Patents

Literature

508 results about "Polyoxymethylene dimethyl ethers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

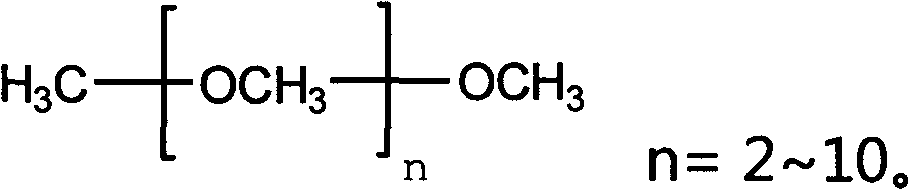

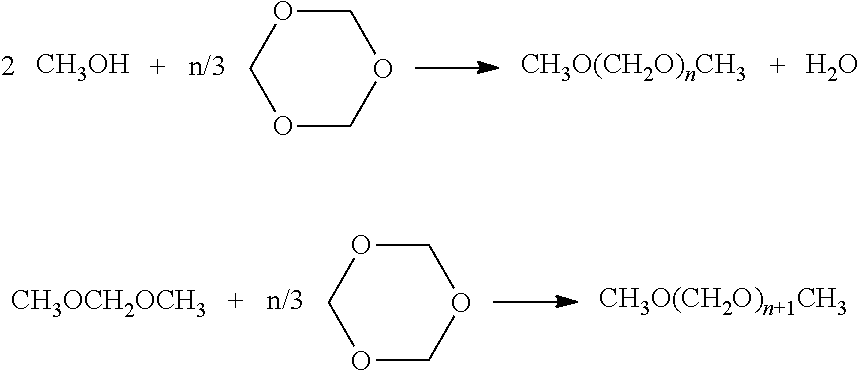

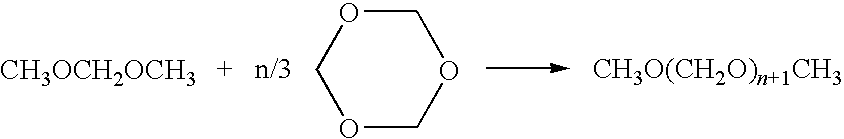

Polyoxymethylene dimethyl ethers (PODE or DMMn) are a class of chemical compounds with the molecular formula H₃CO(CH₂O)ₙCH₃ where n is typically about 3 to 8. PODE can be produced from methylal and formaldehyde or a formaldehyde equivalent such as paraformaldehyde or trioxane.

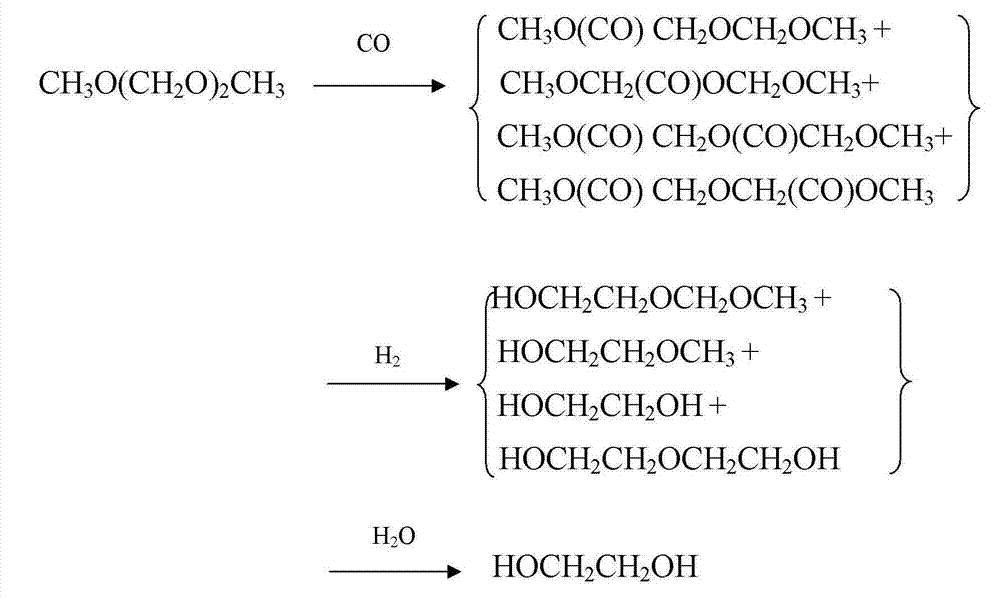

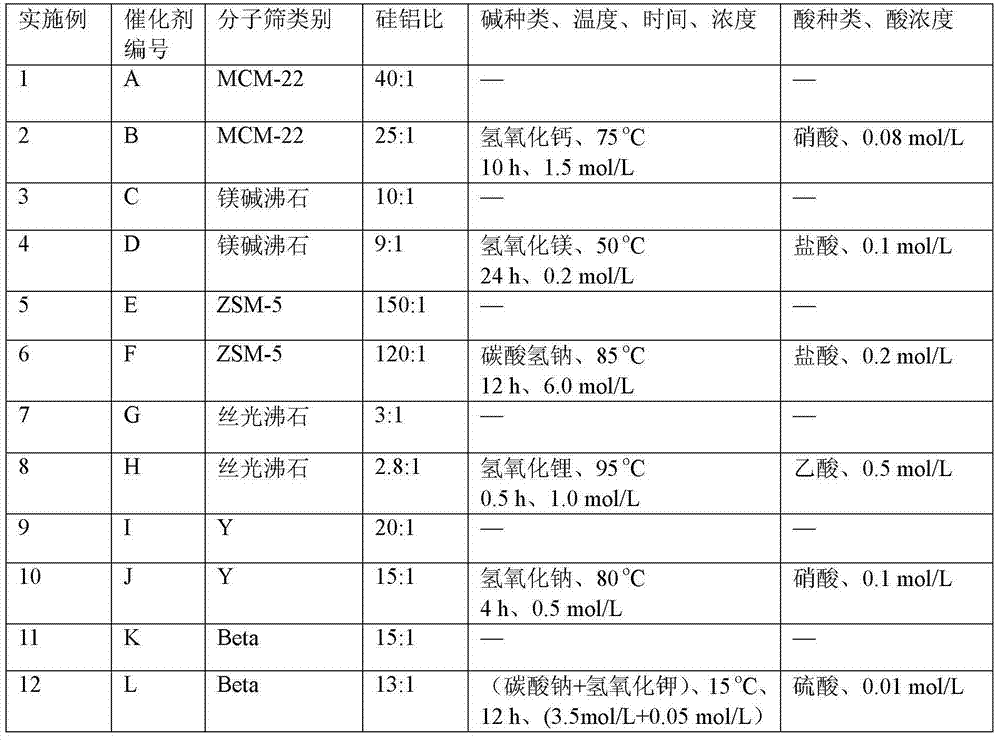

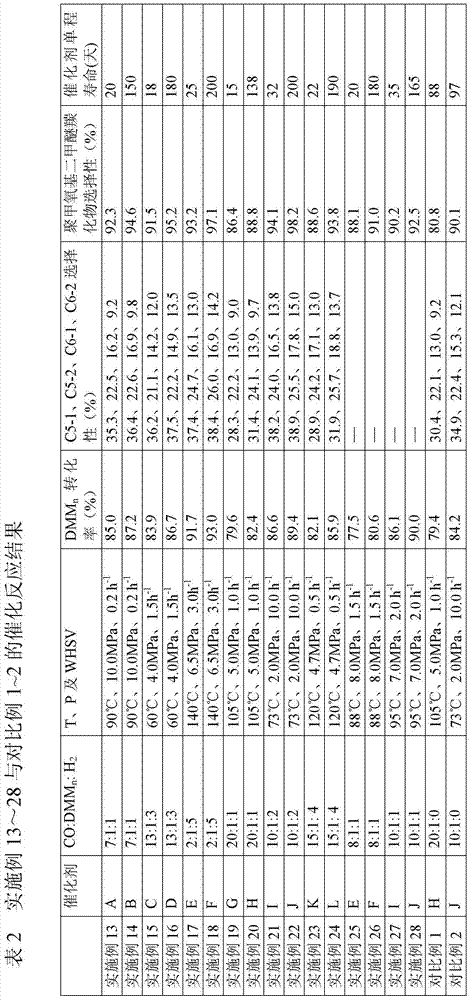

Method for preparing polyoxymethylene dimethyl ether

ActiveCN101768058ANot corrosiveStrong acidOrganic chemistryMolecular sieve catalystsEnergy consumptionReagent

The invention relates to a method for preparing polyoxymethylene dimethyl ether. The invention mainly solves the problems of the prior art that: catalyst is corrosive, and is complexly separated from reactant, and energy consumption is high. The method adopts methanol and trioxymethylene as materials, the materials react with catalyst by way of contact under mild conditions, so that the polyoxymethylene dimethyl ether is produced, wherein the catalyst is selected from Beta zeolite, ZSM-5 molecular sieve, MCM-22 and MCM-56 zeolite molecular sieve. The method effectively solves the problems, and can be used in the industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing polyoxymethylene dimethyl ether

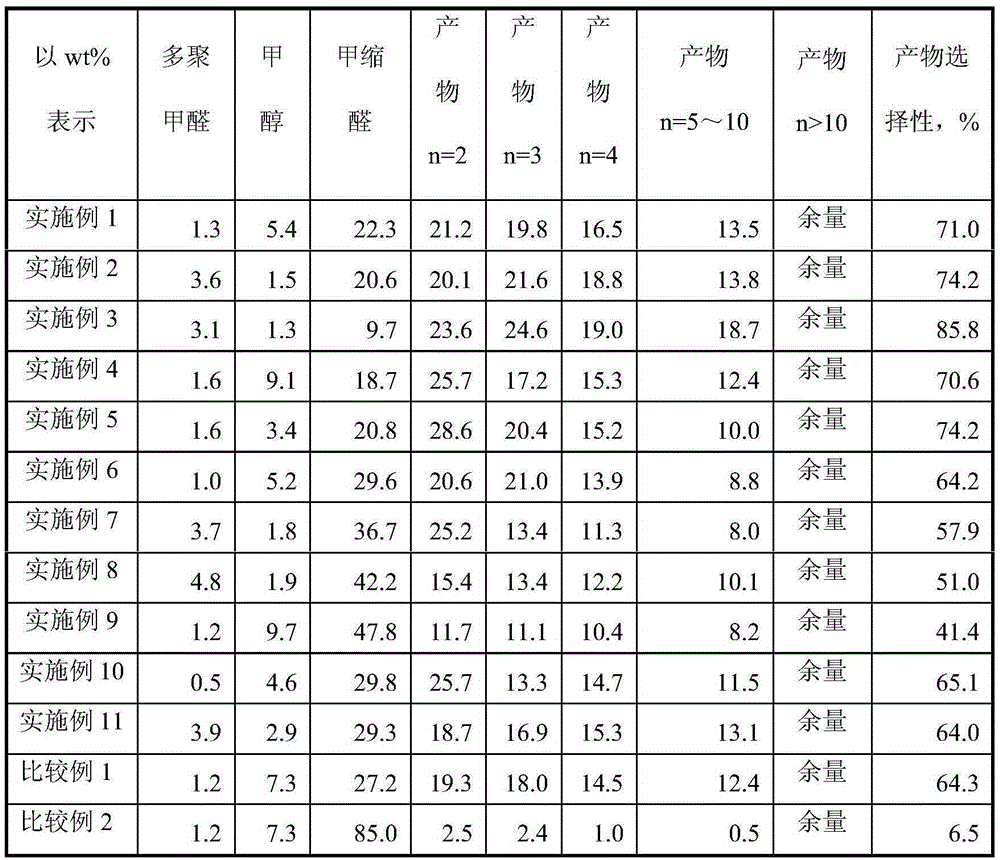

The invention relates to a method for synthesizing polyoxymethylene dimethyl ether. The invention mainly solves the following problems of the prior art that: in the process of synthesizing polyoxymethylene dimethyl ether, catalyst separation is difficult, the material conversion rate is low, and product selectivity is poor. The method adopts methanol and trioxymethylene as materials, the reactiontemperature is 70 DEG C to 200 DEG C, the reaction pressure is 0.5MPa to 6MPa, the materials react with super solid acidic catalyst by way of contact, so that the polyoxymethylene dimethyl ether CH3O(CH2O)nCH3 is produced, wherein the used catalyst is selected from solid superacids. By weight part, the polyoxymethylene dimethyl ethe comprises the following components: (a) 20 to 70 parts of acid selected from sulfuric acid, hydrochloric acid or peroxosulfuric acid or at least one of salt thereof; (b) 30 to 80 parts of carrier selected from at least one of ZrO2, TiO2, SiO2, Fe2O3, SnO2, WO3 andAl203. The method effectively solves the problems, and can be used in the industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for synthesis of polyoxymethylene dimethyl ether and application of catalyst

ActiveCN104549502AHigh yieldEasy to separateOrganic chemistryOrganic compound preparationIon exchangeStrong acids

