Oil/fat liposome and preparation method thereof

A liposome and oil technology, which is applied in the direction of liposome delivery, edible oil/fat, and oil-containing food ingredients, etc., can solve the problems of poor comprehensive usability of oil liposomes and cannot meet the use requirements, and achieve increased stability , inhibit cholesterol absorption, the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention also provides a kind of preparation method of lipid liposome as above, specifically comprises the following steps:

[0038] (1) Grease, fat globule membrane phospholipids, organic solvent, surfactant and PBS buffer are prepared as required for subsequent use; surfactant includes Tween-80, pH of PBS buffer=7.0~7.4, pH of PBS buffer The concentration is 0.005~0.01mol / L; the organic solvent includes anhydrous ether or chloroform; the mass ratio of oil and fat globule membrane phospholipid is 2:8; the oil, fat globule membrane phospholipid, anhydrous ether, surfactant and PBS buffer The mass-volume ratio is (100-200) mg: (800-900) mg: (16.7-25) mL: (200-240) mg: 20 mL;

[0039] (2) Mix the fat and fat globule membrane phospholipids evenly to obtain mixture A, add an organic solvent to mixture A, shake and dissolve, and mix ultrasonically to obtain a mixed solution; the ultrasonic power is 70-90W, the ultrasonic temperature is 25°C, an...

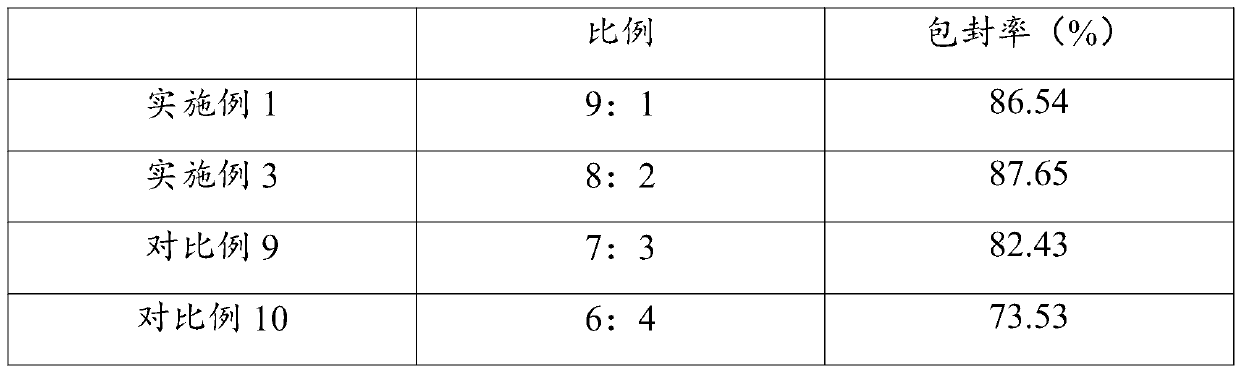

Embodiment 1

[0047] Preparation of lipid liposomes by thin film ultrasonic dispersion

[0048] Weigh 900 mg of fat globular membrane phospholipids and 100 mg of fat for wall material, add 20 mL of anhydrous ether to fully shake and dissolve the mixture, and ultrasonically mix the solution for 1 min; use a rotary evaporator to remove the organic solvent of the mixed solution by rotary evaporation at 45 °C. Until a pale yellow liposome film is formed on the wall, then dry in a drying oven for 4 hours to completely remove the organic solvent; add 20 mL of PBS buffer solution of pH = 7.4, 0.005 mol / L containing 240 mg Tween 80, at 45 °C Rotate and hydrate at normal pressure for 45 minutes to wash the membrane to form a milky white uniform liposome solution;

[0049] Then the swirling solution of the lipid liposome is ultrasonically 20min in a water bath under 80W power, so that the film is swollen and hydrated, and finally, the premixed crude emulsion is homogenized with a high-pressure micro-...

Embodiment 2

[0050] Embodiment 2 film ultrasonic dispersion method prepares grease liposome

[0051] Weigh 800 mg of fat globular membrane phospholipids and mix them with 200 mg of oil, add 20 mL of anhydrous ether to fully shake and dissolve the mixture, and ultrasonically mix the solution for 1 min; use a rotary evaporator to remove the organic solvent of the mixed solution at 45 ° C until the wall A light yellow liposome film was formed on the liposome, and then dried in a drying oven for 4 hours to completely remove the organic solvent; add 20 mL of PBS buffer solution containing 240 mg Tween 80, pH = 7.0, 0.005 mol / L, at 45 °C under normal pressure Rotate and hydrate for 45 minutes to wash the membrane to form a milky white uniform liposome solution;

[0052] Then the swirling liquid of lipid liposomes is ultrasonicated in a water bath under 70W power for 30min, so that the film is swollen and hydrated, and finally, the premixed crude emulsion is homogenized with a high-pressure micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com