Patents

Literature

556 results about "P-Cresol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Para-Cresol, also 4-methylphenol, is an organic compound with the formula CH₃C₆H₄(OH). It is a colourless solid that is widely used intermediate in the production of other chemicals. It is a derivative of phenol and is an isomer of o-cresol and m-cresol.

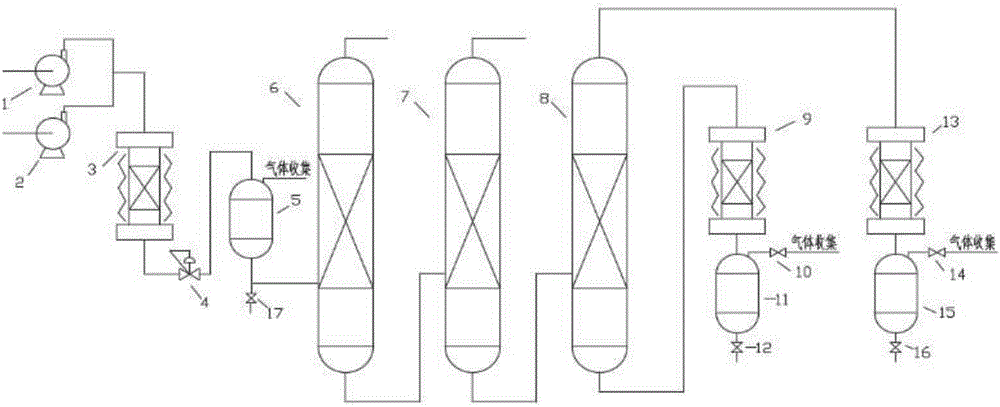

Separation method of m-cresol and p-cresol mixture

InactiveCN101863742AReduce consumption costReduce manufacturing costOrganic chemistryOrganic compound preparationAlkyl transferM-Cresol

The invention discloses a novel method for separating an m-cresol and p-cresol mixture to obtain high-purity m-cresol and p-cresol. The method comprises the following steps: carrying out alkylation reaction on the m-cresol and the p-cresol as raw materials under the existence of an alkylating agent and a catalyst to obtain the mixed solution of 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol; rectifying the mixed solution to obtain the products of high-purity 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol; respectively carrying out dealkylation reaction and rectification on the obtained high-purity 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol under the existence of the catalyst to respectively obtain the products of the high-purity m-cresol and p-cresol; and recovering isobutene generated by dealkylation. The invention has high reaction conversion rate, high atom use ratio, low raw material consumption and production cost and reliable safety performance.

Owner:吴鸿宾

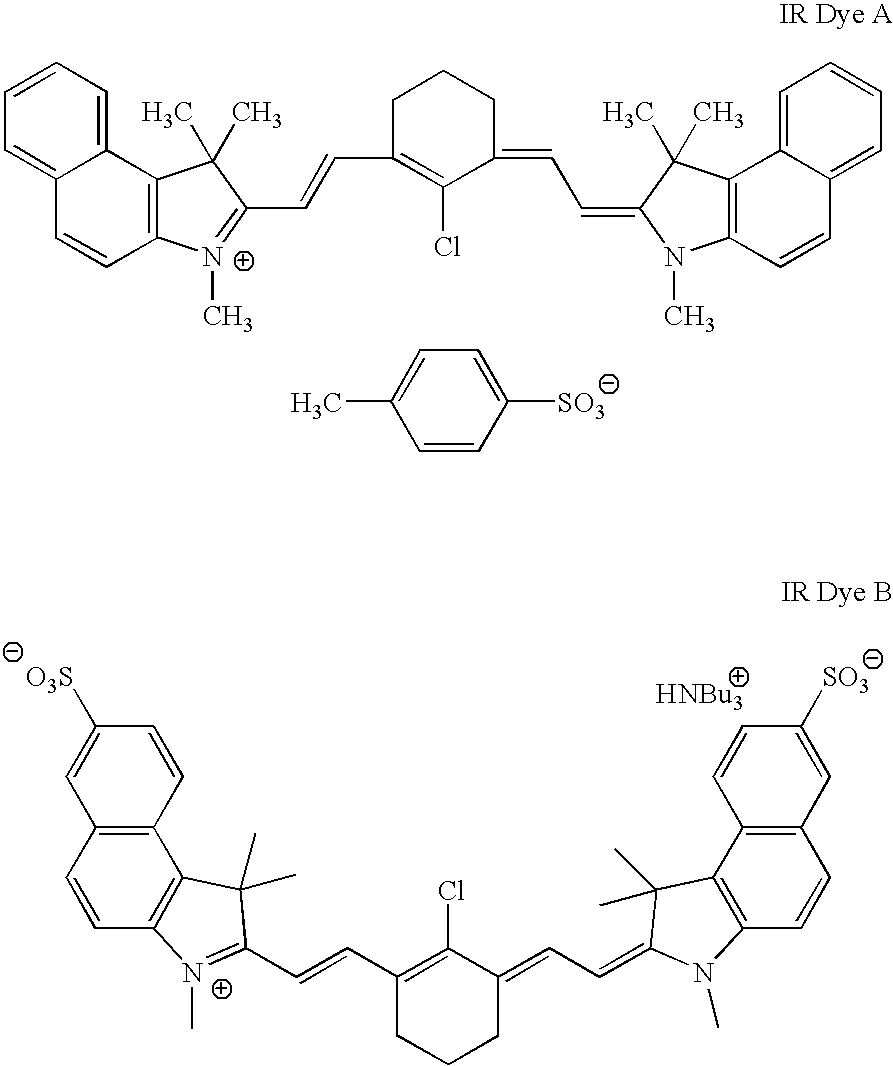

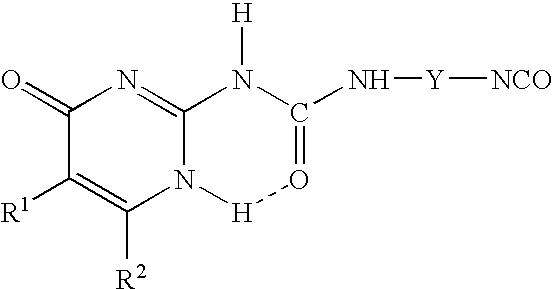

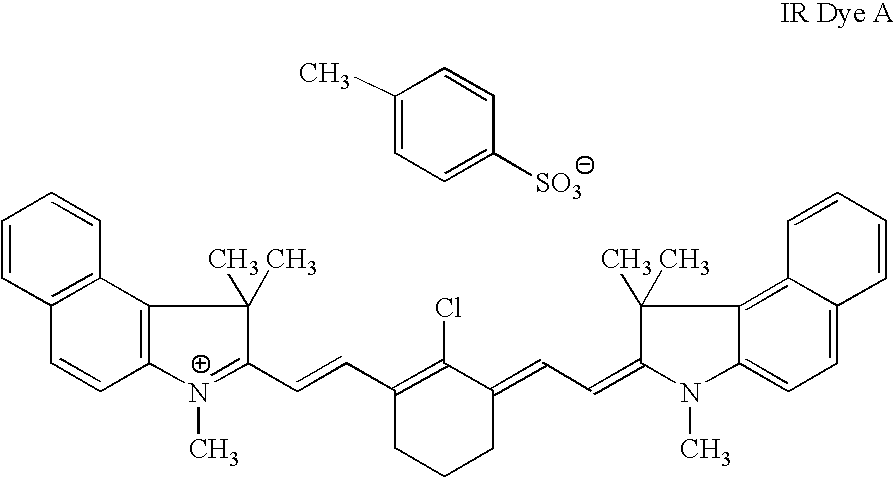

Thermally sensitive, multilayer imageable element

InactiveUS6858359B2Semiconductor/solid-state device manufacturingDiazo compound compositionsHydrogenHeat sensitive

Multi-layer, positive working, thermally sensitive imageable elements, useful as lithographic printing plate precursors, are disclosed. The elements comprises a substrate, an underlayer over the substrate, and a top layer over the underlayer. The top layer comprises polymeric material, which is a solvent soluble novolac resin or a derivative thereof. The polymeric material is a (a) novolac that has a weight average molecular weight of at least 10,000, a derivative thereof functionalized with polar groups, or a derivative thereof functionalized with quadruple hydrogen bonding entities; (b) a solvent soluble m-cresol / p-cresol novolac resins that comprises at least 10 mol % p-cresol and has a weight average molecular weight of at least 8,000, a derivative thereof functionalized with polar groups, or a derivative thereof functionalized with quadruple hydrogen bonding entities; or (c) a mixture thereof. The imageable elements have increased scuff resistance and are thus less susceptible to damage during handling.

Owner:KODAK POLYCHROME GRAPHICS

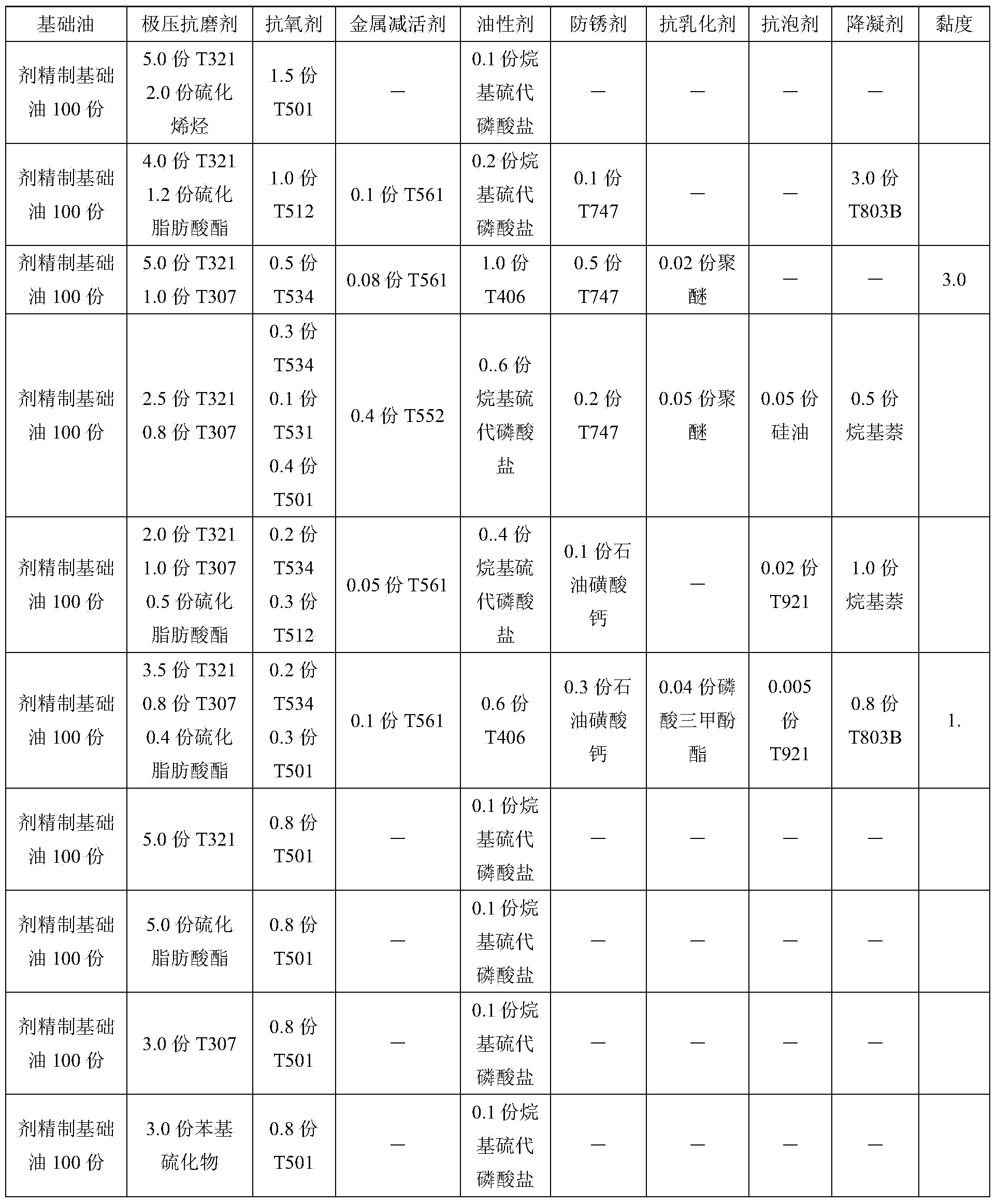

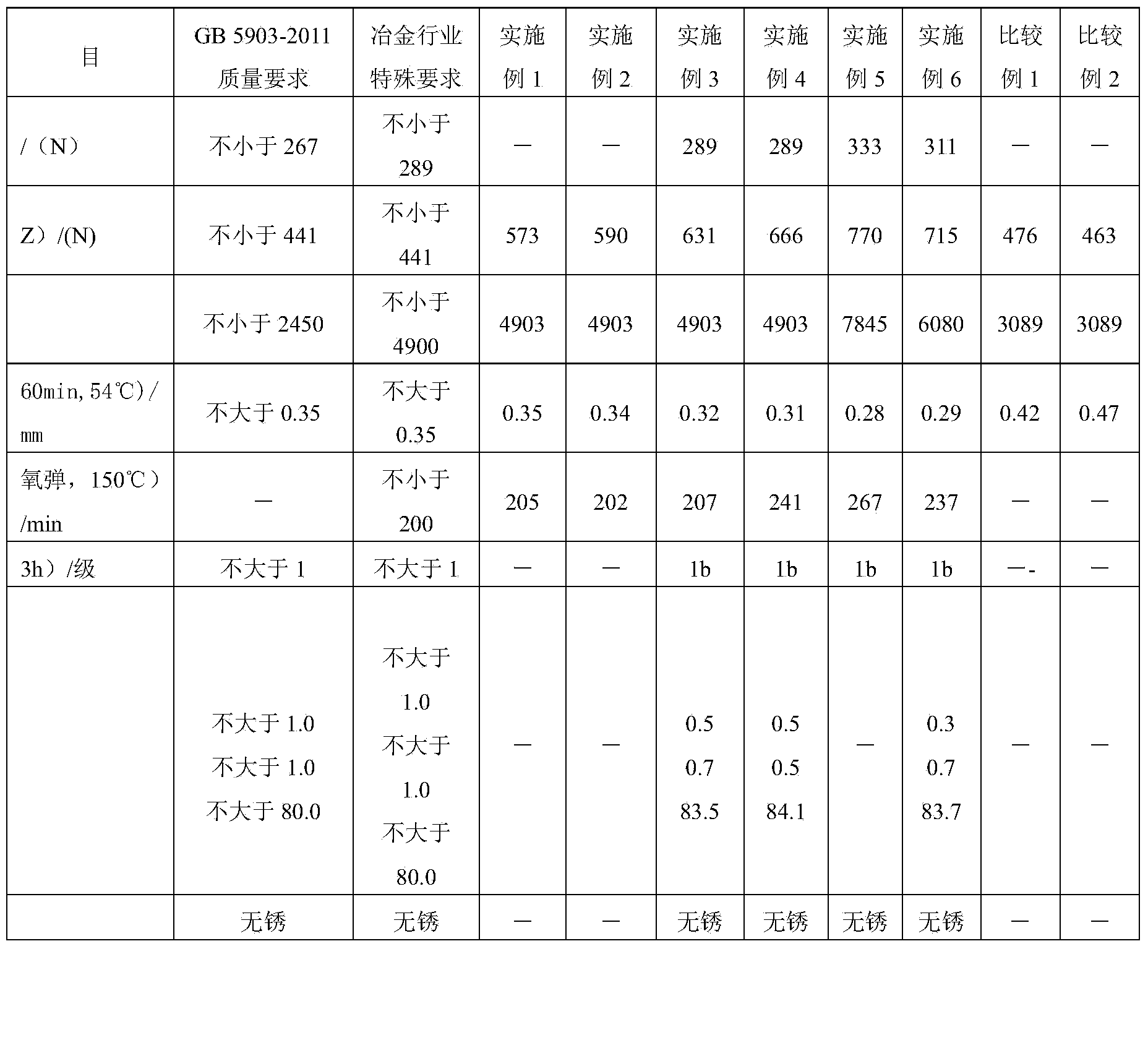

Gear oil composition and applications thereof

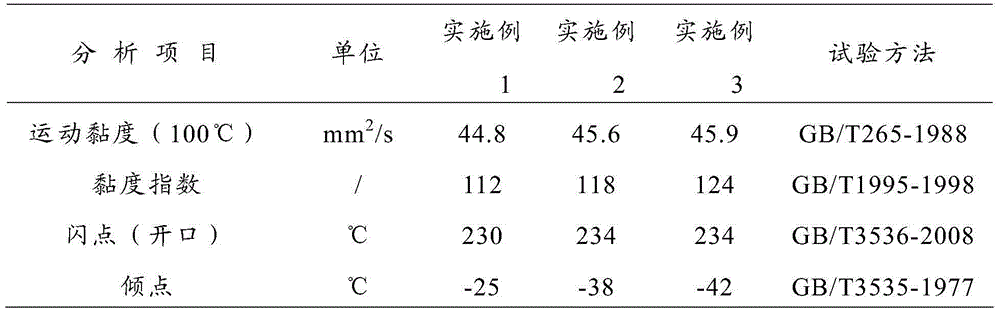

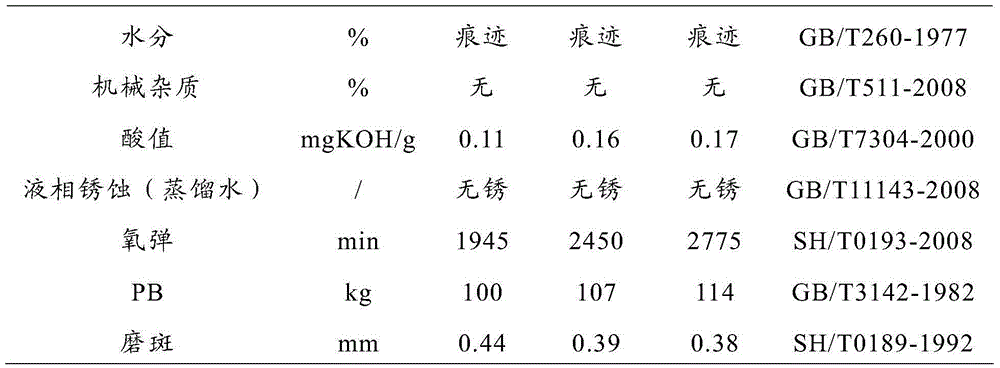

The invention relates to a gear oil composition and applications thereof, mainly solving problems of abnormal gear wear and poor oxidation stability of an oil product which are caused by that the extreme pressure property of industrial gear oil in the prior art fails to satisfy a part of using requirements of the metallurgy industry. According to the technical scheme adopted by the gear oil composition, the gear oil composition comprises following components by weight: a) 100 parts of mineral base oil; b) 0.1-10.0 parts of an anti-wear reagent at extreme pressure; c) 0.01-2.0 parts of an antioxidant; d) 0.01-0.5 part of a metal deactivator and e) 0.01-1.5 parts of an oiliness agent, wherein the anti-wear reagent at extreme pressure is a mixture of sulfurized isobutylene and at least one selected from sulfurized olefin, phenyl sulfide, sulfurized aliphatic ester or amine thiophosphate diester; and the antioxidant is at least one selected from 2,6-di(tertbutyl)-p-cresol, 3.5-di(tertbutyl)-4-hydroxy phenyl acrylate, pentaerythrite tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], N-phenyl-1-naphthylamine or alkylated diphenylamine. By the technical scheme, the problems are solved well and the gear oil composition can be used for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

