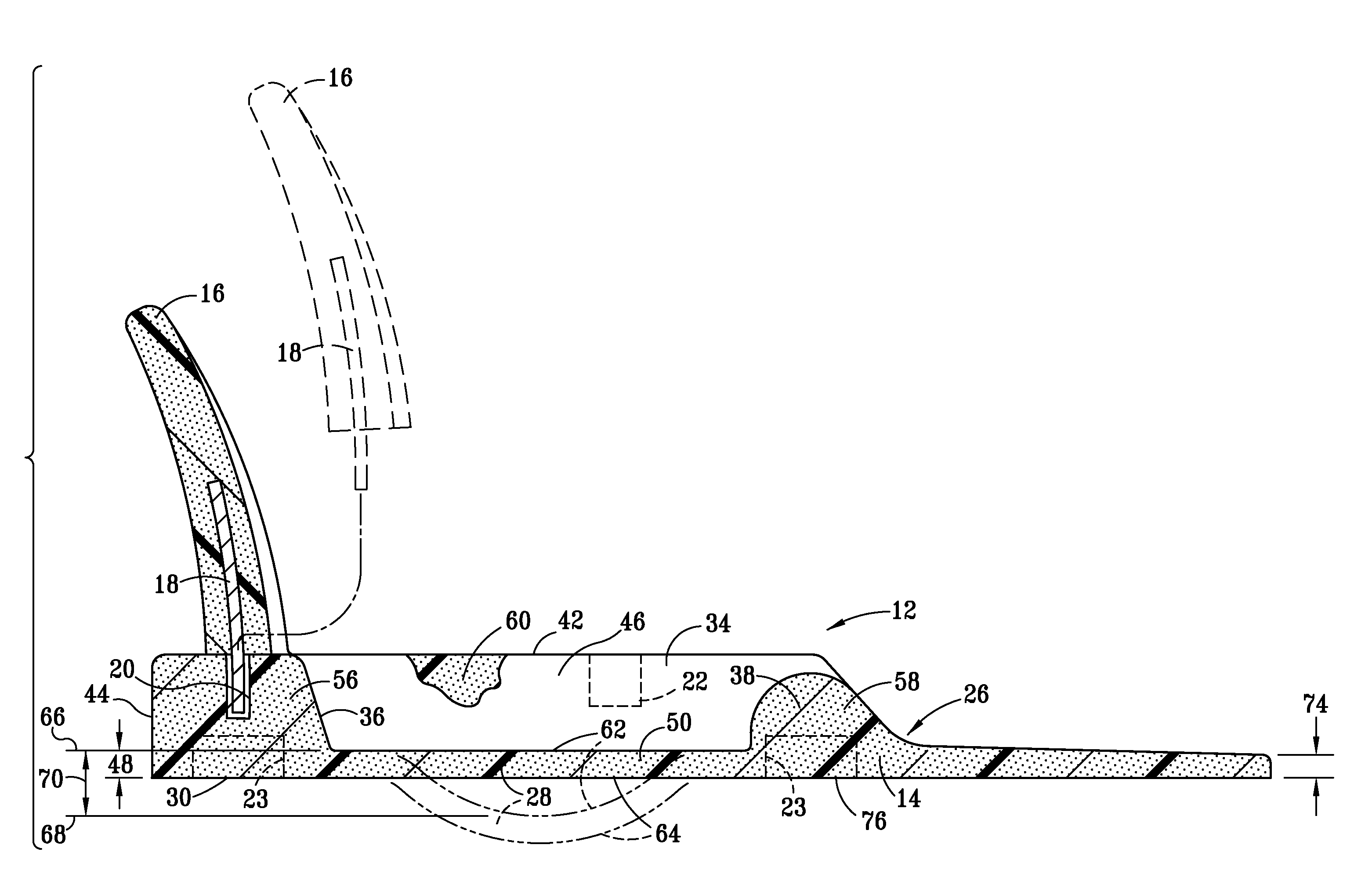

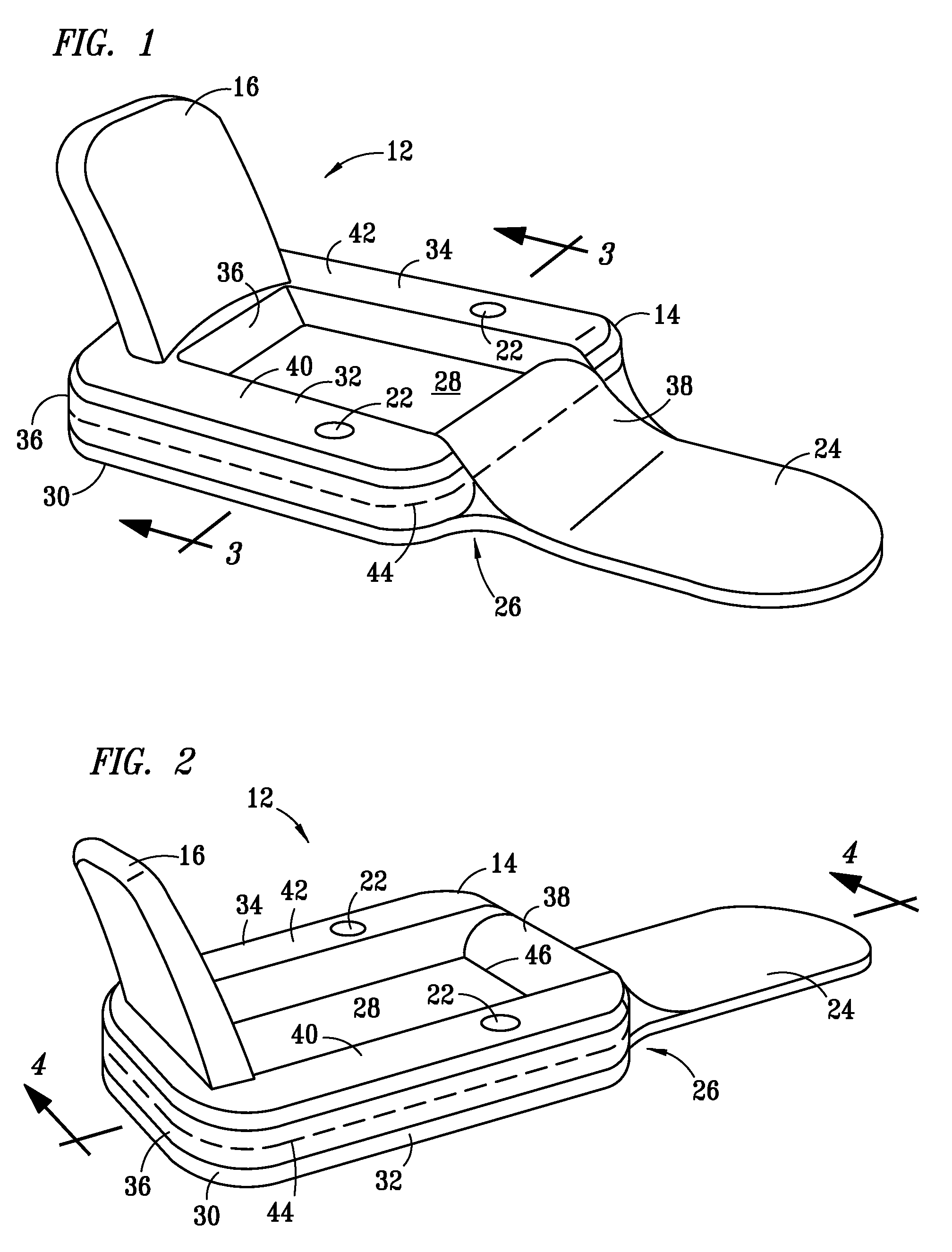

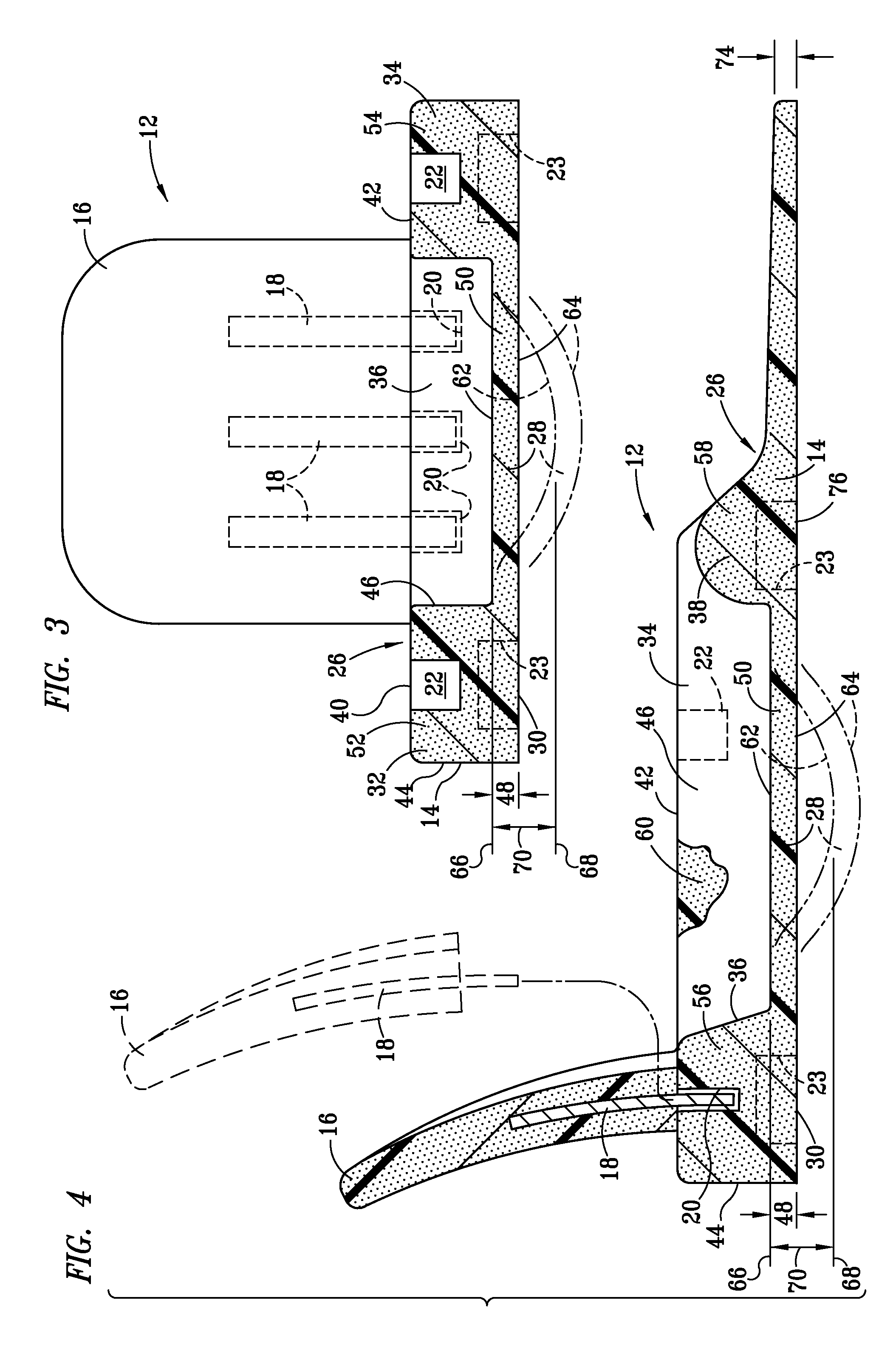

Molded foam pool chair

A molded foam pool chair (12) is provided by a continuous form (26) of pliable foam material of constant density having varying thicknesses to provide a rigid base portion (30) and an elastic seat portion (28). The rigid base portion (30) extends around and is continuous with the elastic seat portion (28). The rigid base portion (30) defines a peripheral edge (44) having a shape and has cross-sectional areas of sufficient thickness and width to prevent substantial distortion of the shape of the peripheral edge (44) between unloaded and loaded conditions. The elastic seat portion (28) has an upper surface (62), a lower surface (64) and a thickness (48) for receiving a substantial portion of the weight of a person and extending downward within water into a loaded position (68), such that the upper surface (62) of the elastic seat portion (28) when in the loaded position (68), is disposed substantially beneath an unloaded seat position (66) defined by the lower surface (64) when disposed in an unloaded position.

