Patents

Literature

533results about How to "Strong acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double micro pore high silicon composite molecular sieve and its preparing method

InactiveCN1944254AGood thermal and hydrothermal stabilityStrong acidFaujasite aluminosilicate zeoliteMolecular sieveCrystallite

The present invention belongs to the field of fine chemical technology, and is especially the preparation process of double pore high silicon zeolite molecular sieve as one kind of composite molecular sieve. The present invention features that by using type-Y high silicon zeolite as silicon and aluminum source, and through dissolving the surface of the high silicon type-Y crystal grain, mixing with ammonia water solution of ammonium tetraethyl bromide, adding certain amount of silica gel via stirring, crystallizing at 140-170 deg.C for 5-10 days, washing, stoving and roasting to eliminate template agent, double pore high silicon zeolite molecular sieve with both type-Y and type-beta molecular sieve pore canals is obtained. The double pore high silicon zeolite molecular sieve has low synthesis cost and high hydrothermal stability, and may be used in petrochemical industry.

Owner:TAIYUAN UNIV OF TECH

Preparation method of high-strength flue gas denitration catalyst

ActiveCN103769137ALarge specific surface areaHigh strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberWear resistant

The invention discloses a preparation method of a high-strength flue gas denitration catalyst. The preparation method comprises the following steps: taking titanium sulfate as the titanium source and critic acid as the complexing agent to prepare a TiO2-SiO2 composite carrier through an impregnation method, loading an active component and an auxiliary agent on the TiO2-SiO2 composite carrier so as to obtain denitration catalyst powder, mixing the denitration catalyst powder with glass fiber, wood slurry, polyacrylamide, carboxymethyl cellulose, ammonia water, and deionized water, and then subjecting the mixture to processes of kneading, aging, extruding, drying, and burning so as to obtain a honeycomb denitration catalyst. The preparation method has the advantages of simple preparation technology, low cost, and tight combination between TiO2 and SiO2 in the composite carrier. The prepared denitration catalyst has the advantages of good mechanical strength, wear-resistant property, and catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

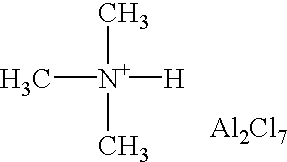

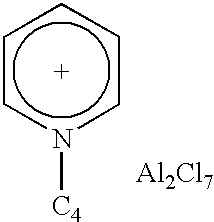

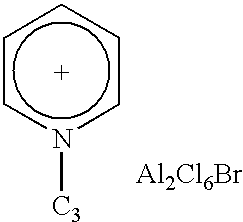

Process of paraffin hydrocarbon isomerization catalysed by ionic liquids

InactiveUS20030109767A1Complicated processingComplicates technologyHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkaneIsomerization

A process for the conversion of paraffin hydrocarbon feed stock via skeletal isomerisation by contacting this feed with a catalyst comprised of an ionic liquid formed from an N-containing heterocyclic and / or N-containing aliphatic organic cation and an inorganic anion derived from metal halides.

