Patents

Literature

249results about How to "Easy to remove impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and electroplating method of normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid

The invention provides a preparation method and an electroplating method of normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid, which relates to electroplating liquid and electroplating technology. The invention solves the problems of poor stability of the traditional trivalent chromium electroplating liquid, low precipitating and depositing rate of harmful gas in an electroplating process, more components of the electroplating liquid, sensitivity for impurities, poor corrosion resistance of an electroplating layer, and the like. The normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid mainly comprises the following components of main salt, a complexation stabilizing agent, a combined additive, a buffering agent and a conducting salt. The electroplating liquid can work at normal temperature, thereby saving energy resources and having simple technology and high deposition rate, wherein the deposition rate can reach above 0.22micron.min<-1> under 6A / dm<2>. An anode of the invention is a Ti-based rare-metal tantalum-iridium-titanium anode, the anode oxygen-evolution overpotential is low, and harmful hexavalent chrome can not be generated. The normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid has good corrosion resistance and high stability.

Owner:HARBIN INST OF TECH

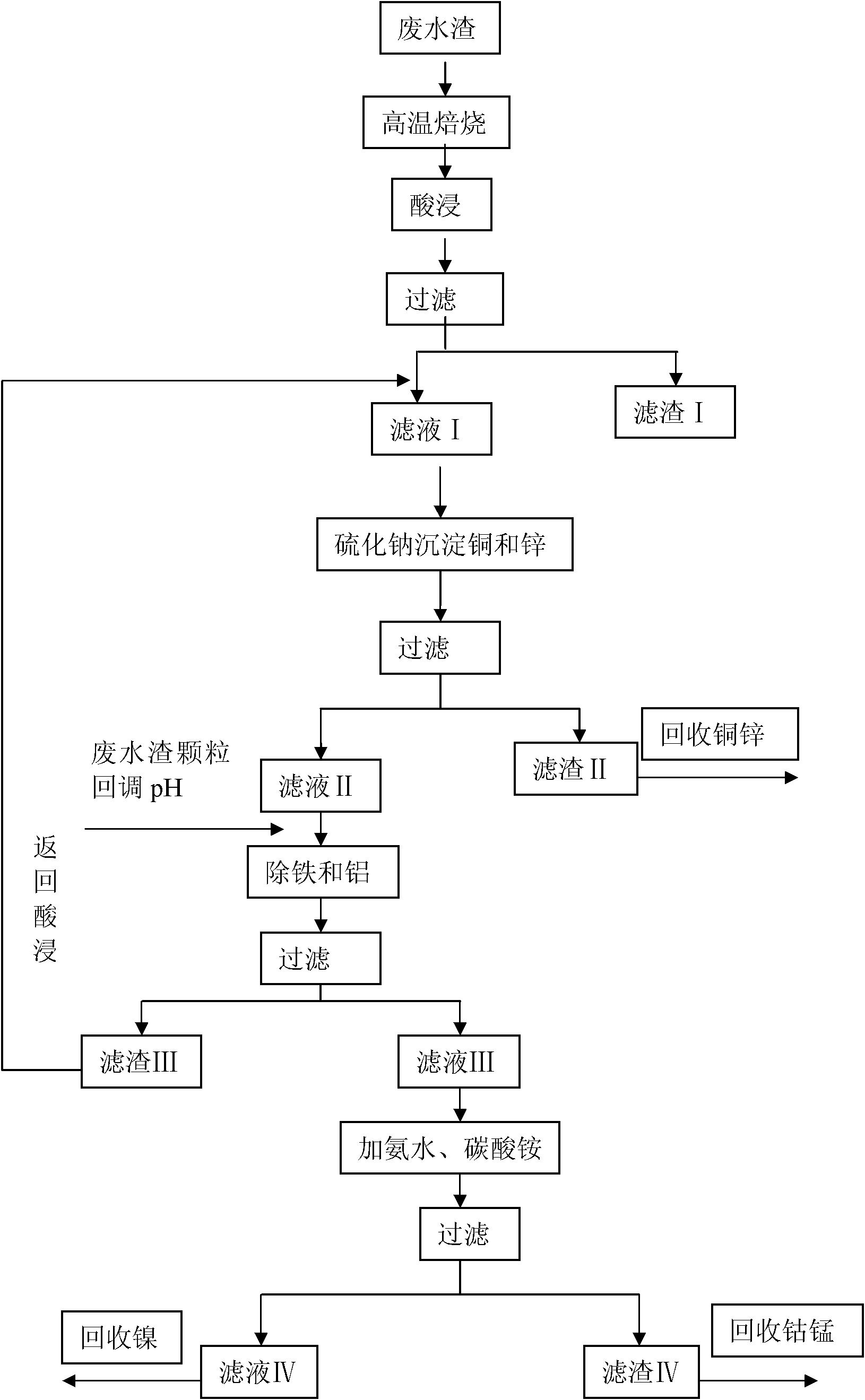

Method for treating cobalt-nickel-copper hydrometallurgy wastewater residue

ActiveCN102925706AReduce adverse effectsGood social benefitsProcess efficiency improvementLow gradedCopper

The present invention provides a method for treating cobalt-nickel-copper hydrometallurgy wastewater residue. The method comprises the following steps: high temperature calcination, acid leaching, copper and zinc recovery, iron and aluminum removal, cobalt and manganese recovery, and nickel recovery. The method can be used for treating various cobalt-nickel-copper hydrometallurgy wastewater residues having different components having different contents, especially for treating low-grade cobalt-nickel-copper hydrometallurgy wastewater residue. According to the present invention, the suitable leaching conditions and the reasonable separation technology are provided to achieve separately recovery of cobalt, nickel, copper, zinc, manganese and a plurality of valuable metals so as to maximize resource recycling; and compared to the conventional acid leaching method, the method of the present invention has characteristics of large treatment amount, low cost, high metal recovery rate and easy performing, and is suitable for industrial production.

Owner:GEM CO LTD

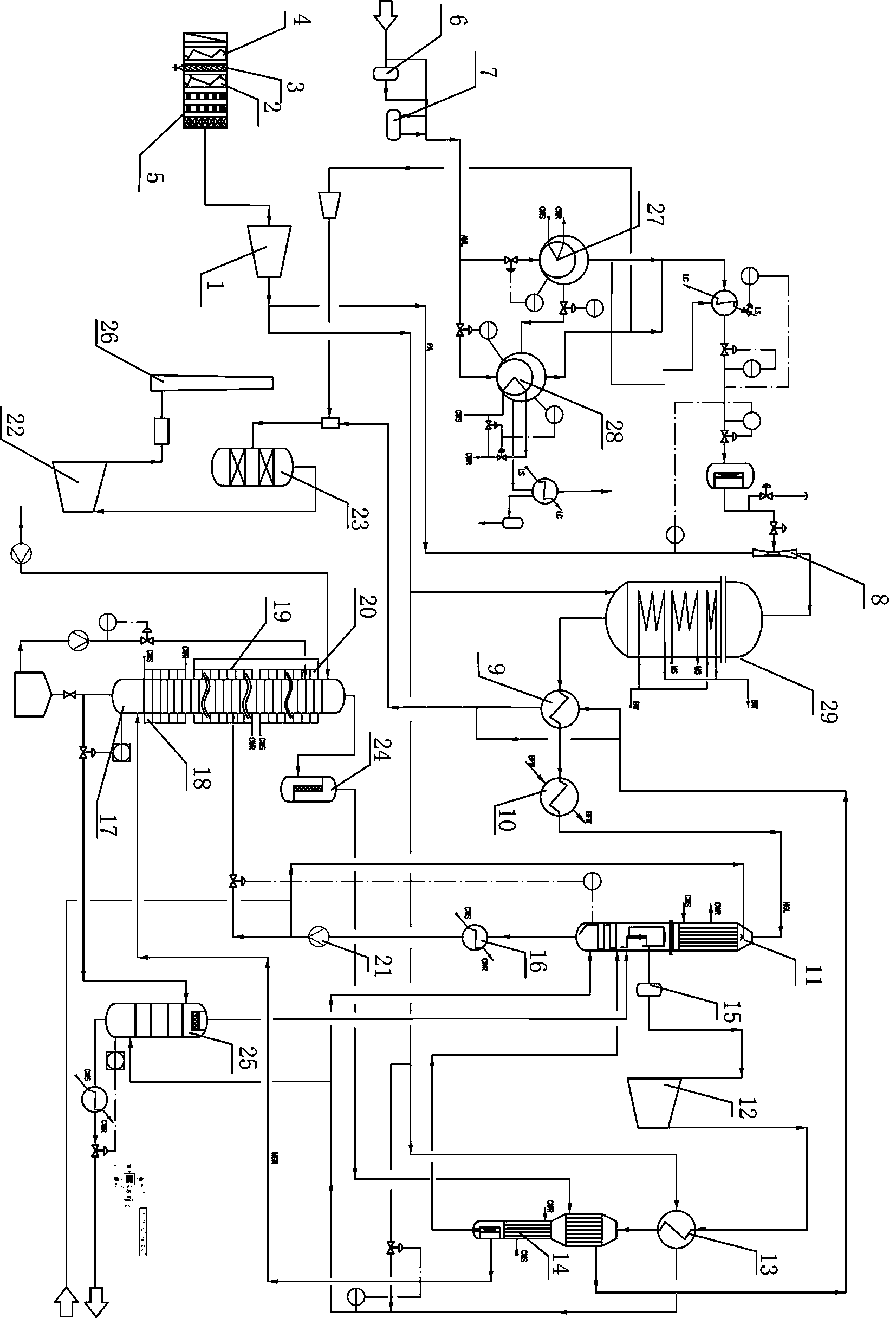

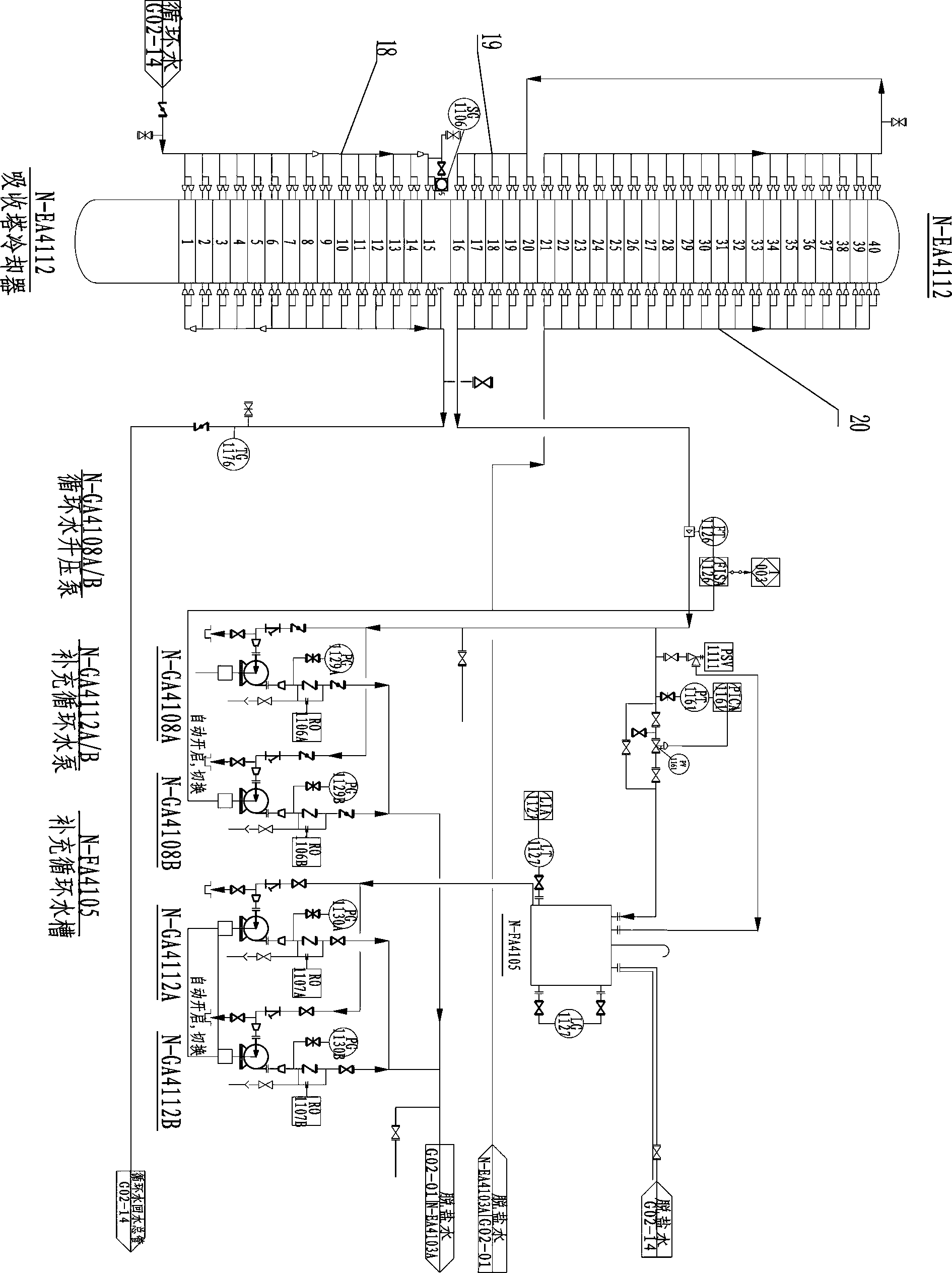

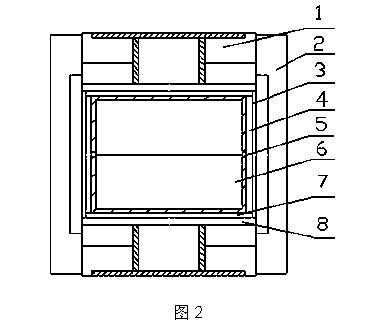

Method and device for preparing high-concentration dilute nitric acid

The invention discloses a method and device for preparing high-concentration dilute nitric acid. The method comprises the following steps: carrying out ammonia-air mixing, ammoxidation, condensation separation and fine separation on air subjected to impurity removal and dehumidification and liquid ammonia subjected to impurity removal, oil removal and evaporation, absorbing in an absorption tower in which 40 tower plates are arranged, meanwhile, carrying out cooling heat exchange by a three-stage water circulation technique to obtain the high-concentration dilute nitric acid of which the concentration is not lower than 68-70%. The method and device effectively enhance the nitric acid absorption efficiency, enhance the concentration of the dilute nitric acid, and can better satisfy the demands of modern industry for high-concentration dilute nitric acid.

Owner:TIANJI COAL CHEM IND GROUP

Preparation technology of yak bone collagen oligopeptide

InactiveCN105385737ALow costHigh purityPeptide preparation methodsFermentationEnzymatic hydrolysisHydrolysate

The invention discloses a preparation technology of yak bone collagen oligopeptide. The preparation technology comprises the following steps: grinding yak bones, which have been dried in the shade, into powder with a size of 50 meshes, processing yak bone powder by alkali and acid, removing fat and other impurities, extracting yak bone powder to obtain high purity yak bone collagen liquid extract; subjecting the yak bone collagen liquid extract to two-step enzymatic hydrolysis, after enzymatic hydrolysis, purifying the enzymatic hydrolysate by a centrifuge under the assistance of a multi-stage membrane separation system so as to obtain a yak bone collagen oligopeptide solution; spray-drying the yak bone collagen oligopeptide solution to obtain yak bone collagen oligopeptide; wherein the purity of yak bone collagen oligopeptide is more than 90%, and the molecular weight of yak bone collagen oligopeptide is less than 1000 Da. The yak processing byproduct namely yak bone is utilized to prepare collagen oligopeptide, the cost is low, the collagen extraction rate is more than 85%, the impurity removing effect and condensing effect are good, and the method is suitable for massive industrial production.

Owner:QINGDAO ARCTIC YAK BIOLOGICAL TECH CO LTD

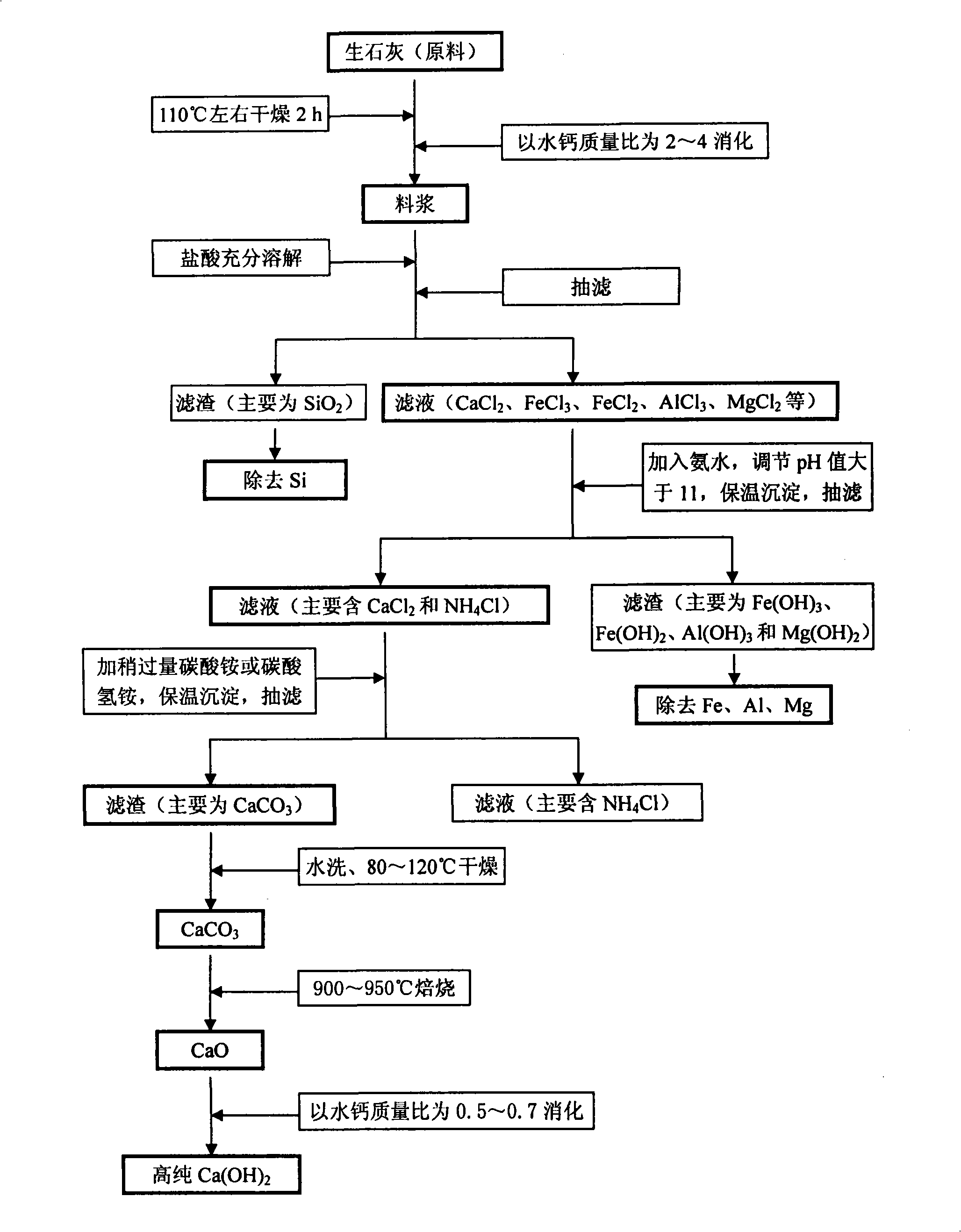

Method for preparing calcium hydroxide with high purity and high activity

InactiveCN101254935AHigh purityWide range of applicationsCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideImpurity ions