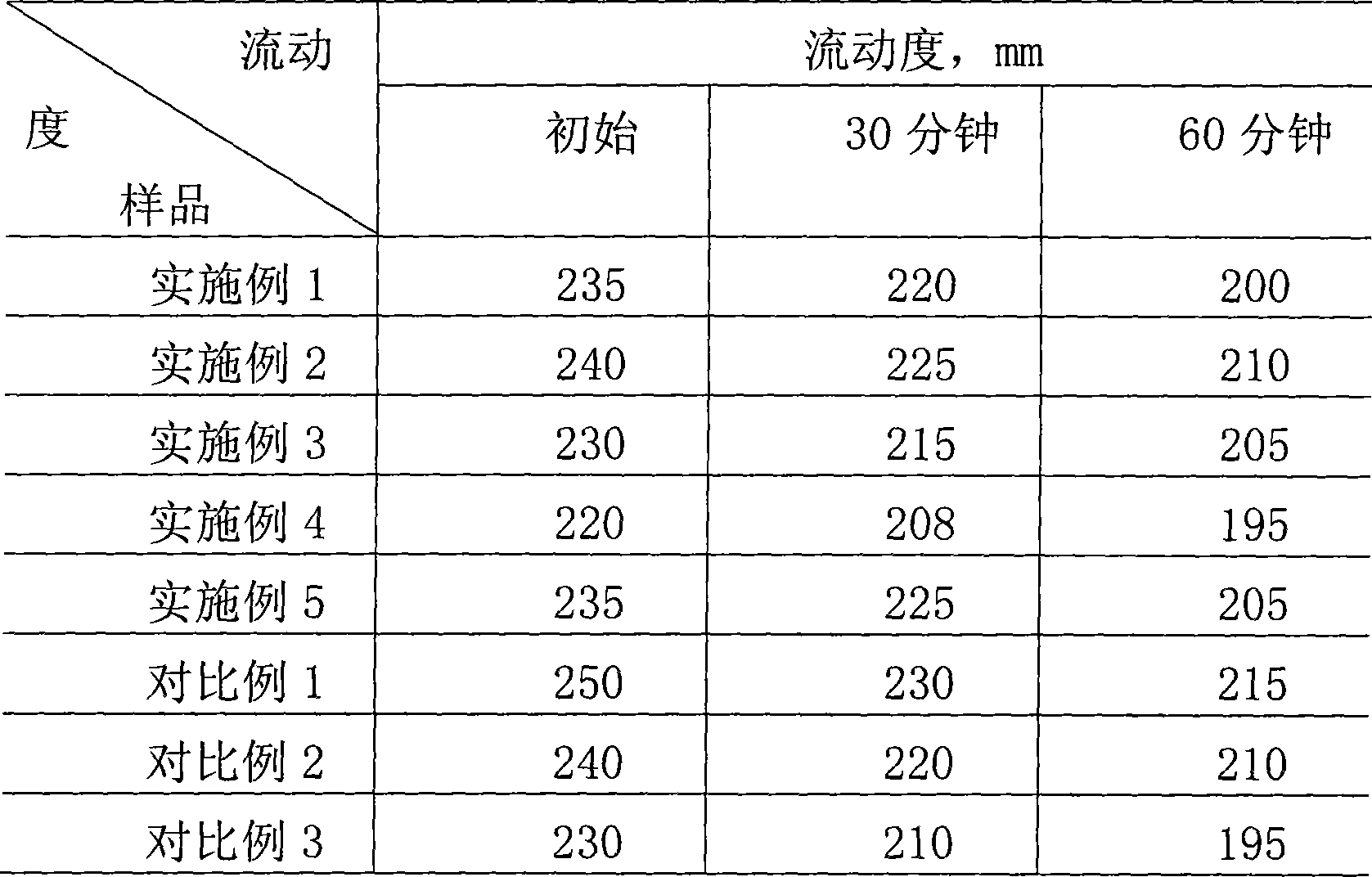

Method for preparing aliphatic high efficiency water reducing agent by using industrial by-product and application thereof

InactiveCN101186459AImprove protectionPromote sustainable developmentSolid waste managementSuperplasticizerP-Cresol

The invention relates to a preparation method of an aliphatic high range water reducer applying industry byproduct and the application thereof, which belongs to the field of concrete water reducer. The invention uses the industry byproduct in production of sulfonation-process phenol or the byproduct (Na2SO3 content is 60-85percent) in production of p-cresol and sodium hydrosulfite to produce the aliphatic high range water reducer and takes acetone, formaldehyde, industry byproduct, sulphite or sodium pyrosulfite as raw materials and then sulfonation and condensation reactions are carried out in aqueous medium, the reactant weight ratio is acetone: formaldehyde: sulphite plus industry byproduct: water is equal to 1:2.5-4.5:1.5-2.6:4.0-6.0, the mass concentration of the condensation compound obtained is 30-42 percent, and the viscosity thereof is 20-100m.Pa.S. The product performance of the invention is similar to the common product, but the cost is reduced by 10-20 percent. The invention has environmental protection and waste utilization, can be applied to preparation of various concrete members and production of ready mixed concrete and has good industrialization prospect.

Owner:BEIJING UNIV OF TECH

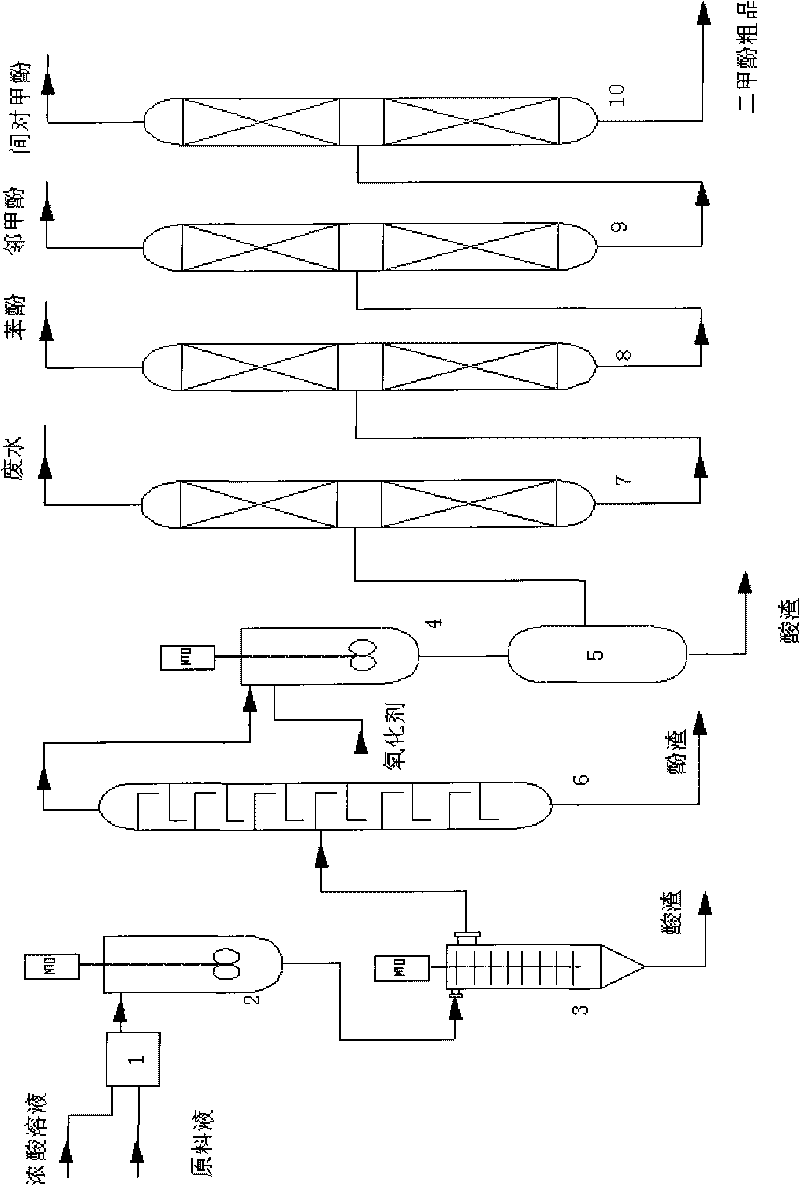

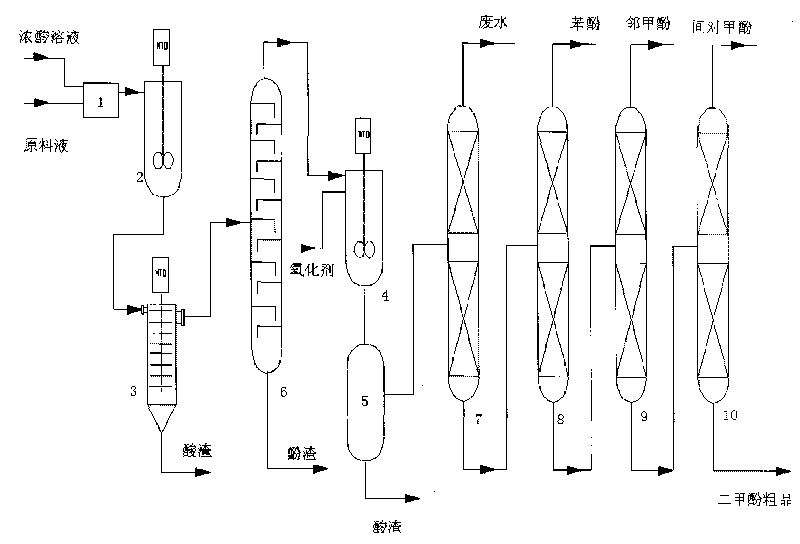

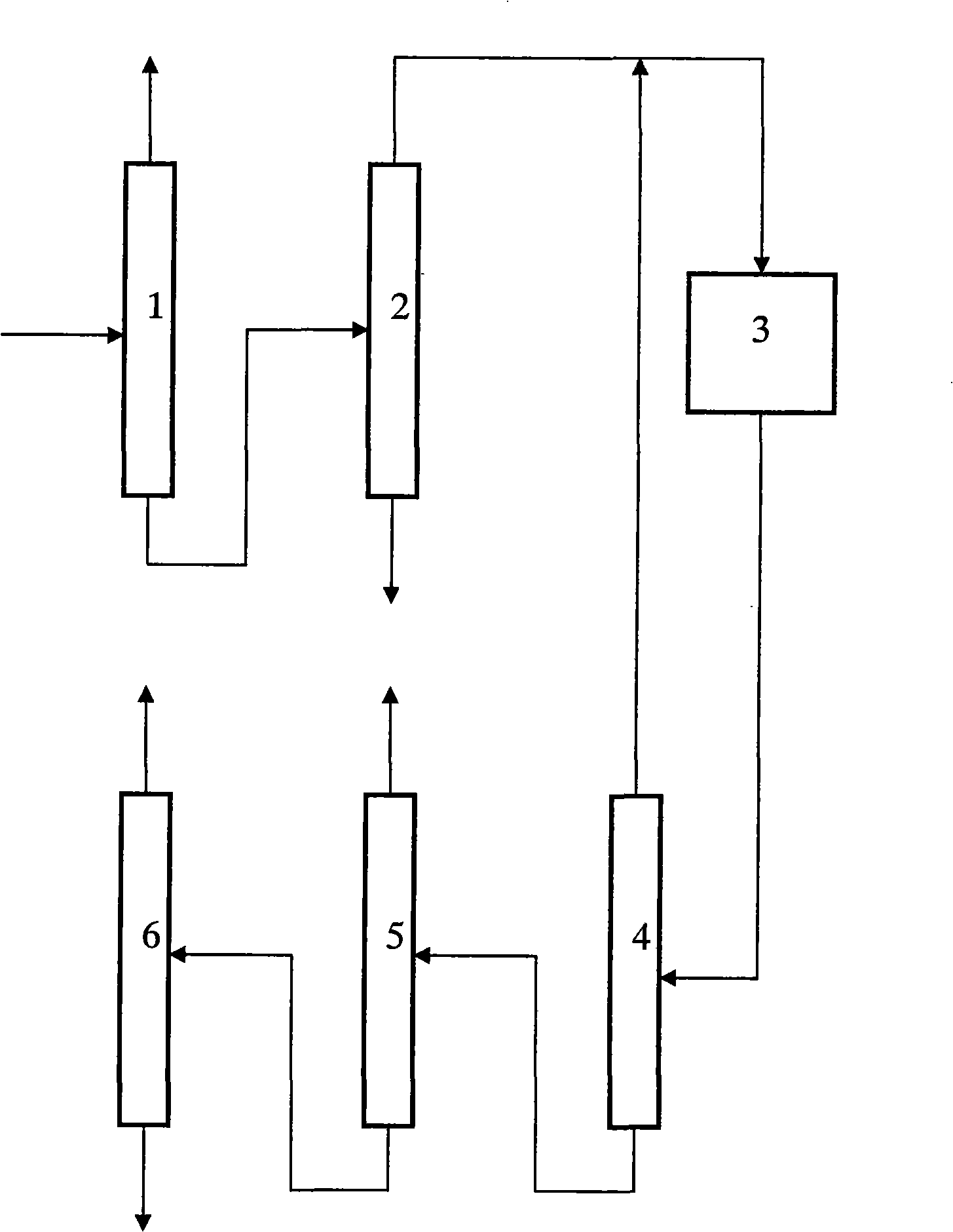

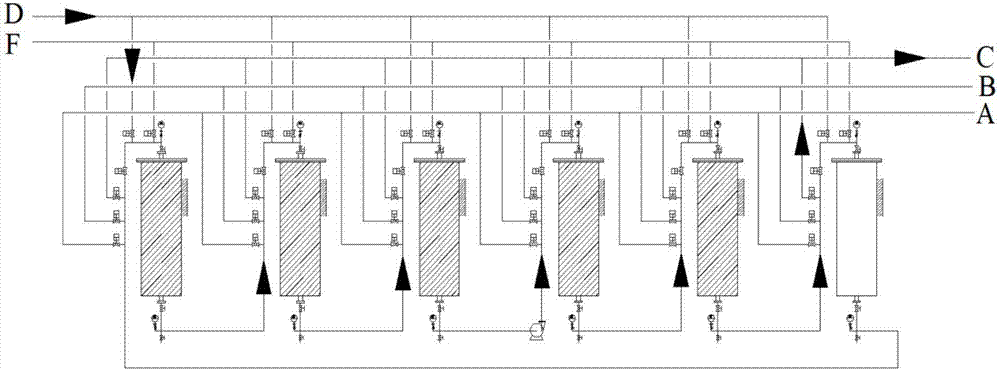

Continuous refinement separation device and method of coked crude phenol

InactiveCN101704726ASolve corrosion resistanceQuality assuranceOrganic chemistryOrganic compound preparationSeparation technologyP-Cresol

The invention relates to a continuous refinement separation device and method of coked crude phenol. The continuous refinement separation device comprises a static mixer 1, a first stage pretreatment acid-adding unit composed of a first stage mixing slot 2 and a wipe film evaporator 3, a second stage pretreatment oxidation unit composed of a second stage mixing slot 4 and a buffer tank, a phenol residue removing tower 6 and a rectification tower system composed of a dewatering tower 7, a phenol refinement tower 8, a orthocresol refinement tower 9 and a m,p-cresol refinement tower 10, wherein the first stage pretreatment acid-adding unit is connected with the phenol residue removing tower, the phenol residue removing tower is connected with the second stage pretreatment oxidation unit, andthen all devices of the refinement tower system are connected together in turn. The device and method of the invention can effectively performs processes of decoloring, deodorizing, desulfurizing, removing impurity and the like to the coked crude phenol raw material through reasonable design to obtain more than 99.5wt% of high purity phenol, more than 99.0wt% of high purity orthocresol, more than99.0wt% of high purity m,p-cresol and xylenol product. The whole process is reasonable, has high degree of automation and is characterized by low process energy consumption, high product quality, good stability and the like, thus the method of the invention is an effective and feasible coked crude phenol continuous refinement separation technology.

