Patents

Literature

52 results about "Wet sieving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for separating silicon from residuals

The invention discloses a method for separating silicon from residuals used in the process of purifying a silicon material by a slag practice, which can effectively separate the purified silicon from residuals after the purification reaction is finished. Based on the method, after the reaction of silicon and residuals is finished and the silicon and the residuals are in a liquid state, the mixed liquid of the silicon and the residuals is poured in a liquid slowly, the liquid can be water or an acid solution or an alkali solution or a water based cooling liquid or an oil-based cooling liquid, and the silicon and the residuals are quenched so as to exchange heat thereof to the cooling liquid, thereby separating the silicon and the residuals due to different physical properties thereof. The silicon and the residuals are quenched, cooled and solidified, the silicon is globoid or botryoidal with a certain size like 3-10mm, the residuals form foam and crisp fine grain solids, the fine grain solids of the residuals are not adhered on the silicon spheres, and the silicon can be taken out by a simple and convenient physical method, e.g. the residuals are kneaded into finer grain solids while the silicon spheres are still in the original shape, and wet sieving is performed to take out the silicon spheres.

Owner:北京应天阳光太阳能技术有限公司

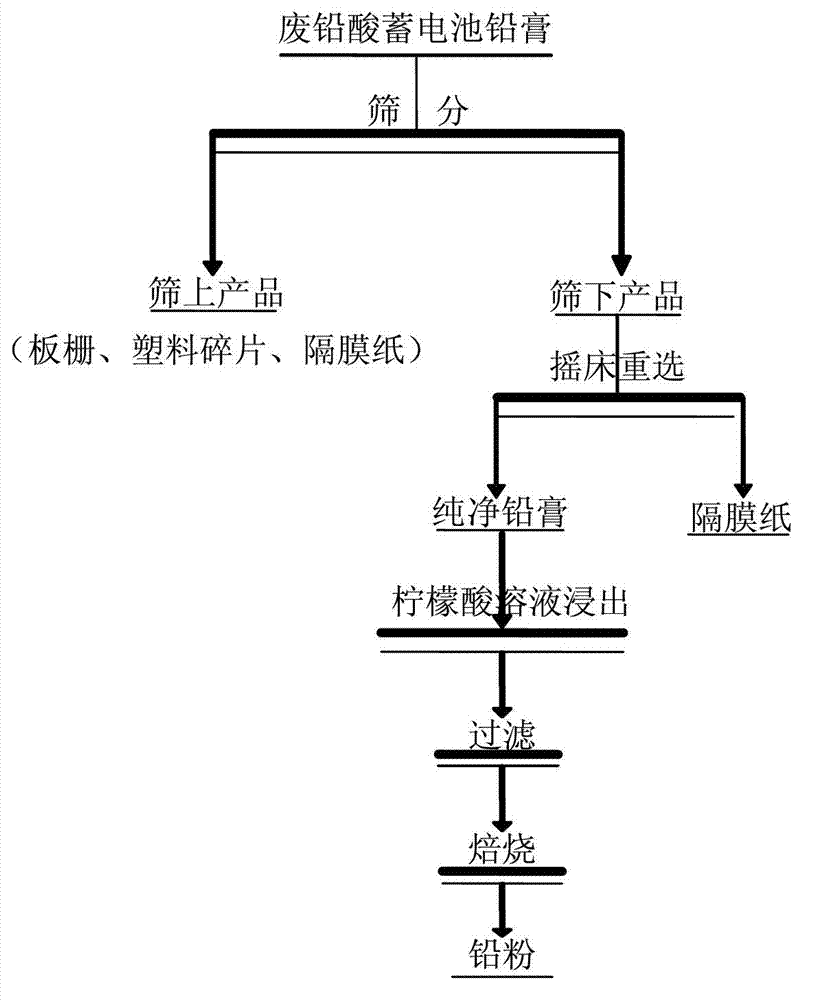

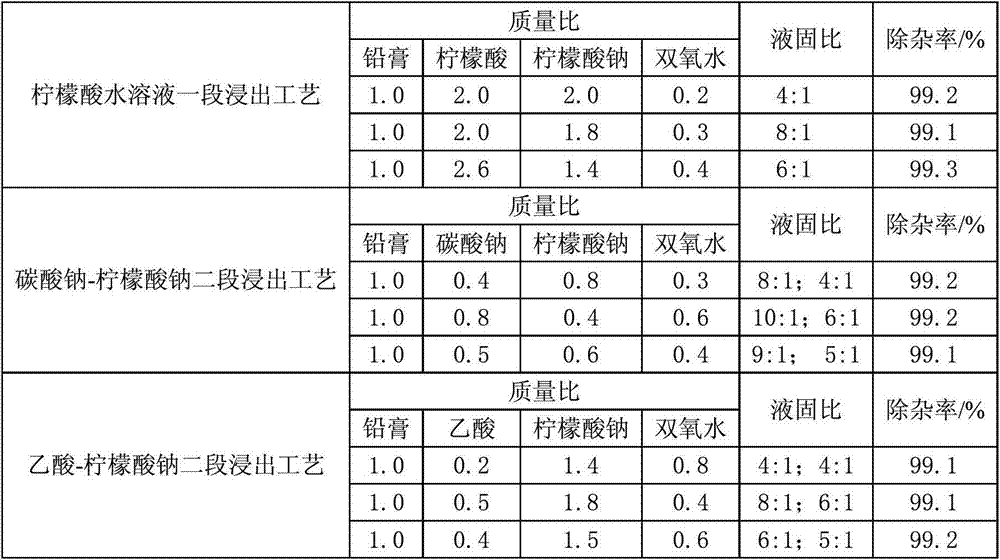

Pretreatment method for lead plaster of waste lead-acid accumulators

ActiveCN103050745AAchieve separationLess investmentWaste accumulators reclaimingBattery recyclingAcetic acidPretreatment method

The invention belongs to the field of utilizing waste lead-acid accumulators to produce secondary lead, and relates to a novel pretreatment method for lead plaster of the waste lead-acid accumulators. The pretreatment method comprises the steps that after the waste lead-acid accumulators are crushed and subjected to preliminary separation, waste lead plaster is obtained; wet sieving or dry sieving is conducted on the waste lead plaster by a 0.85mm-0.106mm sieve; plate grid and plastic fragment products are obtained; table reconcentration is conducted on undersize products; diaphragm paper products and pure lead plaster are obtained; the plate grid and plastic fragment products and the diaphragm paper products can enter a fire smelting system; the pure lead plaster is treated by a citric acid aqueous solution or sodium carbonate or a new acetic acid leaching technology; and lead powder is obtained, and can be used for preparing the lead-acid accumulators directly. The pretreatment method for the lead plaster of the waste lead-acid accumulators is simple in technological equipment, low in investment, low in cost, high in impurity removal rate, clean, highly-efficient and energy-saving.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Process for preparing magnesium hydroxide by light burning bitter spar and concentrated sea water

The preparation process includes mixing light burnt bitter spar and water, heating to 70-90 deg.c and nitration to prepare bitter spar emulsion; wet sieving to eliminate impurity and adding concentrated sea water to produce magnesium hydroxide; precipitation, concentration and filtering to obtain pasty magnesium hydroxide; and further processing via different methods to obtain different magnesium hydroxide products. The present invention has low cost.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

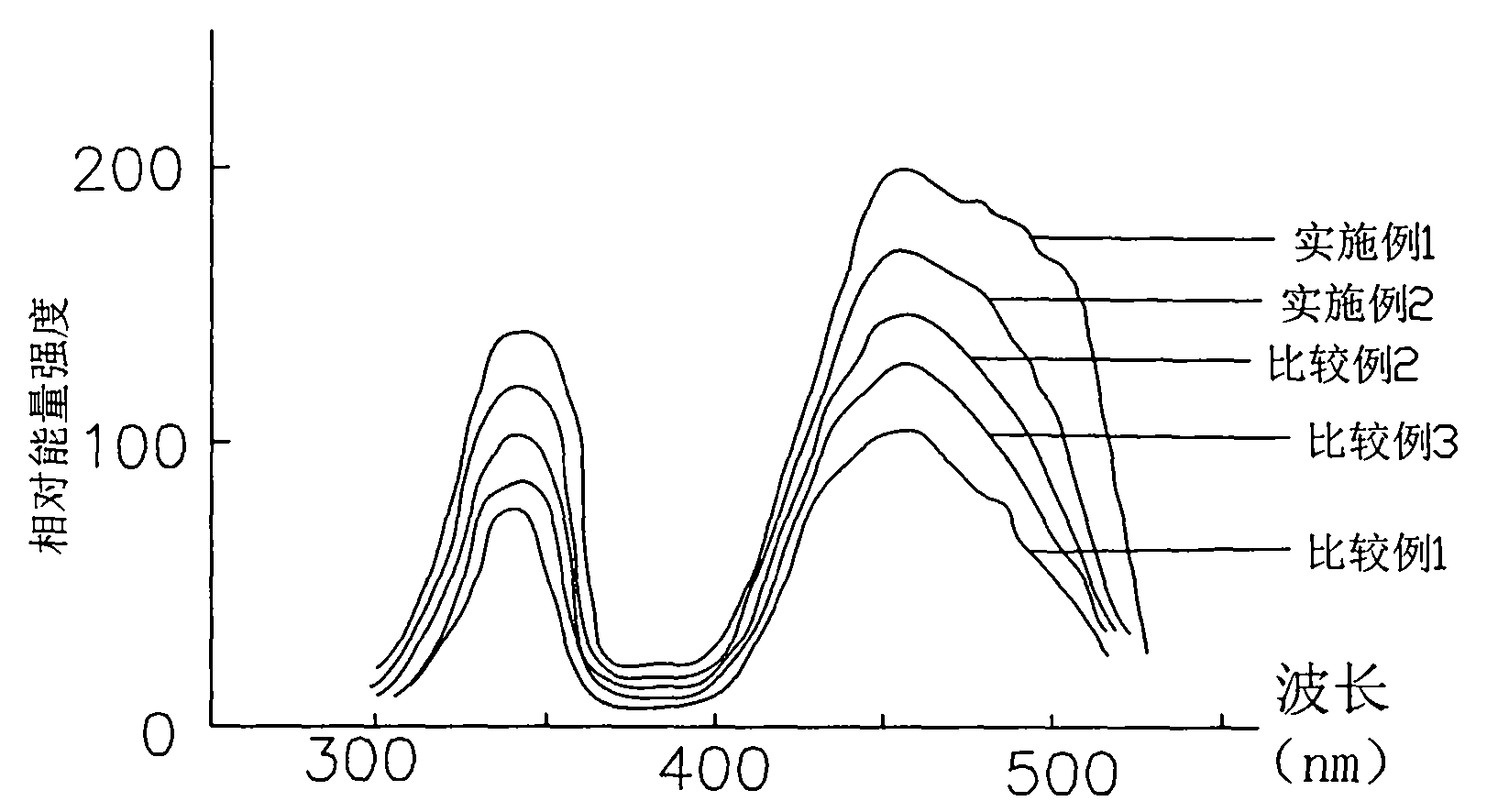

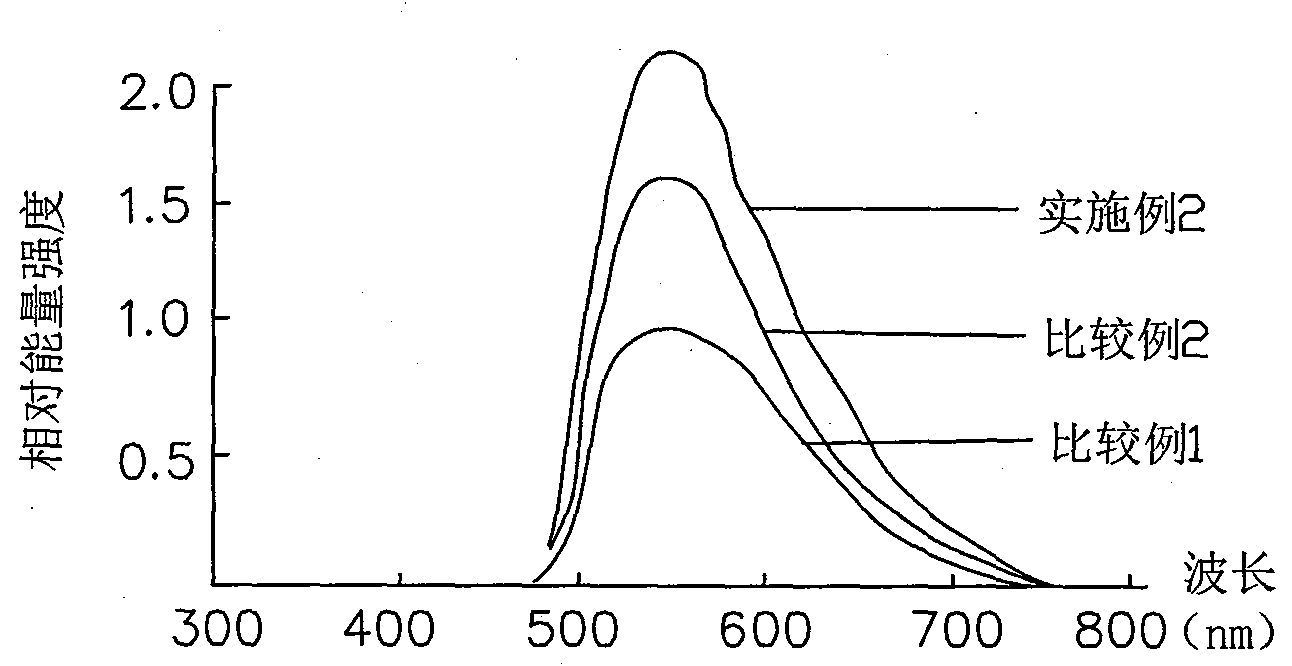

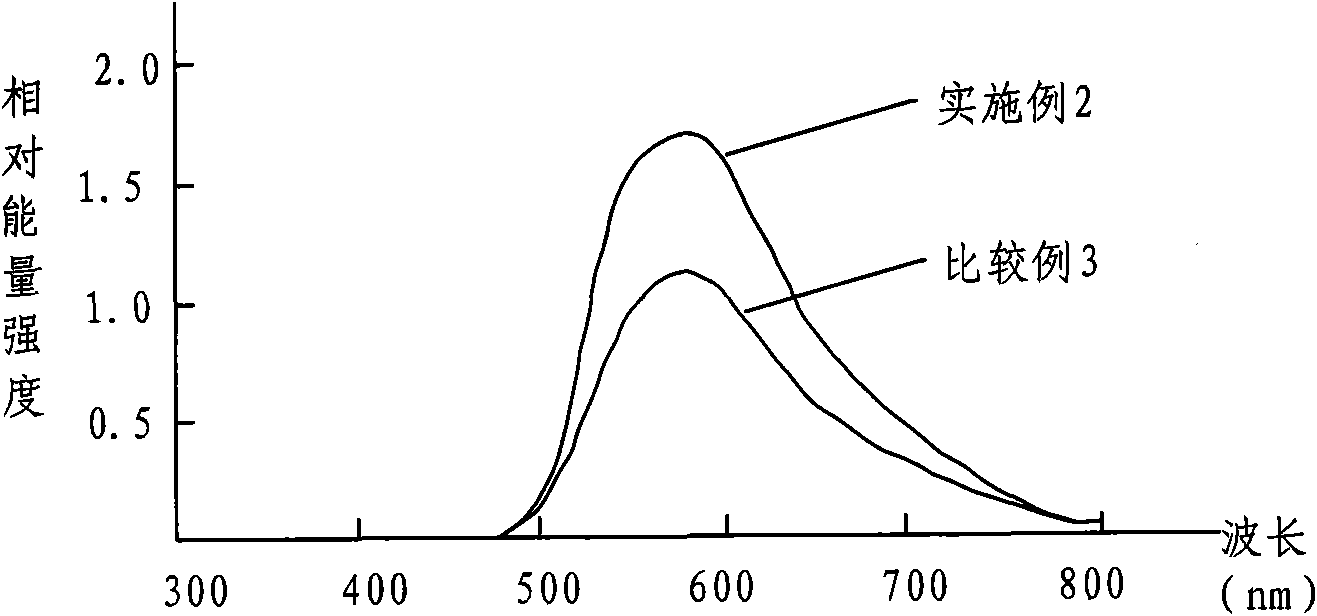

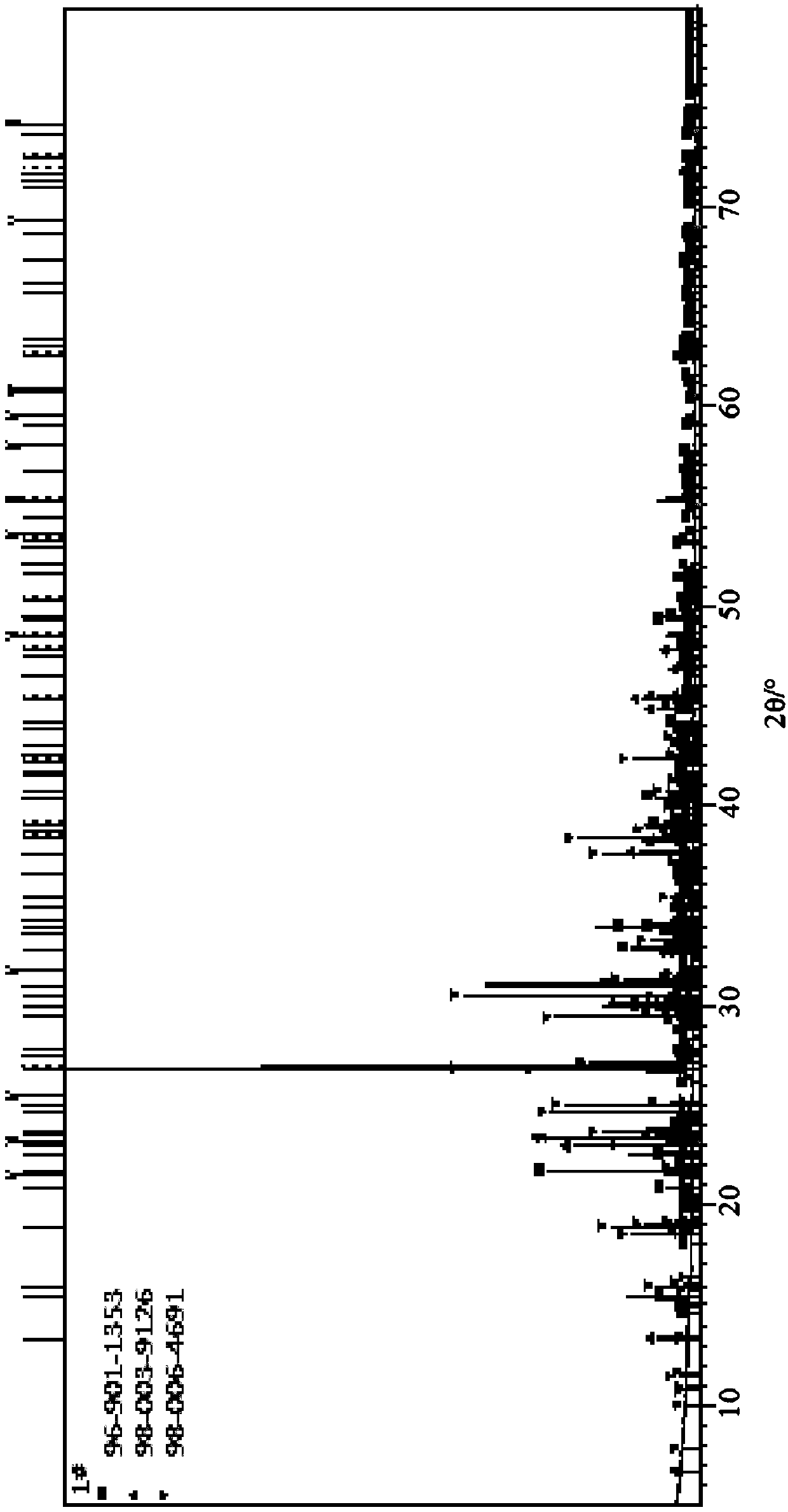

High-property YAG phosphor powder for white LED and preparation method thereof

InactiveCN101838536AIncrease excitation intensityLight attenuation is smallGas discharge lamp usageLuminescent compositionsChemical compositionPhosphor

The invention relates to a YAG phosphor powder for white LED and a preparation method thereof. Sensitizers of Sb, Bi and the like are added and codoped into the YAG phosphor powder, therefore excitation intensity, emission intensity and other good properties of cerium are sensitized and intensified. The YAG phosphor powder has the following chemical composition: Y3-a-b-cGdaAl5012:CebMc, wherein M represents Sb and Bi; a is not less than 0, but is not more than 2.0; b is not less than 0.005, but is not more than 0.2; and c is not less than 0.0001, but is not more than 0.001. The preparation method comprises the following steps of: mixing materials, presintering at high temperature, reducing at high temperature, crushing, sieving, ball milling, wet sieving, cleaning, drying, and reducing and restoring at low temperature. The quadrivalent cerium with damaged crystal plane is restored and reduced into the trivalent cerium, thereby intensifying the excitation intensity and emission intensity of the phosphor powder, intensifying the heat resistance property of the phosphor powder, and decreasing the light attenuation. The phosphor powder has the advantages of high illumination intensity, good thermal stability and good property.

