Patents

Literature

225 results about "Xylenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Xylenols are organic compounds with the formula (CH₃)₂C₆H₃OH. They are volatile colorless solids or oily liquids. They are derivatives of phenol with two methyl groups and a hydroxyl group. Six isomers exist, of which 2,6-xylenol with both methyl groups in an ortho position with respect to the hydroxyl group is the most important. The name xylenol is a portmanteau of the words xylene and phenol.

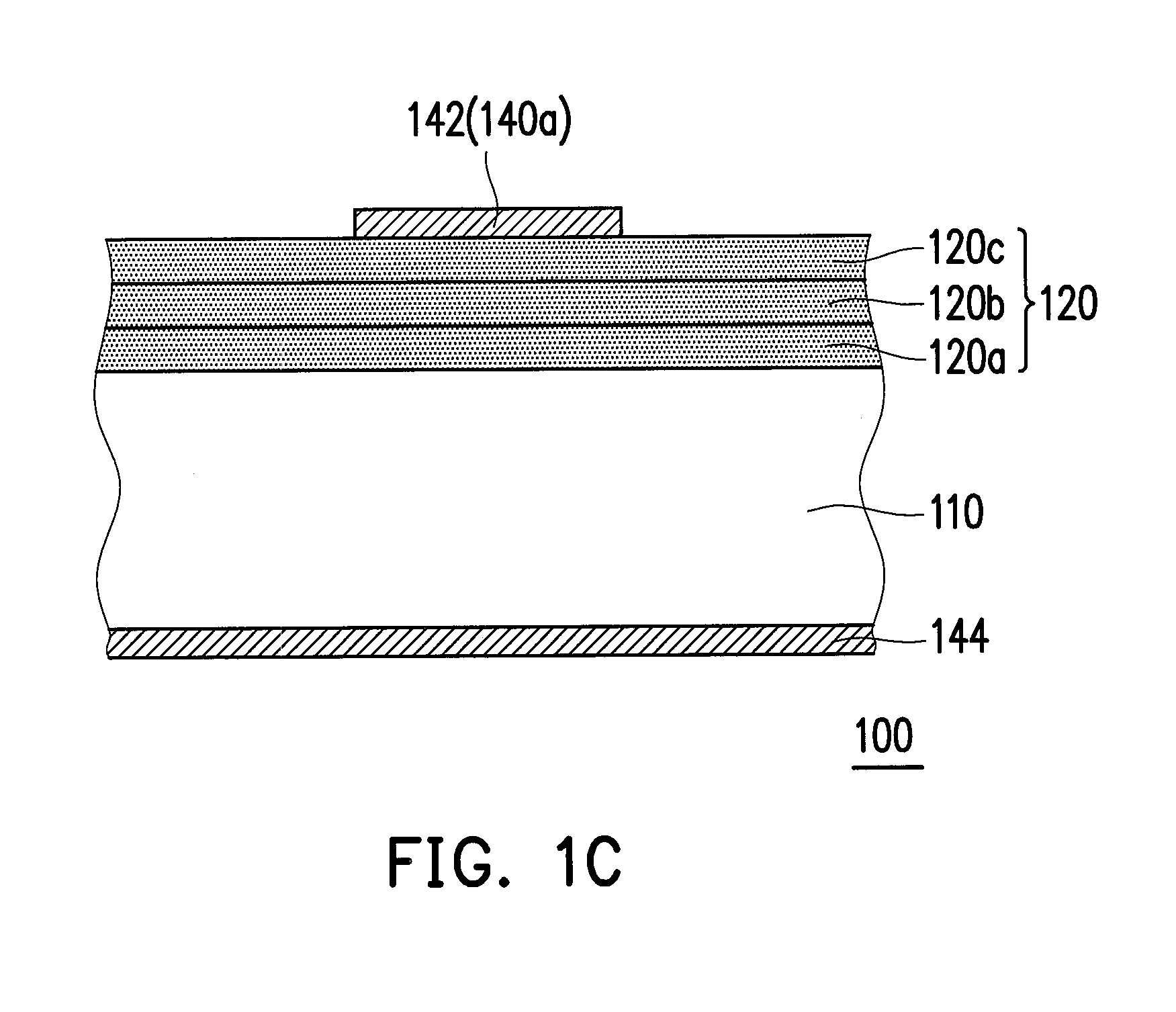

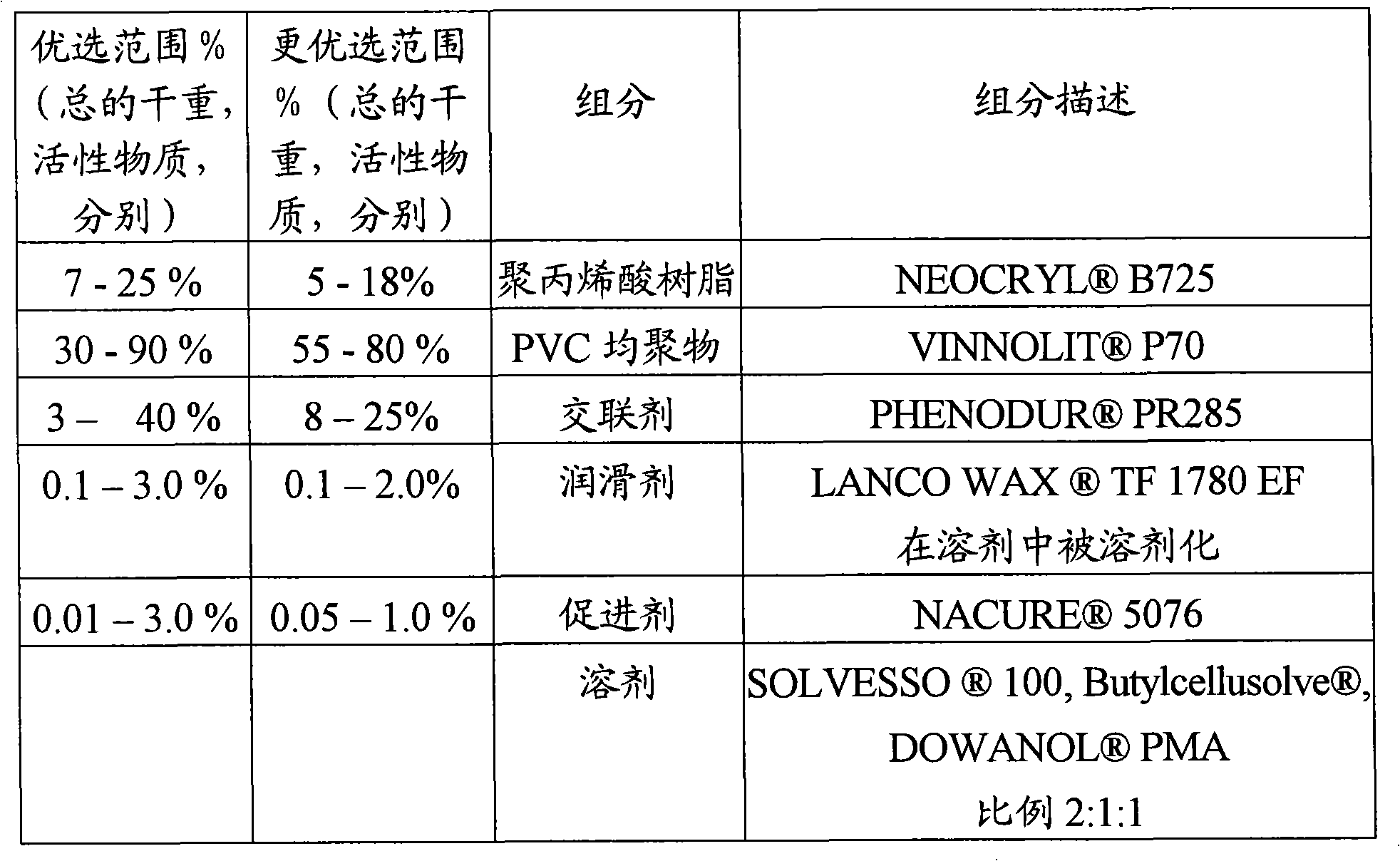

BADGE- and BPA-free can coating

ActiveUS7682674B2Suitable flexibilitySuitable resistanceSynthetic resin layered productsPretreated surfacesAcrylic resinPolyvinyl chloride

The present invention relates to a composition, which is useful for producing coatings for metal sheet substrates of metal cans for storing and / or transporting food or beverages or a lid thereof, and which comprises the following components:(a) 30 to 90 wt. % of a polyvinylchloride-(PVC)-polymer,(b) 7 to 25 wt. % of an acrylic resin,(c) 3 to 40 wt. % of a crosslinking agent, which is produced from phenol, para-tert.-butylphenol, xylenol or a mixture thereof, and formaldehyde,(d) 0 to 8 wt. % additive,(e) 0 to 50 wt. % pigment and(f) a solvent-component,where all weight percentages are on the basis of the total dry weight of the coating composition (without solvents) and the composition is substantially free of bisphenol-A-diglycidyl-ether (“BADGE”) and also substantially free of bisphenol-A-resins. The composition provides metal can coatings that have suitable flexibility, scratch resistance, adherence and sterilization resistance when processed in contact with food. The coatings are suitable for three-piece cans as well as deep-drawn metal cans. In particular they are, however, useful for lids that are to be torn open due to their extraordinary flexibility and sterilization resistance.