The invention relates to a preparation method of high purity and high activity calcium hydroxide from common quicklime, which includes: (1) digesting the quicklime; (2) dissolving into the hydrochloric acid; (3) separating the impurity ions; (4) precipitating Ca<2+>; (5) calcining at high temperature; and (6) digesting to obtain high purity and high activity calcium hydroxide. The method has the advantages that: (1) the method has wide application range, the raw material quicklime containing impurities such as Si, Fe, Mg and Al is applicable to the inventive preparation, and CaO and Ca(OH)2 have a high purity; (2) at the same time the method can conveniently and completely remove multiple impurities by adjusting the pH value of the solution to greater than 11 with the ammonia; and (3) the whiteness of the fabricated calcium carbonate is more than 100, and the activity of calcium oxide made by sintering is more than 400ml.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Method for leaching weathering crust eluvial type rare earth ore with aluminum inhibition

InactiveCN103526014AReduce aluminum ion contentThe leaching rate has no effect onProcess efficiency improvementSodium acetateAluminum Ion

The invention provides an impurity-inhibiting leaching method for inhibiting leaching of aluminum during weathering crust eluvial type rare earth ore leaching process. The method comprises that acetates are added in an ore leaching solution, the ore leaching solution is an ammonium sulfate solution or an ammonium chloride solution or a composite ammonium salt solution composed of the above solutions, the acetates are any one of ammonium acetate, sodium acetate and potassium acetate or any mixture thereof, and the addition amount of the acetates in the ore leaching solution is 0.005wt%-2wt%. In the method, the addition of the aluminum inhibitors can lower the aluminum ion content in the rare earth leaching solution by above 91% effectively, and has no influence on the leaching rate of rare earth, which are beneficial to subsequent processing of the rare earth mother solution. The addition of the aluminum inhibitors can inhibit expansion of clays well. The acetates are non-poisonous and the cost is low.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

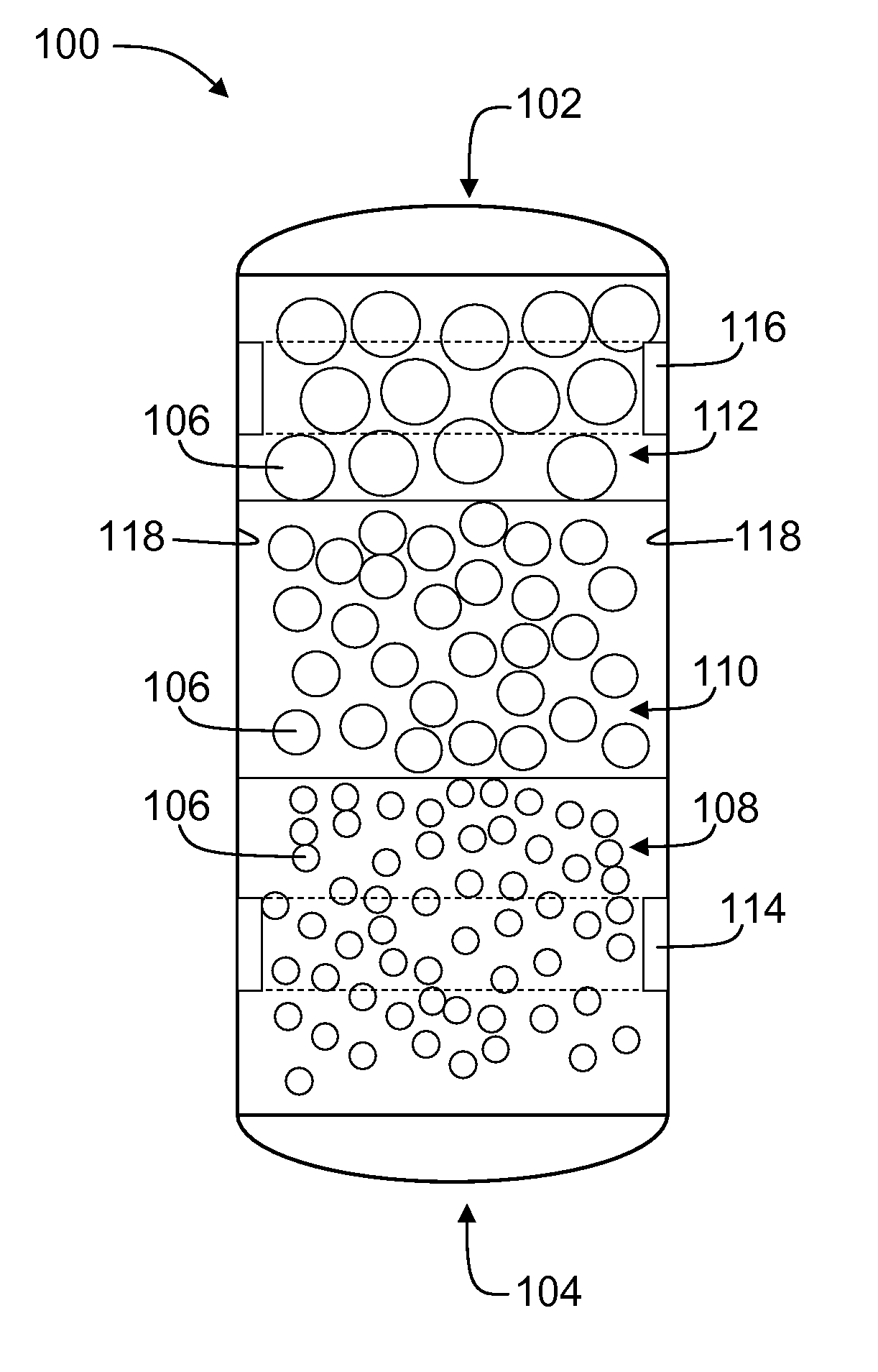

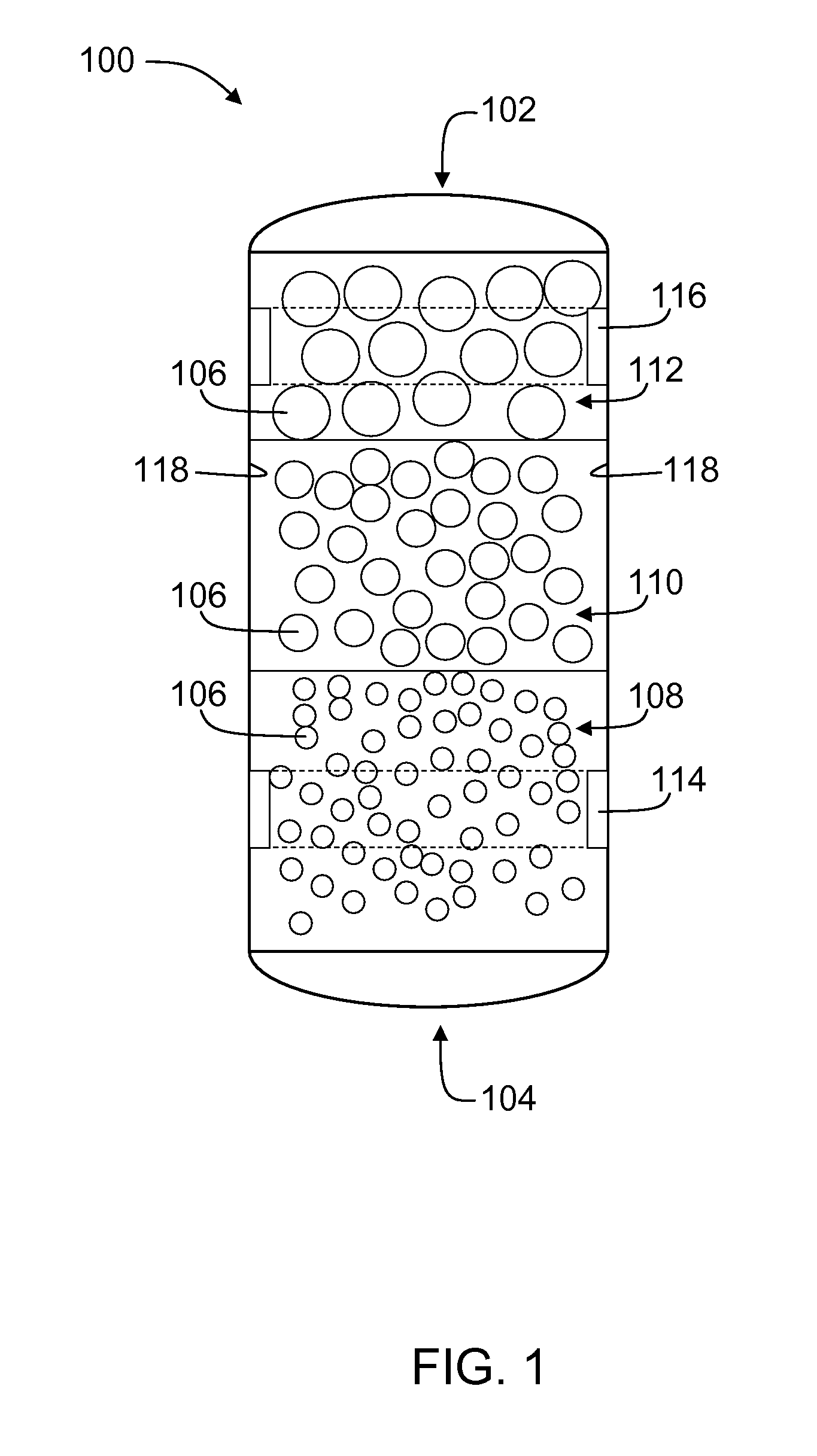

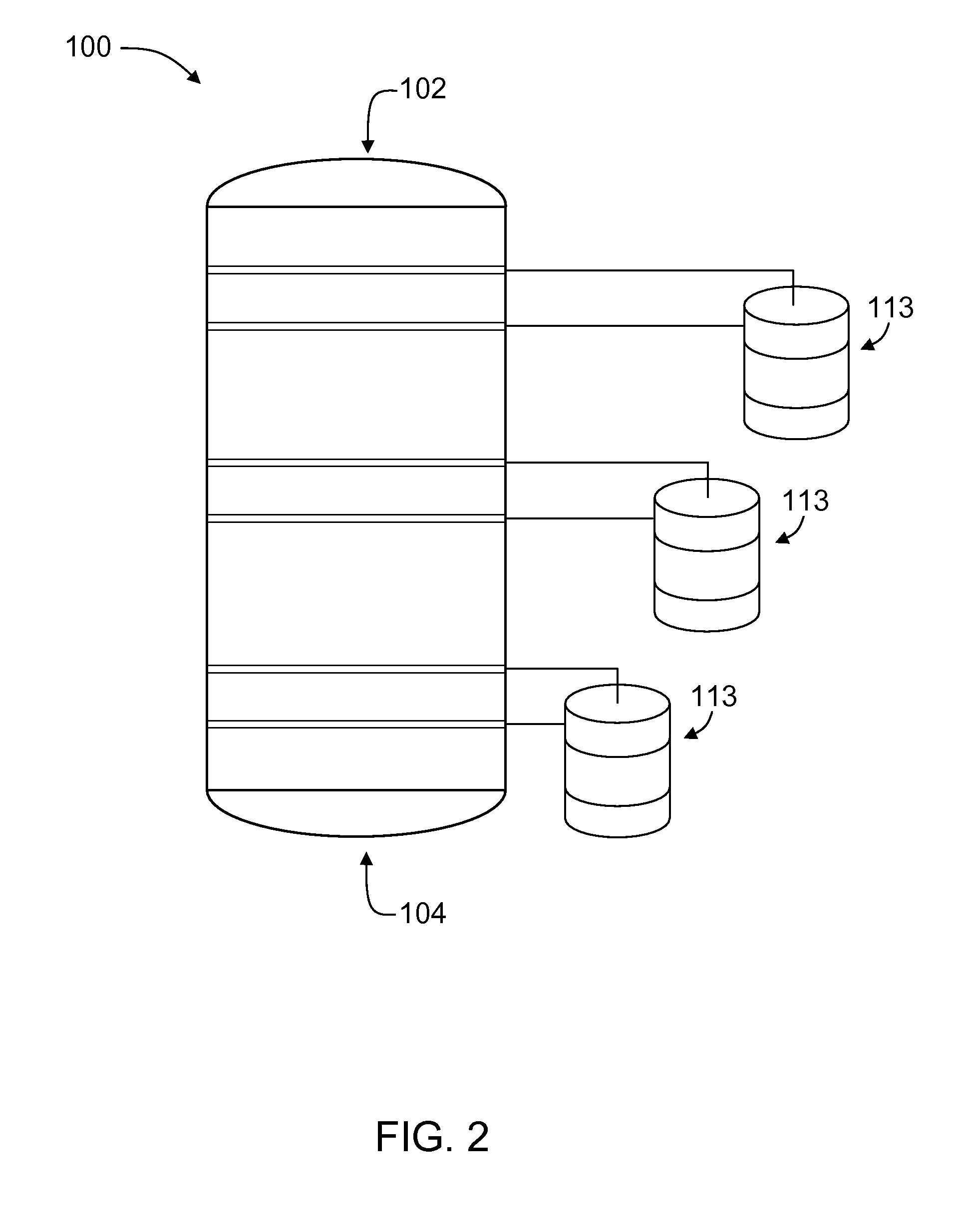

Methods and system for removing impurities from heavy fuel

InactiveUS20090308812A1Facilitate removing impurityEasy to remove impuritiesSolid sorbent liquid separationWater/sewage treatment by ion-exchangeSolventSorbent

A method of removing impurities from heavy fuel includes providing a first stationary adsorption column. The method further includes packing adsorbent particles that have a particle size distribution wherein at least about 50% of the particles have a diameter greater than about 18 microns in the first column. The method further includes diluting heavy fuel with a solvent to form a solvent-fuel mixture, and supplying the solvent-fuel mixture through the first column to facilitate removing impurities from the mixture.

Owner:GENERAL ELECTRIC CO

Processing and production method of selenium-rich rice

ActiveCN106881163AEfficient separationReduce processing costsGas current separationMagnetic separationProcessing costProduct processing

The invention relates to the technical field of agricultural product processing, in particular to a processing and production method of selenium-rich rice. The method mainly comprises the steps of (1) pretreatment of unhusked rice, (2) cleaning up and impurity removal of selenium-rich unhusked rice, (3) magnetic separation and rice hulling, and (4) polishing, color sorting and packaging. Through the technological process, the selenium-rich rice processing technique is simpler, the selenium-rich rice processing quality is improved, the processing cost is reduced, accordingly, the defects that the selenium-rich rice processing procedure is complex, the processing quality is poor, and the cost of rice processing enterprises is severely improved in the prior art are overcome, and the processing and production method of the selenium-rich rice has great practical value and popularization prospects.

Owner:灵武市桂林米业有限公司

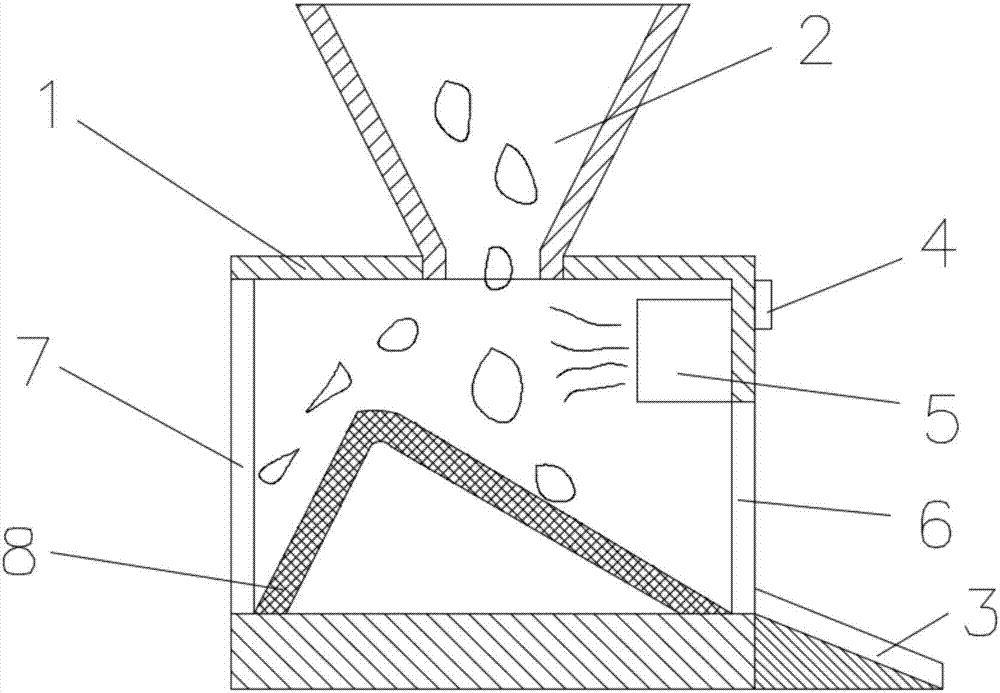

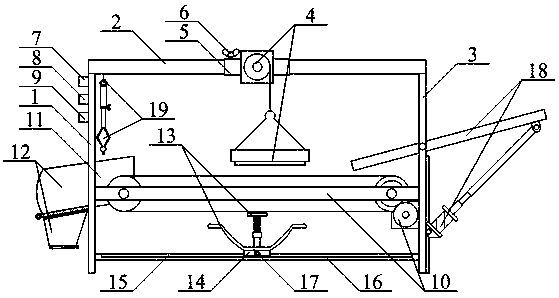

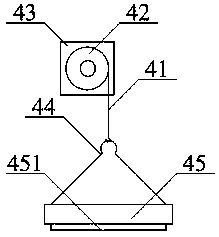

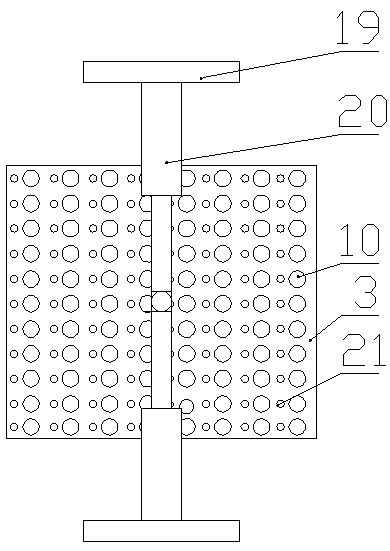

Liquid impurity separation device

ActiveCN106110735AEasy to remove impuritiesImprove efficiencyMoving filtering element filtersEngineeringImpurity

The invention discloses a liquid impurity separation device which comprises a liquid incoming trench, a transmission wheel and a filter cloth cleaning mechanism. An input pipe for delivering liquid waiting for impurity removal to the liquid incoming trench is arranged above the liquid incoming trench, an opening is formed at the bottom of the liquid incoming trench, and annular filter cloth covers the bottom of the liquid incoming trench; the transmission wheel is supported in the annular filter cloth and used for driving the same to rotate to enable the same to move along the bottom of the liquid incoming trench constantly, and the filter cloth cleaning mechanism is used for cleaning impurities of a portion, not corresponding to the bottom of the liquid incoming trench, of the filter cloth in the process when the filter cloth rotates. The filter cloth constantly rotates under action of the transmission wheel to enable a portion, corresponding to the liquid incoming trench, of the filter cloth to perform filtering while a portion, away from the liquid incoming trench, of the filter cloth to perform cleaning under action of the filter cloth cleaning mechanism, so that filtering and cleaning are realized at the same time, the filter cloth can be cleaned without stopping, continuous liquid impurity removal is facilitated, and efficiency is improved.

