Patents

Literature

39 results about "Mixed cresols" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation method of m-cresol and p-cresol mixture

InactiveCN101863742AReduce consumption costReduce manufacturing costOrganic chemistryOrganic compound preparationAlkyl transferM-Cresol

The invention discloses a novel method for separating an m-cresol and p-cresol mixture to obtain high-purity m-cresol and p-cresol. The method comprises the following steps: carrying out alkylation reaction on the m-cresol and the p-cresol as raw materials under the existence of an alkylating agent and a catalyst to obtain the mixed solution of 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol; rectifying the mixed solution to obtain the products of high-purity 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol; respectively carrying out dealkylation reaction and rectification on the obtained high-purity 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol under the existence of the catalyst to respectively obtain the products of the high-purity m-cresol and p-cresol; and recovering isobutene generated by dealkylation. The invention has high reaction conversion rate, high atom use ratio, low raw material consumption and production cost and reliable safety performance.

Owner:吴鸿宾

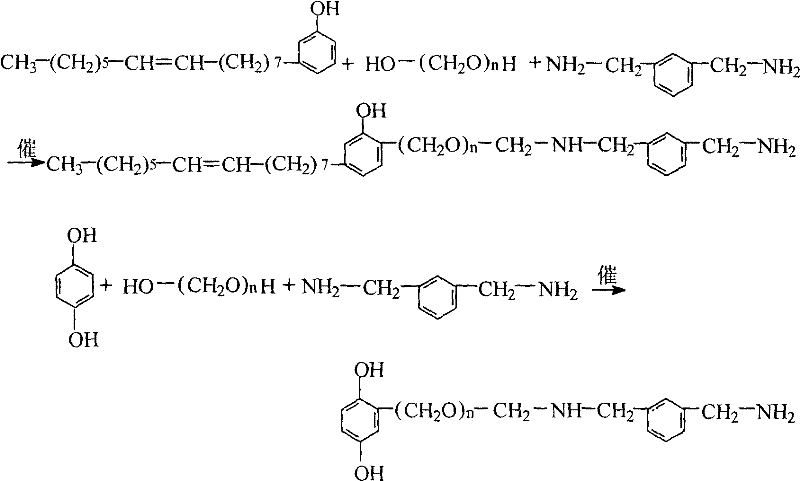

Preparation method of mixed cresol modified meta-xylylene diamine epoxy resin curing agent

InactiveCN102532449AEfficient removalTemperature controlAnti-corrosive paintsEpoxy resin coatingsXylyleneIrritation

The invention provides a preparation method of a mixed cresol modified meta-xylylene diamine epoxy resin curing agent. The method comprises the following steps of: adding meta-xylylene diamine into an N2-charged reaction kettle; raising the temperature to 80-95 DEG C; adding hydroquinone; fully mixing; adding cardanol; keeping the temperature at 85-95 DEG C till a solution is clear and transparent; adding a catalyst; gradually adding polyformaldehyde in batches simultaneously; lowering the temperature to 70-80 DEG C; vacuumizing and dehydrating; after dehydrating, raising the temperature to 130-150 DEG C; undergoing a polymerization reaction; cooling to 70-85 DEG C; filtering the catalyst; diluting to 15-25 percent by using an organic solvent; and discharging to obtain the mixed cresol modified meta-xylylene diamine epoxy resin curing agent. A product prepared with the method has the advantages of stable performance, high curing speed, low toxicity, high transparency, unremarkable whitening phenomenon, nontoxicity and freeness of irritation, can be applied to underwater construction, and is a superior sea heavy-duty coating.

Owner:上海美东生物材料股份有限公司

Method for producing 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol

InactiveCN101353293AReduce manufacturing costReduce processing costsOrganic chemistryOrganic compound preparationCresolMetacresol

The invention relates to a method for producing 2-tertiary butyl-paracresol and 6-tertiary butyl-metacresol from mixed cresol, which is characterized in that the mixed cresol is taken as raw material; firstly, the mixed cresol is rectified and separated to obtain refined mixed cresol; then the refined mixed cresol is alkylated to obtain the mixture of 2-tertiary butyl-paracresol and 6-tertiary butyl-metacresol; and the mixture of 2-tertiary butyl-paracresol and 6-tertiary butyl-metacresol is further rectified; as the difference between the boiling point of 2-tertiary butyl-paracresol and the boiling point of 6-tertiary butyl-metacresol is 6 DEG C, the rectification method can be used for separating 2-tertiary butyl-paracresol from 6-tertiary butyl-metacresol to obtain a 2-tertiary butyl-paracresol product and a 6-tertiary butyl-metacresol product with high purity. The method greatly reduces the production cost.