Owner:天津美科泰化工科技有限公司 +1

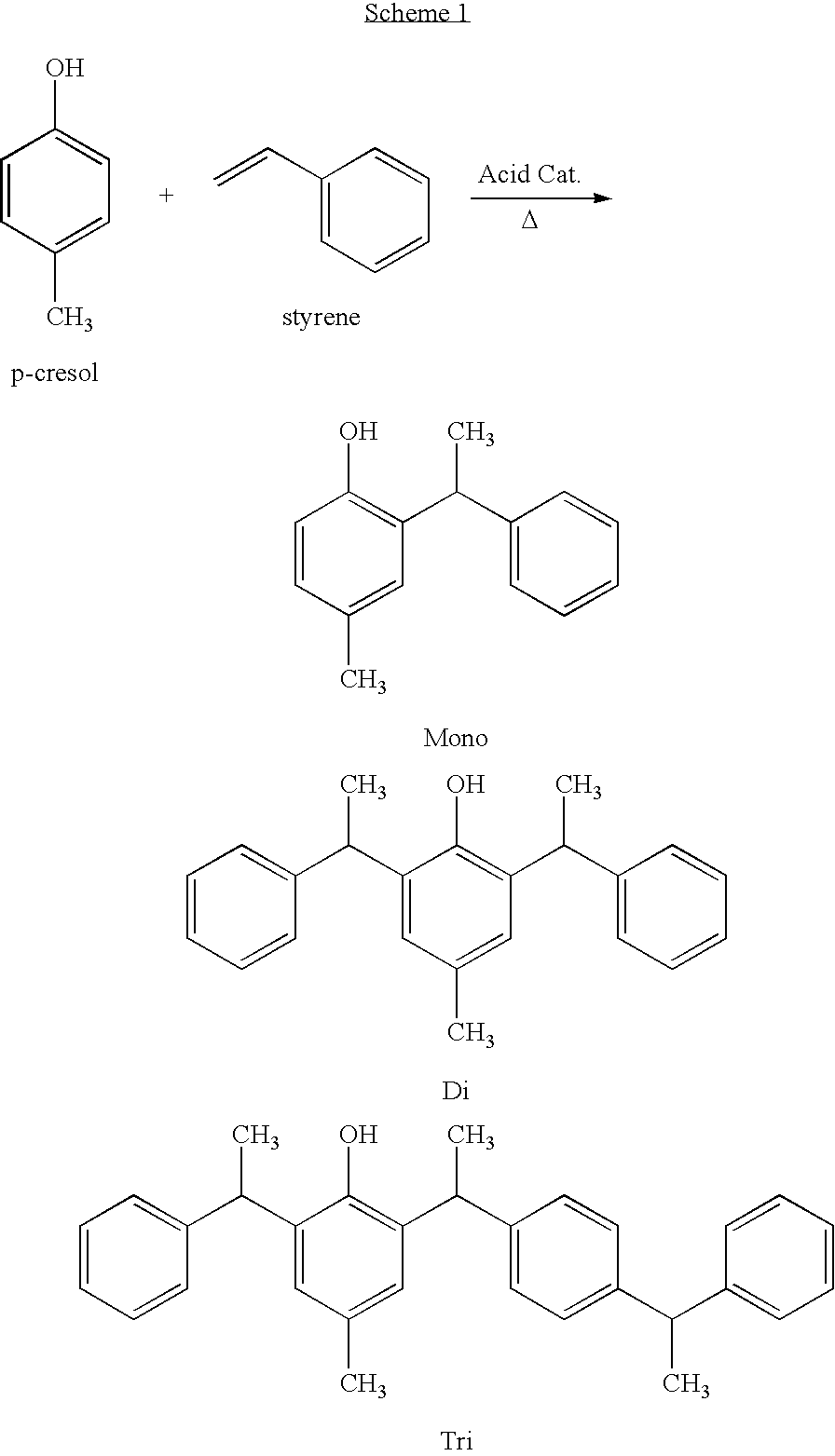

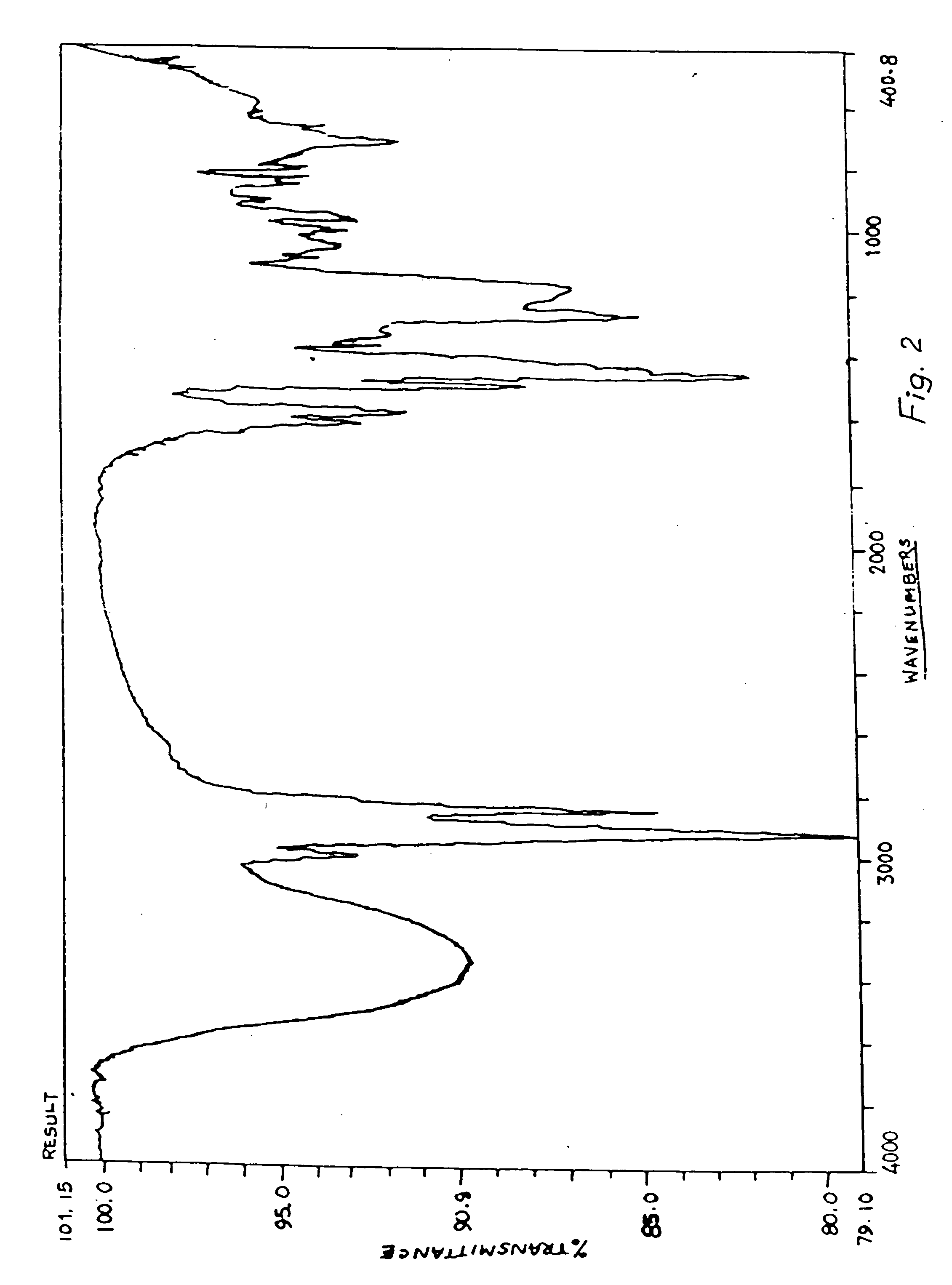

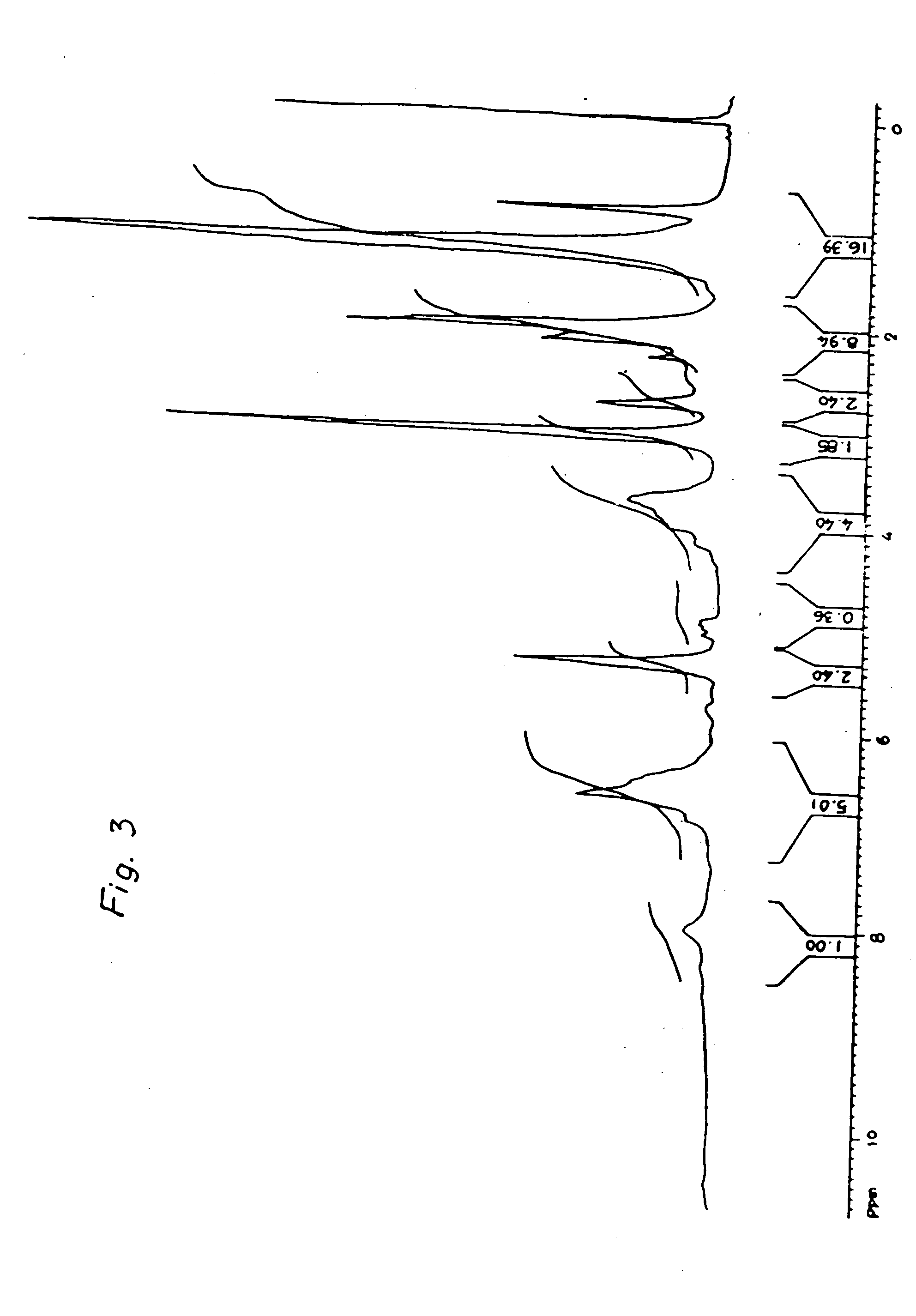

Liquid styrenated phenolic compositions and processes for forming same

Disclosed herein are highly stable styrenated phenolic compositions that are liquids at room temperature, and polymer articles and lubricant compositions containing such styrenated phenolic compositions. Also disclosed are processes for forming such styrenated phenolic compositions, which processes afford distyrenated phenolics assaying at 70% minimum by total GC area, comprising reacting styrene with one or more phenolics, e.g., at least one of phenol, p-cresol and / or o-cresol, in the presence of an acid catalyst, preferably a sulfonic acid catalyst, at elevated temperature, wherein the resulting product mixture comprises one or more monostyrenated phenolics, one or more distyrenated phenolics, and one or more tristyrenated phenolics.

Owner:SI GROUP INC

Polyene phosphatidyl choline injection and method for preparing the same

The invention discloses a polyene phosphatidyl choline injection and the preparation method. The components and the ratio (portion) of the polyene phosphatidyl choline injection of the invention is: 465 portion of polyene phosphatidyl choline injection, 88 portion of benzyl zlcohol, 50 to 800 portion of glycocholic acid, cholic acid or tween-80, 50 to 80 portion of alcohol, propanediol or glycerin, 15 to 200 portion of sodium hydroxide or sodium carbonate, 0.5 to 5 portion of 2,6-D-itert-butyl-p-cresol, 0.8 to 8 portion of Tertiary butyl-4-hydroxyl anisole, 3 to 25 portion of Vitamin E by weight. The polyene phosphatidyl choline injection of the invention has good clarity, high stability, simple preparation process and easy operation.

Owner:SICHUAN HAISCO PHARMA CO LTD +1

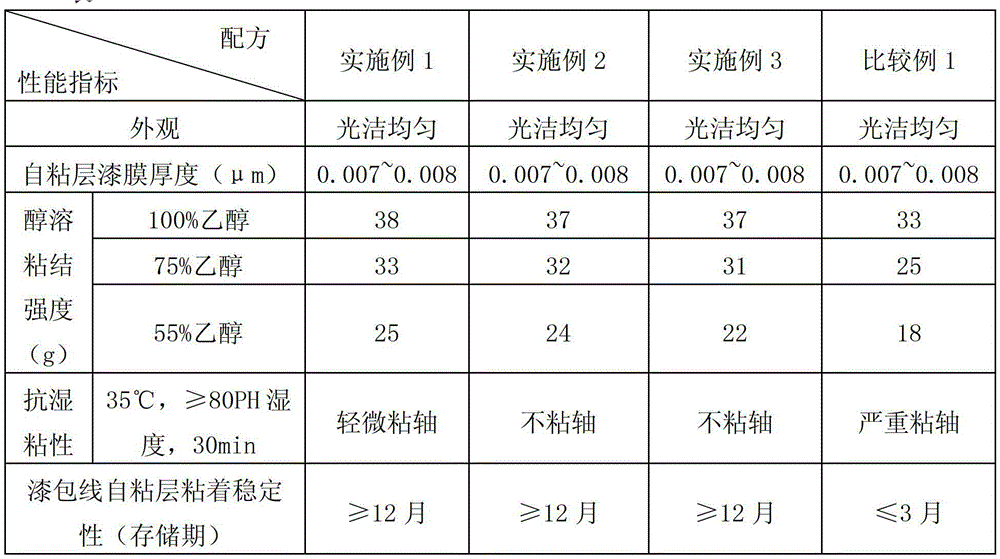

Wet bonding resistant alcohol soluble self-bonded paint and preparation method thereof

ActiveCN103146299AGood compatibilityImprove homogeneityPolyamide coatingsEpoxy resin coatingsWet bondingEpoxy

The invention discloses a wet bonding resistant alcohol soluble self-bonded paint and a preparation method thereof. According to the preparation method, p-cresol, dimethylbenzene and butanol are taken as a mixed solvent, ES-08, IC alcohol-soluble nylon and epoxy resin are taken as the main raw materials, and a lubricant is taken as an addition agent. The alcohol-soluble nylon is added into equipment and is dissolved by the mixed solvent into an intermediate semi-finished product, and the epoxy resin and a certain proportion of lubricant are added for modification and reaction so as to obtain the product. As the epoxy resin with high molecular weight, high softening point and good humidity resistance is taken as the cooperative modified resin of the alcohol-soluble nylon, and a proper proportion of a lubricant and the mixed solvent with gradually steady evaporation property are added for cooperation, so that the wet bonding resistance of the enameled wire self-bonded paint is greatly improved; the prepared product has good homogeneity and storage stability; and chemical components of low chemical activity are adopted for cooperation, so that the production requirement of the product in production process is lowered, and the property of the product is more stable.

