2-carboxyethylphenylphisphinic acid flame-proof agent production method

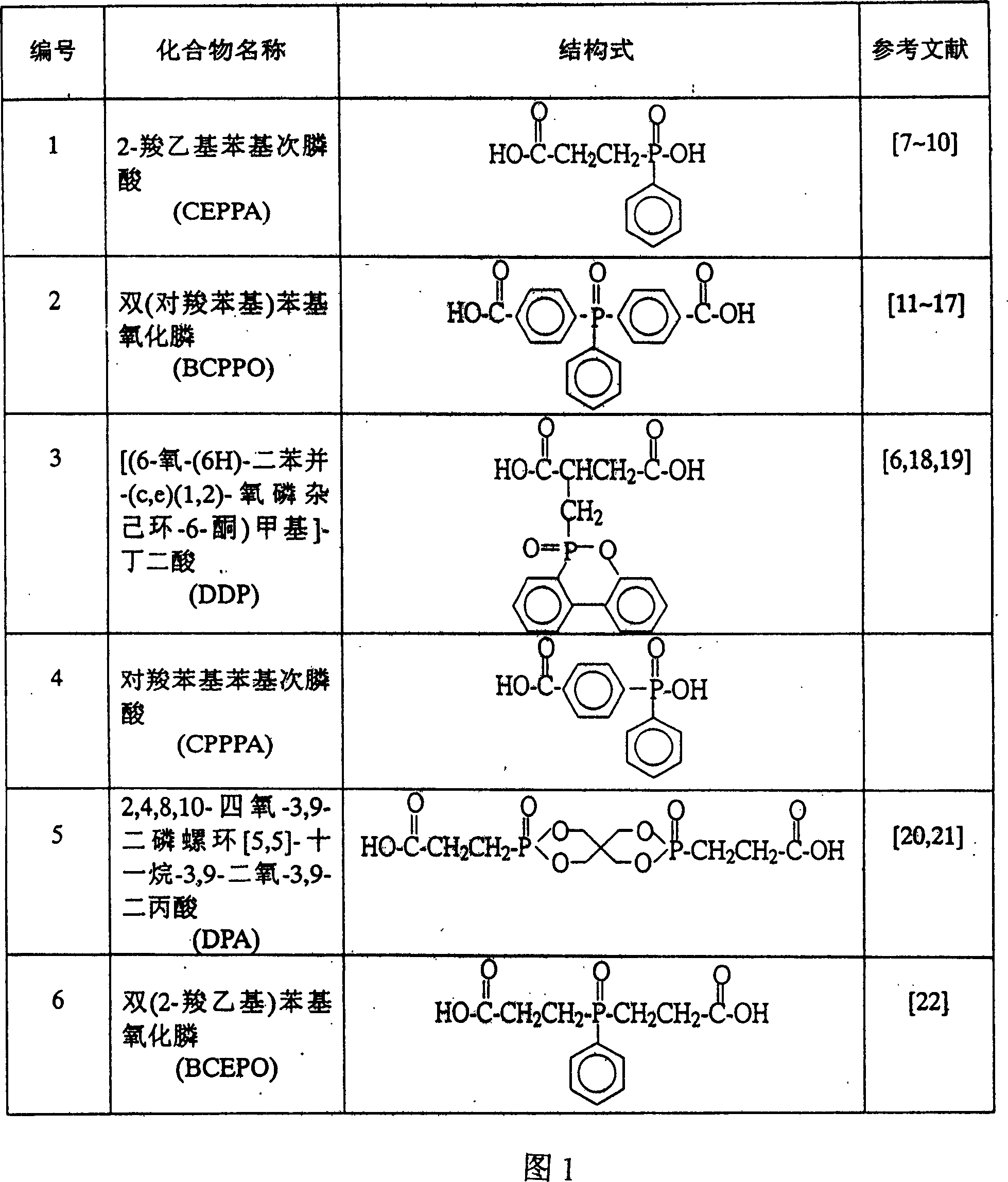

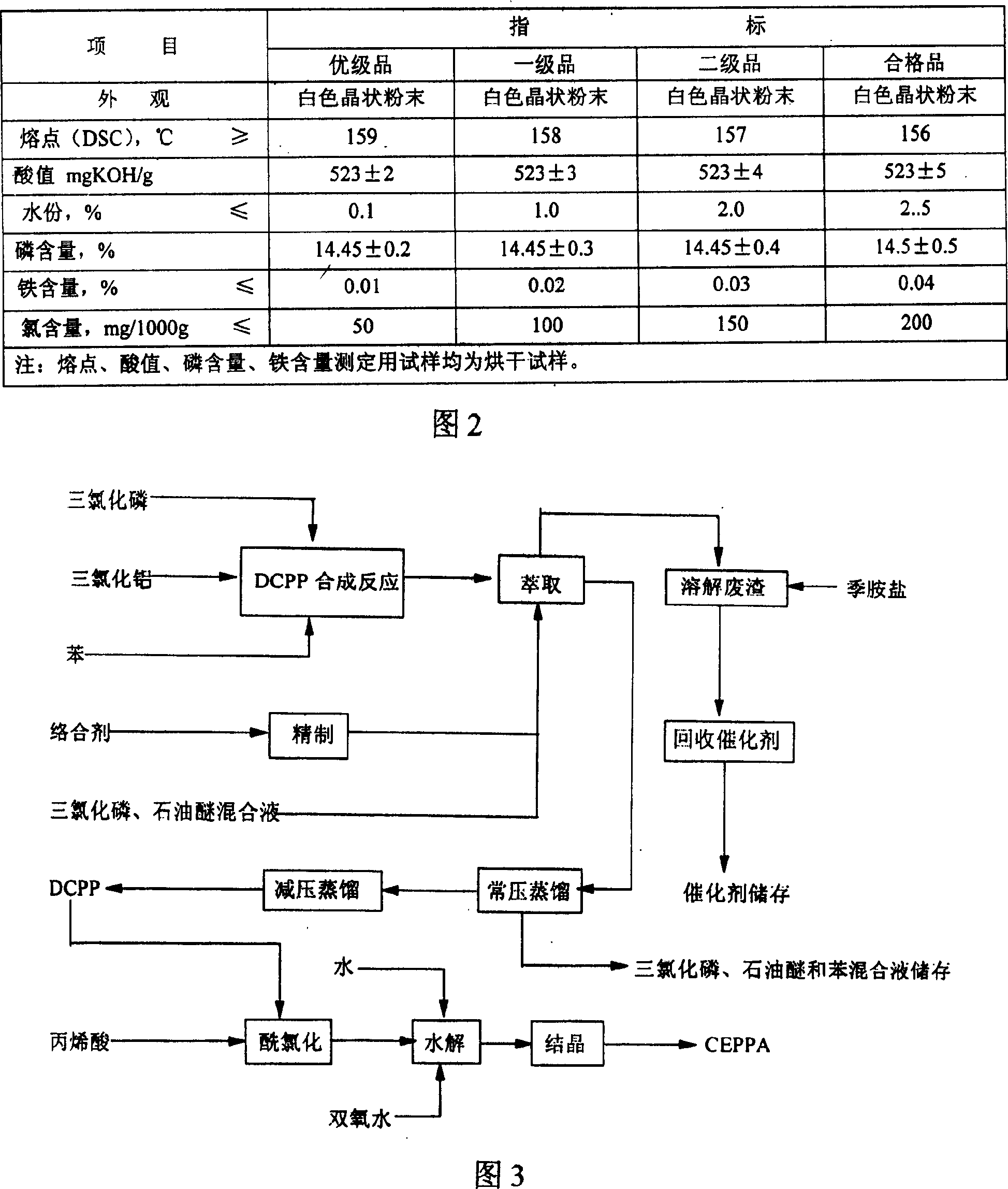

A technology of phosphinic acid and carboxyethylbenzene, which is applied in the production of 2-carboxyethylphenylphosphinic acid flame retardants and the field of preparation of flame retardants, can solve the problem that industrial production cannot be realized and technology is difficult to realize , Long process flow and other issues, to achieve the effect of reducing the release of corrosive toxic gases and smoke, simple process and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

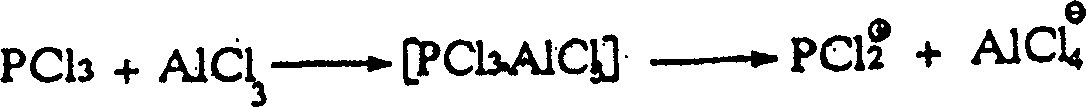

Method used

Image

Examples

Embodiment 1

[0055] 1. Synthesis of phenylphosphorous dichloride-DCPP

[0056] (a) press pcl 3 :Alcl 3 : The mol ratio of benzene=1.5: 0.5: 0.8, first pcl 3 Put into the reaction kettle, then put into Alcl 3 , start the mixer, and heat up to reflux at the same time;

[0057] (b) Add the benzene of the above-mentioned ratio dropwise, and control the drop to finish within 4 hours, the temperature is constant at 80° C., and absorb a large amount of HCl gas generated during the dropwise addition with water to obtain a by-product—hydrochloric acid;