Owner:HENKEL KGAA

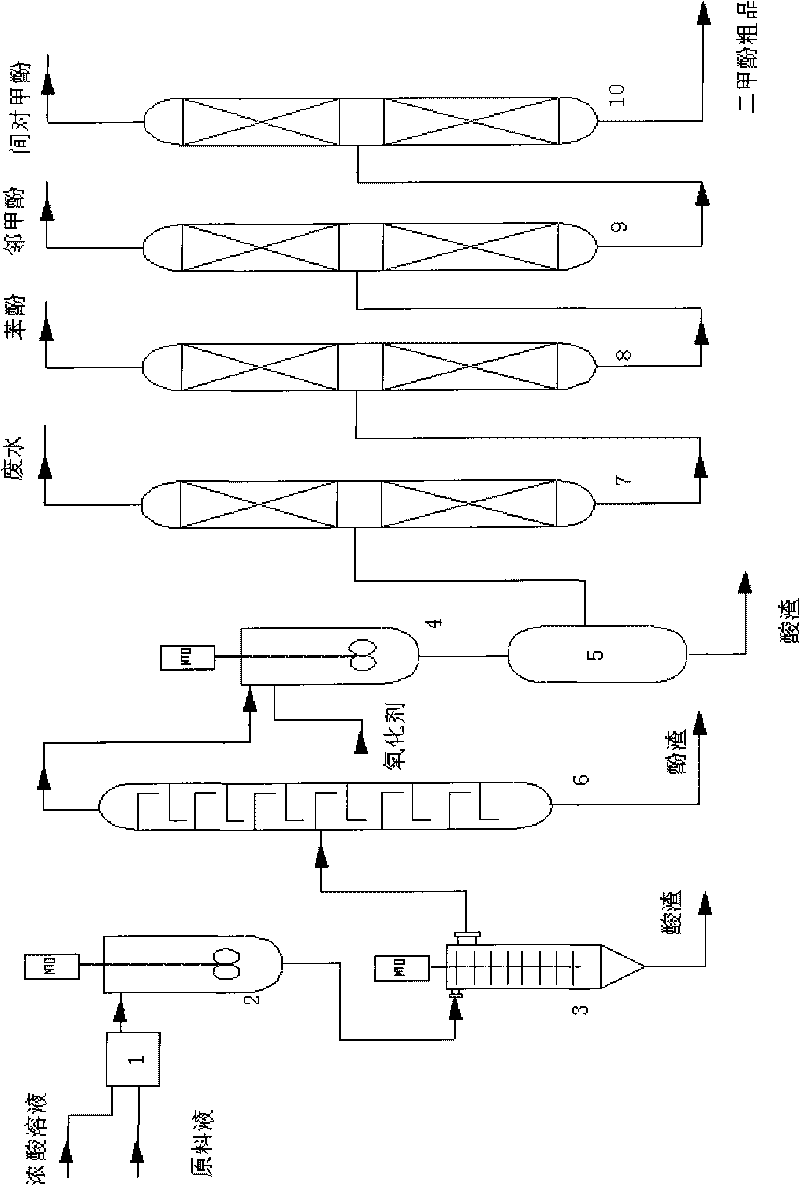

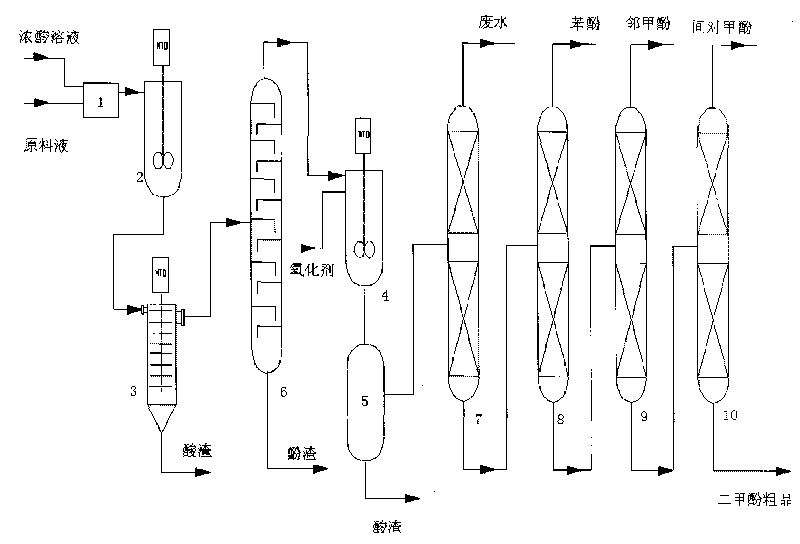

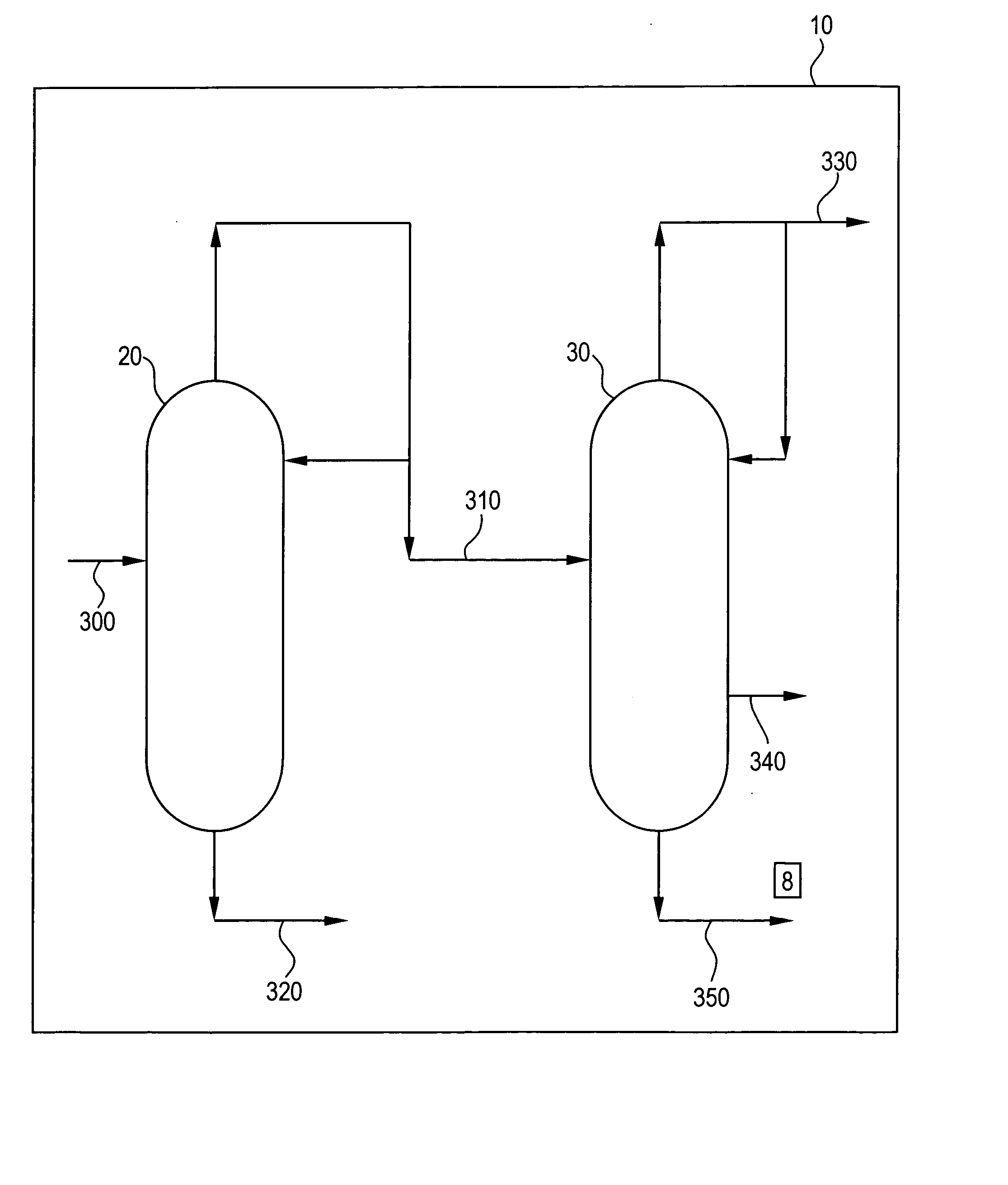

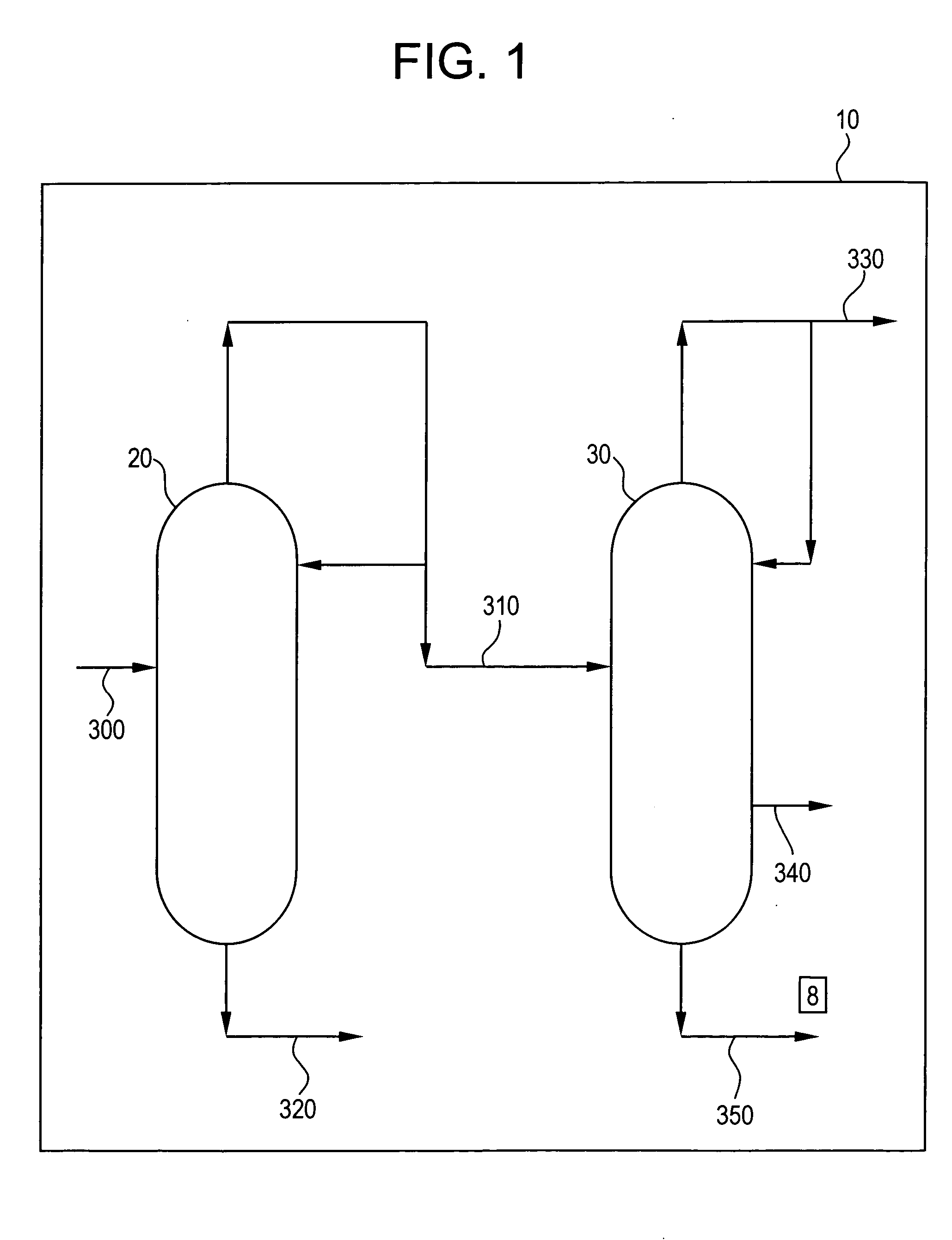

Continuous refinement separation device and method of coked crude phenol

InactiveCN101704726ASolve corrosion resistanceQuality assuranceOrganic chemistryOrganic compound preparationSeparation technologyP-Cresol

