Patents

Literature

84results about How to "Low energy and material consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-channel on-line sampling and sample introducing method for high-temperature high-thickness liquid material

InactiveCN102401834AImprove real-time performanceImprove reliabilityMaterial analysisPhysical chemistryEngineering

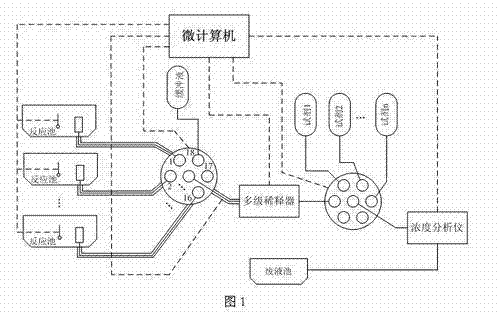

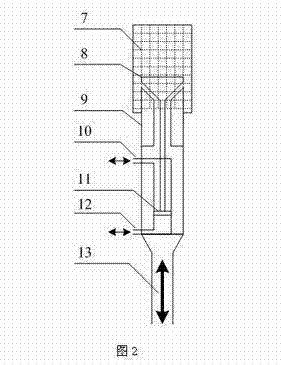

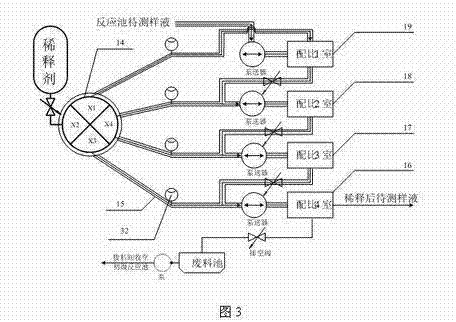

The invention relates to an on-line sampling and sample introducing method for a high-temperature high-thickness liquid material during a process in hydrometallurgical industry. According to the method, on-line sampling is carried out upon the high-temperature high-thickness liquid material requiring detection by using an anti-crystallization and anti-blocking constant-temperature sampler; the liquid material requiring detection is diluted with a precise wide range to a linear sensitivity detection rage of a concentration analyzer by using multiple stages of constant-temperature diluting apparatuses; with an ordered injection method, agents such as the obtained sample, a base solution, a substrate masking agent, and a correcting liquid are mixed, and are sufficiently subject to a reaction; the obtained mixture is delivered into the concentration analyzer, such that the high-temperature high-thickness liquid material on-line sampling, sample introducing and sample preparing processes are realized. The on-line sampling and sample introducing method can conveniently be used in combination with the analyzing and detecting method. With the method, on-line analyzing and detecting of thecomponents of the high-temperature high-thickness liquid material can be stably and reliably realized; real-time and accurate information can be provided for the optimization of the process operation. Therefore, the method has important significances in energy saving and consumption reducing during a hydrometallurgy process, in improving the automation level of productions of enterprises, and in improving the international competitive strengths of the enterprises.

Owner:CENT SOUTH UNIV

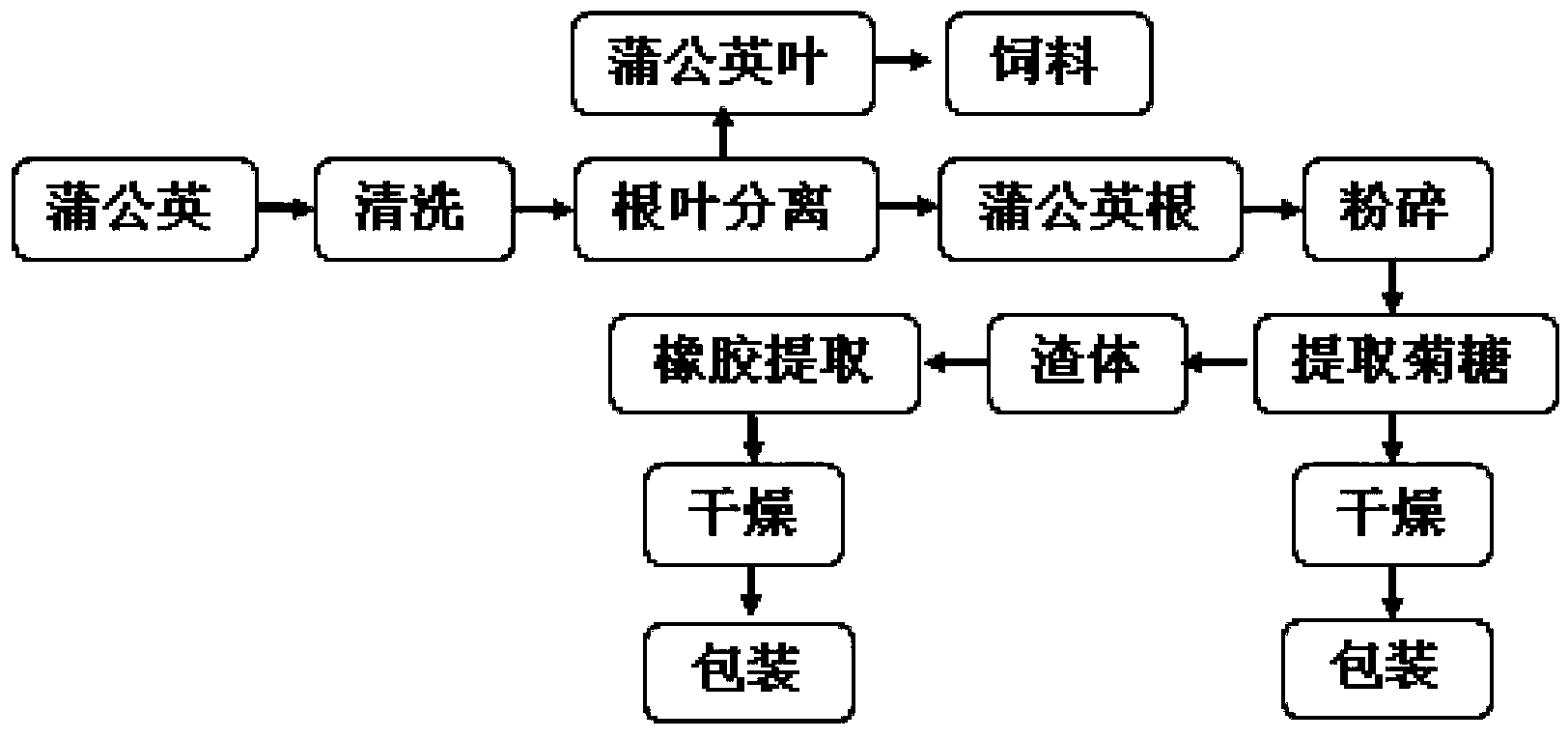

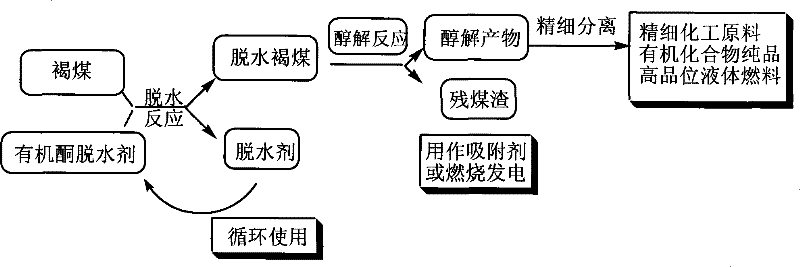

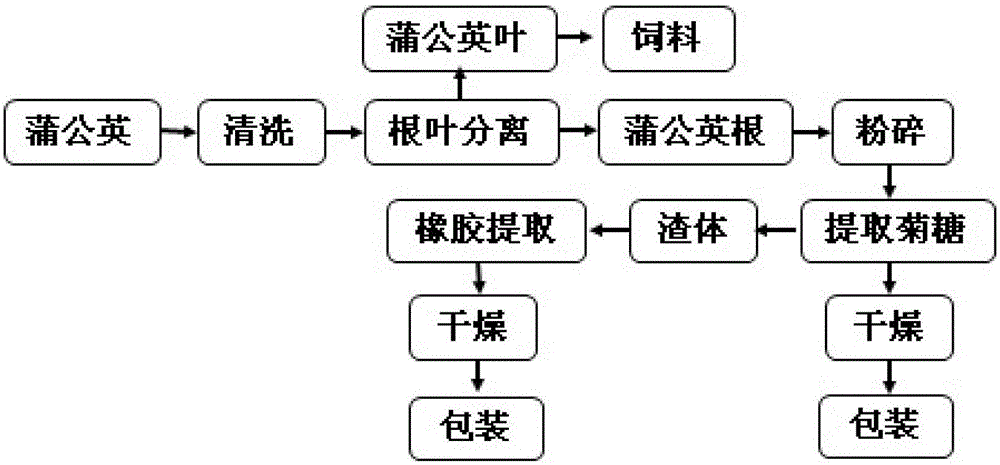

Method for continuously effectively circularly extracting taraxacum rubber and synanthrin from dandelion taraxacumkok-saghyz

ActiveCN103435720AImprove resource utilization efficiencyLow energy and material consumptionResidual biomassPolymer science

The invention relates to a method for continuously effectively circularly extracting taraxacum rubber and synanthrin from dandelion taraxacumkok-saghyz. Taraxacum rubber belongs to a nonpolar substance, synanthrin belongs to a polar substance, and taraxacum rubber and synanthrin are obtained by extraction based on the water-oil separation principle employed by the method of the invention. The extract liquor of taraxacum rubber is subjected to steam distillation for separation of taraxacum rubber, and recycling and reusing of the solvent are realized. The extract liquor of synanthrin is subjected to a spray drying technology for obtaining of refined synanthrin. The final residual biomass residue is subjected to composting and is returned to the field, so that solid pollution is avoided and effective utilization of waste is realized. The method is characterized in that only one organic solvent is employed, and two products of taraxacum rubber and synanthrin are obtained during production. Taraxacum rubber and synanthrin split the cost mutually, and the product price is effectively reduced. The final composting and field returning of the residue help to realize resource utilization maximization. The whole technological process is circulatory, the extraction solvents are utilized circularly, energy consumption and material consumption are substantially decreased, and there are basically no discharged ''three wastes (waste gas, waste water and industrial residue)''.

