Method for on-line producing alkymer from regenerative ionic liquid catalyst

A technology for ionic liquids and alkylated oils, applied in chemical instruments and methods, liquid hydrocarbon mixture production, physical/chemical process catalysts, etc., to achieve the effects of prolonging catalyst life, reducing corrosion, and maintaining selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

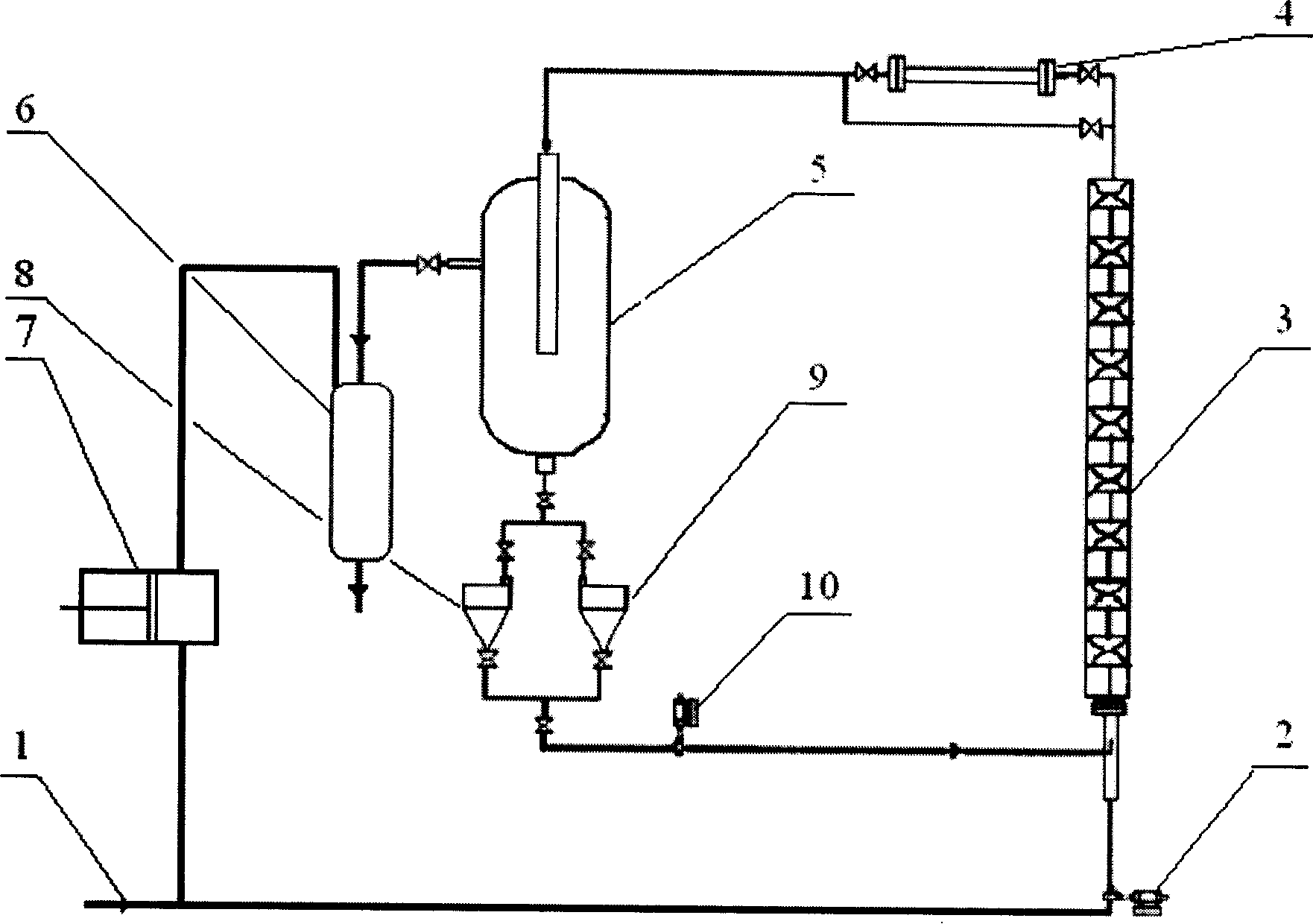

Method used

Image

Examples

Embodiment 1

[0022] Preparation of ionic liquid catalyst

[0023] Slowly add aluminum trichloride to triethylamine hydrochloride at a molar ratio of 2:1, use n-heptane as a solvent, protect with dry nitrogen, stir at room temperature for 30 minutes, then heat up to 80°C, and continue stirring for 2 hours . After cooling, the reactant is divided into two phases, the upper layer is heptane, and the lower layer is composed of [Et 3 h + ][Al 2 Cl 7 - ] of ionic liquids. Add the fresh ionic liquid prepared in the ionic liquid tank, and add the modification auxiliary toluene, so that the mass concentration of toluene is 2000ppm.