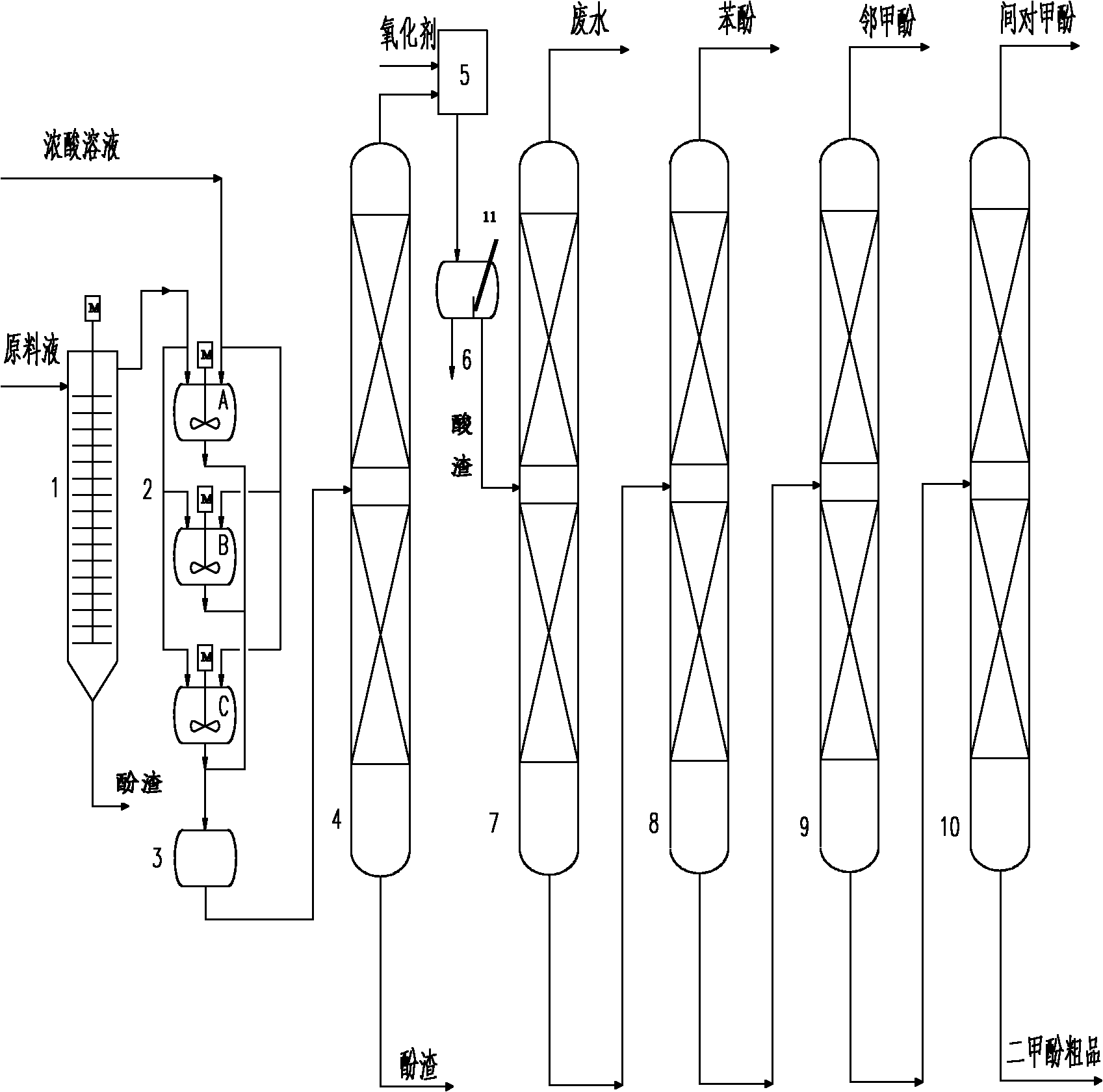

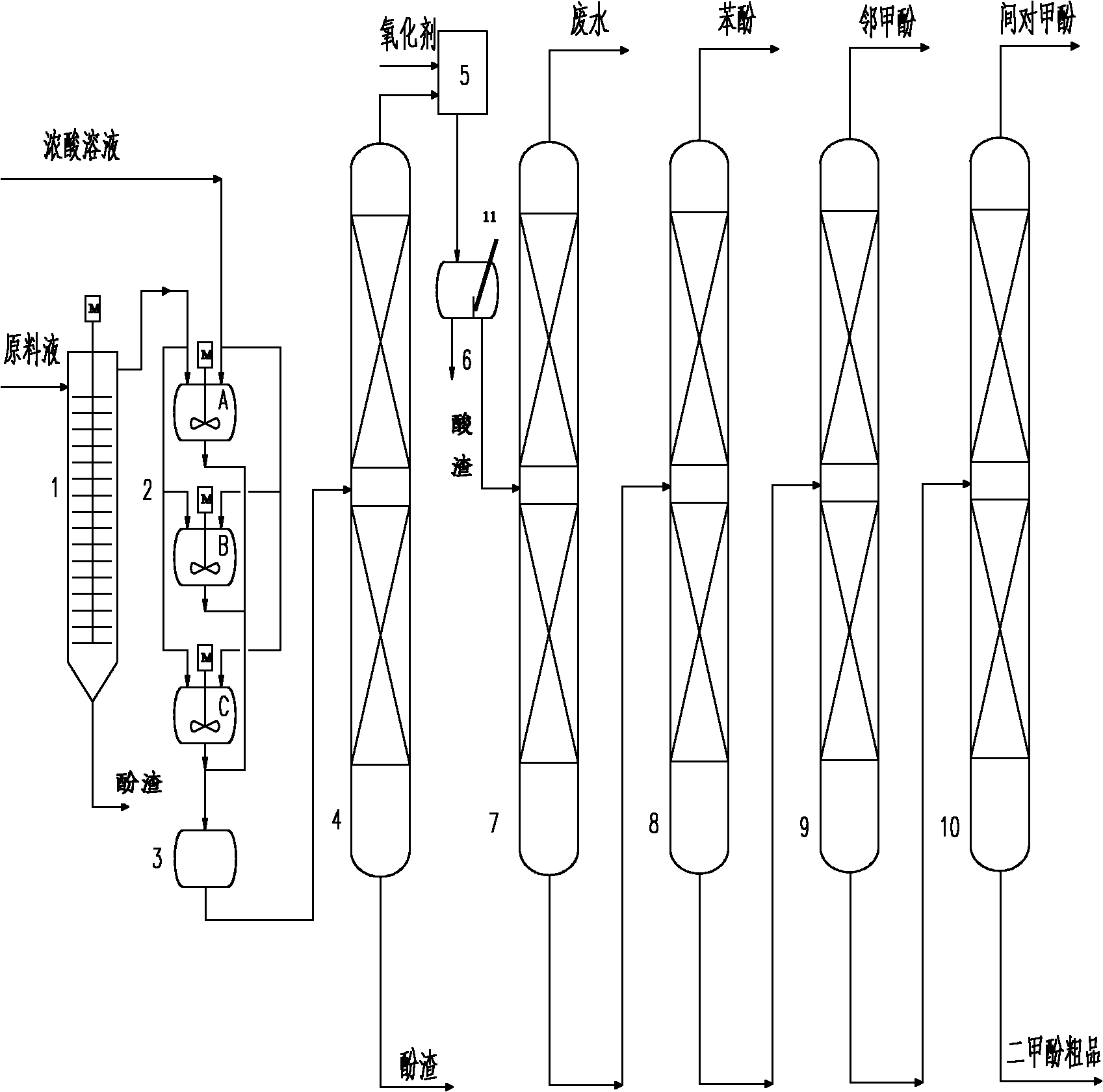

The invention relates to a continuous refinement separation device and method of coked crude phenol. The continuous refinement separation device comprises a static mixer 1, a first stage pretreatment acid-adding unit composed of a first stage mixing slot 2 and a wipe film evaporator 3, a second stage pretreatment oxidation unit composed of a second stage mixing slot 4 and a buffer tank, a phenol residue removing tower 6 and a rectification tower system composed of a dewatering tower 7, a phenol refinement tower 8, a orthocresol refinement tower 9 and a m,p-cresol refinement tower 10, wherein the first stage pretreatment acid-adding unit is connected with the phenol residue removing tower, the phenol residue removing tower is connected with the second stage pretreatment oxidation unit, andthen all devices of the refinement tower system are connected together in turn. The device and method of the invention can effectively performs processes of decoloring, deodorizing, desulfurizing, removing impurity and the like to the coked crude phenol raw material through reasonable design to obtain more than 99.5wt% of high purity phenol, more than 99.0wt% of high purity orthocresol, more than99.0wt% of high purity m,p-cresol and xylenol product. The whole process is reasonable, has high degree of automation and is characterized by low process energy consumption, high product quality, good stability and the like, thus the method of the invention is an effective and feasible coked crude phenol continuous refinement separation technology.

Owner:天津美科泰化工科技有限公司 +1

Polyesterimide enamelled wire paint capable of straightly soldering and method for preparing same

InactiveCN101338157AShort synthesis timeReduce energy consumptionPlastic/resin/waxes insulatorsCoatingsPolyesterLacquer

The invention discloses direct welding polyester imine enamel wire paint and a preparation method thereof. Firstly, polyester imine resin generates from monacid, aromatic dicarboxylic acid, 4-methacryoxypropyl, 4, 4'-diaminodiphenyl-methane, trihydric alcohol, triethanolamine, dihydric alcohol and monoethanolamine through the melt copolycondensation under the function of catalyst; secondly, modified etherifying amino resin is prepared from melamine, urea, benzoguanamine, 37 percent of formaldehyde, methanol, isopropanol and normal butyl alcohol through the hydroxymethylation and etherification; thirdly, modified etherified phenolic resin is prepared from technical xylenol, isopropylidene diphenol, boric acid, 37 percent of formaldehyde, methanol, isopropanol and normal butyl alcohol through the hydroxymethylation and etherification; finally, three products obtained through the three steps are mixed with mixed environmental solvent according to the quality ratio of 1-1.9 to 0.2-0.9 to 0.2-0.9 to 8 to obtain the direct welding polyester imine enamel wire paint. The enamel wire painted through the enamel wire paint of the invention can be welded directly under the condition of not higher than 400 DEG C and the stretch of the enamel wire paint or the fluting of zero pinhole can be realized.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Preparing method for 3,5-dimethyl phenol

A process for preparing 3.5-xylenol features that the isophorone, liquid catalyst, and solid catalyst take part in reaction in inertial gas, and conventional collecting 3,5-xylenol.