Owner:PERRY MICHAEL L

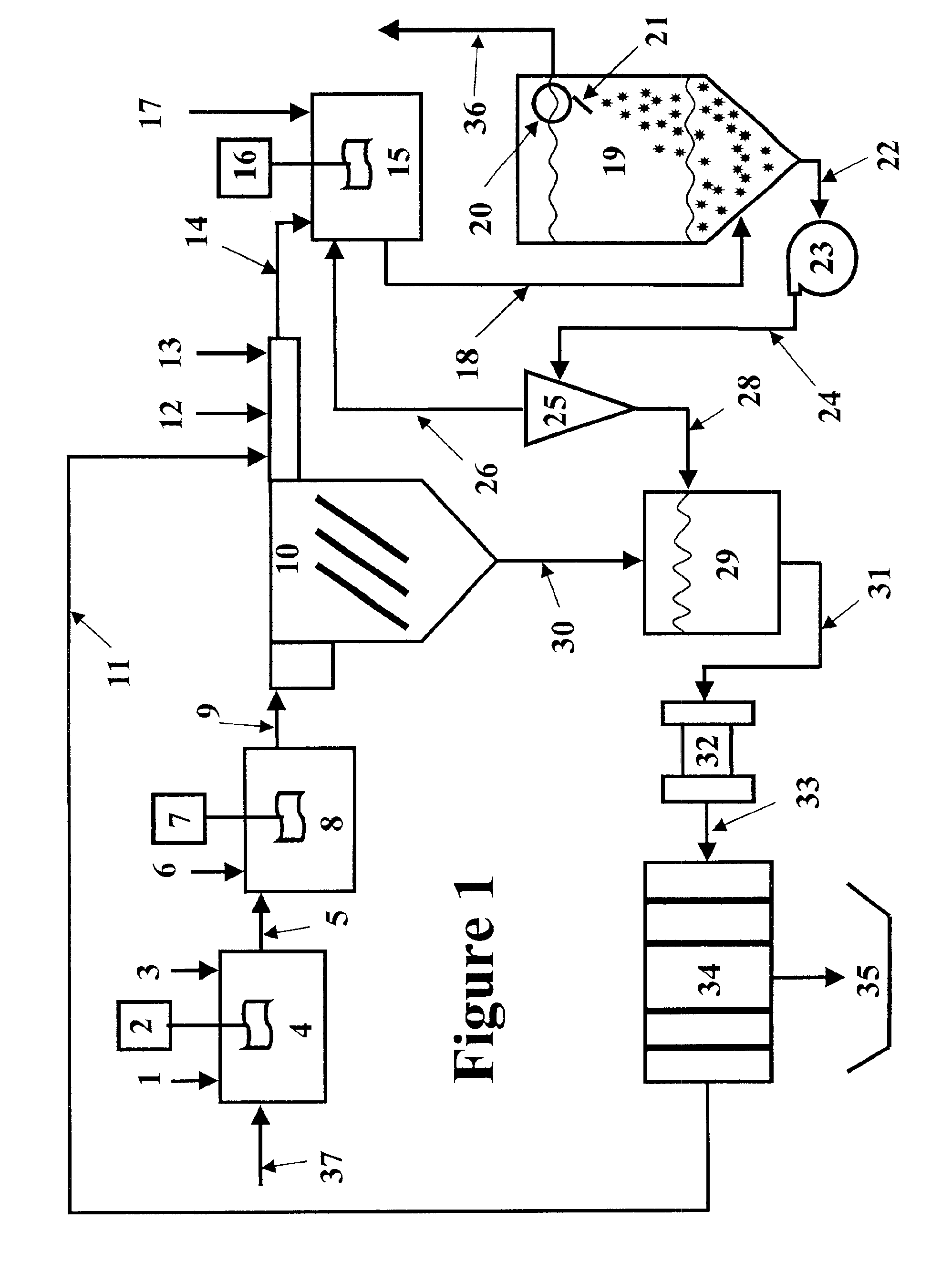

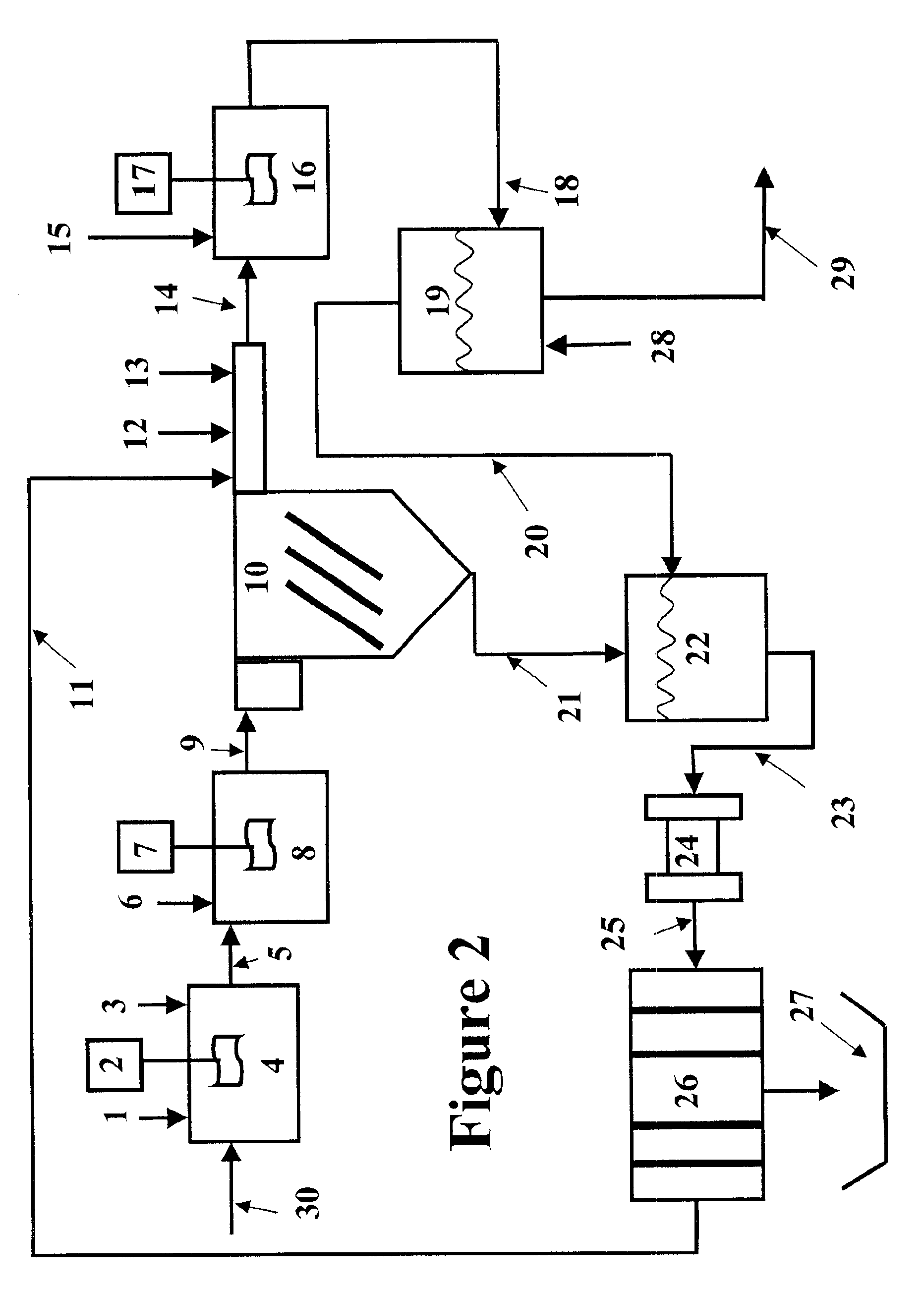

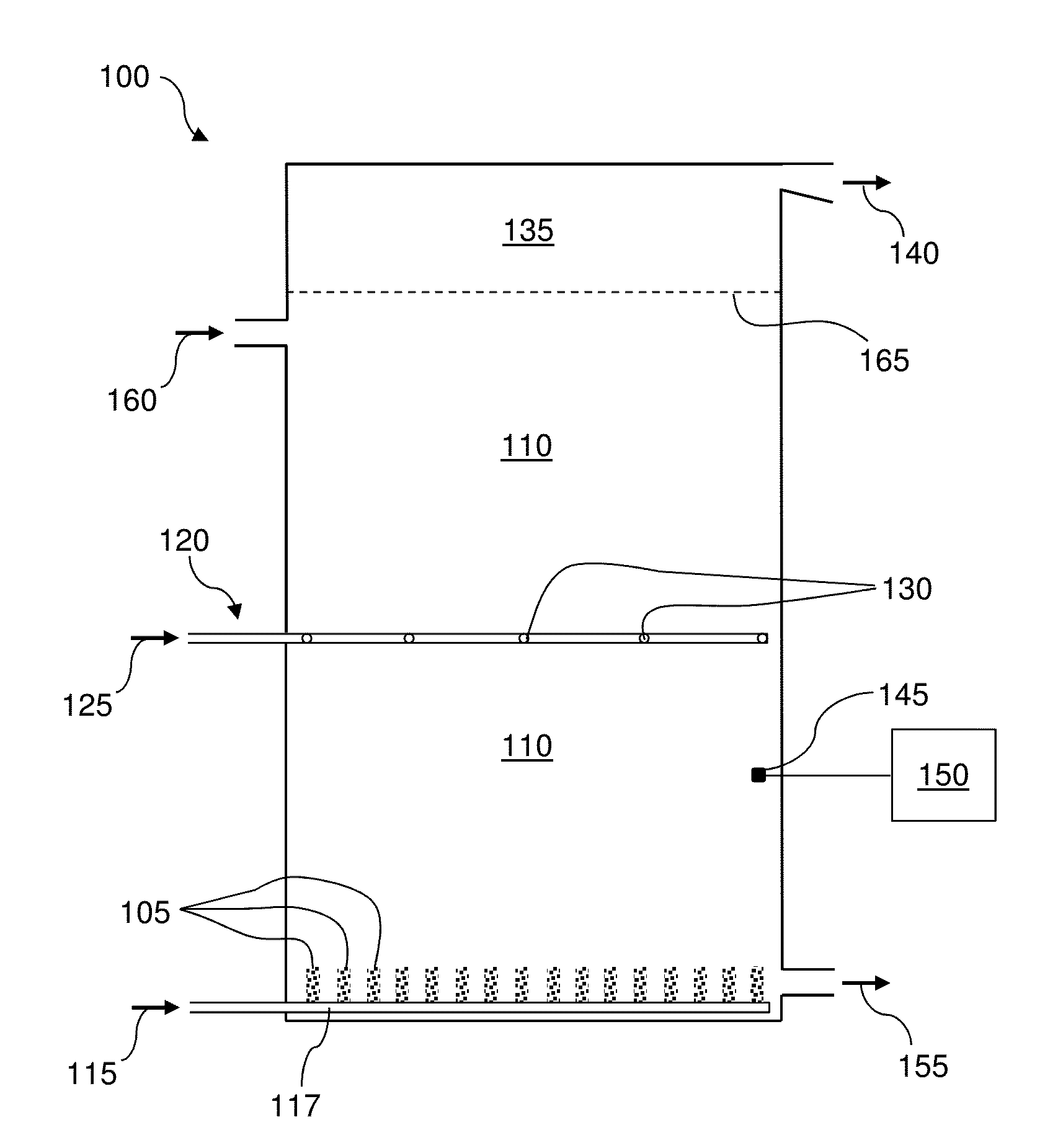

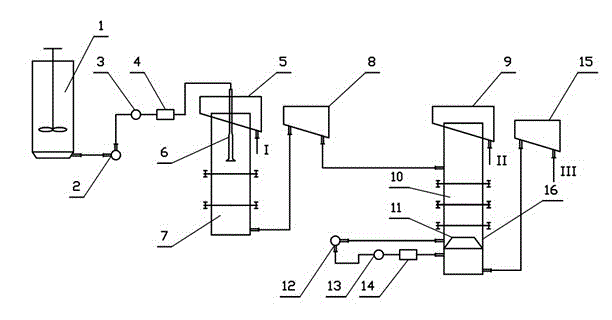

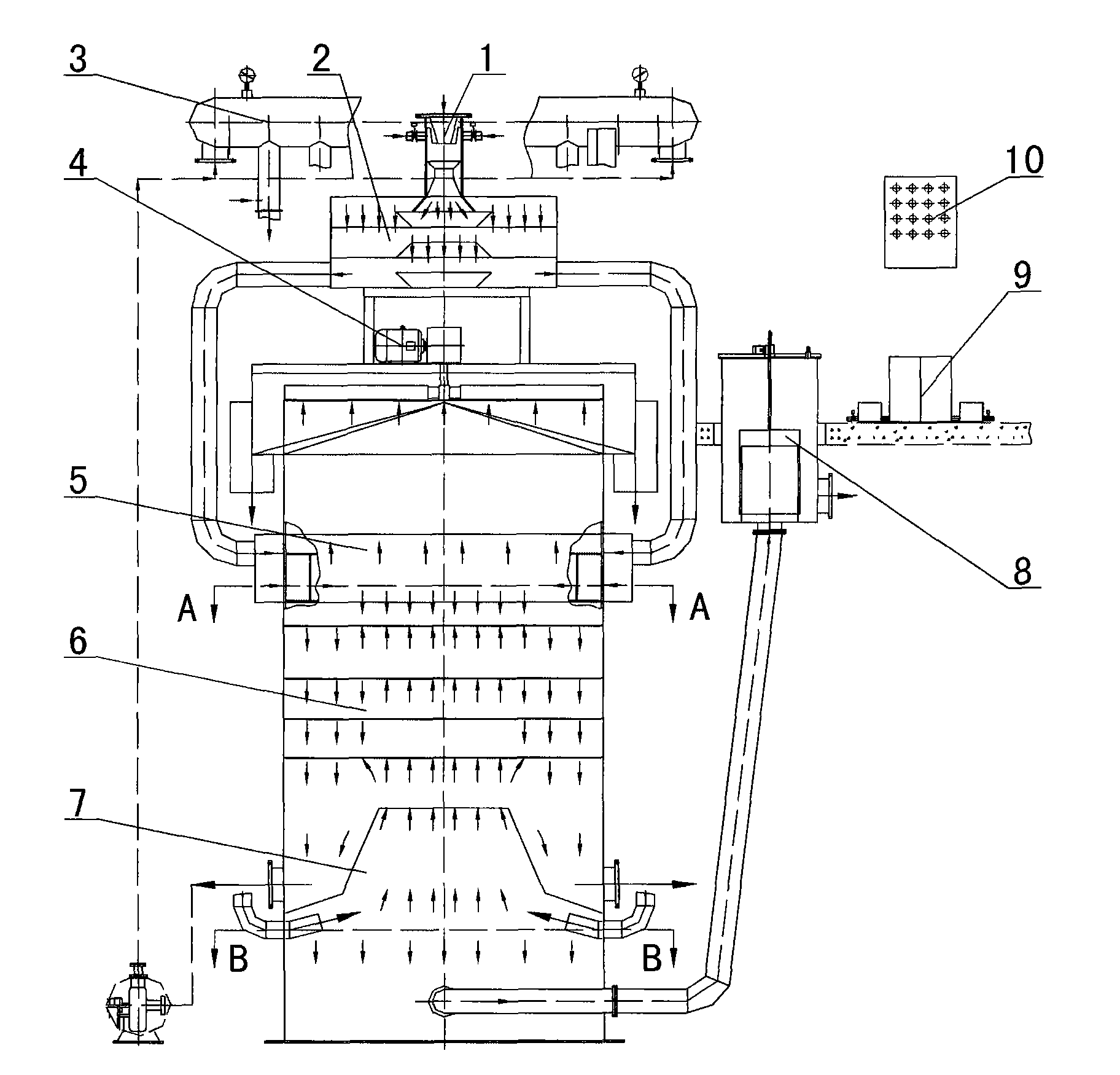

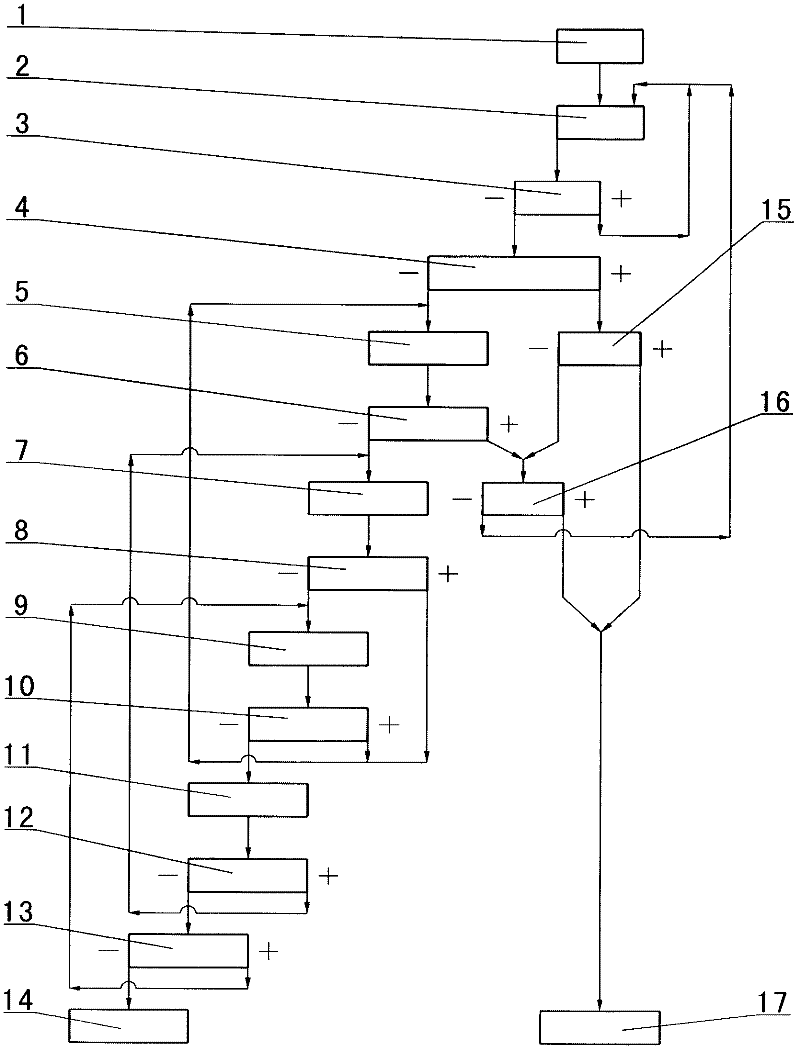

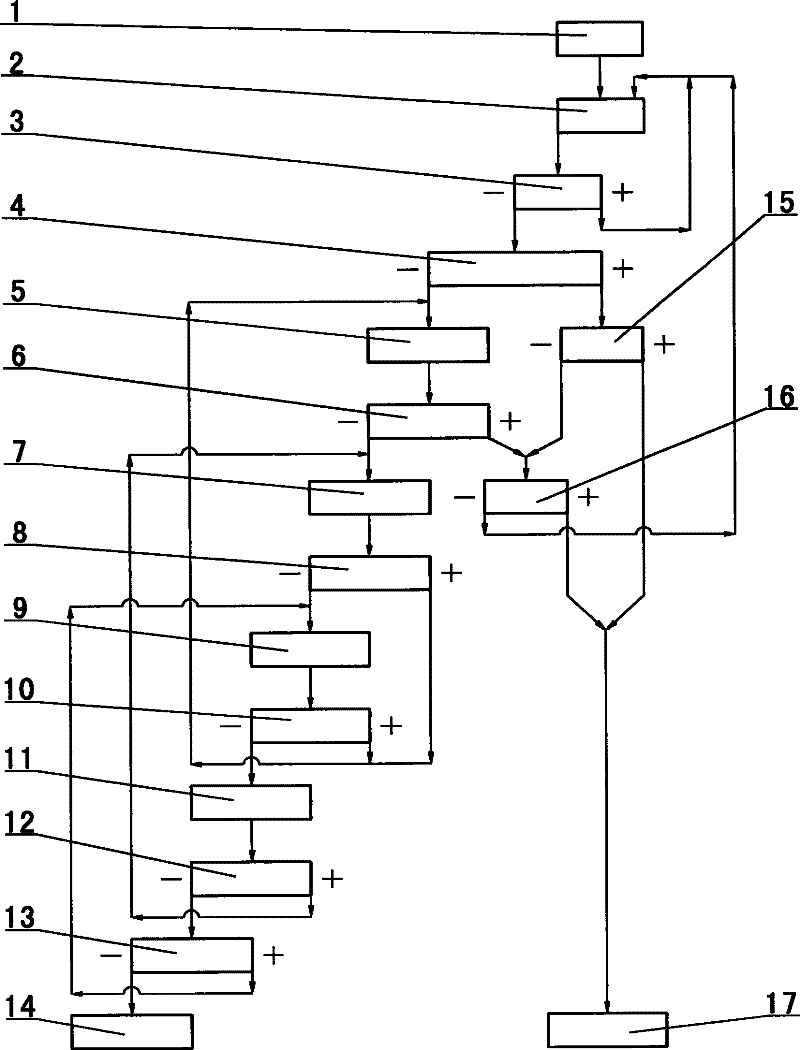

Novel flotation column serial connection test system for improving flotation granularity upper limit

The invention relates to a novel flotation column serial connection test system for improving the flotation granularity upper limit. The equipment of the system comprises a fed material stirring barrel, a feeding pump, a feeding pressure meter, a froth generator, a primary-section foam enriching chamber, a lower catheter, a spray type flotation column chamber, a primary-section tailing box, a secondary-section foam enriching chamber, a column flotation chamber, a rotary flow sorting chamber, a circulation ore pulp pump, a circulation pressure meter, a froth generator, a secondary-section tailing box and an FCMC cyclo-microfroth flotation column, wherein a spray type flotation column and the FCMC cyclo-microfroth flotation column are connected in series by the system, and the primary-section tailing is used as secondary-section fed materials. The system is favorable for the static fast flotation of preference flotation of coal with good flotation performance and the strong power efficient recovery of difficult-to-sort coal, in addition, the problem of high-concentration coal slime flotation can be perfectly solved, the recovery rate of coarse particle coal slime can be improved, and the problem of coarse particle running of coarse particle flotation can be solved.

Owner:CHINA UNIV OF MINING & TECH

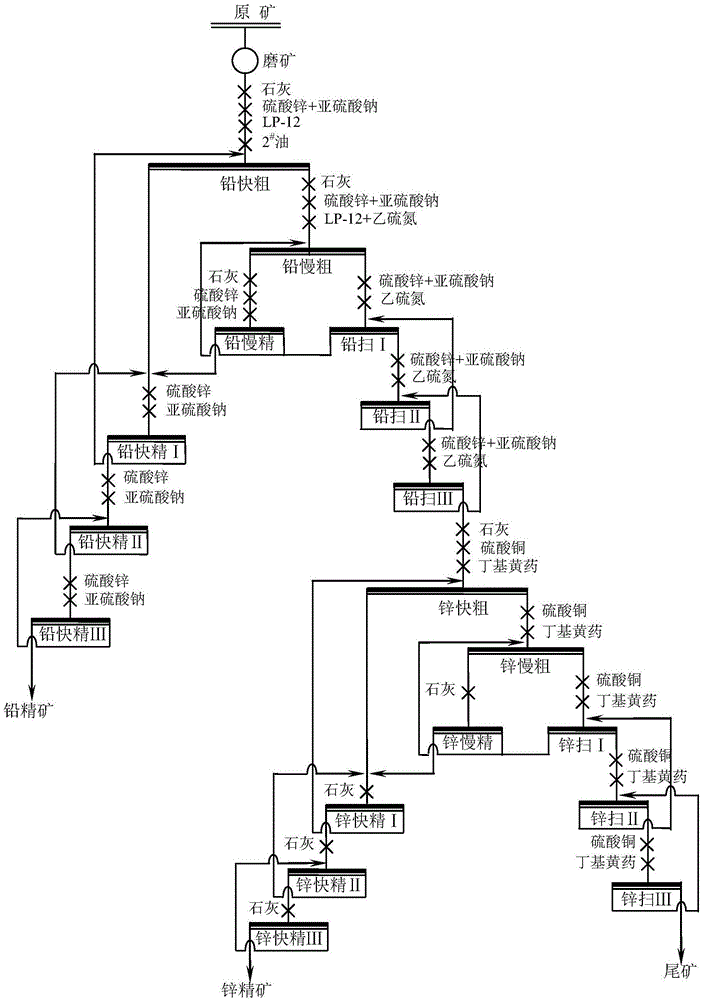

Ore dressing method for lead-zinc-silver poly-metallic ores

The invention provides an ore dressing method for lead-zinc-silver poly-metallic ores. Lead-silver concentrates and zinc concentrates are finally obtained through the steps of raw ore grinding, lead fast roughing, lead slow roughing, lead scavenging, lead fast concentration, lead slow concentration, zinc fast roughing, zinc slow roughing, zinc scavenging, zinc fast concentration and zinc slow concentration. The lead-zinc-silver poly-metallic ores sorted by the ore dressing method provided by the invention are good in sorting index and high in separation efficiency; the ore dressing method is a lead-zinc-silver ore dressing method which is stable, efficient, strong in adaptive capacity, good in sorting effect, high in comprehensive recovery index and low in production cost and is suitable for popularization and application.