Owner:佛山市南海区朗达荧光材料有限公司

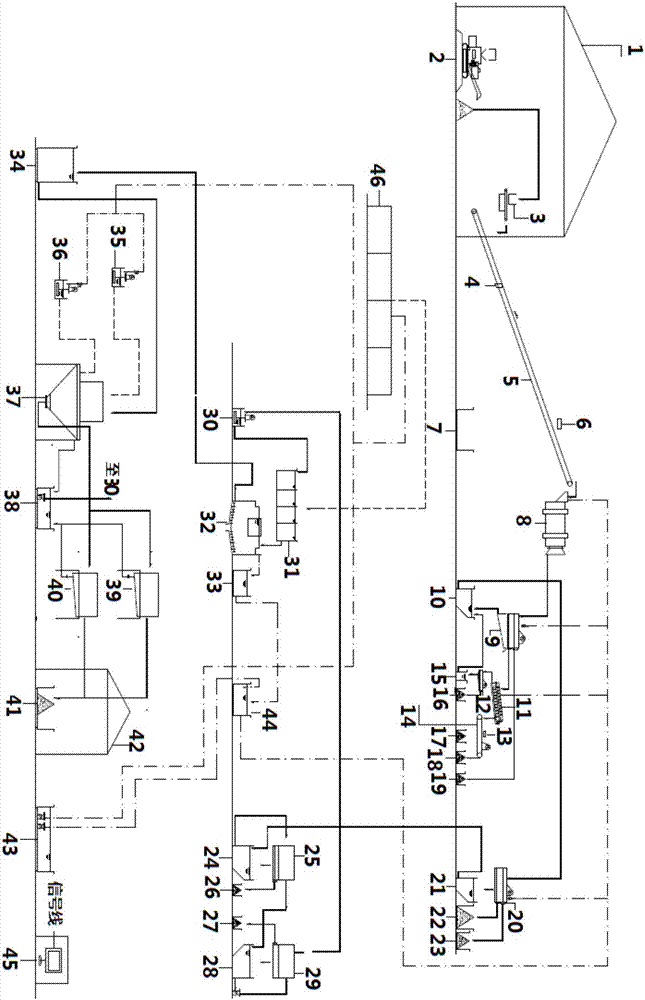

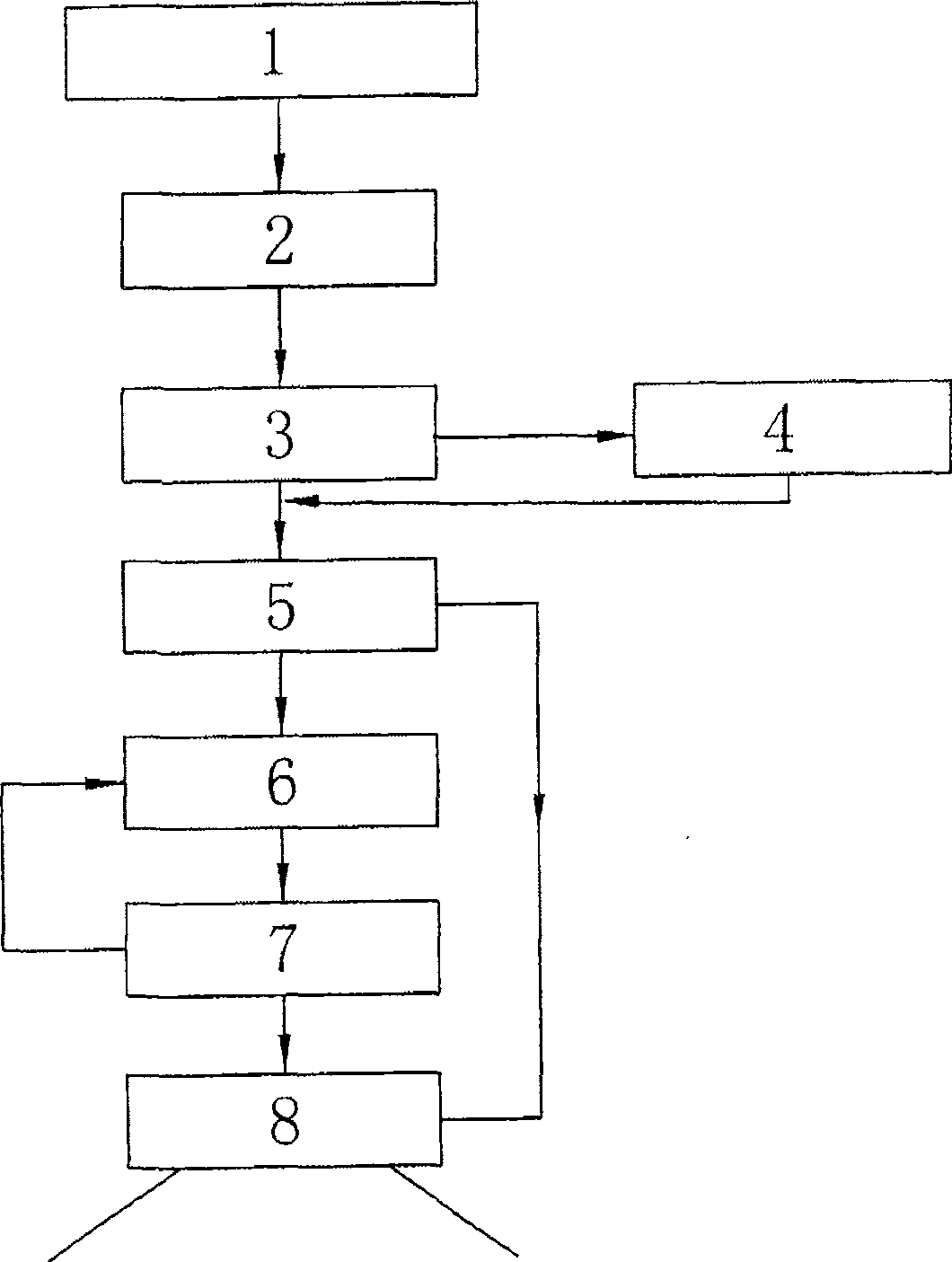

Soil flushing repair system and method

ActiveCN107127210AGuaranteed compatibilityGuaranteed subsequent dryingContaminated soil reclamationEngineeringHigh pressure

The invention discloses a soil flushing repair system and method, and belongs to the technical field of soil repair. The soil flushing repair system sequentially comprises a crushing and screening module, a feeding and mud making module, a flushing and particle size distributing module, a water treatment module, a mud dehydration module, a water supply module and a central control room module. The crushing and screening module including a sieve with the hole diameter of a screen cloth being 30mm-60mm is arranged in front of the operating process of the feeding and mud making module. The flushing and particle size distributing module can achieve level-7 wet sieving and flushing of contaminated soil by means of water jet cutting of a high-pressure spraying system and mechanical vibration of a vibration motor, and discharging cleanliness and recoverability can be guaranteed. The mud dehydration module is provided with a drying workshop and used for preventing rainwater from wetting dehydration mud cakes, guaranteeing subsequent drying of the mud cakes and controlling secondary pollution of pollutants in the mud cakes. By the adoption of the soil flushing repair system and method, the problem that the screen cloth can be blocked easily due to the uneven feeding grain size in the prior art is solved, and the problems of flushing dehydration mud cake storage, subsequent drying and secondary pollution of the pollutants are also solved.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

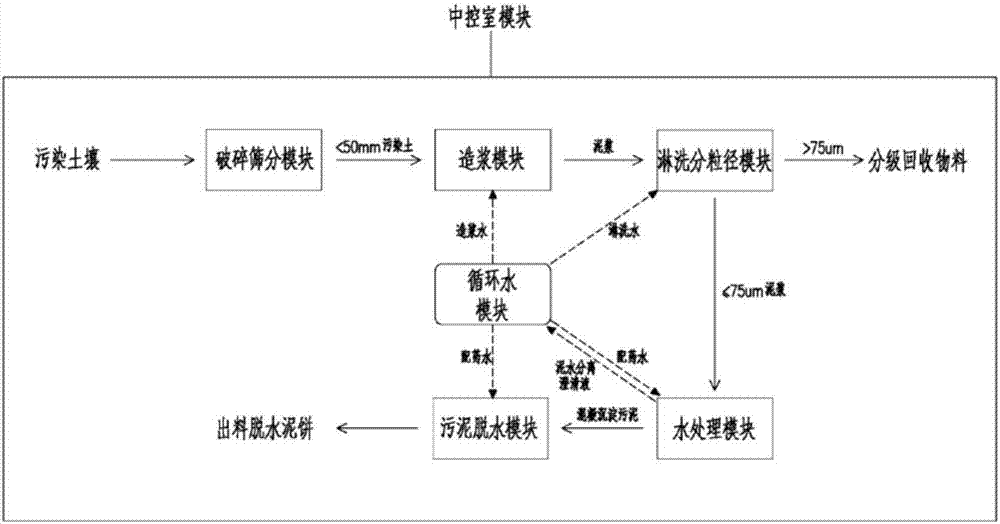

Method for recovering metallic aluminium from aluminum ash

ActiveCN108893615AEnhanced deconstructive separationHigh purityProcess efficiency improvementSlagWet sieving

The invention provides a method for recovering metallic aluminium from aluminum ash. The method comprises the following steps: (1) carrying out selective crushing treatment on aluminium-ash waste slag; (2) carrying out sieving and grading on crushed products, sorting out substances on sieve and residues on sieve, wherein the substances on sieve are coarse aluminium particles; (3) adding the residues on sieve into a ball milling machine to carry out wet milling, and adding a proper amount of water in the ball-milling process; (4) carrying out wet-sieving sorting on ball-milling products to obtain wet-sieved substances on sieve and wet-sieved residual slurry; (5) carrying out drying treatment on the wet-sieved substances on sieve to obtain fine aluminium powder; and (6) carrying out pressing-filtering treatment on the wet-sieved residual slurry to obtain aluminium-extracted tail mud and electrolyte-containing circulating water. The method provided by the invention has the beneficial effects that by the means of selective crushing, wet grinding, wet sieving and the like, high-efficiency separation of the metallic aluminium from the components such as nonmetallic phases, soluble electrolyte salts and the like is realized and a new path is opened up for recycling solid wastes (aluminium ash) produced in the industries of aluminium electrolysis and aluminium processing and the like.

Owner:郑州中科新兴产业技术研究院 +2

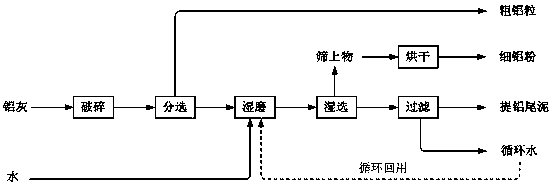

Physicochemical grading method for granular soil components

InactiveCN103900865AImprove effectivenessAccurately get the weightPreparing sample for investigationFiltrationFreeze-drying

The invention provides a physicochemical grading method for granular soil components. The method comprises the following steps: adding distilled water into an air-dried soil sample and carrying out ultrasonic quantitative auxiliary dispersion by using an ultrasonic crusher; then carrying out wet sieving by using a soil sieve with an aperture of 63 mu m so as to divide soil into two parts; subjecting soil on the sieve to density grading with NaI so as to obtain a granular soil component, sand and an aggregate soil component; and subjecting a turbid liquid of soil below the sieve to centrifugation, then subjecting an obtained supernatant to vacuum pumping filtration with a 0.45-micrometer filter membrane, allowing a filtrate to undergo freeze-drying so as to obtain a soluble soil component and oxidizing aleuritic clay with a particle size of more than 0.45 mu m obtained after pumping filtration with sodium hypochlorite so as to obtain an acid-insoluble soil component, wherein the difference between the aleuritic clay and the acid-insoluble soil component is an easily-oxidizable soil component, and so grading of the above-mentioned five soil components is finished. The obtained soil components can be used for determination of related physical and chemical properties like carbon and nutrients of soil. Recycling of NaI is realized through active carbon adsorption and filter paper filtration.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

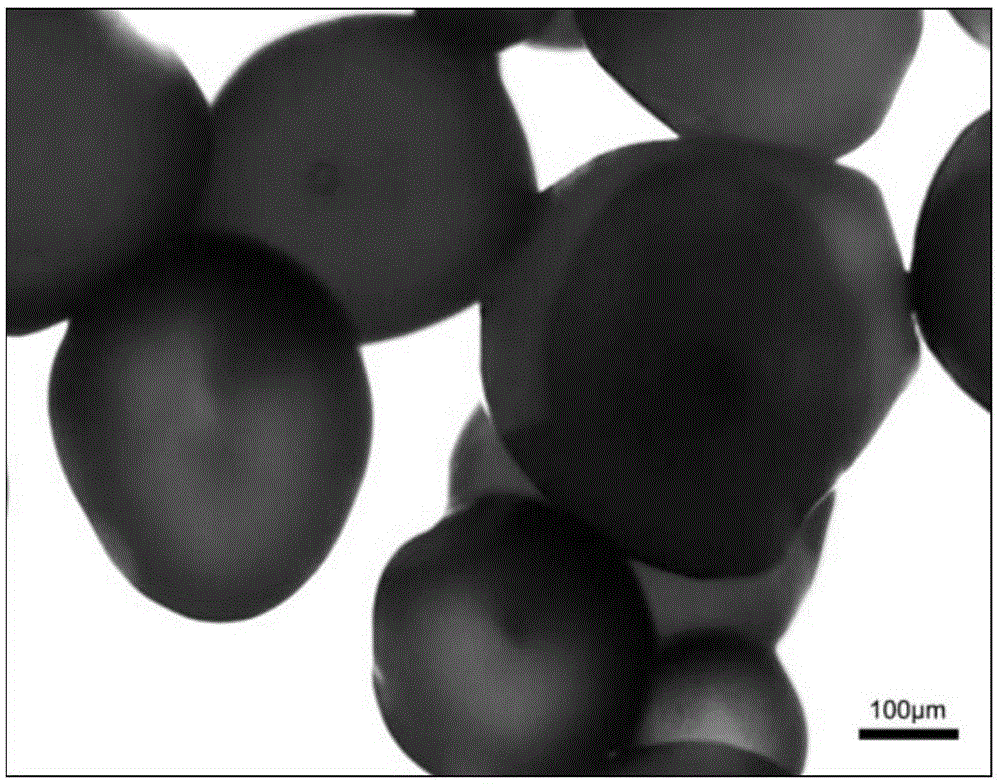

Technique for preparing embolism agent of granule of polyvinyl alcohol

ActiveCN1872343AOvercome electrostatic adsorptionGood dispersionPharmaceutical non-active ingredientsGranular deliveryPolyvinyl alcohol spongePrill

A process for preparing the granular embolizing agent from polyvinyl alcohol includes such steps as dissolving polyvinyl formal in aseptic water for injection, freezing at -20--40 deg.C for 10-12 hr, planning on the obtained ice block multiple times to obtain ice particles, classifying by wet sieving by immersing the sieve in suspension to obtain wet polyvinyl formal particles, freezing again, and dry sieving for classifying.

Owner:杭州艾力康医药科技有限公司

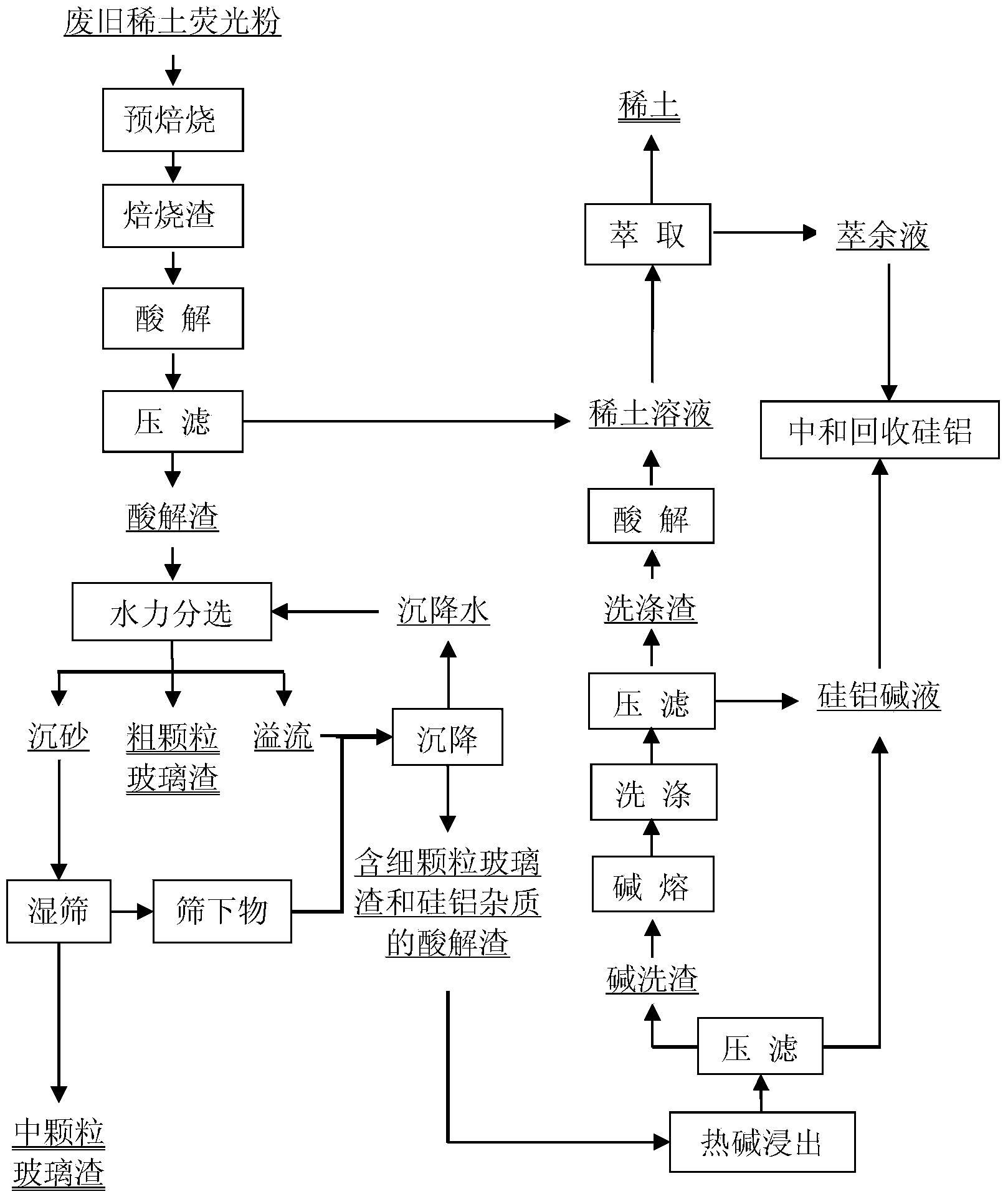

Method for removing glass residue and silicon aluminum oxide in waste rare earth phosphor

ActiveCN103773357AEfficient removalAvoid leachingRecycling and recovery technologiesLuminescent compositionsRare-earth elementPhosphor

The invention belongs to the field of resource recycling, and in particular relates to a method for removing silicon aluminum impurities in waste rare earth phosphor. The method comprises the steps of sequentially implementing pre-baking, acidolysis and filter pressing to the waste rare earth phosphor to obtain acidolysis residue; hydraulically removing coarse granular glass residue in the acidolysis residue, removing medium-granular glass residue through wet sieving, and dissolving fine-granular glass residue and silicon aluminum oxide through hot alkali. The method disclosed by the invention can effectively remove coarse, medium and fine-granular glass residue as well as other silicon aluminum oxide impurities in the waste rare earth phosphor, so as to avoid influence on rare earth element leaching and extraction separation due to silicon aluminum colloid formed in a subsequent rare earth element recovery process. The method disclosed by the invention has the characteristics that silicon aluminum impurities in the waste rare earth phosphor can be effectively removed, the rare earth recovery rate is remarkably improved, the production is reduced, and the method is applicable to industrial production and the like.

