Patents

Literature

1229 results about "Aluminum trichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

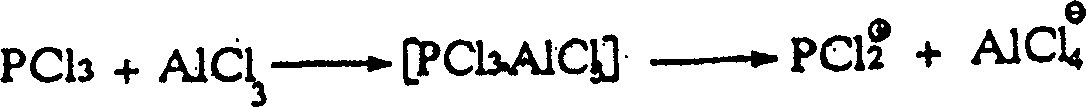

Temperature and conductivity. In boron group element: Trihalides aluminum trichloride (formula AlCl3), in which each aluminum ion has three positive charges, increases rapidly as the temperature is elevated toward the melting point, at which the conductivity suddenly falls to zero.

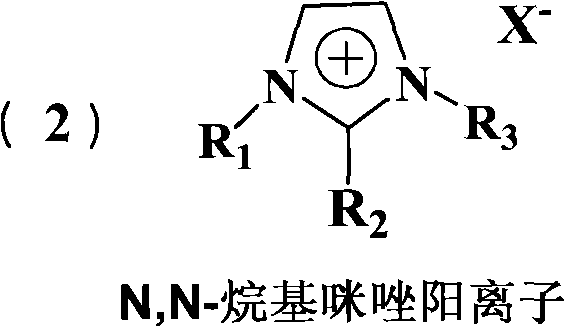

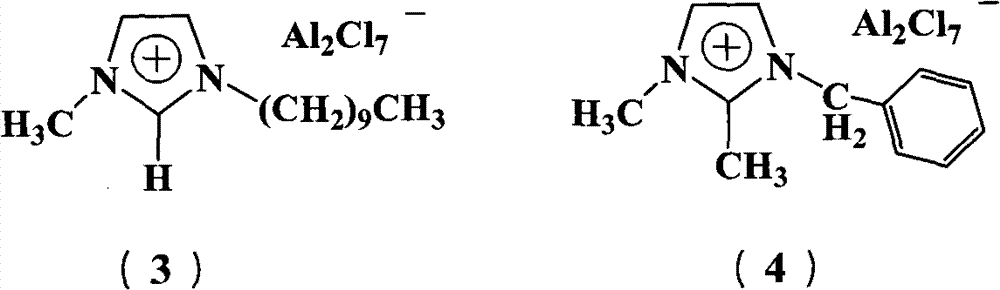

Alkylation process using an alkyl halide promoted ionic liquid catalyst

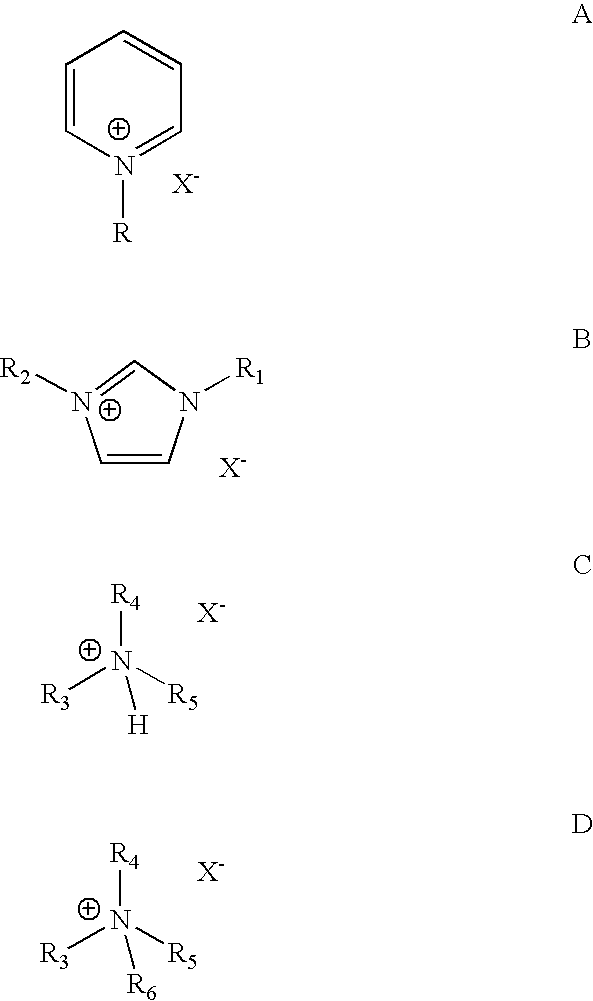

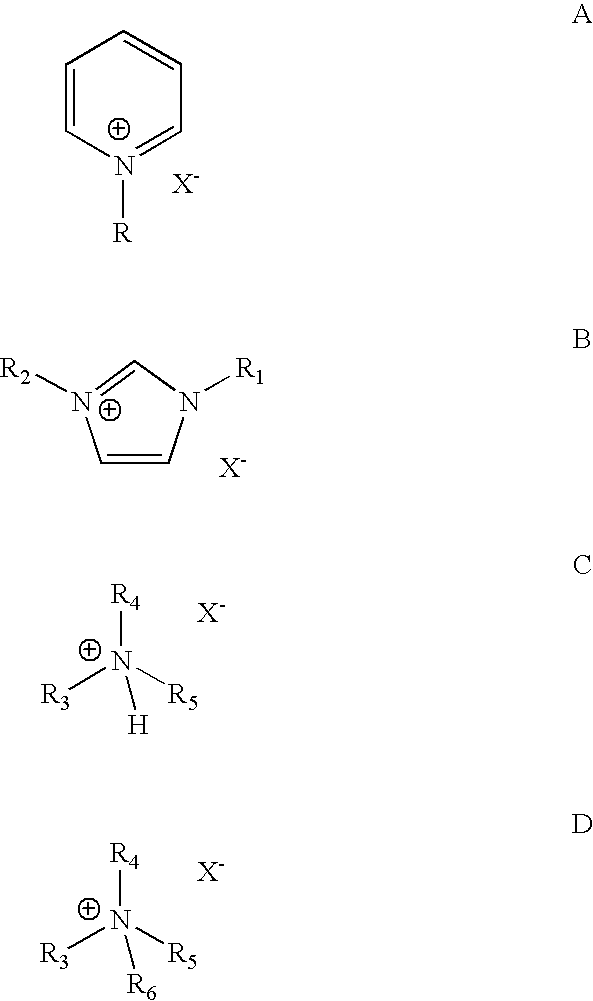

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The alkylation process comprises contacting a hydrocarbon mixture comprising at least one olefin having from 2 to 6 carbon atoms and at least one isoparaffin having from 3 to 6 carbon atoms under alkylation conditions, said catalyst comprising a mixture of at least one acidic ionic liquid and at least one alkyl halide. In one embodiment, the acidic ionic liquid is chloroaluminate ionic liquid prepared by mixing aluminum trichloride (AlCl3) and a hydrocarbyl substituted pyridinium halide, a hydrocarbyl substituted imidazolium halide, trialkylammonium hydrohalide or tetraalkylammonium halide of the general formulas A, B, C and D, respectively,where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same, and R3, R4, and R5 and R6=methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R3, R4, R5 and R6 may or may not be the same.

Owner:CHEVROU USA INC

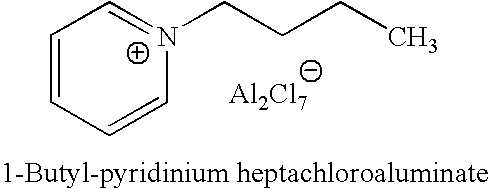

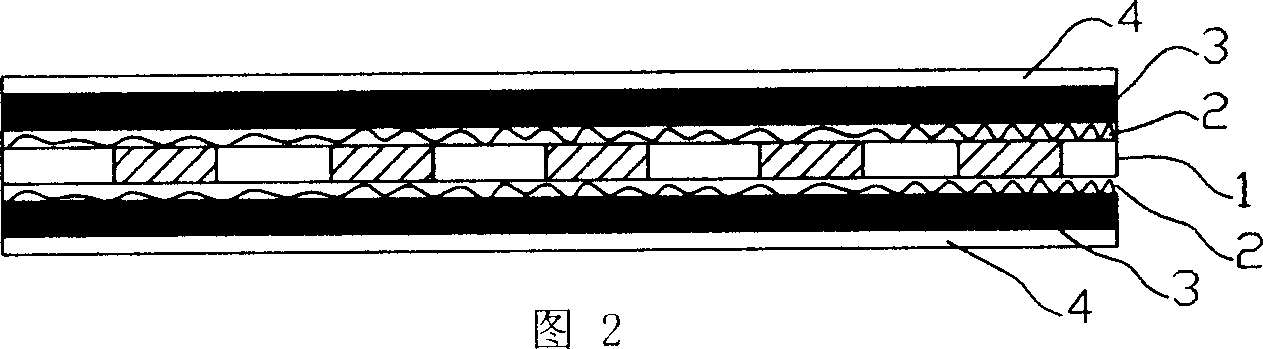

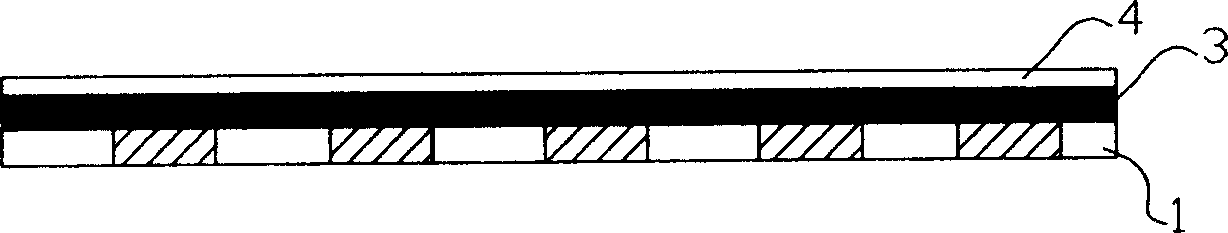

Self adhesive and high molecule self adhesive water-proof coil and producing process

InactiveCN1900207AEliminate pollutionThe process of dispensing glue is simpleOther chemical processesFilm/foil adhesivesCalcium silicateCross-link

The self adhesive consists of cross-linked asphalt, SBS rubber and tackifier, as well as SIS rubber, maleic anhydride, aluminum trichloride, thiram, magnesium chloride and calcium silicate. The self adhesive is cpddd with chemically modified cross-linked asphalt as main material at 150-170 deg.c, and has less pollution and low power consumption. It may be adhered to plasma modified polymer material and wet concrete. The present invention also discloses one kind of self adhering waterproof polymer coil made with the self adhesive and its production process, and the self adhering waterproof polymer coil has high adhesion strength between the adhesive and the main material layer.

Owner:珠海华兴防水科技有限公司

Production of alumina solid acid catalyst fixed carried on aluminum muriate

InactiveCN1939590ASolve problems such as pollutionEasy to separatePhysical/chemical process catalystsSolid acidSewage

An alumina carried AlCl3 solid acid catalyst with high activity, selectivity and stability for the oligomerizing reaction of isobutene on suspended bed is prepared through reaction between CCl4 and high-purity gamma-Al2O3 to generate AlCl3 vapor, reacting on the hydroxy groups on the surface of gamma-Al2O3 with both meso-porous and macroreticular structure, pulverizing and sieving by 10-400 meshes.

Owner:DALIAN UNIV OF TECH

Conversion of direct process high-boiling residue to monosilanes

InactiveUS6013235APromote conversionSilicon organic compoundsPhysical/chemical process catalystsHydrogenBoiling point

A process for the production of monosilanes from the high-boiling residue resulting from the reaction of hydrogen chloride with silicon metalloid in a process typically referred to as the "direct process." The process comprises contacting a high-boiling residue resulting from the reaction of hydrogen chloride and silicon metalloid, with hydrogen gas in the presence of a catalytic amount of aluminum trichloride effective in promoting conversion of the high-boiling residue to monosilanes. The present process results in conversion of the high-boiling residue to monosilanes. At least a portion of the aluminum trichloride catalyst required for conduct of the process may be formed in situ during conduct of the direct process and isolation of the high-boiling residue.

Owner:DOW SILICONES CORP

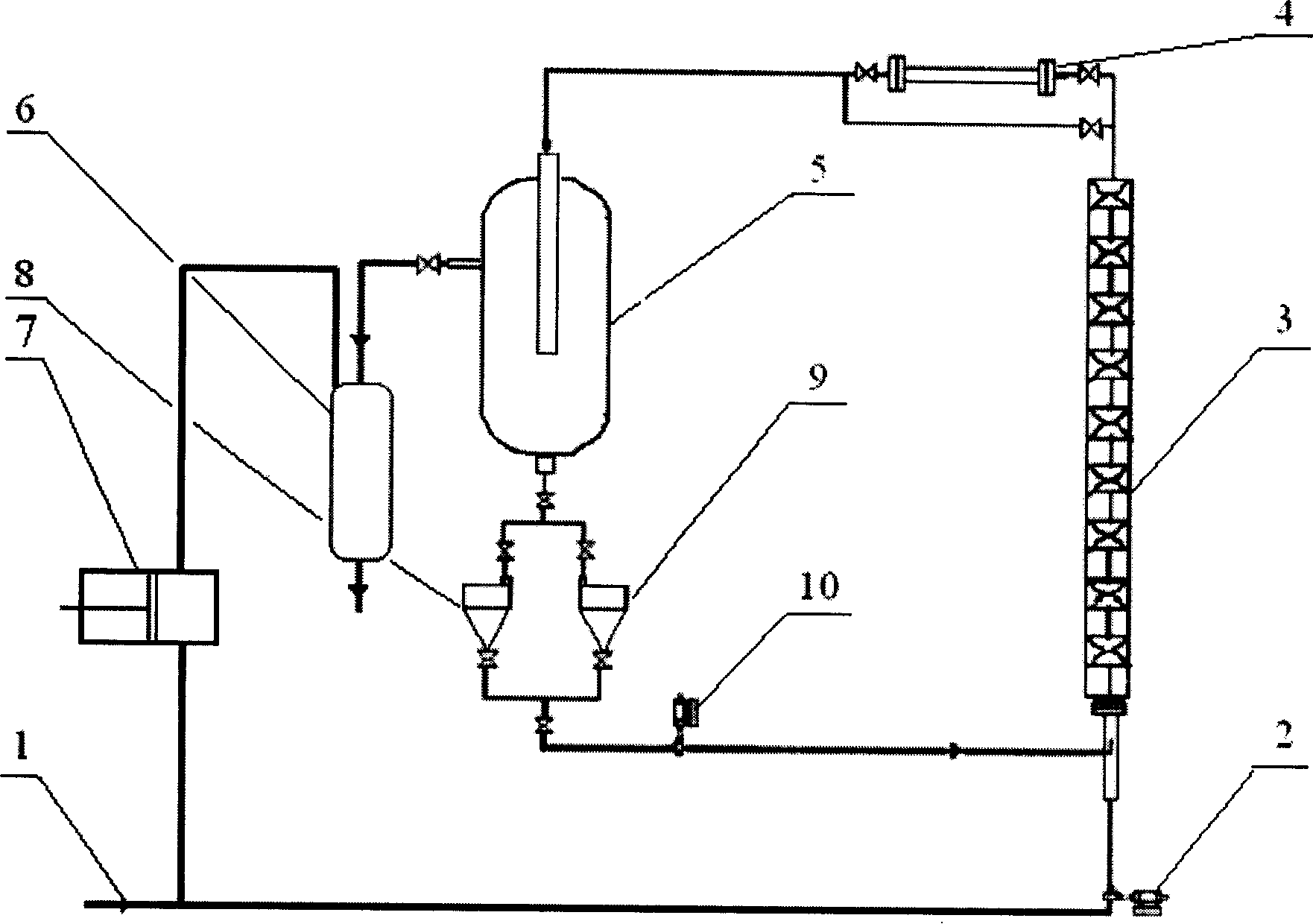

Method for on-line producing alkymer from regenerative ionic liquid catalyst

InactiveCN101234945AExtend your lifeHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionDecompositionOil phase