Owner:江苏佳禾电子材料有限公司

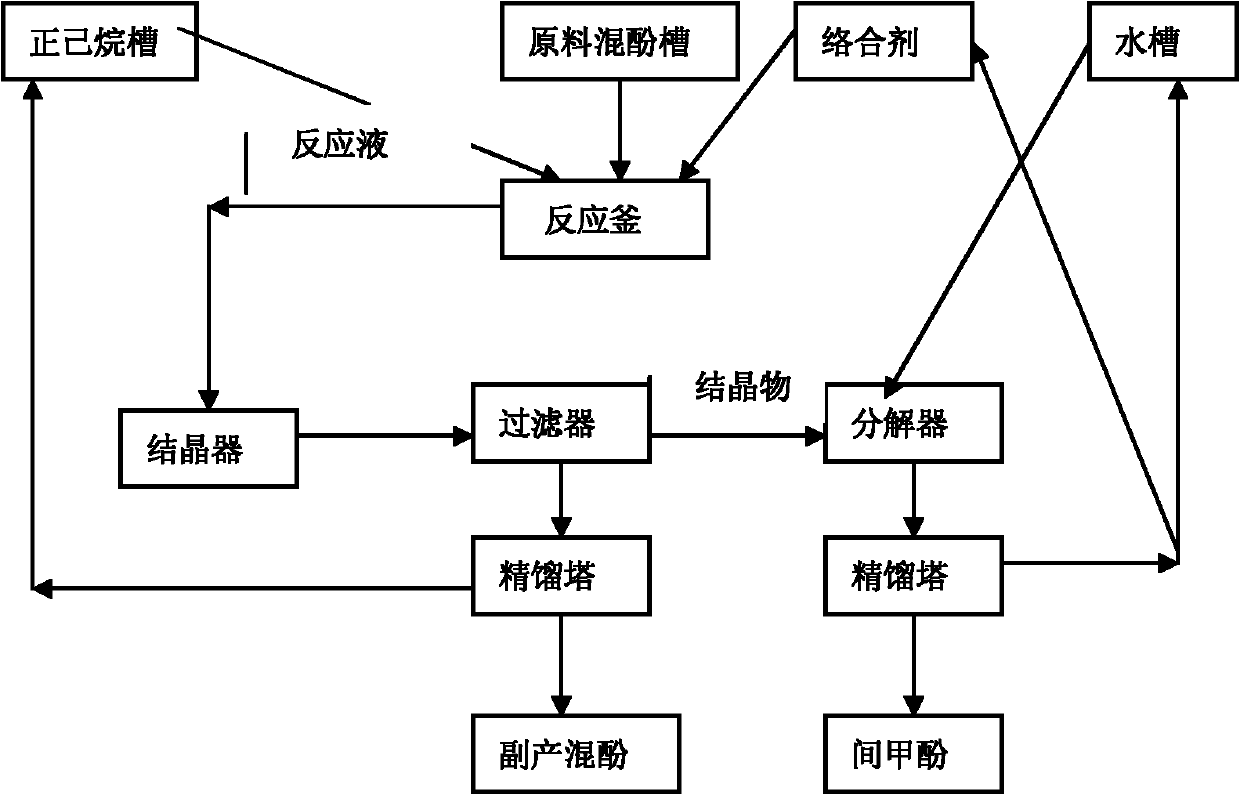

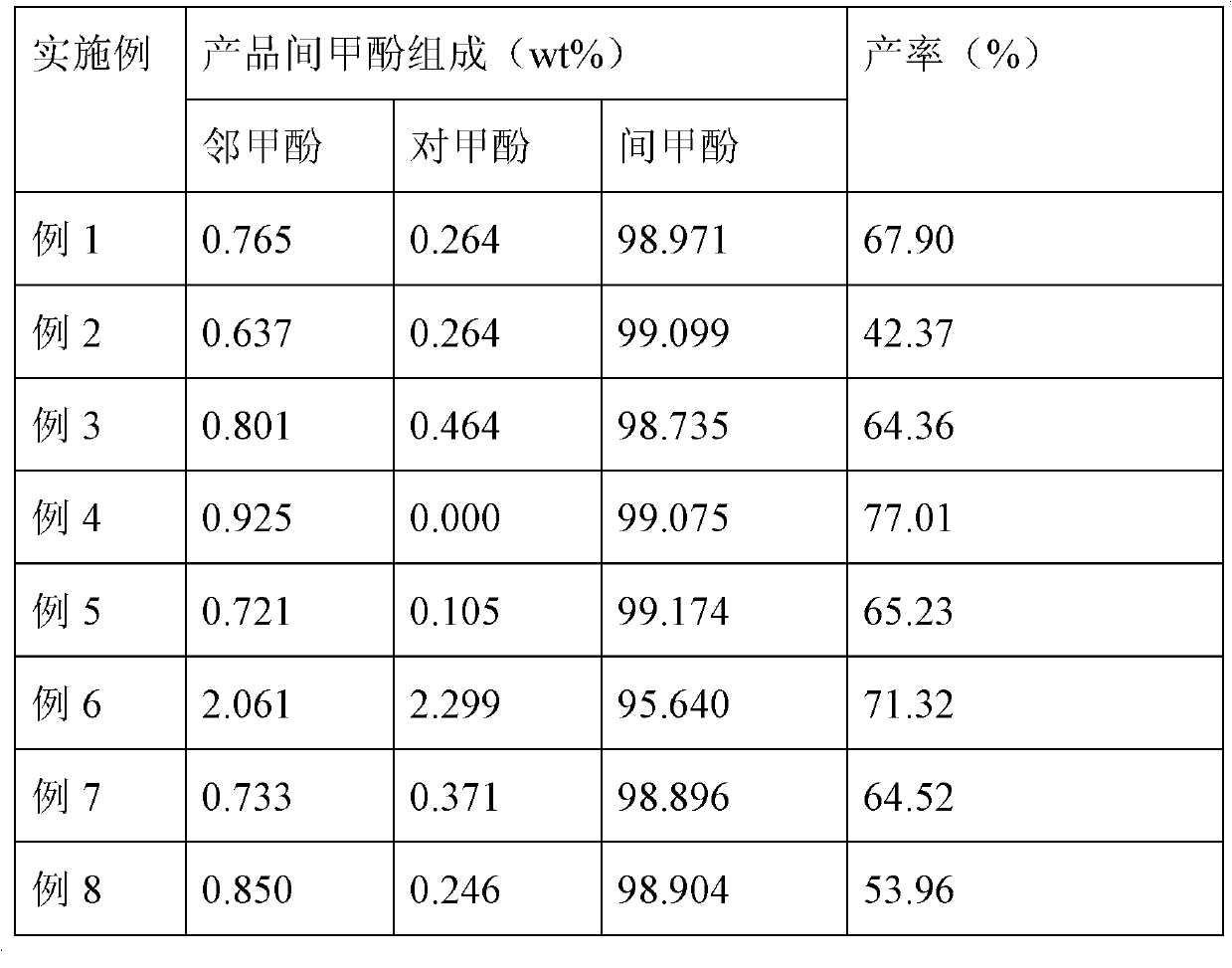

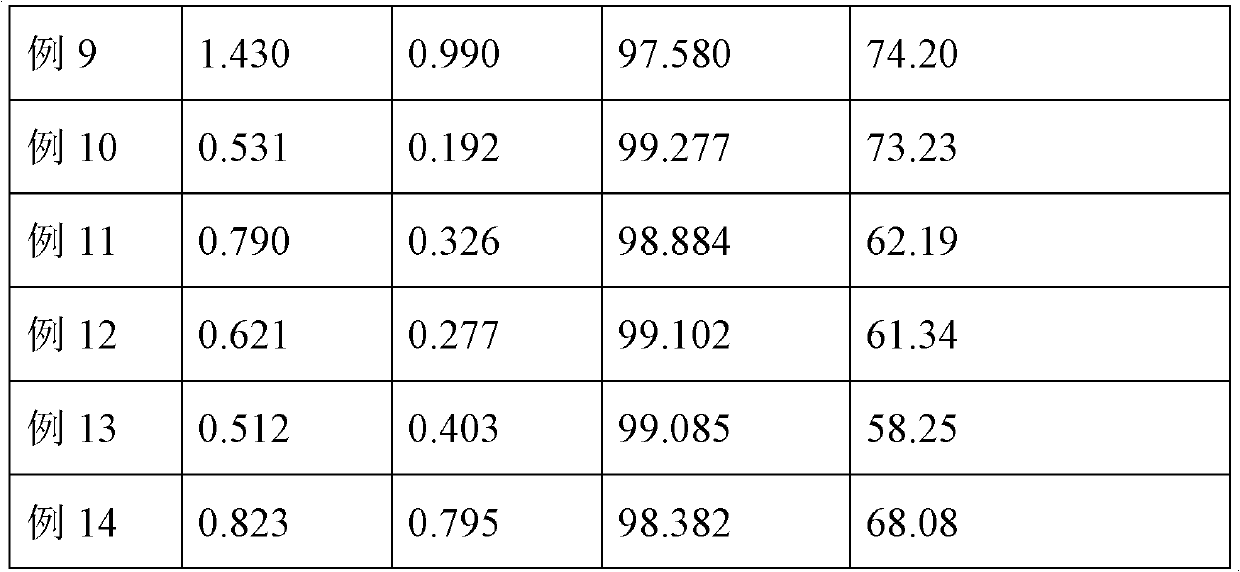

Technology for complexing, crystallizing, separating and purifying metacresol

InactiveCN102167658AReduce usageHigh yieldOrganic chemistryOrganic compound preparationWater bathsChemical industry

The invention provides a technology for complexing, crystallizing, separating and purifying metacresol, belonging to the field of separation and purification in a chemical industry. The technology comprises the steps of dissolving urea in mixed phenol: adding the mixed phenol into a reactor, wherein the mixed phenol comprises 10.907wt% of o-cresol, 34.276wt% of p-cresol, 53.176wt% of m-cresol and 1.641% of dimethyl phenol; adding the urea into the reactor, wherein the mole ratio of the urea to the m-cresol is 1.0-1.8; heating and rising the temperature to be 85-105DEG C in a water bath or an oil bath for 40-80min, so that the urea is completely dissolved in the mixed phenol; cooling, adding normal hexane under the temperature of 60DEG C, and crystallizing for 1-2h under the temperature from -10DEG C to -20DEG C; transporting crystallized serous fluid into a filter to separate solid from liquid; recovering filter liquor in a rectifying way, adding water into crystalline solid, and hydrolyzing during heating at 40DEG C to obtain water phase and organic phase; and recovering the water phase, so that the organic phase is the m-cresol. In the technology, methylbenzene is replaced by normal hexane to be taken as a dissolvent for complexing and crystallizing reaction, so that the technology is higher in the yield of the cresol, the usage amount of the dissolvent can be reduced by one third, and the dissolvent can be covered by less energy consumption.

Owner:BEIJING UNIV OF CHEM TECH

Adhesive for wrapping paper material

ActiveCN102876241AImprove adhesionHigh mechanical strengthNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveIsooctyl acrylateEpoxy

The invention provides adhesive for a wrapping paper material, and belongs to the technical field of adhesives. The adhesive for the wrapping paper materialcomprises the following raw materials in part by weight: 5-10 parts of polyol, 6-12 parts of acrylic acid, 3-5 parts of pigment and filler, 20-40 parts of plant starch, 1 part of coupling agent, 2-3 parts of ethylene-vinyl acetate copolymer, 1 part of trimeric aluminum phosphate, 1 part of ferric chloride, 2-4 parts of alum, 4-6 parts of cellulose, 2-4 parts of polyolefin resin, 1-6 parts of polylactic acid, 2-4 parts of epoxy resin, 1-3 parts of isooctyl acrylate, 2-4 parts of acrylamide, 1-2 parts of pH adjusting agent, 1 part of 2,6-di-tert-butyl p-cresol, 1 part of surfactant and 50-80 parts of water. The adhesive for the wrapping paper material has excellent adhesion property, has good mechanical strength after being applied to a paper wrapping box, and still has good adhesion property after a destructive test.

Owner:DONGGUAN HOPEWAY PACKING CO LTD

Method for producing 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol

InactiveCN101353293AReduce manufacturing costReduce processing costsOrganic chemistryOrganic compound preparationCresolMetacresol

The invention relates to a method for producing 2-tertiary butyl-paracresol and 6-tertiary butyl-metacresol from mixed cresol, which is characterized in that the mixed cresol is taken as raw material; firstly, the mixed cresol is rectified and separated to obtain refined mixed cresol; then the refined mixed cresol is alkylated to obtain the mixture of 2-tertiary butyl-paracresol and 6-tertiary butyl-metacresol; and the mixture of 2-tertiary butyl-paracresol and 6-tertiary butyl-metacresol is further rectified; as the difference between the boiling point of 2-tertiary butyl-paracresol and the boiling point of 6-tertiary butyl-metacresol is 6 DEG C, the rectification method can be used for separating 2-tertiary butyl-paracresol from 6-tertiary butyl-metacresol to obtain a 2-tertiary butyl-paracresol product and a 6-tertiary butyl-metacresol product with high purity. The method greatly reduces the production cost.

Owner:天津天大天海化工新技术有限公司

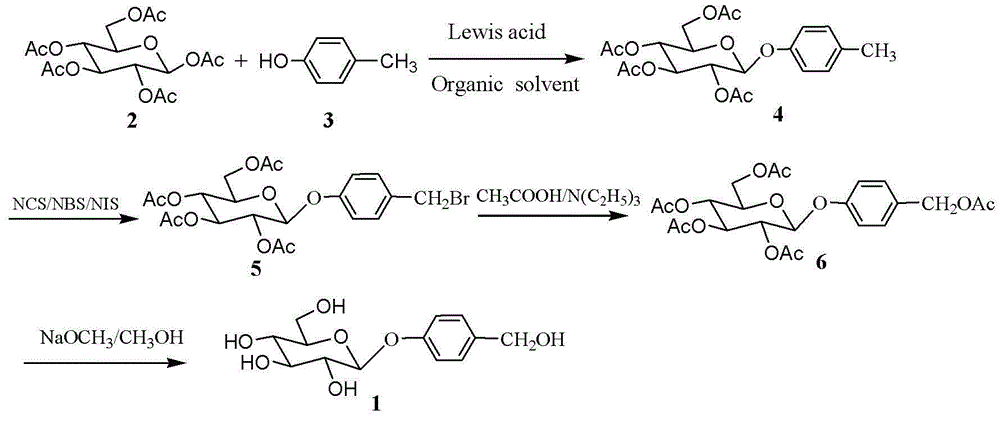

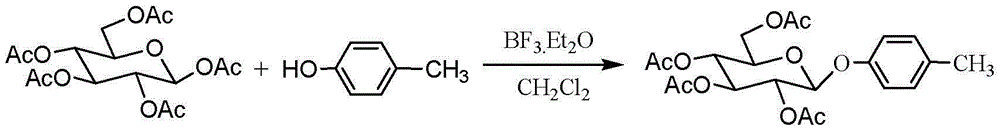

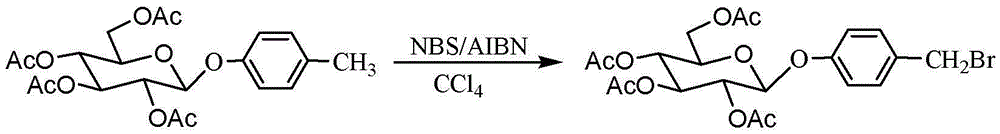

Method for chemically synthesising gastrodin

InactiveCN102977161AImprove stabilityAvoid harmSugar derivativesSugar derivatives preparationChemical synthesisLewis acid catalysis

The invention discloses a method for chemically synthesising gastrodin, comprising the following steps of: in the presence of a molecular sieve, under the catalysis of Lewis acid, and performing glycosylation reaction on pent-acetyl-b-D-glucose and p-cresol in an organic solvent with to generate 4-methylphenyl-2,3,4,6-O-tetra-acetyl-b-D-glucopyranoside; then preparing 4-halomethylphenyl-2,3,4,6-O-tetra-acetyl-b-D-glucopyranoside from 4-methylphenyl-2,3,4,6-O-tetra-acetyl-b-D-glucopyranoside and N-halosuccinimide in the presence of an initiator, and then reacting 4-halomethylphenyl-2,3,4,6-O-tetra-acetyl-b-D-glucopyranoside with the mixed solution of glacial acetic acid and tertiary amine to obtain 4-acetoxylmethylphenyl-2,3,4,6-O-tetra-acetyl-b-D-glucopyranoside; and finally removing the acetyl protecting group from the 4-acetoxylmethylphenyl-2,3,4,6-O-tetra-acetyl-b-D-glucopyranoside in an alkaline condition to obtain gastrodin. Compared with the traditional method, the method disclosed by the invention has easily available raw materials, and is short in reaction time, capable of preparing the reaction product in each step via recrystallization, simple, and more suitable for industrialized production for gastrodin.