Owner:UNIV OF SCI & TECH BEIJING

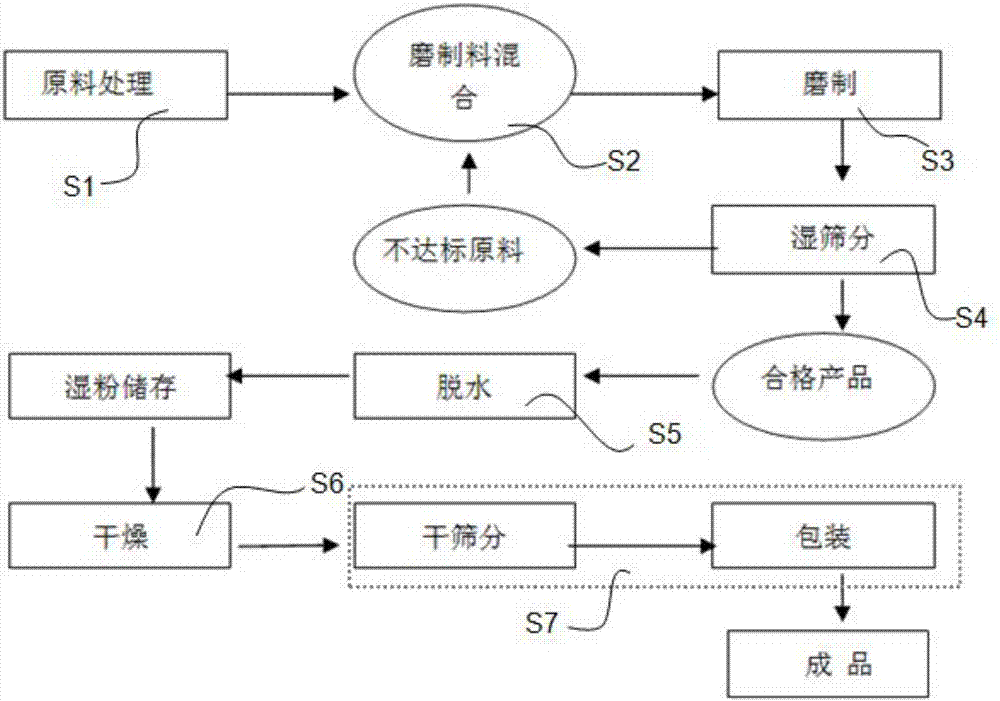

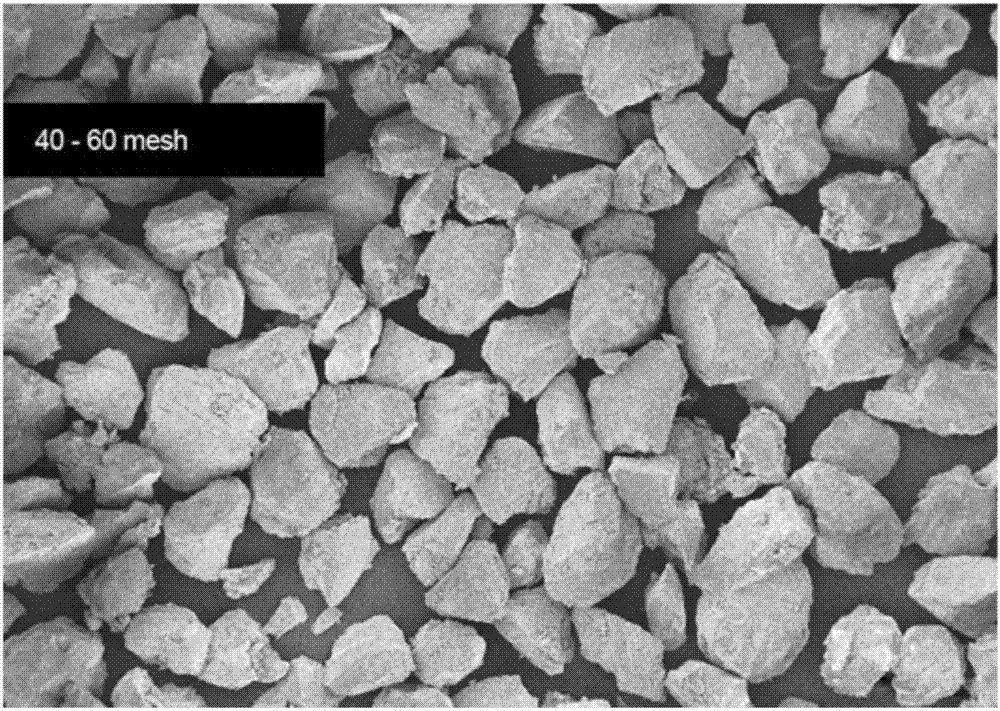

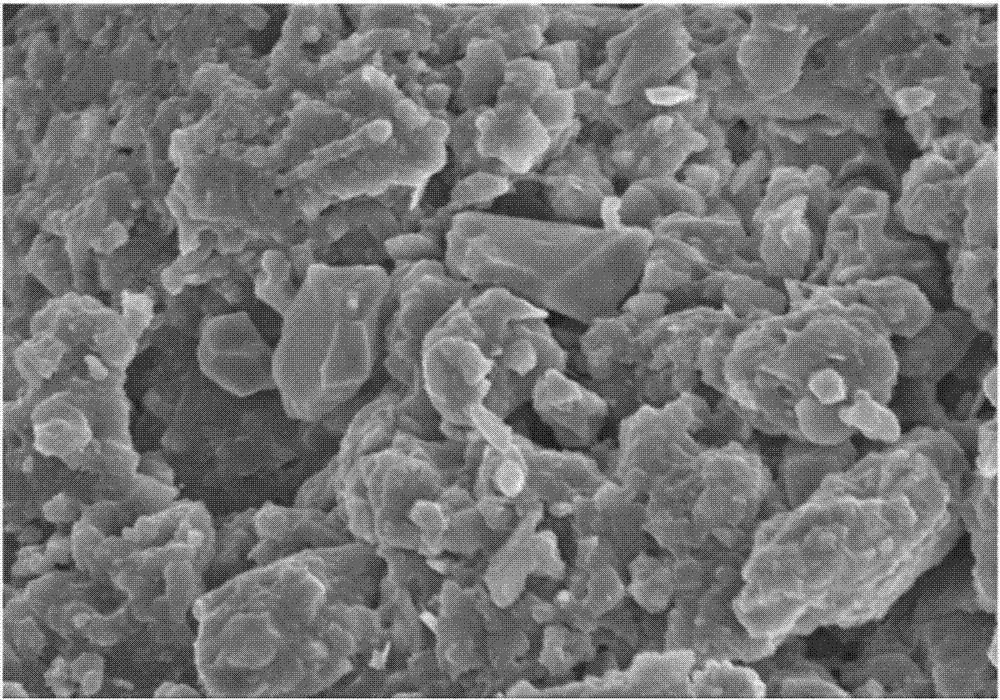

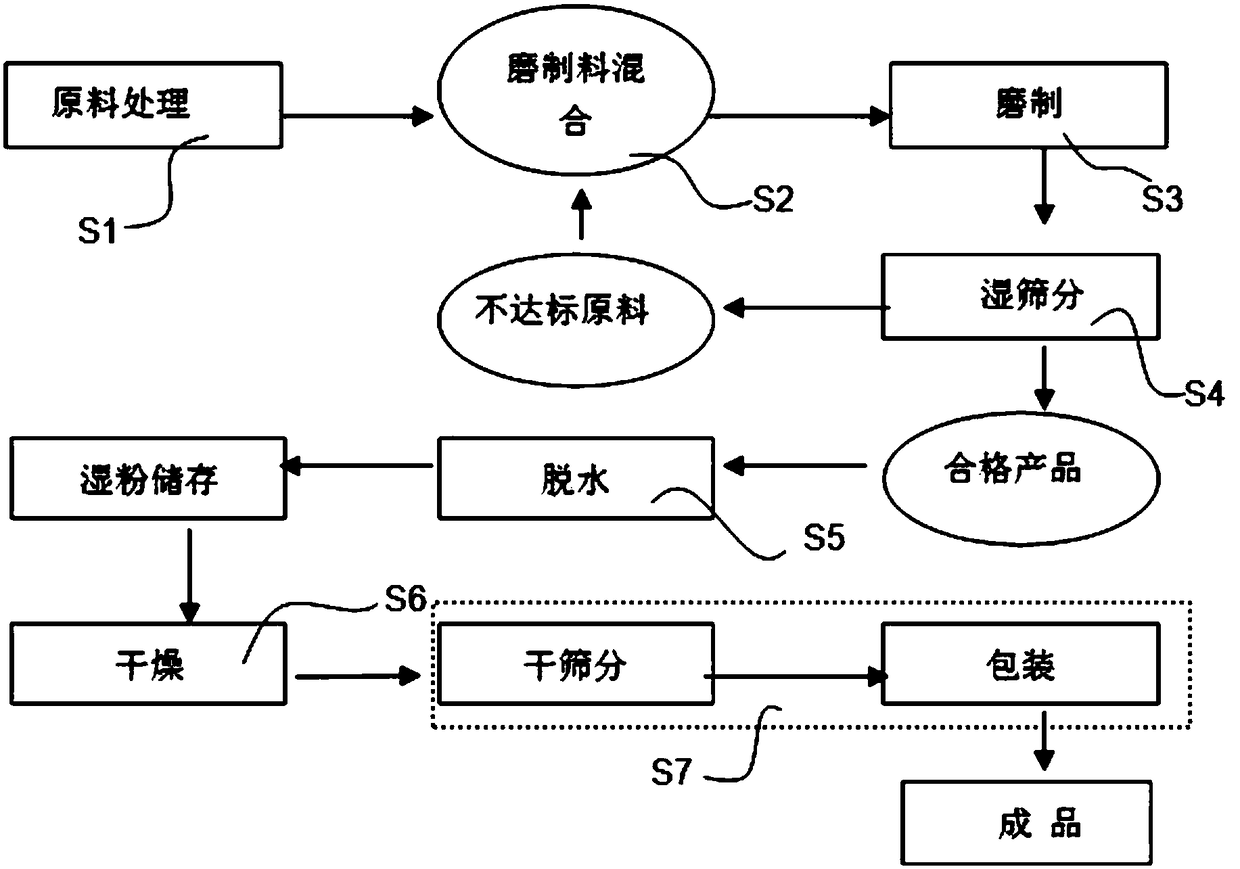

Preparation method for fine rubber powder

ActiveCN107379333ARealize automatic dryingHigh degree of automationPlastic recyclingCocoaAssembly lineColloid

The invention provides a preparation method for fine rubber powder. The preparation method comprises the steps of raw material treating, grinded material mixing, grinding, wet sieving, dehydrating, drying, dry sieving and packaging. According to the preparation method for the fine rubber powder provided by the invention, pre-crushed coarse granular rubber blocks and water are sufficiently mixed, and then are grinded in a circulating mode in a closed assembly line, and automatic drying, sieving and packaging of rubber powder are realized. The preparation method is high in degree of automation, is low in cost, and can be used for preparing ultrafine-grain fine rubber powder without pollution. The fine rubber powder prepared by the preparation method is combined with the surface of a raw rubber group so as to be in canine-tooth-alternating embedding, and therefore, net-shaped contact area is greatly increased in a spatial three-dimensional direction, combination of rubber powder and virgin rubber can be remarkably improved, and combination strength, toughness and wear resistance of glue are greatly enhanced.

Owner:广州泓泰控股集团有限公司

Biological calcium carbonate chitin, preparation method thereof and application thereof

The invention discloses biological calcium carbonate chitin, a preparation method of the biological calcium carbonate chitin and application of biological calcium carbonate chitin, and belongs to the preparation and processing filed of organic polymer matter. Aiming at single development and utilization of extraction of chitin in crab carapaces in the prior art, the invention provides a preparation method of the biological calcium carbonate chitin in which a natural compound structure of calcium-carbonate-chitin in the crab carapaces is kept. The preparation method of the biological calcium carbonate chitin comprises preparing and obtaining even ultramicro crab carapace powder through superfine grinding of the crab carapaces and wet sieving, carrying out removal processing of pigment and fatty acid on the ultramicro crab carapace powder through a repeated boiling and centrifugation method, removing protein through repeated sodium hydroxide solution hydrolysis and high speed centrifugation at a certain temperature, and obtaining the biological calcium carbonate chitin without the pigment, the fatty acid and the protein. The biological calcium carbonate chitin which is prepared and obtained is used in commodity polymer materials and plays a part of strengthening, and can further be used as a calcium supplement agent, be used in bone tissue repair and be used as a calcium source for mouth rehabilitation materials.

Owner:JINAN UNIVERSITY

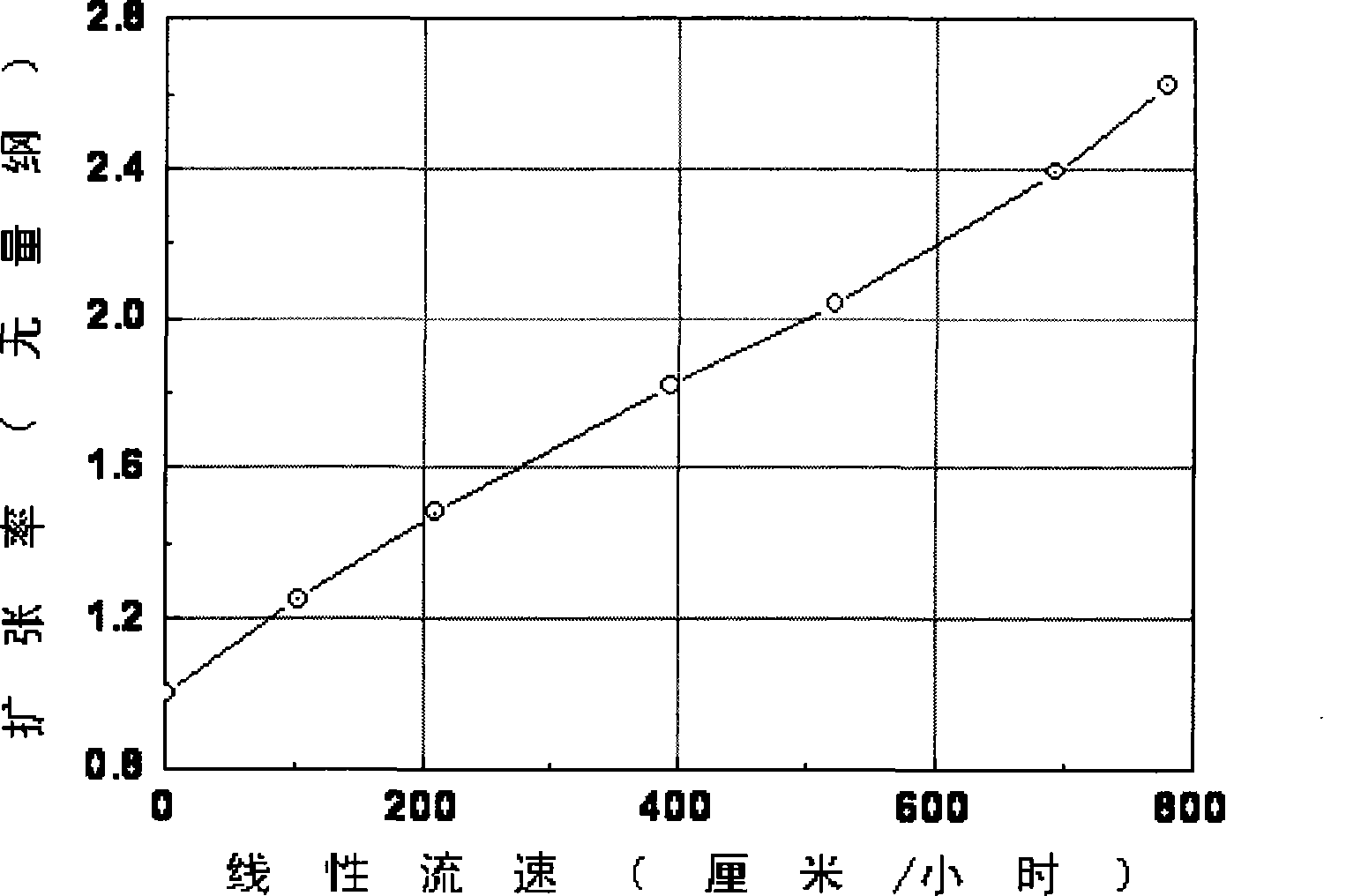

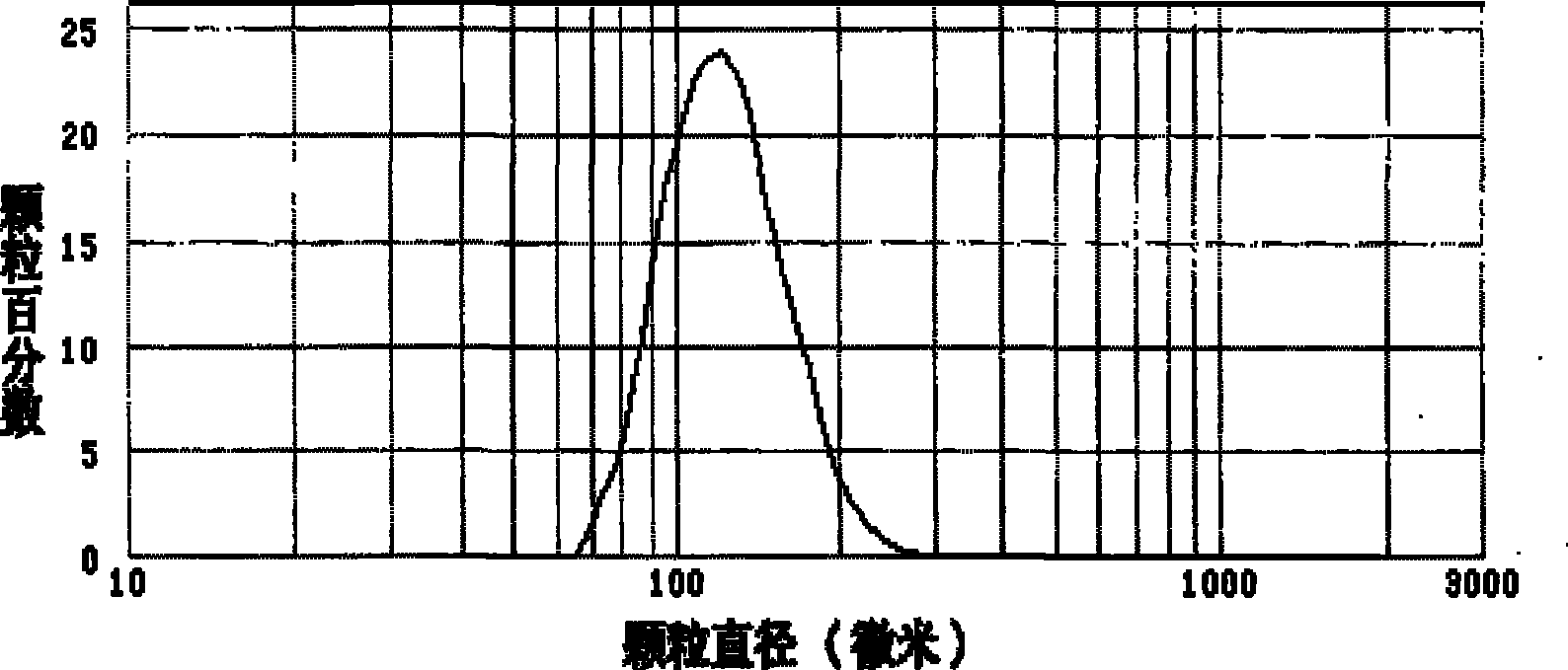

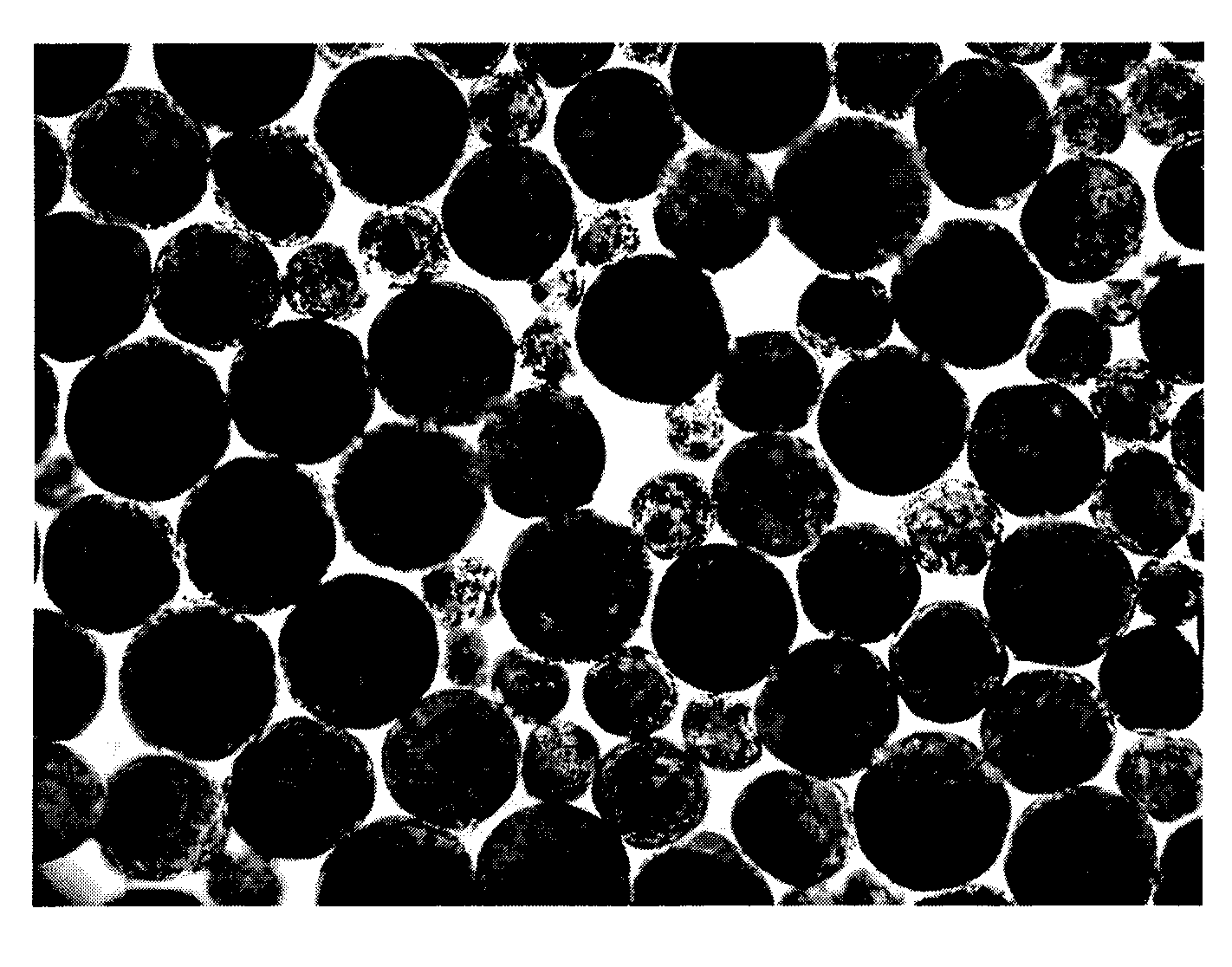

Homogeneous crosslinking beta-cyclodextrin/wolfram carbine composite microsphere and method of producing the same