Owner:BEIJING UNIV OF CHEM TECH +2

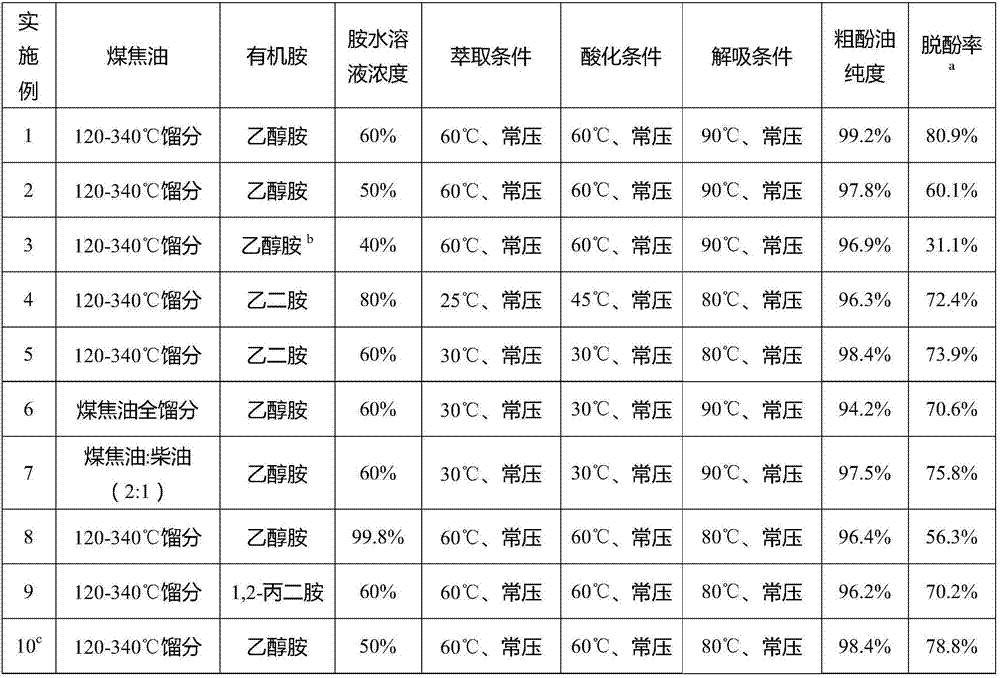

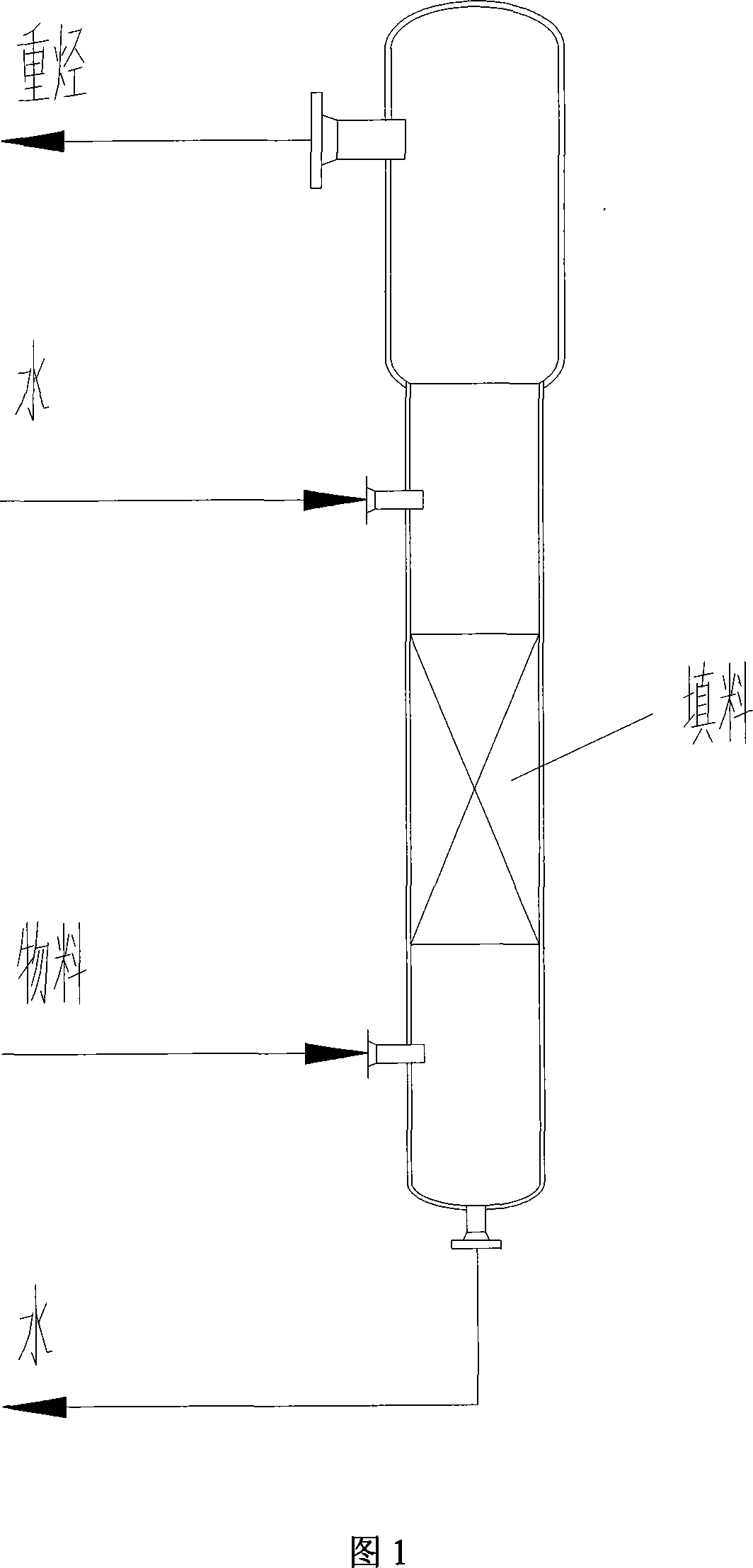

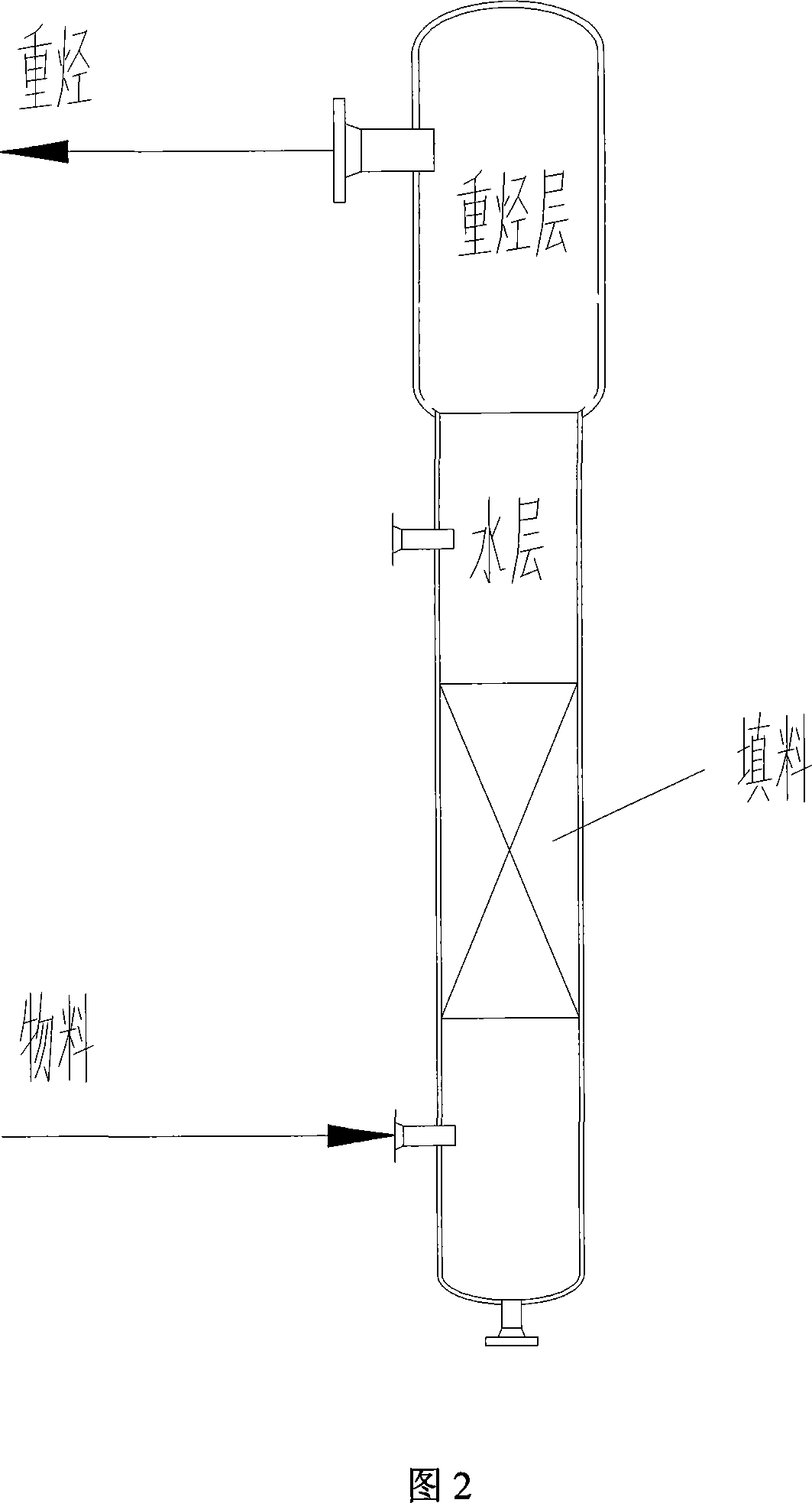

Method for extracting phenolic substance from coal tar or direct coal liquefaction oil

ActiveCN106986750AHigh purityDoes not consume acid and alkaliOrganic chemistryOrganic compound preparationDistillationPhenol

The invention discloses a method for extracting phenolic substance from coal tar or direct coal liquefaction oil, wherein the method mainly includes several processes or steps: (1) applying extracting agent to extract phenolic substance from coal tar or direct coal liquefaction oil, wherein the extracting phase is dephenolized oil, and the extracting phase is the extracting agent enriched in phenolic substance; (2) applying the acidifying agent to acidify the extracting phase, and acquiring crude phenol oil and extracting agent rich in acidifying agent; (3) under the heating and / or depressurizing condition, performing the acidifying agent removal and extracting agent regeneration, circularly using the regenerated extracting agent, and circularly using the removed acidifying agent; (4) recycling a few amount of extracting agent in the dephenolized oil and crude phenol oil by water extraction, distillation and other regular method.

Owner:广州美加华商投资顾问有限公司

Method for removing heavy hydrocarbon from reaction product of preparation of sec-butyl acetate

ActiveCN101130496AImprove operating conditionsLow energy and material consumptionOrganic compound preparationCarboxylic acid esters separation/purificationSec-Butyl acetateImpurity

The invention discloses a separating method of impurity such as heavy hydrocarbon from reacting product in the acetate para-butyl making technique reacted by acetic acid and C4 olefin, which is characterized by the following: extracting materials from heavy hydrocarbon enriching area; contacting the material and water sufficiently; laminating the heavy hydrocarbon and water naturally; draining the heavy hydrocarbon; injecting water into the system again. The method can strip heavy hydrocarbon in the reacting product to prepare acetate para-butyl, which improves the quality of the product and modifies the operating condition to reduce the energy consumption.

Owner:HUNAN ZHONGCHUANG CHEM

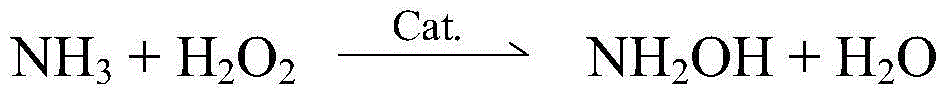

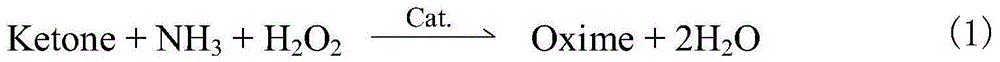

Method for preparing hydroxylamine or hydroxylamine salt from ketone, ammonia and hydrogen peroxide

ActiveCN104129764AImprove product qualityLow energy and material consumptionHydroxylamineHydroxylamineOrganic solvent

The invention relates to a method for preparing hydroxylamine salt / hydroxylamine from ketone, ammonia and hydrogen peroxide. The method has the following basic characteristics: ketone is used as a cyclic reaction medium, and an organic solvent insoluble or slightly soluble in water is used as a circulating solvent medium; the heterogeneous catalytic ammoximation technology and hydrolysis-extraction coupling technology are integrated to realize hydroxylamine and / or hydroxylamine salt preparation from basic raw materials of ammonia, hydrogen peroxide and inorganic acid.

Owner:XIANGTAN UNIV

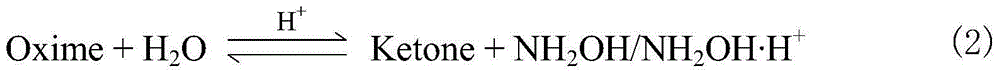

Preparation and purification method of paraphthaloyl chloride with high purity

InactiveCN104003868ALow energy and material consumptionHigh product purityOrganic compound preparationThionyl chlorideDistillationRaw material

The invention discloses a preparation and purification method of paraphthaloyl chloride with a high purity, and belongs to the field of organic chemistry. The method comprises the following steps: carrying out a reflux reaction in the presence of a catalyst by taking terephthalic acid and thionyl chloride as raw materials, cooling and precipitating so as to obtain a crude product; filtering the crude product and then purifying the crude product in a melting crystallization or reduced pressure distillation manner; analyzing the contents of phthalic acid, thionyl chloride and catalyst in a filtrate; replenishing a proper amount of the terephthalic acid, thionyl chloride and catalyst according to the analysis result; then carrying out a circular reaction. Compared with the prior art, the method disclosed by the invention has the main advantage that the excess thionyl chloride does not need to be steamed out after the reaction is finished, but the crude product is obtained in a cooling and filtering manner, so that the filtrate is recycled. Thus, the consumption of energy and materials is decreased.

Owner:TECH CENT CHINA PINGMEI SHENMA ENERGY & CHEM GRP +1

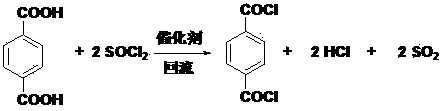

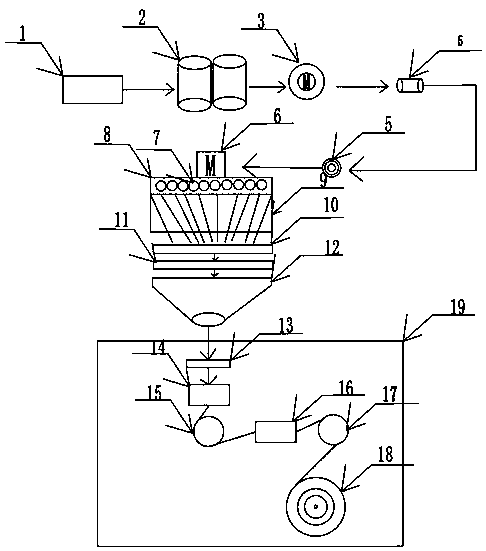

One-step preparation method of POY/POY combined yarn and device

InactiveCN103276457ASoft touchAbundant raw materialsArtificial thread manufacturing machinesMelt spinning methodsYarnEngineering

The invention discloses a one-step preparation method of POY / POY combined yarns and device. The method includes the steps: spinning is carried out with a first spinning assembly using first spinning liquid; spinning is carried out with a second spinning assembly using second spinning liquid; yarns spun through the first spinning assembly and the second spinning assembly pass through lower yarn guide plates of yarn paths respectively, then are combined on an upper yarn guide plate, and then sequentially pass a wire stitching machine and a winding roller to obtain the POY / POY combined yarns. Improvement is made on the basis of an existing production device preparing combined yarns of pre-oriented yarns and fully drawn yarns in a one-step method, the improvement is easy and convenient, compared with the conventional combined yarns of the pre-oriented yarns and the fully drawn yarns, the POY / POY combined yarns prepared in the one-step method are soft in handfeel, materials are various, spinning is flexible, production efficiency is high, the technological process is short, energy consumption and material consumption are low, fixed length and fixed weight are achieved, product quality stability is good, and the POY / POY combined yarns prepared in the one-step method can be directly used for weaving, the combined yarns with different sections, different fineness and different constituents can be prepared, and the combined yarns can be used for simulation fabric or functional products.

Owner:DONGHUA UNIV +1

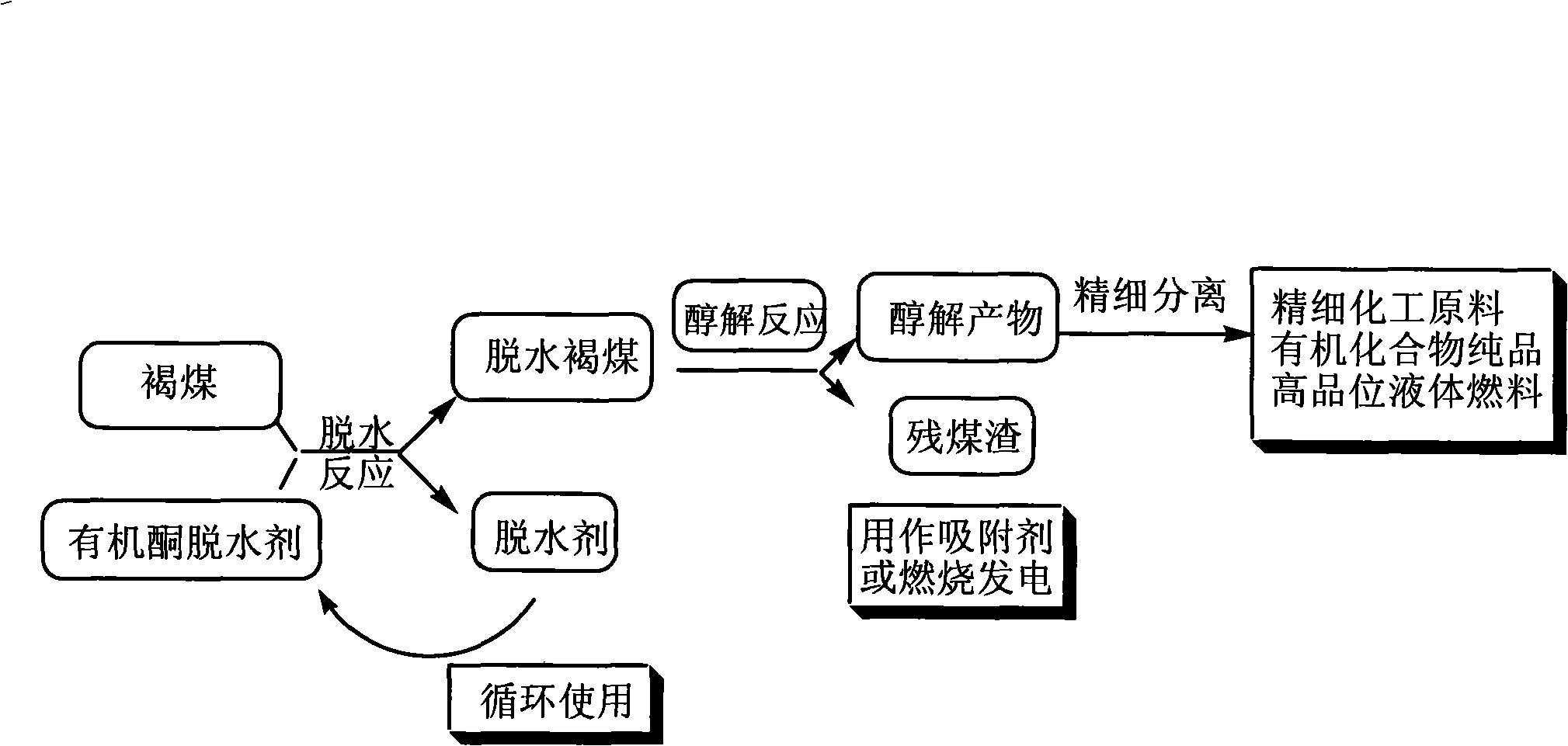

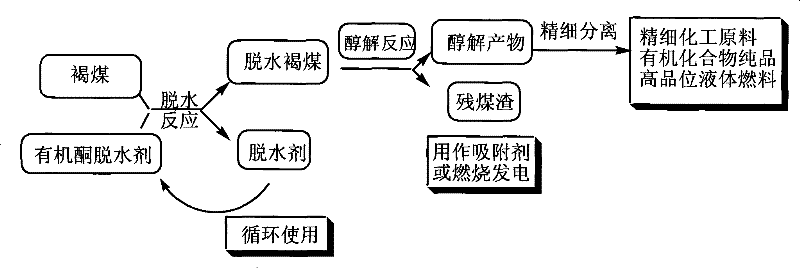

Dehydration and alcohol depolymerization process for low-disintegration coal in mild condition

InactiveCN101314716AReduce material requirementsAvoid cloggingSolid fuelsLiquid hydrocarbon mixture productionDepolymerizationPhenol

A dehydration and alcohol depolymerization process for low-rank coal under mild condition comprises the following steps: mixing acetone and butanone at equal volume ratio to obtain an organic dehydration solvent, adding brown coal powder in a reaction kettle to obtain dehydrated brown coal powder and organic dehydration mixture solution, and separating the organic dehydration solvent for recycling; adding the dehydrated brown coal powder and methanol into a reaction kettle to obtain residual coal and alcoholysis products, and press-filtering the alcoholysis products to an extractor through a filter plate under stirring and the pressure in the kettle; adding the alcoholysis products into the extractor, spraying eluant into the extractor to obtain a soluble material, adding the soluble material into a distilling still to obtain fine organic components rich in low-carbon hydrocarbon, low-carbon alkoxyl organic materials, phenols, esters, heavy organic components, etc.; and recrystallizing the methanol solvent by heating and cooling to obtain pure organic chemicals with high value added such as alkyl naphthalene, alkyl anthracene and chemical containing polyatomic rings with N and S heteroatoms.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing ribostamycin rough products by using membrane separation technology

InactiveCN102532213AEasy to remove impuritiesEasy to separateSugar derivativesSugar derivatives preparationSeparation technologyMicrofiltration membrane

The invention provides a method for preparing ribostamycin rough products by using membrane separation technology. The method comprises the steps of micro filter membrane edulcoration of feed liquid, ultrafiltration decoloration and nanofiltration desalination, enrichment, concentration and drying in a preparation process of the ribostamycin rough products. The feed liquid containing ribostamycin is carried out liquid and solid separation of micro filter membrane, protein micro filter permeating liquid, coloring matters, polysaccharide and other macromolecule impurities are removed through the ultrafiltration membrane, collected permeating liquid is desalted and enriched under normal temperature through the permeating liquid, and the desalt liquid is concentrated and dried to manufacture the ribostamycin rough products. The method for preparing ribostamycin rough products by using the membrane separation technology is novel in conception, mild in productive technology conditions, environment-friendly and clean, simple and easy to do, short in production cycle, low in production cost, high in extraction yield and strong in application, and has big application and dissemination values.