Owner:DONGSHENGMIAO MINING LLC +2

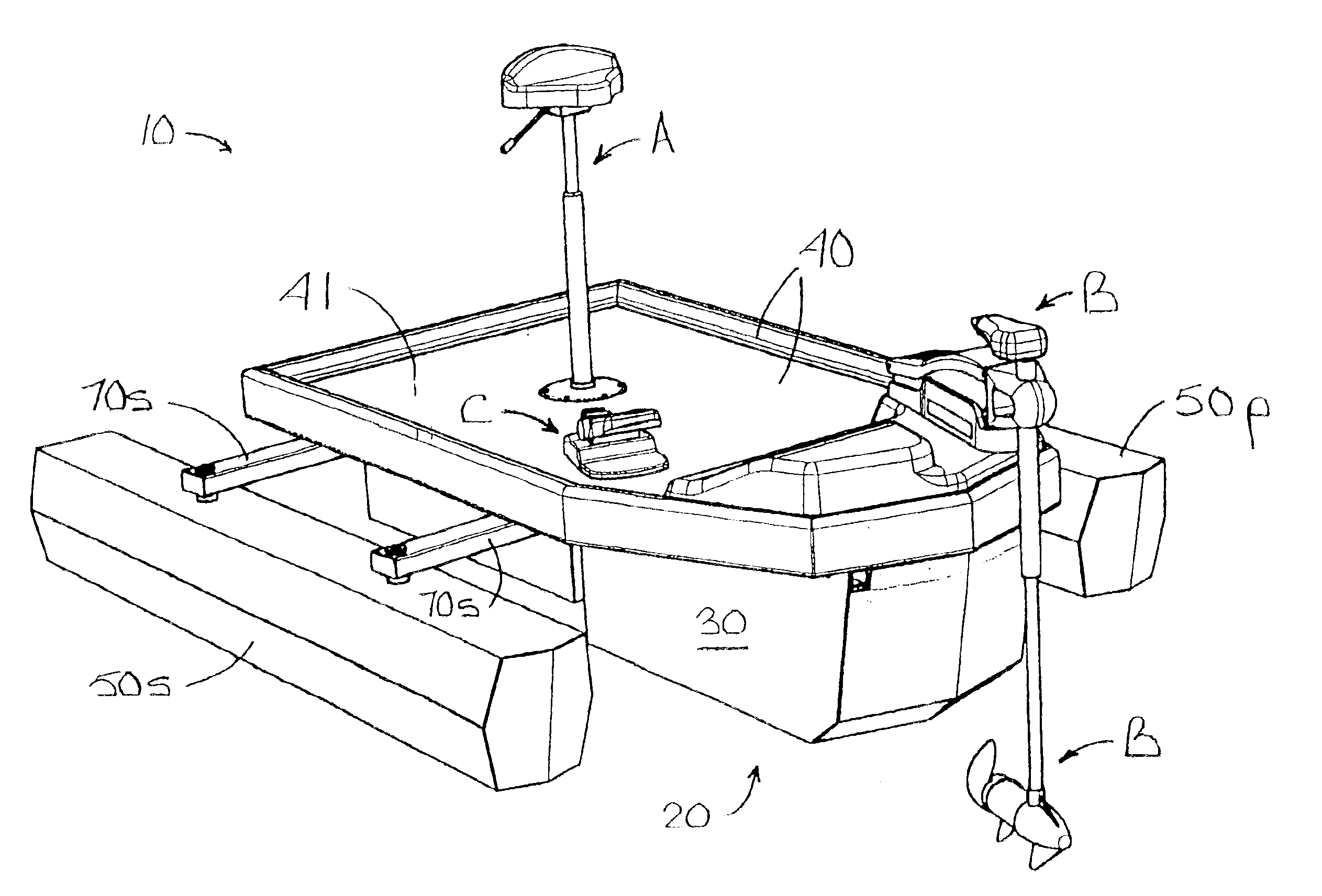

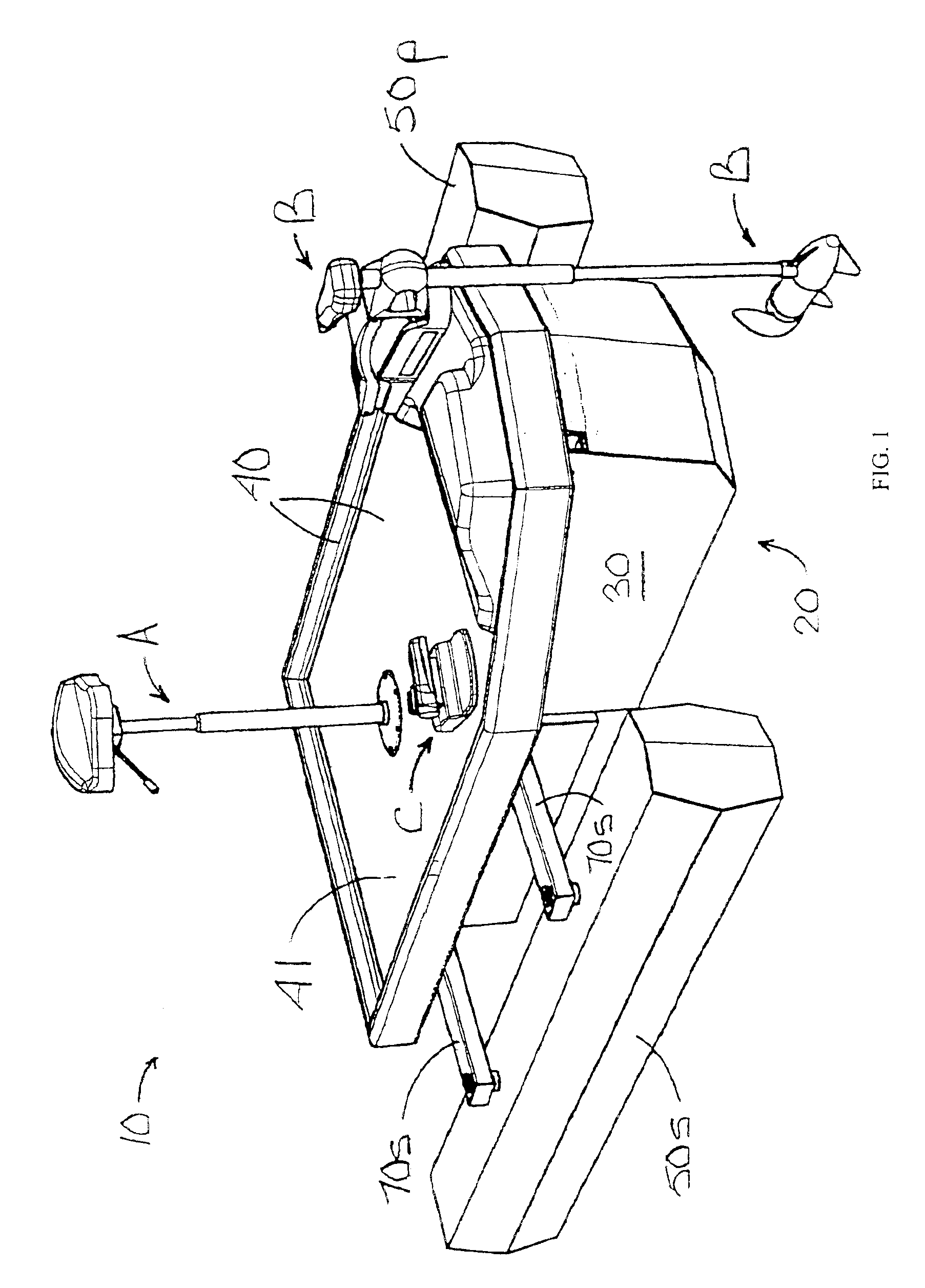

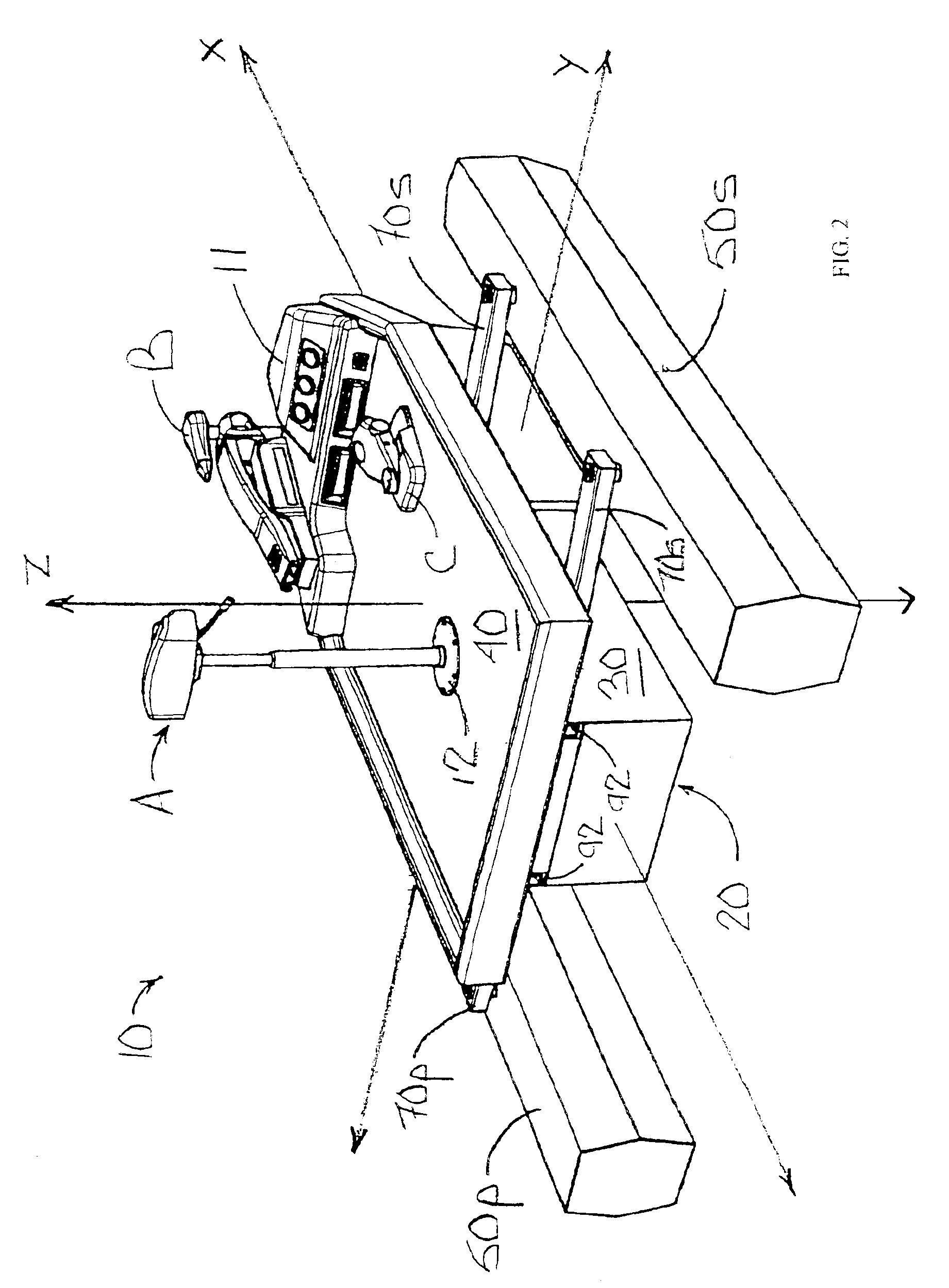

Personal watercraft

InactiveUS6988456B1Easy to transportEasy to storeTowing/pushing equipmentOutboard propulsion unitsWatercraftStern

A personal watercraft including a hull and at least two pontoons repositionably attached to the hull with at least one pontoon attached proximate the starboard side and at least one pontoon attached proximate the port side. The pontoons are laterally and longitudinally repositionable as between a storage position in which the pontoons are generally longitudinally aligned relative to the hull and have a minimized lateral distance between the pontoons, and a flotation position in which the pontoons are shifted aft relative to the longitudinally aligned storage position and have a maximized lateral distance between the pontoons.Also, a personal watercraft having one or both of (i) a pair of laterally spaced hitch attachments secured to the hull proximate the bow of the hull, and / or (ii) a pair of laterally spaced hitch attachments secured to the hull proximate the stern of the hull 20. This aspect of the personal watercraft permits the personal watercraft to be used with various accessories such as a towing attachment, a wheeled attachment, a transom, an interconnecting linkage and a supplemental decking attachment.

Owner:SCHOOLER TIMOTHY E

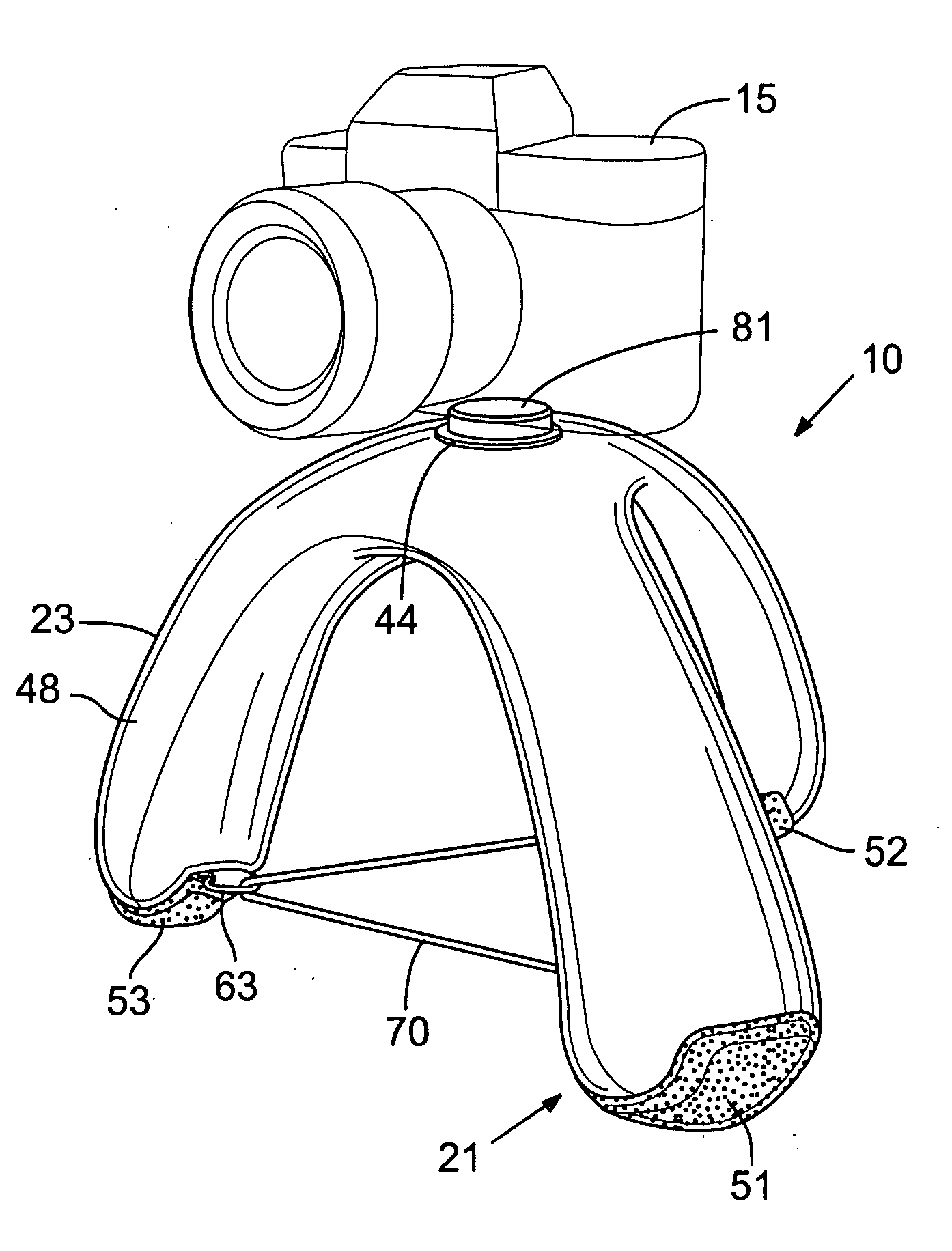

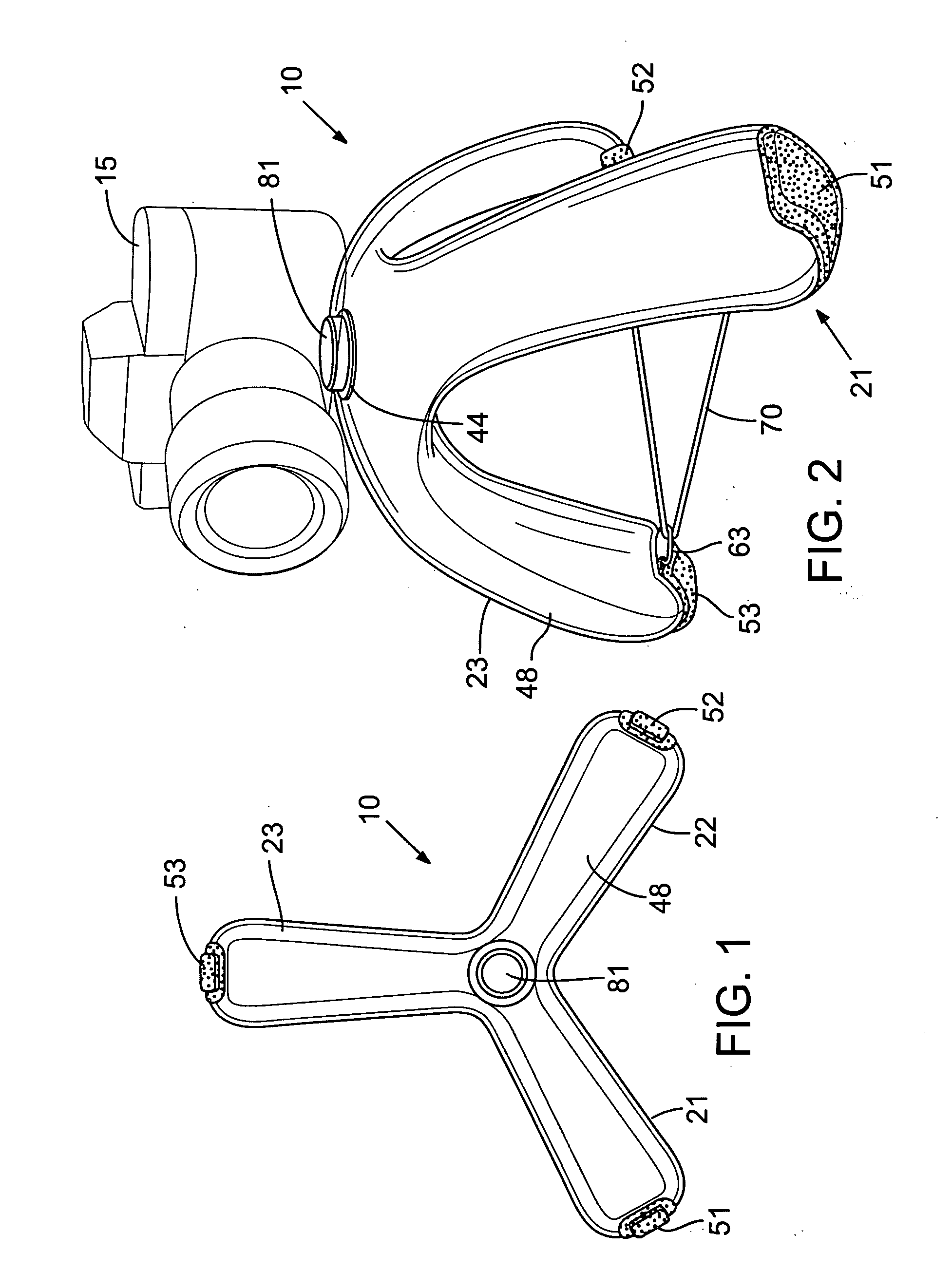

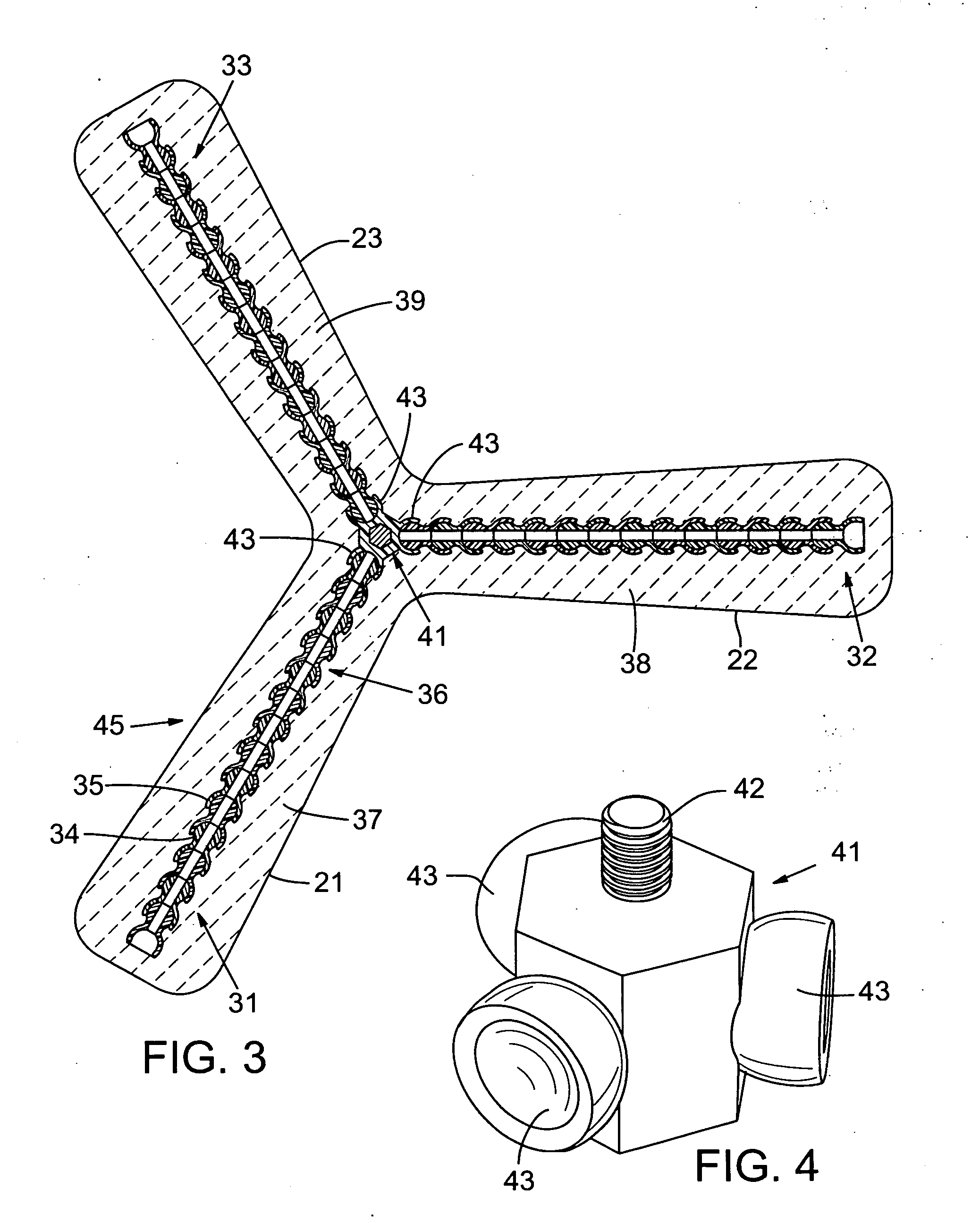

Flexible, positionable and grasping camera or other device mount apparatus

InactiveUS20100021155A1Increase surface areaImprove stabilityCamera body detailsEngineeringSoft body

A camera or other items positioning device including a relatively hard endoskeleton substantially covered by a softer corpulent body. A mount region is coupled to the endoskeleton and configured to permit the releasable attachment of a camera or other device. The attachment mechanism may be mechanically or magnetically based, or both. The soft body permits the devices to be readily grasped by a user and to wrap securely about mounting structures of different size and shape. Several embodiments, including tripod, extra leg and monopod embodiments, are disclosed.