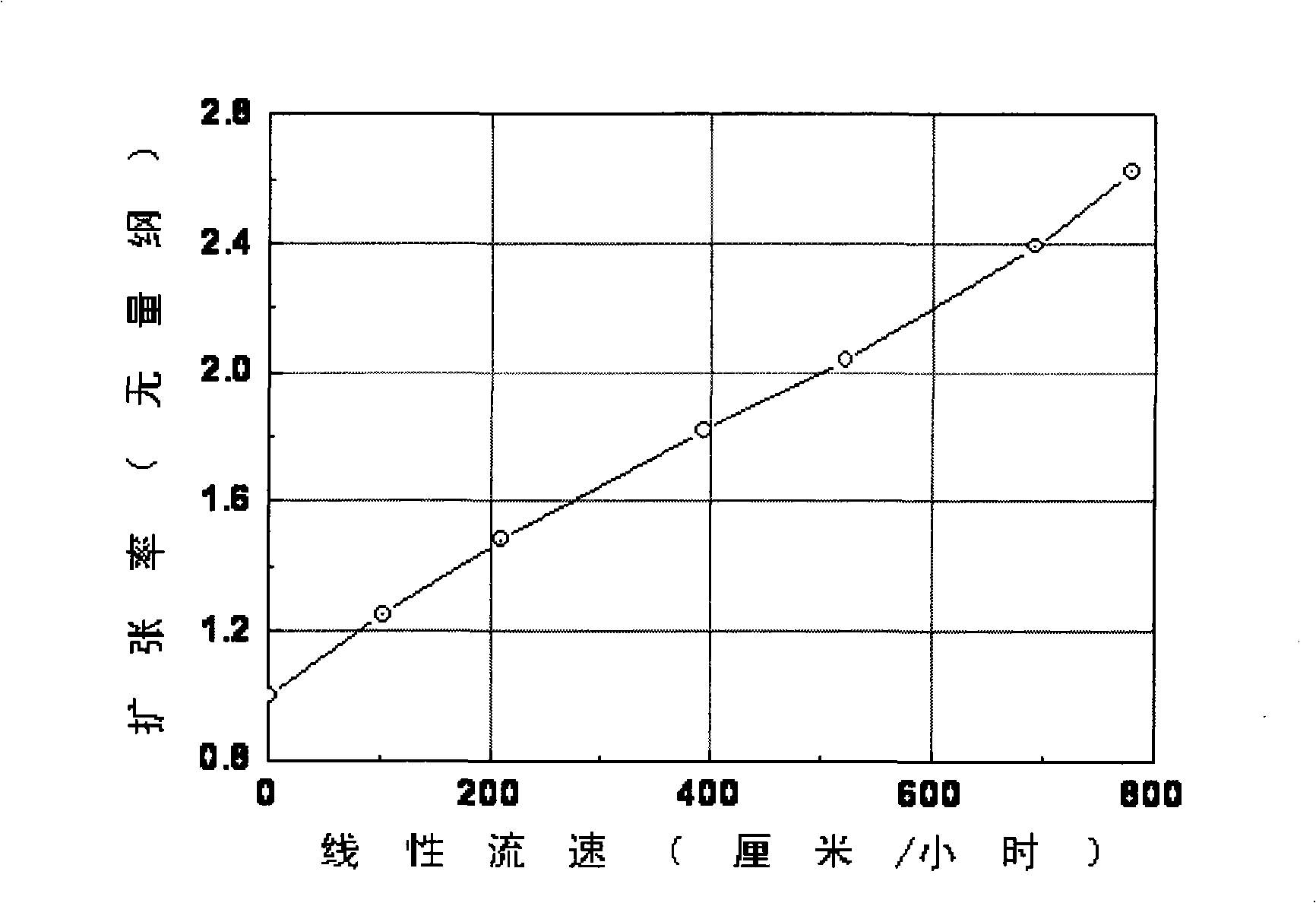

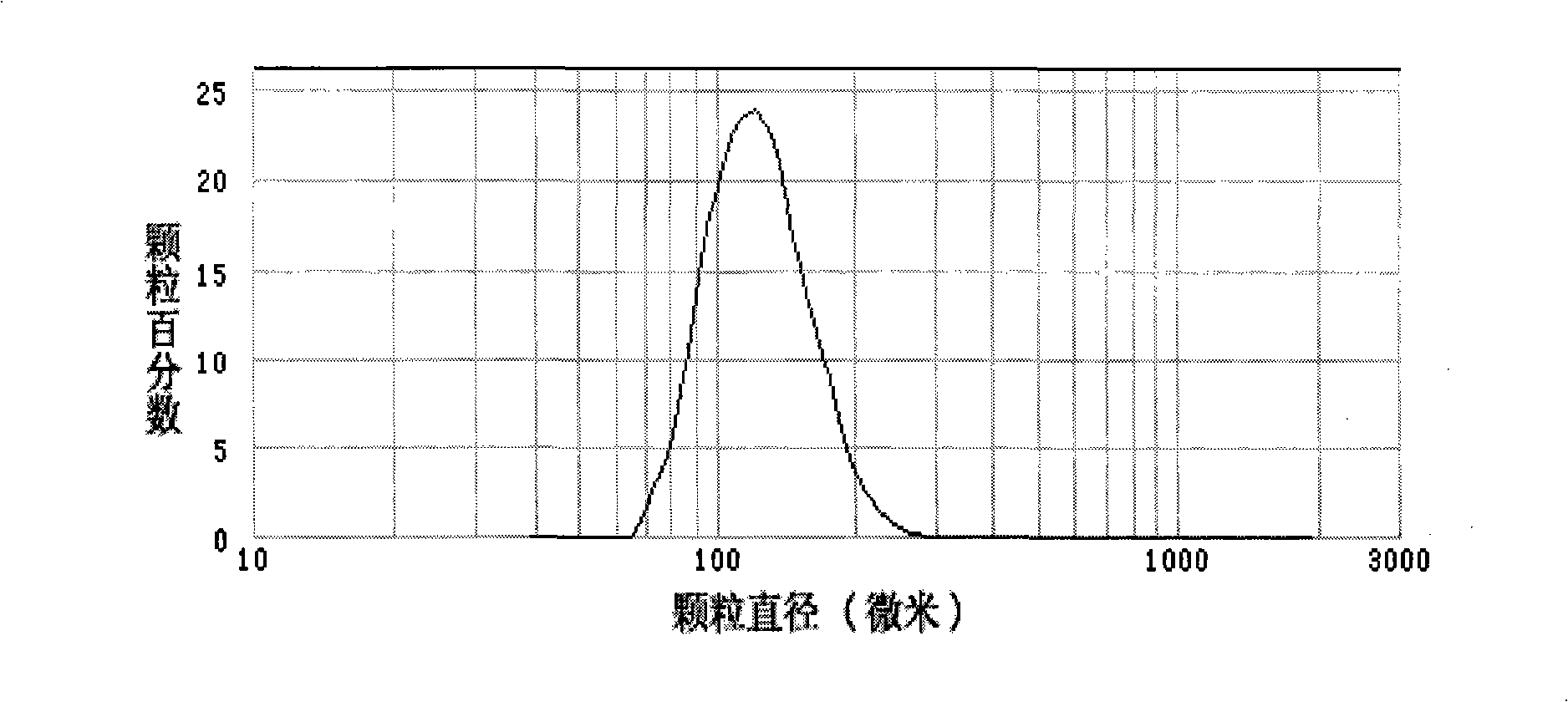

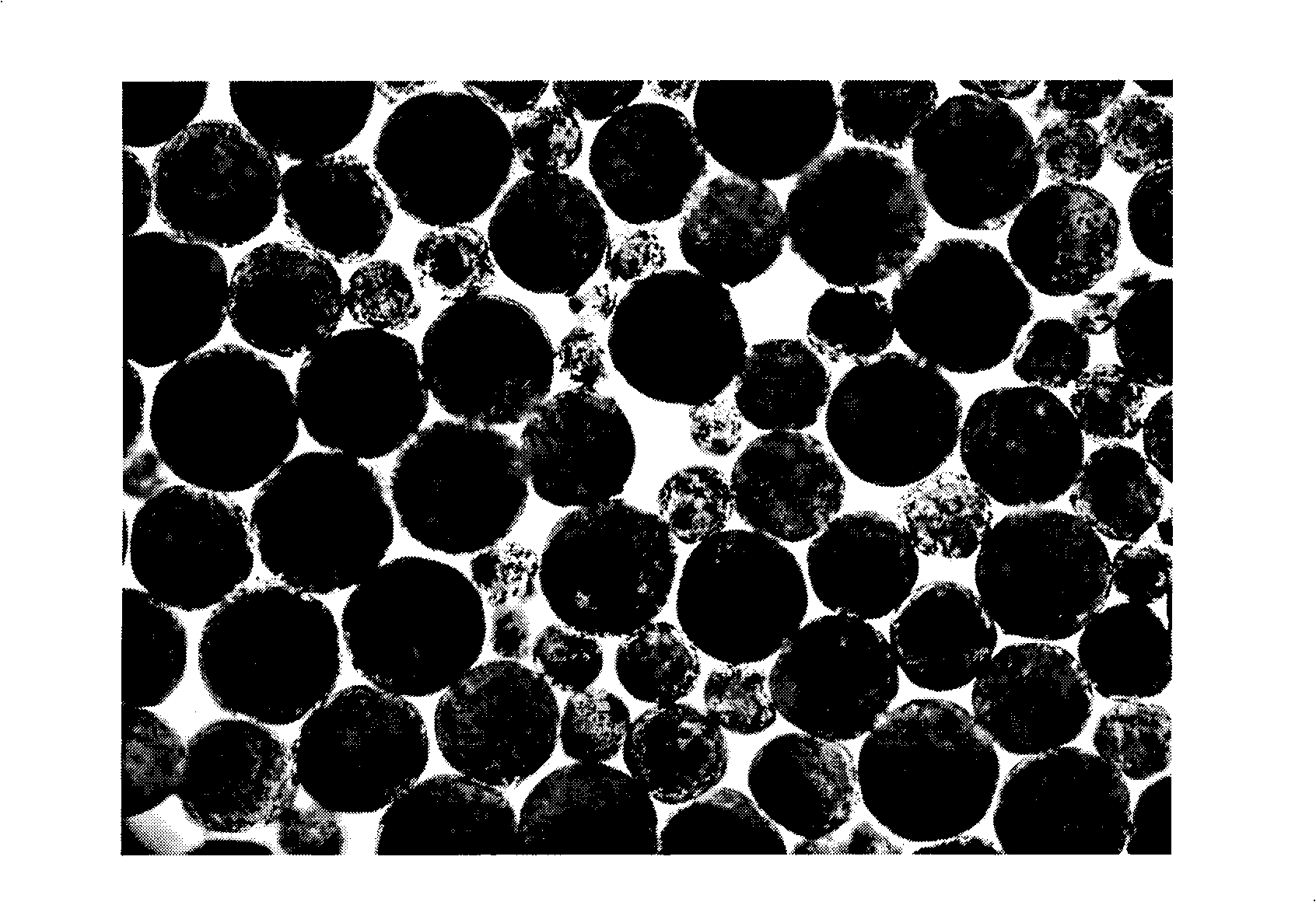

InactiveCN101402029AImprove stabilitySuit one's needsOther chemical processesAlkali metal oxides/hydroxidesHigh densityMicrosphere

The invention discloses an isotropic crosslinking beta-cyclodextrin / tungsten carbide composite microsphere and a preparation method thereof. The preparation method comprises the following steps: firstly, beta-cyclodextrin is dissolved into a sodium hydroxide aqueous solution, and the mixture is dripped with epichlorohydrin and undergoes stirring reaction under heating condition, so as to generate viscose; secondly, the viscose is added with tungsten carbide powder, oil dispersed phase and a dispersant under the condition of mechanical stirring to form a reversed phase suspension dispersion system; thirdly, the epichlorohydrin is added into the reversed phase suspension dispersion system, and the composite microsphere is obtained after mechanical stirring reaction; and fourthly, after the reversed phase suspension dispersion system is cooled, the composite microsphere is filtered, cleaned and neutralized, and subjected to wet sieving and expanded bed floatation. The composite microsphere developed by the method has the advantages of good hydrophilicity and sphericity, stable properties, low cost, high density, easy adjustment and so on, and can be used as a substrate during the process of expanded bed absorption as shown by an expanding performance test experiment.

Owner:ZHEJIANG UNIV

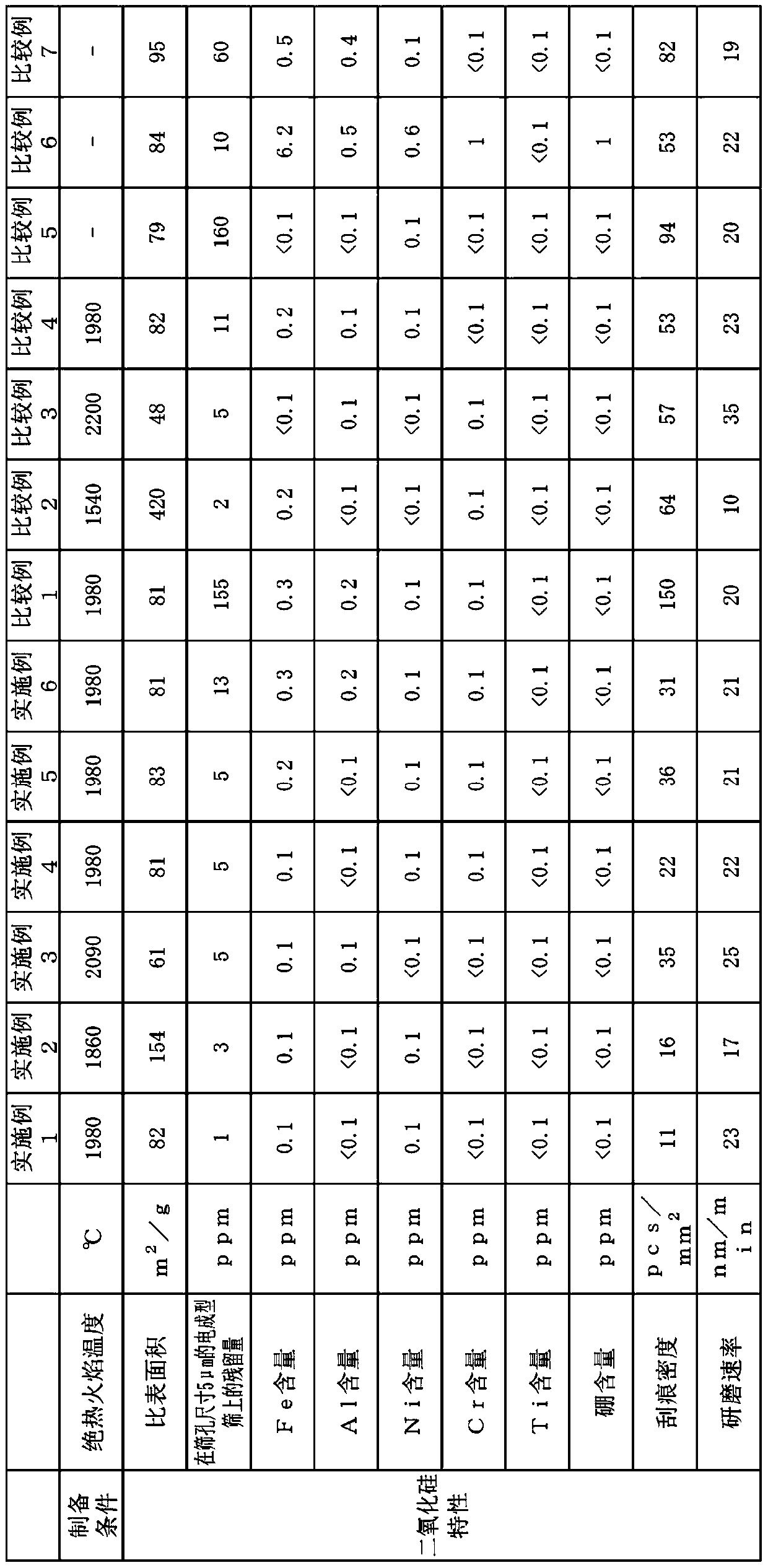

Fumed silica and production method therefor

InactiveCN110167879AImprove grinding efficiencyReduce scratchesSilicaOther chemical processesVibration amplitudePolishing

Provided is a fumed silica for chemical-mechanical polishing with which post-polishing scratches occurring on a surface of an object to be polished can be significantly reduced, and which is importantfor miniaturization and multi-layering of a structure. The fumed silica according to the present invention has a BET specific surface area of 57-400 m<2> / g. In a liquid dispersion which is obtained by ultrasonically dispersing 6.25 mass% of this fumed silica in water at a vibration frequency of 20 kHz and an amplitude of 15-25 mu m for 3 minutes, the amount of residues on a sieve is 5 ppm or lessas measured by wet sieving using an electroformed sieve having a mesh opening size of 5 mu m.

Owner:TOKUYAMA CORP

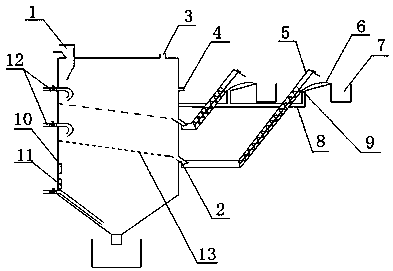

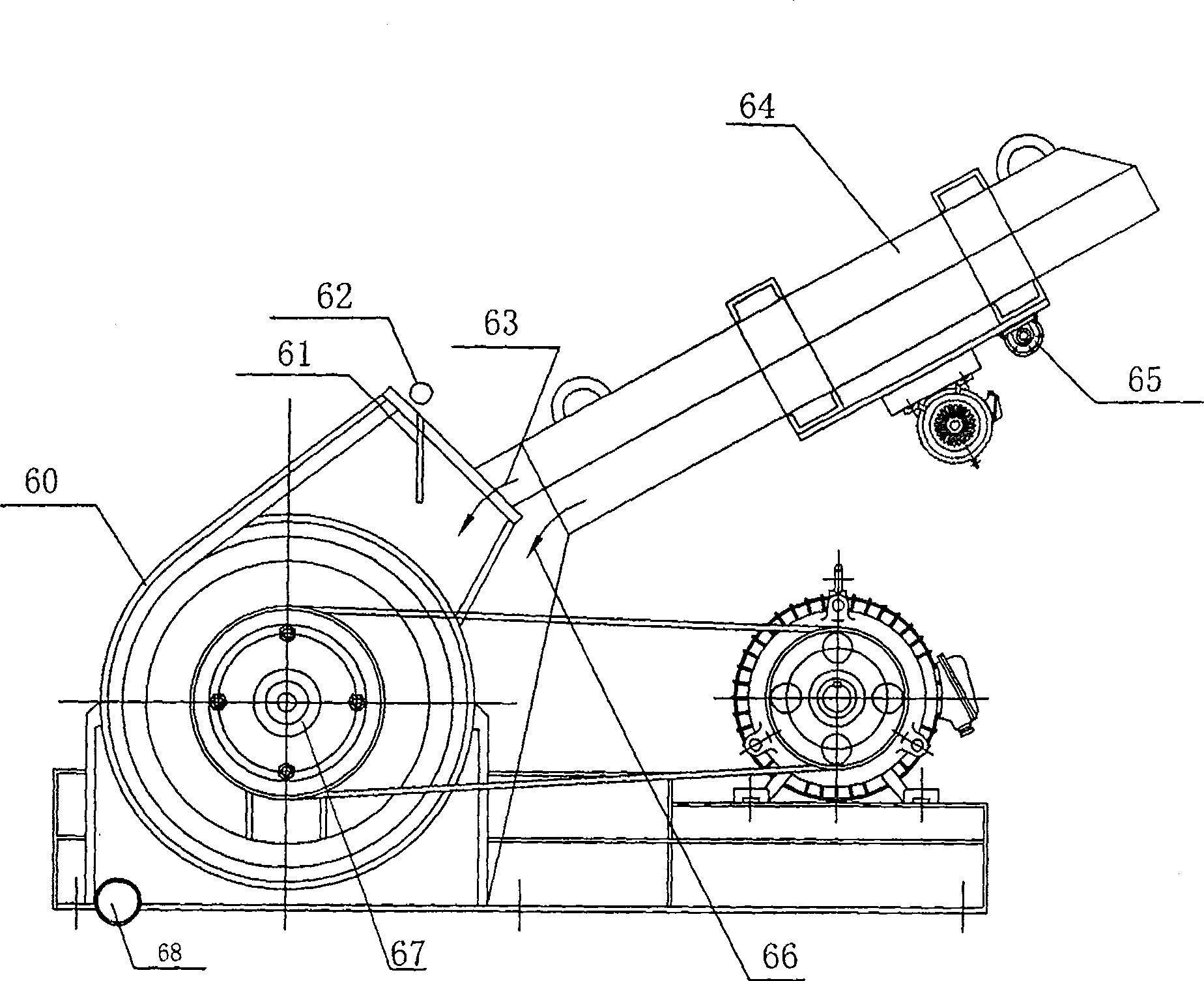

Multi-particle-size-section soil continuous washing and sieving all-in-one machine

InactiveCN108746173ASpeed up the repair processImprove decontamination abilitySievingScreeningWater leakEngineering

The invention discloses a multi-particle-size-section soil continuous washing and sieving all-in-one machine. The all-in-one machine comprises a shell, wherein at least three washing chambers are arranged in the shell from the top to the bottom; every two adjacent washing chambers communicate with each other through one layer of sieve net obliquely placed; each washing chamber is provided with a gas guide-in pipe used for guiding in compressed air and a material outlet connected with a material collector arranged outside the shell; a screw elevator for lifting materials into the material collector and a filter net for filtering the materials are sequentially arranged between the material outlet and the corresponding material collector; a backflow pipe is arranged at the outer part of the shell, and the pipe body of the backflow pipe is provided with a plurality of water leaking openings; liquid in the screw elevator flows back into the washing chamber through the water leaking openingcorrespondingly connected with the screw elevator; the top of the shell is provided with a material inlet and a washing solution inlet; and the top washing chamber is provided with a water level overflow opening. By adopting a wet sieving process, sieving and washing can be simultaneously carried out on soil, and more than three particle size sections of soil can be obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

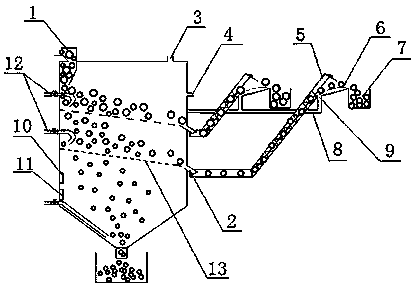

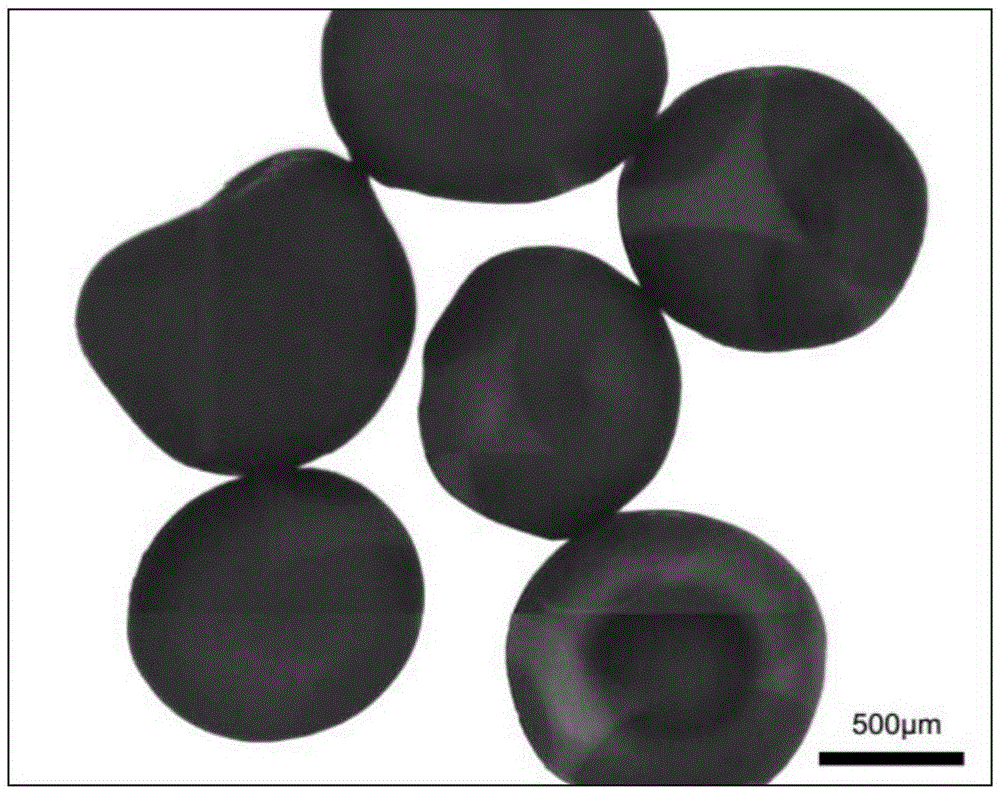

Preparation method for paraffin microballoon

A disclosed preparation method for a paraffin microballoon comprises the following steps: getting slid paraffin and a polyvinyl alcohol solution according to the volume ratio of 2-4:5, fusing solid paraffin to obtain liquid paraffin, then slowly adding into the polyvinyl alcohol solution, and uniformly stirring to form an oil-water emulsion; pouring the oil-water emulsion into brine ice with the temperature of -20 DEG C to 10 DEG C, so as to obtain a mixture; performing wet sieving on the mixture, and filtering after wet sieving is finished, so as to obtain a paraffin midroballoon; and performing pre-freezing on the paraffin microballoon at -20 DEG C to 10 DEG C, and then performing freeze-drying on the pre-freezed paraffin microballoon and storing. According to the paraffin microballoon preparation method, the paraffin microballoon with a complete spherical structure and uniform dimension is obtained through technological processes of wet sieving, freeze drying and the like, and compared with a conventional paraffin microballoon preparation method, the paraffin microballoon is prevented from being mutually bonded and leading to deformation and bonding because of relatively high room temperature, and thus the size and the shape of the prepared paraffin microballoon are easily controlled.

