Method for recycling potassium from industrial raffinate containing potassium

A tail liquid and industrial technology, applied in the field of potassium recovery, can solve problems such as destroying ecological balance and environmental pollution, and achieve the effects of reducing pollution and waste, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

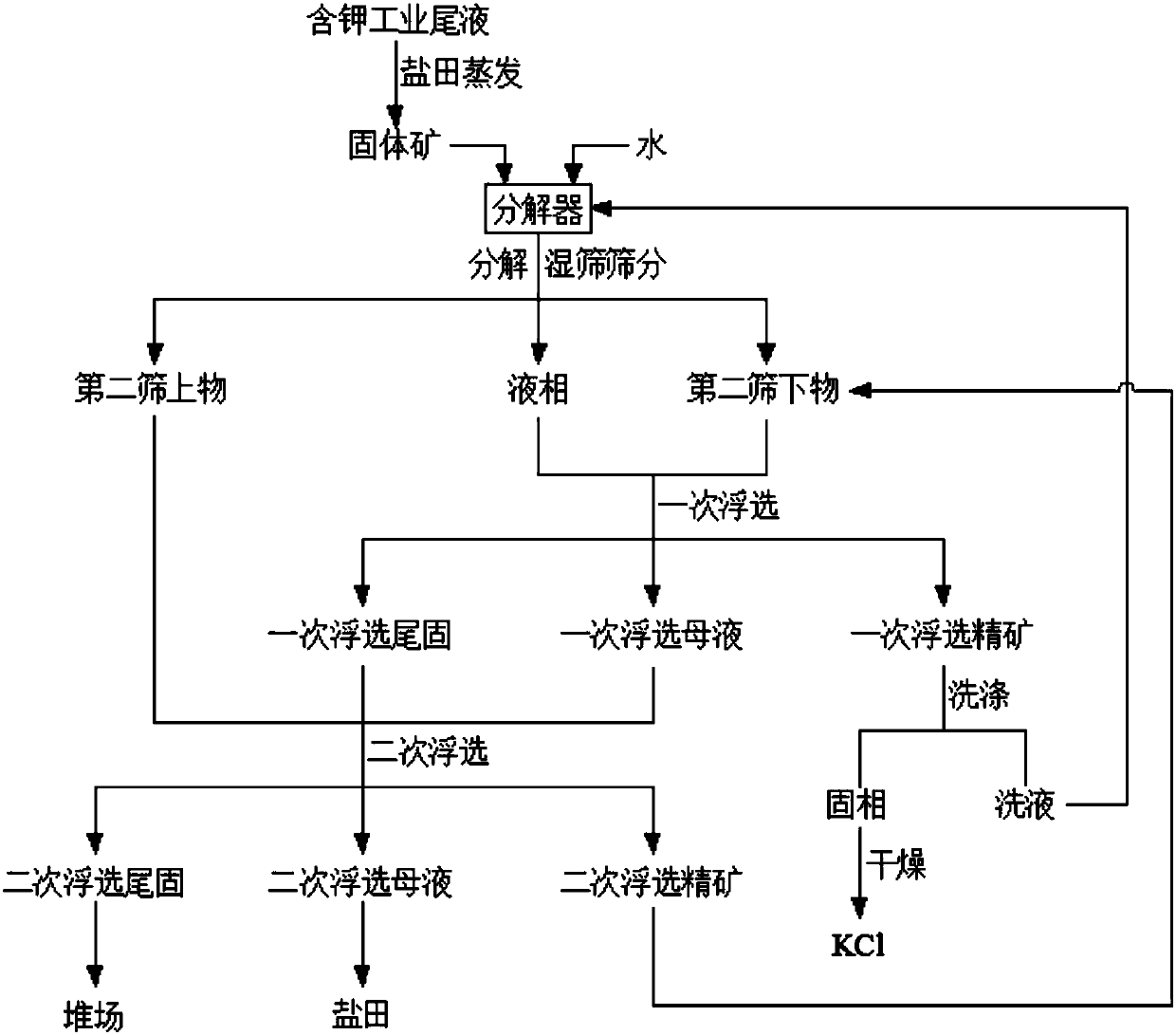

[0045] The method for reclaiming potassium from the potassium-containing industrial tail liquid of the present embodiment may further comprise the steps:

[0046] In step S1, the potassium-containing industrial tail liquid is evaporated in a salt field to obtain a solid ore containing potassium, ammonium and magnesium.

[0047] Specifically, the main chemical composition of the solid ore is: the content of potassium ions is 5.1%, the content of ammonium ions is 1.0%, the content of magnesium ions is 9.5%, and the content of chloride ions is 35.2%; the composition of the solid ore is ammonium light halide Stone, carnallite and bischofite, and a small amount of sand and gypsum.

[0048] In step S2, the solid ore is taken out from the salt pan, crushed and passed through a 40-mesh sieve, and the first sieve is taken for later use.

[0049] In step S3, the first undersize and fresh water are mixed in a mass ratio of 2:1, and stirred at 0°C for 16 hours to fully decompose, and the...

Embodiment 2

[0053] The method for reclaiming potassium from the potassium-containing industrial tail liquid of the present embodiment may further comprise the steps:

[0054] In step S1, the potassium-containing industrial tail liquid is evaporated in a salt field to obtain a solid ore containing potassium, ammonium and magnesium.

[0055] Specifically, the main chemical composition of the solid ore is: the content of potassium ions is 5.9%, the content of ammonium ions is 1.4%, the content of magnesium ions is 10.0%, and the content of chloride ions is 37.1%; the composition of the solid ore is ammonium light halide Stone, carnallite and bischofite, and a small amount of sand and gypsum.

[0056] In step S2, the solid ore is taken out from the salt pan, crushed and passed through a 40-mesh sieve, and the first sieve is taken for later use.

[0057] In step S3, the first undersize and fresh water are mixed according to the mass ratio of 10:7, and stirred at 25°C for 4 hours to fully deco...

Embodiment 3

[0061] The method for reclaiming potassium from the potassium-containing industrial tail liquid of the present embodiment may further comprise the steps:

[0062] In step S1, the potassium-containing industrial tail liquid is evaporated in a salt field to obtain a solid ore containing potassium, ammonium and magnesium.

[0063] Specifically, the main chemical composition of the solid ore is: the content of potassium ions is 5.6%, the content of ammonium ions is 1.2%, the content of magnesium ions is 9.8%, and the content of chloride ions is 36%; the composition of the solid ore is ammonium light halogen Stone, carnallite and bischofite, and a small amount of sand and gypsum.

[0064] In step S2, the solid ore is taken out from the salt pan, crushed and passed through a 40-mesh sieve, and the first sieve is taken for later use.

[0065] In step S3, the first undersize and fresh water are mixed according to a mass ratio of 5:3, and stirred at 10°C for 8 hours to fully decompose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com