Owner:TREK TECH TREK TECH

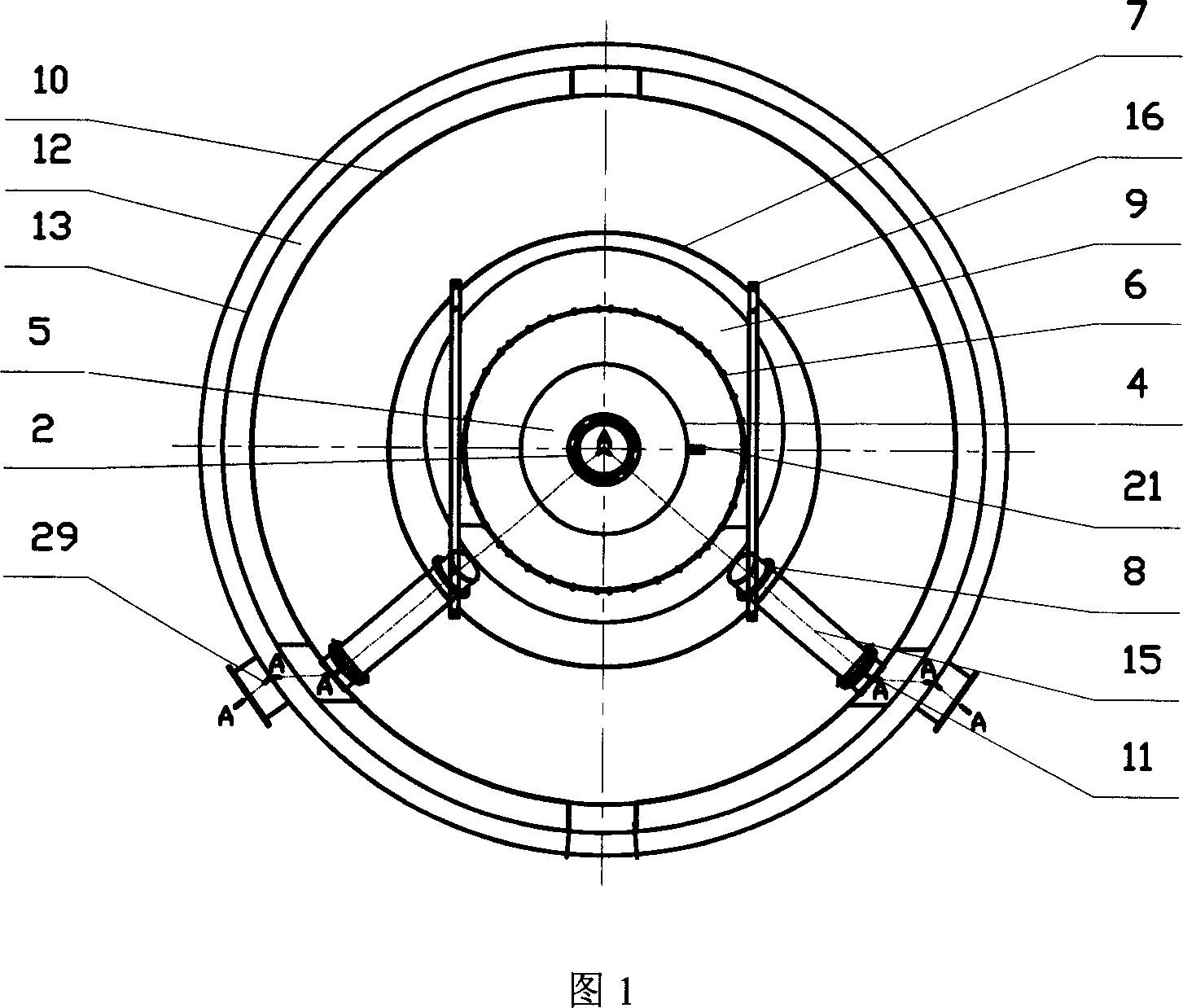

Flotation column special for floating fine flake graphite

InactiveCN102698879AFeeding kinetic energy is smallImplement static flotationFlotationElectricityProgrammable logic controller

The invention relates to a flotation column special for floating fine flake graphite, belonging to the technical field of graphite flotation; the flotation column disclosed by the invention is mainly composed of a mixing device, a static mineralizing machine, an upper column body, a scraping device, a distributor, a lower column body, a gangue discharging device, a middle column body, a dosing device and a PLC (programmable logic controller) control case; the mixing device is composed of a mixing pipe, a nozzle, a throat pipe and an expanding pipe; the static mineralizing machine is composed of a case body, a variable-diameter amplifier, a baffle board, an uniform distribution board and a discharging pipe; the upper column body is composed of an upper barrel body, a finished ore groove and a static charging device; the scraping device is composed of a motor, a decelerator, an output shaft and a scraper; and the distributor is composed of a distributing pipe, an electric valve, an electric contact pressure gauge, a circular pump and a micro-bubble generator. According to the invention, the flotation column has the advantages of good raw ore and medicament mineralizing effect, small charging kinetic energy, large cyclone force field, good flotation effect and large treatment quantity.

Owner:SHANDONG LAIWU COAL MINING MACHINERY

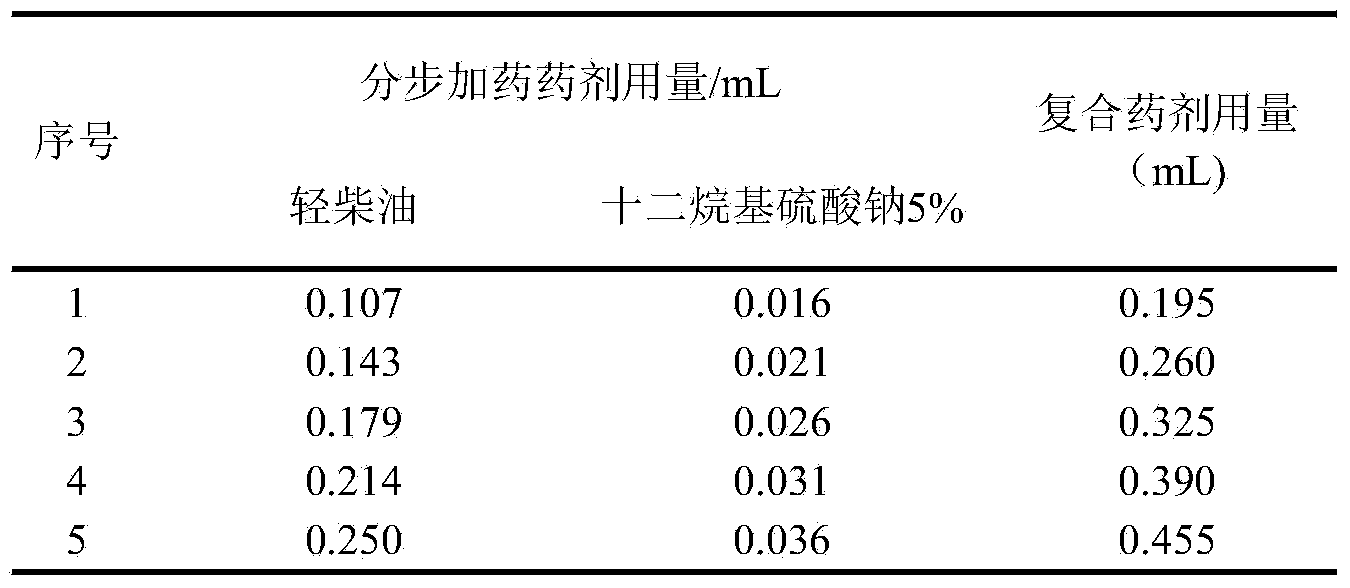

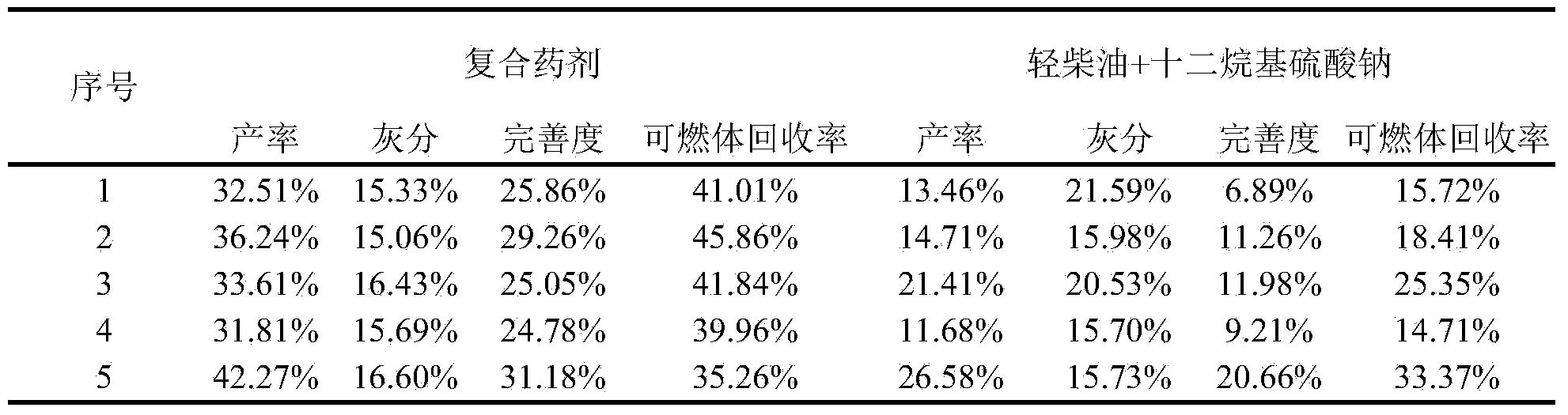

Composite coal-dressing flotation reagent and preparation method thereof

The invention discloses a composite coal-dressing flotation reagent and a preparation method of the composite coal-dressing flotation reagent. The composite coal-dressing flotation reagent is an ivory water-soluble composite coal-dressing flotation reagent which is formed in the mode that light diesel oil, lauryl sodium sulfate, alkyl glycoside, alkylphenol polyoxyethylene ether and water are mixed and subjected to emulsification treatment through a low-temperature emulsification technology. The preparation method of the composite coal-dressing flotation reagent is simple, sources of raw materials are wide, complex operation is avoided, and industrialization can be easily achieved. The composite coal-dressing flotation reagent is used for conducting flotation processing on fine-grained coal slime; compared with a single flotation reagent combination composed of alkyl glycoside and light diesel oil which are added step by step, the composite coal-dressing flotation reagent shows an enhanced coal-dressing flotation effect on fine coal with the granularity smaller than 0.5 mm and overcomes the defect that the reagent is added step by step, the dosage of the reagent is reduced, and the economic benefit is considerable.

Owner:ANHUI UNIV OF SCI & TECH

Coal flotation agent and production method thereof

The invention relates to a coal flotation agent and a preparation method thereof. The product can be obtained through the following steps: mixing 10 to 30 portions of aromatic, 10 to 15 portions of kerosene, 0.05 to 1 portions of alkyl phenol polyoxyethylene ether in proportion; stirring for 20 to 40 minutes at a normal temperature; further adding 60 to 80 portions of gas-oil; and further stirring for 15 to 30 minutes to obtain a finished product. The coal flotation agent of the invention has the advantages of excellent flotation performance, low usage, high clean coal yield, low consumption, easy purchase of raw materials and low cost.

Owner:吉海峰

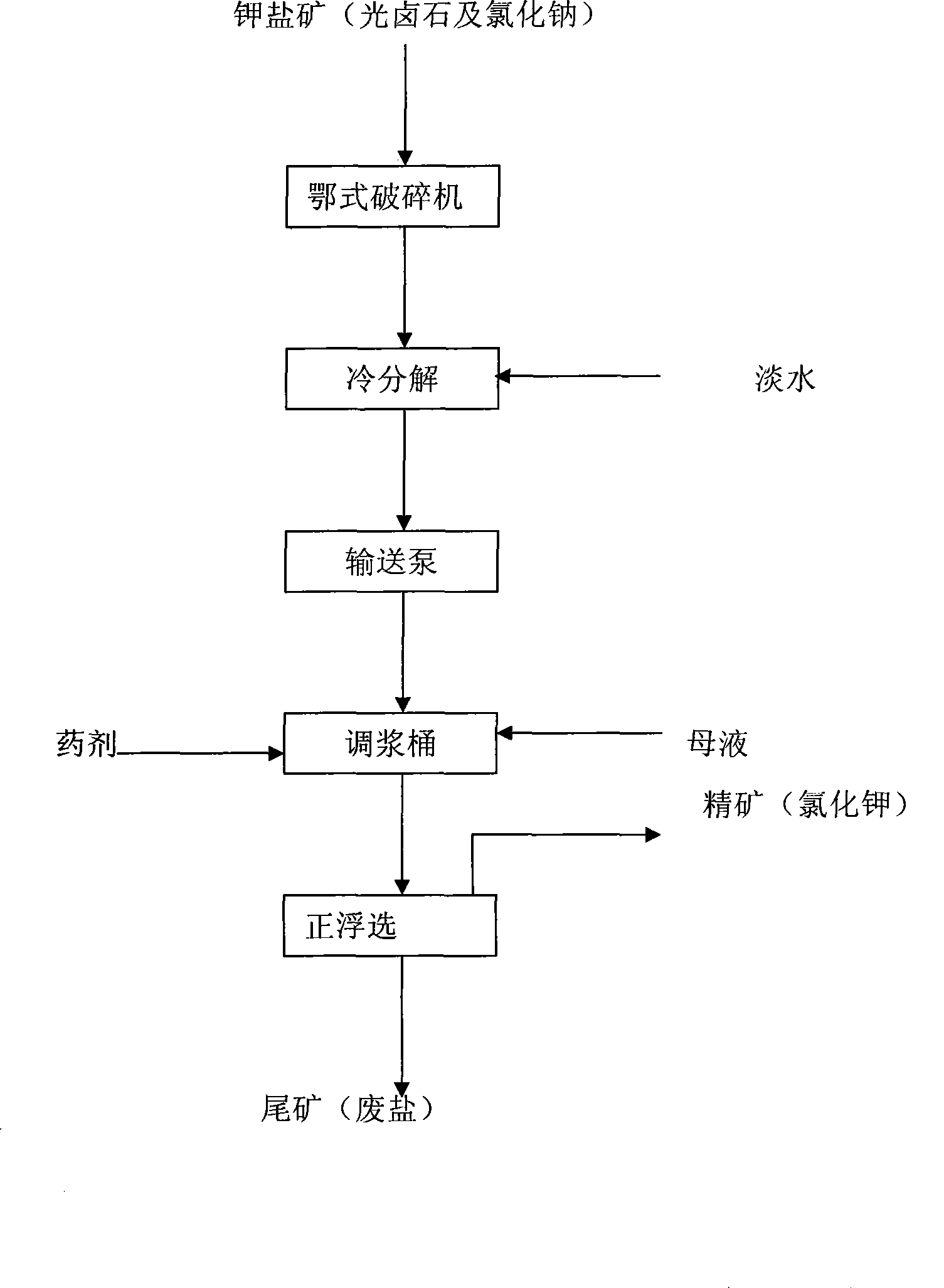

Method for flotation of potassium chloride from potassium salt mine

ActiveCN101474598ASimple equipment structureLarge amount of processingFlotationChemical industryAutomatic control

The invention relates to a method for the floatation of potassium chloride in a sylvite mine, and a method for producing the product of chemical industry, in particular to a novel floatation method for extracting the potassium chloride from the sylvite mine. The method of the invention mainly comprises the following steps: a. the sylvite mine is pulverized and graded, the particle size of the pulverized mine rages from 3 to 8mm, and the pulverized mine is processed by the operation of cooling decomposition by being added with sweet water; b. mine slurry obtained in the step a is led into a mineralization slot and is added with the saturated mother solution of potassium chloride, sodium chloride and magnesium chloride as well as a positive floating agent; and the mine slurry, the saturated mother solution and the positive floating agent are completely mixed to control the concentration of the mine slurry to be from 20 to 40 percent; c. the mine slurry obtained in the step b is led into a flotation separation device to obtain the potassium chloride by the positive floatation; and d. particles fallen to the bottom of a flotation column are milltailings, particles which are discharged from the flotation column and are caused to float to the top end of the flotation column are potassium chloride particles, and the particles are collected to be concentrated, filtered and dried. The method has the advantages of simple and stable process, easier automatic control, favorable flotation effect, low agent consumption and production cost, etc.

Owner:YUNNAN CHEM RES INST

Multifunctional ore dressing chemical, synthesis method thereof and using method thereof

ActiveCN101890398AImprove protectionIncrease productivityFlotationSynthesis methodsOrganic synthesis

The invention discloses a multifunctional ore dressing chemical, and a using technique thereof. The chemical can be widely used for treating various ore resources. A synthesis method of the multifunctional ore dressing chemical comprises the following steps: preparing colloidal solution of an inorganic oxide and a hydroxide; dissolving an organic monomer in the colloidal solution of the inorganicoxide and the hydroxide; adding an initiator into the solution to complete organic synthesis a reaction kettle. The obtained multifunctional ore dressing chemical which has a selective flocculation function is added into the flotation pulp to help ore separation in ore flotation and solid-liquid separation in tailing processing. The using technique comprises: the flotation and tailing processing.The multifunctional ore dressing chemical also can be used in tailing processing alone. The multifunctional ore dressing chemical can improve production efficiency, improve mine environmental protection, greatly improve the economic benefits of the mine, improve the return water recovery effect and reduce mine environment pollution.

Owner:李海红

Reverse flotation collecting agent of cellophane and preparation method thereof

InactiveCN103357509AEfficient removalImprove complexation abilityFlotationCellophaneReverse flotation

The invention relates to a reverse flotation collecting agent of collophane, and particularly to the collecting agent manufactured by the compounding and combination of modified fatty acid, strong alkali solution, and fatty acid, and a preparation method thereof. The method comprises the following steps: mixing raw materials of 1-5 parts of Alpha-hydroxy oleinic acid, 0.2-1.5 parts of strong alkali A, 0-1 parts of oleinic acid, and 1 parts of saturated higher fatty acid in parts by weight, wherein the temperature is controlled between 60-95 DEG C, and the mechanical stirring is 2-5 hours, so as to obtain basic materials; when in use, adding water to preparing 2 wt%-50 wt% water solution. The combination collecting agent obtained by the compounding of Alpha-hydroxy oleinic acid, strong alkali, oleinic acid, and saturated higher fatty acid has the advantages that the ordinary temperature selectivity is strong, the dispersivity is good, the medicine dosage is small, the cost is low, the beneficiation overall efficiency is obviously improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Equipment combination for fine flake graphite flotation technology

InactiveCN102649100AImprove efficiencyReduce energy consumptionWet separationEnergy consumptionMaterials science

The invention relates to equipment combination for fine flake graphite flotation technology, and belongs to a graphite separation technique. The fine flake graphite flotation technology provided by the invention adopts the scheme as follows: graphite mine arrow coarse grinding arrow classification arrow rougher floatation and two times of scavenging arrow four times of regrinding and five times of concentration for rough concentrate. The equipment combination for fine flake graphite flotation technology adopts the scheme as follows: the main equipment comprises a rod mill, a hydrocyclone, flotation columns I,II,III,IV,IV,V,VI,VIIand VIII, and regrind mills I,II,III and IV. The equipment combination has the following benefits: 1) the regrind mills are adopted as regrind equipment so that the efficiency is high and the energy consumption is low; 2) the flotation columns are adopted as flotation equipment so that the efficiency is high, the energy consumption is low and the floatation effect is good; and 3) the graphite concentrate as the final product is high in grade and high in recovery rate.

