Method for preparing polyoxymethylene dimethyl ether carboxylate and methyl methoxy acetate

A technology of polyoxymethylene dimethyl ether and carbonylate, applied in the field of polyoxymethylene dimethyl ether carbonylate, which can solve the problem of short catalyst life, low concentration of methylal, and conversion rate of methylal to methyl methoxyacetate The ester selectivity is not ideal enough to achieve the effect of long catalyst life, high selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

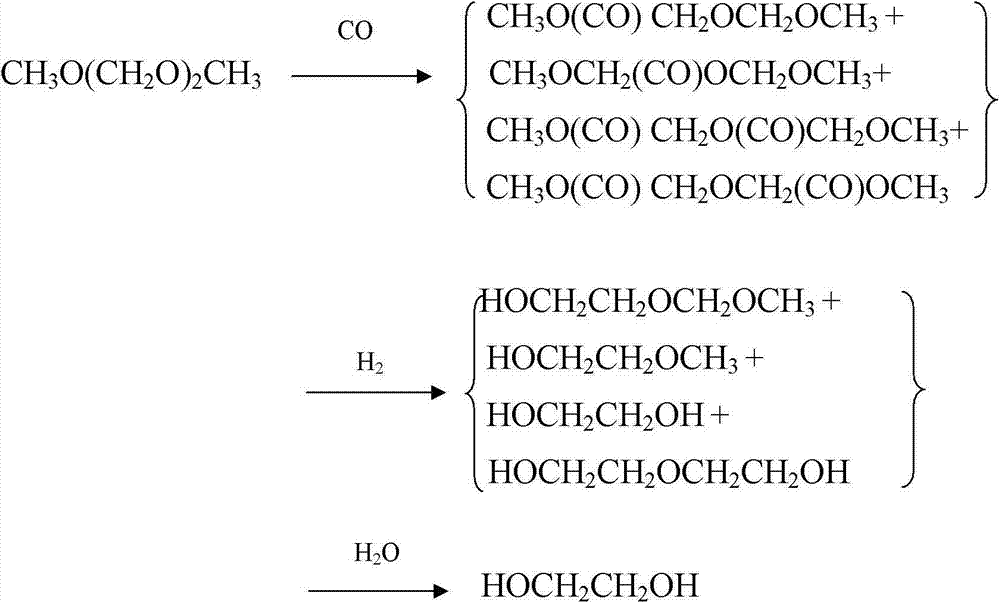

Method used

Image

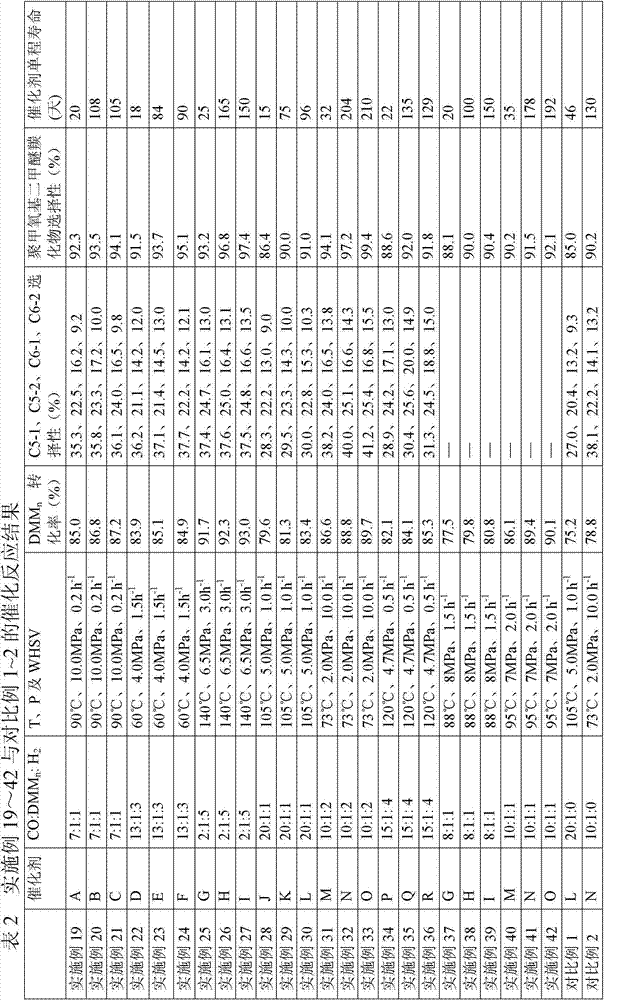

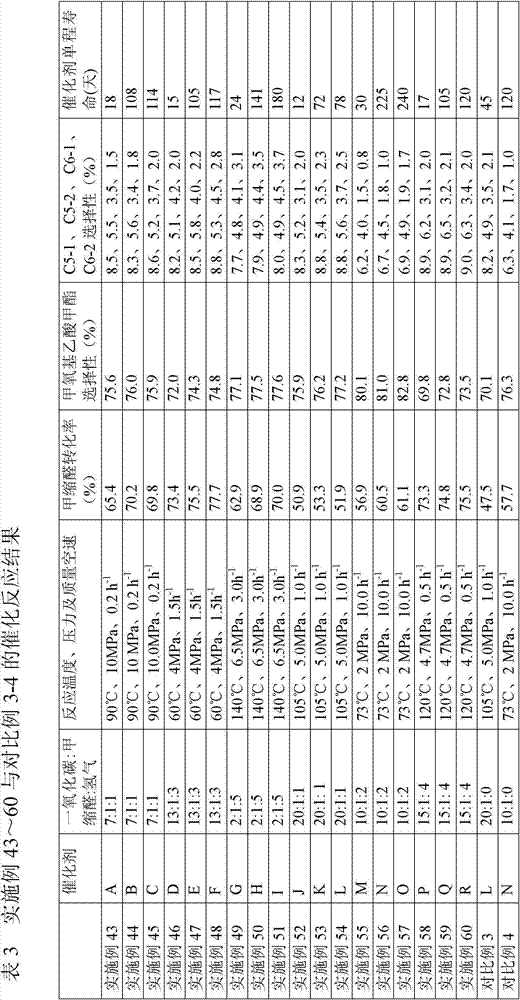

Examples

Embodiment 1

[0053] 50 g of MCM-22 molecular sieves with a sodium-type silicon-aluminum ratio of 40:1 were converted into acidic molecular sieves using standard operating procedures, which were recorded as catalyst A, as shown in Table 1.

Embodiment 2

[0055] 100 g of MCM-22 molecular sieve with a sodium-type silicon-aluminum ratio of 40:1 was treated with steam at 550°C for 4 hours, and then converted into an acidic molecular sieve using standard operating procedures, which was designated as catalyst B, see Table 1.

Embodiment 3

[0057] Treat 100g of MCM-22 molecular sieve with a sodium-type silicon-alumina ratio of 40:1 in 500ml of 0.1mol / L hydrochloric acid solution at 60°C for 1 hour, and then convert it into an acidic molecular sieve using standard operating procedures, which is recorded as catalyst C, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com