Engine carbon deposit combustion cleaning agent and preparation method thereof

A technology of engine and cleaning agent, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of not having a good cleaning effect, and achieve the effects of protection from rust, uniform gas mixing, and increased oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

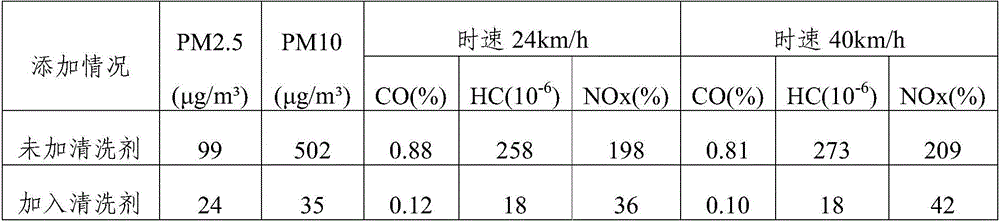

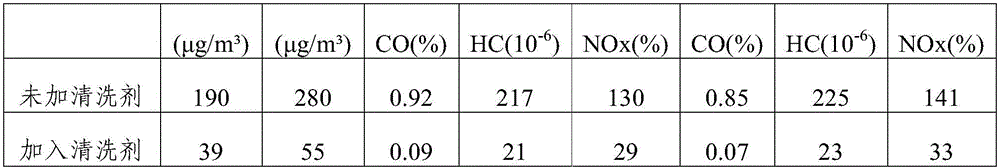

Examples

Embodiment 1

[0028] The engine carbon deposit combustion cleaning agent of the present embodiment is made of the following raw materials in percentage by weight: 75% of dibutyl carbonate, 0.4% of benzotriazole, 1.6% of trimixed cresols, 5% of mixed trimethylbenzenes, 5% ethylene glycol monobutyl ether, 10% n-octanol, and 3% cyclohexanol. The mixed trimethylbenzene is a mixture of mesitylene, partial trimethylbenzene and trimethylbenzene, and the distillation range of the mixture is from 164°C to 176°C.

[0029] The preparation method of the engine carbon deposit combustion cleaning agent of the present embodiment comprises the following steps:

[0030] Step 1, mixing dibutyl carbonate and benzotriazole and stirring evenly to obtain mixture A;

[0031] Step 2, mixing n-octanol, trimixed cresol and cyclohexanol and stirring evenly to obtain mixture B;

[0032] Step 3. Add the mixture B described in step 2 to the mixture A described in step 1. After stirring evenly, add ethylene glycol mono...

Embodiment 2

[0038] The engine carbon deposit combustion cleaning agent of the present embodiment is made of the following raw materials in percentage by weight: dibutyl carbonate 60%, benzotriazole 1.5%, trimixed cresol 2.5%, mixed trimethylbenzene 8%, 8% of ethylene glycol monobutyl ether, 15% of n-octanol, and 5% of cyclohexanol. The mixed trimethylbenzene is a mixture of mesitylene, partial trimethylbenzene and trimethylbenzene, and the distillation range of the mixture is from 164°C to 176°C.

[0039] The preparation method of the engine carbon deposit combustion cleaning agent of the present embodiment comprises the following steps:

[0040] Step 1, mixing dibutyl carbonate and benzotriazole and stirring evenly to obtain mixture A;

[0041] Step 2, mixing n-octanol, trimixed cresol and cyclohexanol and stirring evenly to obtain mixture B;

[0042]Step 3. Add the mixture B described in step 2 to the mixture A described in step 1. After stirring evenly, add ethylene glycol monobutyl ...

Embodiment 3

[0049] The engine carbon deposit combustion cleaning agent of the present embodiment is made of the following raw materials in percentage by weight: 80% of dibutyl carbonate, 0.3% of benzotriazole, 1.7% of trimixed cresols, 4% of mixed trimethylbenzenes, 4% of ethylene glycol monobutyl ether, 8% of n-octanol, and 2% of cyclohexanol. The mixed trimethylbenzene is a mixture of mesitylene, partial trimethylbenzene and trimethylbenzene, and the distillation range of the mixture is from 164°C to 176°C.

[0050] The preparation method of the engine carbon deposit combustion cleaning agent of the present embodiment comprises the following steps:

[0051] Step 1, mixing dibutyl carbonate and benzotriazole and stirring evenly to obtain mixture A;

[0052] Step 2, mixing n-octanol, trimixed cresol and cyclohexanol and stirring evenly to obtain mixture B;

[0053] Step 3. Add the mixture B described in step 2 to the mixture A described in step 1. After stirring evenly, add ethylene gly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com