Owner:天津天大天海化工新技术有限公司

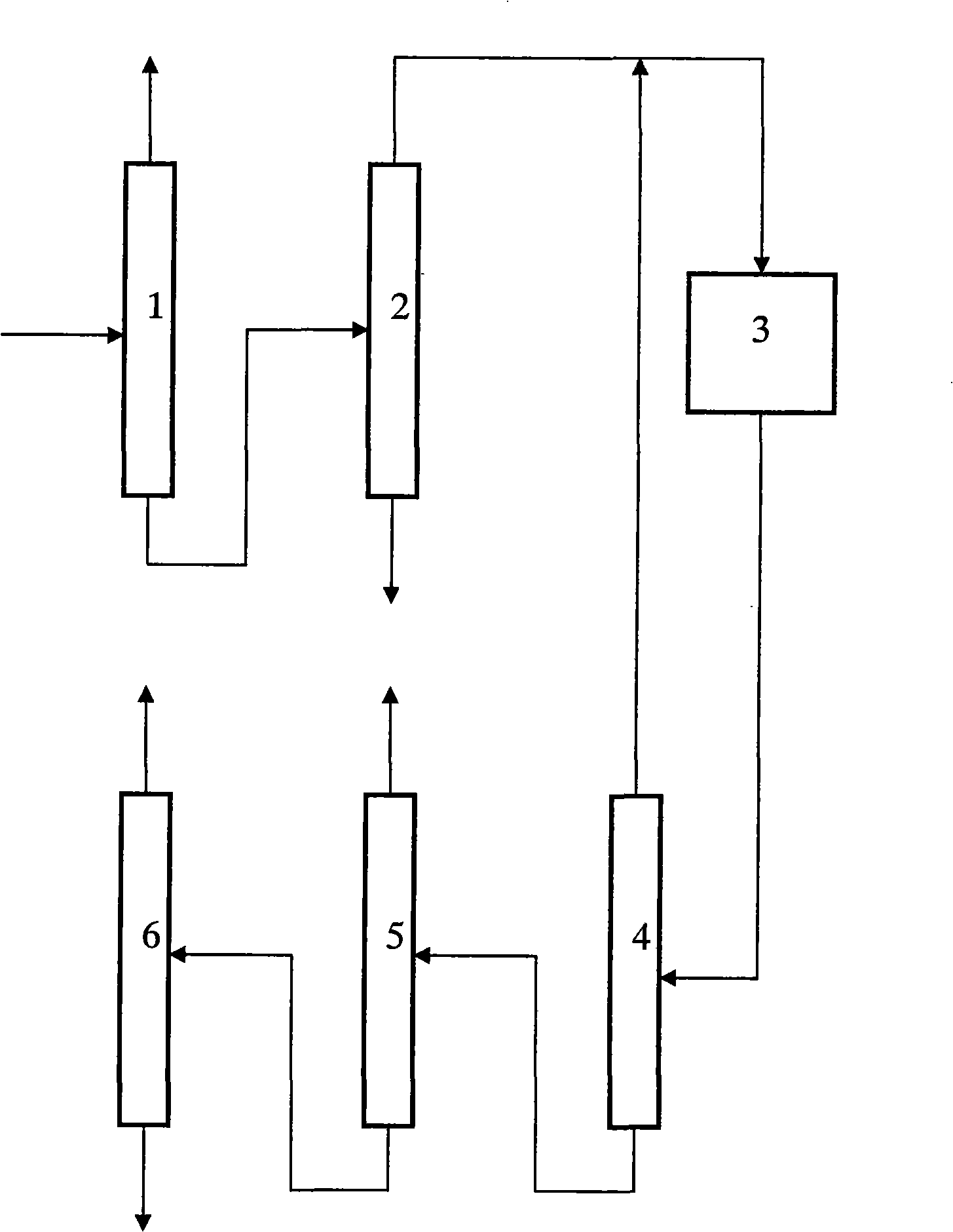

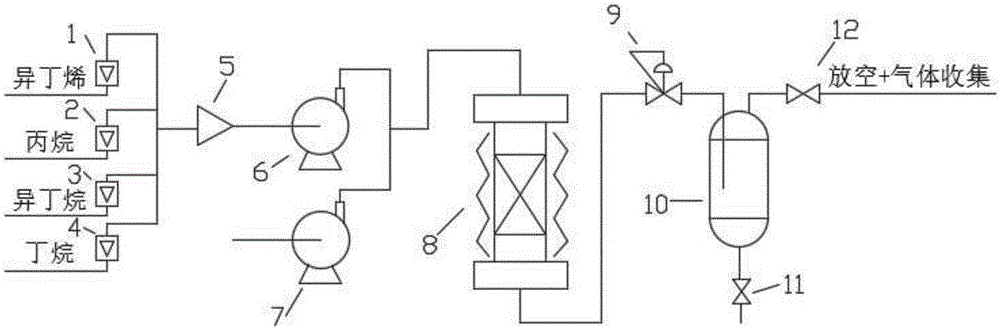

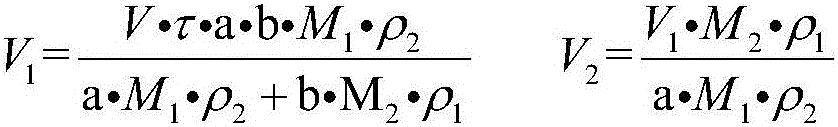

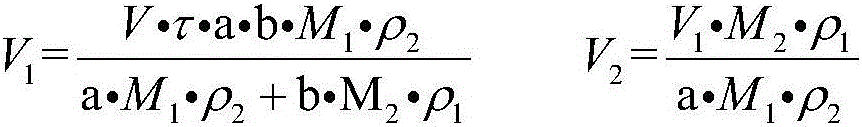

Method for fixed bed alkylation separation of m-cresol and p-cresol

InactiveCN104496759ASuppress generationReduce consumptionOrganic chemistryOrganic compound preparationFixed bedIt technology

Relating to the field of m-cresol and p-cresol separation and its technology, the invention discloses a new method of separating an m-cresol and p-cresol mixture to obtain high-purity m-cresol and p-cresol. The method takes a m-cresol and p-cresol mixed solution and isobutene gas as the raw materials, and employs a solid supported acidic ionic liquid as the catalyst to carry out alkylation reaction in a fixed bed, the obtained alkylation product is separated to obtain mono-t-butyl cresol, which is subjected to de-tert-butylation, thus obtaining the high purity m-cresol and p-cresol.

Owner:ANQING FULLTIME CHEM INDAL +1

Paint remover used for polyester, poly esterimine paint capper covered round wire paint film