Owner:HALDOR TOPSOE AS

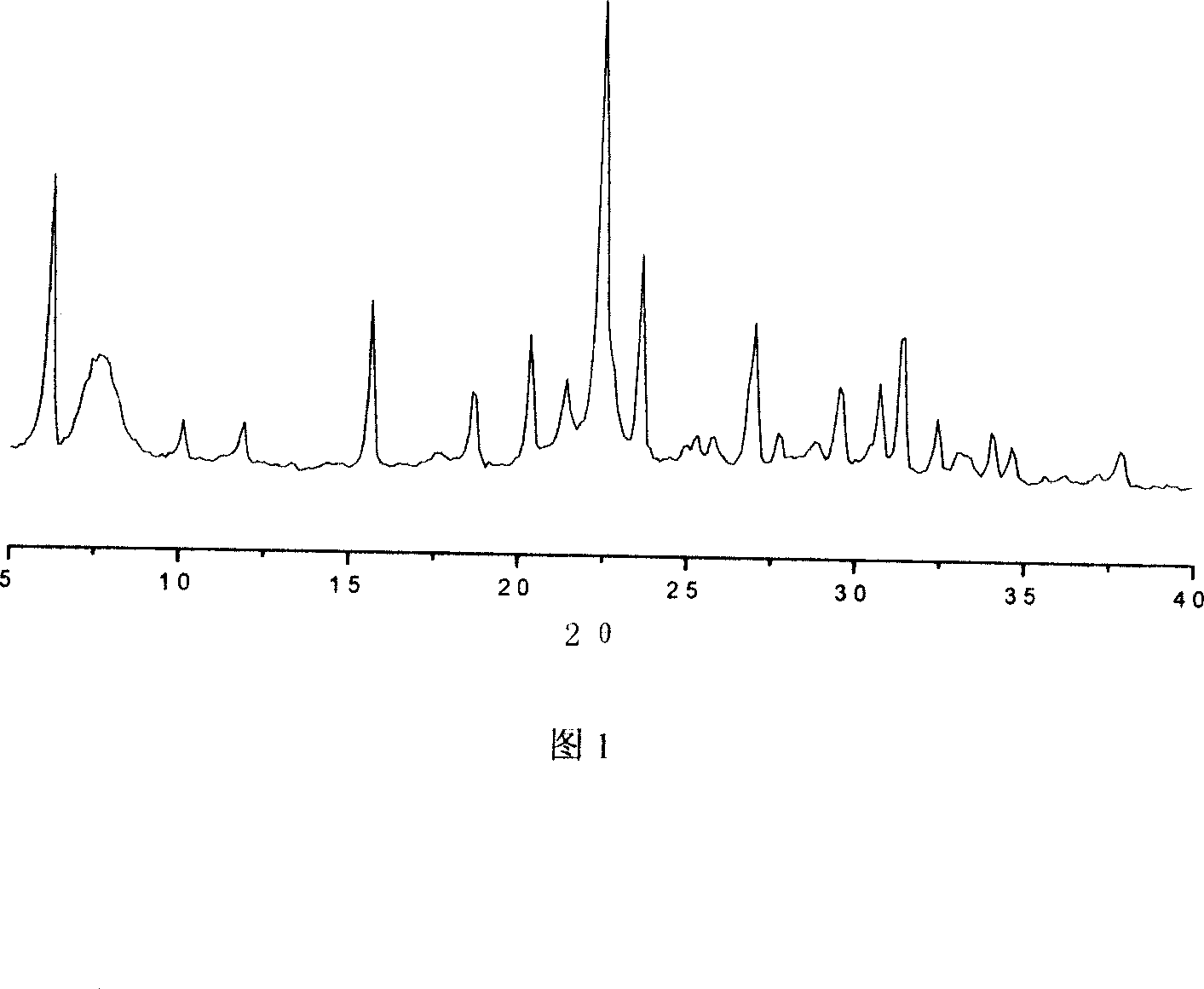

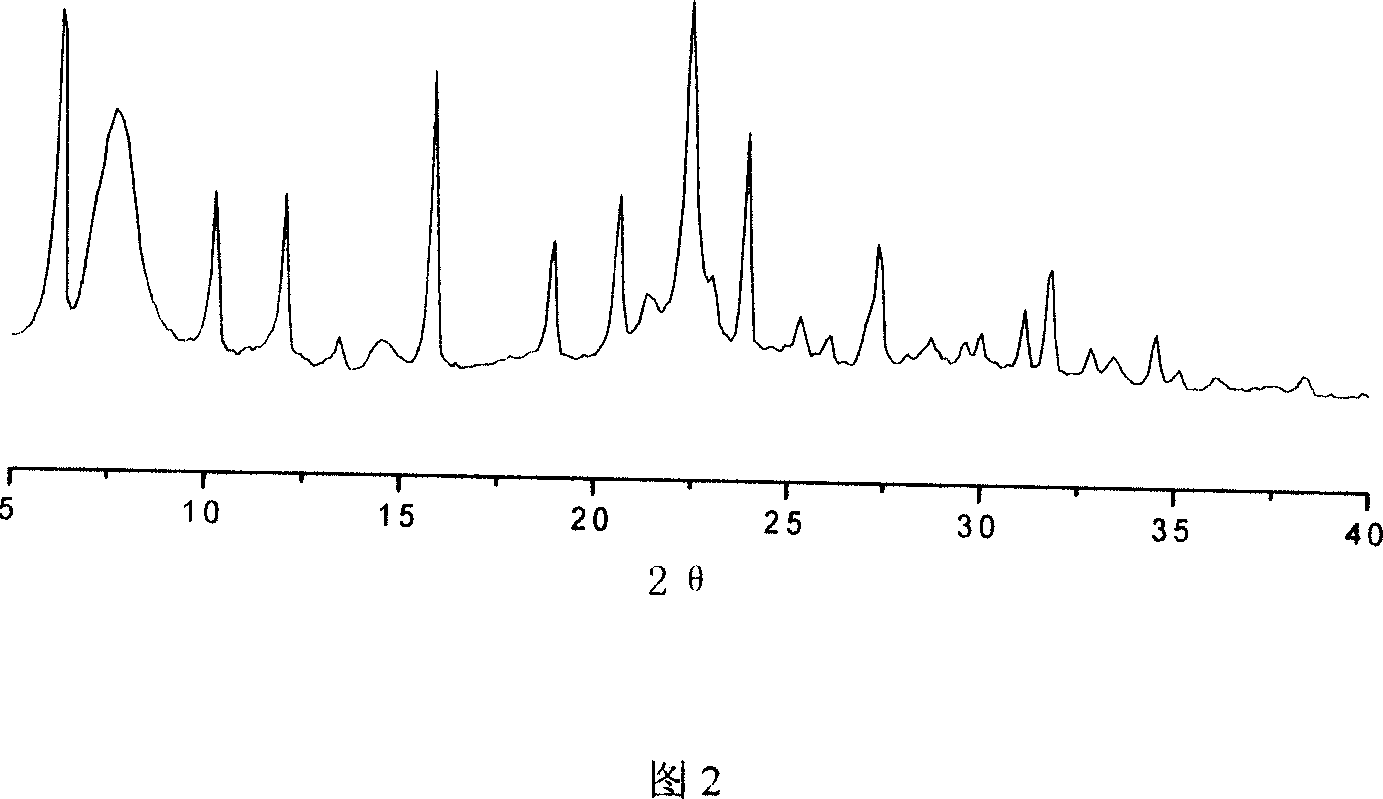

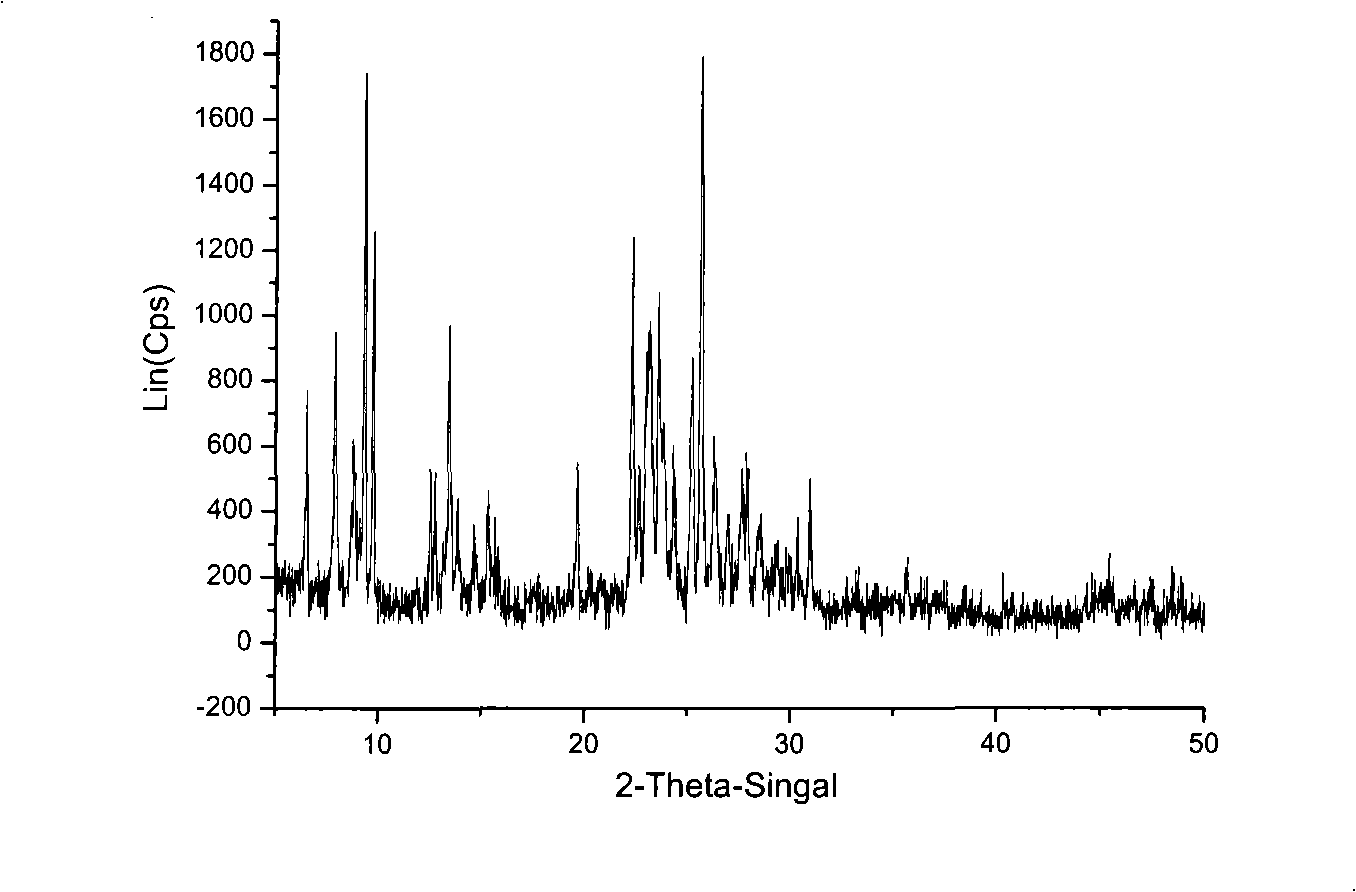

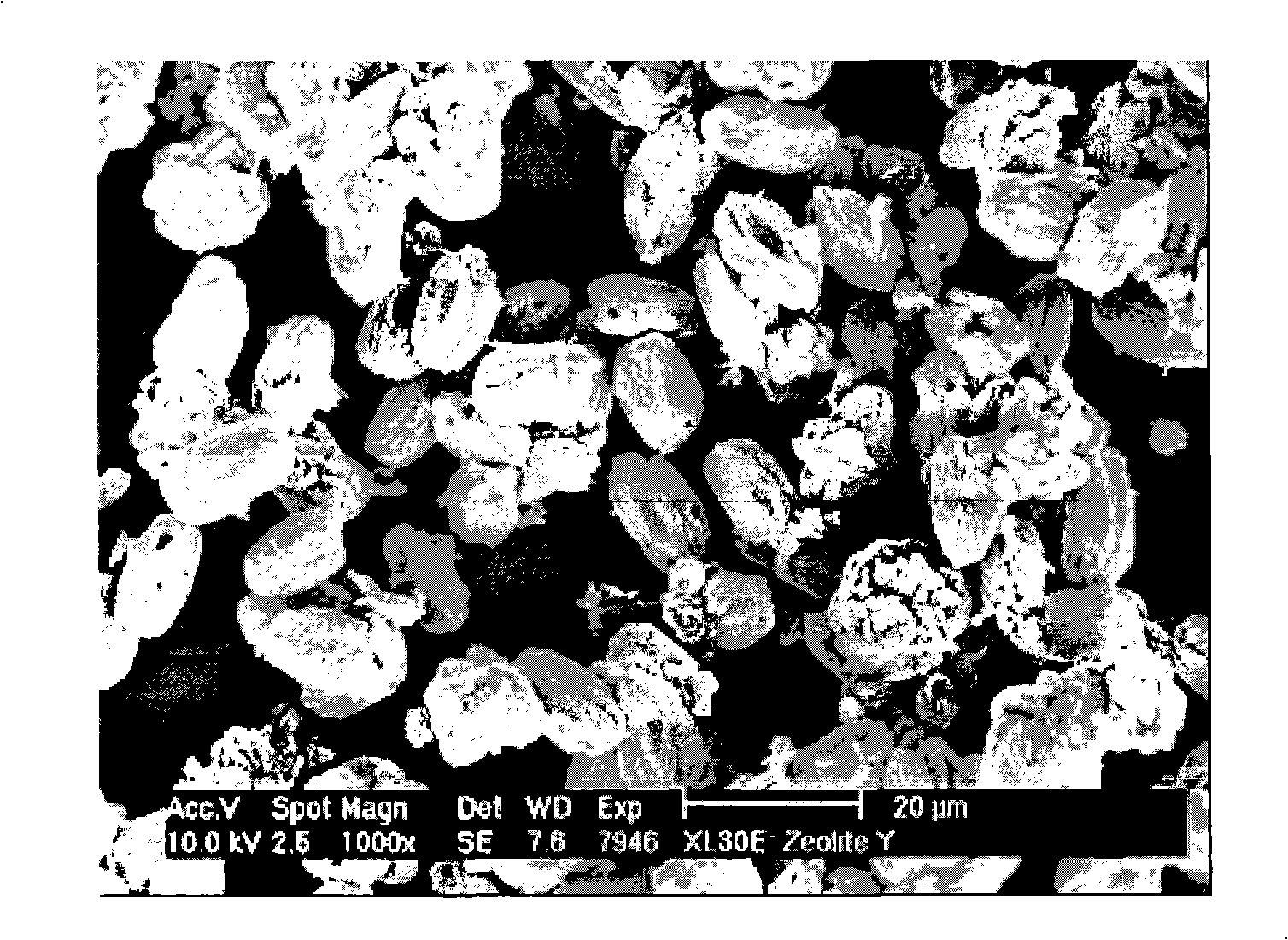

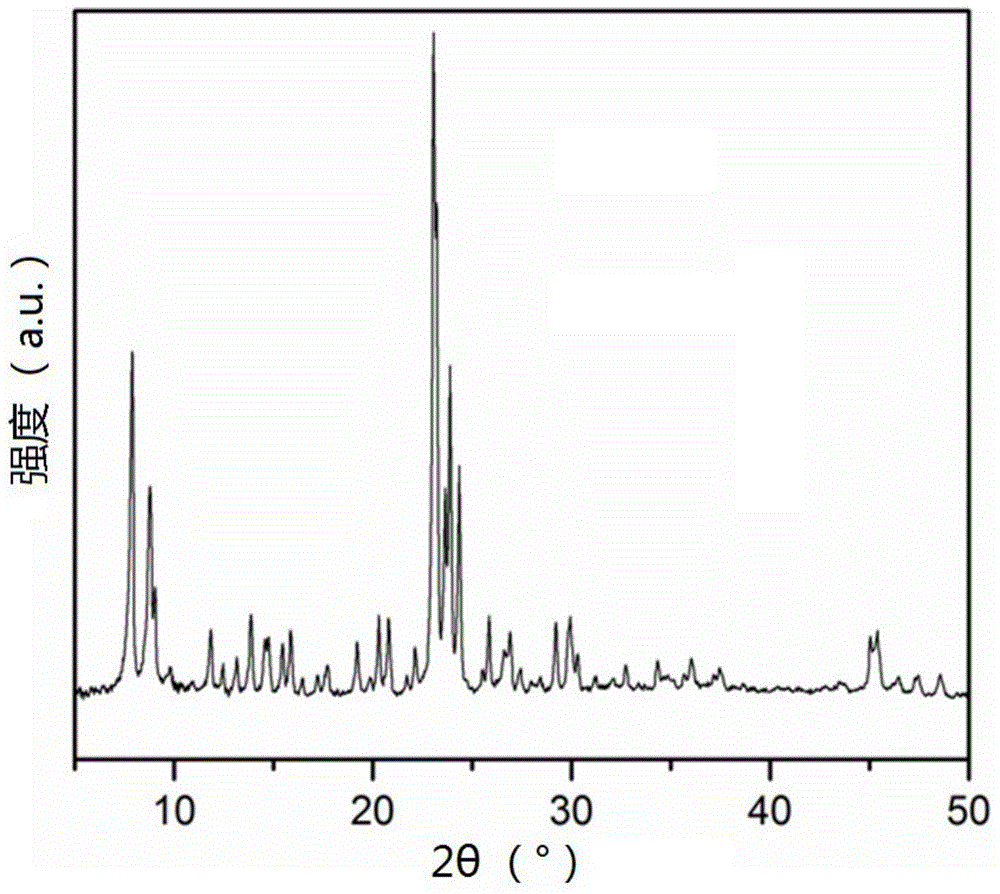

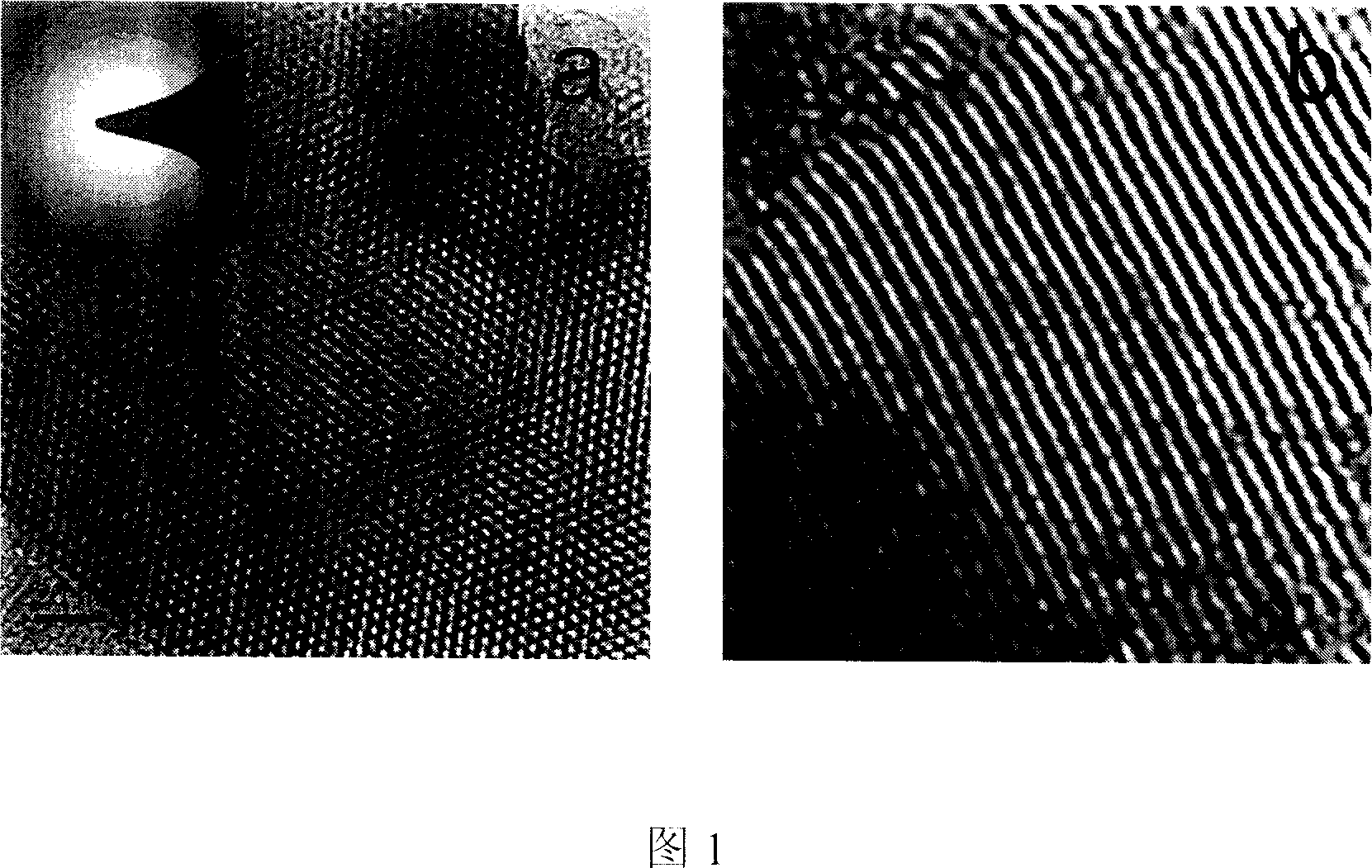

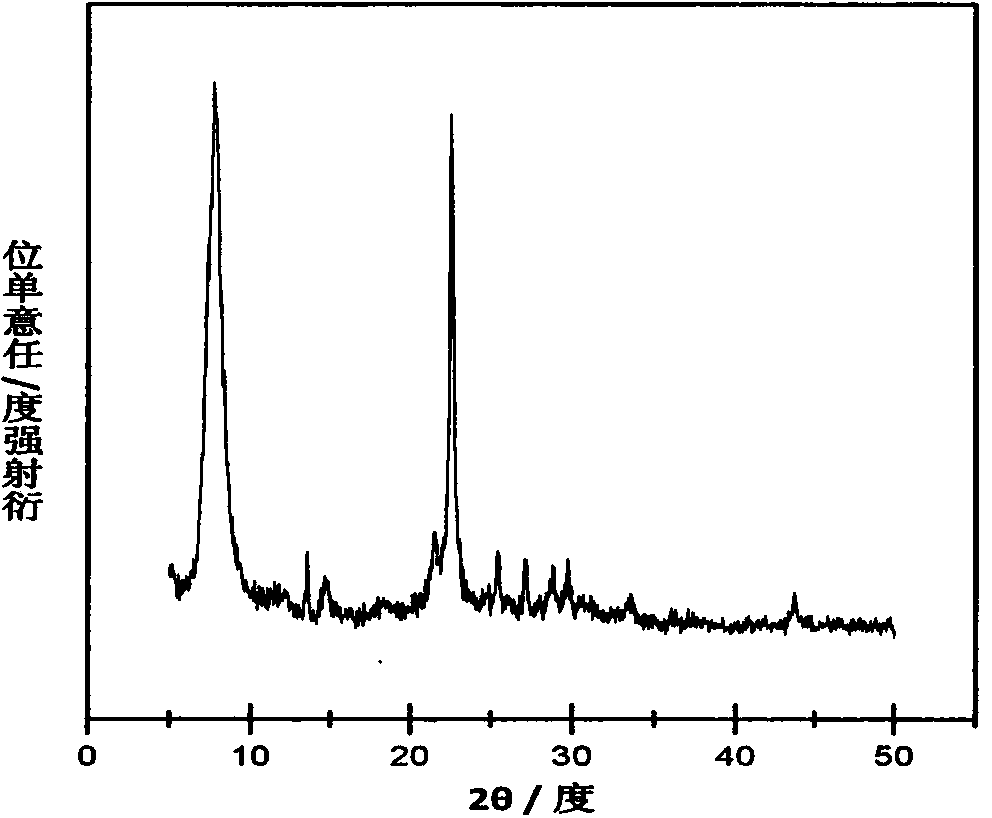

ZSM-5/mordenite/Yzeolite intergrowth molecular sieve and synthetic method thereof

ActiveCN101279747AIncrease acidityStrong acidFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteLow activityChemistry

The invention relates to a ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve and a synthetic method thereof, which mainly solves the problems of singular aperture, rather weak acidity and low activity of porous materials synthesized by the prior art. The invention adopts the technical proposal that the nucleation and process of growth of the molecular sieve are controlled properly by adding crystal seeds containing zeolite Y precursors in the synthetic process of the intergrowth molecular sieve for producing the ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve, wherein the proportion of intergrowth phases is adjustable, and the synthesized ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve adopts the compositions including the following mole relation: nSiO2:Al2O3, where n is between 4 and 400 in the formula, and the method is characterized in that the ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve has more than two phases and an XRD diffraction pattern thereof has the d-space maximum value at the lengths of 14.3+-0.1, 13.58+-0.1, 11.21+-0.1, 10.04+-0.1, 9.47+-0.1, 9.09+-0.1, 6.6+-0.1, 5.7 +-0.1, 4.5+-0.1, 3.98+-0.05, 3.76+-0.04, 3.64+-0.04, 3.53+-0.04, 3.38+-0.02, 3.19+- 0.05 and 2.88+-0.1 angstroms, thereby solving the problems properly. The ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve can be used for preparing ethylene and propylene by catalytic-cracking naphtha in the industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flue-gas denitration catalyst incapable of being deactivated by basic metallic oxides, preparation method thereof and applications thereof

InactiveCN103861628AStrong acidAvoid poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberActive component

The invention discloses a flue-gas denitration catalyst incapable of being deactivated by basic metallic oxides, a preparation method thereof and applications thereof. The catalyst comprises following components by weight: 70-85% of nanometer titanium dioxide, 1-3% of V2O5, 5-15% of heteropoly acid, 3-15% of glass fiber and 4-10% of an inorganic binder. In the preparation method, active components and the heteropoly acid are loaded step by step. The catalyst has high denitration performance and high performance of resistance to deactivation by the basic metallic oxides, and is particularly suitable for flue gas denitration of a power plant, an industrial boiler, an incinerator, a cement kiln, and the like, wherein the power plant, the industrial boiler, the incinerator, the cement kiln, and the like adopt biomass as fuel and contain a large amount of basic metallic oxides in flue gas.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH +1