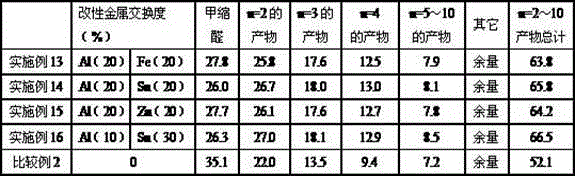

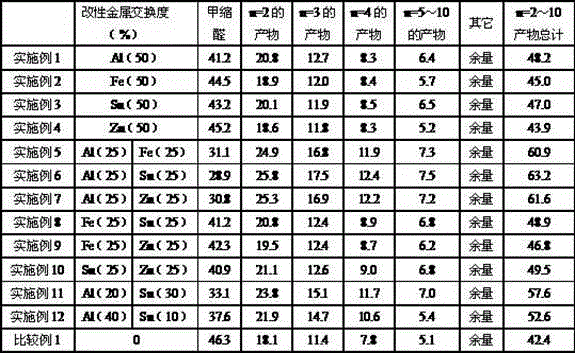

The invention relates to a catalyst for synthesis of polyoxymethylene dimethyl ether, application of the catalyst in synthesis of polyoxymethylene dimethyl ether and a method for synthesizing polyoxymethylene dimethyl ether, and mainly aims to solve the problem that the catalyst has low selectivity and low yield for polyoxymethylene dimethyl ether which has a polymierization degree n of 2-10 in the prior art. The technical problem can be well solved by adopting a technical scheme that the catalyst is a metal ion modified hydrogenous strong-acid ion exchange resin, wherein the modifying metal is at least one of Al, Fe, Sn and Zn; and the ion exchange degree of the modifying metal in the catalyst is more than zero and less than or equal to 50 percent. The catalyst can be used in industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for continuous production of polyformaldehyde dimethyl ether

InactiveCN102786397ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention provides a method for continuous production of polyformaldehyde dimethyl ether. The method is characterized by comprising the following steps: a) feeding dimethoxymethane and hot-melted paraformaldehyde into a fixed bed reactor and adopting an acidic resin catalyst, so as to prepare polyformaldehyde dimethyl ether (DMM3-8), wherein the reaction temperature is 120-180 DEG C and the pressure is 0.1-10 MPa; b) cooling the reaction product, and then performing adsorptive separation through a dehydrating tower, so as to obtain polyformaldehyde dimethyl ether of which most water, cytidine glycol and hemiacetal are desorbed; c) feeding the polyformaldehyde dimethyl ether subjected to desorption into a distillation tower for separation, wherein most of a low-boiling component (dimethoxymethane (DMM)), poly-di-formaldehyde dimethyl ether (DMM2), a by-product (methanol) and triformol are extracted first, and then the materials in a tower kettle are fed into a rectifying tower in the next step, so as to extract the rest of the DMM2 and the triformol; and d) returning the low-boiling component (dimethoxymethane (DMM)), the methanol, the DMM2 and the triformol, which are evaporated out by the distillation tower and the rectifying tower in the last step, into the fixed bed reactor to continue to react to prepare polyformaldehyde dimethyl ether.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Catalytic synthesis method for polyoxymethylene dimethyl ethers (PODE) by molecular sieves

ActiveCN102040491AStrong acidHigh yieldOrganic chemistryOrganic compound preparationSynthesis methodsReaction temperature

The invention relates to a catalytic synthesis method for polyoxymethylene dimethyl ethers (PODE) by molecular sieves, mainly solving the problem of relatively high cost in the conventional method which adopts trioxymethylene as a raw material. In the method, methanol, methylal and paraformaldehyde are adopted as raw materials based on the mass ratio of (0-10): (0-10):1, the raw materials contactwith a catalyst to react and generate PODE, wherein the dosages of the methanol and the methylal can not be zero at the same time; the reaction temperature is 70-200 DEG C; the reaction pressure is 0.1-6MPa; and the adopted catalyst is selected from at least one of beta zeolite, X zeolite, Y zeolite, ZSM-5 molecular sieve, MCM-22, MCM-56, UZM-8 or SAPO-34 molecular sieve. The technical scheme adopted by the invention solves the above problem preferably, thus being applicable to industrialized production of the PODE.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic method for polyoxymethylene dimethyl ether

ActiveCN103880614AEvenly distributedHigh adsorption potentialOrganic chemistryOrganic compound preparationActivated carbonReaction temperature

The invention relates to a synthetic method for polyoxymethylene dimethyl ether, and mainly overcomes the problem of relatively high cost in a conventional method for synthesizing polyoxymethylene dimethyl ether by using trioxymethylene as a raw material. The synthetic method takes use of methanol, methylal and paraformaldehyde as raw materials, wherein a mass ratio of methanol to methylal to paraformaldehyde is 0-10 : 0-10 : 1; and the usage amount of methanol and methylal is not zero at the same time; and the raw materials are contacted with a catalyst under a reaction pressure of 0.2-6 MPa to produce polyoxymethylene dimethyl ether (CH3O(CH2O)nCH3), wherein the used catalyst is selected from activated carbon. By adopting the above technical solution, the problem is overcome relatively well; and the synthetic method can be used for industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing PODE (polyformaldehyde dimethyl ether)

ActiveCN102040488AHigh yieldIncrease profitOrganic chemistryOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a method for synthesizing PODE (polyformaldehyde dimethyl ether), which mainly solves the problems of high content of methylal and low yield coefficient of poly products in the traditional process of synthesizing the PODE with carbinol and trioxymethylene as raw materials. The method adopts the carbinol, the methylal and the trioxymethylene as the raw materials, and the raw materials contact a catalyst under conditions that reaction temperature is 50-200 DEG and reaction pressure is 0.1-10 MPa so as to react to generate the PODE, wherein the catalyst is at least one of Beta zeolum, ZSM-5 molecular sieve and MCM-22 or MCM-56 zeolum molecular sieve. The method preferably solves the problems and can be used for the industrial production of the PODE.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing polyoxymethylene dimethyl ethers

ActiveCN101898943AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationSynthesis methodsStrong acids

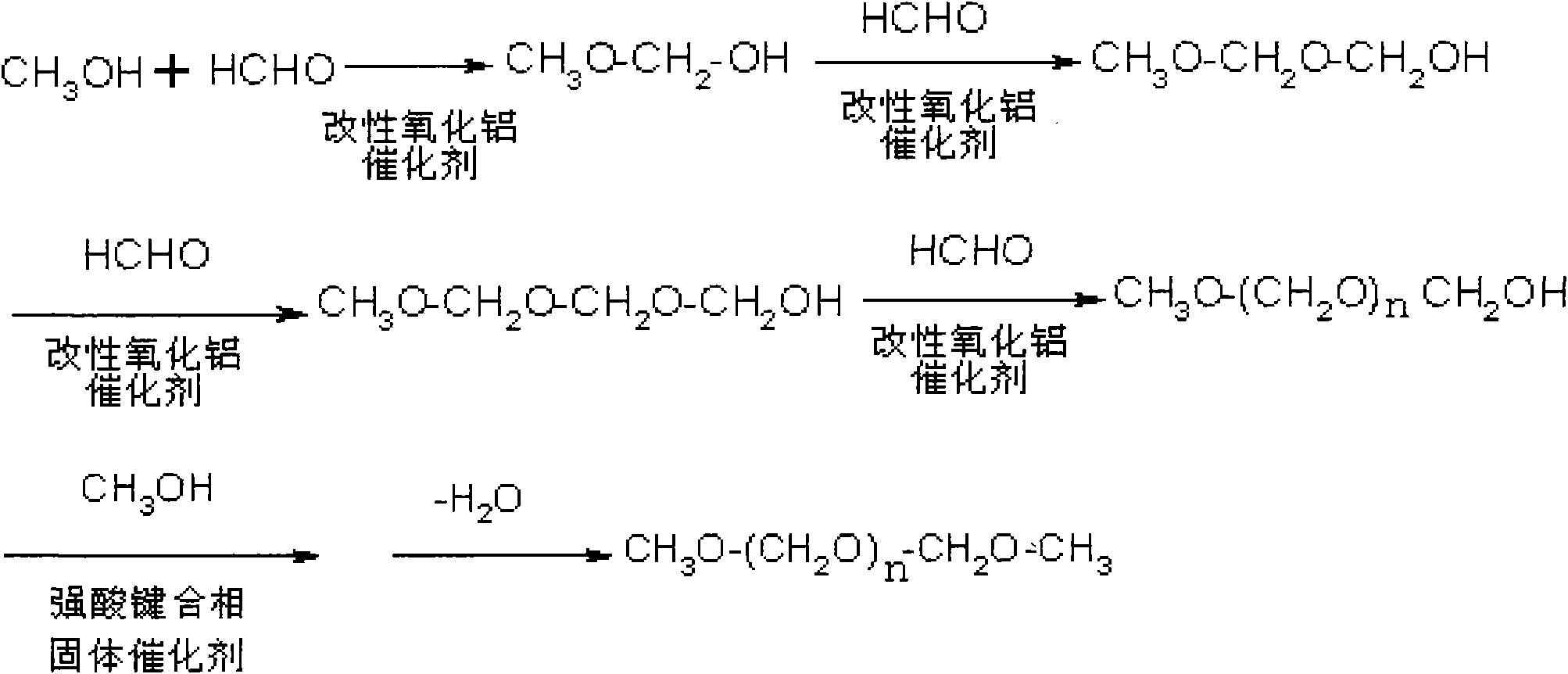

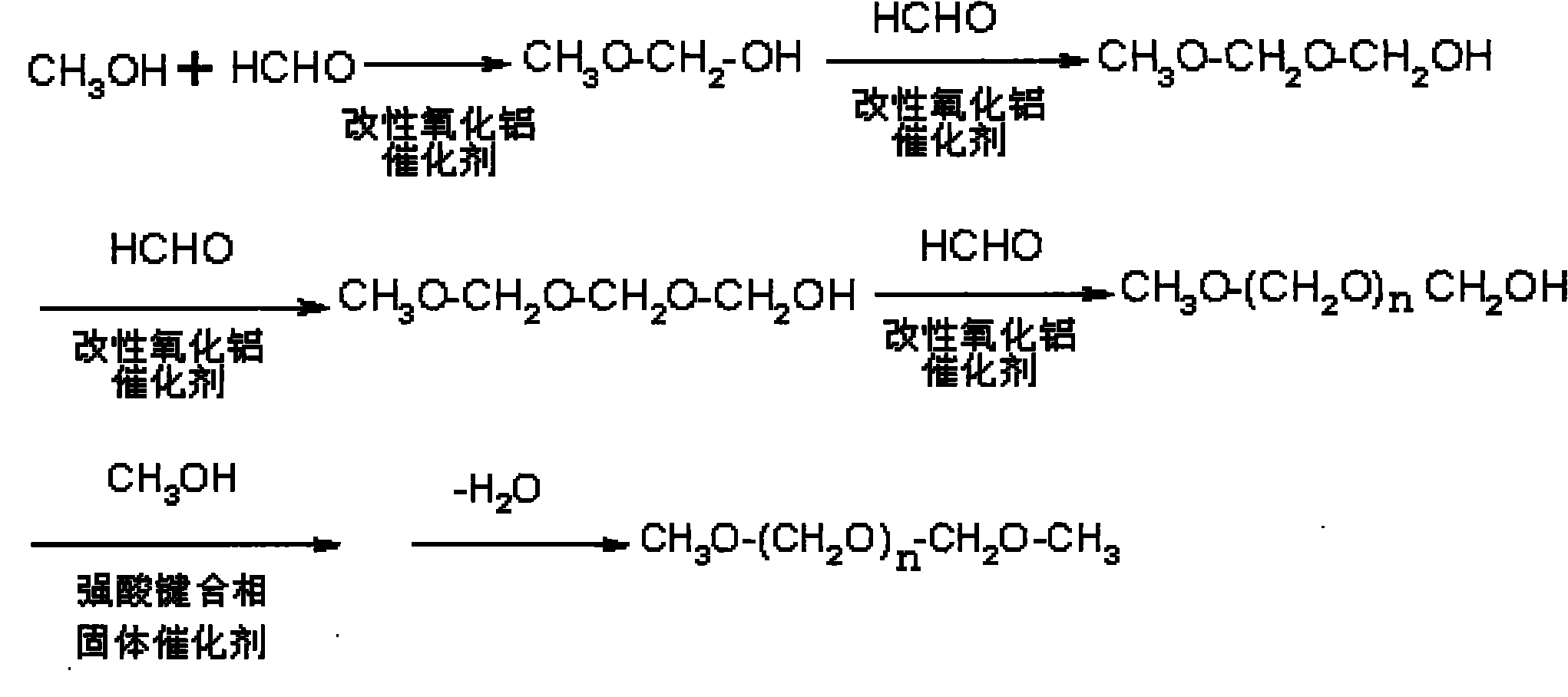

The invention relates to a method for synthesizing polyoxymethylene dimethyl ethers, comprising the following steps: step one, generating hemiacetal by methanol and excessive methanal or paraformaldehyde with low polymerization degree under the existence of a modified alumina catalyst, reacting the hemiacetal with methanal to generate hemiacetal with one more carbon, and successively continuing the above steps to generate poly-hemiacetal with more carbon atoms; and step two, generating the polyoxymethylene dimethyl ethers by the poly-hemiacetal mixture under the existence of methanol and an organic strong acid bonded phase solid catalyst. The invention can achieve the technical targets of improving raw material conversion rate, product selectivity, target product yield and economical efficiency by the two steps of reaction process, adjusts the space velocity by a fixed bed continuous reactor and combines with a catalyst to control the polymerization degree. The synthesis method in the invention has mild reaction conditions and easy control.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