Owner:MAOYANG CHEM IND SCI & TECH DEV SHANGHAI

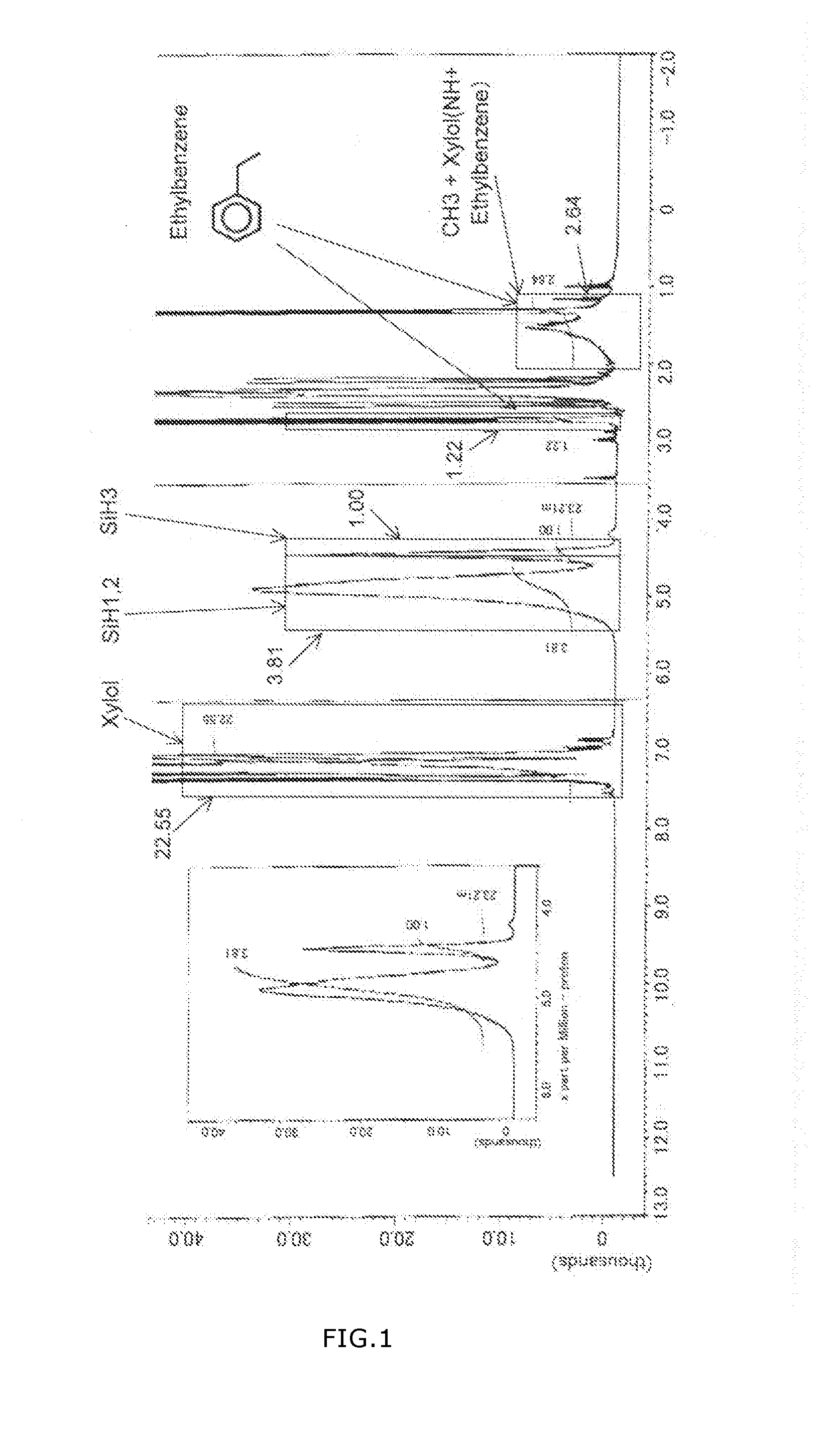

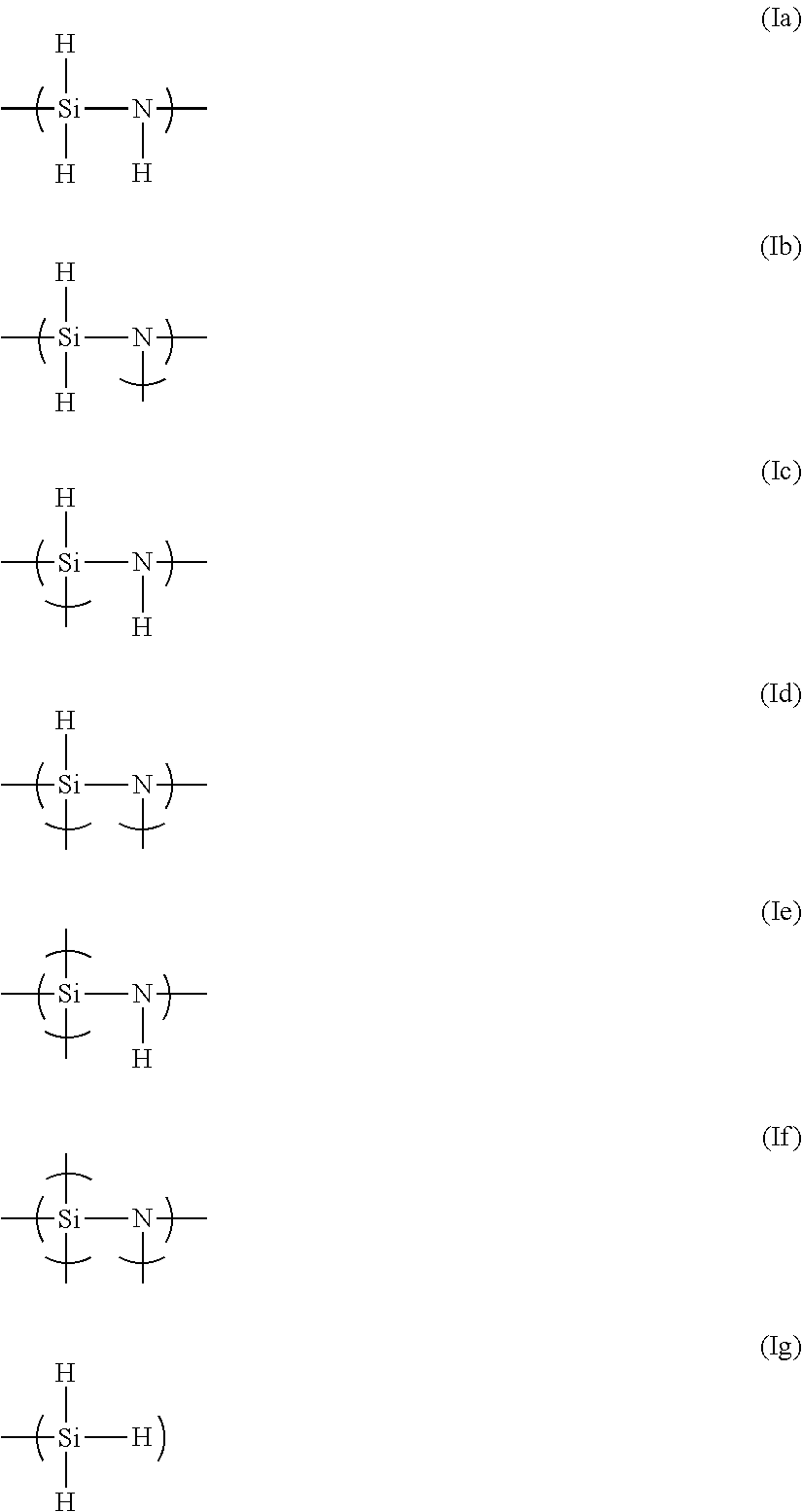

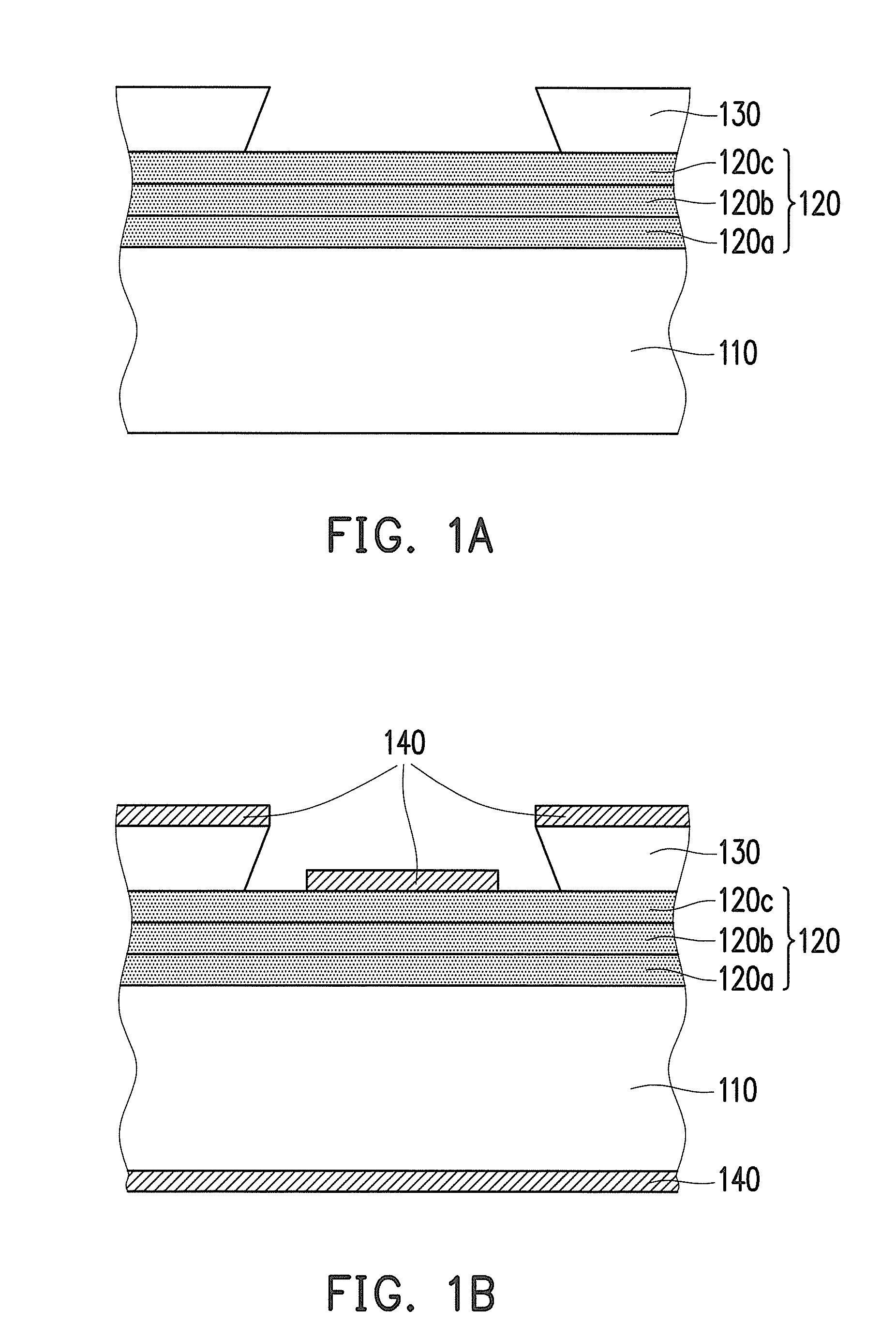

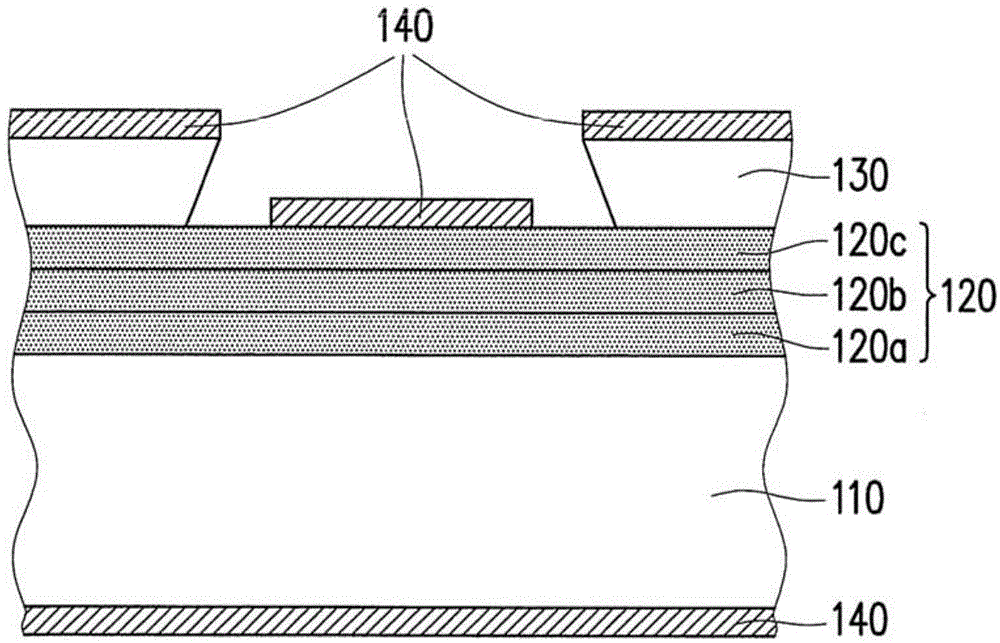

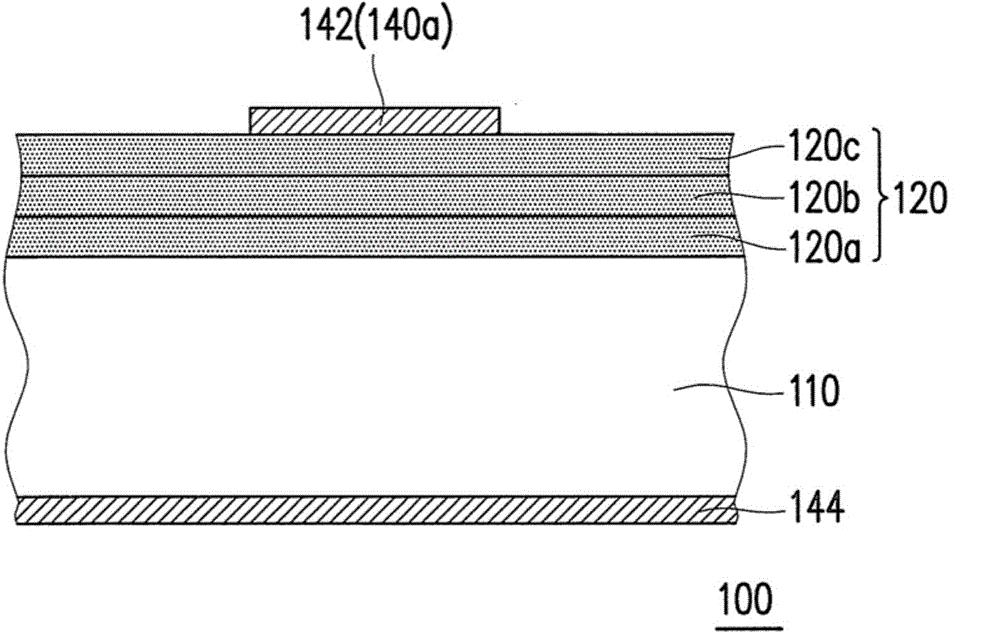

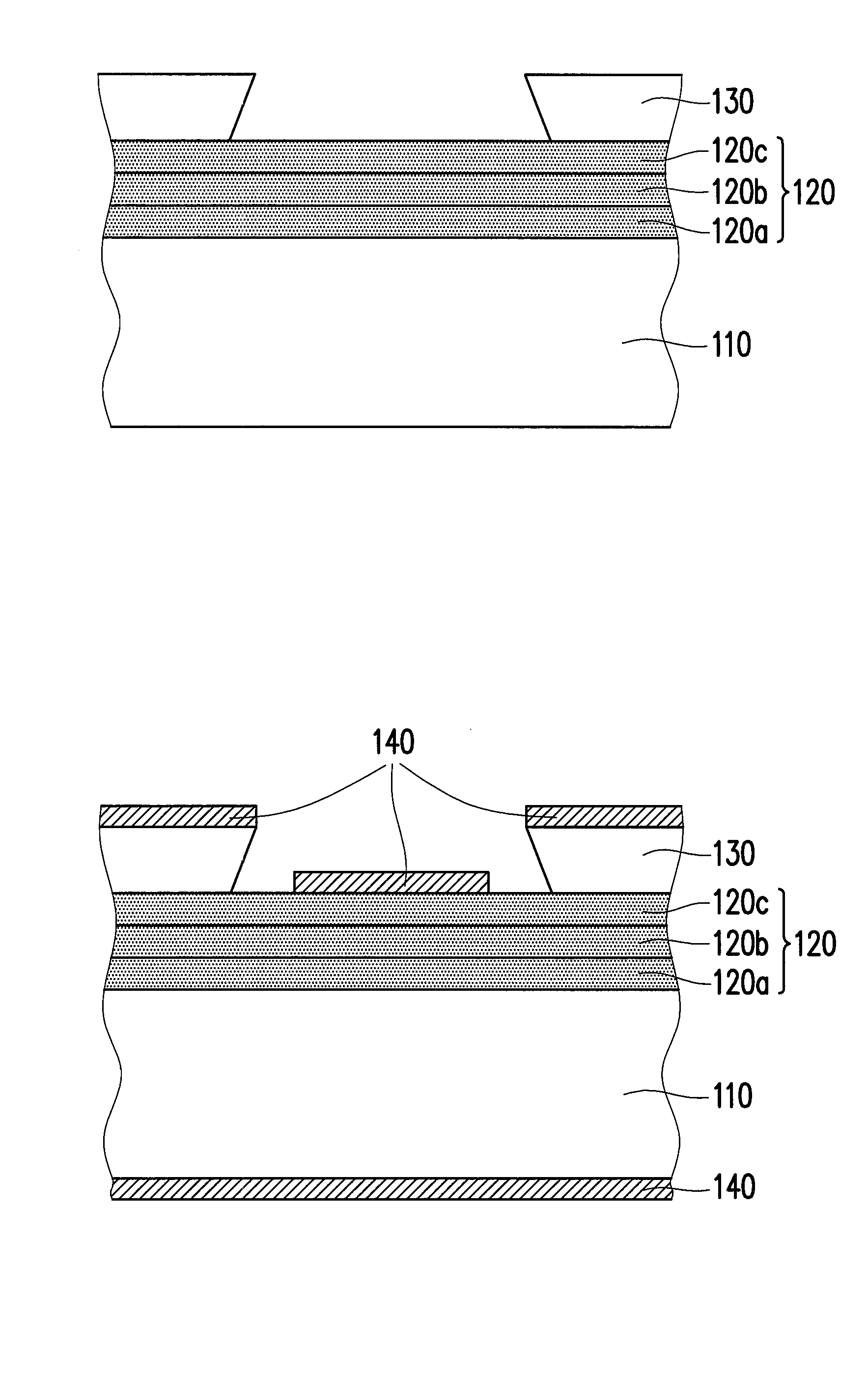

Perhydropolysilazane, composition containing same, and method for forming silica film using same

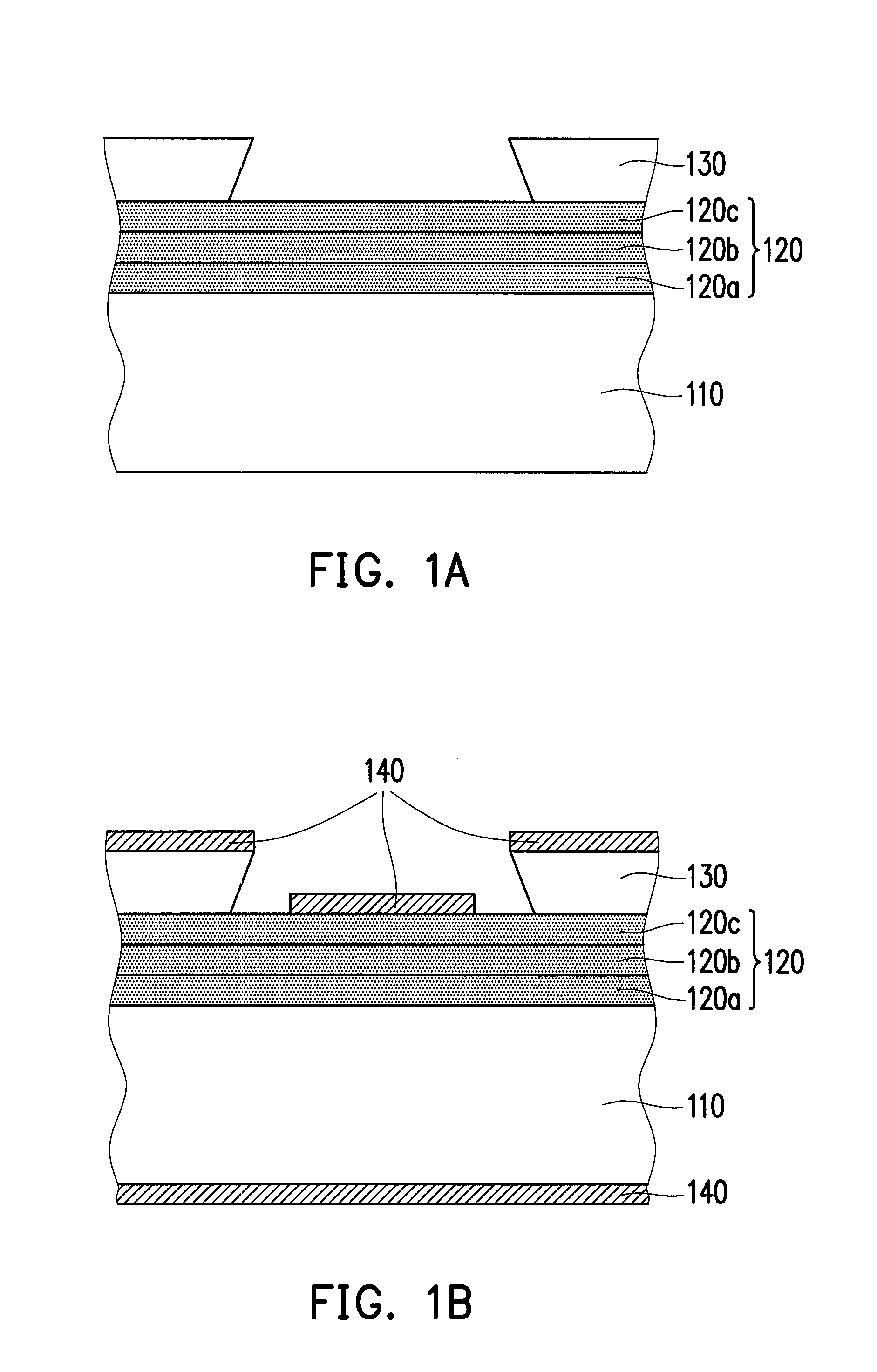

ActiveUS20160379817A1Improve stabilityFew defectSemiconductor/solid-state device manufacturingCoatingsHydrogen contentSilica membrane