Plant-fiber-material transformation method

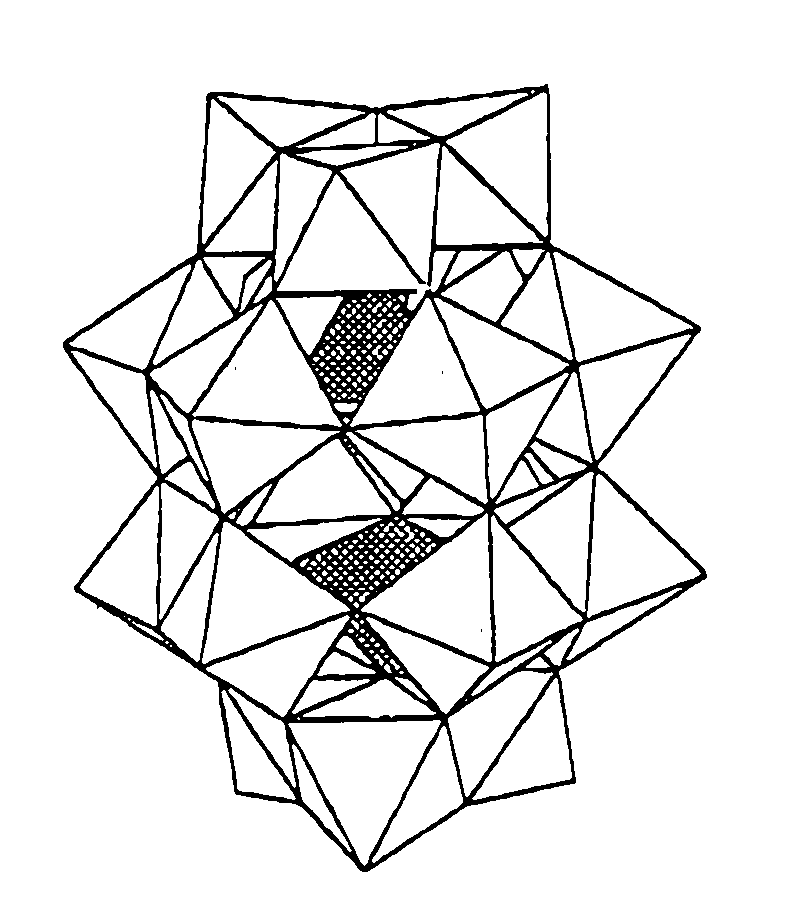

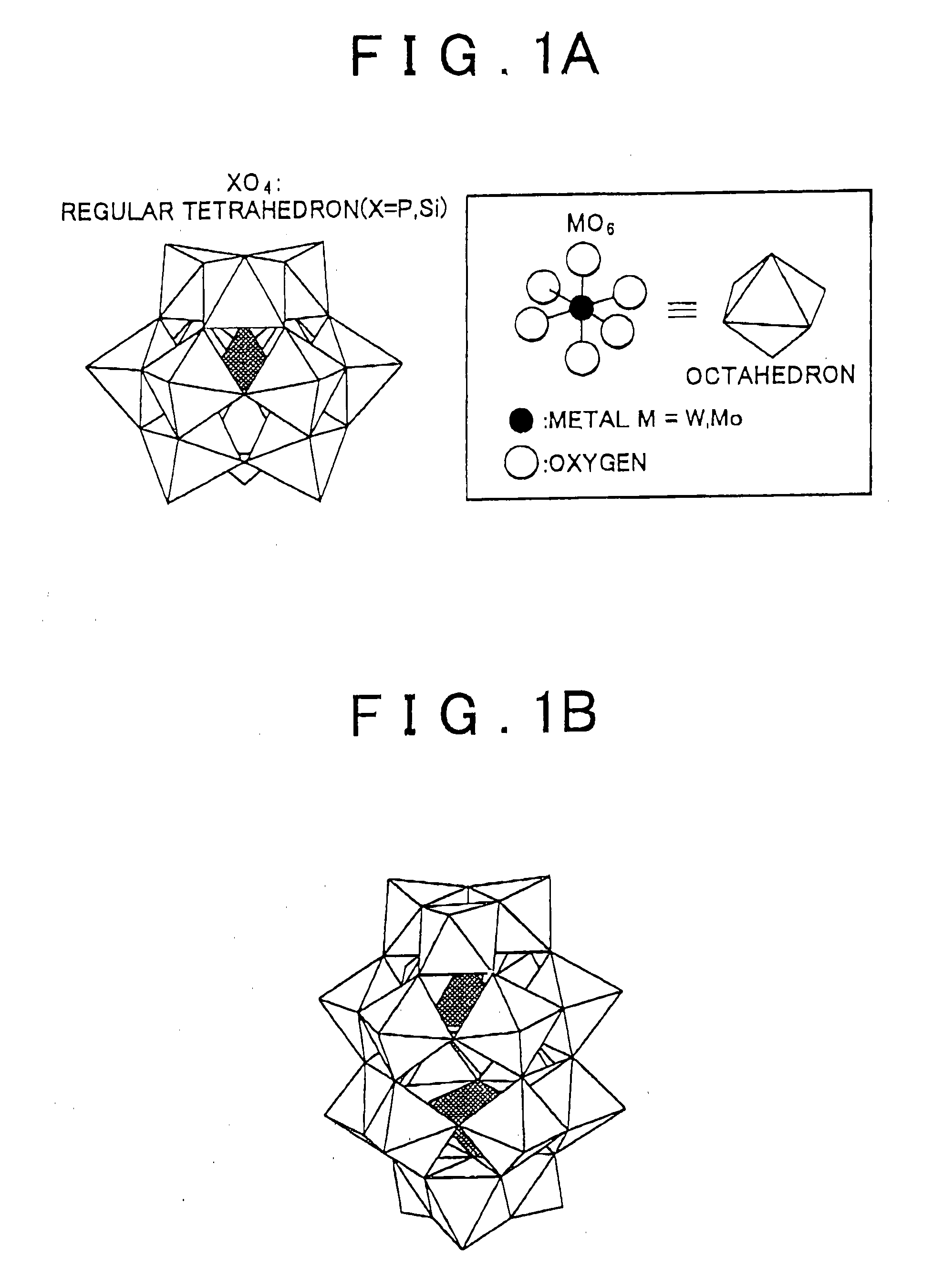

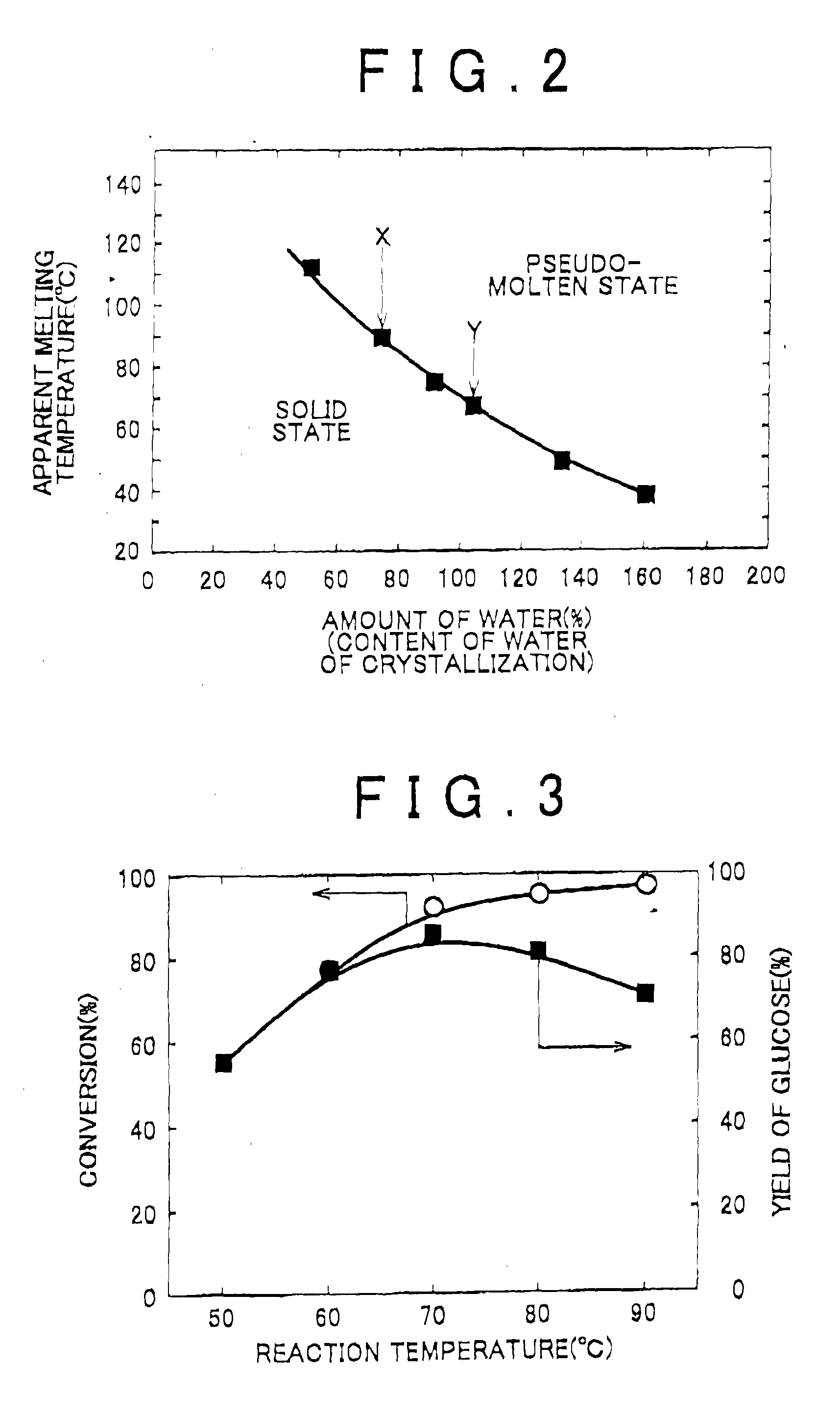

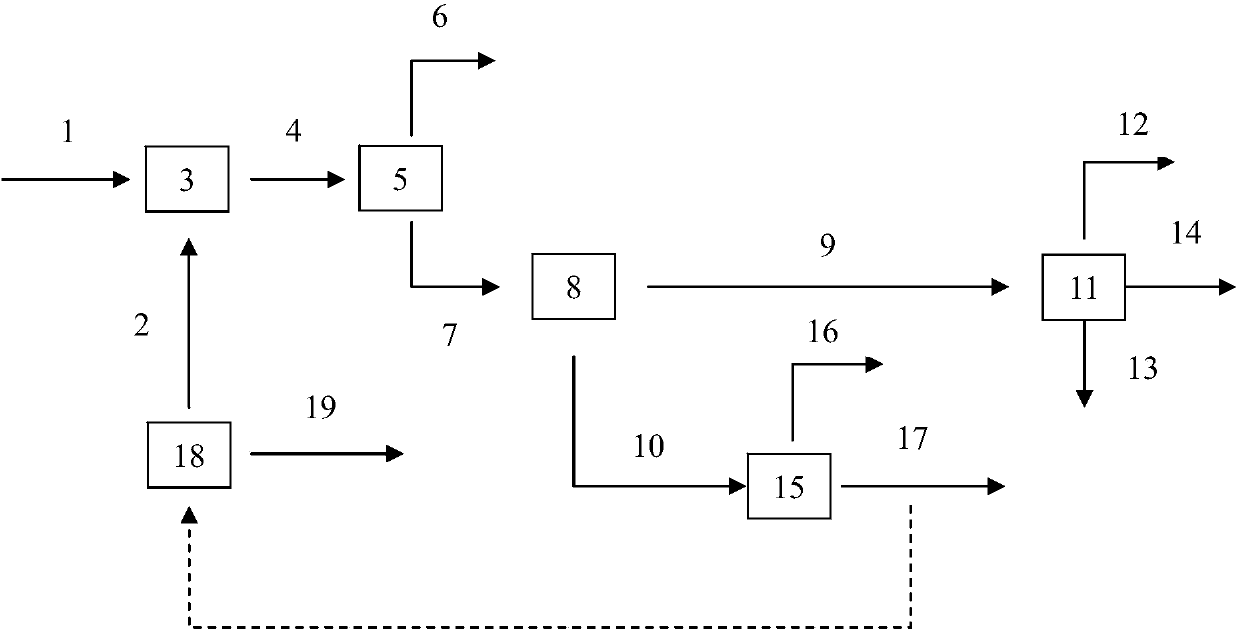

ActiveUS20100126501A1Easy to separateImprove energy efficiencyBiofuelsGlucose productionPlant fibreOrganosolv

Cellulose contained in plant fiber material is hydrolyzed with the use of a pseudo-molten cluster acid as a hydrolysis catalyst to produce saccharide, most of which is glucose. After the glucose is produced, the saccharide is precipitated with the use of an organic solvent, and the saccharide including a solidified saccharide during the hydrolysis and the precipitated saccharide is separated from residues and the cluster acid.

Owner:TOYOTA JIDOSHA KK

Preparation method of tert-butyl peroxide

InactiveCN104557652AStrong acidPore structure highOrganic compound preparationPeroxy compound preparationPtru catalystDi-tert-butyl peroxide

The invention provides a method for preparing tert-butyl peroxide by using a heterogeneous catalyst. The method comprises the following steps: by using tert-butyl alcohol and oxydol as raw materials and an acidic ion exchange resin as a catalyst, reacting under reflux, cooling, standing, and separating to obtain an oil phase and a water phase; and washing the oil phase with alkali and water to obtain a di-tert-butyl peroxide solution (DTBP), wherein the oil phase water washing solution and water phase are the tert-butyl hydroperoxide water solution (TBHP). Since the ion exchange resin has the advantages of large pore structure, high acidity and high catalysis efficiency and the large pore structure can not be destroyed in reaction, the catalyst can be easily separated from the reaction product and can be recycled repeatedly, thereby having higher economic value. Besides, no sulfuric acid or any other strong acid is used in the production process, so the method has the advantages of low corrosion to equipment and no environment pollution, and has higher environmental benefit.

Owner:NORTHWEST NORMAL UNIVERSITY

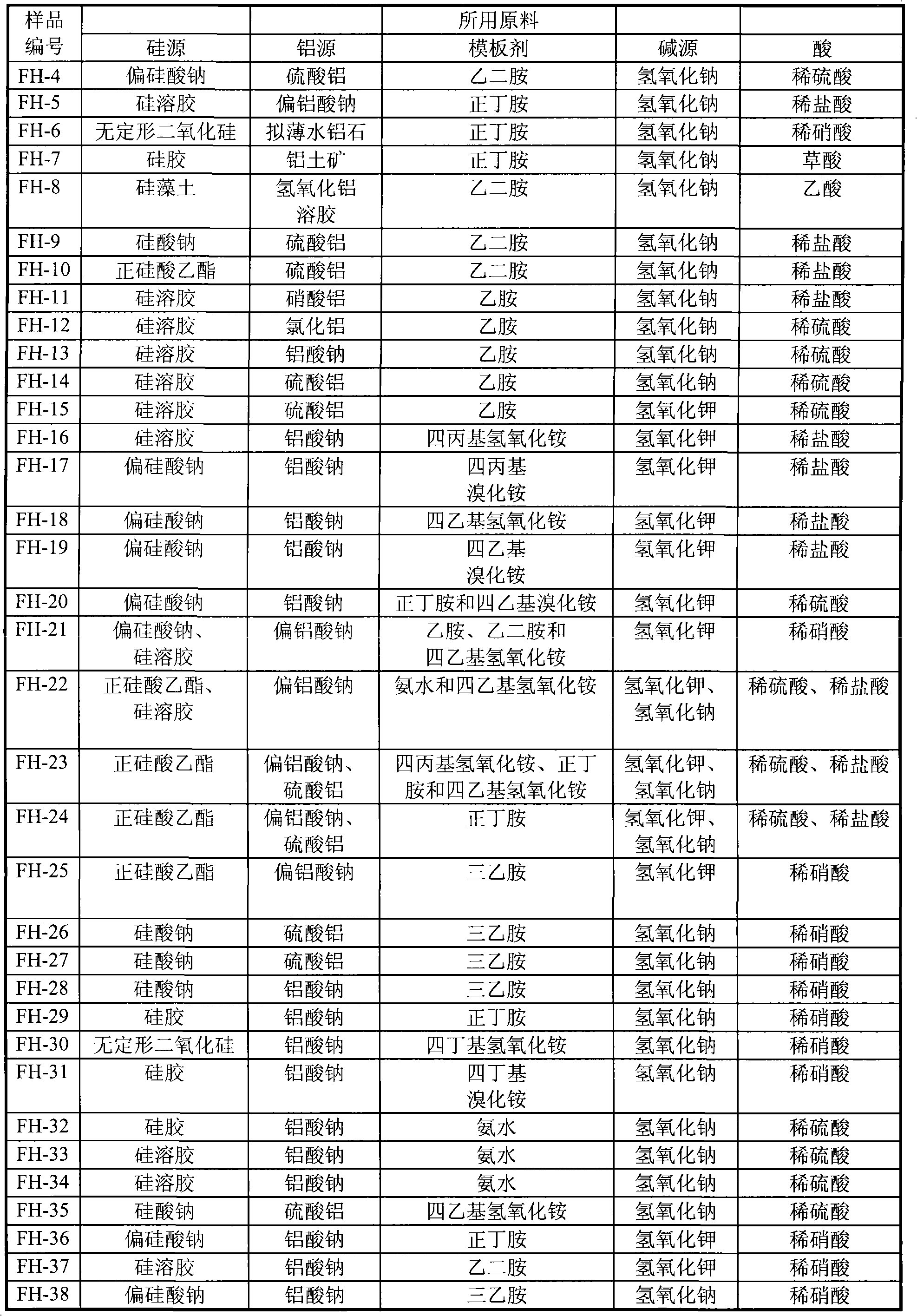

Fast synthesis process of strong acid-type ZSM-5 molecular sieve

InactiveCN1417121AShort synthesis timeStrong acidMolecular sieve catalystsPentasil aluminosilicate zeoliteStrong acidsSilicon

The fast synthesis process of strong acid-type ZSM-5 molecular sieve includes compounding solution A with silicon source, template agent and one half of deionized water in certain proportion; compounding solution B with aluminum source, inorganic acid and the other half of deionized water in certain proportion; adding dropwise solution B to solution A to prepare guiding agent; compounding solution C with silicon source, template agent and one half of deionized water in certain proportio; compounding solutio D with aluminium source, inorganic acid and the other half of deionized water in certain proportion; adding dropwise solution D to solution C and adding guiding agent in the amount of 5-10 vol% of total amount. The process has advantages of short synthesis period and storing acidity.

Owner:SYNFUELS CHINA TECH CO LTD

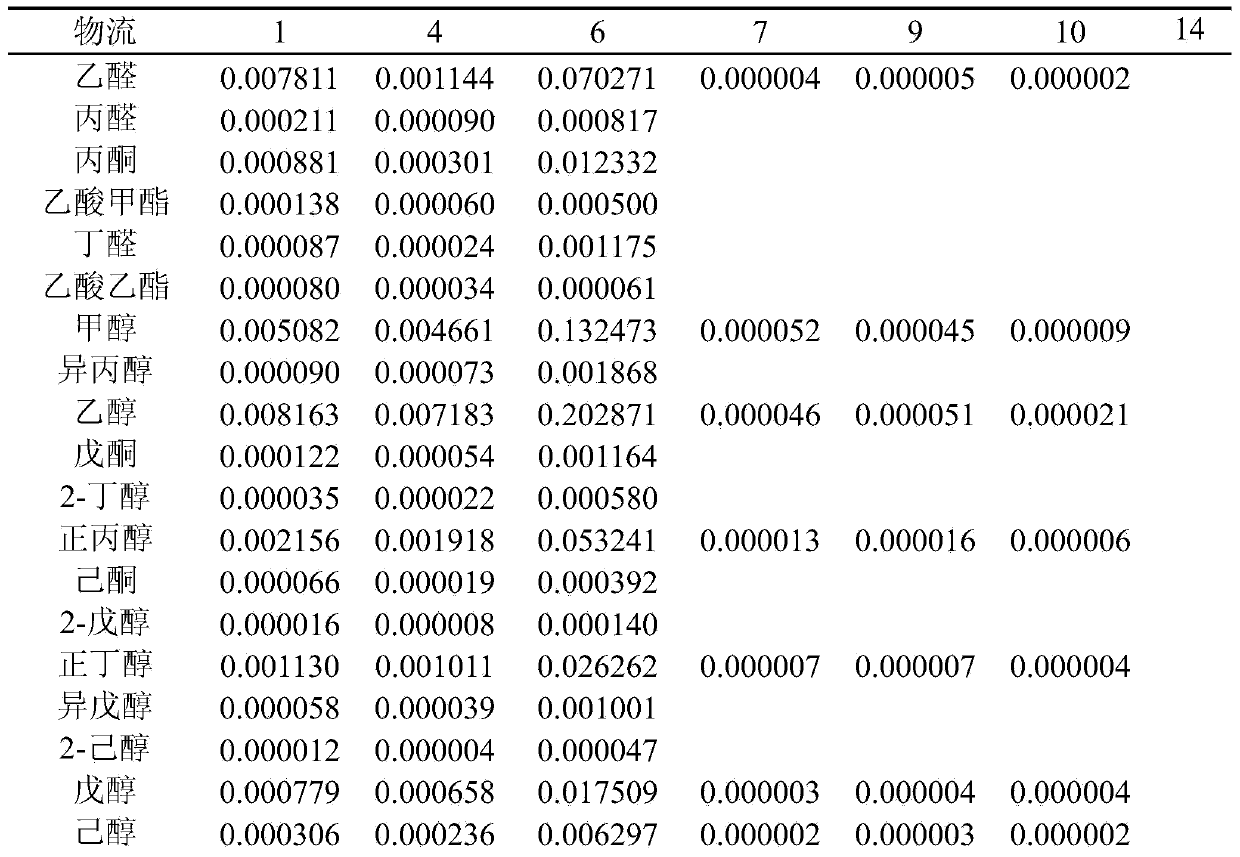

Purification recovery method of Fischer-Tropsch synthesis water

ActiveCN103435211AStrong acidReduce acidityDispersed particle separationWater/sewage treatment by ion-exchangeRecovery methodCarboxylic salt

The invention discloses a purification recovery method of Fischer-Tropsch synthesis water, which comprises the following steps: (1) adding inorganic alkali into Fischer-Tropsch synthesis water to carry out acid-alkali neutralization reaction, thereby obtaining Fischer-Tropsch synthesis water containing oxygenated organic substance and carboxylate; (2) delivering the Fischer-Tropsch synthesis water containing oxygenated organic substance and carboxylate into a rectification tower to carry out rectification, and separating to obtain non-acid oxygenated organic substance and Fischer-Tropsch synthesis water containing carboxylate; (3) removing carboxylate in the Fischer-Tropsch synthesis water containing carboxylate to obtain desalted Fischer-Tropsch synthesis water; and (4) carrying out oxygenolysis on the oxygenated organic substance in the desalted Fischer-Tropsch synthesis water to obtain the recoverable Fischer-Tropsch synthesis water. The method can maximally recover the oxygenated organic substance, such as non-acid oxygenated organic substance, in the Fischer-Tropsch synthesis water on the premise of achieving the goal of purifying and recovering Fischer-Tropsch synthesis water; and the purification can be performed according to the fine chemical engineering purity requirement.

Owner:SYNFUELS CHINA TECH CO LTD

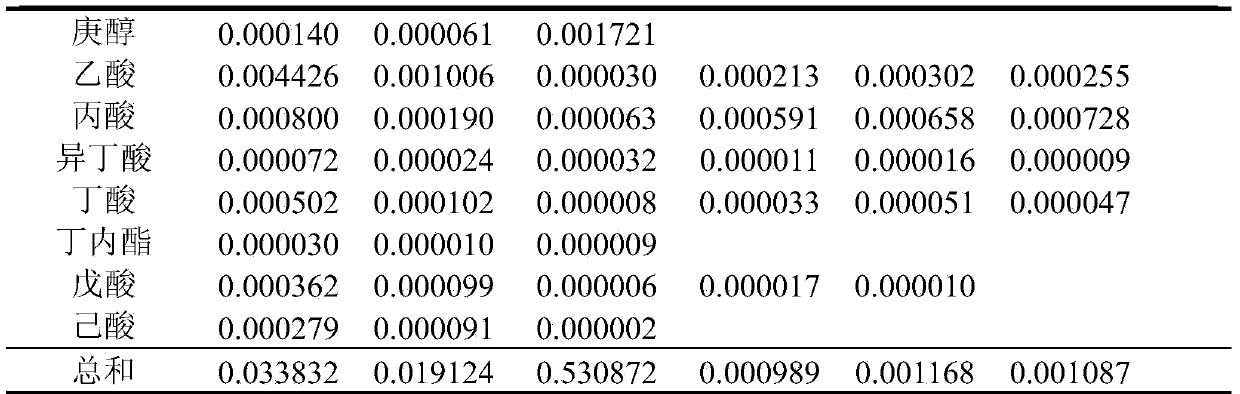

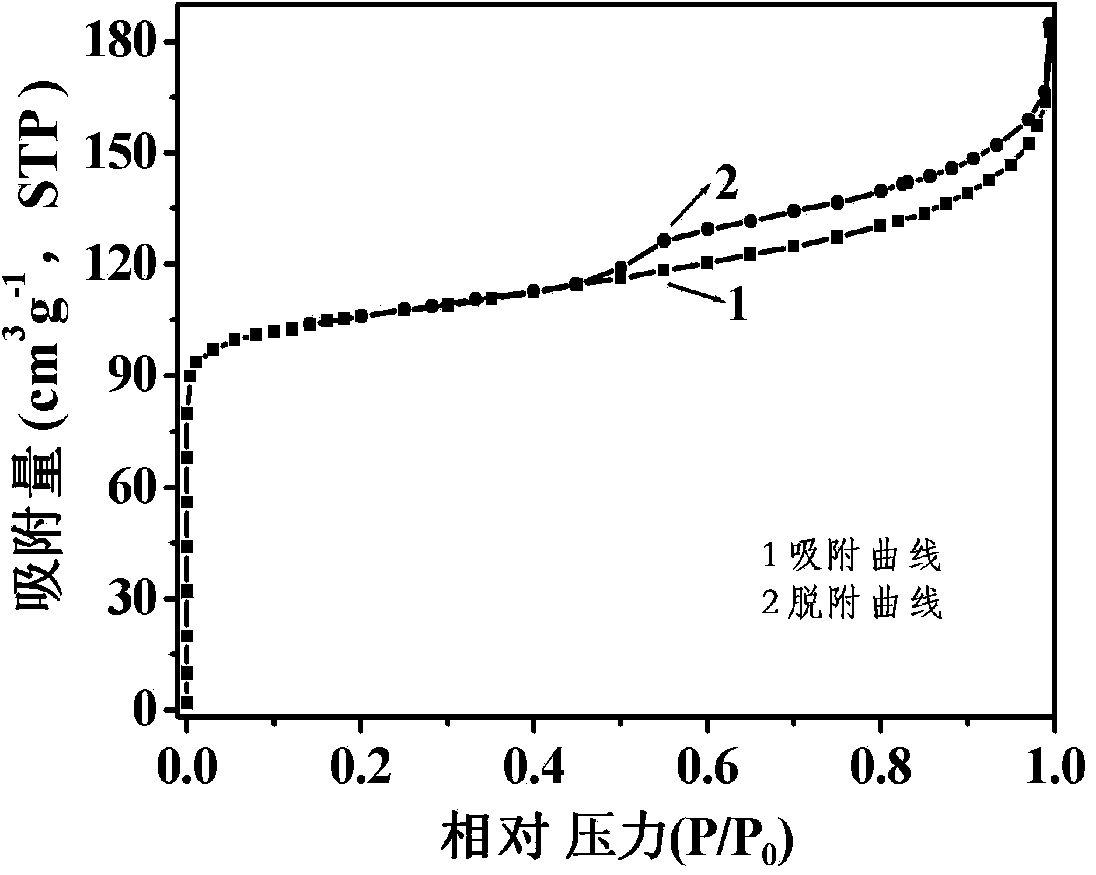

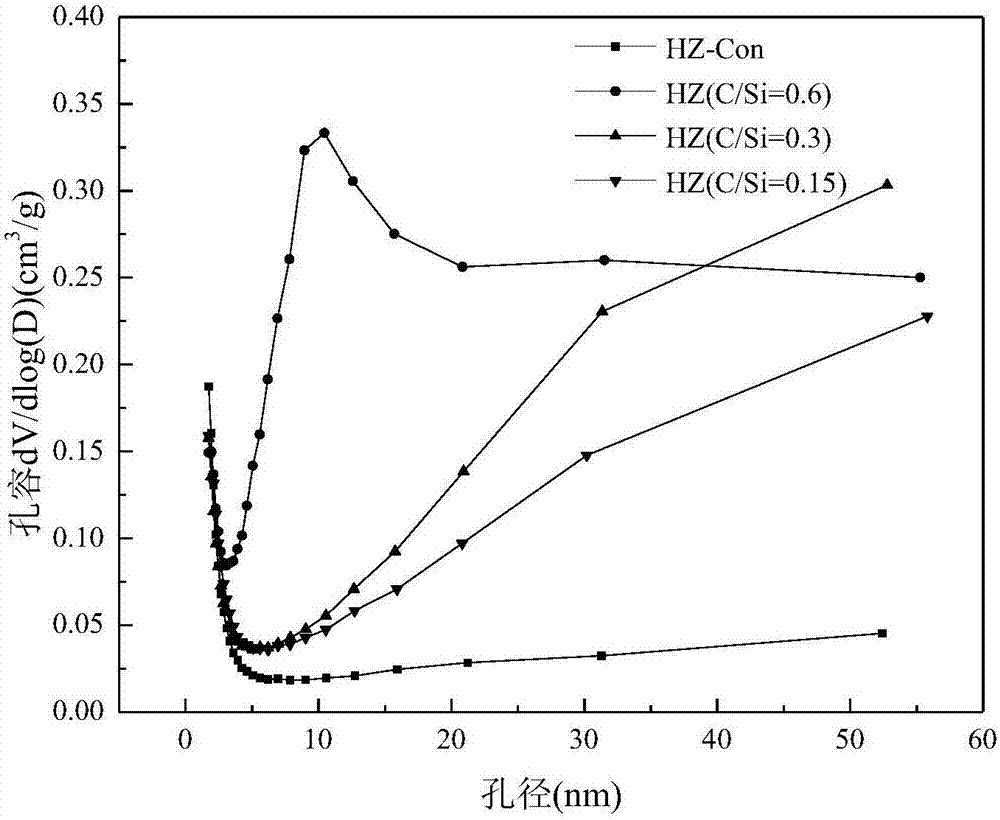

Middle-pore silicon-aluminium material and its preparing method

ActiveCN1709566AStrong acidFacilitated DiffusionPhysical/chemical process catalystsPore diameterColloid