Owner:SHANDONG LAIWU COAL MINING MACHINERY

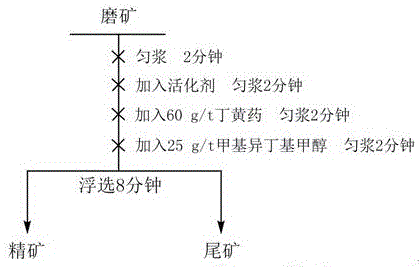

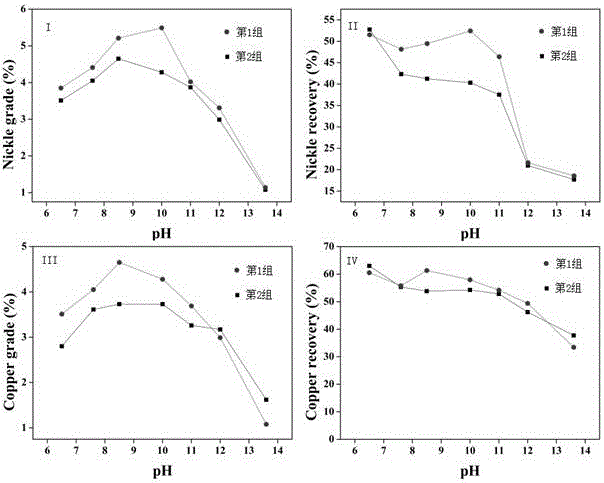

Activating agent for flotation of copper-nickel sulfide ores

InactiveCN105665152ARaw materials are cheap and easy to getApplicable industryFlotationNickel saltPhysical chemistry

The invention discloses an activating agent for flotation of copper-nickel sulfide ores.The activating agent is prepared from a component A and a component B, wherein the component A is copper salt or nickel salt, and the component B is amine, ammonia or ammonium salt.Compared with an existing activating agent for flotation of copper-nickel sulfide ores, the activating agent for flotation of the copper-nickel sulfide ores can remarkably improve the flotation and recovery rate and grade of the nickel-copper the copper-nickel sulfide ores, a good flotation effect can be obtained within the ore pulp pH value range of 7-11, the activating agent adapts to the complicated and volatile ore pulp conditions of industrial flotation, raw materials are cheap and easy to obtain, no harmful gas nor volatile substance is discharged after the activating agent is added into a flotation system, and the activating agent is green, is environmentally friendly, is harmless to the body of an operator and does not corrode flotation equipment.

Owner:LANZHOU UNIVERSITY

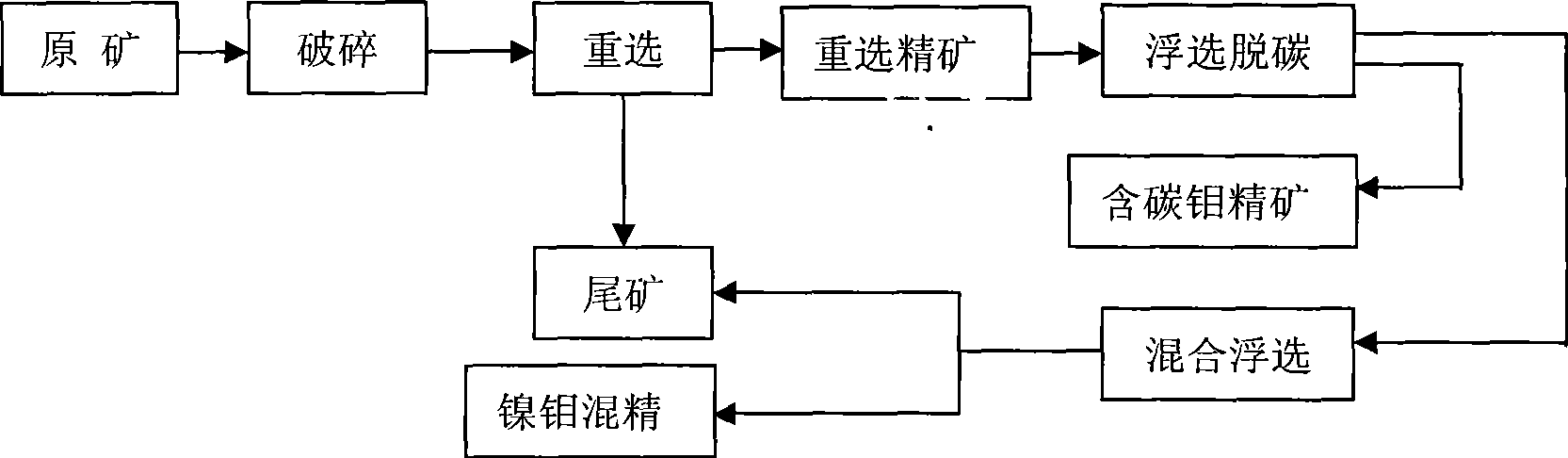

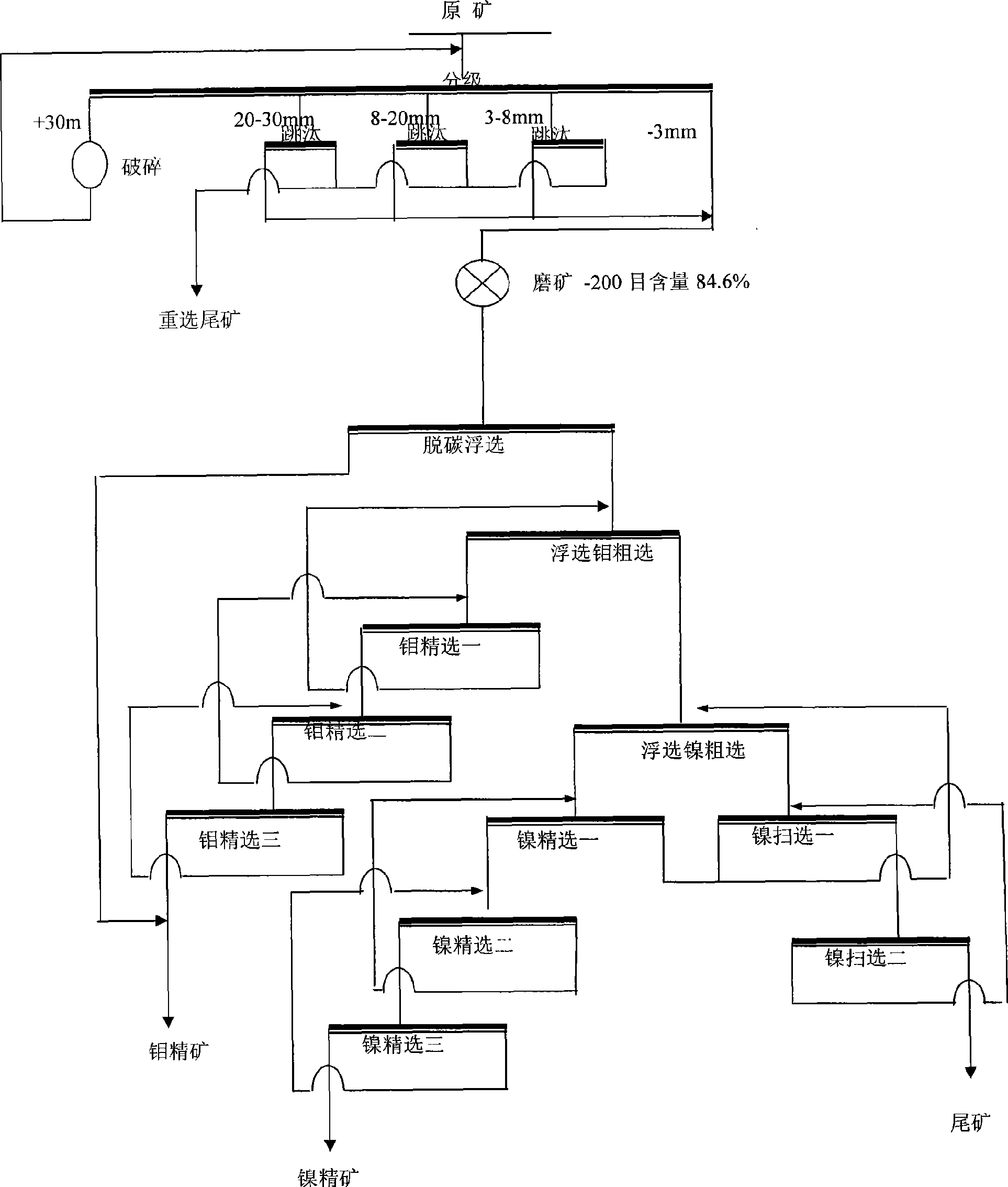

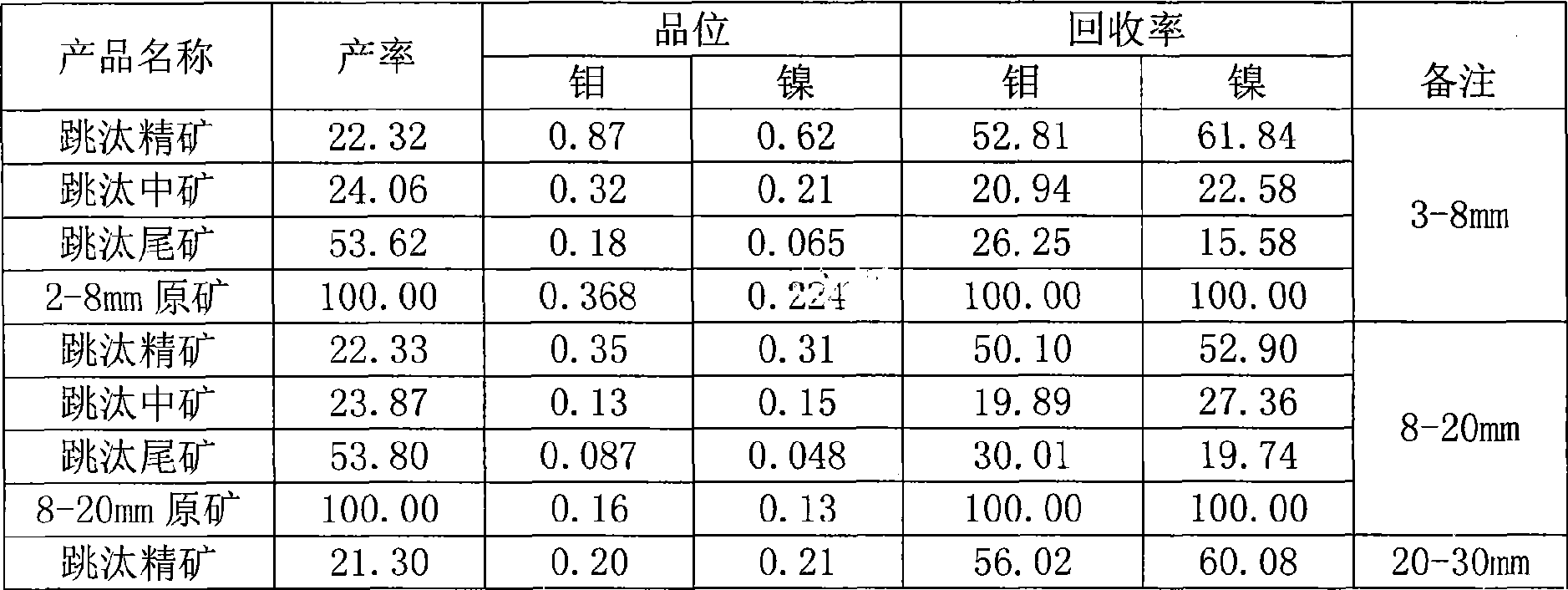

Mineral separation process of high-carbon molybdenum-nickel ore

The invention provides a beneficiation method for a high-carbon molybdenum nickel ore, which adopts floatation decarbonization so as to eliminate the influence of high-content carbon substances on subsequent nickel floatation. Furthermore, the beneficiation process adopts sieve classification with jigging and tail throwing so as to enhance the floatation and selected grade, then rough concentrates are selected again and treated by floatation after being ground, and the ore concentrates are selected again with tail throwing to enhance the floatation and selected grade without ore grinding. The invention can greatly reduce the floatation quantity, has good beneficiation index and provides a new way for developing a low-grade high-carbon molybdenum nickel ore.