Owner:尚川(北京)水务有限公司

Micron-level fine particle diamond synthesis process

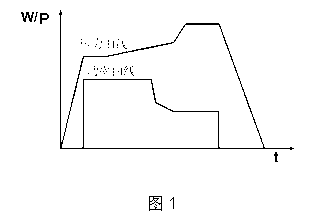

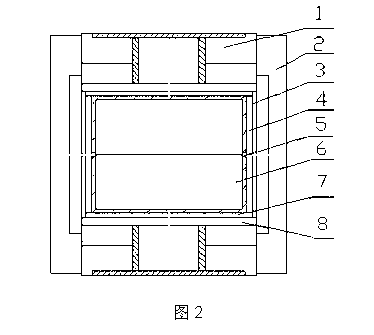

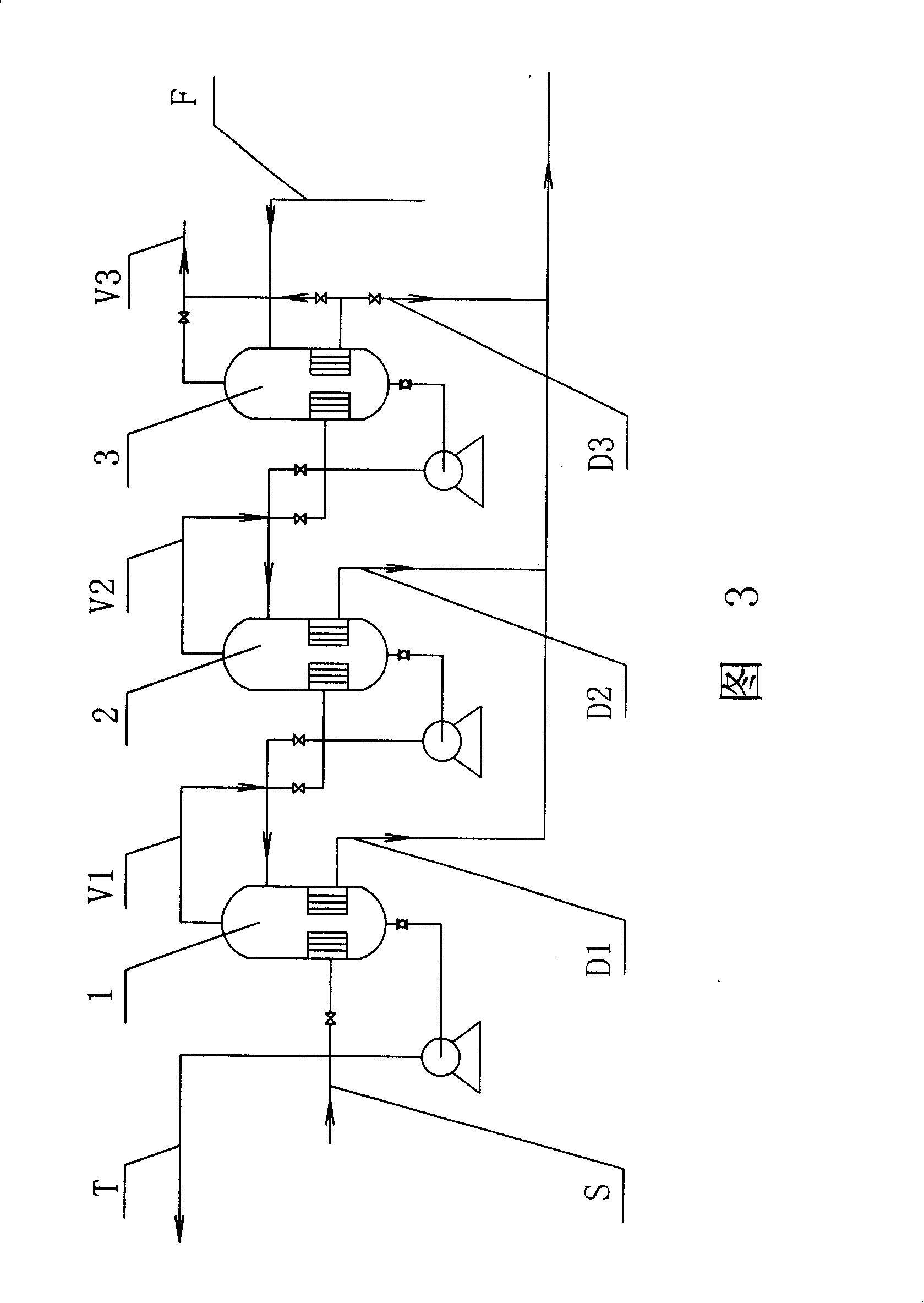

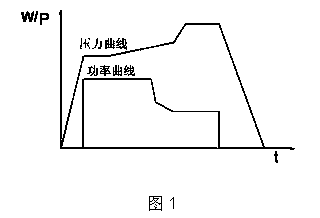

ActiveCN102935346AEasy to remove impuritiesLarge amount of nucleationUltra-high pressure processesPressure curveSingle crystal

The invention provides a micro-level fine particle diamond synthesis process. The micro-level fine particle diamond synthesis process comprises the steps of mixing graphite powder and Fe-based alloy catalyst powder according to the weight ratio of 8:(5-7), then carrying out isostatic pressing and vacuum process and then carrying out compression molding on the mixture in a four-column press machine, putting a core column into a diamond synthesis block, and putting the diamond synthesis block into a cubic press to carry out synthesis, wherein the practical synthesis pressure is 6.1-6.6GPa, the synthesis temperature is 1000-1100 DEG C, and the practical synthesis pressure and the synthesis temperature are finished respectively by utilizing a control pressure curve and a power curve. According to the micro-level fine particle diamond synthesis process disclosed by the invention, the synthesized micron-level fine particle diamonds have the characteristics of large nucleation amount, short growth time and the like, products conform to an artificial diamond national standard and have consistent crystal forms, smooth crystal surfaces, a few of impurities and high hot punching values, the particle granularity of 270 / 325 and 325 / 400 is a peak value, a single crystal ratio reaches to 70-80%, and the micro-level fine particle diamond synthesis process can effectively meet the field of high-grade grinding tools and the like with high requirements on particle granularity.

Owner:山东昌润钻石股份有限公司

Special starch syrup for QQ sugar and preparation method thereof

InactiveCN103710410AHigh in polysaccharidesSpecial physiological functionFermentationLiquid glucoseFlocculation

The invention discloses a preparation method of special starch syrup for QQ sugar, which comprises the following steps: (1) pulping, and liquefying; (2) performing high-temperature filtration; (3) performing low-temperature filtration; (4) saccharifying; (5) decoloring; (6) performing ion exchange desalination; and (7) concentrating. The special starch syrup for QQ sugar, prepared according to the method, comprises the following sugar components: 0.8-1.2% of glucose, 44-48% of maltobiose, 17-19% of maltotriose and 38-42% of maltotetrose. The invention has the following advantages: (1) fine control is performed on the liquefied liquid glucose components through a special injection and liquefying process, thus obtaining low liquefaction liquid having high DE value; (2) high-temperature deslagging filtration and low-temperature protein flocculation are performed, thereby being more beneficial to impurity removal; (3) a mixed enzyme preparation is added in the saccharifying process, thus regulating and controlling the content of the sugar contents more effectively; and (4) the finished product is high in polysaccharide content, and the content of the sugar components presents a discontinuous ascending ratio, thus having a special physiological function.

Owner:河南飞天生物科技股份有限公司

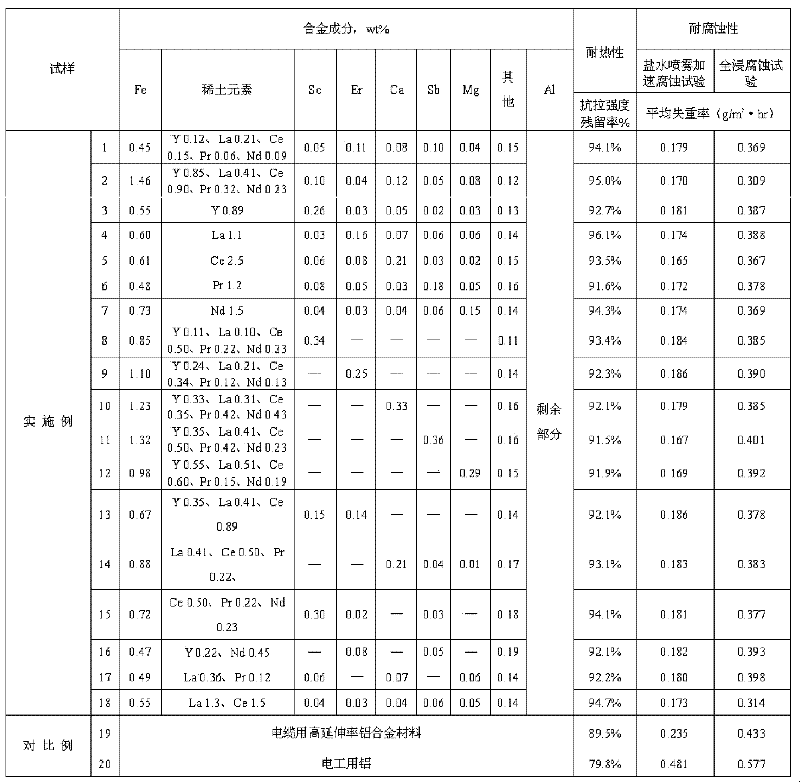

Rare earth high iron aluminum alloy conductor material

ActiveCN102262913AImprove performanceEasy to stretchMetal/alloy conductorsRare-earth elementElectrical conductor

The invention discloses a rare earth high-iron aluminum alloy conductor material, which comprises 0.4 to 1.5 weight percent of Fe, 0.3 to 1.3 weight percent of rare-earth element, 0.01 to 0.4 weight percent of one or several of Sc, Er, Ca, Sb and Mg and the balance of aluminum and inevitable impurities. The aluminum alloy material has various performance indexes of a high-elongation aluminum alloy material for a cable and has excellent heat resistance and corrosion resistance; therefore, the material has higher current carrying capacity.

Owner:于贵良 +1

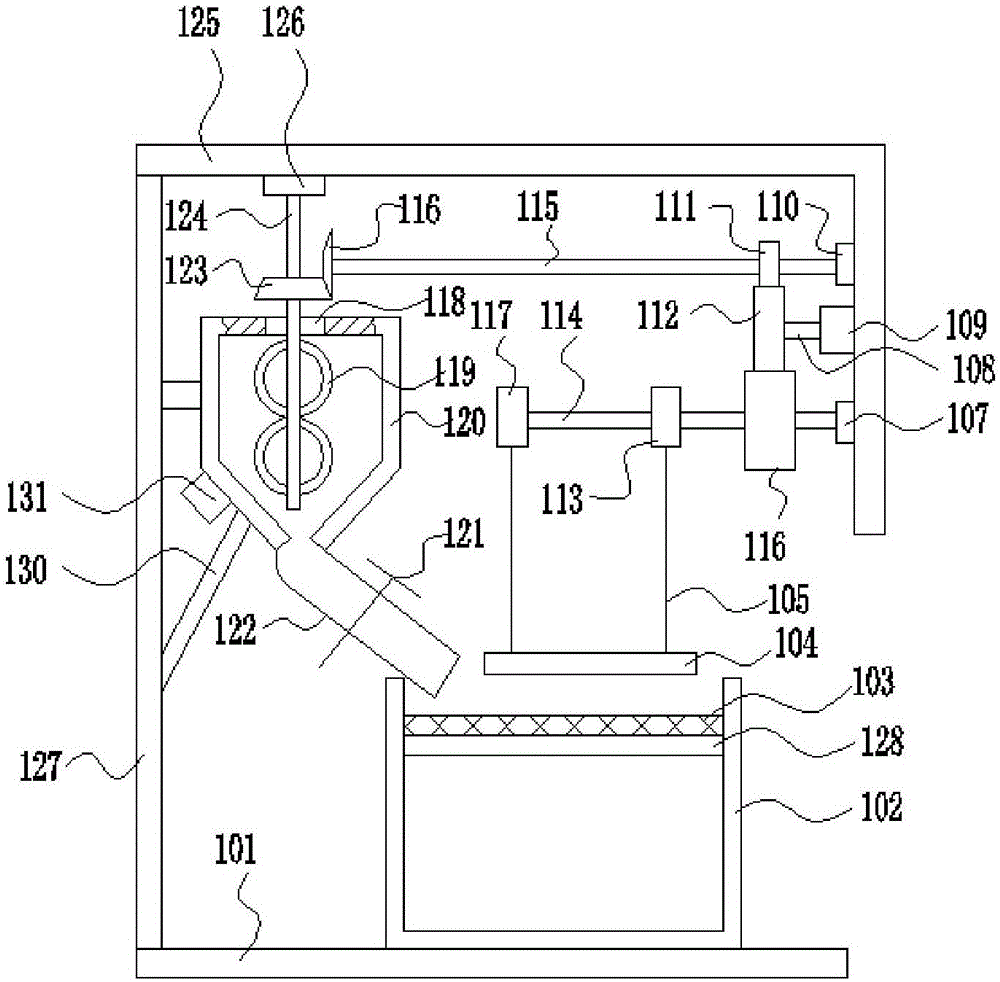

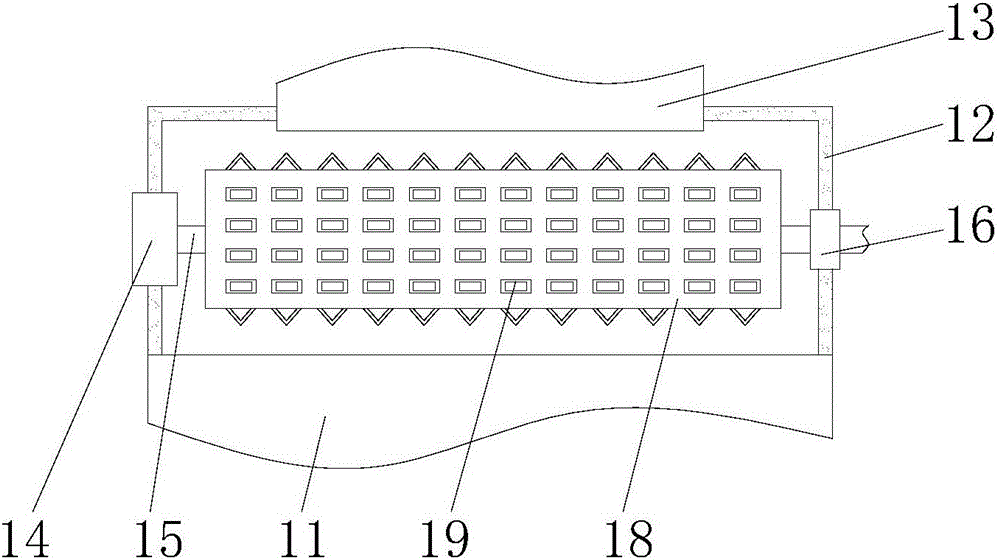

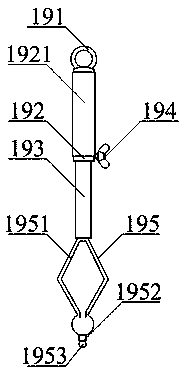

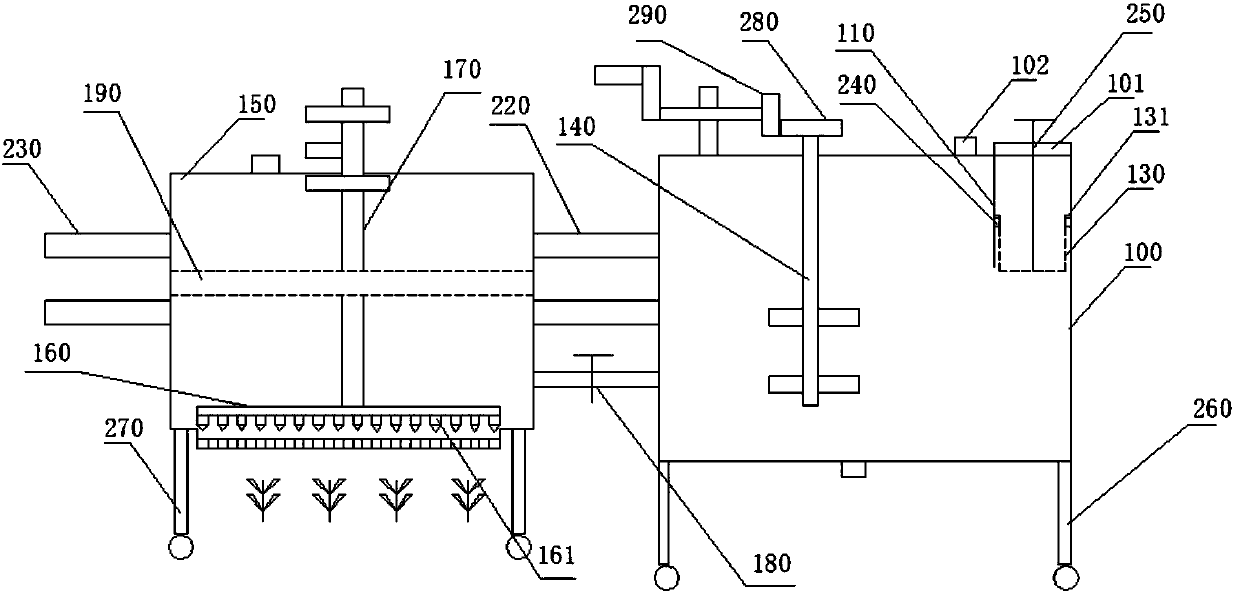

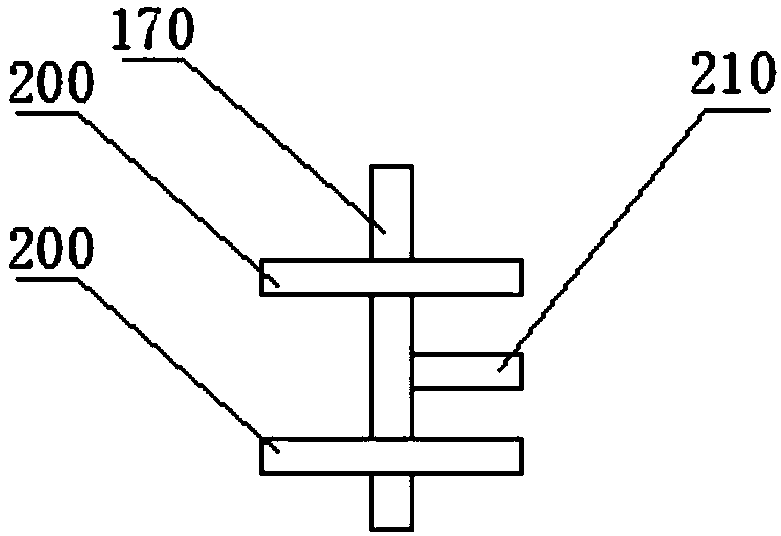

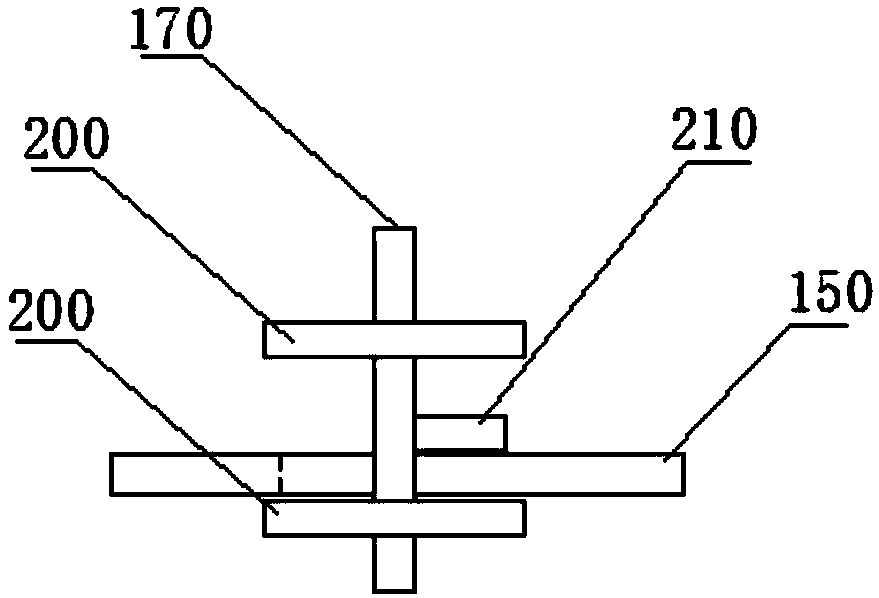

Preparation device of fructus hippophae juice

The present invention discloses a preparation device of a fructus hippophae juice. The preparation method comprises a squeezing device, a horizontal screw centrifuging device, a concentrating device and a filling device. A material outlet of the squeezing machine is connected with a material inlet of the horizontal screw centrifuging machine; a material inlet of the concentrating device is located at the lower part of a liquid collecting box of the horizontal screw centrifuging machine and a material inlet of the filling device is connected to a material outlet of the concentrating device; and the horizontal screw device comprises a horizontal screw main body, a rotary drum and a screw inside, a material feeding tube with a material inlet, a speed reduction motor, a liquid collection tank, and a residue discharge port and a pressure sensor arranged on the residue discharge port used for controlling the outflow of the residues. The device can effectively remove pectin and fibers in the fructus hippophae juice and realizes the automatic production of the fructus hippophae juice.