Owner:福建和泉生物科技有限公司

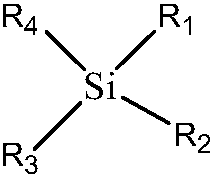

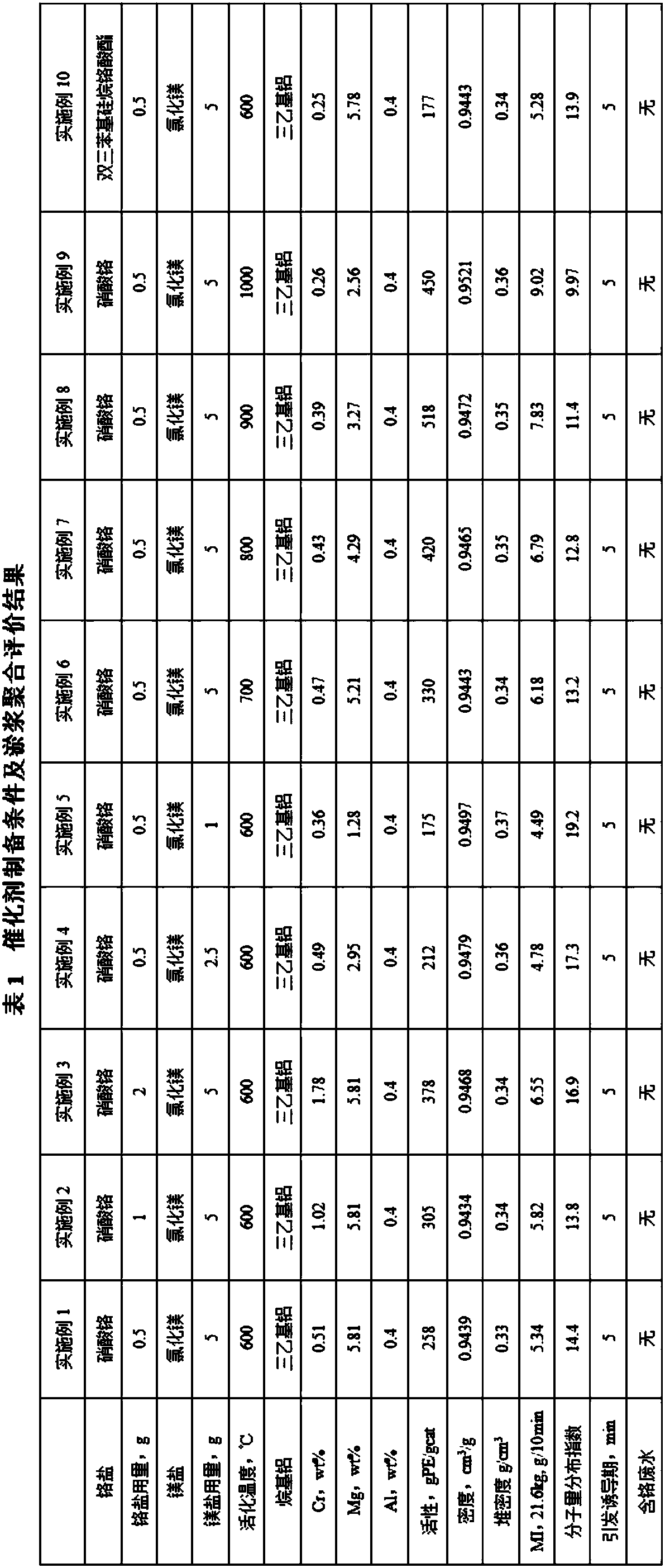

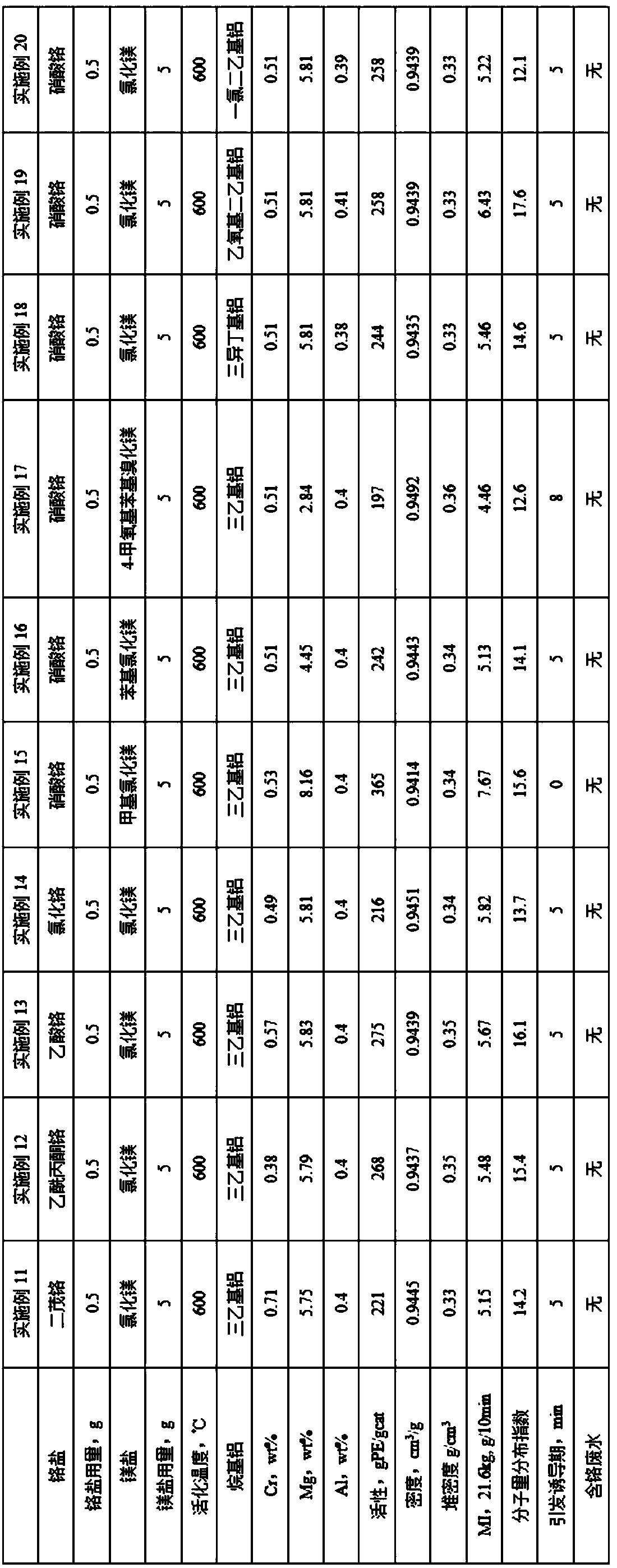

Gas phase polyethylene catalyst and preparation method thereof

The invention relates to a gas phase polyethylene catalyst and a preparation method thereof. In the catalyst, anhydrous magnesium chloride and porous silica gel serve as a composite carrier, titanium-containing transition metal loaded on the composite carrier serves as an active component, an electron donor compound is added in the preparation process to serve as a modifier, and the electron donoris a silane compound with asymmetry. The problems that the common catalyst has low cavity, poor copolymerization ability and high product fine component content are solved, different silane electrondonor compounds are added in the preparation of the catalyst, polyethylene resin with different melt indexes is produced, in particular the gas phase polyethylene catalyst can be used for producing anethylene / 1-hexene copolymerization new product with high additional value, so that the performance of the product is improved, the processibility of the resin is improved, and the application field of the product is widened.

Owner:PETROCHINA CO LTD

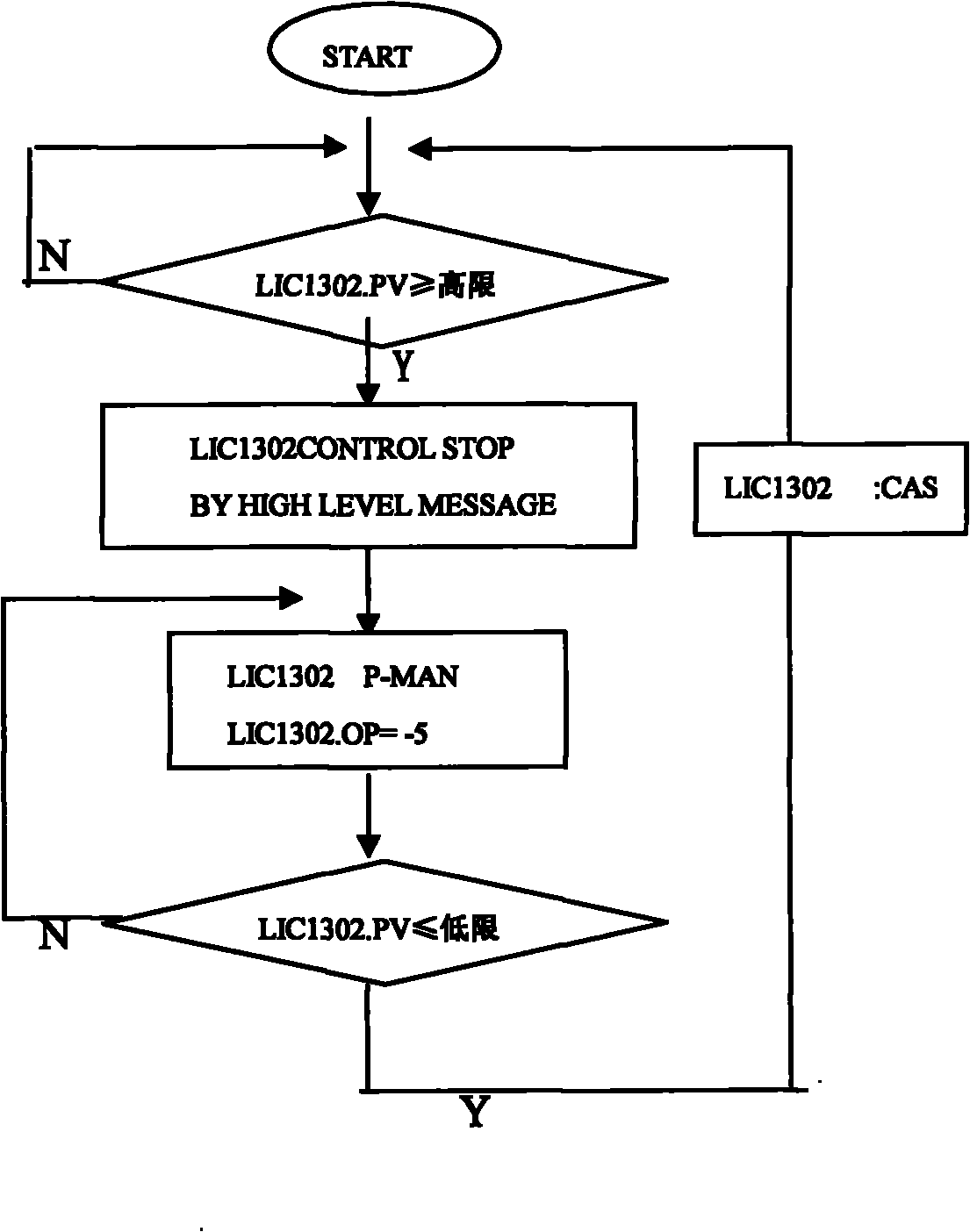

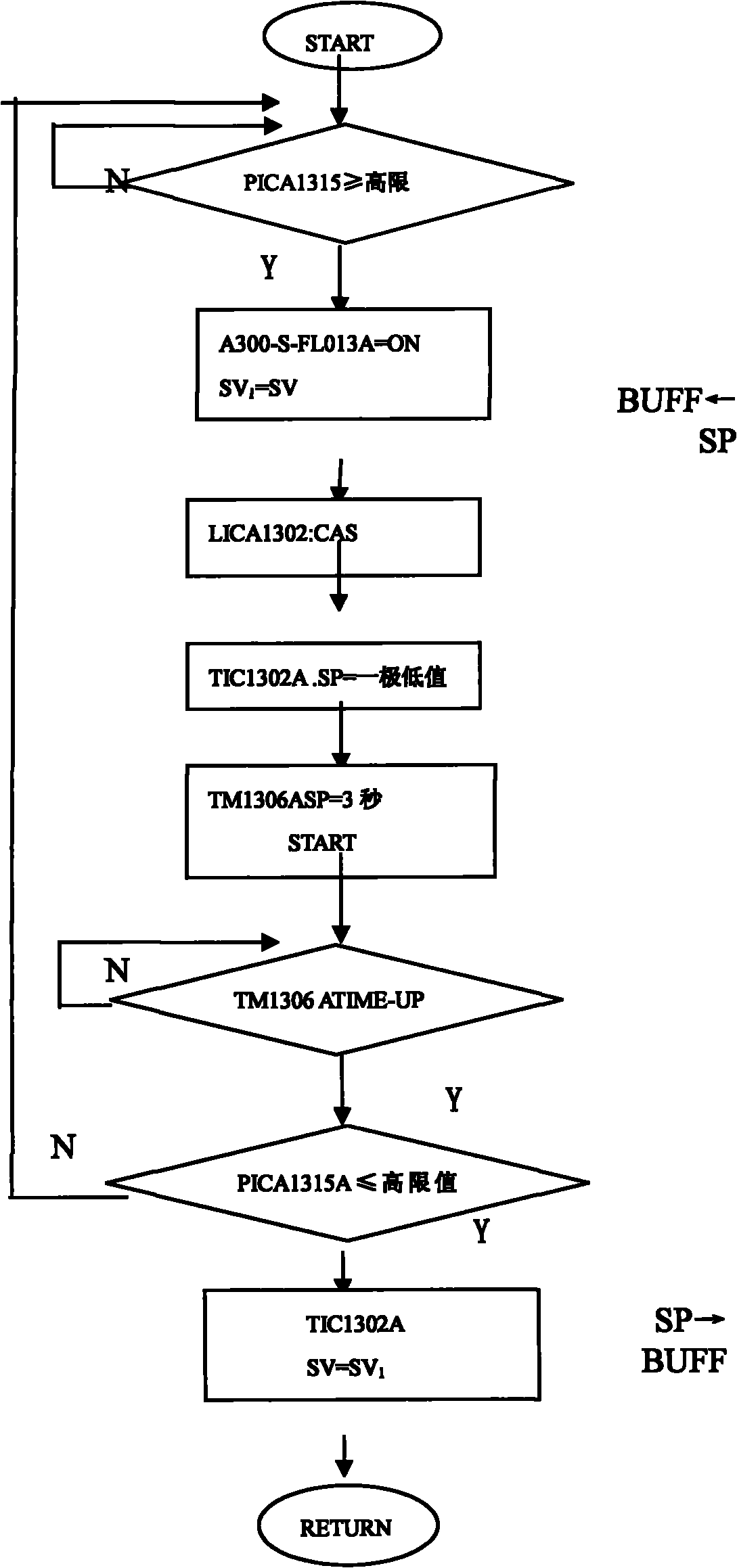

Automatic control method of butadiene polymerization

ActiveCN101864017ARealize automatic controlHigh coincidenceSimultaneous control of multiple variablesLower limitAutomatic control

