Catalyst for PODE (polyoxymethylene dimethyl ether)

A dimethyl ether and catalyst technology, applied in the field of catalysts, can solve the problem of low product selectivity and achieve good yield and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

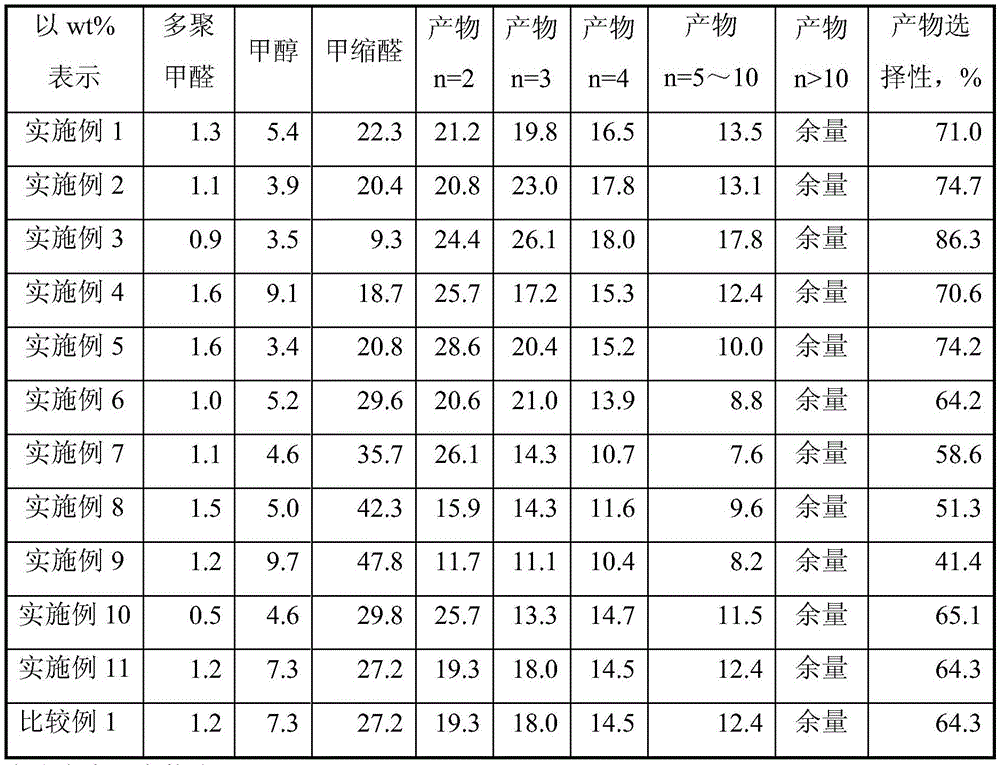

Examples

Embodiment 1

[0027] 1. Preparation of catalyst

[0028] Sodium sulfonate polystyrene cation exchange resin 7320 was washed with deionized water until clear water flowed out, soaked in 4w% hydrochloric acid for 4 hours, then washed with deionized water until pH = 6, and dried at 60°C to obtain sulfonic acid Type polystyrene cation exchange resin, its total exchange capacity is 4.10mmol / g. Take sulfonic acid polystyrene cation exchange resin equivalent to 98 grams of dry base resin and 300 ml of CuCl containing 2 grams of Cu 2 The aqueous solutions were mixed, left standing at room temperature for 24 hours, finally washed with deionized water until no chloride ions existed, and dried in a vacuum drying oven to constant weight to obtain a catalyst with a Cu content of 2w%.

[0029] 2. Synthesis of polyoxymethylene dimethyl ether

[0030] Add 2 grams of catalyst, 100 grams of methanol and 100 grams of paraformaldehyde in a 300 ml tank reactor, react at 130 ° C and 0.5 MPa autogenous pressure...

Embodiment 2

[0032] 1. Preparation of catalyst

[0033] Sodium sulfonate polystyrene cation exchange resin 7320 was washed with deionized water until clear water flowed out, soaked in 4w% hydrochloric acid for 4 hours, then washed with deionized water until pH = 6, and dried at 60°C to obtain sulfonic acid Type polystyrene cation exchange resin, its total exchange capacity is 4.10mmol / g. Get the sulfonic acid type polystyrene cation exchange resin that is equivalent to 98 grams of dry base resin and 300ml contain Zn and be 2 grams of ZnCl 2 The aqueous solutions were mixed, and stood at room temperature for 24 hours, and finally washed with deionized water until no chloride ions existed, and dried in a vacuum oven to constant weight to obtain a catalyst with a Zn content of 2w%.

[0034] 2. Synthesis of polyoxymethylene dimethyl ether

[0035] Add 2 grams of catalyst, 100 grams of methanol and 100 grams of paraformaldehyde in a 300 ml tank reactor, react at 130 ° C and 0.5 MPa autogenous...

Embodiment 3

[0037] 1. Preparation of catalyst

[0038] Sodium sulfonate polystyrene cation exchange resin 7320 was washed with deionized water until clear water flowed out, soaked in 4w% hydrochloric acid for 4 hours, then washed with deionized water until pH = 6, and dried at 60°C to obtain sulfonic acid Type polystyrene cation exchange resin, its total exchange capacity is 4.10mmol / g. Get the sulfonic acid type polystyrene cation-exchange resin that is equivalent to 98 grams of dry base resins and 300ml containing Zn is that 1 gram contains Cu and is mixed with the zinc chloride copper chloride mixed aqueous solution of 1 gram, leaves standstill 24 hours under room temperature, finally uses Wash with deionized water until there is no chloride ion, and dry to constant weight in a vacuum drying oven to prepare a catalyst with a Zn content of 1w% and a Cu content of 1w%.

[0039] 2. Synthesis of polyoxymethylene dimethyl ether

[0040] Add 2 grams of catalyst, 100 grams of methanol and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com