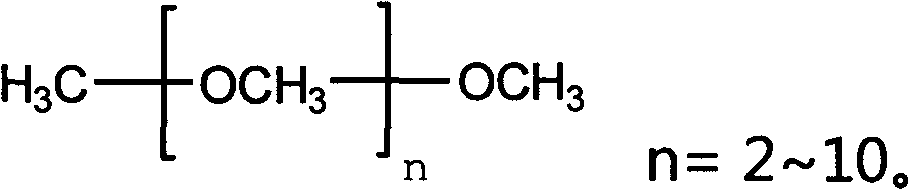

Process for preparing polyoxymethylene dimethyl ether

A technology of polyoxymethylene dimethyl ether and dimethyl ether, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of poor economy, lack of large-scale industrialization, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Heat and stir 500 g of methanol, 200 g of paraformaldehyde and triethylamine (the mass ratio of triethylamine to paraformaldehyde is 13:1000) at 80° C. until it forms a homogeneous mixed solution to obtain poly The homogeneous mixed solution formed by formaldehyde monomethyl ether and methanol is neutralized by adding equimolar hydrochloric acid with triethylamine to obtain a neutral solution. At 50°C, methanol was distilled off by vacuum distillation to obtain a polyoxymethylene monomethyl ether solution containing a small amount of methanol.

[0032] Second step: 30g of the polyoxymethylene monomethyl ether solution prepared above, 120g of methylal, an acid catalyst and a dehydrating agent were mixed, stirred and reacted at room temperature and normal pressure for 4 hours, and obtained polyoxymethylene dimethyl ether (DMM) containing Mixed solution, the obtained product was analyzed by gas chromatography, and the results are shown in Table 1.

[0033] The DMM...

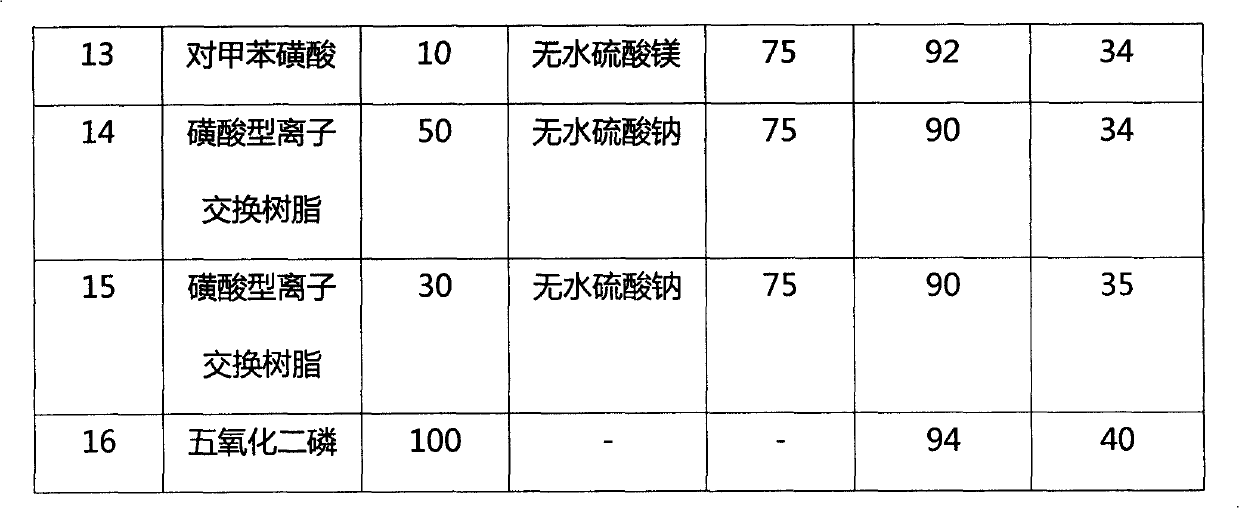

Embodiment 2-16

[0036] The polymerization process was the same as in Example 1, only the types and ratios of the acidic catalyst and water-absorbing agent were changed. The results are shown in Table 1.

[0037] Table 1

[0038]

[0039]

Embodiment 17-23

[0041] The first step reaction is the same as in Example 1, the second step reaction temperature is 50°C, the reaction time is shortened to 2 hours, and the types and ratios of the acidic catalyst and water-absorbing agent are changed. Others are the same as in Example 1, and the results are shown in Table 2.

[0042] Table 2

[0043]

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com