Mesoporous-microporous composite material and synthesis method thereof

A synthesis method and technology of composite materials, which are applied in the field of composite materials with mesoporous structure and microporous structure and their synthesis, can solve the problems of poor thermal stability and hydrothermal stability and limit applications, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

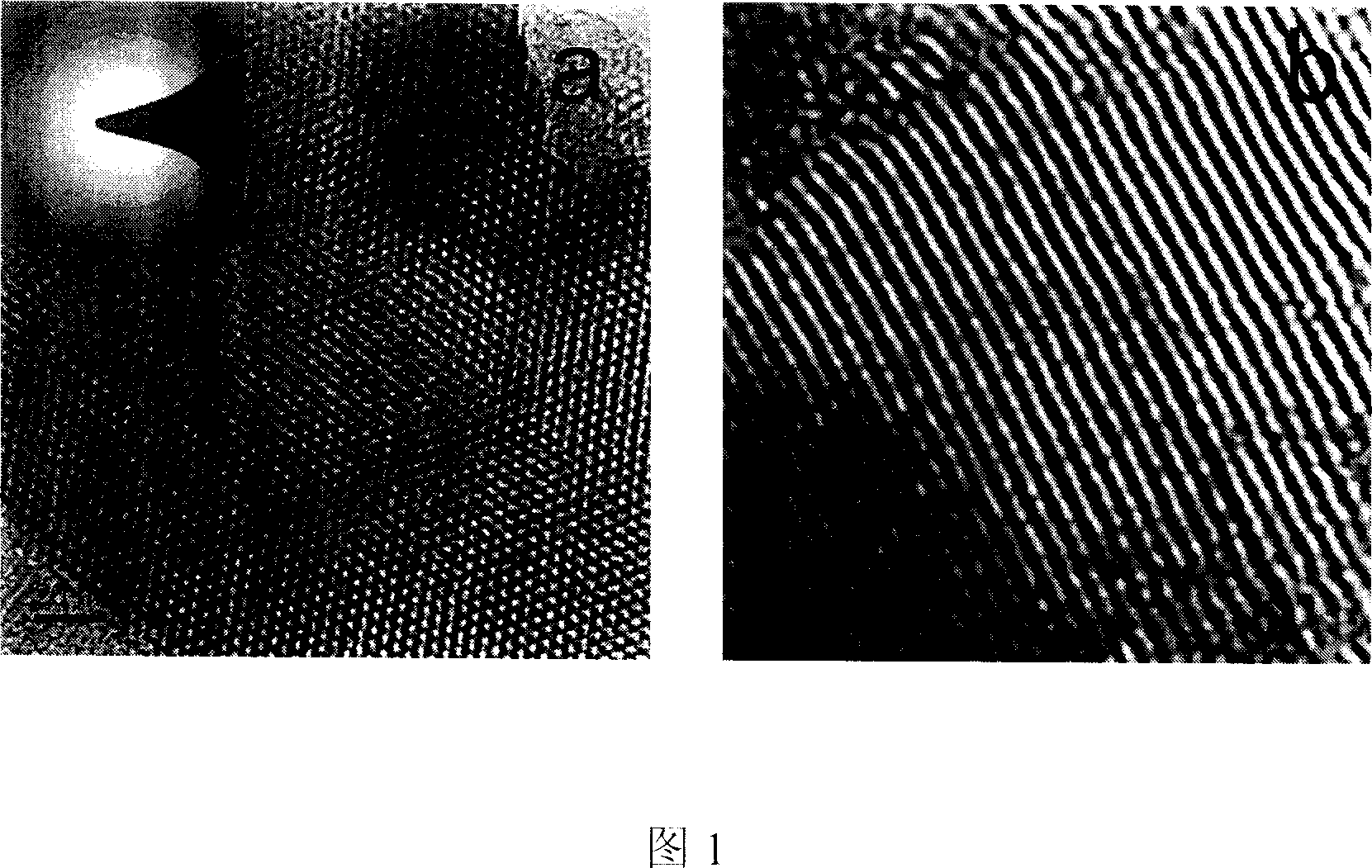

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described in detail below.

[0011] Synthesis of Mesoporous-Microporous Composite Materials

[0012] Sodium metasilicate powder was used to prepare an aqueous solution with a concentration of 20.4% (by mass), and 14 milliliters of the aqueous solution was measured. Weigh 1.0 gram of ZSM-5 zeolite molecular sieve (SiO 2 / Al 2 o 3 =26, the particle size is about 400nm), added to the sodium metasilicate aqueous solution, reacted at 55°C for 30 minutes, and put it into the ice-water mixture for 10 minutes to quench. Then 72 ml of cetyltrimethylammonium bromide (CTAB) aqueous solution (concentration 3.8% (mass)) was added, and the pH value of the above mixed solution was adjusted to 11 with 6M sulfuric acid. Then, it was aged for 2 hours under the condition of vigorous stirring, and transferred to a stainless steel autoclave lined with polytetrafluoroethylene at 120° C. for 48 hours. The obtained solid product was wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com