Owner:GUANGDONG RONSEN SUPER MICRO WIRE CO LTD

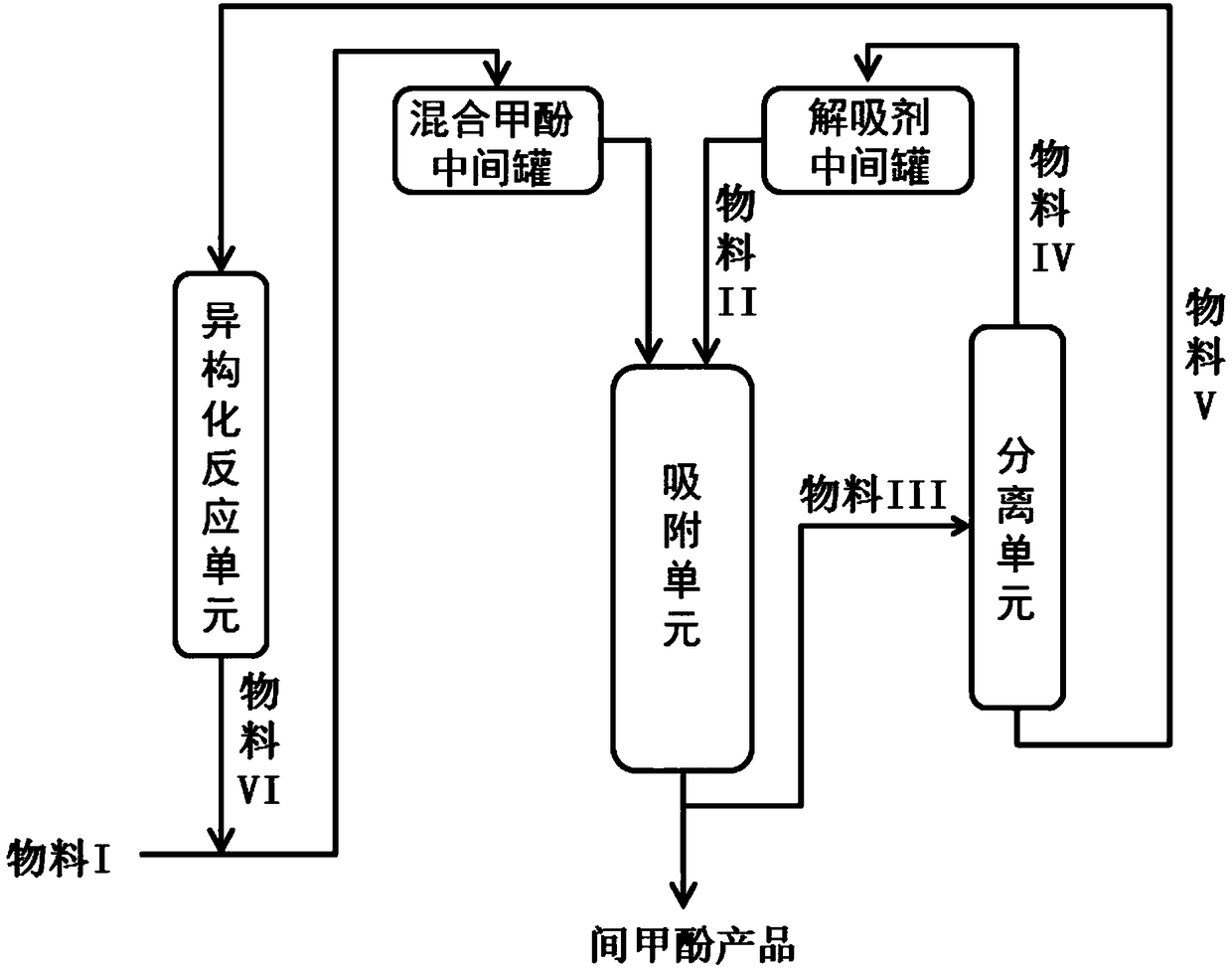

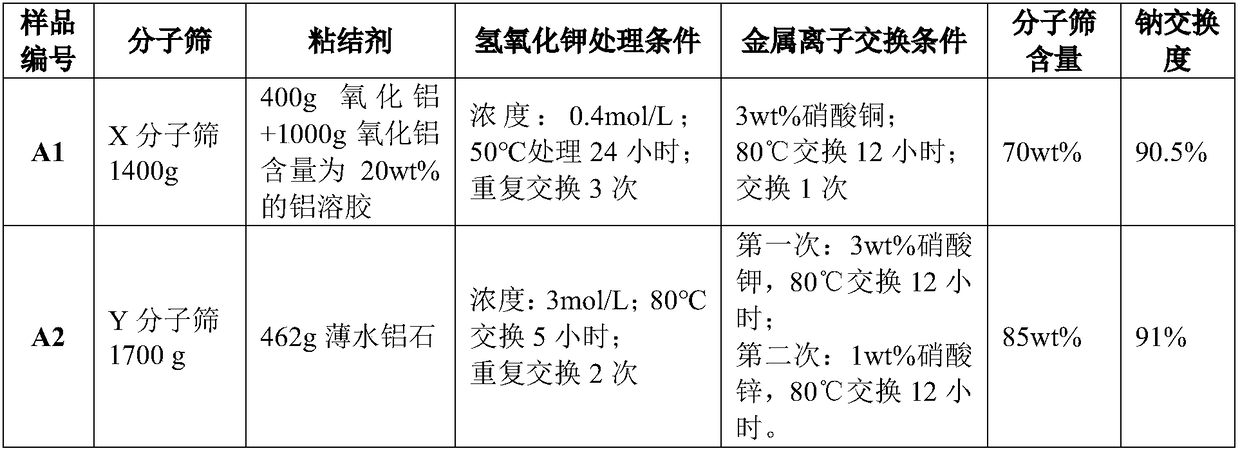

Method for production of high-purity m-cresol

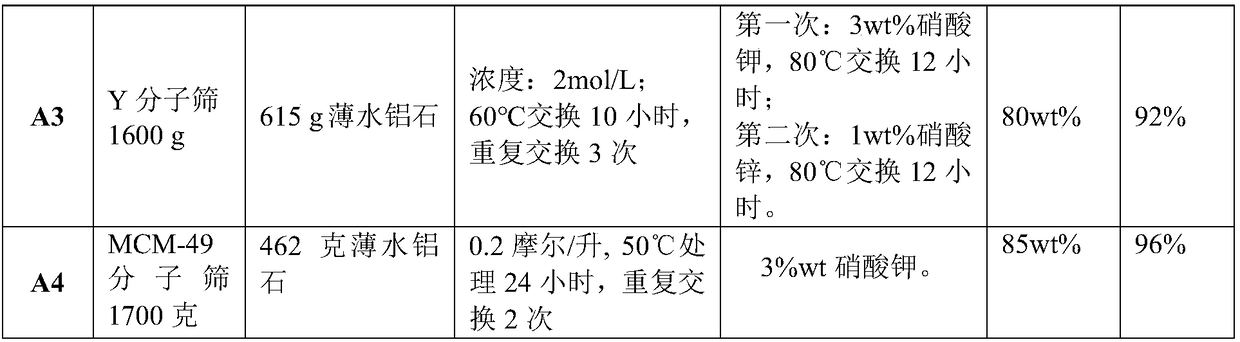

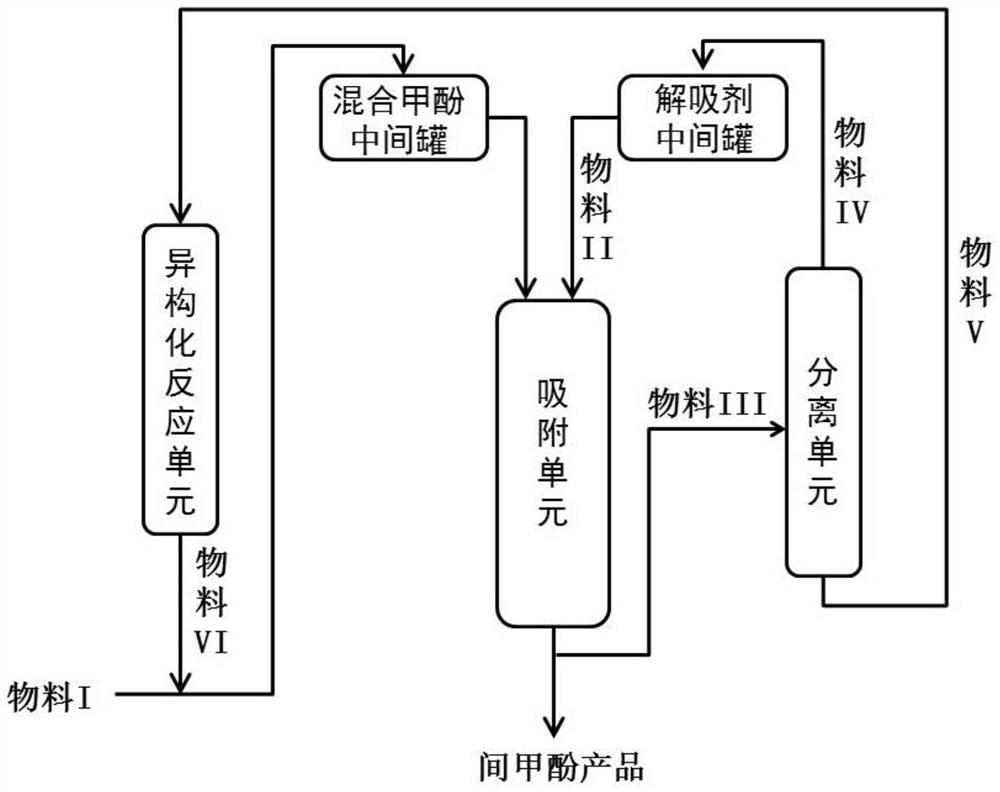

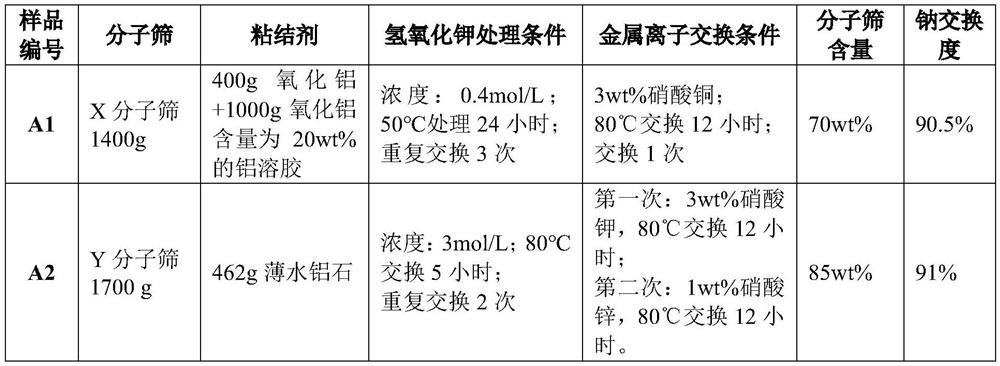

ActiveCN108147945ASolve the problem of low product qualitySolve the problem of complicated process and low quality of m-cresol productsIon-exchange process apparatusOrganic chemistryMolecular sieveIsomerization

The invention provides a method for production of high-purity m-cresol. The method comprises the following steps: (1) injecting a material I containing m-cresol and p-cresol into an adsorption unit for adsorptive separation to obtain an m-cresol product, wherein an adsorption unit comprises one or more adsorbent bed layer, and the at least one adsorbent bed layer comprises a molecular sieve adsorbent; (2) injecting a material II containing a desorbent into the adsorption unit to desorb the adsorbent bed layer in the adsorption unit so as to obtain a desorption material III, injecting the desorption material III into a separation unit, and performing separation to obtain a desorbent material IV and a mixed cresol material V; (3) returning the desorbent material IV obtained through separation in the step (2) into the adsorption unit for recycling; and (4) injecting the mixed cresol material V obtained through separation in the step (2) into an isomerization reaction unit for a reaction to obtain an isomerization product material VI, and returning the isomerization product material VI into the desorption unit.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Separation and purification method of m-cresol