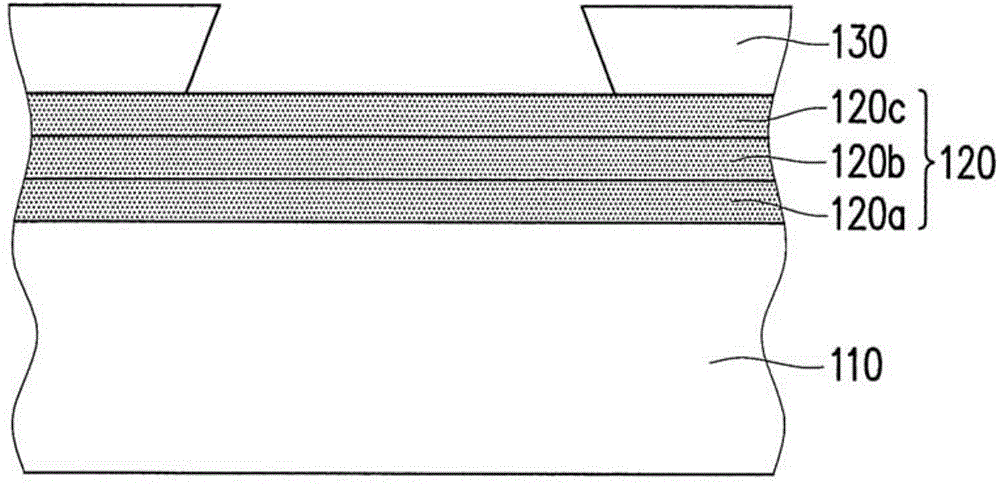

[Problem] To provide a perhydropolysilazane making it possible to form a siliceous film with minimal defects, and a curing composition comprising the perhydropolysilazane.[Means for Solution] The present invention provides a perhydropolysilazane having a weight-average molecular weight of 5,000 to 17,000, characterized in that when 1H-NMR of a 17% by weight solution of said perhydropolysilazane dissolved in xylol is measured, the ratio of the amount of SiH1,2 based on the aromatic ring hydrogen content of the xylol is 0.235 or less and the ratio of the amount of NH based on the aromatic ring hydrogen content of the xylol is 0.055 or less, and a curing composition comprising the perhydropolysilazane. The present invention also provides a method for forming a siliceous film, comprising coating the curing composition on a substrate and heating.

Owner:MERCK PATENT GMBH

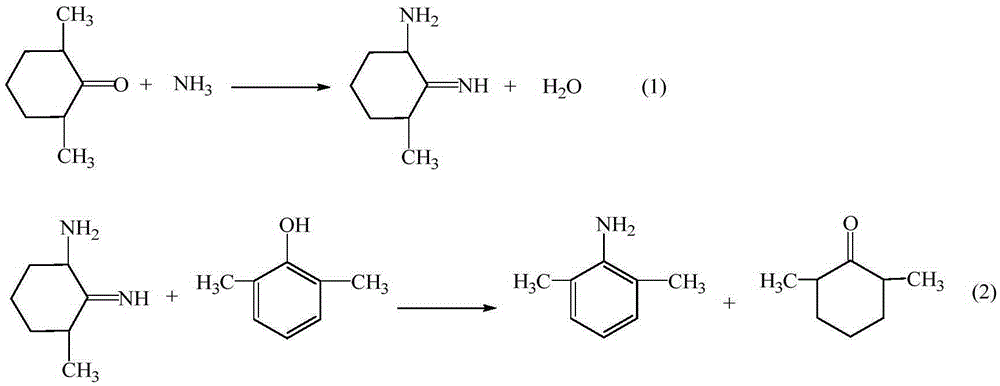

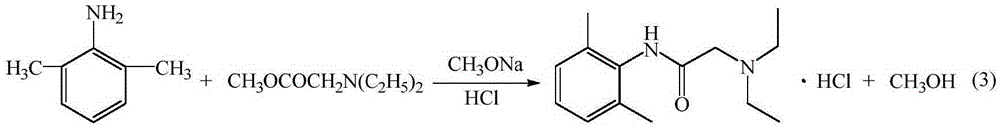

Method for preparing lidocaine hydrochloride

ActiveCN105294477AThe synthesis process is simpleHigh purityOrganic compound preparationCarboxylic acid amides preparationDimethylaniline N-oxideOrganic layer

The invention provides a method for preparing lidocaine hydrochloride, and belongs to the technical field of anesthetic synthesis. The method comprises the following steps: by taking 2,6-xylenol as a raw material, Pd / C as a main catalyst and 2,6-dimethylcyclohexanone as a promoter, performing liquid phase amination with ammonia water at high temperature, thereby obtaining a midbody 2,6-dimethylaniline; enabling sodium methylate, 2,6-dimethylaniline and N,N-lignocaine methyl acetate as raw materials to react at 90-95 DEGC, distilling while reaction is performed to remove methanol till no methanol can be evaporated out, continuously reacting for 30 minutes, cooling to the room temperature, adding dichloroethane, washing with water, and leaving to stand to layer, thereby obtaining an organic layer, namely, a lidocaine based dichloroethane solution; further adding hydrochloric acid into the lidocaine based dichloroethane solution, adjusting the pH value to be 3.5-4 by using hydrogen chloride, adding activated carbon to reflux for 20-40 minutes, filtering, concentrating the filtrate, cooling, crystallizing, and dying, thereby obtaining lidocaine hydrochloride. The lidocaine hydrochloride prepared by using the method is simple in synthesis process and high in product purity, that is, the purity can be greater than 99%, and the total yield is greater than 84%.

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD

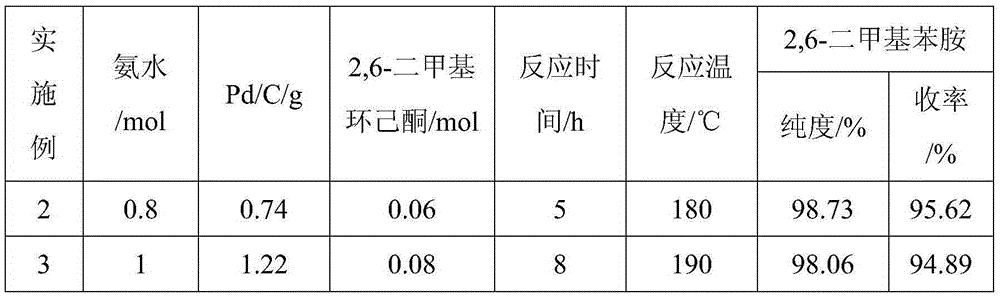

Method for producing methyl phenol

ActiveCN103896740AUniform temperatureSmall temperature differenceOrganic chemistryMolecular sieve catalystsMolecular sieveWater vapor

The present invention provides a process for the production of cresol. The raw materials comprising ethers, phenols and carbinol are preheated, and then continue through the multi-stage solid catalyst bed mixed with steam, carrying out a gas-phase reaction to product cresol at 250-450℃ reaction temperature, with 0.3-5h-1 feed weight airspeed, and under ordinary pressure. The solid catalyst is selected one or more from alumina, kaolin and molecular sieve catalyst. The phenols are selected from phenol, xylenol and mixture thereof. The ethers are selected from anisole, dimethyl ether, methylanisole, and their mixture of any two or more. When the once-through yield of cresol is 0.2g cresol / g catalyst, the para-selective of p-cresol could reach 45%. The catalyst has been characterized by excellent stability, and non-corrosiveness for equipment in productive process, which is a kind of environment-friendly catalyst with predictable industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

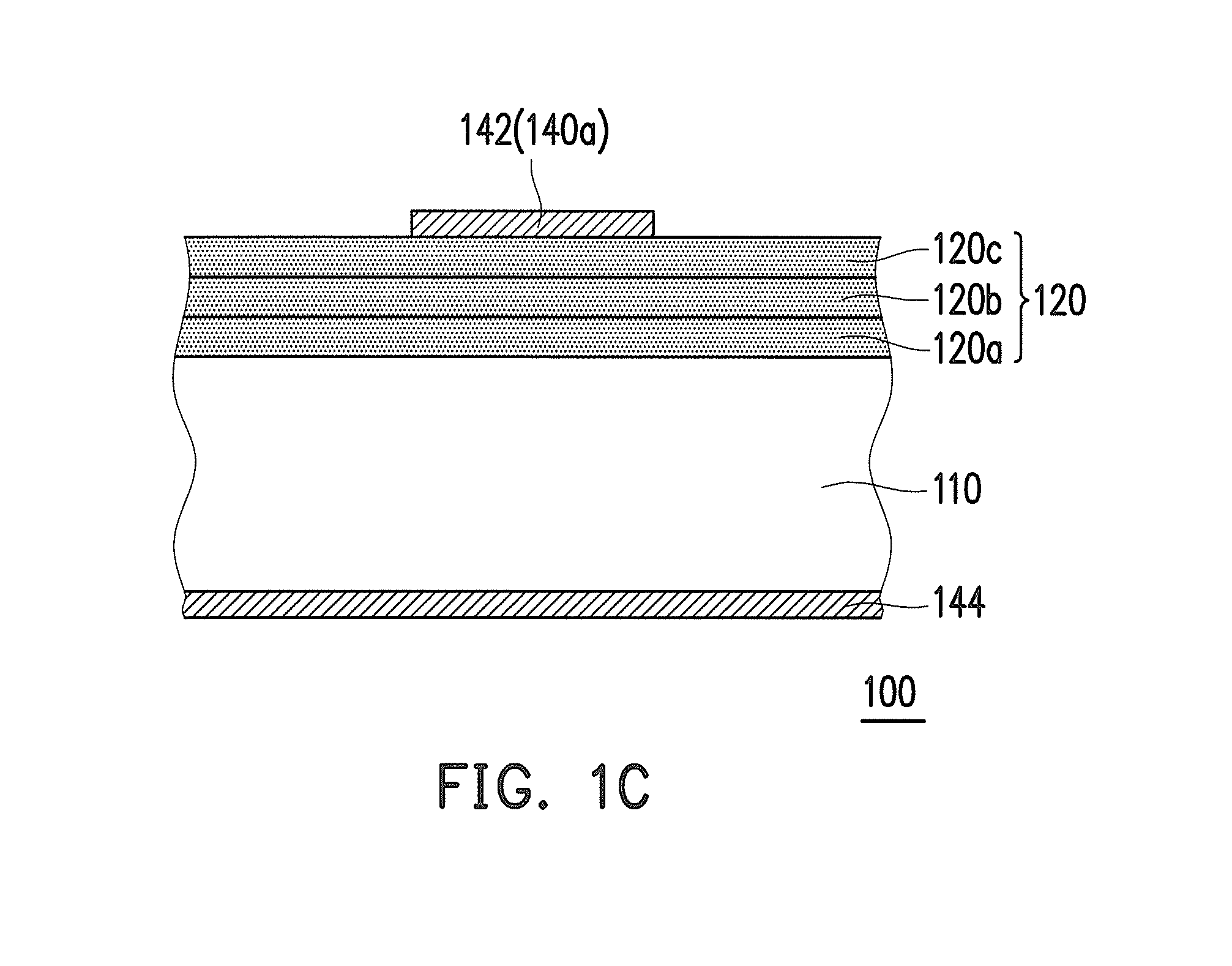

Negative photosensitive resin composition and application thereof

ActiveUS20150044790A1Excellent peelabilityAccelerate evaporationPhotosensitive materialsSolid-state devicesXylylenePolymer science

A negative photosensitive resin composition including an alkali-soluble resin (A), a photoacid generator (B), a basic compound (C), a cross-linking agent (D), and a solvent (E) is provided. The alkali-soluble resin (A) includes an acrylate resin (A-1) and a novolac resin (A-2). The acrylate resin (A-1) is synthesized by polymerizing a monomer for polymerization, wherein the monomer for polymerization includes an unsaturated carboxylic acid or unsaturated carboxylic acid anhydride monomer (a-1-1) and a monomer (a-1-2). The monomer (a-1-2) includes a compound (a-1-2-1) with a tricyclodecane or dicyclopentadiene structure, a compound (a-1-2-2) represented by formula (1), or a combination of both. The novolac resin (A-2) is synthesized by polymerizing an aldehyde compound with an aromatic hydroxy compound, wherein the aromatic hydroxy compound includes a xylenol compound.

Owner:CHI MEI CORP

Production process of phenol products

InactiveCN1974517ALess investmentSmall footprintOrganic chemistryOrganic compound preparationTheoretical plateSlag

The present invention relates to coal chemical technology, and is especially process of producing phenol products. By using crude phenol after dewaterig and eliminating slag as material and through once intermittent rectifying process in a rectifying tower with theoretical plate number of 60-90, phenol, o-cresol fraction, m, p-cresol and industrial xylenol are obtained, with the o-cresol fraction is intermittently decompression rectified to obtain o-cresol product. Compared with tower type process, the present invention has low cost, small area and low power consumption.

Owner:ANGANG STEEL CO LTD

Stable aqueous dispersions of hydrophilic phenolic resins having low xylenol and bisphenol-A content

Storage stable aqueous dispersions of a heat-reactive hydrophilic phenolic resin (e.g., phenol / formaldehyde) are disclosed. The dispersions comprise a base resin that is the reaction product of an aromatic alcohol and an aldehyde, and an etherified resin component selected from the group consisting of an etherified phenol / aldehyde resin, an etherified cresol / aldehyde resin, and mixtures thereof. The dispersions further comprise a protective colloid (e.g., polyvinyl alcohol). The addition of the etherified resin component in an amount of at least about 20% by weight of the base resin provides storage stability, but does not adversely affect the desirable physical and chemical characteristics (e.g., chemical resistance) of end products made from such dispersions. Moreover, the dispersions of the present invention can avoid the use of etherified resin components derived from bisphenol-A and / or xylenols, which present heath concerns in food coating applications.