Owner:新疆慧华沙棘生物科技有限公司

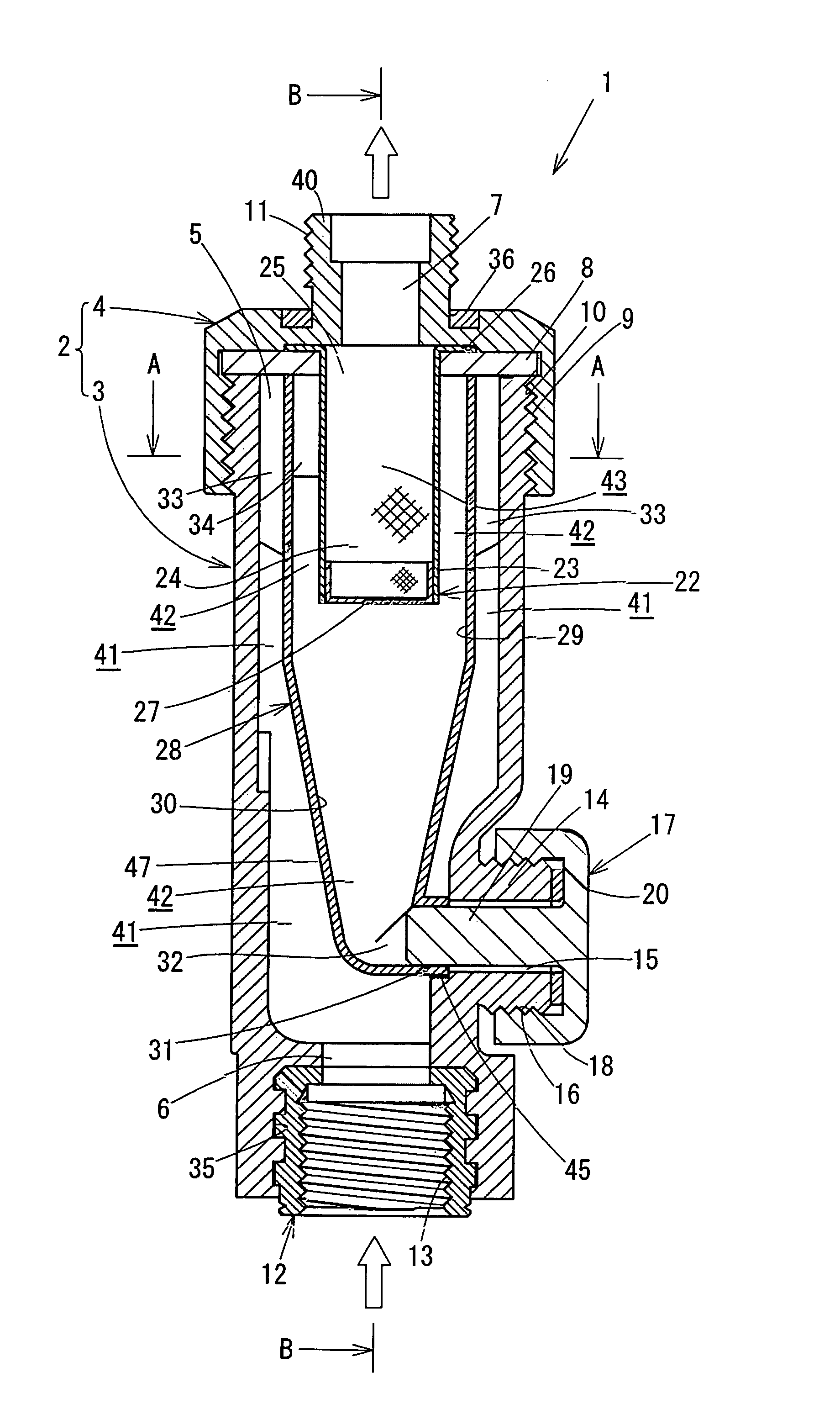

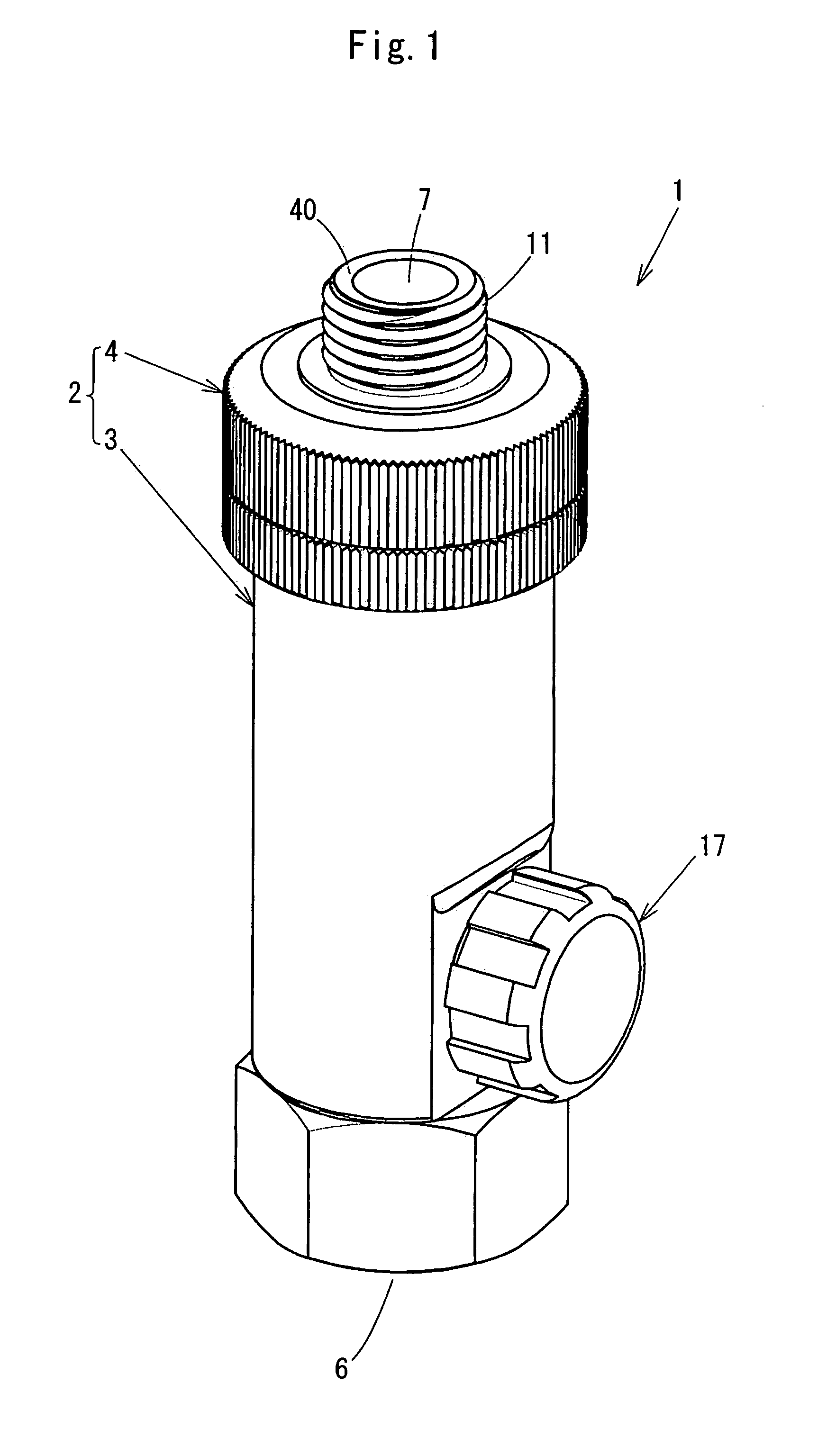

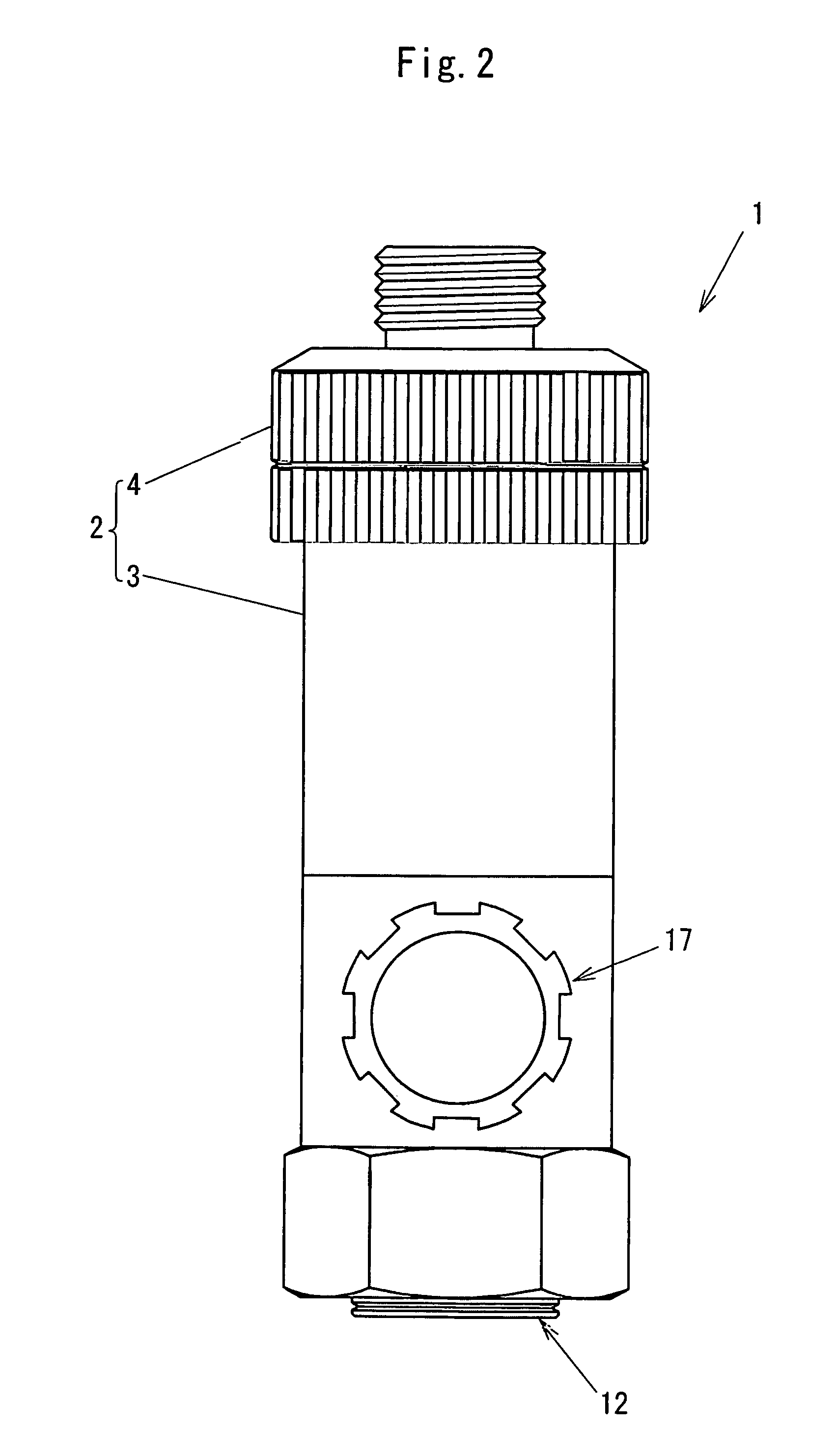

In-line strainer

ActiveUS8828228B2Less frequent cleaningEasy to remove impuritiesCentrifugal force sediment separationFlat flow vortexEngineeringMechanical engineering

An in-line strainer 1 includes: a cylindrical-shaped housing 2 having an inflow port 6 for liquid and an outflow port 7 which are coaxial with each other; and a strainer element 22 disposed in the housing 2. A cyclone cylindrical body 28 having a diametrically-reduced cylinder portion 30 whose inner diameter is reduced toward one end, and having a cyclone inflow port formed on the other end, is arranged inside the housing 2 such that the diametrically-reduced cylinder portion 30 is close to the inflow port 6, and that the cyclone inflow port is close to the outflow port 7. A cylindrical-shaped strainer element 22 having a closed first end and an open second end is in the cyclone cylindrical body 28, and an open second end 25 of the strainer element 22 is connected to the outflow port 7 of the housing 2.

Owner:YAMAHO IND

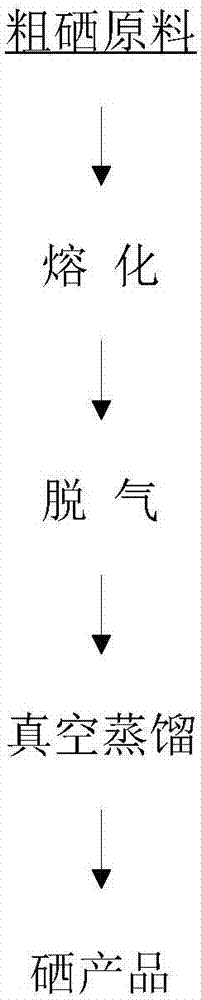

Vacuum refining and purifying method for coarse selenium material

ActiveCN106946233AImprove heat transfer efficiencyMelt increaseBinary selenium/tellurium compoundsElemental selenium/telluriumSelenium productVacuum distillation

The invention relates to a vacuum refining and purifying method for a coarse selenium material and belongs to the field of metallurgy technological engineering. The method is characterized in that a fine selenium product is obtained from the coarse selenium material through procedures of smelting, degassing and vacuum distillation. The method specifically comprises the following steps: S1, adding the coarse selenium material into a closed container to be smelted at 230-350 DEG C; after the material is fully smelted, raising the temperature to 250-400 DEG C to degas, vacuumizing the closed container during degassing, and stirring the selenium melt at the same time to obtain a coarse selenium melt, the density of which is greater than 4g / cm<3>; and S2, putting the coarse selenium melt obtained in the S1 into a vacuum furnace, and distilling the coarse selenium melt for 3-4 hours to output a fine selenium product, wherein the vacuum degree is 1-20Pa and the temperature is 500-1000 DEG C. The method provided by the invention is short in process flow, and 99.9% of fine selenium can be output from the coarse selenium material through procedures of smelting, degassing and vacuum distillation.