The invention relates to an automatic control method of butadiene polymerization, which comprises the steps that: the reaction temperature is divided into six stages, when the temperature in a reactor changes, the actual value of the temperature and the set valve of the temperature have difference, and the output valve of a PID regulation action temperature regulator is taken as the set valve of a liquid ammonia regulator; the temperature of the reactor is controlled within the normal range; when the pressure exceeds the high limit valve, the set valve of the temperature regulator at this moment is stored into a register, and the set valve of the temperature regulator is endowed with lower valve again; the pressure in the reactor is reduced; when the liquid level of ammonia reaches to the high limit valve, the output valve of the ammonia regulator is manually set into a full-closed state until the liquid level of ammonia is lower than low limit valve, and temperature-liquid level cascade stage adjustment is changed back; and the data stored into the register is taken as the set valve of the temperature regulator again for automatic control. The automatic control method improves the quality of butadiene, leads the conversion rate to reach 91-92%, avoids the phenomena of implosion and surfusion, reduces the energy consumption and material consumption, and ensures a device to have stable operation.

Owner:PETROCHINA CO LTD

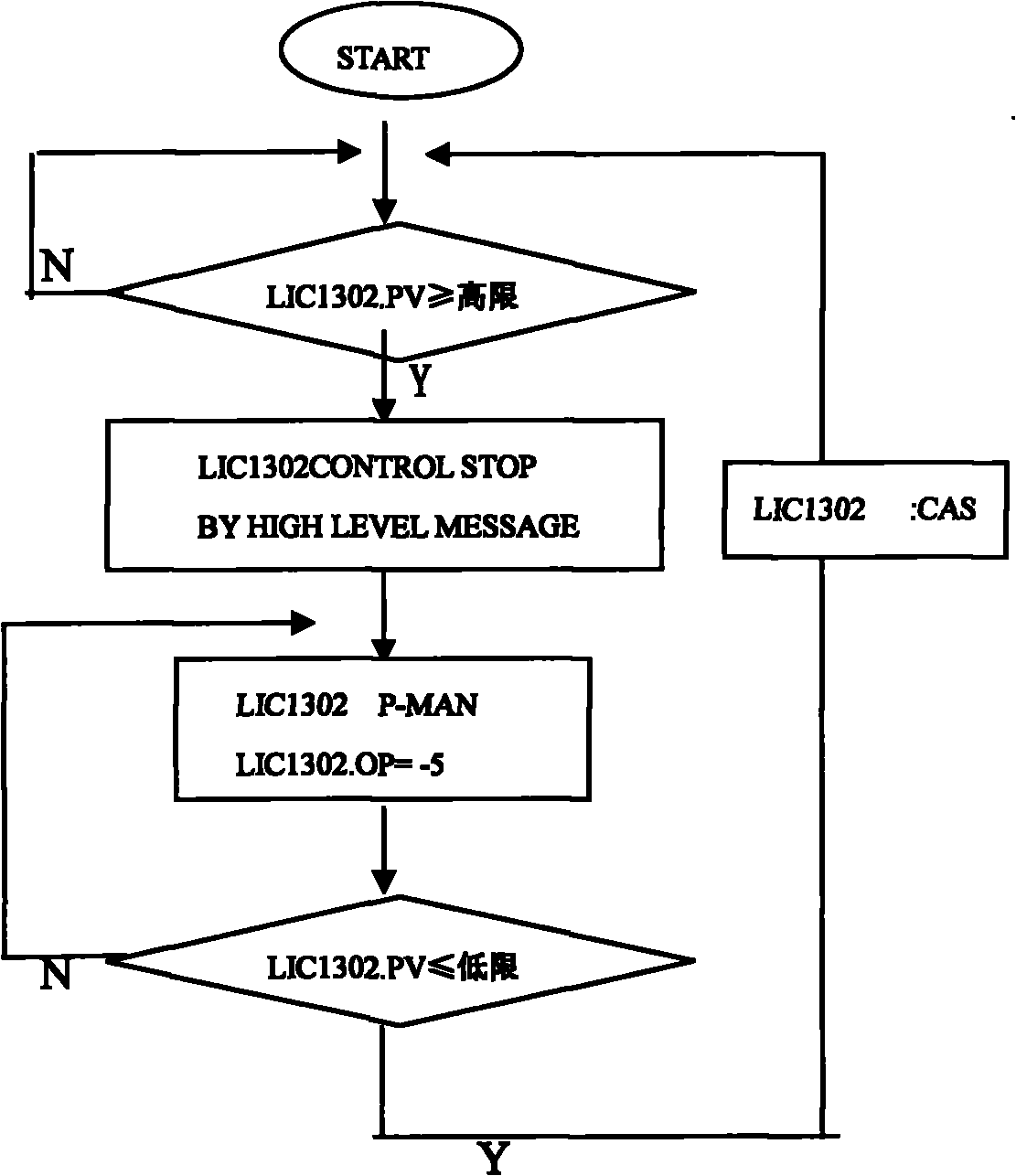

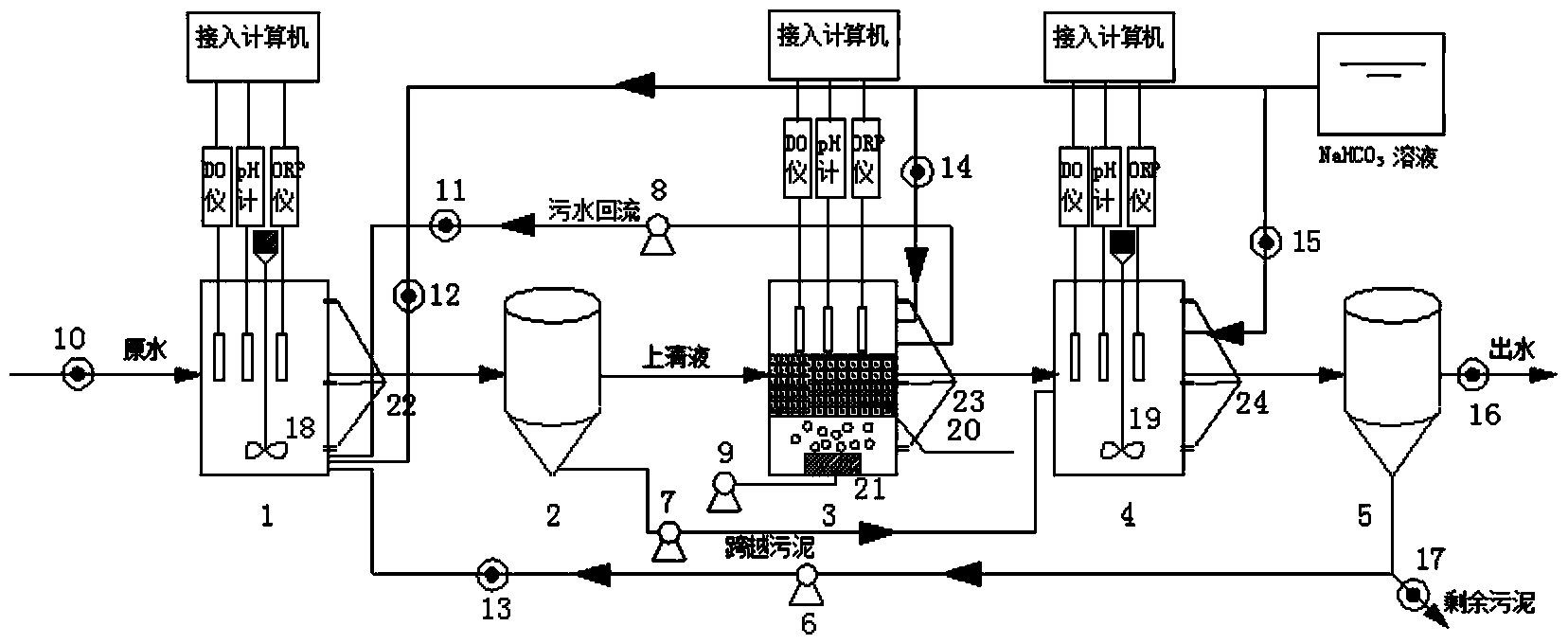

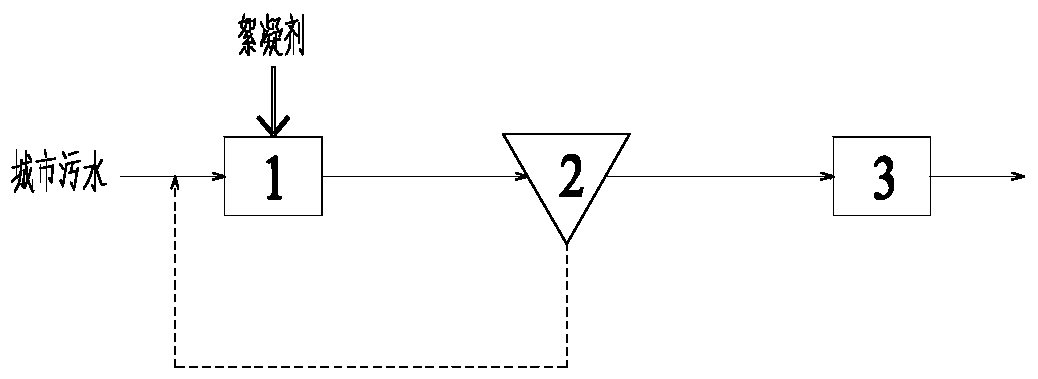

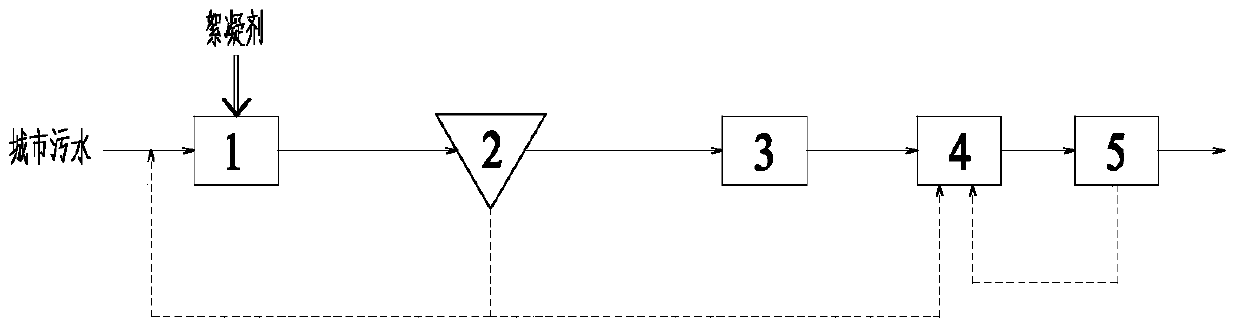

Method for carrying out nitrogen and phosphorus removal on municipal sewage

ActiveCN104108834AEasy to handleReduce outputMultistage water/sewage treatmentBiological sludge treatmentNitriteMaterial consumption

The invention provides a method for carrying out nitrogen and phosphorus removal on municipal sewage municipal sewage. The method comprises the following steps: (1), carrying out anaerobic ammonia oxidation and phosphorus release treatment of short-cut denitrification phosphorus-accumulating bacteria on sewage in an anaerobic tank to obtain muddy water mixed liquor; (2), settling the obtained muddy water mixed liquor in a quick settling tank, firstly carrying out short-cut denitrification phosphorus-absorbing treatment on the obtained sludge, and then carrying out secondary settling in a secondary settling tank; firstly transferring the obtained liquid supernatant to a micro aerobic tank, carrying out oxidization treatment of ammonia nitrogen, then transferring to an anoxic tank, carrying out short-cut denitrification phosphorus-absorbing treatment, and finally carrying out secondary settling in the secondary settling tank; (3), refluxing nitrite mixed liquor produced by the micro aerobic tank to the anaerobic tank; (4), refluxing the sludge obtained by secondary settling to the anaerobic tank, wherein a liquid supernatant is the sludge obtained after nitrogen and phosphorus removal. The method disclosed by the invention can be used for not only realizing efficient nitrogen and phosphorus removal, but also greatly lowering energy consumption and material consumption in a sewage treatment process, and is especially suitable for treating low C / N (carbon / nitrogen) municipal sewage.