Owner:GEORGIA PACIFIC CHEM LLC

Method for making 2,6-xylenol

InactiveUS6620908B2High activityGood choiceOrganic compound preparationOrganic chemistry methodsChloridePhenol

A method for making 2,6-xylenol is described. One embodiment of the method comprises: preparing a magnesium-based solid catalyst composition by dry-blending basic magnesium carbonate with at least one filler; forming the catalyst composition into a suitable catalyst-shape; calcining the shaped catalyst at a temperature in the range of about 350° C. to about 550° C.; and reacting phenol and methanol in the presence of the catalyst, to form 2,6-xylenol. The level of chlorides in the magnesium carbonate is less than about 250 ppm, and the level of calcium in the magnesium carbonate is less than about 2,500 ppm.

Owner:SABIC GLOBAL TECH BV

Stable aqueous dispersions of hydrophilic phenolic resins having low xylenol and bisphenol-A content

Storage stable aqueous dispersions of a heat-reactive hydrophilic phenolic resin (e.g., phenol / formaldehyde) are disclosed. The dispersions comprise a base resin that is the reaction product of an aromatic alcohol and an aldehyde, and an etherified resin component selected from the group consisting of an etherified phenol / aldehyde resin, an etherified cresol / aldehyde resin, and mixtures thereof. The dispersions further comprise a protective colloid (e.g., polyvinyl alcohol). The addition of the etherified resin component in an amount of at least about 20% by weight of the base resin provides storage stability, but does not adversely affect the desirable physical and chemical characteristics (e.g., chemical resistance) of end products made from such dispersions. Moreover, the dispersions of the present invention can avoid the use of etherified resin components derived from bisphenol-A and / or xylenols, which present heath concerns in food coating applications.

Owner:GEORGIA PACIFIC CHEM LLC

Preparation method of gel material for adsorbing heavy metal ions and phenolic compound and product of gel material

InactiveCN105399896AHigh strengthStable molecular weightOther chemical processesAlkali metal oxides/hydroxidesMeth-Hexadecyltrimethylammonium bromide

The invention relates to a preparation method of a composite gel material which has excellent adsorption capacity of heavy metal ions, such as lead, cadmium, nickel, chromium, and molybdenum, and a phenolic compound, such as phenol, methylphenol, and xylenol, at the same time, is high in adsorption quantity and efficiency, and can be reused after washing, and relates to a product of the composite gel material. Attapulgite is subjected to water washing and acid washing, and is modified through a sodium chloride solution, hexadecyltrimethylammonium bromide, and a humic acid to prepare humic-acid-modified attapulgite. The humic-acid-modified attapulgite and acrylamide hydrogel are compounded to prepare the product of the composite gel material. The preparation method of adsorption macromolecule hydrogel is simple in process and low in cost, does not require any special equipment, and is easy for industrial application. The strength of the prepared gel is greatly improved.

Owner:TIANJIN JINLIN WATER TREATMENT SCI & TECH CO LTD

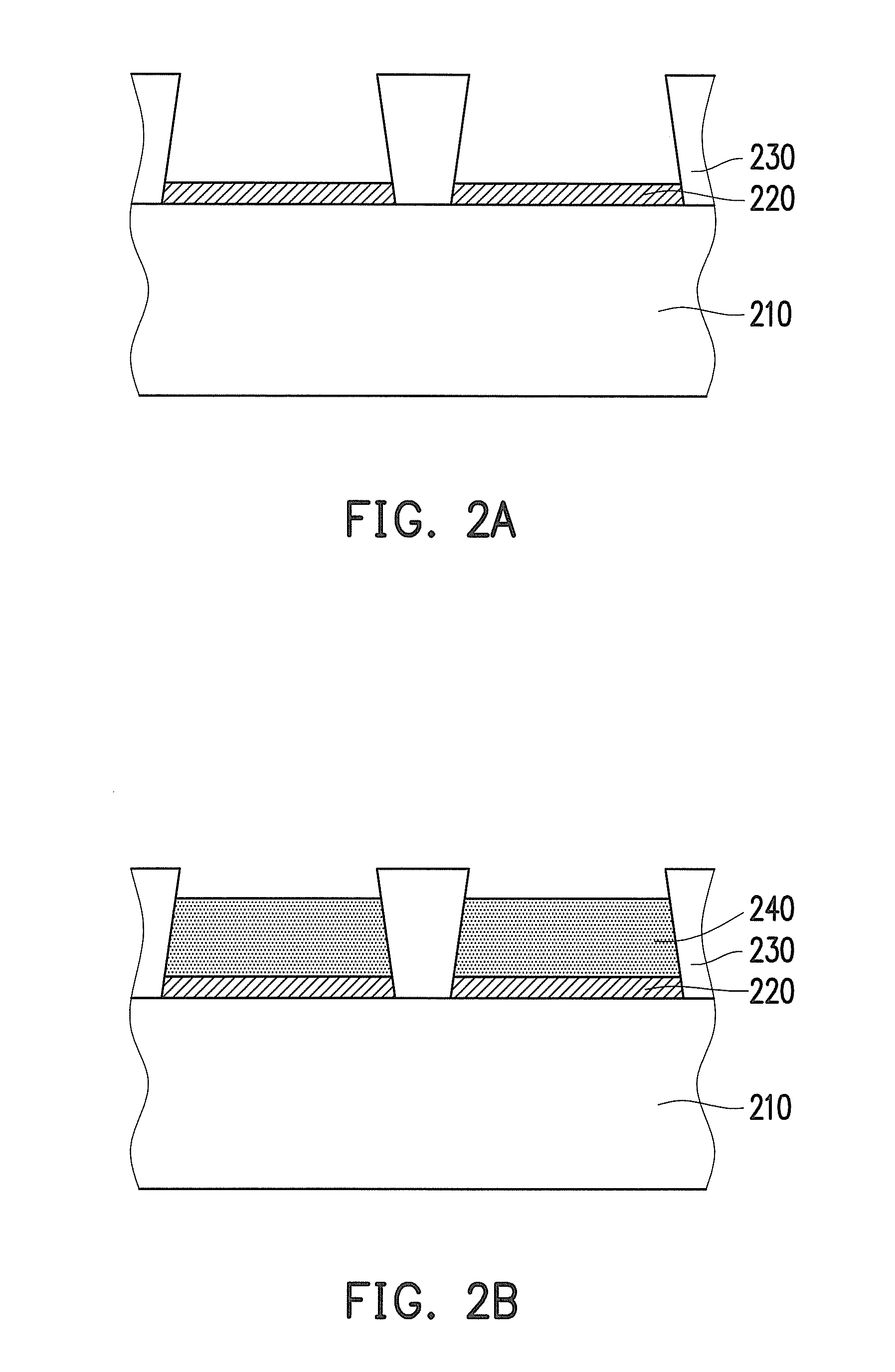

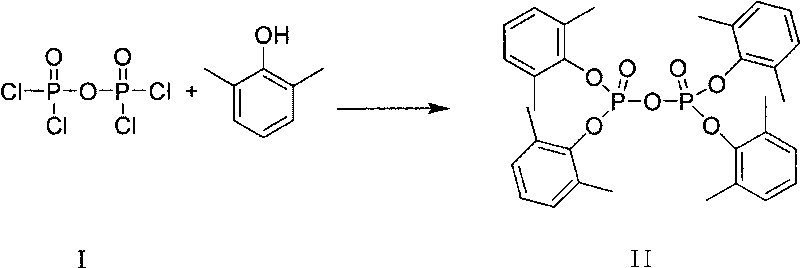

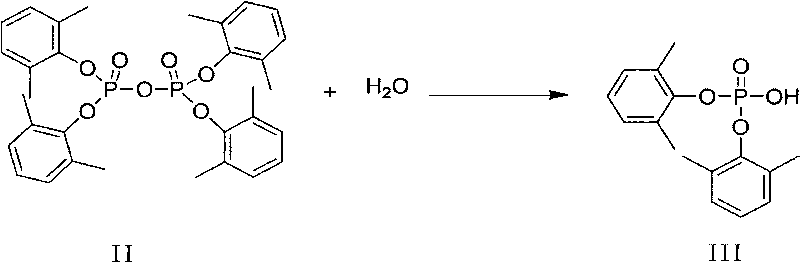

Method for preparing retardant resorcinol bis(2,6-dimethyl ployphosphate ester)

ActiveCN101723974ASignificant progressSignificant positive effectGroup 5/15 element organic compoundsAcid washingSolvent

The invention relates to a method for preparing resorcinol bis(2,6-dimethyl ployphosphate ester). The method comprises the following steps: heating phosphorus oxychloride, catalyst, water absorbent and solvent to a temperature between 110 and 115 DEG C; dripping 2,6-xylenol into the mixture, wherein the molar ratio of the 2,6-xylenol to the phosphorus oxychloride is 2:(1-1.02) to react at a temperature between 145 and 150 DEG C to obtain a colorless intermediate product; continuously dripping resorcinol into the intermediate product at a temperature between 140 and 145 DEG C, wherein the dosage is 0.48 to 0.5 time that of the molar dosage of the phosphorus oxychloride; reacting at a temperature between 150 and 155 DEG C; cooling the reactant to 100 DEG C to obtain a crude product; and carrying out acid-washing, alkaline-washing, water-washing, evaporating and drying for the crude product to obtain the product. The obtained product has a content of the monomer over 99.0 percent by weight, a melting point between 94.5 and 96.5 DEG C, an acid value less than 0.3mg KOH / g, and good quality.

Owner:PETROCHINA CO LTD

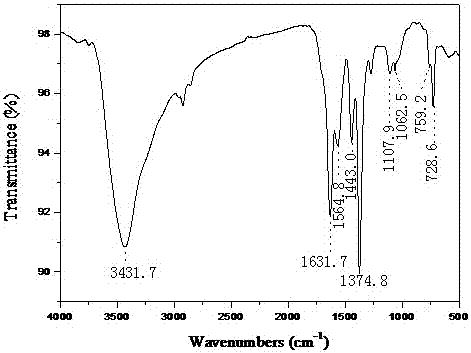

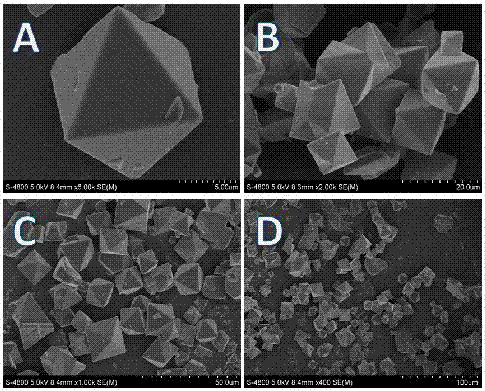

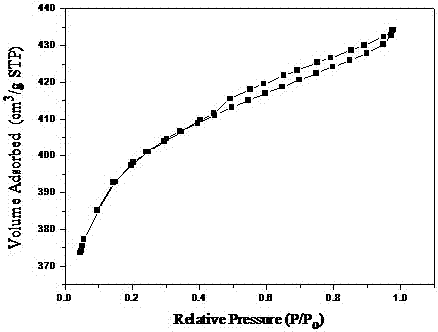

Copper complex built by pyrimidine carboxylic acid base ligand, preparation method and use of copper complex

ActiveCN102633821AWith granularityUnique structureOrganic-compounds/hydrides/coordination-complexes catalystsCopper organic compoundsCarboxylic acidSolvent

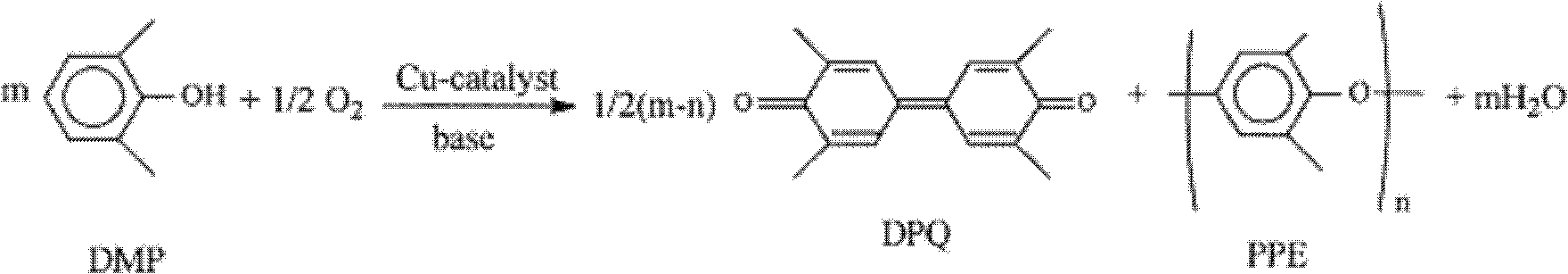

The invention relates to a copper complex, a preparation method of the copper complex, and a catalysis research result related to the copper complex. The copper complex has a mononuclear structure with the chemical formula of [Cu (dpca) (2,2'-bipy) (ClO4) (H2O)], wherein Hdpca=2,4-dyhydroxyl pyrimidine-5-carboxylic acid, and 2,2'-bipy=2, 2'-bipyridyl. The complex is formed by means of self-assembly cultivation of master ligand 2,4-dyhydroxyl pyrimidine-5-carboxylic acid, auxiliary ligand 2,2'-bipyridyl and Cu(ClO4)2.6H2O under room temperature, wherein the product has the characteristics of being high in stability, insoluble in water and most organic solvents, easy to separate, and reusable. The complex is taken as a catalyst to be used for the 2, 6-xylenol (DMP) oxidative coupling reaction, so that the polyphenyl ether (PPE) can be prepared with high selectivity, and a series of problems that the polyphenyl ether generated by the 2, 6-xylenol oxidative coupling reaction is bad in selectivity, low in yield, hard to recover catalyst, and capable of polluting the environment caused by the solvent can be solved.