Owner:QINGDAO AGRI UNIV

Lubricating oil composition used in rotary screw rod air compressor and preparation method thereof

ActiveCN103981005AImprove protectionImprove antioxidant capacityLubricant compositionBenzoic acidButylated hydroxytoluene

The invention provides a lubricating oil composition used in a rotary screw rod air compressor. The lubricating oil composition comprises the following components in percentage by mass: 0.1-3.0% of antioxidant, 0.01-1.5% of metal antirust agent, 0.01-1.5% of metal deactivating agent, 0.5-3.0% of anti-wear reagent at extreme pressure, 0.1-2.0% of pour point depressant, 10-500ppm of defoaming agent and the balance of hydrofined mineral oil, wherein the antioxidant is one or more of 2,6-ditertiary butyl p-cresol, phenyl-alpha-naphthylamine, dialkyl diphenylamine, butyl octyl diphenylamine and 3,5-ditertbutyl-4-hydroxy hydroxyl acetic acid ester; the metal deactivating agent is one or more of benzotriazole, a derivative of benzotriazole, thiadiazole and a derivative of thiadiazole; the metal antirust agent is one or more of long-chain carboxylic acid, alkyl benzoic acid, oleamide, oleoyl amino acid, benzotriazole and derivative of benzotriazole. The invention further provides a preparation method of the lubricating oil composition.

Owner:KASONG SCI & TECH

High heat-stage non-pinhole polyesterimide enamelled wire insulating paint modifier

InactiveCN1919947AReduce the heat resistance levelImprove continuityPolyamide coatingsAcrylic resinSurface-active agents

The invention relates the modifier, which is used to make and modify high-heat polyurethane paint wire insulating paint. The modifier comprises 20-30% phenolic resin, 10-20% amido resin, 10-20% acrylic resin, 2-5% organosilicon surface active agent, and 30-60% M-and P-cresols. The method comprises the following steps: putting the phenolic resin, amidogen resin, acrylic resin and organosilicon surface active agent into M-and P-cresols, then mixing, dissolving, heating to 40-60Deg.C, stirring, and getting the mixture. The modifier is used to make high-heat polyurethane paint wire insulating paint. The method improves the continuity and pinhole property of polyurethane paint wire insulating paint, without reducing heat-proof grade of paint. The properties of the paint modified by the modifier meet international electrician IEC standard.

Owner:上海晟然绝缘材料有限公司

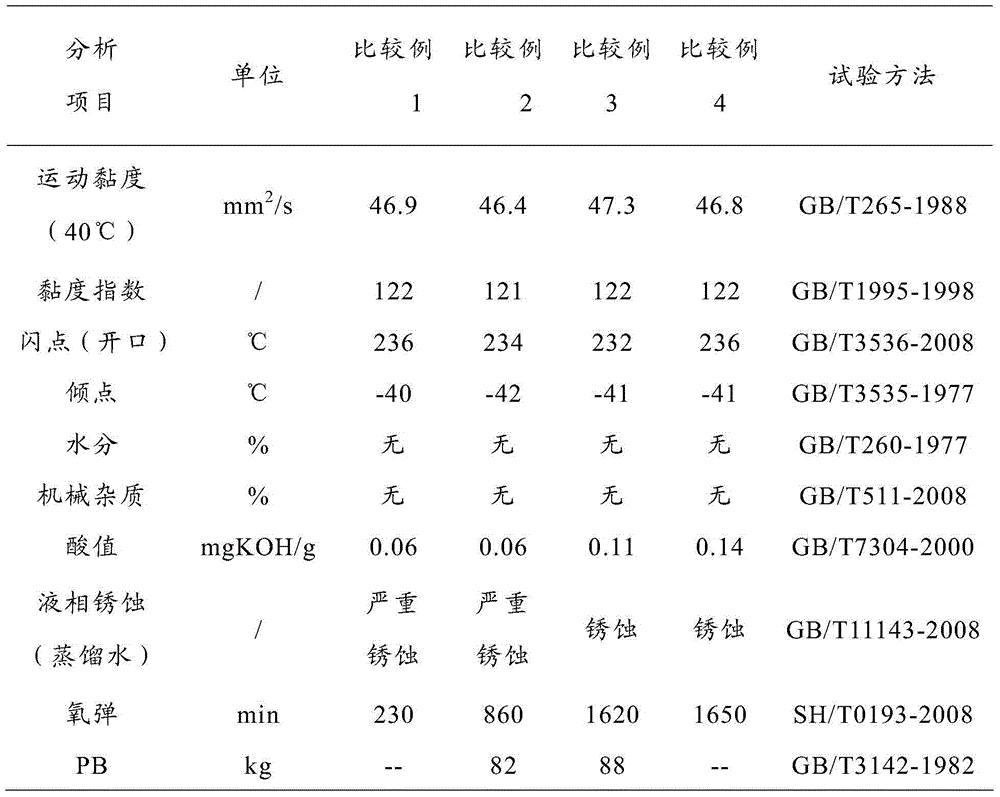

"High ortho" novolak copolymers and composition thereof

InactiveUS20050014086A1UsedPhotomechanical apparatusPhotosensitive material auxillary/base layersResistM-Cresol

A two step process for preparation of “high ortho” novolac resins. A first step involving reaction of phenolic component with formaldehyde carried out at room temperature, which ensures that all the formaldehyde used in the reaction is in liquid state, which almost completely reacts with phenolic compound, leaving no unreacted formaldehyde as effluents. The process uses CNSL or CNSL based phosphorylated prepolymer, or CNSL based monomeric Cardanol or hydrogenated Cardanol or vicinally hydroxylated Cardanol with formaldehyde and other phenolic compounds like m-cresol or p-cresol or o-cresol or 3.5-dimethylphenol or p-chlorophenol or resorcinol or t-butylphenol the positive and negative photoresists are made by mixing these polymers with appropriate photoactive components. For preparation of e-beam photoresist, these novolac resins are fist derivatised by t-BOC and then mixed with photoacid generator.

Owner:DEFENCE RES & DEV ORG GOVERNMENT OF INDIA

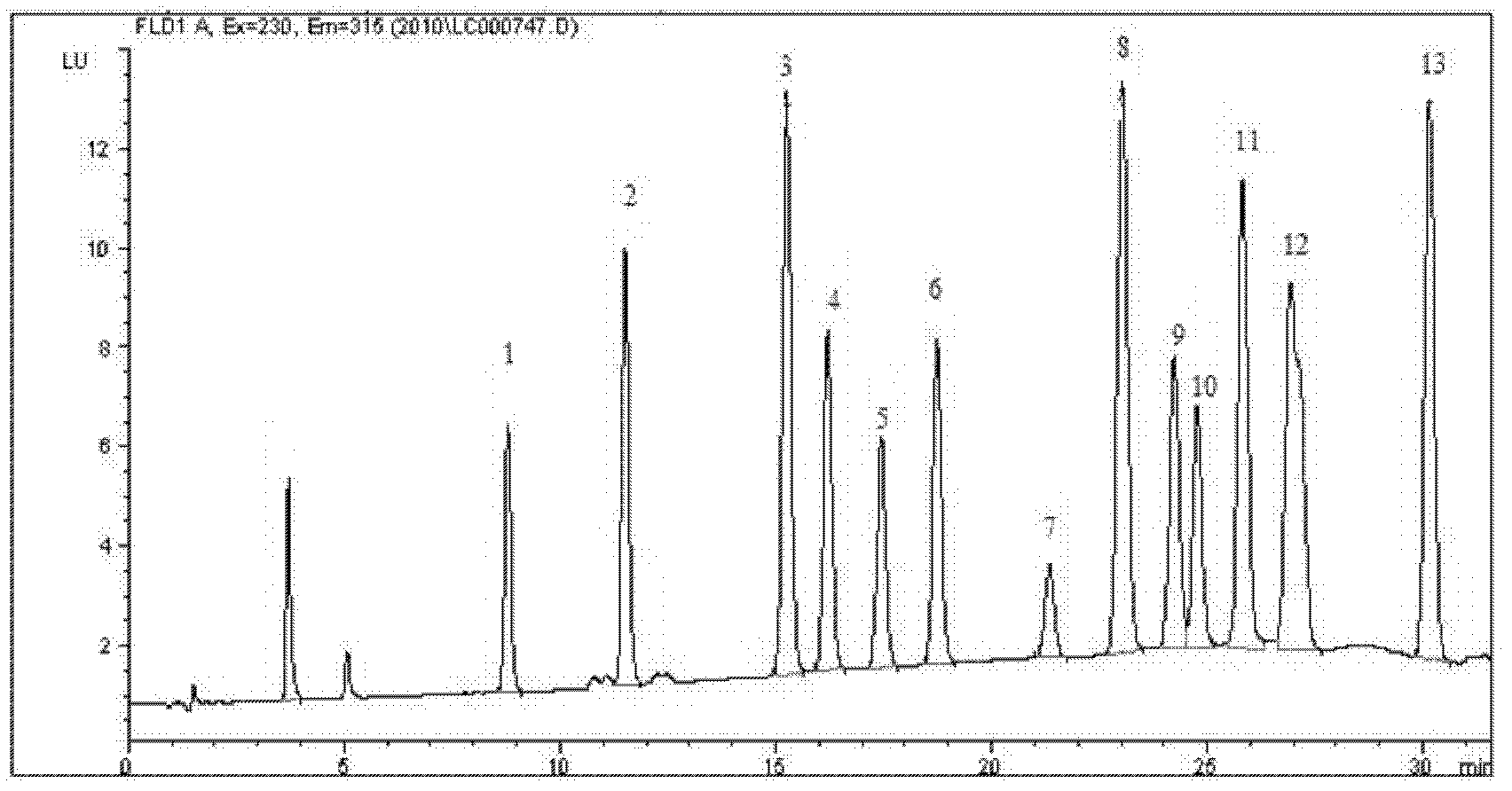

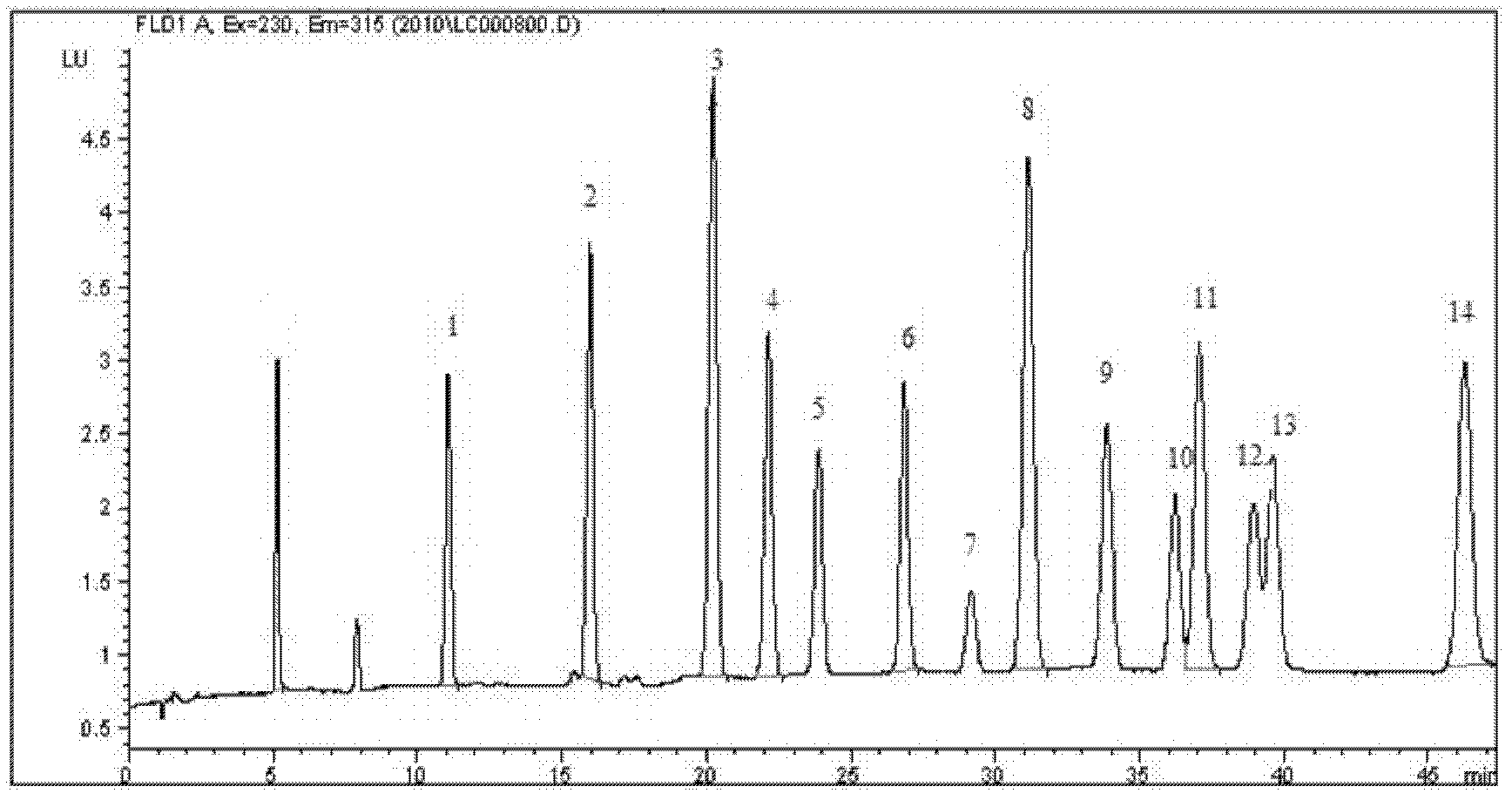

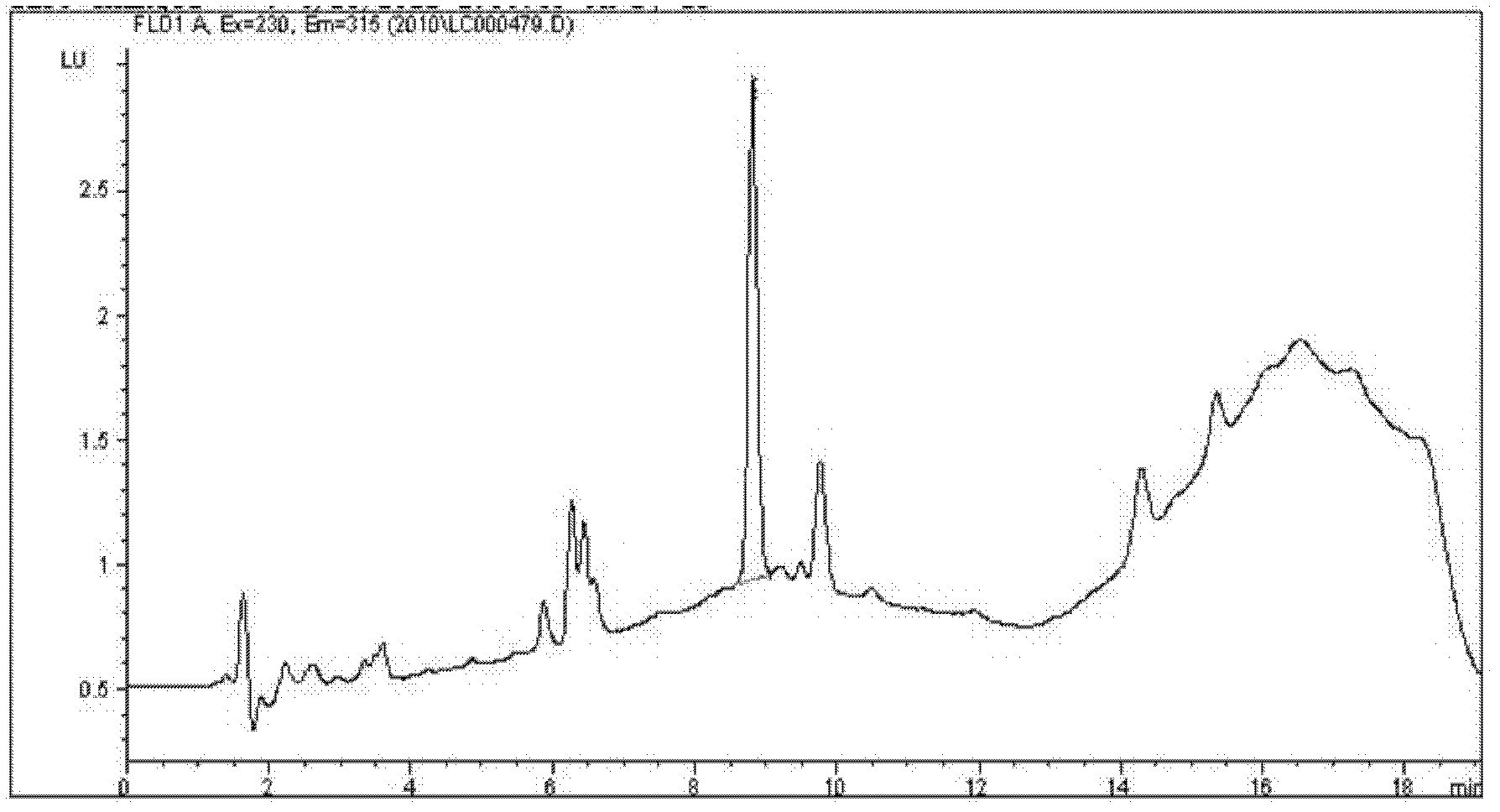

High performance liquid chromatography determination method for volatile phenolic compounds in white spirits

The invention discloses a high performance liquid chromatography determination method for volatile phenolic compounds in white spirits. By adopting a high performance liquid chromatogram-fluorescence detector (HPLC-FLD) technique to analyze volatile phenolic compounds in white spirits, the method of the invention, when used in analysis of volatile phenolic materials, can determine the following 10 volatile phenolic compounds of phenol, guaiacol, p-cresol, m-cresol, o-cresol, 4-methylguaiacol, 4-vinylphenol, 4-ethylphenol, 4-vinylguaiacol and 4-ethylguaiacol in white spirits. And the method has the advantages of no need for derivatization, high accuracy, high sensitivity and good repeatability.