Owner:RENMIN UNIVERSITY OF CHINA

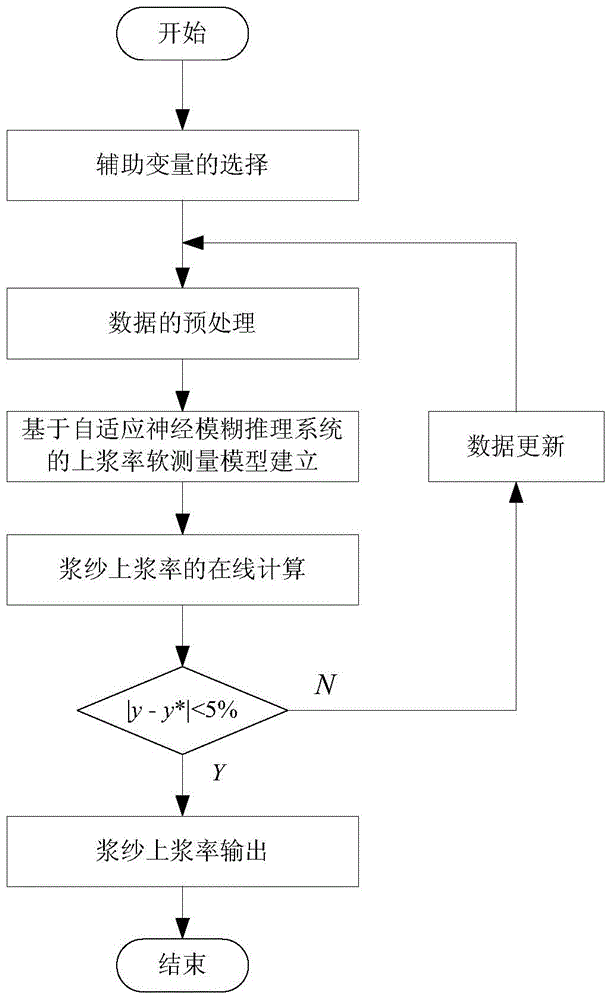

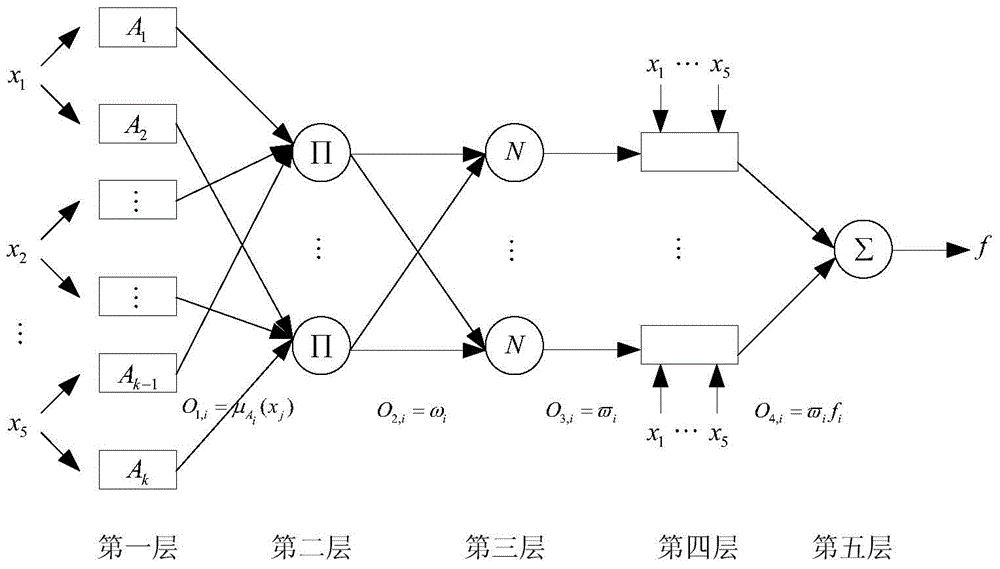

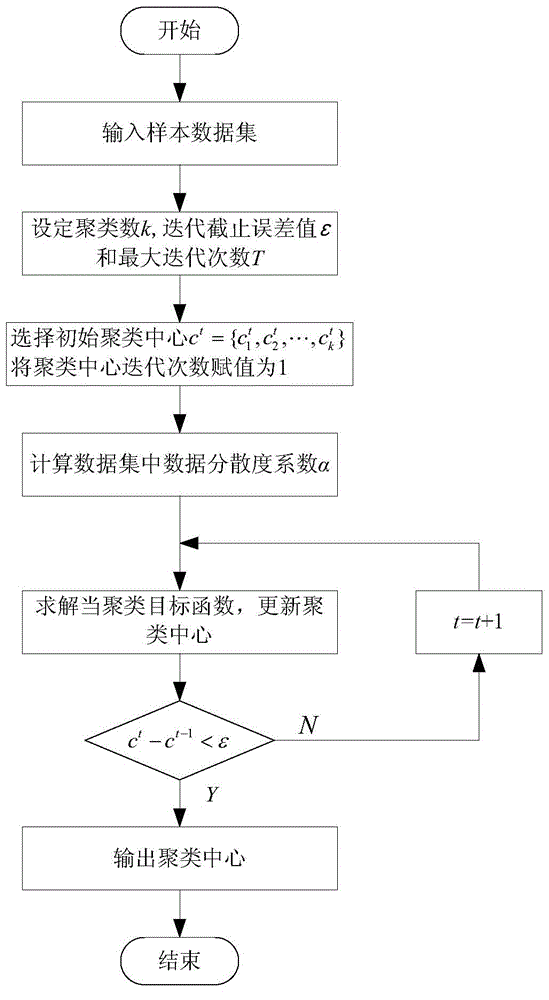

Intelligent soft measurement method of slashing sizing percentage

ActiveCN103559417ACalculation speedHigh precisionFuzzy logic based systemsSpecial data processing applicationsData setMaterial consumption

The invention relates to an intelligent soft measurement method of a slashing sizing percentage, and belongs to the technical field of automatic measurement. The method comprises steps as follows: according to composition analysis of a sizing mechanism and a slasher, auxiliary variables for soft measurement of the slashing sizing percentage are determined and comprise a slasher speed, pressure of a low-pressure sizing roller of the slasher, pressure of a high-pressure sizing roller of the slasher, concentration of size in a size box of the slasher and temperature of the size in the size box of the slasher; historical operating data of the slasher are collected, and a sample data set is established; a slashing sizing percentage soft measurement model is established, and a relation between the auxiliary variables and slashing sizing is obtained; and the slashing sizing percentage is calculated on line. According to the method, the slashing sizing percentage can be accurately calculated on line, the calculation speed and the accuracy are high, the online detection can be realized, and energy consumption and material consumption in the slashing production process can be reduced; the application range is wide, and online soft measurement of other quality indexes such as moisture regain, a elongation percentage and the like can be realized after a data source is appropriately modified; and the slashing production can conveniently share information with other links of cotton textile production, and references are provided for operations of other links.

Owner:SHENYANG POLYTECHNIC UNIV

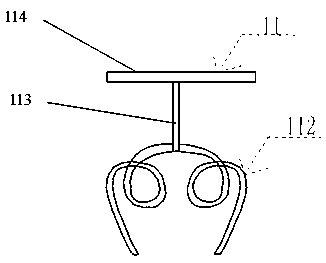

Production equipment of hydrophilic moisture-conducting secondary plied porous fibers and production method of porous fibers

InactiveCN110616469AStrengthen bondageUniform tensionNew-spun product collectionArtificial thread manufacturing machinesPorous fiberMoisture

The invention provides production equipment of hydrophilic moisture-conducting secondary plied porous fibers and a production method of porous fibers. In the production equipment of the hydrophilic moisture-conducting secondary plied porous fibers, a single-rod double-end two-way guider mainly features two-way guidance, so that the binding of the guider to tows is strengthened; the two tows, before being plied, are symmetrically deviated from the angular direction of the guider, the uniform tension of the two tows is ensured, the friction between the two tows before and after plying is reduced, fiber branching and breaking are avoided, and yarn drifting and broken ends are avoided, yarn skipping during winding switching is avoided, the problems, such as hairy fiber falling during cake winding, are avoided, and product quality is improved.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Method for directly preparing mycophenolate sodium from mycophenolic acid fermentation broth

InactiveCN102532078AReduce manufacturing costReduce pollutionOrganic chemistryBiotechnologyOrganic solvent

The invention provides a method for directly preparing mycophenolate sodium from mycophenolic acid fermentation broth. Soda is added into the mycophenolic acid fermentation broth, so that mycophenolate sodium liquor is produced, and after filtration and drying, mycophenolate sodium powder is prepared. The method directly prepares the mycophenolate sodium from the mycophenolic acid fermentation broth, the middle process in the preparation of the mycophenolate sodium powder is dispensed with, and organic solvent is not used, so that pollution is reduced and the production cost is saved, so the industrial production is facilitated.

Owner:福建和泉生物科技有限公司

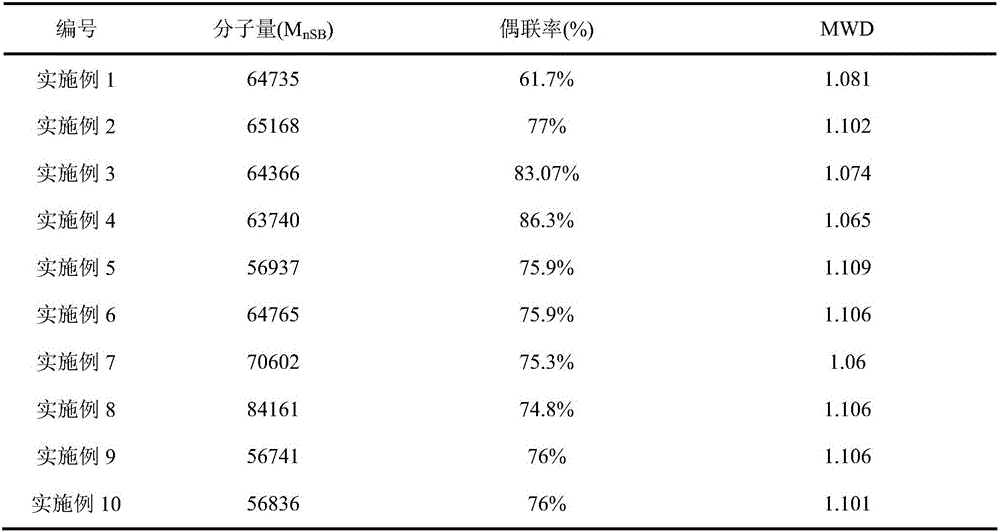

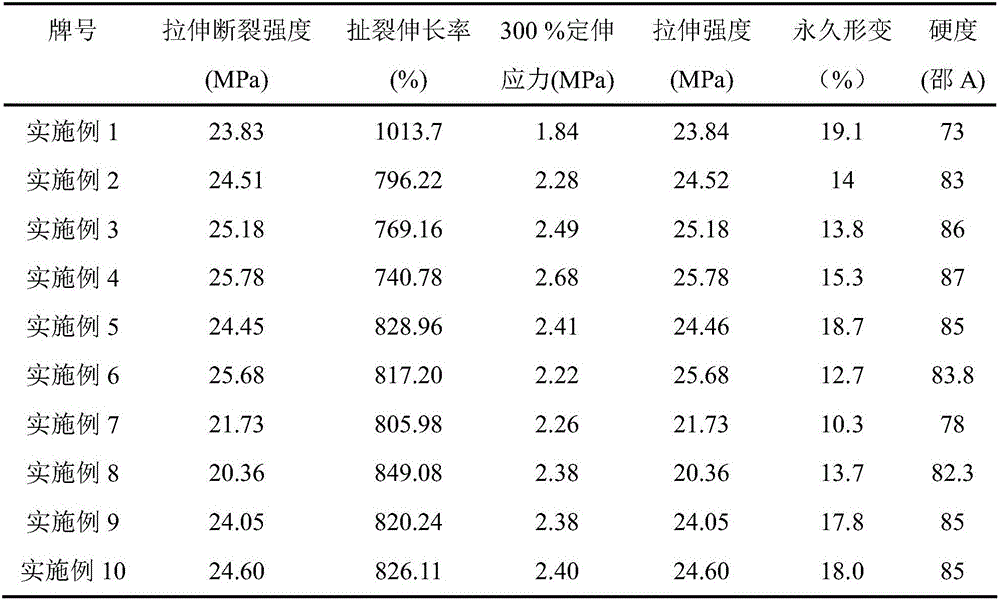

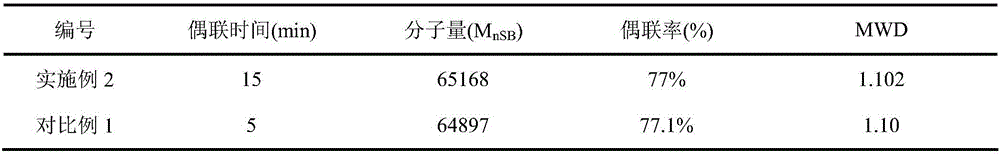

Linear functionalized SBS prepared from bifunctional coupling agent and process

ActiveCN105801784AIncrease polarityHigh coupling rateBuilding insulationsHydrocarbon solventsPolymer science

The invention discloses a linear functionalized SBS prepared from a bifunctional coupling agent. The linear functionalized SBS is prepared by the following steps: (1) adding a hydrocarbon solvent, styrene and a polar additive into a reactor, stirring, heating to 30-60 DEG C, and adding an organic lithium initiator to carry out first-section polymerization reaction for 30-60 minutes; (2) adding butadiene to carry out second-section polymerization reaction for 20-60 minutes; (3) adding the bifunctional coupling agent to carry out coupling reaction for 2-30 minutes; and (4) after the reaction in the step (3) is finished, adding a terminating agent to terminate the reaction, adding an anti-aging agent, removing the hydrocarbon solvent, and drying, so as to obtain the styrene-butadiene-styrene segmented ternary copolymer with linear functional groups. The invention further discloses a preparation process of the linear functionalized SBS. The linear functionalized SBS has good compatibility with polar materials such as asphalt, and the preparation process is simple.

Owner:CHINA PETROLEUM & CHEM CORP

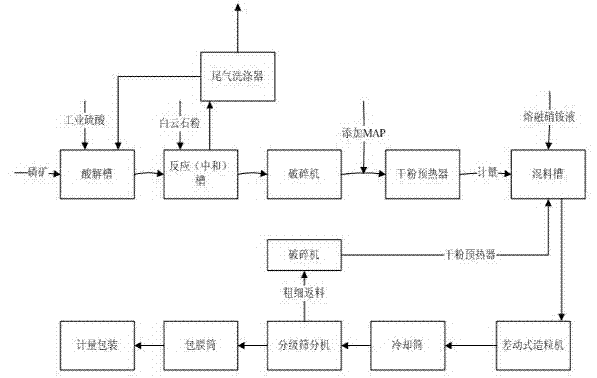

Technology for continuously producing nitrocompound fertilizer by using low-grade phosphorus ore and dolomite

ActiveCN102731186ANo generationEasy to handleFertiliser formsFertilizer mixturesSoil sciencePhosphoric acid

The invention relates to the fertilizer production device field, and is a technology for producing high efficiency nitrocompound fertilizer with low price and easy raw material acquisition, especially relates to a technology by using low-grade phosphorus ore and abundant mineral product dolomite, and concretely relates to the technology for continuously producing nitrocompound fertilizer by using low-grade phosphorus ore and dolomite. According to the technology, phosphorus ore and dolomite extracted by using sulfur to obtain effective phosphor and water-soluble calcium magnesium, a proper amount of monoammonium phosphate is added, and is reacted with melted ammonium nitrate, and is granulated in a high tower to produce the compound fertilizer. The method employs seven steps combination of performing phosphor extraction, performing calcium magnesium extraction, pulverizing, burdening, melting, granulating and cooling. According to the invention, low-grade phosphorus ore is selected for solving the problem of difficult usage of low-grade phosphorus ore, the product contains macroelements nitrogen and phosphor required by the crops, and contains three secondary elements calcium magnesium sulfur required by the growth of the crops as well as a part of trace elements, and the high tower granulation can ensure the full reaction and uniform mixing of various substances.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Preparation method of tris(tri-bromophenoxy) triazine

The invention discloses a preparation method of tris(tri-bromophenoxy) triazine. The method comprises steps of: adding anhydrous chlorobenzene and tribromophenol in a mass ratio of 2.0-2.25:1; adding a catalyst DMF with a weight of 8-10% of the tribromophenol; adding cyanuric chloride for three times with stirring at 25-35 DEG C, wherein a molar ratio of the cyanuric chloride to the tribromophenol is 1:3.03-3.05, and insulating at 40-45 DEG C for 2.5 h after addition; after reaction, adding deionized water with a weight of 1 / 6-1 / 8 of the organic solvent at 30-35 DEG C, adjusting a pH to 9-10 with 5% NaOH, stirring, washing and removing a water layer to obtain an organic feed liquid; transferring the washed organic feed liquid to a water azeotropic crystallization apparatus to carry out water azeotropic crystallization, centrifuging to obtain a wet product, drying the wet product at 110-120 DEG C for 4 h, controlling a water content lower than 0.2% to obtain the tris(tri-bromophenoxy) triazine product. The preparation method can reduce energy consumption and material consumption, increase product quality; and the product has good crystallization state and no dust, and is safe and environment friendly.