The invention relates to a method for producing alkylate finish, in particular to a method by which alkylate finish can be produced with an online continuously regenerated ionic liquid catalyst. Metal aluminum or aluminum trichloride is used as the aluminum resource for replenishing AlCl3 lost due to oil-phase entrainment or decomposition of ironic liquid when meeting water, thereby realizing continuous aluminum replenishment to prolong the service life of the catalyst, so the method is applicable to raw materials with relatively high water content. At the same time, the method can reduce the amount of HCl in the catalytic reaction system, maintaining the selectivity of the target production, isooctane, at a high level in the product and reducing corrosion of existent HCl.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing nanometer aluminum or nanometer aluminum coating in low-temperature electro-deposition form by using ion liquid/additive system

ActiveCN102888630AHigh purityWide variety of sourcesMaterial nanotechnologyElectrochemical windowIonic liquid

The invention designs a method for preparing nanometer aluminum or nanometer aluminum coating in an electro-deposition form by using an ion liquid / additive system. The method is characterized in that: ion liquid and anhydrous aluminum trichloride are mixed into a low-temperature electrolyte and suitable additives are added for preparing the ion liquid / additive system. A processed substrate is taken as a deposition cathode; the direct current electro-deposition is adopted for preparing the nanometer aluminum or nanometer aluminum coating; and the size of the aluminum grains is adjusted according to requirements. According to the method, the problems of high cost and small output of the present technology for producing the nanometer aluminum are solved; the adopted ion liquid is conventional ion liquid and is characterized by wide source, low cost, high conductivity, wide electrochemical window and being non-volatile and environment-friendly; the suitable additives are used, so that the high-quality nanometer aluminum or nanometer aluminum coating obtained in the conventional ion liquid is realized; the obtained aluminum deposited coating is compact, smooth and flat; a nanometer material can be obtained by using the ion liquid / additive system at lower temperature; the reaction is easy to control; the energy consumption is low; the obtained nanometer aluminum is high in quality and high in current efficiency; the size of the nanometer aluminum can be effectively controlled by adjusting the dosage and formula of the additives; the process is simple; the cost is low; and the application prospect is better.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

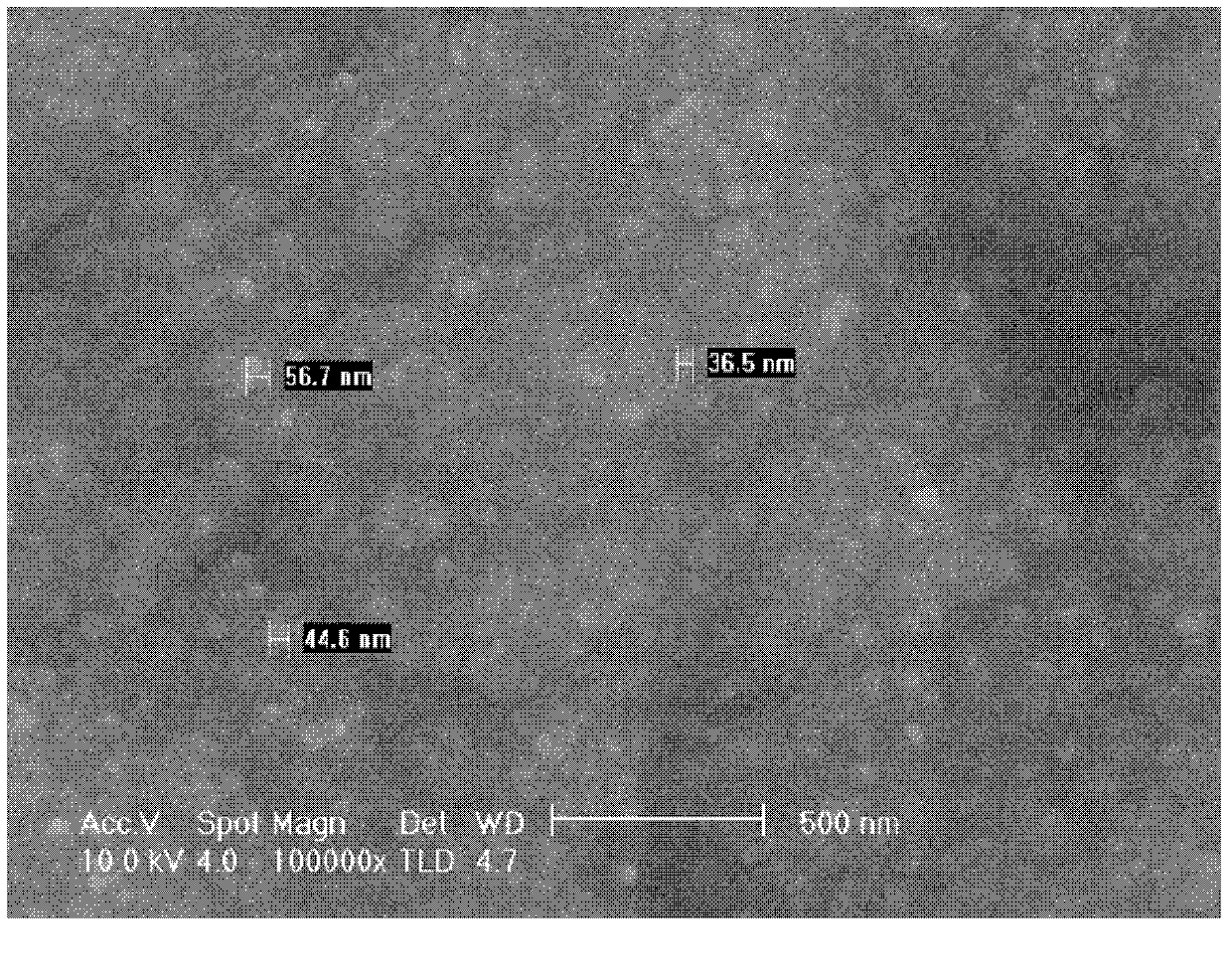

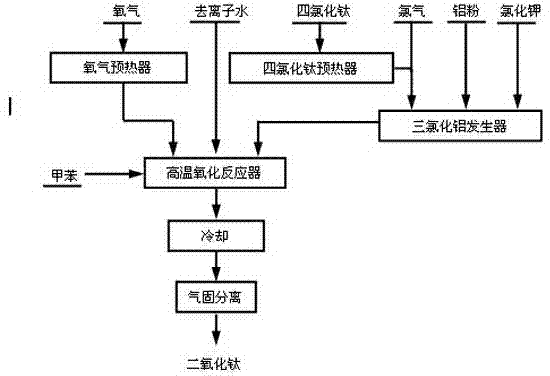

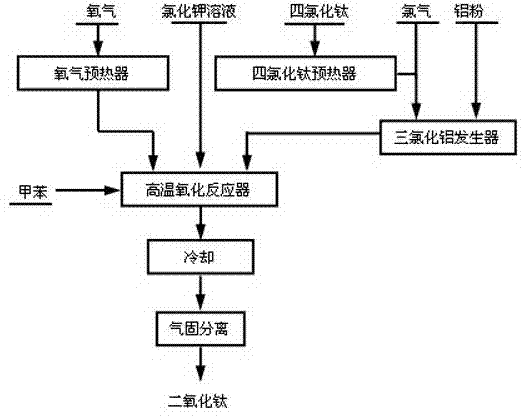

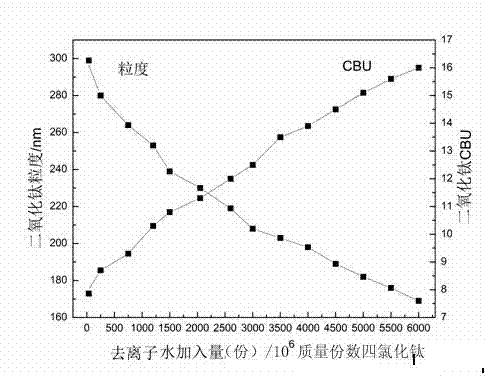

Production method of granularity-controllable titanium dioxide

ActiveCN102583531AIncrease the conversion rate of crystal formGood dispersionNanotechnologyTitanium dioxideFiberGas phase

The invention provides a production method of granularity-controllable titanium dioxide. Titanium tetrachloride and oxygen gas are preheated under pressure of 200kPa to 800kPa and respectively led into a high temperature oxidation reactor; hot oxygen is secondarily preheated in the high temperature oxidation reactor by using heat produced during toluene combustion to enable the titanium tetrachloride and the oxygen gas to produce a gas-phase oxidation reaction, and meanwhile, aluminum chloride, potassium chloride and deionized water are added to the high temperature oxidation reactor; and a gas-solid mixture generated through the reaction is cooled and subject to gas-solid separation, and then the titanium dioxide with the granularity of 160nm to 310nm is obtained. The method has the advantages that the cost is low, the operation is simple, the granularity of the titanium dioxide can be controlled within a large range through regulating the addition amount of the deionized water in the reaction process, and the application field of pigment is widened; and the method can be widely applied to the industries of coatings, plastics, building materials, papermaking, printing, ink, chemical fiber, rubber, ceramics, and the like.

