Method for separating lithium cobalt oxides and graphite from waste lithium ion battery electrode material

A lithium-ion battery and electrode material technology, which is applied in the field of resource utilization of waste lithium-ion batteries, can solve the problems of high-efficiency separation and enrichment of the positive electrode material lithium cobaltate and negative electrode material graphite, and low economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

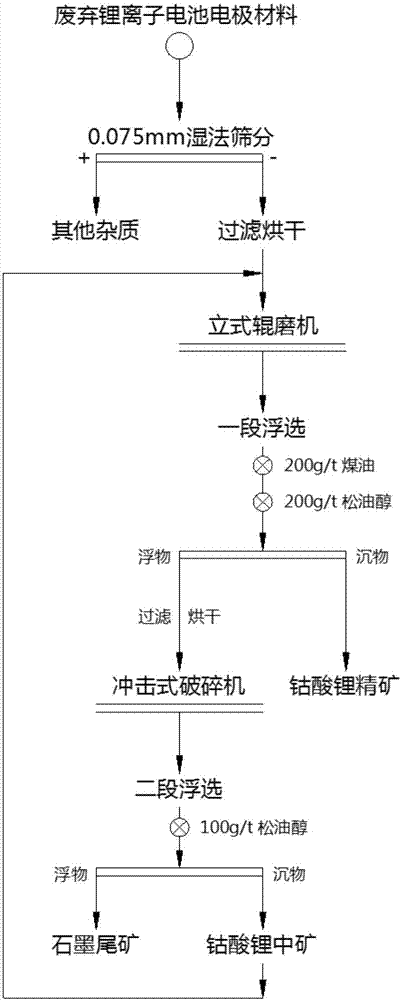

[0027] Such as figure 1 As shown, the present embodiment takes a small-scale experiment as an example, and the present invention is described in detail, including the following steps:

[0028] 1) 50 discarded lithium-ion batteries of the same type were discharged for protection, air-dried naturally, coarsely crushed by a shear crusher, finely crushed by a vertical impact crusher and pre-screened with a 0.25mm standard screen, and the product under the screen was The mixed raw material of lithium cobalt oxide and graphite, that is, the mixed positive and negative electrode materials of waste lithium ion batteries;

[0029] 2) Sieving the mixed positive and negative electrode materials of waste lithium-ion batteries through wet sieving to obtain under-sieved materials with a particle size of less than 0.075mm;

[0030] 3) After the product under the wet sieve is filtered and dried, take 40 g and put it into a Hastelloy grinder for grinding for 5 minutes;

[0031] 4) The ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com