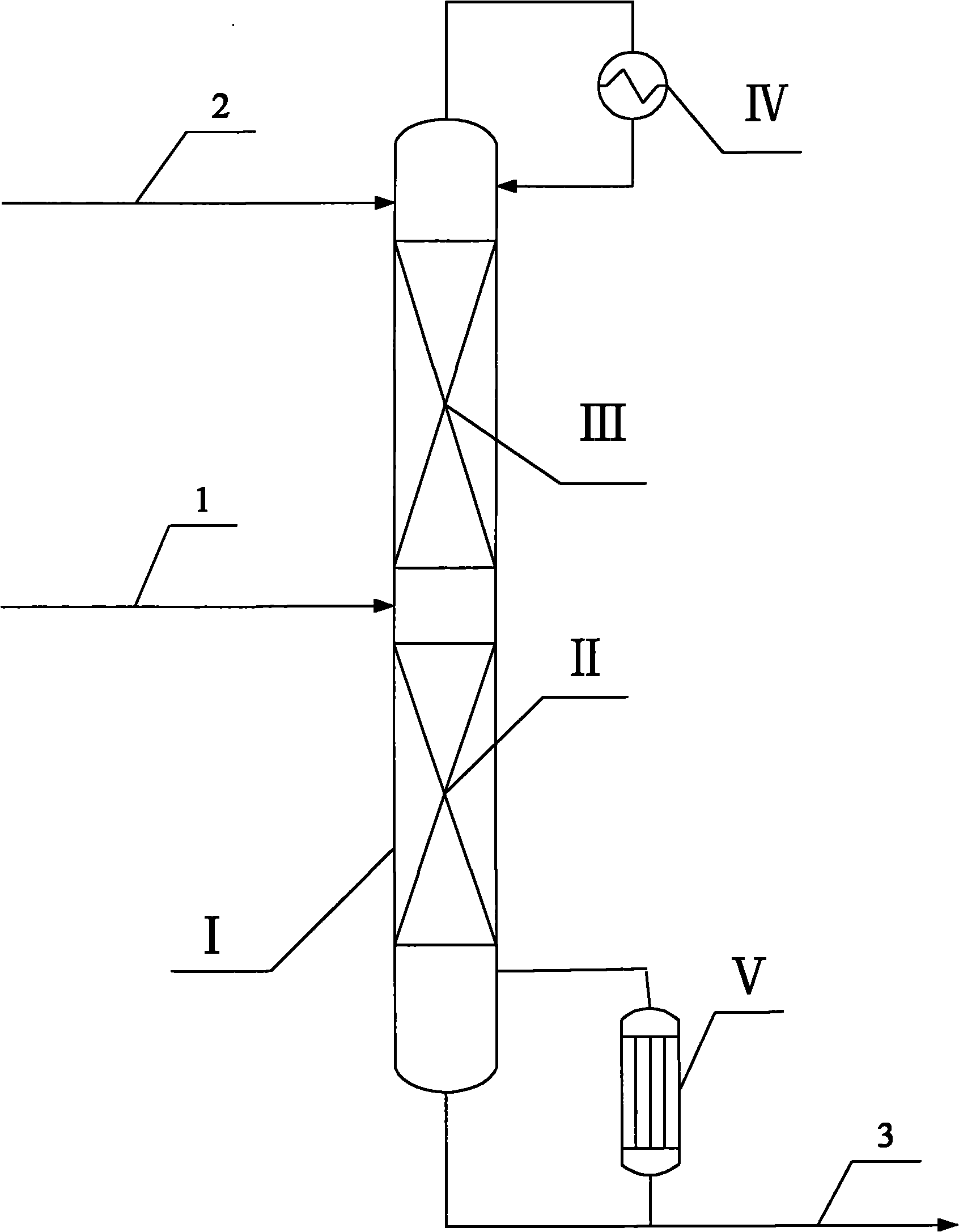

Multi-section reaction tower for polyoxymethylene dimethyl ether synthesis and polyoxymethylene dimethyl ether synthesis process unit

ActiveCN104722249AImprove conversion rateFully absorbedOrganic compound preparationCarboxylic acid esters preparationGas phaseTower

The invention discloses a multi-section reaction tower for polyoxymethylene dimethyl ether synthesis and a polyoxymethylene dimethyl ether synthesis process unit. A tower body of the multi-section reaction tower comprises at least two layers of reaction sections from top to bottom; each layer of reaction section is provided with a tower plate and forms a bent passageway; catalysts are arranged between the tower plates in a filling manner; gas ascension pipes are arranged between the adjacent layers of reaction sections; a gas phase outlet is formed in the tower top of the reaction tower; and each layer of reaction section is provided with an inlet with a valve and an outlet with a valve. According to the multi-section reaction tower for polyoxymethylene dimethyl ether synthesis and the polyoxymethylene dimethyl ether synthesis process unit, the conversion equilibrium point of the reaction is effectively controlled, the advancement of the reaction equilibrium toward bigger polymers is effectively deferred, the conversion rate and the selectivity are improved, the reaction is carried out under the conditions that the catalyst activity is relatively high and the temperature does not excessively influence the reaction equilibrium, and good conversion rate and selectivity are obtained.

Owner:JIANGSU KAIMAO PETROCHEM TECH

Method for preparing polyoxymethylene dimethyl ether

ActiveCN102372611AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationReboilerCatalytic distillation

The invention relates to a method for preparing polyoxymethylene dimethyl ether, which mainly solves the problems of low conversion rate of trioxymethylene and low selectivity of DMM 3-8 in current polyoxymethylene dimethyl ether production. According to the invention, under the effective reaction condition, methylal and trioxymethylene are reacted in a catalytic distillation tower, a components separation is performed simultaneously, steam at the top of the tower is condensed and then reflowed, a first part of the materials at the bottom of the tower is vaporized by a reboiler and returned back to the catalytic distillation tower, a second part of the materials is taken as produced liquid, the mass ratio of the first part to the second part is 1-10:1, wherein the trioxymethylene enters from the top of the tower, methylal can enter from any position from a stripping section to the tower top. The technical scheme of catalyst capable of being a heterogeneous phase acidic catalyst can effectively solve the problem, and the catalyst can be used for industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process method for preparing polyoxymethylene dimethyl ethers

ActiveCN105566077AAvoid cloggingAchieve dehydrationOrganic compound preparationCarbonyl compound separation/purificationCyclic processLiquid water

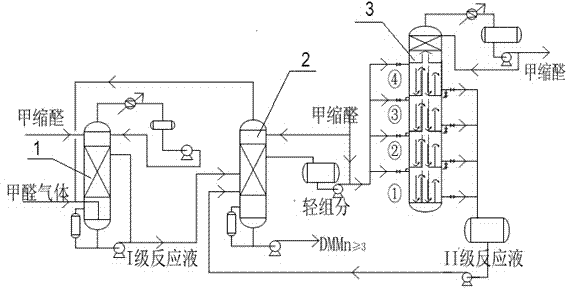

The invention discloses a process method for preparing polyoxymethylene dimethyl ethers. The method includes the steps that formaldehyde gas is cooled to 100 DEG C and below, so that vapor is removed; dehydrated gas formaldehyde is directly absorbed by a mixture of polyoxymethylene dimethyl ethers DMM1-2 and polyoxymethylene dimethyl ethers DMM6-10 of different degrees of polymerization, then a reaction is conducted, polyoxymethylene dimethyl ethers DMM 3-5 are prepared, and DMM1-2 and DMM 6-10 with the DMM 3-5 separated continuously serve as raw materials and are recycled. According to the method, formaldehyde gas generated by methanol oxidation is cooled to 100 DEG C and below, vapor is condensed into liquid water, the purpose of dehydration is achieved, and due to the fact that water in the formaldehyde is removed before being absorbed by reactant, and the situations that a polycondensation reaction occurs and device is blocked by paraformaldehyde generated by formaldehyde polycondensation are avoided; the mixture of the DMM1-2 and DMM6-10 also participates in a polymerization reaction and a depropagation reaction in the cyclic process and is finally converted to the polyoxymethylene dimethyl ethers DMM3-5 of the target degree of polymerization. The method is simple in process and easy to operate, the speed for generating the DMM3-5 is high, the conversion rate of the DMM3-5 is high, and energy consumption and equipment investment are lowered.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Polyformaldehyde dimethyl ether synthesis catalyst

InactiveCN106582835AHigh selectivityOrganic chemistryOrganic compound preparationCross-linkPolystyrene

The present invention relates to a polyformaldehyde dimethyl ether synthesis catalyst. In the prior art, with the application of methanol, methylal and paraformaldehyde as reaction raw materials to synthesize polyformaldehyde dimethyl ether, the activity and the selectivity of the catalyst are low. A purpose of the present invention is mainly to solve the problems in the prior art. The technical scheme of the present invention comprises that by using the polyformaldehyde dimethyl ether synthesis catalyst, the catalyst is a metal ion modified sulfonic acid type polystyrene cation exchange resin, the sulfonic acid type polystyrene cation exchange resin comprises a cross-linked polystyrene skeleton and a sulfonic acid group, and the metal comprises at least one selected from a group IB element and a group VIII element. The polyformaldehyde dimethyl ether synthesis catalyst of the present invention can be used in the industrial production of polyformaldehyde dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

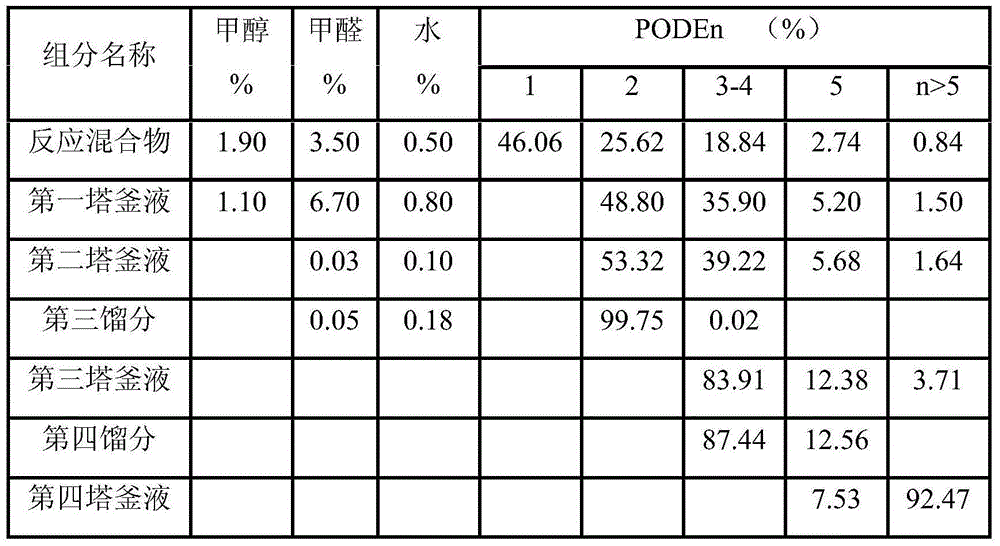

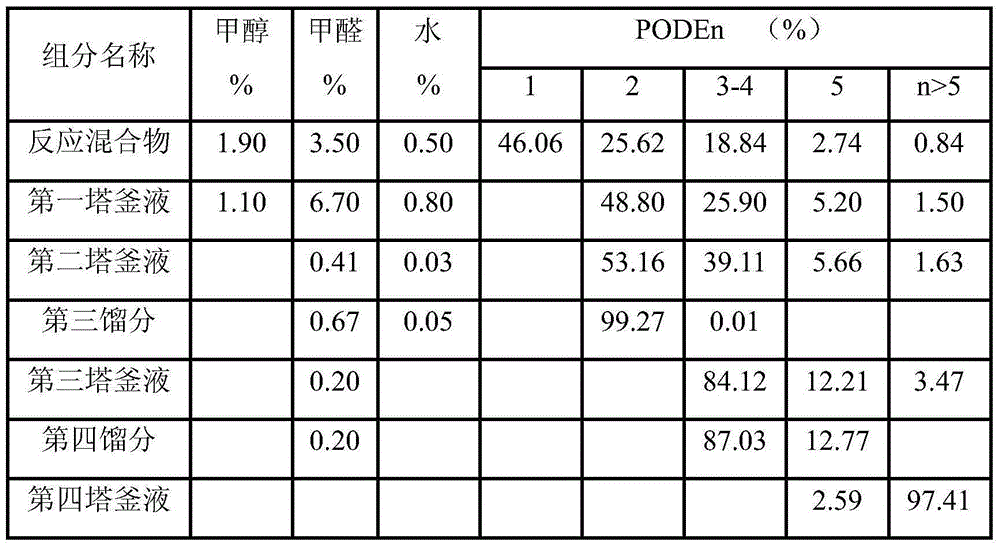

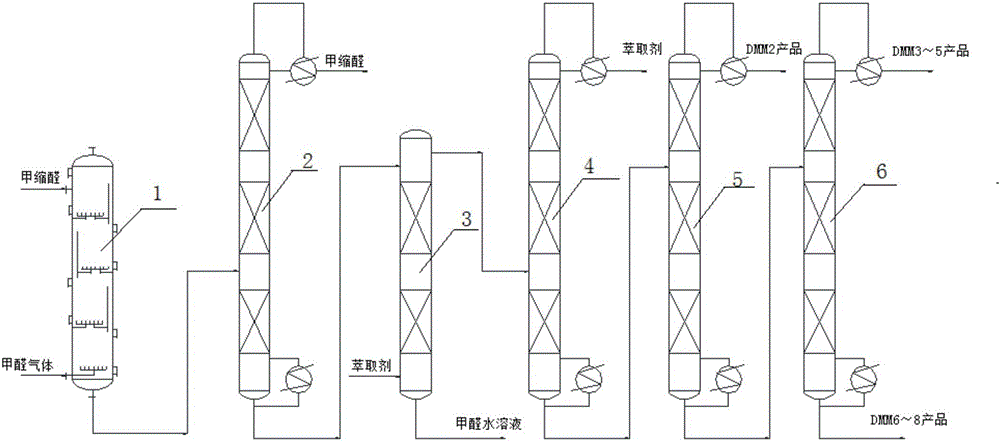

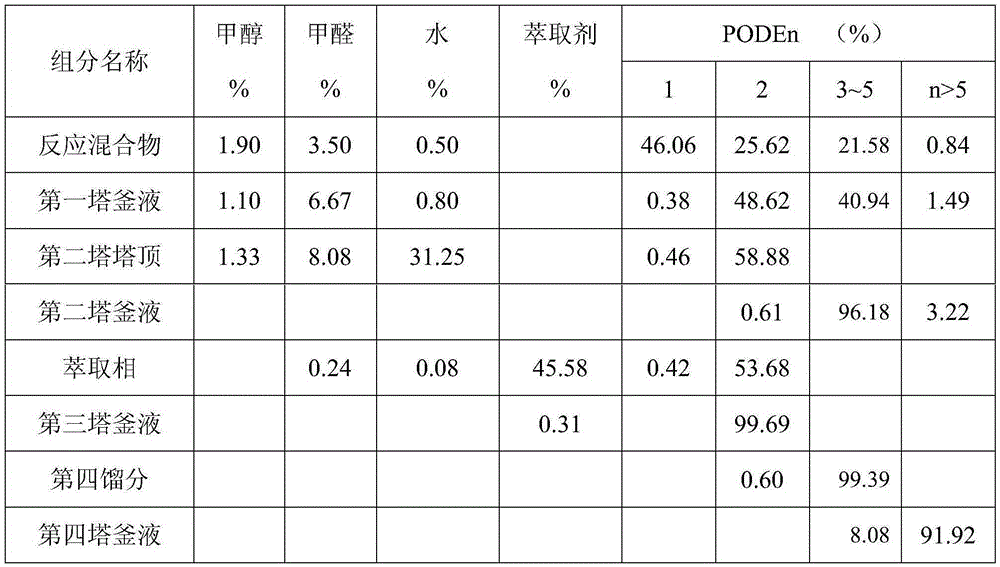

Purification method of PODE (polyoxymethylene dimethyl ether)