Owner:GUIZHOU PROVINCIAL PRODUCT QUALITY SUPERVISION AND INSPECTION INSTITUTE +1

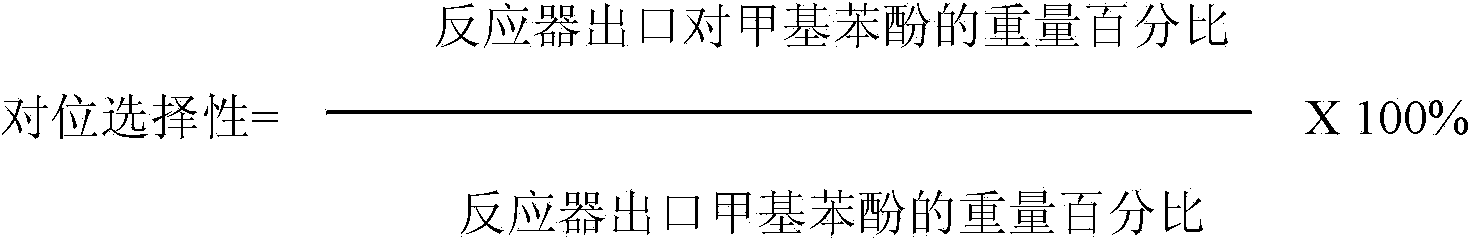

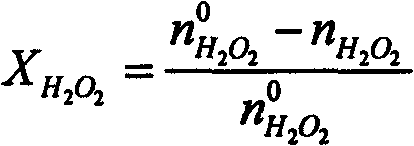

Method for producing methyl phenol

ActiveCN103896740AUniform temperatureSmall temperature differenceOrganic chemistryMolecular sieve catalystsMolecular sieveWater vapor

The present invention provides a process for the production of cresol. The raw materials comprising ethers, phenols and carbinol are preheated, and then continue through the multi-stage solid catalyst bed mixed with steam, carrying out a gas-phase reaction to product cresol at 250-450℃ reaction temperature, with 0.3-5h-1 feed weight airspeed, and under ordinary pressure. The solid catalyst is selected one or more from alumina, kaolin and molecular sieve catalyst. The phenols are selected from phenol, xylenol and mixture thereof. The ethers are selected from anisole, dimethyl ether, methylanisole, and their mixture of any two or more. When the once-through yield of cresol is 0.2g cresol / g catalyst, the para-selective of p-cresol could reach 45%. The catalyst has been characterized by excellent stability, and non-corrosiveness for equipment in productive process, which is a kind of environment-friendly catalyst with predictable industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

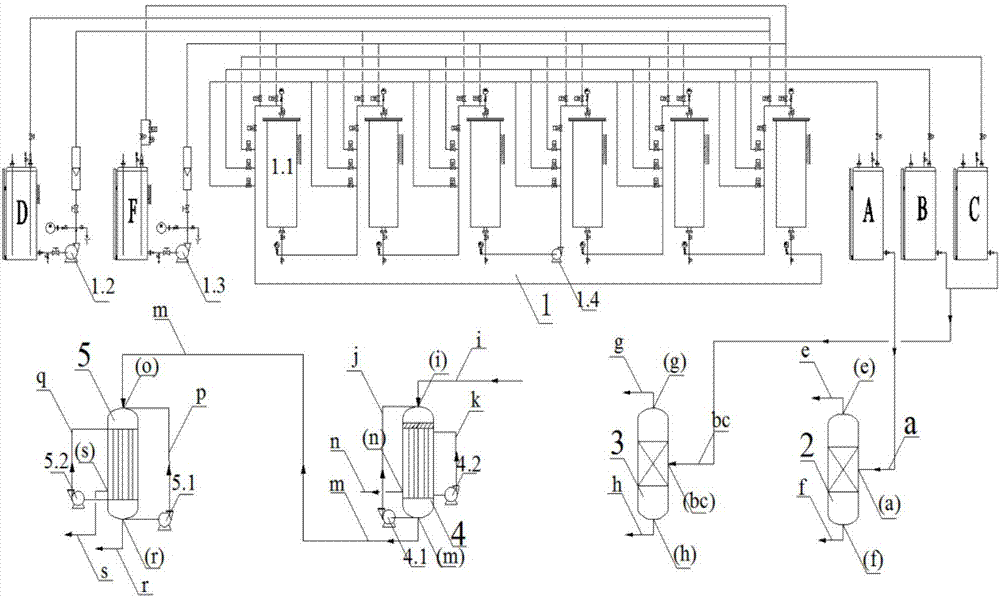

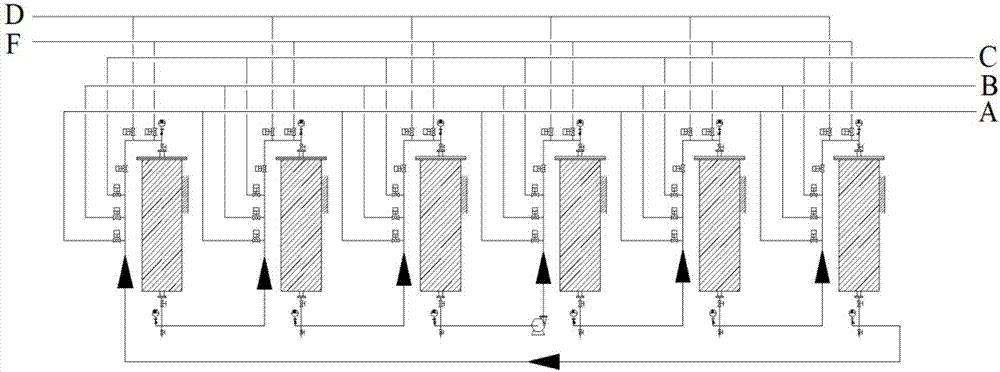

Process method for separating and purifying cresol mixed isomers

PendingCN107879900AHigh purityReduce processing operating costsOrganic chemistryOrganic compound preparationChromatographic separationSimulated moving bed

The invention discloses a process method for separating and purifying cresol mixed isomers. The process method is characterized by comprising the following steps: inputting a mixture primarily comprising m-cresol and p-cresol isomers into a sequential simulated moving bed as a feed to be adsorbed and separated, obtaining a high purity p-cresol solution from a displacing liquid port, and then rectifying, separating and removing a desorption solvent to obtain a m-cresol product; and obtaining a mixed solution primarily comprising m-cresol from a raffinate port, then rectifying, separating and removing the desorption solvent to obtain a mixture rich in m-cresol, and then carrying out crystallization and separation to obtain the m-cresol product. The sequential simulated moving bed disclosed by the invention at least contains four chromatographic columns, a raw material feed inlet, a strippant feed inlet, a strippant discharge port and a raffinate discharge port. The process method can obtain high purity m-cresol and p-cresol products continuously and efficiently at the same time, and has a very good industrial application prospect.

Owner:CHINA CATALYST HLDG CO LTD

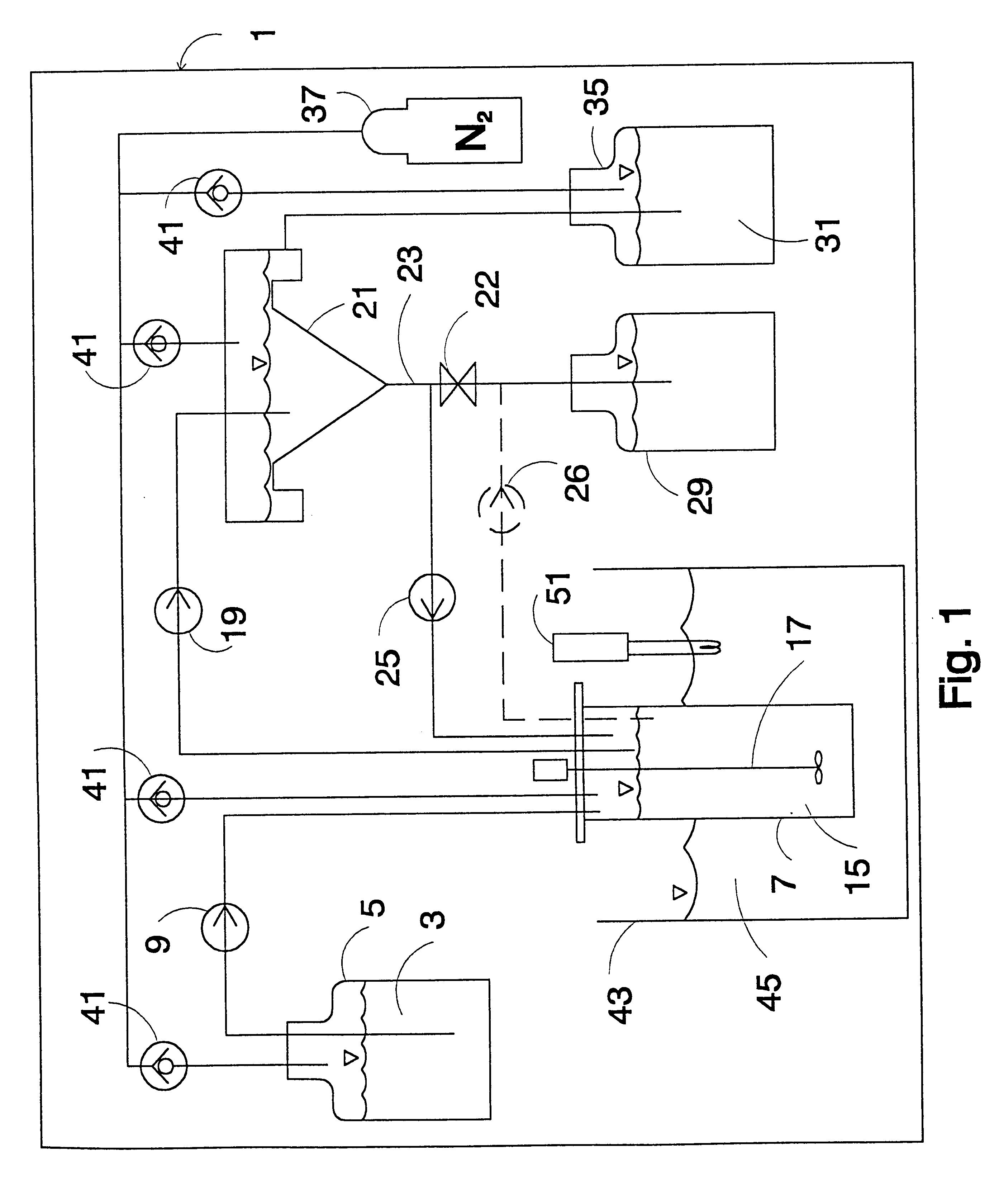

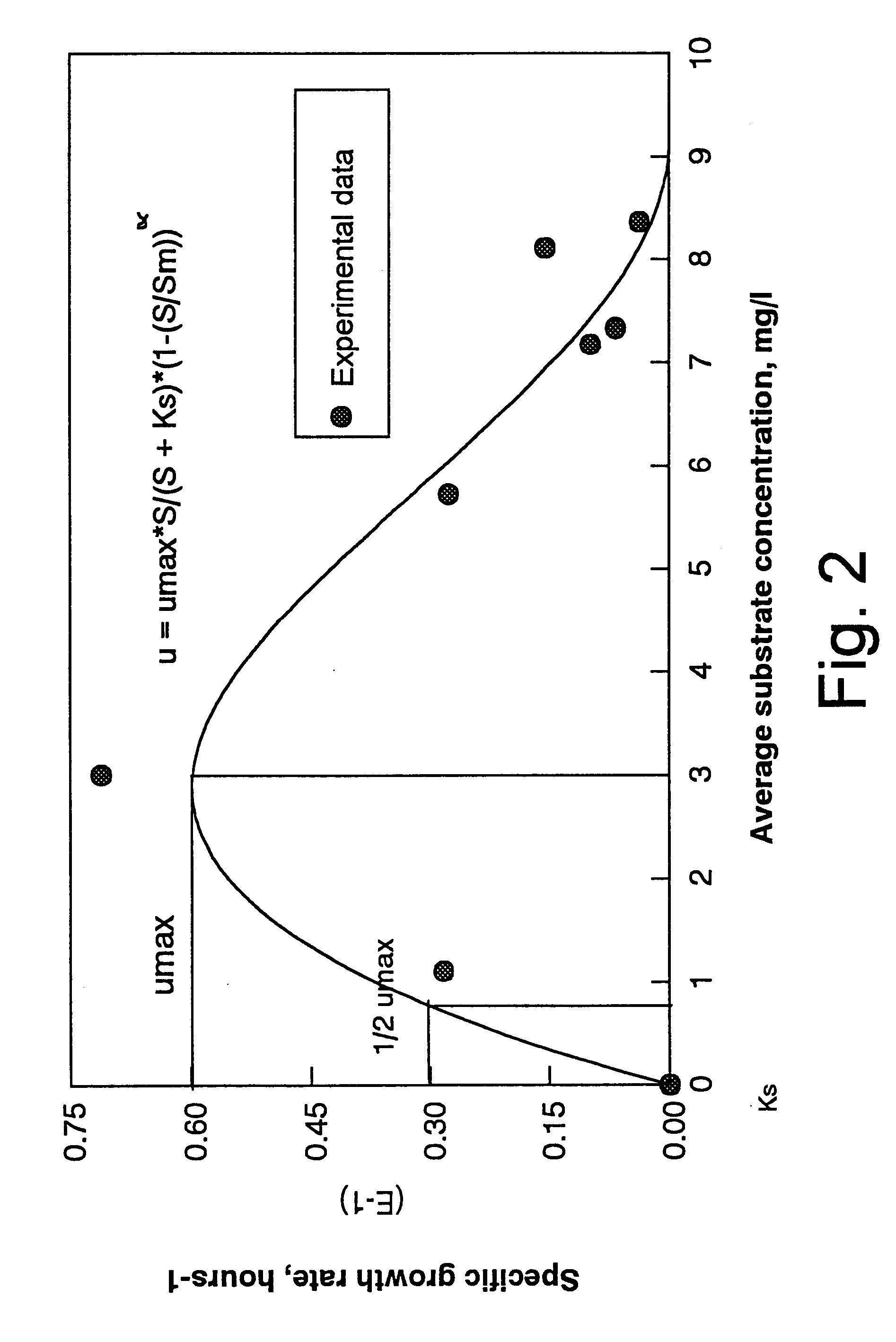

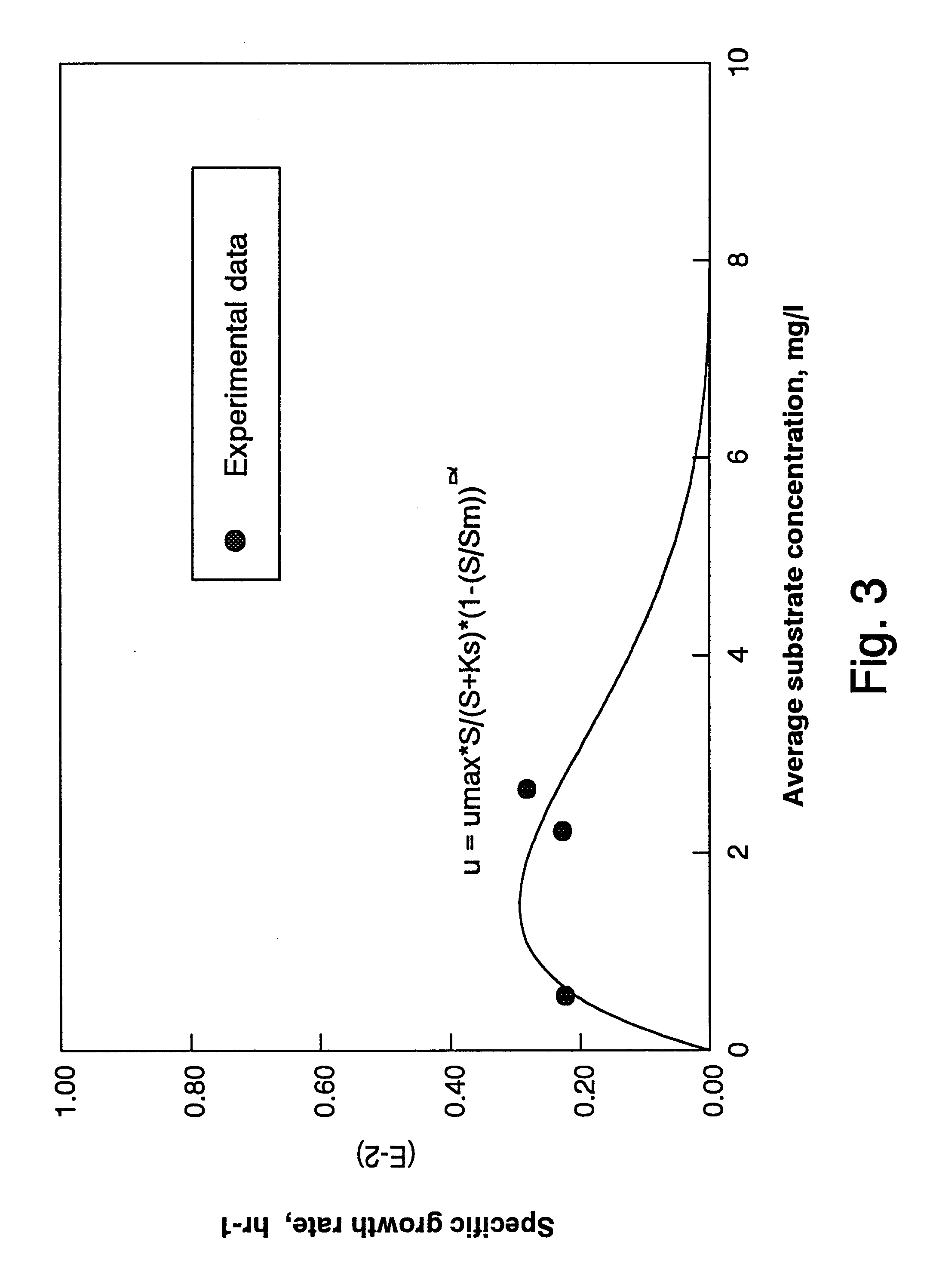

Anaerobic biodegradation of unsaturated, saturated, aromatic and halogenated hydrocarbons