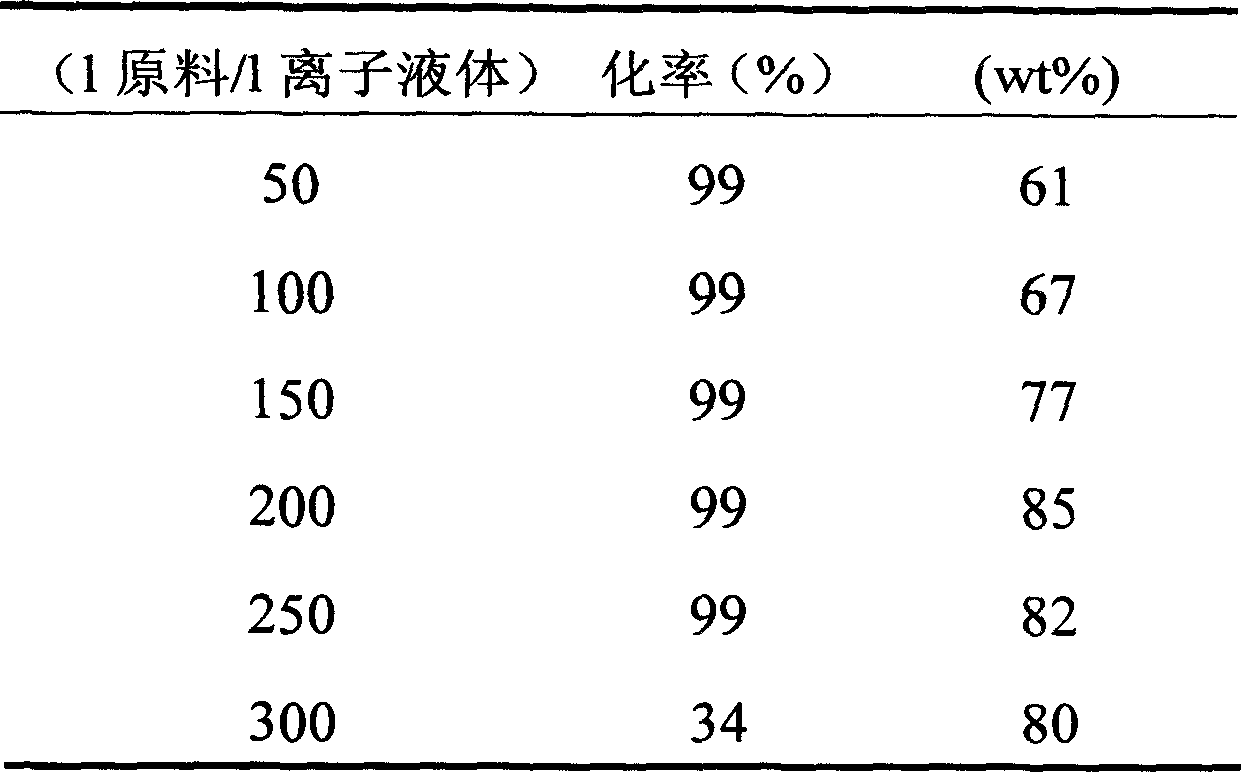

[0024] Alkylation reaction on continuous plant

[0025] The alkylation reaction of isobutane / 2-butene is carried out on a continuous device, the molar ratio of isobutane / 2-butene in the raw material is 20:1, and the material leaves the reactor and enters the liquid-liquid separator through the A road . The pressure of the reaction system is controlled to be 0....

Embodiment 2

[0036] Under the conditions of Example 1, when the accumulative amount of fresh raw material treated per liter of ionic liquid reached 300 liters, the activity of the ionic liquid catalyst decreased significantly. At this time, the aluminum trichloride crystal is used as the source of aluminum supplementation, and the operating temperature of the regenerator is 30°C. Regenerates continuously for one hour. Inject reaction raw material in reaction system then, operating condition is the same as embodiment 1. The reactor outlet product was collected and analyzed for its composition. The results are shown in Table 3. It can be seen that the inactivated ionic liquid recovers the reactivity, and the selectivity of the target product remains unchanged.

[0037]Table 3. Alkylation reaction of isobutane / 2-butene catalyzed by ionic liquid regenerated by aluminum trichloride

[0038]

Embodiment 3

[0039] Embodiment 3: the continuous regeneration reaction of ionic liquid

[0040] The fresh ionic liquid prepared in Example 1 was added to the ionic liquid tank, and the alkylation reaction of isobutane / butene was carried out on a continuous device. After the material leaves the reactor, it enters the liquid-liquid separator through the B channel. The pressure of the reaction system is controlled at 1.0 MPa, the molar ratio of isobutane / 2-butene in the raw material is 50:1, the reaction temperature is 25° C., and the ratio of the circulating flow rate of the reactant to the ionic liquid is 10:1. Aluminum flakes are filled in the regenerator as the source of aluminum supplementation, and the operating temperature of the regenerator is 40°C. The reactor outlet product was collected and analyzed for its composition. The results are shown in Table 4. When the accumulative amount of fresh raw material treated per liter of ionic liquid reaches 600 liters, the ionic liquid is sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com