This is a kind of middle porous silicon aluminum material. Its 27Al MAS NMR spectrogram basically has no apex at the chemical displacement 0ppm position, but has the only apex at the 51.7 mm position; the aluminum content in the silicon aluminum material counted with the weight of Al2O3 is 1.0 - 30%; its specific surface area is 100 - 350 m2 / g; its hole content is 0.4 - 0.8 mL / g; its average aperture is 14 - 30 nm; and its most probable aperture is 10 - 30 nm. The material is made as follows: neutralize silicon source and acid solution into colloid when mixed, add aluminum source after laid to aging, after equably mixed, aging, dry, ammonium exchange, again dry. The center holes of the material distributes concentratively and their apertures are rather big; it has bigger specific surface area and hole volume; the Al atoms in the material almost all exist as four coordination style, after ammonium exchange, it can be used as the carrier of cracking catalyst or directly used as catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

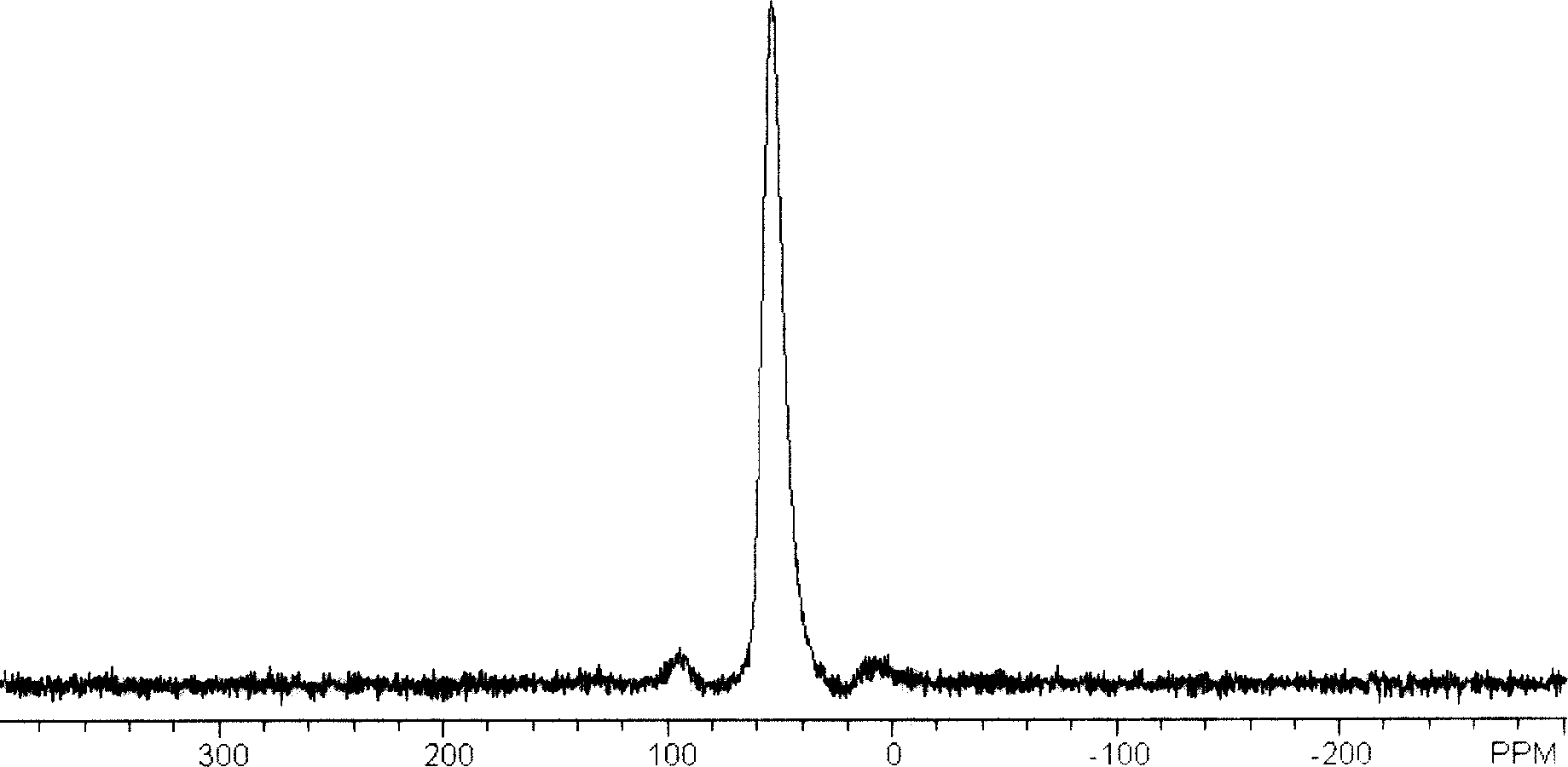

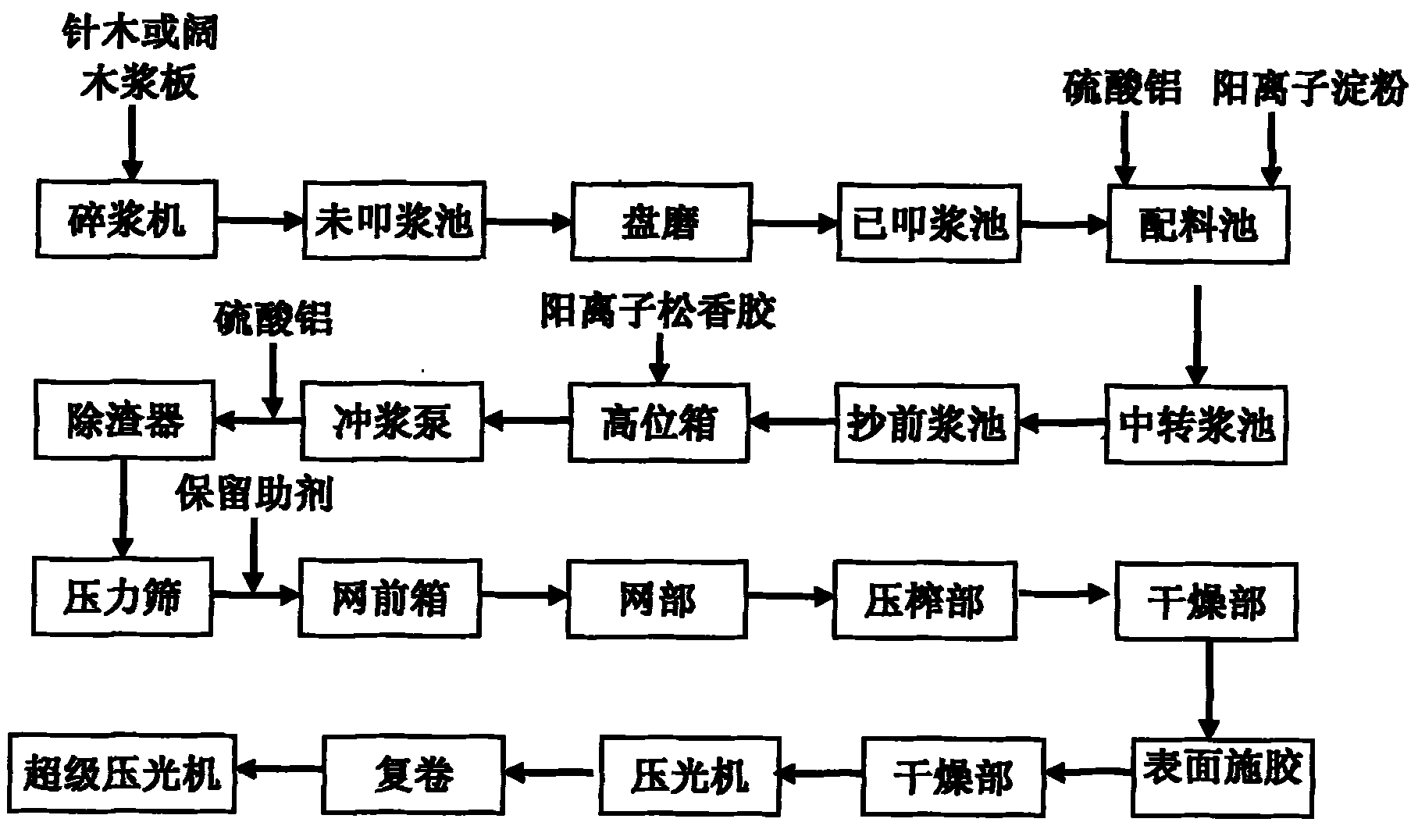

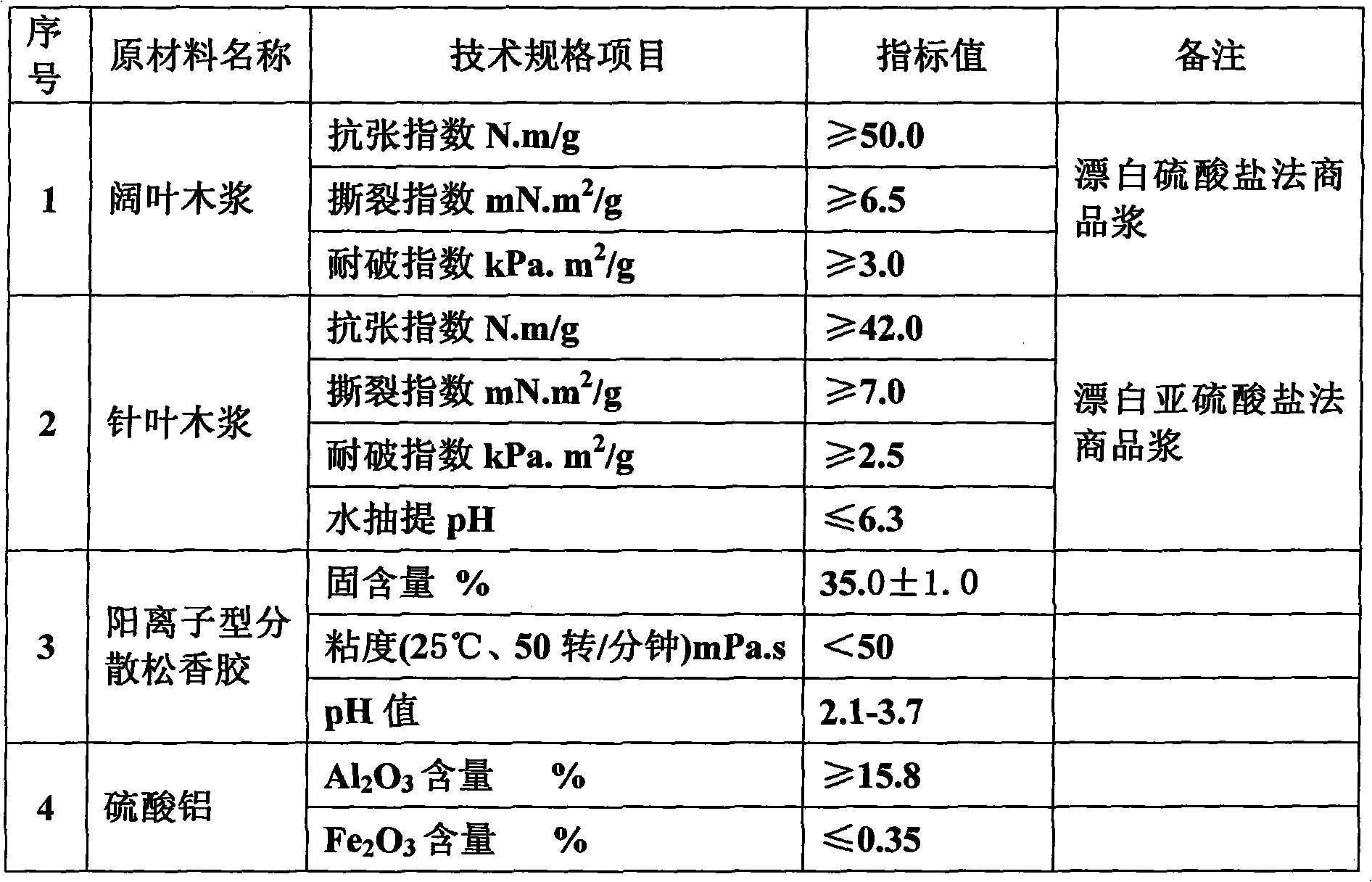

Method for producing computer-to-plate lining paper

ActiveCN101787662ASolve acidityStrong acidNatural cellulose pulp/paperWater-repelling agents additionAluminium sulfateComputer to plate

The invention provides a method for producing computer-to-plate (CTP) lining paper, which is characterized in that: the lining paper is produced by using a common multi-cylinder long mesh paper machine, and the production process comprises the following steps: pulp beating, pulp proportioning, paper manufacturing with pulps, surface sizing, press polish and rewinding to produce base paper, then carrying out subsequent press polish treatment on the base paper to produce finished paper; the CTP lining paper is produced from paper pulps which are made of hardwood pulps and softwood pulps, chemical additive cationic starch, cationic dispersed rosin size and auxiliary sizing agent aluminum sulfate serving as raw materials. In the method, the cationic dispersed rosin size is used and the auxiliary sizing agent aluminum sulfate is added for two times on a proportioning pool and at an outlet of a fan pump, so that the problem of producing the CTP lining paper by using cationic dispersed rosin acid sizing technology is successfully solved. The pH value of the water extract of the produced base paper is kept within a range of 5.2 to 5.8, so that the key indicator of the paper, namely, the pH value of the water extract of the paper, meets the quality requirement on the CTP lining paper.

Owner:ZHENJIANG DADONG PULP & PAPER

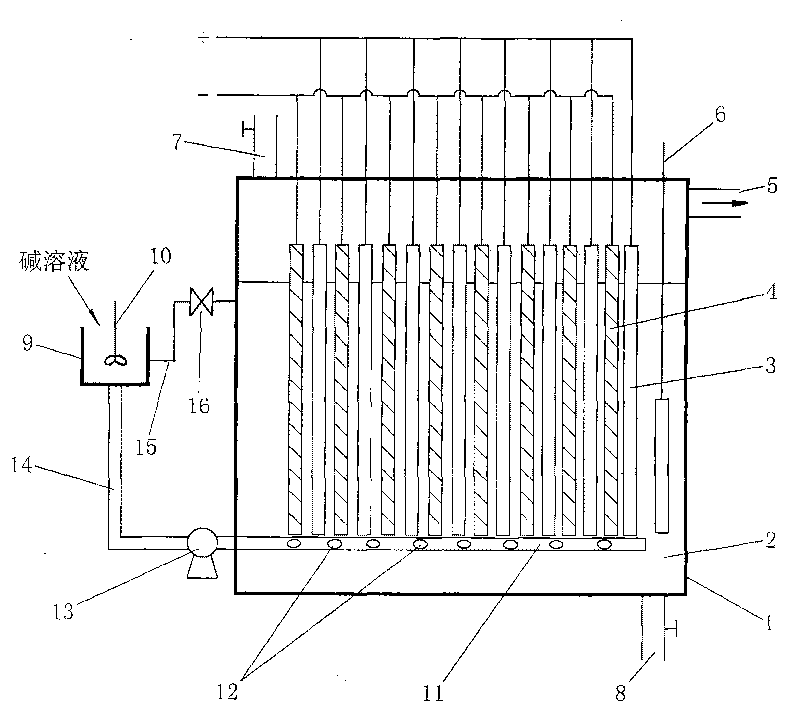

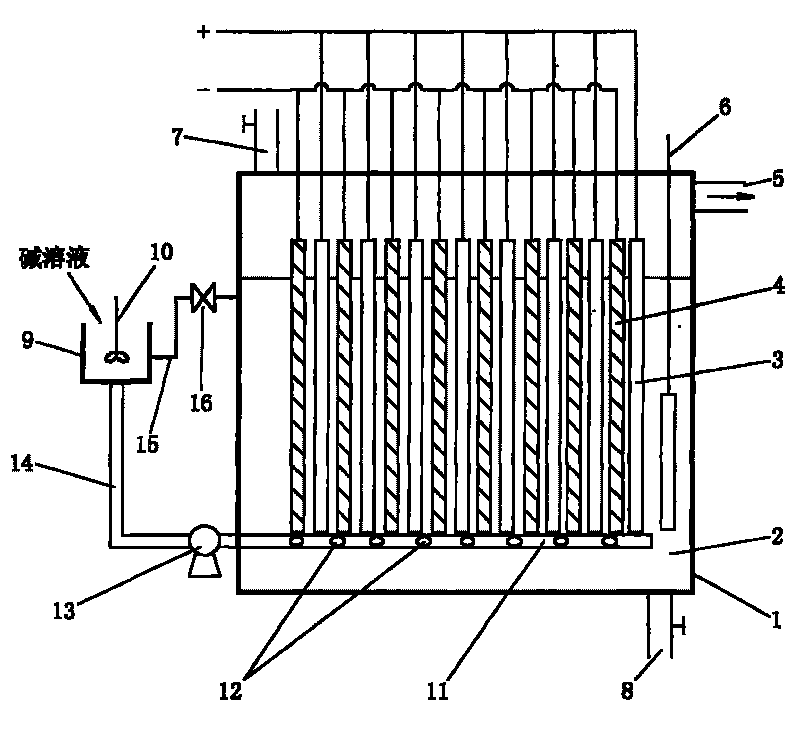

Method for treating nickel-containing electroplating wastewater and recovering nickel by electrolysis

InactiveCN101717135AReduce the side reaction of hydrogen electrolysis on the cathode plateStrong acidWater contaminantsWaste water treatment from metallurgical processGraphite electrodeTitanium

The invention discloses a method for treating nickel-containing electroplating wastewater and recovering nickel by electrolysis. The method has the characteristics of simple process, no secondary pollution, high removal rate and recyclable deposited metallic nickel. The nickel-containing electroplating wastewater is subjected to electrolysis treatment by an electrolysis treatment nickel-containing electroplating wastewater device, which comprises an electrolytic bath and an electrolyte stirring apparatus, wherein the anode adopts a titanium-based platinum electrode; the cathode adopts a nickel electrode or a graphite electrode; and a pH meter is arranged in the electrolytic bath. The method for treating the nickel-containing electroplating wastewater by electrolysis comprises the following steps: before the electrolysis treatment, putting the nickel-containing electroplating wastewater serving as an electrolyte into the electrolytic bath, and adding alkali solution into the electrolyte to adjust the pH value of the electroplating wastewater; and adding the aqueous alkali into the electrolyte during the electroplating to adjust the pH value of the electrolyte to between 6.0 to 9.0, and recycling the nickel precipitated from a negative plate by measuring the charge accumulation amount of the electrolyte.