Owner:HUNAN RES INST FOR NONFERROUS METALS

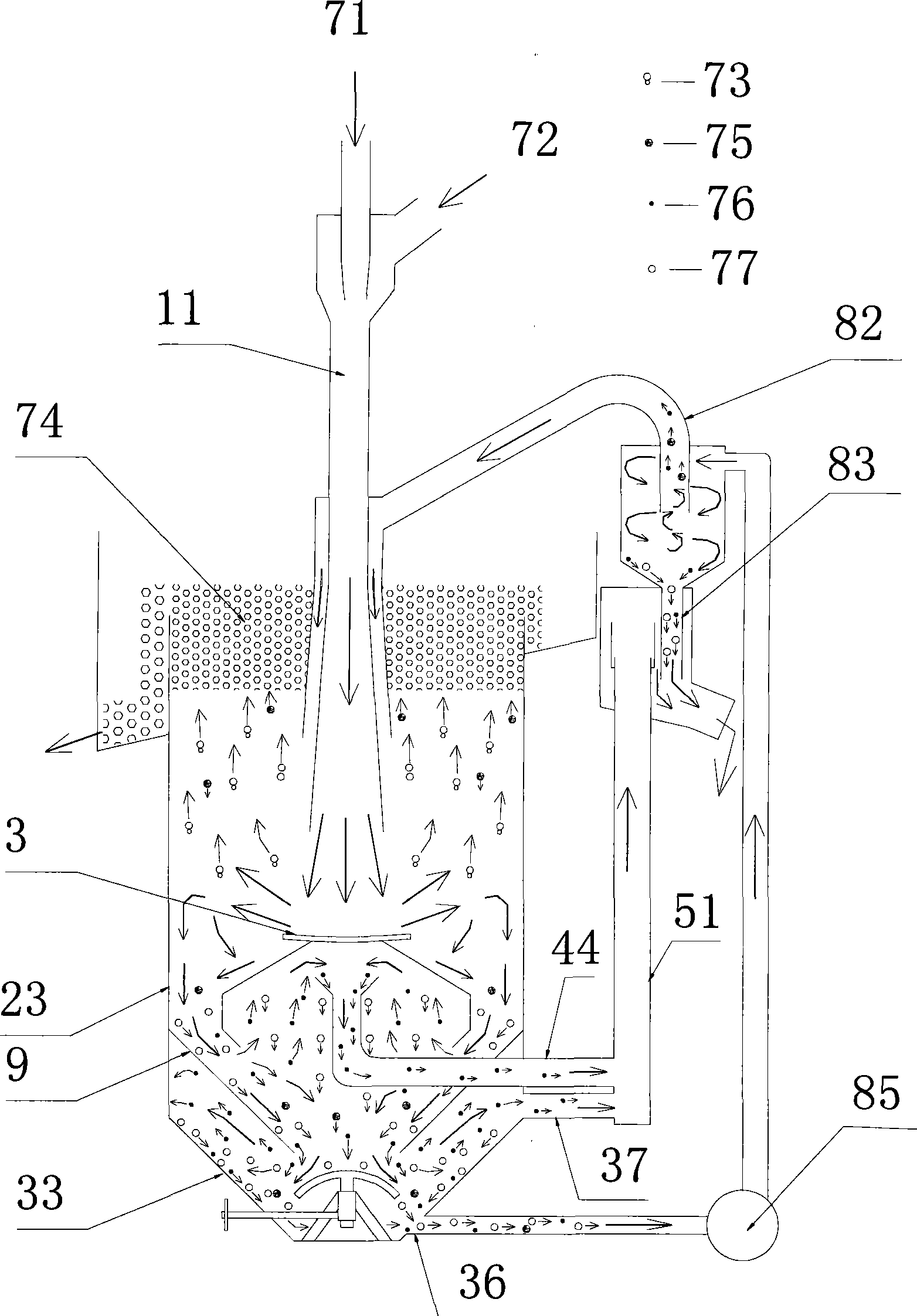

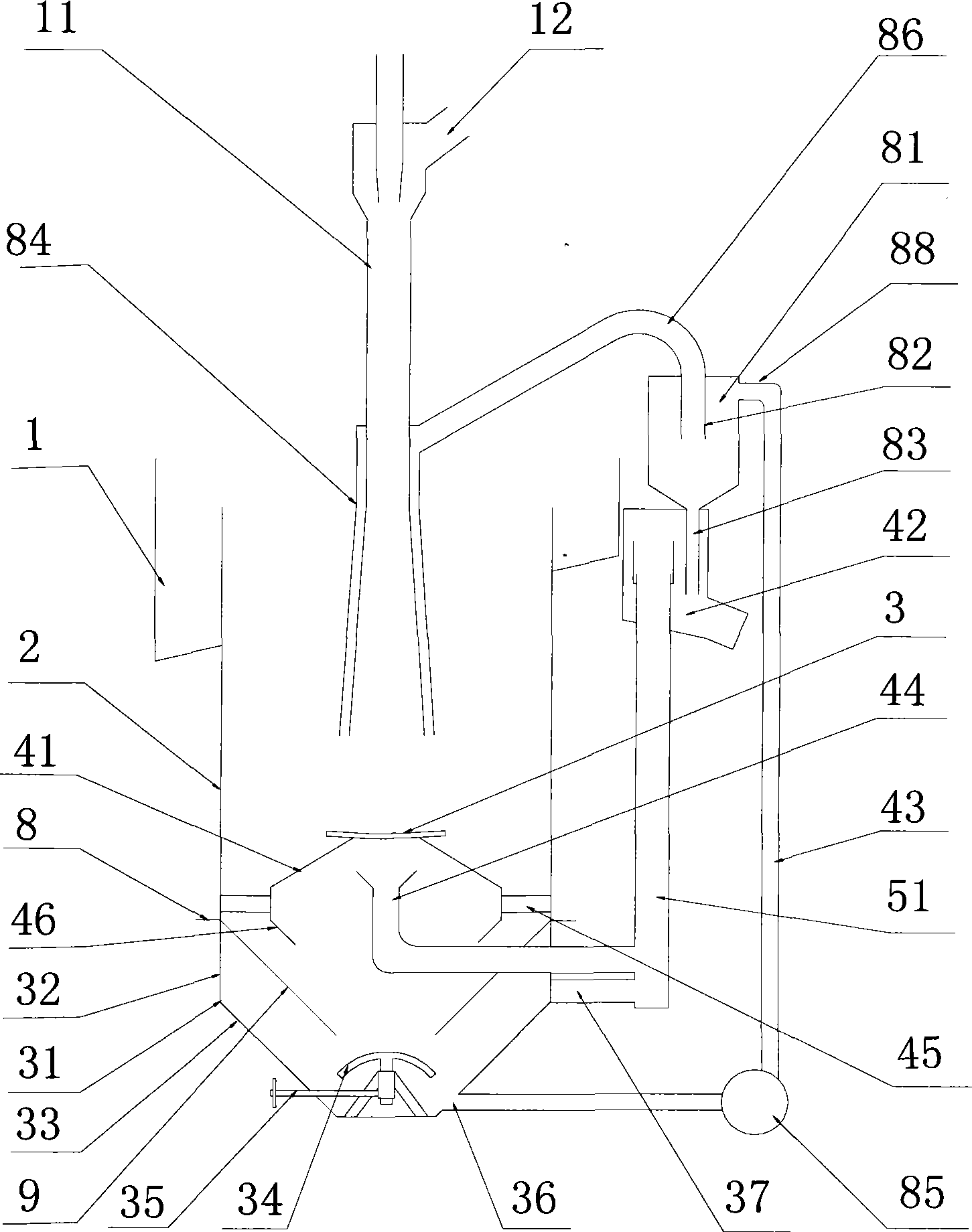

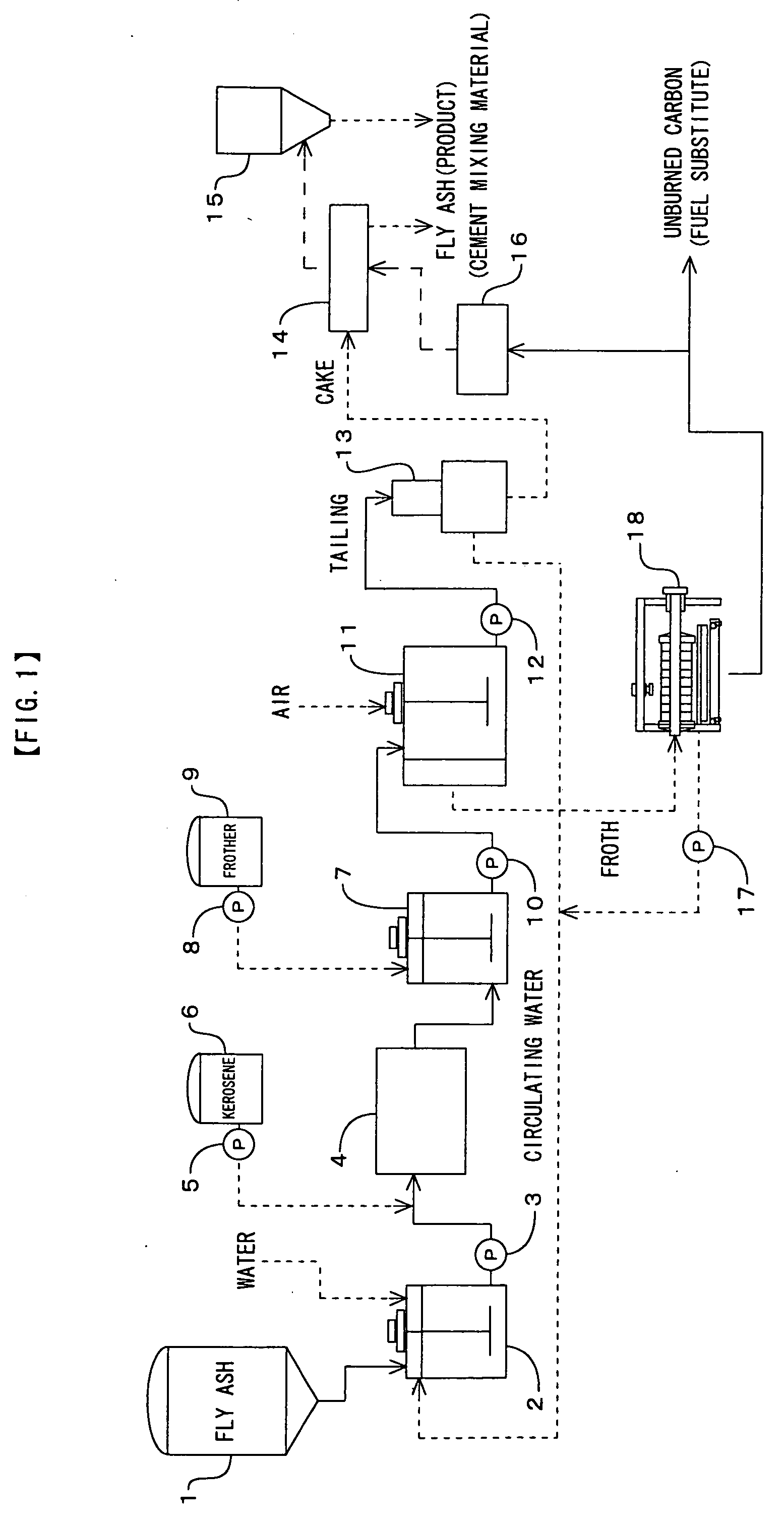

Self-gas supply mixed fly ash multistage flotation separation system

The invention discloses a self-gas supply mixed fly ash multistage flotation separation system, which comprises at least two flotation separation devices, wherein the first flotation separation device comprises a circulating device and the second flotation separation device comprises a gas diffusing device; a circulating tube has a Venturi tube structure, and a gas supplementing device is arranged at a position, which corresponds to the Venturi tube structure and where a negative pressure is formed, on the side wall of the circulating tube; the surface of the gas diffusing device has a plurality of air holes which form different angles with a horizontal plane respectively; and the discharging hole of the first flotation separation device is communicated with a distribution device of the second flotation separation device through a discharge tube. The system has the advantages that: 1, the self gas supply is realized by using the Venturi tube structure; and 2, the floating in a disturbed flow state of air bubbles in a cylinder is realized by using the conical gas diffusing device, so a better flotation effect is achieved.

