Composite solid acid catalyst as well as preparation method and application thereof

A technology of composite solid acid and catalyst, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve the problem of low catalyst activity and achieve the effect of strong acidity, high selectivity and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Composite solid acid [(SO 4 2- +ZnCl 2 ) / silica gel] catalyst preparation

[0025] Using silica gel as a carrier, water as a solvent, and p-cresol to be reacted as a benchmark, according to p-cresol: carrier (silica gel) = 1: 0.03 (mass ratio), p-cresol: ZnCl 2 =1:0.33% (mass ratio), p-cresol:H 2 SO 4 =1:0.66% (mass ratio) to prepare a composite solid acid catalyst.

[0026] After thermal pretreatment, the silica gel was placed in 0.7mol / L ZnCl 2 Soak in water solution overnight, then dry. Then add 1mol / L of H 2 SO 4 The aqueous solution was immersed overnight, and after drying, it was activated at 200°C for 3 hours.

[0027] 2. Preparation of 2,6-di-tert-butyl-4-methylphenol

[0028] In a 100mL round-bottomed flask with a magnetic stirrer, condenser, thermometer and isobutylene introduction tube, add 7.5g p-cresol and the composite solid acid [(SO 4 2- +ZnCl 2 ) / Silicone] Catalyst, a balloon is fixed on the top of the condensation tube to play a role of...

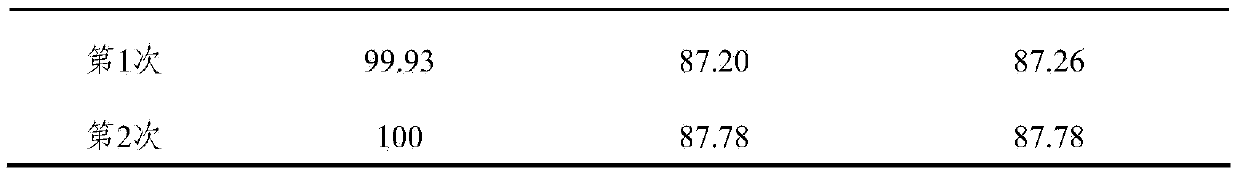

Embodiment 2

[0036] 1. Composite solid acid [(SO 4 2- +ZnCl 2 ) / silica gel] catalyst preparation

[0037] With silica gel as carrier, with water as solvent, take p-cresol to be reacted as benchmark, according to p-cresol: carrier (silica gel)=1:0.03 (mass ratio), p-cresol: ZnCl 2 =1:0.66% (mass ratio), p-cresol:H 2 SO 4 =1:0.66% (mass ratio) to prepare a composite solid acid catalyst.

[0038] After thermal pretreatment, the silica gel was placed in ZnCl 2 Soak overnight in aqueous solution, then dry. Then add 1mol / L of H 2 SO 4 The aqueous solution was immersed overnight, and after drying, it was activated for 3 hours, and the activation temperature was 250°C, 200°C and 150°C for comparative tests.

[0039] 2. Preparation of 2,6-di-tert-butyl-4-methylphenol

[0040]In a 100mL round-bottomed flask with a magnetic stirrer, condenser tube, thermometer and isobutylene inlet tube, add 7.5g p-cresol and the composite solid acid [(SO 4 2- +ZnCl 2 ) / Silicone] Catalyst, fix a balloon ...

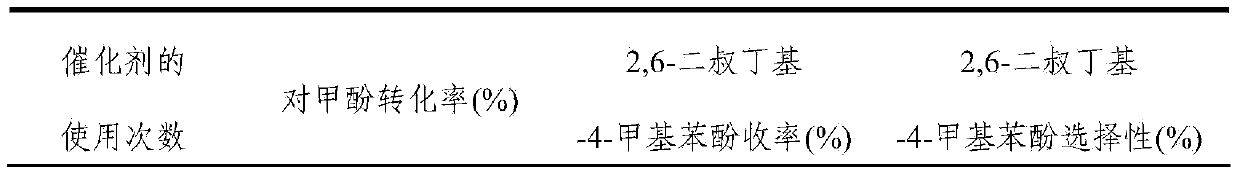

Embodiment 3

[0047] 1. Composite solid acid [(SO 4 2- +ZnCl 2 ) / silica gel] catalyst preparation

[0048] The preparation method of the catalyst is the same as in Example 2, but the activation temperature is 200°C.

[0049] 2. Preparation of 2,6-di-tert-butyl-4-methylphenol

[0050] 7.5g p-cresol and the prepared composite solid acid [(SO 4 2- +ZnCl 2 ) / silica gel] catalyst was added to a 100 mL round bottom flask equipped with a magnetic stirrer, condenser, thermometer and isobutylene inlet. Fix a balloon on the top of the condenser for sealing and safety. Raise the temperature of the reactant to 80°C while stirring; slowly feed high-purity isobutene gas and adjust the feeding speed to ensure that no gas overflows the reaction device. Ventilation was done for 4h and 8h respectively, and the ventilation was stopped.

[0051] 3. Analysis of crude product of 2,6-di-tert-butyl-4-methylphenol

[0052] Sampling was taken from the crude product of 2,6-di-tert-butyl-4-methylphenol obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com