Owner:中信钛业股份有限公司

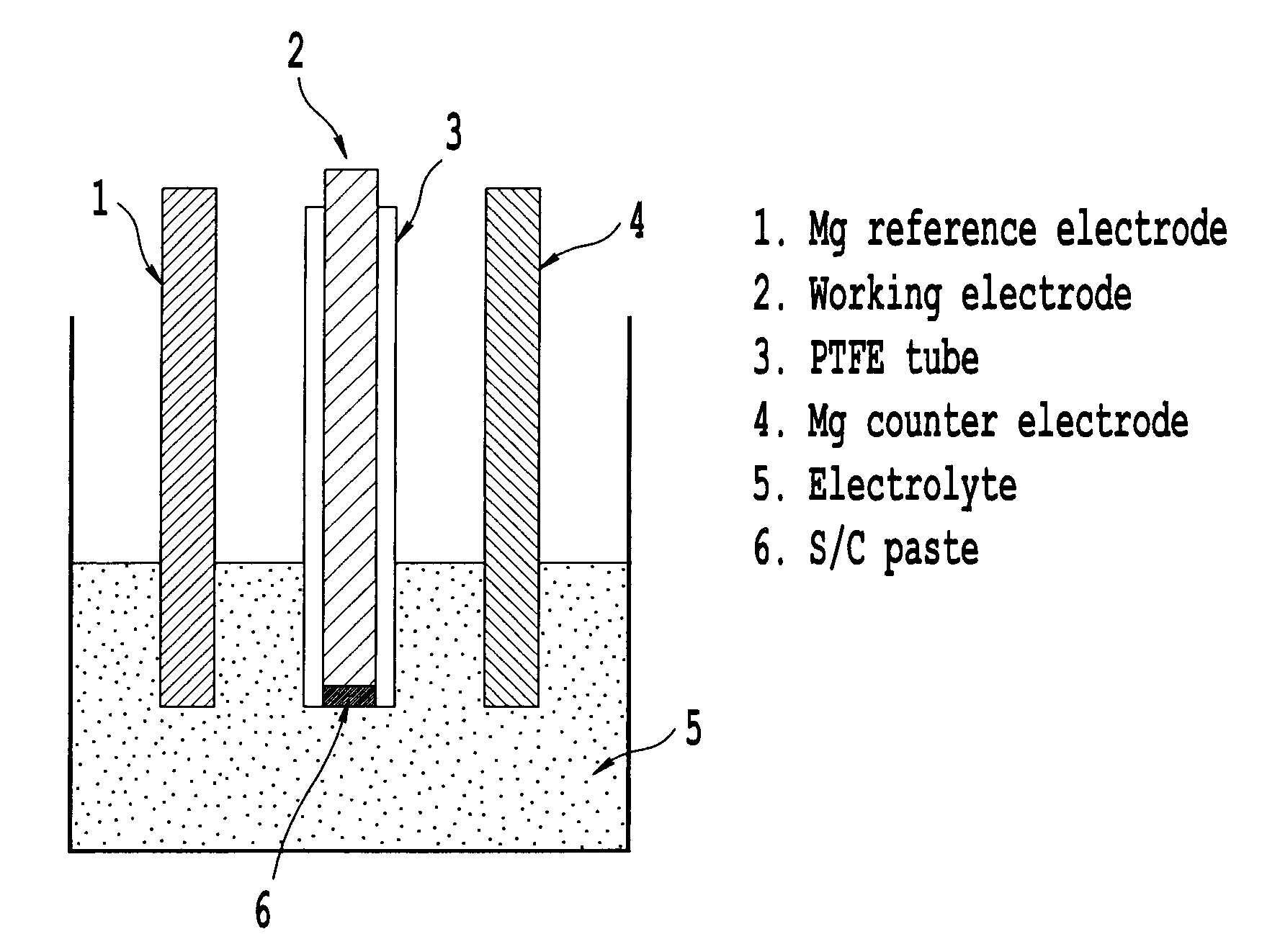

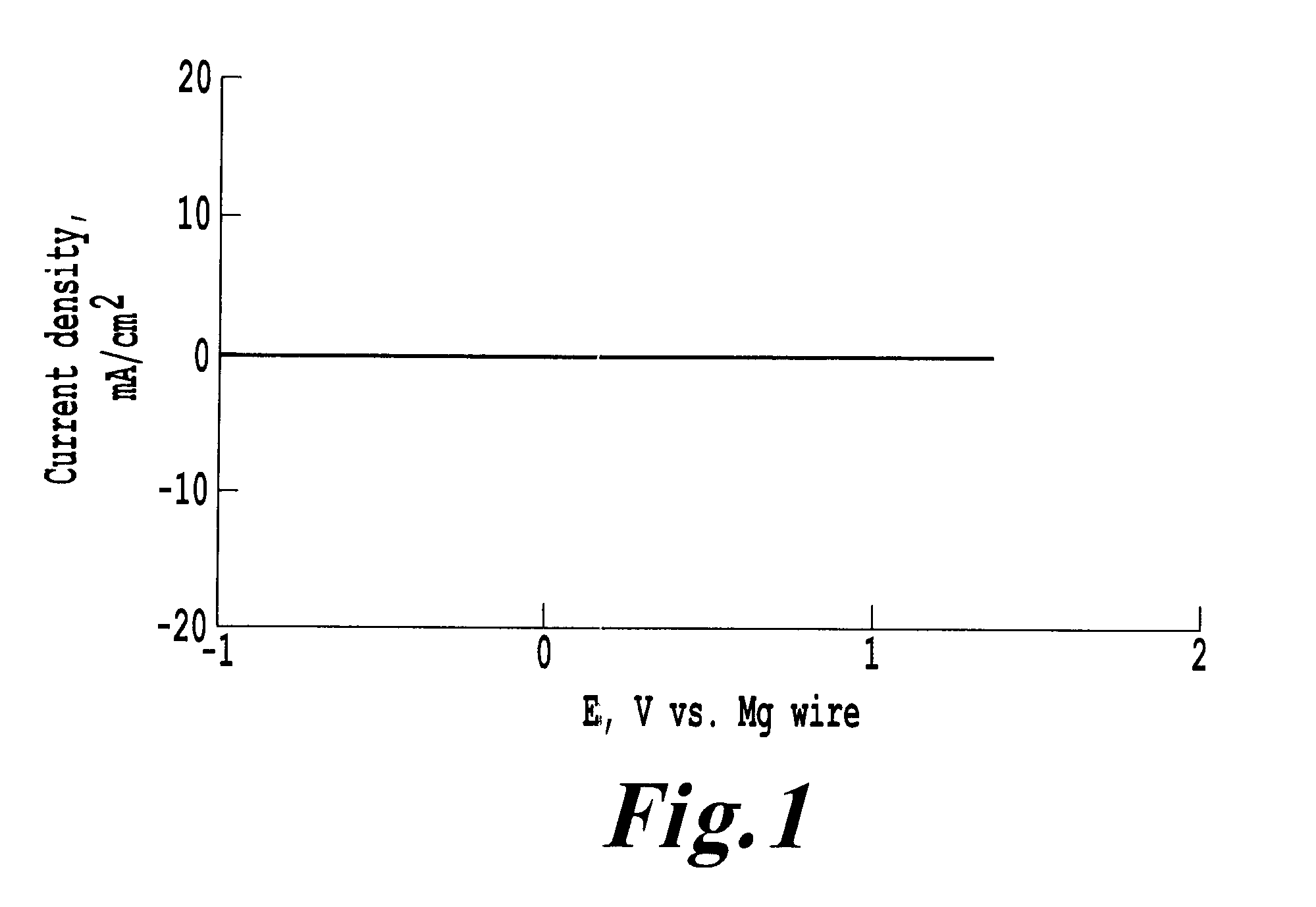

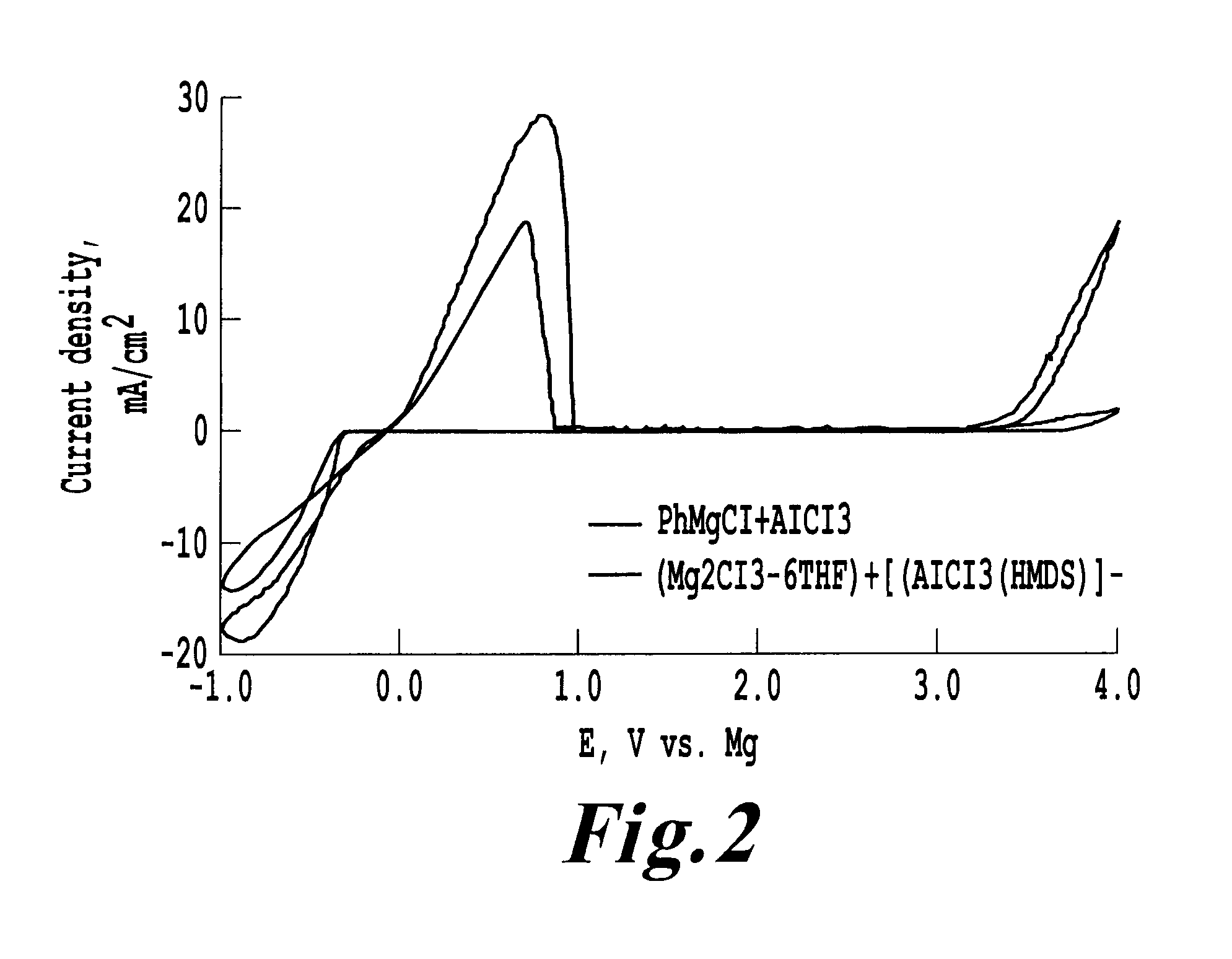

Electrolyte for a magnesium sulfur battery

An electrochemical device, having an anode containing magnesium; a cathode stable to a voltage of at least 3.2 V relative to a magnesium reference; and an electrolyte obtained by admixture of a magnesium salt of a non-nucleophilic base comprising nitrogen and aluminum trichloride in an ether solvent is provided. As sulfur is stable to a voltage of at least 3.2 V relative to a magnesium reference, a magnesium-sulfur electrochemical device is specifically provided.

Owner:TOYOTA MOTOR CO LTD

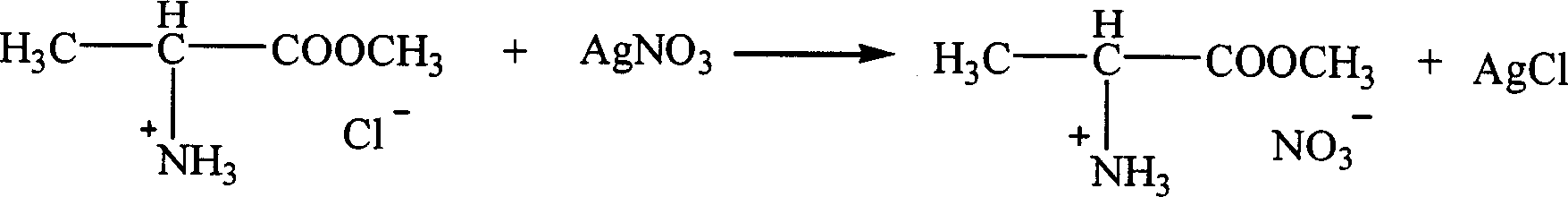

Ion liquid of amino acid ester cation and its preparation method

InactiveCN1621152AEasy to getLow priceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTetrafluoroborateAmino acid

The present invention is ion liquid of amino acid ester cation and its preparation process, and belongs to the field of new chemical material and its preparation technology. The ion liquid of amino acid ester cation is prepared with amino acid ester hydrochloride and through the substitution reaction with nitrate, tetrafluoroborate, hexafluorophosphate, bistrifluoromesyl imine salt or thiocyanate or the direct addition reaction with aluminum trichloride, ferric trichloride or zinc chloride, and the separation. The ion liquid thus prepared has the characteristic of chiral matter except the ion liquid characteristics, has low cost, simple preparation process and no pollution. The present invention is suitable for industrial production and is expected to become important green chemical material.

Owner:PEKING UNIV

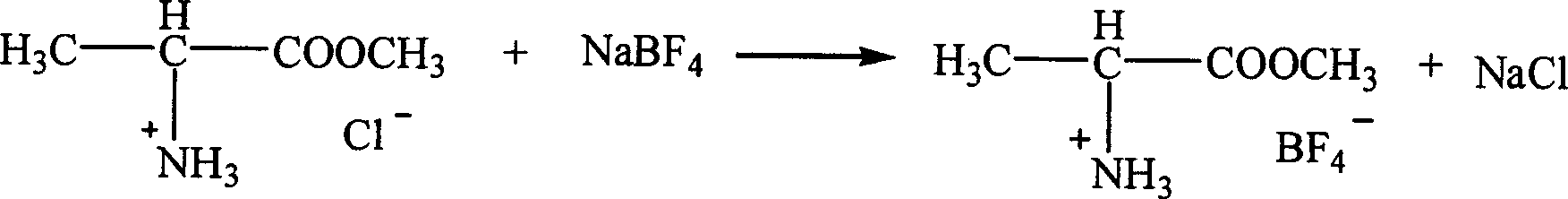

Method for producing aluminum chloride by using fly ash

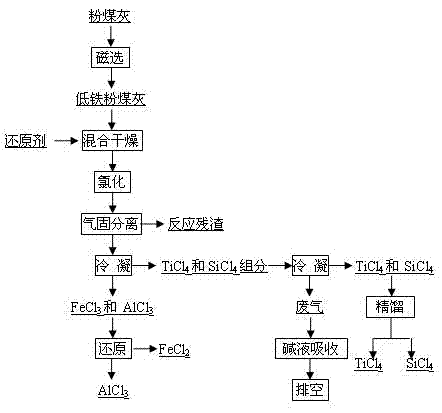

InactiveCN102491394AEfficient use ofReduce manufacturing costAluminium chloridesTitanium tetrachlorideReducing agent

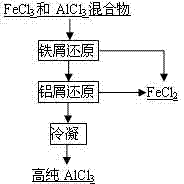

The invention discloses a method for producing aluminum chloride by using fly ash, and relates to a comprehensive utilization method for fly ash. The method is characterized in that the fly ash is adopted as the raw material; a chlorinating agent and a reducing agent are adopted to chlorinate aluminum in the fly ash into the aluminum chloride at a temperature of 500-1300 DEG C, and silicon, iron, titanium and other elements are partially chlorinated into the corresponding chlorides; the chlorinated gaseous mixing product is subjected to step-by-step cooling, wherein ferric chloride and aluminum chloride are condensed from the gaseous mixing product, and then silicon tetrachloride and titanium tetrachloride are condensed from the gaseous mixing product; the tail gas is treated and exhausted; the solid mixture comprising the ferric chloride and the aluminum chloride is heated into the gaseous mixture, and the resulting gaseous mixture is sequentially subjected to reduction reactions with scrap iron and scrap aluminum; the reduced gas is cooled to obtain the purified anhydrous aluminum chloride. With the method for producing the aluminum chloride by using the fly ash, the production cost of the anhydrous aluminum chloride can be effectively reduced, the fly ash is effectively utilized, the environment pressure is reduced, and the comprehensive economic benefits are improved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

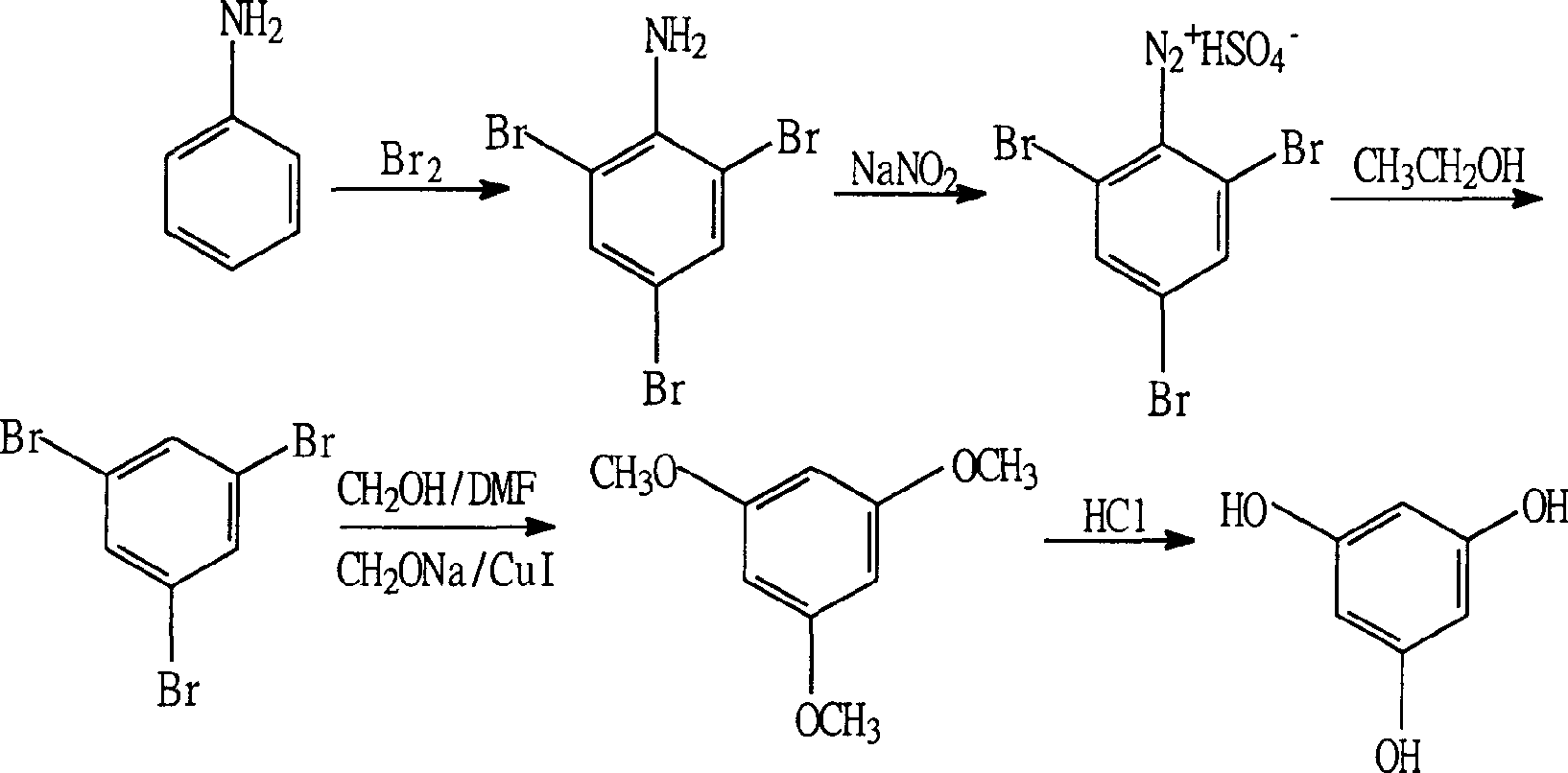

Process for preparing phloroglucinol

InactiveCN1491927AHigh purityShort reaction timeOrganic chemistryOrganic compound preparationBenzeneHydrolysate