ActiveCN104230669AReduce dosageEfficient separationOrganic chemistryOrganic compound preparationAlkanePurification methods

The invention relates to a separation and purification method of m-cresol. The separation and purification method comprises the following steps: a) complexing: adding mixed cresol, urea and a mixed solvent formed by toluene and liquid alkane into a reactor, stirring, heating to increase the temperature to 65-90 DEG C, performing heat preservation for 1-2h, reducing the temperature to 40-60 DEG C, then cooling and crystallizing at the temperature of 0-20 DEG C for 1-2h, and filtering to obtain a complex solid and filtrate A; and b) decomplexing: adding the complex solid obtained in the step a) into an ether type solvent, stirring at the temperature of 10-60 DEG C, performing decomplexing reaction for 0.5-3h, and filtering to obtain urea and filtrate B; and performing decompression rectification on the filtrate B to obtain m-cresol. The method for separating m-cresol from mixed cresol is high in product purity, simple in process, low in solvent consumption, high in recovery rate and low in energy consumption and can operate at normal pressure, prevent the production of three wastes in a separation process and realize recycling of resources, so that the method is environment-friendly.

Owner:江苏富比亚化学品有限公司

Method for separation and purification of p-cresol

ActiveCN104058936AHigh purityAdditional purification stepsOrganic chemistryOrganic compound preparationOxalateOrganic solvent

The invention discloses a method for separation and purification of p-cresol. The method comprises the following steps: 1) complexation: adding toluene and a complexing agent of oxalic acid into a reaction kettle, heating, adding mixed cresol, insulating for reaction, and filtering to obtain a cresol- oxalic acid complex crude product; 2) purification: adding the p-cresol-oxalic acid complex crude product into a purification solvent, stirring and filtering to obtain a p-cresol-oxalic acid complex; 3) decomplexation: adding the p-cresol-oxalate complex into water, insulating for reaction, separating an upper organic phase while hot, extracting the lower aqueous phase by toluene, and merging the extraction liquid into the upper organic phase; and 4) distillation: distilling the upper organic phase to remove solvent so as to obtain p-cresol. Compared with the prior art, a purification step is added to ensure that the final isolated p-cresol has purity of no less than 99%; the amount of organic solvents is reduced, the complexation step employs water, and the organic solvent and water involved in the separation process can be used indiscriminately, thereby saving cost.