Owner:ZHEJIANG NORMAL UNIVERSITY

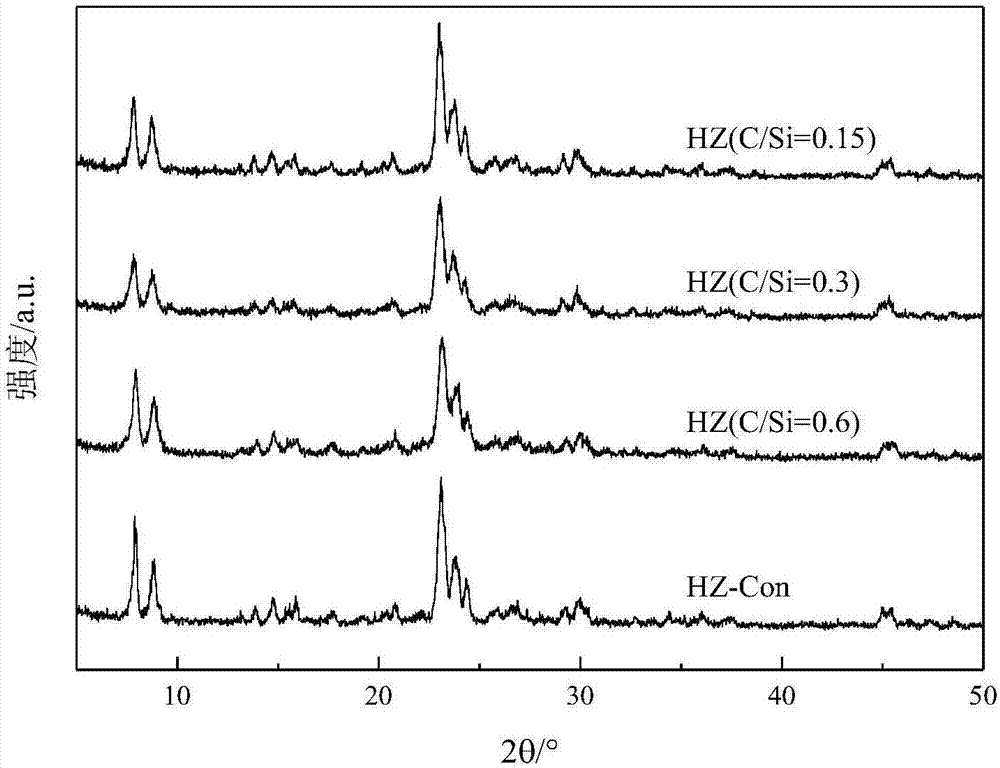

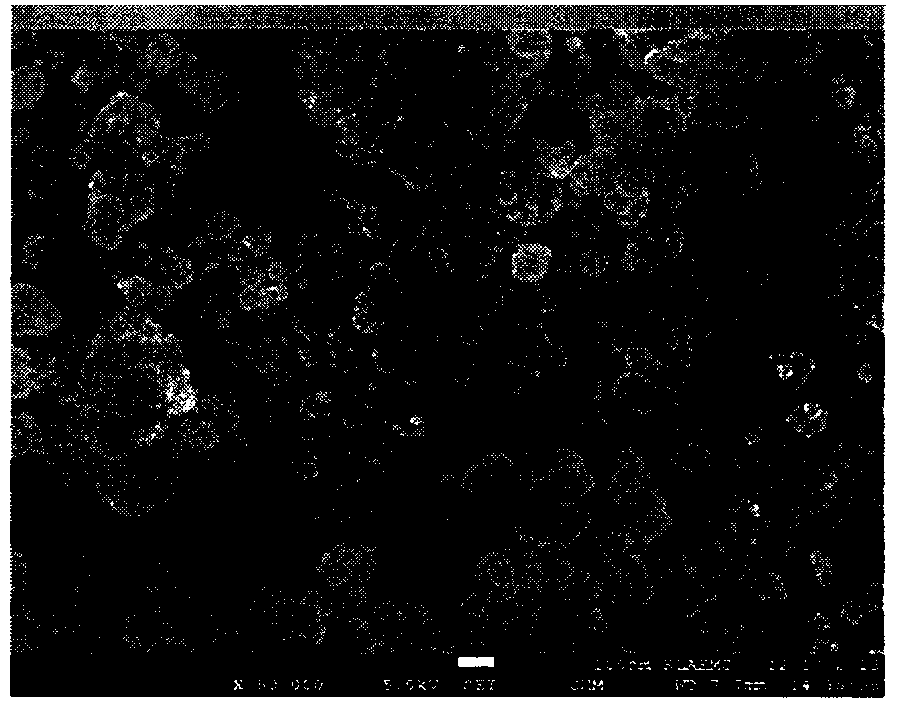

Synthetic method for hierarchical-pore ZSM-5 molecular sieve

ActiveCN105712379AHigh yieldReduce dosageMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveCrystallinity

The invention relates to a synthetic method for a hierarchical-pore ZSM-5 molecular sieve. The method synthesizes the hierarchical-pore ZSM-5 molecular sieve with a high crystallization degree, strong acidity and good hydro-thermal stability from a small amount of a microporous template and a polymer of quaternary ammonium salt without usage of a hard template.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

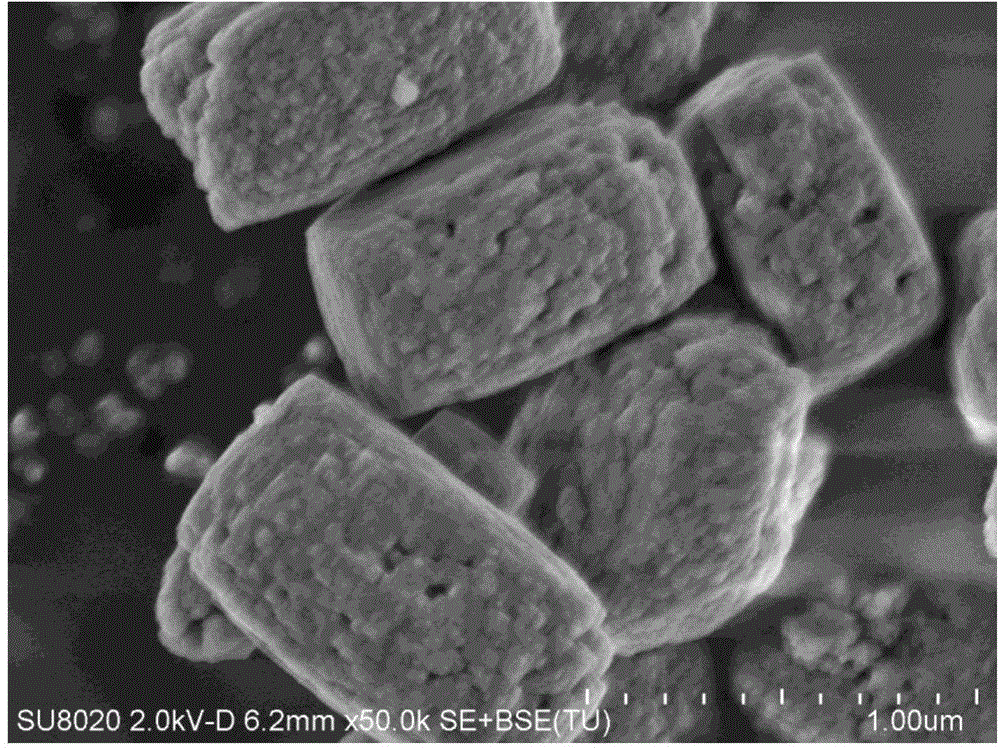

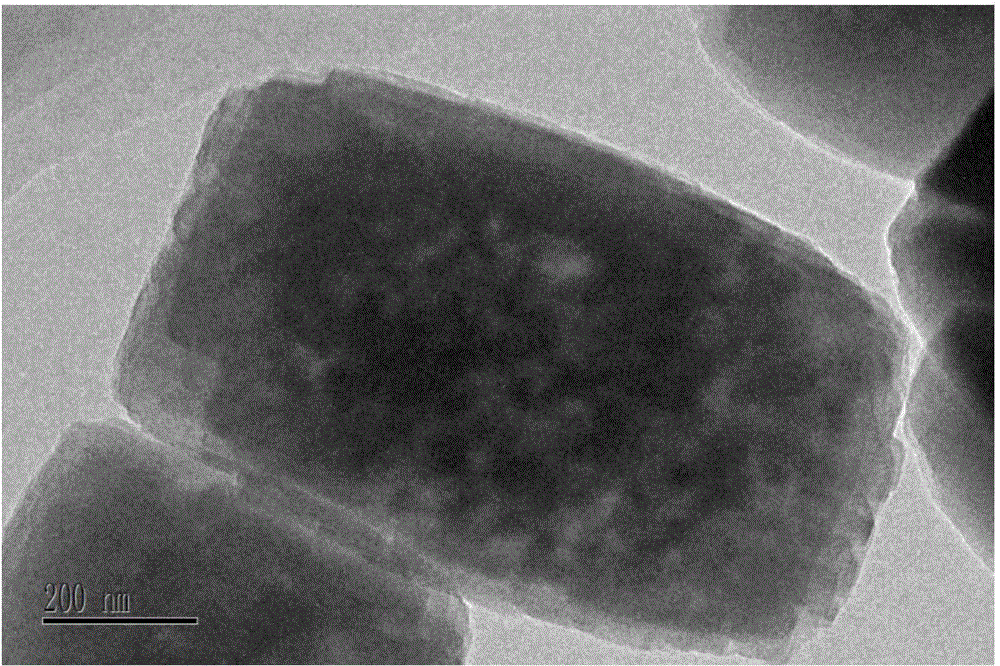

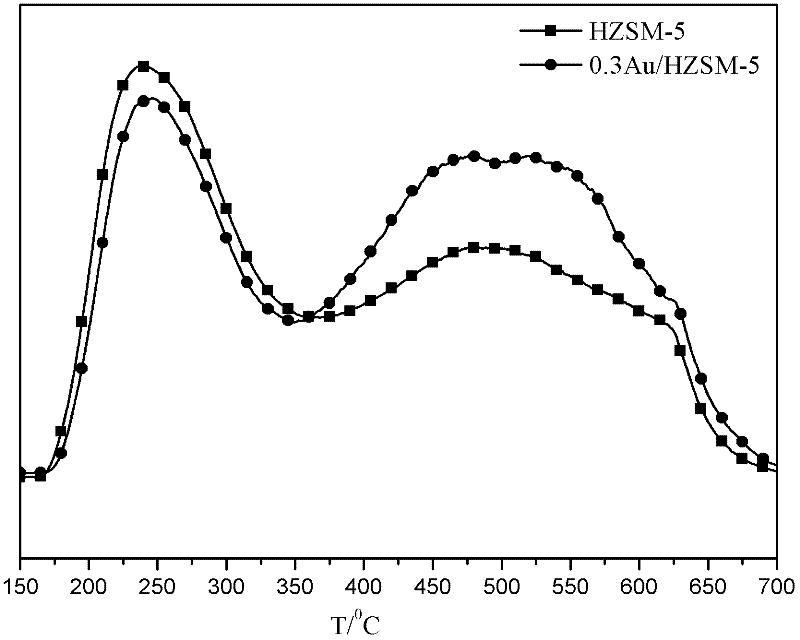

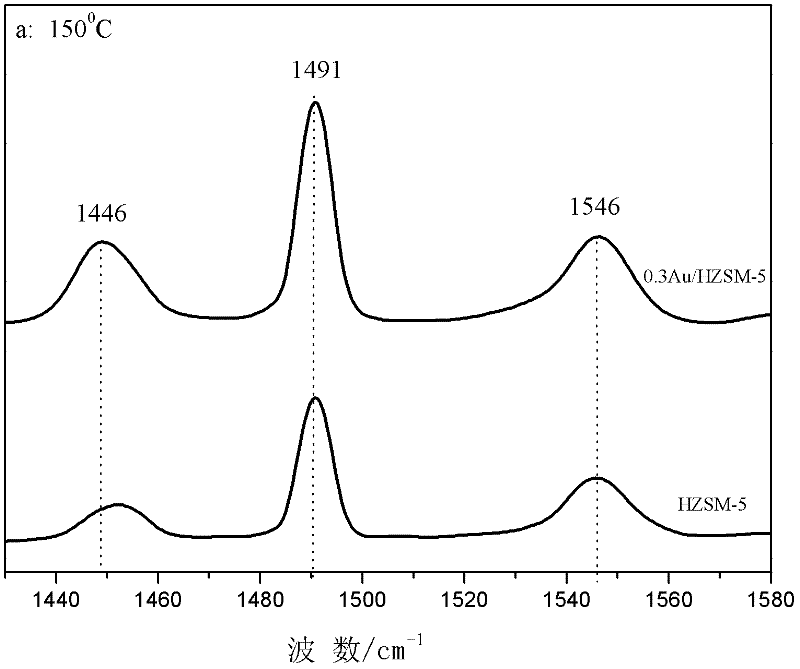

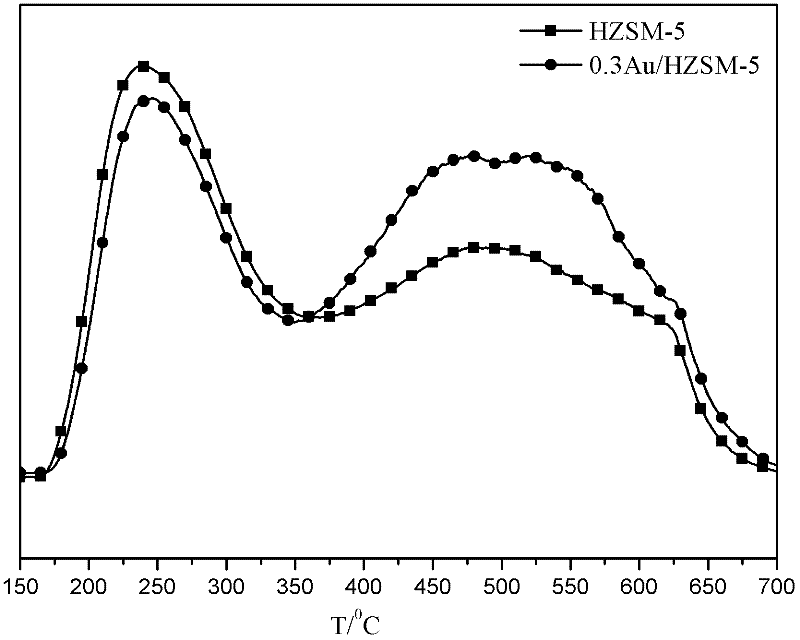

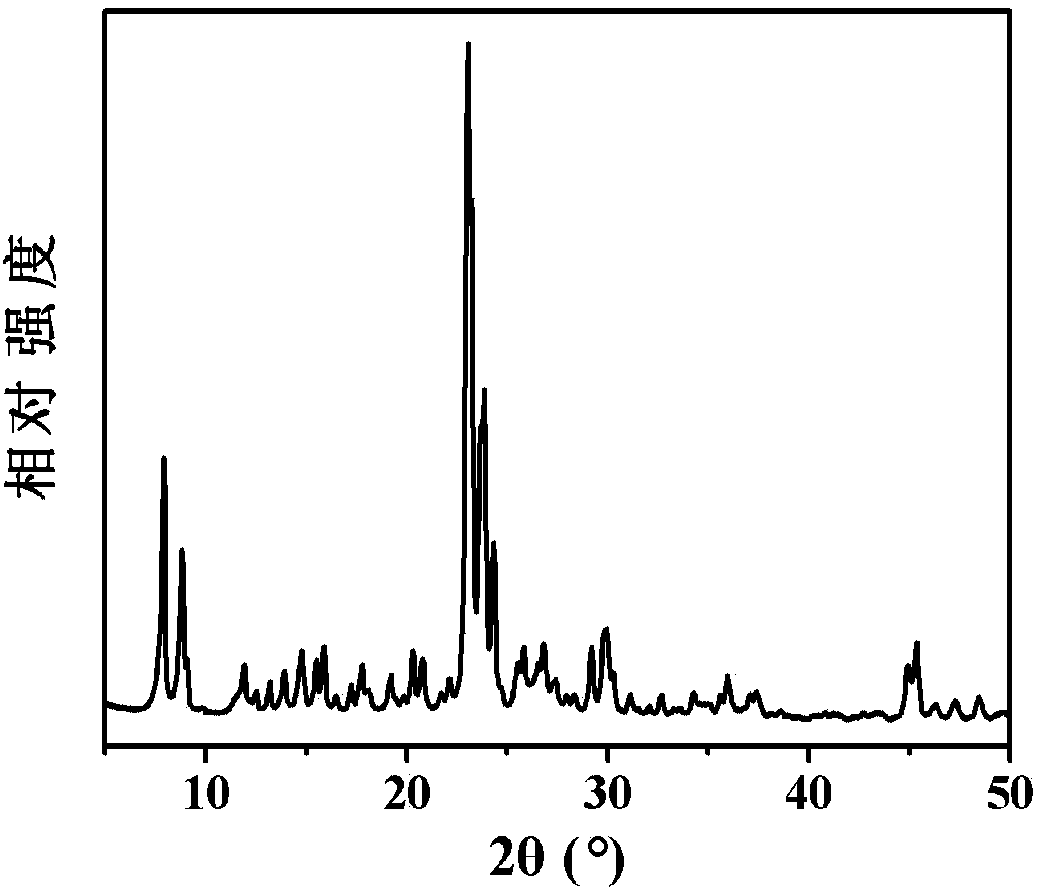

Method for converting n-alkane into isoalkane by gold-loaded molecular sieve catalyst

InactiveCN102416341AEasy to prepareIncrease acidityHydrocarbon by isomerisationMolecular sieve catalystsAlkaneIsomerization

A method for converting n-alkane into isoalkane by a gold-loaded molecular sieve catalyst belongs to the technical field of catalysts. After a molecular sieve is treated by completely negative pressure degasification and purification, a gold precursor is loaded on the molecular sieve carrier by a negative pressure deposition precipitation method so as to form a Si-O(H)-Au structure. The molecular sieve is a high-silica zeolite molecular sieve; the preparation of gold-loaded catalyst under a negative pressure condition by the deposition precipitation method facilitates the purification of the internal and external surfaces and pore channels of the molecular sieve; and Au is easy to enter the pore channels of the molecular sieve to reach high dispersion, and can be combined with silicon hydroxyls on the internal and external surfaces to form the Si-O(H)-Au structure. The method can dehydrogenize n-alkanes to generate alkenes under the difunctional action of metal and the carrier; the alkenes obtain protons at the acid sites to form carbonium ions; and isoalkanes are generated by skeletal isomerization and hydrogenation desorption of the carbonium ions.