Owner:FUJIAN LONGYAN LONGNENG FRYASH COMPREHENSIVE UTILIZATION

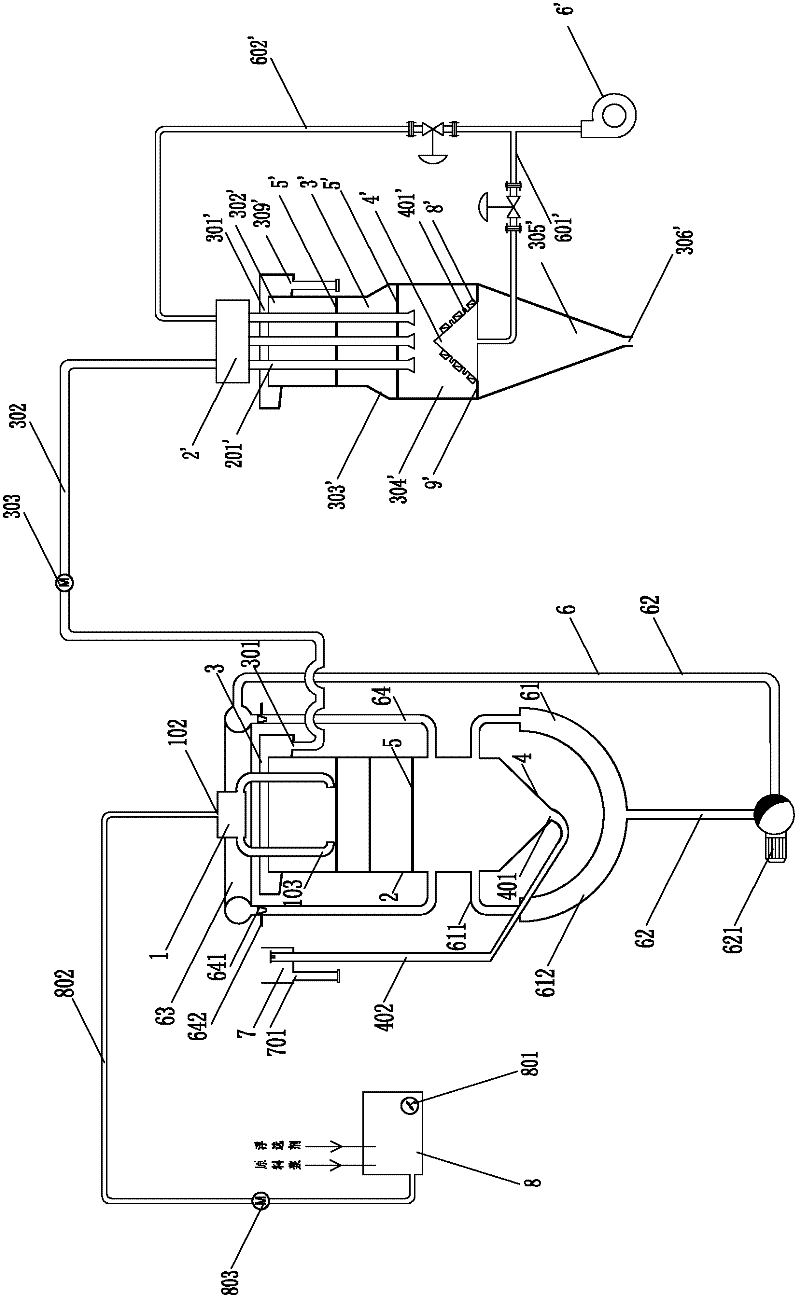

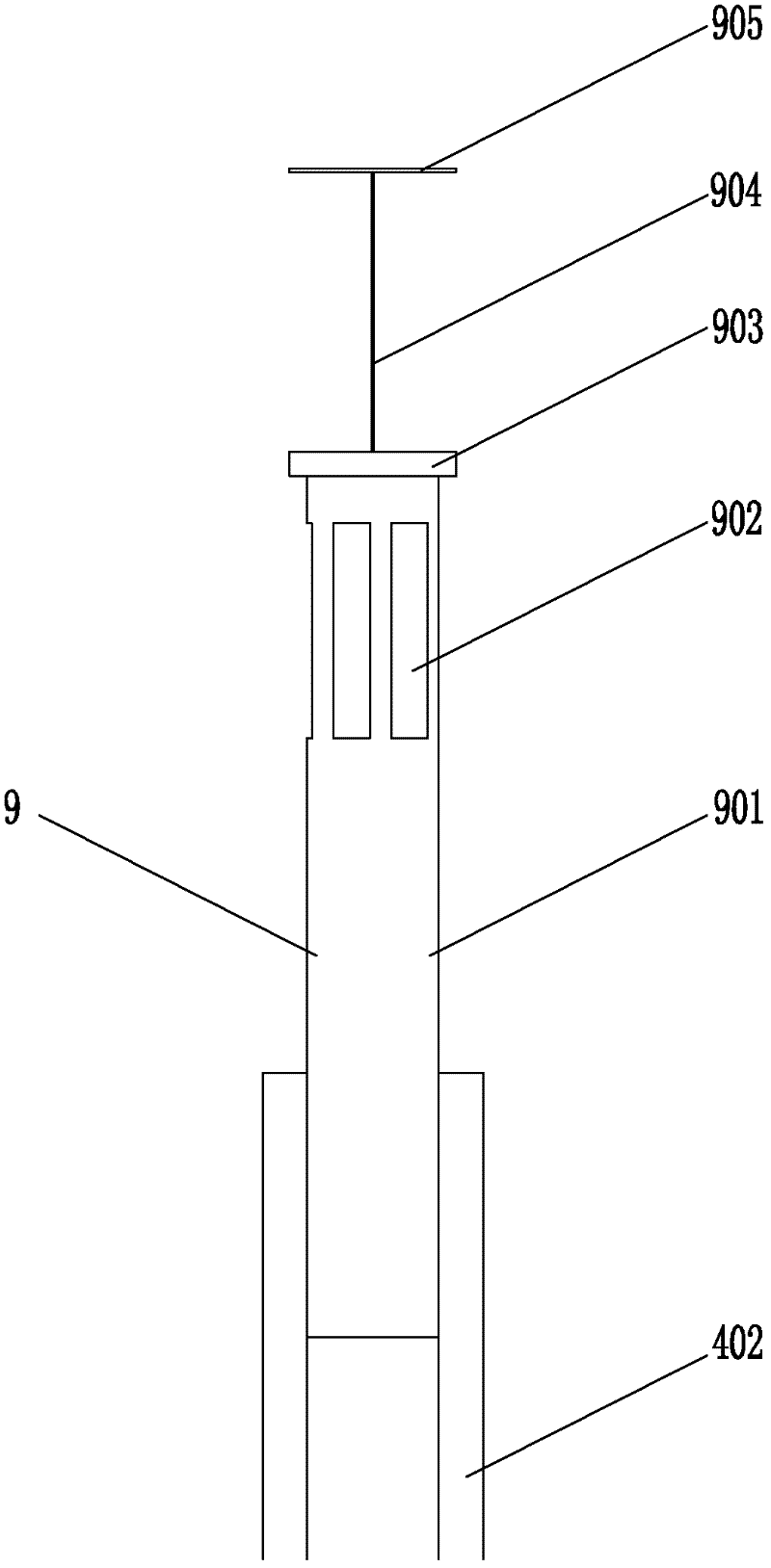

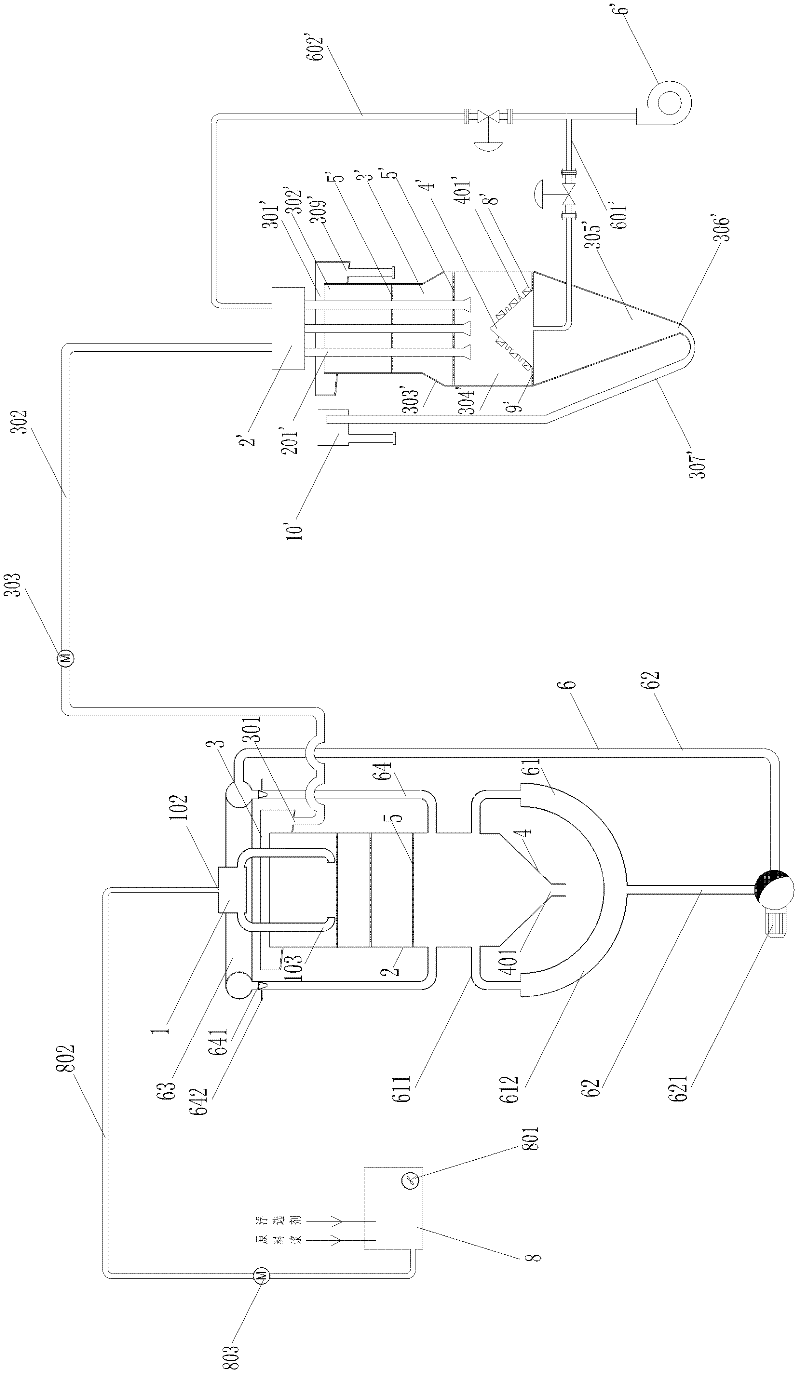

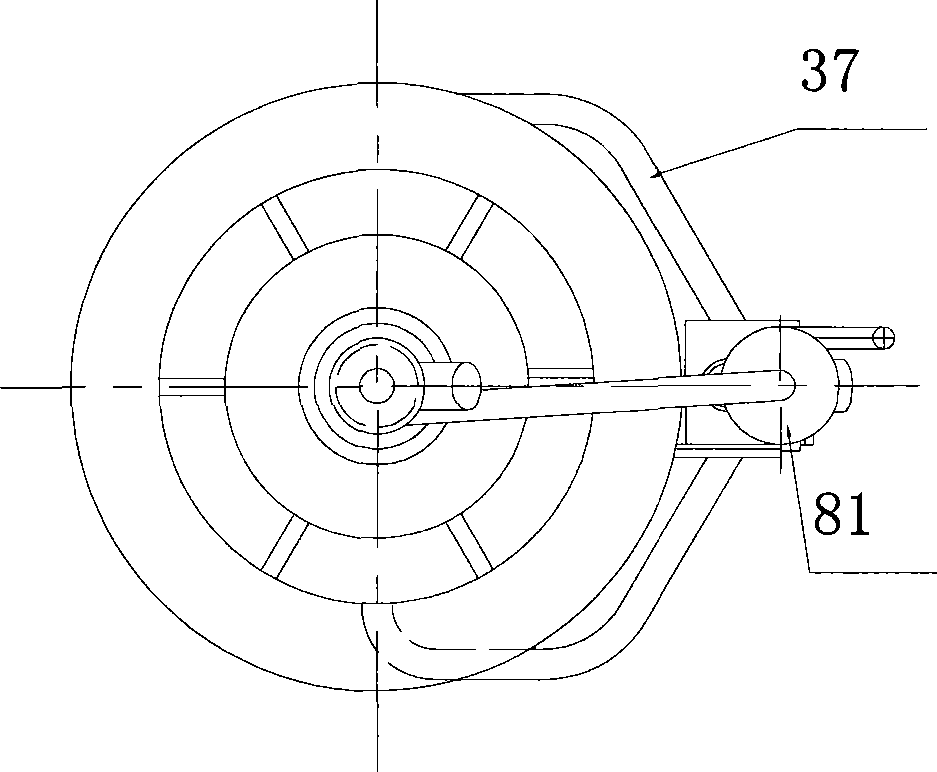

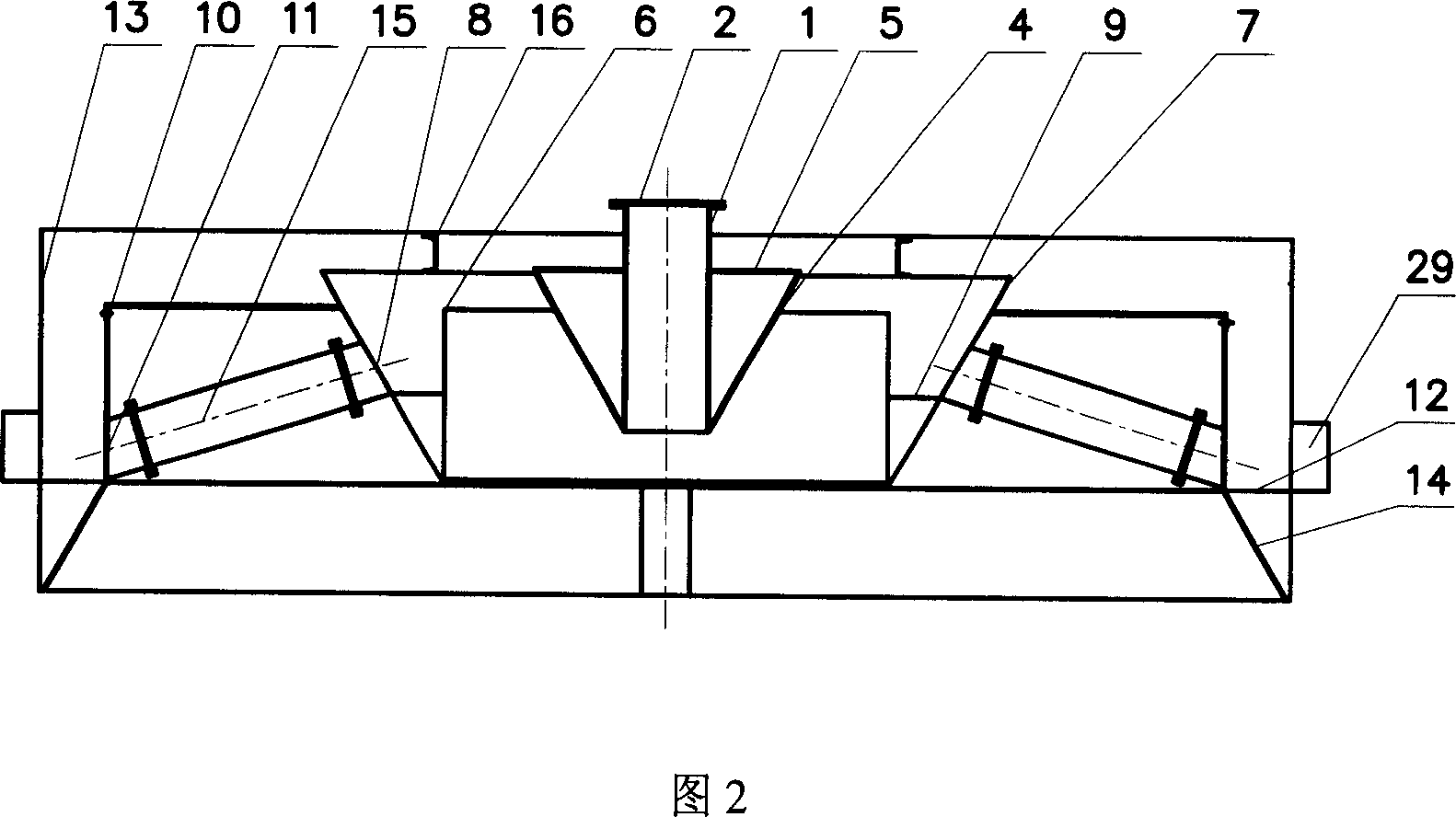

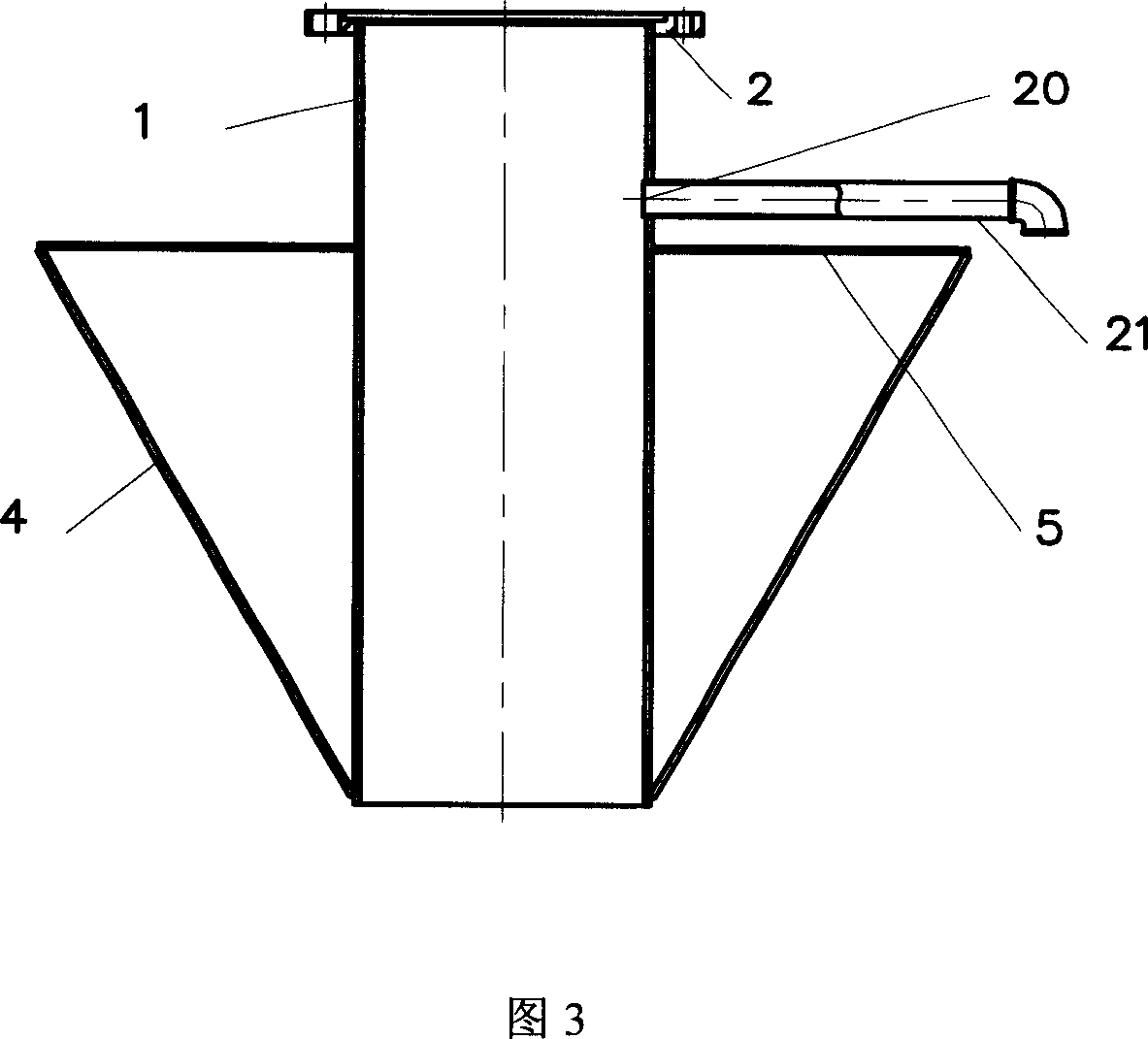

Double tail-removing gravity-flotation combined sorting method and device

The invention relates to a double-tailing discharging gravity-floating combined separation method and a device thereof, and belongs to a double-tailing discharging gravity-floating combined separation method aiming at slime and a device thereof. The aim of the invention is to solve the technical problems existing in the prior flotation machine that the separation effect of ultrafine grains is low and the upper limit of the column flotation is difficult to be effectively related with the lower limit of the heavy medium separation. The method comprises three steps of crude ore flotation and rough separation and graded tailing discharging, gravity scavenging tailing discharging and gravity separation finished ore reflotation. The double-tailing discharging gravity-floating combined separation machine comprises a jet flow flotation column, a first tailing discharging graded device and a secondary tailing discharging graded device; the first tailing discharging graded device is arranged below the jet flow flotation column, a cyclical middling underflow opening of the first tailing discharging graded device is connected with the secondary tailing discharging graded device, and a central ore feeding pipe of the secondary tailing discharging graded device is connected with the jet flow flotation column. The method and the device have multiple effects of coarse slime separation and highly selective floatation of fine coal and ultrafine coal, thereby improving the efficiency of the gravity-floating combined separation.

Owner:TAIYUAN UNIV OF TECH

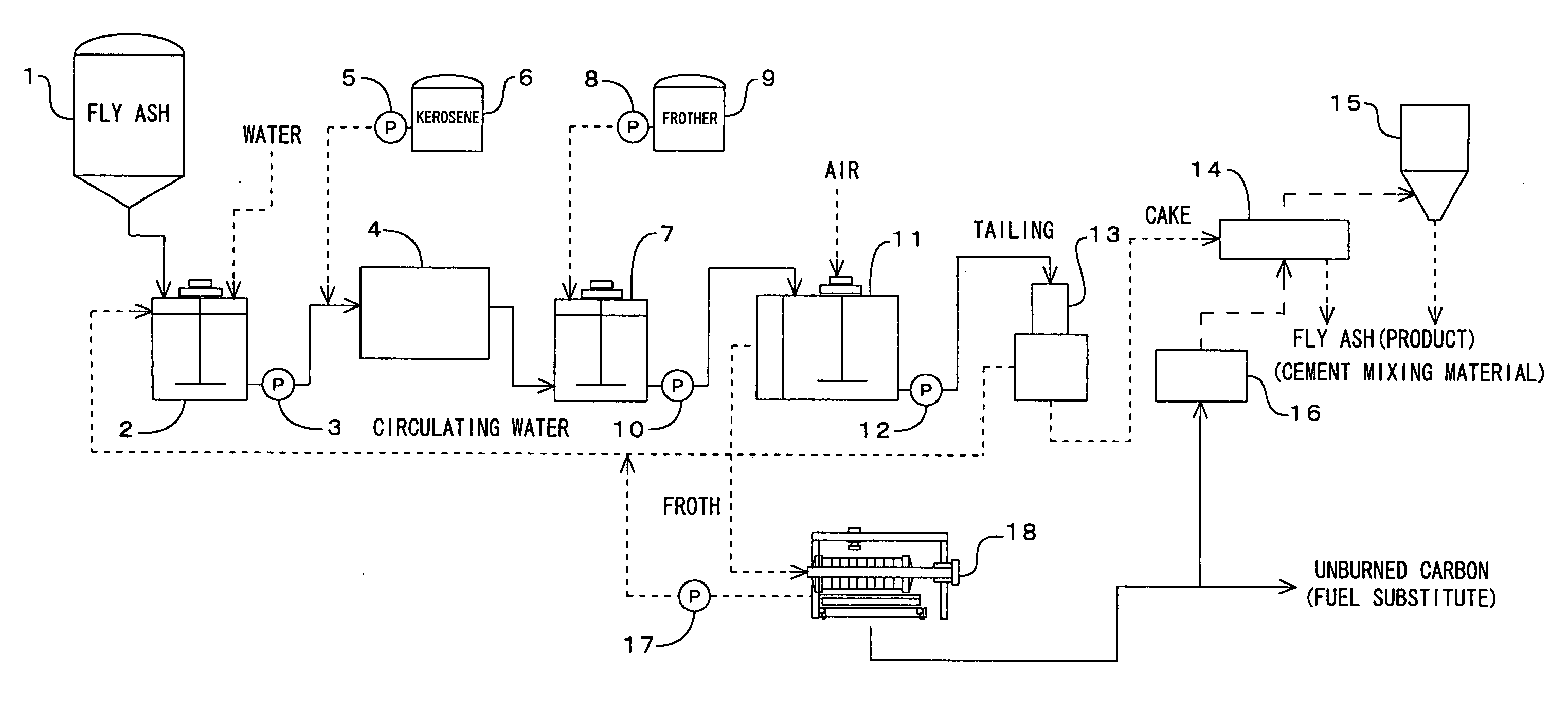

Fan-In Leadframe Semiconductor Package

ActiveUS20070199486A1Reduce the amount requiredLower surface energySolid waste managementElectrostatic separationSemiconductor packageSlurry

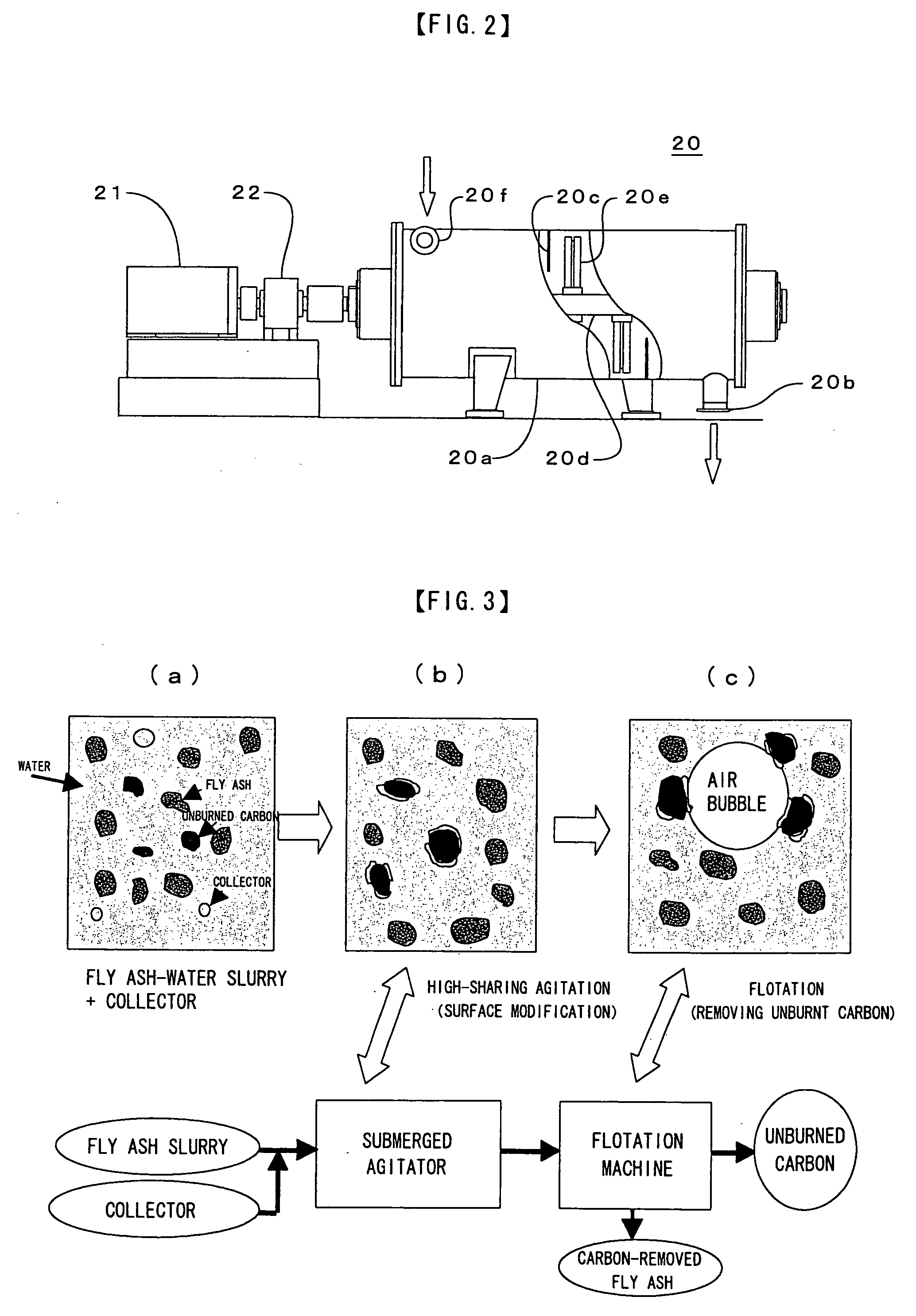

Unburned carbon is efficiently removed from fly ash, and effective utilization of the fly ash and removed unburned carbon is attained. Water is added to fly ash to thereby obtain a slurry. A collector is added to the slurry, and shearing force is applied to the slurry and collector to thereby attain a surface modification. The mixture is subjected to flotation operation at which unburned carbon of fly ash is attached to froths and surfaced. The application of shearing force to the slurry and collector can be carried out by means of a submerged agitator whereby an agitation power of 0.7 to 10 kWh / m3 is applied per unit quantity of slurry. The fly ash concentration of the slurry is in the range of 3 to 50 wt. %, and the amount of collector added is in the range of 5 to 100 wt. % based on the amount of unburned carbon of fly ash. The unburned carbon separated by flotation can be used as fuel, and the fly ash (product) having its unburned carbon content reduced to 1 wt. % or below can be used as a cement mixing material or a raw material for production of lightweight aggregate.

Owner:JFE PROJECT ONE CO LTD +2

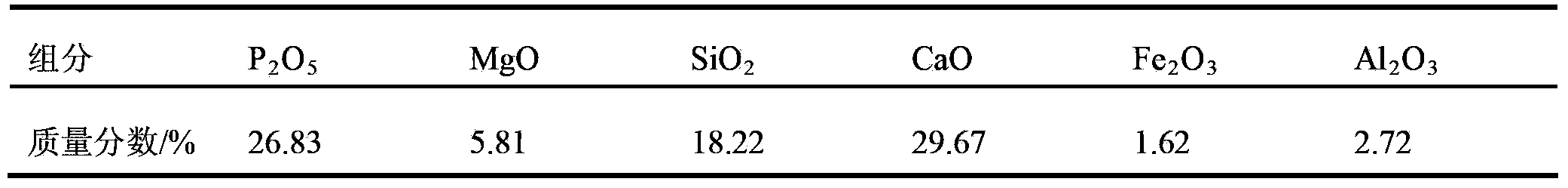

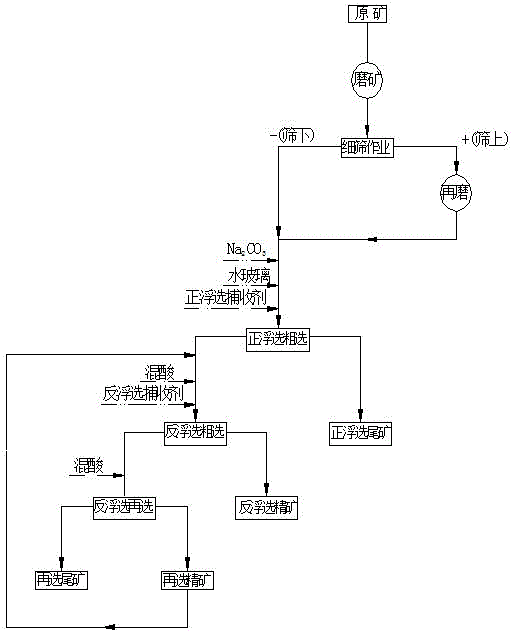

Method for performing fine sieving, regrinding and bulk flotation on low-level silicon calcium collophanite

The invention discloses a method for performing fine sieving, regrinding and bulk flotation on low-level silicon calcium collophanite. The method comprises the following steps: finely grinding the low-level silicon calcium collophanite, adding water to prepare original ore pulp; sieving the grinded original ore pulp by a fine sieve; regrinding materials on the sieve, then adding water to prepare original ore pulp, putting the original ore pulp into a floatation device together with materials under the sieve, performing direct rough floatation so as to obtain under-sieve product direct floatation roughing concentrate and tailings; performing reverse floatation on the under-sieve product roughing concentrate so as to obtain under-sieve reverse floatation recleaning concentrate and tailings. Compared with a two-section continuous ore grinding technology, the method provided by the invention can be used for improving the floatation condition, and reducing the recovery loss caused by fine fraction mechanical entrapment in the floatation operation on one hand, and can be used for reducing the energy consumption of two-section ore grinding and further reducing the ore separation cost on the other hand. The method provided by the invention can play a favorable floatation effect, and can achieve the industrial production of purification of low-level silicon calcium collophanite easily.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

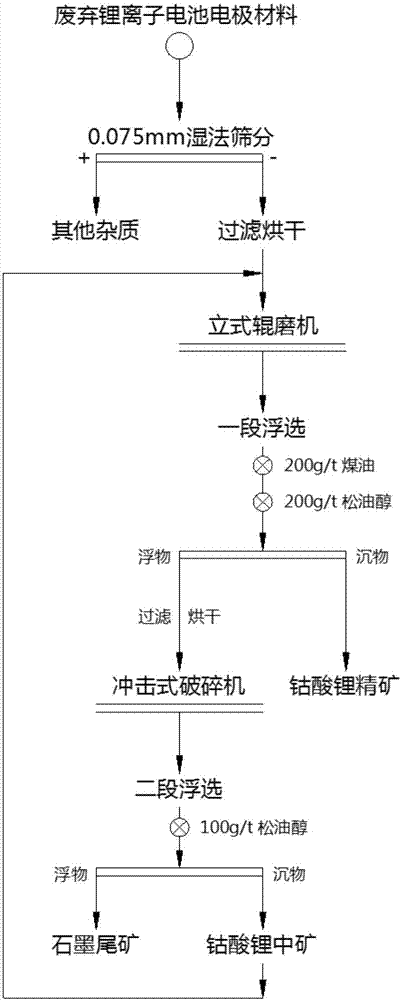

Method for separating lithium cobalt oxides and graphite from waste lithium ion battery electrode material

ActiveCN107262263AImprove hydrophobicityImprove flotation effectWaste accumulators reclaimingWet separationWastewaterGraphite

The invention discloses a method for separating lithium cobalt oxides and graphite from a waste lithium ion battery electrode material. The method comprises the following steps that (1) the waste lithium ion battery mixed anode and cathode material is screened, and an undersize material is obtained; (2) the undersize material enters ore grinding equipment after being subjected to filtering and drying, and an ore ground product is obtained; and (3) the ore ground product enters a flotation machine for reverse flotation separation and enrichment, namely the first-stage flotation, lithium cobalt oxide concentrate is a sediment, a float enters crushing equipment to be treated after being subjected to filtering and drying, then second-stage flotation is conducted, floats obtained through the second-stage flotation are graphite tailings, and lithium cobalt oxide middling is a sediment and returned to the ore grinding equipment in the step (2) for ore grinding flotation again. Through the method, the lithium cobalt oxides with the grade being 92.56% and the graphite product with the grade being 83.67% can be obtained, and the method has the advantages of being high in handling capacity, mature in equipment technology, low in cost investment and free of poisonous gas and wastewater and is a good choice for industrial application.