Owner:RUDONG JINKANGTAI CHEM CO LTD

Non-spangle friction-resisting hot dipping K-S-B zinc aluminum alloy and machining process

InactiveCN108396198ADoes not increase crystallization pointNot easy to produceHot-dipping/immersion processesZincMachining process

The invention discloses a non-spangle friction-resisting hot dipping K-S-B zinc aluminum alloy and a machining process. The alloy comprises, by weight percent, 0.2 to 0.3% of K, 2.0to 2.5% of Mg, 1.0to 1.8% of Ca, 20.0 to 28.0% of Al, 0.2 to 0.3% of Se, 0.6 to 0.8% of In, 0.1 to 0.2% of B, 0.2 to 0.3% of S and the balance zinc. The hot dipping K-S-B zinc aluminum alloy and the process of the alloy solve the key problem in the hot-dip galvanizing aluminum alloy application research and industrialization, a final product has the excellent corrosion resistance property and the non-spangle surface state, and the material can be widely applied in the near future.

Owner:GUANGZHOU YUZHI TECH CO LTD

Magnesium modified chromium-based catalyst for vinyl polymerization and preparation method of magnesium modified chromium-based catalyst

ActiveCN109160963AHigh polymerization activityShort induction periodBulk chemical productionChromium CompoundsMagnesium salt

The invention relates to a magnesium modified chromium-based catalyst for vinyl polymerization and a preparation method of the magnesium modified chromium-based catalyst. The catalyst contains a chromium compound, a magnesium modified silica-gel carrier and an alkyl aluminum compound, wherein chromium accounts for 0.01wt%-5.0wt% of total mass of the catalyst, the magnesium modified silica-gel carrier accounts for 70.0wt%-99.9wt% of total mass of the catalyst, the mass ratio of silica gel to a magnesium compound in the carrier is 100-20:1, and aluminum accounts for 0.05wt%-25.0wt% of total massof the catalyst. When the catalyst is applied to industrial production of polyethylene, produced polyethylene particles are good in form, high in bulk density and wide in molecular weight distribution; the preparation method of the catalyst comprises steps as follows: a magnesium salt solution of tetrahydrofuran is taken as a dispersion medium, silica gel is taken as a carrier, the chromium compound is taken as an active component, an organo-aluminum compound is taken as a promoter, modification of carrier silica gel and loading of the active component are realized by spray drying, then drying, high-temperature activation, reduction, reactivation and re-reduction are performed, and the catalyst product is obtained; the technological process of the method is simple and convenient, no chromium-containing wastewater is produced, and industrial implementation is facilitated.

Owner:吉化集团吉林市天龙催化剂有限公司

Method for preparing crude paromomycin with membrane separation technology

InactiveCN102391329AEasy to remove impuritiesEasy to separateSugar derivativesSugar derivatives preparationBiotechnologySeparation technology

The invention provides a method for preparing crude paromomycin with a membrane separation technology. The method comprises the following steps: 1, a material liquid containing paromomycin is processed by a microfiltration membrane, and remove the fermentation liquor thallus and the residue; 2, macromolecular impurities of proteins, polysaccharides and coloring substances in the microfiltered permeation liquid obtained in step 1 are removed; 3, the collected ultrafiltration permeation liquid is desalinated by a nanofiltration membrane at normal temperature and is enriched; and 4, the desalinated liquid is concentrated and dried to prepare the crude paromomycin. The method of the invention, which has the advantages of novel conception, mild production technology condition, environment protection, cleaning, simplicity, easy implement, short production period, low production cost, high extraction yield, and strong practicality, has a large popularization and application value.

Owner:福建和泉生物科技有限公司

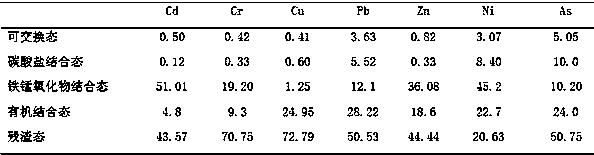

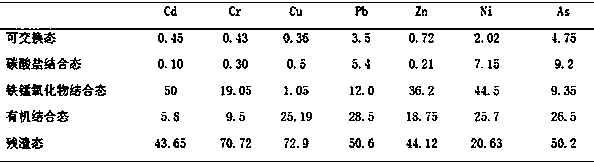

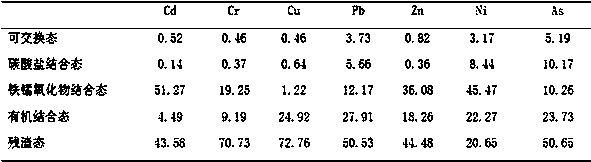

Method for lowering heavy metal content and water content in sludge

InactiveCN108439736AImprove utilizationReduce heavy metal contentSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesAcetic acidSludge cake

The invention discloses a method for lowering the heavy metal content and the water content in sludge. As for the method provided by the invention, by utilizing modified phosphogypsum and acetic acidto treat the sludge in a combination manner, the heavy metal environment risk and the water content in the sludge are lowered; with addition of the acetic acid and the modified phosphogypsum, the content of heavy metals in a sludge filtrate can be remarkably lowered, the content of heavy metal forms with relatively large risk in a sludge cake can also be obviously reduced, and the heavy metal environment risk is lowered; and meanwhile, as for the sludge subjected to treatment with the acetic acid and the modified phosphogypsum, the dewatering rate is remarkably increased, and the water contentin the sludge after dewatering is lowered to 45 percent or below. The method is simple and feasible in production technology operation and low in production cost, achieves the purpose of treating wastes with wastes by fully utilizing phosphogypsum as a waste resource to perform sludge treatment, improves the dewatering performance of the sludge while improving the heavy metal environment risk ofthe sludge, expands the field of phosphogypsum resource utilization, promotes comprehensive utilization of the phosphogypsum and is wide in application prospect and good in market prospect.

Owner:KUNMING UNIV OF SCI & TECH

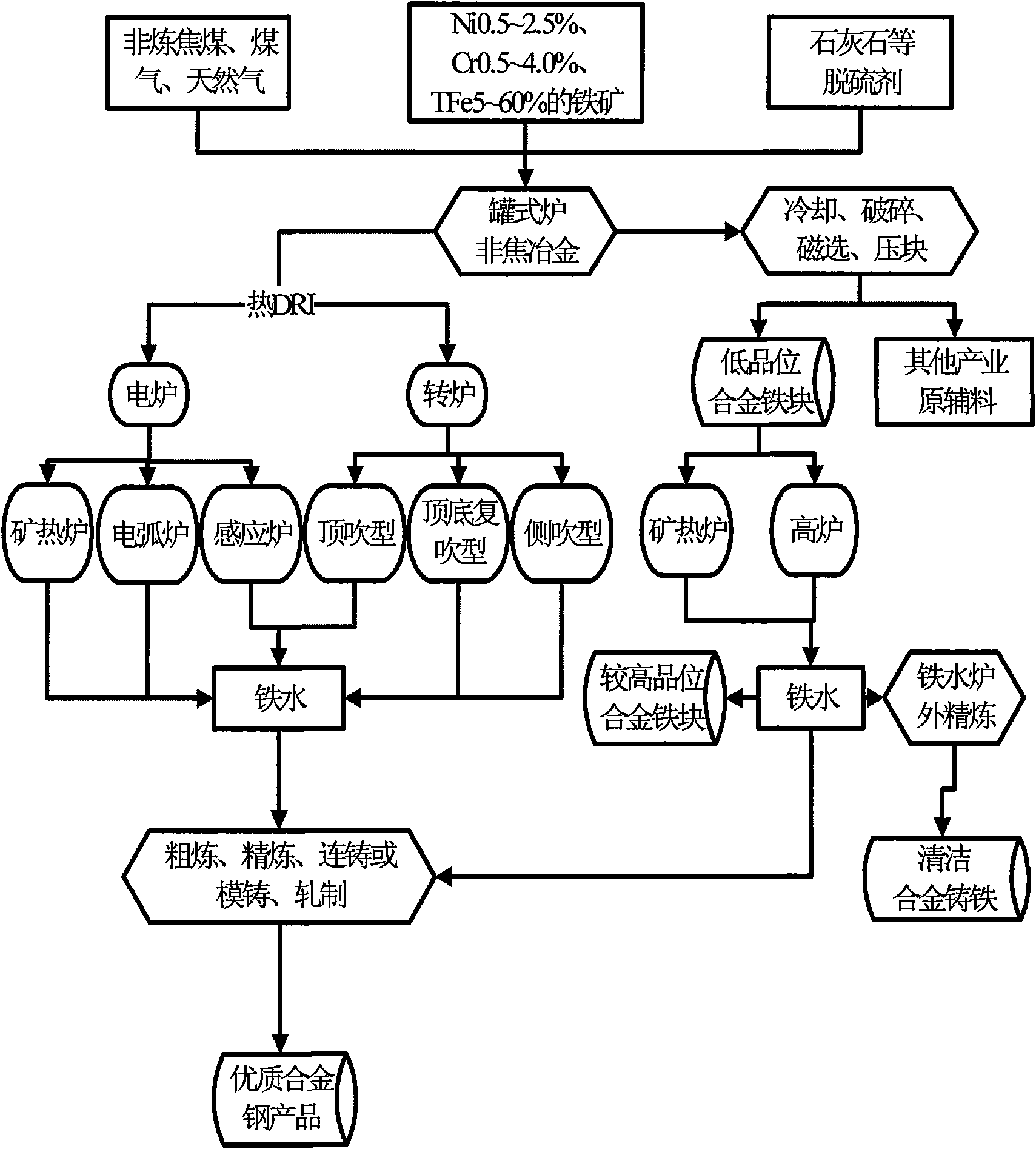

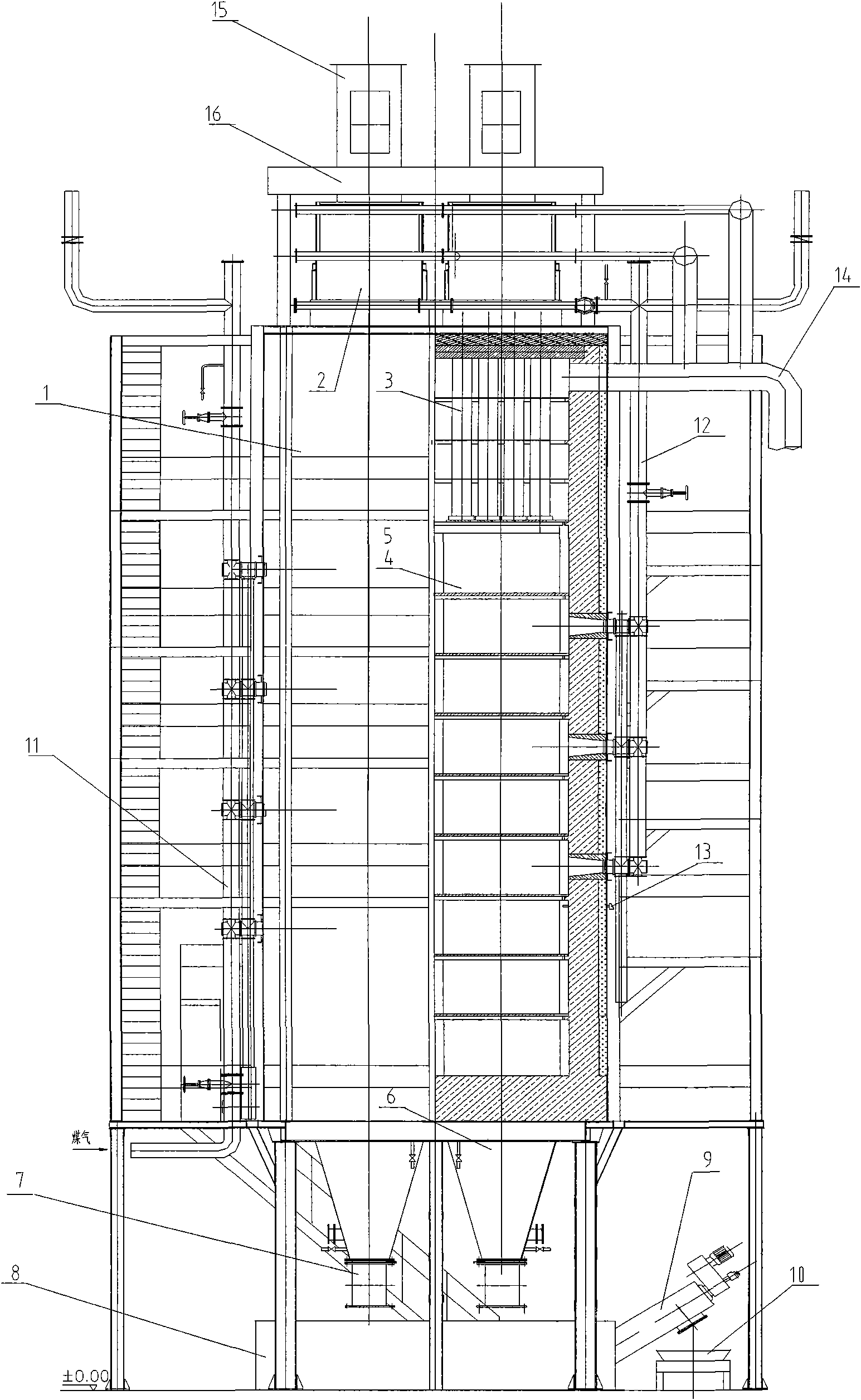

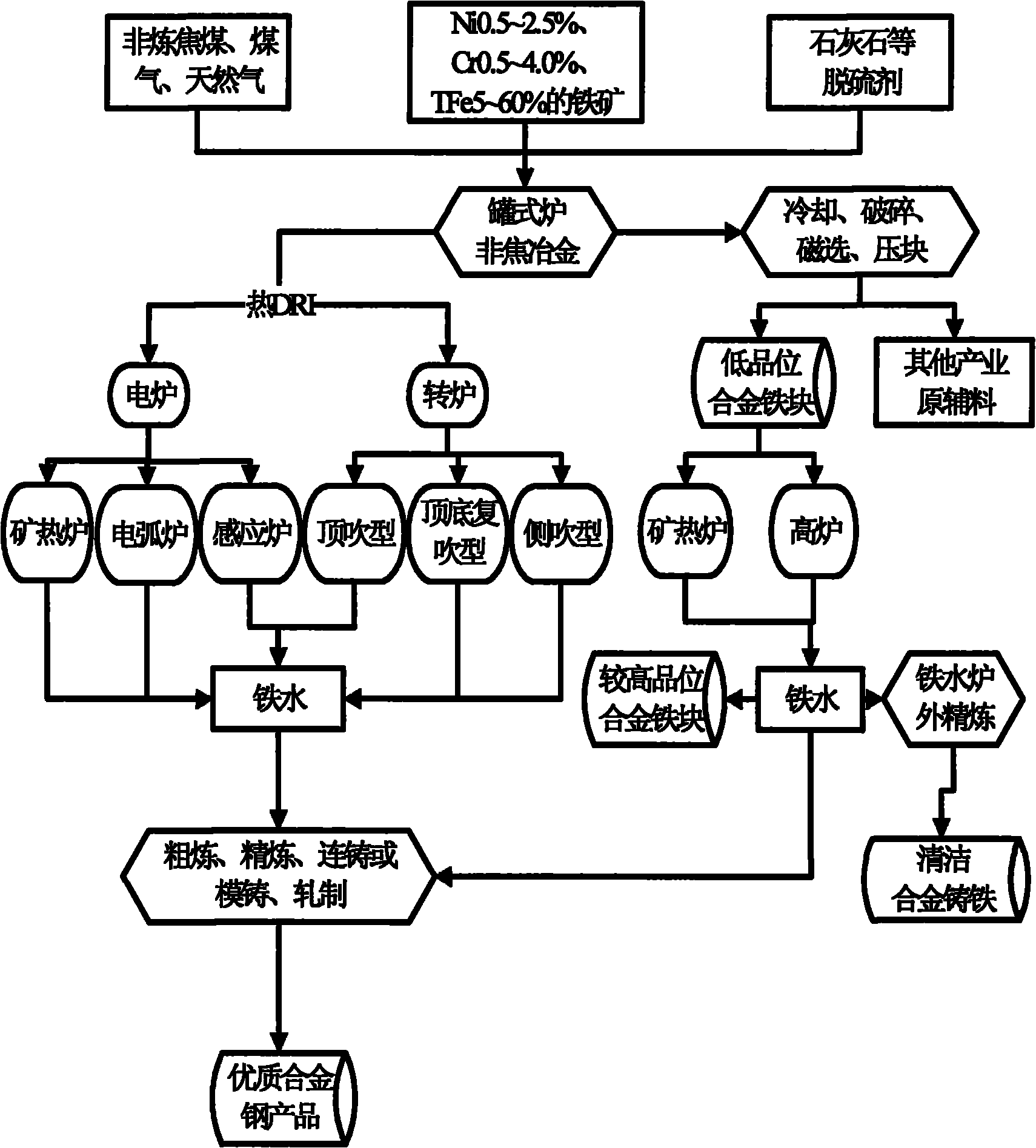

Method for producing alloy steel by directly utilizing low-grade nickel-chromium commensal iron ore