ActiveCN106588599AGuaranteed separation and recoveryReduce cloggingOrganic chemistryOrganic compound preparationOrganic solventPurification methods

The invention aims to solve the technical problem that long-term continuous production operation is difficult due to the fact that materials block the tops of rectifying towers in the PODE (polyoxymethylene dimethyl ether) purification process with a rectification method. The adopted technical scheme comprises steps as follows: (a) a reaction mixture obtained by a reaction synthesis unit firstly enters a first rectifying tower, a first fraction mainly containing methylal is removed through separation, and first tower bottoms are obtained; (b) the first tower bottoms enter an extraction unit and are subjected to extraction with a two-phase extraction agent containing an organic solvent and an aqueous phase, an extract phase containing PODEn (n=2-8) and an organic solvent is obtained, and a raffinate phase is an aqueous phase containing formaldehyde; (c) the extract phase sequentially enters a second rectifying tower, a third rectifying tower and a fourth rectifying tower for rectification, and a second fraction containing an organic solvent, a third fraction containing high-purity PODEn (n=2) and a fourth fraction containing PODEn (n=3-5) are obtained respectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

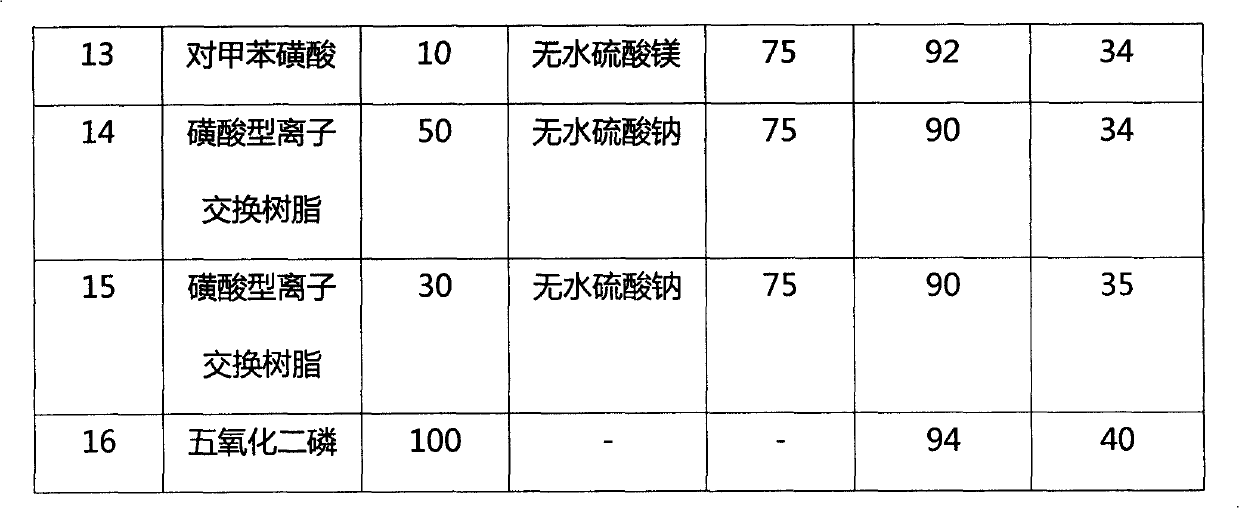

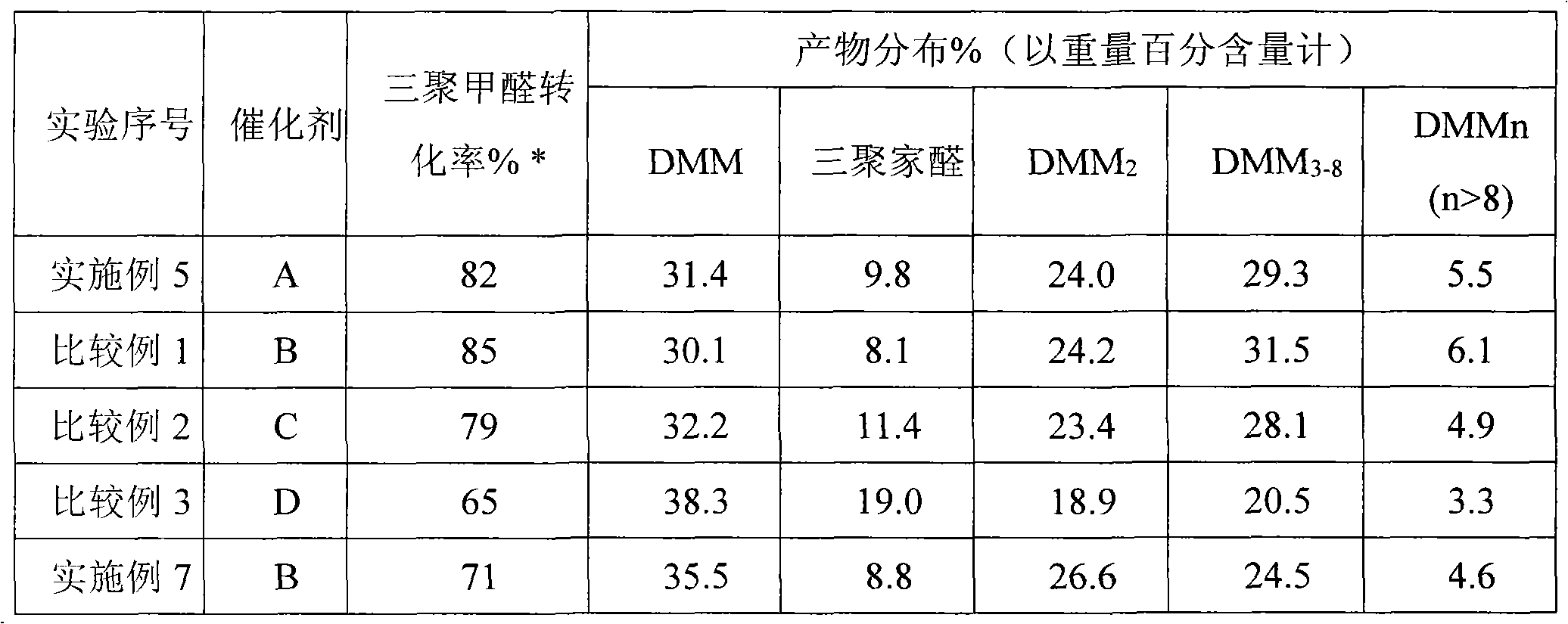

Process for preparing polyoxymethylene dimethyl ether

ActiveCN102617305AMild reaction conditionsReduce energy consumptionOrganic chemistryOrganic compound preparationDimethoxymethaneMedicinal chemistry

The invention provides a process for preparing polyoxymethylene dimethyl ether represented by general formula (1). The process for preparing the polyoxymethylene dimethyl ether is characterized by subjecting methanol, methylal and / or dimethyl ether and formaldehyde and / or paraformaldehyde to reaction under the action of an acid catalyst and a water absorbing agent. The general formula (1) is as follows.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Method for preparing polyformaldehyde dimethyl ether by using loaded niobium oxide catalyst

InactiveCN101972644AImprove stabilityHigh activityOrganic chemistryOrganic compound preparationCombustionBoiling point

The invention relates to a method for preparing polyformaldehyde dimethyl ether by using a loaded niobium oxide catalyst. The method is characterized by comprising the following steps of: a) preparing the polyformaldehyde dimethyl ether by a catalytic reaction, wherein the molar ratio of methylal to trioxymethylene is 0.5 to 5, loaded niobium oxide is taken as a catalyst, the using amount of the catalyst is 0.1 to 5 percent of the molar weight of a reactant, the reaction temperature is between 100 and 200 DEG C, reaction time is between 10 minutes and 48 hours and reaction pressure is between 0.1 and 10 MPa; b) rectifying and separating, namely, separating a low-boiling point component, namely, methylal DMM, polydiformaldehyde dimethyl ether DMM2 and unreacted trioxymethylene out and separating polyformaldehyde diformaldehyde DMM3-8 out, wherein a small amount of polyformaldehyde dimethyl ether DMMn with a high polymerization degree exists at the bottom of a kettle and n is more than 8; and c) adding a small amount of fresh trioxymethylene into the methylal, the polydiformaldehyde dimethyl ether DMM2 and the unreacted trioxymethylene which are separated out in the previous step and continuing reacting so as to obtain the polyformaldehyde diformaldehyde DMM3-8 which is suitable to be taken as a diesel engine blending combustion component. Therefore, the utilization ratios of raw materials are increased.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Process device special for preparing polyoxymethylene dimethyl ethers through formaldehyde gas

InactiveCN105693479AReduce participation in aggregationImprove heat transfer effectOrganic chemistryOrganic compound preparationFluidized bedReaction zone

The invention discloses a special process device for preparing polyoxymethylene dimethyl ether from gaseous formaldehyde. The raw materials for synthesizing polyoxymethylene dimethyl ether are formaldehyde gas and methylal solution. The special process device includes sequentially connecting A fluidized bed reactor, an extraction and recovery unit and a refining unit, the fluidized bed reactor includes at least two layers of reaction sections from bottom to top, each layer of reaction section is filled with catalyst, and the bottom of each layer of reaction section is equipped with gas The distributor is directly connected to the reaction section, and each layer of the reaction section is also provided with a downcomer to connect the adjacent reaction sections, and the top of the downcomer is also provided with a wire mesh; the bottom of the fluidized bed reactor is provided with a There is an inlet for formaldehyde gas, and an inlet for methylal solution is set on the top of the fluidized bed reactor. The invention reduces the cost, improves the synthesis conversion rate and the yield is low, and the invention has a good heat transfer effect, can efficiently promote the reaction, and realizes controllability of the conversion degree.

