System using supported ionic liquid catalyst for continuous preparation of polyoxymethylene dimethyl ether

A technology of polyoxymethylene dimethyl ether and ionic liquid, which is applied in the field of reaction systems, can solve problems such as failure to realize mature industrialized devices, affect reaction efficiency, and low operating temperature, and achieve recycling problems, simplify process flow, The effect of avoiding churn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

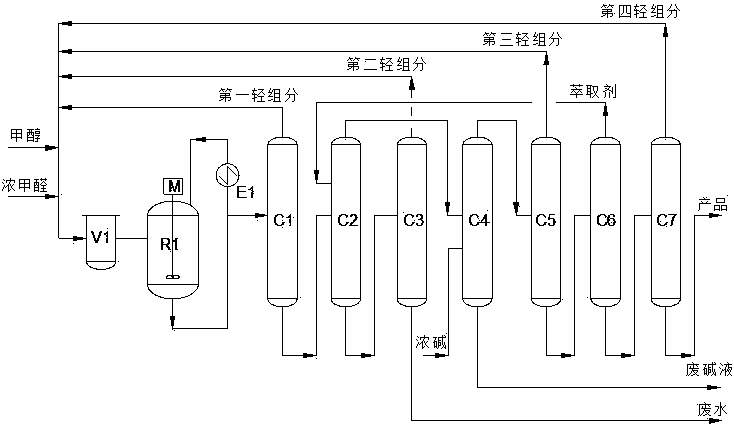

Image

Examples

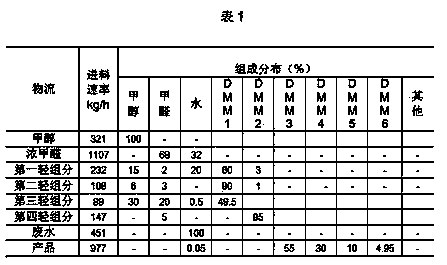

Embodiment 1

[0045] Reaction temperature: 120°C;

[0046] Reaction pressure: 2.0 MPaG;

[0047] Feed ratio of concentrated formaldehyde to methanol: 2.5:1;

[0048] Catalyst dosage: 10%;

[0049] After product and each component reaction reached equilibrium, sampling was carried out, and quantitative analysis was carried out by gas chromatography, and the results were shown in Table 1 below:

[0050]

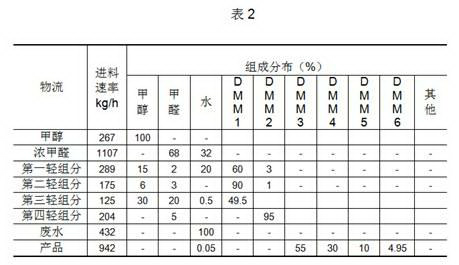

Embodiment 2

[0052] Reaction temperature: 130°C;

[0053] Reaction pressure: 3.0 MPaG;

[0054] Concentrated formaldehyde and methanol feed molar ratio: 3:1;

[0055] Catalyst dosage: 20%;

[0056] Product and each component reaction are sampled after reaching equilibrium, are quantitatively analyzed by gas chromatograph, and its result is as shown in table 2 below:

[0057]

Embodiment 3

[0059] Reaction temperature: 110°C;

[0060] Reaction pressure: 1.0 MPaG;

[0061] Concentrated formaldehyde and methanol feed molar ratio: 1:1;

[0062] Catalyst dosage: 5%;

[0063] Product and each component reaction are sampled after reaching equilibrium, and quantitatively analyzed by gas chromatography, and the results are shown in Table 3 below:

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com