Owner:江苏富比亚化学品有限公司

High-pressure fixed bed alkylation method for mixed m-cresol and p-cresol

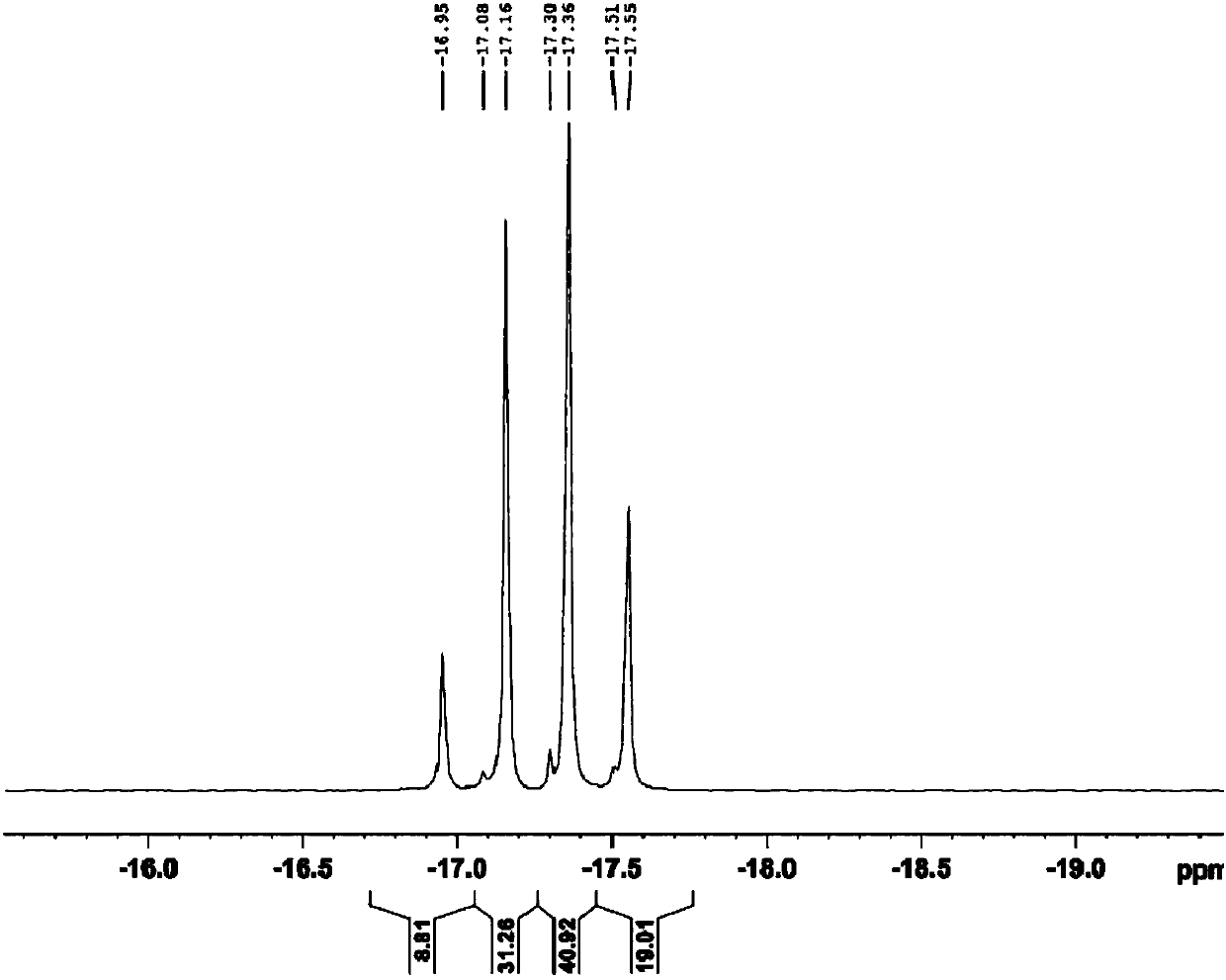

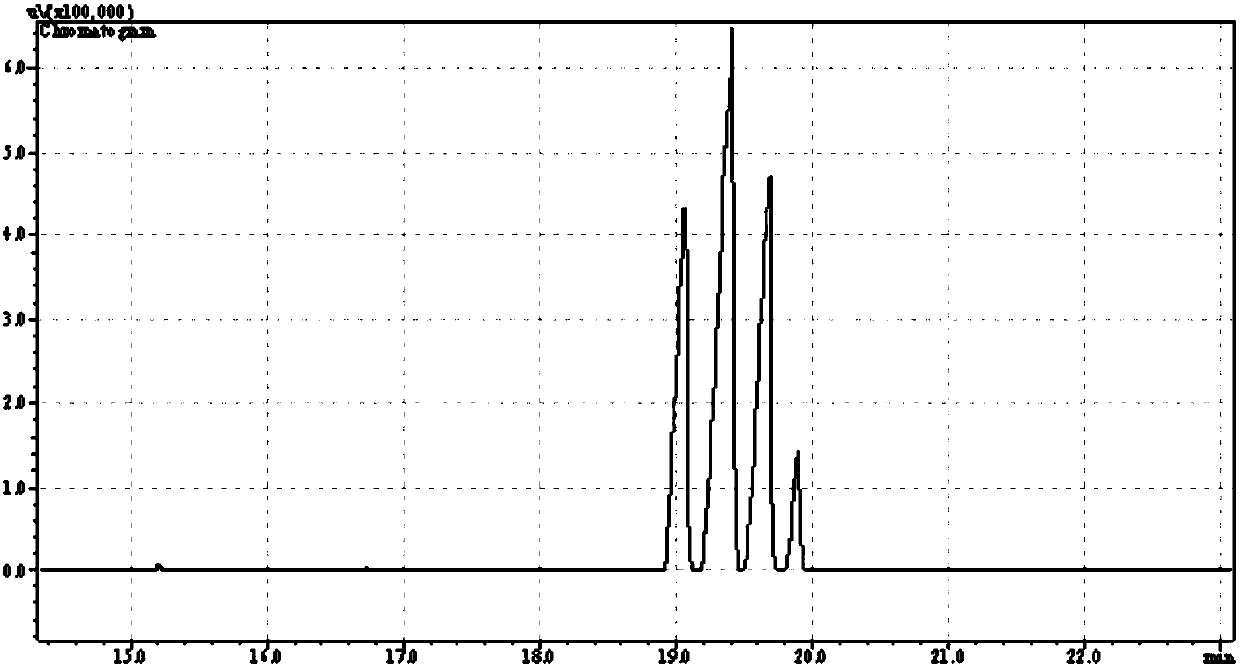

InactiveCN106831355AImprove conversion rateImprove utilization efficiencyOrganic chemistryOrganic compound preparationAlkyl transferCresol

The invention discloses a high-pressure fixed bed alkylation method for mixed m-cresol and p-cresol. The method comprises the following steps: pressurizing and liquefying alkylating agents, injecting the alkylating agents and mixed cresol into a reactor, maintaining the pressure of a fixed bed reactor to be 1.7-4.2MPa at the temperature of 50-110 DEG C, reacting under the space velocity of 0.1-5h<-1>, thereby obtaining a self-polymerized product of isobutene, mono-tert-butyl products of m-cresol and p-cresol and di-tert-butyl products of m-cresol and p-cresol, wherein the reactor is the fixed bed reactor; the alkylating agents refer to isobutene and aids; the volume of the aids accounts for 70-90% of the total volume of the alkylating agents; and a molar ratio of the isobutene to the mixed m-cresol and p-cresol is (0.5-3):1. According to the method disclosed by the invention, the utilization efficiency of the raw materials is improved, the conversion rate of the m-cresol in the method can reach 94.22%, and the conversion rate of the p-cresol can reach 89.46%.

Owner:HEBEI UNIV OF TECH +1

Preparation method of 2, 6-di-tert-butyl p-cresol

ActiveCN111960925ASimple processNo pollution in the processOrganic chemistryOrganic compound preparationChemical synthesisPtru catalyst

The invention relates to a preparation method of 2, 6-di-tert-butyl p-cresol, and belongs to the technical field of organic chemical synthesis. According to the method, a modified mesoporous silica loaded Nb / Mo / Cu three-metal active center catalyst is used as a catalyst, m-cresol, p-cresol and isobutene are mixed to be used as raw materials, ultrasonic cavitation is carried out in the catalytic reaction process, and then 2, 6-di-tert-butyl p-cresol is prepared. Mixed cresol is used as a raw material, so that a cost is reduced, during preparation of 2, according to the method, m-cresol is separated while 2, 6-di-tert-butyl-p-cresol is separated, by research, it is discovered that the modified mesoporous silica loaded Nb / Mo / Cu three-metal active center catalyst has a synergistic catalytic effect of the three-metal active center, the conversion rate of the mixed cresol and the selectivity of the di-tert-butyl cresol are greatly improved, especially, the selectivity of the 2, 6-di-tert-butyl-p-cresol is improved, impurities such as 2-tert-butyl-p-cresol and 6-tert-butyl-m-cresol are reduced, meanwhile, under the action of ultrasonic cavitation, a liquid-gas reaction is promoted to forma microreactor in micropores in a solid catalyst, the catalytic activity is greatly improved, the gas-liquid two-phase mass transfer efficiency and heat transfer area are increased, and the conversion rate of raw materials is further increased.

Owner:ANHUI HAIHUA CHEM

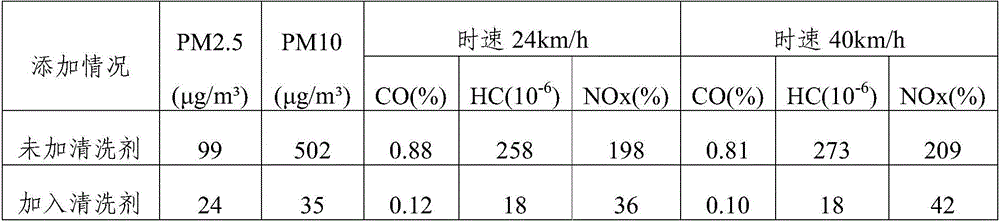

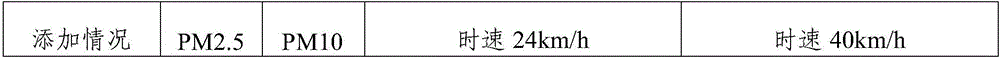

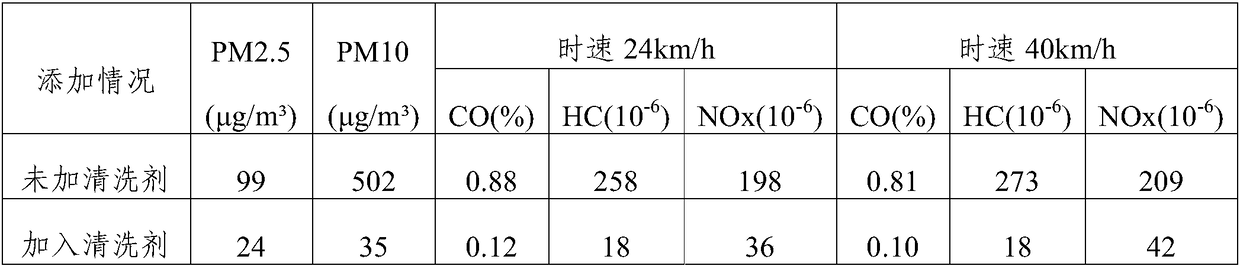

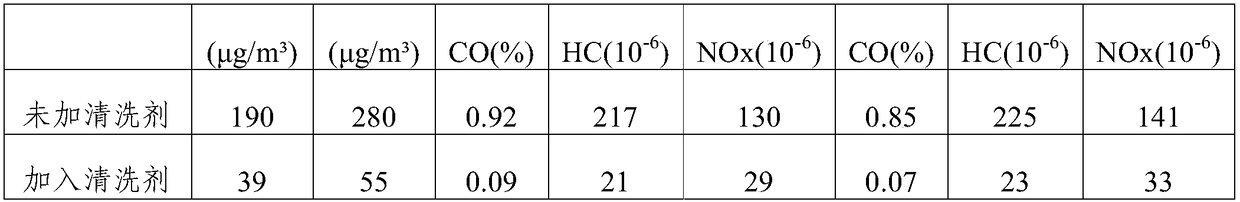

Engine carbon deposit combustion cleaning agent and preparation method thereof

ActiveCN105886158AEffectively remove stubborn carbon depositsRemove stubborn carbon depositsMachines/enginesOrganic non-surface-active detergent compositionsOctanolCarbon deposit