Owner:李建伟

BADGE- and BPA-Free Can Coating

ActiveUS20080299343A1Suitable flexibilitySuitable resistanceSynthetic resin layered productsPretreated surfacesAcrylic resinPolyvinyl chloride

The present invention relates to a composition, which is useful for producing coatings for metal sheet substrates of metal cans for storing and / or transporting food or beverages or a lid thereof, and which comprises the following components:(a) 30 to 90 wt. % of a polyvinylchloride-(PVC)-polymer,(b) 7 to 25 wt. % of an acrylic resin,(c) 3 to 40 wt. % of a crosslinking agent, which is produced from phenol, para-tert.-butylphenol, xylenol or a mixture thereof, and formaldehyde,(d) 0 to 8 wt. % additive,(e) 0 to 50 wt. % pigment and(f) a solvent-component,where all weight percentages are on the basis of the total dry weight of the coating composition (without solvents) and the composition is substantially free of bisphenol-A-diglycidyl-ether (“BADGE”) and also substantially free of bisphenol-A-resins. The composition provides metal can coatings that have suitable flexibility, scratch resistance, adherence and sterilization resistance when processed in contact with food. The coatings are suitable for three-piece cans as well as deep-drawn metal cans. In particular they are, however, useful for lids that are to be torn open due to their extraordinary flexibility and sterilization resistance.

Owner:HENKEL KGAA

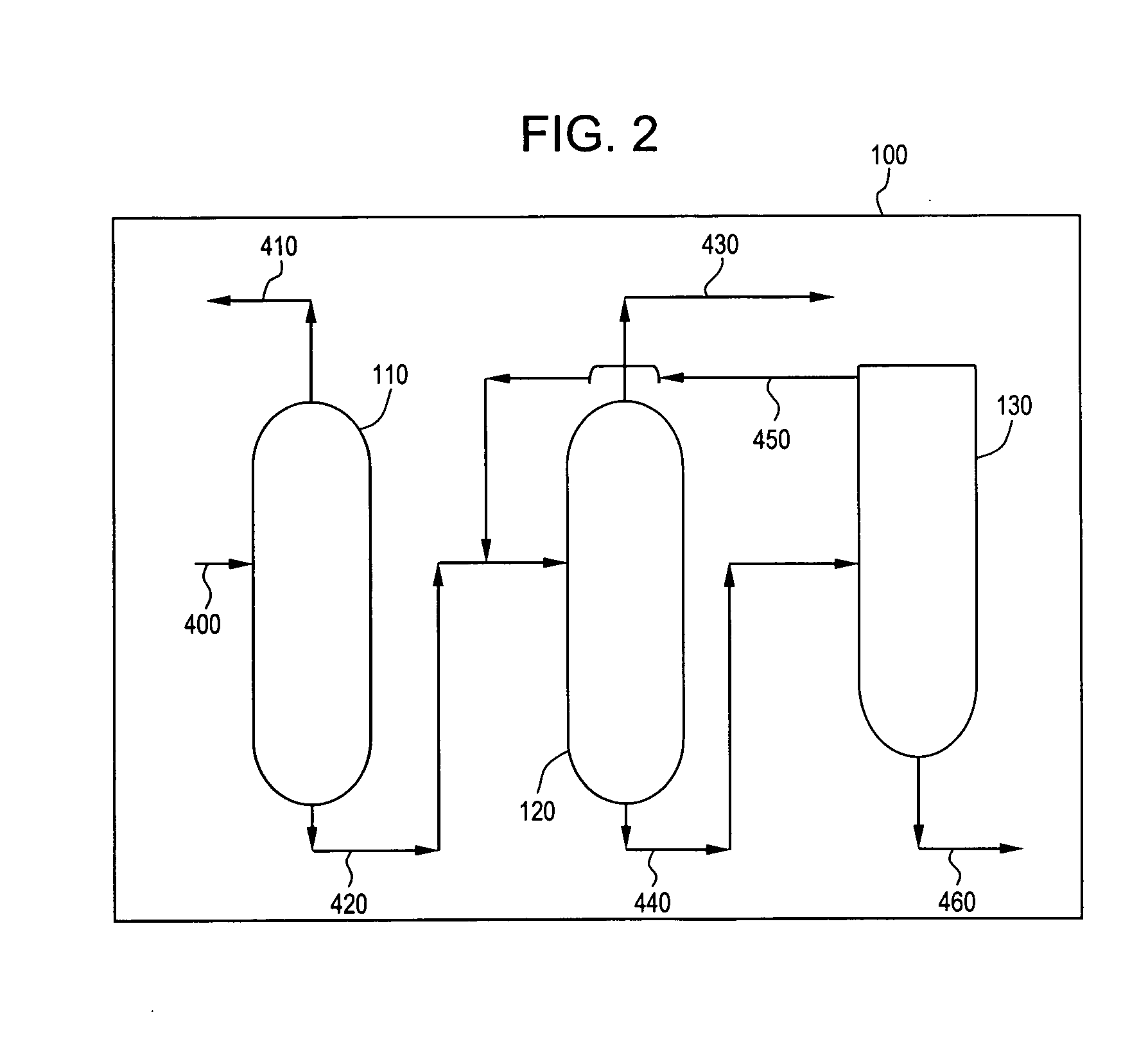

Continuous refining separation device and method for coal gasification crude phenol

ActiveCN102153449ASolve corrosion resistanceQuality assuranceOrganic chemistryOrganic compound preparationP-CresolImpurity

The invention discloses a continuous rectification separation device and a continuous rectification separation method for coal gasification crude phenol. The device comprises a first-level pretreatment acidifying unit consisting of a film scraping evaporator, a primary acid regulating tank group and a buffer tank, a second-level pretreatment oxidizing unit consisting of a static mixer and a secondary acid regulating tank and a rectifying tower system consisting of a deslagging tower, a dehydrating tower, a phenol refining tower, an o-cresol refining tower and a m, p-cresol refining tower, wherein the first-level pretreatment acidifying unit is connected with the phenol deslagging tower; and the phenol deslagging tower is connected with the second-level pretreatment oxidizing unit and is connected with each rectifying tower system respectively. By the device and the method, the raw material of the coal gasification crude phenol is subjected to decoloration, deodorization, desulfuration, impurity removal and the like effectively, so that products of high-purity phenol with the purity of more than 99.5 weight percent, high-purity o-cresol with the purity of more than 96.0 weight percent, high-purity m, p-cresol with the purity of more than 99.0 weight percent, mixed xylenol and phenol residual oil can be obtained. The method has the characteristics of reasonable process, high automaticity, low process energy consumption, high quality of products, high stability and the like, and is an efficient and feasible continuous rectification separation process for the coal gasification crude phenol.

Owner:天津美科泰化工科技有限公司

Negative photosensitive resin composition and application thereof

ActiveCN104345557ASolid-state devicesPhotomechanical exposure apparatusCross-linkPhotoacid generator

A negative photosensitive resin composition including an alkali-soluble resin (A), a photoacid generator (B), a basic compound (C), a cross-linking agent (D), and a solvent (E) is provided. The alkali-soluble resin (A) includes an acrylate resin (A-1) and a novolac resin (A-2). The acrylate resin (A-1) is synthesized by polymerizing a monomer for polymerization, wherein the monomer for polymerization includes an unsaturated carboxylic acid or unsaturated carboxylic acid anhydride monomer (a-1-1) and a monomer (a-1-2). The monomer (a-1-2) includes a compound (a-1-2-1) with a tricyclodecane or dicyclopentadiene structure, a compound (a-1-2-2) represented by formula (1), or a combination of both. The novolac resin (A-2) is synthesized by polymerizing an aldehyde compound with an aromatic hydroxy compound, wherein the aromatic hydroxy compound includes a xylenol compound.

Owner:CHI MEI CORP

Medical sterilization ultrasonic coupling agent and preparation method thereof

InactiveCN101773673AEffective disinfectionNot corrosiveIn-vivo testing preparationsUltrasonographyPhysical well being

The invention provides a medical sterilization ultrasonic coupling agent and a preparation method thereof. The coupling agent comprises the following main components by the weight percentage: 0.2-0.6% of p-chlor-m-xylenol, 4-8% of propylene glycol, 4-8% of glycerine, 0.3-1.2% of crosslinking polyacrylic acid resin, 0.2-1.2% of sodium hydroxide, and 80-90% of distilled water; the preparation method thereof comprises the steps: (1) dissolving crosslinking polyacrylic acid resin in distilled water to obtain liquor A; (2) dissolving p-chlor-m-xylenol in propylene glycol to obtain liquor B; (3) mixing and stirring the liquor A and liquor B, neutralizing with sodium hydroxide and adding glycerine to obtain the finished product. The invention not only meets the property and functions of medical sterilization ultrasonic coupling agent, but also has efficient and disinfectant effect and causes an ultrasonic probe to always maintain at the disinfectant state, thus completely solving the problem that the ultrasonic probe can not realize the effective disinfection in short time. The invention reduces the risk of the mutual pathogenic bacteria cross-infection among ultrasonic examinees and is beneficial to the health of people.

Owner:薛海燕

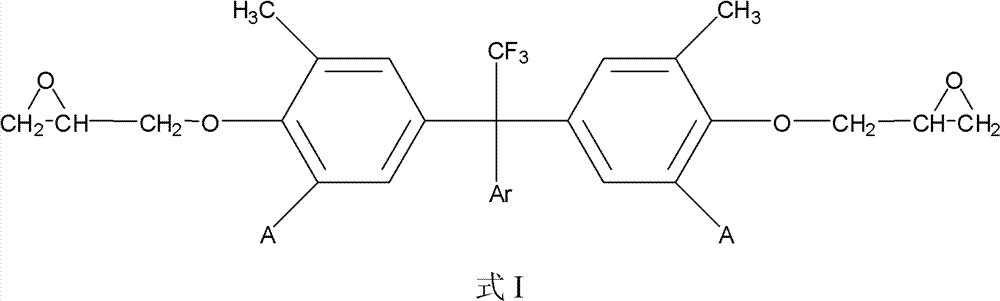

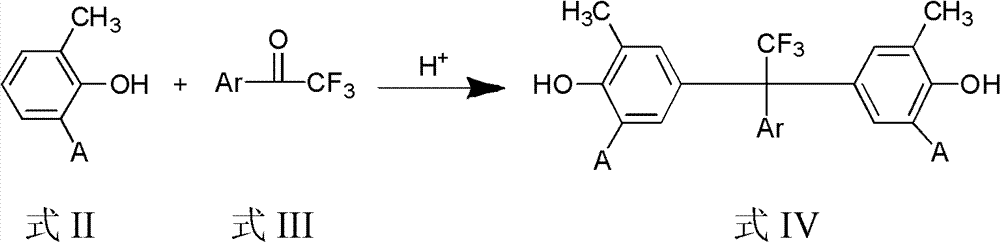

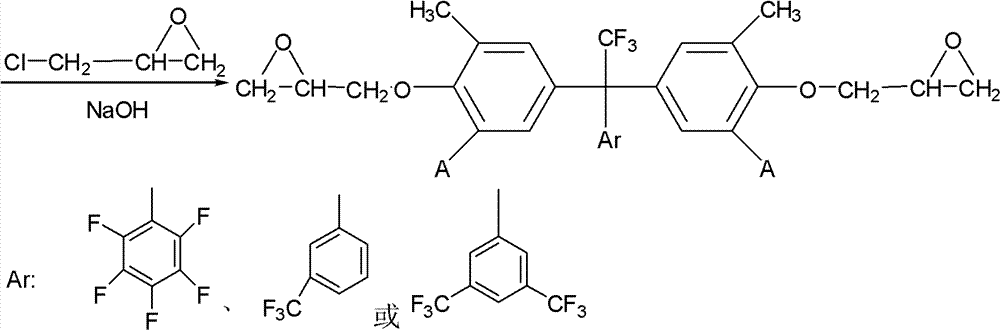

Fluorine-containing epoxy resin and preparation method thereof

InactiveCN103360347AHigh glass transition temperatureImprove electrical performanceOrganic chemistryEpoxyLewis acid catalysis

The invention relates to epoxy resin, and in particular relates to fluorine-containing epoxy resin and a preparation method thereof. The method comprises the following steps of: performing a condensation reaction on a substituted alpha, alpha, alpha-trifluoro-multifluoro-substituted phenyl ethyl ketone and 2-methylphenol (or 2,6-xylenol) under the catalysis of a lewis acid, thereby preparing a fluorine-containing diphenol compound; and then performing a reaction on the fluorine-containing diphenol compound and epoxy chloropropane under the catalysis of an alkali, thereby obtaining the fluorine-containing epoxy resin having the structure in the following formula. The fluorine-containing epoxy resin is cured by using a commonly-used epoxy resin curing agent, so that the cured fluorine-containing epoxy resin has the advantages of high vitrifaction transformation temperature, excellent electrical property, low water absorption rate, strong hydrophobicity and the like. Thus, the fluorine-containing epoxy resin can be possibly applied to the fields of microelectronic packaging and surface coating.