Owner:江苏道尔顿石化科技有限公司

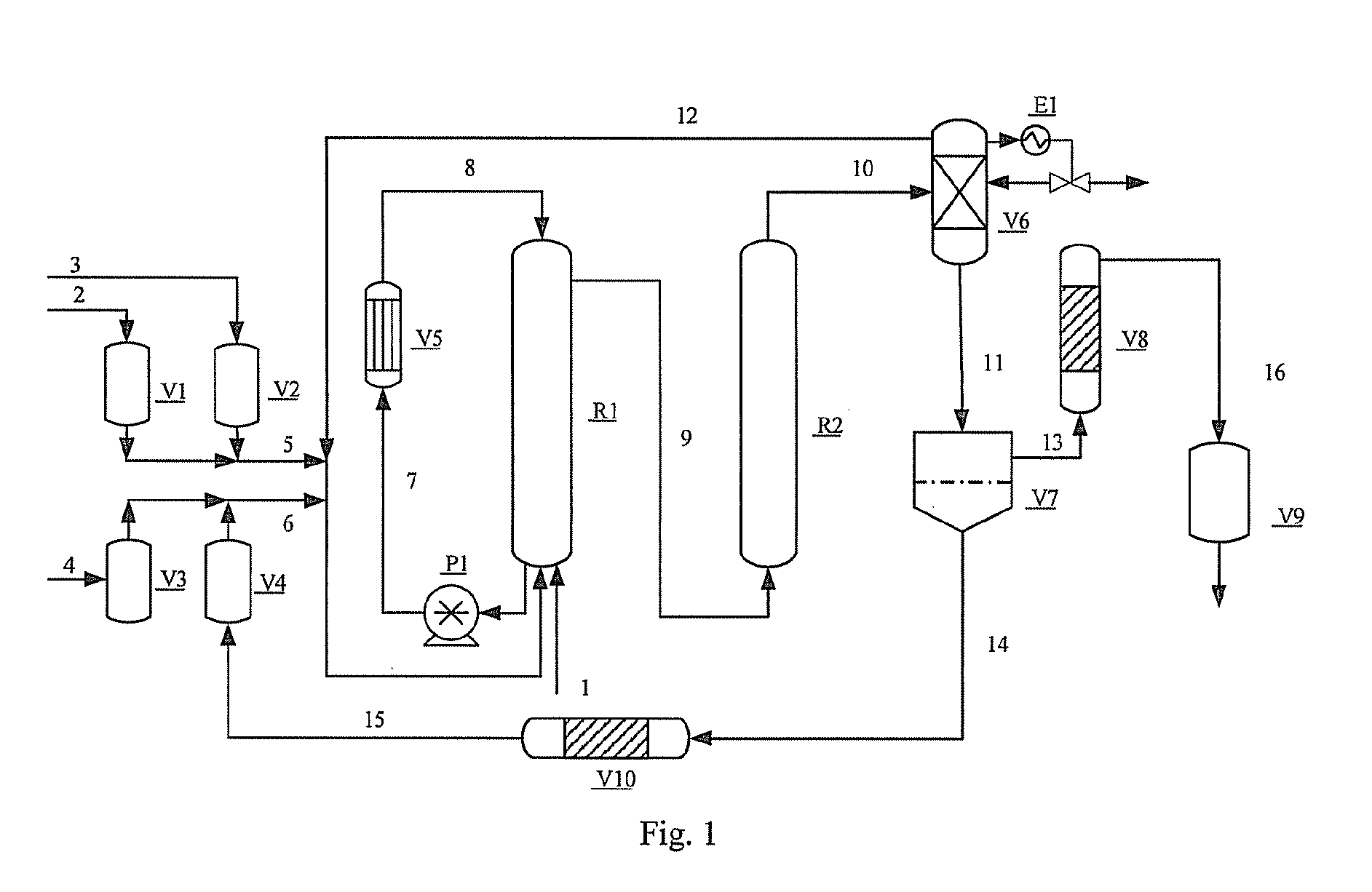

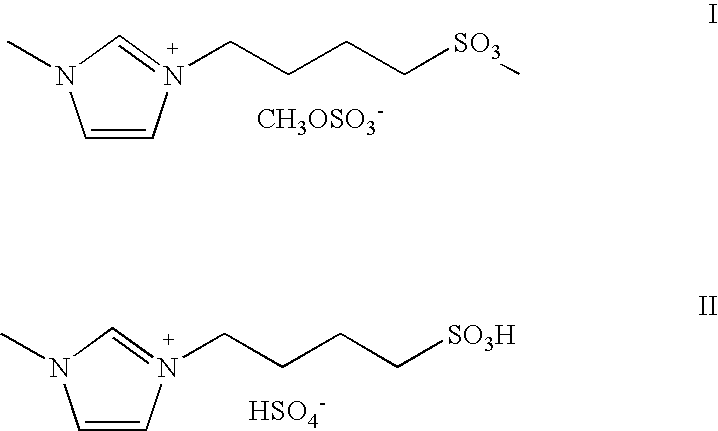

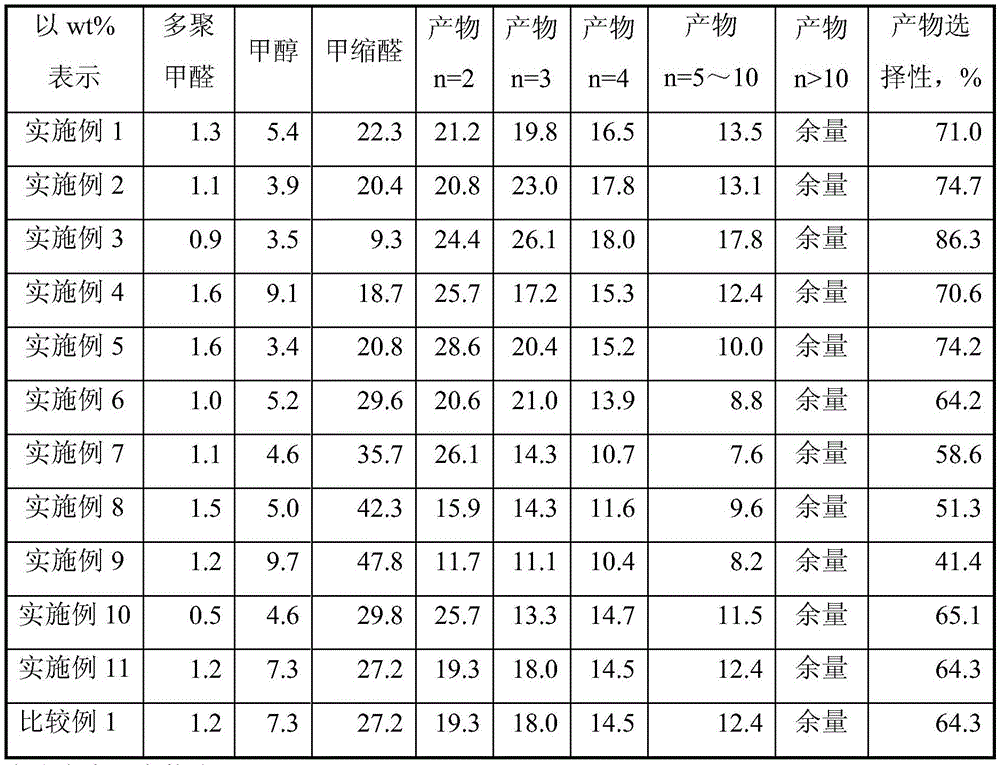

Method for synthesizing polyoxymethylene dimethyl ethers catalyzed by an ionic liquid

InactiveUS20110288343A1Increase conversionsHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction zoneDimethoxymethane

It is related to a method for preparing polyoxymethylene dimethyl ethers by a continuous acetalation reaction of trioxymethylene and methanol or methylal catalyzed by an ionic liquid. The processing apparatus used in the method includes a reaction zone, a separation zone, a catalyst regeneration zone and a product dehydration zone. A manner of circulating tubular reaction is used, resulting in a high external heat exchange efficiency, a simple structure of design and a low investment. A film evaporator is used, realizing a rapid separation and recycling of the light component, with a high separation efficiency. The separation of the catalyst solution from the crude product is simple, thereby realizing the regeneration and recycling of the catalyst.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

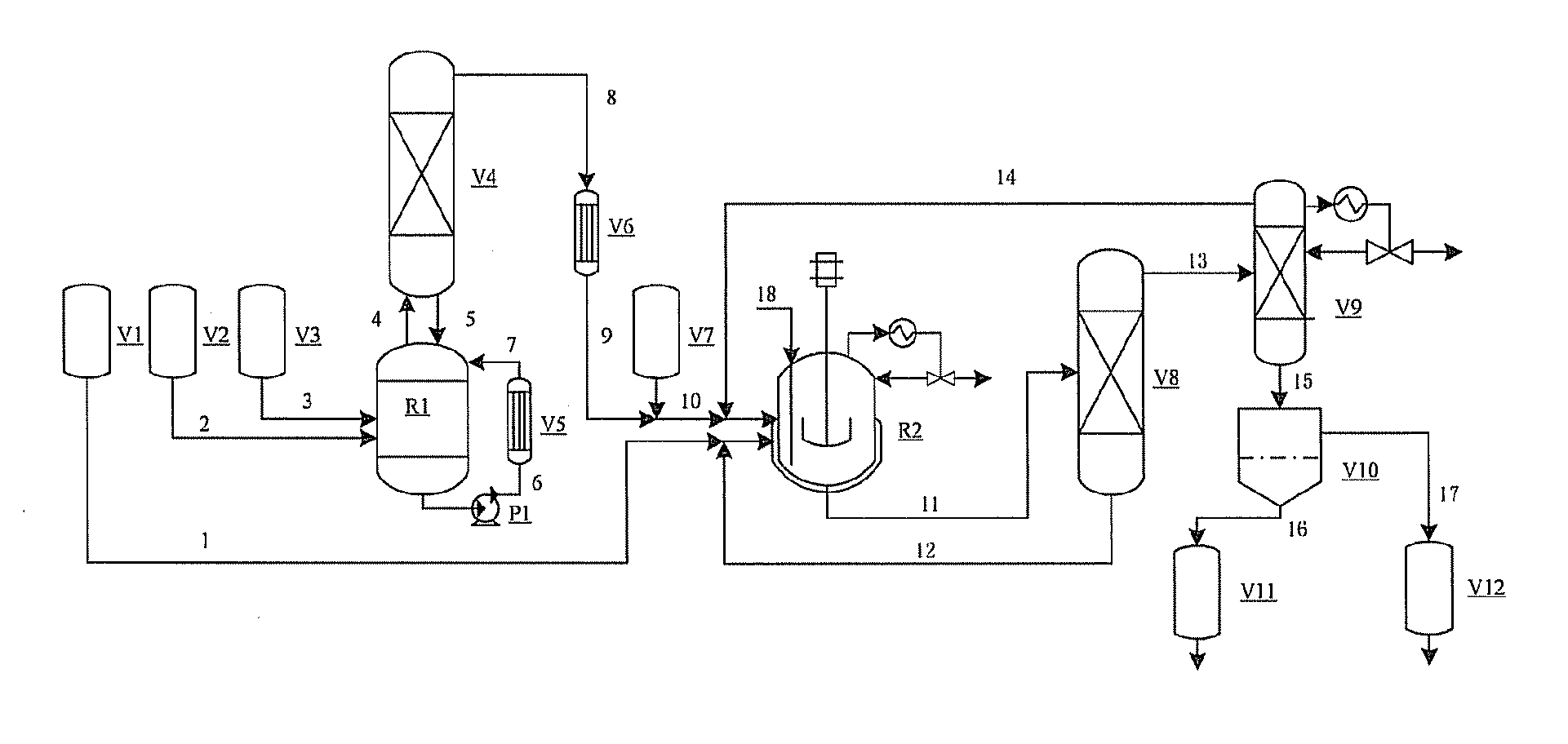

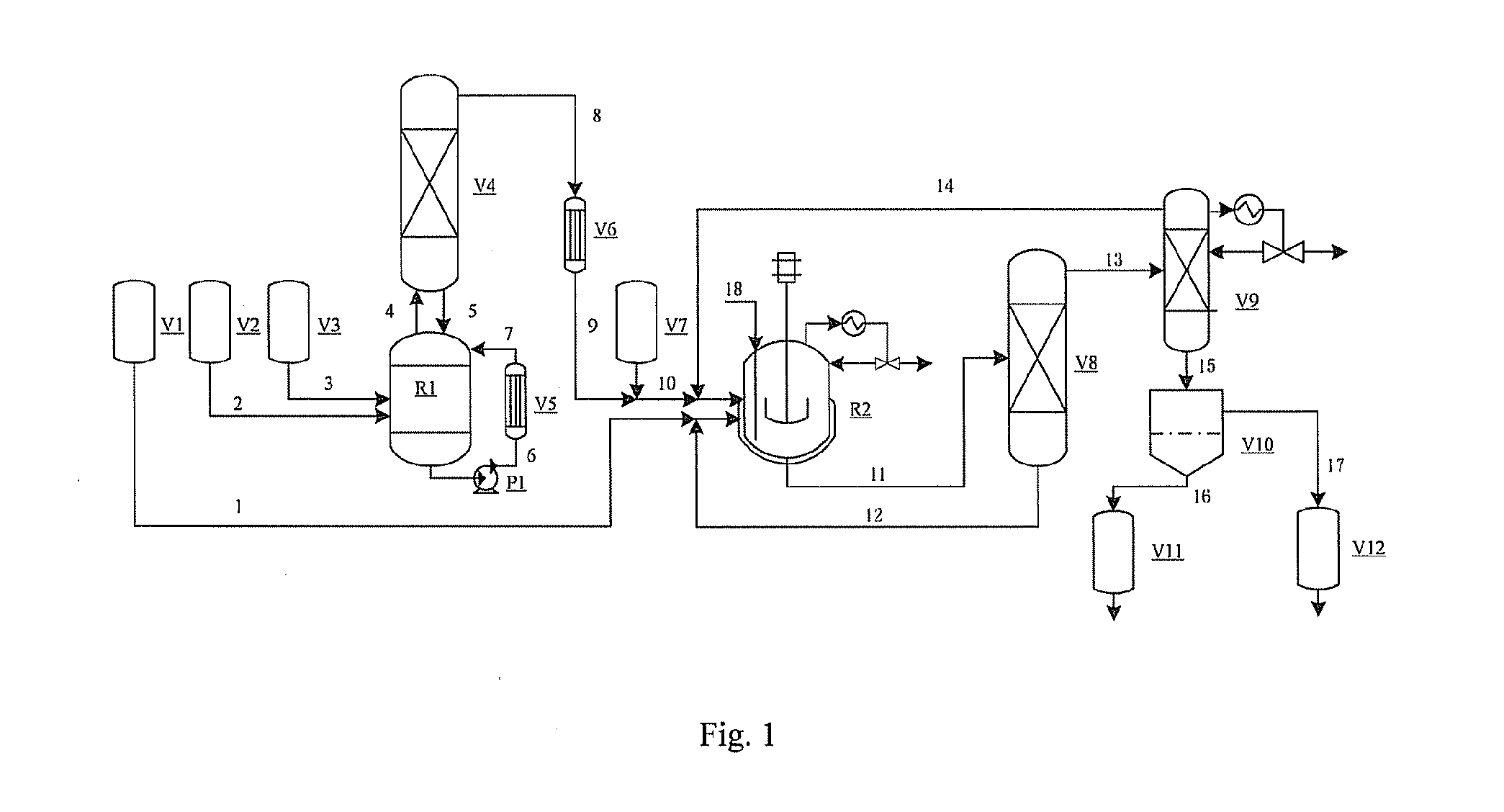

Method for preparing polyoxymethylene dimethyl ethers by acetalation reaction of formaldehyde with methanol

