Method for preparing ortho-cresol and 2,6-dimethylphenol

A technology for xylenol and o-cresol, applied in the field of preparing o-cresol and 2, can solve the problems of inability to guarantee long-period operation of the device, high production cost, and inability to be used for production, and maximizes economic benefits and service life. The effect of long, extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

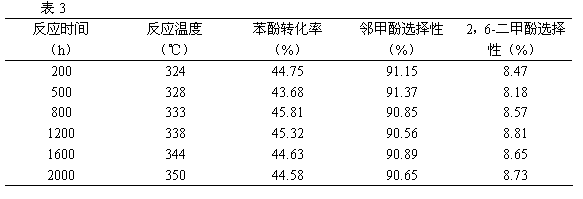

[0018] 40mL FeMg 0.05 Sb 0.01 / O The catalyst is loaded in a stainless steel fixed bed reactor, the raw material is phenol:methanol:water=1:2:2 (molar ratio), and the mass space velocity is 1.0 hr -1 , the carrier gas is N 2 The flow rate was 25 mL / min, normal pressure, and the catalyst was operated stably for 2000 h in one pass. The reaction results are shown in Table 1.

[0019]

Embodiment 2

[0021] 40mL FeMg 0.05 Sb 0.01 / O The catalyst is loaded in a stainless steel fixed bed reactor, the raw material is phenol:methanol:water=1:2:2 (molar ratio), and the mass space velocity is 2.0 hr -1 , the carrier gas is N 2 The flow rate was 25 mL / min, the reaction pressure was 0.2 MPa, and the catalyst was operated stably for 2000 h in one pass. The reaction results are shown in Table 2.

[0022]

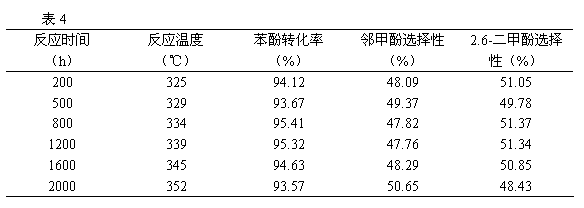

Embodiment 3

[0024] 40mL FeMg 0.01 Sb 0.04 The / O catalyst is packed in a stainless steel fixed-bed reactor, the raw material is phenol:methanol:water=1:3:1 (molar ratio), and the mass space velocity is 1.0 hr -1 , the carrier gas is N 2 The flow rate was 10 mL / min, and the catalyst was operated stably for 2000 h in one pass. The reaction results are shown in Table 3.

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com