Owner:DALIAN UNIV OF TECH

Preparation method of house-of-cards-like hierarchical porous ZSM-5 molecular sieve

ActiveCN104261427AIncrease the outer surface areaStrong acidMaterial nanotechnologyPentasil aluminosilicate zeoliteIonHierarchical porous

The invention belongs to the technical field of synthesis of inorganic porous materials and particularly relates to a preparation method of a house-of-cards-like hierarchical porous ZSM-5 molecular sieve which is low in cost, environment-friendly and fast. The preparation method comprises the following steps: adding an inorganic alkali source and an aluminum source into deionized water, and adding a proper amount of N-methyl-2-pyrrolidone (NMP); then, slowly adding a silicon source; fully and uniformly stirring; and synthesizing a house-of-cards-like hierarchical porous HCL-ZSM-5 molecular sieve by a one-step hydrothermal method. The molecular sieve has remarkable hierarchical porous structural characteristics, is large in external surface area, strong in acidity and good in stability, and has wide application prospects in the fields of catalysis, adsorption, separation and the like. In an alkaline ZSM-5 synthetic system without an organic template, by using non-toxic and cheap NMP as a structural guiding agent which is used for replacing an expensive macromolecular organic template, the method is an economic, efficient and environment-friendly synthetic method which is expected to be applied to large-scale commercial production.

Owner:JILIN UNIV

Heavy oil hydrogenation demetalization catalyst as well as preparation method and application of heavy oil hydrogenation demetalization catalyst

ActiveCN103861606AReduce depositionReduce the chance of cloggingMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemistryFuel oil

The invention provides a heavy oil hydrogenation demetalization catalyst as well as a preparation method and application of the heavy oil hydrogenation demetalization catalyst. The preparation method comprises the following steps: adding a physical pore-enlarging agent into a metal salt solution containing Mo or W so as to obtain a wet powder pore-enlarging agent; mixing aluminum oxide dry glue powder with the wet powder pore-enlarging agent so as to obtain an aluminum oxide dry glue powder material 1; adding the chemical pore-enlarging agent and a phosphorous compound containing solution to the aluminum oxide dry glue powder so as to obtain an aluminum oxide dry glue powder material 2; mixing the aluminum oxide dry glue powder material 1 with the aluminum oxide dry glue powder material 2 so as to obtain wet materials; drying the wet materials, and roasting so as to obtain an aluminum oxide carrier; and dipping the aluminum oxide carrier into a metal salt solution containing one of Mo and W and / or one of Co and Ni, drying, and roasting, thereby obtaining the heavy oil hydrogenation demetalization catalyst. The invention also provides the heavy oil hydrogenation demetalization catalyst. The catalyst provided by the invention not only has favorable hydrogenation demetalization activity, but also has favorable metal and carbon deposit accommodating performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

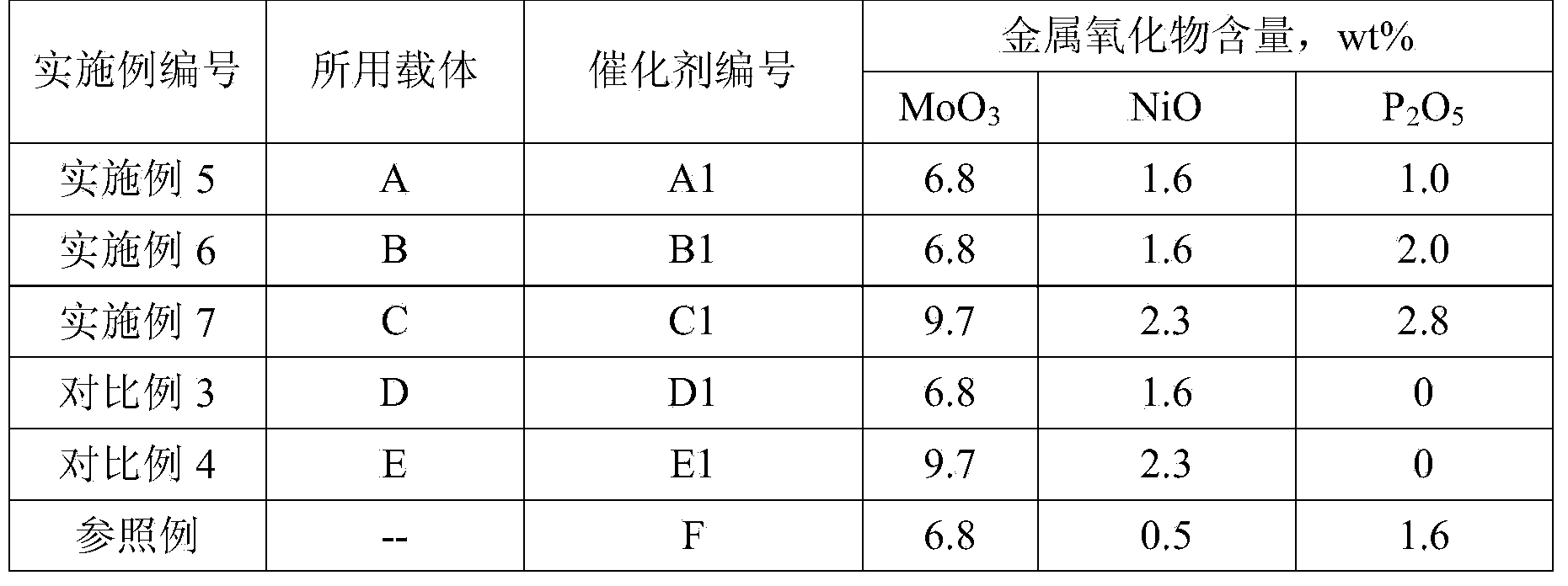

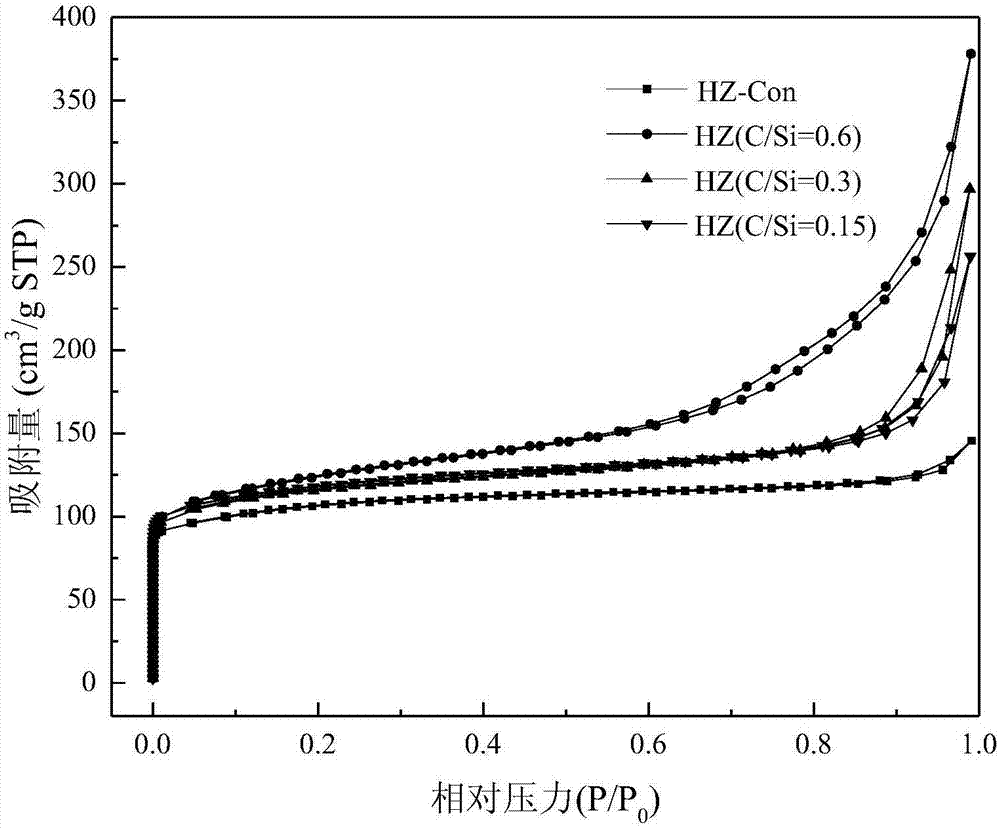

Preparation method and application of hierarchical-pore HZSM-5 molecular sieve

InactiveCN107188195AUnique pore structureEnhanced mass transferMolecular sieve catalystsHydrocarbon from oxygen organic compoundsCatalytic pyrolysisSucrose

The invention relates to a preparation method and application of a hierarchical-pore HZSM-5 molecular sieve. The preparation method includes following steps: 1), dissolving an aluminum source in water, adding a tetrapropyl ammonium hydroxide solution, adding a silicon source, and mixing to obtain a molecular sieve precursor; 2), pre-crystallizing the molecular sieve precursor; 3), adding sucrose into the molecular sieve precursor after being pre-crystallized, and mixing for hydrothermal crystallizing reaction; 4), after crystallizing reaction is completed, separating, washing, drying and roasting to obtain a hierarchical-pore ZSM-5 molecular sieve; 5), subjecting the hierarchical-pore ZSM-5 molecular sieve and an ammonium salt solution to ion exchange, separating, washing, drying and roasting to obtain the hierarchical-pore HZSM-5 molecular sieve. The hierarchical-pore HZSM-5 molecular sieve prepared by the method can improve aromatization ability and anti-coking ability of the same in the process of biomass catalytic pyrolysis.

Owner:ZHEJIANG UNIV

Mesoporous-microporous composite material and synthesis method thereof

InactiveCN101012061AStrong acidReduced Diffusion ResistanceMolecular sieve catalystsOther chemical processesMolecular sieveSodium metasilicate

The invention discloses a dielectric hole-microhole composite material and synthesizing method in the inorganic porous material, adsorbing material and catalytic material technical domain, which comprises the following steps: adopting zeolite molecular sieve as raw material; reacting with sodium bisilicate solution under 30-60 deg.c for 10-300 min; disintegrating particle part of zeolite molecular sieve into piece with microhole structure; adding cetyl trimethyl ammonium bromide as molder; adjusting pH value of mother liquid to 10-12; aging 1-8h; adding in the high-pressure autoclave to do water heat synthesizing reaction at 80-130 deg.c for 24-72h; separating solid; washing; drying; sintering under 500-600 deg.c for 5-10h; obtaining the Si-Al porous material with dielectric hole and microhole composite structure.

Owner:DALIAN UNIV OF TECH

Catalyst for preparing 1,2-glycol by epoxy compound through hydration as well as preparation method and application thereof

InactiveCN103920527AStrong acidEasy to makeMolecular sieve catalystsPreparation by hydrolysisMolecular sieveHydration reaction

The invention relates to a catalyst for preparing a 1,2-glycol by epoxy compound through hydration as well as a preparation method and an application thereof. A beta zeolite molecular sieve is used as a raw material and then is subjected to acid treatment, and active centered metal is introduced through roasting; and the preparation method comprises the steps of mixing the beta zeolite molecular sieve after acid treatment with an organometallic compound precursor according to the proportion, and roasting. The method can solve the problems of high water ratio, high energy consumption and environment pollution caused by a production process in the traditional process; and the catalyst carrier is cheap and easily available, the preparation process of the catalyst is simple and has good stability, and the catalyst has excellent catalytic activity and the good selectivity in the glycol preparation process by the epoxy compound under a mild condition, and can be applied to glycol industrial production through epoxy compound hydration.

Owner:NANKAI UNIV

Method for producing biochemical humic acid through microbial fermentation of furfural residue

ActiveCN102517338AHigh in humic acidStrong acidMicroorganism based processesFermentationFurfuralFermentation

The invention relates to a method used for producing biochemical humic acid, and especially relates to a method used for producing biochemical humic acid through microbial fermentation of furfural residue. The method is characterized in that the method comprises the steps that: a, tower bottom wastewater in furfural production is added into furfural residue, such that water content in furfural residue is regulated; b, carbon nitrogen ratio of the furfural residue is regulated by using urea and wheat bran; bacterium powder is uniformly blended into the furfural residue, and a mass ratio of the furfural residue and the bacterium powder is controlled; the mixture is stacked into a fermentation tank, and is fermented; an alkaline solution is added to the fermented furfural residue, and the mixture is stood under normal temperature; three-stage sedimentation is carried out, such that a clarified supernatant is obtained; hydrochloric acid is added to the supernatant, such that the pH value is regulated; when humic acid is precipitated, the supernatant is filtered, and the precipitate is washed by using distilled water; the precipitate is dried in a spray drier, such that humic acid is obtained. The method provided by the invention is unique. With the method, environment pollution is reduced. According to the invention, humic acid content in furfural residue is improved through microbial fermentation, and biochemical humic acid is prepared from fermented furfural residue.