ActiveUS20110313202A1Rapid separation and recyclingEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTwo stepAqueous solution

It is disclosed a method for preparing polyoxymethylene dimethyl ethers by continuous polymerization and acetalation reactions. The method may include two steps: performing a polymerization reaction of an aqueous formaldehyde solution under catalysis of an ionic liquid IL I to obtain a mixed aqueous solution of trioxymethylene and formaldehyde; and an acetalation reaction of the mixed aqueous solution of trioxymethylene and formaldehyde with methanol is performed under catalysis of an ionic liquid IL II to prepare polyoxymethylene dimethyl ethers. The method may use an aqueous formaldehyde solution as a starting material to prepare polyoxymethylene dimethyl ethers by continuous polymerization and acetalation reactions, achieving a high use ratio of formaldehyde. A film evaporator is used in the invention, realizing a rapid separation and recycling of the light components, with a high separation efficiency. The separation of the catalyst is simple, thereby realizing recycling of the catalyst.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

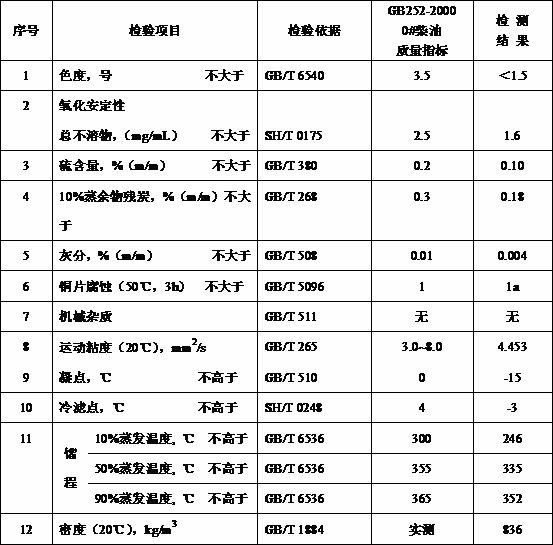

Method for preparing novel clean synthetic diesel oil

The invention relates to a method for preparing novel clean synthetic diesel oil and mainly solves the problems that the conventional diesel oil is low in cetane number and is combusted insufficiently in an engine, and a large amount of solid pollutant, COx and NOx are discharged. The method mainly comprises the following steps of: uniformly mixing 5 to 30 mass percent of diesel oil substitute component, 5 to 30 mass percent of additive and 40 to 90 mass percent of diesel oil at normal temperature, standing for 8 to 10 hours, and after liquid is clarified, canning to obtain the novel clean synthetic diesel. The diesel oil substitute component is polyformaldehyde dimethyl ether, methylal or mixture of polyformaldehyde dimethyl ether and methylal in any ratio. By the method, the combustion efficiency of the synthetic diesel oil is improved, the discharge of free carbon and harmful gas is reduced, the quality of the synthetic diesel oil is improved, cost is reduced, a novel way from coal to oils is developed, and the method has good social and economic benefit. The novel clean synthetic diesel oil can be used independently and can also be mixed with petroleum diesel oil to be used, and the engine is not needed to be changed.

Owner:HENAN COAL CHEM IND GROUP INST

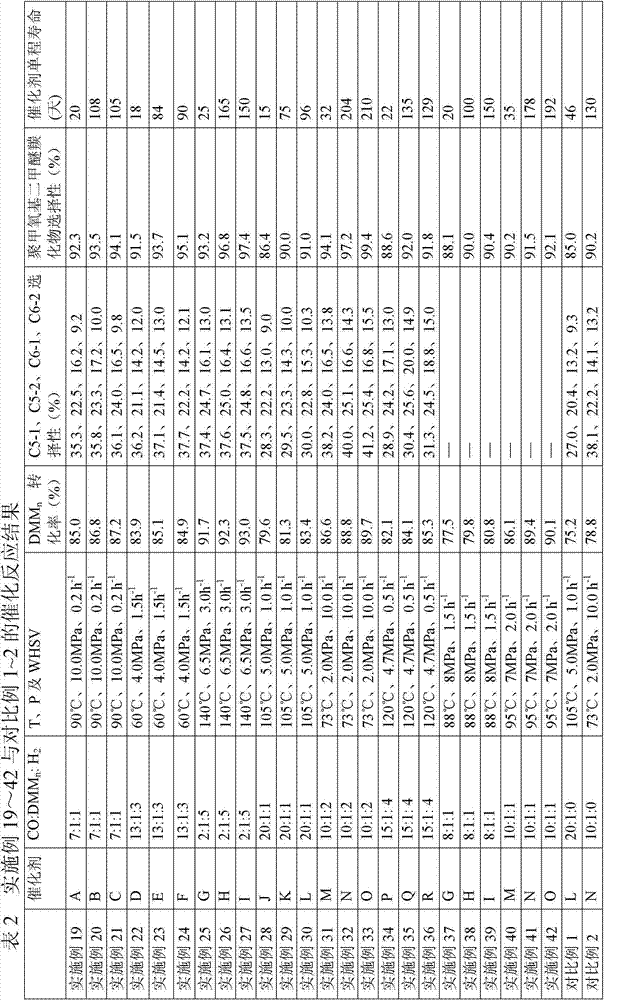

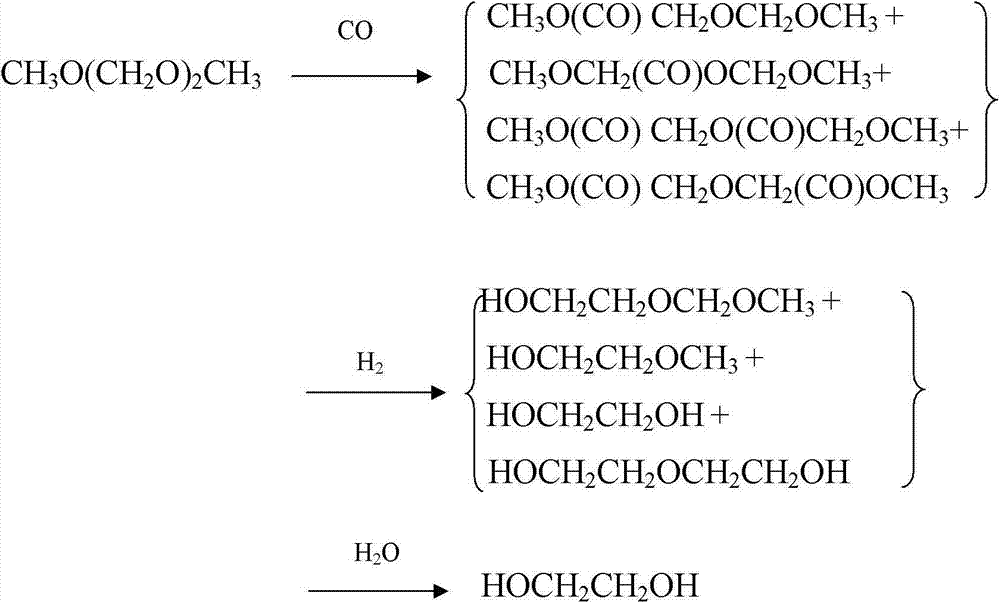

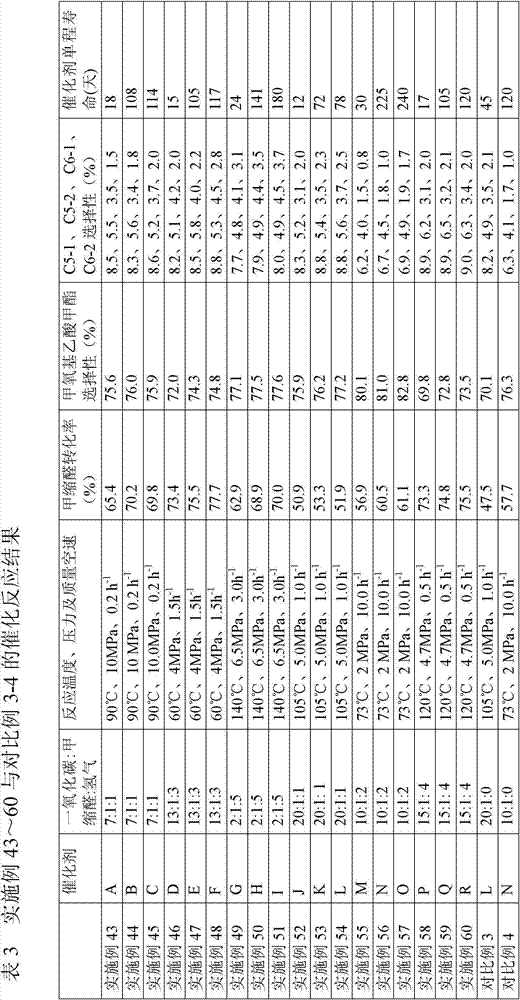

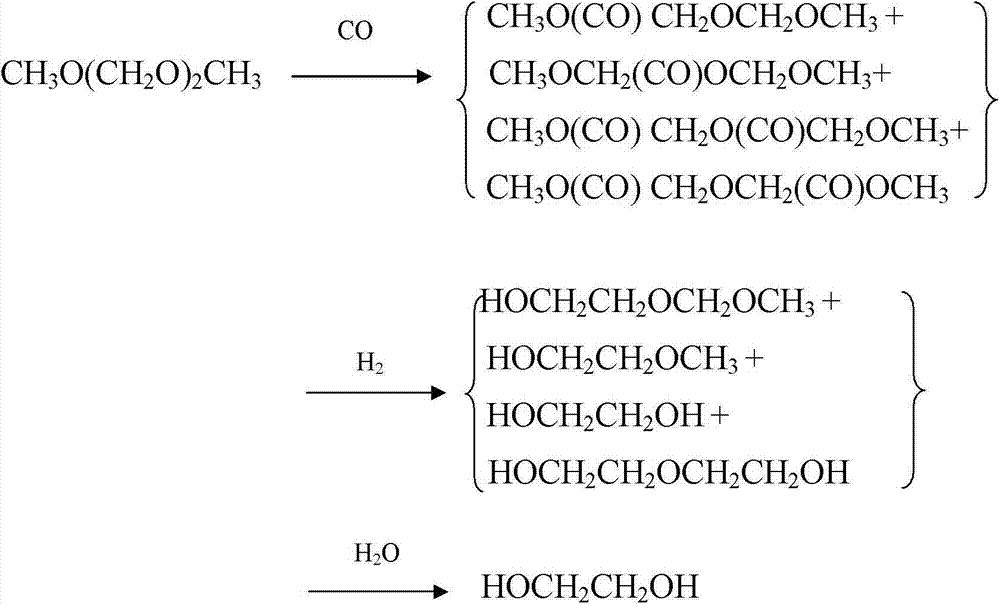

Method for preparing polyoxymethylene dimethyl ether carboxylate and methyl methoxy acetate

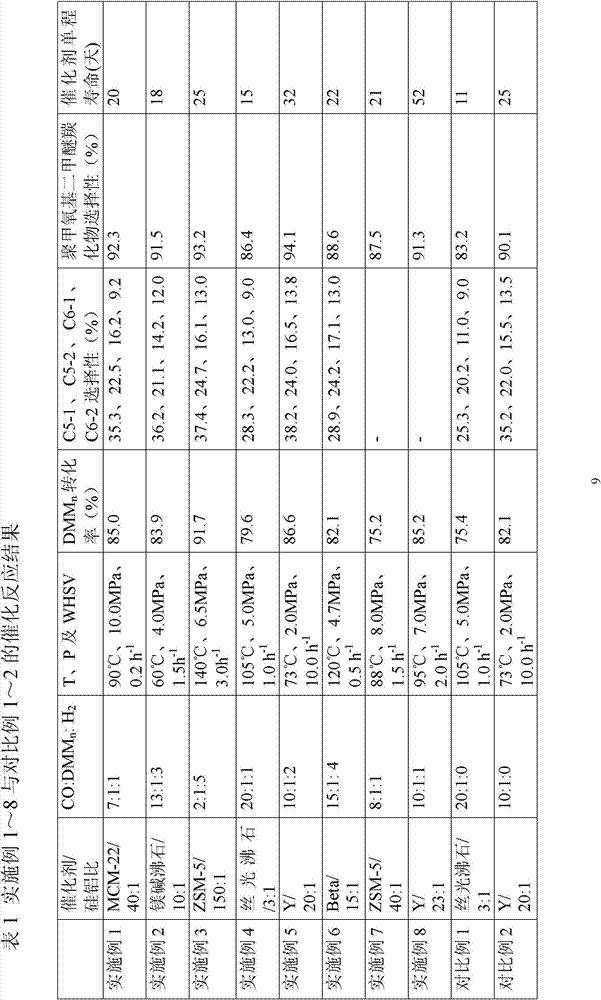

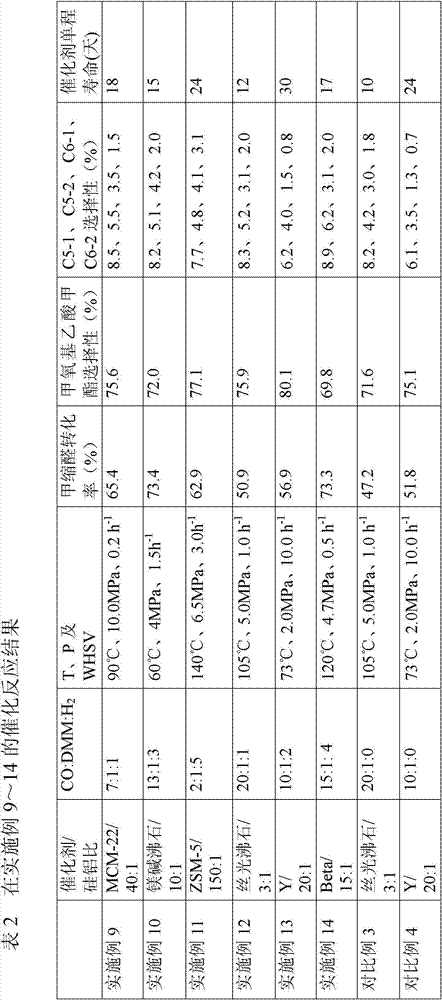

ActiveCN104725229AImprove conversion rateHigh selectivityOrganic compound preparationPreparation by carbon monoxide or formate reactionPolymer sciencePtru catalyst