Owner:SHENZHEN LANDO BIOMATERIALS

A kind of preparation method of fine rubber powder

Owner:广州泓泰控股集团有限公司

Granulation process

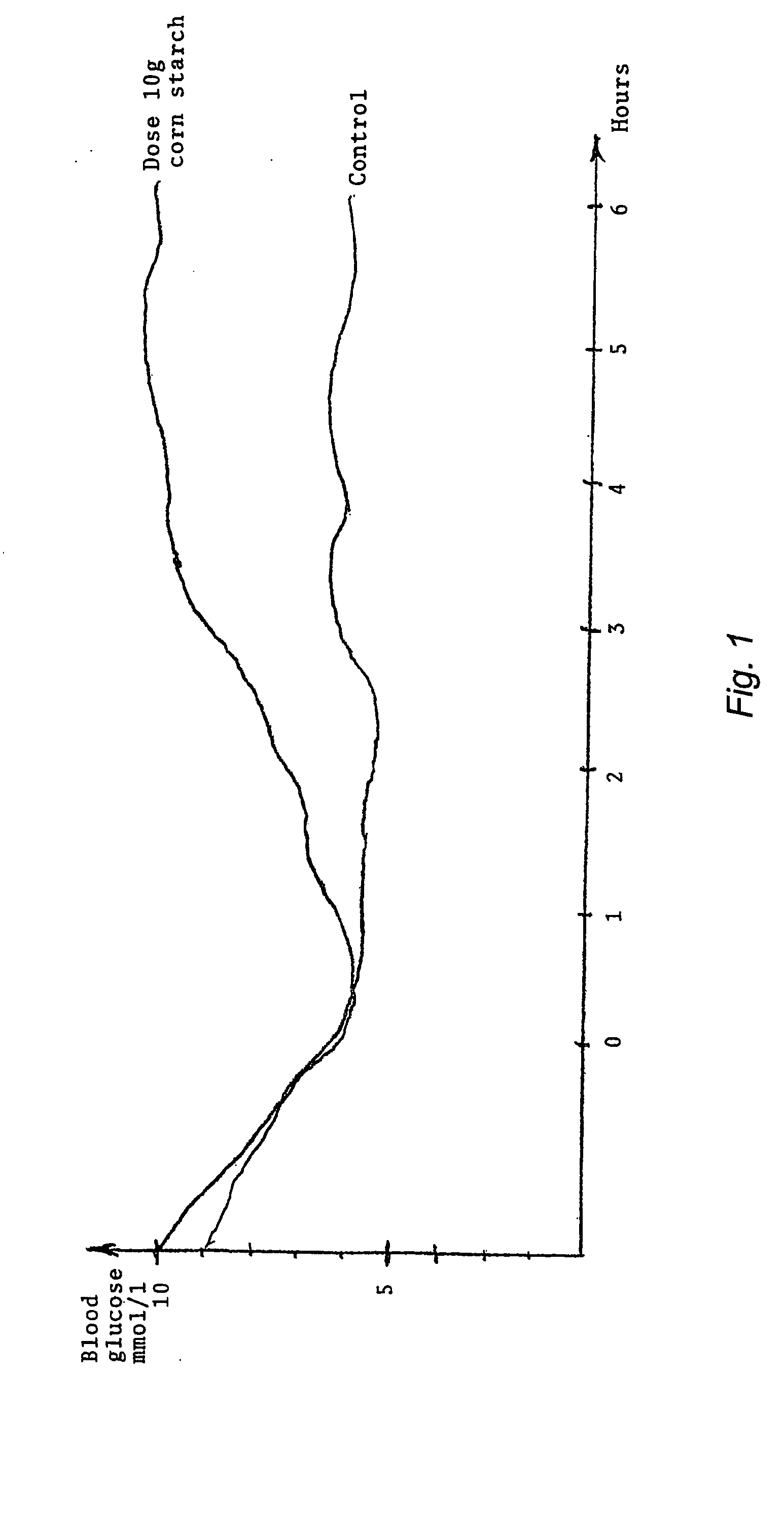

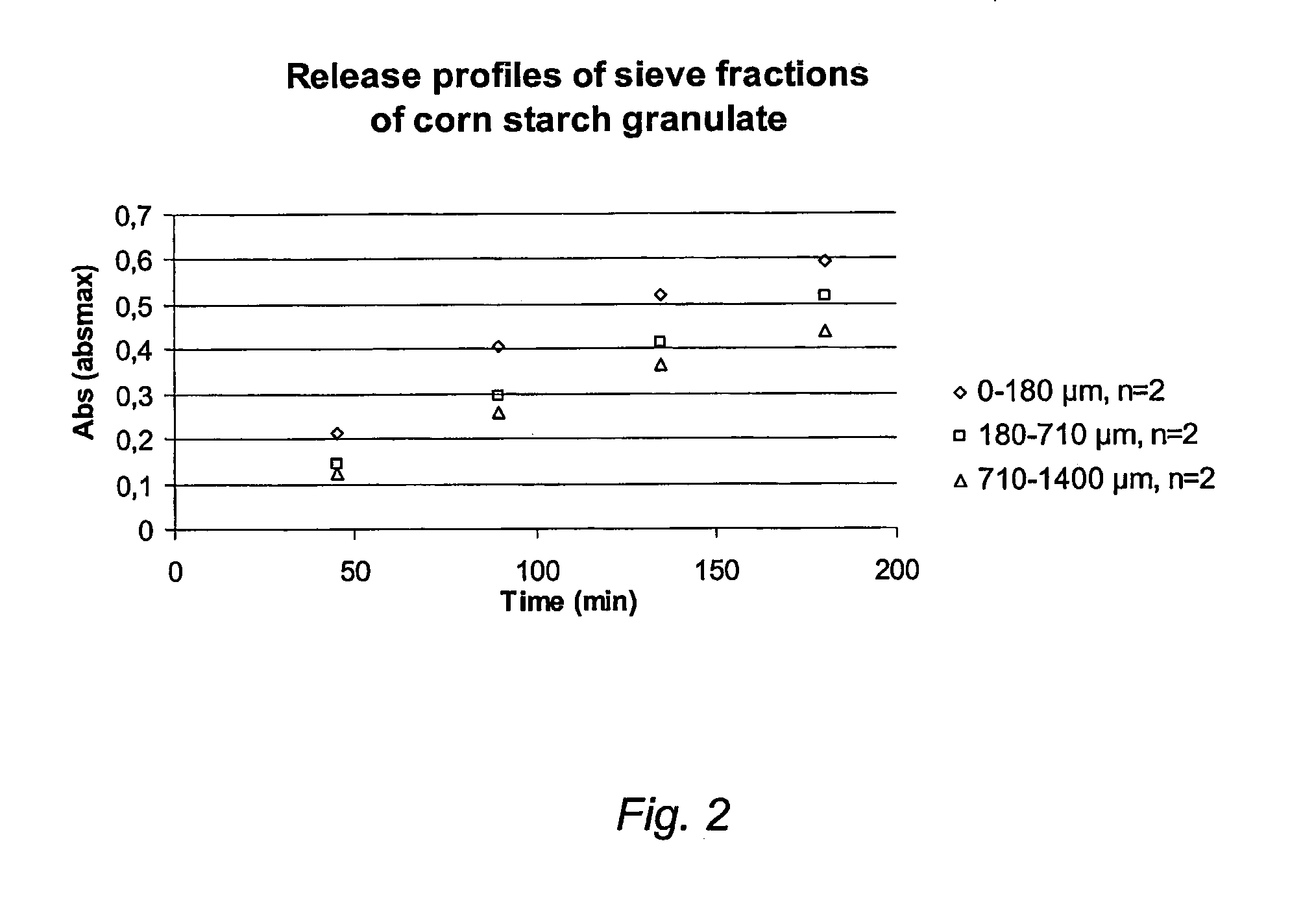

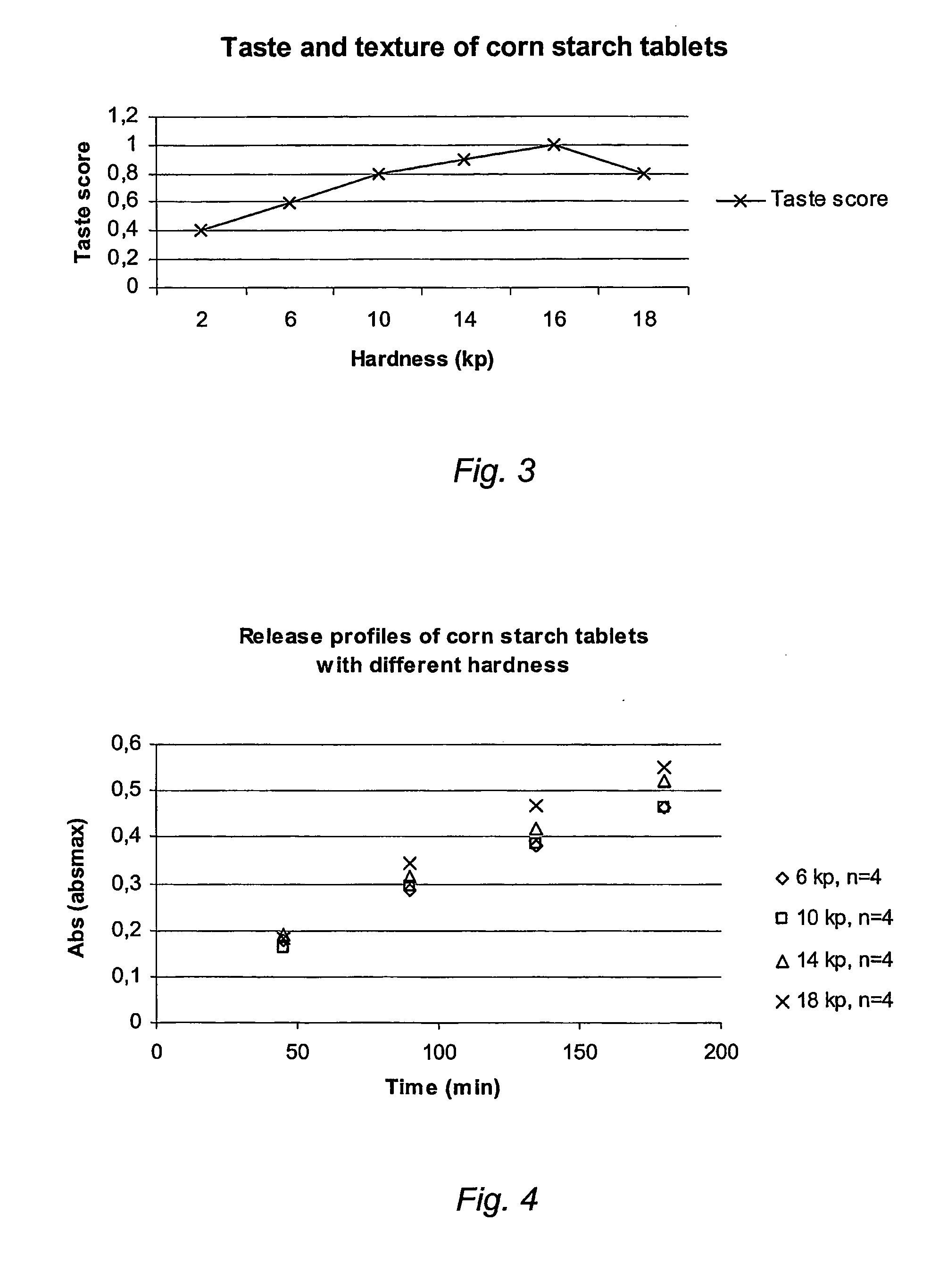

InactiveUS20050155519A1Optimize nocturnal glucose deliveryEffective timeStarch dervative coatingsStarch adhesivesSolventEnzymatic degradation

A process for the manufacture of a corn starch granulate possessing resistance to enzymatic degradation upon oral administration, comprising the steps: a) granulating native corn starch by cautious mixing of a granulation fluid comprising methyl cellulose or ethyl cellulose as a binder, ethanol or water as a solvent, corn starch and a sweetener, b) subjecting the granulated material resulting from step a) to wet sieving; c) drying the granulate obtained in step b) at a temperature less than about 55° C. to avoid gelatinization of the corn starch; and d) sizing the dried granulate from step c) by dry sieving. A corn starch granulate and a corn starch granulate tablet also are provided.

Owner:METCON MEDICIN

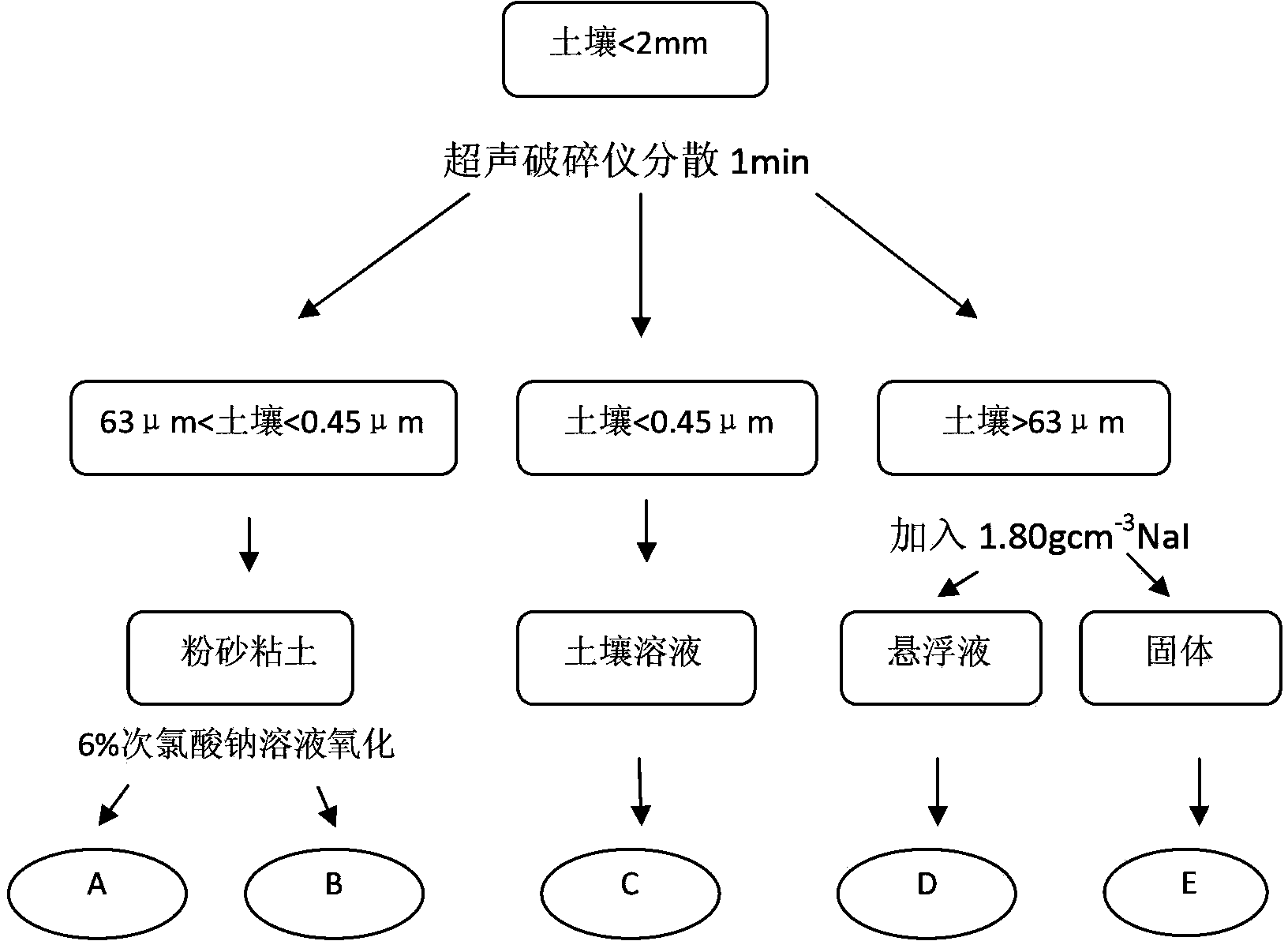

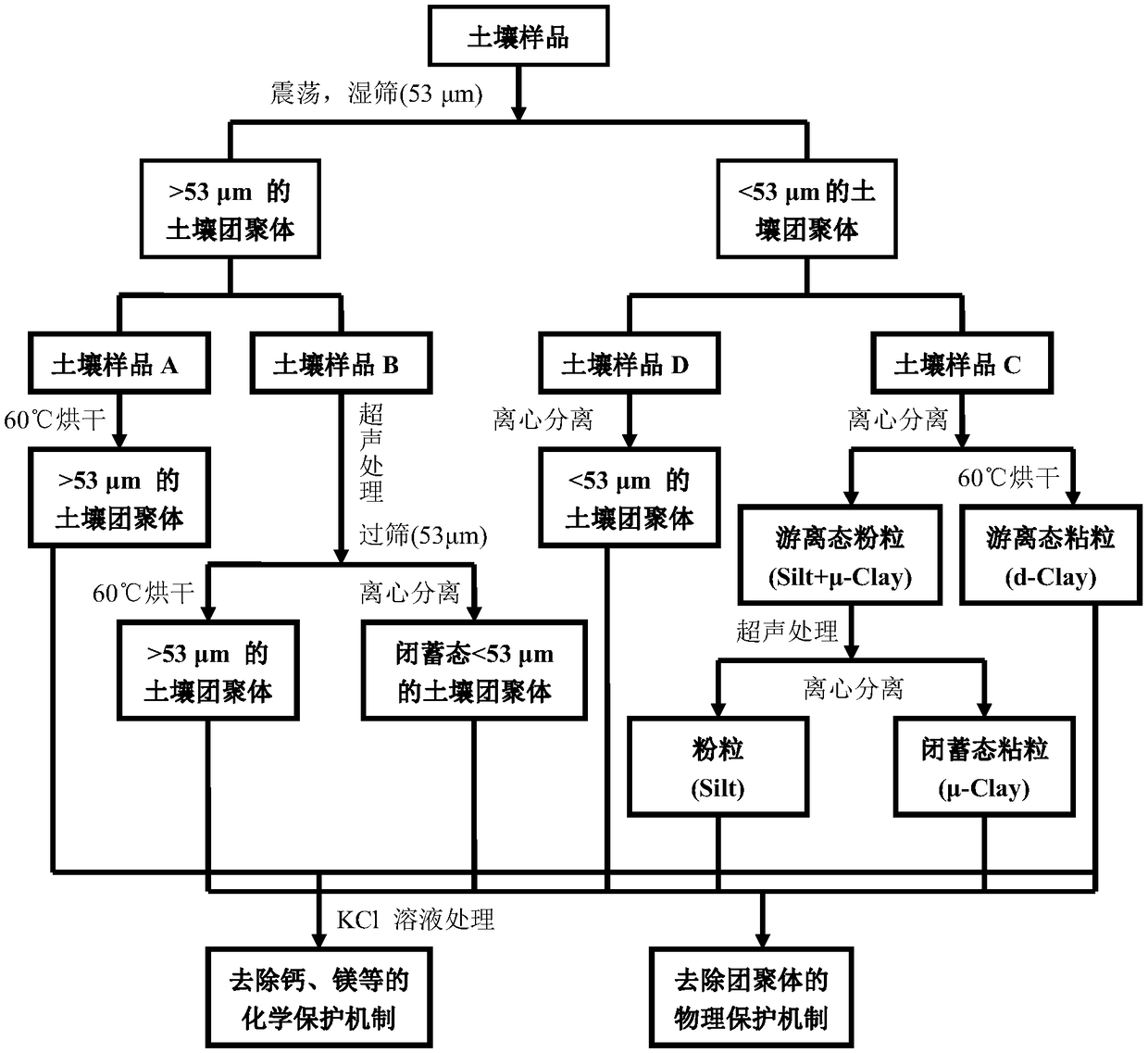

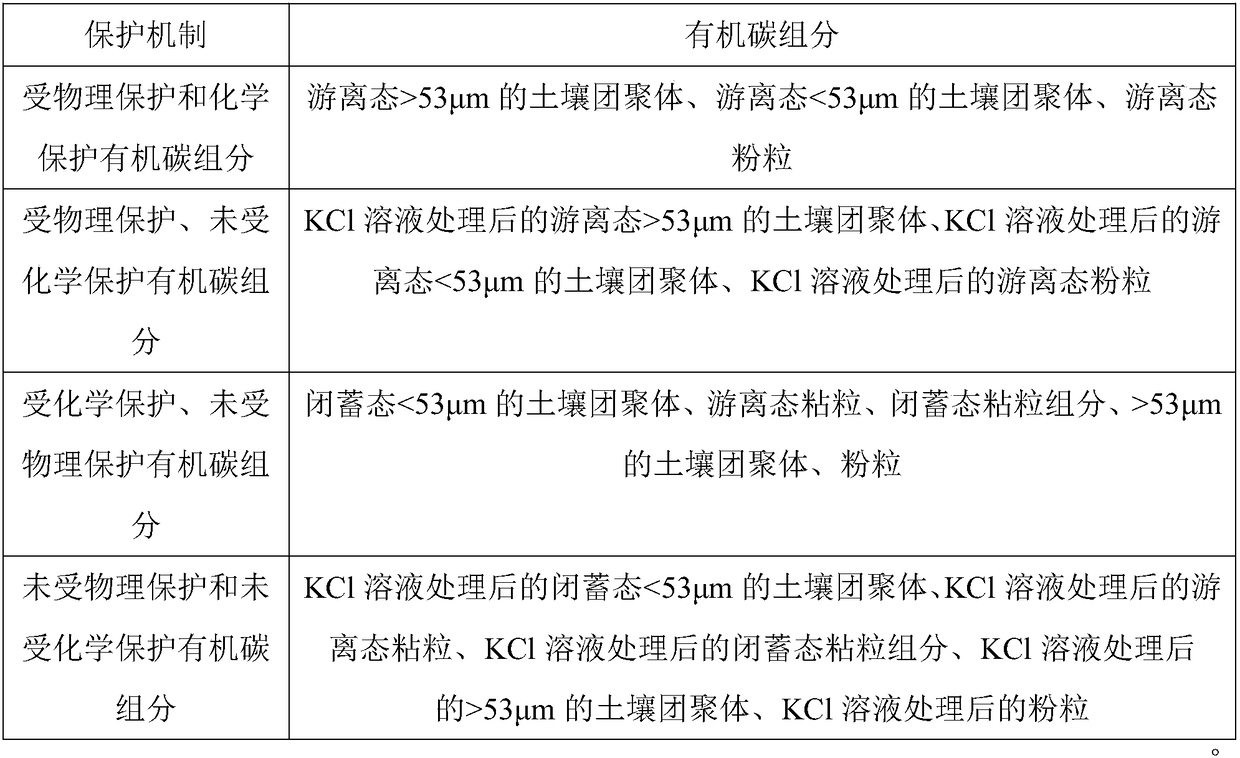

Method for grouping organic carbons in soil by combing physics and chemistry

ActiveCN108593888ASolve the overlapping phenomenonImprove the disadvantages of destroying the chemical structure of organic carbon componentsEarth material testingStability studySmallerThan

The invention discloses a method for grouping organic carbons in soil by combing physics and chemistry and relates to a grouping method of the organic carbons in soil. The invention aims at solving the problem that in the prior art, physics grouping or chemistry grouping is used alone in the stability study of the organic carbons in soil so that the stability of the organic carbons in soil cannotbe determined accurately. The method comprises the steps that an air-dried soil sample is subjected to wet sieving and divided into a soil aggregate with the pore diameter larger than 53 micrometers and a soil aggregate with the pore diameter smaller than 53 micrometers; the soil aggregate with the pore diameter larger than 53 micrometers is divided into two parts, one part is dried and then saved, and the other parts is destroyed by an ultrasonic crusher, so that the soil aggregate with the pore diameter larger than 53 micrometers and an occluded soil aggregate with the pore diameter smallerthan 53 micrometers are obtained; the soil aggregate with the pore diameter smaller than 53 micrometers is divided into two parts, one part is dried and then saved, and the other part is subjected tocentrifugalization, so that free powder particles and free clay particles are obtained; the free powder particles are subjected to an ultrasonic treatment to obtain powder particles and occluded clayparticles; a part of the soil is disposed with a KCl solution to remove chemical protection mechanisms such as calcium and magnesium.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