Owner:林口森豪糠醛有限责任公司

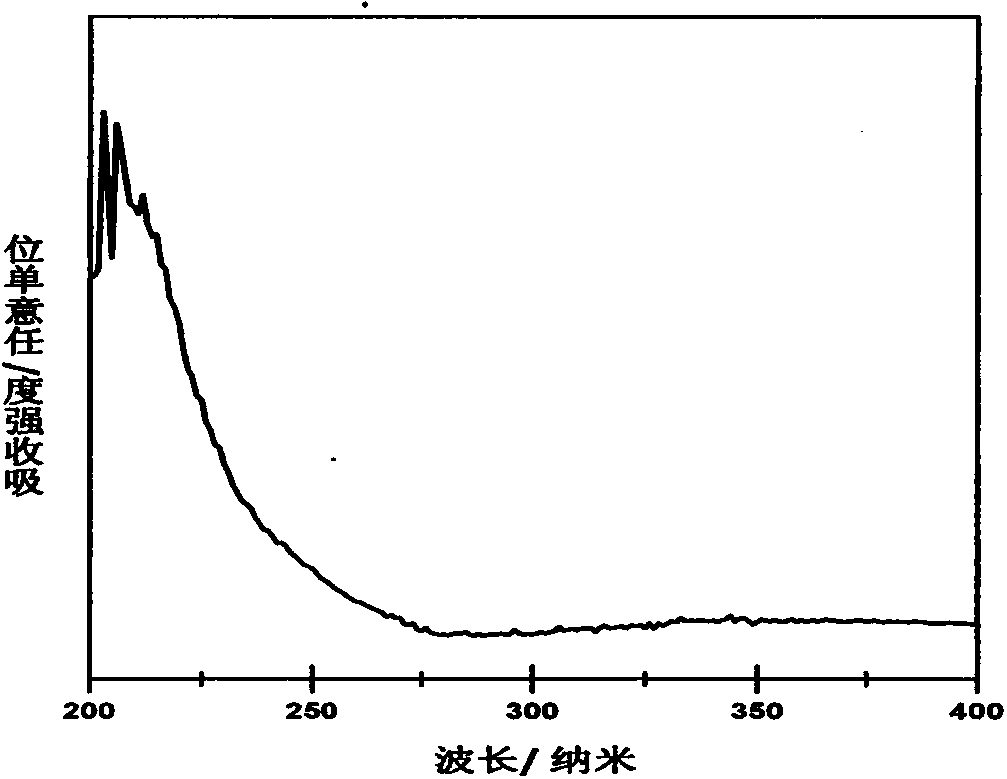

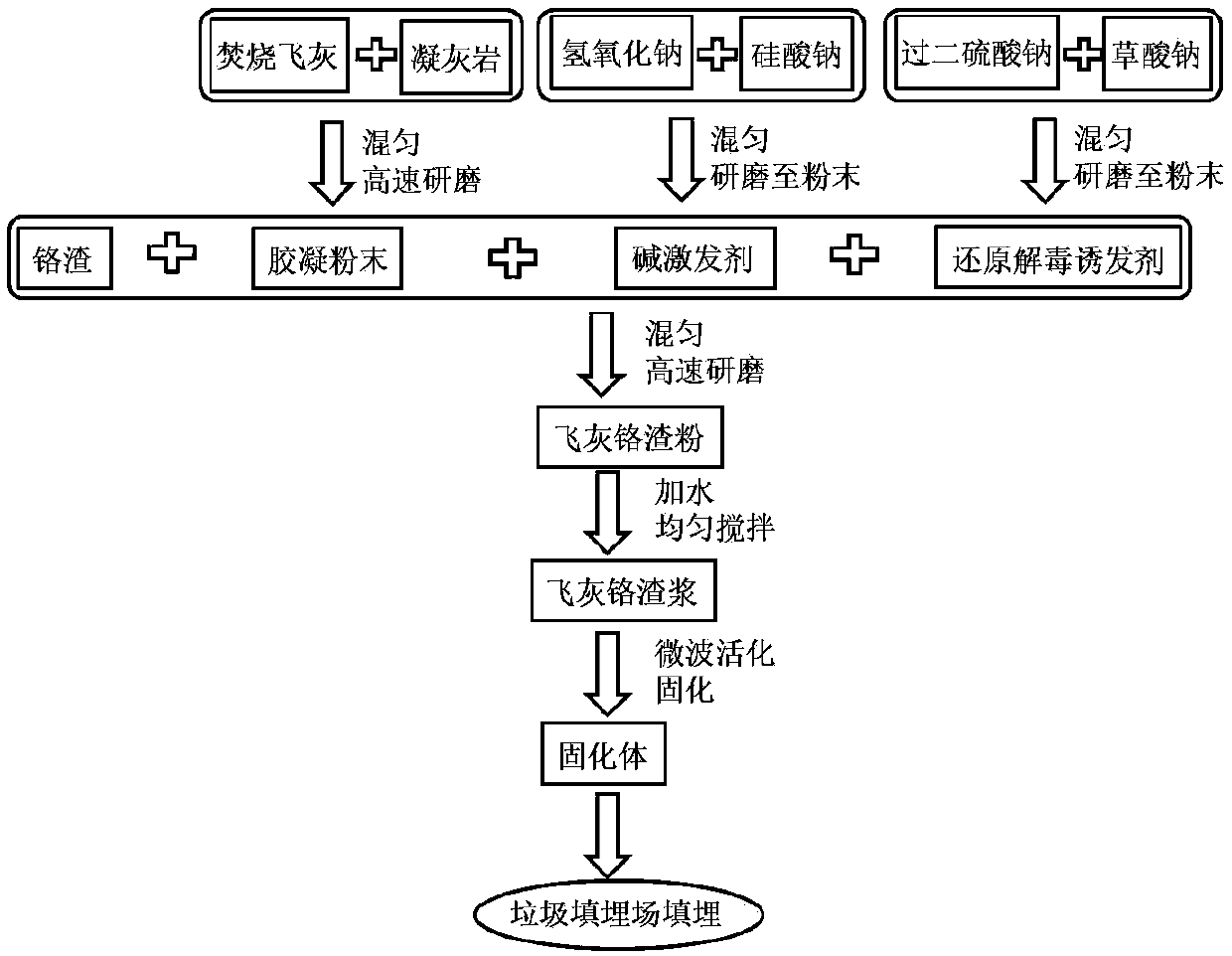

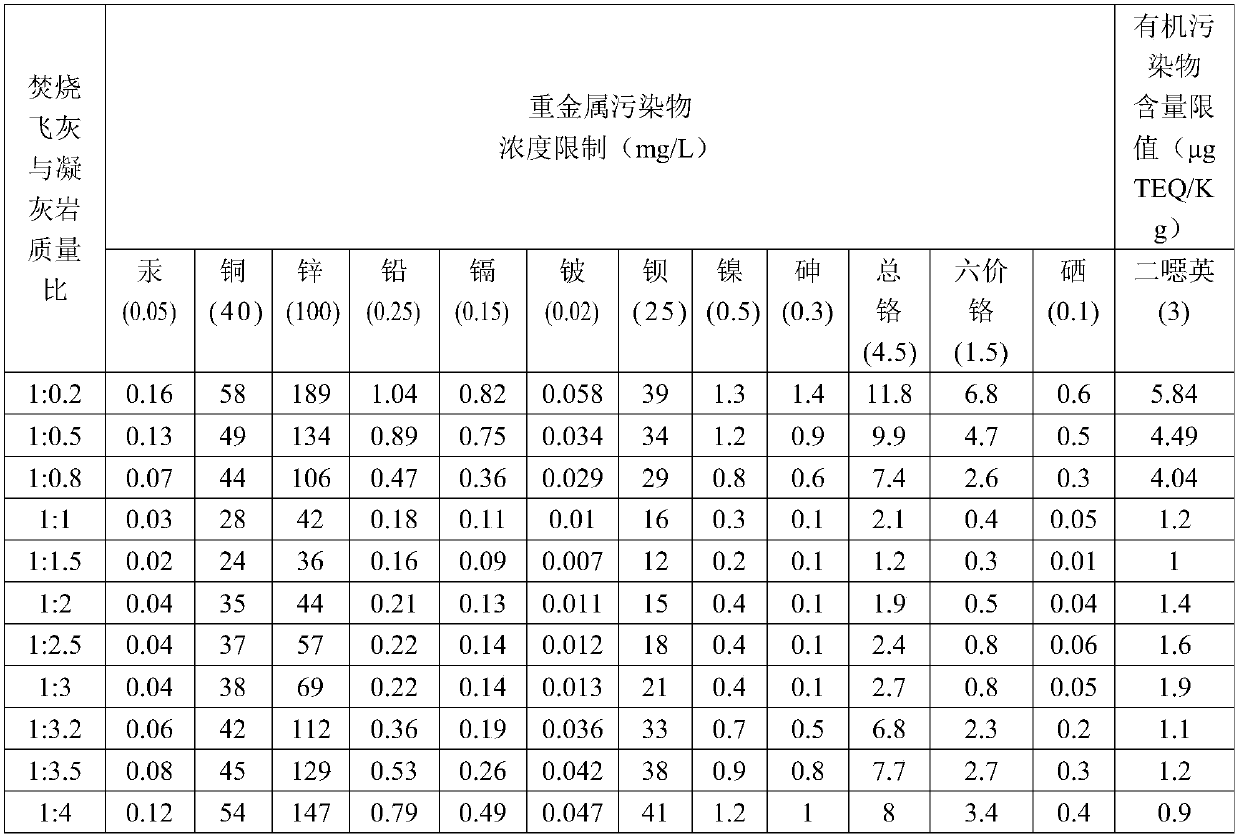

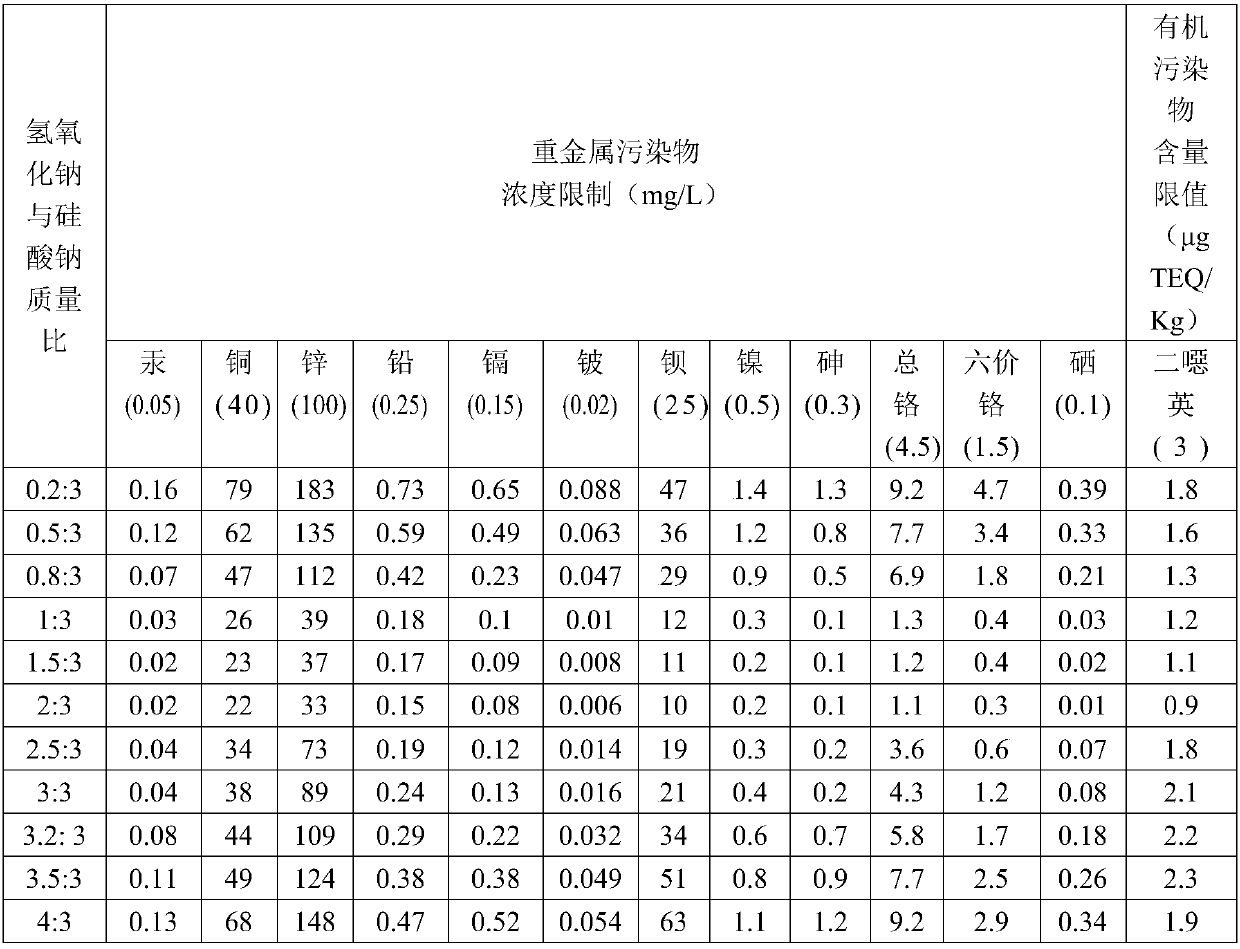

Method for synchronously achieving incineration fly ash detoxification and chromium slag reduction curing

The invention discloses a method for synchronously achieving incineration fly ash detoxification and chromium slag reduction curing. The method includes the following steps that (1), incineration flyash and tuff are weighed, mixed to be uniform and ground, and gelatinized powder is obtained; (2), sodium hydroxide and sodium silicate are weighed, mixed to be uniform and ground, and an alkali activator is obtained; (3), sodium persulfate and sodium oxalate are weighed, mixed to be uniform and ground, and a reductive detoxification inducer is obtained; (4), chromium slag, the gelatinized powder,the alkali activator and the reductive detoxification inducer are weighed, mixed to be uniform and ground, and fly ash and chromium slag powder is obtained; (5), the fly ash and chromium slag powderis weighed and dissolved in water, the materials are mixed to be uniform, and fly ash and chromium slag slurry is obtained; (6), the fly ash and chromium slag slurry is sealed, activated through microwaves, cooled and put in a die to be cured. The leaching concentrations of multiple heavy metals and dioxin in the fly ash and a chromium heavy metal in the chromium slag are all lower than the entrance limiting value of a municipal solid waste landfill. Treated cured bodies have high acid resistance and high constraint capacity for heavy metal inorganic pollutants and organic pollutants.

Owner:浙江中陶环保科技集团有限公司

Acidic soaping agent

InactiveCN102876476ARelieve pressureNo irritating smellOrganic detergent compounding agentsAnionic surface-active compoundsSodium acetateAcetic acid

The invention discloses an acidic soaping agent, which is characterized by comprising the following components in parts by weight: 80-120 parts of carboxy ethyl thio-succinic acid, 20-60 parts of maleic acid-crylic acid copolymer, 0.3-0.9 part of ethylenediamine dihydrochloride salicyl sodium acetate and 2-6 parts of defoaming agent. The acidic soaping agent disclosed by the invention has the beneficial effects that the acidic soaping agent is free from irritant odor because no acetic acid is added, the acidity of the acidic soaping agent is strong, and the acidic soaping agent has a good effect on neutralizing waste liquor. One working procedure of acid pickling or multiple working procedures of washing can be reduced, the sewage processing pressure is lightened, water is saved, and the cost and time for washing are lowered.

Owner:徐磊

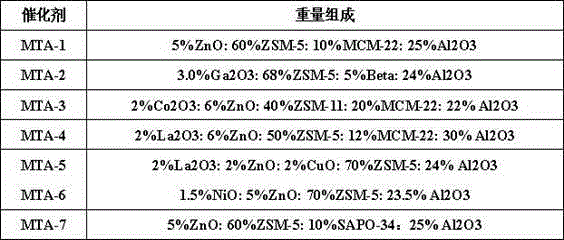

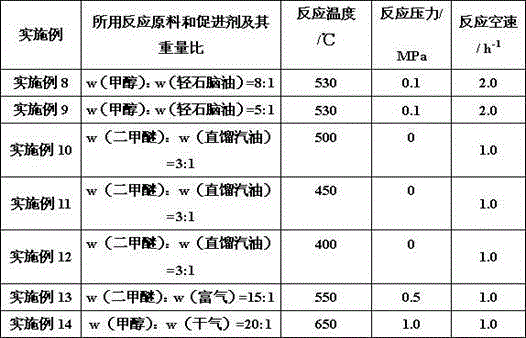

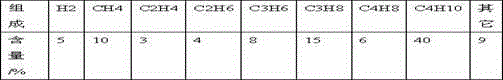

Method for preparing aromatic hydrocarbon from methanol or dimethyl ether

InactiveCN104557419AHigh yieldImprove utilization efficiencyMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAromatizationFixed bed

The invention relates to a method for preparing aromatic hydrocarbon from methanol or dimethyl ether and mainly aims to solve the problems of low yield of aromatic hydrocarbon, serious heat release during reaction, rapid increase of temperature of a reactor and rapid deactivation of a catalyst in the aromatization process of methanol or dimethyl ether. According to the technical scheme of the invention, methanol or dimethyl ether as a raw material is enabled to be in contact with a reaction accelerator, a heat balance agent and a catalyst in a fixed bed reactor at the reaction temperature of 350-650 DEG C, and products of reaction are separated to obtain the methanol or dimethyl ether containing aromatic hydrocarbon. By adopting the technical scheme, the problems can be well solved. The method provided by the invention can be applied to the industrial production of aromatic hydrocarbon through conversion of oxygenated chemicals.

Owner:CHINA PETROLEUM & CHEM CORP +1

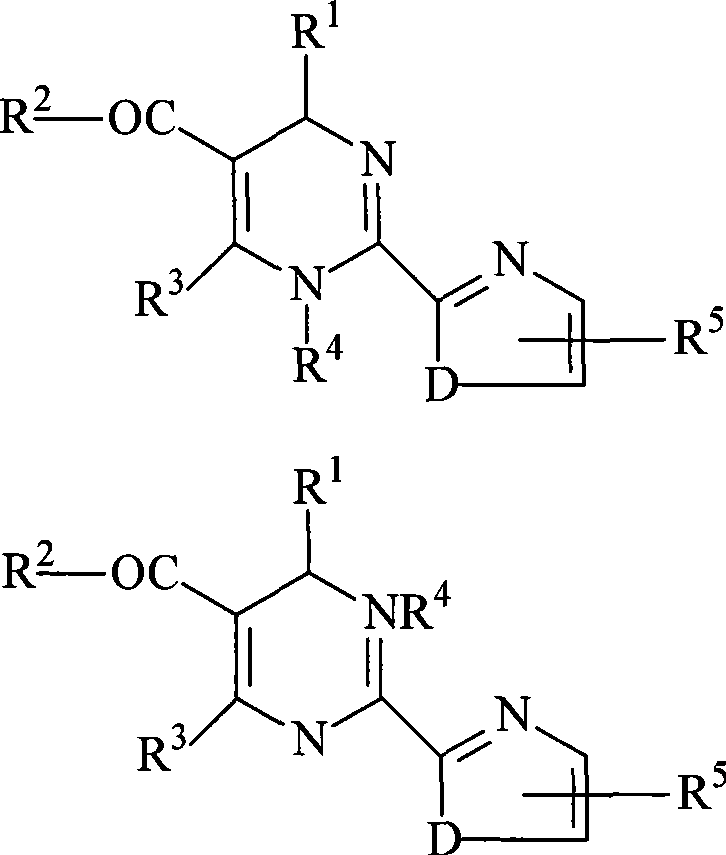

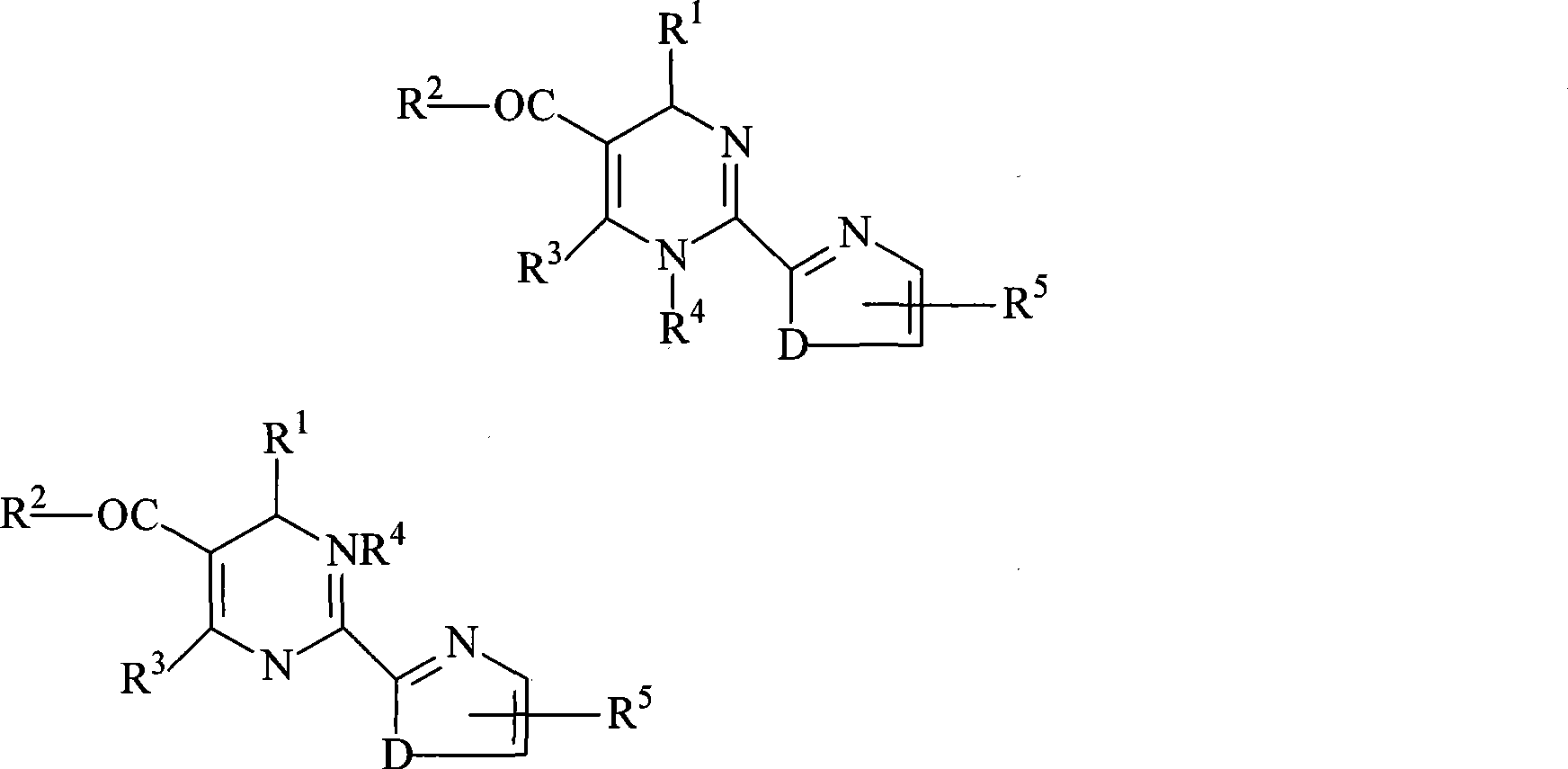

Method for splitting dihydropyrimidine racemic compound

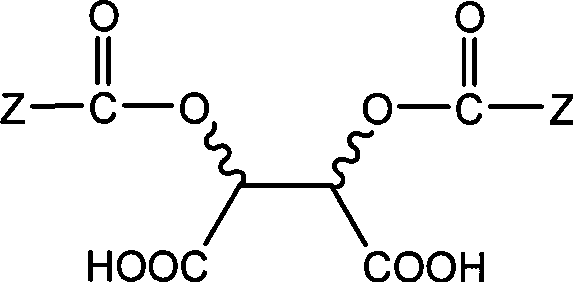

ActiveCN101468986ASplit validOptically activeOptically-active compound separationOrganic racemisationSolventPhotochemistry

The invention provides a method for splitting 2-heterocycle substituted dihydro pyrimidine racemic body, which comprises the following steps: (1) putting the 2-heterocycle substituted dihydro pyrimidine racemic body and O,O-diaroyl tartaric acid resolving agent with optical activity in a reactor, adding a solvent and stirring the mixture; (2) filtering the mixture, concentrating a mother solution and standing the mother solution; (3) filtering and concentrating the mother solution to be dry, and obtaining a concentrate; and (4) refining the concentrate. The splitting method adopted for preparing single chiral 2-heterocycle substituted dihydro pyrimidine compounds has the product yield more than 20 percent and the optical purity above 98 percent; and the splitting method has the advantages of stability, high yield, high optical purity, simple and convenient operation, strong practicability and easy industrialization.