The invention provides a method for preparing polyoxymethylene dimethyl ether carboxylate and / or methyl methoxy acetate which serves as an intermediate for producing ethylene glycol. The method comprises the step of enabling a raw material, namely polyoxymethylene dimethyl ether or methylal, together with carbon monoxide and hydrogen gas to react in a dealuminzation modified acidic molecular sieve catalyst loaded reactor under appropriate reaction conditions without adding other solvents, so as to prepare corresponding products, wherein a reaction process is of gas-liquid-solid three-phase reaction. According to the method provided by the invention, the conversion ratio of the raw material polyoxymethylene dimethyl ether or methylal is high, the selectivity of each product is high, the service life of a catalyst is long, external solvents are not required to be used, reaction conditions are relatively mild, and continuous production can be carried out, so that the method has industrial application potential. Furthermore, the obtained products can be used for producing ethylene glycol through hydrolyzing after hydrogenating or hydrogenating after hydrolyzing.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing polyoxymethylene dimethyl ether carboxylate and methyl methoxy acetate

ActiveCN104725230AImprove conversion rateHigh selectivityMolecular sieve catalystsPreparation by carbon monoxide or formate reactionMethyl methoxyacetateSolvent

The invention provides a method for preparing polyoxymethylene dimethyl ether carboxylate and / or methyl methoxy acetate which serves as an intermediate for producing ethylene glycol. The method comprises the step of enabling a raw material, namely polyoxymethylene dimethyl ether or methylal, together with carbon monoxide and hydrogen gas to react in a desiliconisation modified acidic molecular sieve catalyst loaded reactor under appropriate reaction conditions without adding other solvents, so as to prepare corresponding products, wherein a reaction process is of gas-liquid-solid three-phase reaction. According to the method provided by the invention, the conversion ratio of the raw material polyoxymethylene dimethyl ether or methylal is high, the selectivity of each product is high, the service life of a catalyst is long, external solvents are not required to be used, reaction conditions are relatively mild, and continuous production can be carried out, so that the method has industrial application potential. Furthermore, the obtained products can be used for producing ethylene glycol through hydrolyzing after hydrogenating or hydrogenating after hydrolyzing.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

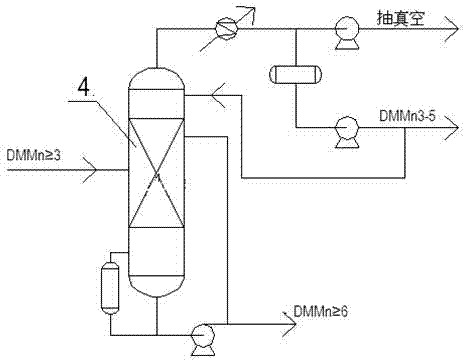

Method for preparation of polyoxymethylene dimethyl ether from paraformaldehyde

InactiveCN102964227ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPolyoxymethyleneMolecular sieve

The invention relates to a method for preparation of polyoxymethylene dimethyl ether from paraformaldehyde, in particular to a method for preparation of polyoxymethylene dimethyl ether in the presence of an acidic resin catalyst and separation of polyoxymethylene dimethyl ether. The method adopts methylal and paraformaldehyde as raw materials to prepare polyoxymethylene dimethyl ether under mild reaction conditions. The reaction product is first subjected to molecular sieve adsorption, then to a reaction with an alkaline substance, and further to atmospheric and vacuum distillation so as to separate low-boiling point by-products and polyoxymethylene dimethyl ether (DMM3-8) as well as higher polymerization degree polyoxymethylene dimethyl ether (DMMn, with n being larger than 8), wherein the low-boiling point part and the high-boiling point part further react to prepare polyoxymethylene dimethyl ether. The separated polyoxymethylene dimethyl ether (DMM3-8) product can be directly used as a component for co-combustion with diesel.

Owner:CHINA NAT OFFSHORE OIL CORP +1

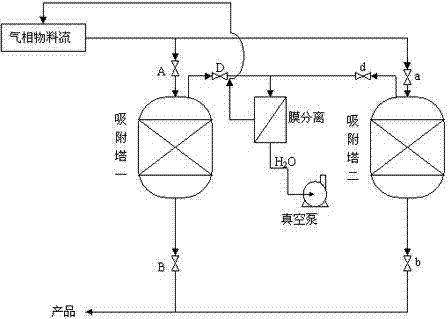

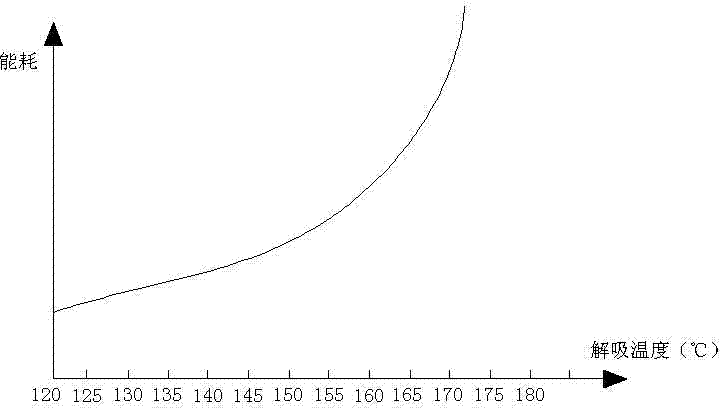

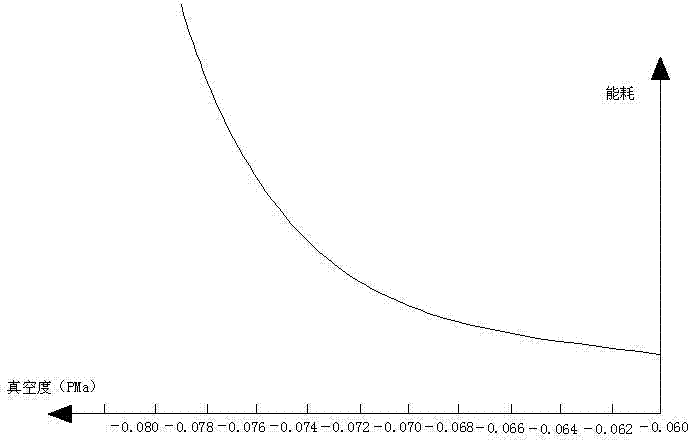

Method for adsorption, membrane separation and dehydration of polyoxymethylene dimethyl ether

ActiveCN104725201AReduce energy consumptionReduce processing timeOrganic chemistryOrganic compound preparationMolecular sieveGas phase

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

Purification method for polyoxymethylene dimethyl ether(PODE)

ActiveCN106588589AGuaranteed separation and recoveryEasy to removeOrganic chemistryOrganic compound preparationPurification methodsDistillation

The invention needs to solve a technical problem of being hard to operate continuously in long-term when materials block an overhead of rectifying column in the process of purifying the PODE by distillation. An adopted technical scheme includes following steps: (a) a reaction mixture, produced through a reactive synthesis unit, enters into a first rectifying column. A first fraction, mainly including Methylal, is separated and a first column residue is produced; (b) the first column residue and make-up water enter into a second rectifying column, and a second column residue and a second overhead of rectifying column light ends including PODE2 raw material are produced by separation; (c) after adding extraction agent in the second overhead of rectifying column light ends, raffinate is separated and extract phase is produced; (d) a second column residue enters into a fourth rectifying column. Production fraction containing PODE 3-5 is separated by the overhead of rectifying column.