Owner:KUNMING DIBOO TECH

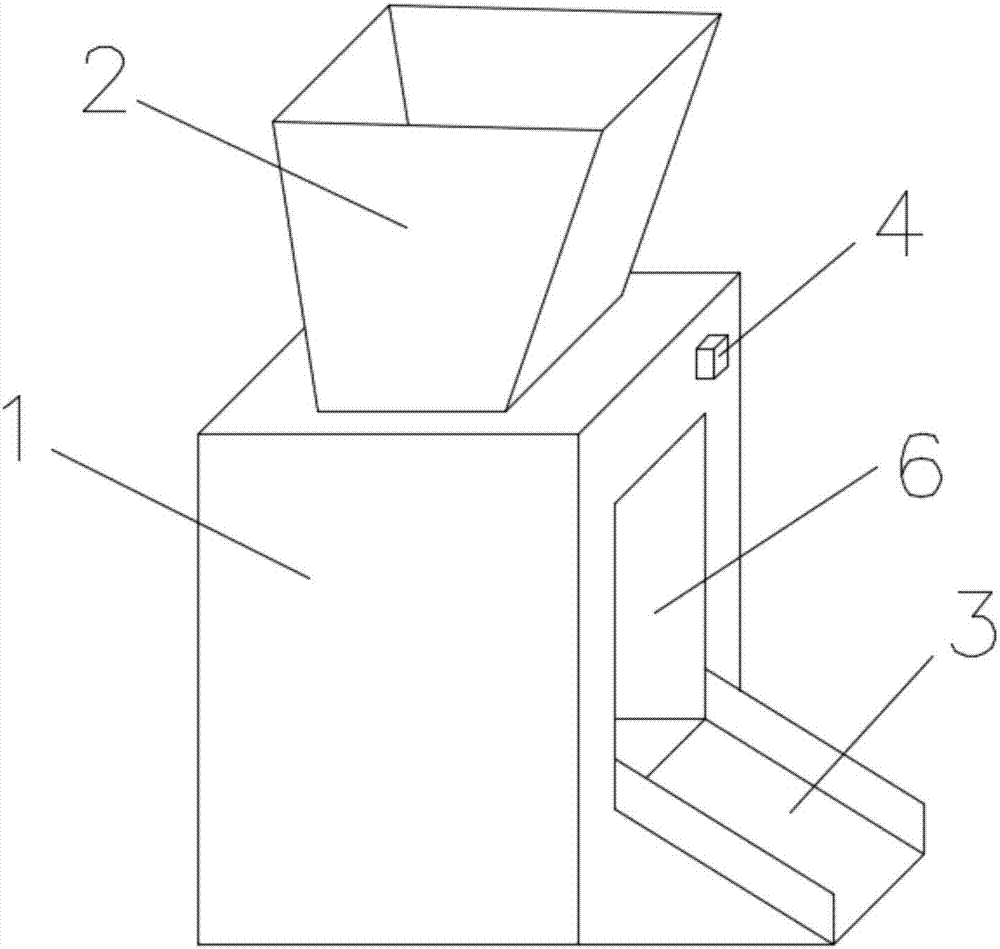

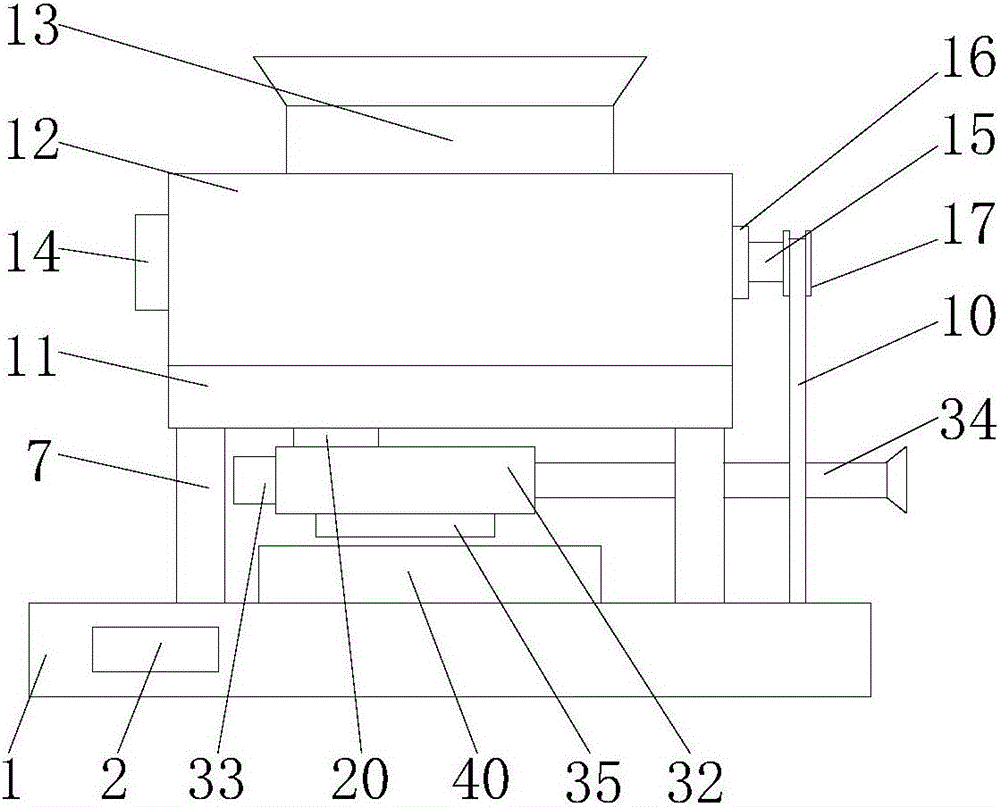

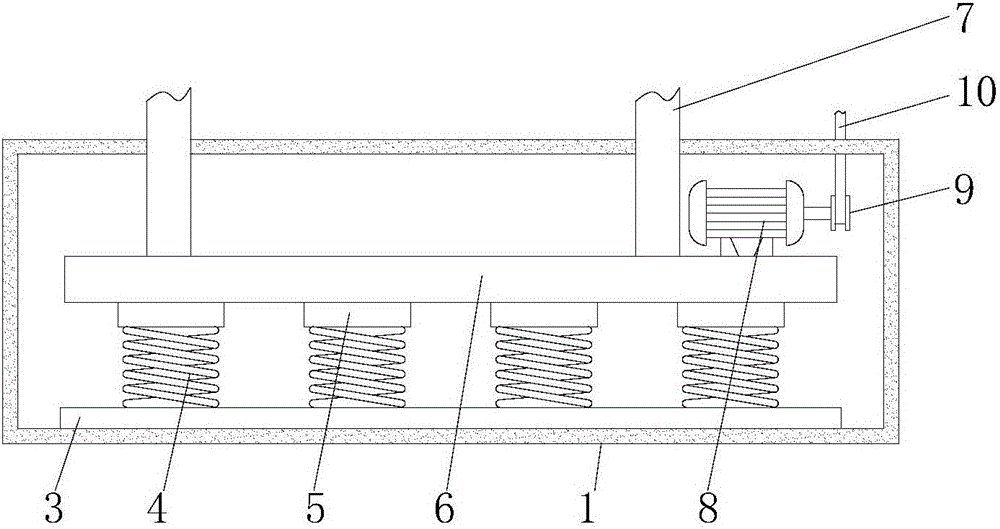

Grain thresher with impurity removing function

The invention discloses a grain thresher with the impurity removing function. The grain thresher comprises a base, a controller is fixedly installed on the front surface of the base, a bottom plate is fixedly installed at the bottom of the inner wall of the base, damping springs are fixedly installed at the top of the bottom plate, cushion blocks are fixedly installed at the tops of the damping springs, a baffle is fixedly installed at the tops of the cushion blocks, two supporting rods and a first motor are sequentially installed at the top of the baffle from left to right, and a belt pulley is fixedly installed on an output shaft of the first motor and provided with a belt. According to the grain thresher with the impurity removing function, as a vibrator, a screen and an impurity box are arranged, grain is fully separated before entering a separating box, impurities in the grain can be effectively removed and prevented from affecting product quality, the grain purity is effectively improved, and production income is increased.

Owner:XINING YIGE INTPROP CONSULTING SERVICE

New method for producing low polyxylose by utilizing microorganism

InactiveCN101914589ALess equipmentReduce production linksFungiMicroorganism based processesChemistryDecomposition

The invention relates to a new method for producing low polyxylose by utilizing microorganism, which takes corncob as a raw material. The method comprises the following steps: smashing corncob, adding water, and carrying out acidification and high-temperature splitting decomposition to obtain mixed liquor of the raw material; directly inoculating fermented culture of aspergillus niger U8-7, carrying out microbial induction enzyme production zymolysing, and then separating, purifying, decoloring, desalinating, filtering, concentrating and spray drying to obtain the low polyxylose. The method of the invention leaves out the production link for producing low polyxylose, reduces production cost, and obviously increases the output capacity of low polyxylose.

Owner:HENAN ACAD OF SCI INST OF BIOLOGY LIABILITY

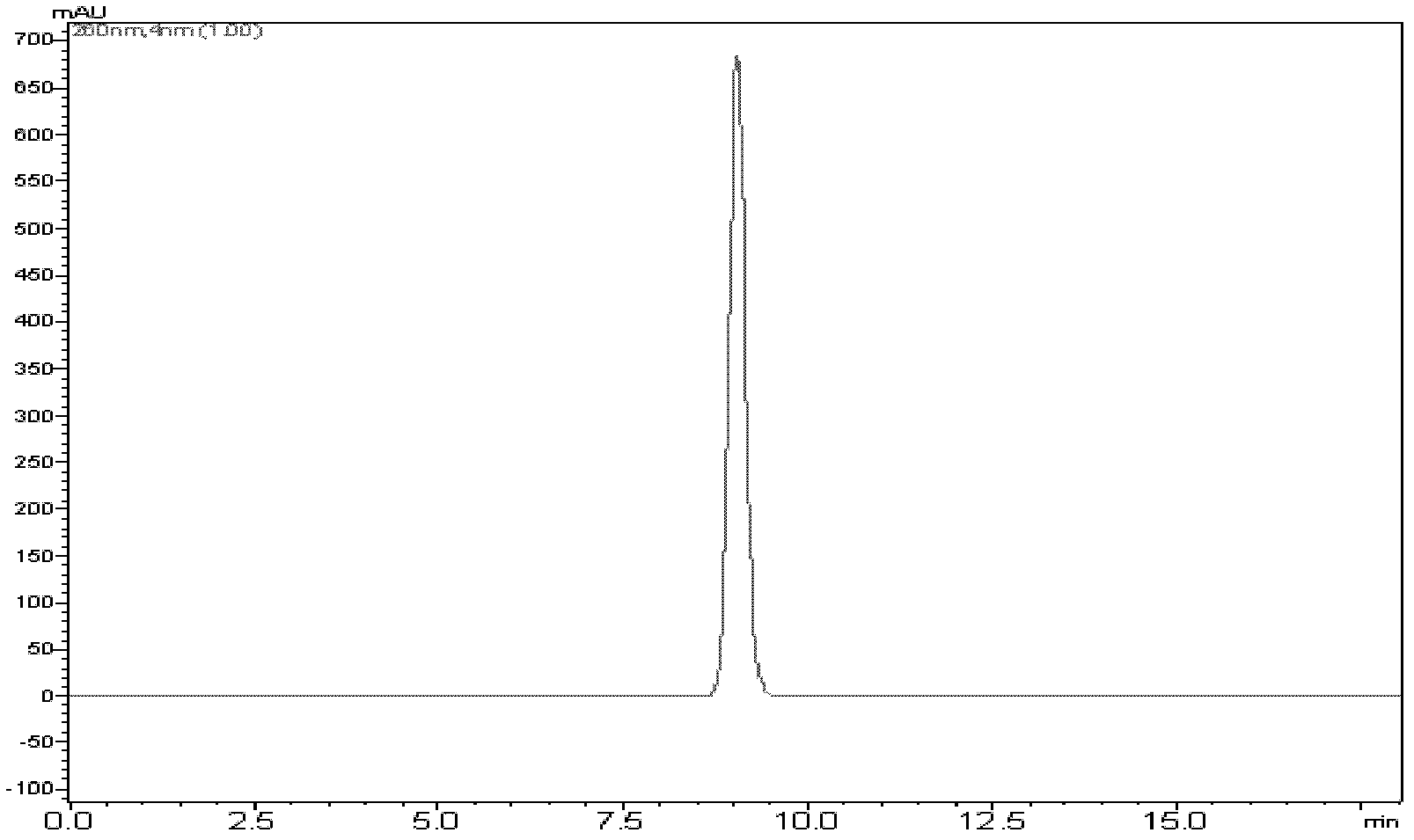

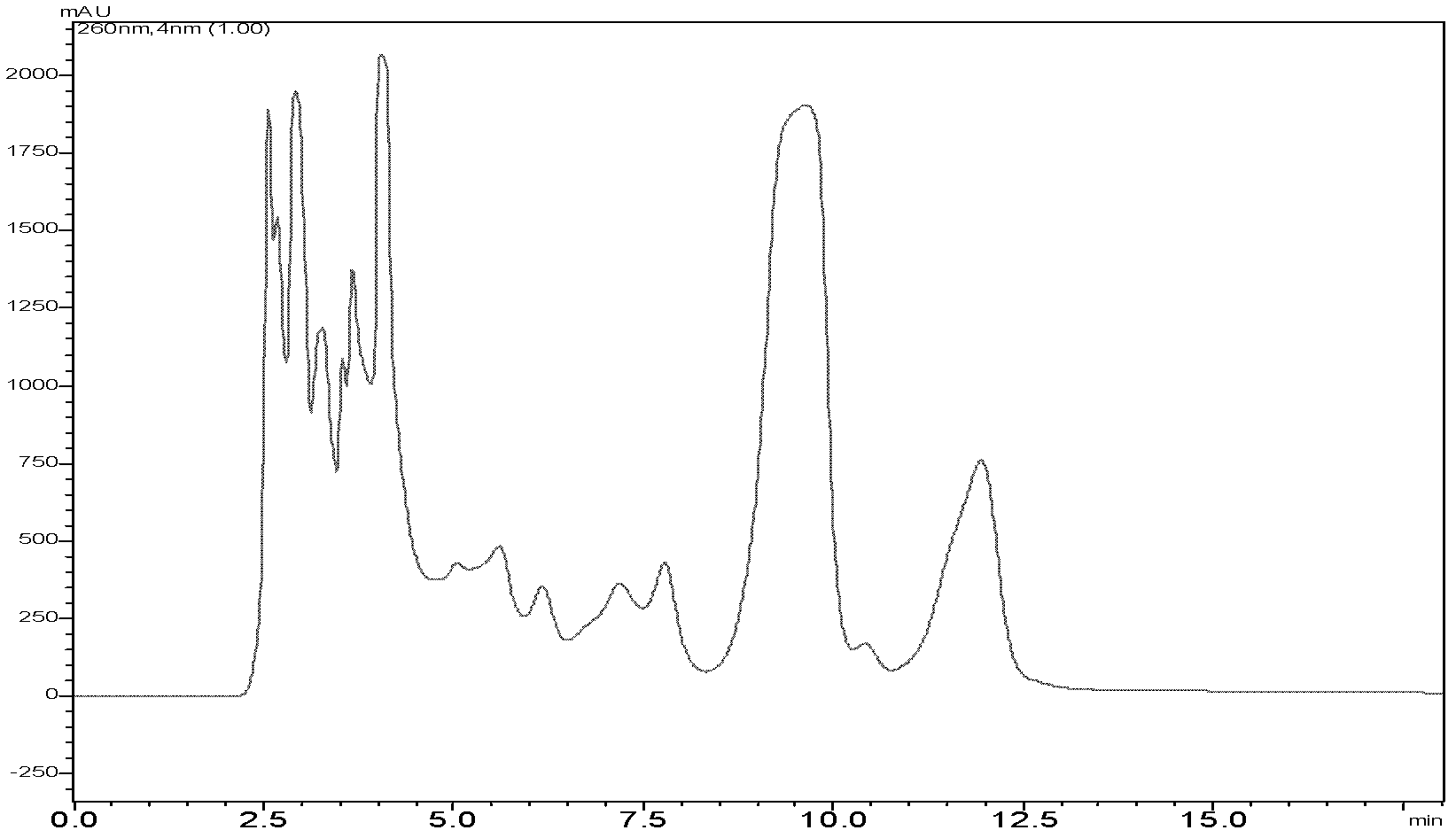

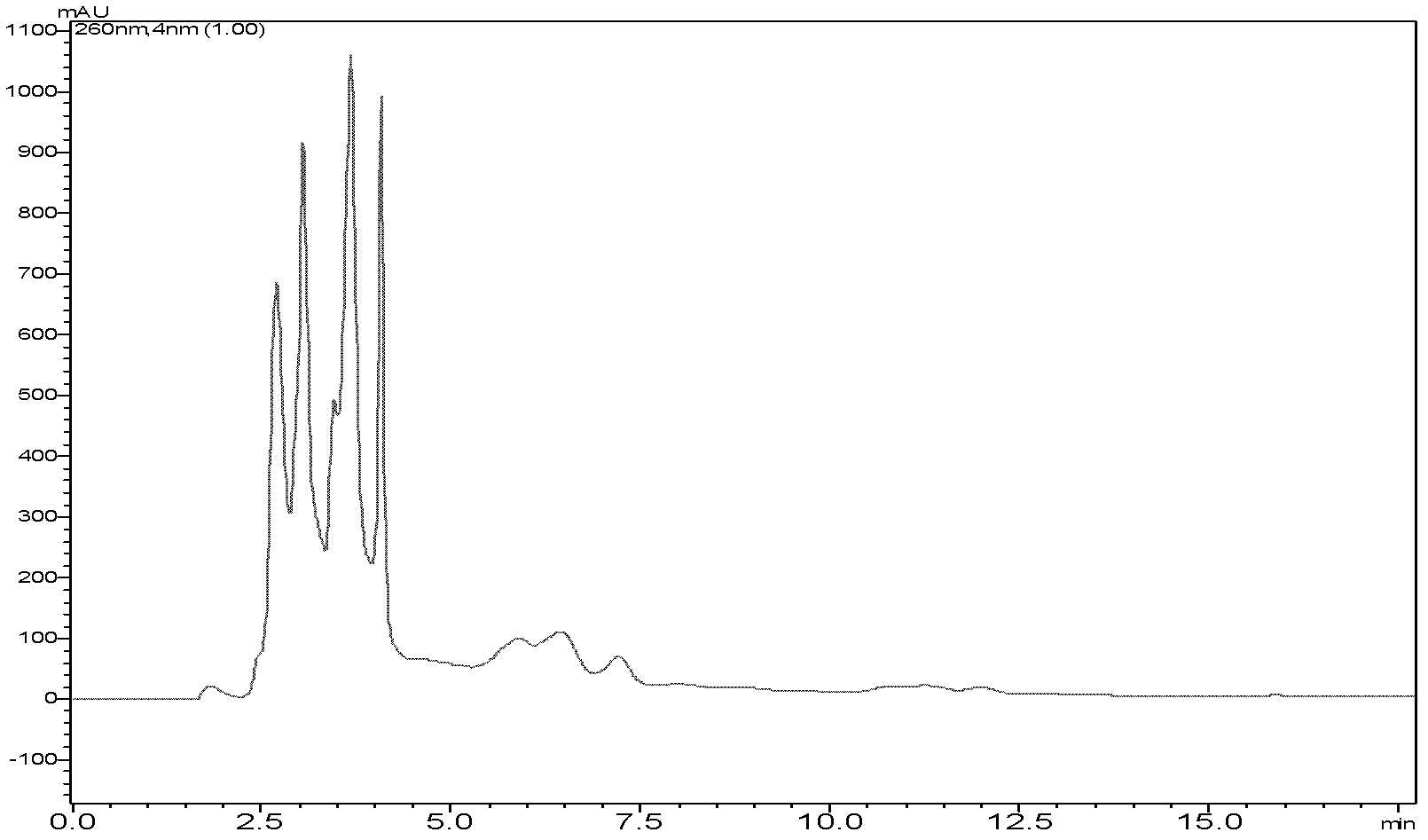

Method for separating and purifying cordycepin by utilizing high-speed counter-current chromatography

ActiveCN102321135AEasy to separateHigh puritySugar derivativesSugar derivatives preparationChromatographic separationColumn chromatography

The invention discloses a method for separating and purifying cordycepin by utilizing a high-speed counter-current chromatography. The method is characterized by comprising the following steps: 1, preparing a cordycepin sample solution; and 2, preparing a two-phase solvent system which can be used for the high-speed counter-current chromatography and has a two-phase distribution coefficient K value ranging from 0.5 to 1.0 according to the physicochemical property of the cordycepin, then carrying out high-speed counter-current chromatography separation and purification on the cordycepin sample solution obtained in the step 1 by using the two-phase solvent system, and collecting a flowing-out mobile phase solution or immobile phase solution, so as to obtain a cordycepin solution pure product. In the invention, the two-phase solvent system having the two-phase distribution coefficient K value ranging from 0.5 to1.0 has excellent good separation effect on the cordycepin, and the peak separation effect in the high-speed counter-current chromatography is extremely good, thus the purity of the cordycepin pure product obtained by separation is extremely high and can reach above 98%.