An apparatus and method for anaerobic biodegradation, bioremediation or bioprocessing of hydrocarbons dissolved in an aqueous matrix, such as wastewater, groundwater, or slurry. Dissolved alkanes (saturated hydrocarbons), alkenes (unsaturated hydrocarbons), aromatic hydrocarbons and / or halogenated hydrocarbons are metabolized or cometabolized. In one form, the invention involves introducing an aqueous stream comprising at least one dissolved aromatic hydrocarbon (such as benzene, toluene, ethylbenzene, o-xylene, m-xylene, p-xylene, phenol, o-cresol, m-cresol, or p-cresol) and a dissolved oxide of nitrogen [such as nitrate (NO3-), nitrite (NO2-), nitric oxide (NO) and nitrous oxide (N2O)] to a reactor, and operating said reactor under conditions that support denitrification of the aromatic hydrocarbon. Alternatively, the aqueous stream may comprise at least one alkane (such as ethane) and / or at least one alkene (such as ethene or ethylene) and biodegradation of these compounds is accomplished. In a preferred form, the aqueous stream also comprises at least one dissolved halogenated hydrocarbon (such as tetrachloroethylene, trichloroethylene, or 1,1,1-trichloroethane) and dehalogenation of the halogenated hydrocarbon is accomplished. The reactor may be a continuous stirred tank reactor, a batch (or sequencing batch) reactor, a plug-flow reactor, a fixed-film reactor, or a pore space in an underground aquifer in situ. The reactor is operated in such a way that molecular oxygen is excluded from the space or zone in which the biodegradation is occurring and the other requirements of denitrifying bacteria are met. In some implementations, kinetic control (control of mean cell residence time) is used to enrich a denitrifying culture in the reactor.

Owner:YESTECH

Solid phase synthesis method for atosiban

ActiveCN101314613AAvoid timeAvoid shortcomings such as incomplete oxidationPeptide preparation methodsSolubilityCresol

The invention relates to a synthetic process of atosiban and solves the technical problem with poor solubility and long reaction time in the air liquid phase oxidation of the prior art. The synthetic process comprises the steps as follows: aminomethyl resin is adopted as a carrier; amino acids are combined one by one according to the Fmoc / tbu solid-phase peptide synthetic method; S-S bonds are formed by adopting the iodine oxidization method on the resin; peptides are cut from the resin with the mixed solution of trifluoroacetic acid, tri-isopropyl silicane, water and p-cresol to obtain a coarse product with S-S bonds; and the product is subjected to the HPLC purification and then frozen to obtain the atosiban. The synthetic process is simple and applicable to the large-scale synthesis of atosiban.

Owner:GL BIOCHEM SHANGHAI

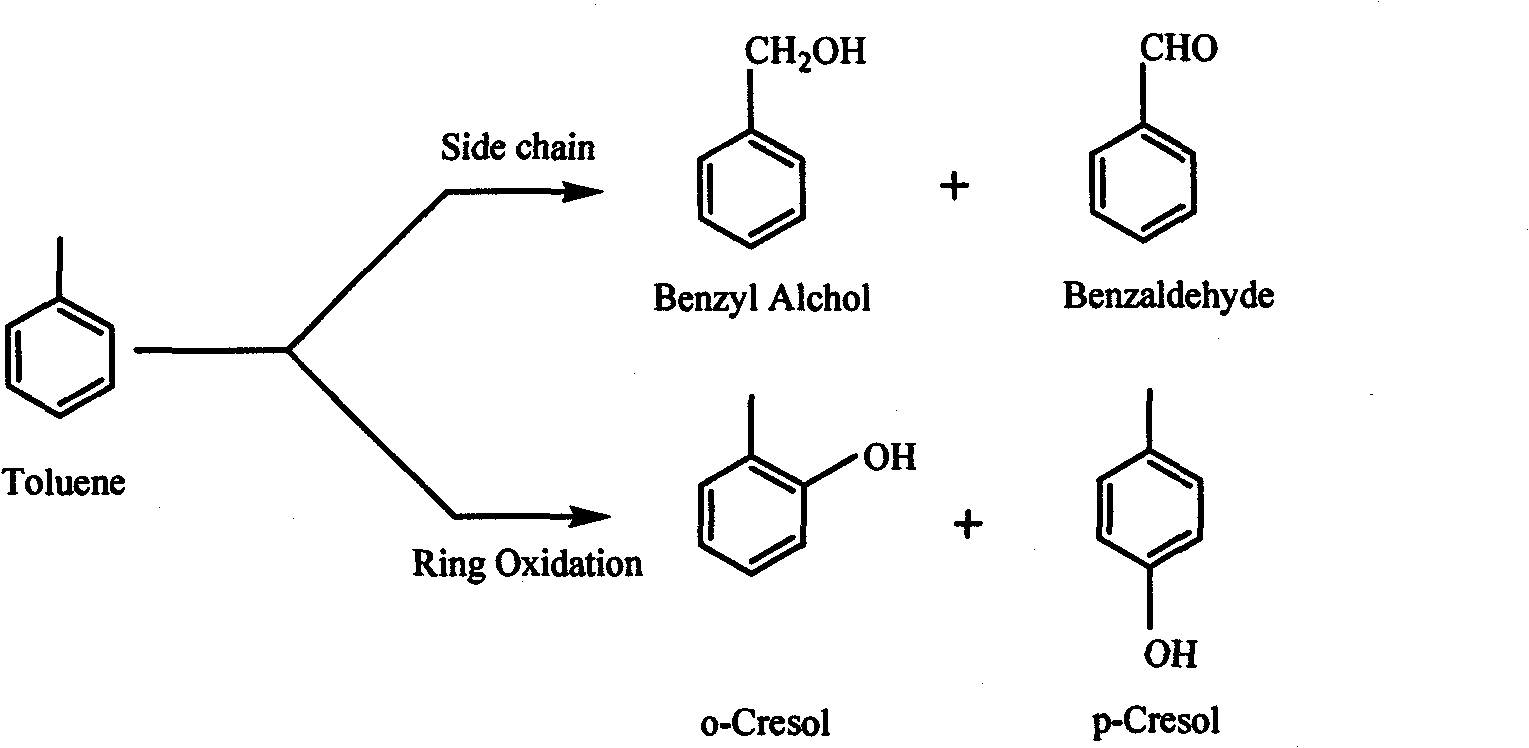

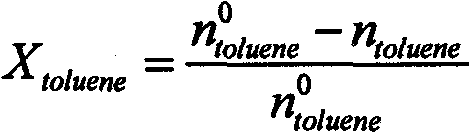

Catalytic synthesis method for preparing cresol by toluene one-step hydroxylation reaction

InactiveCN101786943AImprove effective utilizationIncreased o-cresol concentrationOrganic chemistryMolecular sieve catalystsRare-earth elementSynthesis methods

The invention discloses a catalytic synthesis method for preparing cresol by toluene one-step hydroxylation reaction, which is characterized in that: composite catalyst consisting of titanium silicalites and kieselguhr is adopted, the hydrogen peroxide is used as oxidant and the acetone is used as solvent, a continuous fixed-bed catalytic reaction system is adopted, and the reaction is carried out in solid-liquid two phases. The titanium silicalite in the composite catalyst has a MFI structure, and the kieselguhr is subjected to modification by a specific chemical method; and meanwhile, rare-earth elements are used to carry out modification on the catalyst, so that the catalyst has higher catalytic performance for the cresol-prepared toluene one-step hydroxylation reaction. The reaction process has the characteristics of high selectivity of cresol product, high effective utilization ratio of hydrogen peroxide, molar ratio of o-cresol to p-cresol in the cresol products of 1.3 to 1.4, mild reaction condition, simple and safe technological process, environmental protection and the like; therefore, the invention provides an economic and ecological method for preparing cresol.

Owner:EAST CHINA UNIV OF SCI & TECH

Production process of phenol products

InactiveCN1974517ALess investmentSmall footprintOrganic chemistryOrganic compound preparationTheoretical plateSlag

The present invention relates to coal chemical technology, and is especially process of producing phenol products. By using crude phenol after dewaterig and eliminating slag as material and through once intermittent rectifying process in a rectifying tower with theoretical plate number of 60-90, phenol, o-cresol fraction, m, p-cresol and industrial xylenol are obtained, with the o-cresol fraction is intermittently decompression rectified to obtain o-cresol product. Compared with tower type process, the present invention has low cost, small area and low power consumption.

Owner:ANGANG STEEL CO LTD

Art oil paint containing nano-pigment and method for manufacturing same

InactiveCN101225253ABright and brightSaturated and IntenseWax coatingsArtist's paintsALUMINUM STEARATESCobalt

The invention relates to art oil paint with nano-pigment and the preparation method, which is characterized in that the beeswax is added into refined linseed oil and polly seed salad oil and blended evenly to make bond after heating and melting. The nano-pigment is added into the bond to blend evenly and then the pigment is added in and blended evenly. Then aluminum stearate, 2-ethyl hexanol cobalt (CAS No.13586-82-8), silicon dioxide hydrate, hydrafil, phenoxetol, butyl-p-cresol and lithopone are added in and then blended evenly. The product can be obtained after grinding. The preparation method first disperses the nano-pigment into the bond and drains most air on the surface of the common pigment grain, and then disaggregates the large grain and small gobbet of the sizing agent by the large shearing force, extrusion force and grinding force between the two rollers generated by the turn of the three-roller muller. During the grinding process, the bond with nano-pigment or latex covers the surface of the pigment grain and then permeates through the gaps of the grains. The product made has the advantages of rich color, bright colour and luster, fresh tint, strong tinctorial strength and good chromaticity.

Owner:宋健

Method for preparing ortho-cresol and 2,6-dimethylphenol

InactiveCN102826960AAdjustable pHHigh activityOrganic chemistryOrganic compound preparationPtru catalystOrtho position

The invention discloses a method for preparing ortho-cresol and 2,6-dimethylphenol and is characterized in that a reaction mixed liquid at the mole ratio of phenol to methanol to water being 1: (2-5): (1-3) is pumped the into a reactor by the use of a pump at the feeding space velocity of 0.5-2 hr<-1>; N2 with the flow velocity of 10-25 mL / min is used as a carrier gas; and a vapor-phase alkylation reaction is carried out at the reaction pressure of normal pressure to 0.5 MPa at the reaction temperature of 320-380 DEG C and under the condition of an alkaline Fe / Mg / Sb composite oxide used as a catalyst. The method provided by the invention has advantages as follows: high average conversion rate of phenol, long one-way service life of the catalyst, high ortho-selectivity, and no generation of impurities m.p-cresol and anisole. In addition, the process is simple, and the method is suitable for continuous large-scale production of ortho-cresol, or reallocation of 2,6-dimethylphenol, or co-production of ortho-cresol and 2,6-dimethylphenol.

Owner:HUNAN XINLING CHEM CO LTD

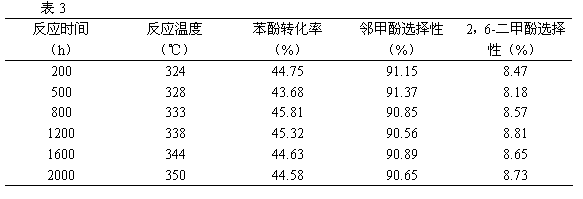

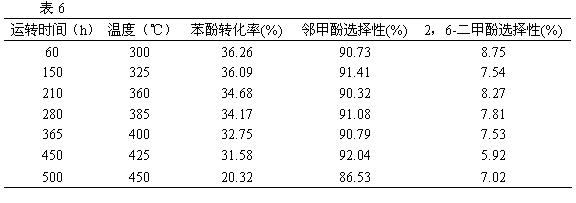

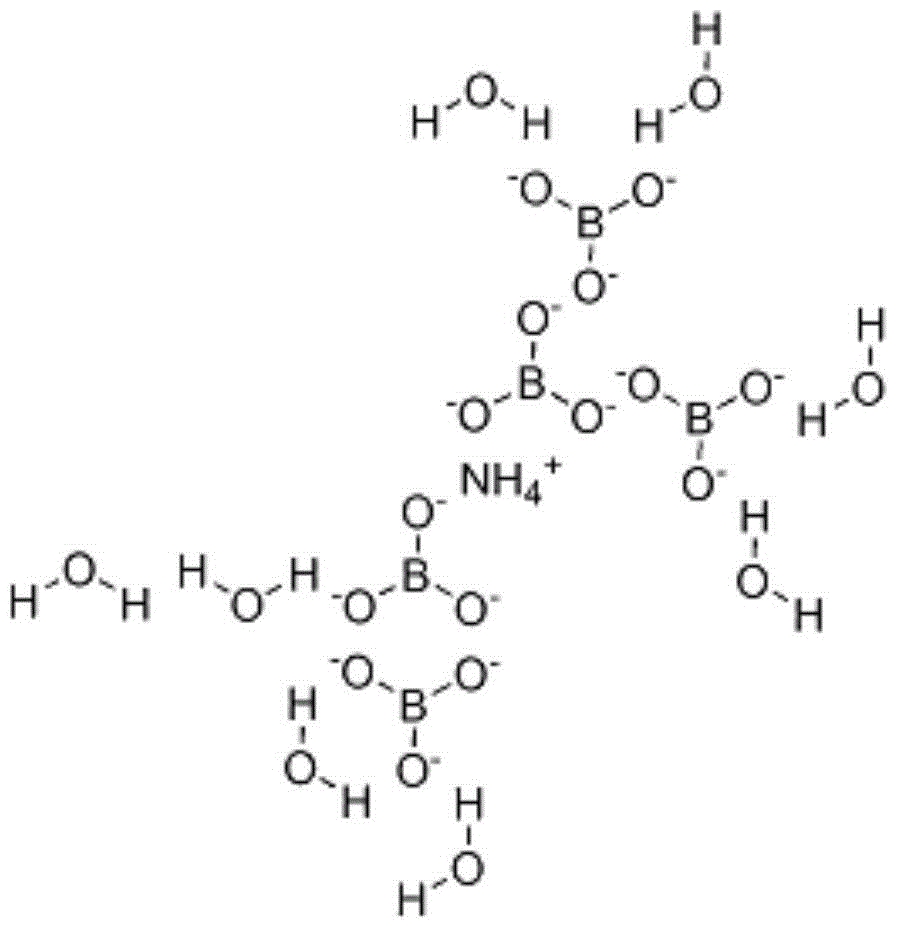

Preparation method of boron oxide-modified microporous molecular sieve shape-selective catalyst

InactiveCN104084233AHigh activityHigh shape selectivityOrganic chemistryMolecular sieve catalystsAlkyl transferBoron oxide

The invention relates to a preparation method of a boron oxide-modified microporous molecular sieve shape-selective catalyst. The preparation method comprises the following step of with a microporous molecular sieve ZSM-5 or MCM-22 as a supporter and ammonium pentaborate as a precursor of boron oxide, supporting boron oxide on the outer surface of the microporous molecular sieve by virtue of dipping and temperature programming roasting methods, wherein the mass ratio of ammonium pentaborate to the microporous molecular sieve is (1:2)-(1:8). The catalyst prepared by virtue of the preparation method has good shape selective catalysis performance in processes of compounding p-cresol and paraethyl phenol by virtue of para-phenol alkylation.