Owner:CHINA PETROLEUM & CHEM CORP +1

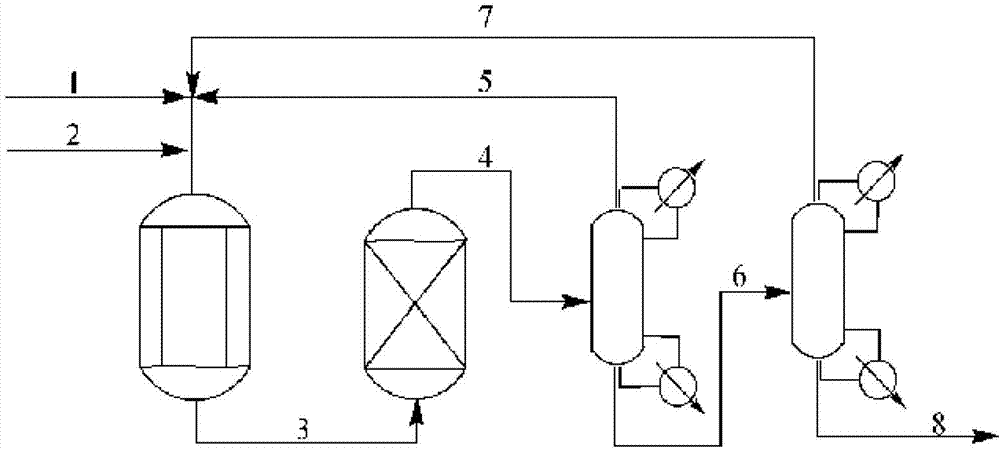

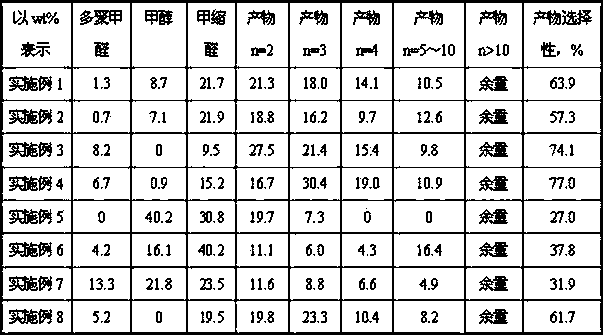

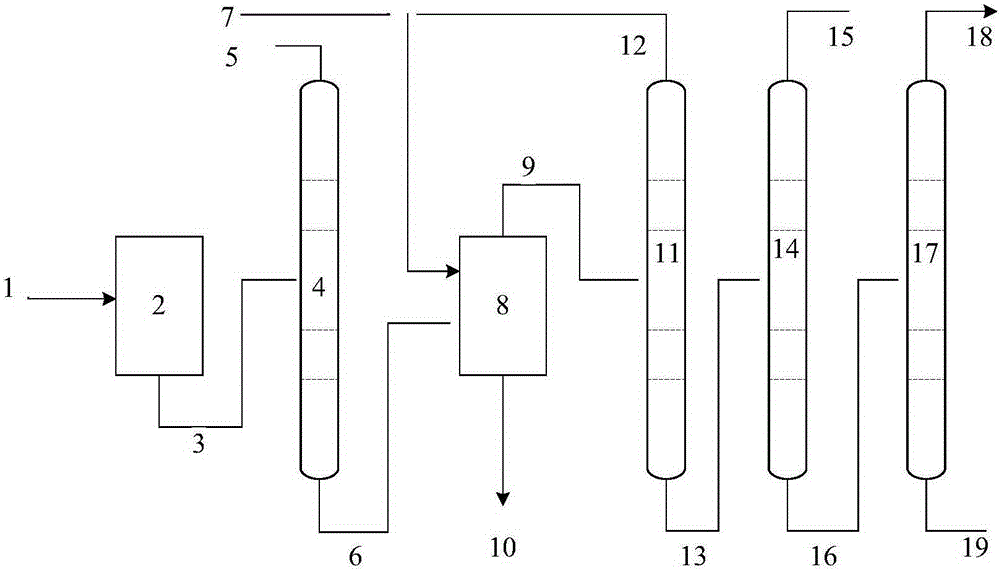

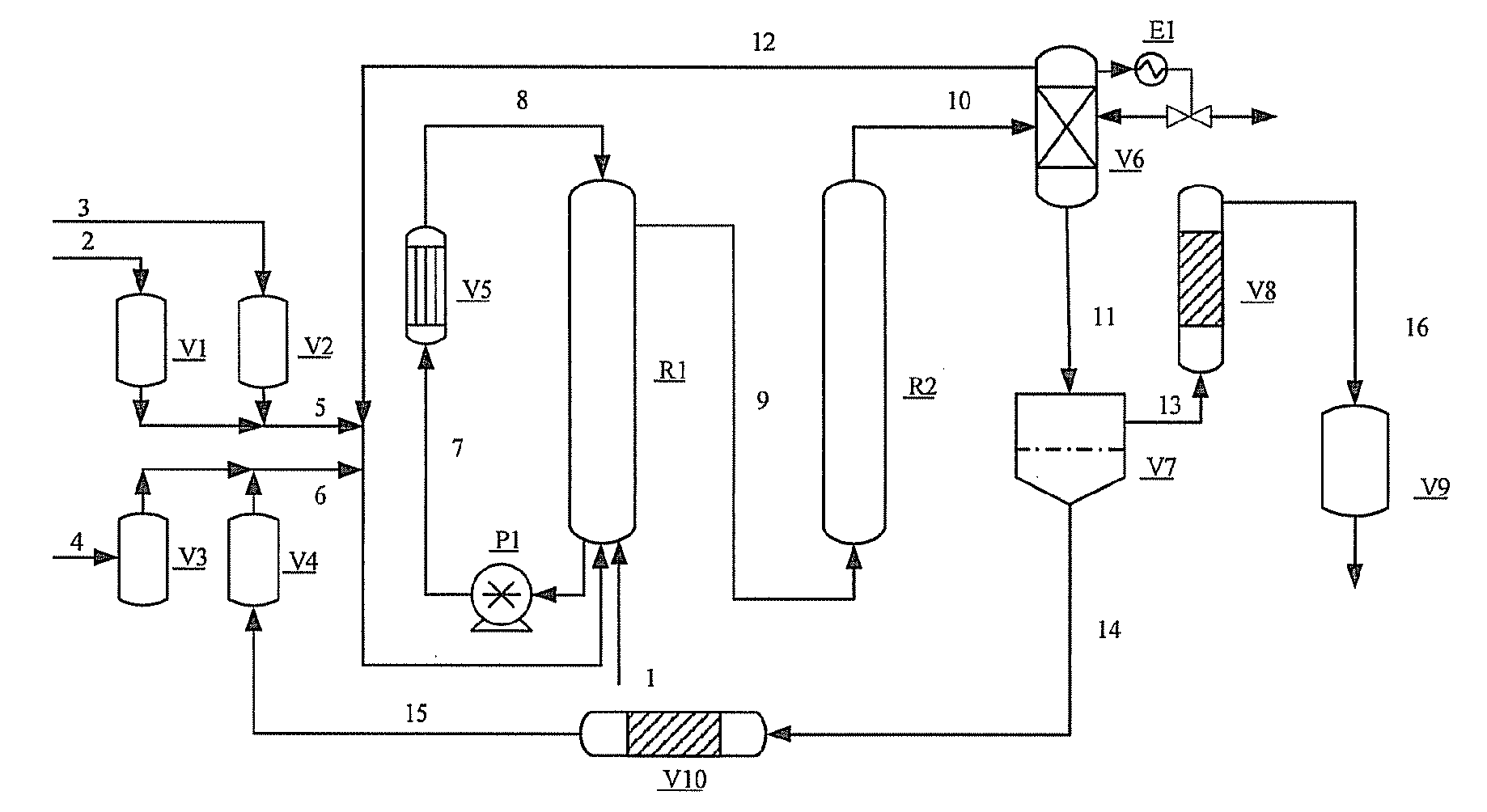

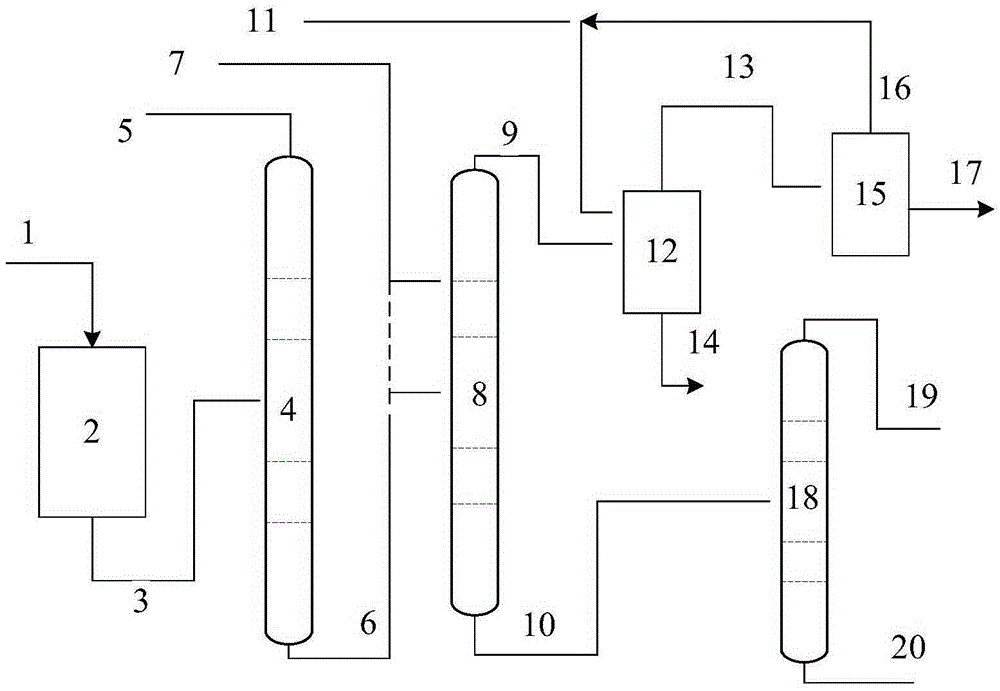

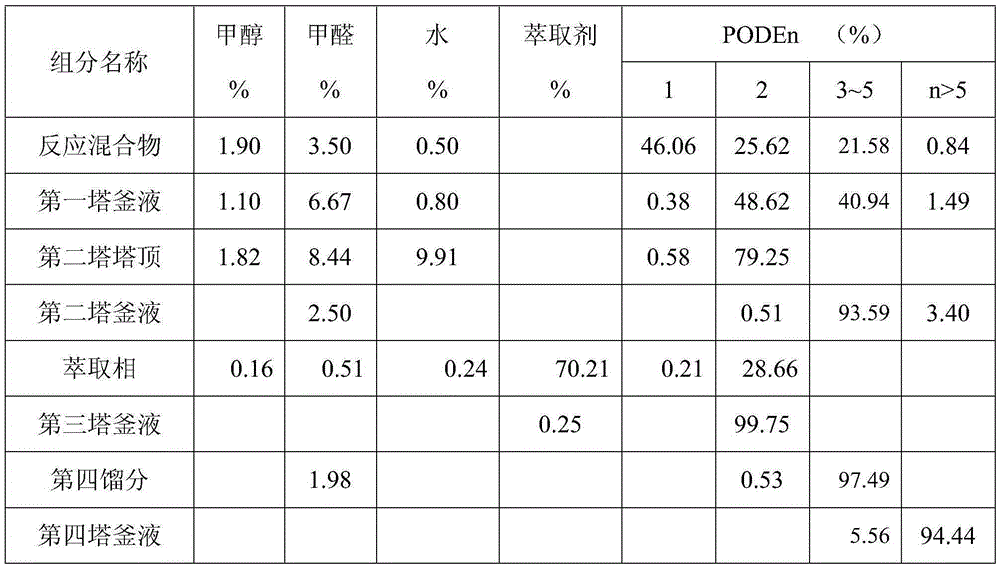

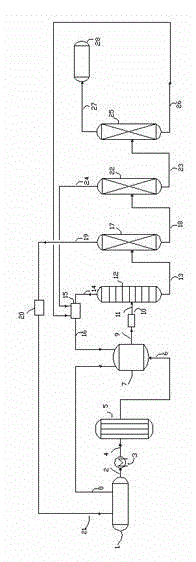

Process method for preparing polyformaldehyde dimethyl ether from methanol

ActiveCN104447237AHigh yieldHigh selectivityOrganic chemistryOrganic compound preparationCatalytic oxidationFixed bed

The invention relates to a process method for preparing polyformaldehyde dimethyl ether from methanol. The process method adopts an oxidation reaction zone and a reaction rectification zone, wherein the oxidation reaction zone comprises a methanol storage tank (1), a preheater (3), a fixed bed reactor (5) and a pre-mixing tank (7); the oxidation reaction zone comprises the following process steps: preheating methanol to be gasified, mixing with preheated air, feeding into the fixed bed reactor, performing catalytic oxidation on a formaldehyde catalyst prepared through methanol oxidization, thereby generating formaldehyde, feeding the formaldehyde into the pre-mixing tank (7), pre-mixing the formaldehyde with methanol and a circulated and recycled mixture inside the pre-mixing tank before being reacted, and further feeding into the reaction rectification zone; the reaction rectification zone comprises a reaction rectification tower (12), three serially connected separation rectification towers and a product storage tank (28) in sequence; the three serially connected separation rectification towers are respectively a first separation rectification tower (17), a second separation rectification tower (22) and a third separation rectification tower (25). The process method has the characteristic that the yields of n=3 and n=4 are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing dimethoxymethane by adopting supported niobium oxide catalyst

InactiveCN102000559AEasy to prepareReduce loadOrganic chemistryOrganic compound preparationBoiling pointReaction temperature

The invention discloses a method for preparing polyformaldehyde dimethyl ether by adopting a supported niobium oxide catalyst, which is characterized by comprising the following steps of: a) performing catalytic reaction to prepare the polyformaldehyde dimethyl ether, wherein a molar ratio of the dimethoxymethane to trioxymethylene is 0.5 to 5; supported niobium oxide is taken as a catalyst and accounts for 0.1 to 5 percent based on the total mass of reactants; the reaction temperature is between 100 and 200 DEG C; the time is between 10 minutes and 48 hours; and the reaction pressure is between 0.1 and 10MPa; b) performing rectification separation, namely separating a low-boiling point component dimethoxymethane DMM, polydiformaldehyde dimethyl ether DMM2 and the unreacted trioxymethylene, and separating polyformaldehyde diformaldehyde DMM3-8, wherein a kettle bottom is provided with high-polymerization degree polyformaldehyde dimethyl ether DMMn, and n is more than 8; and c) adding a small amount of fresh trioxymethylene into the dimethoxymethane, the diformaldehyde dimethyl ether DMM2 and the unreacted trioxymethylene which are separated in the step b and continuously reacting to prepare the polyformaldehyde diformaldehyde DMM3-8, which is suitable to be used as a diesel fuel-blended component so as to improve the utilization rate of the raw materials.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for preparing polyoxymethylene dimethyl ether carboxylate and methyl methoxy acetate

ActiveCN104725224AImprove conversion rateHigh selectivityPreparation by carbon monoxide or formate reactionMethyl methoxyacetateCarboxylic salt

The invention provides a method for preparing polyoxymethylene dimethyl ether carboxylate and / or methyl methoxy acetate which serves as an intermediate for producing ethylene glycol. The method comprises the step of enabling a raw material, namely polyoxymethylene dimethyl ether or methylal, together with carbon monoxide and hydrogen gas to react in an acidic molecular sieve catalyst loaded reactor under appropriate reaction conditions without adding other solvents, so as to prepare corresponding products, wherein a reaction process is of gas-liquid-solid three-phase reaction. According to the method provided by the invention, the conversion ratio of the raw material polyoxymethylene dimethyl ether or methylal is high, the selectivity of each product is high, the service life of a catalyst is long, external solvents are not required to be used, reaction conditions are relatively mild, and continuous production can be carried out, so that the method has industrial application potential. Furthermore, the obtained products can be used for producing ethylene glycol through hydrolyzing after hydrogenating or hydrogenating after hydrolyzing.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

The method for synthesizing polyoxymethylene dimethyl ether

ActiveCN102295734AImprove utilization efficiencyLow selectivityOrganic chemistryOrganic compound preparationMolecular sieveMass ratio

The invention relates to a method for synthesizing polyoxymethylene dimethyl ether, which mainly solves the problems of low reaction efficiency of a solid superacid catalyst, high cost of raw material trioxymethylene and more byproducts after reaction during synthesis of polyoxymethylene dimethyl ether existing in the prior art. In the method, dimethoxymethane and paraformaldehyde are used as rawmaterials, wherein the mass ratio of the dimethoxymethane to the paraformaldehyde is 0.5-10:1; the raw materials are in contact with the catalyst to generate catalytic reaction to prepare the polyoxymethylene dimethyl ether under the conditions of reaction temperature of 70-200 DEG C and reaction pressure of 0.2-6MPa; the amount of the used catalyst is 0.1-5.0 percent; and the used catalyst comprises the following components in percentage by weight: (a) 30-80 parts of molecular sieve carrier; and (b) 20-70 parts of solid superacid. Due to the technical scheme, the problems are solved well; and the method can be used for industrial production of the polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing polyoxymethylene dimethyl ethers by ionic liquid catalysis

InactiveUS20100056830A1Reduce corrosionGuaranteed efficient selectivityOrganic compound preparationEther preparationControllabilityIonic liquid

The present invention discloses a method for synthesizing polyoxymethylene dimethyl ethers by ionic liquid catalysis. The method comprises synthesizing polyoxymethylene dimethyl ethers by using a functional acidic ionic liquid as catalyst and using methylal and trioxymethylene as reactant under a relative mild reaction condition. The invention has advantages of high catalyst activity and reaction conversion, simple reaction process, high operationability and controllability, as well as good product distribution and high raw material utilization ratio.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for PODE (polyoxymethylene dimethyl ether)

InactiveCN106582836AHigh yieldHigh selectivityOrganic chemistryOrganic compound preparationPolystyreneIon-exchange resin

The invention relates to a catalyst for PODE (polyoxymethylene dimethyl ether) and mainly solves the problems of low catalyst activity and low selectivity in the process for synthesizing PODE from methanol, methylal and paraformaldehyde used as reaction raw materials in the prior art. According to the technical scheme, the catalyst for PODE is metal ion modified sulfonic acid type polystyrene cation exchange resin comprising a crosslinked polystyrene framework and a sulfonic acid group; the metals are selected from at least one of group IB and group IIB, so that the catalyst can be applied to industrial production of PODE.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com