The present invention relates to the preparation process of phloroglucinol superior to available preparation process. The present invention features that the preparation process of phloroglucinol includes the complexing reaction between anhydrous aluminum trichloride as complaxing agent and 1, 3, 5-trimethoxy benzene, hydrolysis in concentrated hydrochloric acid solution, cooling and crystallization of hydrolysate to obtain coarse phloroglucinol product, decolorizing with active carbon and re-crystallization in water to obtain refined phloroglucinol product. The said preparation process of the present invention has phloroglucinol product with good color and high purity, short reaction time, less waste liquid exhaust, simple operation condition and high reaction stability.

Owner:ZHEJIANG NHU CO LTD

Synthesis method of methyl phosphorus dichloride

ActiveCN105669748ANo emissionsIn line with the principles of cleaner productionGroup 5/15 element organic compoundsSynthesis methodsDistillation

The invention discloses a synthesis method of methyl phosphorus dichloride. According to the synthesis method, methyl chloride, aluminum trichloride and phosphorus trichloride serve as raw materials, petroleum ether serves as a solvent, ligands CH3PCl4.AlCl3 are generated through reaction, after petroleum ether is recycled through distillation, aluminum powder and petroleum ether are added, and the methyl phosphorus dichloride is obtained through reduction under the action of a catalyst. The synthesis method of methyl phosphorus dichloride can replace an existing technology to solve the problem of emission of organic waste gas in the preparation process, and the method is a complete synthesis technology process according with the clean production principle better. Besides, compared with the prior art, the synthesis method has a better production effect, and in other words, the yield of the methyl phosphorus dichloride can reach 91% (denoted by phosphorus dichloride).

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

Self-gas-generating foam fracturing fluid, its production method and application method

Relating to the technical field of fracturing fluids used for petroleum exploitation, the invention discloses a self-gas-generating foam fracturing fluid, its production method and application method. The elf-gas-generating foam fracturing fluid is composed of a base solution and a reaction solution. The base solution consists of: hydrolyzed polyacrylamide, sodium nitrite, ammonium chloride, a foaming agent, a clay stabilizing agent, a bactericide and water. The reaction solution comprises, by weight part: aluminium trichloride, hydrochloric acid and water. The foam fracturing fluid has the advantages that: it releases a lot of inert gas during reaction, increases pressure of the reservoir stratum, has good discharge aiding ability and simultaneously forms a foam structure, substantially reduces filter loss property, and reduces the harm of the fracturing fluid on the reservoir stratum; it can be crosslinked under a weak acid condition (pH=4.0-6.0), thus avoiding alkali sensitivity and reducing the harm to the reservoir stratum. Compared with the technology of injection along with liquid nitrogen, the application method of the invention reduces construction cost, simplifies construction procedure, and avoids safety problems caused by liquid nitrogen storage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

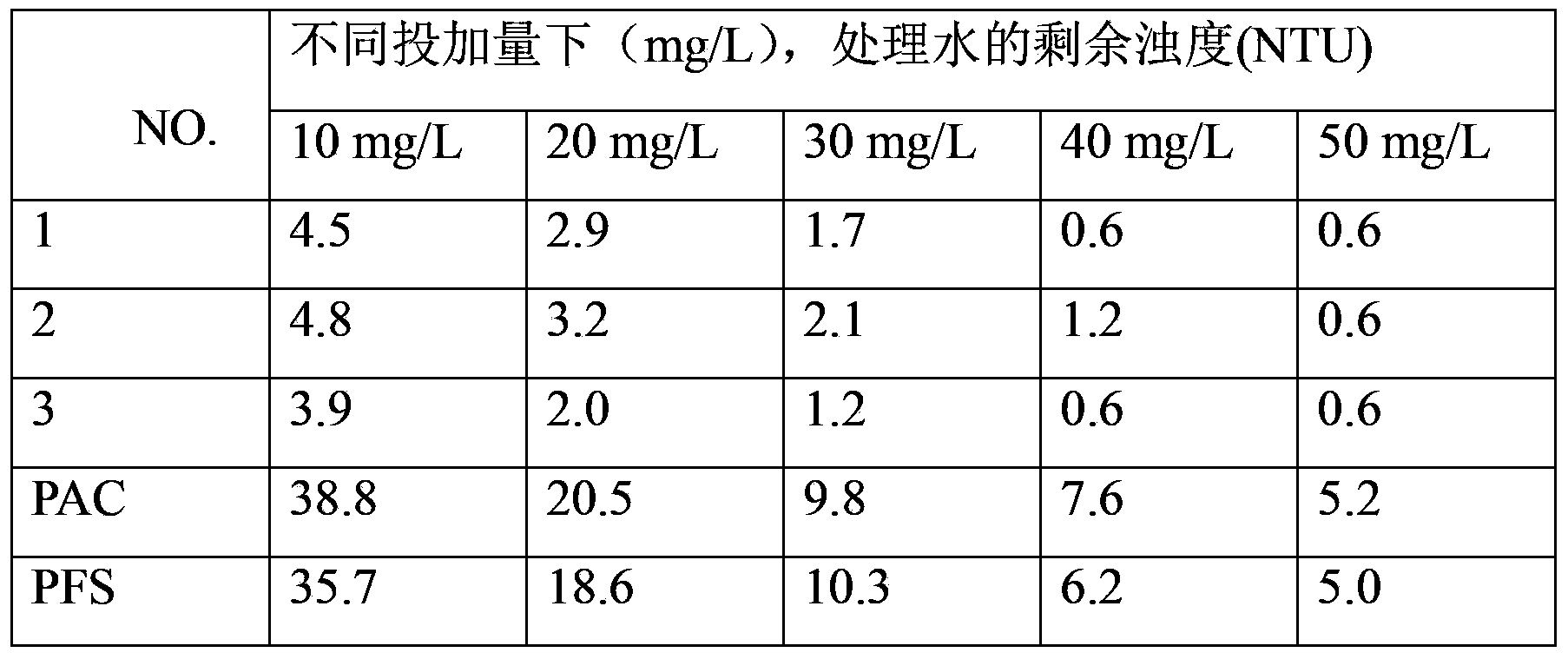

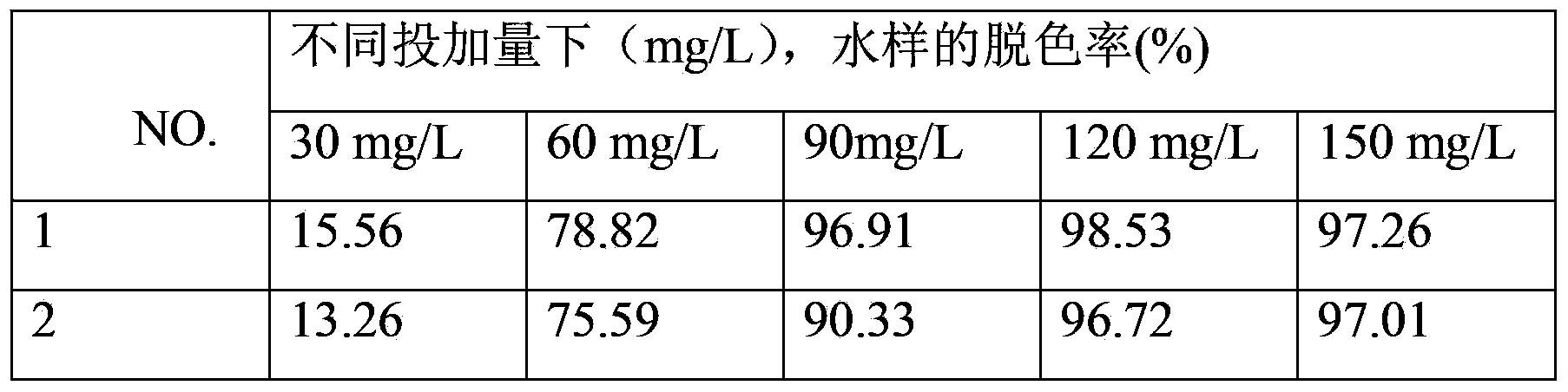

Nano composite polyaluminum ferric chloride flocculant and preparation method thereof

InactiveCN103351045AThe removal rate effect is obviousBig alumWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateMegasonic cleaning

The invention belongs to the field of water treatment agents, particularly relates to a nano composite polyaluminum ferric chloride flocculant and a preparation method thereof. The flocculant comprises the following raw material components in parts by weight: 5-9 parts of alchlor, 1-5 parts of ferric trichloride, 3-4 parts of sodium hydroxide, 0.1-0.6 part of a nano additive, 50-80 parts of water, and 1-3 parts of hydrochloric acid with the concentration of 20%. The preparation method of the flocculant comprises the following steps: adding alchlor, ferric trichloride and water into a vessel; stirring at a certain speed and at constant temperature; dropwise adding sodium hydroxide solution into the vessel during the stirring; pouring the mixture in the vessel into an ultrasonic cleaner after reaction for a while when the temperature is risen to a certain temperature; adding the nano additive subjected to acidizing treatment; pouring out and slaking the liquid for 24 hours after mixing the liquid by ultrasonic wave for a while, so as to obtain the flocculant. According to the invention, the technological process is simple, and three wastes can not be produced; the flocculant and the preparation method adapt to various waste water processing, and have the characteristics of advanced technology, small investment, low cost, excellent effect and the like.

Owner:SHANDONG ZHONGKETIANZE WATER PURIFICATION MATERIALS

Method for generating dimethyldichlorosilance by utilizing disproportionation reaction

ActiveCN101824046AImprove resource utilizationReasonable designGroup 4/14 element organic compoundsResource utilizationReaction temperature

The invention relates to a method for generating dimethyldichlorosilance by utilizing disproportionation reaction, which belongs to the technical field of the comprehensive utilization of three wastes in the production process of methyl chlorosilane. The invention is characterized by comprising the following steps: generating the dimethyldichlorosilance by using methyl trichlorosilane and trimethylchlorosilane as organic silicon monomers, or a high boiling object and a low boiling object as the organic silicon monomers, or the mixture of the methyl trichlorosilane, the trimethylchlorosilane, the high boiling object and the low boiling object as the organic silicon monomers as raw materials under the single or combined catalytic action of aluminum powder and anhydrous aluminum trichloride as catalysts. In the invention, reaction is generated in a high-pressure agitating kettle at the temperature of 180 to 350 DEG C, and in the reaction, the reaction pressure is controlled by the reaction temperature, i.e. the higher the reaction temperature is, the higher the reaction pressure is, and the maximum conversion rate of a target product can reach more than 70 percent. The invention improves the resource utilization level of methyl organic silicon monomer production, the dimethyldichlorosilance is produced in lower cost, and the invention has simple and easy operation and is suitable for large-scale popularization and utilization.

Owner:HANGZHOU JINFADA CHEM IND

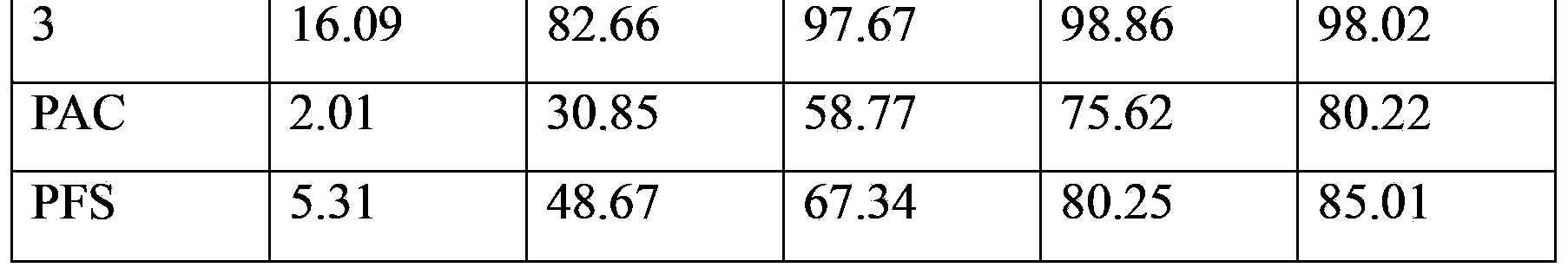

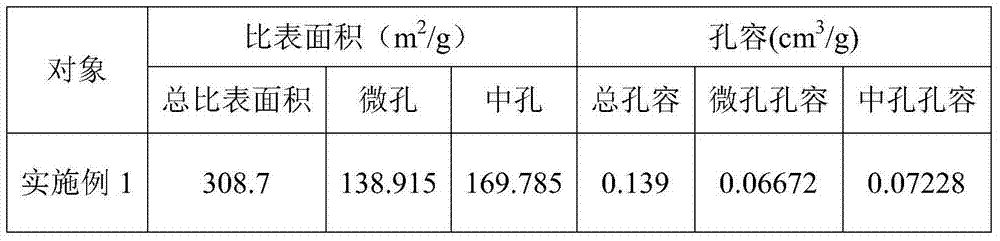

Asphalt-based nanoporous carbon material, negative material thereof, and lithium ion battery

InactiveCN104300150AHas a porous structureLarge specific surface areaMaterial nanotechnologyCell electrodesNanoporous carbonSodium-ion battery

The invention discloses an asphalt-based nanoporous carbon material, a negative material thereof, and a lithium ion battery. The asphalt-based nanoporous carbon material is prepared by mainly using 0.1-10g of asphalt, 3-50g of anhydrous aluminum trichloride, 100-400ml of anhydrous carbon tetrachloride and 200-500ml of a reaction terminating agent, and the amounts of the above raw materials can be freely adjusted in proportion. The asphalt-based nanoporous carbon material is prepared by mainly using asphalt, anhydrous aluminum chloride, anhydrous carbon tetrachloride and the reaction termination agent, and asphalt and anhydrous carbon tetrachloride undergo a Friedel-Crafts crosslinking reaction through a nanometer pore forming technology, so the obtained asphalt-based carbon material has a porous structure and a high specific surface area, and the negative material prepared by using the asphalt-based nanoporous carbon material has the characteristics of strong electrolyte imbibition and retention ability, good processing performance, low price and the like, and can greatly improve the cycle performances of the lithium ion battery.