The invention discloses an engine carbon deposit combustion cleaning agent. The engine carbon deposit combustion cleaning agent is prepared from the following raw materials in percentage by weight: 60% to 80% of dibutyl carbonate, 0.2% to 1.5% of benzotriazole, 0.5% to 2.5% of mixed cresol, 3% to 8% of mixed trimethylbenzene, 3% to 8% of ethylene glycol monobutyl ether, 5% to 15% of n-octanol and 2% to 5% of cyclohexanol. In addition, the invention further discloses a preparation method for the cleaning agent. The engine carbon deposit combustion cleaning agent disclosed by the invention can be used for slowly and gradually stripping hard carbon deposits during the running of an automobile, effectively cleaning stubborn carbon deposits from all parts of an engine and recovering normal functions of the engine; meanwhile, the content of HC in automobile exhaust gas is lowered by 85% or more, the content of CO is lowered by 67% or more, the content of PM2.5 is lowered by 75% or more, and the exhaust emissions reach national V standards; the engine carbon deposit combustion cleaning agent has high octane number and cetane number and has the flash point above 55 DEG C, thereby being capable of being applied to diesel oil and gasoline.

Owner:梁文胜

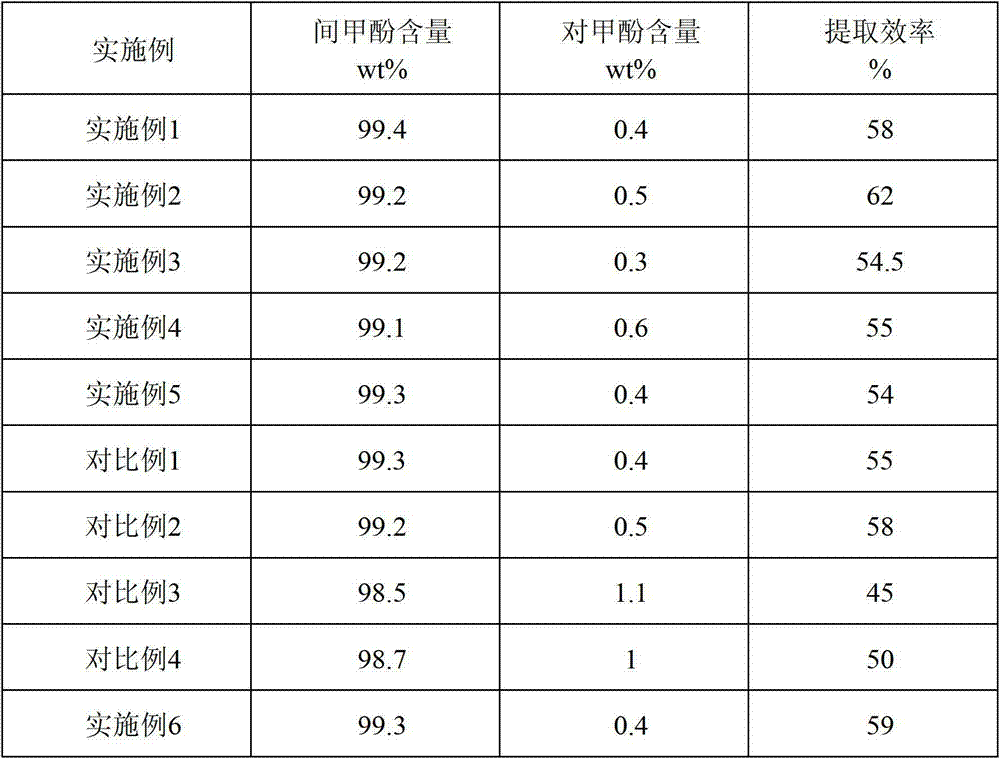

Method for effectively separating and preparing m-cresol

The invention relates to a method for separating cresol to obtain high purity m-cresol by adopting a complex separation method. The method for separating the cresol to obtain the high purity m-cresol by adopting the complex separation method adopts amide as a complex, is specifically combined with the cresol in an organic solvent system after being mixed and heated with mixed cresol, then amide-m-cresol crystals are crystallized to continuously separate out by controlling the temperature of the organic solvent system, high purity m-cresol is obtained through a mode that m-cresol is crystallized, separated and released at a temperature, and the purity of the m-cresol can be above 99.5%. The method for separating the cresol to obtain the high purity m-cresol by adopting the complex separation method has the advantages that the purity of the m-cresol is high, complexes are easy to obtain and can be recycled and the process step is simple and easy to operate and the like. The method for separating the cresol to obtain the high purity m-cresol by adopting the complex separation method has great guidance value in separation, purification and preparation of the m-cresol.

Owner:侯颖

Method for preparing p-hydroxybenzaldehyde and m-hydroxybenzaldehyde from mixed cresol

InactiveCN103265415AYi ShenghuaNot easy to sublimateOrganic compound preparationCarbonyl compound separation/purificationCresolP-hydroxybenzaldehyde

The invention discloses a method for preparing p-hydroxybenzaldehyde and m-hydroxybenzaldehyde from mixed cresol. The method comprises the following steps of: 1, oxidization: adding sodium hydroxide, calcium oxide and a catalyst to mixed cresol and methanol which are used as raw materials for reacting under the conditions of heating and pressurizing, thus obtaining a mixture of p-hydroxybenzaldehyde and m-hydroxybenzaldehyde; and separating the mixture to obtain the crude product of the mixture of p-hydroxybenzaldehyde and m-hydroxybenzaldehyde; 2, refining: refining the crude product of the mixture of p-hydroxybenzaldehyde and m-hydroxybenzaldehyde to obtain the mixture of p-hydroxybenzaldehyde and m-hydroxybenzaldehyde; and 3, separation: sublimating the mixture of p-hydroxybenzaldehyde and m-hydroxybenzaldehyde by virtue of the property of the p-hydroxybenzaldehyde easy to sublimate under heating, and condensing the sublimate, thus obtaining the p-hydroxybenzaldehyde in a condensation tank and keeping the m-hydroxybenzaldehyde in a sublimation tank; and finally, separating out the p-hydroxybenzaldehyde and the m-hydroxybenzaldehyde from each other.

Owner:东营海源化工股份有限公司 +1

Preparation method of high-purity tricresyl phosphate

ActiveCN109593099AAchieve high purityReduce lossesGroup 5/15 element organic compoundsDistillationPlasticizer

The invention relates to a preparation method of high-purity tricresyl phosphate. The preparation method comprises the following steps: (S1) with mixed cresol and phosphorus oxychloride as the raw materials and Lewis acid as a catalyst, simultaneously adding the raw materials and the catalyst into a reactor, and reacting to obtain a crude product of tricresyl phosphate, wherein the mass percentageof o-cresol in mixed cresol is lower than 0.01%; (S2) carrying out reduced-pressure distillation on the crude product of tricresyl phosphate until the acid value of the crude product of tricresyl phosphate is less than or equal to 3mgKOH / g; and (S3) carrying out molecular distillation on the tricresyl phosphate crude product with the acid value less than or equal to 3mgKOH / g. The preparation method is simple, convenient, low in production cost, high in product purity and suitable for industrial production. High-purity tricresyl phosphate prepared by virtue of the preparation method is suitable for the fields of aviation fuel base oil, plasticizers, flame retardants, lubricating oil extreme-pressure anti-wear agents and the like.