Owner:CHINA UNIV OF MINING & TECH +1

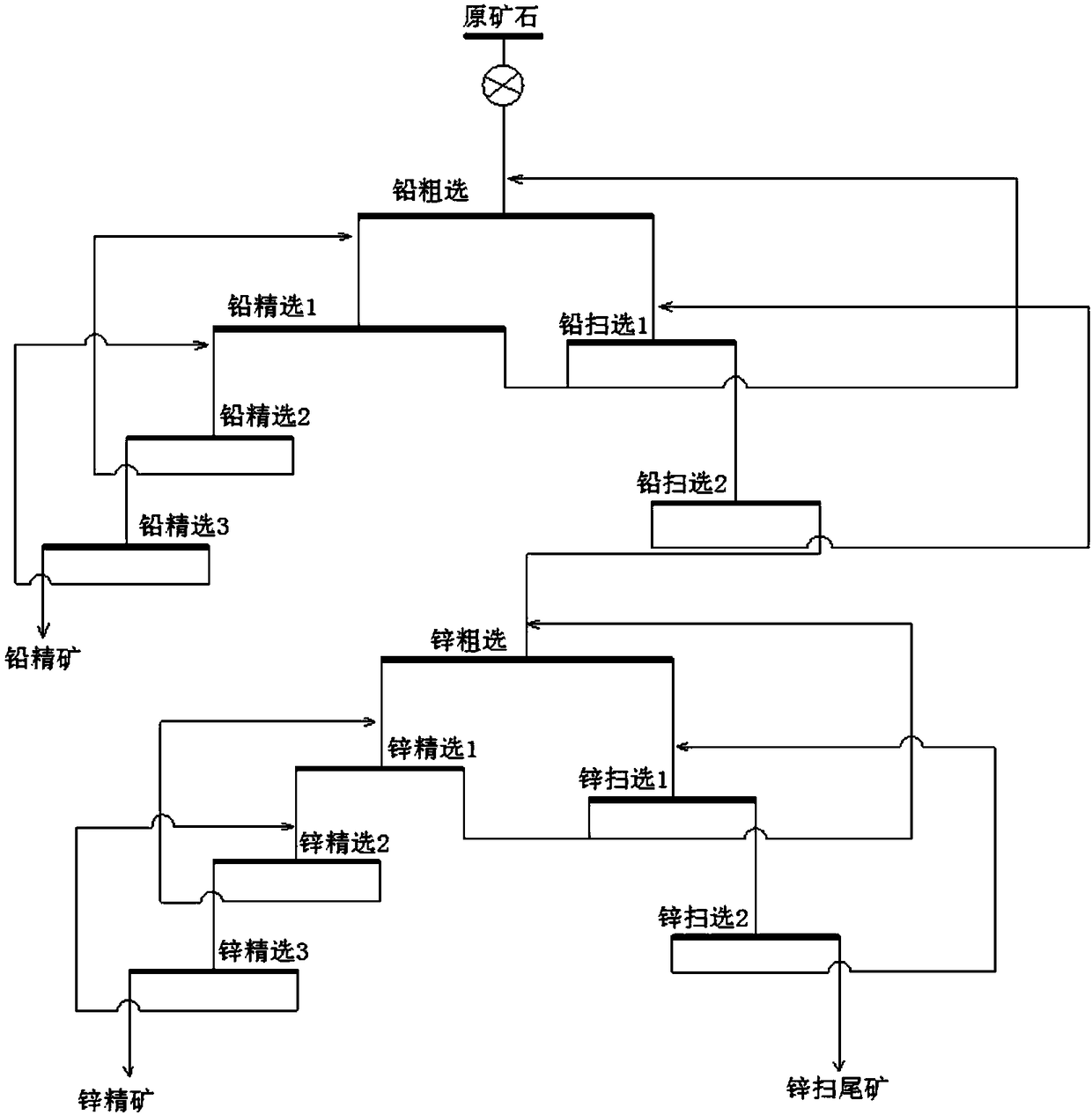

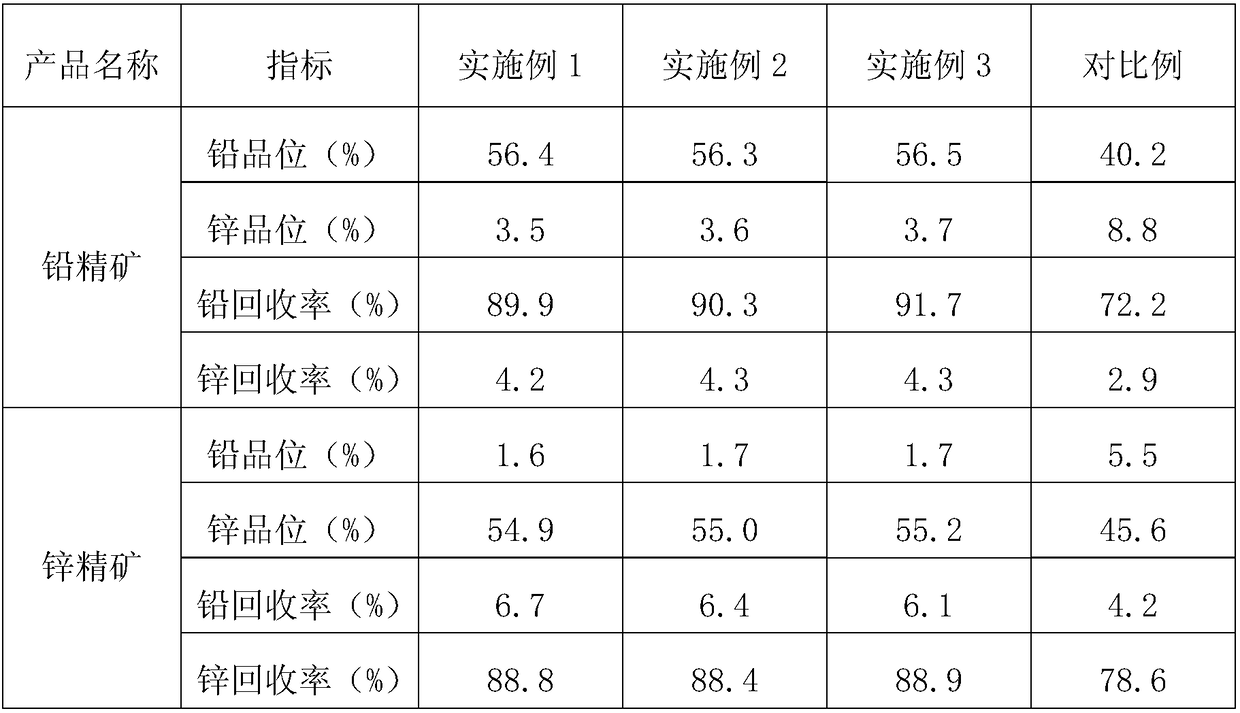

Selection method of lead and zinc sulfide ore

The invention discloses a selection method of lead and zinc sulfide ore, and belongs to the technical field of beneficiation. The selection method comprises the steps of milling of raw ore, flotationof lead and flotation of zinc, wherein during rough flotation of lead, lime, calcium hypochlorite, zinc sulfate, sodium sulfite, sodium sulfide, dimethyl dicarbonate, ethyl thio carbamate, sodium n-butylxanthate, dianilinodithiophosphoric acid, diphenyl amino phosphorodithioic acid and sodium carbonate are added; during fine flotation of lead, lime, zinc sulfate, sodium sulfite and sodium sulfideare added; during scavenging of lead, lime, calcium hypochlorite, zinc sulfate, sodium sulfite, sodium sulfide, dimethyl dicarbonate, ethyl thio carbamate, dianilinodithiophosphoric acid, diphenyl amino phosphorodithioic acid and sodium carbonate are added; during rough flotation of zinc, lime, copper sulfate, ammonium sulfite, sodium n-butylxanthate and terpenic oil are added; during fine flotation of zinc, lime is added; and during scavenging of zinc, lime, copper sulfate, ammonium sulfite, sodium n-butylxanthate and terpenic oil are added. By adoption of the selection method of lead and zinc sulfide ore, the problem that when a traditional flotation method is used for selecting lead and zinc sulfide ore, the recovery rate of lead and zinc is low is solved.

Owner:广西华洋矿源材料有限公司

Preparation method, application and using process of floating agent prepared from drainage oil

The invention relates to a preparation method, application and using process of a floating agent prepared from drainage oil, wherein the preparation method of the floating agent comprises the following steps of: (a) purifying the drainage oil; (b) carrying out hydrolysis reaction on the purified drainage oil obtained from the step (a) to obtain the floating agent used for floating ores. When the floating agent used by the invention and prepared from the drainage oil is used as a collecting agent for floating the ores, the selectivity of the collecting agent can be enhanced, and the technical indicator and the economic indicator of flotation are enhanced favorably; and in addition, because a raw material used for the preparation of the floating agent is the drainage oil, the technical scheme provided by the invention has important significance on the aspects of preventing environmental pollution, simplifying production process, reducing food security threat, and the like.

Owner:鄂尔多斯市君致清环境科技有限公司

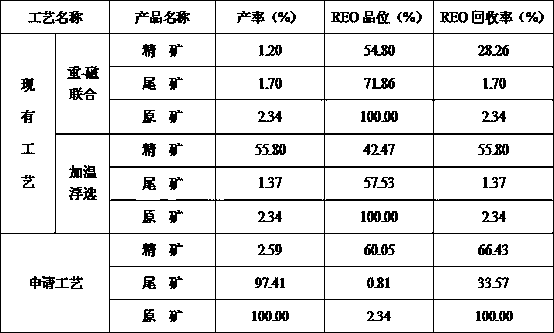

Foaming agent for rare earth ore dressing and normal temperature mineral separation processing for low grate refractory rare earth ore

The invention provides a foaming agent for rare earth ore dressing and normal temperature mineral separation processing for low grate refractory rare earth ore, and particularly relates to a low grade normal temperature mineral separation processing with large slurry containing, fine mineral disseminated extent, complex mineral constitute, and 3% REO grade. The processing provided by the invention is characterized in that the 3% REO grade low grade rare earth ore is taken as the raw material, the mineral pulp temperature ranges from 10 DEG C to 25 DEG C, the flotation pre-enrichment-wet magnetic separation purification beneficiation method is adopted, so as to obtain rare earth ore concentrate with high grade and high recovery. The invention has the marked advantages that the flotation pulp temperature has a wide range of application, needs no warming, is short in processing process, and can remarkably improve the recovery of low grade complex rare earth ore.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Zinc oxide ore floatation agent and preparation method thereof

The invention provides a zinc oxide ore floatation agent. The zinc oxide ore floatation agent comprises a collecting agent, a foaming agent and an emulsifying agent, wherein the mass ratio of the foaming agent to the collecting agent is 1:6-1:1, and the mass ratio of the emulsifying agent to the collecting agent is 1:6-1:1. A preparation method comprises the steps that (1) the foaming agent is added into the collecting agent, dissolved at the temperature of 25-80 DEG C and stirred evenly, and the mass ratio of the foaming agent to the collecting agent is 1:6-1:1; (2) an appropriate amount of water is added into the mixture evenly mixed in the first step to obtain a solution with the mass concentration being 0.1-10%; and (3) the emulsifying agent is added to the solution obtained in the second step, so that the collecting agent and the foaming agent are fully emulsified in the aqueous solution, and the mass ratio of the emulsifying agent to the collecting agent is 1:6-1:1. The floatation agent has the advantages of being good in floatation effect and water solubility, high in dispersing capacity, low in cost, high in recovery rate and the like.

Owner:SHENZHEN RUN SUN CHEM TECH +1

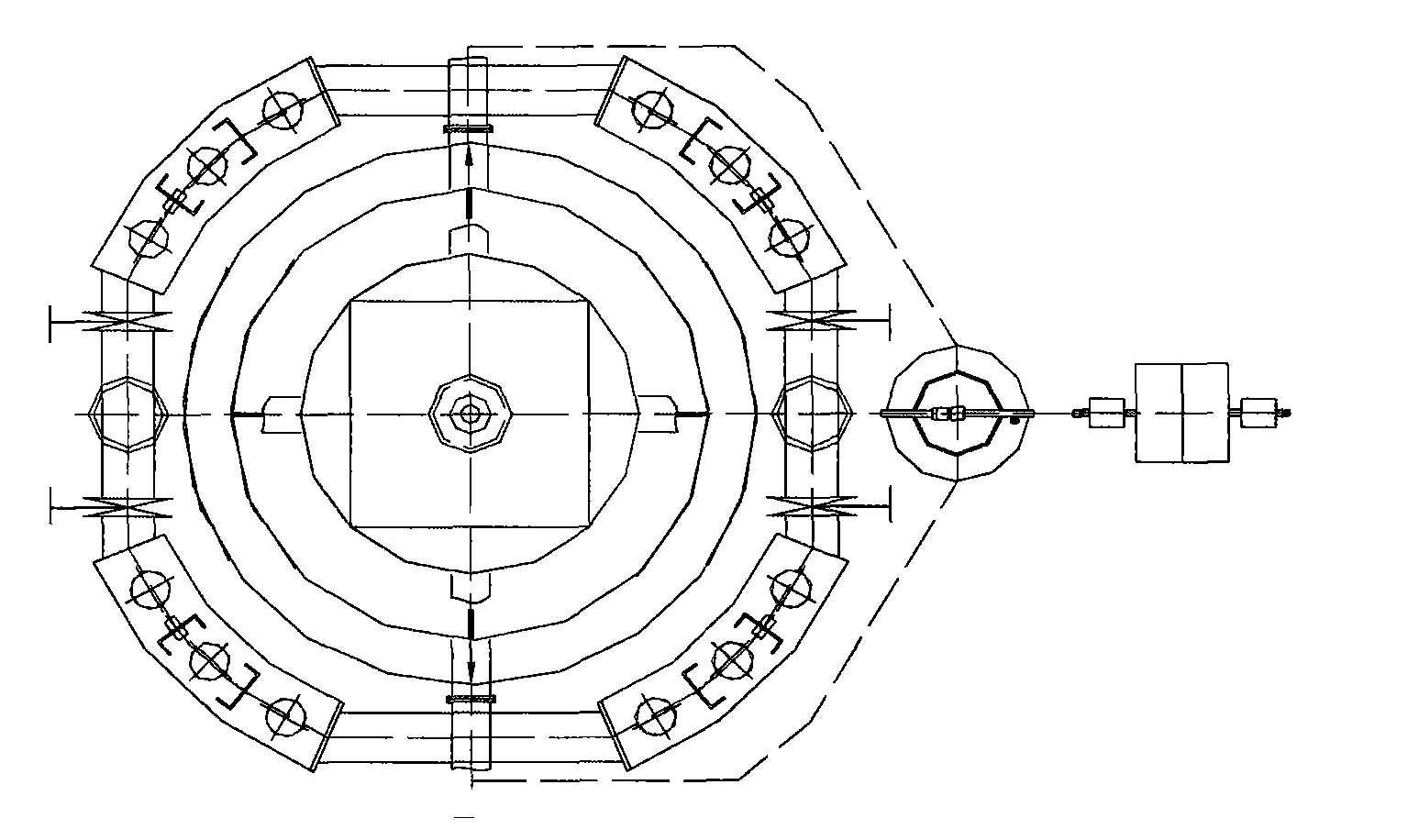

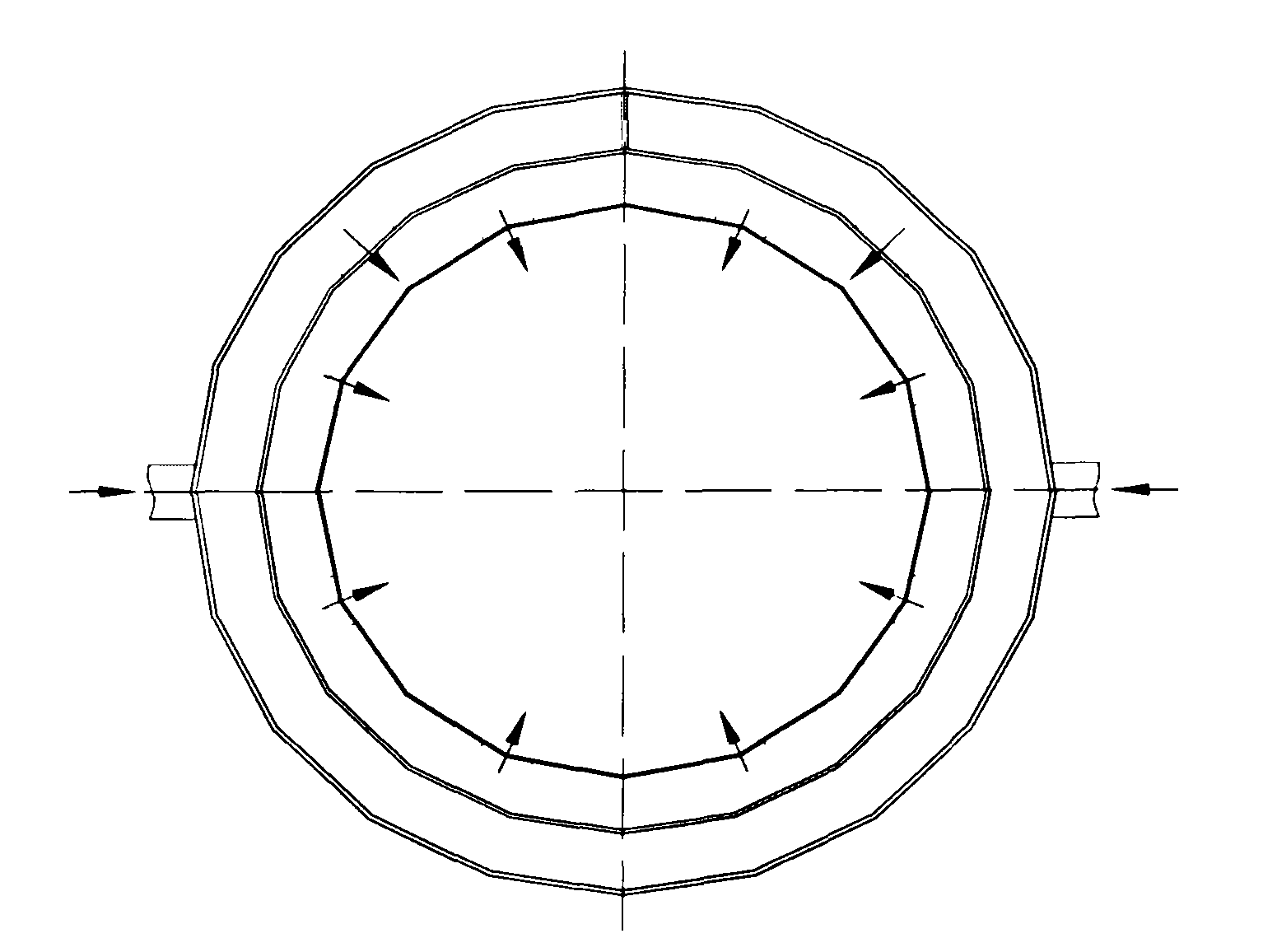

Foam pushing device of floatation machine

InactiveCN1931438AShorten the conveying distanceImprove flotation indexFlotationNon-ferrous metalEngineering

The present invention relates to floatation equipment for separating non-ferrous metal mineral, ferrous metal mineral and non-metal mineral, and is especially foam pushing device for large floatation machine. The foam pushing device is one double foam pushing cone structure comprising an inner foam pushing cone, an inner foam channel, outer foam pushing cone and outer foam channel. The foam pushing device separates the foams inside the floatation tank into two parts, the marginal part exhausted through the outer foam channel and the middle part exhausted through the inner foam channel, and the shortened foam conveying distance ensures the fluent exhaustion of floatation foam and is favorable to the floatation process.

Owner:BEIJING GENERAL RES INSITUTE OF MINING & METALLURGY GUAN MACHINERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com