Owner:HENAN ZHONGLIAN GAOKE NEW ENERGY

Recycling method of waste hydrochloric acid containing aluminum

The invention discloses a recycling method of waste hydrochloric acid containing aluminum and belongs to the technical field of recycling of waste acid containing aluminum. The method comprises the following steps of: (A) carrying out sand filtration on a waste hydrochloric acid washing liquid of an aluminum casting to remove suspended matters; (B) passing the waste hydrochloric acid washing liquid without the suspended matters through a fixed bed adsorption tower which is filled with strong-alkali anion exchange resin and provided with a heat insulation jacket under the conditions that the temperature is 5-45 DEG C and the work flow is 0.5-3.0BV / h; C) adding industrial hydrochloric acid in the processed effluent liquid so that the concentration of HCl is increased to 8mol / L, and then returning the effluent liquid back to a production process to be used as an aluminum casting hydrochloric acid washing liquid for circulating use; and D) passing distilled water or deionized water which is used as a regenerating agent through a resin bed to exchange and elute aluminum complex anions on a strong-alkali anion exchange resin, so as to form an aqueous solution containing aluminum trichloride, wherein the aqueous solution containing aluminum trichloride can be directly used as a purifying agent byproduct. According to the invention, the strong-alkali anion exchange resin is applied to the treatment and resource recovery of the waste hydrochloric acid washing liquid of the aluminum casting, thereby achieving the zero emission of the waste hydrochloric acid washing liquid of the aluminum casting and realizing the complete recycling of hydrochloric acid.

Owner:张炜铭 +3

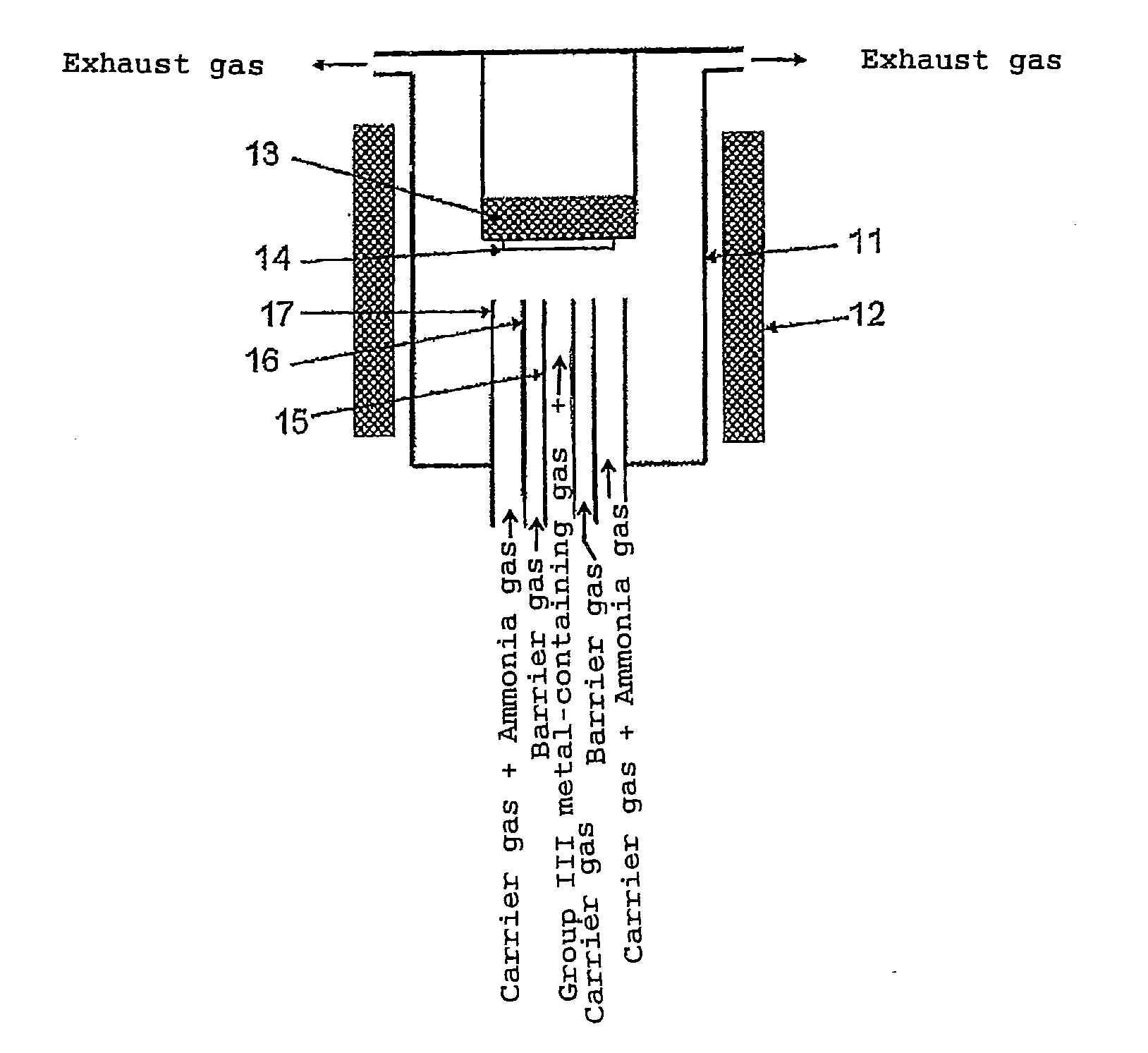

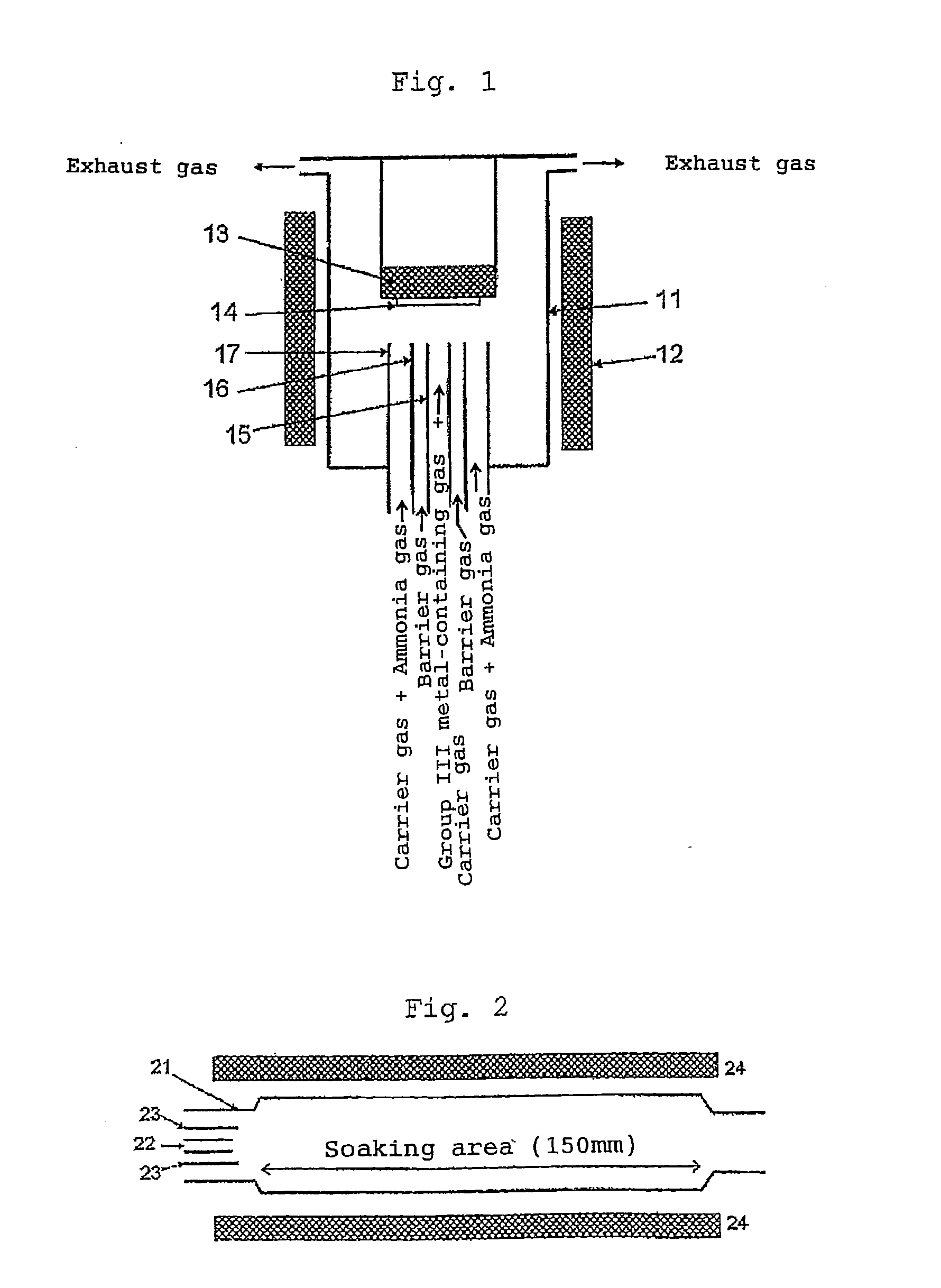

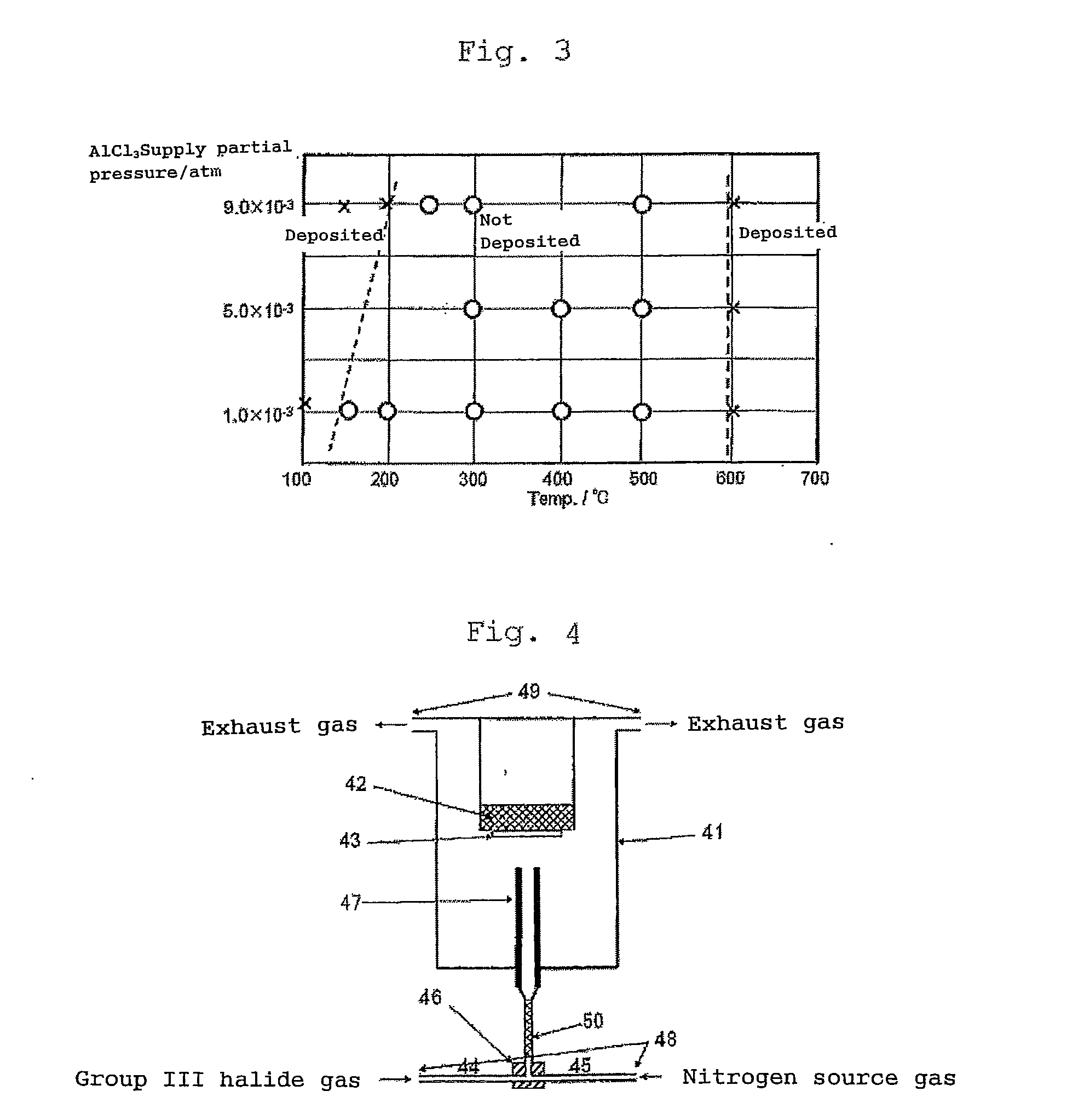

Method and apparatus for producing group iii nitride

InactiveUS20100029065A1High yieldSame qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrogen sourceNitride

A method of producing a group III nitride such as aluminum nitride, comprising the step of reacting a group III halide gas such as aluminum trichloride gas with a nitrogen source gas such as ammonia gas in a growth chamber to grow a group III nitride on a substrate held in the growth chamber, wherein the method further comprises premixing together the group III halide gas and the nitrogen source gas to obtain a mixed gas and then introducing the mixed gas into the growth chamber without forming a deposit in the mixed gas substantially to be reacted each other.For the growth of a group III nitride such as an aluminum-based group III nitride by HVPE, there are provided a method of producing the group III nitride having as high quality as that obtained by the method of the prior art at a high yield and an apparatus used in the method.