Owner:PETROCHINA CO LTD

A kind of engine carbon deposition combustion cleaning agent and preparation method thereof

ActiveCN105886158BEffectively remove stubborn carbon depositsRemove stubborn carbon depositsMachines/enginesOrganic non-surface-active detergent compositionsOctanolCarbon deposit

Owner:梁文胜

Method for preparing chemical intermediates by using mixed o/m/p-cresol

InactiveCN101857529AReduce consumption costReduce manufacturing costOrganic chemistryOrganic compound preparationAlkyl transferM-Cresol

The invention provides a new method for preparing chemical intermediates by using mixed o / m / p-cresol. The method comprises the following steps of: taking mixed solution of o-cresol, m-cresol and p-cresol a raw material, performing alkylation on the mixed solution in the presence of an alkylating agent and a catalyst to obtain mixed solution of 6-tertbutyl-o-cresol, 6-tertbutyl-m-cresol and 2-tertbutyl-o-cresol, and rectifying the mixed solution to obtain high-purity chemical intermediate products of the 6-tertbutyl-o-cresol, the 6-tertbutyl-m-cresol and the 2-tertbutyl-o-cresol. The method has high reaction conversion rate, and can improve the utilization rate of atoms and reduce the raw material consumption and the production cost.

Owner:吴鸿宾

Preparation method of high-purity 2,6-di-tert-butyl p-cresol

ActiveCN111943816AHigh yieldHigh purityOrganic chemistryOrganic compound preparationChemical synthesisPtru catalyst

The invention relates to a preparation method of high-purity 2,6-di-tert-butyl p-cresol, and belongs to the technical field of organic chemical synthesis. According to the method, ethanol and water are recrystallized twice, so that the purity of the product is improved, and the purity of the target product BHT can reach 99.99% or above; besides, water and ethanol separated from the primary motherliquor through the rectifying tower can be recycled, the rectified mother liquor is guided into a crystallization system to be recycled, and the yield of 2,6-di-tert-butyl-p-cresol is increased; meanwhile, the BHT concentration of the secondary mother liquor is detected, recrystallization is conducted, and the yield of BHT reaches 99.89% or above. Secondly, under the catalytic action of the modified mesoporous silica supported Nb / Mo / Cu three-metal active center catalyst, the conversion rate of mixed cresol and the selectivity of di-tert-butyl cresol are greatly improved, and the conversion rate of the raw materials is further improved under the synergistic effect of ultrasonic cavitation.

Owner:ANHUI HAIHUA CHEM

A method for separating industrial p-cresol to prepare pure p-cresol and pure m-cresol

ActiveCN103333052BImprove extraction efficiencyLow equipment requirementsOrganic chemistryOrganic compound preparationSkin complexionCresol

Owner:BEIJING RISUN TECH CO LTD

Separation method of m-cresol and p-cresol mixture

InactiveCN101863742BReduce consumption costReduce manufacturing costOrganic chemistryOrganic compound preparationAlkyl transferM-Cresol

The invention discloses a novel method for separating an m-cresol and p-cresol mixture to obtain high-purity m-cresol and p-cresol. The method comprises the following steps: carrying out alkylation reaction on the m-cresol and the p-cresol as raw materials under the existence of an alkylating agent and a catalyst to obtain the mixed solution of 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol; rectifying the mixed solution to obtain the products of high-purity 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol; respectively carrying out dealkylation reaction and rectification on the obtained high-purity 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol under the existence of the catalyst to respectively obtain the products of the high-purity m-cresol and p-cresol; and recovering isobutene generated by dealkylation. The invention has high reaction conversion rate, high atom use ratio, low raw material consumption and production cost and reliable safety performance.

Owner:吴鸿宾

Preparation method of rubber plasticizer tricresyl phosphate

The invention discloses a preparation method of a rubber plasticizer tricresyl phosphate. The method includes the following steps: 1, adding mixed cresol and TiSiW12O40 / TiO2 in a three-neck flask, heating withle stirring to 60 DEG C, dropwise adding phosphorus oxychloride within 1 h, heating to 100 DEG C, and reacting for 8 h; and 2, filtering out the catalyst, and conducting reduced pressure distillation to obtain a fraction of tricresyl phosphate. According to the preparation method of the rubber plasticizer tricresyl phosphate provided by the invention, supported heteropoly acid is used to substitute Lewis acid for synthesis of tricresyl phosphate; and the catalyst has the advantages of stabilization simple post-treatment for the reaction, recyclability, green and environment-friendliness.

Owner:QINGDAO WANGYU RUBBER

A method for separating and purifying m-cresol from m-p-mixed cresol

ActiveCN103204766BReduce usageAvoid difficult recycling problemsOrganic chemistryOrganic compound preparationM-CresolToluene

The invention relates to a method for separating and purifying m-cresol from a mixture of m-cresol and p-cresol by using a complex crystallization method. The method comprises the following steps: 1) complex crystallization: adding a mixture of m-cresol and p-cresol into a reactor, adding urea and heating to 70-95 DEG C to completely dissolve the urea in the mixture of m-cresol and p-cresol; cooling, adding petroleum ether when the mixture is cooled 50-60 DEG C, wherein the adding amount of petroleum ether is 1-2 times the volume of the raw material of the mixture of m-cresol and p-cresol, and crystallizing at 0 DEG C-8 DEG C for 2-4 h; 2) solid-liquid separation washing to obtain white needlelike m-cresol complex crystals and a filtrate 1; 3) decomplexation: pumping the complex crystal and adding of toluene, decomplexing at 50-60 DEG C under the, and filtering while hot to obtain a solid urea and a filtrate 2, wherein the filtrate 2 is a mixture of m-cresol and toluene; and 4) distillation: separating m-cresol and toluene in the mixture filtrate 2 through vacuum distillation to obtain pure m-cresol and toluene.

Owner:BEIJING RISUN TECH CO LTD

Superhard resin grinding wheel for thinning gallium arsenide wafer and preparation method of superhard resin grinding wheel

ActiveCN108381409AImprove structural strengthImprove overall lifespanAbrasion apparatusGrinding devicesPorosityMass ratio

The invention discloses a superhard resin grinding wheel for thinning a gallium arsenide wafer. The superhard resin grinding wheel is formed by mixing a liquid material with a solid material accordingto the mass ratio of 1: (40-55). The liquid material is formed by uniformly mixing liquid resin with mixed cresol according to the mass ratio of 1: (1-2). The solid material comprises, by volume part, 28-40 parts of diamond, 8-15 parts of silicon carbide, 1-4 parts of cobalt oxide, 9-13 parts of a ceramic bond, 28-35 parts of phenolic resin and 1-3 parts of calcium oxide. The invention further discloses a preparation method of the superhard resin grinding wheel. The prepared superhard resin grinding wheel for thinning the gallium arsenide wafer is sintered by two steps, and therefore, the chipping containing capacity achieved at the high porosity, namely approximately 40%, is guaranteed; the grinding wheel is high in frame structure strength and long in service life; when the grinding wheel is used, the high feed rate is achieved, and it is guaranteed that work efficiency is not deteriorated and the service life is not shortened; and meanwhile, by means of granularity refining, a damaged layer is reduced, and surface quality is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Solid acid catalyst and method for producing m-cresol

PendingCN113731476AHigh m-cresol contentReduce loss rateOrganic chemistryMolecular sieve catalystsPtru catalystSolid acid

The invention particularly relates to a solid acid catalyst and a method for producing m-cresol. The invention relates to a method for producing m-cresol, the method comprises the following steps: 1, heating a mixture raw material containing p-cresol and o-cresol by a preheater, and introducing the mixture raw material into a fixed bed reactor or a simulated moving bed reactor for reaction; 2, under the reaction conditions that the reaction pressure ranges from 0.1 MPa to 12.0 MPa, the temperature ranges from 180 DEG C to 450 DEG C, and the weight space velocity WHSV ranges from 1.0 h <-1 > to 12.0 h <-1 >, generating a reaction product containing o-cresol, m-cresol and p-cresol through the reaction under the action of the solid acid catalysts according to the claim 1 and the claim 6; and 3, separating the reaction product through a rectifying tower to obtain o-cresol and m-cresol and p-cresol mixture, and circulating the o-cresol which is not reacted and converted to serve as a reaction raw material to enter the reactor. The method has the advantages of high reaction efficiency, few dehydroxylation / methyl side reactions, low loss rate of cresol, low surface coking and inactivation of the catalyst, higher content of m-cresol and remarkable economic benefits.

