Solid acid catalyst and method for producing cresol by using same

A solid acid catalyst and solid acid technology, applied in molecular sieve catalysts, bulk chemical production, chemical instruments and methods, etc., can solve the problems of single, low phenol conversion rate, etc., achieve low energy and material consumption, high production efficiency, and raw materials The effect of high conversion rate of phenol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of method of producing cresol, the method comprises:

[0022] Step 1: After heating and vaporizing phenol, methanol and / or dimethyl ether in a preheater, they are mixed with hydrogen in a certain proportion.

[0023] Step 2, when the hydrogen:phenol molar ratio is 1:1-10:1, the phenol:methanol molar ratio is 5:1-15:1, the pressure is 0.1-10.0MPa (gauge pressure), the temperature is 180-450°C, the weight Airspeed WHSV is 0.3-8.0h -1 Under certain reaction conditions, the hydroalkylation reaction is carried out under the action of a solid acid catalyst to generate a reaction product containing mixed cresols of ortho, meta and p.

[0024] Wherein, the phenol in step 1 includes the phenol and dimethylphenol that are recycled and returned from the rectification and separation of the reaction product.

[0025] The reaction product obtained in step 2 is separated by one or more rectification towers to obtain ortho, m and p mixed cresols, and the unreacte...

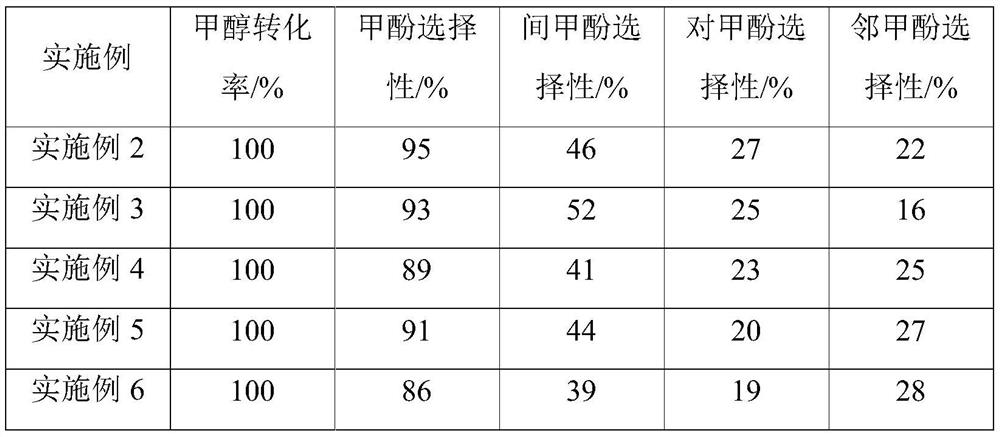

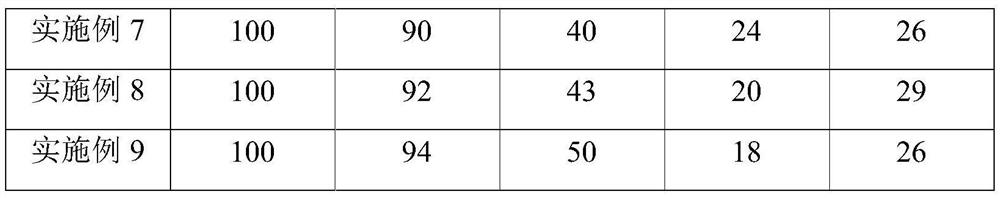

Embodiment 2-9

[0040] The production technology of cresol is specifically expanded in following embodiment 2-9:

Embodiment 2

[0042] After fully mixing phenol and methanol with a molar ratio of 3:1 as the reaction raw materials, they are sent into the preheater through a mass metering pump. The temperature of the preheater is set at 250°C. Fully mixed, the molar ratio of hydrogen and phenol is 3:1, enter the hydroalkylation reaction unit. The reaction conditions in the alkylation reaction system are that the reaction pressure is 1.5MPa, the reaction temperature is 410°C, and the weight space velocity WHSV of the raw material feed is 1.0h -1 . The alkylation reaction unit is pre-filled with hydrogen needle crystal MOR molecular sieves. During the modification process, 2.6wt% Mo is added as the hydrogen active metal, and basic metal elements are added, respectively 2.3 wt% Ce and 0.2 wt% Cu. After the alkylation reaction, the reaction product is separated from gas and liquid and condensed, and the reaction product is separated through multiple rectification towers, and the unreacted converted phenol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com