Owner:INST OF CHEM CHINESE ACAD OF SCI

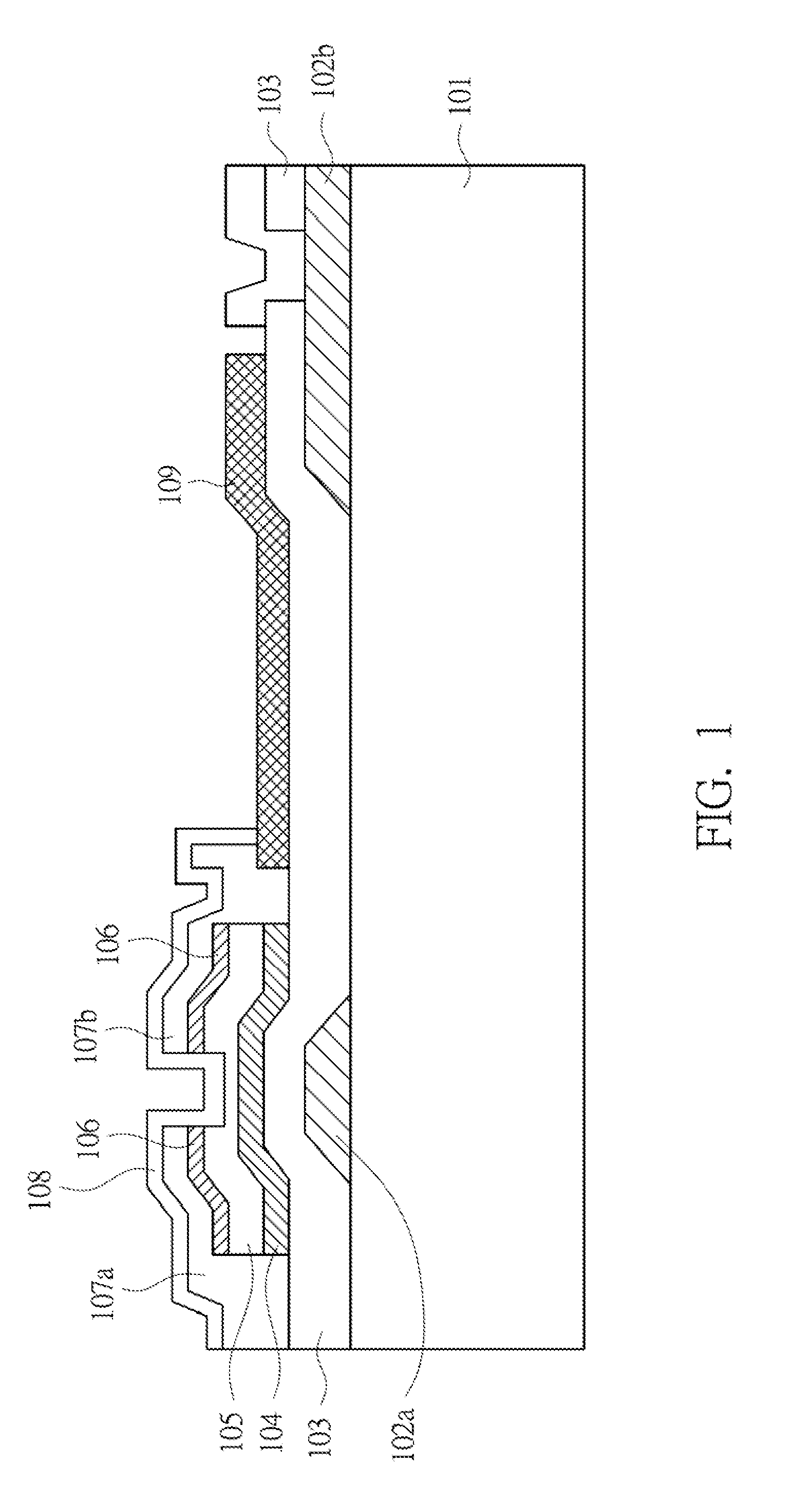

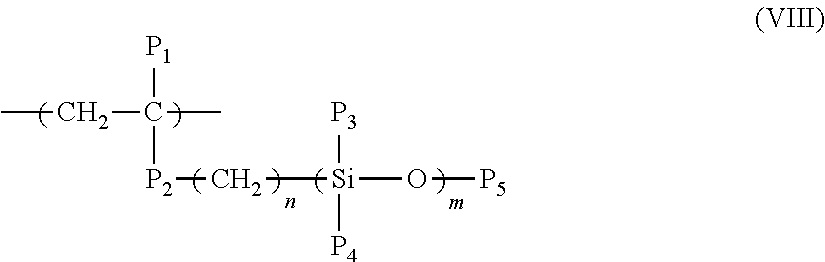

Positive photosensitive resin composition and method for forming pattern by using the same

ActiveUS9395627B2Easy to shapeGreat cross sectionPhotomechanical exposure apparatusMicrolithography exposure apparatusPolymer scienceNaphthoquinone

The present invention relates to a positive photosensitive resin composition and a method for forming a pattern by using the same. The positive photosensitive resin composition includes a novolac resin (A), a polysiloxane (B), an ortho-naphthoquinone diazide sulfonic acid ester (C) and a solvent (D). The novolac resin (A) includes a xylenol-type novolac resin (A-1). The xylenol-type novolac resin (A-1) is synthesized by polycondensing an aldehyde compound with a xylenol compound.

Owner:CHI MEI CORP

Preparation method of polyphenyl ether

The invention relates to the high molecular material field, and more specifically relates to a preparation method of polyphenyl ether. The preparation method of the polyphenyl ether comprises the following steps of adding cuprous chloride, pyridine and 2,6-xylenol to a reactor, and then adding the mixed solvent of 1,4-dioxane and water, and stirring for dissolving; slowly and dropwise adding hydrogen peroxide to the reactor at the room temperature, controlling the dropping time within 1-2h, and further stirring for reacting for 3-5h after finishing dropping; after the reaction is ended, pouring the solution into a methanol solution containing 5% of hydrochloric acid, carrying out suction filtration and collecting precipitate, washing for 3-5 times by using the hydrochloric acid-containing methanol solution, and drying in vacuum to obtain white polyphenyl ether powder. The mixed solvent employed by the preparation method provided by the invention is very effective for controlling the molecular weight of the polyphenyl ether; as the water content is increased and the dissolubility of the polyphenyl ether with high molecular weight is reduced, the polyphenyl ether precipitates as long as a certain molecular weight is achieved to terminate the reaction; the water content can be taken as the effective way to control the molecular weight; the ratio of the mixed solvent can be adjusted according to the desired molecular weight.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

Method for synthesizing high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone through Cu-BTC catalysis

ActiveCN107540529AProcess environmental protectionLow costQuinone preparation by oxidationOrganic-compounds/hydrides/coordination-complexes catalystsEmulsionFenchol

The invention discloses a method for synthesizing high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone through Cu-BTC catalysis. According to the method, trimesic acid and copper nitrate hydrateare hydrothermally synthesized into a Cu-BTC catalyst; under the alkaline emulsion reaction condition, hydrogen peroxide is utilized as an oxidizing agent, and 2,6-xylenol is oxidized and coupled intothe high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone; product quality yield of the high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone is 90 to 95%, and a product purity mass percent of the high-purity 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone is 98%; reaction temperature is 70 to 85 DEG C, and reaction time is 4 to 8h; the catalyst is easy to separate and recycle; after beingrepeatedly used for four times, quality yield of the 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone still reaches 87.5%, and purity of the 3,3',5,5'-tetramethyl-4,4'-biphenyl diquinone is 97.8%; alkaliemulsified filtrate and washing liquor can be recycled and deployed to be used repeatedly; a reaction condition is moderate, and a synthesizing technology has the advantages of greenness and environmental friendliness.

Owner:XIANGTAN UNIV

Negative photosensitive resin composition and application thereof

InactiveUS20140363915A1Poor strippabilityPhotosensitive materialsSolid-state devicesCross-linkPhotoacid generator

Owner:CHI MEI CORP

Paint for pot not containing BADGE and BPA

ActiveCN101316892AModerate flexibilitySuitable for abrasion resistancePretreated surfacesLinings/internal coatingsXylylenePolymer science

The present invention relates to a composition, which is useful for producing coatings for metal sheet substrates of metal cans for storing and / or transporting food or beverages or a lid thereof, and which comprises the following components: (a) 30 to 90 wt. % of a polyvinylchloride- (PVC) -polymer, (b) 7 to 25 wt. % of an acrylic resin, (c) 3 to 40 wt .% of a crosslinking agent, which is produced from phenol, para-tert, -butylphenol, xylenol or a mixture thereof, and formaldehyde, (d) 0 to 8 wt. % additive, (e) 0 to 50 wt. % pigment and (f) a solvent-component, where all weight percentages are on the basis of the total dry weight of the coating composition (without solvents) and the composition is substantially free of bisphenol-A-diglycidyl- ether ('BADGE') and also substantially free of bisphenol-A- resins. The composition provides metal can coatings that have suitable flexibility, scratch resistance, adherence and sterilization resistance when processed in contact with food. The coatings are suitable for three-piece cans as well as deep-drawn metal cans. In particular they are, however, useful for lids that are to be torn open due to their extraordinary flexibility and sterilization resistance.

Owner:HENKEL KGAA

Method of purifying 2,6-xylenol and method of producing poly(arylene ether) therefrom

InactiveUS20040211657A1Reduce odorous impuritySacrificing yieldOrganic compound preparationDistillation regulation/controlEtherImpurity

A method of purifying 2,6-dimethylphenol to remove the odorous impurities includes distilling a crude mixture to yield a first light fraction enriched in 2,6-dimethylphenol, and a first heavy fraction enriched in 2,4,6-trimethylanisole, and distilling the first light fraction to yield a second light fraction, and a second heavy fraction enriched in 2,6-dimethylphenol. The concentration of 2,4,6-trimethylanisole in the second heavy fraction is less than 50% of the concentration of 2,4,6-trimethylanisole in the mixture. The purified 2,6-dimethylphenol is useful for preparing low-odor poly(arylene ether) resins.

Owner:GENERAL ELECTRIC CO

Method for manufacturing non-expansion type halogen-free organic fireproof block material

InactiveCN101130695ALong-term flexibilityImprove water resistanceFireproof paintsFiberHydrogen halide

The invention relates to a making method of non-expansion non-bittern organic fireproof block material, which comprises the following steps: dispensing the raw material according to weight percent with 20%-50% aluminum hydroxide, 10%-25% zinc borate, 20%-40% porcelain powder, 5%-10% alumina silicate fiber, 2%-8% iron oxide red, 13%-20% polyester resin, 1%-2% coumarone resin, 1%-2% xylenol resin, 3%-6% dibutylphthalate, 1%-5% functional agent, soaking the coumarone resin 1%-2% and the xylenol resin in the dibutylphthalate for 24 hours; adding the polyester resin and the functional agent to stir to be sticking resin; adding the aluminum hydroxide, the zinc borate, the porcelain powder, the alumina silicate fiber, the iron oxide red into stirrer to stir for 10-15 minutes to form premix stuffing; squeezing to form shaping through force out machine after blending and stirring the sticking resin and the premix stuffing to form mission of viscous soft. The invention overcomes the problem that current fire-proof block can be produced irritating gas and smog under effect of fire hazard, which avoids toxic hydrogen halide gas to injury human body and corrode device effectively.

Owner:嵊州市电缆防火附件厂

A kind of disinfectant and preparation method thereof

InactiveCN102293199AEfficient killingPrevention and Control of TransmissionSoap detergents with organic compounding agentsBiocideDisinfectantPotassium hydroxide

The invention relates to a disinfectant and a preparation method thereof. The formula of the disinfectant is: p-chloro-m-xylenol, coconut oleic acid, potassium hydroxide, isopropanol, pine oil and deionized water, and its weight percentage is, 5.0 -7.0: 6.5-9.5: 3.7-5.4: 15.0-25.0: 3.0-6.0: margin. The preparation includes: (1) adding deionized water and potassium hydroxide, stirring, heating up to 90°C-100°C, and then adding coconut oleic acid to make potassium coconut oleate soap; (2) mixing p-chloro-m-xylenol with Mix isopropanol, heat up to dissolve, then add deionized water and the above-mentioned potassium coconut oleate soap, stir; cool to 30°C-35°C, add pine oil, stir, add deionized water and continue stirring, and the product is ready. The disinfectant solution of the invention can effectively kill 99.999% of intestinal pathogenic bacteria, pyogenic cocci and pathogenic yeasts; the preparation method is simple, the cost is low, and it is suitable for industrial production.

Owner:SHANGHAI SOAP GRP RUGAO

Antibacterial laundry detergent and preparation process thereof

ActiveCN103740491AImprove the bactericidal effectEliminate odorSurface-active detergent compositionsDetergent compounding agentsCarboxylic saltFatty alcohol

The invention discloses an antibacterial laundry detergent which is prepared from the following substances in percentage by weight: 28-32% of laurinol polyoxyethylene (3) ether sulfosuccinate, 7-12% of alcohol ether carboxylate, 6-10% of fatty alcohol polyoxyethylene ether sulfate, 0.1-0.3% of hydroxypropyl methyl cellulose, 2-4% of fatty alcohol polyoxyethylene ether, 1.2-2.3% of parachlormetaxylenol, 0.1-0.3% of GXL preservative, 3-7% of propylene glycol, 0.3-0.7% of protease, 0.2-0.4% of brilliant blue, 0.1-0.7% of essence and 30.3-52% of pure water, wherein the concentration of the brilliant blue is 0.0008-0.002g / g. The formula of the antibacterial laundry detergent disclosed by the invention has the functions of impurity adsorption, odor elimination, antisepsis and anti-inflammation and automatic cleaning, and in addition, the formula is simple and safe to use and can be applied to washing of underwear clothes. The invention further discloses a preparation process of the antibacterial laundry detergent.

Owner:KINGDOM HEALTHCARE HLDG LTD GUANGDONG

Novel alkylphenol resins and a method of preparing thereof

Compositions, methods, and resins using alkyl aldehydes and phenols are provided herein. In one embodiment, a composition comprising an alkylphenol resin can be prepared by condensing at least one phenolic monomer selected from the group consisting of phenol, cresol, resorcinol, xylenol, ethyl phenol, alkylresorcinols, and combinations thereof; and at least one alkyl aldehyde having from 5 to 12 carbon atom alkyl groups. The alkylphenol resins of the application are free of octylphenol or nonylphenol monomers. In one embodiment, the alkylphenol resins may be prepared using formaldehyde, and alternatively, in another embodiment, the alkylphenol resins may be prepared without the use of formaldehyde. The process to make these new alternative alkylphenol resins is a cost effective process and easy to scale-up.

Owner:BAKELITE UK HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com