InactiveCN101892414ALow investment costReduce manufacturing costRetort furnacesGas emission reductionChromium nickelCoal

The invention discloses a method for producing alloy steel by directly utilizing low-grade nickel-chromium commensal iron ore. In the method, the low-grade nickel-chromium commensal iron ore comprising 0.5 to 2.5 percent of Ni, 0.5 to 4 percent of Cr and 5 to 60 percent of TFe is taken as a raw material and is added with a desulfurizer, and the nickel, chromium and iron in the ore are metalized into nickel-chronium alloy iron blocks in a pot-type furnace by non-coking metallurgy technology of heating and directly reducing by mill coal, coal gas or natural gas; and the nickel-chronium alloy iron blocks are processed in various modes to form the high-quality alloy steel. The method for producing the alloy steel by directly utilizing the low-grade nickel-chromium commensal iron ore is a new process for producing multiple kinds of alloy steel by directly utilizing the commensal iron ore comprising 0.5 to 2.5 percent of Ni, 0.5 to 4 percent of Cr and 5 to 60 percent of TFe, and has the advantages of short flow, low energy and material consumption, reduction of production line project investment and production cost, and improvement of economic and social benefits of enterprises.

Owner:ZHENGZHOU YONGTONG SPECIAL STEEL

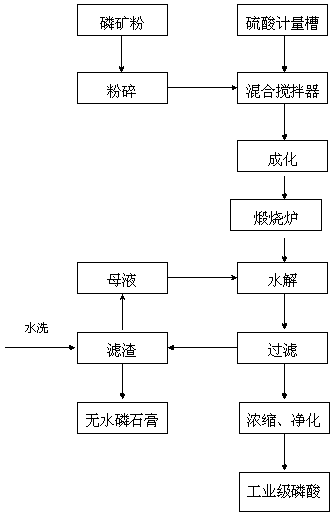

Process for producing industrial phosphate with calcination method

ActiveCN103274379AMeet growth requirementsExcellent indicatorsPhosphorus compoundsO-Phosphoric AcidPhosphate

The invention relates to a process for producing industrial phosphate with a calcination method. The method includes the steps as follows: firstly, crushing: phosphate rock is primarily crushed and then smashed again, smashed phosphate rock powder is sieved with a 120-mesh sieve; secondly, mixing and curing: the phosphate rock powder and sulfuric acid are placed into a mixing stirrer in proportion for stirring, and a mixed material is conveyed to a curing field to be cured for 2-3 hours; thirdly, calcination: cured clinker is conveyed to a calcination furnace for calcination, the calcination temperature is controlled to range from 250 DEG C to 280 DEG C, and the calcination time is controlled to be 1.5 hours to 2 hours; fourthly, hydrolysis: the calcinated gaseous substance is recycled, watered and recycled to generate fluosilicic acid, a solid substance enters a hydrolytic tank and is stirred to generate phosphoric acid, and the concentration of the generated phosphoric acid is controlled to be 12%-18%. According to the process, condition requirements are simple; raw materials with impurities of iron, magnesium and aluminum exceeding a prescribed limit of phosphoric acid by wet process can still be used for producing the industrial phosphate with the adoption of the process, and the product quality is stable.

Owner:SICHUAN SHANGZHOU IND

Method for preparing paromomycin crude product by membrane separation technology

InactiveCN102399248AEasy to remove impuritiesEasy to separateSugar derivativesSugar derivatives preparationMicrofiltration membraneSeparation technology

The invention provides a method for preparing a paromomycin crude product by a membrane separation technology. The method comprises the steps of removing impurities from feed liquid in the preparation process of the paromomycin crude product through a microfiltration membrane, decoloring through ultrafiltration, desalting through nanofiltration, enriching, concentrating and drying and particularly comprises the following steps of: performing liquid solid separation on the feed liquid containing the paromomycin through the microfiltration membrane; removing macromolecular impurities such as protein, pigment, polysaccharide and the like from microfiltration permeate through an ultrafiltration membrane; desalting and enriching the collected permeate through a nanofiltration membrane at normal temperature; and concentrating and drying the desalted liquid to obtain the paromomycin crude product. The method is novel in idea, mild in production process condition, green and clean, simple and practicable, short in production period, low in production cost, high in extraction yield and high in practicability, and has large popularization and application value.

Owner:福建和泉生物科技有限公司

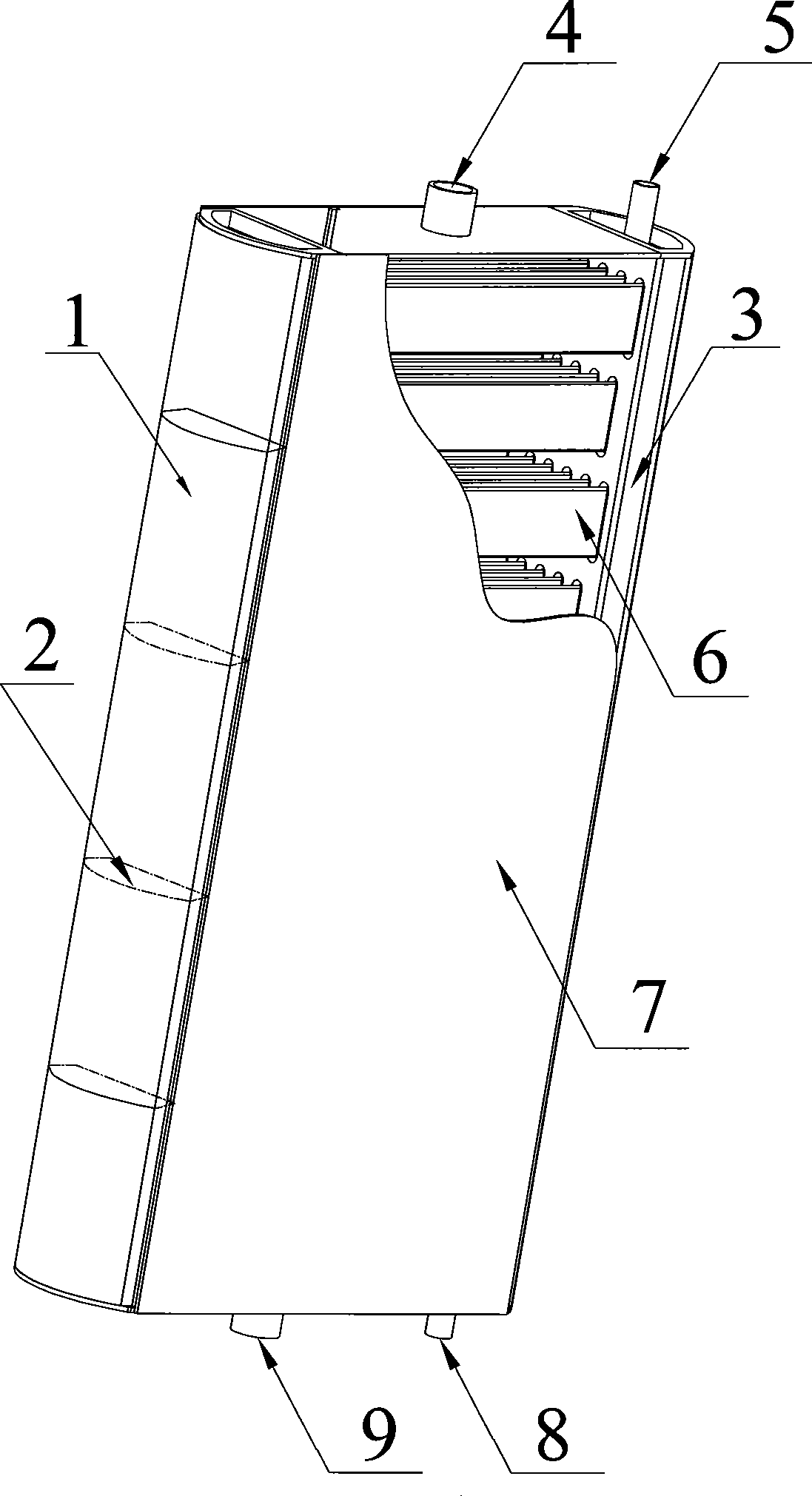

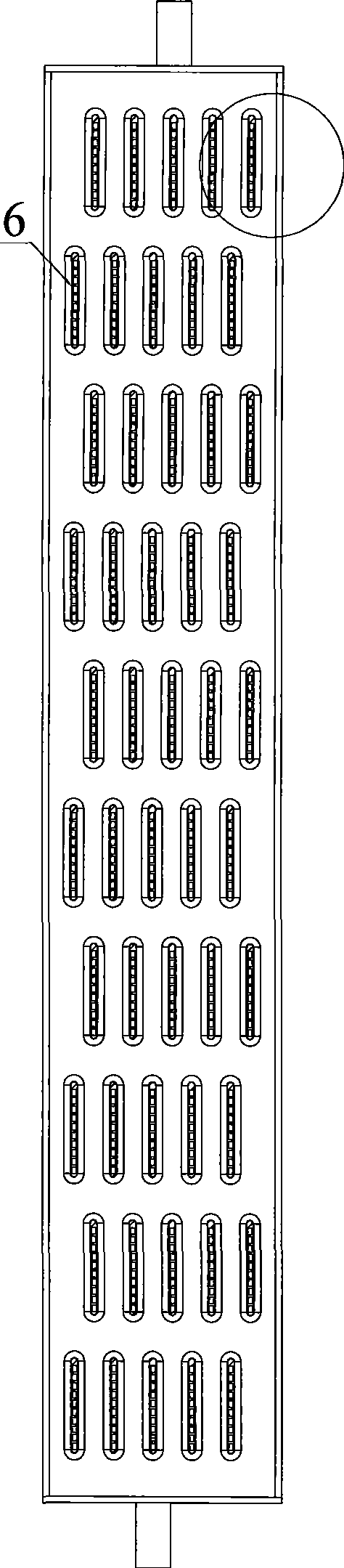

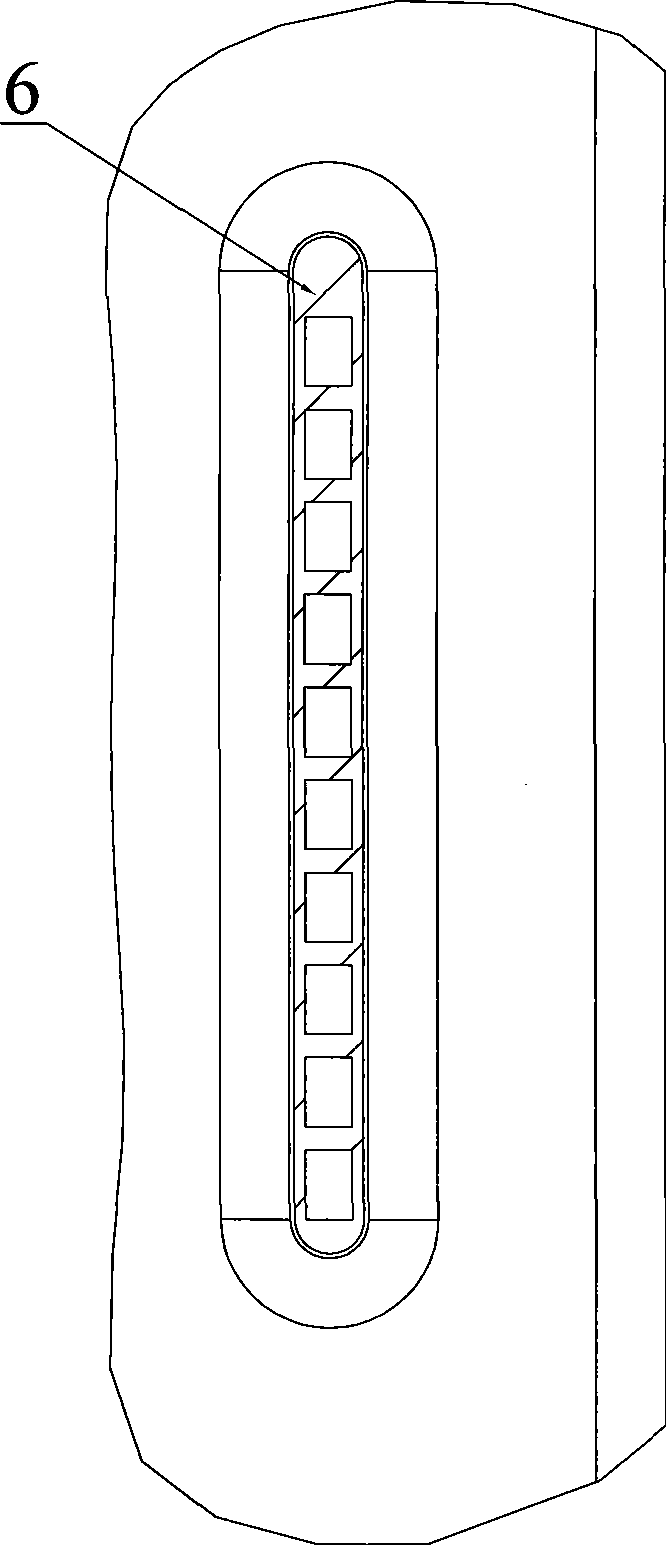

Heat exchanger

InactiveCN101458014AOptimize volumeGood for refrigeration or air conditioning equipment for small volumeEvaporators/condensersHeat exchanger casingsEngineeringAir conditioning

The invention provides a heat exchanger, which comprises a left collecting pipe, a right collecting pipe, a heat exchanging flat pipe and a shell body and forms an enclosed rectangle. Rows of heat exchanging flat pipes are staggered up and down in the rectangular shell; the plane of the heat exchanging flat pipe parallels the axial line of the collecting pipe; the left and right ports of the heat exchanging flat pipe are respectively welded on the left collecting pipe and the right collecting pipe; a baffle is arranged in the left collecting pipe and the right collecting pipe so as to form a sealed and end-to-end circulation channel between the left and right collecting pipes and the heat exchanger flat pipe, and the inside of the heat exchanger flat pipe is provided with a plurality of circulation channels; in addition, the bottom part of the shell body is provided with a fluid inlet and the upper part of the shell body is provided with a fluid outlet; an air inlet pipe and a fluid outlet pipe are communicated with the right collecting pipe or the right collecting pipe. As the invention adopts the heat exchanging flat pipe and the heat exchanging flat pipes are staggered, the heat exchanging effect of parallel flows is strengthened, the structure is quite compact and the heat exchanging efficiency is very high, thus well satisfying the fact that cooling or air-conditioning equipment requires small heat exchangers.