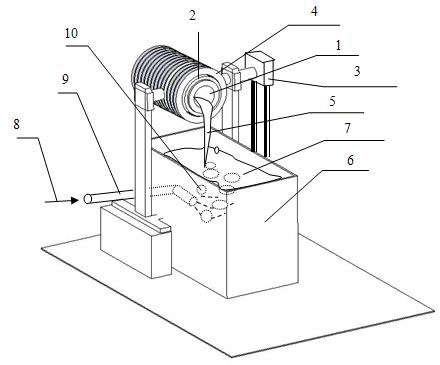

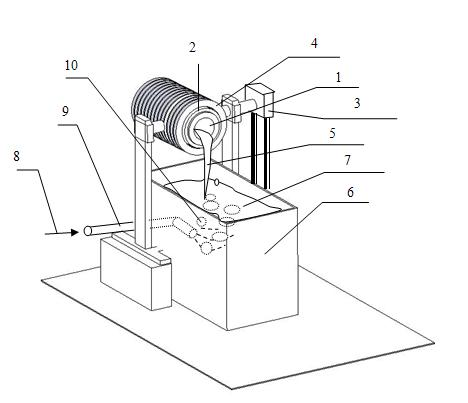

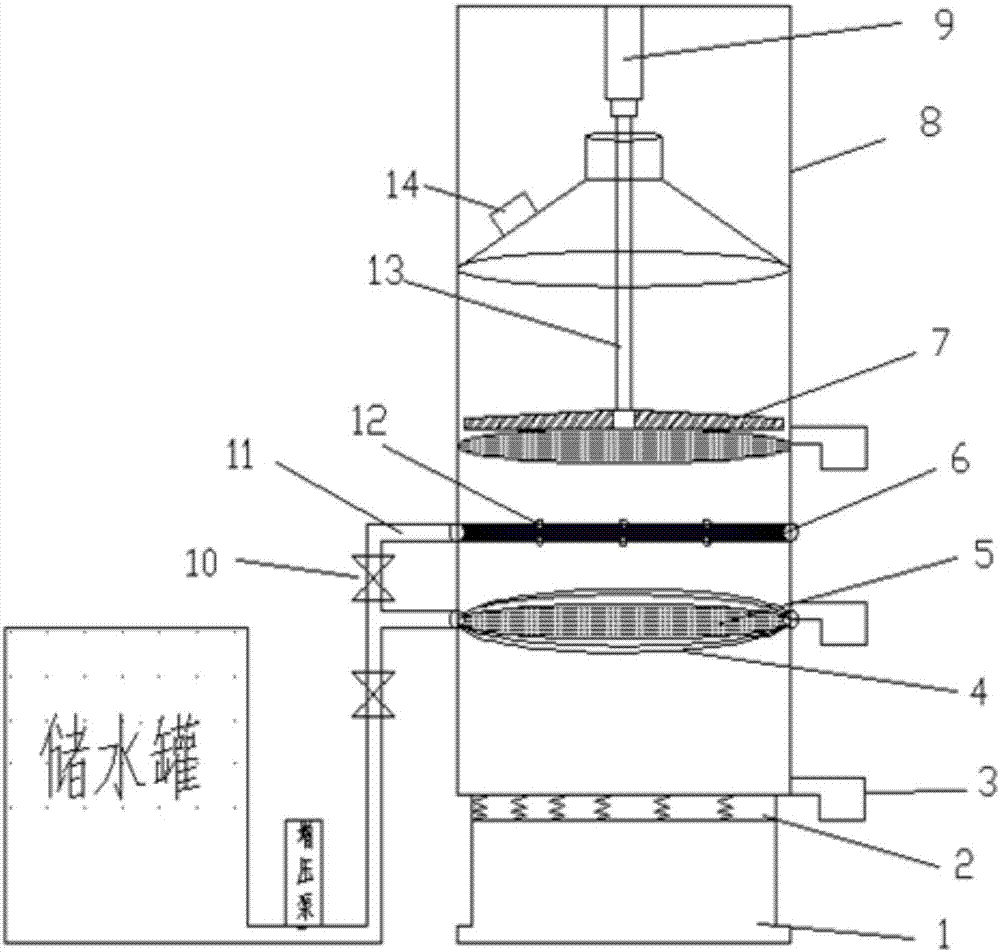

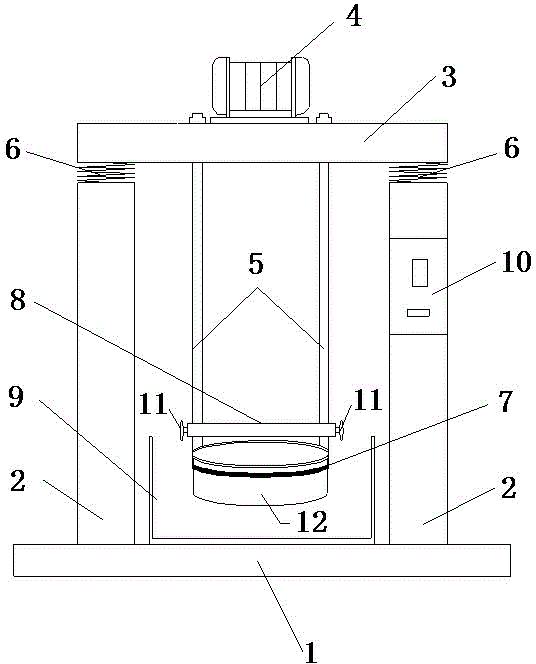

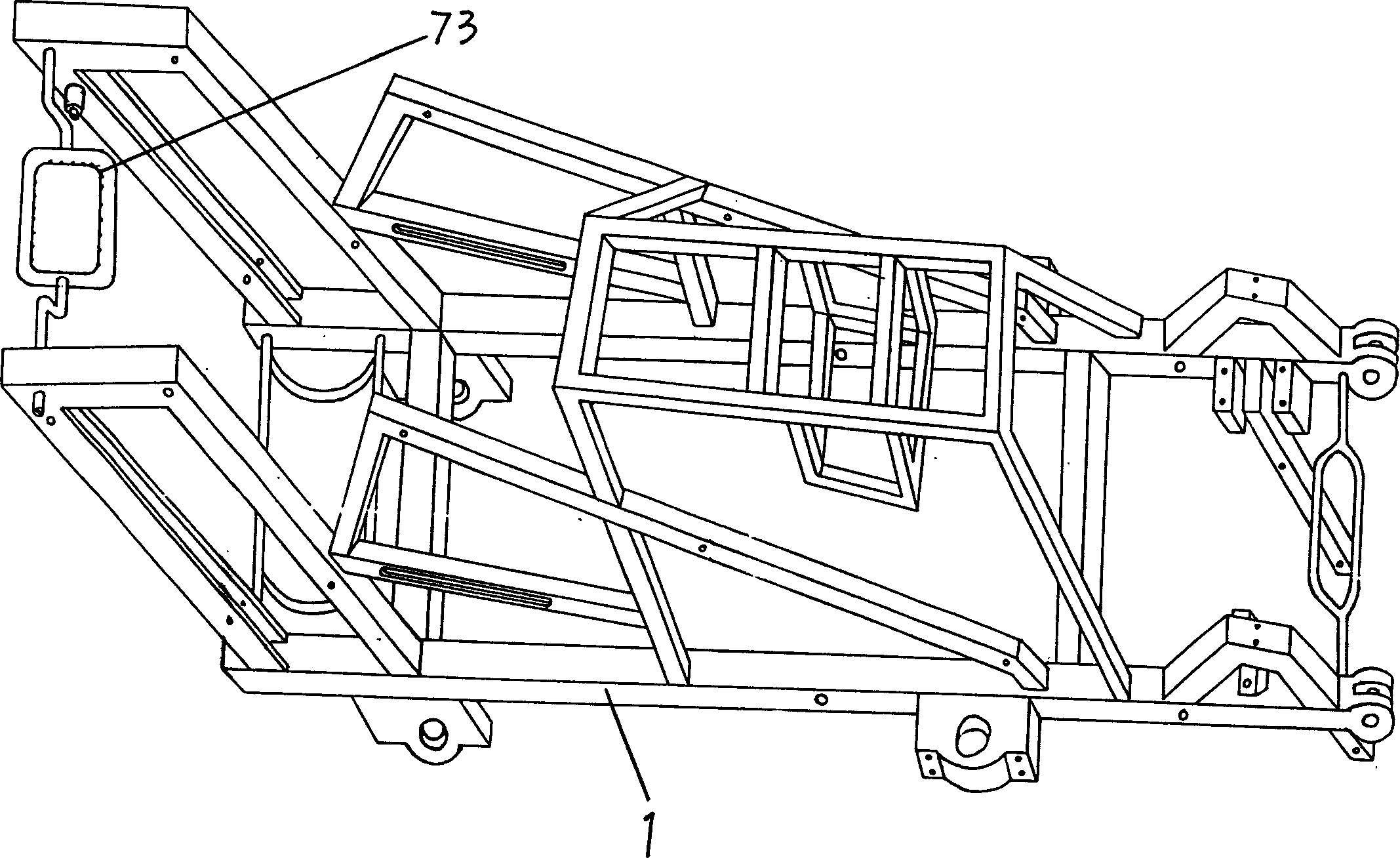

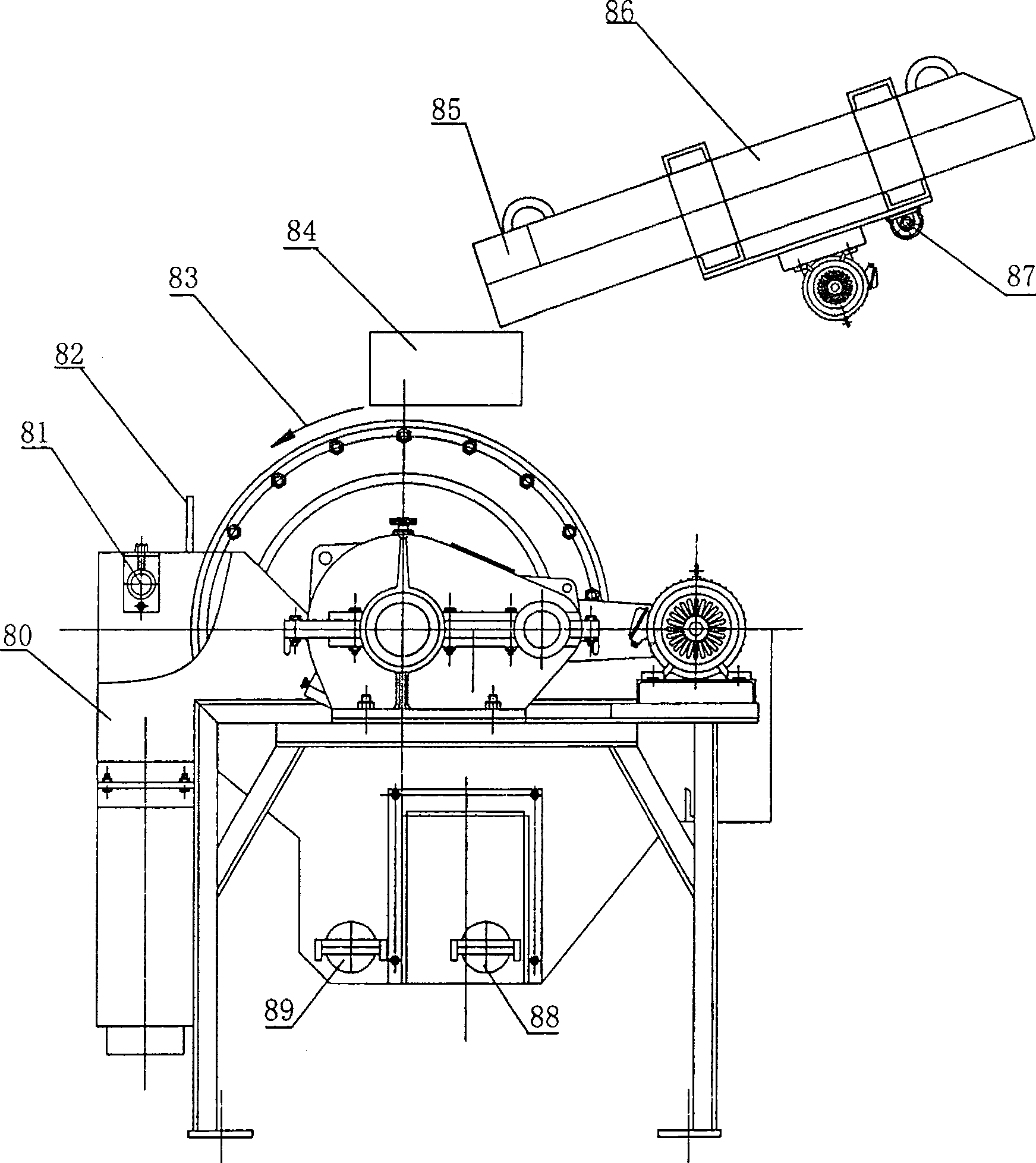

Vibrating screen for wet sieving

The invention discloses a vibrating screen for wet sieving. The vibrating screen comprises a plurality of layers of screen cloths, a distributor and a material outlet, wherein the screen cloths are sequentially and vertically arranged; the distributor is arranged above the first layer of screen cloth; a stirring device is arranged above the distributor; the material outlet is arranged below the last layer of screen cloth; at least one layer of screen cloth in the screen cloths is provided with a flushing device in parallel; the flushing device is connected with a flushing pipeline; and flushing sprayers are arranged on the flushing device. The phenomenon that meshes of a vibrating screen are prone to being blocked in the use process can be avoided, the solid-liquid ratio of filtered powder is increased, and the production efficiency of the powder is improved.

Owner:青海万加环保新材料有限公司

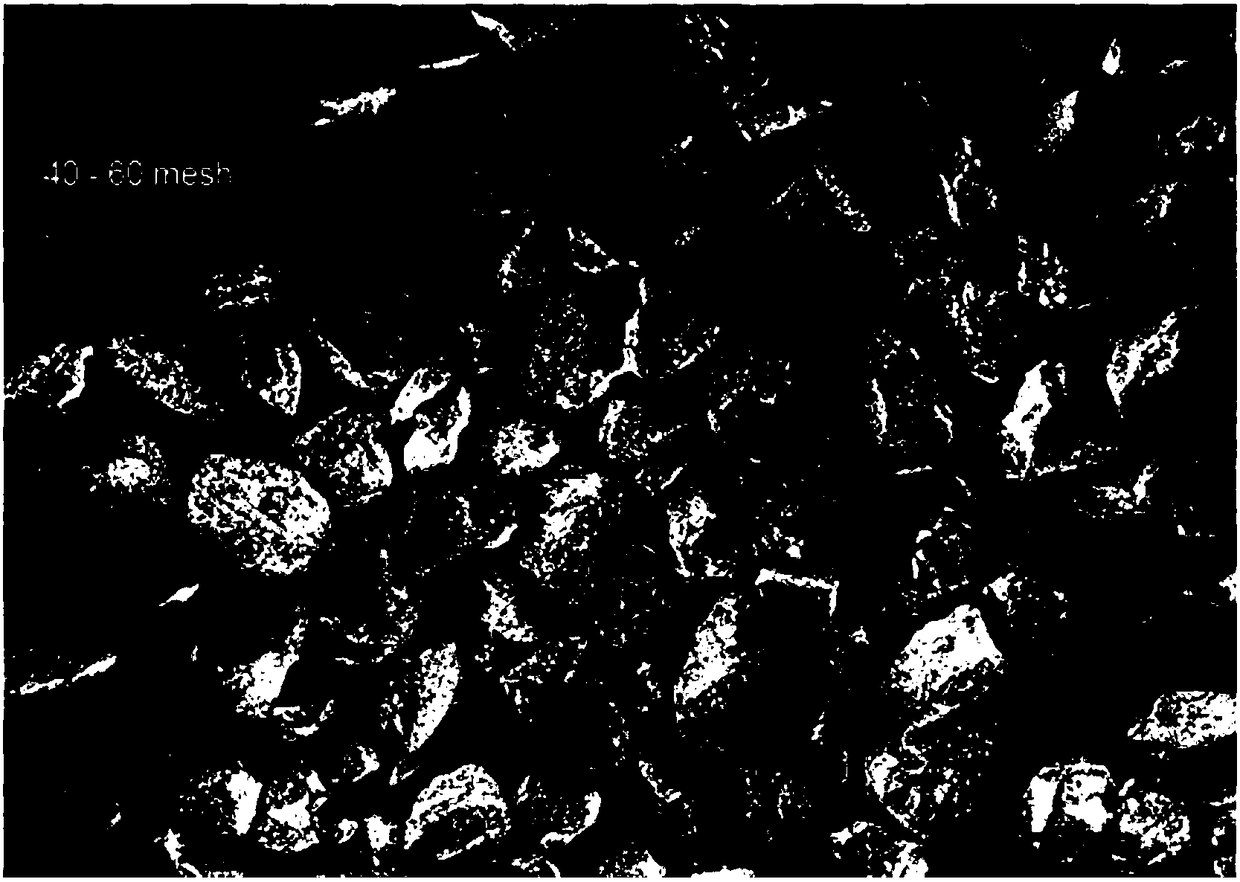

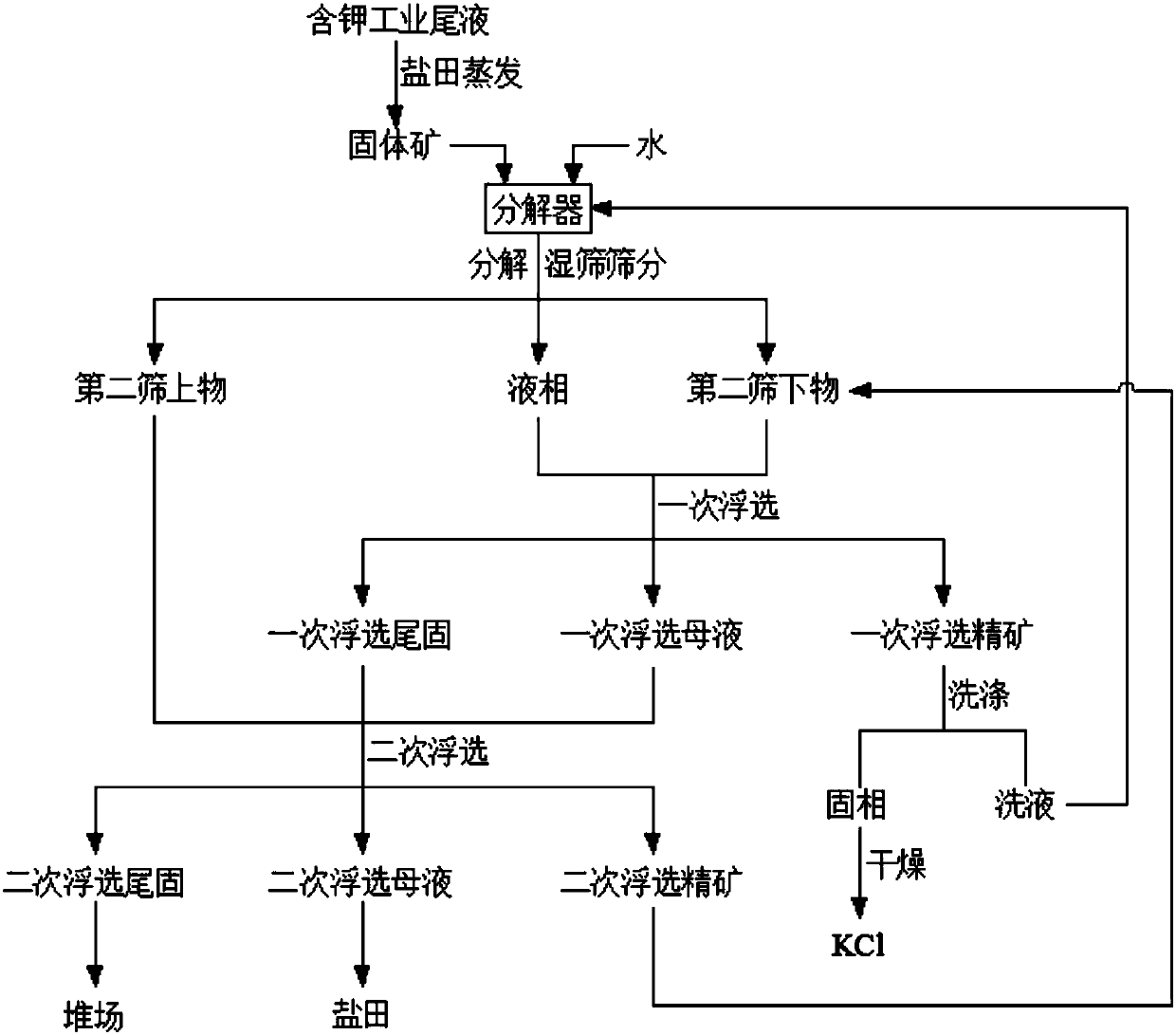

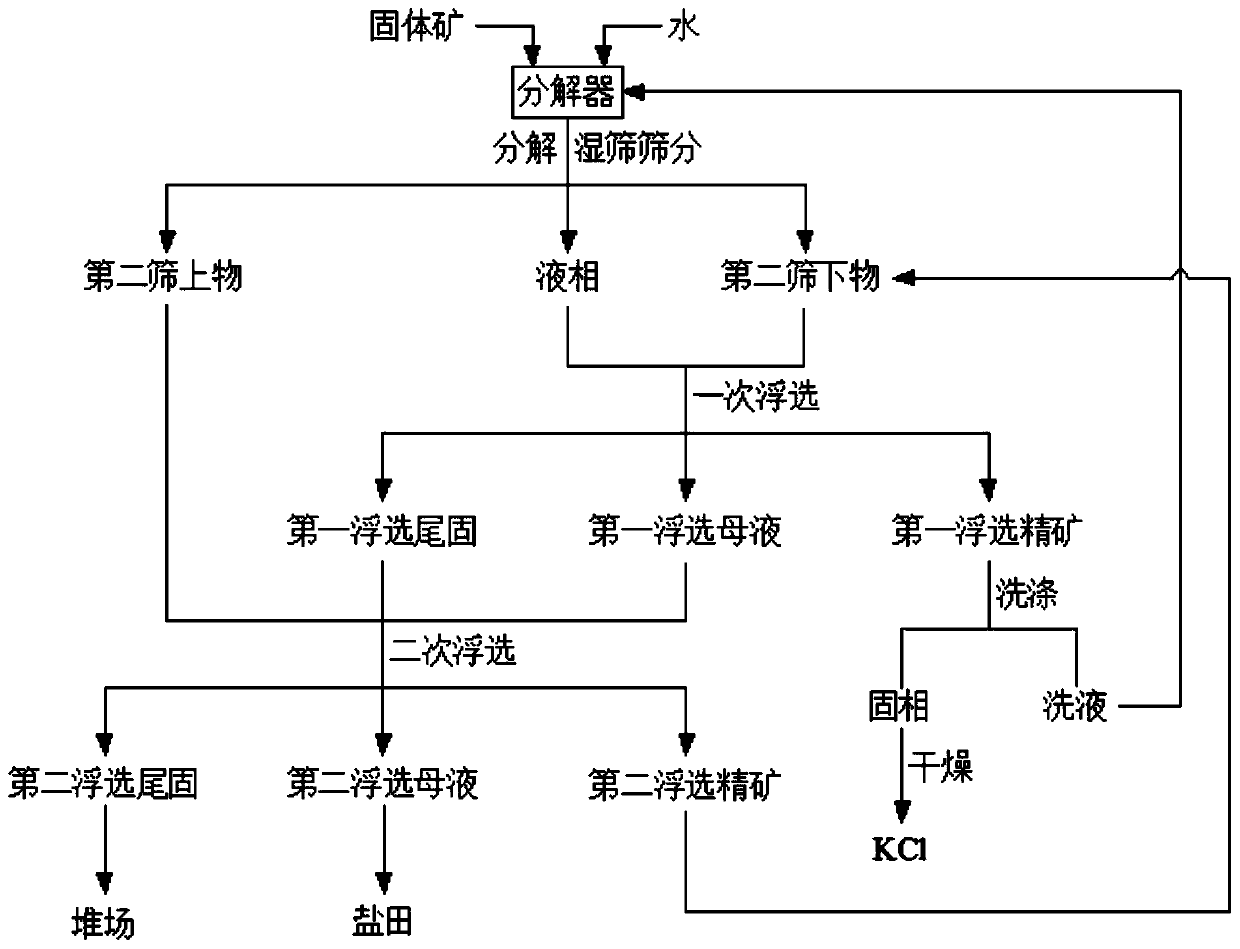

Method for recycling potassium from industrial raffinate containing potassium

ActiveCN108017071ASolving RecyclingReduce pollutionAlkali metal chloridesPotassium nitrateDecomposition

The invention provides a method for recycling potassium from industrial raffinate containing potassium. The industrial raffinate containing potassium is the mixed raffinate generated in the process ofproducing potassium nitrate and magnesium nitrate. The method includes the steps of conducting salt pan evaporation on the industrial raffinate containing potassium to obtain solid ore containing potassium, ammonium and magnesium; crushing and sieving the solid ore containing potassium, ammonium and magnesium to obtain first sieved substances; blending the first sieved substances with water according to a mass ratio of 100:(50-70), fully decomposing the mixture, and then adopting a 40-80-mesh sieve for conducting wet sieving and solid-liquid separation to obtain second sieved objects; conducting flotation on the second sieved objects once, and then conducting washing, solid-liquid separation and drying on correspondingly obtained flotation concentrates to obtain a potassium chloride product. According to the compositions of the industrial raffinate containing potassium, a technology for salt pan evaporation, decomposition, sieving and flotation is made for preparing potassium chloride, obtained potassium chloride can be used as the raw material for production, the whole technology is simple in process and low in cost, the utilization problem of potassium is solved, and the resource utilization rate is effectively increased.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

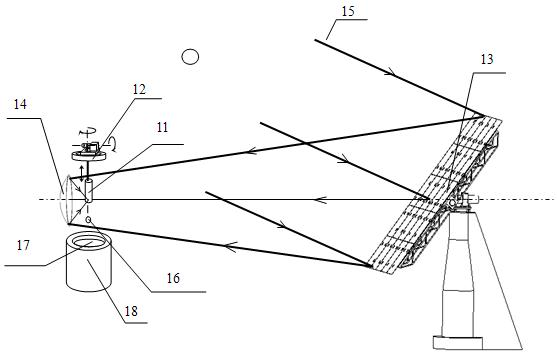

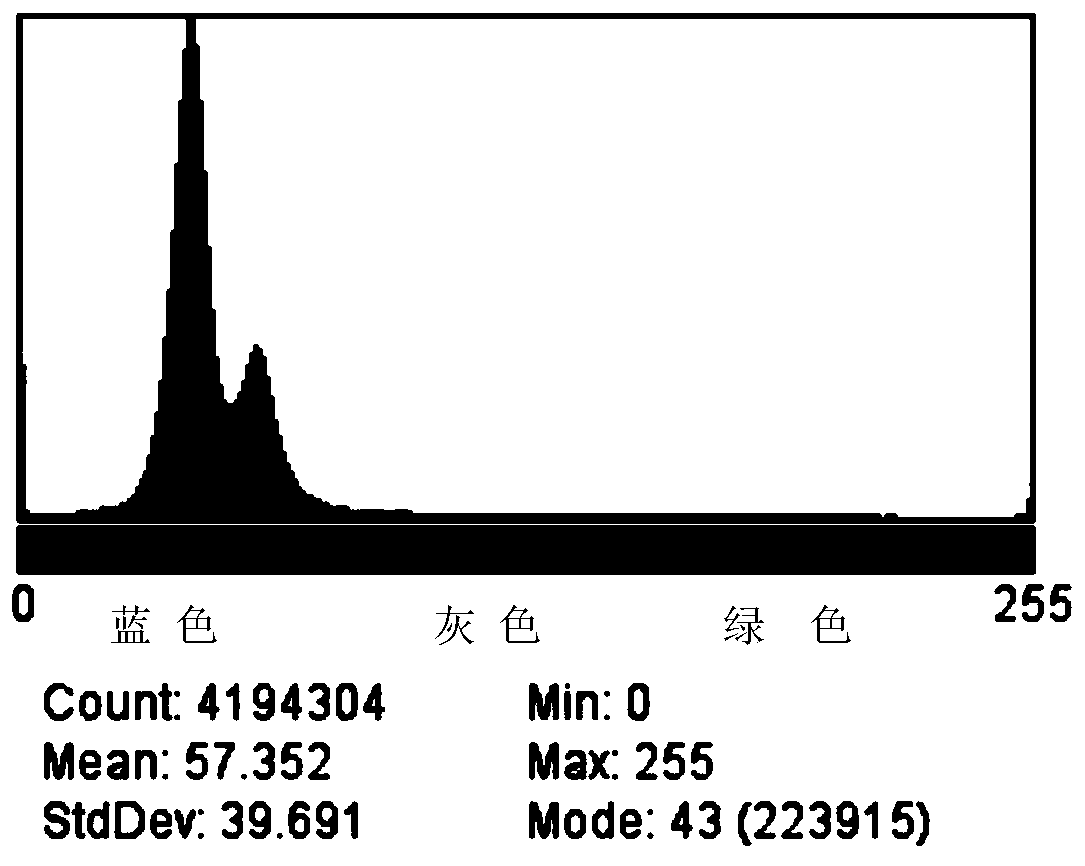

Wet and dry sieve shaker for laboratory

The invention discloses a wet and dry sieve shaker for a laboratory. The wet and dry sieve shaker comprises a base, a rack, a vibration bracket, a vibration motor, a vibration connecting rod, a vibration spring, a retainer ring, a locking slide rod, a water channel and a control panel, wherein the rack and the base are welded into a whole, the vibration bracket is connected with the rack through the vibration spring, the vibration motor is fixed on the vibration bracket, and the vibration frequency of the vibration motor is subjected to stepless regulation through a frequency converter. One end of the vibration connecting rod is fixed on the vibration bracket, the retainer ring is fixed at the other end of the vibration connecting rod, and the locking slide rod can slide up and down on the vibration connecting rod. The water channel is arranged on the base and is right below the retainer ring. The control panel is located on the rack, can control the frequency converter to regulate the vibration frequency of the vibration motor, and has a timing function. The wet and dry sieve shaker is simple in structure, is convenient to operate, and works reliably, manual work is replaced to carry out wet sieving, the labor intensity is reduced, the working efficiency is improved, the wet and dry sieve shaker is suitable for both dry sieving and wet sieving, one sieve shaker is used for two purposes, and the rate of equipment utilization is increased.