Owner:ZHEJIANG HUANHUA TECH CO LTD

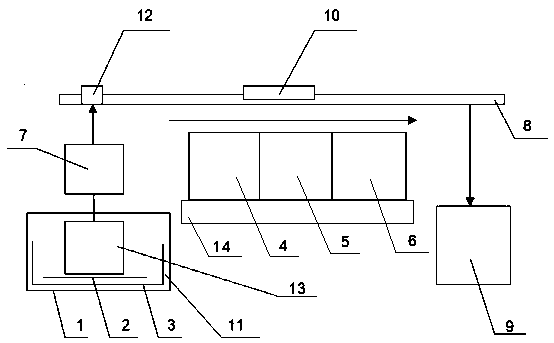

Device and method for removing surface substances of wire spool and wire box of bonding wire

InactiveCN109530330AEfficient removalSmooth runningDrying gas arrangementsCleaning using gasesEngineeringCleansing Agents

The invention discloses a device for removing surface substances of a wire spool and a wire box of a bonding wire. The device comprises a soaking system, a spraying and filtering system, an air knifesystem and a drying system, and further comprises a conveying system and a finished product material collecting system, wherein the soaking system, the spraying and filtering system, the air knife system and the drying system are sequentially arranged; the wire spool and the wire box of the bonding wire to be cleaned sequentially pass through the effect of the soaking system, the spraying and filtering system, the air knife system and the drying system, and is finally collected by the finished product material collecting system. The cleaning agent for removing by using the device disclosed bythe invention comprises the following components of, in percentage by mass, 1%-2% of surfactant, 8%-10% of dichloromethane, 3%-5% of formic acid, 8%-10% of phenol, 10%-12% of mixed cresol, 5%-8%of butyl acetate, 3%-5% of ethanol and the balance water. The device has advantages of being stable and reliable in operation, high in efficiency, simple in structure, low in use cost, none in dead angle existence during removing, saved in water resources, and avoidable in pollution.

Owner:北京达博有色金属焊料有限责任公司

A method for producing high-purity m-cresol

ActiveCN108147945BNo pollution in the processEasy to produceIon-exchange process apparatusOrganic chemistryMolecular sieveIsomerization

The application provides a method for producing m-cresol, at least including the following steps: (1) passing material I containing m-cresol and p-cresol into an adsorption unit for adsorption separation to obtain m-cresol product; The adsorption unit contains one or more adsorbent beds, and at least one adsorbent bed includes a molecular sieve adsorbent; (2) the material II containing the desorbent is passed into the adsorption unit, and the adsorbent bed in the adsorption unit is Desorb to obtain the desorption material III; pass the desorption material III into the separation unit to separate and obtain the desorbent material IV and the mixed cresol material V; (3) return the desorbent stream IV obtained by separation in the step (2) to the adsorption unit for recycling (4) Pass the mixed cresol material V obtained in step (2) into the isomerization reaction unit for reaction to obtain the isomerization product material VI; the isomerization product material VI is returned to the adsorption unit.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Paint remover used for polyester, poly(ester-imide) paint capper covered round wire paint film

A paint remover for polyester and polyesterimide enamelled copper round wire paint film, including formic acid, chloroform, mixed cresol, and additives, the content percentage of each component is as follows: formic acid: 30%-50% , Chloroform: 30%-40%, mixed cresols: 5%-35%, additives: 0%-5%, add formic acid, mixed cresols and additives into chloroform, stir and mix evenly . The paint remover provided by the invention can remove the primer as polyester or non-weldable polyesterimide thermosetting self-adhesive enameled wire paint film in a very short period of time (for example, within 4MIN) at normal temperature, with good effect and high efficiency ,low cost.

Owner:GUANGDONG RONSEN SUPER MICRO WIRE CO LTD

A kind of preparation method of 2,6-di-tert-butyl p-cresol

ActiveCN111943816BHigh yieldHigh purityOrganic chemistryOrganic compound preparationChemical synthesisPtru catalyst

The invention relates to a preparation method of 2,6-di-tert-butyl-p-cresol, which belongs to the technical field of organic chemical synthesis. The present invention utilizes ethanol and water to recrystallize twice to improve the purity of the product, and the purity of the target product BHT can reach more than 99.99%; in addition, the water and ethanol separated from the primary mother liquor through the rectification tower can be recycled and reused, and the mother liquor after rectification Imported into the crystallization system for reuse, the yield of 2,6-di-tert-butyl-p-cresol is improved, and the BHT concentration of the secondary mother liquor is detected at the same time, and recrystallization is carried out, so that the yield of BHT reaches more than 99.89%. Secondly, the catalytic effect of the Nb / Mo / Cu trimetallic active center catalyst on the modified mesoporous silica greatly improved the conversion rate of mixed cresol and the selectivity of di-tert-butylcresol, and the synergistic effect of ultrasonic cavitation Under the action, the conversion rate of raw materials is further improved.

Owner:AZUREWAVE TEHNOLOGIES INC

Solid acid catalyst and method for producing cresol by using same

ActiveCN113351250AFacilitate the realization of selective productionEnable selective productionOrganic chemistryMolecular sieve catalystsPtru catalystFluidized bed

The invention relates to a solid acid catalyst and a method for producing cresol by using the same, wherein the method comprises the steps: taking phenol as a raw material, carrying out hydroalkylation reaction on the phenol and methanol and / or dimethyl ether, and generating a product containing o-cresol, m-cresol and p-cresol mixture in a fixed bed reactor or a fluidized bed reactor, wherein porous solid acid which is modified by metal and has medium acidity is used as a hydroalkylation reaction catalyst. Compared with an alkylation reaction process of phenol and methanol used in current industrial production, the cresol production process provided by the invention has the characteristics of high reaction conversion rate, high selectivity of m-cresol and p-cresol with high added value, low energy and material consumption, good operation stability and environmental friendliness.

Owner:ANHUI HAIHUA CHEM

Emulsion-type highly-dispersed antioxidant

The invention discloses a preparation method of an emulsion-type highly-dispersed antioxidant. The preparation method comprises the following steps: performing a phenol methylation reaction on phenol and methyl alcohol under the action of a catalyst Cs / SiO2 to obtain mixed cresol as a product; adding methylbenzene and oxalic acid as a complexing agent into a reaction kettle, adding the mixed cresol, and filtering to obtain a filtrate and a white granular p-cresol-oxalic acid complex; adding the p-cresol-oxalic acid complex granules into a mixed solution of methylbenzene and methyl alcohol, and filtering to obtain the p-cresol-oxalic acid complex; adding the obtained p-cresol-oxalic acid complex into water, and separating to obtain an upper organic phase and a lower water phase; distilling the upper organic phase to remove a solvent to obtain p-cresol; adding the obtained p-cresol into silicon sol with the solid content of 40-50%, and stirring to obtain the emulsion-type highly-dispersed antioxidant. The emulsion-type highly-dispersed antioxidant is good in dispersion and has excellent oxidation resistance.

Owner:JIANGSU FEIYA CHEM IND

A method for separating and purifying p-cresol

ActiveCN104058936BHigh purityAdditional purification stepsOrganic chemistryOrganic compound preparationOrganic solventCresol

Owner:江苏富比亚化学品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com