[0058] (c) Cool down the reacted material to 60°C, put it into the extraction kettle, and add the complexing agent Nacl with a particle size of 120 objects in the weight ratio of extract: Nacl=5:1 to carry out the first extraction, and the temperature is controlled at 50°C, after stirring for 1 hour, let it stand for 30 minutes, collect the extracted upper layer material liquid, and pump the material liquid into the storage tank;

[0059] (d) ...

Embodiment 2

[0075] 1. Synthesis of phenylphosphorous dichloride-DCPP

[0076] (a) press pcl 3 :Alcl 3 : The mol ratio of benzene=2.5: 1.5: 1.5, first pcl 3 Put into the reaction kettle, then put into Alcl 3 , start the mixer, and heat up to reflux at the same time;

[0077] (b) Add the benzene of the above-mentioned ratio dropwise, and control the drop to finish within 4 hours, the temperature is constant at 80° C., and absorb a large amount of HCl gas generated during the dropwise addition with water to obtain a by-product—hydrochloric acid;

[0078] (c) Cool down the reacted material to 60°C, put it into the extraction kettle, and add the complexing agent Nacl with a particle size of 200 objects in the weight ratio of extract: Nacl=7:1 to carry out the first extraction, and the temperature is controlled at 50°C, after stirring for 1 hour, let it stand for 30 minutes, collect the extracted upper layer material liquid, and pump the material liquid into the storage tank;

[0079] (d) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com