Owner:CHINA UNIV OF MINING & TECH

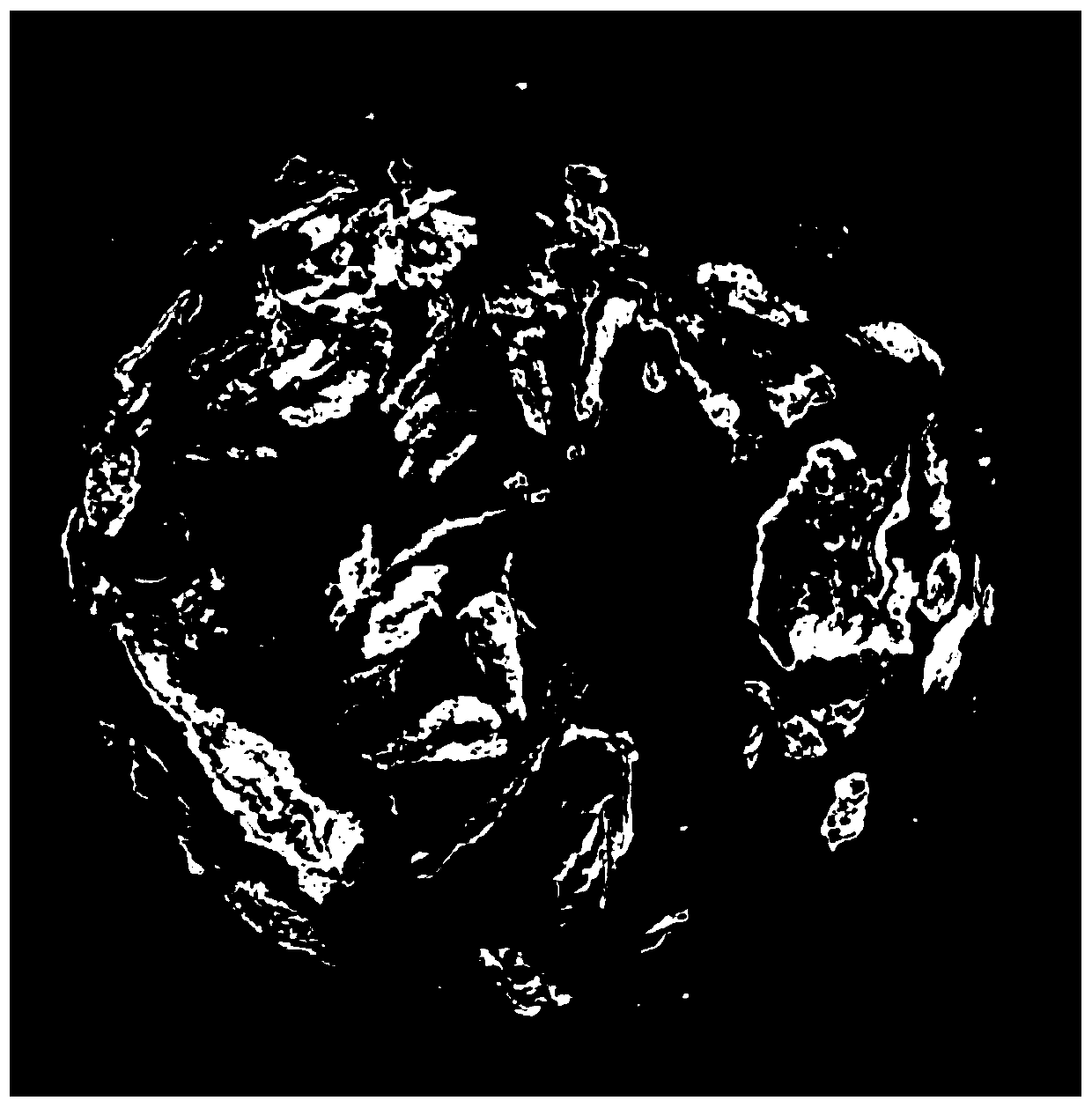

Method for quantitatively measuring spatial structure of soil particulate organic matters

ActiveCN109959602AMaterial analysis using wave/particle radiationPreparing sample for investigationParticulatesSpatial structure

The invention discloses a method for quantitatively measuring the spatial structure of soil particulate organic matters. According to the method, the particulate organic matters in the soil are extracted by means of wet sieving, classification and density extraction; with the micro-CT technology, image scanning is carried out on the particulate organic matters; and artifact removing, threshold calculation, image segmentation, and three-dimensional reconstruction are carried out on the scanned image successively, thereby measuring the soil mechanical morphological characteristics, organic matter quantity, volume ratio, volume distribution, pore size distribution quantitatively. With first utilization of the micro-CT technology, the spatial structure characteristics of soil particulate organic matters are measured quantitatively; and thus the foundation is laid for the deep study of the soil science, especially the soil organic matters.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

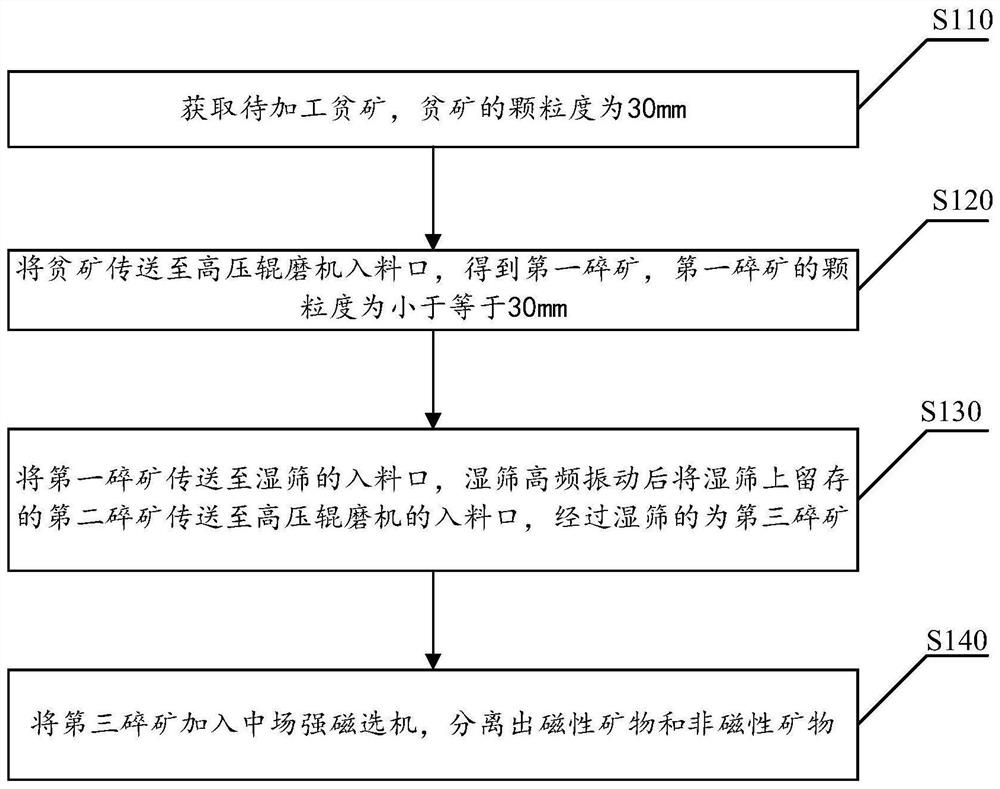

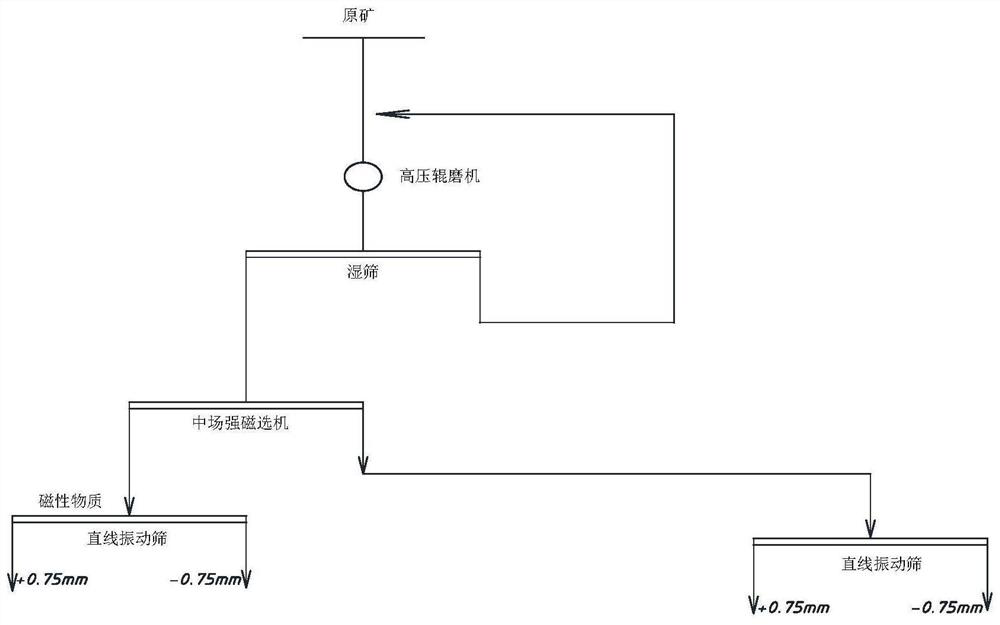

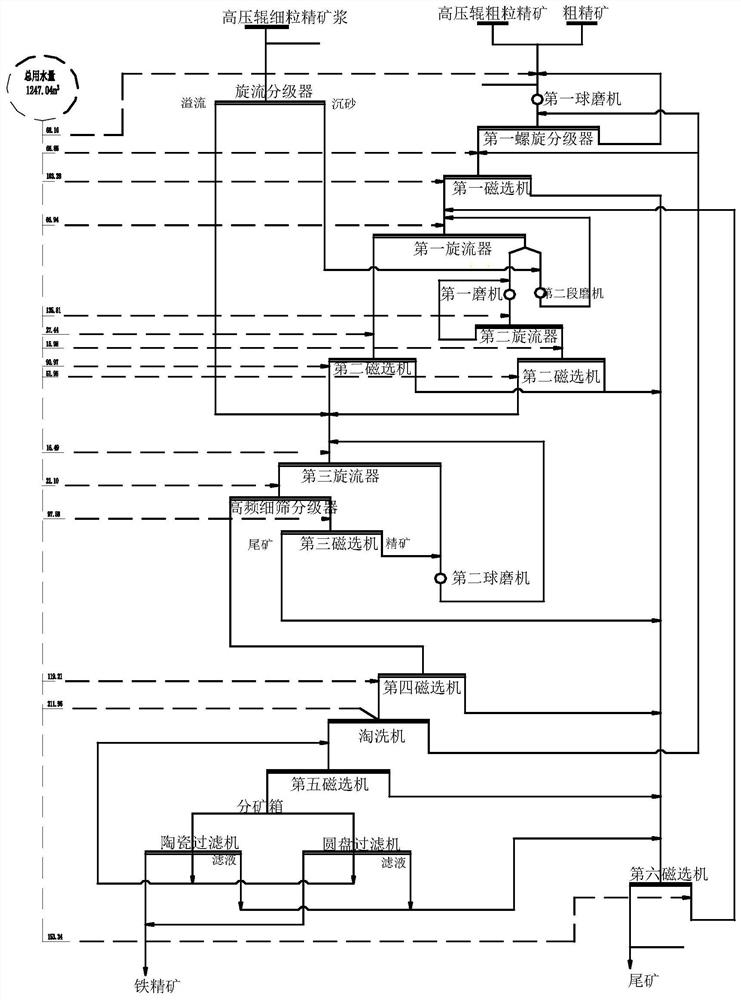

Lean ore processing method based on high-pressure roller mill

ActiveCN111659528AReduce contentImprove processing efficiencySolid separationGrain treatmentsMining engineeringMagnetic separator

The invention relates to a lean ore processing method based on a high-pressure roller mill. The method comprises the steps that lean ore to be processed is obtained, wherein the granularity of the lean ore is 30 mm; the lean ore is conveyed to a feeding port of the high-pressure roller mill, and first crushed ore is obtained, wherein the granularity of the first crushed ore is smaller than or equal to 30 mm; the first crushed ore is conveyed to a feeding port of a wet sieve, after the wet screen vibrates at high frequency, second crushed ore left on the wet sieve is conveyed to the feeding port of the high-pressure roller mill, and the ore passing through the wet sieve is third crushed ore; and the third crushed ore is added into a medium field intensity magnetic separator, and magnetic minerals and non-magnetic minerals are separated. According to the lean ore processing method based on the high-pressure roller mill provided by the embodiment, corresponding single quality standards are established for the iron contents of the first crushed ore, the second crushed ore and the third crushed ore, so that the magnetic minerals in the lean ore are separated as much as possible, and thecontent of magnetic substances in tailings is reduced.

Owner:包头市石宝铁矿集团有限责任公司

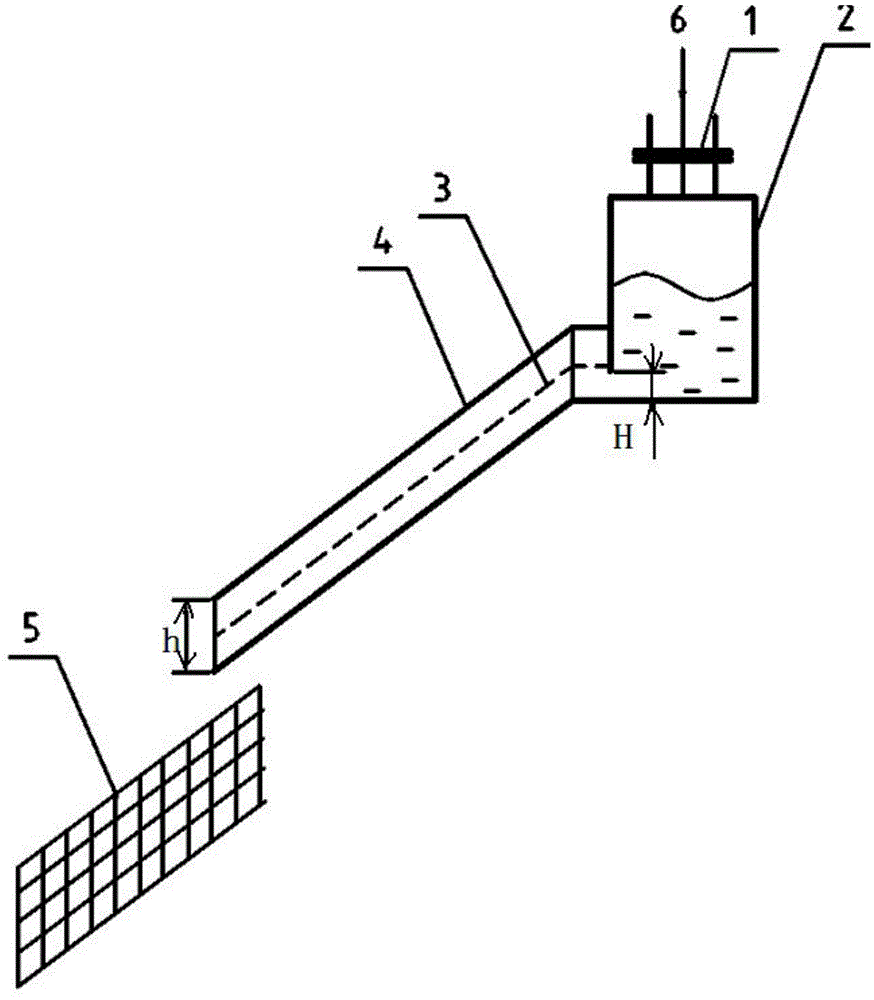

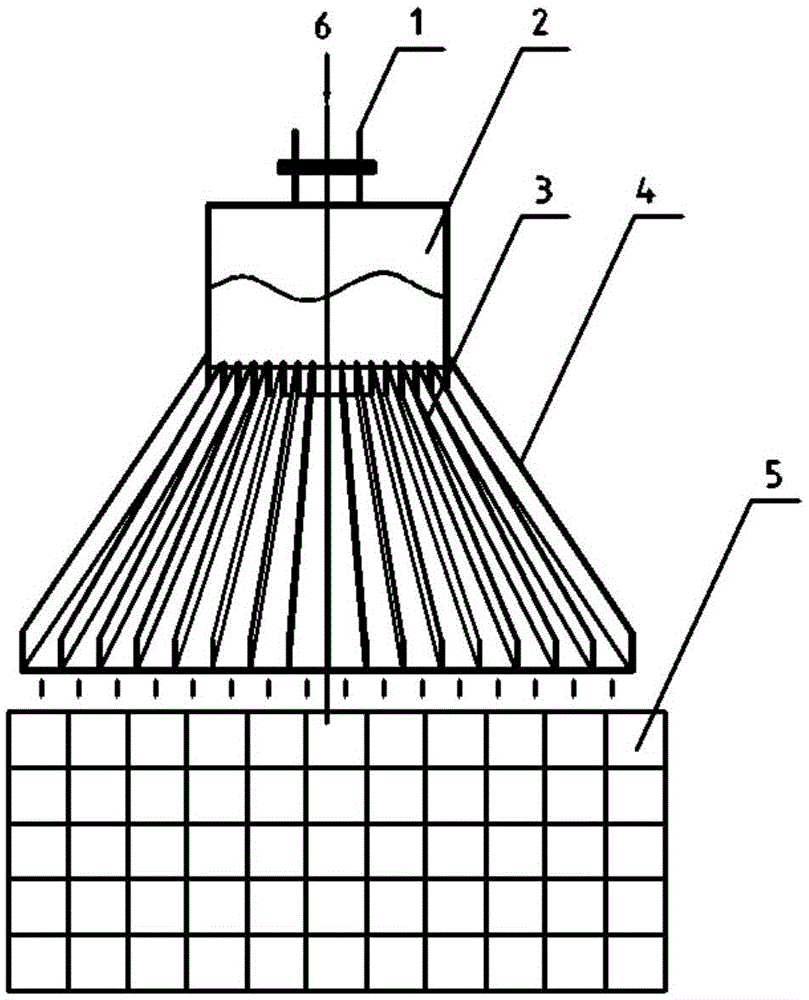

Uniform feeding method and device by adopting wet sieving method

The invention provides a uniform feeding method and device by adopting a wet sieving method. Self-pressure feeding and uniform distribution technology in multiple sections are adopted so that uniform feeding of qualified plup after grinding is achieved. The device is composed of two parts including a feeding buffer tank and a distribution chute. The feeding buffer tank is provided with a feeding port and a discharging port. Multiple baffle plates are arranged in the distribution chute and spaced at an equal interval. The height of each baffle plate is in the same as that of an outlet of the feeding buffer tank. The distribution chute is uniformly divided into multiple individual sector-shaped distribution areas by the baffle plates. Pulp is uniformly distributed and enters any one fan-shaped distribution area.Pulp flows out of outlets of the multiple individual fan-shaped distribution areas from the distribution chute and is uniformly fed into a high-frequency screen net.The uniform feeding method and device by adopting the wet sieving method have following beneficial effects: qualified pulp after grinding can be uniformly distributed on the net through self-pressure feeding and distribution technology in multiple sections so that processing capability and screening efficiency of the high-frequency screen net are enhanced; impact of chute deformation on production is reduced; working efficiency of the high-frequency screen net is increased; and maintenance intensity of equipment is decreased.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Fully automatic dry wet rinsing sand screening machine

InactiveCN1631545AImprove work efficiencyStandards compliantWet separationPulp and paper industryPower equipment

The invention unfurls a kind of full-automatic dry-wet sieving sand machine of water washing. It includes: walking body, revolving funnel, cloth funnel, transferring fix, funnel, sieve, water-in fix, motor, speed changing box, generator, electrical machine, changing height fix. There are four rounds under the walking body; the body is low in front and high behind. The revolving funnel is fixed in the front of the body and wringed with the body, behind and under the funnel, there is cloth funnel. The transferring fix is low in front and high behind which is fixed under the cloth funnel. The cloth funnel is fixed under the walking body; sives is on the body, declining direction is same to the transferring fix. The water-in fix is on the cloth funnel; the changing height fix is connected witty the revolving funnel on one side, the other side is connected with the walking body; motor, speed changing box, generator, electrical machine are the power equipment, which are fixed on the walking body and above the transferring fix.