Owner:ZHONGSHAN LEAGUE PRODS

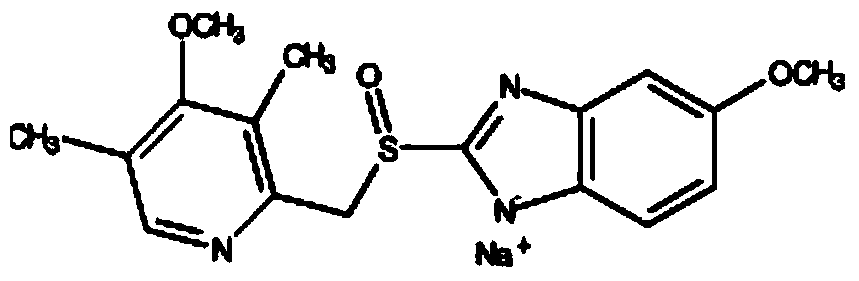

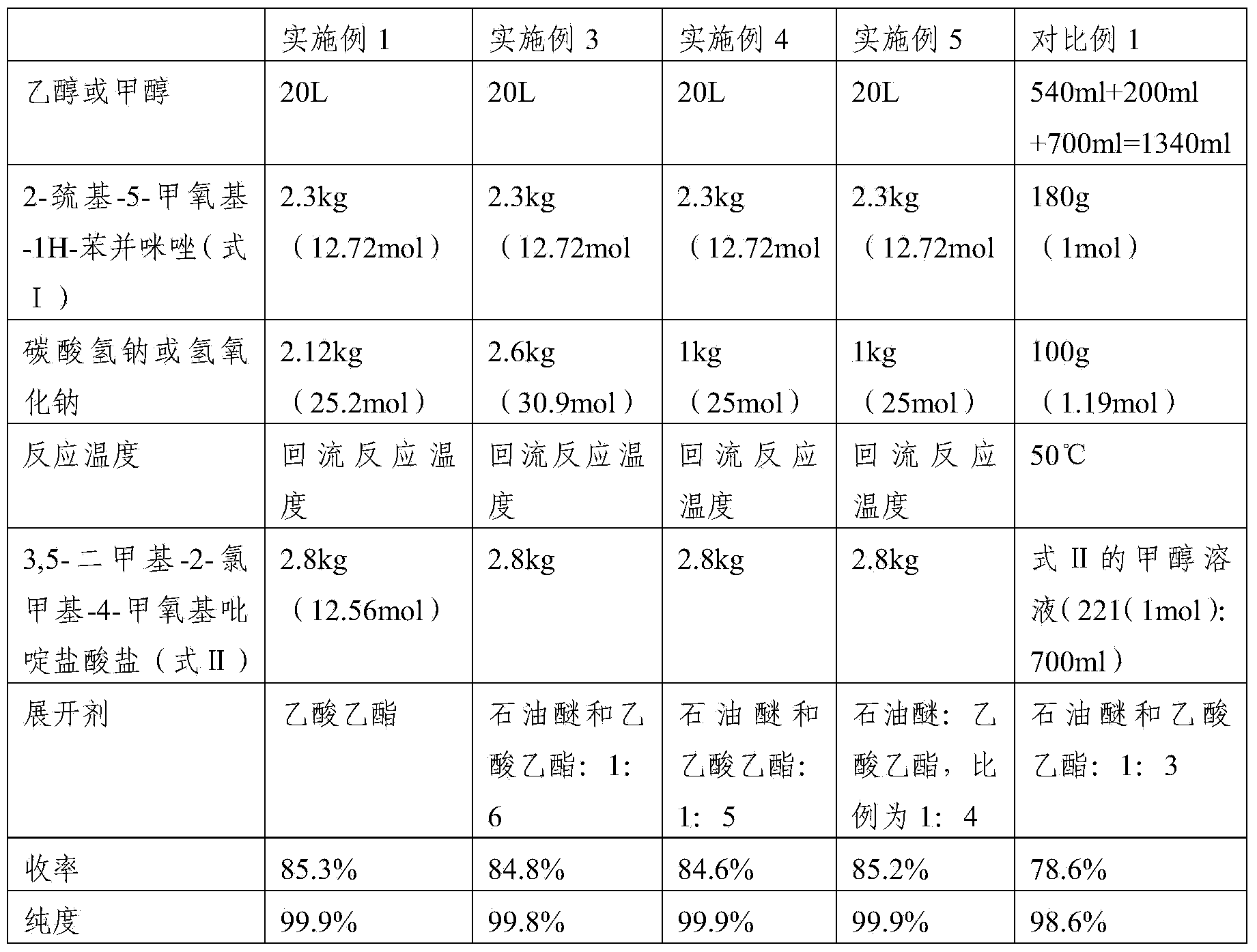

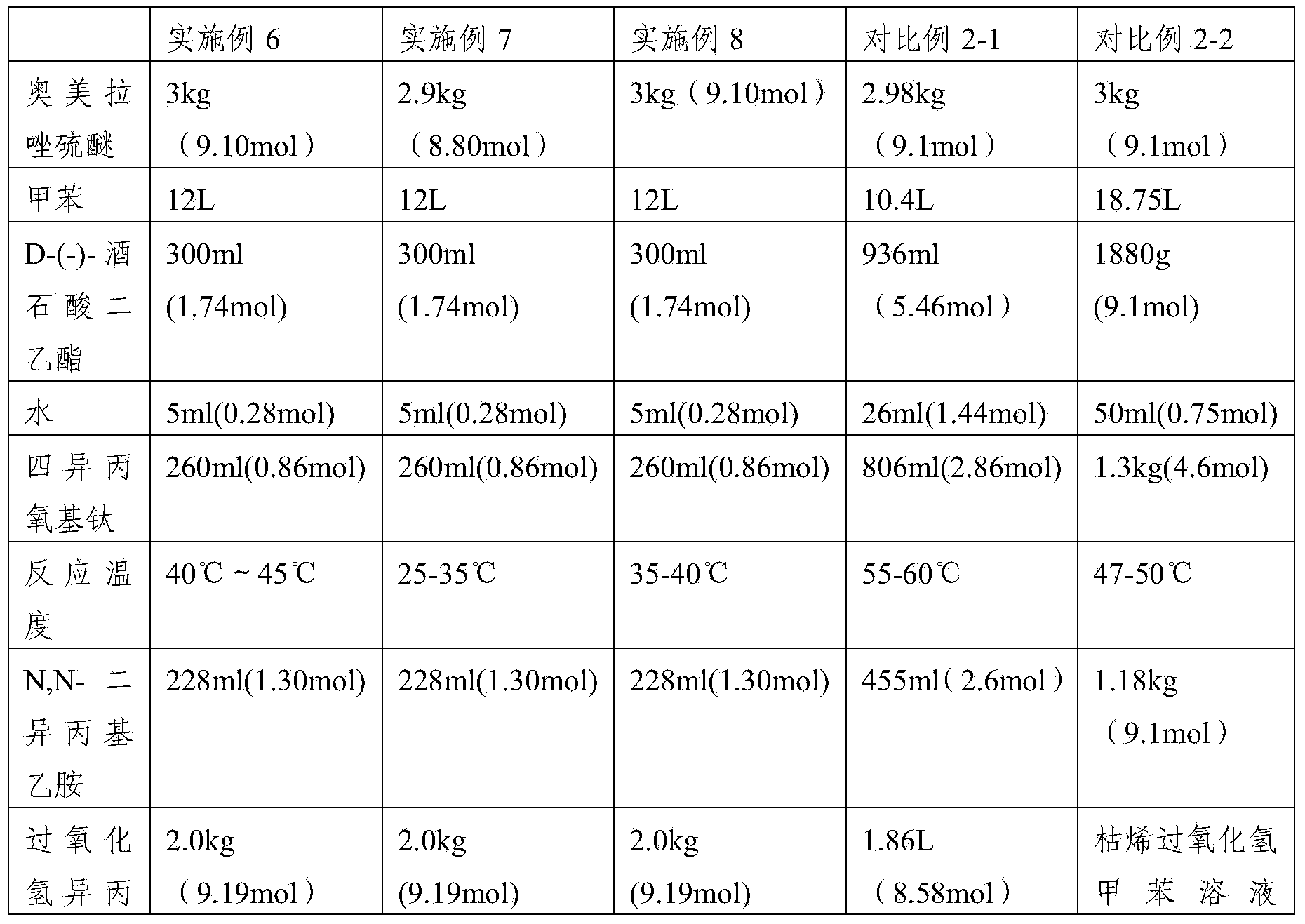

Refining method and synthesis method of esomeprazole

ActiveCN103936715AEffective dissolutionImprove solubilityOrganic chemistryEsomeprazole SodiumOrganic solvent

The invention relates to a refining method and a synthesis method of esomeprazole. The refining method comprises the following steps: firstly, suspending a crude esomeprazole product in 2-5 times of good organic solvents, stirring at low temperature, filtering to remove the impurities, slowly adding 10-20 times of adverse organic solvents, stirring to crystallize over night, and centrifuging to dry, thereby obtaining a refined esomeprazole product. The refining method of the esomeprazole is stable and controllable in process, simple and convenient to operate and easy to industrialize; the prepared esomeprazole is hihg in purity, high in yield, high in optical purity and stable in component, and happening of adverse reaction accidents is greatly avoided.

Owner:HEILONGJIANG ZBD PHARMA +1

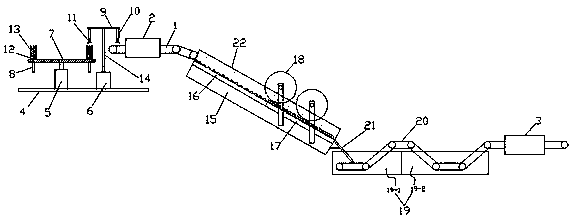

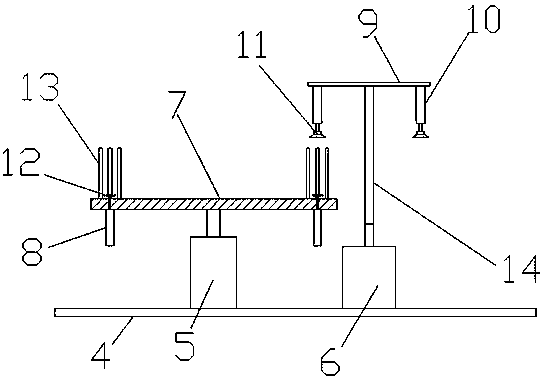

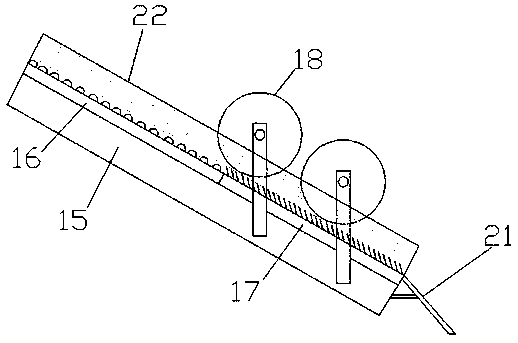

Multi-function mineral resource comprehensive utilization equipment

ActiveCN108554628AHeight adjustableMagnetic selection works smoothlyWithdrawing sample devicesCleaningMineral SourcesEngineering

The invention discloses multi-function mineral resource comprehensive utilization equipment. The multi-function mineral resource comprehensive utilization equipment comprises a first stage bracket, ahorizontal column, a second stage bracket, a strong magnetic separation iron elevator, a sliding tube, an adjusting bolt, a first stage switch, a second stage switch, a third stage switch, an ore-transmitting conveyor, an ore-transmitting hopper, a impunity-removing filter hopper structure, a scraper structure, a sliding block, a sliding groove, a bottom block, a fastening bolt, a ore hauling conveyor and a sampling rod structure. The first stage bracket is longitudinally installed on the lower left portion of the horizontal column in a bolted mode. The second stage bracket is longitudinally installed on the lower right portion of the horizontal column in a bolted mode. The arrangement of a connecting rope with a hook, a winding wheel, a winding motor, a cable and a strong magnetic separation iron plate is conducive to adjusting the height of the strong magnetic separation iron plate according to the magnetic separation demand, so as to facilitate the smooth magnetic separation work; the strong magnetic separation iron plate is made of a round stainless steel plate; and a strong magnetic sheet adopts circular permanent magnet sheet and is conducive to the rapid absorption of iron impurities in the mineral resources, so as to guarantee the purity of the mineral resources.

Owner:滦平县聚源矿业有限责任公司

Method for preparing ribostamycin rough products by using membrane separation technology

InactiveCN102532213AEasy to remove impuritiesEasy to separateSugar derivativesSugar derivatives preparationSeparation technologyMicrofiltration membrane

The invention provides a method for preparing ribostamycin rough products by using membrane separation technology. The method comprises the steps of micro filter membrane edulcoration of feed liquid, ultrafiltration decoloration and nanofiltration desalination, enrichment, concentration and drying in a preparation process of the ribostamycin rough products. The feed liquid containing ribostamycin is carried out liquid and solid separation of micro filter membrane, protein micro filter permeating liquid, coloring matters, polysaccharide and other macromolecule impurities are removed through the ultrafiltration membrane, collected permeating liquid is desalted and enriched under normal temperature through the permeating liquid, and the desalt liquid is concentrated and dried to manufacture the ribostamycin rough products. The method for preparing ribostamycin rough products by using the membrane separation technology is novel in conception, mild in productive technology conditions, environment-friendly and clean, simple and easy to do, short in production cycle, low in production cost, high in extraction yield and strong in application, and has big application and dissemination values.

Owner:福建和泉生物科技有限公司

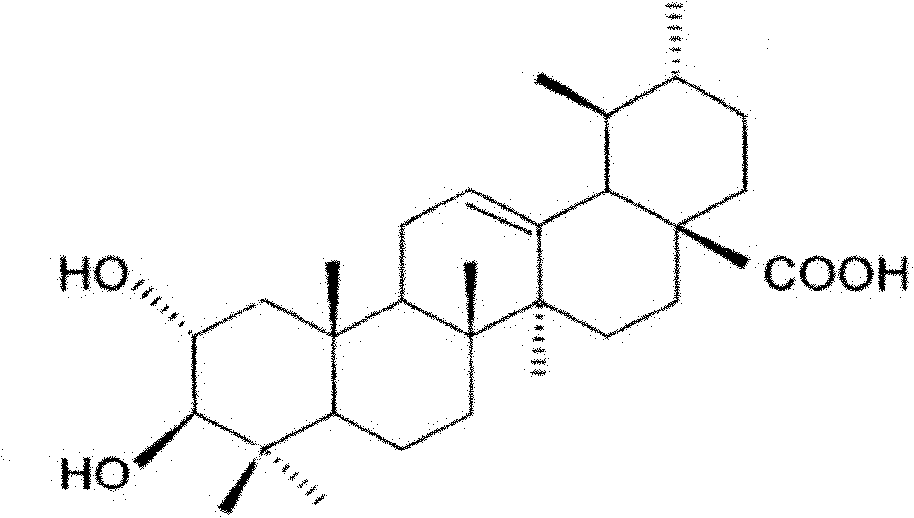

Method for extracting corosolic acid from loguat leaf

The invention discloses a method for extracting corosolic acid from loguat leaf. Based on the loguat leaf as a raw material, the high pure corosolic acid is obtained by combination of ultrasonic extraction, acid precipitation, alkaline alcohol solution dissolution, macroporous resin absorption, crystallization, re-crystallization and the like. The method disclosed by the invention has the advantages of simple process, low production, high extraction efficiency and the like.

Owner:天医堂(厦门)生物工程有限公司

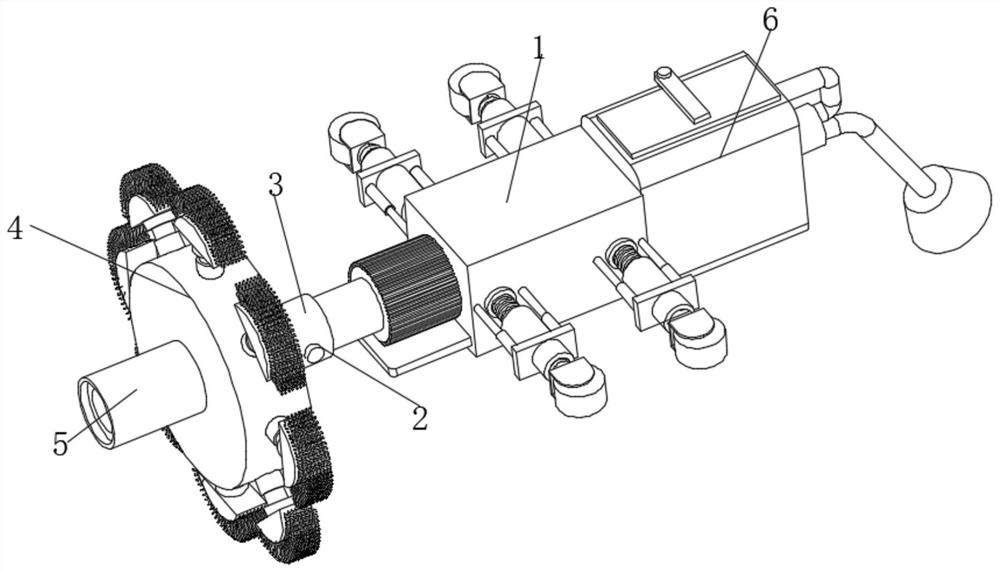

Gas pipeline cleaning device and using method

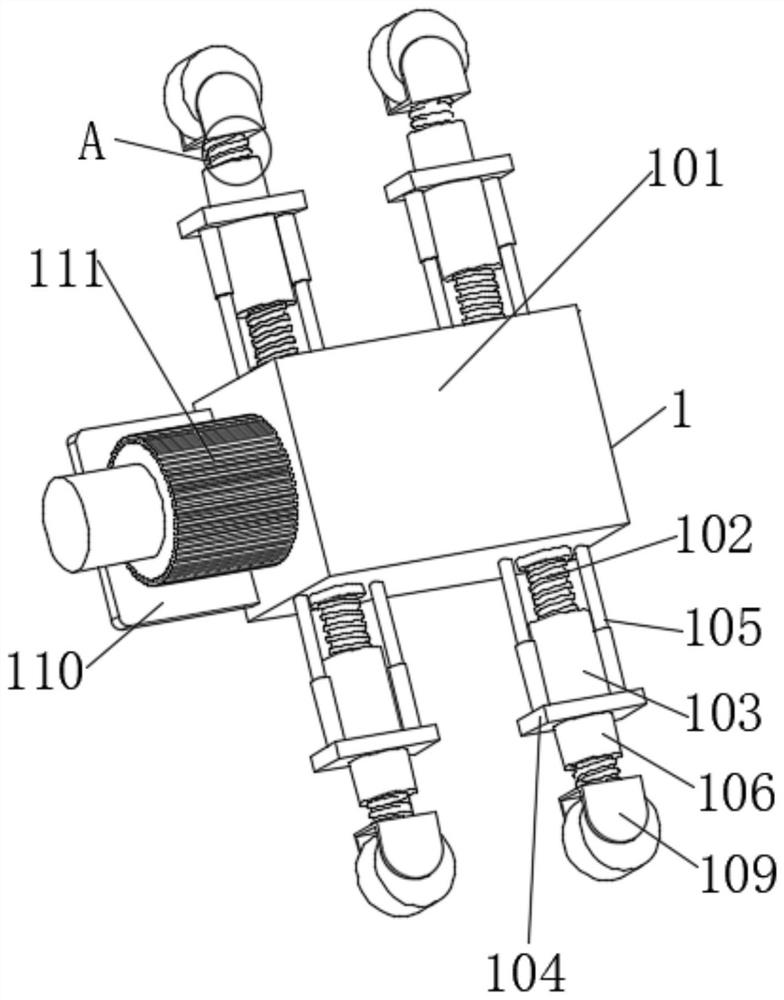

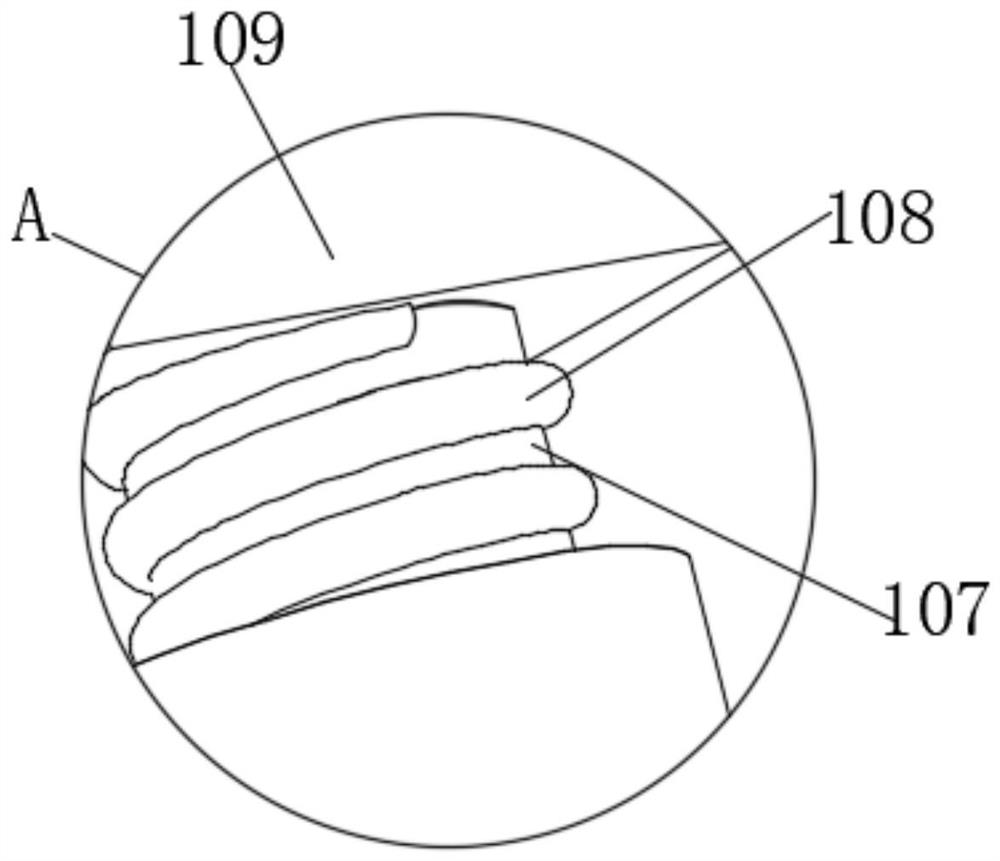

PendingCN113731974AEasy to useEasy to remove impuritiesHollow article cleaningPigs/molesGas pipelineWheel drive