Owner:TOKUYAMA CORP

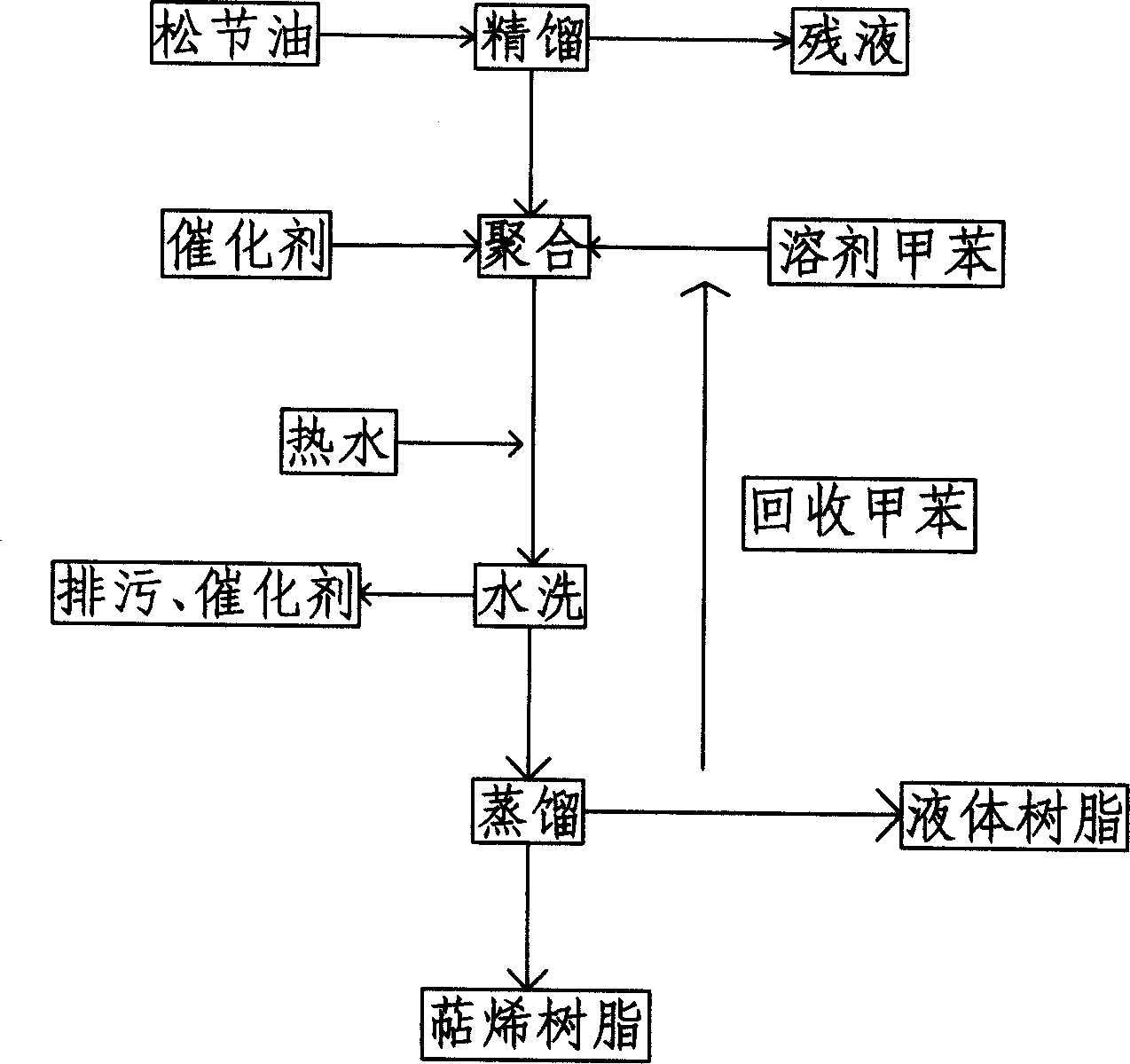

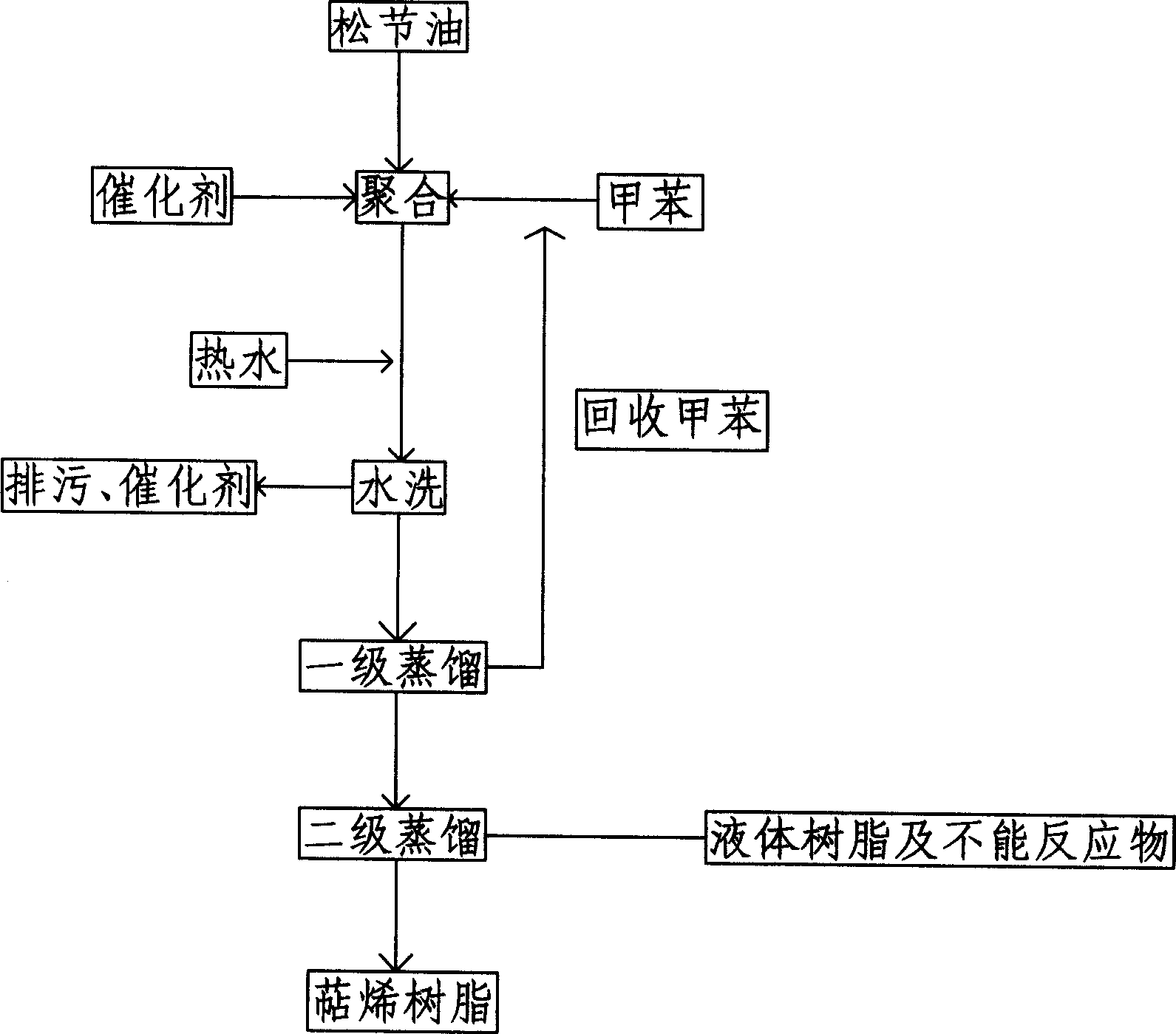

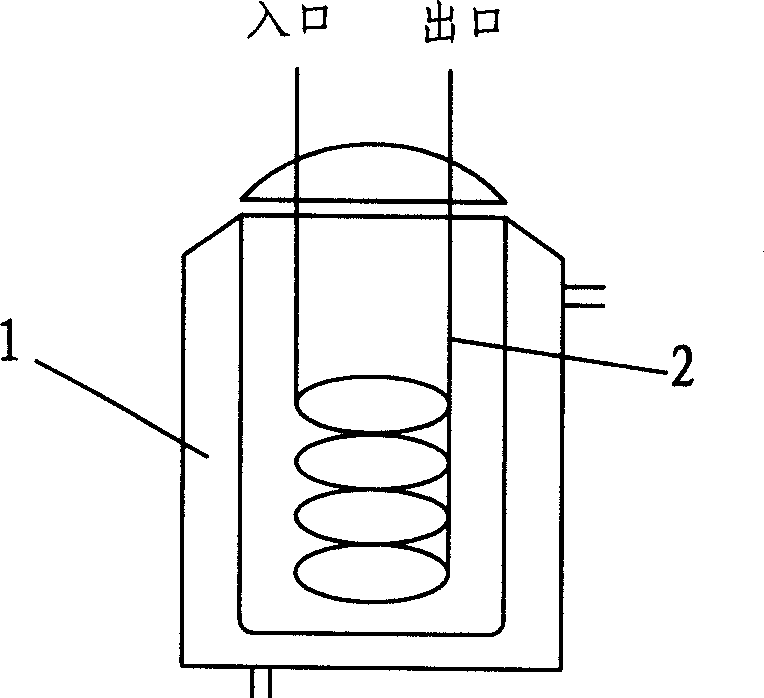

Production method of terpene resin

InactiveCN1631916AMild and even reactionThe reaction temperature fluctuation range is smallAluminium chlorideDistillation

A method for producing terpine resin has the steps follows: turpentine oil, toluene, catalyst aluminium chloride have polymerization in the wash the mixed outcome with hot water for draining the catalyst and waste out, then distil the outcome, recycle toluene and clear the liquid resin and the material which did not join the reaction in the course of distillation, then the toluene is made. The reactor includes enamel glass and inside cooling device which is steelless pipe groups filled with saturated salt solution of indoor temperature in the polymerization. The invention has friendly reaction, small fluctuating range of temperature, stable operation, productiving being raised by 20%, fewer equipments, low cost fir energy and production good economic benefit.

Owner:蓝运泉

Synthetic method of perfume o-tert-butylcyclohexyl acetate

InactiveCN103193638AExpand sourceLow costOrganic compound preparationCarboxylic acid esters preparationTert butyl phenolAcetic anhydride

The invention relates to a chemical synthetic method, and concretely relates to a synthetic method of a perfume o-tert-butylcyclohexyl acetate. The synthetic method comprises the following steps: reacting a raw material phenol with isobutene under the catalysis of anhydrous aluminum trichloride to obtain o-tert-butyl phenol, carrying out catalytic hydrogenation of o-tert-butyl phenol under the catalysis of Raney nickel to obtain o-tert-butyl cyclohexanol, and carrying out an esterification reaction of o-tert-butyl cyclohexanol and acetic anhydride under the catalysis of anhydrous sodium acetate to obtain o-tert-butylcyclohexyl acetate. The method has the advantages of mild reaction conditions, safe and convenient operation, high reaction yield, fine and strong fragrance of the obtained product, raw material source enlargement and raw material cost saving because of the adoption of industrially cheap phenol and isobutene as initial raw materials, total synthetic reaction yield improvement, suitableness for the industrial adoption, and good economic benefit.

Owner:南昌洋浦天然香料香精有限公司

N-substituted carbazole-amide room temperature phosphorescent molecules and preparation method and application thereof

