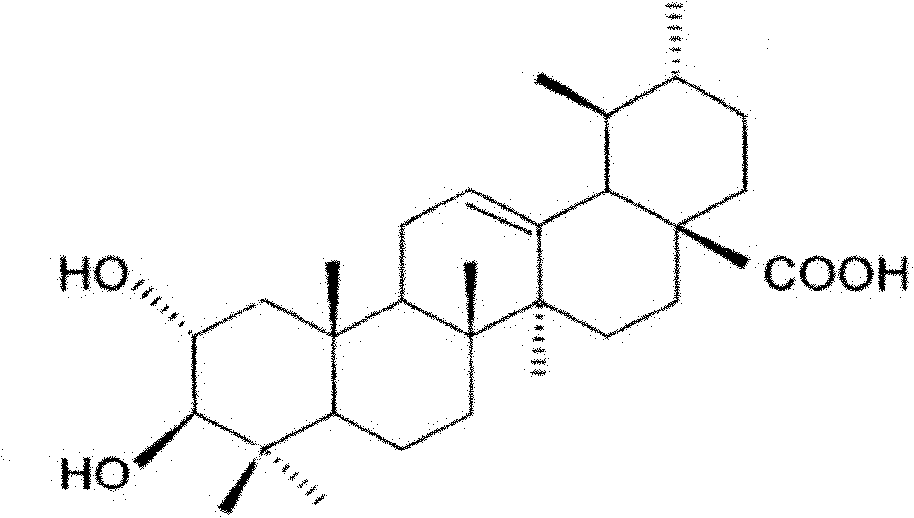

Method for extracting corosolic acid from loguat leaf

A corosolic acid and extraction method technology, which is applied in the field of corosolic acid extraction, can solve the problems of high cost and cumbersome process, and achieve the effects of increasing yield, good dissolution effect and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) After the loquat leaf raw material is pulverized, the mass ratio of 8 times of the dry weight of loquat leaf is 80% ethanol aqueous solution ultrasonic extraction 2 times, the ultrasonic power is 220 watts, the working time is 40 minutes, the working temperature is 60 ℃, and the ultrasonic working mode is Work for 5 seconds, rest for 5 seconds, combine the extracts, filter the extracts, and concentrate them in a vacuum to form a concentrated solution;

[0025] 2) Add 8 times the volume of the concentrated solution and acid water with a pH value of 5-6 to the concentrated solution, let it sit and filter to obtain a filter residue;

[0026] 3) Add mass ratio to filter residue and be 40%, PH=11 aqueous ethanol solution is fully dissolved, obtains mixed solution, and mixed solution is added above-mentioned ethanol aqueous solution, adjusts the content of corosolic acid in mixed solution to be about 1.5g / L;

[0027] 4) The macroporous resin adsorbs the corosolic acid mixt...

Embodiment 2

[0030] 1) After the loquat leaf raw material is pulverized, the mass ratio of 10 times of the dry weight of loquat leaf is 75% ethanol aqueous solution ultrasonic extraction 2 times, the ultrasonic power is 250 watts, the working time is 20 minutes, the working temperature is 40 ℃, and the ultrasonic working mode is Work for 5 seconds, rest for 5 seconds, combine the extracts, filter the extracts, and concentrate them in a vacuum to form a concentrated solution;

[0031] 2) Add 10 times the volume of the concentrated solution and acid water with a pH value of 5-6 to the concentrated solution, let it stand and filter to obtain a filter residue;

[0032] 3) add mass ratio to the filter residue and be 50%, PH=9 aqueous ethanol solution is fully dissolved, obtains the mixed solution, the mixed solution is added above-mentioned ethanol aqueous solution, makes the content of corosolic acid in the mixed solution be about 1.5g / L;

[0033] 4) The macroporous resin adsorbs the corosolic...

Embodiment 3

[0036] 1) After the loquat leaf raw material is pulverized, use 12 times the mass ratio of loquat leaf dry weight as 85% ethanol aqueous solution ultrasonic extraction 2 times, the ultrasonic power is 180 watts, the working time is 30 minutes, the working temperature is 50 ℃, and the ultrasonic working mode is Work for 5 seconds, rest for 5 seconds, combine the extracts, filter the extracts, and concentrate them in a vacuum to form a concentrated solution;

[0037] 2) Add 12 times the volume of the concentrated solution and acid water with a pH value of 5-6 to the concentrated solution, let it stand and filter to obtain a filter residue;

[0038] 3) add mass ratio in filter residue and be 45%, the ethanol aqueous solution of PH=10 is fully dissolved, obtains mixed solution, and mixed solution is used to add above-mentioned ethanol aqueous solution, makes the content of corosolic acid in corosolic acid mixed solution be 1.5g / About L;

[0039] 4) The macroporous resin adsorbs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com