The invention provides a gas pipeline cleaning device and a using method, and relates to the technical field of pipeline cleaning. The gas pipeline cleaning device comprises a moving device, one side of the moving device is fixedly provided with a fixing device, the outer surface of the fixing device is sleeved with a fixing sleeve, and the side, away from the moving device, of the fixing sleeve is fixedly provided with a clearing device. The invention further provides a using method of the gas pipeline cleaning device. The using method comprises the steps that S1, when the cleaning device is used, the clearing device is placed in a pipeline, a one-way device is connected with an inflation pipe, the one-way device is inflated with gas, during passing of a curve, gas on the inner wall of a gas shell changes, a brush head still can clean the pipeline thoroughly, and when the moving device moves to the curve, moving wheels drive wheel rods to move in clamping cylinders, so that the moving wheels make contact with the inner wall of the pipeline, the moving wheels cannot be clamped in the pipeline in the curve, and the device is convenient to use.

Owner:新奥新能源工程技术有限公司

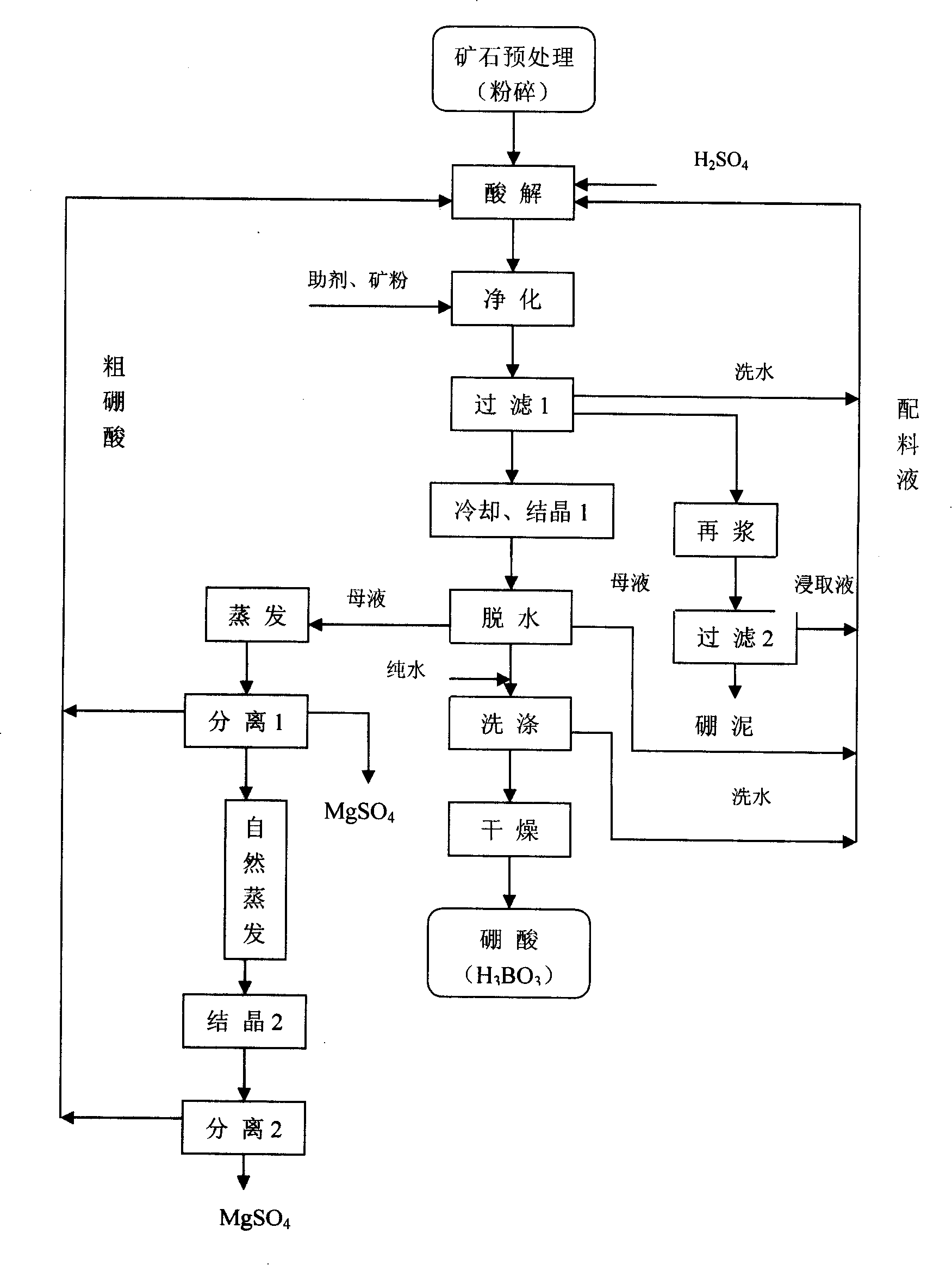

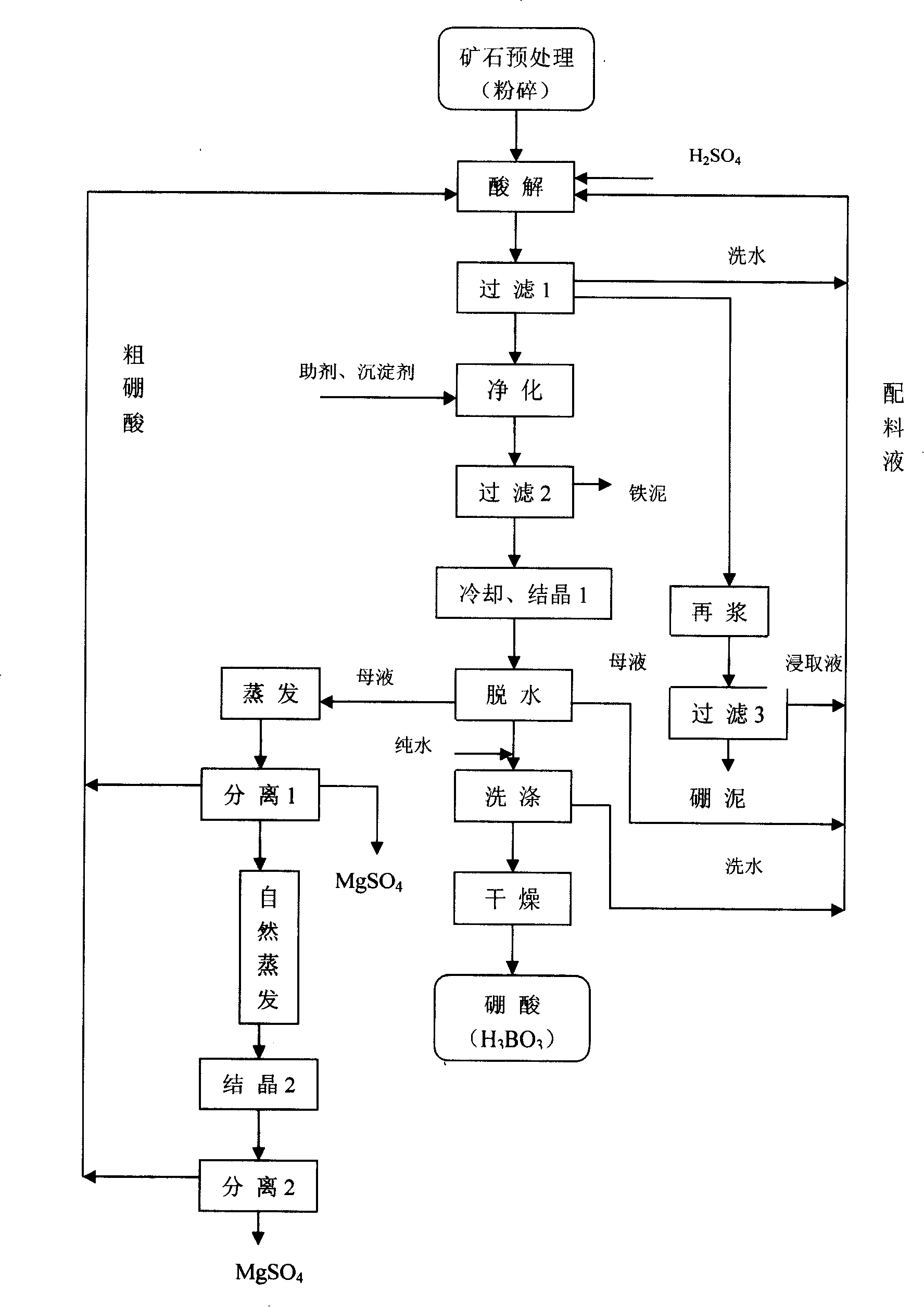

Technique for preparing high quality boric acid from salt lake type boron ore by one-step method

InactiveCN101209844AEasy to separateAchieve the purpose of separationBoron-oxygen compoundsHigh energySludge

The invention relates to the technical field of extracting boracic acid, in particular to a technological method for preparing boracic acid from a saline boron rock in one-step. On the base of preliminary treatment of ore-acidolysis-filtering-crystallization-dehydration-washing-drying- boracic acid, the invention adds a purification process, namely, impurity removal through chemical oxidation between the acidolysis and crystallization processes. The invention has beneficial effects that: compared with activated carbon absorption method, the oxidizing impurity removal and decoloring techniques of the invention has the advantages of thorough impurity removal, complete decoloring, simple flow process, low operation cost and stronger operability; the product yield is further improved by that boric sludge is leached and then treated with slurry, in which rudimental boron is collected; an independent design of a three-way counter current concentration boron and magnesium separating technique for the technical process overcomes the disadvantages of high energy consumption, inefficiency and incomplete separation in a technique of atmospheric concentrate, decompression single-effect concentration and boron and magnesium separation, which saves energy source and reduces cost. The invention can be widely applied for preparing boracic acid from a saline boron rock.

Owner:肖莹

Synthesis process of ultrafine-grade diamond

InactiveCN103846058AFully interpenetrating and miscibleEasy to remove impuritiesUltra-high pressure processesPressure curvePeak value

The invention provides a synthesis process of ultrafine-grade diamond. The synthesis process comprises the steps: after mixing a graphite powder and an Fe-based alloy catalyst powder according to the weight ratio of 8:5-7, carrying out isostatic pressing treatment and vacuum treatment, then carrying out press forming in a four-column pressing machine, followed by putting the column core into a diamond synthetic block, next putting the diamond synthetic block into a six-side jacking press machine, and synthesizing, wherein the actual synthesis pressure is 6.1-6.6 GPa, the synthesis temperature is 1000-1100 DEG C, and the actual synthesis pressure and the synthesis temperature are completed respectively by adopting a control pressure curve and a power curve. The synthesized diamond with micron-sized fine particles has the characteristics of large nucleation amount, short growth time and the like; the product meets national artificial diamond standards, has the advantages of consistent crystal form, integral crystal faces, less impurities and high heat flush value, has the particle granularity with peak values of 270 / 325 and 325 / 400, allows the single crystal ratio to reach 70-80%, and can effectively meet the fields of high-end abrasive tools and the like having extremely high requirements on the particle fineness.