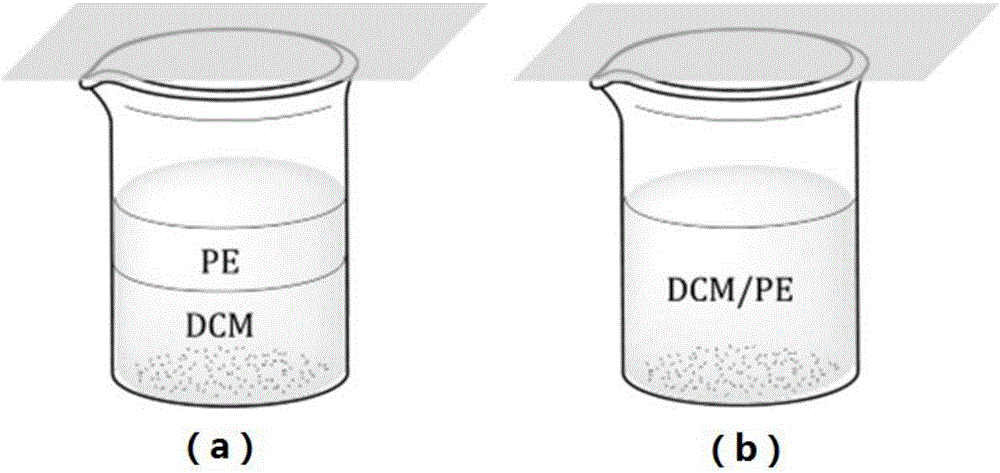

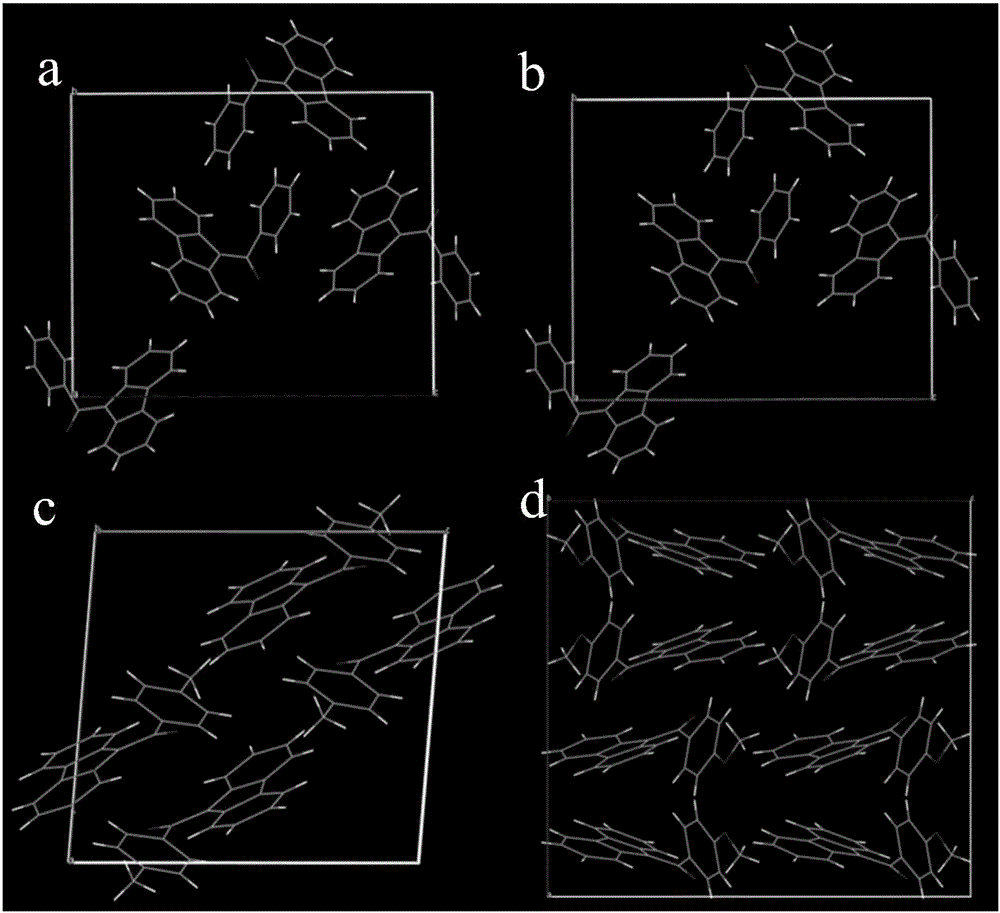

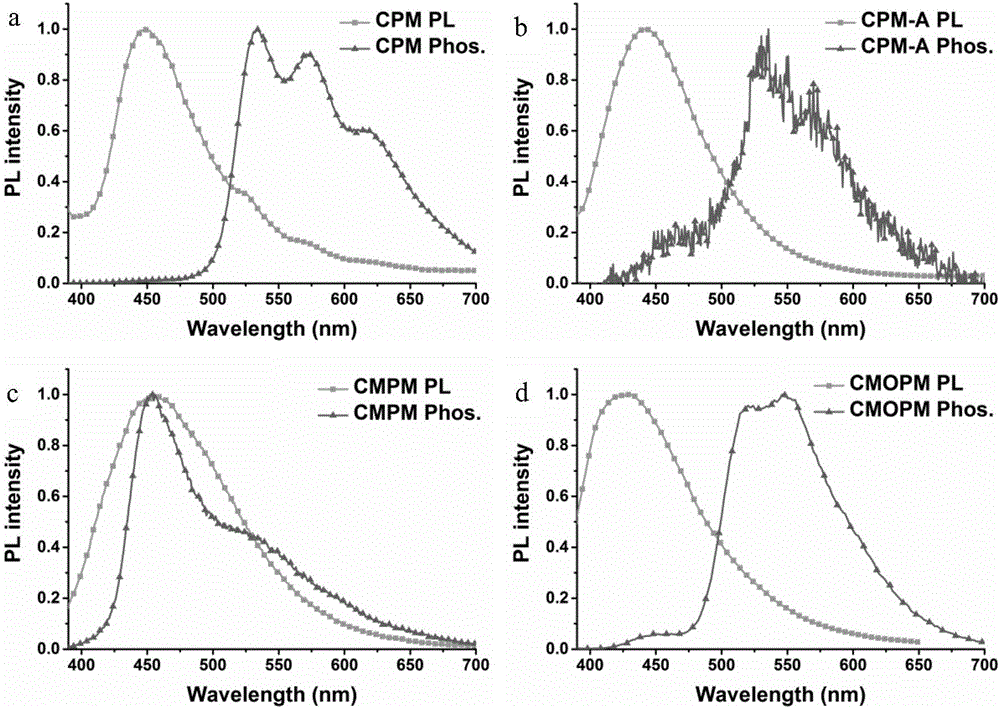

ActiveCN106543070ALong phosphorescence lifetimeImprove luminous efficiencyOrganic chemistry methodsLuminescent compositionsSolubilitySingle crystal

The invention discloses a room temperature phosphorescent compound and a preparation method, a single crystal culture method and application thereof in the field of anti-counterfeit. According to the invention, through acylation reaction with the participation of aluminum trichloride or sodium hydride, benzoyl chloride and derivatives thereof react with carbazole, benzoyl or derivatives thereof are connected with carbazole through N atoms, and by changing R groups connected with the benzoyl, three room temperature phosphorescent compounds CPM (R=H), CMPM (R=CH3) and CMOPM (R=OCH3) are obtained, and then the three compounds are cultured into single crystals through a solvent volatilization method by using two solvents with different solubility, boiling point and volatility. The obtained single crystals can be used in the field of anti-counterfeit, and can be matched with a material with better fluorescence-emission ability in use to complete two modes: color reliquid and time reliquid. Especially, the phosphorescence life of the obtained compound CPM at room temperature reaches 748ms, so that the compound CPM can be practically used in the field of anti-counterfeit.

Owner:WUHAN UNIV

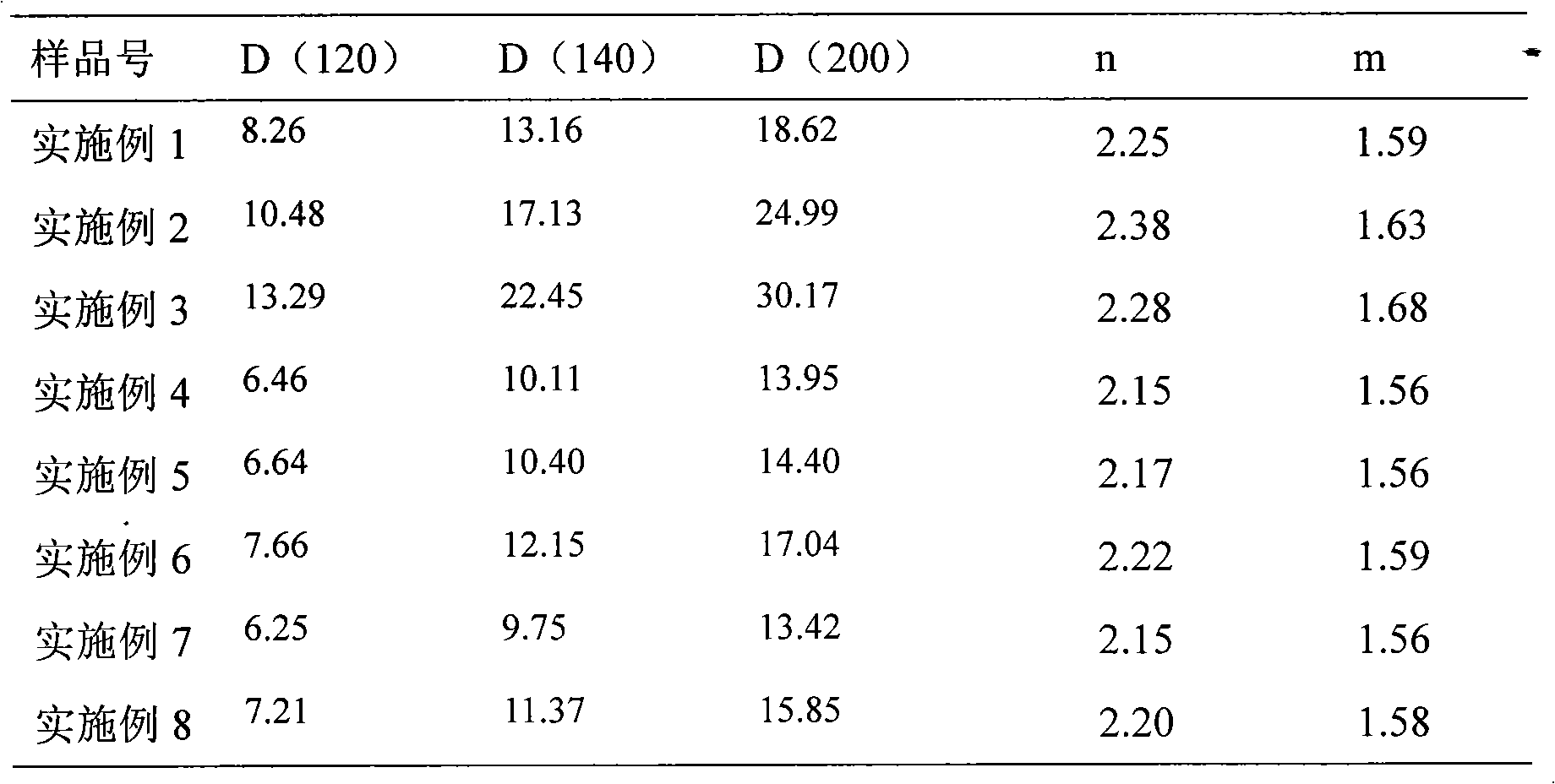

Preparation method of high-purity boehmite

InactiveCN102120597AHigh puritySave investmentAluminium oxide/hydroxide preparationHigh carbonSolvent

The invention provides a preparation method of high-purity boehmite, belonging to the technical field of synthesis of metallic organic compounds. The preparation method comprises the following steps of: preparing alkoxyl aluminum by adopting metallic aluminum with the purity more than 99.5 percent and mixed alcohol of C5-C8 and n-butyl alcohol under the existence of aluminum choride and alkylbenzene solvents; and hydrolyzing, aging and drying the alkylbenzene to obtain the high-purity boehmite. The invention overcomes the defects that the purification is difficult when the alkoxyl aluminum is prepared with low-carbon alcohol and the reaction efficiency is low when the alkoxyl aluminum is prepared with high-carbon alcohol and can obtain the boehmite with the purity up to 99.9 percent by controlling the proportion of the mixed alcohol and the metallic aluminum and the hydrolysis condition. The method provided by the invention ensures that the preparation process of the high-purity boehmite is simplified, the preparation efficiency is high, and the preparation cost is low.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

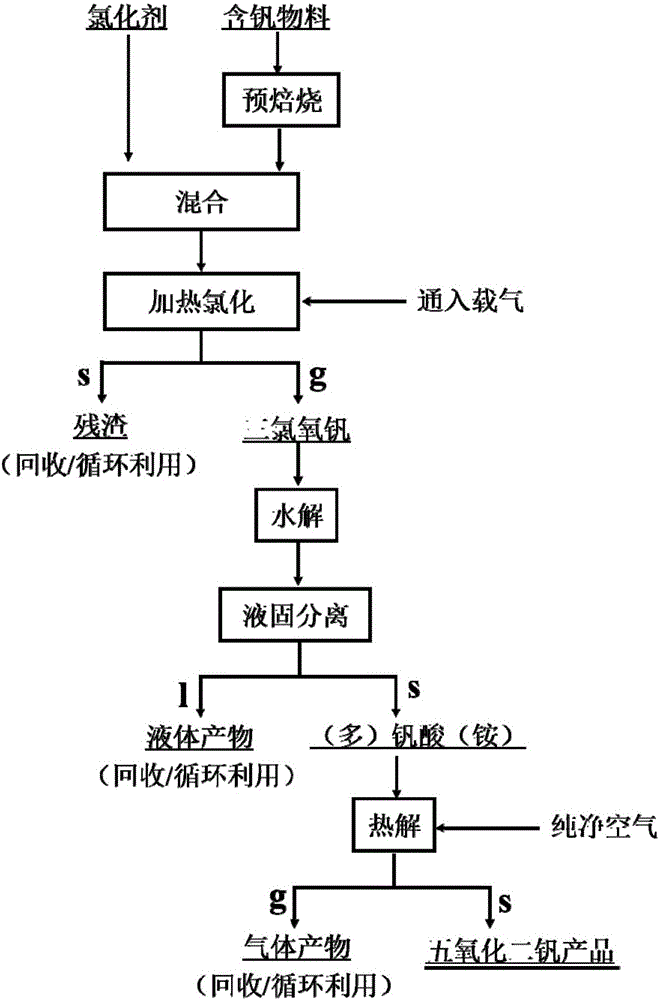

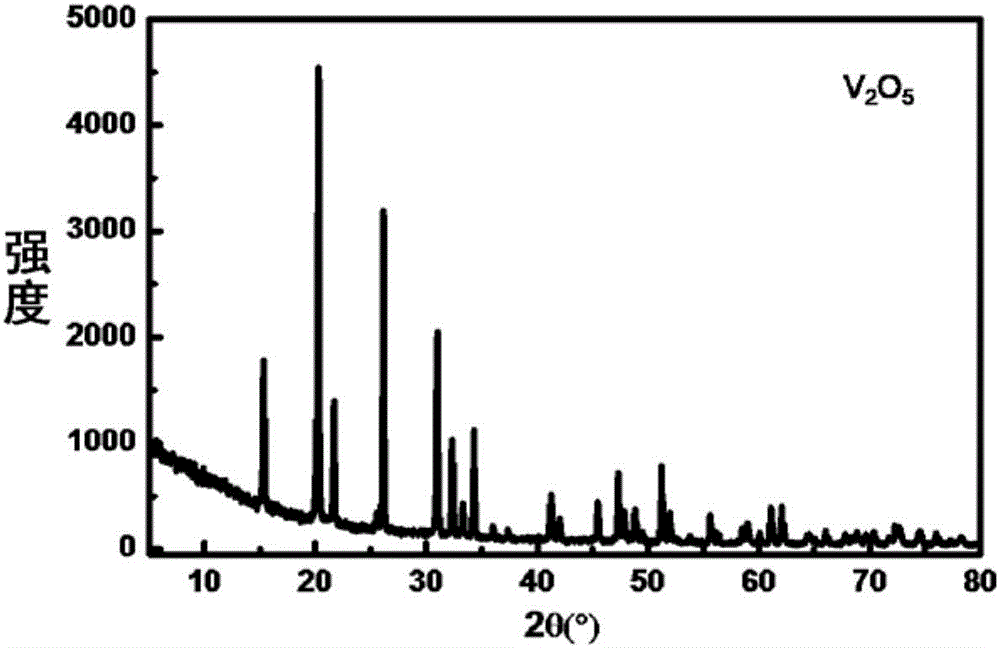

Method for preparing high-purity vanadium pentoxide by using vanadium-contained material

ActiveCN106676289AHigh purityMild process conditionsVanadium oxidesProcess efficiency improvementReaction temperatureImpurity

The invention provides a method for preparing high-purity vanadium pentoxide by using a vanadium-contained material. The method comprises the following steps: the vanadium-contained material is roasted to obtain a roasted product with the content of vanadium pentoxide below 49 wt%; then, the roasted product and a chlorinating agent are reacted in an inert atmosphere at a reaction temperature of 150-200 DEG C to obtain vanadium oxytrichloride gas and residues; the aftertreatment is performed for the vanadium oxytrichloride gas to obtain the high-purity vanadium pentoxide; and the chlorinating agent is selected from anhydrous aluminum trichloride or a mixture of anhydrous aluminum trichloride and sodium chloride. The method is mild in conditions, escapes vanadium in a gas form, is easy to separate vanadium from other substances, is higher in product purity, saves subsequent separation and impurity removal steps, and can obtain vanadium pentoxide products with the purity of not lower than 99%. The method is simple in technological process, short in needed reaction time, wide in raw material sources and easy to obtain raw materials, effectively reduces the production cost, reduces generation of three wastes, and is low in environmental pollution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Alkylation process using an alkyl halide promoted ionic liquid catalyst

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The alkylation process comprises contacting a hydrocarbon mixture comprising at least one olefin having from 2 to 6 carbon atoms and at least one isoparaffin having from 3 to 6 carbon atoms under alkylation conditions, the catalyst comprising a mixture of at least one acidic ionic liquid and at least one alkyl halide. In one embodiment, the acidic ionic liquid is chloroaluminate ionic liquid prepared by mixing aluminum trichloride (AlCl3) and a hydrocarbyl substituted pyridinium halide, a hydrocarbyl substituted imidazolium halide, trialkylammonium hydrohalide or tetraalkylammonium halide of the general formulas A, B, C and D, respectively, where R-H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2-H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same, and R3, R4, and R5 and R6=methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R3, R4, R5 and R6 may or may not be the same.