Owner:池龙岩 +2

A kind of method for preparing potassium chloride from solid ore containing potassium ammonium magnesium

ActiveCN107758696BSolve the use problemImprove resource utilizationAlkali metal chloridesResource utilizationPotassium ions

The invention provides a method for preparing potassium chloride from a solid ore containing potassium, ammonium and magnesium. The solid ore contains the following components in percentage by weight:5.1%-5.9% of potassium ions, 1.0%-1.4% of ammonium ions, 9.5%-10.0% of magnesium ions and 35.2%-37.1% of chloride ions. The method comprises the following steps: (S1) crushing the solid ore containing potassium, ammonium and magnesium, and sieving, so as to obtain a first screen underflow; (S2) mixing the first screen underflow with water in a mass ratio of (100) to (50-70) to adequately decomposing the first screen underflow, carrying out wet sieving by virtue of a 40-80-mesh sieve, and carrying out solid-liquid separation, so as to obtain a second screen underflow; and (S3) carrying out primary flotation on the second screen underflow so as to obtain a first flotation concentrate, and carrying out washing, solid-liquid separation and drying, so as to obtain the potassium chloride product. According to the method, a decomposing-sieving-floatation process is formulated according to the constitution of the solid ore containing potassium, ammonium and magnesium and is utilized for preparing potassium chloride, obtained potassium chloride can be used as a production raw material, the whole process flow is simple and low in cost, the utilization problem of potassium is solved, and theresource utilization rate is effectively increased.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for enriching semi-vitrinite components of coal

ActiveCN112284871AGrind fullyLow chance of exposurePreparing sample for investigationProcess efficiency improvementPhysical chemistryDistilled water

The invention discloses a method for enriching semi-vitrinite components of coal. The method comprises the following steps: (1) crushing raw coal to be less than 0.2 mm; (2) putting a crushed coal sample, a medium ball and distilled water into a ball milling tank for ball milling; (3) carrying out wet sieving on the ground coal sample, and then carrying out ultrasonic treatment, suction filtrationand drying; and (4) enriching semi-vitrinite components by using a heavy liquid separation method. According to the method, wet grinding and ultrasonic treatment technologies are adopted in a feed coal crushing treatment stage so that the hydrophilic and hydrophobic characteristics of microcomponents are changed to a certain extent, different microcomponents and mineral substances of coal are dissociated, and the semi-vitrinite component enriched coal is prepared.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

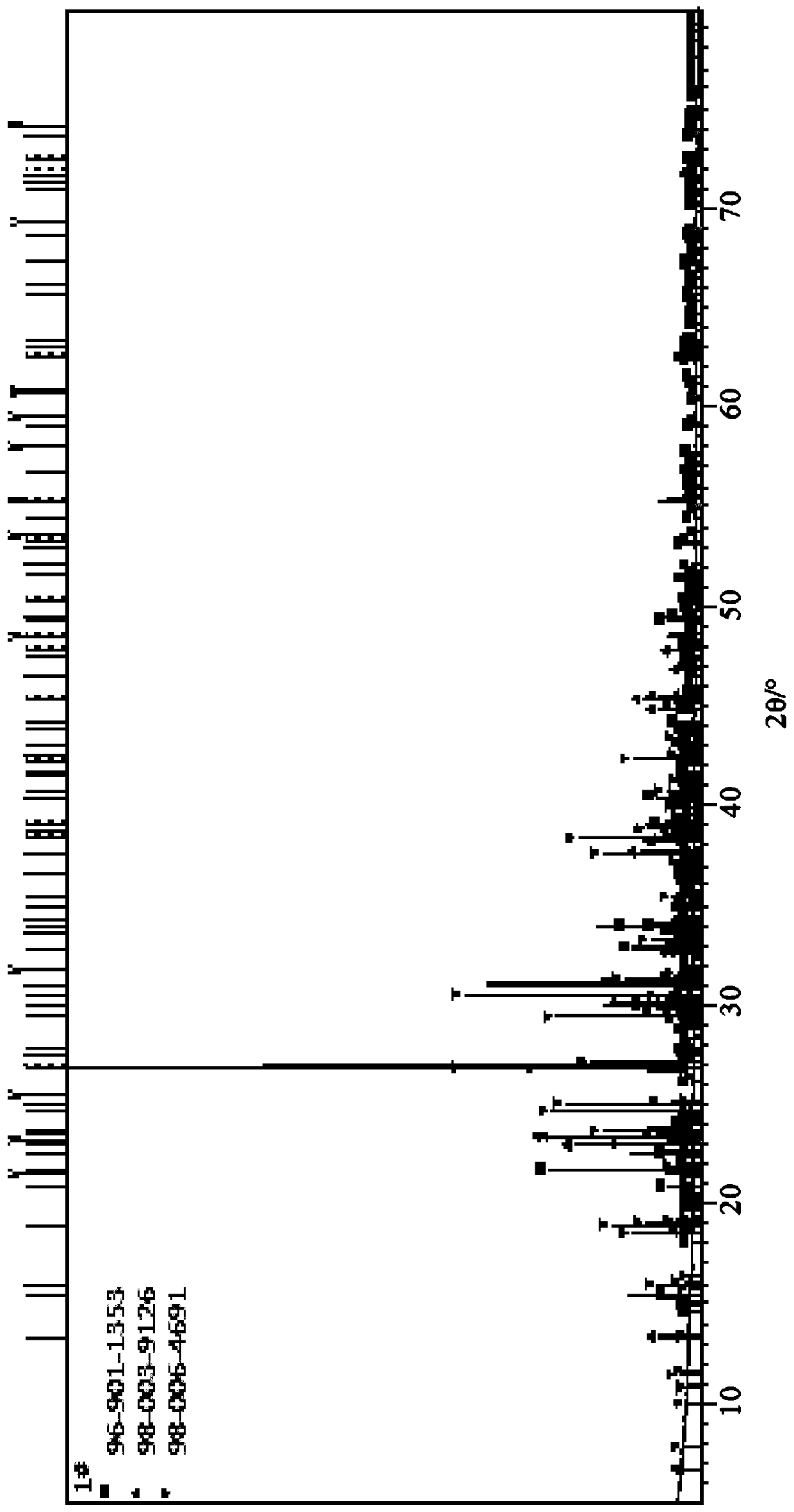

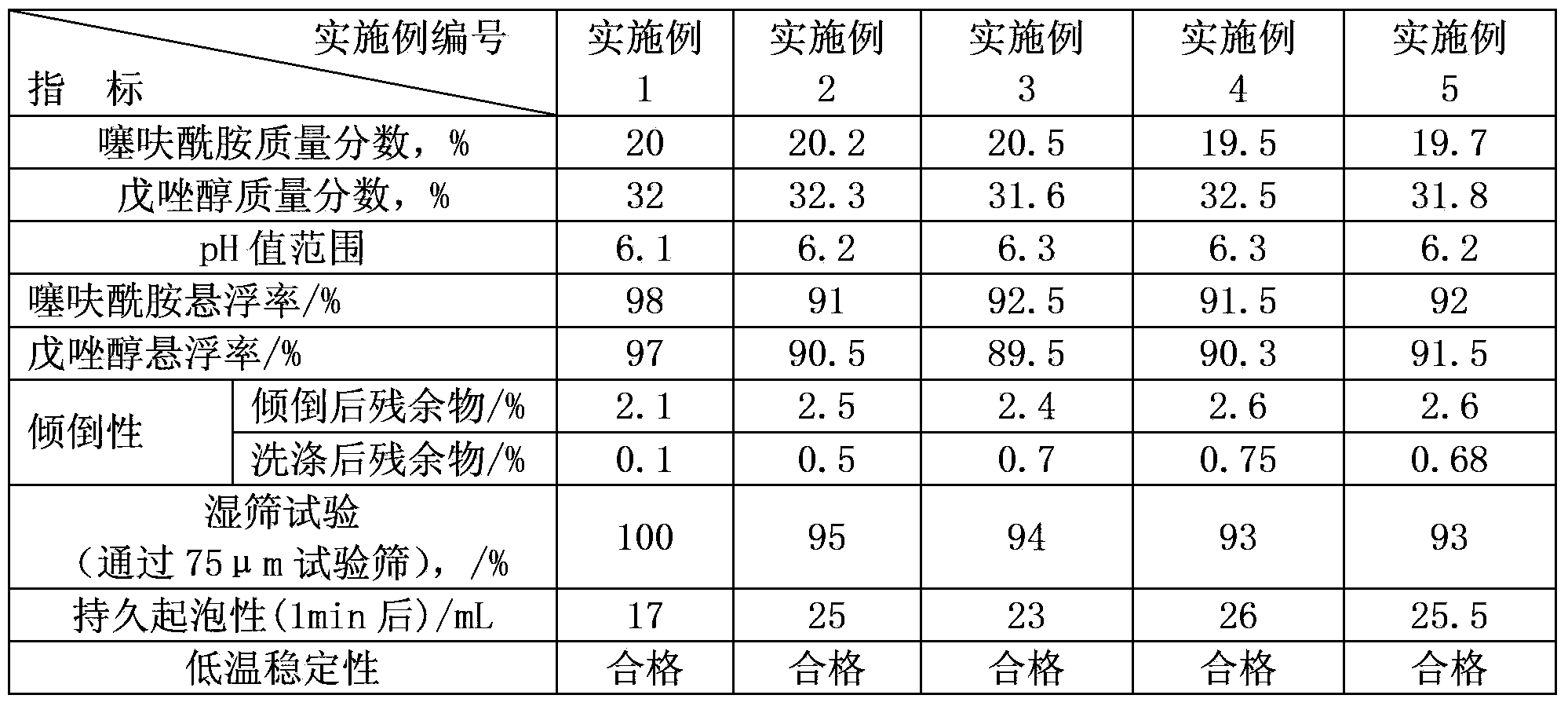

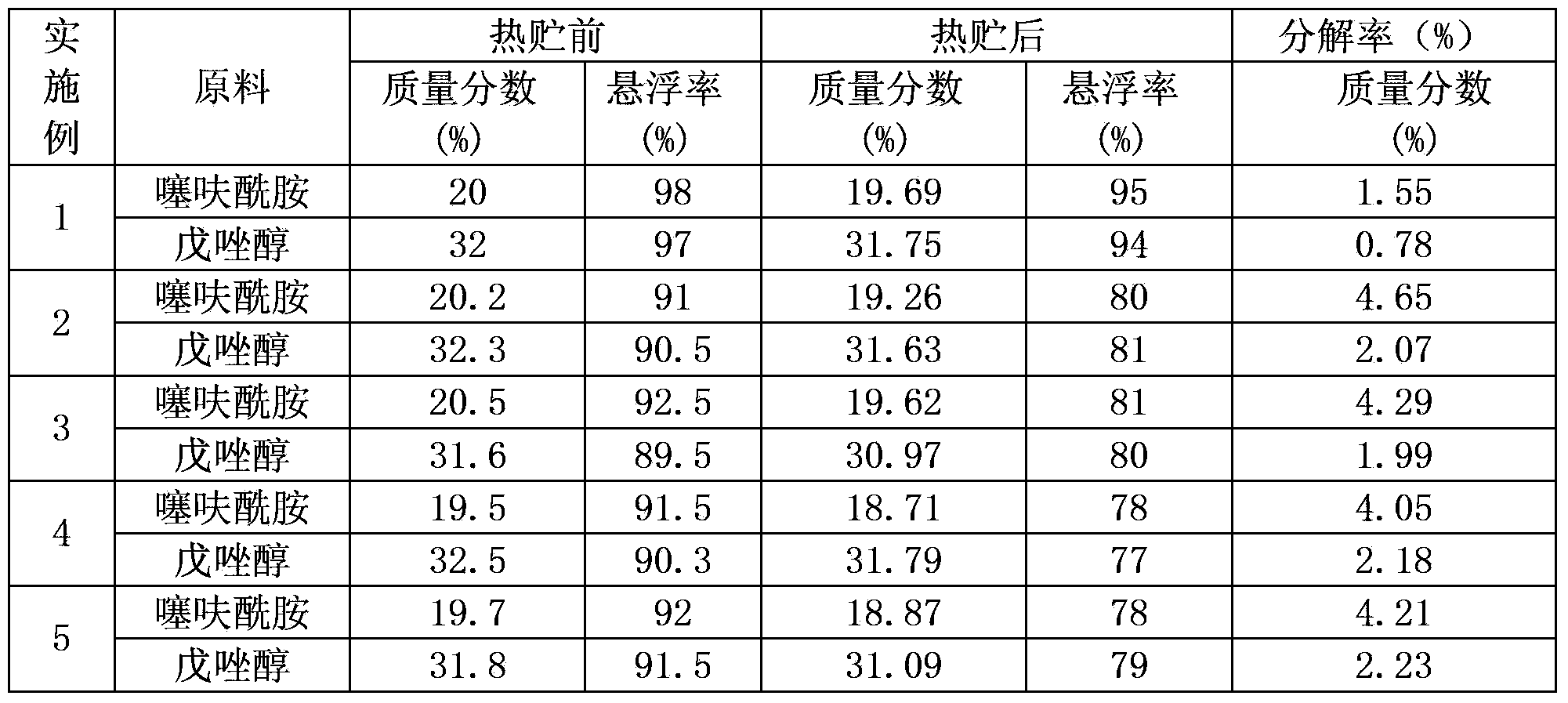

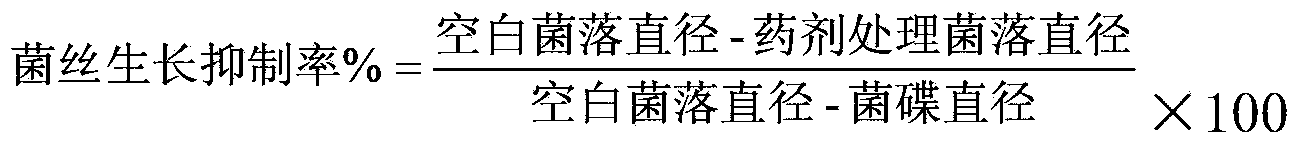

Suspending agent of thifluzamide and tebuconazole composite pesticide and preparation method of suspending agent

ActiveCN103329892BGood suspension rateExcellent long-lasting foamingBiocideFungicidesSuspending AgentsSolvent

The invention relates to the technical field of pesticide for controlling rice sheath blight diseases and false smut, in particular to a suspending agent of thifluzamide and tebuconazole composite pesticide and a preparation method of the suspending agent. The suspending agent is prepared by the following ingredients in parts by weight: 20 parts of thifluzamide, 32 parts of tebuconazole, 18 parts of emolsifier and 30 parts of solvent. The prepared suspending agent is obviously superior to products prepared according to other proportions in suspensibility, persistent foamability, wet sieving test, thermal stability and the like. Experiments verify that the cotoxicity coefficient of the suspending agent reaches 154.19, the suspending agent falls in an obvious synergistic action scope, and preparations mixed in other proportions cannot reach the obvious synergistic action scope. In addition, the actual toxicity of different proportions is not raised with theoretical toxicity, and no change law exists between the actual toxicity and the theoretical toxicity. The suspending agent of the thifluzamide and tebuconazole composite pesticide is suitable for controlling the rice sheath blight diseases and the false smut, and has good popularization and application values.

Owner:ANHUI MEILAND AGRI DEV

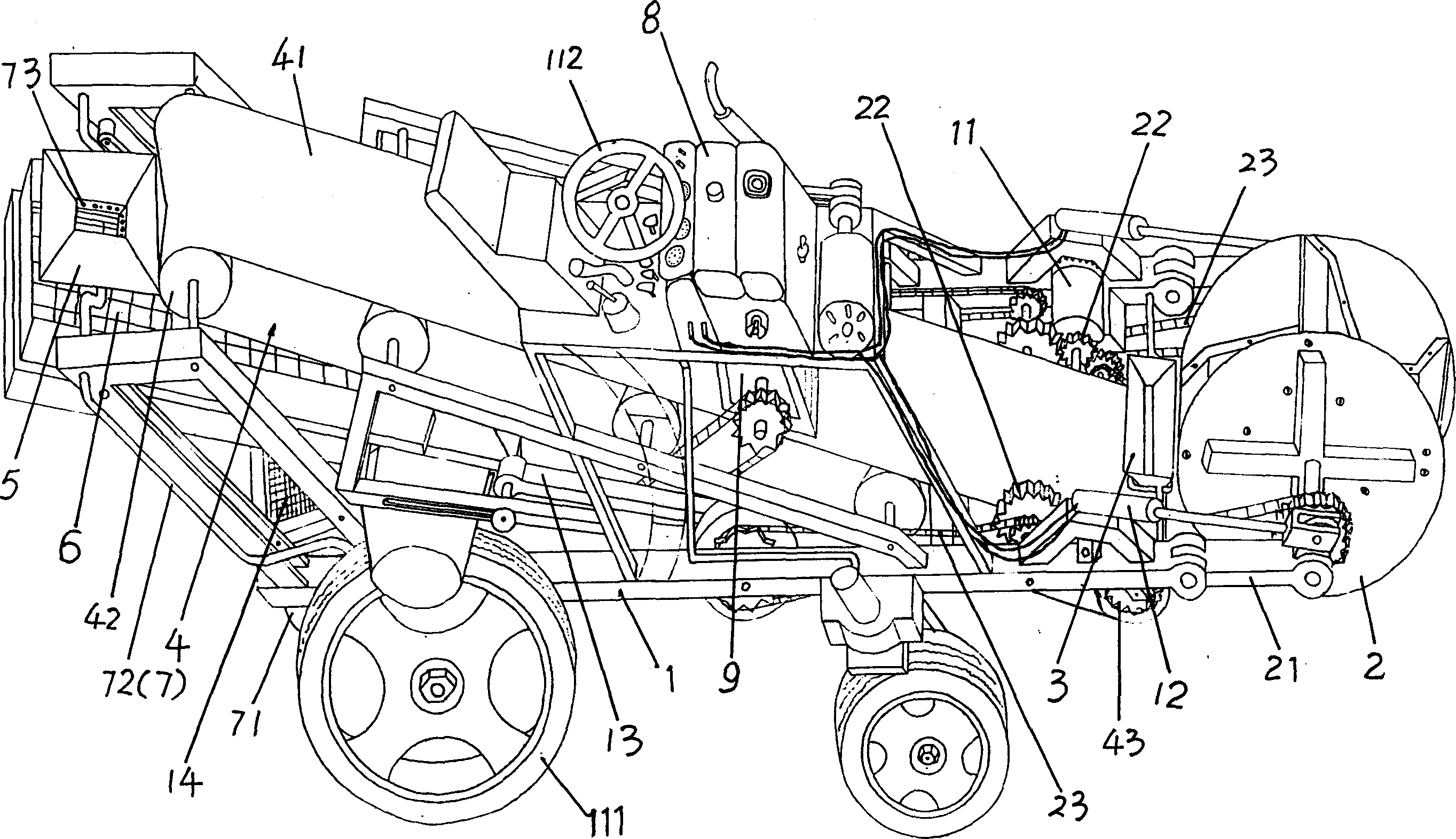

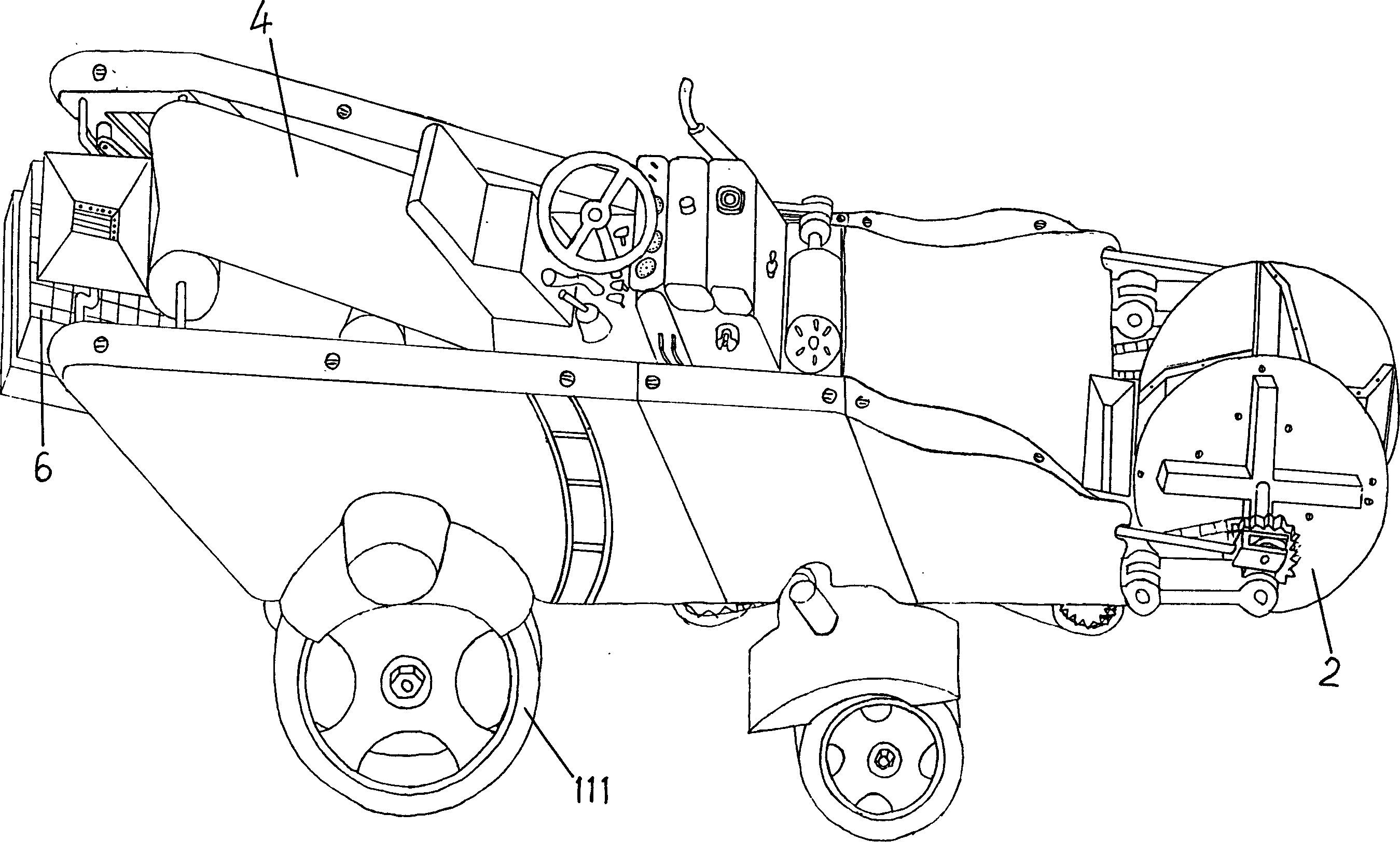

Roughing separation technique for low ore grade iron ore and mineral dressing equipment thereof

The invention relates to the technical field of mineral processing, in particular to a low-grade iron ore roughing process and mineral processing equipment. The beneficiation process includes coarse crushing, primary fine crushing, and dry screening. The steps are as follows: secondary screening of ore materials, secondary fine crushing of the screened coarse ore, wet rough separation of fine materials, and selection of fine ore The raw material is coarsely selected iron ore products. The beneficiation equipment includes coarse crusher, fine crusher, dry screening machine and storage bin. After the storage bin, there is a set of wet roughing unit, including sequentially connected conveyor belt, secondary screening machine, wet fine crusher, wet type Sieving machines and wet roughing machines. The wet fine crusher is a wet hammer crusher, and the wet rough separator is a wet coarse iron ore strong magnetic separator equipped with a water adding device. The screening feeder is a vibrating screen with an eccentric vibrating device. Compared with the existing technology and equipment of the same scale, the production of the same low-grade iron ore can be sorted by 1-2 times under the same power consumption conditions, so as to make full use of low-grade iron ore resources.

Owner:王林

Homogeneous crosslinking beta-cyclodextrin/wolfram carbine composite microsphere and method of producing the same

InactiveCN101402029BImprove stabilityMeet actual needsOther chemical processesAlkali metal oxides/hydroxidesHigh densityMicrosphere

The invention discloses an isotropic crosslinking beta-cyclodextrin / tungsten carbide composite microsphere and a preparation method thereof. The preparation method comprises the following steps: firstly, beta-cyclodextrin is dissolved into a sodium hydroxide aqueous solution, and the mixture is dripped with epichlorohydrin and undergoes stirring reaction under heating condition, so as to generateviscose; secondly, the viscose is added with tungsten carbide powder, oil dispersed phase and a dispersant under the condition of mechanical stirring to form a reversed phase suspension dispersion system; thirdly, the epichlorohydrin is added into the reversed phase suspension dispersion system, and the composite microsphere is obtained after mechanical stirring reaction; and fourthly, after the reversed phase suspension dispersion system is cooled, the composite microsphere is filtered, cleaned and neutralized, and subjected to wet sieving and expanded bed floatation. The composite microsphere developed by the method has the advantages of good hydrophilicity and sphericity, stable properties, low cost, high density, easy adjustment and so on, and can be used as a substrate during the process of expanded bed absorption as shown by an expanding performance test experiment.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com