Owner:周存文

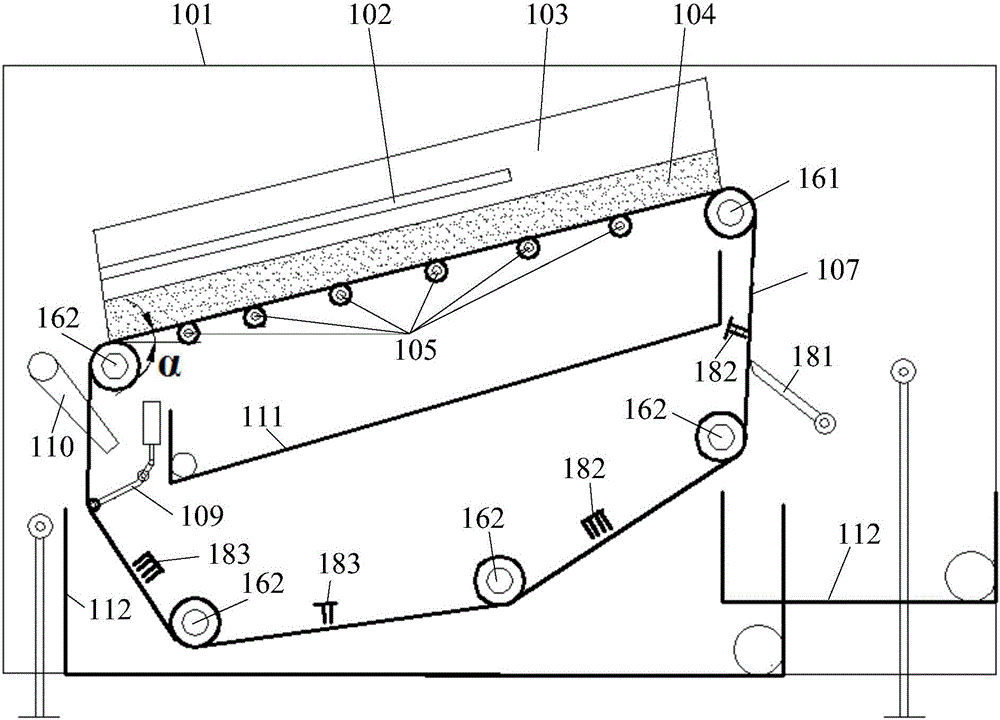

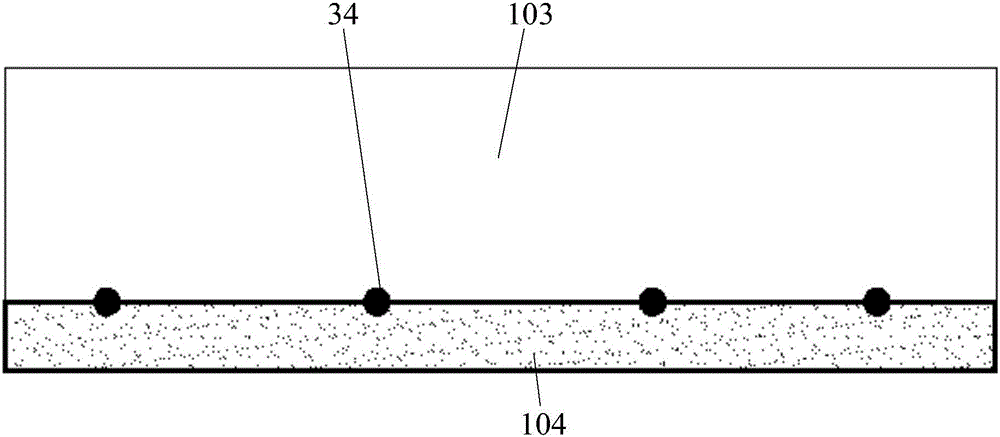

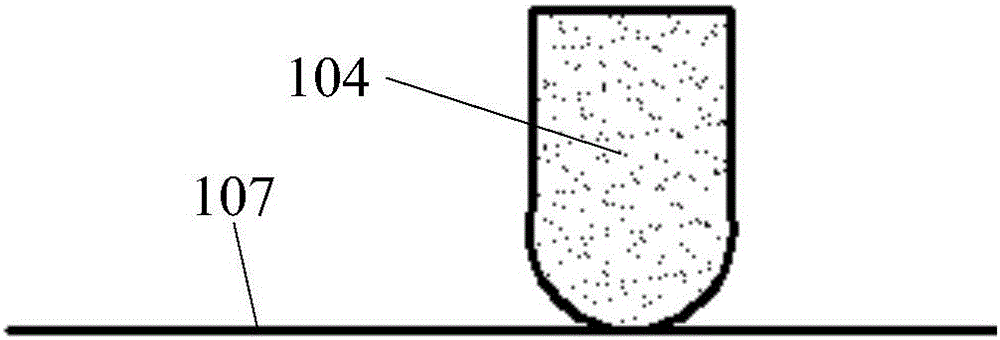

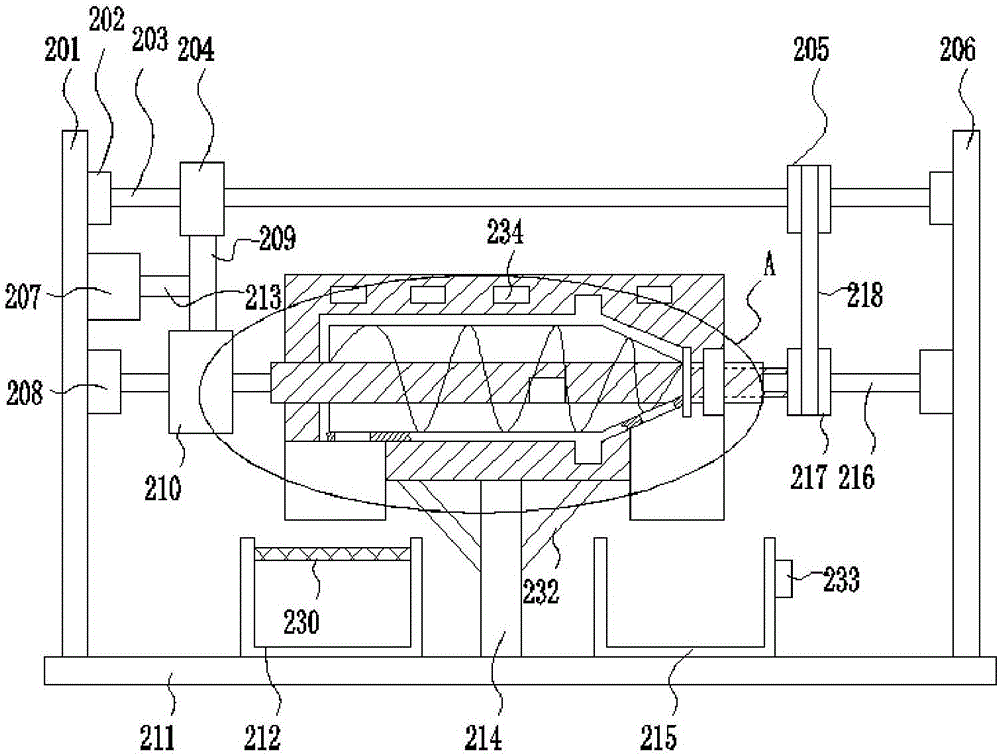

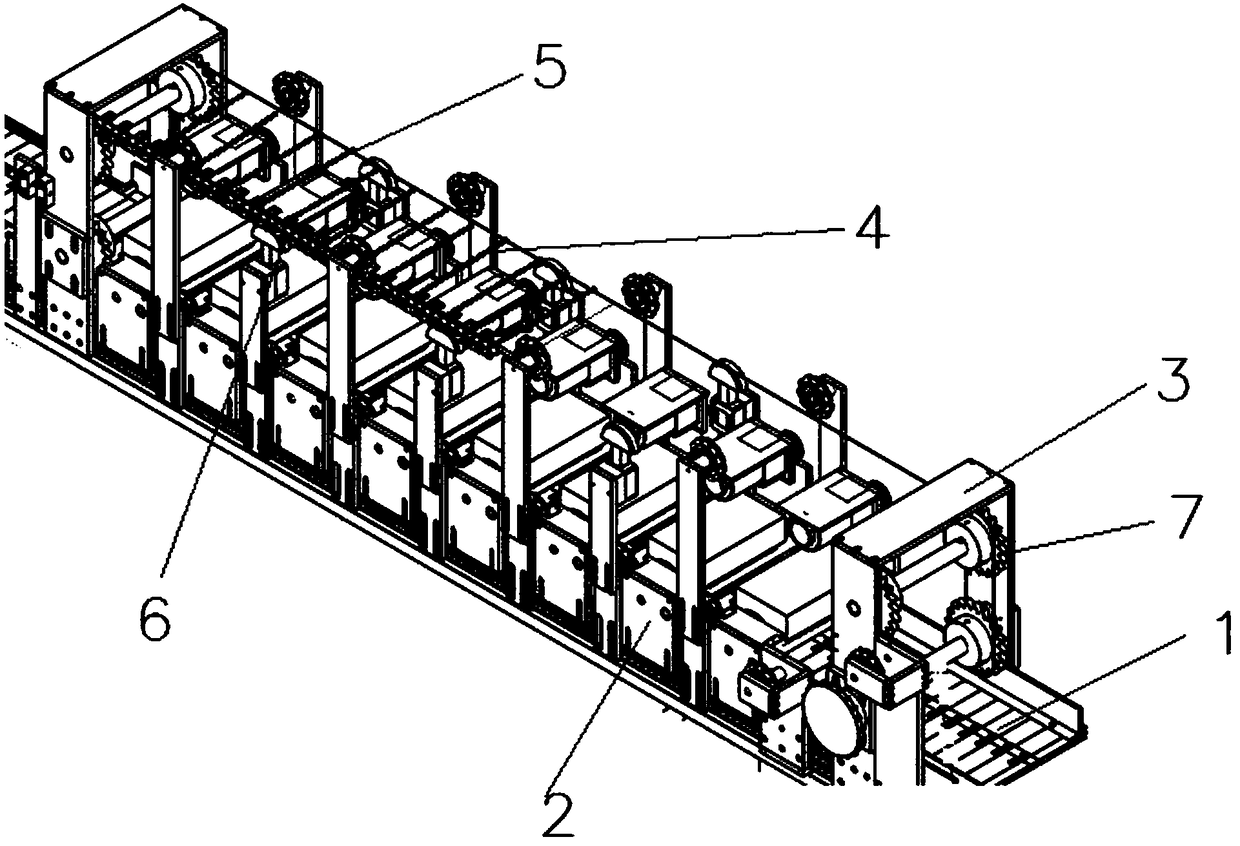

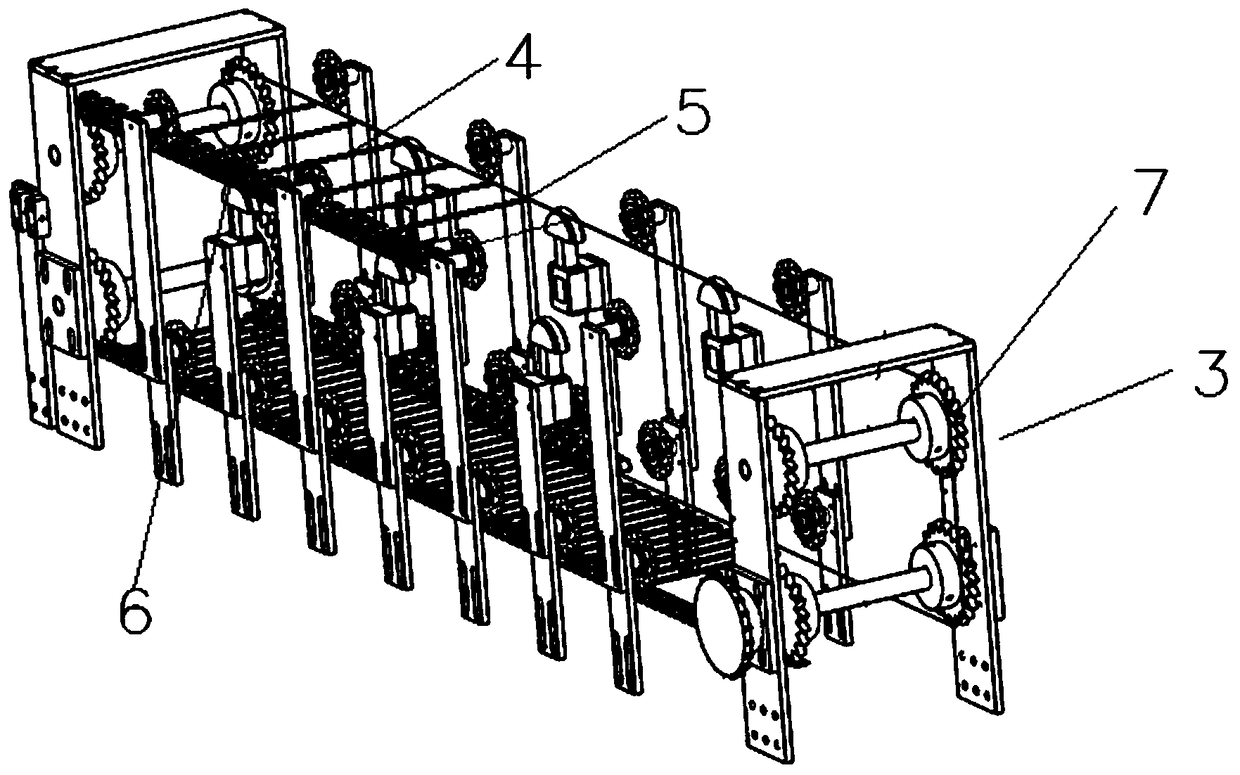

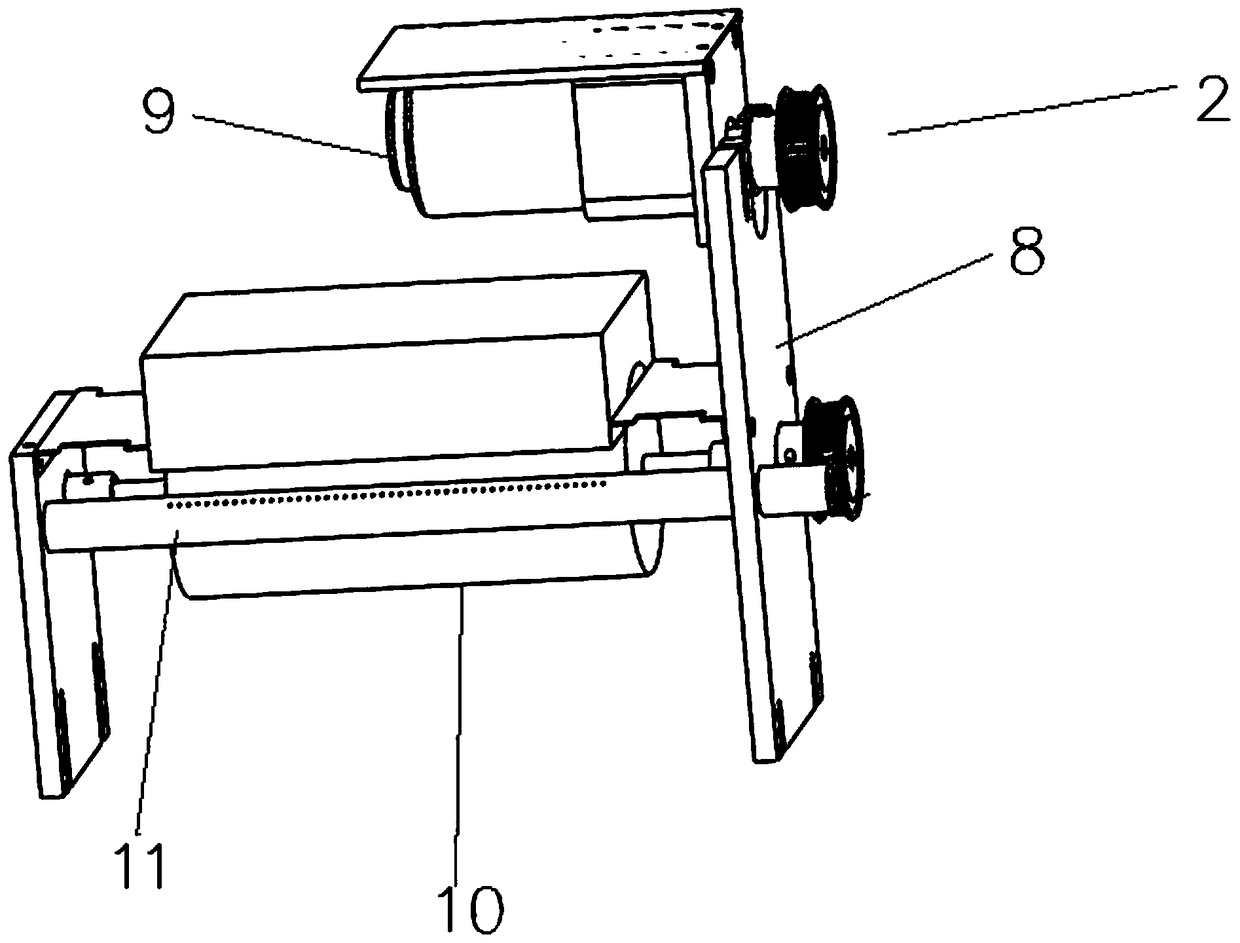

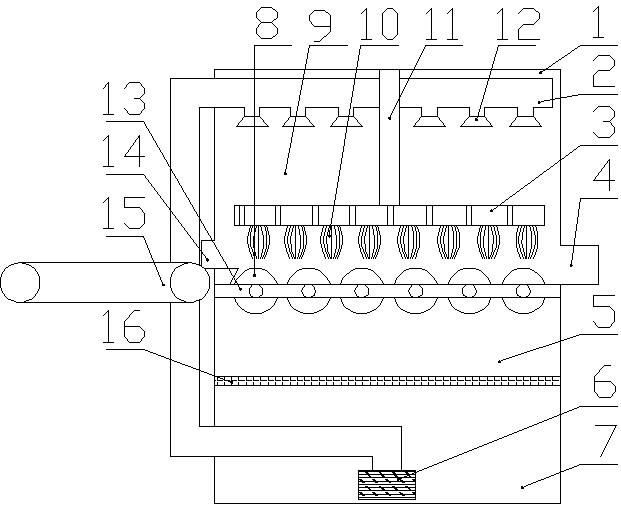

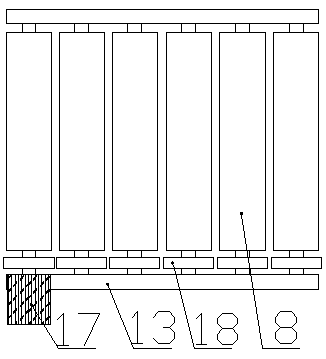

Production-line-type mummified aphid separation and brushing device

ActiveCN109225981AAvoid harmNot easy to gather into groupsTobacco preparationCleaning using toolsProduction lineBrush device

The invention discloses a production-line-type mummified aphid separation and brushing device. The device comprises a conveying belt, brushing modules and synchronous fixing modules; the brushing modules are arranged on the surface of the conveying belt, each brushing module comprises at least one brushing device, each brushing device comprises a rotating hairbrush, and the rotating hairbrushes can separate mummified aphids from the surfaces of leaves; each synchronous fixing module comprises a rotating device and a pressing strip, the brushing devices are located in a space fitted by the pressing strips and the rotating devices, and at least partial pressing strips or partial sections of the pressing strips fit the conveying belt, so that the leaves and the conveying belt fit fixedly. Bymeans of the device, the mummified aphids can be efficiently separated, and the damage rate of the mummified aphids can be effectively reduced.

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH +1

Chinese medicine cleaning device

InactiveCN109622442AEasy to remove impuritiesSmooth rotationCleaning using toolsCleaning using liquidsWater leakageGear wheel

The invention relates to a Chinese medicine cleaning device, which comprises a box. The box sequentially comprises a cleaning box, an impurity removing box and a water tank from top to bottom, the topof the cleaning box is slidably connected with a connecting rod, hydraulic telescopic rods are symmetrically arranged on the two sides of the middle of the connecting rod, a cleaning plate is fixed to the end of the connecting rod and provided with water leakage holes arrayed at equal distances, cleaning brushes are arranged at gaps of the water leakage holes, rolling shafts are arranged below the cleaning brushes at equal distances, gears are arranged at one ends of the rolling shafts correspondingly, one of the rolling shafts is connected with a motor, a discharging outlet corresponding tothe rolling shaft is formed in the right side of the box, and a corresponding feeding inlet is formed in the left side of the box; and a filtering plate is arranged at the bottom end of the impurity removing box, a water pump is arranged at the bottom of the water tank and connected with a water pipe, the water pipe communicates with the cleaning box, and spraying devices are arranged on the waterpipe at equal distances. The Chinese medicine cleaning device has the advantages that the structure is simple, cleaning is flexible, mass cleaning can be achieved, water for cleaning is subjected toimpurity removal, water recycling is achieved, and practicality is high.

Owner:YUZHOU HETONGTAI PHARMA CO LTD

Full-automatic silicon wafer cleaning device

PendingCN110328166ANovel structureHigh degree of automationSemiconductor/solid-state device manufacturingCleaning using toolsMegasonic cleaningSilicon

The invention discloses a full-automatic silicon wafer cleaning device. The full-automatic silicon wafer cleaning device comprises a feeding mechanism, a conveying belt, an electrostatic removal channel, an auxiliary discharging mechanism, an ultrasonic cleaning mechanism and a drying channel. The full-automatic silicon wafer cleaning device is novel in structure, low in manufacturing cost and high in automation degree; and a silicon wafer sequentially passes through the feeding mechanism, the conveying belt, the electrostatic removal channel, the auxiliary discharging mechanism, the ultrasonic cleaning mechanism and the drying channel, and thus automatic feeding, automatic cleaning, automatic drying and discharging of silicon wafers are achieved, the operation is simple and convenient, the production time is greatly shortened, and the working efficiency is improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

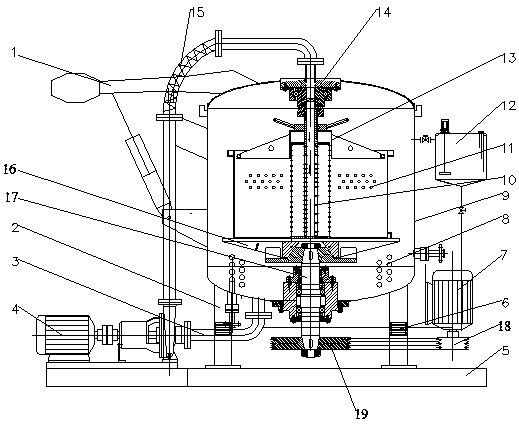

Environment-friendly energy-saving loose-wool dyeing and dehydrating all-in-one machine

ActiveCN108978070AOptimize the dyeing processSimple processSucessive textile treatmentsTextile treatment machine arrangementsFiberMaster cylinder

The invention discloses an environment-friendly energy-saving loose-wool dyeing and dehydrating all-in-one machine, and the machine comprises a pedestal. The pedestal is provided with a dye liquor circulating pump and a main cylinder body. The main cylinder body is fixed on the pedestal through a support connection system, and a dehydrating motor is connected below the main cylinder body. The interior of the main cylinder body is provided with a loose-wool cage and a dye liquor heating system. The main cylinder body is also provided with a charging system, and the top of the main cylinder bodyis provided with a dye liquor spraying nozzle. The all-in-one machine can optimize the water circulation, improve efficiency, reduce the waste of water resources, save water and energy, and reduce the number of water cleaning times. The all-in-one machine is better in stability and balance for the processing of loose fibers (more than 150kg). Dyeing equipment and dehydrating equipment are perfectly combined into the all-in-one machine, thereby shortening the technological process, reducing the labor intensity, reducing the equipment investment, alleviating the environment protection pressure,achieving the low-investment and high yield purpose, and maximizing the benefits.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Liquid fertilizer and pesticide spraying device

ActiveCN107593071AAvoid cloggingGuaranteed continuityRotary stirring mixersPressurised distribution of liquid fertiliserAgricultural engineeringUltimate tensile strength

The invention discloses a liquid fertilizer and pesticide spraying device. The device comprises a stirring tank, a first partition, a second partition, two filter screens, a stirring device, a spray tank, a water baffle, a first rod and a water pipe, wherein two first water inlets and a pesticide liquid inlet are formed in the top of the stirring tank; two ends of the first partition are fixedly connected with two side walls of the stirring tank in the width direction respectively; two ends of the second partition are fixedly connected with the first partition and one side wall, opposite to the first partition, of the stirring tank respectively, and the second partition divides the area between the first partition and the side wall, opposite to the first partition, of the stirring tank into two filter areas; the two filter screens are arranged in the two filter areas respectively; a plurality of first water outlets are formed in the bottom of the spray tank; a plurality of second wateroutlets and a plurality of convex columns are arranged on the water baffle; the bottom of the first rod is fixedly connected with the top of the water baffle; the water pipe is communicated with boththe spray tank and the stirring tank. The device can push the stirring tank and the spray tank to move forward, labor intensity is reduced, and spray height can be adjusted, so that the applicabilityis higher.

Owner:北京丰泽晟华农业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com