Owner:CHEVRON USA INC

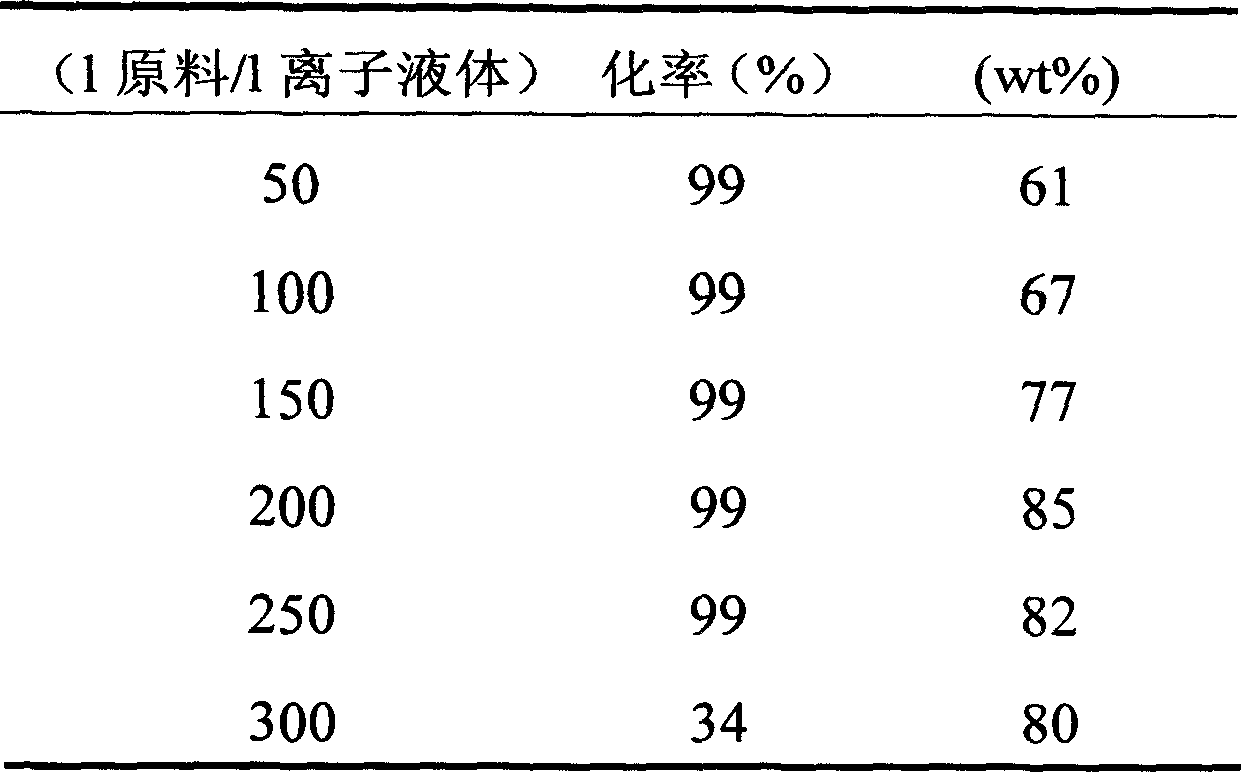

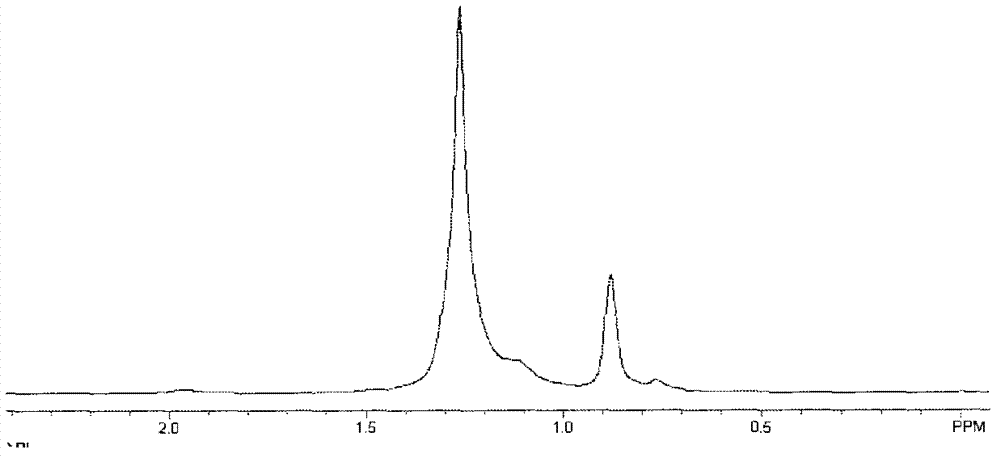

High-viscosity poly alpha-olefin synthetic oil and preparation method thereof

ActiveCN102776022AReduce contentHigh catalytic activityLiquid hydrocarbon mixtures productionAlpha-olefinIonic liquid

The invention provides a poly alpha-olefin synthetic oil (PAO) and a preparation method thereof. The preparation method comprises the following steps of contacting alpha-olefins with an ionic liquid at a temperature of -10-100 DEG C to form a polymerization reactant; separating the polymerization reactant from the ionic liquid; and distilling and hydrorefining the polymerization reactant, thus obtaining the poly alpha-olefin synthetic oil. The ionic liquid is composed of anionic components and cationic components, wherein the anionic components are one or more selected from aluminum trichloride, alkyl aluminium, halogenated alkyl aluminium and aluminium bromide; the cationic components are one or more selected from imidazolium salts; the molar ratio of the anionic components and cationic components is 1-3 : 1; the mass ratio of alpha-olefins and the ionic liquid is 1-200 : 1; and reaction time is 15-360 min. Kinematic viscosity at 100 DEG C (K.V[100 DEG C]) of the obtained PAO is larger than 40 mm<2> / s. The high-viscosity PAO product is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

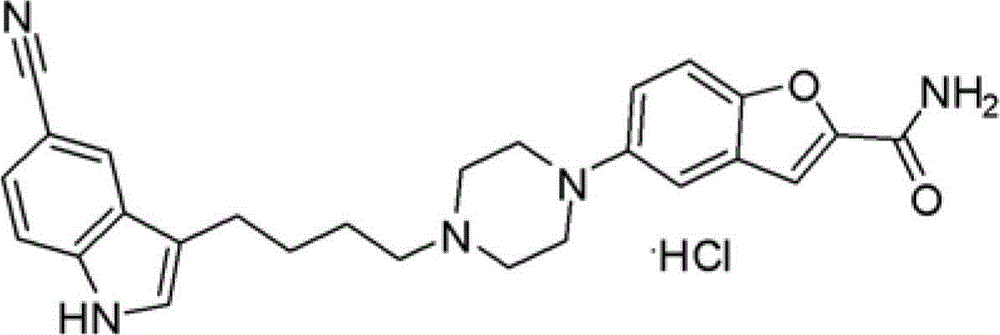

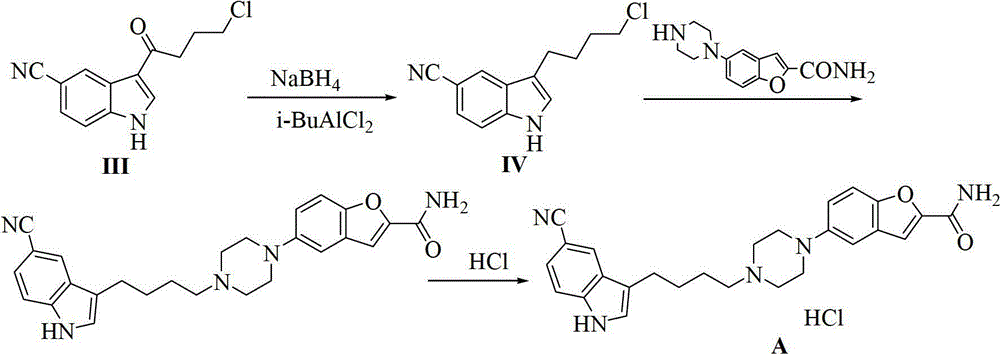

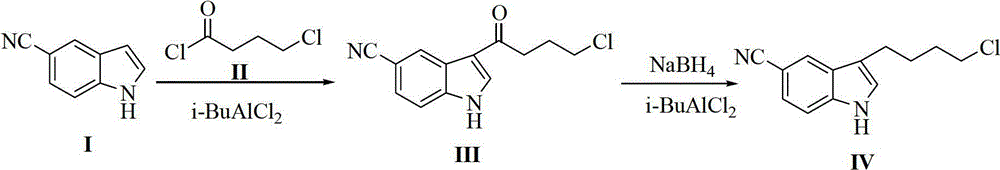

Preparation method of 3-(4-chlorobutyl)-5-cyanoindole

ActiveCN102875440AReduce usageOperational securityOrganic chemistryPotassium borohydrideLewis acid catalysis

The invention discloses a preparation method of 3-(4-chlorobutyl)-5-cyanoindole which is shown as the formula IV. The preparation method comprises the steps as follows: carrying out following carbonyl reduction reaction on a compound III and a hydroboron reducing agent in the solvent under the catalyzing of Lewis acid to obtain the product, wherein Lewis acid is one or more of aluminium trichloride, magnesium chloride, zinc chloride and ferric chloride; and the hydroboron reducing agent is one or more of sodium borohydride, potassium borohydride, lithium borohydride and borane. The preparation method disclosed by the invention is safe in operation, low in requirement on equipment, low in cost, simple in post-processing steps, high in yield of product, high in purity, and is suitable for industrialization.

Owner:CHIRAL QUEST (SUZHOU) CO LTD +1

Method for the production of alpha-alane

A method of forming α-alane. The method includes reacting aluminum trichloride and an alkali metal hydride to form an alane-ether complex solution. An aqueous diethyl ether solution is optionally added to the alane-ether complex solution to form a partially hydrolyzed ether / alane-ether complex solution. A solution of a first crystallization additive is added to the alane-ether complex solution or to the aqueous ether / alane-ether complex solution to form a crystallization solution. The first crystallization additive is selected from the group consisting of polystyrene, polybutadiene, polystyrene-co-polybutadiene, polyisoprene, poly-alpha-methylstyrene, polystyrene-co-polyindene, poly-alpha-pinene, and mixtures thereof. Optionally, a second crystallization additive is added to the crystallization solution. The second crystallization additive is selected from the group consisting of squalene, cyclododecatriene, norbornylene, norbornadiene, a phenyl terminated polybutadiene, 2,4-dimethyl anisole, 3,5-dimethyl anisole, 2,6-dimethyl anisole, polydimethyl siloxane, and mixtures thereof. Solvents are removed from the crystallization solution to crystallize the α-alane.

Owner:NORTHROP GRUMMAN SYST CORP

Synthetic method of m-dichlorobenzene

InactiveCN101696151ASolution to short lifeImprove conversion rateChemical recyclingHalogenated hydrocarbon preparationAutomatic controlGas phase

The invention discloses a synthetic method of m-dichlorobenzene which is obtained by transposition in the presence of a catalyst by taking o-dichlorobenzene and / or p-dichlorobenzene as raw materials. The catalyst is a composite catalyst comprising a solid phase catalyst and a gas phase catalyst, wherein the solid phase catalyst is aluminum trichloride or halide of transition metal, and the gas phase catalyst is anhydrous hydrogen chloride or other anhydrous halogen acids. The raw materials have no limitation of water, have arbitrary ortho-para proportion and react under normal pressure; the solid catalyst has long service life, and the gas catalyst can be recycled after gas-liquid separation and has high conversion ratio; and the synthetic method can be used for large-scale industrial production. The process realizes the automatic control easily and has energy saving, safety, environment protection and low cost.

Owner:JIANGSU EQUALCHEM

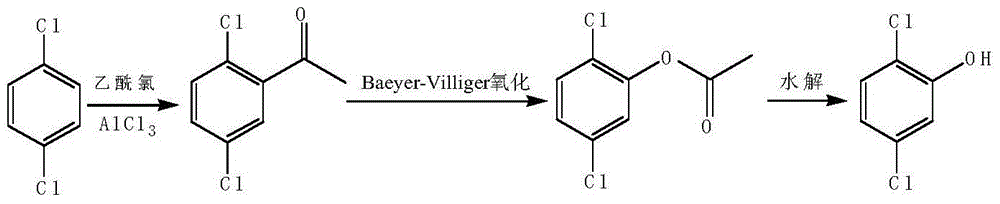

Preparation method of 2,5-dichlorophenol

InactiveCN104591973AThe synthesis process is simpleShort routeOrganic compound preparationCarboxylic acid esters preparationHydrolysisPeroxide

The invention discloses a preparation method of 2,5-dichlorophenol and relates to the technical field of pesticide intermediate synthesis. The preparation method comprises the following steps: with p-dichlorobenzene as a start raw material, performing a Friedel-Crafts acylation reaction between the p-dichlorobenzene and acetyl chloride in the presence of aluminum trichloride to obtain 2,5-dichloroacetophenone; performing a Baeyer-Villiger oxidation reaction between the 2,5-dichloroacetophenone and a peroxide in the presence of a catalyst at room temperature to obtain 2,5-dichlorobenzene acetate; and performing a hydrolysis reaction between the 2,5-dichlorobenzene acetate and inorganic aqueous alkali in a reflux condition to obtain 2,5-dichlorophenol. The preparation method disclosed by the invention has the characteristics of simple synthesis process, short line, low production cost and high yield; and moreover, with less quantity of generated three wastes and high environmental protection property, the preparation method is more suitable for large-scale industrial production.

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com