Owner:SUNSHINE LAKE PHARM CO LTD

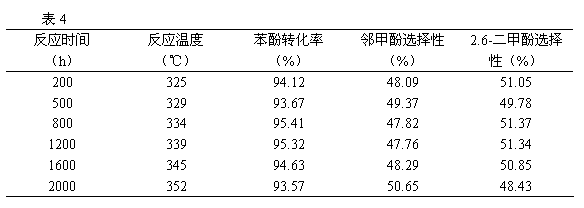

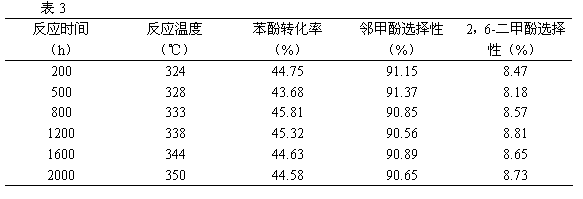

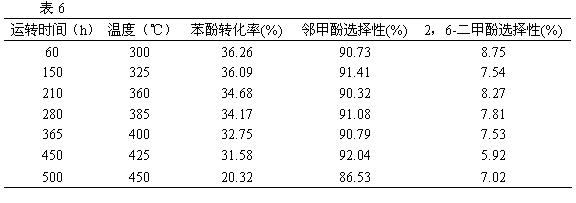

Method for preparing ortho-cresol and 2,6-dimethylphenol

InactiveCN102826960AAdjustable pHHigh activityOrganic chemistryOrganic compound preparationPtru catalystOrtho position

The invention discloses a method for preparing ortho-cresol and 2,6-dimethylphenol and is characterized in that a reaction mixed liquid at the mole ratio of phenol to methanol to water being 1: (2-5): (1-3) is pumped the into a reactor by the use of a pump at the feeding space velocity of 0.5-2 hr<-1>; N2 with the flow velocity of 10-25 mL / min is used as a carrier gas; and a vapor-phase alkylation reaction is carried out at the reaction pressure of normal pressure to 0.5 MPa at the reaction temperature of 320-380 DEG C and under the condition of an alkaline Fe / Mg / Sb composite oxide used as a catalyst. The method provided by the invention has advantages as follows: high average conversion rate of phenol, long one-way service life of the catalyst, high ortho-selectivity, and no generation of impurities m.p-cresol and anisole. In addition, the process is simple, and the method is suitable for continuous large-scale production of ortho-cresol, or reallocation of 2,6-dimethylphenol, or co-production of ortho-cresol and 2,6-dimethylphenol.

Owner:HUNAN XINLING CHEM CO LTD

Heteroatom zeolite adsorbent and preparation method thereof

ActiveCN104549141AHigh adsorption activityImprove technical effectMolecular sieve catalystsOther chemical processesMolecular sieveSulphur compound

The invention relates to a heteroatom zeolite adsorbent and a preparation method thereof and mainly aims at solving the problems that purifying accuracy of an adsorbent is low, adsorption capacity is low and regeneration stability is poor in existing olefin adsorption purification. The preparation method comprises the following steps: introducing at least two metal cations by adopting an ion exchange or impregnation method for modifying zeolite, and moulding by virtue of a binding agent, so as to obtain a solid adsorbent. By adopting the technical scheme, the problems are relatively well solved, and the heteroatom zeolite adsorbent provided by the invention can be applied to adsorption purification industrial production and can be used for removing sulphur compounds in various olefin raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing polyformaldehyde dimethyl ether by taking methanol and methanal as raw materials

InactiveCN102320941ASimple processHigh reaction conversion ratePhysical/chemical process catalystsOrganic chemistryChemistryPolyoxymethylene dimethyl ethers

The invention relates to a method for synthesizing polyformaldehyde dimethyl ether by taking methanol and methanal as raw materials. Dimethoxymethane or methanol or the mixture of the dimethoxymethane and the methanol and methanal are used as raw materials, the mass ratio of the dimethoxymethane or the methanol or the mixture of the dimethoxymethane and the methanol to the methanal is 0.2-10:1, the reaction temperature is 70-200 DEG C, the reaction pressure is 0.2-6MPa, solid super strong acid is used as a catalyst for catalytic reaction to prepare polyformaldehyde dimethyl ether, the dosage of the catalyst accounts for 0.05-10% of the total weight of the raw materials, wherein the solid super acid catalyst comprises the following components in percentage by weight: 20-70% of at least one of sulphuric acid, hydrochloric acid or peroxosulfuric acid or salt thereof, and the balance of carrier selected from at least one of ZrO2, TiO2, SiO2, Fe2O3, SnO2, WO3 and Al2O3. The method disclosed by the invention solves the existing technical problem of high cost in producing the polyformaldehyde dimethyl ether.

Owner:HENAN COAL CHEM IND GROUP INST

Method for preparing magnetic SO42-/ZrO2/Fe3O4/attapulgite solid acid catalyst

InactiveCN101898140AHigh catalytic activityThe synthesis method is simplePhysical/chemical process catalystsOrganic compound preparationFerrous saltsSolid acid

The invention discloses a method for preparing a magnetic SO42- / ZrO2 / Fe3O4 / attapulgite solid acid catalyst, which comprises the steps of: firstly, dissolving attapulgite clay, zirconium oxychloride, ferric salt and ferrous salt in water to form mixed size; then slowly dripping alkali liquor into the mixed size under mechanical stirring to form black precipitates; aging, filtering, washing, drying and grinding the black precipitates to obtain mixed powder; and finally, acidifying the mixed powder with sulfuric acid, leaching, drying, pulverizing and calcining to prepare the magnetic SO42- / ZrO2 / Fe3O4 / attapulgite solid acid catalyst. By taking low-cost attapulgite clay as raw materials and loading magnetic materials and solid acid, the method is simple and has available raw materials and low production cost, and the prepared catalyst has high catalytic activity and magnetism and is easy to separate from products.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

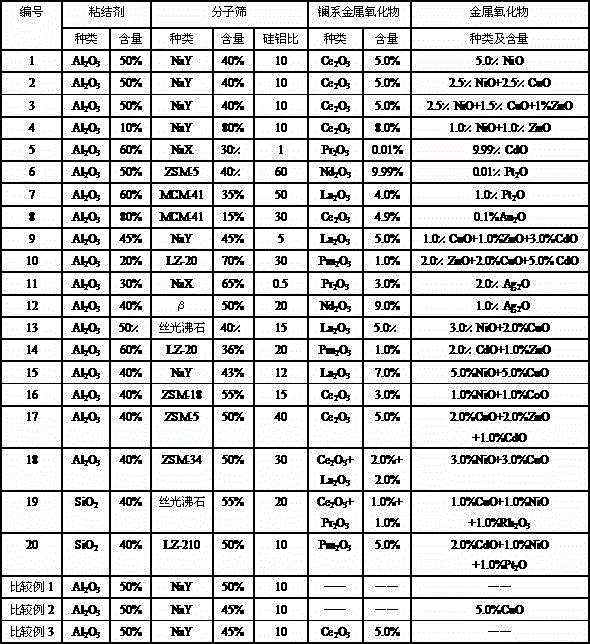

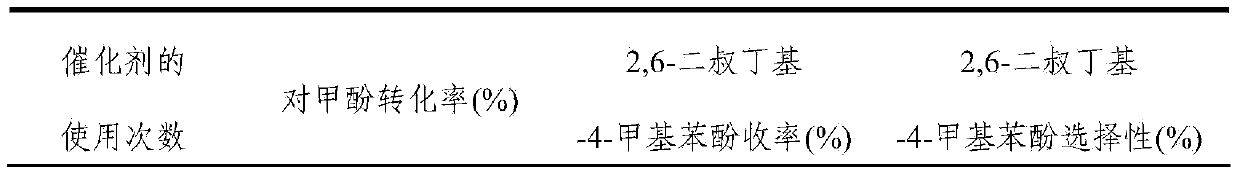

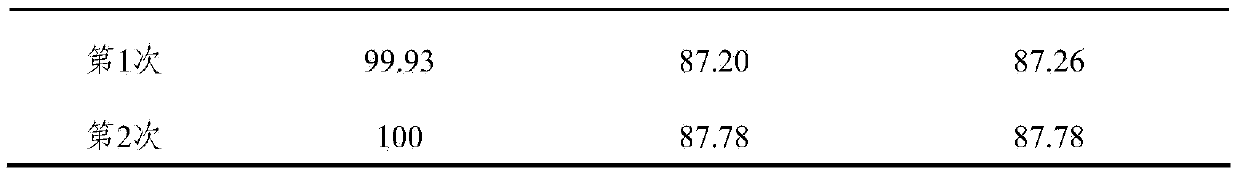

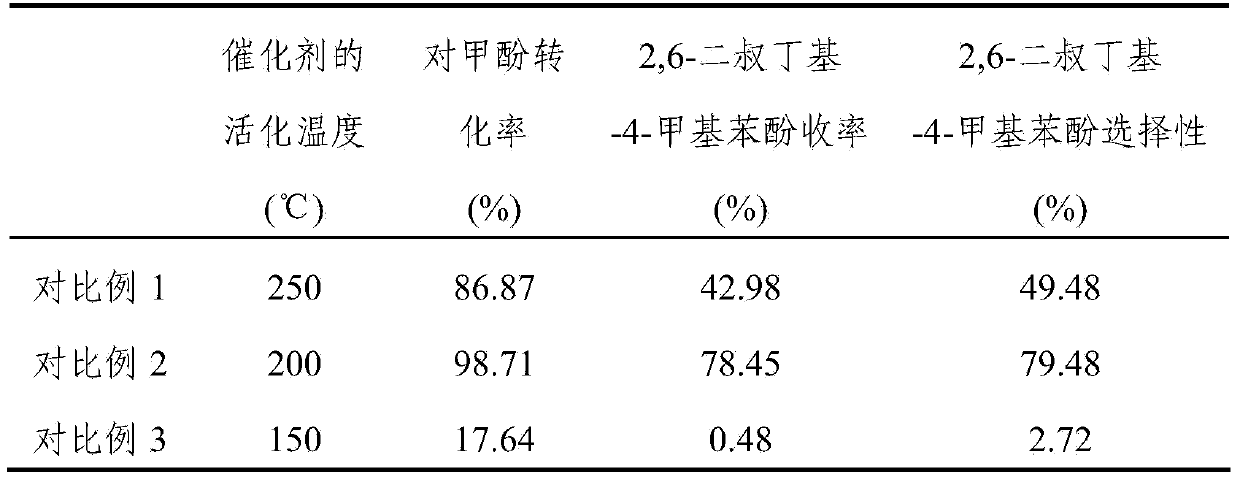

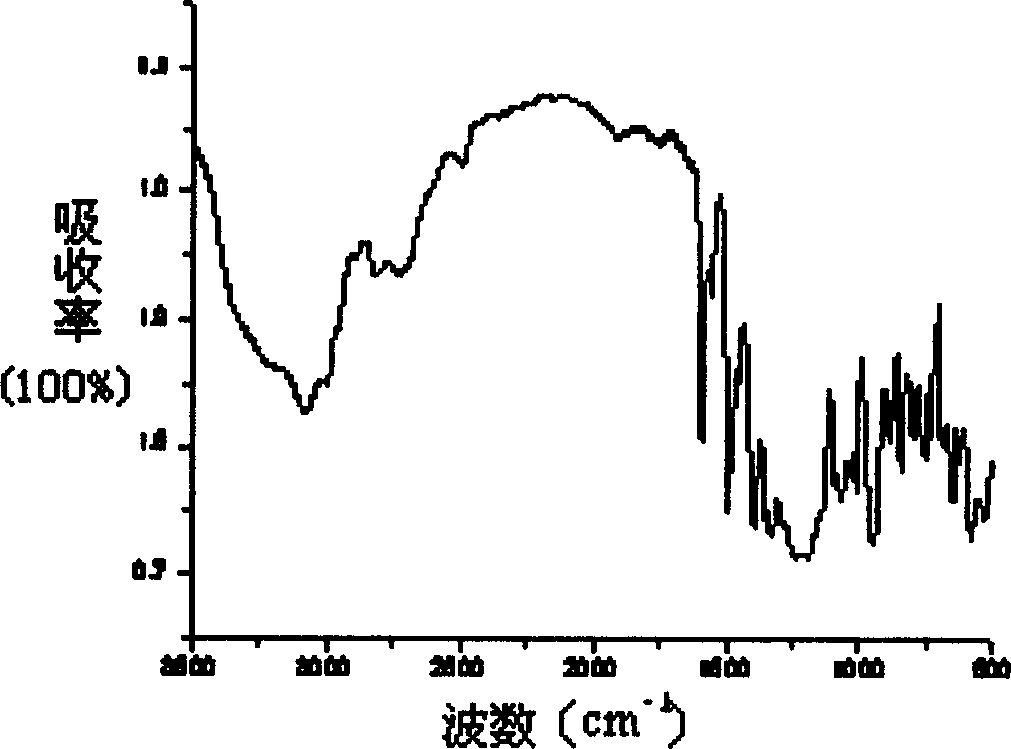

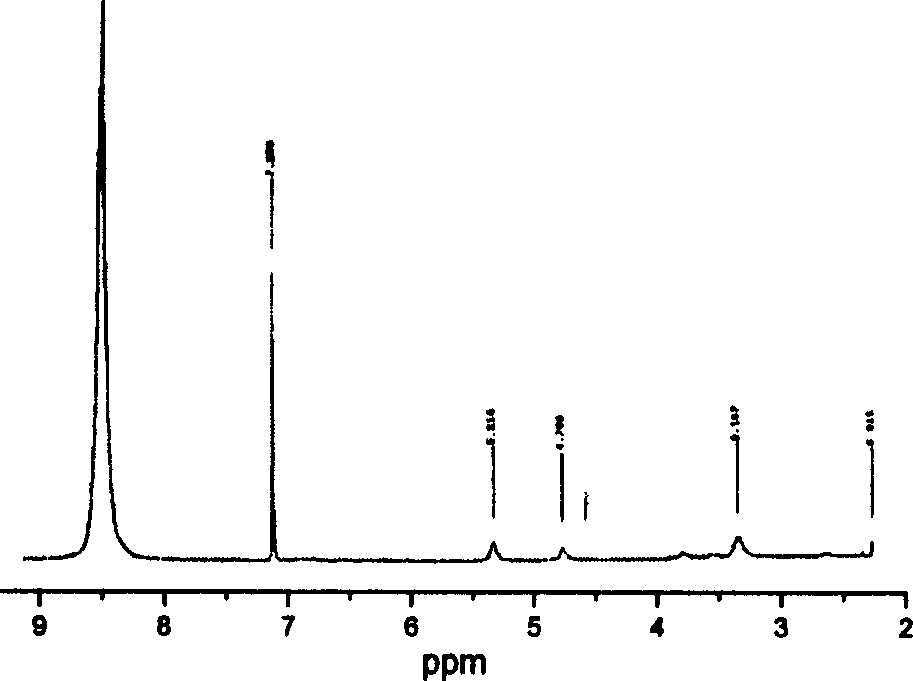

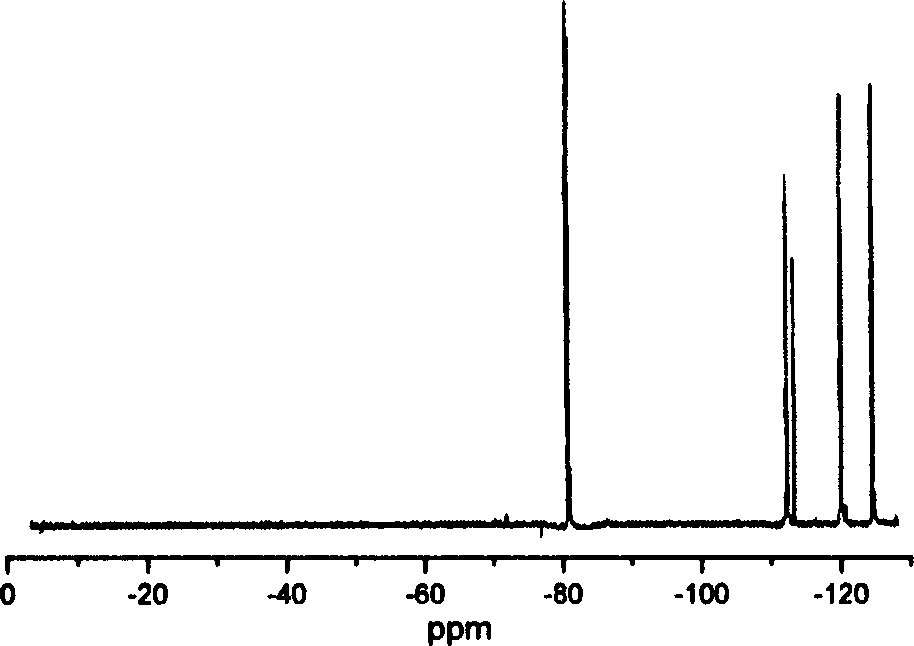

Composite solid acid catalyst as well as preparation method and application thereof

ActiveCN103990475AStrong acidHigh activityPhysical/chemical process catalystsOrganic chemistryOrganic solventOrganic synthesis

The invention belongs to the technical field of organic synthesis and provides a composite solid acid catalyst. The composite solid acid catalyst is (SO4<2->+ZnCl2) / silica gel and is formed by compositing zinc chloride, sulfuric acid and silica gel. A preparation method of the catalyst comprises the following steps: hot pretreating the silica gel, dipping in zinc chloride solution, drying, adding into sulfuric acid solution, dipping for one night, drying and activating to obtain the (SO4<2->+ZnCl2) / silica gel composite solid acid catalyst. The composite solid acid catalyst provided by the invention has the characteristics of strong acidity, good activity, high selectivity, recyclability and environmental friendliness; when being used for synthetizing 2, 6-di-tert-butyl-4-methylphenol, the composite solid acid catalyst has the characteristics of simplicity and convenience in operation, low reaction temperature, normal pressures, no use of any organic solvent, high conversion ratio, short reaction time, high selectivity and environmental friendliness; the composite solid acid catalyst meets the requirements of green process and is very suitable for industrial production.

Owner:湖南瑞冠生物化工科技有限公司

High-molecular polymer containing perfluoro alkyl sulfimine side-chain and its synthesizing method

The present invention discloses one kind of polymer containing perfluoroalkyl sulfonyl imido side chain. It is synthesized through chlorosulfonating one of polyhydroxy ether phosphonitrile, crosslinked polystyrene and polystyrene with alkyl long side chain; grafting sulfuryl chloride group to the benzene ring; and final reaction with perfluoro sulfonamide. The obtained polymer containing perfluoroalkyl sulfonyl imido side chain has strong acidity and excellent heat stability, and excellent catalyzing effect on esterification, Dies-Alder reaction, Friedel-Crafts reaction, etc., and may be reused. Therefore, the present invention has latent value in use as green organic synthesis catalyst and electrolyte material. It has simple synthesis and low cost, and is favorable to industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com