Owner:SUZHOU QUTU THERMAL CONTROL SYST

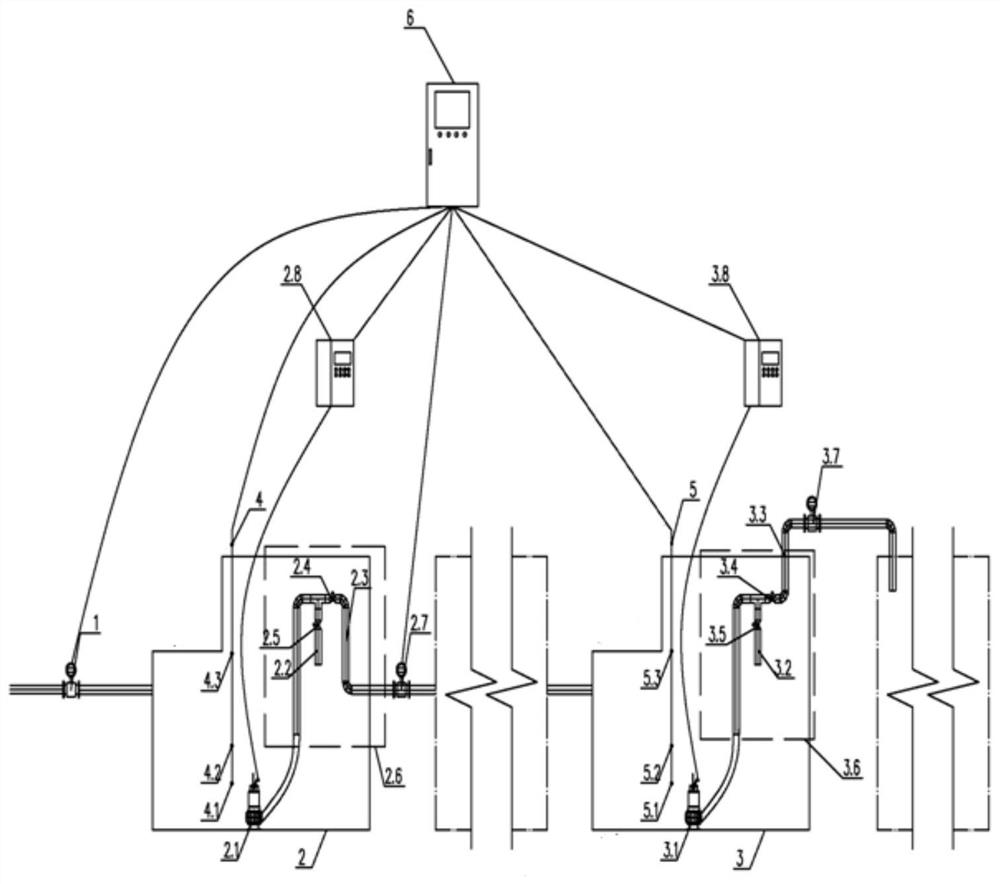

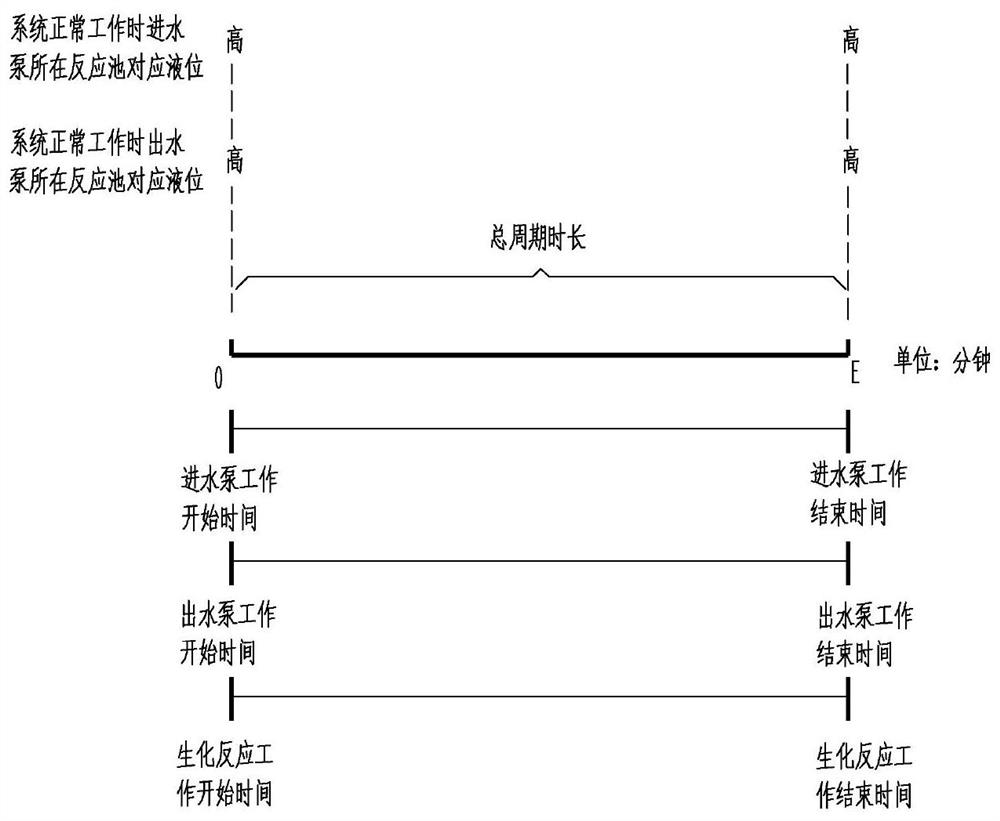

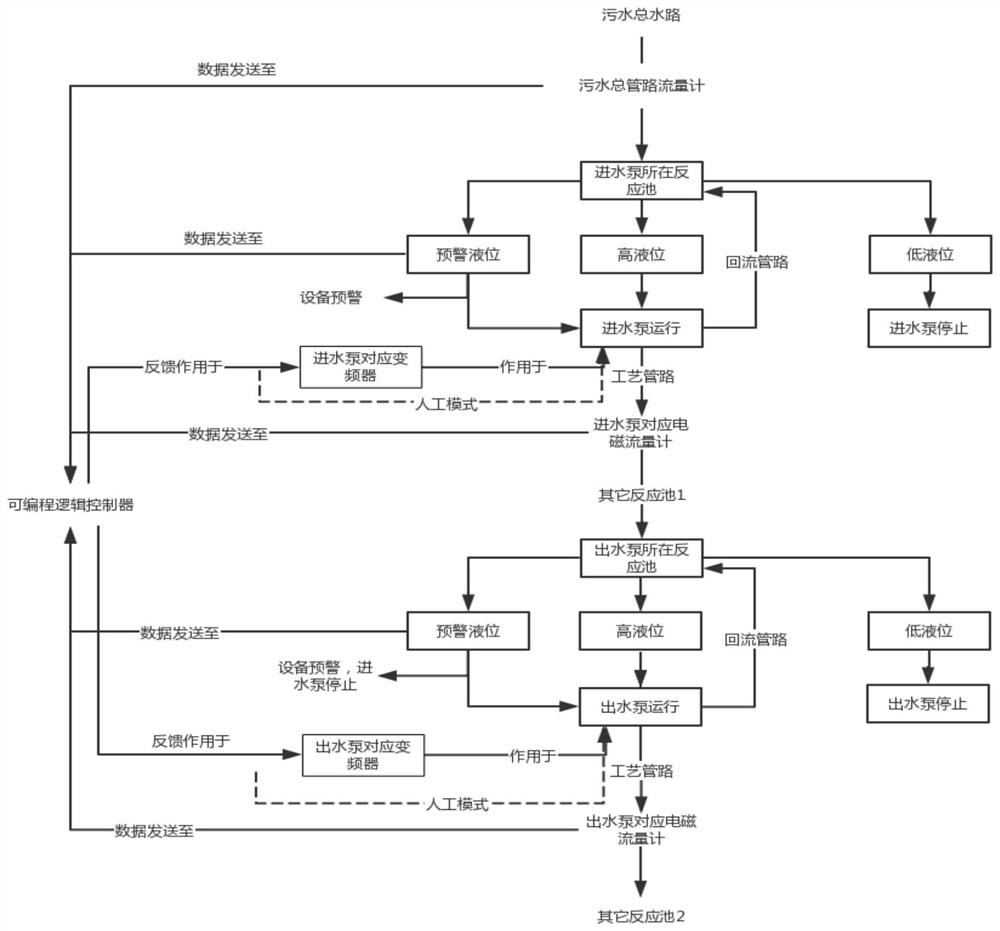

Operation early warning system and method for decentralized micro sewage treatment device

ActiveCN112645441AFlexible and reliable operationGuaranteed uptimeWater treatment parameter controlSustainable biological treatmentEarly warning systemProgrammable logic controller

The invention discloses an operation early warning system and method of a dispersed micro sewage treatment device. The early warning system comprises a reaction tank where a water inlet pump and a water outlet pump are located, a liquid level signal monitoring system, a flow monitoring system, a flow control system and a programmable logic controller. The programmable logic controller is provided with a total period duration, a water inlet pump work starting time, a water inlet pump work ending time, a water outlet pump work starting time, a water outlet pump work ending time, a biochemical reaction work starting time and a biochemical reaction work ending time. The programmable logic controller compares and analyzes the collected data and achieves system early warning and switching of a system continuous flow operation mode or a sequencing batch operation mode through the time and liquid level signal monitoring system and the flow control system under the action of operation logic. The operation early warning system is simple to install and transform, convenient to operate and switch, capable of effectively adapting to the characteristic of large fluctuation of sewage quantity in decentralized areas and stable in treatment effect.

Owner:山西省交通新技术发展有限公司 +1

Dehydration and alcohol depolymerization process for low-disintegration coal in mild condition

InactiveCN101314716BReduce material requirementsAvoid cloggingSolid fuelsLiquid hydrocarbon mixture productionDepolymerizationPhenol

A dehydration and alcohol depolymerization process for low-rank coal under mild condition comprises the following steps: mixing acetone and butanone at equal volume ratio to obtain an organic dehydration solvent, adding brown coal powder in a reaction kettle to obtain dehydrated brown coal powder and organic dehydration mixture solution, and separating the organic dehydration solvent for recycling; adding the dehydrated brown coal powder and methanol into a reaction kettle to obtain residual coal and alcoholysis products, and press-filtering the alcoholysis products to an extractor through a filter plate under stirring and the pressure in the kettle; adding the alcoholysis products into the extractor, spraying eluant into the extractor to obtain a soluble material, adding the soluble material into a distilling still to obtain fine organic components rich in low-carbon hydrocarbon, low-carbon alkoxyl organic materials, phenols, esters, heavy organic components, etc.; and recrystallizing the methanol solvent by heating and cooling to obtain pure organic chemicals with high value added such as alkyl naphthalene, alkyl anthracene and chemical containing polyatomic rings with N and S heteroatoms.

Owner:CHINA UNIV OF MINING & TECH

A method for continuously and efficiently extracting dandelion rubber and inulin from dandelion rubber grass

ActiveCN103435720BImprove resource utilization efficiencyLow energy and material consumptionPolymer scienceResidual biomass

The invention relates to a method for continuously effectively circularly extracting taraxacum rubber and synanthrin from dandelion taraxacumkok-saghyz. Taraxacum rubber belongs to a nonpolar substance, synanthrin belongs to a polar substance, and taraxacum rubber and synanthrin are obtained by extraction based on the water-oil separation principle employed by the method of the invention. The extract liquor of taraxacum rubber is subjected to steam distillation for separation of taraxacum rubber, and recycling and reusing of the solvent are realized. The extract liquor of synanthrin is subjected to a spray drying technology for obtaining of refined synanthrin. The final residual biomass residue is subjected to composting and is returned to the field, so that solid pollution is avoided and effective utilization of waste is realized. The method is characterized in that only one organic solvent is employed, and two products of taraxacum rubber and synanthrin are obtained during production. Taraxacum rubber and synanthrin split the cost mutually, and the product price is effectively reduced. The final composting and field returning of the residue help to realize resource utilization maximization. The whole technological process is circulatory, the extraction solvents are utilized circularly, energy consumption and material consumption are substantially decreased, and there are basically no discharged ''three wastes (waste gas, waste water and industrial residue)''.

Owner:BEIJING UNIV OF CHEM TECH +2

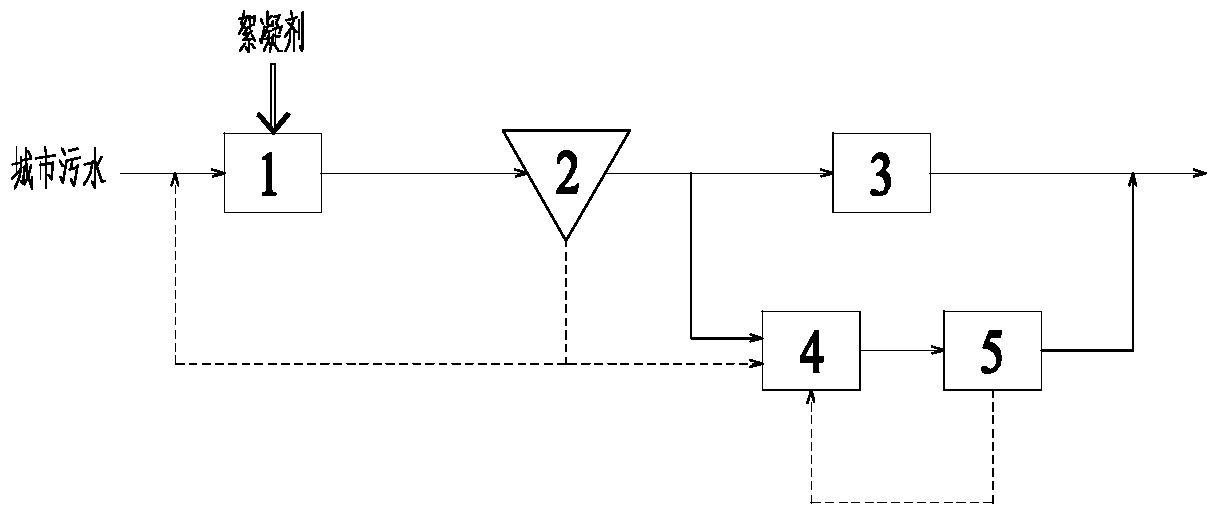

A high-standard nitrogen and phosphorus removal system for urban sewage without additional carbon sources

ActiveCN105366889BAvoid the disadvantages of unstable operation of the anaerobic ammonium oxidation processSimple processTreatment using aerobic processesTreatment with anaerobic digestion processesSludgeWater quality

The present invention relates to a high-standard urban sewage nitrogen and phosphorus removal system without external carbon sources. Urban sewage is fed into an urban sewage water inlet of a chemical-biological flocculation reaction tank; flocculant is fed into a flocculant adding port of the chemical-biological flocculation reaction tank; a drainage port of the chemical-biological flocculation reaction tank is connected with a water inlet of a sedimentation tank by a pipe; a drainage port of the sedimentation tank is connected with a water inlet of a mainstream anammox reaction tank by a pipe; a drainage port of the mainstream anammox reaction tank is connected to a drainage pipeline; and a sludge discharge port of the sedimentation tank is connected into the urban sewage water inlet of the chemical-biological flocculation reaction tank by a pipe. According to the system provided by the present invention, an anammox process and a traditional process are integrated organically, the drawback that in the case of a large amount of water flow and significant fluctuations of water quality, quantity and environmental conditions, the anammox process runs unstably is avoided; nitrogen removal efficiency is high; and the external carbon sources are not required even if the carbon nitrogen ratio is low.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com