Owner:CHANGZHOU UNIV

Method for directly separating phenols from coal pyrolytic oil

InactiveCN104324519ASimple processMild conditionsOrganic chemistryOrganic compound preparationEtherOil phase

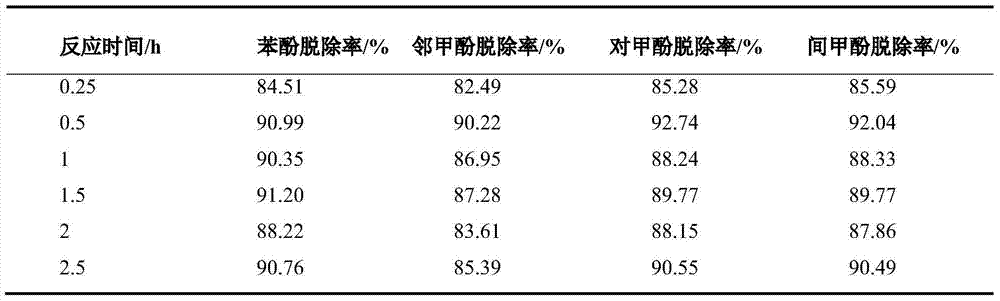

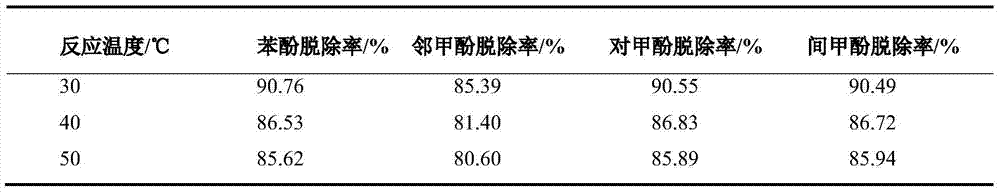

The invention discloses a method for directly separating phenols from coal pyrolytic oil. Amide compounds are taken as extracting agents and form eutectic solvent solvents or solid complexes insoluble in the oil phases with phenols in oil, and therefore, the phenols are separated from the oil phases. Ether compounds are adopted to recycle the extracting agents by virtue of reverse extraction; the recycled extracting agents can be continuously applied to the extraction process. The phenols can be one or more of phenol, o-cresol, p-cresol, m-cresol, ethyl phenol, naphthol, butyl phenol, propyl phenol, dihydroxyl phenol and polyhydroxyl phenol; the oil includes model oil and pyrolytic oil; the concentration range of the phenols is 10-400g / L; the molar ratio of the amide compounds to the phenols is within the range of 0.1-2.0; the separation temperature ranges from 0 to 100 DEG C and the separation time ranges from 1 to 100 minutes. The removal rate of the phenols under appropriate reaction conditions is above 90%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Antiwear hydraulic oil specially used for injection molding machine and preparation method thereof

InactiveCN101560435ALow costReduce manufacturing costAdditivesBase-materialsOxygenInjection molding machine

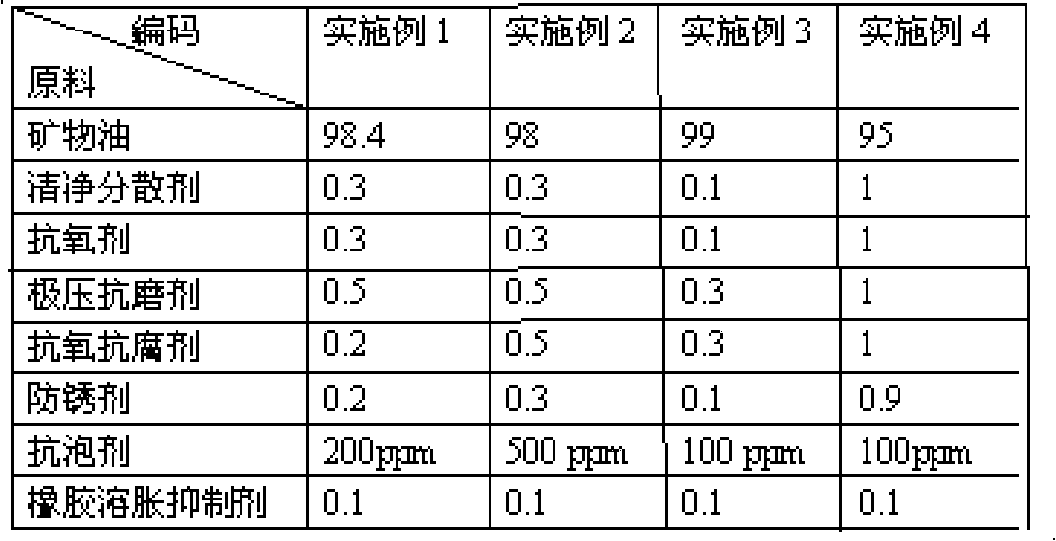

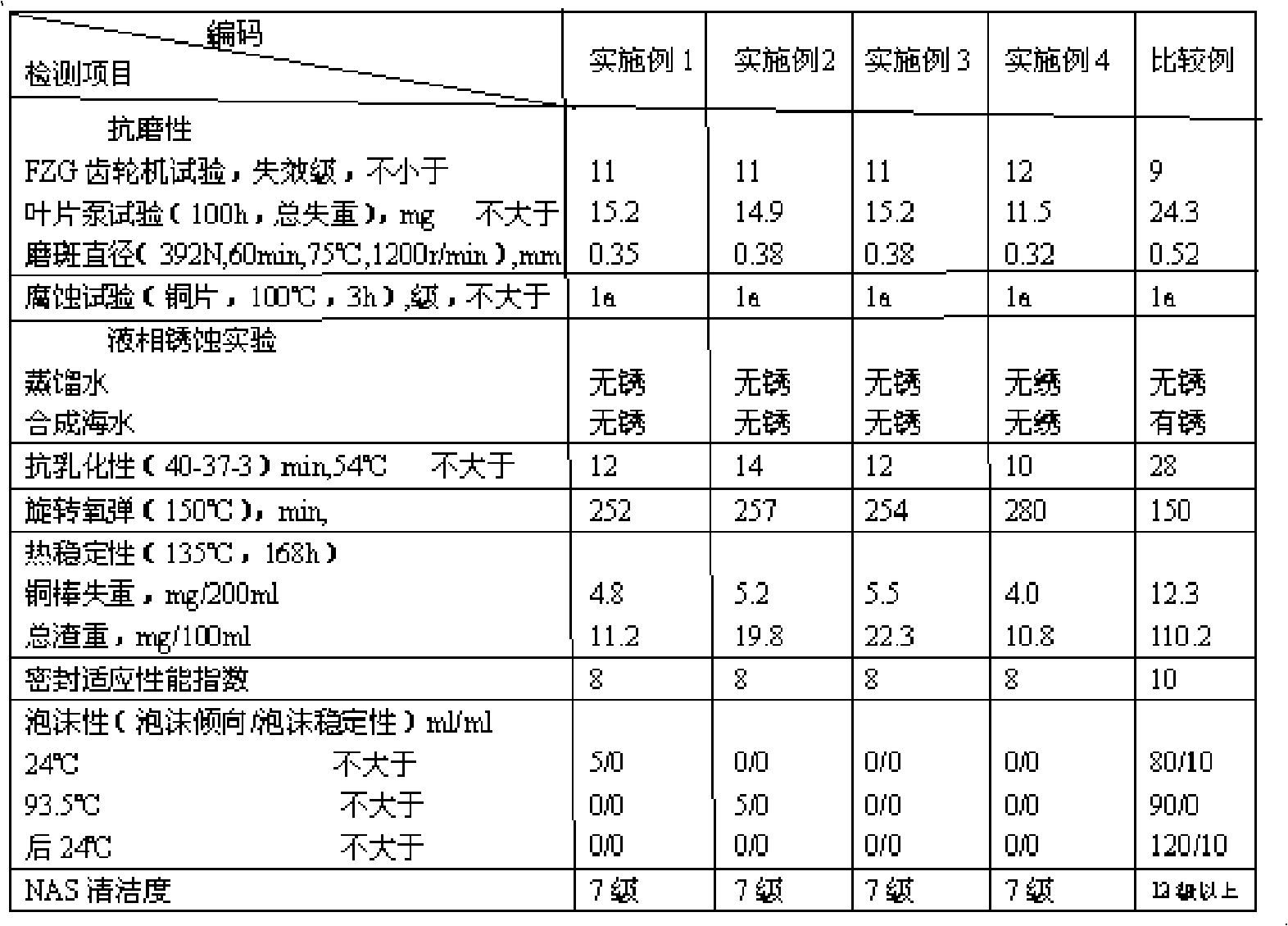

The invention discloses an antiwear hydraulic oil specially used for an injection molding machine, which is prepared by the following raw materials by weight percentage: 95-99% of mineral oil, 0.1-1.0% of detergent dispersant: high alkali synthesis calcium sulfonate, 0.1-1.0% of anti-oxidant: 2,6-di-tert-butyl-p-cresol and / or alkylated diphenylamine, 0.3-1.0% of extreme pressure antiwear additive, 0.2-1.0% of antioxidant and corrosion inhibitor, 0.1-0.9% of antirust: neutral dinonylnaphthalene sulfonic acid, 100-500ppm of defoaming agent and less than 0.1% of rubber swelling inhibitor. The invention also provides a method for preparing the hydraulic oil. The hydraulic oil has the advantages of excellent wearability, anti-rust performance, rotation oxygen bomb and thermal stability; simultaneously, the preparation method of the hydraulic oil is simple, is easy for industrial production and has low production cost.

Owner:NINGBO RUNBEI WANLING LUBRICANT

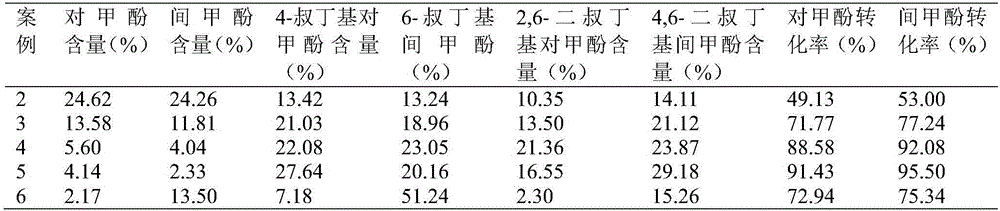

Method for separating m-cresol and p-cresol mixture by liquid-phase alkylation method

InactiveCN106810422AImprove conversion rateIncrease profitOrganic chemistryOrganic compound preparationCresolMetacresol

The invention discloses a method for separating an m-cresol and p-cresol mixture by a liquid-phase alkylation method. According to the method, alkylation reaction between isobutene mixed gas and the m-cresol and p-cresol mixture are performed through a fixed-bed reactor under the liquid phase state, the reacted mixture is separated to obtain metacresol and paracresol, the isobutene mixed gas serves as an alkylating agent, the m-cresol and p-cresol mixture serves as a raw material, the alkylation reaction is performed for the alkylating agent and the m-cresol and p-cresol mixture, and the treated mixture is separated to obtain pure metacresol and pure paracresol. The method overcomes the shortcomings of low utilization rate and serious environmental pollution of alkylating agents in gas-phase alkylation reaction in the prior art and solves the problems that production cost is high as high-purity isobutene serves as the alkylating agent in the gas-phase alkylation reaction.

Owner:HEBEI UNIV OF TECH +1

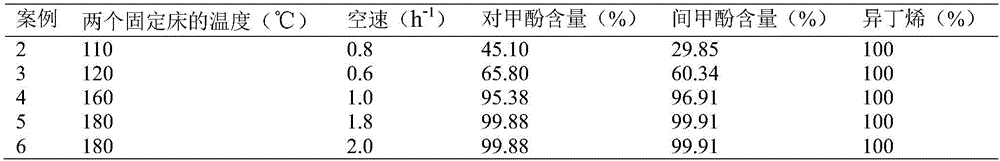

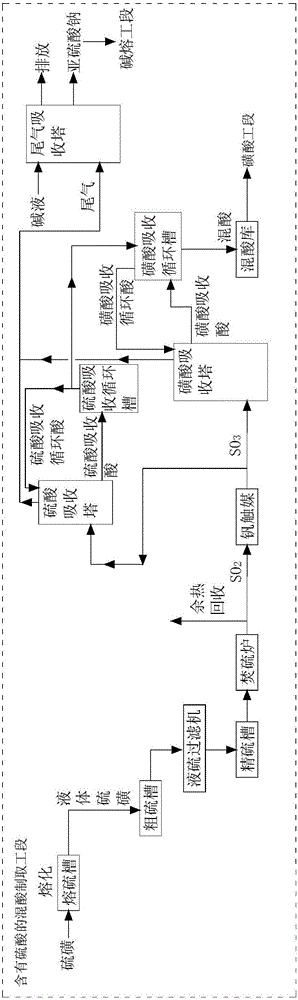

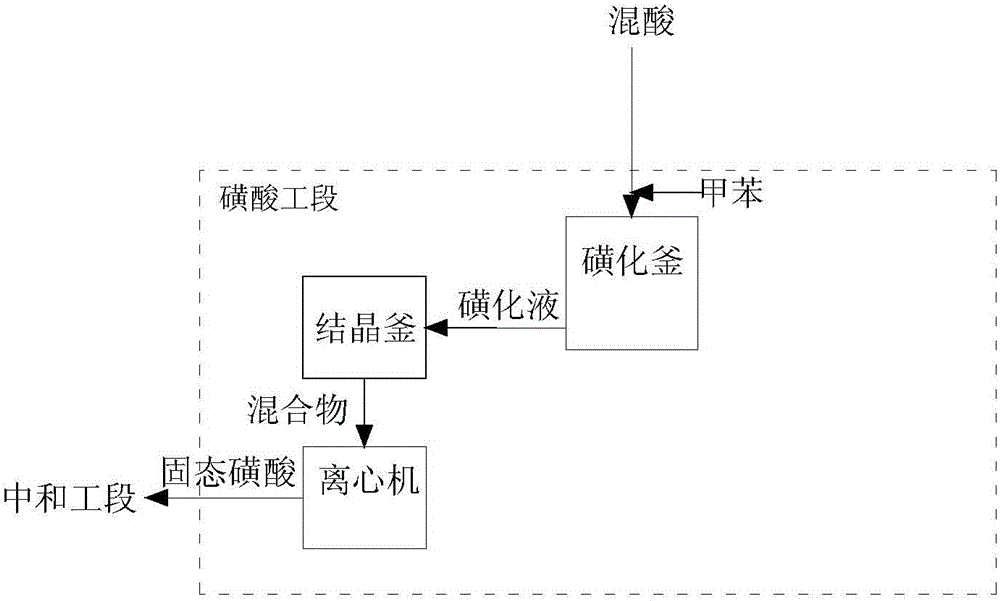

P-cresol preparation method and equipment

InactiveCN105906481AShort processReduce in quantityOrganic compound preparationSulfonic acids salts preparationSlagSulfite salt

The invention provides a p-cresol preparation method and equipment. The method comprises the following steps that toluene and sulphuric acid take a reaction to obtain paratoluenesulfonic acid; the paratoluenesulfonic acid then takes a reaction with sodium sulfite to obtain sodium p-toluenesulfonate; the sodium p-toluenesulfonate generates sodium p-cresol under the alkaline condition; the p-cresol is generated by the sodium p-cresol under the alkaline condition. The method and the equipment can thoroughly solve the problem that in the current p-cresol production process, a great amount of waste water, waste gas and waste slag are generated; the automation level of the equipment is improved; most intermittent production is changed into continuous production; the work environment is improved.

Owner:JINNENG SCI & TECH

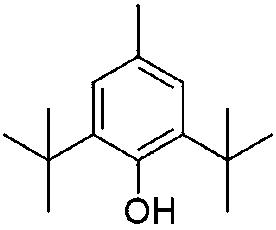

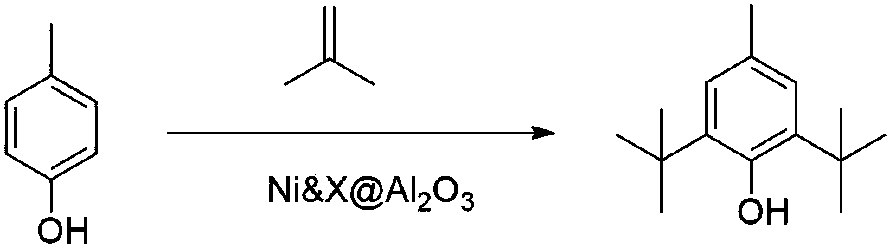

Preparation method of antioxidant BHT

InactiveCN108285406AIncrease acidityImprove thermal stabilityOrganic chemistryOrganic compound preparationP-CresolMetal

The invention discloses a method for synthesizing antioxidant BHT. Among current synthetic methods, some methods are highly corrosive to equipment, some methods are high in three wastes, and some methods cannot continuously produce, are low in synthesis efficiency, and are not conducive to industrialization. The method utilizes p-cresol and isobutylene as raw materials, and conducts catalytic reactions in a nickel-doped active aluminium oxide solid catalyst prepared by a sol-gel method, the structure of the active aluminium oxide catalyst is Ni&X@Al2O3, and the weight ratio of the nickel is 0.2-10%; the X is a VIII-group transition metal other than the nickel, and the content of the X is less than the nickel. When synthesizing target products, the method has the advantages of easy control,green environmental protection, long catalyst life, high stability, continuous production and convenient industrialization.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com